Steam Boilers

Gas, Oil, Wood, Biomass, Coal, and Solid Fuel fired Steam & Hot Water Boilers

Hurst Boiler & Welding Company has been designing, engineering and servicing a complete line of solid fuel, solid waste, biomass, gas, coal and oil-fired steam and hot water boilers since 1967, for thousands of satisfied customers.

Co-generation

DIGESTER GAS

GAS

Hurst also manufactures a complete line of boiler room peripherals such as blowdown separator surge tanks, and pressurized make-up feed water tanks.

PURPOSE DESIGNED

The leading manufacturer of GREEN Project Wood-Fired and Biomass Boiler Systems.

CANADIAN BIOMASS

14 The daily grind

The ability to adjust to changing wood species and market conditions has helped Pacific Bioenergy thrive in the Canadian wood pellet industry.

18 Export worthy

Having a strong supply chain in place helps a Canadian company land one of Europe’s largest wood pellet clients.

21 Packaging pellets

A look at the newest technology and innovations for packaging pellets for domestic and foreign markets.

24 Hammermill spotlight

Hammermill suppliers for the Canadian biomass industry talk about their newest models available for pellet manufacturers.

26 Bioenergy expansion

The University of Northern British Columbia continues to expand the use of bioenergy on its campus.

COLUMNS

Good news for biomass

Lower oil prices bring upside to renewables.

This year’s big story has been the plunge in oil prices followed quickly by a fall in the Canadian dollar. As analysts watch to see how low prices will go, there has been a flurry of prediction about who will be the winners and who will be the ultimate losers in this altered economy. The energy sector looks glum while manufacturers are predicted to find some relief.

When the manufacturer makes renewable energy products, however, the story is not as easy to predict. Manufacturing will benefit from lower transportation costs that will make remote feedstocks more affordable. Mills that use oil or natural gas for energy will see some relief, though many in the forest industry have shifted to use more residuals. There are some specific advantages to different biomass products.

Since the majority of Canadian pellets are sold into the U.K. on long-term contract, they aren’t subject to the volatility of oil prices. The U.S. dollar is strengthening against the British pound and the euro, which is making U.S. pellets more expensive. A recent study released by FutureMetrics predicts American pellet producers will have to find efficiencies to remain competitive in light of their strong dollar. In this scenario, Canadian pellet producers have the competitive advantage.

The U.S. isn’t just a competitor in the pellet business: in 2014 Canadian pellet producers sold 150,000 tonnes of pellets to our southern neighbour. They’ll benefit from the lower loonie. And though it may be cheaper to buy oil to heat the average American home than pellets, dropping oil prices won’t convince consumers to

abandon pellet stoves. But they may take away any incentive to invest in new ones, cautions RISI’s bioenergy economist Seth Walker. The lower cost of Canadian-made pellets may lessen the sting for those who have already made the switch to green fuel.

It isn’t as easy to predict where Italy will get its wood pellets this winter, however. Walker points out that with the temporary upheaval in Belgium and the Netherlands (see page 10 for details), Italy was the second biggest market for Canadian wood pellets. “It’s going to be interesting to see how the Italian market plays out because the Euro has dropped so much. Their purchasing power for importing pellets is down quite a bit,” Walker notes.

The story is different for biofuels that are mandated for blending, like ethanol. As prices at the pump drop, consumers are more likely to plan that extra road trip. Since the Canadian Biofuels Mandate calls for five per cent renewables in gasoline and two per cent in diesel, the demand for ethanol will rise with the demand for gas.

Another benefit ethanol producers in Canada will notice is that ethanol prices rise as oil prices fall. “I think there is a little bit of an inverse relationship in that when the price of gas drops, the demand for gas increases and therefore the demand for ethanol increases.”

For updates on how the markets wax and wane in 2015, keep an eye on canadianbiomassmagazine.ca as we continue to monitor the situation. •

Volume 15 No. 1

Editor - Amie Silverwood (289) 221-8946 asilverwood@annexweb.com

Editor - Andrew Macklin (905) 713-4358 amacklin@annexweb.com

Contributors - Gordon Murray, Treena Hein, Carroll McCormack, CRFA

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Business Media.

Printed in Canada ISSN 2290-3097

Circulation

Carol Nixon e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription

Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $60 US; Foreign – 1 Yr $77 US

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2015 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

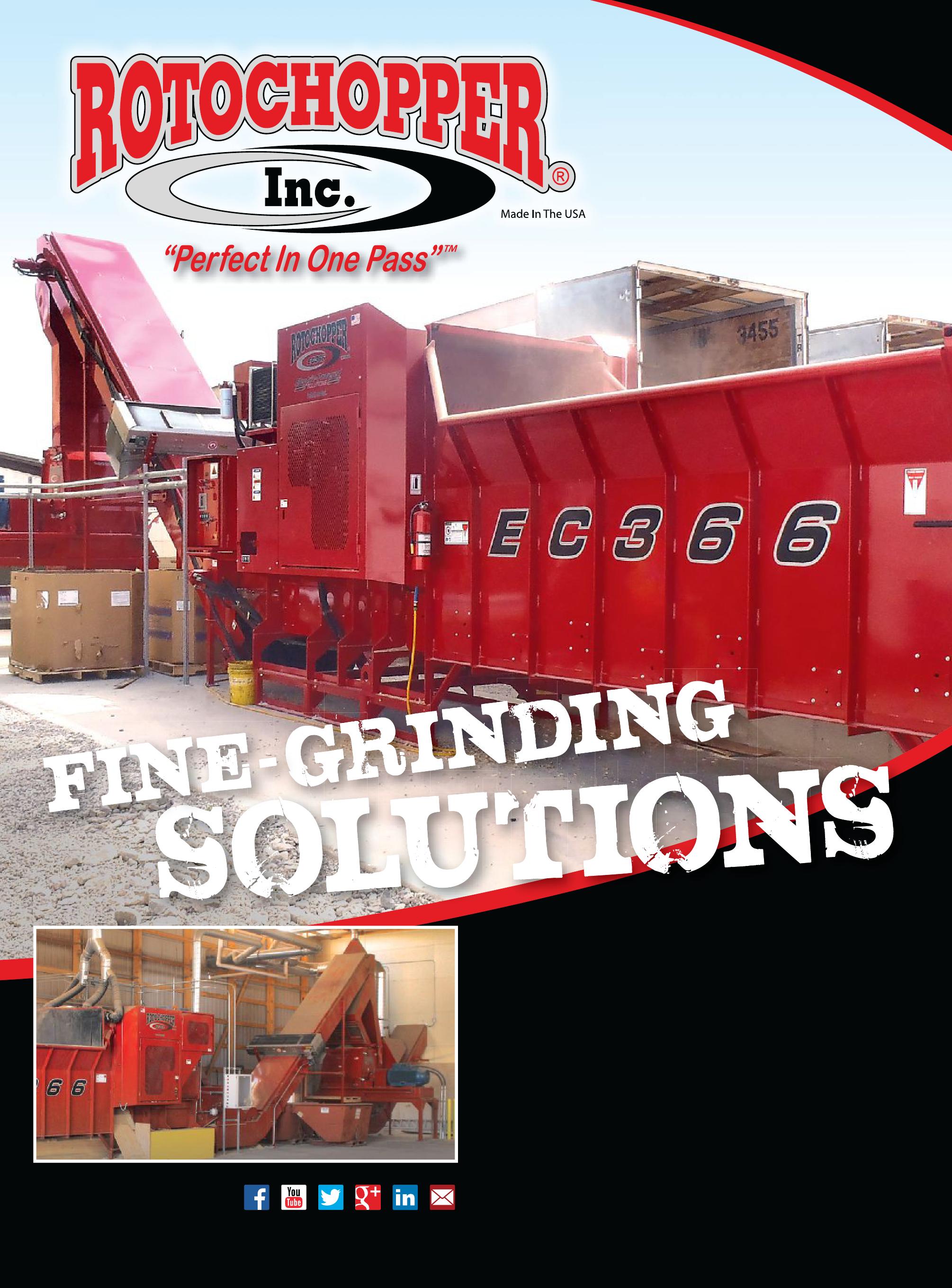

Bandit Builds your Bottom Line.

The savings in running a Bandit Microchipper should come close to making your monthly chipper payment.

Energy Efficiency.

Our chippers fully load trailers without the need for an auxiliary blower or accelerator, which makes them 30% more fuel efficient. Accelerators pull 80 to 100hp, plus they require regular maintenance. With a Bandit, you’ll average above 3 tons of chips per gallon of fuel

A Higher Yield.

Bandit’s new Clean Feed System increases production because of the system’s superior pulling and crushing power, and it nearly eliminates the discharge of chips under the feed system, increasing yield by as much as 5%. It’s like giving yourself a 5% raise. Plus you eliminate the mess

More Uptime.

Bandit whole tree chippers are known for their productivity and reliability. That is why we guarantee our chipper drum and feed systems for 5 years. We call it our “GUTS” warranty, which also includes a 5-year warranty from our engine supplier.

Micro chips from a Bandit are the most preferred by the pellet mills –nearly all are 3/8”-minus and most are ¼”-minus. Bandit’s Card Breaker system reduces oversized material and is easy to install and remove. Bandit’s new proportional drive provides a continuous flow of material through the chipper and adds to the quality of the microchip. And if markets change, it is simple to convert a Bandit Microchipper to produce a ¾” fuelwood chip.

Contact us and lets us show you why your next whole tree chipper should be a Bandit. 1-800-952-0178 or visit us online at www.banditchippers.com

MODEL 3590

Better End Product.

BIOMASS update

SCHUTTE-BUFFALO CHANGES OWNERSHIP

Effective December 29, 2014, ownership of industrial manufacturing company, Schutte-Buffalo Hammermill, LLC has been acquired by Mr. Martin Berardi.

Incoming chief executive officer Martin Berardi is a recent retiree from Moog, Inc. where in the course of 34 years he served in a variety of roles ranging from sales, operations and

general management to senior corporate leadership. Berardi’s long-term experience in a successful manufacturing company, both domestic and international, positions Schutte-Buffalo Hammermill for continued growth potential and additional avenues to explore.

Ownership of Schutte-Buffalo Hammermill has transferred from Thomas Warne

DIACARBON RECEIVES GOVERNMENT FUNDING

Vancouver’s Diacarbon Energy Inc. (Diacarbon) received $2 million from Export Development Canada (EDC). This financing will allow Diacarbon to complete the development of a thermal biomass refinery in the interior of British Columbia.

Once completed, this plant will convert wood waste into environmentally friendly, low carbon bio-fuels ready for distribution. Diacarbon is a startup cleantech company producing wood pellets and developing torrefied biocoal, both of which can be used as a replacement for fossil coal. Since 2009, Diacarbon has focused its efforts on perfecting its biocoal product made from natural wood waste and now aims to demonstrate commercial scale production and distribution.

“EDC’s investment provided the working capital that allowed us to grow our business and expand our technological base,” said Jerry Ericsson, President and CEO of Diacarbon. “The export markets are very interested in both our pellets and biocoal over the near and long term.”

“Cleantech is one of Canada’s highest growth sectors and more than half of the industry’s revenues come from exports,” said Carl Burlock, senior vice-president of financing and investments at EDC.

“Diacarbon is an example of great innovation in clean energy technology and EDC is pleased to help close gaps in their financing,” added Burlock.

POINT TUPPER

BOILER OFF

and James Guarino who purchased the company in 2004 following a merger with Buffalo Hammermill Corporation. During their tenure Warne and Guarino brought about significant growth by maintaining a leadership role in key industries such as wood waste reduction, feed and grain processing, and mining, while broadening their reach

to emerging markets including biomass processing and alternative fuels, as well as e-scrap, asphalt, and carpet recycling.

“Both Jim and I are excited to be a part of this new phase of Schutte-Buffalo Hammermill. We look forward to being on Marty’s team as we continue to provide the highest quality equipment to our customers”, says Tom Warne, president.

DUTCH SUSTAINABILITY QUESTIONS

North American pellet producers are on edge, waiting for the Netherlands to define the terms that will determine whether wood pellets have been sustainably harvested. Rather than reach out to the public at large for consultations and in an effort to avoid making an unpopular decision, the government asked the NGOs (such as Greenpeace and other environmental groups) to sit down and negotiate a sustainability system with the power companies.

The utilities involved were unable to reach an agreement with the environmental groups and walked away from the process, not wanting to be put in a position where they may be targeted by the NGOs in a smear campaign.

The NGOs have specified that any biomass used in the Netherlands’ utilities will have to be FSC-certified. The problem for Canadian producers is that most forests in Canada have undergone CSA or SFI certification, which is PEFC-endorsed rather than FSC-certified, and would not qualify under these sustainability terms.

“From a Canadian perspective, we’ve sent in two protest letters to the WTO and then we’re also following up with the European Commission. But until the Dutch are emphatic about what they’re going to do, it’s hard to put in a complaint to the commission,” executive director of WPAC Gordon Murray explains.

TARGET

Only half of Nova Scotia Power’s Point Tupper owned by Nova Scotia Power biomass boiler’s needs are being provided by waste wood.

The other 335,000 green tonnes come from forests cleared to feed the boiler, Allan Eddy, associate deputy minister at the Natural Resources Department told The Chronicle Herald.

“The shakeup of the province’s forest industry over the last five years has resulted in a severe decline in the province’s harvesting capacity. The NewPage Port Hawkesbury bankruptcy and the closure of Liverpool’s Bowater Mersey mill resulted in a lot of harvesting contractors jumping ship from the forest industry,” the paper reports.

SFI LAUNCHES NEW RULES

The launch of the new Sustainable Forestry Initiative (SFI) 2015-2019 Standards and Rules marks an important advancement to support better decision making all along the supply chain and to promote sustainable forest management.

A major change to the structure of the SFI 2015-2019 Standards and Rules is the establishment of three stand-alone standards:

The SFI 2015-2019 Forest Management Standard promotes sustainable forestry practices based on 13 Principles, 15 Objectives, 37 Performance Measures and 101 Indicators. These requirements include measures to protect water quality, biodiversity, wildlife habitat, species at risk and forests with exceptional conservation value.

The SFI 2015-2019 Fibre Sourcing Standard promotes responsible forestry practices based on 14 Principles, 13 Objectives, 21 Performance Measures and 55 Indicators that address the 90 percent of the world’s forests that are not certified. These fibre sourcing requirements include measures to broaden the conservation of biodiversity, use forestry best management practices to protect water quality, provide outreach to landowners and utilize the services of forest management and harvesting professionals. Because it directs how SFI Program Participants procure fibre from non-certified land, this standard encourages the use of responsible forestry practices.

The SFI 2015-2019 Chain of Custody Standard tracks the percentage of fibre from certified forests, certified sourcing and recycled content through production and manufacturing to the end product. Organizations can use physical separation, average percentage or volume credit methods to track and communicate their chain of custody claims. The SFI Chain of Custody standard is applied globally.

“The revised SFI standards will continue to serve as a proof point for responsible forestry in North America,” said Lawrence Selzer, Chair of the SFI Board of Directors and President and CEO of The Conservation Fund. “These standards are shaped by the people and communities who put them into practice every day.”

CONSTRUCTION BEGINS IN LAVINGTON

Construction of the Pinnacle/ Tolko pellet plant at Tolko’s Lavington mill is underway.

The decision to move forward with construction follows a significant consultation and review process, and permit approval from the Ministry of Environment (MoE) and the District of Coldstream.

The plant will employ technology, which significantly advances the manner in which pellets are produced in Canada. Well-known in Europe, the drying technology has a low operating temperature which translates into both a lower emission concentration and minimized fire risk. This in combination with the election to proceed with the implementation of bag house filtration on both the pellet plant and Tolko fibre delivery systems will improve

the overall air quality in the Lavington area.

Tolko’s CEO Brad Thorlakson said: “We want to acknowledge everyone for their work throughout this process. Thanks to the combined efforts of the MoE, the community and our planning team, we’re moving forward with an exciting project that will be good for the community and the environment.”

Leroy Reitsma, president and COO of Pinnacle Renewable Energy, said: “We’re looking forward to becoming a valued member of the local community. As we begin the next phase of this project, we look forward to hiring local service providers and keeping the local community informed about the construction progress.”

At Tolko’s existing Lavington mill, Troy Connolly,

SECOND GEN BIOFUEL MARKET GROWS

A new report claims that the global second generation biofuels market will reach $23.9 billion by 2020.

General manager, B.C. Lumber, is getting ready for construction and is positive about the impact the pellet plant will have on the Lavington operation.

“Co-locating the plant here at Lavington will bring a number of benefits. It will allow us to deal with the excess of sawdust and shavings that has been collecting, on site and at other locations in the Valley, since Domtar Kamloops reduced its operations in 2013. It will also help us to create more efficient rail and trucking logistics and improve the level of both emissions and fugitive dust control. This is a good project for the community and the mill, and one that supports the long-term viability of the Lavington sawmill.”

The pellet plant is expected to be operational by September of this year.

According to a new report by Allied Market Research titled, “Global Second Generation Biofuels - Size, Industry Analysis, Trends, Opportunities, Growth and Forecast, 2013 - 2020”, the global second generation biofuels (Advanced Biofuels) market would reach $23.9 billion by 2020, registering a CAGR of 49.4% during 2014 - 2020. Currently, Biodiesel garners the largest market share; however, the latest and the most commercially viable Cellulosic ethanol would surpass Biodiesel and eventually lead the market by 2020. North America generated largest revenue, as it has over 50% of the globally installed capacity base.

Second generation biofuel production is more energy efficient than the conventional fossil fuels. Such biofuels minimize greenhouse gas (GHG) emissions by over 90%; thus, are more environment-friendly.

FROM THE EDITORS

Statistics published in the November/December issue of Canadian Biomass were inaccurate. It was stated that five large forestry companies control 75 per cent of provincial forests, however, that number is closer to 36 per cent. We apologize for the error.

Heating with pellets

MThe real cost of wood pellet heating at home

By Gordon Murray

y column usually focuses on marketing, trade, and policy issues facing the Canadian wood pellet sector. For a change, I thought readers might find it interesting to hear about my personal experience as an ardent user of wood pellets for home heating.

I live in Revelstoke, a community of about 7,200 people nestled in the Columbia Mountains of southwest British Columbia. Due to our low population and surrounding mountainous terrain, Revelstoke is not served by natural gas. The most common home heating energy sources are propane, electricity, wood pellets and heating oil.

I recently installed a new 35,000 BTU wood pellet stove on the main floor of my 1,800 square foot house. Although I have propane and electric backup, my pellet stove heats my entire house. The stove and chimney liner cost $4,734 including tax and I paid a WETT-certified technician $650 for installation; total cost, tax included was $5,384.

Most will agree that wood heat is special. It has an ambience and coziness that can’t be matched by propane, electricity or oil. And since wood pellets are cheaper than other forms of energy, I don’t mind when my wife wants to keep the heat up high.

Operating and maintaining my pellet stove is easy. I buy pellets – about ten bags at a time, which is all that fits in my car – and store them in my garage. Due to the stove’s small hopper size, I fill it twice daily. It takes me about one minute each day to fetch the window spray and wipe the stove glass clean so we can enjoy the pellet flame. Once a week I need to spend about 10 minutes cleaning ash from the inside of the stove and emptying the ash pan.

Other than the cozy heat, the next most attractive feature of my pellet stove is the

Annual Home Heating Cost - Revelstoke BC

low operating cost. In Revelstoke, pellets cost $5.24 per bag or $262 per tonne. This works out to $15.41/ gigajoule (GJ). Add $0.50 /GJ to operate the stove’s auger and fan for a total pellet cost of $15.92/ GJ. This compares with $24.36/GJ for propane (including delivery, carbon tax and electrical fan); $29.47/GJ for electricity; and a whopping $33.93/GJ for heating oil.

Revelstoke has a cool winter climate; from November to February the average daily temperature is about -5°C. From my old propane bills, I know that my home uses about 0.7 GJ/day of heat energy (including heating appliance efficiency losses) during the coldest part of the winter. Annually my house requires 81 GJ of heat energy – equivalent to 4.8 tonnes of wood pellets. So now, on the coldest winter days, I spend $11.14/ day for wood pellets. If I used propane, it would cost $17.05/day; electricity (adjusted for greater energy efficiency) would cost $17.94/day; and heating oil would cost $23.75/day. On an annual basis, pellets will cost $1,290; propane would cost, $1,973; electricity, $2,076; and heating oil, $2,748.

The only drawback of installing a pellet stove is the relatively high upfront cost. My

stove, including installation, cost $5,384. The City of Revelstoke administers the provincially-funded Woodstove Changeout Program that pays a rebate of $500 to homeowners who replace old inefficient wood stoves with new EPA/CSA certified high-efficiency pellet, wood or gas stoves. Unfortunately, since I changed a gas stove for a pellet stove, I did not qualify for this rebate.

The annual savings from using wood pellets instead of propane is $683, yielding a simple payback of 7.9 years.

I am happy with my pellet stove. I like the ambience and cozy heat. It operates automatically and requires infrequent filling. Maintenance is very easy. And pellets are cheaper than such alternatives as propane, electricity and heating oil. I am grateful that I was able to afford the cost of purchasing and installing my stove. However, lower -income families may not have the same ability. Moreover, they may not be willing to accept a 7.9 year payback period. Nevertheless, wood pellets provide the best heat and are the lowest cost energy source in my hometown, Revelstoke, and in many other Canadian communities. •

EForestry innovation

Expect us in the unexpected

By David Lindsay

ven those working in today’s forest products industry may not realize the vast potential for wood fibre – in everything from car parts, to clothing to cosmetics. Most people would not conceive of wood frame buildings soaring to 40-storeys high either.

However, forest product innovation is making all that a possibility and more. The Canadian industry is diversifying into areas such as bioenergy, biochemicals, nanotechnology and advanced construction materials. In fact, Canada’s forest products sector is emerging as a global leader in innovation.

Some of these pioneering products made from Canada’s renewable forest resource are already found in the marketplace. Wood fibre is being used to produce high strength composite auto parts that are lighter and reduce vehicle emissions. Specialty cellulose is being used as a film coating for pills or as a binder and time release ingredient for slow-release capsules. Dissolving pulp is used to produce rayon that can imitate the feel of cotton, linen, silk or wool.

Other products are in the offing including using lignin, a renewable byproduct of pulp mills, to provide the substrate for 3D printers; touch screens just two cellulose fibre thick for the next generation of smart phones to replace screens now made from non-renewable plastic; and “intelligent” packing with bioreactivity properties to extend shelf life, monitor freshness and identify allergens such as peanuts.

We can expect more surprising forest products in the future thanks to Canada’s unique innovation system based on a shared vision, and alignment between the forest products industry, governments, academics and research institutions, and other partners. Industry leadership comes from the Forest Products Association of

Canada (FPAC); the federal government has funded strategic programs such as Investments in Forest Industry Transformation (IFIT); FPInnovations is a world-leading public-private research body; the FIBRE network is tapping into the creativity of 27 universities, 100 professors and 400 students.

The world-leading research and development behind cellulose nanocrystals (CNC) is a shining example of Canada’s innovation partnerships in action. FPInnovations led the research with support from the federal and Québec governments. The creativity of the academic world was in evidence with Professor Derek Grey of McGill University winning the prestigious Wallenberg Prize in Sweden for his pioneering work on CNC. The world’s first pilot plant for CNC was built at the FPInnovations laboratory in 2011 and the next year CelluForce Inc. became the world’s first commercial demonstration plant producing CNC at the Domtar pulp and paper mill in Windsor, Québec. Work continues to identify unique and advanced uses for this high value nano-material that comes from a renewable, recyclable natural resource.

the research effort and joined forces with Kruger to open the first demonstration plant in the world in Trois-Rivières. Two other companies, Resolute and Mercer, have joined forces in a joint venture called Performance BioFilaments to explore commercial applications for this exciting new biomaterial that strengthens traditional pulp and paper products but also has numerous non-traditional uses such as flexible packaging, thermoplastics, coatings and construction panels.

If we can build on recent success, Canada can truly lead the pack in these game-changing technologies and eco-friendly materials.

All this groundbreaking work is helping to put Canada in the pole position for forest product innovation. The key now is to build on the momentum. International competitors are also moving quickly down the road of innovation. For example, forest companies in northern Europe have announced plans to invest $3 billion to diversify their product lines into new bioproducts and bioenergy.

Canada has also led in the development of the next generation of cellulose-based materials because of collaboration, targeted investment and research on cellulose filaments (CF). Support came from the Canadian, Québec and British Columbia governments. Academics provided technical support for process and product development. FPInnovations led

However, if we can build on recent success, Canada can truly lead the pack in these game-changing technologies and eco-friendly materials. And that can only be good for Canada’s future prosperity and job creation. •

Wood pellets in demand

European markets remain strong while new markets in Asia emerge

By Amie Silverwood

In2015, European demand for Canadian wood pellets will remain strong for both the utility and heat markets while new markets open up in Asia. Canadian wood pellets are produced from waste products and are primarily sourced from certified forests, making them a premium pellet on the world market even as the weakening Canadian dollar makes them more affordable.

The low oil prices are dragging energy stocks down but the wood pellet industry will continue to grow because pellet demand is tied to regulations, sustainable energy policies and long-term contracts rather than being subject to the volatility of oil and gas prices. As such, pellet production in Canada will be steady through 2015 with an uptick in exports coming from Ontario as Rentech comes online at its Atikokan and Wawa pellet plants.

PELLET PRODUCTION IN CANADA

In 2015, there will be a substantial increase in pellet shipments from Rentech out of the Port of Quebec. If the company is able to ramp up into full production in Atikokan and Wawa this year, the number of pellets exported from Ontario through Quebec will swell.

Rentech, however, is still relatively

new to the industry and any new plants are bound to have a few hurdles to cross in the first year of production, explains Gordon Murray, executive director of the Wood Pellet Association of Canada. “You design a plant to run at a certain capacity but you never actually get to the designed capacity in the first year. They’re new in the business, it’s a new plant, new location and there aren’t many other plants around for them to share information with.”

Seth Walker, a bioenergy economist with RISI, is watching developments in Ontario and neighbouring provinces with interest. He sees plenty of potential for amalgamation now that the infrastructure is in place to ship pellets from the Port of Quebec.

“What happens to the smaller and midsize producers all over Eastern Canada that aren’t necessarily close to any markets and don’t have any long-term contracts? Do they somehow benefit from all this? That still remains to be seen,” says Walker. “I think that once Rentech gets all their operations running smoothly, they’re going to see that they have a good opportunity to aggregate from other producers in Eastern Canada and ship out of their facility in Quebec. But I think it’s going to take a bit of time.”

While there wasn’t much growth in

MAIN: Unlike European countries like Sweden, few pellets produced in this country are used for the domestic heating market.

2014 in B.C. (production was flat around 1.7 million tonnes according to Walker’s data), a number of new projects have been planned. Tolko and Pinnacle recently announced that they would begin construction on their project in Lavington, TimberWest is considering adding a pellet plant to pelletize their residuals from their logging operations on Vancouver Island and Canfor and Pacific Bioenergy have plans for two pellet mills together in northern B.C. But Murray doesn’t expect production at these plants to begin until 2016.

HOT SPOTS IN EUROPE

The European commitment to wood pellets is strong and the United Kingdom is the world leader in wood pellet consumption. It will continue to import vast amounts of pellets as Drax, the power station in North England that has been converting from coal to wood pellets, continues to secure new contracts.

“It’s all Drax that’s sucking everything up for the next two years or so until they finish the next version,” explains Seth Walker. Drax’s second unit has been doing enhanced cofiring (which means it was burning a mix of 85 per cent wood pellets and 15 per cent coal) until the end of 2014. It plans to convert the third of its six generating units by the end of 2016.

BOTTOM LEFT: Pellet growth in Canada in 2015 will be dictated by what capacity current mills run at, at which proposed new projects are able to get up and running.

BOTTOM RIGHT: An emphasis on price versus quality will make it difficult for producers to expand their exports into some Asian nations.

Walker notes that the ramp up is slow because of the enormous volume of pellets the company requires. “It’s really not the technical constraint of converting the boiler, it’s getting all the infrastructure in place to be able to get seven million tonnes of pellets to one power plant.”

Drax was unable to secure a contract for difference (CFD) for its third conversion but Walker doesn’t expect that will put an end to the project. “Their argument in court was that they needed the contract for difference not to make the unit make financial sense for them but to make it easier and more bankable to sign contracts to encourage developers.”

The loss will set the project back but the issues should be resolved in time. The company has also announced that it is considering converting another unit to biomass. “I’m pretty skeptical about a fourth unit from them but we’ll see,” Walker adds. New legislation will come into effect in 2018 that will limit large conversions in the U.K. but projects that are currently underway will not be impacted.

Denmark, on the other hand, is looking to increase its use of wood pellets in the aim of phasing out coal by 2025 with several coal CHP stations targeted for conversion to biomass. Because these large plants have traditionally relied on imported coal, they are well positioned to receive more wood pellet imports.

The Netherlands’ use of renewable energy sources is low in comparison to other European countries. The Dutch want to grow their share of renewable energy use from four to 14 per cent by 2020. It plans to achieve this partially by cofiring pellets at large coal power plants but only if they come from sustainable forestry practices.

They have a committee working on the details of these regulations. “The U.S. is pushing hard against this because their certification levels are extremely low and they’re going to have a harder time meeting this than us,” Murray explains.

There is currently only one power plant that is set up to cofire wood pellets but once the regulations are established, the other utilities will determine whether or not to do conversions.

“While we would see it as a competitive advantage, the size of the total supply may be so small that the utilities decide not to go ahead with it,” Murray says. “It’s my worry that those boards may conclude

that there is too much supply risk because the conditions are too onerous and all the U.S. supply is taken off the table.” This is a developing story that we’ll follow over the coming months.

A CHILL IN THE HEATING MARKET

While the industrial wood pellet market won’t be impacted by the volatility in oil prices, the heating market will react as oil becomes cheaper than pellets around the world. While homeowners won’t switch back to heating oil from pellets, cheap oil may remove the incentive for those considering a pellet stove. This will inhibit domestic growth over the short term. Last year, around 150,000 tonnes were used domestically, while 180,000 tonnes of Canadian pellets were sold into the U.S.

Walker says he will be watching how the markets develop in Europe, however, where the falling euro is making American products more expensive for European consumers. “You’ve got record low heating prices so it’s going to be interesting to see how that effects demand over the next year or two for the heating market in Europe.” Walker explains that Italy was the second biggest market for Canadian producers last year.

TRADE INTO ASIA

In March 2014, the government of Flanders, in Belgium, cut off the subsidies it had issued for electricity generated from imported wood pellets from Electrabel for its Max Green Rodenhuize biomass power plant in Ghent. The company shut down the power plant until a new agreement was reached in August. Electrabel, a subsidiary of GDF Suez, had some longterm contracts with Canadian pellet producers that were FOB Vancouver. It was able to trade these pellets into the Korean market on a tender basis because its facility did not need the pellets.

“They got lucky in that they found a fairly convenient customer for those pellets because Korea was ramping up at the right time when they had extra pellets available on the West coast,” Walker said. “A lot of the trade that’s happened (a couple hundred thousand tonnes probably this year going from Vancouver to Korea) is not negotiated by Canadian producers, it’s negotiated by European utilities that still have these long-term contracts.”

South Korea implemented a Renewable

Portfolio Standard in 2012 with renewable energy taking up two per cent of the country’s energy mix. Over the next 10 to 15 years, the country plans to increase the portion of renewable energy it uses to ten per cent. This has initiated rapid growth in this market – a year over year increase of 519 per cent and Canada has provided a significant source for this growth.

The challenge faced by Canadian companies in this market is the South Korean tender system that prioritizes price over quality. An additional challenge is that North American pellet producers are looking for stability through long-term contracts. Walker predicts that European utilities with long-term contracts with B.C. pellet producers will continue to facilitate trade between Canada and the growing Korean market.

The Wood Pellet Association of Canada is trying to make it easier for Canadian pellet producers do sell directly into Korea. It will participate in a trade mission to Korea in February in the hopes of opening up a dialogue.

“Mr. Ed Fast, the minister of international trade, is going over and we’re hopeful that he might help us with that issue because he’s going to be meeting with his counterparts in Korea and we’ll have some of our members on that trip,” Murray explains.

Though trade into the South Korean market does not provide long-term stability, trade into the Japanese market is well established for Canadian producers. Japan has introduced feed-in tariffs for renewable energy and the majority of its wood pellet imports are already from B.C. There is significant potential for increased co-firing as the country aims to reduce its dependence on coal. And while South Korea is not focused on sustainability, Japan is increasingly focused on sustainable pellet sources.

A cheap loonie is making Canadian wood pellets affordable, while sustainable forestry practices make them desirable. Together, it adds up to good news. for pellet producers across the country. •

For more information about the domestic, North American and global pellet markets, visit canadianbiomassmagazine.ca

The daily grind

Versatility gives PacBio an advantage

By Amie Silverwood

Oneof the oldest and most prolific pellet producers in Canada, Pacific BioEnergy operates in Prince George at the heart of the mountain pine beetle epidemic that devastated B.C.’s forest region. Though the region is the forestry capital of Canada, the epidemic has wiped out up to 80 per cent of the forest’s live trees. Sawmills have closed and as the dead trees continue to deteriorate in value, the competition for fibre is tightening. Much of the pine forest is nearing the end of its use as sawlogs and most of the trees left standing are remote, making the logging costly.

WASTE NOT, WANT NOT

Pacific BioEnergy’s current pellet plant was built in 2007 to turn unwanted sawmill shavings into sellable wood pellets. But it has been redesigned to accept a full array of feedstock to take advantage of the abundance of dead pine that make up

the region’s forests.

“We purposefully designed it understanding we had to be as sharp as we can on buying fibre and be as competitive as we can on processing it. So that’s the philoshophy behind it,” explains Brad Bennett, the vice-president of operations for Pacific BioEnergy.

Drying capacity was doubled. The facility runs two single pass dryers instead of the two triple pass dryers it used to rely on. The single pass dryers are able to tolerate a wider range of moisture content than the triple pass dryers. “The manufacturers say they all come out the same but they don’t,” Bennett says.

Selling into the European market means adhering to very strict standards. The pellet mill in Prince George was designed to achieve those standards no matter what raw material was secured as the feedstock. Designed to be versatile, it uses sawdust, shavings and even up to 60

per cent forest residuals.

“If we are versatile in what we can use, we can be selective when we buy from sawmills,” Bennett says.

Finding the right mix of fibre is tricky even when the mill is designed to make high quality pellets out of broken trees, tops and limbs that would otherwise be burned on site. There is a lot of bush grind to be bought, but the company has to be selective in which operations it buys from and how far these residuals are being trucked.

“How much you want dictates what it’s going to cost,” Bennett says. “The more you want - you just keep pushing yourself up the cost curve.”

Theoretically, the mill can run on 100 per cent bush grind with the addition of another Biosizer, but the mix has remained below 60 per cent to date. Its fibre content fluctuates depending on what makes the most economic sense and what is available.

NOT ALL WASTE IS FIT FOR PELLETIZING

The most important part of pelletizing bush grind is staying on top of the quality of the raw material. It is important to take the time to pre-select the material before it is harvested.

“We’ve learned operating in the field you don’t want to get every last stick. If the guy is picking the dirt out and mixing it into the ground material, it will just end up in our plant.”

Some sites are at a higher risk of contamination and a lot of the company’s quality control includes making sure the raw material is managed properly from the get-go.

Bennet explains, “We’re starting to evolve into a cycle so people are providing us with their plans beforehand so we can select blocks that we think make sense for us. We communicate with them what we need from a quality perspective and ask that they prepare it so we have the best chance of success with the material. The worst thing would be to get good raw material but because it’s been prepared improperly, we turn our nose up at it and say, go ahead and burn it because we can’t use it.”

Rocks, root balls and dirt resulting from pushing the residuals into a pile can cause havoc in the pellet mill. But, the company has started making strides and Bennett believes the primary licence holders are now more attuned to what pellet mills need – which is for them to handle the material as little as possible. The company has three grinding contractors who grind roughly 120,000 tonnes a year in total.

When pre-selecting blocks, Bennett looks for pine ones because they tend to have a higher level of breakage and are drier than greener stands. Some of the dead pine can have a moisture content as low as 20 per cent versus sawdust from sawmills that can have a moisture content as high as 50 per cent.

When it comes to affordability of raw material, moisture content and distance can determine the best value. “Forest residuals are actually better in some cases than wet sawdust that’s brought

Pacific Bioenergy’s custom fleet of 165 rail cars will hold 99.2 tonnes of wood pellets each –just below the 100-tonne limit.

in from a long distance even if they may be cost competitive. Sometimes the pine’s better because it has a lower moisture content,” Bennett says.

Wet sawdust can require as much as a third of its volume to get the other two-thirds dry enough to pelletize. And besides the economic advantage of using the dead, dry pine, there are social benefits to keep the residuals away from the match. Nobody likes to think of all that wood going up in smoke.

RUNNING THE MILL

It takes about 40 employees to keep the pellet plant running 24 hours a day, seven days a week, but half the crew is on maintenance duties. In fact, the mill could run on as few as two people: one loader operator to put the raw material into the plant and somebody to operate it. In reality, however, on top of the two essential operators, there are a couple loader operators, a quality control crew, a crew loading the finished pellets into rail cars and those maintaining the machinery and keeping the plant clean.

The forest residuals go through a Brunette Biosizer to reduce them to the required size before joining the sawdust and shavings on the conveyor belt. It goes through a metal detector, which aborts the material by reversing the belt if metal is detected. The mill has an old hammermill that isn’t very efficient but can be used if it’s needed to grind extra forest residuals. When it isn’t needed, the material is diverted around the piece of equipment to conserve power.

The material passes through a SolaGen single pass dryer that isn’t slowed by the

wide range of moisture content. “The theory is the lighter, smaller particles will go through the dryer very quickly, the larger and heavier particles will take longer to move through,” Bennett says.

The dryer uses what is called “flighting” to lift the fibre and cascade it through the heated gas stream. It creates suction that draws the material through the dryer and into a cyclone which then separates the air from the fibre, drops the fibre into an airlock and the air flows through a PPC Air Pollution Control Systems electrostatic precipitator.

A lot of the fire explosion risk is within the drying system itself, but if the dryer is tightly sealed, the material is processed in a hot, steamy but oxygen-free environment. Operators need to follow procedures carefully at start-up and shut-down to avoid introducing oxygen into the system, but Bennett stresses the system is perfectly safe in operation.

The system is well monitored to detect any defects or explosion risks (with 40 zones of extinguishment throughout the mill that are all computer-monitored) and there are aborts built in to safely redirect any explosions. There is a burner chamber that runs on wood dust and residual heat is recycled within the system. Particulates from the process are scrubbed out of the exhaust before it is released.

Bennett is well versed on how the particulates are kept out of the atmosphere. “That water attaches itself to the particles and there’s an electric charge that draws the particle with the water to the sides of the tubes. There’s a whole series of tubes and it essentially runs down and flushes

John Gillis monitors the flow of fibre and the spark detection systems that have been strategically placed throughout the pellet mill.

it out - pulling it right out of the airstream,.” he says.

Out of the air lock, the fibre drops into hammermills; another high-risk area that is closely monitored. The hammermills pulverize the fibre into a uniform size before it enters the plant.

INSIDE THE PLANT

Walking in the doors, it’s remarkable how clean the facility is – a lot of time, money and thought was put into developing a system that would ensure the air and surfaces are free of dust. An industrial vacuum system runs around the clock to pull the ambient dust out of the air, but it also takes a crew entrusted with the job of keeping the place clean by manually sweeping the mill.

“We produce dust so we’ve got to be all over it,” Bennett says.

The plant has 10 pellet mills, three of which are older (the company is in the process of replacing all of the mills with new Andritz pelletizers). The pellets drop from the pellet mills into the coolers. Half the pellet mills have their own individual coolers, while the other half share a large one. Once cooled, they are shaken to remove the fines and are then loaded into the silos or directly into the rail cars during day shift.

WATCHFUL EYES

John Gillis is the operator at the helm when Canadian Biomass visits the plant. He’s able to monitor the flow of fibre and the spark detection systems that have been strategically placed throughout the process.

Gillis points out the 40 zones of ex-

tinguishment on his screens. “We’ve got 29 GreCons all over the plant. If there’s a spark, some of them will shut down the whole plant, some will take down parts of it,” he says.

Flamex is another system the operator relies on that uses infrared detection. It works well on hot metal and is therefore used for the coolers. A Firefly system is used in the cyclones. The trick is to customize the best control system for the risk point. Of course, the operator has a big red button that will take the whole place down, if necessary, Gillis says.

A quality control person monitors the finished product, looking at things like ash content and the individual particle size within the pellet. Pure sawdust and shavings run about 0.4 per cent ash. Pacific BioEnergy is able to keep the ash content to below two per cent with the addition of quality bush grind, which can be as low as 0.8 per cent. Sand and rock can raise the ash content.

Pellets are conveyed into two silos for storage or directly into rail cars during day shift. The silos can fit 3,500 tonnes of pellets each seven-day production cycle. Its custom fleet of 165 railcars will hold 99.2 tonnes each – just below the 100-tonne limit. From Prince George, the rail cars are sent directly to the port where they are loaded for export.

Designed to be a versatile pellet producer, Pacific BioEnergy is well positioned for success in its pellet mill, but this isn’t the only way the company is preparing for the future. Stay tuned to learn more about the innovative methods it is using to secure the wood fibre it needs. •

The wood pellets are conveyed into two silos for storage or directly into rail cars during day shift.

Export worthy

A robust supply chain was critical for attracting a major European wood pellet client

By Carroll McCormick

Drax

has a monstrous appetite for biomass.

The operator of a 4,000-megawatt power station in North Yorkshire, England, it supplies about 7% of the country’s electricity. Drax needs large, reliable suppliers with cost-effective, reliable supply chains and able to guarantee long-term commitments. Los Angelesbased Rentech Inc. has assembled just this combination to land a 10-year supply contract with Drax, making it Eastern Canada’s de facto leader in wood pellet exports.

Just before Rentech announced the Drax deal, Canada-based professional

services firm CPCS published a report, “Supply, Logistics and Export Strategies for Wood Pellets Produced in Eastern Canada”, that it prepared for the Quebec Wood Export Bureau (QWEB) and the Wood Pellet Association of Canada (WPAC). In it, CPCS details the requirements for a successful export strategy.

Rentech has met each of the big-ticket requirements CPCS outlined for becoming a major wood pellet exporter. Of all the wood pellet producers in Ontario, Quebec and the Atlantic Provinces, only Rentech has the required combination of high production volumes, direct rail

access, dedicated pellet handling facilities at a year-round deep-water port and high-volume shipping to attract an European customer the size of Drax.

The CPCS report also discusses the possibility that a strong leader in the region could organize other producers to consolidate their pellets and use its supply chain to collectively create a strong exporter bloc. In its report, CPCS notes, “[There is] no export-focused producer in Ontario/Quebec to be a leader.” With the emergence of the Rentech production, export and contract structure, however, the landscape has changed. CPCS principal

Drax believes that Eastern Canada could become as large an export market as Western Canada; western producers shipped 1.6 million tonnes of pellets out of Port Metro Vancouver in 2012.

and study author Jean-François Arsenault agrees that, should Rentech wish to, it would qualify as a suitable export-focused producer to be a leader for the other producers. “Definitely,” Arsenault says.

In fact, at the eastern Canadian Pellet Logistics Workshop that QWEB and WPAC organized last summer, Rentech announced, “… we are able to consolidate volume and provide a conduit for other producers to the export marketplace.”

On the production end of the supply chain, in 2013 Rentech purchased two decommissioned fibre mills in Ontario: a former strand processing mill in Wawa from Weyerhauser, and a former particle board processing mill in Atikokan from Atikokan Renewable Fuels. Rentech is converting the Wawa mill for the production of approximately 450,000 tonnes of pellets annually, and converting the Atikokan mill for the production of approximately 100,000 tonnes of pellets annually.

To feed the facilities, Rentech will purchase between 900,000 and 1,000,000 tonnes a year of Canadian Crown fibre. “The Ontario government has provided

use rights to the fibre supply for as long as we continue to use it,” says Julie Cafarella, vice president communications, Rentech.

Rentech is selling the pellets from the facilities under two long-term contracts: Under a ten-year contract, OPG, Ontario’s provincial power utility will purchase 45,000 tonnes annually from Atikokan, with an option to purchase an additional 45,000 tonnes annually from Atikokan. OPG will receive its first shipment in the first half of 2014.

Also under a ten-year contract, Drax is purchasing 400,000 tonnes of pellets from the Wawa facility, with the first delivery scheduled for the fourth quarter of 2014.

Both facilities have on-site access to mainline rail service. Wawa, for example, has a rail siding with room to store rail cars. Arsenault notes that virtually none of the other eastern Canadian pellet producers have direct access to a railhead. This poses a serious challenge. “Trucking to railhead is unlikely to be viable for the large majority of producers, but of course, this depends on the price,” Arsenault says.

Under long-term contracts with Ren-

LIGNA 2015

Innovations – Solutions – Efficiency

■ The most important event for the industry world-wide with more than 1,500 exhibitors from almost 50 countries.

■ See all the latest technical innovations and solutions in the wood working and processing sector.

■ So don’t miss it. Make sure of your ticket now and register!

tech, CN will transport the pellets from the Wawa facility 1,100 kilometres to the Port of Quebec City. The journey is direct, with no switches to other carriers. “The specific tenure of the long-term contract with CN has not been disclosed,” Cafarella notes. “OPG will purchase the pellets from the Atikokan facility FOB at the plant gate.”

The large volume of pellets that Rentech is committing for transport, with long-term guarantees, allowed Rentech to negotiate the most cost-effective rail and car lease rates. (Rentech will be leasing around 200 covered hopper rail cars from a third party to move the pellets.) “Rail was the most cost-effective on a longterm contractual basis,” notes Rentech in a combined Rentech/Drax presentation titled “A Case Study in Logistics and Export Strategies in Eastern Canada.”

The Port of Quebec is not the only port on or leading to the Atlantic Ocean that handles pellets. Thunder Bay, Trois-Rivieres, Belledune and Halifax, for example, handle pellets. But Rentech has made an exclusive arrangement with Quebec Stevedoring Limited (QSL) that

has QSL investing up to $20 million to build dedicated pellet unloading, storage and vessel loading facilities at the Port of Quebec. The facility should be completed prior to Rentech’s first shipment of pellets to Drax.

The facility will have 75,000 tonnes of storage, with space reserved to expand that by another 37,500 tonnes, if needed. The current plan is for rail car unloading with plenty of existing siding capacity. Truck unloading can be added later, if required. Should other pellet producers get onboard with Rentech, Arsenault notes that, “For some, trucking directly to the facility in Quebec City is likely more viable than trucking to a railhead.” This also speaks to the possibility and advantage of of virtual consolidation, where producers’ pellets are consolidated on paper before transport, and only physically consolidated in ships’ holds.

Due to the limited U.K port infra-

structure, Drax needs to use the fewest and largest ships possible. Drax has targeted Panamax/modified chip carriers to transport the pellets to the U.K. To this end, says Cafarella, “We plan to use Panamax ships that can carry approximately 50,000 tonnes of pellets.”

The higher-volume ships stand to add to the viability of Rentech’s pellet export venture. Knud Jensen, executive vice-president, Canfornav, illustrates what higher shipping volumes can mean. “The freight difference between a 40,000-tonne load and a 30,000-tonne load will be 15-25%. We will look at freight rates much differently on a longterm strategy than on the spot-market.”

Although Rentech has not revealed details of all of its supply chain contracts, what it has made public suggests it has largely achieved another key requirement for the success of a supply chain agreement: synchronized agreements. In short, Arsenault explains, “It means that

contract periods are similar, to minimize risks. If not, you have to include cost escalation indicators in your contracts to transfer risk to the buyer. Otherwise, if costs outside your control (as a producer) increase, you [are vulnerable.]”

Eastern Canadian pellet producers currently have a production capacity evaluated at 1.18 million tonnes and production of about 600,000 tonnes of pellets a year, according to the CPCS report. Yet, notes CPCS, plans for new and expanded capacity could push this to 1.88 million tonnes in the short to medium term. Implicit in this observation is that producers’ supply chain and export shortcomings will only worsen.

Drax states that foreign demand is there. In fact, Drax believes that Eastern Canada could become as large an export market as Western Canada; western producers shipped 1.6 million tonnes of pellets out of Port Metro Vancouver in 2012. Yet, warns the CPCS report, “Logistical constraints and unfavourable market conditions, however, are preventing this export potential from materializing.”

With Rentech’s wood pellet export operation soon to be in play, the largest, industry-sized supply chain constraint has vanished. Drax notes in the presentation, “The Rentech controlled export infrastructure will now provide existing suppliers a route to consolidate small incremental volumes onto larger ships.”

Rentech has similar thoughts. “The storage and handling infrastructure being built at the Port of Quebec would allow for additional pellets to be stored and handled through the Port beyond our existing contract with Drax,” Cafarella says. “As such, there could be opportunities to work with other pellet producers to leverage our Port access and storage.” •

Strong logistics infrastructure, including viable rail and port infrastructure, has been vital for getting European clients to purchase Canadian wood pellets.

Packaging pellets

The newest packaging technology for the Canadian pellet market

By Treena Hein

asit is with any product, increasing the sales of pellets is a multi-faceted endeavour. Packaging can certainly play an important role, and the trends in what’s available today in pellet bags reflect the same trends being seen in many other industries. There’s a bigger focus on flexibility than ever before, so that pellet manufacturers can provide the exact bags that meet their customers’ needs. It’s all about more sizes, and features that make handling easier or attract the eye on store shelves. Canadian Biomass looked into

recent changes in wood pellet bags and the bagging process – and perhaps this will start a conversation at your firm.

Eagle Valley in Princeton, B.C. produces 12 different styles of wood pellet bags for the heating and animal bedding markets. In addition to domestic sales, Eagle Valley currently ships to countries such as the U.S., Italy, Germany, the United Kingdom, Bahrain, the United Arab Emirates, Korea, Malaysia and Australia. Their ‘Advanced Bedding Management’ (ABM) product for horses, small animals and more is manufactured of 100 per

cent whitewood and contains approximately four per cent moisture, which the company says is more absorbent than traditional bedding materials of wood shavings, crumbled newspaper or corn cobs.

While some Eagle Valley bags are the same as they have always been, sales and logistics manager Richard White notes that others have changed quite a bit as technology and materials have allowed. “In the almost 20 years that we have been producing bagged product, Eagle Valley has seen a remarkable change in the sophistication of plastic technology,” he

The RethPack VFF-5010 pellet bagging system has fewer moving parts, so that customers spend less time and money on maintenance and more time packaging product.

says. For example, the company has worked with one of its suppliers to get a non-slip additive added to the chemical makeup of the plastic it provided. “This has helped us virtually eliminate pallets falling apart while they are on the stacker, the wrapper or during shipping,” White notes. “The product takes a beating in transit and we are constantly working on ways to ship better, build it stronger and keep our customers happy.”

Balcan Plastics in Saint Leonard, Quebec has also kept up with plastic developments, stepping up bag durability over the last few years through securing plastic with added co-polymers. Sales manager Nissim Assayag says this provides greater rigidity, durability and puncture resistance. “The wood pellet bag market is a new segment for us, and sales are growing,” he notes.

In addition to plastic being able to provide better handling and durability, it’s also come to play a bigger role in helping companies differentiate their products from the competition. “There are so many features to help the client [with easier handling] and advertise at the same time,” notes Chuck Guigui, the president of Polypro Solutions in Kirkland, Quebec who has 30 years of experience in the biomass industry. “We can put any style of print onto the bag, whether you want to promote the product, provide easy identification or customer information. Bags can also be made in different colours if needed, with multi-coloured logos.”

Increased colour choices and better imaging has also allowed Eagle Valley to develop a high-end glossy bag “that looks much better in the store, not just out back, where traditionally pellets are stored,” explains White. At Balcan, they now offer up to eight colours on their pellet bags. “Our European customers mostly use five or six colours, but it’s usually two to three here in North America,” says Assayag.

Beyond the durability and appearance

KAHL Wood Pelleting Plants

changes, pellet bags today also offer easier handling for end-use customers. A wider range in sizes, especially for the cooking appliance market, is the biggest pellet bag change that Rethceif Packaging of Ossian, Indiana has seen in the recent past. “Our machines allow for quick changeovers and accommodate a wide range of sizes,” says sales manager Jeremy Collins.

“It is no longer just a standard bag which serves for every industry,” agrees Guigui at Polypro. “Bags are made to measure for each individual client, tailored to what would work the best for the machines they have at hand.” In the last few years, Balcan has gone to offering two pellet bag sizes, 15 kg and 18 kg, with the smaller ones going mostly into the European market according to Assayag.

In addition to different sizes, other features have been added to bags to make handling safer and easier. “Spout top, spout bottom, duffel top, flat bottom, different-sized lifting loops – the variety of bag you can get goes on and on,” Guigui explains. He adds that pellet bags can now come in a baffled format, so that

they don’t bulge out and can easily fit into containers. Another option available these days is a liner that can be sewn directly into the bag so moisture can’t penetrate and ruin the product. “There are also UV stabilizers, so the bags can stay in the sunlight without deteriorating, losing valuable product and avoiding costly claims,” Guigui notes. “Bags can be coated as well for extra protection against the elements.”

BAGGING PROCESS

When Eagle Valley decided to get involved in bagging, staff spent time researching options. “Hamer was our choice then and if we were to start again we would stay with Hamer,” White says. “The machinery is durable, the maintenance is doable and affordable, and the technical support is fantastic.”

Rethceif is a bagging machine maker, and now offers two models of vertical free-flow machines with capacities ranging from 14 to 24 tons per hour. Their baggers are designed to remove all unnecessary movement, which Collins says

has proven to be a robust and long-lasting approach. “With fewer moving parts, our customers spend less time and money on maintenance and more time packaging product,” he explains.”

Of all the things he’s noticed over the last few years having to do with pellet bagging, handling and transport, Collins notes that automated palletizing has become a significant priority among Rethceif customers, and the company has taken action to meet these needs. “We are a Kawasaki robot integrator and offer a full range of palletizing solutions,” he notes. “We also build our own conveyors and pallet dispensers, which allows us to control the quality. For transportation and storage, a stable stack with a complete moisture barrier is a must.”

Whether you have been using the same bags for a year or a decade, it might be worth looking at how they could be updated in order to boost sales. Customers appreciate packaging that meets their needs and is easy to use, and the investment you make in research time and new bag features may well be worth the effort. •

Spotlight on Hammermills

The newest hammermill technology available for Canada’s wood pellet industry

By Staff Report

Theexpansion of the wood pellet industry in Canada has caused hammermill manufacturers to expand their product offerings to the North American market. As a result, there are more options for pellet mill equipment than ever before here in Canada.

Here is a look at the newest in hammermill innovation and technology available for the Canadian wood pellet industry.

ANDRITZ

Andritz Series 6 Hammer Mill is now offered in both 38-inch (965 mm) and 43inch (1,092 mm) diameters with grinding chamber widths ranging from 12-inch (305 mm) to 60 inches (1,524 mm). These mills can accommodate motor sizes ranging from 125 HP (90 kW) to 600 HP (450 kW). This unique Series 6 design was created to satisfy today’s demanding applications and safety guidelines.

TerraSource Global’s Jeffrey Rader brand offers a wide range of hammermills including FT and FTE Flextooth Crushers for larger products and Mini-Mill™ E, 30ABE, and 34ABE models for smaller products and sampling. “E” designations in each model signify the brand’s exclusive E-Z Access technology, which allows safe, fast, and easy access to hammers, rotors, and liners. All models are equipped with heavy-duty rotors that can be set up with three, four, or six rows of hammers.

BRUKS

BRUKS has developed a high efficiency hammermill for biomass and biofuel applications. The hammermill features different types of rotors can be used for wet and dry milling, aswell as different types of screens guarantee a top fibre quality. The unique design allows for fast and easy access for maintenance and service.

The machine can be equipped with various cleaning devices to avoid impurities like metal and stones in the milling chamber.

JEFFREY RADER

DIEFFENBACHER

The machine is used for preparation of organic substrates for biogas production, wood-dust for energy and heat generation, wood-flakes for pellet production and many other applications. The working principle is based on the impact effect. Inside the impact chamber the material is resized with high kinetic energy by the fast rotating rotor and interaction of the particles itself. A final calibration is realized by screens. The ClassiSizer is able to process different and inhomogeneous input materials to variable sized final particles.

BLISS INDUSTRIES

Bliss Industries, LLC is a leading manufacturer of size reduction equipment. Bliss maintains a reputation of manufacturing the most efficient, reliable and well-built equipment in the industry. Bliss offers the largest hammermill on the market, our ED-4460-TF hammermill with 7200 sq. in. of screen area. With the ability to provide a wide range of mill sizes, tip speeds and drive power, Bliss can more than meet your requirements for high quality at a reasonable cost.

AMANDUS KAHL

The KAHL Pan Fiberizer provides optimum crushing and grinding of wet wood chips and torrified biomass. This grinding process is appropriate for wet raw and dry torrified material, and is an excellent alternative to a traditional hammer mill. The system does not require an aspiration system, nor explosion suppression, bagging houses or cyclones. There are no noise protection measures needed, the mill is smooth running in a very silent operation.

The Fiberizer is extremely cost effective due to the fact, that it uses shear force to grind and cut the fiber instead of the high speed - high impact principle applied in traditional hammer mills. Thus the energy required and the wear costs are less in comparison with old style hammer mills.

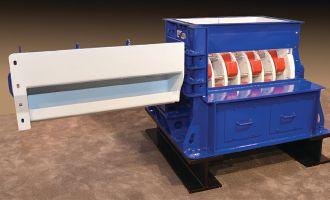

SCHUTTE-BUFFALO

The Schutte-Buffalo Hammermill Series 15 Hammer Mill is the most efficient, high production fine grinder of its kind. Built specifically for the wood waste market it can process chips, shavings, bark, hogged scrap and other materials to the exact finished particle size required for downstream processing. With over 80 years of experience, Schutte-Buffalo Hammermill has built more fine grinding hammer mills for processing wood than any other hammer mill manufacturer.

WEST SALEM MACHINERY

High speed, high volume hammermills with 20,000 fpm hammer tip speed for high capacity grinding to a small particle size. Features a large diameter hammer circle and throat widths from 20” to 60”. These rugged mills have near full circle sizing screens to maximize production and deliver a consistent end product.

For more information about the newest hammermills available for the Canadian wood pellet industry, as well as other new innovations for wood pellet production, visit canadianbiomassmagazine.ca.

Bioenergy expansion

UNBC continues to expand its bioenergy capacity

By Andrew Macklin

CanaDa’s

green university continues to demonstrate its commitment to bioenergy technology as it has completed the next phase of its expansion project.

The University of Northern British Columbia in Prince George began the integration of bioenergy into the campus’ energy system with the introduction of a pellet boiler to provide heat for its Enhanced Forestry Lab and greenhouse facility before investing in a $16.7 million Nexterra gasification system in 2012. The Nexterra system has replaced much of the natural gas consumption at the school, saving the university approximately $700,000 per year.

The next phase of the expansion of the bioenergy system involved incorporating

the pellet boiler into the Nexterra gasification system. That involved moving the pellet boiler from beside the Enhanced Forestry Lab to beside the Nexterra system, while also running pipe from the boiler location to the lab to continue serving that building with the necessary heat.

More importantly, the move provided the additional capacity to bring another set of campus building onto the bioenergy system: the campus’ two first-year student residences.

Civil construction to run piping to each of the student residences was down at the same time as moving the pellet boiler. The work began in mid-September; with local contractor IDL Projects Inc. awarded the contract. Specialized piping was brought in from Europe, building on some of the successful construction elements from similar bioenergy systems there.

Moving the boiler and putting the pipe network in the ground now rounds out the bioenergy system, providing the necessary distribution points to meet current demand and provide options for future demand.

“There is pipe in the ground from the bioenergy facility, which runs to the Enhanced Forestry Lab, and then runs to the two residences and the daycare,” said David Claus, assistant director of facilities management at UNBC. “In getting that completed, we’ve got all of the civil construction works and the outdoor work done. We have yet to connect the piping inside each of the buildings, to the heat loads. So we’re not running the system now but we’ve got the ground portion of it completed.”

The delay is the complex design needed for connecting the pipe network to the

The piping network connects the pellet boiler and Nexterra gasification system with the first-year residences and the daycare.

Your global equipment supplier for the biomass industry

existing natural gas heating systems in place in each of the residences. That design is expected to be done shortly, which will allow the work to go out for tender. The hope is that the work can be done in the spring, but renovations planned for each of the residences following this school year could delay the work until the summer.

FUTURE EXPANSION

By moving the boiler, and running the pipe network to the residences, the bioenergy system is in a position to facilitate future expansion. Claus admits that there are few buildings to currently expand the network, but it does open up energy supply for expansion opportunities that the campus could be considering. Two things discussed at length in the university community are the potential for adding upper-year residences, as well as buildings to house food production that could help make the area more self-sustainable.

Claus recognizes that more heat could also be captured through the Nexterra system. The flue gas from the system is not condensed, causing a lot of heat to come off of it. There is energy in the hot water vapour that is not being utilized and, by condensing the flue gas, additional heat can be recovered without burning any more fuel.

“That is what, on the supply side, I would like to see as the next step,” said Claus. “It looks like we could probably boost the output by about 10 per cent by doing that.”

EDUCATION FIRST

There has always been an educational component to the bioenergy system at UNBC. The Nexterra system provided an example of a small-scale biomass heating system that could be used in remote communities throughout northern B.C., and the current expansion will provide information on how to expand the system to surrounding buildings that may need to be brought online.

Now the university is in development of a video series that will help teach remote communities about district heating. Grad student Titi Kunkel is helping to produce the videos while travelling to remote communities, particularly First Nations communities, to provide an understanding of the benefits of district heating using biomass. She has already brought leaders from a few remote First Nations communities to UNBC to show them how the bioenergy system works, and to teach them about how the system could work in their respective communities based on the existing wood waste supply in the area.

The videos, now in production, will be an educational tool for providing an overview of community heat using biomass. Once those videos are released, Kunkel and her colleagues hope that they will be distributed beyond the current campus’ reach in B.C. to interested communities for nationally and internationally.

That will help the university’s continued push as Canada’s green university, and become a model for community bioenergy systems across Canada. •

ANDRITZ is one of the world’s leading suppliers of technologies, systems, and services relating to equipment for the biomass pelleting industry. We offer single machines for the production of solid and liquid biofuel and waste pellets. We have the ability to manufacture and supply each and every key processing machine in the pellet production line.

ANDRITZ Feed & Biofuel A/S Europe, Asia, and South America: andritz-fb@andritz.com USA and Canada: andritz-fb.us@andritz.com

www.andritz.com

The foundation for the pellet boiler next to the Nexterra system. The roof of its former location, at the Enhanced Forestry Lab, can be seen in the background.

MARTIN CONVEYOR SYSTEM REDUCES WEAR

Martin Engineering has introduced two conveyor system components designed to mitigate expensive spillage and belt wear issues at material transfer points. The EVO Slider Cradle and the Martin Slider Cradle both support the belt and prevent spillage due to belt edge sag. Located under the skirt board in the chute box after the impact cradle, the units utilize “double-life” slider bars, which offer a superior seal with low friction. The result is a flat and stable belt surface throughout the settling zone, reducing fugitive material and extending belt health. The Martin Engineering slider cradles are designed for conveyor systems

with speeds up to 700 fpm (3.5 m/sec) and belts lengths of more than 50 feet (15.2 m). Typically 48 inches (1220 mm) long, the units are also available in custom sizes for special applications. The belt glides over low friction 62 durometer (shore D) UHMW polyethylene sidebars featuring the company’s unique “box” design and low drive-power consumption. They display minimal heat buildup during operation and can handle service temperatures of -20° to 140°F (-29° to 60°C). The shape allows operators to turn the bars over for a second service life without disassembly of cradle components. Manufactured to accommodate belt width sizes of 36 inches (915 mm) for single bar models and 42-60 inches (1066-1524 mm) for double bar designs, operators simply pull the cradle away from the frame to perform maintenance on idlers and sidebars. It can be ordered to suit any CEMA standard trough angle.

NETT TECH VERIFIED BY EPA

Nett Technologies Inc. of Mississauga, Ont. has received verification of its BlueMAX PLUS 100 SCR system by the U.S. Environmental Protection Agency (EPA). The BlueMAX PLUS 100 SCR