MODERN.CLEAN.SAFE.

Residential wood biomass heating technology from Viessmann

Celebrating 100 years in the business, Viessmann has been providing homeowners with industry-leading heating solutions for generations.

The Vitoligno 300-C wood pellet-fired boiler is a modern, compact and fully-automatic heating solution for residential and light commercial applications.

High efficiency up to 85%

Environmentally-friendly, carbon neutral heating

Easy conversion from automatic to manual fuel feed

Easy to obtain, locally and sustainably sourced wood fuel

WINNER of the 2015 German Design Award

CANADIAN BIOMASS

14

10 INTEGRATED OPERATION

Premium Pellet is one cog in a well-functioning wheel of valueadded production at the Nechako Lumber operation in Vanderhoof, B.C.

Dotting the pellet map

Skeena BioEnergy is launching as a new company, in a brand-new pellet facility in B.C. The $20-million pellet plant is being built next to Skeena Sawmills. Construction started in June and is expected to be completed by December 2018, with commissioning in January 2019

18 Sludge to energy

A Precision Energy Services (PES) sludge-to-energy system at Atlantic Packaging’s Whitby mill processes 100,000 tonnes per year of paper mill sludge that was previously being sent to local area landfills, eliminating the cost of sludge disposal and reducing the cost of fossil fuels by the offset generation of plant steam.

20 WPAC show guide

Find everything you need to know about the 2018 Wood Pellet Association of Canada AGM & Conference taking place this September in Vancouver.

“From

page 10

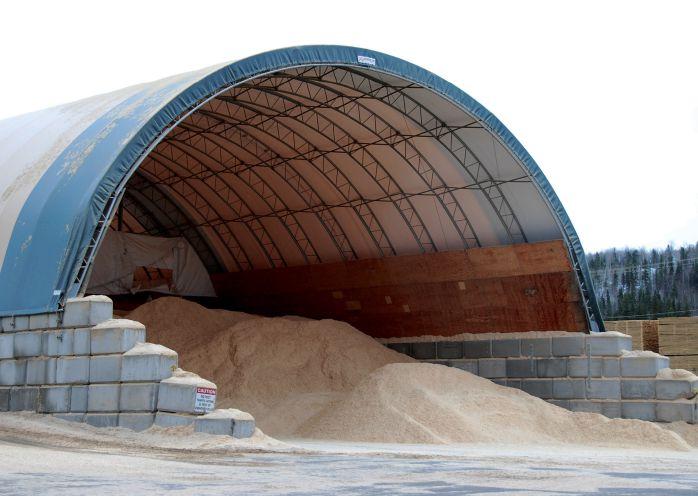

Premium Pellet ingests about 185,000 oven-dried tonnes of sawdust and shavings to produce about 165,000 tonnes a year. Read the full story on page 10.

M‘Don’t wait for the government’

Swedish city sets a high green bar for Canadian municipalities

ayor Anna Tenje of Vaxjo, Sweden, is enormously proud of her city. She lovingly describes sleek wooden apartments built alongside sparkling blue lakes and lush green forests in the municipality of 92,000.

But it wasn’t always this way. In the 1970s the Swedish city underwent a restoration of its central lakes, and in 1996, Vaxjo became the first city in the world to mandate a fossil-fuel free future by 2030. To reach its ambitious goal, the city uses bioenergy via a wood-fuelled CHP district energy system that supplies 90 per cent of the heating demand, as well as municipal waste biogas plants and smallscale hydro, solar and wind installations. City buses run on biofuel, and smart urban planning encourages bicycle commuting.

and municipalities around the world. “I would like to see more communities take the chance,” Tenje said.

For years the community has designated itself Europe’s greenest city, and in 2017 the EU Commission validated their claim with the European Green Leaf Award 2018.

Since the 1996 decision, Vaxjo has reduced emissions by 58 per cent and improved economic growth by 32 per cent. “We have shown that this is possible,” Tenje told an audience of hundreds in Prince George. Tenje gave a keynote address at the Canadian Bioeconomy Conference and Exhibition in early June, and I had the pleasure of being in the audience for her talk. (Read coverage of the conference on page 7.)

Her most poignant advice for the crowd: “Don’t wait for the national legislation; it won’t come for years.” Effective change, she said, begins not at a federal or even international level, but in the cities

I could almost feel the head nods around me; particularly from host city Mayor Lyn Hall, who has long been an advocate for the bioeconomy in Prince George. The city boasts a wood-based district energy system that connects 11 downtown buildings, while the Prince George campus of the University of Northern B.C. has a biomass gasification plant. Unfortunately, Tenje’s message was preached to the choir. The conference room was packed, but attendees more often than not were industry insiders or politicians already on board to support the bioeconomy. It’s a message that all Canadian municipalities large and small should hear: When it comes to the environment, don’t wait for government. Economic prosperity and clean energy can go hand in hand; Vaxjo and Prince George both prove that it’s possible.

But there’s a lesson in there for the bio-industry as well. Continue making pitches to municipal governments. Don’t wait for Ottawa or your province to further incentivise your project. Funding programs come and go (they are very much ‘going’ in Ontario courtesy of the new provincial government) but as the changing climate continues to put pressure on all municipalities around the world, the right solution will make sense to a growing number of cities, towns and rural and remote communities. •

CANADIAN

Volume 18 No. 4

Editor - Maria Church (226) 931-1396

mchurch@annexbusinessmedia.com

Associate Editor - Tamar Atik (416) 510-5211 tatik@annexbusinessmedia.com

Contributors - Alyssa Dalton, Pat Liew, and Gordon Murray.

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexbusinessmedia.com

Account Coordinator - Stephanie DeFields Ph: (519) 429-5196 sdefields@annexbusinessmedia.com

National Sales Manager - Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Alison Keba

Circulation Manager – Jay Doshi jdoshi@annexbusinessmedia.com Ph: (416) 442-5600 ext. 5124

President/CEO Mike Fredericks

Canadian Biomass is published six times a year: February, April, June, August, October, and December. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

– 1 Yr $104.00 US

CIRCULATION mchana@annexbusinessmedia.com Tel: (416) 510-5109 Fax: (416) 510-6875 or (416) 442-2191 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2018 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

BIOMASS update

ONTARIO CANCELS CAP AND TRADE, ENDS GREENON PROGRAMS

Following through on his campaign promise, new Ontario Premier Doug Ford’s first order of business has ended the cap and trade regulation in the province and begun a wind down of the Green Ontario Fund (GreenON) programs.

The GreenON fund was created last year to allocate $25.8 million in proceeds from Ontario’s carbon market towards the creation and commercialization of green technologies. Four wood heat

programs for rural, Indigenous communities were part of the GreenON fund.

“We are getting Ontario out of the carbon tax business,” Ford said in a statement. “Our focus will be to give people lower gas prices, lower energy bills and a real break in their wallets in order to get our economy going and create jobs. Help is here.”

Ford said his government will honour contracts that have already been signed through GreenON, such as

energy efficient insulation and window retrofits. The fate of other initiatives currently supported by the fund will be decided on a case-bycase basis.

The statement notes that the Auditor General’s review of Ontario’s cap-and-trade program found the system could cost Ontario consumers and businesses $8 billion, with a “negligible impact” on the province’s carbon emissions.

The decision has sparked

a letter of concern from members of Canada’s Clean50 Awards, who say the decision to cancel the cap and trade system risks losing the $420 million the federal government gave Ontario to help the province meet the federal Pan-Canadian Framework on Clean Growth and Climate Change. Ottawa has mandated that provinces without a carbon-pricing scheme by the end of 2018 will have a tax of $10 per metric tonne imposed.

BIOECONOMY LEADERS CONVERGE IN PRINCE GEORGE FOR CBCE

We’ve come a long way, but there is still a ways to go. This was a prevailing sentiment from industry leaders speaking at the Canadian Bioeconomy Conference and Exhibition that took place in Prince George, B.C., in early June.

“Sometimes we forget that we are a fledgling industry,” Rob McCurdy, CEO of pellet producer Pinnacle Renewable Energy, told the crowd.

McCurdy said Canadian pellets are world recognized as a quality product, but there are challenges faced by the industry, one of which is demonstrating to international buyers the sustainability of their product. “How do you meet a demand that is growing 20 per cent a year? How do we grow sustainably to meet that demand? This is a good challenge to face,” McCurdy said.

Advanced Biofuels Canada CEO Ian Thomson outlined two other hurdles to producing fibre-based biofuels. First, that there is just one fibre basket in Canada and many players competing for it. And second, the high cost of developing technologies to process wood fibre into biofuel. Carbon pricing, Thomson said, can help overcome the cost challenge.

A number of conference speakers addressed the need for Canada to develop a national bioeconomy strategy.

Mayor Anna Tenje of Vaxjo, Sweden, gave a keynote address on the efforts the community underwent over almost 50 years that lead to their official designation as the greenest city in Europe. “Don’t wait for the national legislation; it won’t come for years,” Tenje said. “I would like to see more communities take the chance. It starts in the cities and municipalities around the world.”

Vaxjo has set a goal to be fossil fuel free in 2030. The city is using bioenergy to achieve that goal, and, since it set the target in 1996, has already reduced emissions by 58 per cent and improved economic growth by 32 per cent. “We have shown that this is possible,” Tenje said.

Complementing this idea, Clean Energy Consulting’s Tim Hoy’s presentation as part of a low-carbon economy opportunities panel centred on the idea that bioeconomy growth must come from community-level projects. “It takes a lot of the complexity out of the larger systems, and it solves community-specific problems,” he said.

During a panel dedicated to discussing community projects that are advancing the bioeconomy, Council member Blair Hogan from the Teslin Tlingit First Nation in Yukon presented an overview of the community’s project to install 10 wood chip boilers connected to three district heating systems. Wood heat not only reduces the community’s reliance on diesel, but will also help them reduce the fuel load surrounding the community. “There is a huge risk of wildfires so that creates an economic incentive for us to harvest around the community,” he said.

In his keynote address to the conference, B.C. Environment Minister George Heyman indicated his support for the growth of the biomass industry in the province, confirming there is a place for bio-solutions to climate change.

“I think, and I think you’ll agree, it’s much better to take waste and turn it into an economic advantage than pollution,” he said. •

Read the full article at www.canadianbiomassmagazine.ca

Teslin Tlingit Council member Blair Hogan, far right, presents an overview of the Yukon community’s project to install 10 wood chip boilers connected to three district heating systems.

Air Canada operates biofuel flight from Edmonton to San Francisco

On May 2 an Air Canada Airbus A320-200 aircraft flew from Edmonton to San Francisco with biofuel, the company announced. The flight was scheduled for the trade mission delegation led by the Alberta government, the City of Edmonton and Edmonton-area businesses to California.

“Air Canada is proud to partner with the Edmonton International Airport (EIA) to operate today’s flight with biofuel,” Teresa Ehman, director of environmental affairs at Air Canada, said in a news release on May 2. “Air Canada continues to support and advocate for the development of biofuel in Canada to become commercially viable; a big

PINNACLE SIGNS NEW OFF-TAKE CONTRACTS IN SOUTH KOREA AND JAPAN

Pinnacle Renewable Holdings Inc. has entered into two new long-term, take-orpay off-take contracts with customers in South Korea and Japan.

Pinnacle Renewable Energy’s Meadowbank pellet plant in Hixon, B.C., produces 230,000 tonnes annually. Photo supplied.

The contract in South Korea is with CGN Daesan Power Co., Ltd., a subsidiary of CGN New Energy Holdings Co., Ltd, a diversified independent power producer in Asia. The contract in Japan is Pinnacle’s second with Toyota Tsusho Corporation, a trading and investing company and a group member of Toyota.

As a result of these two new contracts, the weighted average remaining life of Pinnacle’s portfolio of off-take contracts with customers has been extended from seven years as of March 30, 2018,

to more than nine years.

Under the terms of the Daesan contract, Pinnacle will supply 315,000 metric tonnes per annum of industrial wood pellets to Daesan beginning in 2021. The industrial wood pellets will be used in a biomass power generation plant in South Korea.

“Entering into this longterm relationship with Daesan is an important milestone for Pinnacle as it represents our first long-term contract in South Korea and our largest contract to date in Asia,” said Robert McCurdy, CEO of Pinnacle. He also commented on the country’s growing commitment to decarbonization.”

Under the terms of the Toyota Tsusho contract, Pinnacle will supply 170,000 metric tonnes per annum of industrial wood pellets to Toyota Tsusho beginning in 2021. The industrial wood pellets will be used in a biomass power generation plant in Kanda, Fukuoka Prefecture, Japan.

“We are pleased to enter into our second long-term supply agreement with Toyota Tsusho, and our fifth new contract overall in Japan this year,” McCurdy said.

step towards creating more sustainable aviation in Canada and internationally.”

Since 1990, Air Canada has improved its fuel efficiency by 43 per cent, Ehman said. The airline has committed to meet the targets set by the International Air Transport Association, including carbon-neutral growth from 2020 and to reduce CO2 emissions by 50 per cent by 2050.

“This biofuel demonstration flight reflects our combined commitment to bring forward low carbon, renewable fuels into the aviation and airport sectors,” said Tom Ruth, president and CEO of Edmonton International Airport.

BUILDING A WORLD-CLASS SAFE PELLET INDUSTRY

The

Wood Products Safety Summit 2018 offered more than 50 delegates a day of diverse presentations on safety – with a clear focus on the value of both increased collaboration and process safety.

Held at the Prince George Conference and Civic Centre on June 6, 2018, there is one thing above all else that consistently permeated each of the presentations during the safety day and that was simply that process safety management, strong safety culture and high performance in any industry require collaboration, participative management of all stakeholders and a walk the talk attitude where results prove that many heads are better than one.

Kicking the day off, Darrin McCaskill, WorkSafeBC’s director of programs, projects and initiatives, said that employers, workers and labour had made gains in health and safety performance, and thanks to everyone’s hard work “more workers are going home safe that at any time in our history”.

He said the multi-faceted forestry industry includes everything from harvesting, transportation, processing and manufacturing to silviculture. He noted that there are many high risk work activities involved in bringing a tree or fiber to market and the sector has seen some darker days. “The prevailing attitude at the time was not if, but when a serious incident would occur.”

McCaskill said fast forward to today and we have seen a noticeable change, a new world where employers are actively engaged in health and safety; a robust health and safety association, the BC Forest Safety Council, providing the infrastructure for health and safety and resources; and, there is an industry emphasis on training and supervision. “Clearly, the culture of risk-taking is being replaced by safety-first approach,” he said.

“We know that workers do not need to die or get hurt to cut down a tree or transport logs or manufacture lumber. Overall industry has vastly improved its safety practices; some remarkable achievements have been made and there are fewer injuries and fewer fatalities,” said McCaskill. “But maybe, just maybe, good is not good enough.”

– article submitted by Pam Agnew

Read the full article at www.canadianbiomassmagazine.ca.

TMeeting demand in Japan

WPAC takes part in CMT Biomass Pellets Trade & Power Conference

By Gord Murray, WPAC executive director

ogether with a large group of member companies, the Wood Pellet Association of Canada participated in the annual CMT Biomass Pellets Trade & Power Conference in Tokyo from May 12–17. WPAC was the platinum sponsor, and reception organizer-sponsor.

This was an important event for us. Japanese wood pellet imports have grown almost six-fold in the period from 2014 to 2017, and growth is expected to accelerate until at least 2025. Canada shipped 360,000 tonnes of pellets to Japan in 2017, up from just 90,000 tonnes in 2014. Canada currently holds a 70 per cent market share for wood pellets in Japan. Our objective at the CMT conference this year was to continue to brand Canada as a preferred supply source, emphasizing our sustainable fibre sourcing, high product quality, reliable and efficient supply chain, and creditworthy producers. We aim to continue increasing exports to Japan and to maintain our market share.

From May 12–13, for the first time ever, WPAC — with the support of Sumitomo, Pinnacle Renewable Energy, Pacific BioEnergy, Premium Pellet, Fibreco, and Tolko Industries — hosted a hugely successful golf event in nearby Ishioka for about 30 Japanese and South Korean customers. Festivities included dinner, an evening of karaoke, and a golf tournament at Summit Golf Club.

WPAC members provided significant conference content. I assisted with setting the conference agenda and recruiting speakers and moderators. Canadian presenters included Pinnacle’s Scott Bax and Vaughan Bassett, Pacific BioEnergy’s Paul Kalil, and Fibreco’s Kerry Lige.

On the evening of June 15, WPAC hosted a reception. In addition to the conference delegates, we invited our entire Japanese customer network. We dubbed the event Canada Wood Pellet Day. We decorated the ballroom with Canadian flags, banners, streamers, and balloons. The Canadians began the night wearing Canadian hockey sweaters and flag hats, but had to give them up to our Japanese guests who proudly wore them and then took them home as souvenirs.

Following the conference, a group of WPAC members visited the 49 MW Keihin Biomass Power Plant in Kawasaki for a first-hand view of Canadian wood pellets being used to create Japanese electricity. Keihin Biomass consumes a 50-50 blend of Canadian pellets supplied by Pinnacle Renewable Energy and Pacific BioEnergy (approximately 100,000 tonnes per year) and Indonesian and Malaysian palm kernel shells.

There were a dozen key conference takeaways from the

various speakers.

• Issea Sawa, Japanese Biomass Power Association: The national target for renewable power is 22–24 per cent by 2030, of which biomass power should comprise 19 per cent — i.e. 4.5 per cent of total electricity. This will require 7–10 times the amount of biomass consumed in 2017.

• Paul Kalil, Pacific BioEnergy: The reasons that Canada is a preferred wood pellet supply source include: close proximity and efficient logistics; ample secure sustainable feedstock; reliable and safe transportation infrastructure; safe manufacturing that results in high-quality product and uses best available technologies; well-funded reliable ownership; and economic and political stability.

• Yasuhisa Okamoto, Sumitomo: Legality, traceability and long-term sustainability are the most important factors to Sumitomo for raw materials. This is why they decided to make a major investment in Pacific BioEnergy. Sumitomo has been importing wood pellets and wood chips for the big regional power utilities since 2008 and continues to acquire many supply sources to ensure stability for the long-term. Sumitomo’s share of wood pellet import volume to Japan

Delegates at the Canada Wood Pellet Day Reception in Tokyo on May 15. Left to right: Rob McCurdy, Tony McRae, and Vaughan Bassett Pinnacle Renewable Energy; Koike Yuka, Sumitomo Corp.; and Gordon Murray, WPAC.

was 55 per cent in 2017. Sumitomo expects Japanese wood pellet demand by 2030 will be 15 to 20 million tonnes. They are looking for 15–20 year term contracts.

• Shuji Aoki, NYK Carriers: NYK accounted for 140,000 tonnes of wood pellets being imported into Japan in 2017, some 27 per cent of Japan’s total. From Western Canada, NKY uses vessels with total DWT of 28–38,000 tonnes and pellet carrying capacity of 24–32,000 tonnes.

• Kerry Lige, Fibreco: Export terminals have an integral role in the wood pellet supply chain. Terminals manage receiving and unloading rail cars, storage, and vessel loading. He discussed considerations for storage, soft handling to maintain product quality, fire and explosion hazards, off-gassing, and dust management.

• Henry Pease, RWE Supply and Trading: Wood pellets are now traded globally. As RWE is a large European buyer, it has the ability to supply both Japanese and European markets. RWE sees Canada as a swing supplier. RWE can purchase cargoes from Western Canada, then make the decision regarding which direction to send them.

• Yoshiomi Todo, Nippon Paper Energy: NPI has two biomass power plants — Yatsushiro Power Plant, 6 MW, completed in 2015 and Ishinomaki Hibarino Power Plant, 149 MW, completed in 2018. NPI requires evidence of forest certification. They prefer to receive cargoes of 10,000 tonnes due to storage constraints. NPI works with 10-year contracts.

• Miyuki Tomari, president, Biomass Industrial Society Network: As of April 2018, Japan’s Clean Wood Act requires that biomass used for power generation must be accompanied by chain-of-custody forest certification including proof of legality. Feed-intariff requirements are more constrained than the Clean Wood Act.

This was the fourth consecutive year that WPAC and our members have participated in the CMT Biomass Pellets Trade & Power Conference in Tokyo. However, this was the first year that we held our golf event, became a platinum sponsor, organized and sponsored the main conference reception, and organized our own tour of a biomass power plant. Canada’s accelerating growth in wood pellet exports to Japan, coupled

with our 70 per cent market share, are good reasons for us to continue with this annual event.

The Wood Pellet Association of Canada gratefully acknowledges financial support from Natural Resources Canada’s Expanding Market Opportunities Program and Forestry Innovation Investment’s Market Initiatives Program. We could not have held such a successful event without their help. •

• Yoshinobu Kusano, Renova: Renova is doubtful that biomass cofiring projects will not proceed as planned due to opposition to coal in Japan. Renova believes that the best solution for biomass power is construction of independent power projects with dedicated biomass boilers between 50 and 110 MW.

Implementing Bulk Material Handling Solutions

Since 1947

STANDARD

Extended Arm Drive-Over Dumper Live Bottom Hoppers

Integrated operation

By Maria Church

Overnearly 20 years, Premium Pellet in Vanderhoof, B.C., has established itself in Canada and globally as a provider of highgrade white wood pellets for the heating market. The brand is a recognized pellet leader, competing with the likes of Pinnacle Renewable Energy and Pacific BioEnergy in northern B.C.

Behind the scenes, Premium Pellet operates as one cog in a well-functioning wheel of value-added production at the Nechako Lumber site on which it resides.

“Being an integrated site, we consume our own residues which provide electricity for the site and pellets for the domestic and international markets, which is good for us but ultimately it’s good for the community. This model

works really well,” says Nechako site manager Dave Herzig.

Nechako Lumber was originally built in 1969 as a planer mill. A sawmill, L&M Lumber, was constructed on the same site in 1972. Premium Pellet was added in 2001, and Nechako Green Energy — an Organic Rankine cycle (ORC) Turboden generator — in 2011.

All companies operated separately until last year when Sinclar Group Forest Products out of Prince George, B.C., purchased them and merged the sawmill and planer mill under the banner of Nechako Lumber. Premium Pellet is retaining its name.

Located on a 112,000 square foot

site, pneumatic conveyors connect each of the facilities and are continually transporting sawdust, shavings or hog to its respective end use. The sawmill pumps out about 245 mmbf a year, while the pellet mill produces about 165,000 tonnes, and the energy system consumes 56,000 dry tonnes of hog.

The pellet plant ingests about 185,000 oven-dried tonnes of sawdust and shavings a year. The bulk of the fibre diet is white wood from Nechako’s sawmill and planer mill, but the plant also consumes sawdust trucked in from other suppliers in the area.

“Premium Pellet has strategic partnerships with Nechako, Premium,

Premium Pellet was built in 2001 on the Nechako Lumber site in Vanderhoof, B.C. The plant is fed by planer chips and shavings conveyed directly from the sawmill to produce 165,000 tonnes of pellets a year.

Premium Pellet rounds out Nechako Lumber site

Canfor, and Conifex,” Herzig says. “These partnerships help all of the organizations keep their transport freight costs down, and maximizes the use of residuals in the region.”

Premium Pellet exclusively produces high-grade white wood pellets for the residential heating market in Canada and globally to support the move to a more environmentally friendly fuel source. Located in northern B.C. and on a rail line, the plant is ideally situated to ship to markets in Asia.

PLANT FLOW

Baum pneumatic conveyors spanning nearly half a kilometre bring sawdust and shavings to the pellet plant from the planer mill or sawmill, which are then stored in hoppers. A truck facility allows the plant to unload trucks full of shavings or sawdust directly into an infeed area for storage, and a separate section allows loaders to feed directly into the hoppers if needed.

For the planer shavings the production cycle begins with two Bliss

4460 hammer mills to break down the fibre, while the sawmill sawdust is treated to a MEC 56000 pounds/hr WB dryer to remove the moisture. The fibre is then stored in silos before heading down to one of five Pioneer pellet mills.

“The original build was with three pellet mills, then they added the other two over the years,” says Tammy Scott, controller for Nechako Lumber and Premium Pellet.

Pellets exit the pellet mills onto a BM&M shaker screen, and are then sent

YOUR CHOICE FOR ANY BIOMASS DRYING NEEDS

Our Rotary Drying Systems

A covered holding area stores sawdust that is sent in from other suppliers. A rail line behind the Nechako site allows finished pellets to be loaded directly into rail cars to be shipped to international markets.

to a Bliss cooling tower before storage in a Westeel silo. “We can hold up to two days of product in the silos, and they feed directly into the rail cars,” Herzig says.

About 90 per cent of the pellets are loaded bulk on rail cars, with the remaining 10 per cent getting bagged via a Hamer packaging system, and shipped out on trucks for the domestic market. The bagged pellets are only produced during the winter season. In the spring and summer 100 per cent of the pellets are sent bulk via rail.

While the pellet markets are strong, Herzig says there are no current plans to expand the mill’s production. “We’re having conversations about what the future looks like in terms of expansion. How do we get bigger? Can we get bigger? Is there more fibre? And what’s the cost?” he says.

The greatest value of Premium Pellet for Nechako is its role in extracting the full value of each log that enters the site. “From log in the gate to finished goods out, we have a fully integrated site that has a sawmill and planer mill, and then

I can take my residuals and create heat for the facilities on site and generate electricity to offset our Hydro cost, and then sawdust and shavings are made into pellets that are going back into communities or internationally to help move away from coal and diesel,” Herzig says. “To have that full integration on site is pretty unique.”

Nechako’s original boiler was built in 1999 — a thermal oil/wood residue boiler that replaced a beehive burner. “The original boiler was a big initiative to start using all the residuals from the bush on this site so we were leaving a better environmental footprint,” Scott says.

In 2011 Nechako Green Energy was brought online, the first system of its kind built by Turboden at a forest products facility in North America. Hog from the mill is burned in a (GTS) boiler, which is attached to an ORC or organic rankine cycle turbogenerator that uses heated thermal oil to produce electricity. The 2.2 megawatt hour produced by the ORC offsets the site’s power requirements. Heat produced by

TIMELINE

1969 – Nechako Lumber is originally built as a planer mill

1972 – The sawmill, L&M Lumber, is constructed on site

1999 – A thermal oil/wood residue incineration site is installed to heat the sawmill

2001 – Premium Pellet is built

2011 – The current ORC energy system, Nechako Green Energy, is built on site

2017 – Sinclar Group Forest Products purchases all companies on Nechako site

the boiler is also used in the kilns and to heat the planer mill in the winter.

PARTNERSHIPS

Along with its production flexibility and value-added products, Nechako’s strength is in its partnerships, whether it’s with the community, other producers, customers or First Nations in the area. Much of the mill’s volume is purchased from upwards of 60 private contracts.

A key partner is Saik’uz First Nation, located just south of Vanderhoof, which runs one of Nechako’s main logging contractors, Tin Toh Forest Products Ltd. Nechako also employs band members in its operations.

“This is something Sinclar has put a lot of effort into. Whether it’s partnership around fibre or around key customers, our goal is to continue those solid relationships,” Herzig says.

Under its new ownership group, Nechako is in a transition phase. “As part of a larger organisation we have an opportunity to ask ourselves, ‘what

is that way forward and what does the future look like?’” Herzig says.

What’s not going to change is the mill’s importance to the Vanderhoof community, both as an employer and as an economic driver.

“We are just a bigger family now,” Scott says. “We have more people,

more resources, more expertise brought to the table. We’re keeping the mill’s community culture as it has been, but working under the same Sinclar umbrella with the same end goal.”

Watch a video tour of the Nechako site at www.woodbusiness.ca/tag/video. •

WOOD PELLETING PLANTS

QUALITY WORLDWIDE

AMANDUS KAHL GmbH & Co. KG

Dieselstrasse 5-9 · 21465 Reinbek

Hamburg, Germany

+49 (0) 40 72 77 10 info@akahl.de · akahl.de

AMANDUS KAHL GmbH & Co. KG

SARJ Equipment Corp.

29 Golfview Blvd · Bradford, Ontario

L3Z 2A6, CANADA

001 905 778 0073 rbmacarthur@sympatico.ca

The majority of Premium Pellet’s production is sent out bulk in rail cars, but about 10 per cent is bagged for the domestic market.

New pellet plant coming on the map

Skeena BioEnergy is launching as a new company, in a brand-new pellet facility in BC

By Tamar Atik

Anew pellet plant taking shape in Terrace, B.C., is expected to set a new standard in environmental compliance for the industry, if the company and supplier building it have it their way.

“It will be Prodesa’s first complete system installation in B.C. and we would like this to be a showcase for both our company and for them. We’d like it to set a high benchmark for environmental compliance,” Skeena Sawmills’ vicepresident Roger Keery tells Canadian Biomass

Skeena BioEnergy is the name of the new $20-million pellet plant (and company) being built next to Skeena Sawmills. Construction started in June and is expected to be completed by December 2018, with commissioning in January 2019.

“It took us four years, and we looked at a wide range of alternatives,” Keery says. “We looked at some different technologies re-using sawmill residuals. We looked at bionaphtha and bio-ethanol and we also looked at producing biogas in a closed electrical Agenerating system.”

Skeena BioEnergy is being built in an existing building that used to house a veneer company. Skeena Sawmills owns the site and the building. It operates a large sawmilling operation in Terrace and its need for an adjacent pellet plant was clear.

“We needed to add value to our sawmill residuals — sawdust and hog fuel,” Keery says. “We’re currently not able to recover any value from our shavings or sawdust or hog fuel and our pellet business turns that into a revenue source

Contract employees complete the first concrete pour of the cooler foundation at the Skeena BioEnergy site. Photos supplied.

for the company.”

The residuals are currently split into two flows. The bark component is land-filled and the whitewood component is sold to a pellet manufacturer which Keery says is approximately a 12-hour round-trip haul.

Skeena BioEnergy is being sized based on consuming all of the residual material from Skeena Sawmills, which will supply the feedstock to the pellet plant. The plant will produce pellets from all residuals including planer shavings, sawdust, hog fuel and bark.

Keery says there is a possibility for Skeena BioEnergy to receive feedstock from neighbouring sawmills or biomass harvesters, depending on the demonstrated capacity of the plant.

“The plant has designed an additional capacity that may be able to take material from other producers, but it will depend on the run-ability of the plant,” Keery says.

The need to operate Skeena BioEnergy under a different name was also a carefully thought-out decision, Keery explains. “We see the pellet business as a very different business from our sawmilling business,” he says. “It’s also possible we’ll have partners in the business at some point, so it allows us to do that without dealing with the partnership in

the bigger context of our sawmilling and timber operations.”

Keery says there are a number of potential customers identified from the Asian market, but a final decision has not been made yet on who the customers will be.

“Our focus is Asia. It’s the focus of our lumber business, and naturally is the focus of our pellet business, so we’re looking in Asian countries — Japan, Korea, and potentially China, although that’s not possible at this point due to regulatory restrictions,” Keery explains.

Upon completion, Skeena BioEnergy will employ 12–15

A glimpse of the cooler basement at Skeena BioEnergy where foundation work is being completed.

people and is expected to produce 75,000 tonnes of pellets a year. There are currently six contract employees working on the construction site.

“We have an excellent crew of people working on the job,” Keery says. “Our primary civil and mechanical contractor is Salem Contracting, and we believe they’re one of the best companies in the industry at their work.”

Prodesa is Skeena BioEnergy’s chosen equipment supplier for the entire project.

“We looked at a variety of suppliers, and we chose Prodesa because of their experience in pelletizing, the quality of their equipment and their ability to supply a complete designed system,” Keery says. The goal for both Skeena and Prodesa is to be a showcase for environmental compliance in the industry.

Keery says Skeena BioEnergy’s plant emissions are going to be very tightly controlled, and safety is top of mind with investments in the fire detection systems, explosion prevention and a control system.

There are two technologies involved in the control of the plant’s emissions. Keery explains that the first is a wood drying technology which is a belt dryer system that is fired by natural gas. Keery says the emissions testing results of that technology been excellent, noting that a couple of other installations of this system are in place elsewhere.

The second technology, Keery explains, is the control of dust emissions from the various dust generating points in the plant. They’re all collected to one location and put through a filter unit, so the discharge will be filtered through an air filtration system, he says.

“Those are the only two airborne discharges from the plant and both are very well-controlled and will be standards that are orders of magnitude less than those normally associated with our sawmill operation,” Keery says.

The investments in the various systems within the plant are with different suppliers. Prodesa, as mentioned, is supplying the major equipment in the plant, each with its own fire and explosion protection system. This includes the dryer, hammer mill, pellet cooler and storage silos among other pieces.

The VETS Group is supplying the dust filtration system, which also includes fire protection and explosion control.

And SonicAire is supplying a dust control system that will control dust in the air inside the plant.

Skeena BioEnergy will have one belt dryer, two infeed lines, three pelletizers and one cooling tower.

“We used the best available technology in designing the safety systems and the dust control in the plant,” Keery says. “And we’ve designed the plant to allow us to blend different types of input material, so the infeed system allows us to blend different products in a controlled way in our feedstock.

The process involves two separate feed systems that are individually controlled and allow a blending of materials on the infeed to the plant, Keery explains. “We have a dual infeed system that’s controllable to give the operator of the plant the ability to mix the two products in a controlled proportion,” he says.

Although Skeena BioEnergy is located adjacent to a rail

line, all the products will ship out on trucks. Keery says the option of rail is available but requires trans-loading because it isn’t immediately accessible at the plant.

Keery says Skeena BioEnergy doesn’t have plans to put in a bagged pellet system currently, but is interested in considering the domestic market, possibly through local access to bulk pellets.

“The local market is appealing to us. While small, we think it’s an important part of being in the community, that the community can use our product,” he says. “So, we’re interested in considering how we might best do that. We haven’t decided that yet.”

“This is perhaps the most important project for our company,” Keery notes. “Our company has struggled with both addressing the issue of sawmill residuals and finding value in those residuals, so there’s a great deal of excitement around this project. It’s an enabling project for Skeena Sawmills to be successful.”

Skeena Sawmills and Skeena BioEnergy are owned by Roc Holdings, which was launched in 2012 by Chinese immigrant Teddy Cui. Skeena Sawmills was purchased from West Fraser Timber the same year and began operation under its new private ownership in 2013.

The Skeena BioEnergy project is also entirely privately funded through its ownership.

Sludge to energy

Producing process steam from sludge-waste residuals

By Alyssa Dalton

Anew fluidized bed combustion system is offsetting tipping fees at an Ontario recycled paper mill. In operation for more than a year, a Precision Energy Services (PES) sludge-to-energy system at Atlantic Packaging’s Whitby mill processes 100,000 tonnes per year of paper mill sludge that was previously being sent to local area landfills, eliminating the cost of sludge disposal and reducing the cost of fossil fuels by the offset generation of plant steam.

The mill, formerly a producer of newsprint, reopened in 2013 after the company undertook a conversion project allowing it to produce 100 per cent recycled lightweight paper for the manufacture of high performance corrugated packaging products.

In addition to the Whitby location, Atlantic Packaging owns and operates two other recycled paper mills – the New Forest Paper mill and the Scarborough Liner mill – located in Scarborough, the home of Atlantic Packaging’s corporate office.

The Whitby mill project is the integrated corrugated packaging company’s second PES sludge-to-energy system implementation. In 2011, PES supplied a similar system to Atlantic Packaging’s Scarborough Liner facility — 111 Progress Avenue — replacing

combustion technology that was unable to reliably burn the wet paper mill sludge.

“We are excited to announce that our client’s second sludgeto-energy plant was completed in early 2017. Our client will see a sufficient reduction in the plant’s overall waste disposal cost as well as a major reduction of their energy costs by the savings obtained in burning the biomass fuel to produce steam, offsetting the use of natural gas,” Mike Oswald, president of Hayden, Idaho-based PES, says.

THE BIOMASS PROJECT

In 2016, PES received a design, supply, supervise and startup contract at the Whitby facility for a complete biomass energy system incorporating its Fluid Bed Combustion System. It designed the system to supply the necessary energy in the form of hot gas to dry the 60 per cent plus MC wet basis sludge to 40 per cent MC wet basis with the majority of the energy produced from the sludge used to generate process steam. As a result, the combined energy is produced from a single system without the use of natural gas, says PES, explaining that natural gas is only

used for startup of the system to obtain the required temperature for sludge feeding.

Producing process steam from the sludge-waste residuals promotes the plant’s green energy independence and the company’s green recycling plan by reducing the volume of waste sent to landfills.

“I think [an increasing number of] pulp and paper companies are being more green-oriented and [concerned] with the recycling and reutilization of waste fibre,” says Oswald.

PES designed the complete system and supplied all system equipment, including: the wet and dry sludge storage bins, the wet sludge feed system to the dryer, a single pass rotary drum dryer, the dry sludge collection and storage bin, the dry sludge fuel metering and conveyance system, the PES Fluidized Bed Combustion System with automatic ash cleaning system, a 35,000 PPH, 250 psig waste heat boiler specially designed by PES to allow removal of the high ash quantities generated from the fuel, the boiler economizer and air heater, gas cleaning system, and ash collection and storage silo.

“Many recycled pulp and paper plants have this problem. When you [operate] recycled paper plants, you have to take what is available as far as raw material and all that material does not necessarily repulp for you and you get a degree of material that is fibre but is not usable for paper. It is an industry-wide problem,” Oswald say.

PES explains that the majority of the sludge-to-energy system was designed to fit into the Whitby plant’s existing infrastructure, allowing most of the equipment — including the boiler system — to be inside the existing building with only the dryer, baghouse and ash silo outside of the building. A small portion of the building roof was removed to install the boiler system, although the height of equipment required a penthouse to be installed over the boiler.

The sludge-to-energy system receives and processes the incoming sludge, and combusts the sludge leaving only an ash that is white in colour with no carbon residual. This ash, according to PES, is collected from nine points throughout the boiler, economizer, air heater, multiclones and baghouse and is conveyed pneumatically to an ash silo. The ash system was designed and supplied by PES to have no rotary valves, which it describes as a constant maintenance issue on biomass boilers. The sealed ash system conveys all of the fly ash to a sealed ash silo for unloading into sealed trailers, which PES says will help ensure the complete boiler system is sealed from the point that the fuel is pneumatically conveyed into the fluid bed combustor.

The ash is held in the ash silo for pick up by a nearby cement plant where it is utilized as an admixture to the manufactured concrete. As a result, the ash from the sludge presents the mill with major environmental and sustainability advantages, as it does not require landfilling, Oswald explains.

PES says the ash produced by the boiler system has very similar properties to Kaolin clay, a feedstock which accounts for approximately 40 per cent of cement’s composition. The sludge ash can be added (substituted) at approximately five per cent by weight, and actually, improves the final concrete performance. If the ash were to be used in a ready-mix plant, it could be used to directly substitute cement, but the sludge ash would require grinding to a consistent, fine particle size. PES has successfully designed and implemented ash-grinding equipment in other energy systems to increase the marketability of the ash.

In business since 1945, Atlantic Packaging is a vertically integrated packaging products company with key business divisions including Corrugated and Color Packaging, Recycled Paper Mills, Retail Packaging & Displays, Paper Bag Products, Supply & Inventory Management, and Recycling. •

This article was originally published in the Spring 2018 issue of Pulp & Paper Canada.

PES received a design, supply, supervise and startup contract for the complete biomass energy system.

Producing process steam from the sludge-waste residuals promotes the plant’s green energy independence and the company’s green recycling plan by reducing the volume of waste sent to landfills.

WELCOME

On behalf of the board of directors of the Wood Pellet Association of Canada I would like to extend an invitation to everyone to attend the 2018 annual general meeting and industry conference September 17th to 19th in Vancouver.

There is lots of exciting activity happening in the pellet industry lately. The emergence of the Asian market and recent off-take agreements with western Canadian producers is one of the most notable. Demand from Europe for Premium Pellets has bolstered interest for that product here as well and many Canadian producers are well positioned to participate in those markets. WPAC is focused on helping Canadian producers develop both the international and Canadian markets for both industrial and premium pellets.

Our venue this year is the Vancouver Marriott Pinnacle located at 1128 W Hastings St., Vancouver, B.C., V6E 4R5. Elegance, convenience and modern comfort await you at the Vancouver Marriott Pinnacle. Ideally situated in the heart of the city centre just moments from all of the things that make Vancouver such a popular destination.

This year we will kick off our conference on Monday Sept. 17 with an industry golf tournament. Seymour Golf and Country Club is North Vancouver’s original social network. It has been an integral part of the North Vancouver and North Shore community since 1953, when the course was formed out of the wilderness to create a community for members who love the game of golf. www.seymourgolf.com Much of that wilderness still surrounds the golf course, providing a retreat from the noise and hectic pace of city life. You can leave downtown Vancouver and be there in 15 minutes, but when you step onto the first tee, you’ll feel as if you’re miles away! Known for its superb conditioning, treed fairways and tough greens, Seymour has allowed generations of members, their children and their grandchildren to learn and enjoy the game of golf together.

As an extra bonus, from 5:30 to

8:30 p.m. there is a welcome reception aboard the MV Magic Charm. Join us aboard for a three-hour cruise through Indian Arm, a steep-sided glacial fjord formed during the last ice age. This two-level yacht has a fully functional bar at the bow with an outdoor seating area perfect for networking and capturing stunning pictures. The second level is a sleek, modern lounge that opens onto a large, outdoor deck that offers the perfect arena to mingle and take in the breath-taking views. The Magic Charm departs from Westin Bay shore Marina promptly at 6:00 p.m. for a trip along Burrard Inlet to Deep Cove.

Don’t think twice, come on out and join the fun! Golf is a great way to forge lifelong friendships and partnerships and there is no better way to see Vancouver than from the water.

The Wood Pellet Association of Canada’s conference and annual general meeting is Canada’s largest gathering of the Canadian wood pellet industry. Each year, this event attracts hundreds of wood pellet, biomass and bioenergy professionals from across the country, as well as the U.S., Europe and Asia, to discuss the issues and opportunities that are impacting the industry here in Canada.

Our theme this year is “Powering Asia with Canadian Wood Pellets.” Day One of our conference will include an update on the global pellet market, sourcing sustainable fibre, wood pellet supply chains and world-class research and development.

We will wrap up the day with a pellet barbeque and reception. Back by popular demand is John Swaan and his world-famous ribs. Don’t miss this opportunity to network, socialize and experience the taste of wood pellets in a grill.

Day Two of our conference will focus on the Canadian market and the work being done here on safety and the growth of the pellet option. Be sure not to miss our special keynote!

The wood pellet industry is still a new and emerging industry with incredible potential. The Wood Pellet Association under executive director Gordon Murray’s leadership has played and will continue to play a leadership role globally as our industry grows. Come and attend WPAC’s board at our AGM and hear first-hand about the work being done by your association. The AGM will immediately follow the conference.

On Thursday Sept., 20 and Friday, Sept., 21, join association members as they head north and tour some of B.C.’s pellet producers and the Westview Terminal in Prince Rupert. Thanks in advance to Pacific Bioenergy, Premium Pellet and Pinnacle Renewable Energy for the opportunity to visit world-class producers.

Register at www.wpac.org/wpac-agm.

See you all in Vancouver!

Rene Landry President Wood Pellet Association of Canada

WPAC president Rene Landry (left) and executive director Gordon Murray at WPAC’s 2017 conference and AGM in Ottawa.

AGENDA

> MONDAY, SEPT. 17, 2018: PRE-CONFERENCE DAY

8:00 a.m. to 4:00 p.m.

Golf Tournament – Seymour Golf and Country Club

• Bus from Marriott Pinnacle Hotel to Seymour Golf and Country Club

• Coffee and rules explanation

• Golf – eight flights

• Lunch and awards

• Bus from Seymour Golf and Country Club to Marriott Pinnacle Hotel

6:00 p.m. to 9:00 p.m.

Opening Reception Aboard the MV Magic Charm

Join us aboard the Magic Charm for a three-hour cruise through Indian Arm, a steep-sided glacial fjord formed during the last ice age!

> TUESDAY, SEPT. 18, 2018: CONFERENCE PART 1 - FOCUS ON ASIA

8:00 a.m. to 9:00 a.m.

Breakfast and Registration

Check in at registration outside the exhibition area and enjoy a hot breakfast before sessions commence.

9:00 a.m. to 10:30 a.m.

Global and Asian Markets

Moderator: Gordon Murray, Executive Director, Wood Pellet Association of Canada

Speakers:

• Rene Landry, President, Wood Pellet Association of Canada — Welcoming Address

• Christian Hansen, Director, Pacific Region, Global Affairs Canada — Canada as a Trading Nation

• Argus Biomass Markets — Global Supply and Demand Dynamics

• Seth Walker, Senior Bioenergy Economist, FutureMetrics — Asian Pellet Market Development

10:30 a.m. to 11:00 a.m.

Networking Break

Beverages and light snacks will be available in the exhibition area.

11:00 a.m. to 12:00 p.m.

Sustainable Fibre Sourcing

Moderator: Robert Tarcon, General Manager, Wood Pellets, Tolko Industries Ltd.

Speakers:

• Dr. William Strauss, President, FutureMetrics — Asian Biomass Fuel Options: Sourcing, Sustainability, Cost of Production, and Fuel Characteristics

• Shawn Bells, Vice-President of Operations, Pacific BioEnergy — Managing Pacific BioEnergy’s Fibre Supply Chain

• Joseph Aquino, Head of Sustainability, Pinnacle Renewable Energy — Ensuring Sustainable Fibre Sourcing in Western Canada

12:00 p.m. to 1:30 p.m.

Networking Break

Lunch buffet will be available in the exhibition area.

> TUESDAY, SEPT. 18, 2018: CONFERENCE PART 1 - FOCUS ON ASIA

1:30 p.m. to 3:00 p.m.

Wood Pellet Supply Chain

Moderator: Scott Bax, Senior Vice-President of Operations, Pinnacle Renewable Energy

Speakers:

• Robert McCurdy, CEO, Pinnacle Renewable Energy Inc. — Pinnacle’s Journey: Becoming One of the World’s Leading Pellet Manufacturers and Distributors

• Fiona Murray, Vice-President, Industrial Products, CN — CN’s Role as a Vital Link in the Wood Pellet Supply Chain for Canada’s Asian Customers

• Kerry Lige, CEO, Fibreco Export — Considerations in Wood Pellet Handling Through Port Facilities

• Henry Pease, Solid Fuels Trading, RWE Supply and Trading — How the Biomass Supply Market is Becoming Global: What This Means for Asian & European Wood Pellet Buyers

3:00 p.m. to 3:30 p.m.

Networking Break

Beverages and light snacks will be available in the exhibition area.

3:30 p.m. to 4:50 p.m.

World Class Research and Development

Moderator: Dr. Shahab Sokhansanj, Professor and Director, University of British Columbia, Biomass and Bioenergy Research Group (UBC-BBRG)

Speakers:

• Dr. Sokhansanj — Introduction to UBC-BBRG

• Dr. Fahimeh Yazdan Panah, Research Associate, UBC-BBRG — Developing Wood Pellet Combustible Gas Characteristics in Support of Ocean Shipping Regulations

• Dr. Hamid Rezaei, Postdoctoral Research Fellow, UBCBBRG — Pellet Raw Material and the Effects of Particle Size on Industrial Boiler Performance

• Jun Sian Lee, Doctoral Candidate, Biological and Chemical Engineering, UBC-BBRG — Analyzing the Impact of Rain Intensity on Wood Pellet Durability: Implications for Ship Loading During Wet Weather

4:40 p.m. to 4:50 p.m

Wrap-up and Key Takeaways

Vaughan Bassett, Senior Vice-President, Pinnacle Renewable Energy

5:00 p.m. to 7:00 p.m.

Wood Pellet Barbeque and Reception

John Swaan, the grandfather of wood pellets and FutureMetrics pellet expert, will be cooking his world-famous pellet-smoked ribs.

> WEDNESDAY, SEPT. 19, 2018: CONFERENCE PART 2FOCUS ON CANADA

8:00 a.m. to 9:00 a.m.

Networking Breakfast

Enjoy a hot breakfast in the exhibition area before sessions commence.

9:00 a.m. to 10:00 a.m.

Keynote: Making Our Industry Safer

• Brad Livingstone, Safety Awareness Speaker — The Ripple Effect

10:00 a.m. to 10:30 a.m.

Networking Break

Beverages and light snacks will be available in the exhibition area.

10:30 a.m. to 11:50 a.m.

Growing Canada’s Pellet Market

Moderator: John Swaan, Manager, Senior Consultant, FutureMetrics

Speakers:

• David Dubois, Manager of Business Development, Fink Machine — Growing the Biomass Boiler Market in Canada

• Martin Bentele, Managing Director, German Wood Energy and Pellet Association — Growth of the German Pellet Heating Market: Is the Same Possible for Canada?

• Dr. Harry “Dutch” Dresser, Founding Director, Maine Energy Systems — Tackling the Challenge of Bringing European Biomass Boiler Technology to Canada: Is There a Path for Canadian Adoption of EN 303-5?

• Rene Landry, Director, Wood Pellet Operations, Shaw Resources — Evaluating WPAC’s Domestic Marketing Toolbox

11:50 a.m. to 12:00 p.m.

Wrap-up and Adjournment

12:30 p.m. to 2:00 p.m.

Annual General Meeting

Open to all WPAC members. Lunch will be served.

Board meeting to follow AGM from 2:00 p.m. to 3:00 p.m.

EXHIBITORS

AGI

AGI is a global leader in the planning, engineering and manufacturing of full solutions and systems across five platforms: grain, fertilizer, food, feed and seed. AGI partners with customers on six continents to leverage the AGI advantage and engineer unique market-specific systems which are delivered for farm and commercial applications. www.aggrowth.com

AIREX ENERGY

Airex Energy develops, manufactures and markets torrefaction systems that convert biomass into torrefied pellets, a clean, renewable alternative to coal. Benefits over industrial-grade pellets include: superior energy content, one similar to that of coal; superior energy density, therefore reducing transportation and handling costs; water-resistance allowing the pellets to be stored in a pile; and easily integrates into existing systems for handling and grinding coal. www.airex-energy.com

AIROFLEX

Airoflex Equipment engineers and designs bulk material handling equipment, which includes standard and extended-arm truck dumpers, standard, extended-arm, portable, and semi-permanent trailer tippers, receiving hoppers, hydraulic telescoping cylinders, service legs, as well as refurbished truck and trailer dumpers. With over 70 years of experience, Airoflex provides quality-built equipment that meets clients’ needs. www.airoflex.com

ANDRITZ

Andritz provides a comprehensive product portfolio for biomass industries all over the world. With its technologies and service solutions, Andritz is the world leader in wood processing, biomass handling, and wood pellet production facilities. Process technologies, equipment, plants, and systems; Andritz is your complete process partner. www.andritz.com

BIOMASS ENERGY LAB

Biomass Energy Lab (BEL) provides analytical testing services for the biomass and pelletized fuel industry. As an ISO 17025 accredited lab, BEL specializes in certifications for export shipments and offers testing per CEN/EN methods as well as ASTM methods. Along with testing services, BEL also provides auditing services for both the Pellet Fuels Institute and the

ENplus fuel certification programs. www.tpinspection.com

BRUKS

Bruks is a global leader in mechanical engineering and equipment supply for the bulk materials handling industries. Customer service and product performance are at the heart of its corporate culture; it provides specialized customer solutions, including the development of custom machines and systems. Its services include project engineering, technical support, start-up training and remote-monitoring/ servicing of machine functions. www.bruks.com

BRUNETTE MACHINERY COMPANY

Brunette Machinery Company, with its head office in Surrey, B.C. is an independently owned and operated company serving the North American forest industry since 1942. Brunette’s long history of manufacturing experience guarantees its customers an unsurpassed level of quality and leading-edge technology built into every single one of Brunette’s innovative products. Brunette’s commitment to quality gives customers an important advantage as they compete in an ever-changing global economy. www.brunettemc.com

CERTIFIED

Certified is an international company established in 1949 with global manufacturing facilities. Certified is a major supplier of advanced finished lubricants, fuel quality programs and services designed to increase asset reliability and reduce operating costs by reducing downtime, replacement parts, labor costs and most importantly your safety and environmental impact. www.certifiedlabs.com

CN

CN is a true backbone of the economy whose team of approximately 25,000 railroaders transports more than C$250 billion worth of goods annually for a wide range of business sectors, ranging from resource products to manufactured products to consumer goods, across a rail network of approximately 20,000 routemiles spanning Canada and mid-America. www.cn.ca

DANSONS

Dansons Industrial Bulk Lubricants proudly supplies high quality greases to pellet mills

across Canada. Working in tandem with

www.dansons.com

www.pellet.org/wpac-agm

reliable equipment to enable customers

some of the lowest emissions in the www.playerdesign.net handling and ash handling equipment for a www.processbarron.com

Prodesa designs and provides compre-

and skilled trades are well-versed in lean and on budget.

storage and handling. www.hd-pellets.de

MoistTech Corp. is a world leader in

arena. Prodesa covers all technological stages in the development of industrial

www.prodesa.net

www.shw-shs.com

TSI designs and builds equipment for engineered wood and biomass industries. -

www.tsi-inc.net

Our competitors say we’re old and slow to change. That our machines are ugly. That we’re not on the cutting edge.

We say, “Yup.”

“Old” means we’ve been around for over 100 years—and we’ll be here for 100 more.

“Slow to change” means we don’t do fads. Oh, we’ll turn on a dime to make changes that our customers need. But fads? Nah. We’d rather protect your investment.

“Not cutting edge” means we’re proven. We build what works and we stick with it.

And “ugly”? Well. You don’t need to be pretty to make a damn good pellet mill.

Dealing with dust

Dust collection and suppression systems for pellet producers

Staff Report

KICE

Spanning over half a century, Kice’s experience in designing and building filter systems provides an insight unique in the market. Kice has studied filtration principles and developed some of their own, many of which are patented. For maximum operating efficiency, the dust must be allowed to settle into the hopper for discharge out of the system. If bags are spaced too closely together or if the housing size is too small, excessive “can velocity” results, holding

the dust in suspension. Suspended dust can choke the system regardless of the cleaning mechanism and air to cloth ratio. Kice filters are conservatively designed to provide proper bag spacing, which eliminates this potential problem. Kice filters are very efficient, up to and above 99.9 per cent, even with low micron dust.

www.kice.com

MARTIN ENGINEERING

Martin Engineering has introduced a new insertable dust collector that features improved filtering and a smaller footprint, helping bulk material handlers minimize

airborne dust at belt conveyor loading points. The Martin Insertable Dust Collector is an automatic, selfcleaning filter designed to remove dust from the air in conveyor loading and transfer points, silo vents, bucket elevators and screens. The smaller filter elements allow a significant reduction in the dust collector’s “footprint,” so it can be installed in locations where tight quarters complicate the installation of other systems.

www.martin-eng.com

SONICAIRE

SonicAire fans are industrial fans designed to proactively eliminate overhead combustible fiber and dust in your facility. Not only will employees enjoy a cleaner, healthier and safer work environment, but cleaning costs will be dramatically reduced. Overhead dust control fans also help keep companies in compliance with the U.S. Occupational Safety and Health Administration (OSHA) and NFPA regulations. Airmax Systems is Western Canada’s leading distributor of SonicAire fans. Airmax works with Canadian pellet manufacturers, sawmills and pulp mills to eliminate fugitive dust. Airmax is now offering the new SonicAire XD2 fan, certified for Class II Div 2 Hazardous Areas. www.airmaxsystems.ca

BOSSTEK

BossTek has introduced the newest model in its growing family of self-powered dust suppression equipment, as BossTek announces the debut of the DustBoss DB-30 Fusion. The new design is a versatile and transportable atomized mist unit, engineered with a workhorse electric motor and 30-kW generator. Permanently mounted on a rugged road-worthy trailer, the company’s Fusion lineup is proving to be a popular and effective means of delivering powerful dust suppression technology to sites that lack a convenient power source. The extremely water-efficient design consumes just 2.5 gallons per minute. www.bosstek.com

SCIENTIFIC DUST COLLECTORS

eliminates the venturi at the top of the filter bag/cage. This results in a pressure drop reduction of two inches water column (wc).

www.scientificdustcollectors.com

FLAMEX

The Flamex Spark Detection and Extinguishing System is a cost effective solution for the prevention of baghouse fires and explosions. Drying and hammermilling operations among others can often cause sparks, which are typically the ignition source for process fires in wood pellet facilities. The Flamex System uses infrared detectors to identify sparks in ductwork and effectively extinguish them. The system can also be programmed to activate deluge valves, alarms, abort gates, and equipment shut down. Flamex is the first system of its type to gain factory mutual approval and has been successfully used in numerous woodworking and pellet manufacturing facilities throughout North America. www.sparkdetection.com

AIRCON CORPORATION

Aircon Corporation designs and manufactures industrial air systems for dust control, pneumatic conveying systems, ventilation systems, and equipment. It offers baghouses, bin vents, compressed air filters, elevator leg filter units, and reverse air filters; and high efficiency and low-pressure cyclones. The company also provides equipment, including rotary airlocks, below roof separators, control panels, material handling fans, paper scrap rotary valves, and screw conveyors; components, such as ductwork, angle rings, structural steel, and flat back elbows; steel fabrication solutions; and spare parts. It offers engineered systems for woodworking, grain, paper trim, paper and folding carton, feed mill, and wood and biomass pellet, chemical, coal, food, plastic, foundry, and gypsum industries worldwide. The company was founded in 1976 and is based in Memphis, Tenn. www.aircon-corporation.com

GRECON

The aggressive nature of processing biomass through drying, shredding, granulating and pelletizing processes create sparks or embers. These hazards are quickly transported along the production line

Scientific Dust Collectors (SDC) offers the ability to calculate the potential horsepower energy savings available by using SDC’s unique baghouse design. This unique nozzle based baghouse filter design allows SDC to clean the filter media better than ever before. In addition, using this baghouse design

through pneumatic conveying systems and can ignite product and waste dust causing fires and explosions. GreCon Spark Detection and Extinguihing Systems are a cost effective preventative system, which detect these hazards and activates counter measures before they cause fires or explosions. GreCon Spark Detection Systems are factory mutual approved and can reduce your risk of fires and dust explosions in transport and collection system as outlined in

NFPA 69, 654, and 664 standards.

www.grecon.us

BAUM

Baum builds 14x18 through to 45x55-size feeders as well as firelock isolators, as per NFPA 69. Airlocks are considered passive isolation due to their 10 vane rotor construction. Vanes are always

blocking a blast pathway, regardless of what position the rotor is in, while operating or not operating. Two-hp to 20-hp drives available are (American Dodge TXT or European SEW Eurodrive). Top and bottom flanges on airlocks are industry standard, and available dimensions include A1400 and A1410.

www.baumpneumatics.ca

IEP TECHNOLOGIES

The Smart/DS Dynamic Explosion Detector System by IEP Technologies is designed for demanding process applications requiring leading edge rate-of-rise explosion pressure sensing. Its unique ability to analyze rate of pressure rise and differentiate it from non-explosion pressure provides maximum explosion protection with minimal false alarms. Typical applications include dust collectors, drying systems, pneumatic conveying systems and reaction vessels. The SmartDS is designed as part of an explosion suppression system, installed and serviced by experienced IEP Technologies engineers and technicians throughout the world.

www.IEPTechnologies.com

VETS SHEET

METAL

Founded in 1921 VETS Sheet Metal serves Canada’s wood and biomass industries’ dust collection and HVAC needs with locations in Edmonton, Kelowna, B.C., and Surrey, B.C. The company’s strength is building and installing dust containment, abatement and suppression systems that meet stringent NFPA guidelines and significantly reduce our client’s cleanup and operating costs. VETS has installed numerous NFPA compliant systems with third party verified emission test results. A number of VETS’ supplied and/or installed multi-cyclone systems have had impressive air emission readings measuring an average PM emission rate of 0.006g per KG of effluent particulate matter released in the atmosphere. This is 15 times below the maximum allowable emissions as per the Alberta

government’s 2006 code of practice for new sawmills (0.09g per KG of effluent).

www.vetsgroup.com

FIKE

With over 70 years of field experience in providing dust explosion protection systems, Fike’s team of engineers, application specialists and combustion researchers understand the complexities of plant processes, relevant code compliance and the critical nature of plant operation. Fike designs and provides venting, suppression and isolation systems to ensure the safest and most effective solutions for plant and employee protection. Fike’s updated second generation ValvEx is a passive explosion isolation valve engineered to prevent flame and pressure propagation through interconnected pipes, ducts or conveying lines.

www.fike.com

ALLIED BLOWER

For wood processing facilities demanding larger system capabilities Allied Blower & Sheet Metal has successfully certified a line of Back Blast Dampers (BBD’s) that reach sizes up to 50” (1270 mm) in diameter. The BBD can resist a

THE MOST ADVANCED FIRE PREVENTION AND PROTECTION TECHNOLOGY FOR THE BIOENERGY INDUSTRIES

Firefly is the only company with FM-approval for detection of both sparks and hot particles with temperatures down to 250°C (TD-detector) and 400°C (GD-detector).

www.firefly.se

vented dust collector explosion reaching a Pred of 5 psi (0.35 bar) for dusts with a Kst of up to 200 bar-m/sec. This range provides safe operation for a large range of deflagrable dusts used in industry. When comparing the options of using a Passive Mechanical System or an Active Chemical Suppression system the Mechanical Systems are perceived to have less maintenance costs due to simplicity in function, design, training requirements, and the low frequency of inspections.

www.alliedblower.com

OPTIMIL MACHINERY

Optimil Machinery Inc. has redesigned machinery to incorporate superior sawdust and chip containment with systems on chipping/sawing centres, saw boxes, bandmills and conveyors. Some new features include new chipping sections with increased head diameters and enlarged chip chutes. Reconfigured chip chutes allow for fewer transitions and diversion points deliver optimum chip flow and reduced pockets for chips to strike and create dust and debris; new guarding promotes safety by preventing debris entering work areas from saw boxes and bandmills. Optimil also specialises in the EDEM brand of vibrating conveyors for sawmills, wood processing, pellet and biomass plants.

www.optimil.com

CFinalThoughts

Heavy options

Energy challenges for heavy industries under a carbon pricing policy

By Pat Liew – Business development manager for Ecostrat, Inc.

anada’s heavy industries are notorious for being the biggest emitters of carbon in Canada. With the price of carbon being tagged onto emissions, these heavy industries are finding ways to reduce emissions. Despite the government narrative about fossil fuel use reduction, there is no perfect substitute to fossil fuels for heavy industries like steel, cement, mining and insulation manufacturing.

The steel industry requires coal or petroleum coke (pet coke) as a carbon source for steel manufacturing. The stone wool insulation manufacturing requires the heat intensity of coal to melt rock. Cement manufacturers require the same heat intensity of coal or natural gas to provide enough energy for their process.

Despite trials in adopting alternative fuels, such as tires, shingles, wood and plastics, as substitutes in these industries, wider adoption has not taken place. So, what are the major challenges of these alternatives to fossil fuels?

WOOD WASTE

Wood waste has the most mature and established supply chain to serve the market. Wood waste can vary from recycled wood to sawmill/forest waste. Wood waste is priced competitively in the market and has been widely used by pulp mills, industrial greenhouses and power plants. The challenge with wood waste is its energy density and storability. Wood has half the energy content compared to coal and it deteriorates fast if not used quickly. Wood, unlike coal, also absorbs water easily if stored outside, lowering its quality effective energy content.

ASPHALT SHINGLES

Asphalt shingles have higher energy content compared to wood waste. Asphalt shingles have approximately 8500 BTU/

LB. It is significantly higher than wood but still slightly lower than coal. The challenge with asphalt shingles is that they are currently being used in the road paving industry, lowering their availability on the market. Additionally, asphalt shingles need extensive pre-processing before they can be used as fuel. Therefore, currently the asphalt shingle supply chain is not able to meet the heavy industry’s fuel needs.

RAIL TIES

Waste rail ties show a lot of promise. They have very high energy content. Rail tie availability is high and price is low because the material poses a liability to rail companies. However, rail ties have to be extensively processed before being used as fuel. Rail ties have coarse metal spikes and contain sand and stone, causing potential problems in pre-processing and, sometimes, utilization. Additionally, burning rail ties as fuel can be heavily regulated as rail ties contain creosote.

TIRES

Tires also show lots of promise in terms of heat content. Tires are currently used in cement kilns in the United States. In Canada, the bulk of used tires are recycled into other rubber materials. Therefore, any facility looking to use tires as fuel would have to compete for the limited supply. Additionally, tire burning can be a public relations nightmare. The public’s perception is typically negative towards burning waste. This can pose a challenge to get approval from the government to use tires as fuels.

TORREFIED WOOD

Torrefied wood, also known as bio-coal, is a perfect coal replacement. It is similar in heat content to coal and can provide the carbon needed for steel manufacturing. Torrefied wood is also hydrophobic and doesn’t have

the rotting issues other wood fuels have. The challenge with torrefied wood is price and availability. There are a few successful companies in Canada, the U.S. and Europe that can provide torrefied wood, but the price is high and production capacity is limited. Currently, torrefied wood is too expensive for industries that don’t manufacture high value goods, such as cement and insulation manufacturing.

As of yet there is no perfect substitute to coal today. The price, availability and heat value of coal is not rivaled by any other alternative fuel. However, the alternative fuels mentioned can be used as a coal supplement. For the industry to fully embrace alternative fuel, expensive retrofit needs to be performed to existing infrastructure. This is where the revenue generated from the carbon tax or cap and trade policy can help. Revenue could help heavy industries bridge the gap of quarterly profits and long-term viability with the carbon pricing policy.