High hopes for new trout disease vaccine in Scotland

BY MARI-LEN DE GUZMAN

BY MARI-LEN DE GUZMAN

Meaningful progress in operational efficiencies and technologies in the hatchery sector have contributed significantly to the overall growth of the aquaculture industry. Here’s a look at how far it has come.

BY MATT JONES, COLIN LEY AND MARI-LEN DE GUZMAN

As Hatchery International celebrates 20 years of covering the aquaculture industry’s hatchery sector, we look back to the last couple of decades to examine the developments and progress that have transpired in hatchery operations around the world, and the impact they have made in the global aquaculture industry. We speak to industry veterans and

New project to increase aquaculture of low-trophic species

experts for their views on how far this industry has come.

No doubt, one of the most transformative developments in hatcheries have to do with advancements in recirculating aquaculture systems (RAS). This technology is not new to hatchery operators. In fact, the

on page 14

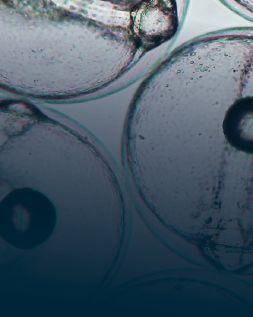

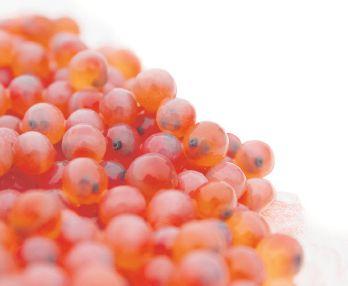

Aconsortium of fish farmers and aquaculture research organizations in Scotland have teamed up to develop a commercial vaccine for rainbow trout fry syndrome (RTFS), a pervasive disease among trout.

The initiative is spearheaded by UK’s largest rainbow trout producer, Dawnfresh, and the University of Stirling’s Institute of Aquaculture. Scottish trout farmer Kames Fish Farming, and aquaculture research firm Tethys Aquaculture are also part of the project, with funding from the Scottish Aquaculture Innovation Centre (SAIC).

The group will conduct field trials of the new vaccine in a bid to secure the necessary licence for commercial use. The vaccine was developed by the University of Stirling as part of a five-year European Commission-funded project called ‘Targetfish’.

RTFS has been a major problem for the rainbow trout industry, according to Dr. Rowena Hoare of the University of Stirling’s Institute of Aquaculture. “We are delighted that this project has been funded by SAIC, enabling our novel RTFS vaccine to be tested on two fish farm sites. We hope in the future to combine this with other vaccines to assist in the sustainability of the trout industry.”

BY MARI-LEN DE GUZMAN

A new international project to increase aquaculture production of low-trophic species has launched in Tromsø, Norway, with more than 70 scientists and industry professionals from 16 countries in attendance during the inaugural event, Nofima has announced.

Funded by the European Union’s Horizon 2020 program, the AquaVitae research and innovation project will be conducted over the next four years and will focus on increasing production of low-trophic species in and around the Atlantic Ocean through sustainable means.

The project consortium consists of 36 partners, from 16 countries across four continents. In addition to Europe, partners are situated in countries bordering the Atlantic Ocean, including Brazil, South Africa, Namibia, as well as in North America.

RTFS is a common disease in trout and has been responsible for substantial loss of stocks, with some sites reporting high average early-stage mortality rates. Rainbow trout is the second most-produced finfish by volume on UK fish farms, making RTFS a particularly important issue on British shores.

continued on page 11

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

You take pride in your operations and the health of every fish matters. Infectious Hematopoietic necrosis (IHN) is highly dangerous and unpredictable and now, more than ever, it is imperative that your fish stocks are protected. With one small dose of Apex-IHN you can help protect your fish against this deadly disease by stopping it before it starts.

Editor Mari-Len De Guzman, mdeguzman@annexbusinessmedia.com

Associate Editor Jean Ko Din, jkodin@annexbusinessmedia.com

Regular Contributors Ruby Gonzalez, Ron Hill, Matt Jones, Nehul Jagdish Kumar, Colin Ley, Liza Mayer, John Mosig, Vladislav Vorotnikov

Advertising Manager Jeremy Thain, jthain@annexbusinessmedia.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Circulation Manager Barbara Adelt, badelt@annexbusinessmedia.com Tel: 416-442-5600 ext. 3546

Production Svetlana Avrutin, savrutin@annexbusinessmedia.com

Group Publisher Todd Humber, thumber@annexbusinessmedia.com

COO Scott Jamieson, sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA

105 Donly Drive South, Simcoe, ON N3Y 4N5

Hatchery International is published six times a year by Annex Business Media

The authority for statements and claims made in Hatchery International is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

A subscription to Hatchery International (six issues) is $37.00 within Canada, $37.00 US within North America and $47.50 US outside North America. To subscribe visit our website at www.hatcheryinternational.com

Subscriptions Angie Potal, apotal@annexbusinessmedia.com Tel: 416-410-5113 • Fax: 416-510-6875 or 416-442-2191

Printed in Canada. Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Hatchery International. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

ISSN 1922-4117

Next Ad Deadline

The advertising deadline for the November/December issue is September 10th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the November/December issue is September 10th. Contact Mari-Len De Guzman at mdeguzman@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

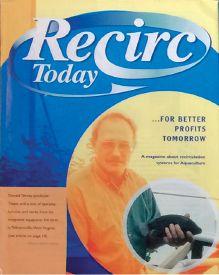

Twenty years ago, Capamara Communications published its very first issue of Recirc Today. Recognizing the potential of recirculating aquaculture systems (RAS) to disrupt the industry, Recirc Today was launched as a resource for readers in the aquaculture industry interested in this emerging technology.

Most RAS applications back then were finding successes in the hatchery sector, offering a more sustainable alternative for rearing fish in the early stage of its lifecycle. It soon became apparent that the magazine’s mandate needed to evolve to respond to market needs, and so the publication transitioned into a broader – but still very niche – publication, Hatchery International.

The importance of hatcheries not only for conservation and enhancement initiatives but also as a foundation for building a stable aquaculture industry was evident.

“Hatchery International was a natural evolution of the company’s aquaculture magazine (then called Northern Aquaculture),” explains Peter Chettleburgh, founder and former publisher of Hatchery International, when asked to comment about the publication’s 20th anniversary. “It was readily apparent that the specialized technology and processes involved in the hatchery sector could best be served by its own publication.

“It was also apparent that the technology was international in nature and the sector could benefit from a global publication that provided information to a cross section of the industry in all parts of the world.”

Creating a publication that serves the hatchery sector was a no-brainer; and making it available to an international audience was necessary. Thanks to an excellent editorial and sales team, Hatchery International has grown into one of the more well-known publications in the industry.

As the industry continues to evolve, so does this publication. Now owned by Annex Business Media, Canada's largest privately-owned, business-to-business publishing company, Hatchery International's commitment to being the primary resource for hatchery professionals means our finger is always on the pulse of the industry. We have contributors from all over the world, keeping us informed of new

BY MARI-LEN DE GUZMAN

More than just a print publication, our mandate is to serve as a resource for hatchery professionals around the world, and we continue to find meaningful ways to engage our audience.

developments in their jurisdictions that will be of interest to our readers.

Our newest magazine supplement is a result of that. Having seen the advancements in RAS technology and the increasing interest in its application beyond hatcheries moved us to launch RAStech – a publication dedicated to RAS developments and deployments across the globe. The team at Hatchery International is also instrumental to the launch of the RAStech Conference and Tradeshow, an event focused primarily on RAS.

Hatchery International is more than just a print publication. Our mandate is to serve as the information source for hatchery professionals around the world, and we continue to find meaningful ways to engage our audience. Our team is constantly brainstorming ways to bring relevant content to you, through a variety of platforms: print, digital, social media, events, just to name a few.

Like this publication, the hatchery sector has come a long way but it still has far to go to reach its full potential of contributing to the aquaculture industry’s ultimate goal of sustainable seafood production. Count on Hatchery International to be there every step of the way as the evolution continues.

Have you got a story tip or a hatchery operation with a great story to tell? Send me an email at mdeguzman@annexbusinessmedia.com.

“Christmas Tree Bill” gives Oregon hatchery another year to secure funding

The 70-year-old Leaburg Fish Hatchery on the McKenzie River in Oregon, U.S.A., was set to close on July 1st, when funding for the hatchery was not included in the state’s budget, but efforts from the community have given this hatchery a new lease on life.

After passionate efforts by the public and local politicians, the hatchery has been given a reprieve through an end-of-session “Christmas Tree Bill,” which provided $1.3 million to hatchery operations. This will effectively provide the hatchery another year to operate and to locate additional operating funds for the future.

Hatchery coordinator Ryan Couture said there was not much hope that the funding would be approved. However, the hatchery received loud support from the public, which he feels made a difference. Protests were held at the state capital, where members of the public spoke of how the hatchery provides fishing and educational opportunities.

“And it wasn’t just anglers associations,” said Couture. “We heard from those folks certainly, but it was also local folks and elementary school kids and other folks just from the local community that sent the message to the capital about the importance of the facility.”

One of the proposals to save the hatchery was to convert it into a state park. Proposed by Rep. Cedric Hayden, this idea would have allowed the hatchery to draw operating funds from state lottery income. Hayden described that proposal as a “last-minute Hail Mary,” and while it was not adopted by the end of this legislative session, it is one of the possible options that could be explored to fund the hatchery in the future.

“I do plan on meeting with the Department of Fish and Wildlife and the State Parks and Rec about that concept going forward,” said Hayden. “Maybe we’ll have something in a year or so on that conversation.”

– Matt Jones

The construction of the $1 million Jack Brooks Hatchery on the Charters River in British Columbia continues, with the main structure expected to be completed by press time. The hatchery is a result of a partnership between the Sooke Salmon Enhancement Society and the Juan De Fuca Salmon.

“We’re just in the process of pouring our last piece of the concrete slab,” said lead volunteer Wally Vowles. “We’ve had to plant six tanks in the ground before we could pour our last bit of concrete. The boys will be finished with the concrete slab now and I think probably 85 per cent of the plumbing for the hatchery itself is in place. The roof is on, the framing is done, we’ve got a membrane on the roof. It’s coming along well, we’re ahead of schedule.”

Significant numbers of fish were found dead in Coquitlam, B.C., including roughly half the 5,000 coho fry at the Hoy Creek Hatchery. A pollutant in the river is suspected but specific testing in late May has been inconclusive.

“I was devastated by what I saw,” said Hoy Scott Watershed Society president Robbin Whachell. “You’re used to seeing the odd fish dead, or maybe there’s, you know, a fungal situation happening but to see what looked like, at the time, 80 per cent of our fish floating or at the bottom of the trough, I was gutted.”

The losses at the hatchery were discovered after residents reported seeing dead lamprey, crawfish, trout and coho in the waters in the area. Whachell said she could smell and taste a chemical in the air, similar to bleach or ammonia.

“We do have one in-flow area north of the creek that has been a spot where we’ve seen contaminants enter the stream and the hatchery manager said the smell of ammonia around that area was quite high.”

Whachell said the city was unable to perform a water test in that area until 24 hours after residents had reported dead fish in the creek. The results were inconclusive. Fisheries and Oceans Canada received a report on the incident and referred it to Environment and Climate Change Canada (ECCC). A spokesperson for ECCC said they monitored the situation at the hatchery and recovered the mortalities, but the source of the pollutant could not be identified.

Whachell suspects the cause was someone improperly disposing of chemicals and hopes that an education campaign can be undertaken. Long-term impacts on the hatchery’s operations will be gauged going forward.

is complete, and the facility is on track to be ready for when chinook salmon make their way through the Sooke River in September.

Vowles said the hatchery needs to be up and running by September, when the chinook will be coming up the Sooke River. The aim is to have tanks ready by that time to hold adults and then the incubation room ready when it’s time to take eggs.

There are only a few minor challenges remaining, Vowles said, including meeting a new B.C. provincial regulation on returning water to a stream or river, limiting parts per million of phosphorus. There are several potential ways to meet that regulation, including filtration or settling ponds, but the exact path forward has not yet been chosen.

There was some minor drama in May, when a Stop Work Order was issued because a building permit had not been issued due to missing documentation. Though the issue was quickly cleared up and the Stop Work Order lifted only a few days later, things became heated enough that Vowles himself briefly resigned from the project.

“I don’t like to say too much about it,” said Vowles. “It was an unfortunate incident, but it got taken care of and we never really did stop work. It carried on.”

–

Get it together.

As the primary external input into recirculating aquaculture systems, feed is essential to get right because we’re not only feeding the fish, but also feeding the system. It is well-known that RAS need high performance feeds in terms of physical and nutritional quality, to help the fish grow faster and healthier and to maintain the water quality in the system. The use of ingredients with high digestibility maximise nutrient utilisation for fish growth and minimise nutrient loss, while the use of patented ingredients in Skretting RAS feed ensure that the output is just as good as the input.

Read more at www.skretting.com and contact your local sales representative for more information.

The Russian government has allocated Rub800 million (US$12 million) to modernize three hatcheries in the Republic of Buryatia in an effort to enhance the ecological campaign in Lake Baikal.

Since the beginning of 2019, the state-owned hatcheries in the region have released 450 million units of fry in Baikal, 4.5 times higher compared to the same period of the previous year and eight times higher compared to the entire 2016 year, said Dmitry Grudinin, director of the Baikal branch of Gralvrybvod, the government agency authorized to run state-owned hatcheries.

There were some big changes in the production process, Grudinin said. In the past, employees had to catch fish with their own hand. Today, new equipment has made the breeding process much more automated.

Alexey Tsidenov, governor of Buryatia, said the money was allocated under the national program called, Ecology, aimed at restoring fish species population in the

regions where the environment was negatively affected by anthropic activity. Tsidenov said the modernization of the three hatcheries – Bolsherechensky, Selengvinsky and Gusinoozersky – was ordered by Russian President Vladimir Putin.

As soon as the modernization is completed, these hatcheries would be able to release up to 1.5 billion units of fry per year, all in Lake Baikal, Tsidenov stressed. In addition, the hatcheries are mandated to grow 1.5 million fingerlings of Omul (Coregonus migratorius) and 1.5 million units of sturgeon (Acipenseridae), he added.

The need to protect Lake Baikal is associated with poor ecological conditions of the lake. Over the past few years, around 800,000 tonnes of garbage end up in the lake every year, not including wastewater and petrochemicals, dramatically reducing the population of some fish species in the lake.

By Vladislav Vorotnikov

I

n an effort to provide more fish seed varieties to fish farmers and aquaculturists, India’s Marine Products Export Development Authority (MPEDA) has started the sale of silver pompano seeds from its Multispecies Aquaculture Complex in Vallarpadam, based in Kochi, Kerala state.

Central government fisheries secretary Rajni Sekhri Sibal said the sale will help farmers fetch a good price for their produce. The seeds have been developed by MPEDA, with the help of its research wing, Rajiv Gandhi Centre for Aquaculture (RGCA). State fisheries can adopt the technology from MPEDARGCA and set up similar facilities to cater to the needs of the aquaculture farmers.

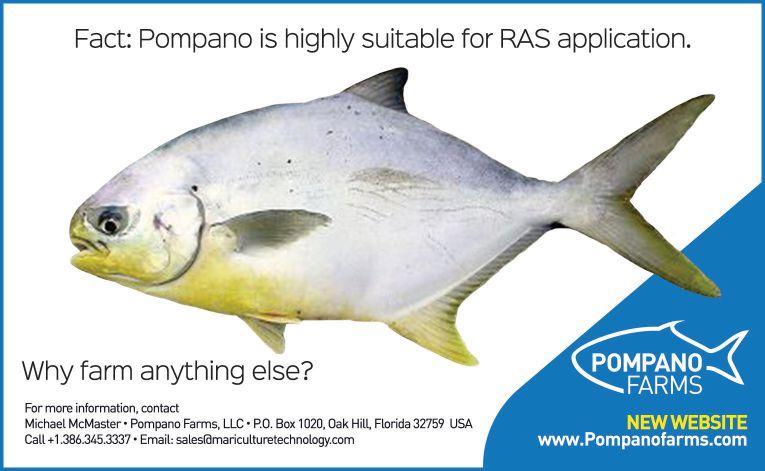

According to MPEDA, Pompano (Trichinotus blochii) is highly suitable for farming. It is commonly found in the Indo-Pacific region and have been very popular in the Indian aquaculture sector. A cultured pompano ranges from 250 grams up to one kilogram. The fish grows up to 350 to 400 grams within six months in ideal climate conditions, with a production cost not exceeding $2 per kilogram. Pompano is widely cultured in the U.S., China, Taiwan, Malaysia, Indonesia, India, Vietnam and the Philippines. It is an alternative species for low salinity (5 to 35 ppt) shrimp culture.

MPEDA is not the only one that mastered the seeding process, according to Kochi-based Central Marine Fisheries Research Institute (CMFRI) director A. Gopalakrishnan. In 2017, he claimed the institute has been successful in the mass-scale seed production of Indian pompano. The technology was developed at the CMFRI’s Visakhapatnam Regional Centre after two years of research.

CMFRI has already developed seed production technology for cobia, silver pompano, orange spotted grouper and pink ear emperor.

By 2050, India should produce at least 10.5 million tonnes of marine fish to meet the growing seafood demand.

The Vallarpadam complex was inaugurated by then Indian Commerce and Industry minister Suresh Prabhu in December 2018. The center has achieved a turnover of US$150,000 in 100 days by selling seeds of GIFT (genetically improved farmed tilapia), seabass and black tiger shrimp.

Nehul Jagdish Kumar

With a view to revive black tiger shrimp farming, the Marine Products Export Development Authority (MPEDA) has supplied 100,000 seeds to farmers in Kerala, India.

These seeds are supplied from high-health black tiger shrimp seeds from its new Multi-species Aquaculture Complex (MAC) at Vallarpadam.

While handing over the seeds to farmers, MPEDA chairman K. S. Srinivas said that “during the past decade, we have learnt a lesson on relying on only one variety. Black tiger shrimps were very popular until 2009, but after, we started experiencing huge problems in getting seeds, so farmers shifted to exotic Vannamei species.”

Today, farmers are relying on Vannamei species, which is not good for the sector and the revival of black tiger shrimp will solve this problem, Srinivas stressed.

According to media reports, major Vannamei-producing countries, such as Thailand, Vietnam and China, have been facing serious shrimp disease problems during the past five years.

Taking a cue from that, MPEDA has decided to encourage and expand the production of black tiger shrimp endemic to South Asia. Production of black tiger shrimp can support the shrimp exports much more in the long run, Srinivas said.

Srinivas also said that the black tiger shrimps supplied from the nine-acre MAC have been showing excellent performance in various parts of the state.

Hormis Tharakan, a progressive shrimp farmer and former director general of police in Kerala, said the seeds showed very good performance during the three months of culture period. "Within 90 days of farming, I got 260 kg out of 10,000 seeds, and I am rearing 90,000 seeds more."

In addition to this, the nine-acre hatchery for black tiger shrimp and six nurseries have also begun supplying fingerlings of other fish species such as GIFT (genetically improved farmed tilapia), Asian seabass, Cobia, Pompano and Mud Crab. Since December 2018, MPEDA supplied a total of over 700,000 fish seeds to farmers in Kerala.

Nehul Jagdish Kumar

Oil and gas producers in the Russian Far East have to stop giving money to hatcheries to breed pelyad (Coregonus peled), since there are no longer any problems with the population of this fish species, said Marat Abrakhmanov, member of the Parliament of the Yamal Nenets Autonomous District, during a parliament meeting.

In 2016, the Russian government obligated all industrial companies in the country engaged in business considered as potentially harmful to the environment to spend money on projects that protect the environment, including restoring fish populations in some regions.

Over the past several years, oil and gas manufacturers in the Russian Far East were providing money to hatcheries to produce pelyad fingerlings, Abrakhmanov said. This is

cheaper compared to breeding whitefish (Coregonus muksun) or Siberian white salmon (Stenodus leucichthys) – the species that are actually endangered, Abrakhmanov added. There is a broad range of fish species considered endangered. In particular, the population of the Russian sturgeon (Acipenser gueldenstaedti) in the Ugra River was around 300,000 back in the 60s, but it has been depleted to only 50,000 units today. The situation is very similar for the whitefish, said Ruslan Romancyuk, director of the ecological control department of the Ugra River.

The regional authorities in Yamal Nenets Autonomous District is negotiating with the industrial companies on the terms of a new agreement that would obligate businesses to breed certain fish species, Abrakhmanov said.

The government agencies warn that these efforts could be in vain. Russian federal agency of fisheries Rosrybolovstvo recently made a statement saying numerous fish species are really endangered in the Russian Far East as well as in the Arctic. All pelyad released by the local hatcheries that received money from oil and gas companies end up in the poachers’ nets, Rosrybolovstvo said.

The only meaningful solution is to introduce a complete ban on fishing in this part of the country, Rosrybolovstvo said. During recent inspections, the local law enforcement agencies found 16,500 units of whitefish and round-nosed whitefish (Coregonus nasus) illegally caught in Far East, which is believed to be an all-time record. This is clearly evidence that poachers expand their operations together with the hatcheries, according to Rosrybolovstvo.

Although the problem of poachers must be addressed, there is a need to build at least one more hatchery in the Yamal Nenets Autonomous District, Abrakhmanov said. This is because the capacity of the Soba Hatchery, which is the biggest one in this part of the country, as well as other hatcheries are clearly not enough to restore fish populations in the local rivers, Abrakhmanov added.

Oil and gas companies were not available for comment, but Russian company Alrosa, one of the biggest diamond producers in the world, said that in June 2019, alone the company released 1.6 million units of whitefish fingerlings in the rivers of the Yakutia Republic. In 2020, the company plans to begin releasing round-nosed whitefish and Russian sturgeon as well, the company added.

– Vladislav Vorotnikov

Fish farms have been among the businesses that were negatively affected by the floods of an unprecedented scale that captured nearly half of the Western Ukraine. The state of emergency has been declared in seven out of 27 regions of the country as 2,000 houses were damaged, 7,000 households affected and there was a blackout in as much as 163 settlements.

This is believed to have been the strongest flood in Ukraine in the past decade, and one of the few that caused human losses. Surprisingly, some local ecologists believe that fish farms are to blame.

This problem traces its roots to the Soviet time, when all households and all collective farms were authorized to establish a lake or a pond on its territory without any special permission, commented Oleg Peregon, spokesperson of the local environmental protection organization Green Front.

Quite predictably they began to interfere with the natural distribution of rivers in the country, Peregon said. Soon enough, some of these water bodies began stagnating and the only reasonable solution was to start breeding fish to clean them up, he explained.

Now, there are hatcheries in the country breeding silver carp (Hypophthalmichthys molitrix) and Chinese carp (Cyprinus carpio) so that the numerous water bodies abandoned since the Soviet times would not turn into swampland completely.

The government gives money to hatcheries to breed those fish species, but this turns out to be a “black hole” since these fish species are not willing to reproduce their population in the local waters, Peregon admitted. It is believed that at some point the authorities would have to

50% lower energy consumption

60% less cleaning

85% less area

The hatching system has eight levels, consisting of two hatching sections in each level and has a capacity of 360,000 eggs and fry.

Delivered with EasyHatch the unique and patented hatching substrate

abandon this project, since the recent floods show that the irrigation system in the country is not getting better.

In addition, there are reports stating that dozens of fish farms were either destroyed or damaged by the recent floods, with fish is found lying on the banks in numerous regions.

In particular, a dam failure resulted in the destruction of the Baltsky Fish Cooperative in Odessa Oblast, with fish ending up at the neighboring fields, said Andrey Dolishuyk, spokesperson for the company. Baltsky has been running its farm for seven years and now “everyone is shocked and have

A complete hatchery with greater capacity, better control and easier handling

no idea what to do” as business is ruined, Dolishuyk added. Hatcheries in Ukraine are generally doing well, commented Petro Kornelyuk, spokesperson of the Dnepr Hatchery. In the past five years the government ordered fish fry to be released in the Dnepr River, which were not happening during the previous 20 years. The floods are a real disaster, and some farms are destroyed, but they should not affect the hatcheries over the long run and should not cause any change in government policy in the area of recreational activities, Kornelyuk added.

– Vladislav Vorotnikov

Peter Chettleburgh, the founder and former publisher of Hatchery International (HI) and Aquaculture North America (ANA), and fellow industry veteran and aquaculture research scientist Cyr Couturier, were honored by the Aquaculture Association of Canada (AAC) at its annual conference for their contributions to the aquaculture industry.

Chettleburgh and Couturier were awarded honorary memberships to the AAC.

Chettleburgh was publisher of HI and ANA from 1985 to 2017. “Peter has flown the flag for Canadian aquaculture publishing, providing fish farmers in the region with Aquaculture North America, and fish hatchery managers in over 90 countries with Hatchery International,” said Joanne Liutkus, outgoing AAC president.

“Sticking closely to the publishing formula that made Peter so successful, both publications are now under the new ownership of Annex Business Media and remain the go-to industry news resources for aquaculture professionals,” Liutkus added.

Chettleburgh traced his start in publishing to AAC. “The farmed salmon industry was growing very quickly in 1984, ‘85, ‘86. It was quite remarkable. So I knew about aquaculture when I got approached to take over the publishing of AAC’s official organ. Life is so often that way; I just happened to be at the right place,” he says. He transformed AAC’s official bulletin into a national industry publication and renamed it Canadian Aquaculture.

continued from cover

“It’s an exciting challenge to bring together industry and research partners from across the length and breadth of the Atlantic to address relevant societal challenges,” said project coordinator Philip James. James is a senior scientist at Nofima – the Norwegian Institute of Food, Fisheries and Aquaculture Research. With a total budget of €8 million (US$8.96 million), this is the second largest EU project ever coordinated by Nofima.

The project’s purpose is to introduce new lowtrophic species, products and processes in marine aquaculture value chains across the Atlantic. The five chosen value chains include macroalgae, Integrated Multi-Trophic Aquaculture (IMTA), echinoderm species (e.g. sea urchins), shellfish and finfish. IMTA is a process that farms several species together, using waste from one species as feed for another.

“The value chains were selected because of their promising contributions to sustainable food and feed production. There is a lot of potential in these value chains and we wish to discover new ways to improve them,” James said.

“I thank the AAC for the beginning of my career. That AAC magazine became Northern Aquaculture from 1991 to 2009, and ultimately Aquaculture North America,” said Chettleburgh.

Chettleburgh was also instrumental in the launch of RASTech, a new international magazine dedicated to recirculating aquaculture systems.

Cyr Couturier, chair of Aquaculture Programs at the Marine Institute of Memorial University of Newfoundland, was fêted by the AAC for becoming a pillar of the organization since its early days. He holds the distinction of being the first ever student elected to the board of AAC in 1990, and for the multiple leadership roles he held over the past 27 years in the association, including as president-elect for four terms.

“Cyr has encouraged and found ways to get as many of his former and current students as possible to attend Aquaculture Canada and make it affordable to them,” Liutkus said.

“Personally, Cyr has been mentor to myself and many students from the Marine Institute at Memorial University. He inspired our continued participation in the AAC. He’s done the same for countless other students since the 1990s. He has been a major supporter and advocate for the success of AAC and students, and his vast array of volunteering speaks to this. We cannot think of anyone else more deserving of this award,” she added.

– Liza Mayer

This correlates with recommendations made in the Food from the Oceans report (2017), which highlighted the need to expand low- and multi-trophic marine aquaculture as an ecologically efficient source of increasing food and feed.

To complete the objectives, 11 case studies will be conducted across the Atlantic, with emphasis on developing new products from low-trophic species (e.g. macroalgae and sea urchins), optimising production in existing industries (e.g. shellfish and finfish) and moving towards zero waste and a circular economy in aquaculture (e.g. IMTA and Biofloc).

Some of the cross-cutting activities involve research into biosensors, Internet of Things (IoT), product characteristics, market potential, sustainability, environmental monitoring, as well as conducting risk assessments, analyses of value chains, studying profitability and the legal framework.

Furthermore, the project will implement a "multiactor" approach to ensure stakeholder involvement in all phases of the project. Industry actors serve as partners in the consortium alongside research institutes and universities, which will also help to establish a durable aquaculture industry and research network around the Atlantic Ocean.

However, the diversity of the bacteria that cause RTFS has made vaccine development challenging, while the very small size at which fish tend to be affected renders injections unsuitable, according to the SAIC.

“Although antibiosis is a treatment option, the industry’s drive to minimise antibiotic usage, reduce losses, and improve welfare required a new approach,” the SAIC said in a statement.

In an effort to find a solution, the University of Stirling developed a dip vaccine for trout which can be administered to fry in a very low-stress and low-risk manner. Proponents are hoping that the vaccine, combined with best farm management practices, will protect the fish until they are large enough to fend off infection themselves.

“We are constantly striving to improve sustainability, health and welfare within the trout farming sector. We believe this vaccine could bring great benefits in these areas, as well as the potential to reduce antibiotic usage even further to some of the lowest levels for all food-producing animals,” said Richard Hopewell, fish health manager at Dawnfresh.

The vaccine, if successful, could be significant for fish well-being and the trout farming industry, according to Polly Douglas, aquaculture innovation manager at SAIC.

“If successful, this vaccine could provide a sustainable foundation for growing trout farming in the UK, unlocking additional capacity for the sector and potentially leading to a significant reduction in cost. It’s another example of how industry and academia can work together to solve some of the biggest problems faced by aquaculture,” Douglas said.

In order to meet the demand for fish, Indian state Jammu and Kashmir (J&K) will be importing rainbow trout seed from Denmark.

With the import, the state will be able to produce fish in just 12 to 14 months, as compared to other varieties of fish that take around 24 months to harvest.

This import will also help J&K meet a target of 5,000 tonnes in the next five years – a far cry from the 500 tonnes it is producing today.

Speaking on this, principal secretary for Animal, Sheep and Fisheries Department Dr. Asghar Hassan Samoon said these imported seeds will be reared up to brood in the facility. They will then be distributed among fish farmers and other hatcheries of the department.

“The state has huge resources of fresh water that is favorable for rainbow trout farming. Looking at this we have decided to tap this. We believe that our fish demand can be met, if we utilize our resources and plan properly,” Samoon said.

The first consignment of 225,000 eyed ova rainbow trout was imported from Billund in Denmark Rever Roheamger, which was implemented successfully for broodstock production in the state.

This will add to the state’s fish production, as the state already has 533 units of trout farms in the private sector, of which there are 59 trout rearing units and hatcheries.

A memorandum of understanding (MoU) was signed by Samoon on behalf of the J&K government with the government of Denmark for the transfer of recirculating aquaculture system (RAS) technology, automatic feeds, and brood equipment for rearing trout for export purposes.

After signing the MoU, Samoon said with the introduction of rainbow trout, he hopes more entrepreneurs will move towards fish farming due to its high returns.

“Our department is also creating awareness in the state and helping youth know the benefits of trout fish farming. Other than this, we will also provide the marketing support to the aspiring entrepreneurs, besides seeds and feed on subsidy, so that they can successfully run fish rearing ventures,” he added.

The state is also investing to develop aquaculture infrastructure in the city and state, under which the department will be spending US$60,000 on proper maintenance of the hatchery.

Nehul Jagdish Kumar

After more than a decade of developing its selective breeding program, one Australian company is now reaping the benefits.

BY JOHN MOSIG

MainStream Aquaculture currently produces over 30 per cent of the world’s commercial barramundi (Lates calcarifer) seedstock, including exclusive supply to seven of the world’s 10 largest producers. The company’s intensive R&D program has been significant in its ability to serve the global market with improved barramundi fingerlings. Through a selective breeding program that was developed 12 years ago, on-farm productivity has increased substantially through better growth and survival rates.

MainStream’s flagship hatchery in Wyndham, Australia, can produce three million fry per month. Capacity was increased to six million per month in 2018 with the addition of another four broodstock systems and a large-scale larval room. MainStream is currently developing a third satellite hatchery to complement its R&D hatchery, which is located in Townsville, Australia.

Following multiple generations of successful selective breeding, MainStream embarked on a partnership with leading farms throughout the industry to accelerate its breeding program and to customise fingerling production for selected farming environments.

As chief scientist Dr. Paul Harrison explained, “We’re part of the CRC-Project (Cooperative Research Centre) Rapid iteration selective breeding: Australia’s ‘fish to feed the world’ – which is partnered with Sealord, Pejo Enterprises, Marine Produce Australia and Barramundi Asia. By accessing the knowledge from our breeding program, broodstock pairs can be identified to produce the next generation of offspring that are best suited for specific grow-out environments. Each grow-out environment is unique and all are influenced by a range of environmental factors, such as the level of salinity, water temperature and even tidal flows. Through genotype by environment experiments and data analysis, we will be able to select fingerlings that are going to be the most robust in a particular environment.”

The on-going nature of the selection program at Maintream is a clear demonstration of the amount of resources they’ve been prepared to invest.

“It’s not good enough just to have an individually good fish,” says Harrison. “It’s the parental combination and family that’s important. What we’ve actually achieved over the last twelve years is a marked improvement in the performance of commercial cohorts, predominantly by identifying which parents contribute to poor growing fish and removing them from the breeding population.”

In addition, the MainStream team is also trying to identify broodstock families that outperform the mean and are superior for traits such as fast growth, Harrison explains. “We have really good evidence that we’ve developed a truly domesticated genotype, far removed from the wild fish. The larger, more sophisticated farms around the world are starting to pick up the benefits from these selectively improved, calmer, genetically fit offspring. We have a lot of repeat business because of the performance attributes of our fish.”

While growth rates are a base measure of genetic improvement, Harrison points out that the economic gains went deeper than that.

“The quality fish we produce has increased dramatically. They demonstrate much narrower bell curves, which is commercially more valuable than outright increases in growth rates because we are interested in the performance of the entire cohort. Now our production cycles are more predictable with a tighter size range. Grading is a cost bearing operation on the business and this has also been minimized.”

That said, growth rate improvements are in the order of 30 to 35 per cent and the MainStream lines of seedstock consistently produce the deep, thick-bodied fish favoured by the market.

Having reached this level of genetic sophistication, MainStream is now in a position to adapt lines even more sharply focused on individual situations; particularly around disease resistance.

“That’s actually the biggest challenge in other parts of the world, especially in Asia. Here in Australia we don’t tend to have the same level of disease challenges. Our increased production capacity has enabled us to dedicate a stream of research strands to breeding a robust fish tailored to counter specific diseases and environmental issues confronting different customers.”

Production, beginning in the hatchery to the final phases of grow-out follows three main stages. After 50 days the fry are 0.5 grams and leave the hatchery for the nursey tanks where they spend approximately six weeks growing to 20 grams. Grading is conducted weekly at this stage, to minimize any size variation between groups and to control the natural tendency of barramundi to cannibalize.

From there, the cohort is transferred to the first grow-out stage in 80,000-litre tanks and grown to 100 grams, for approximately eight weeks. Their final move is to 600,000-litre tanks where they are grown to between 700 and 800 grams. Batches are closely monitored for superior performance.

Research and development officer, Dr. Shannon Loughnan is part of the team on the CRC-Project. “Now that we are able to employ the latest technology in genetic mark-

ers, we can perform a more sophisticated level of genomic selection and target traits with a higher level of resolution. In addition, our focus is to control inbreeding levels and maintain genetic diversity through the relationships of broodstock.”

This has also helped them maintain commercial balance within the aims of the CRC project. “In addition, climate change is an important factor that can influence the culture of barramundi, due to the impacts on pH, water temperature and salinity. By investigating genotype by environment interactions, the CRC-Project will provide a lot of development in this area,” Loughnan says.

“The single nucleotide polymorphism (SNP) marker panel developed for the CRC-Project will be an important tool in the acceleration of the breeding program and to develop superior seedstock for the industry,”

Mainstream’s breeding program is ahead of its time.

The sophistication of the program is on par with the best programs being applied on developed species like salmon and tilapia, and there is now enormous opportunity worldwide for expansion of the barramundi industry. At market, barramundi fills a much-needed gap in the premium white fish category and the ability to grow this fish worldwide is being fuelled by a highly reliable supply of domesticated stock selectively bred for optimised productivity across environments that include fresh, salt and brackish waters. By embarking on a bold, long-term investment strategy in research and development, MainStream Aquaculture has been able to significantly increase the production capability of barramundi and, in doing so, has been instrumental in taking the species to a new level globally.

For further information, contact Dr. Paul Harrison at paul@mainaqua.com.au

Since 1958, Faivre has been developing and manufacturing high quality equipments for the aquaculture industry

technology has been deployed in hatcheries as far back as the 1980s.

“The emergence of recirculating systems, as a practical and functional (alternative) – it really impressed me rather than surprised me,” says John Nickum, an aquaculture industry veteran. “The emergence of recirculating systems and the idea of having land-based salmon, in particular, and landbased saltwater systems is one of the things that changed markedly in the last 20 years.

Now retired and living in Arizona, U.S.A., Nickum was actively involved in the aquaculture industry for more than 40 years. For 10 years, he was the national-international fish health and aquaculture coordinator for the U.S. Fish and Wildlife Services of the Department of the Interior in Washington, D.C.

Through the years, Nickum has seen a lot of changes in the aquaculture industry, but one particular thing he feels has not changed is the misinformation that fish farms are introducing diseases to the wild population.

“It’s interesting that that claim still goes on,” Nickum says. “The people that are opposed to fish farming in the commons basically will weed as many arguments as they can. That kind of opposition is still going on today.”

Mark Hambrook, manager of Canada’s oldest salmon hatchery, the Miramichi Salmon Conservation Centre in New Brunswick, Canada, has seen many changes in hatchery operations first hand, as the centre changed from being part of a network of federally funded hatcheries to a private hatchery operated by the local community.

The biggest single change during that time in his view:

the use of oxygen and venting carbon dioxide.

“You can do so much more,” says Hambrook. “It can be a little bit pricey but in the overall operation, it doesn’t cost hardly anything. That made a big change – you can use less water and recirculate. If you didn’t supplement with oxygen, you couldn’t do any of that.”

Feed advancements are a close second. Hambrook notes that years ago, there was only one shipment of food a year that came from the United States via rail car. The feeds were then distributed to all the hatcheries in their network.

“The food was crap,” recalls Hambrook. “Hexamita issues and poor nutrition would manifest themselves in unfit fish and fish that are susceptible to disease.

"Having good food eliminates a lot of your problems. Good water quality, good food. You don’t have near the issues today as we used to have.”

Hambrook also notes that with advances in technology, hatchery staff must receive more specialized training in order to effectively utilize these state-of-the-art equipment.

On the shellfish side, Don “Mutt” Merrit has been working in oyster hatcheries in the U.S. since 1973, and has been a fixture at the University of Maryland’s Horn Point Oyster Hatchery for many years.

In Merrit’s view, one of the difficult things about looking at oyster hatcheries from an overall perspective is how varied the conditions are at hatcheries for different species and different sites.

But technological advances have made a huge impact on the industry, he points out. At Horn Point hatchery, in particular, Merrit says they have developed an algae feeding

system that has been a huge benefit to production.

Automation and remote management technologies and equipment have also benefited the wider industry, Merrit says, allowing operators to control and manage production more efficiently.

“When you’re doing something like oysters, which thrive in an estuary that is constantly changing, being able to negate the major swings in water quality, temperature and salinity really has helped,” says Merrit. “Filtration, sterilization techniques – we use ozone to sterilize water, we use a variety of filters. Most of that stuff was not around 20 years ago, or if it was it was in its infancy.”

Changes in breeding, genetics, technology and control over environmental parameters have been the most significant developments in the hatchery sector over the last two decades, says Neil Manchester, managing director of Hendrix Genetics Aquaculture, based in the Netherlands.

“We’ve become much more consistent producers of eggs, fry and smolts than was previously possible when we were having to cope with so much more variability of water temperatures, quality and so on,” he says.

“This is thanks largely to the development of modern RAS systems which are so much more reliable today than when they first appeared. It has only been in the last five to six years, in fact, that RAS has gained such reliability, but it’s here now and will continue to grow and develop.”

Looking back to the late 1990s, when he was part of the senior management team at Landcatch, the pioneering Scottish salmon breeding unit which was taken over by Hendrix in 2011, Manchester is still proud of the industry-

leading quality of what the unit has achieved, especially without the technology that exists today.

“Automation developments, such as they apply to pumping, grading and vaccinating, for example, have allowed us all to create modern welfare-friendly systems that are highly efficient and cost-effective,” he says. “They’ve also freed the many excellent stockmen and women in our industry to concentrate on the fish under their care, rather than the workload and processes which used to dominate their time.”

Manchester is also encouraged that the salmon sector’s hatchery advances of the past 20 years are now being taken on and customized for other species.

“This could be the next quantum leap,” he notes. “The big difference this time is that while salmon hatcheries took fully two decades to work through their changes, new species will be able to do the same in no more than two to three years, thanks to our developmental experience.”

RISE OF RAS

It’s the productive scale of the hatchery sector that has changed most over the last 20 years, according to Ove Martin Grøntvedt, who spent his entire working life in fish farming and whose family was among the earlier pioneers of the industry in Norway.

“We started out with hatcheries producing 200,000 smolts, then 500,000 and then, by around (the year) 2000, we were up to five million,” he said. “There are now plenty of sites producing 20 million, of course, and the good news is that they’re doing it with less water intake than the old 2-million units needed.”

Currently working as a fish health specialist with Salmar, one of the world’s largest farmed salmon producers, Grøntvedt believes the big game-changer was the development of good recirculation systems.

“RAS has given us control over water quality in a way

that wasn’t possible 20 years ago,” he says. “As a result, it’s become far easier to produce a smolt than it used to be. We know exactly when to start feeding and also when to grade and vaccinate.

“There’s also been a big change in terms of planned delivery dates. We used to know the month when smolt delivery would be possible while now we can almost set an individual delivery day.”

Like Grøntvedt, industry sources interviewed for this article agree that improvements in RAS technologies over the years have opened up significant opportunities for the various sectors of aquaculture. The ability to control the rearing environments for fish and other species, and the sustainability promise of re-using resources have made RAS virtually a catalyst for advancements in the industry.

Hatchery International also traces its roots to the developments happening in RAS in the late 1990s. Under its original name, Recirc Today, the publication’s founder Peter Chettleburgh saw an emerging market then and decided to launch a new resource to cover developments in this up-and-coming technology that promises improved efficiencies for hatchery operations.

Recirc Today evolved into today’s primary resource for hatcheries around the world - Hatchery International.

“Hatchery International was a natural evolution of the company's aquaculture magazine (then called Northern Aquaculture). It was readily apparent that the specialized technology and processes involved in the hatchery sector could best be served by its own publication," Chettleburgh says.

"The industry has come a long way in the last 30 years, but it’s got a long way to go before it can be characterized as a truly mature industry."

Founded in 1971, the Institute of Aquaculture at the University of Stirling in Scotland is the largest of its kind in the world, providing highquality research and technology development for the industry.

Asked for his take on the hatchery sector ’s biggest changes over the last 20 years, Alastair McPhee, aquaculture facility manager at the Institute, summarized his views in the following seven-point list:

Use of controlled temperature water to give predictable results for ova to hatch

Use of dedicated broodstock facilities to focus on disease -free and healthy ova production

Widespread use of genetic traits for resistance to disease/growth or other parameters

Move to more compact systems that allow many more ova to be hatched in a smaller area

Overall control of the lifecycle from egg to har vest, or from broodstock to har vest. Improvements in the nutrition of all stages of development, with targeted diets for certain lifecycle stages

The almost year-round availability of ova, which in turn allows the year-round supply of fish for har vest cycles

BY LIZA MAYER

Shellfish growers remember 2007 for the death of millions of oyster larvae in the Pacific Northwest. For the global industry at large, the year is remarkable because it shone a light on how climate change could devastate coastal economies.

In the U.S., Whiskey Creek Shellfish Hatchery on Netarts Bay in Oregon saw its oyster seed die en masse that year. Die-offs were also seen at Taylor Shellfish hatcheries in Washington State. Wild oyster larvae in Willapa Bay perished, too. It took a collaboration among shellfish growers in the region and scientists to uncover the culprit: ocean acidification. To this day, the uptick of carbon dioxide from the atmosphere remains a concern. The impact of 2007 is still palpable.

“That crisis was what put ocean acidification and oysters on the front page,” recalls Dr. John Supan, co-owner of Navy Cove Oyster Co LLC in Ft Morgan, Alabama. Efforts to find answers influenced adaptation and mitigation strategies in hatcheries. Growers became more aware of the quality of the water in their farms. The crisis was also noteworthy because it convinced many that global warming, called by some as the “evil twin” of ocean acidification, is real and growing.

Supan believes, as do other experts interviewed for this report, that the world’s most precious resource, its quality and availability, will continue to guide aquaculture development over the next 20 years.

“Nine times out of 10, your problem at hatcheries is water chemistry,” says Supan, the former director of the Louisiana Sea Grant Oyster Research Lab. “I think the days of straight flow-through hatcheries are very, very limited. And we know certainly that with climate change, it’s going to get worse instead of better.”

Mallet, hatchery manager at L’Étang Ruisseau Bar in Shippagan, New Brunswick, Canada, also anticipates the trend will continue. “So we’ll have to deal with that, whether it’s at the level of hatchery operations, like remediating or testing our water, or treating our water; or whether it’s at the breeding level in terms of selecting strains or lineages that have better tolerance, assuming or hoping that such genetic variation actually exists within the species.”

As an industry consultant, water quality is top of mind for Supan. “When I design a hatchery now, I reflect on coastal water quality being very unpredictable, especially

salinity, depending of course on the site. But water quality is always going to be an issue. I prefer to design a hatchery where you calculate what your daily water needs are going to be, and you store it first so you can ‘polish’ it for 24 hours by dosing it for the proper pH, proper alkalinity and proper hardness. So instead of a single pass and then water going into the larval rearing and algal rearing rooms, you polish it for 24 hours before sending it to your tertiary.”

Mallet says one offshoot of the earth’s warming waters would probably be beneficial at first for shellfish growers in colder climes like Atlantic Canada. But he’s concerned about its long-term effects.

He explains: “For a place like where we are, where we’re at the northern range limit for the oysters, there’s some diseases we just don’t have here. While in the short term we’re probably going to see better growth as the water warms up, we’re also probably going to see some new diseases that we didn’t have before. So emerging diseases and invasive species – I think those are going to be an important and concerning ‘collateral effect’ of warming.”

He believes climate change and its impact on water quality will be decisive in breeding innovations. “A stated goal of many shellfish breeding programs is to provide seeds that are more resistant and more robust. If you look at the main drivers for a lot of the shellfish breeding programs, it’s not necessarily optimizing growth that’s the first goal. Often, these breeding programs are in response to some kind of crisis, whether it’s oyster herpes virus in Europe and now in Australia and New Zealand, or MSX on the eastern seaboard. A lot of the time, mortality events like these have been the driver. So producing robust seed I think is really a key component. But these programs are almost all still in their infancy; they’re less than 10 generations in. So it’s in the next 20 years or so that we’re really going to see the benefits of that work.”

Research work at the University of Wisconsin-Stevens Point (UWSP) provides another example of how the ocean’s changing chemistry is driving breeding innovations. Researchers at the university are advancing the technology of rearing walleye and hybrid walleye intensively for both food and stocking purposes.

“Walleyes are a mainstay in North America and certainly in the Midwest, but the wild populations are being

A bigger fish and a much shorter cycle in seawater is perhaps the most sustainable way and most economical way of farming. – Frode Mathisen, director of freshw

pushed further and further north. As this is making it harder to gather them from wild sources, we’re seeing openings for aquaculture to come in and potentially fill that gap,” says Gregory Fischer, assistant director/research program manager at UWSP’s Northern Aquaculture Demonstration Facility.

Fischer notes that more stringent regulations are an offshoot of concerns for water quality and wastewater discharges into the environment. These rules are prompting the industry to move indoors, he says.

“Increased concern over water and water quality, not necessarily just from aquaculture but also other water-intensive industries, is prompting tighter regulations around the country,” says Fischer.

“We just can’t do business the way that we used to do in aquaculture,” he continues. “What you saw in the old days, where facilities that did a lot of flow-through would have large amounts of water running through their facilities and they would kind of ‘cure’ the problem of pollution with dilution, that’s not happening anymore. Now, we’re seeing much tighter facilities, more recirculation aquaculture, either partial recirculation or full recirculation, and much smaller discharge streams. Much tighter regulations that are forcing that,” he emphasizes.

The advancement in recirculating aquaculture systems (RAS) is making this move possible, he noted. “More facilities are going indoors with control over their systems, not only environmental control, but also control for pests and fish health issues. I think we’re seeing better systems and better design. And I think we’re also learning more and more how the fish behave in those systems. ”

Frode Mathisen, director of freshwater production at Grieg Seafood BC Ltd, acknowledges that freshwater is the most valuable resource in the world and will remain so in the future.

“The problem we had in Atlantic salmon production before was that even to find water to produce a hundredgram fish was difficult. So when we got RAS, suddenly we had plenty of water. Even in old hatcheries with very little water capacity, that water was still plenty for a RAS system. So RAS made it possible.”

The number of RAS systems being built now will affect the next 20 years in many ways, he added. “We’re in the middle of transition, in a way. Over the last five years the Atlantic salmon sector has basically been where all

the money invested into RAS went. But there are a lot of people that still don’t know what RAS is. For some of us that have now worked with it for quite a long time, we start to feel that RAS is the normal thing to do. That will go on but perhaps it will be used even more in raising other species.”

He says one practice that’s beginning to happen now in Norway and could be more widespread over the next several years is raising smolts longer on land-based facilities before moving them to ocean cages to grow them to market size.

“It has started in Norway, where the government has now increased the size of the fish that can go to sea. Here in B.C. we haven’t gone as far as in Norway but we are

starting to look into it,” says Mathisen.

“A bigger fish and a much shorter cycle in seawater is obviously making the footprint significantly smaller. I would even say that’s actually perhaps the most sustainable way and most economical way of doing it because you’re utilizing RAS efficiency on land for a longer time. You don’t have to do it for the whole cycle. To do RAS the whole way is using a lot of energy and a lot of water.”

He notes however that the adoption of the practice in other salmon farming jurisdictions would need the support of the local regulatory authorities because it changes the typical management plan. “But the industry is always moving much faster than regulators can keep up with. That would be the biggest obstacle.”

The all-new HydroHatch Incubation System from MariSource gives hatcheries increased efficiency. With recirculation, germicidal UV filter and a titanium heat exchanger, the HydroHatch delivers increased survival rate and significantly reduces water consumption.

Features and Benefits:

65 gallon sediment and recirculation tank

Requires only 150 gallons to completely fill the unit and reservoir

High-quality, long-life quartz germicidal UV filter

Complete isolation of eggs

Easily able to increase the dissolved oxygen content of the water

230 volt 30 amp control panel

Insulated titanium heat exchanger

Precise temperature control

Comes standard with four 8-stack incubators

Additional four 8-stack incubator option available

The new HydroHatch Incubation System is ideal for Salmon, Trout, Steelhead, Perch, Channel Cat Fish, Walleye, Eels, Shrimp and Muscles.

BY JOHN MOSIG

EDITOR’S NOTE: John Mosig is the Australian correspondent of Hatchery International and has been writing about the aquaculture industry since the 1990s. We asked John to offer his observations of the developments in the hatchery sector over the last 20 years.

Advances in the hatchery sector over the last 20 years have been significant and have hugely influenced parallel changes in the aquaculture industry overall.

Increased hatchery capacity and reliability have been drivers for farming productivity and profitability, bringing capital and management and marketing sophistication into the industry on a global scale. Always destined to replace the wild catch sector as the primary source of seafood to the planet’s ever-growing population, the changes in hatchery technology and productivity have underwritten the extraordinary year-on-year growth of aquaculture around the world.

The sector’s improvements have fallen into three significant areas, each of them crucial in their own way.

Firstly, there have been huge advancements in recirculation technology, which allowed broodstock to be held in closed conditions that can be manipulated to exploit and expand seedstock output of several serial breeders. One that comes to mind is barramundi (Lates calcarifer). This species' serial breeding biology and high fecundity, under controlled conditions, can produce prodigious numbers of fry.

A 20-kilogram female can spawn 20 million eggs and can be used up to six times a year. While this has always been the case – and hatcheries of 20 years ago exploited the opportunity as the season allowed – it wasn’t until the installation of hi-tech RAS that hatcheries were able to manipulate photoperiod and temperature regimes and began producing seedstock on an industrial scale.

In the case of salmonids, RAS has allowed hatcheries to control the incubation period, which in turn enabled farm stocking over more seasonally ideal timetables.

“With advances in biological understanding, water chemistry management and investment in quantities of scale, the hatchery sector has become the foundation stone upon which the modern aquaculture industry is built."

Incidental to this, hatcheries have used RAS technology in nurseries to grow juveniles to larger smolt sizes. This maximization of genetic potential under 24/7 optimum conditions, has proven to be extremely profitable for hatcheries and allows growers to release a more robust smolt into their grow-out facilities, as well as increase their overall tonnage from the same capital outlay.

Secondly, having greater control over breeding cycles has enabled genetic marking and family-line breeding programs to be developed. This is not inexpensive research, in terms of both funding and time. However, it has been a well-placed investment, resulting in increases in growth, feed conversion efficiency, fillet weights and the narrowing of the bell curve. These hatchery research programs have made a significant impact to the overall growth of the aquaculture industry.

The third major difference a time traveller from the 20th century would notice in the 2019 hatchery environment is the automation and degree of refinement in so many of the operational stages. This has been by degree, but as capital expenditure was justified, the step into the modern world was huge. With decades of experience to draw from, hatcheries that were developed piecemeal over the years have been replaced with ergonomically designed and atmosphere-controlled industrial sites, reliably turning out high quality seedstock in huge numbers.

The changes in the way shellfish seedstock is produced over the last 20 odd years have been nothing short of revolutionary, and has been the driving force behind the growth of that seafood sector. The incorporation of hatchery-based spawning technology has taken the industry from reliance on natural spat settlement – something that is becoming ever more precarious as changing climatic conditions impacted oceanic conditions – to one that can now determine when it stocks its leases, giving them optimum growing conditions; and to stock them with genetically-improved seedstock. These options are giving farmers better growth rates and improved meat weights.

Aquaculture, as the last hunter-gatherer to come in from the cold, has been able to compress a hundred years of intensive terrestrial animal protein production into less than half that time. With advances in biological understanding, water chemistry management and investment in quantities of scale over the last two decades, the hatchery sector has become the foundation stone upon which the modern aquaculture industry is built.

As a footnote, this writer started breeding Murray cod (Maccullochella peelii peelii) and callop (Macquaria ambigua) in a converted shearing shed in 1980, injecting powdered carp pituitary glands as an inducement agent. We caught and extracted the pituitary glands ourselves.

Fish hatcheries and hatchery technology have come a long, long way from there.

BY RUBY GONZALEZ

The South Pacific island of Kiribati was once a milkfish industry capital in the heart of Asia. But with the extreme heat and the lack of rainfall that the island has been facing in the last several years, milkfish ponds have dried up and the increasing salinity of existing ponds are killing the few fish that are left.

The Republic of Kiribati and its Ministry of Fisheries and Marine Resources are relying on Taiwan’s International Cooperation and Development Fund (ICDF) to help revive the island country’s economy.

The Milkfish Aquaculture project, which began in January 2017, has been a promising venture, said ICDF project leader Chih-Chen Chen. The project target of collecting 200 broodstock (sourced from local waters) was completed in March 2019.

Chen said coming up with the number early on is important in keeping them on track for the 2021 target of 2,000,000 fry. As of the same period, 400,000 fry, 10,240 litres of rotifer medium, and 44 tons of milkfish feed had been produced.

The facilities to support the broodstock, hatchery and nursery operations were set up in the capital city of South Tawara. A fishery hub, it is the center of landings by commercial fishery.

Training and documentation of transfer of technology are also integral aspects of the project. Fifteen aquaculture training workshops have been scheduled, including the capacity-building on management of broodstock, breeding, feed and live food.

A manual and handbooks have already been produced and more will follow. These include: the supply and demand, production and marketing of milkfish fry in Kiribati; the management of milkfish broodstock breeding, milkfish fry propagation and live food and feed preparation; the cost-benefit analysis of milkfish farming; the current status of aquaculture species and their value chain in Kiribati; and the feasibility of milkfish cage culture in Tarawa.

The latter will involve building cages for milkfish cage farming.

Although ICDF manages the project, the agency also teaches staff from the Kiribati government the ins and outs of larval rearing.

“Milkfish are back to every island, like in the old days when they are easily found everywhere,” said Chen.

Kiribatis’ history of milkfish farming goes back for centuries, when every island council had a milkfish farm. The ensuing years of marine resource and environmental degradation, and absence of effective management have taken a serious toll on both its wild-caught and farmed fish.

Milkfish farms were known to have an unstable supply

of fry and a lack of adequate facilities to support artificial breeding and food production.

Taiwan has become an important champion for the revival of Kiribati’s milkfish industry.

In 2012, an aquaculture milestone was reached when milkfish broodstock spawned naturally at the Taiwan Ambo Aquaculture Station, the first occurrence of its kind in Kiribati.

The following year milkfish fry was produced through artificial breeding for the first time. This made Kiribati the fourth country in the world to have accomplished this feat. The other states are Taiwan, the Philippines and Indonesia. This was the time when the island’s milkfish aquaculture industry was restarted.

Kiribati waited for such breakthroughs for a very long time. More than four decades ago, a government-funded 80-hectare fish farm was constructed for growing baitfish for longline tuna operations and providing a source of protein for the people. It didn’t take off, however, because of grassroots problems such as unsustainable supplies of fry and lack of fish feed.

These concerns have been and are being addressed by

According to Food and Agriculture Authority estimates, the Kiribati milkfish aquaculture industry produced two tons in 2016.

Oceanic tuna is the country’s most economically valuable aquatic commodity. The country has some of the world’s richest tuna fishing grounds.

“There are some lines of evidence suggesting that translocated fish can adapt to the new environment, interbreed with local stocks and eventually, they may compromise the resilience of the species."

The impact of translocated cleaner fish has been factored into an environment-friendly approach to solving sea lice problems in Northern Europe.

“Considering that cleaner fish are intended to be used as ‘symbiotic organism’ feeding on sea lice, but not for human consumption, RACleanFIsh-Aqua considers moving away from traditional selective breeding programs. Instead, it is encouraged to incorporate the conservation of the genetic diversity in case of accidental escapees,” Dr. Enrique Blanco Gonzalez, told Hatchery International. He is an associate professor at the Norwegian College of Fishery Science, the Arctic University of Norway.

The adoption of RACleanFIsh-Aqua can contribute to preserving the local biodiversity by avoiding translocations of genetically and phenotypically different organisms, using a large number of local breeders with regular replacements, and monitoring the genetic diversity of their offspring. It will also provide offspring that are more suitable to the local environment, he explained.

Restricting the use of cleaner fish from local breeders helps reduce bio-security issues related to the presumed risk of introgression between farmed and wild organisms, he explained.

“Translocations should be restricted to fish genetically and phenotypically similar, but avoided among distinct populations,” Blanco Gonzalez said.

He has conducted studies on the interaction between translocated cleaner fish wrasse with the local population.

As a natural solution to sea lice problems, wrasse can feed on sea lice continuously, even at small densities, and could consume as much as three times the volume of sea

lice that lumpfish eats. It helps to keep sea lice numbers low without risk to human health and can be co-cultured with salmon even under non-optimal health conditions.

“The development of rearing techniques will have some associated risks as in other species. However, it will also help to reduce the ongoing intensive fishing pressure on natural populations, especially considering that the species display sexual size dimorphism,” he said.

“Males grow faster than females and sneakers, which are alternative males. Since fishery is size-regulated, it may target younger, larger males and unbalance the sex ratios.”

In his report, "Interbreeding between local and translocated populations of a cleaner fish in an experimental mesocosm predicts risk of disrupted local adaptation," Blanco Gonzalez and his team evaluated the genetic consequences of large‐scale translocation of cleaner wrasse that has become a common practice within the salmon aquaculture industry in northern Europe to combat sea lice infestation.

The experimental setting represented a simulated translocation of corkwing wrasse (Symphodus melops) that occurs on a large scale in the Norwegian salmon industry. Parentage assignment analysis of mesocosm's offspring revealed 30 percent interbreeding between the two populations, despite their being genetically and phenotypically differentiated.

“In sum, we can’t extrapolate our results as a rule of thumb, but at least there are some lines of evidence suggesting that translocated fish can adapt to the new environment, interbreed with local stocks and eventually they may compromise the resilience of the species,” he said.

-Ruby Gonzalez

Goulburn River Trout’s hatchery upgrade is proving to be a worthy undertaking for one of Australia’s oldest fish farms

The Smart Flow System uses software to gather and store

BY JOHN MOSIG

Goulburn River Trout (GRT) is one of the oldest aquaculture enterprises in Australia. Established by the Leake family in 1974 as an adjunct to their dairy farm, it was bought by the Meggitt family in 1990. It has been built up since then to become the country’s major producers of fresh and smoked rainbow trout (Oncorhynchus mykiss).

Situated on two sites on the Goulburn River, a short distance downstream from the Lake Eildon impoundment, the farms use a combination of gravityfed and pumped water, depending on the river flow, to produce 1,000 tons of fish a year in flow-through raceways and earthen ponds.

While the operation is based on a high-volume, low margin model, which gives it market accessibility, the GRT brand has maintained its reputation for quality and reliability. Production is split evenly between smoked and fresh fish and although primarily marketed domestically, some product is exported.

To make life easier and for greater seedstock security, the company recently upgraded its hatchery at a cost of about a million dollars. As half its production goes to the weekly fresh fish market, regularity and reliability are key elements of the company’s production model.

The new hatchery has a very clean, simple layout. GRT director Ed Meggitt says keeping things simple across its operation has been a key to the company’s success.

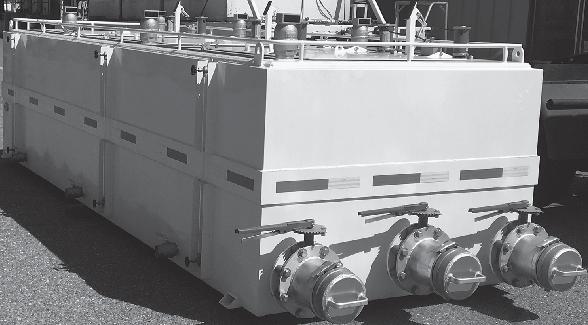

The hatchery is a flow-through design using upwelling incubators, 45 hatching throughs and 8 x 32m3 indoor concrete raceways.

One of the key elements of the hatchery is a small recirculating chiller incubation line that allows the hatchery season to be extended. Late season eggs eggs are incubated at a temperature of 3C to slow embryonic development.

Lengthening the spawning season is important for GRT as Australian quarantine laws prohibit the importation of eyed-ova from the Northern Hemisphere. Meggitt said he was supportive of this stance as it was an important tool in protecting Australian trout populations, which are free of most of the bacterial and viral diseases found elsewhere.