DISPLAY YOUR WAY

Headless HMI

With the C-more headless HMI, you can display your factory floor data how and where you choose. The EA9-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device of any size to display real-time operational data or messages. Use the C-more Remote HMI mobile app or the embedded Web Server if you prefer no local display at all.

Features include:

• HDMI Video/Audio output with multiple resolutions

• VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720

• Compatible with ELO Resistive Touch screens

• Multiple connections

• All the functionality of a C-more Touch Panel without the display size limitation

• Ethernet and RS-232/422/485 serial ports support programming and device connections

• USB-B port for programming, monitoring and configuration

• USB-A port for USB HID devices such as pen drives, touch screen displays, keyboard, mouse and bar-code scanners

• SD card slot for log files, project memory or graphic media

• Get control on-the-go with the C-more Remote HMI mobile app and embedded Web Server

• 82MB of user memory

Remote HMI App For only $4.99 you can have remote access and control on the go!

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada To see all products and prices, visit www.automationdirect.com

All prices shown are U.S. Dollars

training tools

Virtual and augmented reality headsets are improving training times, optimizing workflows and prioritizing safety

By Jennifer Paige

Applying smart automation

Sensors and AI are providing new ways for humans and machines to interact in the pursuit of operational excellence

Jacob Stoller

industrial operations vulnerable?

Inventory management helps to identify your vulnerable assets

Umair Masud

Manufacturing must go beyond making products. Here’s why By Dave Borelli

Siemens says sayonara to its PLM division as it seeks to turn manufacturing complexity into competitive advantage

Kristina Urquhart

OVERHEARD ON TWITTER

@EksoBionics

#Exoskeletons are entering the mainstream –what does this mean for #manufacturers? Read this article by @ AutomationMag

bit.ly/34c9hvl

@ChrisCasemore

I was recently interviewed by Manufacturing AUTOMATION magazine on the government funding landscape. Check out the article here: bit.ly/2kTb5Hw

@GemcoValve

What is blockchain and how [is] it used in #manufacturing applications?

ht.ly/7iny30pjygS @AutomationMag

@HumberToday

With #automation changing the types of #manufacturing jobs available in Canada, leaders look for ways to attract new workers & re-engage existing ones. Read about @humbercollege #BarrettCTI and the future of #skilledtrades

ow.ly/ S21150v9kYv @AutomationMag

FROM THE EDITOR

BY KRISTINA URQUHART

From data to actionable insights

Last month I attended a conference for media and research analysts hosted by Siemens (for an overview of the event, including some key announcements, turn to p. 24), where one of the themes was the ongoing effort to streamline how manufacturers gather, sort, and, most importantly, act upon data to reduce overall costs, optimize production and increase material output.

Historically, data was – or is, depending on where your organization falls on Industry 4.0 implementation – collated from sensors, PLCs, etc. and spit out into reports that not only could be difficult to distil, but also got tied up in various departments, never to be seen – or followed up on – again.

“Too much information tends to act like too little information,” said Tony Hemmelgarn, CEO of Siemens Digital Industries Software, in his opening remarks at the conference. “You need insights from that data.”

Those operational insights, derived from data that is properly managed, are what lead to meaningful actions that can fundamentally improve the manufacturing process from design through to production to final delivery. The insights are what truly drive a company’s digital transformation – not the digital infrastructure itself.

Every year, Siemens and other industry giants are refining how companies can access these insights. Perhaps most significantly, they are figuring out useful ways to communicate the information to machine operators. Whereas operational data was once trapped in a silo, squirreled away in a control room or IT centre, mobile apps now allow shop floor workers to view production data on the spot.

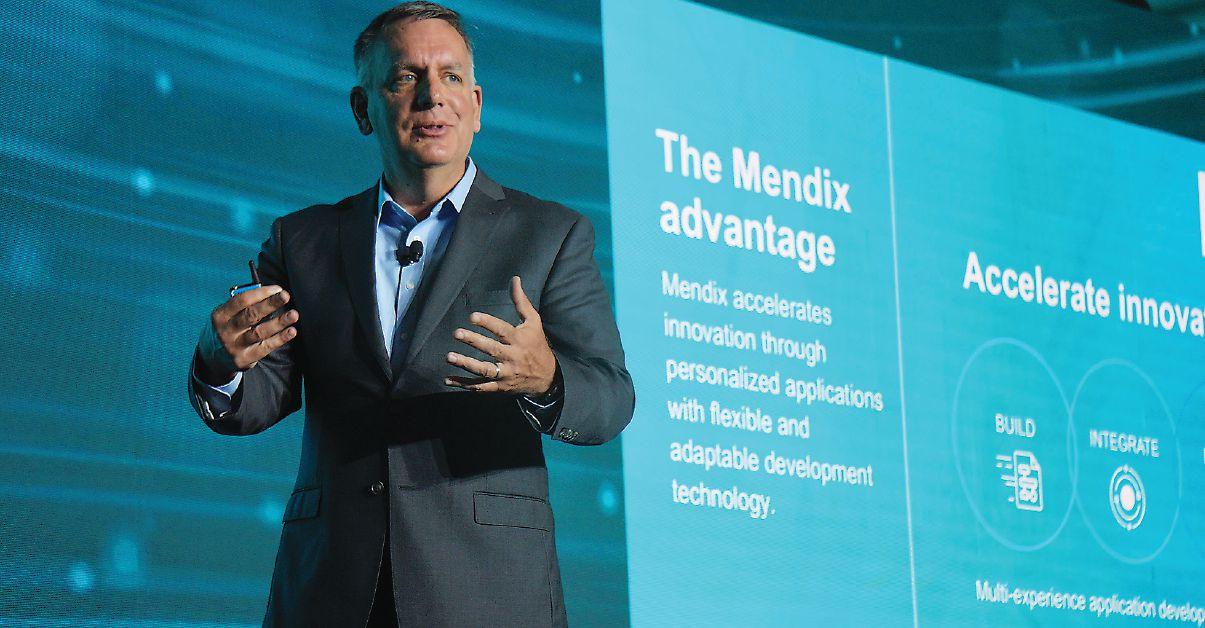

Derek Roos, CEO of Mendix, the mobile application development platform that Siemens acquired in 2018, says this shift over the past few years has been an important one in actually realizing data insights. “If you came from the OT world, you can identify where the correlations are between the machine and the data,” he said.

Humans can turn insights into actions – but so can artificial intelligence (AI), which can make recommendations based on data. Hemmelgarn summed it up nicely: “AI is just another tool to be used by an engineer,” he said. “I need data to tell me why something is overheating, not that it is overheating.”

Hemmelgarn said that like all new technology, AI has been met with a certain level of hype that will level off as it becomes integrated more widely. “AI and machine learning will continue to grow – but we need to get to realistic applications, not things that look cool,” he said.

Canadian analytics companies are already actualizing AI for manufacturers in a very real way. The tech is being used for quality inspections, maintenance scheduling and preventing unplanned shutdowns. Journalist Jacob Stoller, who wrote our March 2019 feature on the state of AI implementation in Canada, follows up that story on p. 18 with some home-grown examples that are pushing operational excellence forward.

We’re also digging into another new technology in this issue: using augmented or virtual reality headsets for training employees (p. 16).

You’ve probably heard a lot about AI, AR and VR. Now’s the time to push past the acronyms to find out what they can really do for your company. | MA

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com Tel: 416-510-6757

VICE-PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

MEDIA DESIGNER - TEAM LEAD

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-442-5600 ext 3537

PRESIDENT & CEO

Mike Fredericks

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Dave Borelli, Paul Hogendoorn, Umair Masud, Jennifer Paige, Jennifer Rideout, Jacob Stoller

Manufacturing Automation is published seven times a year by:

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

The contents of Manufacturing Automation are copyright © 2019 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

AUTOMATION UPFRONT

ROBOTICS

Report: North American robot orders up in 2019

The North American robotics market is up 7.2 per cent in the first half of 2019, according to a new report released by the Robotic Industries Association (RIA), part of the Association for Advancing Automation.

From January to June, North American companies ordered a total of 16,488 robots, valued at $869 million.

The largest driver of the yearto-date growth was an 83 per cent increase in units ordered by automotive OEMs. Other industries that saw increases include semiconductor and electronics (12 per cent), life sciences (eight per cent), and food and consumer goods (three per cent).

In the second quarter alone, North American companies ordered 8,572 robots, valued at $446 million. This represents a growth of 19.2 per cent in number of robots ordered, and a 0.6 per cent boost in dollars compared to the same time period in 2018.

“Robot use continues to grow, which is helping make U.S. companies more competitive and leading to new job growth,” says Jeff Burnstein, president of the Association for Advancing Automation. “We are currently experiencing the greatest period of robot expansion in history – over 180,000 robots have been shipped to American companies since 2010, and more than 1.2 million new manufacturing jobs have been created during this time.”

INVESTMENTS

New funding program for automotive parts manufacturers

A new program administered by the Ontario government and the Automotive Parts Manufacturers’ Association (APMA) will allow small- to –medium-sized automotive supply companies in the province apply to receive funding for projects.

Under the Ontario Automotive Modernization Program (O-AMP), companies apply to receive up to $100,000 to match investments for projects that will take less than two years to complete.

Projects may be based on new technology adoption using advanced manufacturing hardware, software or training, such as implementing logistical systems or production tracking. Projects

can also be based on adopting Lean manufacturing techniques to increase operational efficiency and competitiveness, such as hiring a Lean consultant to help with implementation.

Slash cabling costs with EtherCAT P

The North American robotics market is up 7.2 per cent in 2019.

AUTOMATION UPFRONT

To be eligible, companies must be for-profit with less than 500 employees globally and less than $1 billion in global revenues. They also must have at least two years of financial statements and have at least 50 per cent of their sales revenue in the auto supply sector.

Advanced Manufacturing Supercluster begins first project

Next Generation Manufacturing Canada (NGen), the administrator of Ontario’s Advanced Manufacturing Supercluster, has greenlit $1.89 million in funding for a $4.2-million project to develop an advanced manufacturing process for gene therapies.

The investment is expected to create 470 jobs.

The project, led by iVexSol Canada, focuses on the development of lentiviral vectors (LVVs), which are

For Absolute Feedback, we’ve

the vehicles used to deliver genetic material into patients. These gene-editing reagents are critical to the manufacturing processes of cell and gene therapies (CGTs).

iVexSol (intelligent Vector Solutions) Canada is a vector manufacturing company that is using a new technology to produce LVVs. In collaboration with other partners, the project will enable the development of an advanced LVV manufacturing platform in Canada – a first of its kind – and aims to establish the country as a world leader in gene-editing tools and technology.

iVexSol’s clinically proven LVV manufacturing process promises to address shortages by producing nearly 10 times the quantity of potent, high-quality vectors with less cost and time to produce.

“Advanced technologies are not just leading to the development of new life-saving therapeutics; they’re opening up new ways to

solution

EPC’s Absolute Encoders o er:

• SSI, CANopen, EtherCAT , or PROFINET

Resolution up to16 bits single turn/43 bits multi-turn

• communication protocols

• models

Electronic cam switches on CANopen and EtherCAT

• magnetic design

Maintenance-free and environmentally-friendly

•

Energy harvesting magnetic multi-turn technology

manufacture biomedical products,” says Jayson Myers, NGen’s CEO. “This project shows how advanced manufacturing leads to more investment and high value jobs in Canada.”

Quebec SMEs receive $1.9M for automation

Mecademic, the manufacturer of compact industrial robotic arms, has been awarded over $600,000 from the federal government in a $1.9-million round of non-repayable funding that is allowing three Montreal-based SMEs to make automation improvements.

Mecademic is receiving $656,251 to set up an electronic board assembly line, automate its assembly process using, among other things, its own robots, and to carry out marketing activities for its products.

Comptoir Agricole Ste-Anne, which specializes in the sale and installation of agricultural equipment used for grain handling, will acquire and install new production equipment, including a laser-cutting machine as well as a device for optimizing the management of raw material and product flows. It will also automate its production lines with its $1-million investment.

Groupe Somac, a family business based in Mirabel that specializes in the production of aluminum shelters, will purchase a five-axis machining centre and will upgrade its products. The $250,000

contribution from the government will allow the company to streamline the shelter installation process and make the shelters accessible to a broader clientele.

The total investment is also expected to create 30 new jobs in Quebec.

Manufacturer to add automation, jobs in $8.5M upgrade

A Canadian artisan dessert manufacturer is receiving nearly $3 million from the federal government to implement new automation and add 64 full-time jobs in an $8.5-million project.

La Rocca Creative Cakes in Richmond Hill, Ontario will create 60 manufacturing jobs and four management jobs as it positions to diversify its export markets.

In addition to FedDev Ontario’s contribution, the project includes $5.5 million in private investment.

As part of the project, La Rocca Creative Cakes will expand and renovate its existing facility, adopt Industry 4.0 technologies, and add advanced equipment to increase production capacity and further its manufacturing capabilities.

Newly adopted automation and digital planning tools will help to improve efficiencies, reduce operating costs and minimize waste. In addition, the project will help shorten the development time needed to bring new products from design to market.

Mecademic, the Montreal-based manufacturer of industrial robots for small-scale applications, is one of three Quebec SMEs receiving a total of $1.9 million from the feds to scale up automation.

PRODUCTION

Bombardier secures contract for Metrolinx

Metrolinx, Ontario’s regional transportation agency, has agreed to buy 36 more bi-level cars from Bombardier Transportation, which will be manufactured at the company’s Thunder Bay plant.

The agreement will enable Metrolinx to add 31 standard and five accessible cars to its existing order. Bombardier has confirmed that its previously announced layoff of 550 workers will still go ahead in November.

The new cars include Bombardier’s Orbita system that will allow Metrolinx staff to see real-time performance data and pinpoint issues relating doors, the HVAC system and electrical equipment.

Production on the new cars is expected to start in early 2020 and wrap up by spring 2021.

TRAINING

NIMS launches new parts inspection credential

The National Institute for Metalworking Skills (NIMS) has launched a new credential to validate an instructor’s or evaluator’s parts inspection skills.

Designed for manufacturers and schools, the new NIMS Inspector Credential allows a faster, more efficient performance validation process within the NIMS online structural framework.

Until now, shops and schools had to send test parts to be inspected and evaluated by a review committee, which guaranteed quality control, but could take up to four weeks and often created a backlog of uninspected parts. Now, the validation can be done on site by instructors, and credentials can be issued much quicker.

NEW DIGS

Beckhoff opens two new U.S. locations

Beckhoff Automation has opened two new U.S. offices in Greater Boston and Philadelphia. Both locations, strategically

selected based on growing customer demands and market share in these areas, will provide additional applications engineering, sales and training resources. New automation technology showrooms at the two offices will also offer hands-on experiences with Beckhoff hardware and software

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

NIMS has launched a new credential for parts inspection skills.

for engineers and business leaders.

The Philadelphia Technology Center in Wayne, Pa., comprises about 5,000 square feet while the Boston-area sales and support office, located in Burlington, Mass., occupies 3,500 square feet. Sizable training rooms at each office will offer numerous educational opportunities for customers.

Beckhoff plans to open several new North American facilities in 2019 and 2020 in or near Los Angeles, Houston, Denver, Milwaukee and Orlando, Fla., as well as Mexico City and Vancouver, B.C.

Beckhoff Canada is headquartered in Mississauga, Ontario, and maintains a regional office in Laval, Quebec.

SAFETY Connectivity

manufacturer fined $70K for critical worker injury

Belden Canada Inc., a manufacturer of connectivity and networking products in Cobourg, Ontario, has been fined $70,000 by the Ontario Ministry of Labour after a worker was critically injured in operating machinery at its facility.

Belden Canada pleaded guilty to the offence, which took place February 15, 2018. The conviction

took place September 11, 2019, at which time the court also imposed a 25-per-cent victim fine surcharge as required by the Provincial Offences Act. The surcharge is credited to a special provincial government fund to assist victims of crime.

On the date of the incident, a worker was working on a machine used to process wire. The wire arrives wound around a spool and is then fed from the spool into the machine.

Almost immediately upon starting the machine, the worker became entangled in several loops of the wire. The machine had doors and a locking mechanism but no

key or tool is required to open this lock; therefore it is not considered to be a fixed guard.

The Industrial Establishments Regulation states that a machine shall be guarded so that the material being processed will not endanger the safety of a worker.

DEAL MAKERS

Bosch Rexroth strengthens partnership with Atlantic distributor

Bosch Rexroth Canada’s Atlantic Canada distributor, TRC Hydraulics Inc., will assume a greater strategic role to support the company’s

hydraulic products, services and customers.

TRC will also grow Bosch Rexroth’s business from its four locations in Atlantic Canada: TRC Hydraulics Inc. and TRC Manufacturing, both in Dieppe, New Brunswick; TRC Hydraulics Inc. in Dartmouth, Nova Scotia and TRC Hydraulics Inc. in Paradise, Newfoundland and Labrador.

As a result, many of Bosch Rexroth hydraulic accounts will be transferred to TRC Hydraulics, who has been the company’s distributor since April 2017.

Matrox co-founder acquires full ownership

Matrox has announced that its co-founder, Lorne Trottier, has acquired 100 per cent ownership of the Matrox group of companies, including its three divisions Matrox Imaging, Matrox Graphics and Matrox Video.

Since 1976, Matrox, which is headquartered in Montreal, has pioneered a number of innovative hardware and software solutions, including machine vision, for an array of high-tech industries.

“I am excited to lead this great organization as we implement growth initiatives,” Trottier says. “Matrox is a great Canadian success story.”

Beckhoff Automation has opened new offices in Boston (pictured) and Philadelphia, and has plans to open more outposts, including one in Vancouver, within the next year.

MOVERS AND SHAKERS

Atlas Copco Compressors Canada has appointed Ariel Rubinstein as president and general manager. Rubinstein joined Atlas Copco Argentina S.A.C.I. in 2004 as a service engineer. In 2005, he became the service responsible for the compressor technique business area. From 2007 until 2008, he was aftermarket manager and in 2008 he was appointed compressor technique service business line manager. In 2011, Rubinstein worked as service and engineering manager for Toyota Material Handling Mercosur. In February 2013, Rubinstein became general manager of Atlas Copco Argentina S.A.C.I. Rubinstein is an industrial

engineer from the Merchant Navy University in Argentina. Atlas Copco Canada sells and services air and gas compressors, generators, construction equipment and assembly systems manufactured by its parent company, Atlas Copco.

AMETEK Surface Vision, a provider of automated online surface inspection solutions, has appointed Éric CharetteBéchamp as its regional sales manager for Canada. In addition to AMETEK Surface Vision, CharetteBéchamp will also serve as regional sales manager for AMETEK Land, reflecting the close application and market synergies between the surface inspection and temperature

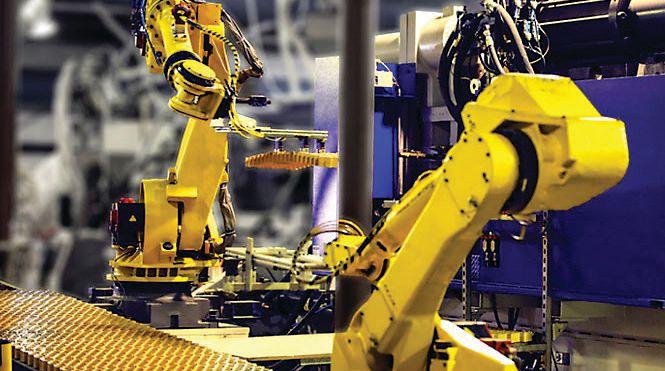

3 WAYS TO WIRE = 1 FAMILY

measurement process solutions provided by these two business units of AMETEK, Inc. Charette-Béchamp has more than 20 years of experience in the manufacturing sector in Canada. He joins AMETEK from Albany International, where he was a sales and service engineer for 14 years. He has also worked as a paper machine superintendent for Bowater (now Resolute Forest Products), in Donnacona, Quebec.

ABB has announced Björn Rosengren, currently president and CEO of Sandvik, as its new chief executive officer effective March 1, 2020. Rosengren will join ABB on February 1, 2020 and succeed current CEO Peter Voser a month later. At that time, Voser

will revert to his position at ABB solely as chairman of the board. Rosengren, a Swedish citizen, is an international executive and leader of industrial businesses. He has been the CEO of Sandvik, a high-tech global engineering group, since 2015. During this time, he has overseen the successful implementation of a decentralized structure and improved both the profitability and financial strength of Sandvik.

General Motors has named Scott Bell as the president and managing director of GM Canada. Bell began his career at GM in 1989, with his most recent position being vice-president of sales, service and marketing for GM Canada. Outgoing GM Canada president Travis Hester will now serve as global vicepresident of customer experience, a newly created position. | MA

TOPJOB® S Terminal Blocks

Now with Push-buttons and Levers!

• Choose the right version for your application: lever, push-button, or open tool slot

• All three versions share the same Push-in CAGE CLAMP® technology for direct insertion of solid or ferruled conductors – no tools needed

• Mix and match technologies on the same rail and share accessories (jumpers, marking, etc.)

Request a sample: www.wago.us/leverTB

Ariel Rubinstein

Éric CharetteBéchamp

Bjorn Rosengren

With manufacturing trending toward flexibility and modularity, enclosure manufacturer Rittal now also runs an automation division for customized off-the-shelf solutions. TIM ROURKE, president of Rittal Systems Ltd. (Rittal Canada), discusses the shift.

MA: How have you seen the industry change over the last 25 years since you first started at Rittal Canada?

TR: The digitization of everything has had a big impact in terms of how our customers work with us and work with our products. They really relied on us back then, in the ’90s, to provide them with all of the technical information that they required. So much of that information now is available selfserve. So it’s really about communicating to customers about what you can do and how you do it. Today, we’re completely selling around a system concept and utilizing our value chain.

MA: How has Rittal’s product line shifted to meet market demand?

TR: The [enclosure] cabinet today is doing much more than it did 20 years ago. They’re more efficient in terms of the amount of space that they’re using within the manufacturing facility. It’s more about flexibility. That’s what we see with the dramatic increase in popularity of modular solutions that have a variety of accessories that allow you to customize that solution. It’s standard off the shelf, but you can customize it to your unique application. With our modification centre, we’ll put the solution together for you. We’ll do all of the holes, drilling and tapping that you need for mounting your equipment – your components, push buttons, DIN rail, controllers, PLCs – inside the cabinet.

[Companies] have fewer resources than they had five years ago, 10 years ago, two years ago. So any way that you can provide more value to them that’s going to allow them to save time and even engineering costs is a big advantage. If you can engineer off a standard platform versus

trying to engineer off a custom solution, you can save money.

MA: Do manufacturers tend to over-customize?

TR: If you’re an engineer and designing a new control system, or a new machine or any piece of equipment, there’s kind of a vision of what you have in a world of “anything’s possible.” But there needs to be the focus on, well, what is going to make it easy to manufacture that? And easy to manufacture that more than once, if it’s something that you’re doing on a repeat basis.

That’s where there’s a challenge with the self-serve aspect – our ability is to work as a technical consultant. It’s really important for our sales organization to be working with the customer to get the raw data and have a good understanding of where you want to go. And then we like to come in and help them create the simplest, most efficient, optimized version of their vision.

MA: Rittal has expanded beyond enclosure solutions into the

automation market. Can you talk more about that?

TR: It’s a growing piece and represents a lot of opportunity for us. Rittal automation extends from small, portable machines for wire process automation – so cutting wires to length and automatically stripping and crimping a ferrule onto the end of a wire to save a lot of time in wire processing. You can imagine how much savings there are to be realized if you can take that process from a minute to strip and crimp a wire to 10 seconds, or five seconds, and there are 500 wires in a control panel.

[With] the Perforex machines, we can do cut outs in the side of the box, in the door of the enclosure, the side walls, the control top, the mounting panel. When you’re talking about 10 per cent of the time it takes to do that manually, the ability to automate at the manufacturing side of control panels creates an opportunity for those industries to gain an advantage over their competition in their particular space.

In the higher-end wire terminal machine, which is much more

complex, you can have 36 wires with different gauges and colour insulation feeding into it [and] it produces the wire bundle that you need for a particular control panel. So if you need 250 wires, you will get a bunch of wires that are all cut to the right length, all stripped, all crimped with the ferrule on the end and all marked with the proper wire markings. Fifty per cent of the time in the manufacturing of a control panel goes into wire processing and wire landing. So there’s a lot of savings to be had for system integrators and panel shops.

MA: What’s been your biggest challenge at Rittal?

TR: I’ve been president for four years and we have 55 staff. Our biggest challenge is staffing and personnel. As we grow, we need to look for people, new skill sets. We need to put people into positions that maybe didn’t exist in our organization two or three years ago. The first challenge is finding the people, and then the second is creating the environment where they want to stay.

MA: What kinds of roles didn’t exist before?

TR: We’ve had some technical people in place, and the job that they’re doing has evolved. It was technical support at the beginning and now it has really moved more into an engineering type of role within our organization. That’s one area we’ve really had to grow to support the modification side of our business – to support the increasing complexity of what our customers are trying to do, and the increasing complexity of our product as well.

MA: What are clients are trying to overcome when they first come to you looking for a solution?

TR: Quite often they come to us when they’ve failed to find a solution somewhere else and they’re looking for something different.

We have one particular customer where we now drill and tap the mounting panel for them, so that when they get it they just have to start mounting their components onto the panel inside the enclosure. There are over 700 holes in that. That takes us about 45 minutes for us to do on our machine, and that used to take one person [on their end] one whole day. So maybe we are 10 per cent more expensive for the product itself in the door, but we just saved you eight hours of shop time with your guy. Now you can take that person and have them do something that’s more productive than simply drilling and tapping a mounting panel.

MA: What do you see the Canadian manufacturing landscape looking like over the next three to five years?

TR: It’s tough to predict – what the Canadian manufacturing landscape needs is some support from government. We’re suffering from continual contraction in the manufacturing space in Canada. And the industry needs some assistance to continue to be competitive and continue to be an attractive place for companies to establish manufacturing. We do show that you can be profitable manufacturing things in Canada, but you’ve got to be efficient and you’ve got to be innovative in your approach. Where we go depends on what governments want to do in terms of supporting innovation, cost efficiency and automation of the manufacturing processes, and training people to support these new technologies.

The manufacturing environment is changing; we can’t put all these people out of work. We have to find a way to retrain so they can work in

the new manufacturing environment. Companies can do that. We all bear a responsibility to help train and develop the people that we need within our particular spaces and industries […] but it also needs the support of consistent, cooperative government programs at the federal level and the provincial level. Everybody should be coming together to create an

environment for the manufacturing community in Canada that can compete with the rest of the world.

In our particular industry, electricity isn’t going anywhere. There are going to continue to be opportunities in the electrical industry because of the increasing move toward powering things with electricity. We’re moving away from

fossil fuels, and moving more to electricity. The consumption and purchase of electric cars is skyrocketing right now. So to continue to build the infrastructure to support that is going to be good for the electrical industry. Some of the other industries are going to be more of a challenge. | MA

This interview has been condensed and edited.

Always get a star performance every time

Whether you’re designing control systems or programming PLCs, you need to know the core products are going to perform like stars. Festo’s Stars of Automation offers you a one-stop solution for products, with over 4,000 quality-engineered, high-performance components.

Keep your maintenance needs backstage with Festo’s Stars of Automation.

For great value, look to the stars. Choose Festo.

Fast Shipping

24 hours 5 days or less

GOING DIGITAL

BY JENNIFER RIDEOUT

Reducing email threats: 5 tips for cybersecurity awareness month

Last year, email spam turned 40. Since 1978, spam has grown exponentially in prevalence, inundating inboxes with unwanted offers for pharmaceuticals, diet products and job opportunities. Not only that, it’s been joined by its far more dangerous cousins, phishing and malware.

Today, the volume is staggering — 85 per cent of all email in April 2019 was spam, according to Talos Intelligence. The volume of unwanted email is on the rise too; spam hit a 15-month high the same month.

You could argue that email makes it almost “too easy” for scammers. Email forces a user to read and make assessments about what they receive, then make decisions as to what they open or click as a result. Just the right amount of social engineering – exploiting the individual’s good nature – can push them to action. It’s this social engineering that not only makes email an enticing delivery vector, but also so challenging to defend.

No wonder email is one of the primary challenges that keep chief information security officers (CISOs) up at night. In a recent CISO Benchmark Study, we learned that 56 per cent of CISOs surveyed felt that defending against user behaviours, such as clicking a malicious link in an email, is very or extremely challenging. This ranks higher than any other security concern surveyed – higher than data in the public cloud, and higher than mobile device use. Even if your manufacturing organization doesn’t have a CISO, email security needs to rank high on your priority list.

So how do you secure something that’s both a necessity and a risk at the same time? At least for manufacturers – unlike securing industrial zones or managing physical access permissions – email security best practices are applicable across industries, meaning that what’s proven to work for a financial institution or retailer will work for you, too. Here’s how you can keep your business safe and reduce the risk that email threats pose.

Run regular phishing exercises.

Your employees are your greatest defense against cybersecurity threats, especially when it comes to tailored phishing attempts. Employees that can learn to recognize a phishing attempt outright can stop the number one source of endpoint compromise.

Cyber and email security awareness are vital for manufacturers and their employees as more advanced solutions, such as the IIoT, are adopted across the factory floor.

To raise awareness, run regular phishing exercises to test and educate users. Emulate the latest real-world techniques to keep people abreast of what they may encounter. For users that fall for emulated phishing attacks, provide education immediately by directing them to webpages with further information about phishing. For highrisk users in your organization, where significant damage could occur if they fall for a ruse, practice tailored phishing campaign exercises.

Use multi-factor authentication (MFA). If your employee’s email account credentials are successfully stolen, multi-factor authentication can prevent an attacker from gaining access to the account and wreaking havoc.

Here’s how it works: let’s say that someone does manage to get a hold of your login credentials, or someone’s on your network, and attempts to log in. With MFA, a message is automatically sent to the owner to check if they just attempted to log in. The user, in this scenario, realizing that they did not just attempt to log in, denies the request outright. The attack is thwarted.

Keep software up-to-date. In some cases, emails that include malicious URLs may point users to pages with exploits. Keeping browsers and software updated, as well as any plugins, helps alleviate the risks posed by these attacks. Be careful with requests to log in. Malicious actors, intent on stealing login credentials, go to great lengths to make their pages look like the login pages you would be familiar with. If encountering such a login prompt, check the URL in the address bar to ensure it is correct. If encountering a pop-up style window, expand the window to make sure that the full URL, or at least the full domain (i.e. www.yourcompanyname. com), is visible.

Make sure the email sounds plausible. In the case of scams like digital extortion and advance fee fraud, the senders often craft elaborate stories to try to convince you that the email is legitimate. Does the scenario as laid out make sense? Are there any holes in their stories, from a technical side, financial process perspective, or other? If so, approach with an eye of skepticism.

Cybersecurity awareness and email security awareness are vital for manufacturers and their employees as more advanced solutions, such as the IIoT, are adopted across factory floors. Keep your networks and data safe this cybersecurity awareness month with these tips, and don’t let hackers win. | MA

Jennifer Rideout is the manufacturing marketing manager for Cisco Canada. She is responsible for developing go-to-market strategies for the manufacturing sector in Canada, including channel alignment and content development. She can be contacted at jerideou@cisco.com.

In partnership with our global leading suppliers, Wainbee has developed solutions that allow for the collection and exchange of real-time data for greater visibility. Our cloud based packages enable remote visibility and condition monitoring of machines working in the most remote area’s or from equipment within the factory.

By tailoring and consolidating data, insights can be gained to reduce downtime and service costs, as well as improving the performance and efficiency of machines and equipment.

Wainbee’s systems are modular based in design with seamless connectivity and customizable software, thus suitable for future development as may be required.

Our systems are designed to be implemented into existing mobile systems and various industrial automation control architectures, ensuring the seamless flow of data across many platforms.

Real-time analytics helps to make better business decisions.

Industry 4.0 is now well in progress and will transform how the manufacturing industry stays competitive and efficient. With 60+ years of expertise, combined with our class leading Mobile and IoT Industrial product lines, Wainbee can help Canadian Manufacturers keep pace with the new digital landscape.

INDUSTRY WATCH

BY PAUL HOGENDOORN

Hitting the trifecta

Paul Hogendoorn co-founded FreePoint Technologies seven years ago with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at paul.hogendoorn@ getfreepoint.com or getfreepoint.com.

Just in case you don’t know the term, “hitting the trifecta” is the expression used to describe the ultimate winning bet on a horse race. It means picking the top three finishers of the race, in the correct order. Since the odds against doing so are extremely low, the winning payouts are often extremely high. If you picked the right horses in the right order, a two-dollar bet could return a four-digit payout.

Wouldn’t it be great to know which three horses to bet on, and in which order?

In many manufacturing companies in North America today, there are many competing ideas and priorities being considered by companies seeking to win the improvement race. What is the most important improvement to make

It’s a simple three-step process, and picking the order is just as important as picking the

horses.

first? What investment will yield the biggest return? Which improvements will hit it out of the park, and which ones will result in minimal, if any, gain?

There is an approach that your manufacturing company can follow to “hit the trifecta.” It’s a simple threestep process. The first step is easy, and relatively low cost. The second step requires a bit more effort, but is risk mitigated because it is based on the results delivered in the first step. The third step requires the most investment of the three steps, but since it is based on the results delivered in the first two steps, it is not only risk mitigated, the cost of the investment may have already been paid for by the results of the first two steps. Picking the order is just as important as picking the horses.

So, are you interested in knowing

how you can hit the manufacturing trifecta?

Step 1: Establish an empirical baseline to truly understand the critical “value-adding” activities on your plant floor. This is done simply by connecting your machines to a data collection system. With the advent of Industrial Internet of Things (IIoT) technologies, it is remarkably inexpensive and can be done in typically less than an hour without modifying the machine or your current infrastructure – even on old machines. Within 30 days of placing this small bet, you will not only have established an empirical baseline of your plant, you will have given real-time visibility to the plant that puts everyone on the same page, aiming for the same thing you are: productivity and profit improvement.

Step 2: Engage your people in the process of improvement by using available off-the-shelf tablets and engagement software. You will now be collecting all the information you need to determine all the reasons your equipment and processes aren’t running as effectively as they should be. And more importantly than that, you will have made your people a part of the solution and improvement process, every hour of every day. They will be engaged.

Properly constructed and presented, this kind of software will be embraced by workers when they conclude that management is not monitoring them, but rather listening to them. This is a powerful game changer for many companies, especially those companies where people are their biggest input cost. Those same people can also be their biggest advantage and asset.

Step 3: Connect your live, empirical machine data, and your fully engaged people, to your schedule and workflow plan dynamically, in real time. Most plants use a combination of accounting systems, whiteboards, even Excel spreadsheets, to plan and then report on the performance of their productivity. Some may have an enterprise resource planning (ERP) system deployed and some may even be considering a manufacturing execution system (MES) system. The problem with most ERP or MES system deployments is that they represent a single, very large bet that will take a very long time to pay out, if it pays out at all.

The best approach, in my opinion, is to use the knowledge, insight, and early financial payback from the first two stages, and then tie them together using visualization tools that line up with your plant’s current effective processes. Placing a bad bet on a system that takes years to fully implement, and that requires your manufacturing processes to be modified for the system to work, is not just a bad bet – it’s often a losing bet.

If you are still reading, you are

probably wondering how long it should take to hit this trifecta. The first step should only take 30 days and should result in a payback 30 days later. The second step should also only take 30 days, and it too should result in a payback in 30 days. The third step should take about 120 days, but it can take as long as you like for payback – because at that point, you will already have great empirical data,

engaged and motivated people, and your system can be built to match your improved, and continually improving, manufacturing processes.

What is the expected payback on hitting this trifecta? From my experience, manufacturers should typically see a 10 to 15 per cent improvement at step one, a further 10 to 15 per cent improvement after step two, and a 20 to 30

per cent improvement after step three. Doing the math, that would work out to productivity improvement, or capacity increase, of between 45 and 79 per cent.

If you had the knowledge of which horses to bet on, and which order to bet on them on, would you? Our suggestion: bet on achieving empirical data first, engaging your people second, and digitizing your plan third. | MA

Raise the STANDARD

• Customer-driven designs and options

• Increased robot speed and capability

• World’s smallest controller

• Proven life-tested positioners

• Intuitive welding interface

• Improved diagnostics

• Smarter safeguarding

• World-class customer support

We’ve upped the ante.

Our proven ArcWorld ® workcells are faster, stronger and more compact than ever. These highly flexible solutions are simple to customize, easy to install and extremely reliable. Increase your productivity, part quality and safety standards with an ArcWorld configuration designed for you.

Raise your standards! Visit us at FABTECH.

SENSORY-RICH TRAINING TOOLS

Virtual and augmented reality headsets are improving training times and skill retention, all while reducing costs, optimizing workflows and prioritizing safety

BY JENNIFER PAIGE

In an effort to improve safety and enhance the transfer of knowledge from experienced to new employees during the training process, North American manufacturing companies are beginning to employ augmented (AR) and virtual reality (VR) technologies.

“Those who experience immersive, sensory-rich training simulations are more likely to recall what they learned.”

“This technology is something that is really taking a hold,” says Craig Resnick, vice-president at ARC Advisory Group, a technology research and advisory firm for industry, infrastructure and cities. “In the manufacturing industry it tends to be more of an evolution than a revolution, but I would say in three to five years you will probably see these systems being extremely commonplace as training tools. This technology is being very enthusiastically accepted on the factory floor and I think this is something that is going to have a significant impact on productivity and profitability.”

A R technology works by leveraging advanced sensors and computer vision to capture audio and visual cues that can document location and work processes. Using 2D and 3D eyewear, smartphones or tablets, AR can superimpose a computer-generated image on a user’s view of the real world, thus providing a composite view.

Mike McCready, an instructor and applied research chair in virtual and augmented

reality at Lethbridge College in Alberta, is currently exploring and researching how VR/AR technologies can be used to improve training and day-to-day operations in various sectors.

“ With AR, a lot of the value comes from on-the-job training and guidance. There are a number of AR devices that allow employees to pull up schematics or an operation manual of a device they are working on, load up real-time instrumentation data or share live video of the work environment with a supervisor – all voice activated. These devices [will] prove as invaluable assets to any technician, machine operator or tradesperson in the near future,” says McCready. “Gone will be the days of flipping through a 100-page machine manual, stopping work to call a supervisor or struggling to operate or repair machinery.”

With the ability to superimpose digital information on real-world surroundings, navigating and instructing employees through new processes or facilities has become easier and safer, as the AR technology can highlight dangerous areas, pinpoint safe locations and provide real-time guidance.

“Say you are walking by a closed cabinet,” Resnick says. “This would be like having X-ray vision because the AR screen would be able to supplement what is inside the cabinet and provide different variables.” AR can also connect users with experts anywhere in the world as they work through various scenarios and tasks.

“ Think of it as having an instructional YouTube video at your disposal,” Resnick says. “Let’s say you buy a new piece of furniture and you open the box and there are 8,000 different parts. Now imagine if you had a

wearable that was instructing you on which part to take, how to connect everything, what tool you need and the next step. How much faster do you think you could assemble the piece of furniture? A third or half the time?”

Sensory-rich simulations

VR takes training to a new level by providing the ability to fully immerse an employee in a simulated environment, allowing the user to roleplay, make decisions and live out the consequences.

“ Traditional scenario-based training for emergencies can be challenging to accomplish while maintaining the safety of the employee,” says McCready. “With VR, unlimited scenarios could be created ranging from power failures, to fires, to chemical spills – all with zero risk to the employee and environment. These scenarios can be dynamic and responsive.

“It’s not just the various scenarios that can be programmed that make VR training an important option, it’s the effectiveness of the training as well. Those who experience immersive, sensory-rich training simulations are more likely to recall what they learned. This is because multiple senses are being stimulated, and [humans] think spatially.”

Lorne Fade, co-founder of VR Vision, a Toronto-based development studio that creates custom-tailored VR and AR training solutions for large companies in a number of sectors, explains that VR also allows the ability to easily

Honeywell’s Immersive Competency uses augmented reality to provide practical, hands-on guidance, preparing industrial personnel for a variety of situations.

replay recorded training sessions for unlimited replicability of complex training processes.

“ This allows companies to train more people, faster, as well as increase learning retention overall. With optimized workflows and learning procedures, you are able to surpass audits and meet compliance regulations much more efficiently as well,” Fade says. “This all leads to reduced costs, insurance premiums as well as environmental footprint. Not to mention the reduction of travel expenses […] companies in the past had to use specialized trainers by flying them around the world to facilities. With multi-player support in VR, we can now connect teams anywhere in the world for enhanced collaboration and easy access to specialists and expertise.”

In terms of safety training, VR allows employees to play out dangerous and rare scenarios, or virtually train in areas where the physical environment may be unavailable, such as remote or unsafe locations, or those that are under construction.

“ The real benefits of using VR for training applications are that you are able to eliminate risky and harmful environments, which can prevent training injury and accidents,” Fade adds.

Resnick says that while employee safety throughout the training process is a top priority, the return on investment for manufacturing companies should not be understated. “One disaster averted as a result of having a

confident and properly trained employee –the ROI is almost immediate.”

Applying AR/VR to the real world

In March 2018, Honeywell Process Solutions introduced an AR/VR cloud-based simulation tool to help enhance its training process. The company uses two headsets: Microsoft’s HoloLens, a self-contained holographic computer, and Windows Mixed Reality.

“Emerging technologies, such as AR or VR, can unlock new opportunities to secure, transfer and communicate knowledge,” says Veronica Turner, the Connected People business development lead, Americas at Honeywell Process Solutions. “Specifically, they allow for a true ‘learning-by-doing’ approach, letting operators practice critical industrial work activities in a safe, virtual space. Similar to a flight simulator, trainees can safely practice for daily activities and emergency situations, without putting at risk the live operation of a plant and its workers. This approach improves skill retention versus traditional training methods by up to 100 per cent and reduces the amount of training time for new operators by up to 60 per cent.”

With the immersive technology, Honeywell Process Solutions is able to simulate various scenarios for its C300 controllers, including certain tasks that do not occur often or that may present safety or production risks, such

as primary failures, switchovers, or cable and power supply failure.

“ We target specific job roles and develop custom programs aimed at developing concrete skills, where students are evaluated on their competency and not on the course itself,” says Turner. “This targeted approach shortens the learning curve, increases knowledge retention, boosts morale, and consequently increases employee satisfaction and retention.”

Getting started

In terms of implementing immersive technology as a training tool in the manufacturing sector, Fade says cost and timeline for implementation varies greatly depending on the specific needs of the AR/VR program and the kind of training content that is required. VR Vision, for example, works with clients to develop personalized VR/AR training applications. “The basic framework for this involves a lot of back and forth with clients to ensure the training process is accurate and meaningful.”

In terms of hardware, Fade suggests manufacturers should explore some of the latest available technology, including VR headsets such as the Oculus Quest, the Oculus Rift S or the HTC Vive Plus, and AR headsets such as the Microsoft HoloLens 2 or the RealWear HMT-1. | MA

Jennifer Paige is a freelance writer and editor at Annex Business Media.

APPLYING SMART AUTOMATION

Connected sensors and artificial intelligence provide new pathways to operational excellence

BY JACOB STOLLER

Although smart automation is a hallmark of manufacturing’s digital age, one of its most influential innovations is now approximately a century old.

In the early 1900s, Toyota founder Sakichi Toyoda developed an automated loom with a mechanism that stopped production automatically when a thread broke. The innovation helped his company, which eventually became Toyota, pursue two goals: improve quality by catching defects at the point of occurrence and, since the machines could run unsupervised, increase worker productivity.

The underlying principle was dubbed “autonomation” ( jidoka in Japanese), meaning automation with human-like intelligence. Jidoka became, along with just-in-time, a pillar of the Toyota Production System and the Lean manufacturing movement.

Today, manufacturers are applying artificial intelligence (AI) to pursue a very similar goal – catch defects at the point of occurrence in order to improve quality and free workers from repetitive tasks so that they can spend their time on higher-value work. The new tools are so effective at detecting anomalies that they are likely to have a major impact on operational excellence and the quality movement.

Improving inspection methods I n one example, Kitchener, Ontario–based Acerta Analytics

Solutions is helping a Japanese Tier 1 automotive OEM reduce defects in the manufacture of transmissions. The problem presented to Acerta was that the end-of-line (EOL) quality management process, which was based on statistical process control (SPC), was producing false negatives that resulted in warranty claims.

The company wanted an AI model that could generate an abnormality score indicative of quality in order to improve the accuracy and efficiency of the EOL process.

Acerta applied unsupervised machine learning to signal data from sensors across the value chain in order to establish patterns that might be indicative of pending failure. This approach is fundamentally different from established SPC methods.

“ The main difference in the machine learning approach versus statistical process control is that we’re not just dictating ‘here are the tolerances or thresholds – just stay within them,” says Acerta CEO and co-founder Greta Cutulenco. “We’re learning over time how the data across all these different operations and hubs are related to each other, and what the basic behaviour is across these different stations. And unlike just looking at thresholds, we’re a lot more precise – we can look at very precise correlations and relationships between the different signals.”

Based on the validation of the abnormality scores generated by the model, the company expects to be able to eliminate steps connected with the previous EOL inspection process and reduce the

costs of warranty claims by up to 30 per cent. Acerta is currently expanding the solution to work with other lines.

Keeping equipment healthy M achine learning’s anomaly detection capabilities are also being applied to another important operational excellence area – anticipating and preventing equipment failures in order to reduce the costs of expensive repairs and downtime.

“A lot of what we’re doing is related to asset operation certainty,” says Rajiv Anand, CEO and co-founder of Oakville-based AI solution provider Quartic.ai. “People call it predictive maintenance, but we don’t believe in that term. We believe it’s about building an asset to do what it’s supposed to do when you want it

Workers see that they no longer have to rely on their intuition, but can make better decisions based on data.

to do it.”

The distinction is an important one – instead of focusing on what failure looks like, the Quartic platform uses machine learning to establish a baseline for the normal health and operation of an asset, regardless of the varying conditions that it might operate under. The platform then monitors the equipment 24/7 according to that baseline.

Anand points out that machine learning is not necessary for machines that make only one product and run at a steady state. Where it’s valuable is when the equipment has to operate under varying temperatures and pressures, or to produce a wide variety of products.

In a recent use case, Quartic helped a pharmaceutical manufacturer ensure reliable operation for their industrial autoclave, which is central to many of their processes. The manufacturer now plans and schedules maintenance on the asset based on intelligent data from the Quartic platform.

“ They wanted to make sure their people had confidence that the equipment would run, but the outcome was that they got not only confidence – they got to reduce the major overhauls from the OEM,” says Quartic cofounder Blair Fraser, noting that it can host hundreds of thousands of dollars to service the equipment.

Using the platform to schedule maintenance also means fewer emergency work orders, and providing the flexibility to schedule maintenance work according to production requirements.

“ What we’re trying to drive for the CEO is operational excellence,” says Anand.

Overcoming fear

There is considerable concern that Industry 4.0 automation will either eliminate jobs or put workers on a steep learning curve. The emerging use cases, however, indicate a desire to maintain the existing workforce and help them be more productive.

“ We haven’t had a client come

knowledge. Better safety.

to us and say ‘I want to reduce the headcount’,” says Humera Malik, CEO of Toronto-based Canvass Analytics. “The impact to the workforce, I believe, is not about eliminating jobs. It’s about creating higher level function –augmenting the workforce to a point where they are becoming the future workforce.”

Hamilton-based steel producer Stelco has selected Canvass to help make this transition.

“By partnering with Canvass Analytics, we are systematically transforming our facilities into intelligent operations environments and augmenting a digitally oriented workforce in order to take the efficiency of our operations to the next level,” says Stelco executive chairman Alan Kestenbaum in a press release.

A I interacts with workers at two different levels, Malik explains. Low-level machine learning is used to learn and then automate repetitive processes done by humans, such as quality inspections or making manual changes to functions. “You learn how it’s being done,” says Malik, “and you then can do it better and faster and more accurately.”

For sophisticated tasks that require human intervention for decision-making, AI can provide information to support those

decisions. “With high-level AI, you can actually equip [workers] with the right information at the right time so that actionable intelligence can be applied by humans,” says Malik.

One of the challenges is getting workers to accept the new tools as part of their work environment. “We’re working to get the fear out of AI and empower operators to use it in their day-to-day operations,” says Malik. One of the “a-ha” moments, Malik notes, occurs when workers see that they no longer have to rely on their intuition, but can make better decisions based on data. Canvass is working to adapt its analytics platform so that it can be used by process engineers, and not just data scientists.

Ultimately, manufacturers are hoping that the new technology will help them address the growing skills gap caused by the pending retirement of large numbers of experienced workers.

“ The next generation of people going into manufacturing is not what we had 40 years ago,” says Malik. “This is a digital generation. When we go in with AI, we’re giving our customer more opportunity to attract and retain.” | MA

Jacob Stoller is a journalist and author.

– Certified Machinery Safety Expert

– The leading international qualification for machinery safety. With TÜV certificate!

a CMSE® – Certified Machinery Safety Expert!

CMSE® is a globally recognized qualification enabling a 360° approach to Machinery Safety.

PILZ has developed with TÜV a four-day training which provides an overall view of the subject of machinery safety and gives to attendees the understanding of safety regulations and standards in reference to existing machinery, as well as to the design and construction of new machinery. The training provides guidance on how to implement the legal and statutory requirements pertaining to machinery.

Don’t miss our 2 last sessions in 2019!

Mississauga, ON - November 19-22

Montreal, QC (French training) - October 15-18

WHERE ARE YOUR INDUSTRIAL OPERATIONS VULNERABLE?

Inventory management can help to identify and protect your vulnerable assets

BY UMAIR MASUD

Does your cybersecurity approach sometimes feel like you’re playing a game of Whack-aMole – attempting to patch vulnerabilities as they pop up, rather than strategically and proactively managing your cyber risks? If so, you’re not alone. In a 2016 Deloitte study, only 52 per cent of manufacturing executives said they were either very confident or extremely confident that their organization’s assets were protected from external threats.

A robust asset inventory is a foundational requirement of any cybersecurity program. After all, in order to

protect your operations, you need to know what’s in your environment, from machines and other devices on the plant floor to the computers in your offices. Once you’ve built out your inventory you can take steps to address your attack surface, or your vulnerable areas. Beyond that, you can begin to determine which assets are critical to your operations, how to better protect them, and how you’ll respond to and recover from any potential breaches.

Develop your inventory

D epending on your needs and resources, decide the best route for taking stock of your inventory. When determining which approach to take, you should consider what your plant’s network infrastructure looks like: what is your network capacity and

how is it configured? Each approach will impact your network differently, so this information is important.

A manual approach is just like it sounds – grab a notepad and pencil and walk around the plant, taking notes on your inventory. You can get a good idea of what’s out there, and this is a cost-effective option, but it has a few downsides. Not only will you likely have a few gaps in your inventory, but it will also be out of date the minute you put your pencil down, as devices may be connecting and disconnecting from your network constantly.

A tool-based approach involves deploying a technology on your network to continuously poll your environment to develop an inventory. These tools can be used in one of two ways: active and passive.

In an active approach, a query is sent out to devices and they are asked to respond by identifying themselves. The downside to this approach is that the constant communication can

The number of manufacturing execs who told Deloitte they were very or extremely confident in the cybersecurity of their plant’s assets.

In order to protect your operations, you need to know what’s in your environment, from machines and other devices on the plant floor to the computers in your offices.

impact network performance and even cause some devices and machines to go down – particularly legacy devices, as they may not be accustomed to receiving unsolicited queries.

A passive approach is similar, but rather than asking devices to identify themselves via a query, you listen to your network traffic and obtain identity information as traffic passes by. The bonus here is that this approach doesn’t put as much pressure on your network, because it doesn’t involve constantly sending out signals and receiving responses.

An ideal strategy combines these passive and active approaches. It uses a passive listening approach to get a good understanding of what is out there in your environment. Then, it uses that information to inform a more targeted active approach to learn more detailed attributes about a device.

Include environmental context

When developing your inventory, identifying what assets you have is just the start. You also need to understand their context. This includes asset locations, functions they may perform, other assets they’re connected to and which of your resources rely on a particular asset operating properly. You should also know which software applications each asset uses. Taking a broader look at your environment, note what zones you may have your assets divided into. For example, a food producer may group its assets into “wet” zones and “dry” zones. All this information is helpful in developing the full picture of your plant, so that you can begin to prioritize your assets by criticality, which is key to a good inventory.

If you are using a tool to help

develop your inventory, it will check your assets against vulnerability databases and flag which ones are vulnerable. This is where the context comes in: you can look at the list and determine how critical an asset is. Managing a vulnerability related to a scrap conveyor drive is probably not as important as one related to, for example, a boiler control system.

A helpful exercise to determine criticality of assets is to use a process flow diagram of your operations. Running through failure modes and impact analysis across this process flow will help determine which zones, areas or machines are critical to the availability of your operations. The assets within those critical areas should be designated as critical assets.

Improve your cyber resiliency

Of course, a cybersecurity program is ongoing. That’s why an inventory tool does more than give you a snapshot of what’s in your plant’s environment. It can help you create a more formal vulnerability management program to protect your business on a continuous basis by constantly monitoring your environment, tracking existing vulnerabilities and looking for new ones that may pop up based on newly released vulnerability disclosures.

Once the foundation is set, you can begin to create a more formal vulnerability management program around it, allowing room for growth and evolution as your business grows and your environment evolves. All of this will help you continue reducing your attack surface and ultimately improve your cyber resiliency. | MA

Umair

Masud is the director of technical security strategy at Rockwell Automation.

CONNECTING WITH CUSTOMERS

Manufacturing must go beyond making products. Here’s why

BY DAVE BORELLI

As a customer, you probably feel an affinity to some brands more than others. It could be the clever branding or customer service that draws you in. Your connection with the company is also influenced by the structure of that company. For manufacturers, the distance between the product and the customer can be significant. The relationship is generally handled by the retailer, but

40B

manufacturers can get back in the game – and closer to their customers – with the right tools.

This represents a shift in manufacturing and a great opportunity for today’s manufacturers. Driven by advances in cloud, social, mobile, internet of things (IoT) and artificial intelligence (AI) technologies, by 2020, there will be 40 billion IoT-connected devices in the world sending trillions of signals daily into the cloud, according to Gartner. According to Salesforce’s recent research study, Future Ready: Advancing Canadian Business in the Digital Economy, Canadian manufacturing businesses anticipate a 32 per cent increase in IoT-connected devices over the next three years. Yet, behind every one of those products, sensors and signals, is a customer.

For the manufacturing industry, it’s

not enough to simply add sensors to products. Companies must start with customers and leverage the data they generate to change business processes, organizational structures and strategy

The legacy of legacy systems

Manufacturers often have complex legacy systems in place that don’t lend themselves to integration. Often, data is dispersed all over the company and sales reps, especially those in the field, have a hard time viewing it. However, 49 per cent of Canadian manufacturers say that an increased use of technology has given them a leg up on competitors. While this is one of the many advantages to upgrading, sharing information across systems and devices can have a profound impact on your customer experience. Reps, like consumers, do a lot of their personal and professional

Gartner expects the Internet of Things will connect 40 billion devices by 2020.

Every worker is encouraged to flag any activity that has affected their productivity to ensure the team is constantly improving to deliver the best possible experience.

business on their mobile devices. To streamline and speed up communication between stakeholders, sales reps have to have the information in-hand.

Today, manufacturers have the potential to know far more about their customers — and how they use their products — than ever before. The smarter ones have recognized this, and are leveraging that data to drive value and a competitive edge by moving from providing services to predictive services.

Providing a service? Focus on the customer

Regardless of the company, product type or industry, there’s one common truth, moving from selling products to providing services, and using data, helps build a more direct relationship with customers. This is not a technological

challenge — it’s shifting the mindset of an entire business from focusing on making products to connecting with customers.

Today, customer experience is the key differentiator for every industry, especially manufacturers. A fact that Edmonton-based manufacturer, Innovator Industrial, knows well. As a provider of specialty services across maintenance, turnarounds, inspections, fabrication and construction phases, attracting, winning and retaining customers is a priority.

The team began its digitization journey in 2012, when Innovator Industrial had just 15 full-time employees. Over this time, the team has developed more than 100 apps ranging from team optimization and meeting planning to training and project delivery. Digitizing these processes has provided the entire team with greater insights and actionable data,

allowing them to reduce the average time for raising an invoice from 36 days to 30 minutes and a sales-win rate of 95 per cent.

And for Innovator Industrial, it doesn’t stop there. Every member is encouraged to flag any activity that has affected their productivity – whether it’s a late delivery, or lack of information – to ensure the team is constantly improving to deliver the best possible experience.

The path forward

For manufacturers today, building services to complement product offerings is table stakes. Manufacturers must incorporate metrics such as customer satisfaction, churn rate and monthly recurring revenue, to measure the depth and quality of customer relationships, helping all departments, customer facing or otherwise, align around the customer. By harnessing the power of technology and intelligent data to focus on customer outcomes – and delivering unique value as a result –manufacturers can truly thrive in the age of the customer. | MA

Dave Borelli is area vice-president of Salesforce Canada.

MEET YOUR NIGHT SHIFT

A FOCUS ON FLEXIBILITY

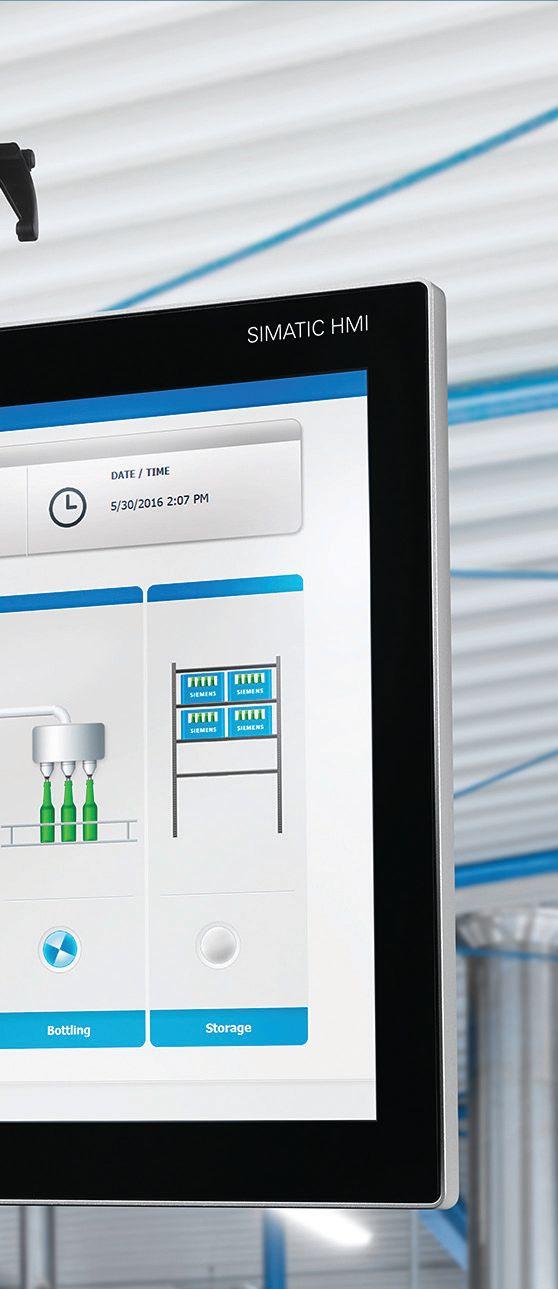

Siemens says sayonara to its PLM division as it seeks to turn manufacturing complexity into competitive advantage

BY KRISTINA URQUHART

In an increasingly complex manufacturing environment, companies must pursue continuous improvement in operations in order to stay competitive.

That was the main message at a media and research analyst conference hosted by Siemens last month in Brooklyn, New York, where the company discussed the shift from fixed automation toward flexible, autonomous, end-to-end solutions.

In light of that change, the Siemens PLM Software division has rebranded to Siemens Digital Industries Software (DIS). While product lifecycle management (PLM) remains a core offering, the new name better reflects that the company’s digitalization solutions portfolio now includes modelling, apps, IoT analytics and manufacturing operations management.

“What I sense today is a little bit of anxiety,” Don Kurelich, VP strategic products for Siemens DIS, told the crowd. “People are looking at the way forward and what they have been doing for years may not cut it anymore. They’ve been known as quality manufacturers, but now they have to become innovators.”

According to the Siemens experts, continuous improvement – while not a new concept in manufacturing – may actually be more important than ever. And it can’t happen without digital transformation.

Beginning the digital transformation journey seems to be where the bottleneck begins for many manufacturers – either with the overwhelming number of options out there or with implementing a solution without a strategy. But there is no one-size-fits-all package out there – flexibility is paramount. “Customers want to learn how to implement Industry 4.0 now,” said Alastair Orchard, vice-president digital enterprise for Siemens DIS. “But the line drawn has to be continuous – it needs to be a journey that doesn’t have them falling off the edge or making bad investments.”

Redefining ‘digital twin’

PLM providers have been promoting the digital twin – a virtual representation of a physical asset – for a while now. Historically, it’s been used in product design and asset management.

“Most of our customers are struggling

with complexity,” Tony Hemmelgarn, CEO of Siemens DIS, said. “The digital twin is not an option in a complex world. It’s a necessity.”