A TELLTALE TWIN:

The edge is helping companies leverage the power of unlimited computing resources from the cloud, on the shop floor. p.12

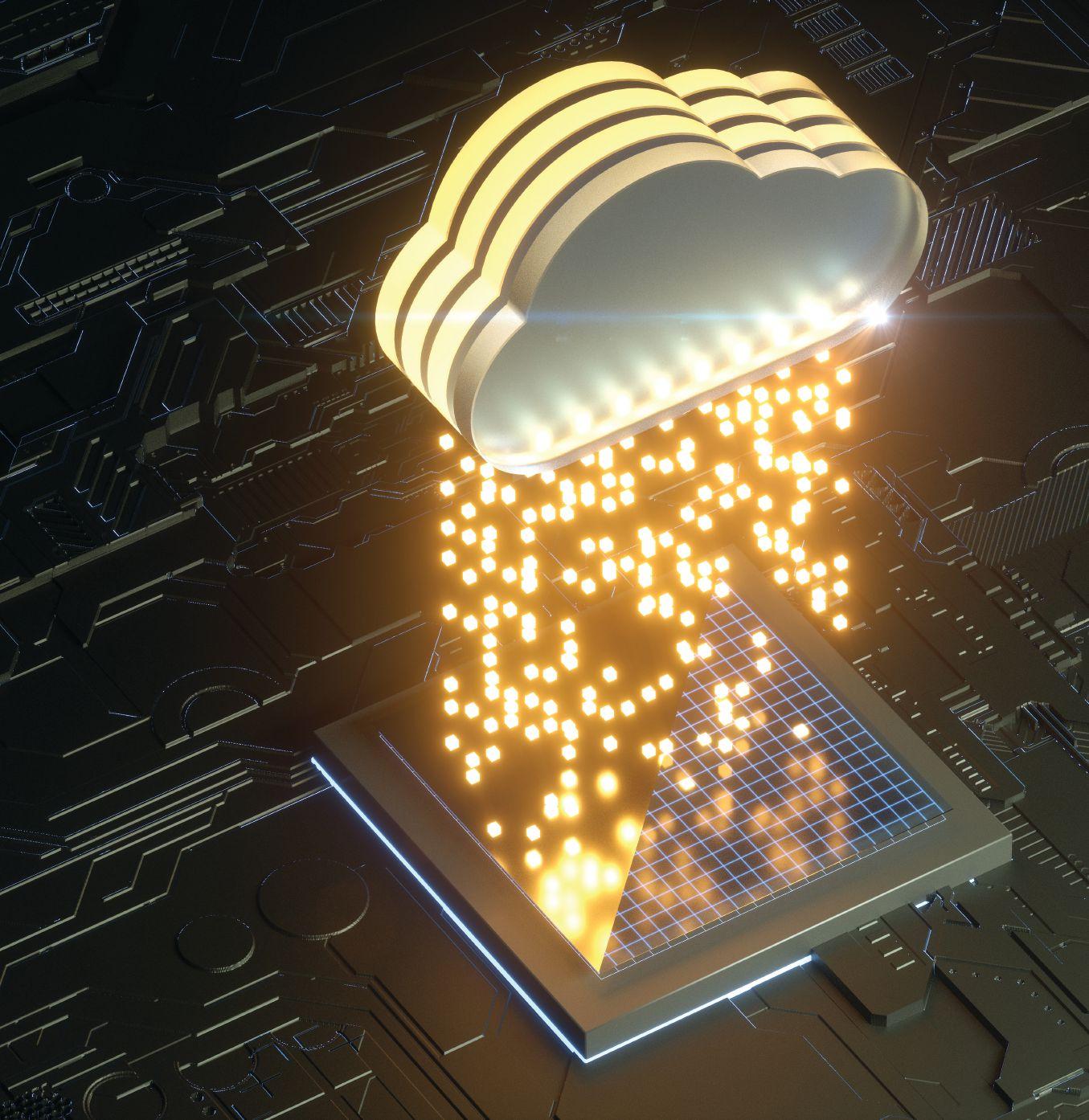

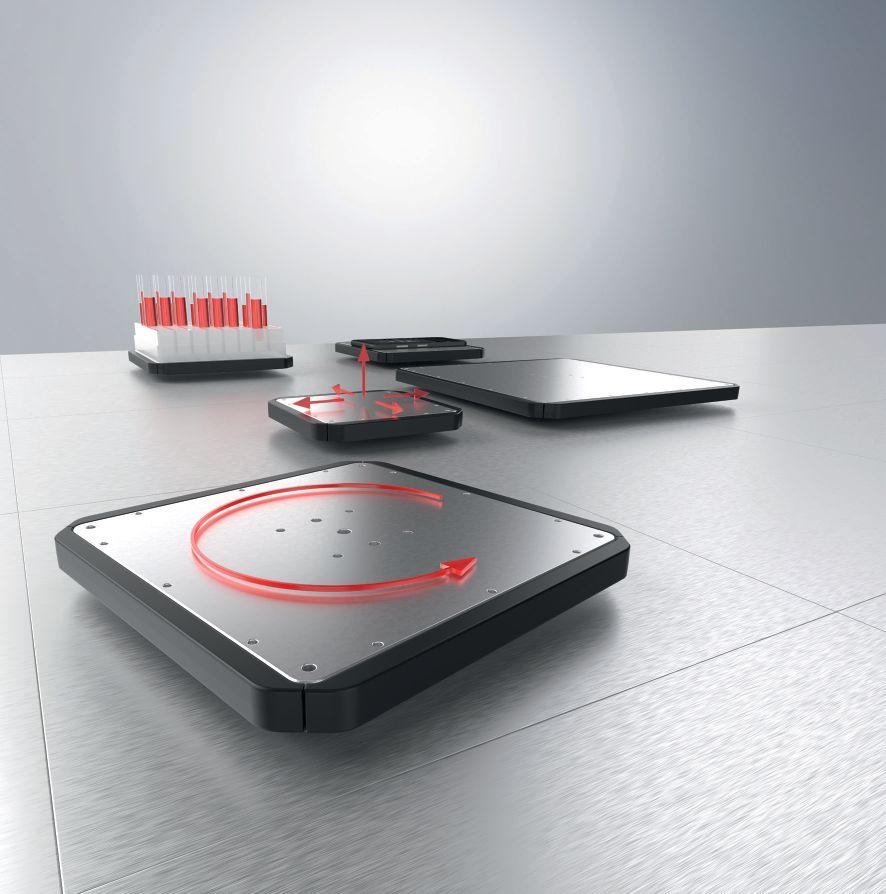

The PS-AMC motion controllers are designed to work seamlessly with select Productivity PLCs and provide accurate, coordinated, plug-and-play motion control. Up to 16 independent axes of motion control, or up to four groups of coordinated motion with four axes each, is possible with these new controllers.

• Available in 1, 2, 3, or 4 axes models

• Maximum switching frequency of 1MHz

• Up to 24 general-purpose high-speed inputs

• Up to 12 general-purpose high-speed outputs

• Easy configuration of standard motion profiles (flying cut-off, rotary table, etc.) with the FREE Productivity Suite software and built-in motion instructions

2 4 1 3

The primary function of a ying cut-o system is to synchronize the speed of a servo-driven carriage, on which a cutting mechanism is mounted, with the speed of a continuously fed material to make a perpendicular cut without stopping the feed. The ying cut-o shown above employs four axes of motion, a rotating pipe cutter1, a continuous pipe infeed system2, carriage positioning drive3, and outbound conveyor4. With the PS-AMC4, all four of these axes can be easily controlled and synchronized within the same controller, and it's only $465.00!

Research, price, buy at: www.automationdirect.com/motion-controller-productivity

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Leading

Cloud computing provides companies access to unlimited computing resources, while operational technology (OT) edge computing helps them leverage that power on the shop floor.

By Jacob Stoller

A once-traditional mouldmaker goes all in on robotics and automation to diversify operations and embrace the future of manufacturing.

By Kristina Urquhart

Racer Machinery uses a digital twin to shorten the critical path for implementing complex machinery.

By Karen Smock

It is my pleasure to introduce myself as the new editor of Manufacturing AUTOMATION. I come from Annex Business Media’s Light Construction Group, where I had the opportunity to work on four different media brands. I have also covered the automotive industry in a previous role.

As I step into this new role, I believe this is an interesting time to cover the manufacturing automation industry. The global pandemic has forced people to innovate, evolve and pivot on a regular basis. The manufacturing industry in Canada has seen plenty of disruptions and faced several challenges over the past year, for example, supply chain issues and labour shortages. However, opportunities have also opened up for beginning a journey towards a wider digital transformation. And this seems like the perfect time to begin the conversation about automating for the future.

This Fall, we are seeing a lot of popular industry events coming back in a mix of in-person, hybrid and virtual formats. People and companies are ready to connect as a community. 2020 was ruled by virtual events and online education dissemination, as the virtual space was able to offer tremendous possibilities, with attendees from across Canada being able to join in from the convenience and safety of their homes. With the hybrid format, people can connect face-to-face once again, and have the choice to join virtually if that is what they prefer. In-person events offer a chance to enter into organic conversations and build relationships on a personal level. However, public health and safety remains a priority. Event organizers everywhere are taking extra precautions and following government guidelines to ensure that the return to live events is a true success. Many have imposed limitations on the number of people who can attend. The virtual option is especially useful in such cases as no one has to miss out on the information and education, even if they are not able to attend the live version. The key takeaway here is that these events are offering excellent

platforms to have conversations about making the journey towards advanced manufacturing and industry-wide digitalization. This is also a chance to build a stronger community in the manufacturing automation sector with a Canada focus.

On a separate note, I recently had the opportunity to listen to a group of industry experts discuss about the future of automation in Canada. Concerns were raised about a seeming gap in the knowledge base about practical applications of high-level concepts like Industry 4.0. As a community, this industry has to come together to find solutions and break down such barriers. It is not possible, of course, to go from zero to 100 in a single day, where all companies suddenly have fully integrated optimized systems. The group agreed that there is education that needs to happen about the practical business applications and business benefits of automation.

I would love to hear about all the exciting things that are happening in your company lately – what has worked for you the best.

It all comes down to having continuous conversations across all levels. And that is why I am here. In my role as editor of Manufacturing AUTOMATION, it is my job to ensure that all of you have this platform at your disposal. I am not the expert here – you are. You know more about the latest automation technologies, the actual challenges the industry is facing and what are the best solutions to these challenges. My focus will always be on ensuring that you are heard and information is shared.

I would love to hear about all the exciting things that are happening in your company lately. I want to know what has worked well for you, what plans you have for the future and the lessons learned along the way. Do you know people whose achievements and contributions to the industry need to be celebrated? Tell me about them. What are the topics that have caught your interest the most lately? Share your stories and ideas with me at srayghosh@annexbusinessmedia.com. I look forward to meeting all of you soon sometime in the near future. | MA

@AutomationMag srayghosh@annexbusinessmedia.com /company/automation-mag

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

SHELLEY FELLOWS, Chair, Automate Canada

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquires or changes, please contact:

Urszula Grzyb, Audience Development Manager Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh SRayGhosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Alena Barreca, Jon DeSouza, Treena Hein, Paul Hogendoorn, Maxime Lacouture, Karen Smock, Jacob Stoller

Manufacturing AUTOMATION is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing AUTOMATION are © 2021 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Association Partner

Launched on Aug. 31, Formic Technologies, a robotics-as-a-service company, is offering manufacturers the option to hire robots to help them do more with automation without high costs. Fully customized robots from top suppliers are available on an hourly rate basis, at no upfront cost. Aimed at helping small and medium-size manufacturers, Formic will take care of every aspect of financing and deployment, including scoping, engineering, purchasing, implementation and maintenance. Formic’s customers will not have to pay for system downtime.

Purchasing robots can be a lengthy and expensive process. With this service, Formic intends to eliminate such barriers from the path of small manufacturers so they are able to embrace automation.

“We started Formic because we saw all that automation can do and we wanted to provide a way for any manufacturer to easily adopt automation in a simple, risk-free and on-demand way,” said Saman Farid, CEO and co-founder.

The federal government is investing $5 million in the Automotive Parts Manufacturers’ Association (APMA) to support Project Arrow, the automotive industry’s first Canadian-made, zero-emission concept vehicle.

APMA will use its connections in the automotive manufacturing industry – its membership accounts for 90 percent of all independent automotive parts manufacturers in Canada – to bring together industry and academic partners in southern Ontario to facilitate the project. The partners will work

together to design, engineer and build a connected and autonomous zero-emissions vehicle (ZEV) concept car and its digital twin, which will be used as a virtual platform for testing and validating connected and autonomous (CAV) technologies before they are integrated into the physical car.

FedDev Ontario’s investment in this project will support 80

jobs, leverage over $6.6 million in other funding, support at least 40 automotive suppliers and technology firms, and generate $50 million in additional investment.

Linamar Corporation plans to manufacture a drive transmission system for industrial robotics developed by Netherlands-based Innovative Mechatronic Systems (IMSystems). The companies entered into a global manufacturing agreement that will see the Guelph, Ont.-based Linamar bring the Archimedes Drive transmission system to market once the design has been proven and production is at the point where it requires scale-up.

The Archimedes Drive system is comprised of an assembly module that uses frictional contact instead of gear teeth to transmit torque, resulting in a more efficient and precise gearbox – and one that promises to be more scalable.

“This strategic partnership is another great step for us into the opportunistic industrial robotics market, given the growing global trend of industrial automation and the ongoing demand for better, more accurate robotic systems,” says Linda Hasenfratz, Linamar’s CEO. “IMSystems is truly a leader in this area, disrupting a technology that has not seen significant innovation or improvement in decades.”

IMSystems’ existing shareholders include ABB Technology Ventures and InnovationQuarter (IQ), a regional economic development agency for the greater Rotterdam – The

Hague area in the Netherlands. This latest Series A Investment brings Linamar and Finindus, a Belgium-based early-stage and growth investment company, into the consortium.

ReadyForce Holdco, a division of the Metro Group of Companies, has acquired Valley Mechanical. The deal allows the companies to offer comprehensive service, strengthens their position within the industry and opens avenues for future growth.

Valley Mechanical specializes in industrial, commercial and process mechanical contracting. As per the agreement, Valley Mechanical will continue to function as an independent entity under the ReadyForce banner. Valley Mechanical’s complementary set of capabilities, expertise and services will help the companies address growing demands and evolving customer needs.

Mat Glen, past president of Valley Mechanical, is staying on as general manager to lead the company and its team in alignment with Ready Machinery.

IBM is partnering with Black & Veatch to build Asset Performance Management (APM) solutions, such as remote monitoring technologies that incorporate data analytics and artificial intelligence. The offering will combine Black & Veatch Asset Management Services (AMS) and digital analytics with IBM’s Maximo Application Suite.

Black & Veatch operates four monitoring and diagnostics centres and conducts near real-time detection and analysis of emerging problems by running thousands of models and scenarios to predict changes in asset performance.

IBM Maximo Application Suite’s Assist, Monitor, Health, Predict and Visual Inspection capabilities will integrate Black & Veatch monitoring and diagnostics expertise and data analytics with maintenance management.

The two companies also plan to expand the IBM Digital Twin Exchange by selling Black & Veatch’s digital twin asset models in IBM’s inventory.

As assets and facilities continue to evolve and the volume of data they generate grows, knowing how to effectively manage and use this

information is a major challenge for many organizations. As a result, the dashboards used for monitoring data can be overwhelming and have so many alerts that important ones may be ignored. AI and machine learning can help bridge that gap and reduce this “alarm fatigue” by sorting through the thousands of incoming data points, so organizations can prioritize alerts and decisively plan their actions. With their solution, IBM and Black & Veatch aim to reduce the number of incoming data points to a handful of actionable insights.

Advanced Design & Manufacturing is returning in-person to Toronto with its five well-known event brands. ADM is taking this step with the support of key industry partners, including Annex Business Media.

The 2021 edition will take place from Nov. 9 to 11 at the Toronto Congress Centre. Automation Technology Expo (ATX) is one of the five event brands that will occupy the show floor.

Attendees will have the opportunity to explore the latest trends and technologies shaping the future of advanced design and manufacturing across automation, robotics and more.

“The power of face-to-face connection plays an undeniable role in the industry’s advancement and has been sorely missed over the past eighteen months,” said Jenny McCall, group event director of ADM, Informa Markets. “This event is strategically held in Toronto, as it is home to a selection of the world’s leading injection mould and toolmakers, additive manufacturing metal powder suppliers, and emerging R&D in machining technology. Many of these innovators will walk the halls of ADM in search of new deals and peer-to-peer connection.”

The event is geared up to connect 250 brands with thousands of buyers and reunite the community in-person.

Attabotics has hired Cyra Richardson as its chief technology officer and chief product officer, and Julien Seret as vice-president of the company’s network supply chain. Coming into Attabotics with 30 years of experience, Richardson will lead the company’s product strategy, commercialization, product development and technical strategy in her new positions. In her various previous roles, her work has focussed on IoT technology, AI, cloud connectivity, robotics and scaling technology products and organizations. She has been involved in scaling up businesses as well. She has held leadership positions in Wind River, Microsoft and Amazon. Seret will be in charge of Attabotics’ novel supply chain approach in his new role. He has previously served in several leadership positions at SoftBank Robotics. He brings with him his expertise in microfulfillment and knowledge of automation and robotics technologies.

The Shape Process Automation (SPA) group has appointed Sargon Haddad as the vice-president of its Burlington division in Ontario. Haddad will be a part of the company’s senior leadership team and will report to Nino LaDuca, global president of SPA. Haddad will be in charge of several key functions within the company, including applications, engineering and operations. Sargon has been an integral part of SPA’s Burlington leadership and operations team since June 2015. He has led several key projects and also oversaw the recent operational transition in the company’s Burlington facility.

• Pressure-relieving thread that improves safety by slowly releasing trapped gas pressure upon disassembly

• Easy Bluetooth connection

• Customized module within SCOUTTM mobile app software

• Consistent, accurate pressure & temperature readings

• Connected mode for data collection & analysis

• Broadcast mode for access to any user within range

• No external power supply needed

• LED indicator for sensor status

The four founding members of German Technology Day –ANDREAS SOBOTTA , CEO and general manager at Pilz Automation Safety Canada; ANDRE BOUSETTE, president of Rittal Canada; JULIANO MATIAS, president of Wago Canada; and ROLAND YOUNK, president of Eplan Canada – share their story of the show’s journey.

MA: Andreas, this is the third year for German Technology Day. How did it all begin?

AS: Whoever has had a chance to visit the Hanover trade show has probably seen the huge number of German technology companies, especially in automation halls nine and 11. When I was at the show in April 2018, I started thinking about showcasing German technology here in Canada. Many mid-sized German companies (mid-size could mean anything from $50 million to $3 billion in sales) are globally successful, but are not very well known in North America. A special event like the German Technology Day (GTD) benefits these companies as well as their Canadian customers.

MA: What were the next steps that you took to make this show a reality?

AS: I contacted the Canadian German Chamber of Industry and Commerce to get its feedback. Thomas Beck (former president) and Yvonne Denz (the new president) liked the idea. They offered their support and connections to have even the German ambassador and the German consulate involved. With this backup, it was easy to convince the first companies to join.

MA: Andre, how did Rittal become a founding member of GTD?

AB: After Andreas contacted our former president Tim Rourke, Tim approached me to support the event. He believed it would be a game changer. I was all over it from

the beginning and thought that this was a great opportunity to showcase that Rittal offers more than just enclosures. A part of the Rittal solution is the Eplan software. So, we contacted Roland and shared this idea.

RY: It took me a split second to say yes. This was the perfect opportunity to show the Canadian market that the Eplan software works with a lot of products, and that these products can be in one panel, working as one solution.

JM: When Andreas shared this idea with me and said that I had the first shot, I did not hesitate at all to join. Each of our companies individually can address a certain part of the Canadian market, but all four together can attract much more customers to an event like this.

MA: The first GTD had four participating companies. How did the event pan out?

AS: We approached a couple of

other companies, but they weren’t prepared at that time. So, the first event had Eplan, Pilz, Rittal and Wago – the “fab four”. We had two venues, one in Mississauga, and one in Kitchener. All marketing departments worked closely together to promote the events. The IT teams from Wago and Eplan did a great job creating a website.

AB: The turnout was great. The attendance in Mississauga exceeded 130, and in Kitchener we had over 30 people. I think what made it so successful was the mixture of educational seminars and a trade show. The attendees had the chance to speak to various people at the booths, as well as attend the seminar sessions.

RY: Most of the attendees were there for several hours, starting with breakfast and staying back even after lunch. By the way, the entire event is free of charge. It includes the seminars, parking, food and beverages, plus some giveaways.

MA: The 2020 GTD was a virtual event. How did that go?

AS: This was an even greater success. We had over 350 participants! One reason was that Murrelektronik and Bosch-Rexroth joined the group. Another reason probably was the chance to win up to $1,000 cash. The German ambassador provided a welcome video, while the presidents of the six companies gave an introductory presentation. The seminars were conducted live in 30-minute slots.

RY: Eplan has several years of experience with virtual trade shows. We used the Eplan platform for the 2020 GTD. The feedback from the attendees was amazing.

MA: What have you planned for this year’s event?

AS: With Festo joining us, we have seven companies this year. We have planned two face-toface events, one in Toronto on Oct. 26, and one in Montreal on Nov. 2. We also have a virtual event parallel to the Toronto event. We will live-stream all presentations and keep the virtual booths open. If people cannot make it in person, they still have the option to attend virtually. The German ambassador and the consul will join us for the opening sessions.

MA: What do you have in mind for future events?

JM: So far, we have only noncompeting German companies as members. For 2022, we plan to include direct competitors of our seven current members in the event. We hope to get a total of 15 participating companies. | MA

Matthew Mongeon is a marketing coordinator at Mentor Works. He helps business owners by creating educational content on what government funding opportunities are available to Canadian businesses. To find out your business’s eligibility for grants and tax credits, visit mentorworks.ca.

Enterprise resource planning (ERP) software can help businesses streamline and manage all core business activities, processes and communications with suppliers and other partners. This can revolutionize key functions of a business, including supply chain operations, production, project management, accounting, procurement, finance, trade and more.

Implementing ERPs and embedding the tool into employees’ day-to-day workflows can be quite costly and time-intensive given how complex these systems need to be when managing so many facets of a company. The Canadian government has introduced several non-repayable funding programs for the implementation, training and upgrading of ERP systems.

The Canadian Agricultural Strategic Priorities Program (CASPP) provides funding for projects that address national or sector-wide priorities that help the agricultural industry mitigate emerging issues and capitalize on opportunities. CASPP provides up to 50 percent of eligible project costs to a maximum of $1 million in non-repayable funding. Eligible projects include adopting new technologies, such as ERP systems, to help improve productivity, environmental sustainability, strategic planning, capacity building and emerging issues.

Eligible businesses include not-forprofit organizations and associations, cooperatives, marketing boards and indigenous groups. This program is accepting applicants until funding is depleted. The projects cannot exceed five years in duration.

The Canadian Agricultural Partnership (CAP) is a $3 billion investment from the federal, provincial, and territorial governments to grow the agri-food sector over the course of five years (2018 to 2023). One of the streams within this program is the CAP Ontario: Agri-Processors Stream, which provides between 25 percent to 50 percent of eligible expenses to a maximum of $20,000 to $250,000 in grant funding depending

on the funding stream that an applicant applies under, including streams covering costs towards ERP implementations, productivity improvements, waste monitoring, and more.

The goal of the Canada Job Grant program is to increase employability of Canadian workers by teaching them new skills that are desirable in their industry and role.

Applicants for this funding stream must be Ontario-based manufacturers that have a CRA number. They must have under 200 fulltime equivalent employees, a valid Premises Identification Number and vendor quotes that demonstrate project costs. They must be directly involved in transforming agricultural commodities, food, beverage or agri-based bio-products. Application intake periods for this program are announced on the program’s website throughout the year for their various project focus areas.

The Ontario Automotive Modernization Program (O-AMP) is an Ontario provincial government funding

program administered by the Ontario Centre of Innovation (OCI) and the Automotive Parts Manufacturers’ Association (APMA). It helps automotive supply chain businesses improve their operational efficiency and global competitiveness through the adoption of lean manufacturing processes and Industry 4.0-related technologies, including hardware and software implementation and related training. This program covers up to 50 percent of eligible project costs to a maximum of $100,000 in Ontario government grants. Businesses eligible for O-AMP funding must be an Ontario automotive business with fewer than 500 employees and at least 50 percent of revenue coming from the automotive supply sector. The O-AMP program is currently closed. Watch out for information about future funding rounds in fall 2021.

The Canada Job Grant (CJG) is a federal-provincial co-funded program that launched in 2014 with the purpose of upskilling new and existing employees. The goal of the program is to increase the employability of Canadian workers by teaching them new skills that are desirable in their industry and role. The CJG maintains a provincial stream for each province, except for Quebec, and each provincial stream has varying funding amounts and eligibility criteria.

Each provincial variant of the CJG program has unique eligibility criteria and funding limits. Between 50 to 100 percent of eligible training costs are covered based on the type of training, employer and trainee. Eligible training costs typically include third party training costs, course fees, textbooks, materials, supplies and examination fees. Eligible training themes vary by province. Many variants allow training for post-secondary courses, technical skills development and transferrable skills development.

Implementing ERPs and embedding the tools into employees’ day-to-day workflows can be quite costly and time-intensive.

The program is generally open to the majority of small and medium-sized enterprises to train Canadian employees and new hires and can be used towards ERP training.

The Ontario Manufacturing Training Program (OMTP ) provides up to $100,000 in grant funding or 25 to 50 percent of eligible trainer costs (third party or in-house) and 25 to 50 percent of trainees’ internal labour costs for time spent being trained. The training projects that are eligible for funding must be related to software (for example, ERP, CRM or CAD software), equipment and processes to improve

manufacturing productivity and promote exports.

The applicant must be a Southern Ontario manufacturer that is financially stable, has ten to1000 employees, has been incorporated for more than three years and is currently exporting or intends to as a result of the training. This funding initiative has been around for several years and releases funding periodically

as it receives funding top-ups from the government.

One common element across all of these programs is the need to proactively submit a funding proposal to the funding agency before starting your project. Most government grants and repayable funding programs require applicants to wait until their funding

Looking for cost effective and energy efficient positioning?

application is approved and a contribution agreement is signed before carrying out project activities or expenses. If you need help determining which program is best for your business, please call Mentor Works team at 1-888-599-3111 who can help you target the most suitable programs for your business’ unique investments and streamline the application process. | MA

The simplicity of pneumatics combined with the advantages of electric automation The Simplified Motion Series axes are ideal for simple positioning and pressing/clamping movements.

• Quick and easy commissioning using the integrated buttons on the motor or via IO-Link

• Connection via IO-Link for enhanced functionality including diagnostics

• Simple control with 2 digital inputs for basic functions or enhanced control with IO-Link for additional functions

Cloud computing has given companies access to unlimited computing resources. Operational technology (OT) edge computing is helping them leverage that power on the shop floor.

BY JACOB STOLLER

Assembly line cameras that can sense minute paint quality defects are, by today’s standards, ordinary devices. What’s difficult is reducing the massive amounts of data they collect to timely information for updating ERP systems, adjusting machines on the fly, alerting operators or even shutting down production lines.

Industrial edge computing, sometimes called operational technology (OT) edge computing, provides the computing brainpower that makes this possible. According to IDC research data, annual growth for the segment in Canada is 12.3 percent, with the annual total reaching $7.5 billion by 2024.

“If you’re looking at a very simple high-definition webcam setup to track paint quality on cars, there’s a huge amount of data it’s processing,” says Dave Pearson, research vice-president of infrastructure at IDC Canada, “but only a tiny portion of that ever needs to be acted on.”

Edge computing is tough to define because it’s a topology rather than a class of technology. “Edge computing is really a networking philosophy, so it’s a very broad umbrella,” says Mike Daly, vice-president of sales at St-Laurentbased automation provider Rotalec. “It brings computing together to simplify it and it works across many different platforms. So, it’s defined by what you are using it for.”

What the approach does is fill in gaps where cloud computing and storage are not viable options. The most commonly

discussed issue here is latency – the delay in sending and receiving data to and from the cloud. By bringing the necessary computing power to the shop floor, edge computing lowers the latency significantly, enabling the instantaneous response required in high-speed automation applications.

“I often illustrate this by pointing out that you don’t want to have a system that’s sending an email off to find out whether or not it needs to shut off a machine when an employee’s hand is caught inside it,” says Pearson.

A related data transmission problem is one that manufacturing shares with mining and agriculture – limitation in bandwidth between the work facility and the cloud. In many situations, the bandwidth is simply not available. In others, the cost of transporting high volumes of data between the plant and cloud servers is prohibitive. This is amplified by what IDC calls source density – the staggering number of IoT devices that are collecting data in the typical plant.

“You never want to send all the data back,” says Pearson. “You want to process it there, discard the non-essential information and deal with the outliers that you’re finding on the floor.”

Edge computing not only makes local decisions for automated processes but provides real-time information for enterprise apps hosted in the cloud. As such, it acts as an intelligent grid that understands the apps that it is communicating with – for example, a supply chain control tower – and decides

whether information gets transmitted, stored or deleted.

“When I have a control tower, I want summarization data,” says Vijay Pandiarajan, director of product management at IBM Sterling. “Later on, I might need some other portion from the millions and millions of data bits that I’ve got, but I don’t know what portion I need. So you want to keep and process that data on the edge.”

According to IDC research data, annual growth for industrial edge computing in Canada is 12.3 percent, with the annual total reaching $7.5 billion by 2024.

Edge computing also keeps sensitive data within the factory walls, reducing its exposure to potential hackers. “I think security is one element that’s driving the adoption of cloud and connected edge computing, allowing customers to view and manage security holistically across their IT infrastructure,” says Henrik Gutle, general manager, Microsoft Azure, Microsoft Canada.

A common issue, Gutle says, is compliance with security standards such as ISA 95. “This has specific requirements around network isolation that can be really tricky to deal with,”

By bringing the necessary computing power to the shop floor, edge computing lowers latency significantly, enabling the instantaneous response required in high-speed automation applications.

he says. Another is data residency –keeping sensitive data from crossing international boundaries.

As Daly points out, edge computing adoption is being driven by particular use cases. Rotalec is seeing strong demand for predictive maintenance, which uses artificial intelligence (AI) to scan large amounts of IoT data for potential failure patterns.

Bringing technologies like AI and video processing to the shop floor has become increasingly viable with the

release of ultra-fast server technology from the likes of Xeon and NVidia.

“Hardware has changed a lot in the last couple of years,” says John Younnes, cofounder and COO of edge platform provider Litmus. “With the high-powered servers and chip processors that are coming out, a lot more can be done on the edge with AI and video processing.”

Graphics processing units (GPUs) and vision processing units (VPUs), for example, are enabling use cases for image processing and recognition.

Implementing automation projects that leverage edge computing, however,

involves some serious hurdles from an IT perspective. The primary one is integration with legacy equipment that might be thirty years old.

“I think probably the hardest thing for manufacturers to do right now is to integrate this technology into existing legacy systems,” says Pearson. “A lot of those systems are proprietary and don’t communicate well with each other. So, if we say we’re suddenly going to make our processes machine-learning centric, that becomes a very difficult task.”

As Younnes explains, the Litmus edge computing platform functions as a smart data broker that processes and transmits data from diverse legacy devices. “Our core competency is really solving that first piece, which is dealing with data collection from control systems and legacy devices,” says Younnes. “We’ve developed hundreds of different drivers, so we can connect to all the data sources, collect that data and then we normalize it into a common structure and format. And then we have different tools where you can do things like KPI calculations, or run different AI models on top of the data with closed loop control back to the control systems.”

The challenge, however, is not just technical – there is often a significant culture gap between the engineers that plan automation projects and the IT people who support edge computing. “Generally, it’s the IT people who control the budgets,” says Younnes, “but people who fully understand how they should be grasping the benefits of these technologies are not always easy to find.”

A vision processing unit (VPU) is a specialized microprocessor that accelerates macine vision, machine learning and artificial intelligence technologies.

The future of edge computing is tied to the use cases it enables. Predictive maintenance, quality control, augmented reality, safety and robotics are frequently-discussed examples, but the possibilities span the entire field of manufacturing automation. Once manufacturers have mastered the learning curve of installing and maintaining an edge computing environment, automation is likely to accelerate.

“As manufacturing gets more and more connected and generates more and more data, this will drive accelerated edge computing adoption,” says Gutle. | MA

BY ROBERT PIASENTIN AND ANIKA KLASSEN

The manufacturing technology landscape has evolved drastically over recent decades. As we enter the fourth industrial revolution, assessing the various technologies available and identifying those best suited for your business can be a daunting task. In recent years, innovation in automation technology (AT) has burgeoned and, with a healthy push from changes caused by the COVID-19 pandemic, has resulted in a significant acceleration in AT adoption.

T houghtfully integrating technology can help streamline operations, improve output quality and cut costs, all of which can lead to competitive industry positioning and profit maximization. Conversely, rushed or ill-conceived integration can lead to inefficiencies, material cost increases and operational headaches for management.

T he first step in integrating manufacturing technology is to determine what motivates your pursuit of automation. AT can help your business by improving quality control, enhancing scalability, improving speed to market, lowering operational costs, improving safety, or some combination of each. Clearly articulating your goals and needs for automating early in your analysis will enable you to focus your pursuit towards AT that maximizes efficiency and profitability within your business systems.

In the automation space, data analytics is indispensable and leveraging data-driven solutions is imperative. Proactive identification of process improvement opportunities as well as scalable data analytic tools and their respective license offerings are integral to securing and maintaining

Robert Piasentin is a partner in McMillan LLP’s technology group. He offers practical legal advice that drives the success of his clients’ leadership, governance and strategic negotiation initiatives. His commercial practice encompasses technology outsourcing transactions; software development and licensing solutions; strategic IP and technology commercialization arrangements; and privacy and cybersecurity issues.

is an articling student at McMillan. For more information about the authors, please visit mcmillan.ca.

competitive industry positioning. Demand for sustainability and energy efficiency throughout the manufacturing supply chain is another important AT integration consideration. Environmentally unsustainable and inefficient energy practices can both derail any material cost-savings arising from AT investments and contribute to negative consumer perceptions of your business. Climate-focused initiatives and increased consumer pressures to incorporate sustainable practices are compelling manufacturing companies to adopt environmentally sustainable automation processes. Early adoption of sustainable and environmentally sensitive AT can yield competitive advantages by reinforcing consumer loyalty, decreasing operating costs and minimizing future regulatory compliance costs.

B efore committing to an AT vendor, it is paramount that your licensing agreement accurately authorizes your intended use of the technology. Licenses will often contain limitations on the duration or scope of the license, number of licensed users and locations for permitted use. Some limitations may be agreeable, but it is critical to ensure that prescribed limitations do not impede the execution of your

business plan. For instance, if your affiliate companies need to use your AT, you must ensure the license does not impose significant additional costs or blanket prohibitions on such use. Relatedly, it is prudent to understand all applicable licensing fees (per user, monthly, per transaction, etc.) and how changes in vendor fee structures can affect your bottom line.

It is also crucial to understand whether the license grants ownership of any copyright, patent or other intellectual property rights associated with production outputs to the technology vendor. For example, if by using AT you are able to develop a more effective means for manufacturing or delivering your products and services, you will want to preserve commercialization and use rights under license terms that reflect those requirements adequately. Accordingly, it is important to verify that such developments do not immediately become vendor property requiring an additional fee to use them. Neglecting to consider ownership terms at the outset of an AT licensing relationship may result in costly litigation, inability to profit from innovation and missed market-penetration opportunities.

A dopting any form of modern

technology poses cybersecurity risks. Malicious actors frequently take advantage of vulnerabilities in operational technology (OT) ecosystems, the networks of hardware and software that enable manufacturing equipment and processes to operate efficiently. As these actors develop more sophisticated attack strategies, OT networks are often slow to or fail to adopt corresponding defences. Traditional information technology defence strategies and regulatory responses to cyber-threats are often unsuitable for OT networks. For instance, OT devices may lack the programming sophistication to enact precautionary measures such as encryption as a first line of defence. Moreover, OT ecosystems that rely on multiple AT vendors have heightened cybersecurity risks because of the increased scope of infrastructure exposure to malicious actors. Each AT product must have its own cybersecurity protocols while working cohesively within the ecosystem. Simply assuming that various technologies are secure and can securely interact is a dangerous game.

There are abundant opportunities for manufacturing businesses to leverage AT for improved operational efficiency and profit maximization. However, it is easy to fall into the trap of licensing or acquiring AT simply because others are taking that approach. AT specifically tailored to your business needs can certainly help you achieve your business goals when you have thoughtfully and carefully considered and identified your short-, mediumand long-term goals, surveyed available AT options and negotiated appropriate AT licensing terms. Like any technology, AT has the potential to grow your business and yield efficiencies, but AT cannot overcome a lack of preparation or analysis with respect to your business needs and requirements. | MA

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at hogendoorn.paul@gmail.com or linkedin.com/in/ paulhogendoorn.

I’m continuing the series of sharing tips I’ve learned from manufacturing companies and leaders I had the privilege of working with that were clearly succeeding and thriving, rather than just surviving. The tips are the best things I gleaned from them. The idea behind this series is to share all so everyone can do even better.

In the first column, the two tips were: 1) “Don’t make a big production of it”, and 2) “Your people are the smartest people in the room”. The first dealt with introducing new ideas and technology to the floor, and the second was to make sure you listened to the smart people involved in your day-to-day operation before relying on outside advice or influence. (You can find that column in the September 2021 edition).

Tip #3: “What gets measured gets improved.”

You might’ve heard this before, but there’s a catch – two actually. The first is “what” you measure is very important. If you measure the wrong thing, the improvements you make won’t make much difference – if any at all – to your operation. The best example I saw was a large tool and die company undertaking a major project to measure the OEE of their critical machines to improve that number. Several years into the project and their second attempt at doing it, one very astute manager concluded that they were focusing on the wrong thing. He observed that the time “under spindle” was relatively short compared to all the time that the pieces of work sat on skids at the end of aisles waiting for the next process to be run on them. He also found that minimizing the time between machining processes was a more pertinent objective than minimizing time under the spindle. The net result of measuring and improving that more relevant metric was a near 100 percent capacity increase in their facility, eliminating all overtime and outsourced operations as well as winning more business and taking on more work. The second catch is that to engage everyone in the improvement effort, the measurement must be shared in real time and be meaningful

for the people actually involved. Sharing reports at the end of a month may be good for plant managers and executives to review in their meetings, but that has little motivational or behavioural change value.

“Giving credit where it’s due adds to your currency in the organization as well as puts another potentially impactful contributor on the corporate radar.”

Tip #4: “You can get a lot more done when you don’t care who gets the credit.”

I learned this one early on, from one of my mentors at the London Economic Development Corporation (LEDC). He quarterbacked all sorts of small and large initiatives, deferring the credit to others. He was making investments into the people that he knew could leverage the projects’ successes, and if he ended up placing great champions to lead them from that point on, it would become a recurring win with an exponential result. Plus, he’d be free to quarterback another project. One of his most successful endeavours was the formation of the London Region Manufacturing Council. He initiated it and then placed it in the hands of a series of people (myself included) that received a lot of the credit for what the organization accomplished. Twenty years later, his initiative continues to

be a strong advocate for manufacturers in the region.

But there is a catch to this tip too. Be careful that the right people get the credit. There are ‘credit takers’ in every organization who will quickly fill every credit void. Even worse, there are ‘credit destroyers’, people sensitive to the perception that when someone else looks good, it’s not good for them. To counter this, praise and credit should be shared publicly and evenly sprinkled over a larger group. The primary praise and credit should be shared more specifically and shared up the ladder a couple of rungs so that the individual may receive more opportunities to do even more great things for your company. Giving credit where it’s due adds to your currency in the organization as well as puts another potentially impactful contributor on the corporate radar. True winning team players are never afraid of having another high performer on the team. ‘Credit’ is an important currency and needs to be invested back into the business wisely.

Feel free to send me a note at hogendoorn.paul@gmail.com if you have tips to share. We are in this together! | MA

A once-traditional mouldmaker goes all in on robotics and automation to diversify operations and embrace the future of manufacturing

BY KRISTINA URQUHART

Aquick turnover for a Tesla order prompted Windsor, Ont., tooling company LAVAL to purchase its first two robots five years ago. When the electric vehicle maker asked LAVAL to deliver 1,000 parts for the Model X in a month’s time, president Jonathon Azzopardi says he knew there was no other way to get the work done.

“Since then, our robots haven’t shut down,” he says. “They’ve been on 24/7 doing client work.”

Not only have the robots not stopped operating, they’ve been joined by two others, as well as a host of other automated solutions, such as a hot air oven, a portable measurement arm, and seven presses ranging from 250 to 2,000 tons of power.

“Robots have allowed us to do the things that human beings are incapable of doing,” explains Azzopardi. “You can’t design for human error. You can somewhat predict it, but human error exists no matter what. Robots allow us to be able to move past that.”

Diversifying into development If robotics and automation setups in a mouldmaking company seem novel, that’s because they are. They’ve also been essential to the company’s survival. LAVAL has been laser-focused on broadening

its scope beyond traditional mould manufacturing over the past decade.

The company was founded in 1975 as Laval Tool & Mould by Jonathon’s dad, Larry Azzopardi. In the years after its inception, Laval Tool & Mould designed and built injection moulds for the automotive industry. But by the early 1990s, the company had lost a significant chunk of business to lower-cost countries, Jonathon Azzopardi says.

“This transition, although slow, has had a huge impact on the Canadian mouldmaking industry,” he says. “It has forced mould makers to think in different ways, and to come up with ways to stay relevant and still retain market share.

“The route we took was to come off of the crack cocaine we call the automotive industry,” he laughs. “That is only about 30 percent of our business now.”

The youngest Azzopardi took over the family business in 2009, and now employs 80 people at two locations in Canada. The company still offers injection moulding for specialized projects, but focuses primarily on compression moulding with a thermoplastic and thermoset process using traditional materials as well as new options such as biocomposites, renewable polymers and carbon fibre.

The tail of the company has

grown longer, too – instead of solely manufacturing moulds, the company (still formally called Laval Tool & Mould but now operating as LAVAL) takes responsibility for the entire part by performing the processes that occur before and after the mould.

And that’s what has pushed the company to install technology more commonly used by engineering firms and Tier 1 manufacturers, not mouldmakers – the benefit to clients being that outsourcing these processes can save costs and reduce disruption on their own shop floors.

“I create processes in a box,” says Azzopardi. “My primary role, as a company, is to de-risk the composite solution journey for my clients. That means I must be able to do everything that they would normally do.”

This includes product prototyping that moves a part from engineering and moulding through to assembly, using simulators to predict a product’s quality or

longevity, and production documentation, customization and assembly. LAVAL will also sample products at volumes on a longer-term basis – for example, the company produced and shipped parts directly to an automotive manufacturer for two years before LAVAL’s actual client, Magna International, was ready to bring the part production in house.

“ When you’re responsible for the parts themselves, not the piece of equipment, your scope of risk and your scope of influence is much larger,” Azzopardi says. “In the engineering phase, I now have to go through a full failure and mode analysis, and actually make sure it’s strong enough or that it looks nice enough, or that it can actually go through the process without any obstacles. I have to make sure it’s mouldable, so I have to look at that part totally differently.”

L AVAL embarks on an engineering review at the start of every project, redesigning and

reengineering along the way until they have a working sample for the customer.

“ Now I need to build the whole process – so that not only requires moulds, but also it requires press, it requires material verification and selection. It requires all of the fixtures that part depends on,” Azzopardi says. “If a part warps, if it needs holes, if it’s discoloured, if it gets scratched, if it has any deformations or imperfections – we’re responsible for all of that now.”

Developing a more nose-to-tail process for composite solutions is why LAVAL has had to bring in more automation. “When you start to invest in technology, you have to continue to invest in technology. And you have to continue to invest in the replacement technology,” says Azzopardi.

Flexible setups

This has been a key ingredient in LAVAL’s secret sauce: state-ofthe-art technology is propelling the company toward a more flexible future.

Azzopardi sees the market trending toward regional flexible manufacturing, where production is localized and the processes and products vary within one facility, all using the same machines and tooling. As such, he’s purposefully

designing LAVAL that way, too.

“Say the GM Oshawa plant could make cars, but it could also make industrial air conditioners – sounds totally crazy, right? But we do it every day at LAVAL,” Azzopardi says. “We’re not doing full assemblies like they would be – we’re doing a small fraction of that – but it shows that you can actually do it. You can have a product mix in the same space at the same time if you set yourself up for it.”

Azzopardi admits that building out flexibility comes with challenges because the technology hasn’t quite caught up with the vision. “Simple things like cables hanging down from a robot – if you’re doing the same part all the time, you can put those cables in one location and they’re safe,” he says. “But as soon as you stick a different part in there, now the cables are in the way because you didn’t predict all possible outcomes. Now, we have to figure out the technology to get these wires out of the way. We’re still working through it.”

T he company has had to source robots that are universal enough for a variety of processes, and, consequently, that they have enough facility space to accommodate the setups. LAVAL is also collaborating with

multiple stakeholders on digital commissioning, or a digital twin, that will provide the level of flexibility the team needs. Getting to a stage where they can plan the entire engineering and production process virtually first means that they won’t waste time and money proving out physical prototypes, and that they’ll be ready to go when the project hits the shop floor.

L AVAL is working with St. Clair College, NGen Canada, the National Research Council (NRC), Siemens and InCycle Automation Services on the digital commissioning research project, which involves the use of simulation software, RFIDs, vision and other automation technologies to evaluate processes, parts and fixtures.

“It will look for problems and make adjustments on the fly without a human being actually having to be part of the solution,” says Azzopardi. “The computer and the robots do it all.”

The goal is to have production cells that can immediately recognize fixtures and parts and adjust themselves automatically. “Today it costs us $5,000 every time we put a fixture in, because it has to be all recalibrated and re-set up,” Azzopardi says. “We want to be at the point where you can drop

any fixture in there and as long as it’s been programmed off site and [the machine] knows what it is, it’ll go ahead and run.”

Canada’s path forward F lexible manufacturing is the way forward not just for LAVAL, but for companies across the country, Azzopardi says. He sees it as Canada’s ticket to competitiveness in the global marketplace, since it demands high quality but also carries relatively high risk since it involves investment and low volumes. In order to achieve flexibility, Canada – individual companies, industry and the supply chain, all levels of government – will have to think differently about how it leverages its facilities, technologies and geographic location.

“And they are – there are a select few who are doing a great job of that,” Azzopardi says. “But there is another group that is just doing the same thing they were doing 50 years ago, over and over again. And those are the ones that are going to disappear.

“ We have a rule here at LAVAL – if you’re not moving forward, you might as well be going backwards.” | MA

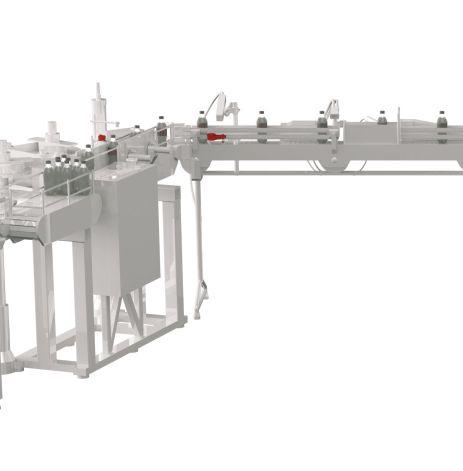

Racer Machinery uses a digital twin to shorten the critical path for implementing complex machinery.

BY KAREN SMOCK

Alex Vojinovich, chief operating officer at Ontario-based automation and custom machinery builder Racer Machinery International was impressed by the results from using the digital twin of the new Sinumerik One controller from Siemens. “Even during the global pandemic, we saw an acceleration in our development and process time by up to 33 percent.”

A digital twin is a virtual representation of a product – in this case, a machine – that is used to simulate a process. Evolved well beyond mock-ups, these digital simulations have earned the label “twin.” The accuracy and reliability of a digital twin is making it an

essential tool for designing, optimizing, troubleshooting and even providing machinery training.

For a project involving a complex piece of machinery, Racer engineers were working with Siemens to use the Sinumerik One digital-native CNC. Tiansu Jing, product manager at Siemens says, “For this project, Racer had a customer request for a solution to drive a multi-axis machine that used complex technology. When Racer came to us, we introduced the newly-released Sinumerik One controller, which covered all the requirements and performance needed for Racer’s customer’s machine. And, when we introduced the new Sinumerik One, we also introduced the native digital twin, which is unique in the market.

At that time, neither Racer nor Racer’s customer were thinking about this kind of digital twin.”

Vojinovich explains, “We were not familiar with digital twin technology; however, we knew that we could trust in Siemens and its product’s quality. The fact that Sinumerik One allows us to have an acceleration in the development time of our machines and test them before being launched, encouraged us to use the digital twin.”

Having the digital twin available became extremely important once the pandemic restricted cross-border travel. Jing explains that normally they would do in-person training for a new piece of equipment. Since the Sinumerik One had a native digital twin, Siemens and Racer engineers each had a virtual machine on their computers. They were able to use online conferencing tools for training and troubleshooting.

No waiting necessary

Not only did the digital twin save time that would have been lost due to

“The accuracy and reliability of a digital twin is making it an essential tool for designing, optimizing, troubleshooting and even providing machinery training.”

training delays, it also allowed the engineers to work on the solution without waiting out the two-to-three-month lead time to receive a physical controller. Jing explains, “Because they have the digital twin, Racer’s engineers did not need to wait for the real controller. They could start working on the digital twin to build the controller for that machine and start designing.”

In addition to normal lead time for the controller and other equipment, the pandemic caused delivery delays. However, since the engineers had the digital twin, they could continue to build the 3D model of the machine and configure the controller without waiting for delivery.

Vojinovich says, “With the virtualization feature, we can see how the machine will perform and make adjustments to our designs before proceeding through the building process, benefiting both the customer and the production process.”

When designing a new solution for complex machinery, challenges come up. Jing explains that normally, to help with troubleshooting, Siemens would send someone to the machine builder or have them send an archive of the machine that would allow Siemens engineers to replicate the issue on a test rack. To build the right test environment, the Siemens engineers have to make sure they have the same system software and setup and make the necessary PLC changes to create the same configuration as the customer. But, in this case, Racer

engineers were able to simply send their digital twin project for the Siemens engineers to load and troubleshoot. The digital twin saved the time it would have taken to configure a physical test environment. Instead, the solution was found right away using the digital twin.

The time-saving benefits of the digital twin aren’t limited to the design phase. Jing says, “If everything including training and testing is done on the real machine, then all these tasks are on the critical path of the overall project. But, with the digital twin, they can move the training to the virtual machine. With the 3D model Racer built, you can see the movement of each axis on the machine, and also see the material removed by the different tools. It can also simulate or detect if there is any potential collision.”

Jing explains the importance of taking the material removed into account, “At the beginning, the raw material is very big, but for example, after hours of cutting, the material is much smaller. So, when the machine is moving where there used to be raw material, there’s no collision alarm because the software knows that part is cut out.”

The training benefits include not only saved time, but saved raw materials and reducing the exposure of the actual machine to operator errors. With a digital twin, production doesn’t have to stop to allow a new operator to be trained.

Jing sees the digital twin as beneficial to vocational training programs as well as manufacturers. Schools that teach students how to design parts and operate machines, don’t have to be limited to the physical equipment in the labs. They can use digital twins to provide additional training. New students can make mistakes on the digital twin without damaging a physical machine or risking an accident. Using a digital twin will reduce raw material costs and wear on the tool. First cuts can be dangerous, but by having them verified virtually, problems can be identified and resolved with virtual simulations.

Jing explains how real the virtual machine can be for training purposes, “With the Sinumerik One digital twin, we offer software which is exactly the same as the real machine, as well as programming and a 3D model that’s the same as the real CNC controller. We can even add a

real machine control panel so that instead of using a mouse, the operator does everything exactly the same way as they would do on a real machine.

Using the digital twin in academic settings also has Vojinovich’s support, “We are working with universities and colleges to develop and use academic platforms with Sinumerik One for operator training such as CNC machining, maintenance and repair.”

Vojinovich is impressed with the results. “With the digital twin, customers from education to manufacturing can learn, develop and experiment before they produce components on the machine. This brings us more integrated automation, the next level of Industry 4.0, the online and connectivity aspects and greater levels of productivity.”

The digital twin proved itself during the challenges brought on by the pandemic, but the benefits apply to normal business as well. Says Vojinovich, “Racer is always looking for advanced technology to address our customers’ needs and help them address the growing complexities and changes to manufacturing today. The digital twin helps not just to fulfill this goal, but also represents an improvement in our quality, productivity and performance.” | MA

Balluff has released a new vision system software expansion package that allows users to add up to four additional cameras to the SmartVision controller. This brings the total camera count to eight. Each camera operates independently using its own instance of the Balluff Cockpit software. Cockpit, Balluff’s camera interface and programming tool, allows users to set up tasks like verifying

Rockwell Automation has released its new PowerFlex 6000T medium-voltage drive in a compact design. The drive accepts up to 13.8 kilovolts of primary voltage in a footprint that is 2,310 to 3,010 millimetres (7.58 to 9.87 feet) wide. The product’s compact design is targeted at new and retrofit industrial applications in IEC markets, especially those with space constraints. The PowerFlex 6000T drive allows the direct

measurements or reading codes.

The SmartVision controller runs these tasks without the need for additional software. The Cockpit graphical user interface is accessible from a web browser. The Cockpit software, which is licensed for up to four cameras, comes preinstalled on the SmartVision controller. The new expansion package provides licensing for an additional four cameras. The expansion takes advantage of the existing power of the controller. The controller

offers the connection of up to four GigE and USB3 cameras each for a total of eight. To upgrade an existing SmartVision controller, users have to purchase the expansion license through the Balluff WebShop. balluff.com

Vision Research has added two models to its line of Phantom cameras. Featuring a CMOS sensor with back side illumination (BSI), the new T3610 and TMX 5010 cameras sustain their image throughput with optimized light sensitivity for high frame rates

and sub-microsecond exposures. Part of the T-Series platform, the Phantom T3610 achieves high frame rates of 38,040 frames per second (fps) at 1280 x 800 resolution and up to 875,000 frames per second at reduced resolution. T-Series benefits include a compact form factor and low power requirements. The TMX 5010 joins the TMX 6410 and 7510 cameras as the entry point to the TMX family. Features include a RAM capacity of up to 512 gigabytes, a partition offering of 511 segments, standard 10 gigabytes ethernet with a rugged RJ45 port and the ability to upgrade to higher throughput models at a later date. Both the T3610 and TMX 5010 camera models include a two-by-two binned mode for high vertical resolution at the camera’s top frame rates.

phantomhighspeed.com

connection of high-voltage feeds from the main distribution line without an additional step-down transformer or substation equipment. The A-Frame PowerFlex 6000T drive also features adaptive control, an economizer mode and predictive maintenance. It is designed for managing motor control for heavy applications in industries. rockwellautomation.com

Roboze, a manufacturer of industrial 3D printing technology, has developed a 3D printer with a heated chamber designed to produce large-scale parts with super polymers and composites for industrial applications. The ARGO 1000 printer can now offer customizable, industrial parts and on-demand production at scale, and produce parts

AutomationDirect is offering a new range of pneumatic vacuum grippers and related parts from Schmalz. The product lineup includes suction cups in a flat style up to 60 millimetres in diameter made of Elastodur; bellowed style cups up to 78 millimetres made of Elastodur, silicone or nitrile rubber; and vacuum ejectors that support a suction rate of up to 860 I/ min. The company is also offering replacement cups, vacuum couplers and mounting accessories. The products come with a one-year warranty. automationdirect.com

up to one cubic metre (nearly 40 inches by 40 inches by 40 inches). The printer is intended for use in the aerospace, energy, transportation, MedTech and automotive industries, and uses sustainable super polymers

and composites such as PEEK, Carbon PEEK and ULTEM AM9085F. The company’s industrial automation system and proprietary gear-based (beltless) technology allow the production of parts that are six times more precise than those made with belt-driven printers. The ARGO 1000 will be available for commercial distribution in 2022.

roboze.com

Harold G. Schaevitz Industries’ ILPS-19 series of inductive linear position sensors uses LVIT technology. The contactless devices are designed for factory automation, as well as industrial and commercial applications. The ILPS-19 sensors are suitable for both industrial testing laboratories and OEM applications. Their contactless operation prevents wear out from dither or cycling. The series is available in six ranges, from one to eight inches (25 to 200 millimetres). The series features 0.75-inch (19-millimetre) diameter anodized aluminum housing sealed to IP-67. The radial cable exit version comes with swivel rod eye ends. Axial termination versions are available with either M-12 connector or cable. hgsind.com

The new version of the Chesterton Connect sensor is certified for use in hazardous environments dealing with high pressures, high temperatures and flammable liquids. The sensor is rated for Class 1/Division 1 (gas and vapour environments) and Class 2/Division 1 (dust environments) and IP66 for outdoor use.The Connect sensor communicates with a mobile application via Bluetooth. The app supports multiple sensors to provide a comprehensive view of a plant’s equipment health. It alerts the user when equipment pre-set operating limits are exceeded. The collected data from multiple sensors can be exported to the Chesterton Connect Cloud platform to spot trends and compare data. The new version also allows remote monitoring in hazardous areas. chesterton.com

Monitor with a stainless-steel waterproof enclosure

TRU-Vu Monitors has introduced a new 27-inch industrial-grade LCD monitor – the VMW27R-SS. The monitor features a NEMA 4X waterproof and corrosion-resistant stainless-steel enclosure. The monitor can be used in environments with high humidity, condensation, splashing or sprayed liquids, dirt, dust, airborne particulates and

more. Designed for demanding industrial environments and applications, the monitor is suitable for manufacturing facilities, metal-working plants and other dirty environments. Features include 1920 x 1080 full high definition resolution; waterproof, sealed cable entry port; VGA, HDMI and DisplayPort video inputs; 300 Nits brightness; auto restart after power loss; and TRU-Tuff Treatment for shock and vibration resistance. The operating temperature range is between 32 degrees Fahrenheit and 122 degrees Fahrenheit. The monitor can be modified or customized as per the user’s specific needs. It comes with a full three-year warranty. tru-vumonitors.com

Beckoff’s TwinCAT Analytics now includes condition monitoring functions without programming requirements. They use a simple configuration. This addition optimizes both the standard workflow and spontaneous measurements, such as during machine commissioning or service. The TwinCAT Condition Monitoring library includes numerous algorithms that support moment coefficients, discrete classification and vibration assessment according to the ISO standard, in addition to functions such as magnitude spectrum, envelope spectrum, zoom FFT, power Spectrum and multiple RMS calculations.

All functions are available as standard PLC function blocks. The condition monitoring functions integrate directly into the machine controller. All condition monitoring algorithms are available in the analytics toolbox. They can be dragged to the Analytics editor and configured. After using the “Start Record” function, the results are available at the output of the algorithms. They can be displayed clearly and graphically in the charting tool based on the interaction between TwinCAT Analytics and TwinCAT Scope View. The TwinCAT HMI visualization solution rounds out the Analytics workflow by automatically creating analytics dashboards. beckhoff.com

BY DES CARTER

Advanced manufacturing is constantly changing the way we live and work. It’s not only about installing digital interfaces in traditional infrastructure or streamlining operations, it also uses technology and data purposefully to make better decisions and improve everyone’s quality of life. Using sustainable methods and materials means building a great career and a better future for all.

Achieving a leading position in the future requires ongoing investment in research and development. SICK Canada (SICK) partnered with Humber College not only to invest in research and development but to co-create a SICK Sensor Lab in Humber’s Barrett Centre for Technology Innovation (Barrett CTI). This investment reaffirmed SICK’s commitment to research and development while supporting leaders of the future. In 2018, SICK made a commitment to Humber College’s Barrett CTI to develop a state-of-the-art technology lab that incorporates sensor intelligence for connecting systems and technology.

A key purpose of the SICK Sensor Lab is to showcase how digital transformation is gaining traction among Canadian companies.

Through SICK’s close cooperation with post-secondary institutions in its headquarters in Germany, SICK leveraged opportunities to advance the skills of our students here in Canada. Leveraging Humber’s technical expertise, we have invested as a key partner to create proof of concepts (POC) and enable innovation with Humber’s third-year Electromechanical Engineering Technology students to design and implement new applications for future projects. Two student-driven projects, the Humber “Hawk Automated Guided Vehicle” and the “Brick Sleeve” use SICK’s vision and detection sensors, as well as LiDAR

Des Carter leads marketing and communications for SICK Sensor Intelligence. SICK is an industrial automation company that provides sensor applications and solutions that efficiently process, secure and protect individuals from accidents and prevent damage to the environment.

technology in a (POC) Humber drone. SICK is also working with Humber staff and students to enhance the robotic labs throughout the Barrett CTI facility.

A key purpose of the SICK Sensor Lab is to showcase how digital transformation is gaining traction among Canadian companies. Typically, companies invest for a few reasons: to improve business processes, create additional value for customers and foster innovation. Prior to the lockdown, SICK technology experts hosted solutions training at the Barrett CTI to introduce “SICK AppSpace: Intelligent solutions” for identification, positioning, detection, inspection and quality assurance.

SICK technology experts have created a wide range of scalable portfolios of 2D and 3D vision sensors and have equipped the Barrett CTI with AppSpace and vision technology to create automation architecture that will adapt in the wake of Industry 4.0. With the advances in research and technology over the past year, the AppSpace software can now be used on sensors in addition to computers. The software is able to communicate with the cloud – either directly or via a Sensor Integration Machine (SIM).

With computing capacity for individual programmable remotely, cross-technology sensor integration and sensor data fusion, it uses these components to make technology ready for the future. AppSpace provides a complete digital object transformation for data detection and archiving, quality assurance, process analysis and predictive maintenance within the digital

transformation environment. Feedback from their built-in sensors allows them to navigate intelligently, establish boundaries of sensory technology and lay the foundations for future solutions.

SICK AppSpace offers users, system integrators and original equipment manufacturers the “freedom and flexibility” to independently develop application solutions that are tailored to the specific needs and requirements of any task. Whether it’s designing the ideal online user interface, selecting the most suitable programming technology, or distributing the sensor app on various SICK sensors, SICK AppSpace gives users the power to develop their own customized solutions. Users experience a simple graphical user interface on the front end while the software does all the heavy lifting behind the scenes.

SICK is extremely proud to work together with students, staff and businesses at the Barrett CTI. This is a tremendous opportunity to demonstrate that sensor intelligence is a promise to the present and the future. Digital transformation offers endless career choices. With the continued advancement of sensor technology as the data supplier for intelligent manufacturing, those career opportunities are infinite.

From October 6 to 7, SICK is doing a physical tradeshow in Germany, as well as an international online conference. Titled SICK Solution World, the event will discuss and showcase practical digital transformation solutions for all industries.

Now that’s intelligent. | MA

Have company news, case studies, events or story ideas to share? Send to srayghosh@annexbusinessmedia.com and you could be featured in Manufacturing AUTOMATION!