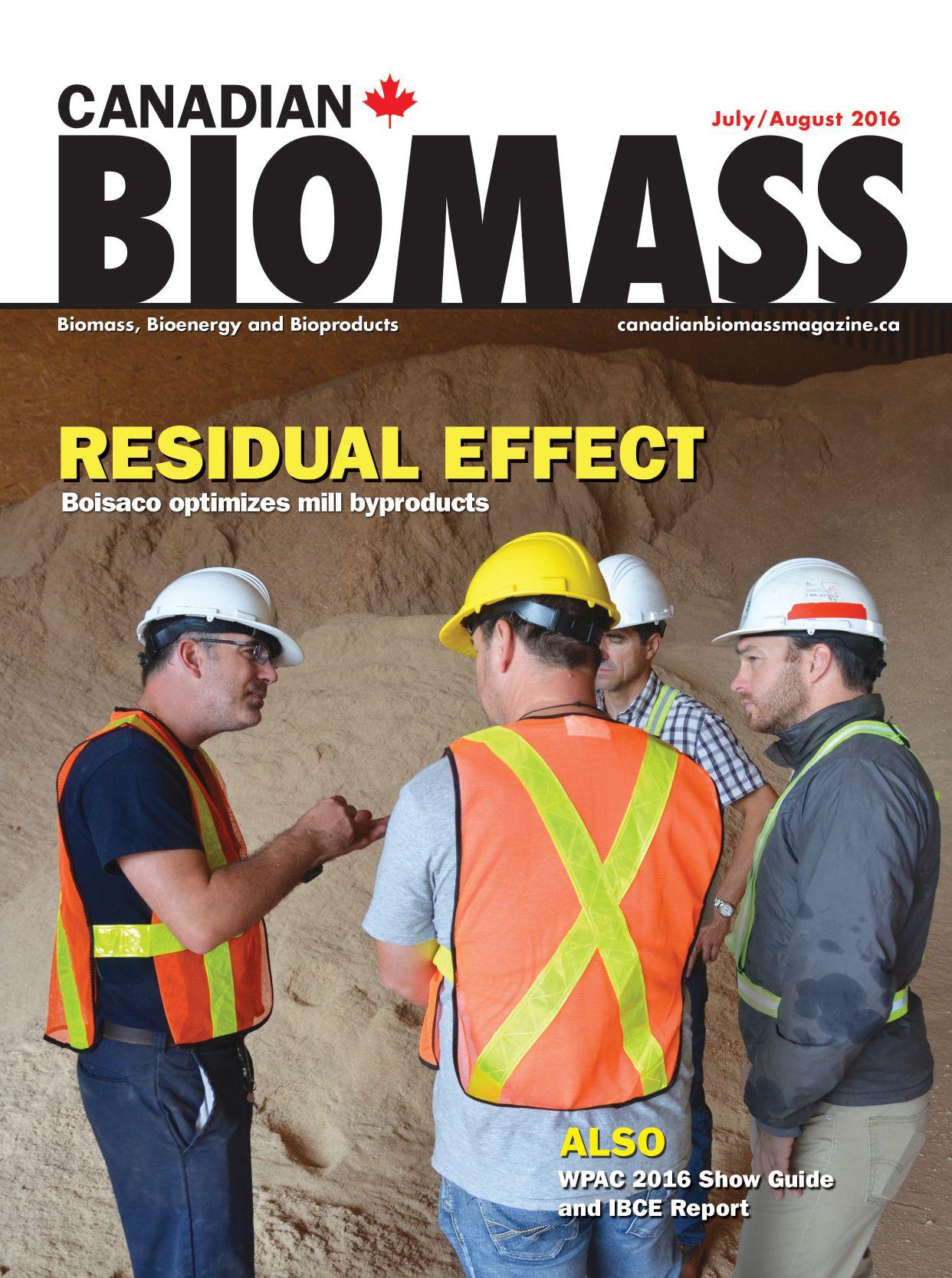

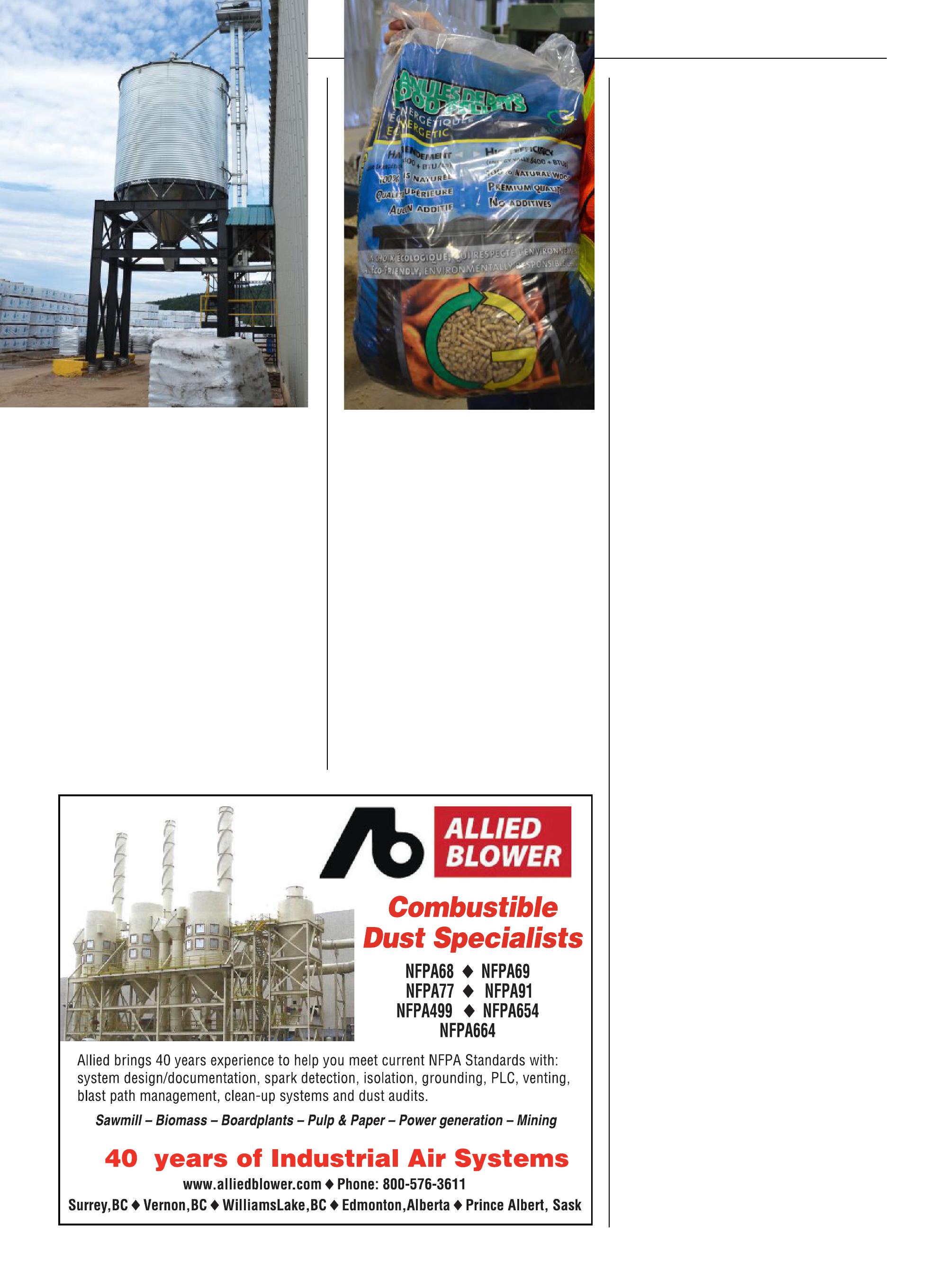

Boisaco diversifies the use of its residuals by creating new products, including wood pellets.

Lafarge searches for low carbon fuel solutions, including the use of torrefied wood pellets.

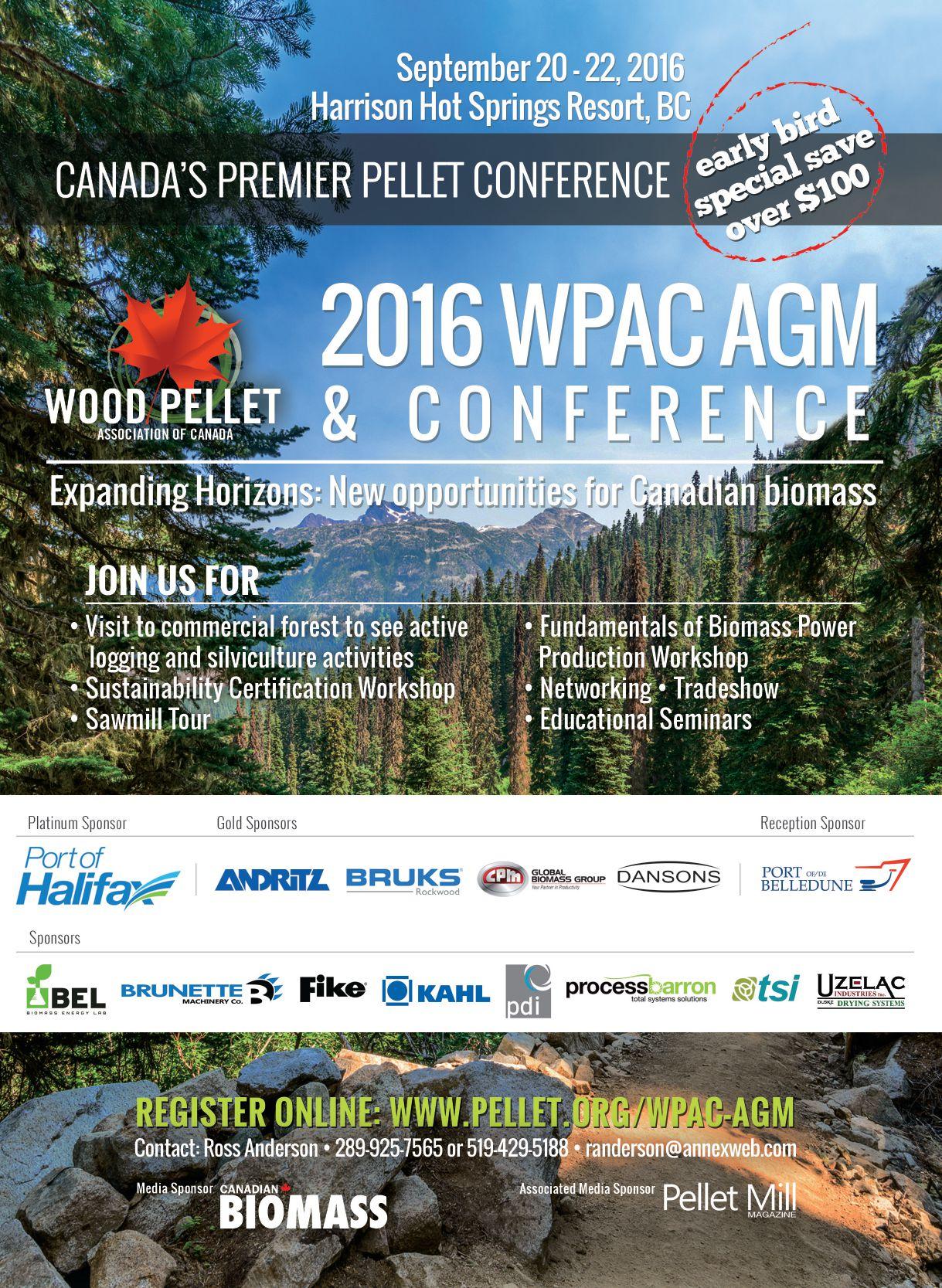

Your exclusive guide to the upcoming Wood Pellet Association of Canada Conference and AGM, taking place from Sept. 20 to 22 in Harrison Hot Springs, B.C.

A look back at the sessions and news stemming from the 7th International Bioenergy Conference and Exhibition that took place this summer in Prince George, B.C.

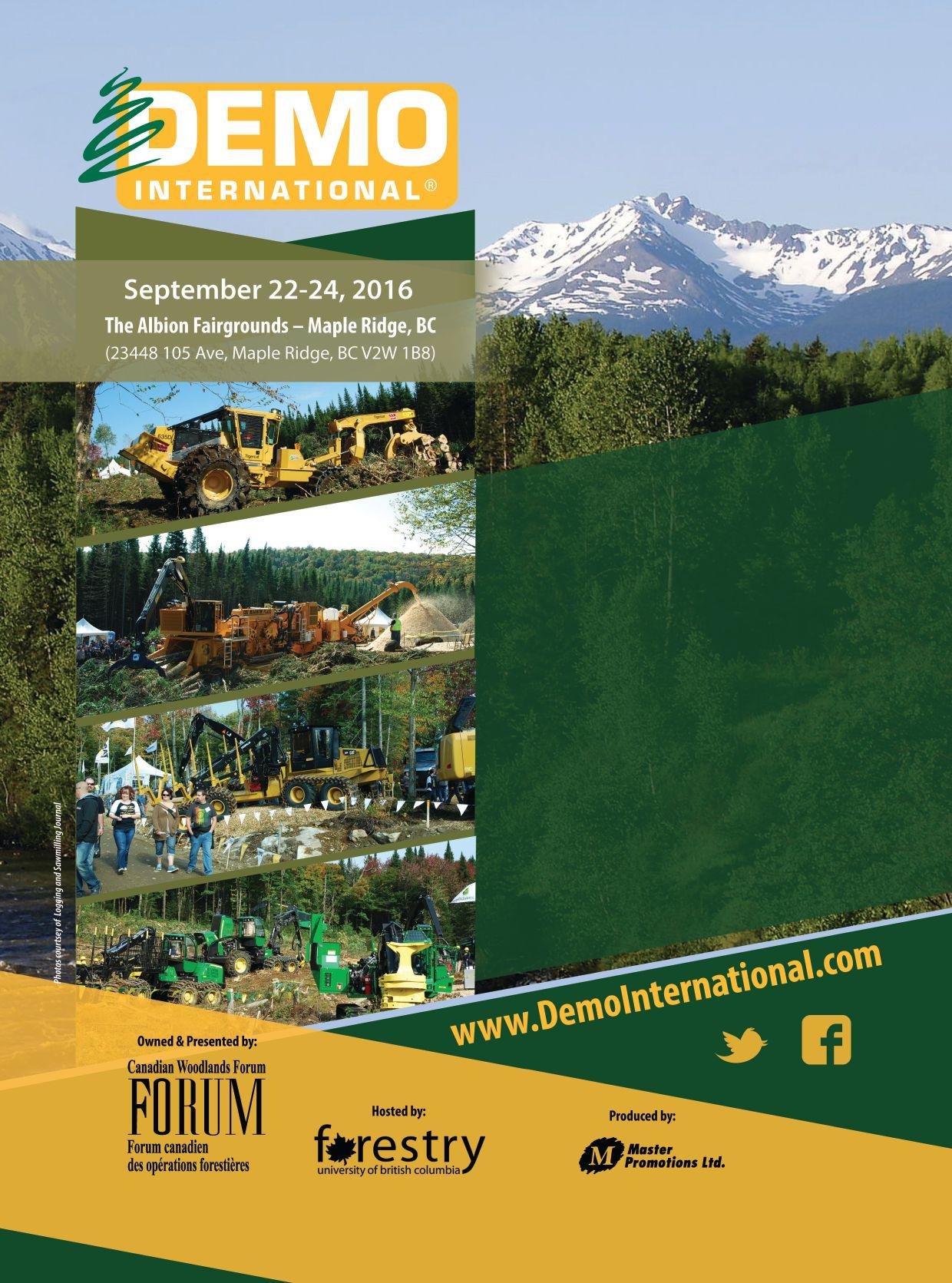

With the 2016 DEMO International show coming to Maple Ridge, B.C. this September, Canadian Biomass fills you in on the exhibiting chipper and grinder companies.

Boisaco is finding ways to optimize the use of its sawmill residuals and is generating new products and employment in the process. See full article on page 10.

Interesting times ahead for the U.K. and our wood pellet sector.

ith the United Kingdom (U.K.) voting to leave the European Union (EU), this decision has likely raised a few eyebrows of wood pellet producers this side of the North Atlantic.

The U.K. is by-and-large the current world leader in the use of biomass for energy production and the home for the majority of Canada’s wood pellet export market.

By early July, the pound had decreased in value by more than 10 per cent since the U.K. voted to leave the EU, making it more expensive for companies to purchase wood pellets in North America. Will the U.K.’s currency decline significantly impact existing business in Canada? Not likely. Could it hurt Canadian companies’ abilities to secure supply contracts in the U.K. in the future? Maybe.

the three projects could increase the U.K.’s industrial wood pellet demand by about 3 million tonnes per year by 2020.

The Lynemouth project owned by EPH, a Czech-based energy company, is a particularly interesting case to watch. While the project did obtain EU state-aid approval last year, it will be interesting to see how EPH responds if the U.K. decides to exit the EU, since the country would no longer necessarily need to follow EU regulations and the potential for increased fuel supply costs exists due to fluctuating currencies.

On a positive note, EPH has secured contracts for half of its expected wood pellet demand from U.S. producer Enviva (MGT has secured its expected wood pellet demand from the same producer).

Volume 16 No. 4

Editor - Andrew Snook (905) 713-4301 asnook@annexweb.com

Contributors - Gordon Murray, Staffan Melin

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Market Production Manager Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Brooke Shaw

Circulation Manager Carol Nixon – cnixon@annexweb.com 450-458-0461

Canadian Biomass is published six times a year: February, April, June, August, October, and December. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

This is a particularly important factor to consider in British Columbia, where there are 12 wood pellet factories currently producing approximately 1.7 million wood pellets annually. About 70 per cent of those pellets are currently destined for the U.K.

Another factor to consider is the impact that leaving the EU could have on the country’s wood pellet demands in the future – if the country does go ahead with leaving the EU (the Brexit referendum is not necessarily legally binding). The U.K.’s biomass industry is very dependent on government subsidies for growth and there are major projects coming up the pipes: Drax’s full conversion of its 645MW Unit 1 co-firing power plant, EPH’s 420MW Lynemouth coal-to-biomass conversion and MGT Power’s 299MW Teeside combined heat and power plant. Combined,

Drax is currently awaiting a decision from an EU state aid investigation for the CFD subsidy it was granted back in 2014 for its Unit 1 conversion. Media are questioning whether the referendum results will create delays in the process. That said, the unit is already co-firing at 85 per cent, so I don’t see the decision on full conversion creating a big impact on its operations either way. The bottom line is that the U.K.’s appetite for North American wood pellets isn’t likely to dry up anytime in the near future – current demand for Drax’s two full unit conversion power plants is about 6.8 million tonnes annually.

For now, we will have to watch and see if the U.K. decides to leave the EU. Either way, there are interesting times ahead.

Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $60 US; Foreign – 1 Yr $77 US

CIRCULATION

Tel: (416) 442-5600 ext 3552 Fax: (416) 510-5170 blao@annexbizmedia.com 80 Valleybrook Drive, Toronto, ON M3B 2S9

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2016 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

SHOW HOURS: Thursday, September 22 9am-5pm Friday, September 23 9am-5pm Saturday, September 24 9am-4pm

is now open with special pre-show DISCOUNTS offered!

Don’t miss the Demo International® Conference, “Canada’s Forest Sector: Adapting to a new reality. Technology and innovation as a catalyst for success” held September 19-21, 2016 at the Four Seasons Hotel in Vancouver, BC. The two-day event is co-hosted by the Faculty of Forestry, UBC and the Canadian Woodlands Forum in association with FPInnovations, the Council on Forest Engineering and the Canadian Institute of Forestry.

Visit www.demointernational.com for details!

Over 250 biomass professionals met in Québec City in June for the inaugural Residual Forestry Biomass Heating Conference organized by the Québec Wood Export Bureau, Vision Biomasse Québec and the Wood Pellet Association of Canada.

The event featured high-ranking government officials including Pierre Arcand, Québec’s Minister of Natural Resources and Energy, who showed up to launch the conference.

Arcand stated that the province is on its way to “decarbonizing” its economy. Québec’s new energy transition plan states that the province needs to reduce its greenhouse gas emissions by 37.5 per cent, use 25 per cent more renewable energies and 50 per cent more bioenergies by 2030. To achieve this goal, Québec will create Transition énergétique Québec, which will manage a $4-billion budget to fund energy efficiency and sustainable projects submitted for residential, business or public organizations.

But can forest biomass compete against other energy sources? From an economic standpoint, biomass is less

expensive than any other energy source, notes Jean-Pierre Bourque, industrial advisor for the Ministry of Forest, Wildlife and Parks (MFWP).

“The effective cost of biomass is very competitive for heating purposes,” he said. “For example, electricity is the most expensive at $86/MWh, and biomass is the least expensive at $17.12/MWh [not including processing].”

Although it is the cheapest energy, investing in new equipment, like a boiler, greatly increases biomass conversion project costs. This is why funding those projects is vital, and government subsidies often make the difference.

While Québec’s subsidy programs has rapidly run dry, Fondaction, a workers’ union fund, Investissement Québec and the Fédération des coopératives forestières du Québec created the Biomass Energy Fund, with a $20.2-million capitalization, to offer professional advice and money for conversion projects.

Furthermore, Fondaction will invest $50 million in greenhouse gas reduction projects over the next two years, stated Claire Bisson, assistant chief

investor for Fondaction. When reviewing which biomass heating projects to fund, Fondaction first looks for stable biomass supplies, proven technologies and available expertise. For the healthy development of the biomass sector, better and more specialized training must be provided to the emerging workforce.

To reach its 37.5 per cent GHG reduction target by 2030, Quebec will need to displace oil and propane, but also natural gas, according to Normand Mousseau, professor and Canada Research Chair in Computational Physics of Complex Materials, at l’Université de Montreal. Even if there is still a lot of work to be done to fully develop the biomass sector

Canfor is looking at the possibility of converting pulp mill wood waste into biocrude on a commercial scale with the construction of a biocrude plant in Prince George, B.C.

Earlier this year, Canfor formed a joint venture with Licella Fibre Fuels, the Australian start-up behind a process that transforms biomass waste from paper-making into stable biocrude oil. The biocrude can be fed into existing petrochemical refinery streams to produce renewable fuels. Licella has been running trials on the technology at Canfor’s Prince George mills since 2013.

Over the next few years, Canfor hopes to integrate the tech-

in Québec, some businesses are ready to take risks to save some money and develop new markets. This is what Fromagerie Boivin, a cheese-making company in Saguenay did in 2008, when they invested in a 800-hp boiler.

Fromagerie Boivin’s goal was to evaporate lactoserum, a milk byproduct, into powder to reach animal food markets.

Norforce Énergie also developed a new business model to implement biomass-heating projects in mines.

Since 2013, their turnkey solutions have become a success at the Casa Berardi mine.

The company hopes to implement this model in other mines over the coming years.

- By Guillaume Roy

nology into its existing pulp mills and funnel the waste, as well as virgin fibre, into an estimated $70-million crude oil processing facility that could have a production capacity of more than 400,000 barrels of biofuel per year.

“Biofuels and biochemicals represent the next frontier in the utilization of sustainable wood fibre to produce green energy and chemicals,” said CPPI CEO Don Kayne. “This initiative underscores Canfor Pulp’s commitment to innovation and the importance of green energy and chemicals in our future product mix, and we look forward to developing this potentially transforming technology with Licella.”

Pinnacle Renewable Energy Inc. has curtailed operations at its Quesnel, B.C., pellet plant.

Several factors contributed to the decision to close the plant. One key element was that the plant, first opened in 1988, was designed to process a diet of dry residuals from the local sawmills.

“That source of fibre is no longer available,” said Leroy Reitsma, president of Pinnacle. “As a result, there is currently no secure, sustainable, economically available fibre to support the operation of the Quesnel mill.”

The Mountain Pine Beetle infestation has created an inventory of standing timber that, while useless as sawlogs, is suitable for wood pellet manufacturing.

Pinnacle will continue to work with tenure holders and the provincial government to determine whether secure access to non-sawlog standing timber can be achieved within an eco-

nomically viable framework.

However, significant capital upgrades are also necessary at the Quesnel plant in order to be able to economically, efficiently and safely process this new fibre source into wood pellets.

“We believe it makes sense right now to take the time to do the analysis required to determine the scope and feasibility of making those upgrades. This period of curtailment is necessary to do that work,” Reitsma said. “We share our employees’ desire for certainty. We have not come to this decision lightly and will be working to minimize the duration of this decision to nine to 10 months.”

Pinnacle Renewable Energy Inc. is the longest-established wood pellet producer in Western Canada. Founded in Quesnel in 1988, Pinnacle runs seven pellet plants throughout B.C., producing more than one-and-a-half million tonnes annually, and employing more than 250 people.

Murray McLaughlin has stepped down as the executive director of Bioindustrial Innovation Canada (BIC), but will continue on in the role of government and partner relations.

Effective July 1, Sandy Marshall took over the position of executive director. Marshall brings a strong industry background to the

$76.5M

role, having spent 30 years in various capacities with Polysar, Bayer, and Lanxess. Marshall has been a member of the BIC board since 2008 and the chairperson for the last three years. Marshall has a strong understanding of the organization and its role.

“I am very excited about this opportunity to grow BIC into the future,” Marshall

said. “Murray has done an outstanding job as executive director building BIC and I look forward to his continued support and mentorship.”

Bill White will replace Marshall as chairperson of the BIC board. White is the retired president of DuPont Canada and has held a variety of global business

unit leadership roles in his 34 years with E.I. DuPont de Nemours.

With the recently announced funding for BIC from the province of Ontario, McLaughlin felt it was time for fresh leadership to continue to grow BIC and the portfolio for the Sustainable Chemistry Alliance Investment Fund.

The Governments of Canada and Quebec will provide $76.5 million in funding to AE Côte-Nord Canada Bioenergy Inc. for the production of renewable fuel oil from forest residues.

Canada’s Minister of Natural Resources, the Honourable Jim Carr, and Laurent Lessard, Quebec’s Minister of Forests, Wildlife and Parks, made the announcement on July 13 in Port-Cartier, Que.

The Port-Cartier plant will be the first commercial-scale facility of this kind in Quebec. The goal of the project is to convert forest residues into 40 million litres of renewable fuel oil per year. When upgraded into transportation fuels, this will remove up to 70,000 tonnes of CO2-equivalent emissions per year. Production of renewable fuel oil is set to begin in 2017.

The Government of Canada is providing $44.5 million for this project, through a $27-million investment from Sustainable Development Technology Canada and $17.5 million from Natu-

ral Resources Canada’s Investments in Forest Industry Transformation program.

The Government of Quebec is contributing $32 million to the project, including $10 million from Investissement Québec. To ensure the fibre supply for the project, in March the Quebec Ministry of Forests, Wildlife and Parks reserved 170,000 green tonnes of residues from government forests for the plant.

Through an alliance of three companies — Ensyn Bioenergy Canada, Arbec Forest Products and Rémabec Group — the private sector is demonstrating its substantial involvement with the confirmation of a $27.4-million investment.

The project’s renewable fuel oil is a cleaner alternative to conventional fossil fuels; it reduces greenhouse gas emissions by 70 to 90 per cent compared with fossil fuels and has a multitude of uses, including for heating and the production of transportation fuels.

Source: Natural Resources Canada.

TBy Gordon Murray, Executive Director, Wood Pellet Association of Canada

he Netherlands (NL) was briefly the world’s largest importer of industrial wood pellets for co-firing. Under its former biomass support scheme - Milieukwaliteit van de Elektriciteitsproductie or MEP – wood pellet consumption for co-firing peaked at about 1.5 million tonnes annually. However, from 2012 and 2014, imports declined rapidly and eventually stopped altogether, as power utilities’ MEP contracts expired.

Although the Government of the Netherlands (GNL) quickly replaced MEP with a new support scheme known as Stimulering Duurzame Energieproductie or SDE+, biomass co-firing has remained stalled, mainly over sustainability concerns.

On September 6, 2013, GNL announced the Energy Agreement for Sustainable Growth. The Energy Agreement was negotiated by a group of 47 stakeholders including government, environmental organizations, industry, trade unions, and others. Among its 159 measures, the Energy Agreement provides that biomass co-firing should contribute a maximum of 25 petajoules (PJ) annually. This equates to approximately 3.5 million tonnes of pellets. By comparison, co-firing of biomass for electricity generation produced 11.7PJ in 2010, 11.5PJ in 2011 and 10.6PJ in 2012. The Energy Agreement provides that five 1980’s era coal power plants will be shut down permanently. When co-firing resumes, it will take place in six newer, more efficient coal power plants.

The Energy Agreement also provides that any biomass eligible for an SDE+ subsidy

must be sustainable. On March 18, 2015, the Dutch energy sector and NGOs agreed upon the sustainability criteria for biomass. On March 30, 2015 these requirements were laid down in official Dutch legislation.

The next order of business was for GNL to determine how the energy industry, particularly pellet producers, would demonstrate compliance with the biomass

sustainability criteria. This has taken more than a year. The Ministry of Economic Affairs (MEA) developed draft verification procedures, finally making them available on March 29, 2016 for public consultation.

Although Canadian pellet producers are confident in their ability to meet the Dutch biomass sustainability criteria, they are anxious to ensure that when finalized,

the GNL’s verification procedures will be practical and that they will align with Canadian forest certification and chain-of-custody schemes such as FSC, SFI, and CSA.

The Government of Canada coordinated our national response to the Dutch consultation, including an invitation for representatives of GNL to visit Canada to view wood pellet manufacturing and forest management practices first hand.

From June 27 to 29, four officials from the Government of the Netherlands’ Ministry of Economic Affairs visited British Columbia. The GNL participants were: Jon Eikelenstam, program manager, Energy Agreement for Sustainable Growth; Patrick Todd, senior policy advisor, Bio-energy and Energy Subsidies; Sipke Castelein, senior advisor, Sustainable Energy; and Nico Bos, policy officer.

Canadian participants included government officials and representatives from the forest, sawmill, pulp and wood pellet industries.

From Canada’s perspective, the purpose of the mission was to present Canada’s approach to forest management and allow GNL officials to contrast that with what they saw in the U.S. southeast (MEA visited Virginia and Alabama in fall 2015); showcase the integrated nature of the industry and how wood pellets help to make full use of existing wood product waste streams; and help the MEA better understand the scale and practicalities of the industry in order to better inform their policy development process.

The GNL biomass mission included three days of meetings, mill and other site visits, field visits and networking opportunities in and around Prince George and Vanderhoof.

Topics that garnered the most attention and discussion during the week included:

• Features of the GNL SDE+ renewable energy subsidy system:

• The SDE+ program features a competitive bidding process for subsidy grants; lowest bid wins per amount of energy produced. The government’s funding commitment to successful bidders will last for eight years.

• The GNL decision about continued operation of coalfired plants is under review. This decision is expected by fall 2016 and will have major implications for the potential NL biomass-to-energy market. Fortunately, GNL sees opportunities for pellets not only in electricity generation, but also in residential, commercial and industrial heating.

• Forest certification schemes used in Canada and regional prevalence of FSC vs PEFC (SFI and CSA).

• Forest planning, governance, monitoring and enforcement on public lands, including the division of forest management responsibilities between government and industry.

• Reforestation of harvested areas, including planting, spacing, stand tending and reaching free-to-grow status.

• Industry logistics:

• How fibre is used, e.g., how logs are transformed into products and what percentage is directed toward lumber, chips, pellets, raw log exports. Transportation of finished and intermediary products, including routes and methods of moving pellets from central B.C. to Europe.

• Manufacturing technology was discussed in detail. En-

ergy production (co-generation) was featured at the Nechako Lumber Company mill during the tour of their organic rankine cycle equipment and at Canfor’s Northwood pulp mill. There was also a visit to the distribution hub for Prince George’s downtown district energy system (which uses heat supplied by the Lakeland sawmill).

The GNL delegation remarked on several occasions that they appreciated the transparency shown by the Canadian participants throughout the visit. The delegation gained a good appreciation for the scale of the industry in B.C., the nearly complete utilization of the wood fibre that is harvested and industry’s efforts/needs to optimize the value from each log (from higher value sawlogs to pulp and paper chips to wood pellets). The visitors also saw that public versus private land is a fundamental difference between the Canadian and U.S. pellet industries, and that that there is more oversight on activities on public lands.

On June 14, 2016, the MEA published the second draft of their biomass sustainability verification protocol. The adjusted protocol will be field tested, including in Canada, during the summer. The final verification protocol will be published in October 2016.

WPAC gratefully acknowledges the efforts of Dave Patterson of Forestry Innovation Investment and Wendy Vasbinder of Natural Resources Canada for helping to bring our Dutch vistors to Canada and for arranging an excellent program. •

By Guillaume Roy

Inthe 1970s, building a sawmill in Sacré-Cœur, Que. –a village of 2,000 residents in the Cote-Nord region – seemed like a good idea to create jobs and develop the local economy. But it took three bankruptcies before a group of visionaries made it work.

In 1985, two worker cooperatives, Unisaco and Cofor, united their efforts to fund Boisaco, a softwood sawmill. A local investment fund of 421 shareholders, Investra, also joined the venture. From the beginning, the sawmill made good money, but the leaders were not satisfied.

“We wanted new ways to create more wealth in the community,” says Guy Deschènes, one of Boisaco’s founders and the former CEO.

To create that wealth, the company decided to look at ways to

diversify the use of its byproducts, such as wood chips, sawdust and shavings.

Marc Gilbert, Boisaco’s general manager from 1985 to 1998 and from 2008 to 2012, says that the sawmill was often far away from its buyers, which made it difficult to sell the mill’s residual products. So instead of continuing to look for ways to sell some of its residuals, the company decided to produce new products.

In 1999, Boisaco launched a new door panel mill, Sacopan. Two years later, they made a partnership with the American giant Masonite, to help enter new markets. This allowed the sawmill to use 35 per cent of its wood chips on its industrial site. But it wasn’t enough. In 2002, they created Ripco, a joint-venture between Boisaco and Royal Wood Shavings, a company that specializes in animal products distribution.

“Royal Wood Shavings takes care of marketing and distribution and we take care of operations,” explains André Gilbert, Boisaco’s general manager. “We could have bought the operations but we prefer to have a strategic partner. We are stronger together.”

Building partnerships is how Boisaco developed all of its sister companies.

To make high-quality horse bedding, wood shavings are blown from the planer to the packing area via an aerial system.

The company has one market for its big shavings, another for its medium-sized shavings and the dust goes to the small animal market (the dust sifted out because some horses are allergic to wood dust). This byproduct venture generates more than 800,000 40-pound bags of horse bedding annually, and has created jobs for 15 people.

With an annual production of 550,000 m3, Boisaco still had some byproducts left. So to use 100 per cent of the sawdust and shavings, they made a plan to build a wood pellet plant. Even when the markets deteriorated during the financial crisis in 2008, Boisaco decided to go ahead and create Granulco in 2009 – a wood pellet company built on Boisaco’s sawmill site.

To make this new business flourish, Granulco entered into a joint venture with Essipit, a nearby Innu First Nation, and la Société de développement économique de Sacré-Coeur.

Last year, Granulco made 1.25 million 40-pound bags and some bulk sales to reach a 25,000-ton production, still short of the facility’s 35,000-ton capacity.

“We don’t produce enough sawdust to use Granulco’s equipment at 100 per cent,” says Éric Gravel, Boisaco’s quality and production superintendent.

To fill the gap, they started using poplar sawdust produced by Bersaco –another sister company 28 kilometres away – but they stopped using it after customers complained about the smell generated by the use of poplar.

To ensure the samwill’s byproducts are sent to the best application, the mill installed a 8’ x 4’ Forano chip screen that separates the different chip sizes.

The small chips go to the company’s Sacopan door panel company, while the large chips are sold to pulp-making businesses, and the sawdust goes to Granulco or Ripco.

“Everybody wins, because pulp and paper mills prefer big saw chips,” Gravel says.

Before entering the pellet mill, the sawdust goes through a biomass dryer, using up to 15 per cent of the resource. Burning the poplar sawdust helped for a time, but carrying the material did not make economic sense, long-term.

After being dried, the dust is sent to its Pioneer pellet mill, cooled and finally bagged. With increasing popularity of residential biomass heating systems in Québec, Granulco sells nearly almost all of its production in advance.

“Our biggest client, Rona, would like to buy our entire production, but we pre-

fer to have many clients – it would be too dangerous to rely on only one,” says Eddy Gauthier, Granulco’s general manager, who supervises a group of 15 employees.

For Granulco, being on the same site as the sawmill makes the transportation costs go down to nearly zero. But it’s not the only advantage.

“All together, we qualify as a big enterprise and we have access to the industrial price – Tariff L – with Hydro-Québec. This nearly cuts our utility bill in half,” Gilbert explains.

All the mills also share professional services, specialized equipment and storage areas.

“A small business like Granulco could not hire full-time mechanics, but we can share the cost of those professionals,” Gravel explains.

The sawmill also produces all the wood pallets and other components needed by its industrial partners. All these extra products create more jobs and additional wealth for the community. Since different shareholders own the companies on the industrial site, all the products are sold at market price.

“The wood products market is always going up and down. Other sectors, like door panels and pellets, now make Boisaco a more stable and more profitable business,” Gilbert says.

This model now stands out. While some forest communities are struggling, SacréCoeur is in better shape than ever and is willing to keep building its future with timber. The different companies on the industrial site now employ over 550 people, the equivalent of more than 25 per cent of the entire Sacré-Cœur population. The tax income from the site also accounts for 30 per cent of the town’s $3-million municipal budget.

Boisaco currently uses 70 per cent of the 60,000 tons of bark produced on the site to heat the mills on site and dry the different products, but they want to create extra value with the remaining 30 per cent (and the bark built up over time). So they have begun another project with another partner, a 9-MW cogeneration mill with Hydromega, an independent renewable resource energy producer. The project is planned for 2019.

Even with all those businesses, Boisaco will still be left with 65 per cent of its woodchips being sold outside the industrial site, primarily to pulp and paper companies like Resolute Forest Products. Going forward, the company would like to continue building new products with its remaining residuals. It is currently reviewing emerging technologies for developing a bioenergy or green chemistry project. Ideally, Boisaco would like to transform 100 per cent of the logs that come to the site into an end product, and if the mill continues to find homes for its residuals that dream may one day be realized. •

By Andrew Macklin

Ithas become a key lever of our industry to reduce our carbon emissions,” says Robert Cumming, environment director for Lafarge Canada Inc.

Cement production is one of Canada’s largest emitters of carbon into our air, thanks in part to its use of coal and petroleum coke to create the energy necessary for production. The average temperature at the fuel end of the kiln registers at 1,450 degrees, equivalent to one-quarter of the temperature of the surface of the sun. Getting to that temperature requires a lot of fuel.

The benefit of running kilns at that

temperature, however, is that any fuel with energy content can be used safely and efficiently in lieu of petroleum coke or coal.

Bearing that in mind, the cement industry has made a strong commitment to reducing carbon emissions by replacing fossil fuels with lower carbon fuels, and Lafarge is playing a leading role in this development.

Three years ago, the team at Lafarge Canada applied for permission to conduct a full-scale project under the Natural Resources Canada ecoENERGY Industrial

Fuel Initiative Program. The project would allow the company to locate and demonstrate low carbon solutions. They initially teamed with Queen’s University in Kingston, Ont., along with WWF Canada and community stakeholders to understand how low carbon fuels could replace part or all of the supply of coal and petroleum coke currently used for energy production.

Low carbon fuels (LCF) are low in carbon for one of two reasons: they contain lower carbon chemistry or are considered to be biogenic carbon. An LCF containing a lower carbon chemistry means that the fuel releases less carbon dioxide for the

same amount of energy produced. Biogenic carbon is carbon that is considered to form part of the natural carbon cycle. This is what wood combustion is considered, since a new tree absorbs the carbon emitted when another is used, making it a carbon neutral process.

With support granted from Natural Resources Canada to move forward, Lafarge Canada began construction of the fuel handling system needed at its Bath, Ont. plant to begin using LCF. At the same time, Lafarge began working with its partners to develop the scope of the research program, including the different types of fuel that could be collected and tested.

For the new fuel handling system, the company looked to a compact footprint

on the southwest corner of the property where they could develop a transloading facility. From there, trucks unload the fuel, which is then put through a shredding system to eliminate any lumps that may have formed in transit. The fuel is then conveyed to one of two storage bins, passing under a magnetics system that removes any metallic content. From the bins, the fuel is conveyed into the plant and to its final destination inside the kiln.

With the fuel handling system in place, the company was able to conduct its first test in 2014. The test involved having a predicted lower carbon fuel replace 10 per cent of the coal/petroleum coke. The first

trial included three different materials: railway ties, construction and demolition (C&D) waste and asphalt shingles.

After the fuel was used, the emissions results were given to the team at Queen’s University to conduct a thorough statistical analysis. The result was that no increase in any emissions was found when using the fuels, and there was an over 80 per cent carbon reduction for every tonne of coal/coke replaced.

The result was very positive for the company, putting them in a position to use the fuel on a permanent basis. In order to do so, they must apply to the government for permission, moving from compliance approvals on a three-year trial basis to a permanent approval. This must be done for each individual fuel that provides successful results.

A second trial was conducted in October of 2015, using the same formula for fuel replacement but this time testing non-recyclable packaging, manufactured rejects, and non-recyclable commercial products such as carpets and K- Cups. Initial data showed similar results to the first trial and that all emission limits were met; however, Queen’s University is still working on the full statistical analysis.

While the importance of the positive emissions data using LCF cannot be overstated, Cumming recognizes that it isn’t simply a matter of what comes out of the stack.

“It’s important for our employees, for us as a company, for our neighbours and for the environmental NGOs that we work with that there is not a trade-off here. We’re not trying to reduce carbon at the expense of some other pollutant. We’re trying to show that the fuels can be used safely and efficiently in our process. That’s one piece. But the other piece is a life cycle assessment.”

A life cycle assessment analyses the full environmental impact associated with a product from cradle to grave. It factors in all of the emissions created, and the types of emissions created at all stages of the process. For the Bath plant, that means a comparison to the coal it is replacing, which is mined in Virginia, brought by barge to the Bath plant on the north shore of Lake Ontario, and grinding the coal for use in the kiln. Using the example of construction and demolition debris, there

is the energy to sort the debris, truck the debris and shred the debris at the Lafarge site. However, the diversion from the landfill, where it would eventually rot and become methane, also must be considered in the analysis.

According to Cumming, the life cycle assessment provides “…the most transparent, comprehensive, and accurate way of assessing fuels and their carbon emissions.”

The introduction of the new fuels into Lafarge’s energy production system has its staff learning as the process unfolds. That goes for the fuel suppliers as well, being asked to change the way they approach their waste.

“Getting the infrastructure changed for processing the material from jobsite to end user has been a challenge,” Cumming says. “Using C&D waste as an example, that means having the mindset to separate the waste that can be used as LCF while others continue to go to previous outlets like landfills.”

That challenge extends to building sustainable infrastructure for supplying LCF to Bath, which can’t be done as the company experiments with multiple types of fuel. That makes it cost-prohibitive for many fuel suppliers until someone like Lafarge is in a position to ask for consistent supply.

On the plant side, the challenge comes in the intake process. New processes for quality control, storage, moisture, logistics, safety and training have to be established at the plant for dealing with the new types of fuel versus what has already been established using coal and petroleum coke. Cumming cites that it is the infrastructure and the logistics that will be the biggest hurdle for the adoption of low carbon fuels.

“But once you get it right, the other fuel users will be able to benefit from those supply chain systems,” he says.

But the lessons already being learned have been shared with other Lafarge Canada facilities that are also experimenting with alternative fuels. In Nova Scotia, Lafarge’s Brookfield plant is working

with Dalhousie University on tests using non-recyclable plastics, asphalt shingles and scrap tires.

There are also experiments being done with a new type of fuel at the Richmond plant in B.C., one that just recently received national recognition thanks to work being done by Ontario Power Generation in Thunder Bay, Ont.

The fuel is known as torrefied or black pellets. The pellets are wood pellets that are pre-cooked to become a product that closely resembles charcoal’s textural and energy properties.

“In most plants, you can get to 20 to 30 per cent co-fire before running into mechanical and thermodynamic issues,” Cumming says. “But if you can convert C&D wood into something that works like charcoal, then you can use it in your existing process and at a higher substitution rate.”

OPG Thunder Bay discovered just that during testing phases with the pellets, supplied by a company in Norway. OPG then

converted its plant to the pellets at a minimal cost, using most of the equipment originally in coal-based energy production.

A few years ago, Vancouver-based Diacarbon Energy created the pellets at a pilot scale, providing them to Lafarge for testing as an LCF at the company’s Richmond plant with very good results. Now Diacarbon is scaling up the technology at its plant in Merritt, B.C., with hopes of producing consistent volumes by the end of 2016.

That would be a welcome development for Cumming and his team.

“In order to move past that 20 to 30 per cent co-fire barrier to get to 50 to 60 per cent, you need to process the fuel,” Cumming says. “Torrefaction, and the process that Diacarbon has is very exciting for us. I think that, all across the country, we are going to benefit from that research.”

As Lafarge anticipates the scaling up of Diacarbon’s technology, the company continues to experiment with new types of low carbon fuels to expand its knowledge of the products available to replace petroleum coke and coal. Cumming and his team understand that there are still years of testing ahead.

“The process moving forward is to test the fuels, get the results, share the results with the public and then get permanent government approval,” Cumming says.

That process will be especially important as several types of fuels are constrained by seasonal availability, such as recycled shingles and C&D waste.

But now the company has another asset moving forward; its recent merger with Holcim. LafargeHolcim means incorporating best practices and LCF experiments from Europe, which Cumming mentions is “way ahead of us” on the use of low carbon fuels.

With the knowledge and expertise gained from its European colleagues, and the extensive experiments taking place across the country, Lafarge Canada is leading the charge to significantly reduce emissions in the cement industry. •

Sept. 20-22, 2016 • WPAC 2016 Harrison Hot Springs, B.C. www.pellet.org/wpac-agm

Sept. 22-24, 2016 • DEMO International 2016 Maple Ridge, B.C. http://www.demointernational.com/

Sept. 26-27, 2016 • Clean Energy Transition Conference Calgary, Alta. www.euci.com

Sept. 27-29, 2016 • SFI Annual Conference Clearwater Beach, Fla. www.sfiprogram.org

Oct. 5-6, 2016 • European Biomass To Power Conference Seville, Spain www.wplgroup.com/aci/event/european-biomass-to-power

Oct. 17-21, 2016 • German Bioenergy Fact-Finding Visit Munich, Germany http://kanada.ahk.de/en/events/trade-fairs/detail-view/ events/bioenergy-fact-finding-visit-to-germany/

For more on events, go to canadianbiomassmagazine.ca

We are back on the beautiful west coast this year with a new venue and a great lineup of speakers, representing all stakeholders in the industry, all geared to help you learn, network and have a bit of fun!

The calibre of people throughout our industry always amazes me. There is a mix of intellect and entrepreneurialism, science and business. All are pioneers in a new and complex global business!

The wood pellet industry has seen its share of ups and downs over the last several years and this last year has been a challenging one. Nevertheless the pioneers persevere, put things into perspective, seeing and capitalizing on the opportunities that lie ahead.

Our theme for this year’s conference is “Expanding Horizons: New opportunities for Canadian Biomass,” and reflects that spirit to look to the future and work to capitalize on the opportunities that are in front of us.

This year’s conference will be kicked off on the morning of day one with a wood pellet quality certification workshop. A great opportunity to expand on your knowledge base!

The wood pellet quality workshop will cover the international pellet stan-

dards requirements and review the quality certification schemes and how to obtain them (ENplus, CANplus and PFI). This is a must-do workshop and very relevant as the industry works towards standardization.

The workshop will be followed by the opening of the general plenary session of the conference. We will begin with an overview of the global markets followed by a global biomass power project update, a look at the future for biomass power generation in the Netherlands and a North American heat market update.

You do not want to miss our backyard barbecue party from 6 to 9 p.m. on the evening of day one. Dress down and come to network and socialize with everyone in a casual environment. I am told one of the industry’s true pioneers will be ensuring the food will blow you away and I am sure the entertainment will as well.

Day two will begin with the always popular “Power Panel”. Join the industry’s thought leaders from both producers and utilities as they share their views on the state of the industry and its future.

Then learn about the Canadian fi-

bre outlook – the lifeblood of all pellet plants.

Rounding out the morning we have one of the most important topics covered annually, “Keeping our People Safe.” Find out about the great work WPAC’s safety committee is doing and how that work is being deployed in plants across Canada.

In the afternoon learn about the business case for biomass co-firing in Alberta; Alberta’s emissions and Canada’s biomass resources in perspective; and the role of biomass in Alberta’s Clean Energy Plan.

Day two will end with a networking reception from 5 p.m. to 7 p.m.

Then on day three we are partnered with DEMO International for a full day of forestry equipment demonstrations in beautiful Maple Ridge, B.C. This event is only held every four years and is a must-see.

See you all Sept. 20 to 22 in B.C., as we work to “expand our horizons” at the 2016 WPAC AGM and conference. An event you do not want to miss!

Rene Landry President Wood Pellet Association of Canada

ANDRITZ is one of the world’s leading suppliers of technologies, systems, and services relating to equipment for the biomass pelleting industry. We offer single machines for the production of solid and liquid biofuel and waste pellets. We have the ability to manufacture and supply each and every key processing machine in the pellet production line.

> TUESDAY, SEPTEMBER 20, 2016

BUSINESS MEETINGS

9 a.m. to 11 a.m.

11 a.m. to 12 p.m.

10 a.m. to 12 p.m.

ANDRITZ Feed & Biofuel A/S Europe, Asia, and South America: andritz-fb@andritz.com USA and Canada: andritz-fb.us@andritz.com

12 p.m. to 1:30 p.m.

Annual General Meeting - Open to all WPAC members

Board Meeting

WOOD PELLET QUALITY WORKSHOP

Luut Brink, Control Union & Chris Wiberg, Biomass Energy Lab

• International pellet standards and where they are applied (ISO, CSA, ENplus, PFI, industrial)

• U.S. New Source Performance Standards

• Review of pellet quality schemes (CANplus, Enplus, and PFI)

• Steps in obtaining CANplus and Enplus certifications.

Networking Luncheon

WELCOME TO WPAC 2016

1:30 p.m. to 1:35 p.m. Rene Landry, Wood Pellet Association of Canada

1:35 p.m. to 1:45 p.m. His worship Mayor Leo Facio, Harrison Hot Springs (invited)

GLOBAL MARKETS

1:45 p.m. to 2:15 p.m. Global Pellet Outlook - John Bingham, Hawkins Wright

2:15 p.m. to 2:35 p.m.

2:35 p.m. to 2:55 p.m.

3 p.m. to 3:30 p.m.

3:30 p.m. to 4 p.m.

Lynemouth Power Station biomass conversion - Nigel Hildyard, EPH (invited)

Biomass power development in Japan - Yoshinobu Kusano, Sumitomo Corp (invited)

Coffee Break - Networking in exhibition area

Global Biomass Power Project Update

Rachael Levinson, Argus Media

Project review: U.K., Belgium, Netherlands, Denmark, Finland, Sweden, Japan. Status, timing, likelihood of proceeding, cost, new build versus conversion, capacity, planned fuel type and consumption, financing status, environmental approval status, and applicable support scheme.

4 p.m. to 4:30 p.m. Is there a Future for Biomass Power Generation in the Netherlands?

Jason Woods, Vattenfall (invited)

NL Energy Accord; biomass sustainability criteria; controversy over verification procedures; NGO/utilities covenant; phase out of old coal plants; government review of coal power strategy; status of SDE+ subsidies, and likely path forward for NL co-firing.

4:30 p.m. to 5 p.m.

North American Heat Market Update

Keta Kosman, Madison’s Lumber Reporter

NA regional review - Western Canada, Ontario and Quebec, Atlantic Canada, northeastern U.S., northern midwest, rest of U.S. Prices, inventories, supply and demand, comparison to oil, implementation of U.S. NSPS, Ontario biomass boiler approval system, quality certification.

6:00 p.m. to 9:00 p.m

Backyard Pellet Barbecue

Barbecuing by world renowned pellet chef John Swaan. www.andritz.com

> WEDNESDAY, SEPTEMBER 21, 2016

8:00 a.m. to 8:30 a.m. Breakfast - Networking in exhibition area

8:30 a.m. to 9:30 a.m. Power Panel - Producer and Utility Viewpoint

9:30 a.m. to 10:00 a.m. Canadian Fibre Outlook

Charles Friesen, FPInnovations

10:00 a.m. to 10:30 a.m. Coffee Break - Networking in exhibition area

10:30 a.m. to 10:50 a.m. Keeping our People Safe

Scott Bax, Pinnacle Renewable Energy

Progress under WPAC’s Safety Committee Work Plan: combustible dust, confined space entry, lockouts, guarding, training and supervision, safe work procedures, and a new initiative - process safety management.

10:50 a.m. to 11:20 a.m. Speaker TBA

Process safety management in the pellet industry: moving beyond occupational safety by blending engineering and management skills to design and maintain safe processes to protect capital assets, environment, and people.

11:20 a.m. to 12 p.m. Candace Carnahan, Workplace Safety Advocate (invited)

Candace recalls how she lost her left leg below the knee to an unguarded conveyor belt system, as well as the many contributing factors. However, Candace places great emphasis her own role and responsibility in what happened in an effort to encourage people to “own” their right to a safe workplace.

12 p.m. to 1:30 p.m. Lunch - Networking in exhibition area

1:30 p.m. to 2 p.m. Will There be Biomass Co-firing under Alberta’s Climate Leadership Plan?

William Strauss, FutureMetrics: The case for biomass co-firing in Alberta

2 to 2:30 p.m. Alberta’s emissions and Canada’s Biomass Resources in Perspective

Jamie Stephen, Torchlight BioResources on Behalf of CCEMC and AI Bio

2:30 p.m. to 3 p.m. The Role of Biomass in Alberta’s Clean Energy Plan

Alberta Government TBD

3 p.m. to 3:30 p.m. Coffee Break - Networking in exhibition area

3:30 p.m. to 5 p.m.

Technology Review

A review of the latest innovations in: grinding equipment, drum dryers, belt dryers, hammer mills, pellet presses, coolers, storage domes, silos and packaging.

5 p.m. to 7 p.m. Networking Reception - Networking in exhibition area

> THURSDAY, SEPTEMBER 22, 2016

7:30 a.m. to 4 p.m.

DEMO International

Join us from 7:30 a.m. to 4 p.m. at DEMO International. Held only once every four years, we are pleased to announce that DEMO is in beautiful Maple Ridge, B.C., just a short one-hour drive from Harrison Hot Springs Resort. Transportation and lunch provided.

Andritz is the leading supplier of technologies, systems, and services relating to the equipment for the biomass pelleting industry. Andritz has the ability to manufacture and supply each and every key processing machine in the pellet production line. Visit us at www.Andritz.com/fb.

Biomass Energy Lab (BEL) specializes in solid biofuels testing. ISO 17025 Accredited for CEN/EN methods, BEL provides analytical certifications for export shipments of wood pellets and other solid biofuels to help meet contractual needs. Along with testing services, BEL also offers EN Plus auditing and consulting, and can assist with internal lab design/setup and the development of quality management systems.

Bruks is a global leader in mechanical engineering and equipment supply for the bulk materials handling industries. Customer service and product performance are at the heart of its corporate culture. It provides specialized customer solutions, including the development of custom machines and systems. Its services include project engineering, technical support, start-up training and remote-monitoring/ servicing of machine functions.

Specializing in wood processing machinery and material handling systems for the biomass and forestry industries: BioSizer, vibrating conveyors, Grizzly Mill, chippers for pulp-chips or micro-chips, electric log sweeps, log decks, log singulators, rotary debarkers. Custom engineered solutions to take control of your fibre supply and get more from your mill.

CPM has been a leader in biomass pelleting for over 20 years. With the formation of the Global Biomass Pelleting Group, CPM can now call on all of its resources worldwide to ensure that you receive the

highest quality equipment along with the highest quality support worldwide.

Dansons Inc. is the leader in the field of supplying specialty lubricants to the biofuel industry. Not only has it developed and supplied specialized lubricants to the pellet mill industry, it also provides technical support and expert advice on how to get maximum life out of wear components.

Fike has over 65 years of field experience and a team of engineers, application specialists and combustion researchers delivering a complete line of products and innovative technologies to the explosion protection market.

The philosophy behind PDI is simple – design and supply state-of-the-art, reliable equipment to enable its customers to succeed in today’s manufacturing markets. By combining innovative engineering and practical experience, PDI has created a line of machinery that delivers substantial economic benefits, superior finished product quality, and some of the lowest emissions in the industry.

Port of Belledune is a modern, year-round marine transport facility and deep-water point of access that is innovative in developing its services and facilities to the fullest. The port has proven itself capable of handling any and all goods, offering flexible services, creative solutions and excellent rates. Additionally, the port specializes in the handling of bulk and break-bulk cargoes and is the only existing point of export for wood pellets on the east coast of Canada.

The Port of Halifax is a regional economic engine, generating more than 11,800 jobs and contributing over $1.6 billion in economic impact. The world’s largest shipping lines call on the Port of Halifax, connecting

the port to more than 150 countries. The beautiful Halifax Seaport is a premier destination, attracting more than 1.2 million visitors each year. Collaborating and working with strong partners and stakeholders, the port community continues to deliver excellent service. Whether its cargo, cruise or business opportunities, the Port of Halifax is your competitive solution.

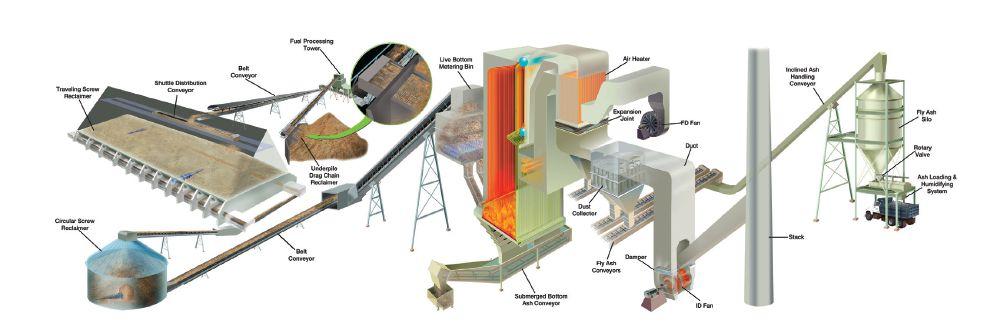

ProcessBarron is a turnkey solutions provider specializing in air handling and materials handling equipment. ProcessBarron offers design, manufacture, installation, maintenance and repair for all these products and services. ProcessBarron is an industry leader thanks to its quality products, proven reliability and dedication to customer service.

TSI designs and builds equipment for today’s highly automated plants in the Engineered Wood and Biomass Industries. TSI offers solutions for dryer islands, (heat energy, drying and emission control) and finishing lines. Designed with the customer needs in mind, the systems are customized for the specific applications, whether updating aging equipment, adding to an existing line or creating a new green-field production plant.

Walinga Central Vac Systems help minimize debris or residue from spills, and minimizes health and explosive risks associated with dust. Install a C.V. system for production line retrieval and reuse of product. Multi-floor, multi-drop systems available for larger installations from feed mills to steel mills. The Walinga Ultra-Veyor is the ultimate system for your bulk transferring needs. The push system moves bulk by air, maximizing accessibility for any drying or storage facility. Move your bulk safely and easily, without potentially dangerous augers. Minimize airborne particles and dust.

*Exhibitor list at press time.

By Andrew Snook

ThePrince George Civic Centre filled with bioenergy professionals from around the world to take in a host of sessions at the seventh International Bioenergy Conference and Exhibition in Prince George, B.C., this past June.

Prince George Mayor Lyn Hall welcomed the 260 delegates in attendance to the conference. Hall discussed the importance of the forestry sector, including the bioenergy sector, to the city’s culture and its community.

“For us in Prince George, there’s no question that the forest industry is the foundation of our community,” he told the crowd. “We have upward of 3,000 people employed in those industries.”

OPPORTUNITIES AND CHALLENGES

“Where do you see opportunities and risks for the bioenergy sector in the next decade?” That was the question posed to the participants of an executive panel session during IBCE 2016.

Gordon Murray, executive director of the Wood Pellet Association of Canada, stated that the wood pellet sector remains the most successful and vibrant sector in the bioenergy industry. However, the sector’s historical biggest challenge still remains an issue that needs to be addressed.

“Domestically here in B.C., fibre supply does continue to be our No. 1 issue,” he told the crowd.

Although the B.C. government has put together a 13-point fibre action plan, Murray said it has yet to assist bioenergy producers in securing additional fibre.

“We do acknowledge that they’ve had good intentions and put a lot of effort forward, but the implementation of this has been frustrating and it has not resulted in any more fibre for us,” he said. “We’d like to see a ban on all slash burning with an

exception where the producers can prove that there is no viable option for the residuals.”

As for new opportunities for the wood pellet sector, Murray discussed overseas growth markets such as Japan, which has abandoned nuclear power and has been building biomass-fuelled power plants.

Doug Hooper, director of policy and regulation at Advanced Biofuels Canada, discussed the opportunities for the bioenergy sector related to carbon pricing.

“There’s a large stimulus coming from the carbon funds back into our sectors,” he said.

Hooper added that there would be a long-term reliance on energy dense liquid fuels, including lower carbon renewable biofuels; however, he added that the bioenergy sector needs to improve telling its story on how the sector offers a reliable and versatile source of energy.

“Bioenergy has really got a strong story to tell and I think one of the challenges is how do we tell our story better,” he said.

Carrie Annand, executive vice-president of external affairs for the Biomass Power Association discussed biomass policy in the U.S. She said that one challenge in the U.S. bioenergy sector is getting the

There’s a saying that gets tossed around a lot here:

“It just runs.”

Our hammermills and pellet mills aren’t the prettiest. But they’re rock solid. And they run—year after year after year.

But “It just runs” isn’t just about our products.

It’s about our company, which literally spans centuries.

And it’s about our ongoing relationships with our customers—how we’ll always be there for you.

Give us a call, and find out just how CPM can run for you.

Your Partner in Productivity

CPM Biomass Group 1-601-932-9080 • www.cpm.net

different states to acknowledge the positive impacts of a strong biomass industry, including keeping foresters employed, keeping forests intact and creating homes for residuals. She added that you could see the positive affects of the sector in the U.S. states where bioenergy has been embraced.

Michael Weedon, executive director for the B.C. Bioenergy Network added that the bioenergy sector in B.C. needs to realize that the province doesn’t live in isolation and has to acknowledge global competition.

“We have to offer cost-effective, competitive solutions,” he said.

Weedon added that by focusing on finding “negative carbon” solutions, the province of B.C. will help allow the bioenergy sector’s innovators to come up with profitable solutions.

One speaker during the panel sessions put forth an interesting wildfire strategy that also has the potential to provide an economic stimulus for the region while servicing home heating needs for people in northern B.C.

David Dubois, chief of engineering and

technical outreach specialist for the Community Energy Association, told the crowd that there is great potential for local managing of high-risk wildfire areas in northern B.C. communities while simultaneously harvesting biomass in a sustainable manner for use in residential heating.

“There’s a real opportunity and need to increase the amount of work being done,” he said.

Dubois offered a few examples of successful projects already completed in the region, including Telkwa’s biomass district heating system, which is fuelled by wood chips and materials from their own wildfire mitigation management system.

Telkwa is a small village with a population of about 1,350 people located just southeast of Smithers, B.C., about 350 kilometres northwest of Prince George.

From a life cycle cost point of view, biomass is competitive with many of the other energy options in communities with little or no access to natural gas pipelines. One major benefit for adopting a local biomass system for residential heating is that the jobs generated for installing and maintaining these types of systems, and harvesting the biomass, would mean a large portion of the money spent on fuelling residents’

home heating needs would stay in the local economy.

“I think biomass can be a real benefit to rural and remote communities,” he said.

Another example of a town that could benefit from this type of system is Sicamous, B.C., which has a high risk of wildfire.

DuBois said that after the initial thinning for wildfire prevention is performed, the Sicamous area could manage the regrowth of those areas through harvesting for residential heating. He said that area has anywhere from 26,000 to 32,000 tons of biomass available from managing regrowth that could be used as a base case for fuel for a district energy system to supply 80 to 90 per cent of the total heat load with other fuels used for meeting peak heat demand.

He added that putting these types of systems in place in remote communities aren’t without their challenges.

“The biggest challenge for small communities is capacity,” he told the crowd, adding that sorting out ownership of fibre is another issue that needs to be addressed for these types of systems to be successful.

Another highlight of the conference was the announcement that Prince George is

expanding its district energy system (DES), which fuels many of its downtown buildings. The expansion will include heating of two more provincial buildings – the province’s courthouse and the Plaza 400 building.

The DES, which was fully commissioned in 2012, currently reduces annual CO2 emissions by 1,820 tons a year. Fuelled mainly by sawmill residuals from the Lakeland Mills sawmill, the DES already generates hot water used for domestic hot water and space heating in the Prince George Civic Centre, City Hall, Prince George Coliseum community arena, Four Seasons Leisure Pool, Prince George Public Library, Two Rivers Art Gallery, RCMP building and the Wood Innovation and Design Centre.

Ninety-six per cent of the energy used in the DES system is supplied by waste heat generated by burning hog fuel from Lakeland Mills, with the remaining power coming from two 2.5MW natural gas backup boilers that are used when the mill shuts down for maintenance, or if the system requires additional heat during harsh winter months.

For more coverage of IBCE 2016, visit www.canadianbiomassmagazine.ca. •

. . .

Industry -preferred design with stable infeed across spout width.

. . .

High capacity and high performance.

Whole Log Chippers . . . Robust and long-lived.

Look to us for chippers that produce:

more than 90% acceptable chips

few pin chips and overthick chips

an increased ratio of large to small accepts chips

Excellence in Chip Processing

Web Site: www.acrowood.com

Phone: (425) 258-3555

Fax: (425) 252-7622

E-mail: sales@acrowood.com CBM_Acrowood_JulyAug16_CSA.indd

DEMO 2016 Booth: A-7

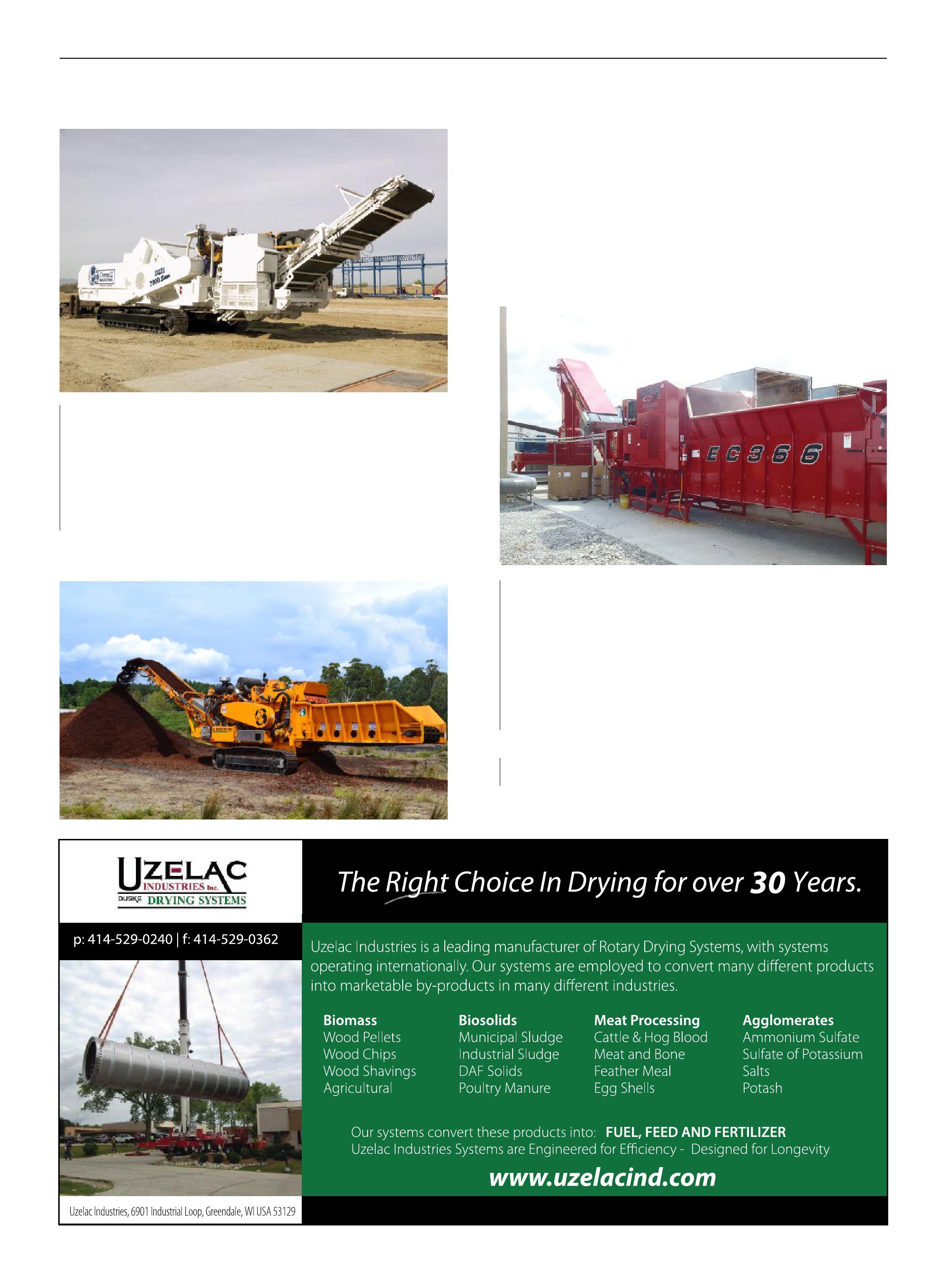

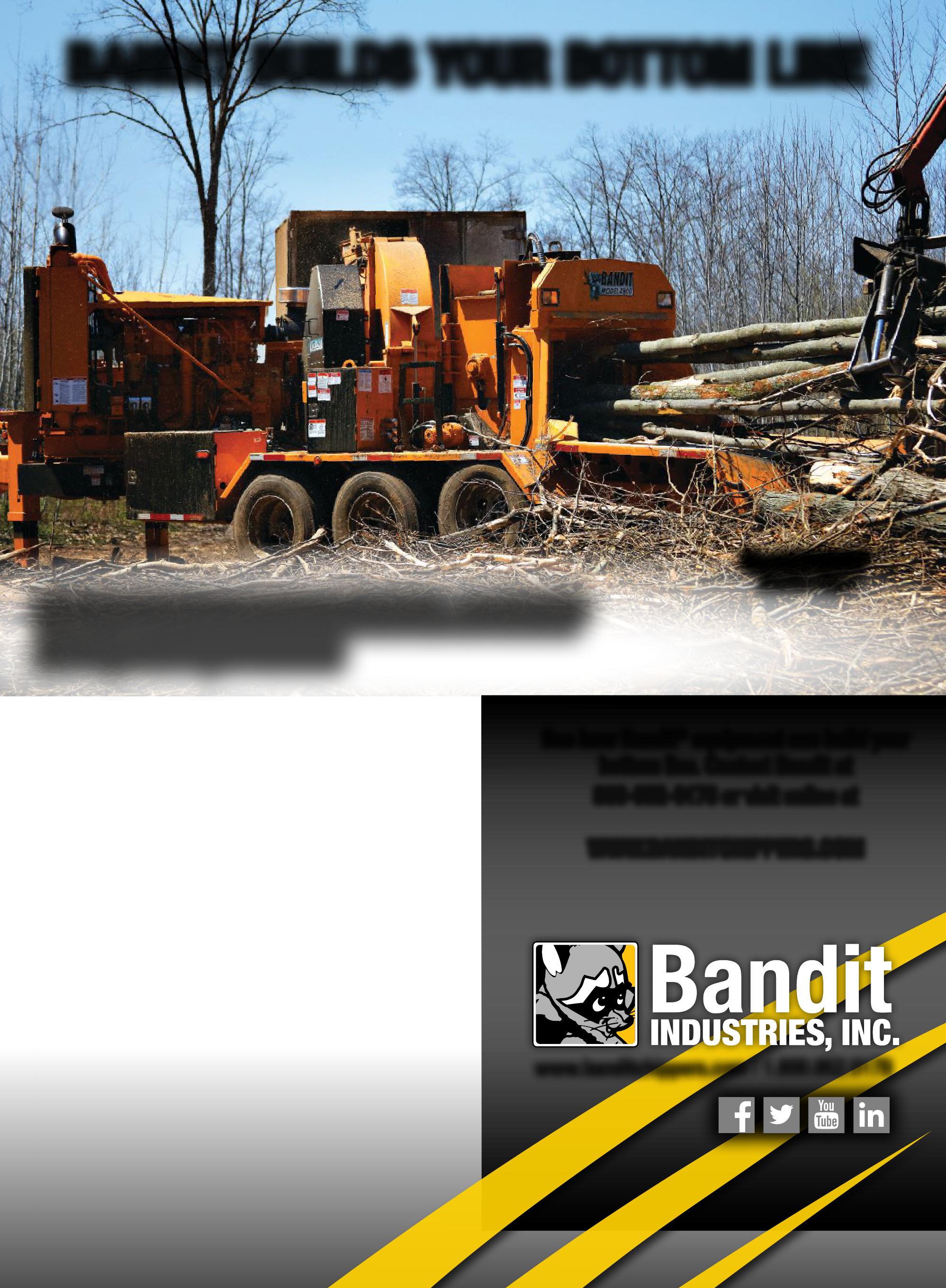

Bandit Industries Inc., is a leading manufacturer of wood processing equipment for the logging, tree care, land clearing, biomass and recycling industries. Bandit offers a complete line of hand-fed and whole tree chippers, stump grinders, forestry mowers and The Beast Reduction Machines. The Beast, which will be on-site at DEMO 2016, will feature model options ranging from 16-inch to 45-inch capacity and engine options up to 1,000 horsepower. The Beast Reduction Machines are all manufactured in Remus, Michigan. See why professionals trust Bandit to build their bottom line. Visit www.banditchippers.com or call 1-800-952-0178 to learn more.

DEMO 2016 Booth: A-2

At 88,500 pounds (40,150 kg) the 5710D horizontal grinder is designed for operations that require frequent moves between jobs without a special permit. An optional transportation dolly allows the Peterson 5710D to be easily moved, and then setup for operation within minutes. With a feed opening of 60 x 40 inches (152 x 102 mm) combined with Peterson’s high lift feed roll; the 5710D

Woodlands Forum’s flagship event is coming to Maple Ridge, B.C. from Sept. 22 to 24, 2016, so Canadian Biomass is keeping you in the loop about the chipper and grinder companies that will be at DEMO 2016.

can readily reduce a wide range of material including stumps. The Peterson 5710D horizontal grinder is powered by a Tier 4i Caterpillar C27 1050hp engine.

DEMO 2016 Booth: A-5

The redesigned 40/36 Whole Tree MicroChipper is perfect for micro-chip producers. The latest model includes an enhanced drum set with 16 knives utilizing standard hardware, an operator-friendly slide-in forestry grate system to reduce oversized chips and a mechanically driven chip accelerator to fully load vans with the micro-chips. In customer tests, up to 95 per cent of the micro-chips produced passed through a 1/2inch grate, and an average of 65 per cent passed through a 1/4-inch grate.

DEMO 2016 Booth: A-16

The HG6000TX horizontal grinder from Vermeer is powered by a 755-horsepower (563 kW) Caterpillar C18 Tier 4 final engine. The HG6000TX is equipped with 26-inch (66 cm) double grouser track pads to help reduce ground pressure. The suspension provides 7 inches (17.8 cm) of ground clearance under the track undercarriage, making it ideal for tough-to-reach jobsites and uneven terrain. With a ground speed of up to 2.6 mph (4.2 km/h), the HG6000TX can move quickly from jobsite to jobsite to help it keep pace with loading equipment.

DEMO 2016 Booth: A-19

Formerly known as the CBI 5800BT, the TBG 650 portable grinder was developed to feature the same principles of the TBG 680, but is purpose-built for contractors dealing with lower production needs or transportation restrictions. The TBG 650 gives land clearing companies, yard waste and demolition wood processors, and mulch yards what they need for high-volume throughput and maximum reliability. Among its notable features are the unique clamshell opening hog box for ease of maintenance, hydrostatic feed system and diverter pan.

DEMO 2016 Booth: A-8

Attention to detail that lasts. The featured high-capacity, low maintenance DZH7000 packs the power you need for any grinding application. With quick screen changes of 20 minutes or less the DZH7000 keeps your downtime to a minimum. With horsepower options up to 1200hp and production capabilities up to 1,000 yards per hour (143 tph) this heavy-duty mobile grinder is equipped to chew up and spit out material with ease. The DZH7000 is available in transport and combination track and transport models.

DEMO 2016 Booth: A-18

The EC series are built for mid-sized grinder uptime and efficiency and can deliver engineered fibre commodities from a wide range of raw materials. Upgrades to the EC platform include a full-length roller bed collection conveyor, roller bed discharge conveyor, wear liners, and independent colorizer controls (optional). These upgrades result in even cleaner operation, simpler maintenance, and lower operating costs than before. The advantages of these upgrades become particularly evident in facilities that grind steady streams of green fibre.

For daily show coverage of DEMO 2016, visit www.woodbusiness.ca or www.canadianbiomass.ca.

By Andrea Kent - president of Renewable Industries Canada

s all levels of government look for ways to fight climate change, bio-products and a diversified fuel mix are essential options to replace high carbon products and fossil fuels. Producers of renewable fuels and bio-based products reduce greenhouse gas (GHG) emissions and provide economic opportunity to the benefit of all Canadians.

“The association’s focus now goes beyond renewable fuels to include advanced biofuels, biobased products and policy programs that will support greater product research, development and commercialization.”

RICanada member companies have been growing their businesses and diversifying their products for some time. These value-added products provide governments with more and better ways to reduce carbon emissions. The federal government has made climate change a top priority, initiating ambitious emission reduction targets – and provinces such as Ontario are creating climate change plans that will fundamentally alter our economies and potentially our way of life. These targets will not be met without the use of RICanada-member products, which are integral to reducing transportation sector emissions, transitioning our country to a low-carbon economy and securing a sustainable energy future.

one million cars worth of carbon emissions from Canada’s roads every year. More can be done, as liquid fuels will be required for years to come while the potential of other renewable energy sources and electric vehicles are being harnessed sufficiently.

With that in mind, RICanada is proposing a strategy to reduce emissions equivalent to another one million cars by increasing the mandated amount of ethanol blended into Canadian gasoline from five per cent to 10 per cent and the biodiesel content of diesel fuel from two per cent to five per cent. These two simple mandate increases can be achieved in the short term, requiring no changes to existing infrastructure, vehicles or consumer behaviour; helping governments to meet their emission targets; helping our environment; and providing more economic benefits here at home.

The Canadian Renewable Fuels Association recognized the importance of the complete bio-based industry in the fight against climate change, and has expanded its mandate to become Renewable Industries Canada (RICanada). The association’s focus now goes beyond renewable fuels to include advanced biofuels, biobased products and policy programs that will support greater product research, development and commercialization. The evolution is a natural extension of what RICanada is and what it does best.

RICanada will build on decades of success that resulted in federal and provincial renewable fuel mandates, and an industry that generates billions in economic activity, returns billions on government investment, and reduces 4.2 megatonnes of GHGs annually. RICanada will work tirelessly to advocate for increased use of renewable fuels, carbon pricing systems that are designed to ensure a fair value for GHG reductions, and for increased support for clean technology and Canada’s bioeconomy.

While the association has evolved, it is clear that renewable fuels will always be a focus and proud part of RICanada’s work. Canadian renewable fuel producers already help remove the equivalent of

Extending RICanada’s reach to the overall bioeconomy represents an opportunity for further industry growth. Advocating for increased use of renewable fuels and bio-based products, as well as further research and development, could result in more efficient production methods, products and environmental and economic benefits. This opportunity cannot be ignored if Canada is to transition to a low carbon economy.

Founded in 1984, Renewable Industries Canada (RICanada) is a non-profit organization that represents the interests of over 30 member companies and is Canada’s leading voice in promoting the role of renewable fuels and value added products in reducing GHG emissions through consumer awareness and government liaison activities.

Based on Bandit’s popular Model 2400 disc design, the 2400XP features additional knife coverage, a new chipping angle and other hardware enhancements to produce a 5/8”- 7/8” with a chip thickness ideal for pulp and paper mills.

This 24” capacity chipper with Bandit’s proven slide box feed system aggressively pulls and crushes whole trees into the chipper and is positioned within inches of the chipper disc increasing chip uniformity while reducing oversize chips and fines. The 2400XP features Bandit’s clean feed system that limits the discharge of chips under the feed system.

• A dirt separator is provided to remove dirt and twigs.

• The dirt separator can be closed when the chipper is used to produce fuel chips.

• A 765 hp diesel provides plenty of power to produce 15 minute chip loads and fully pack 50 ft trailers.

This chipper is ideally suited to chip trees coming from a flail debarker.

See how Bandit® equipment can build your bottom line. Contact Bandit at 800-952-0178 or visit online at WWW.BANDITCHIPPERS.COM