Yellowtail borne from research to RAS

BY MARI-LEN DE GUZMAN

Kingfish Zeeland, based in The Netherlands, is ready to take its high-value RAS-grown Dutch Yellowtail (Seriola lalandi) to the North American market with plans to establish a production facility in the United States this year.

Kees Kloet, Kingfish Zeeland’s chief operating officer, tells Hatchery International that his company is scoping out prospective locations in the U.S. to set up shop. It plans to build a land-based production facility with an initial capacity of 4,000 tons of Yellowtail Kingfish. Kloet, however, declined to provide further detail of the location until his company has finalized and identified the site of the planned facility.

Kingfish Zeeland already sells its Yellowtail Kingfish to the U.S. market, but the growing market demand for this sashimi-grade, high-end product is creating further growth opportunities. As with many intercontinental product transactions the costs can be significant.

“What we have learned is that the market is big and it’s growing fast and there’s lots of opportunities,” Kloet

says. “Like everybody else, we run into all the costs for air transport and importation and... the most logical step is to move here and start producing over here.”

R&D TO REALITY

The beginnings of Kingfish Zeeland could be traced to a research and development project with Wageningen University in The Netherlands. The company was founded in 2015 and, with technology from Billund Aquaculture, began constructing a 5,000-sq.m. RAS farm along the Oosterschelde marine estuary in the province of Zeeland.

“We are guaranteed pure quality of intake water,” Kloet says.

Current production capacity at the facility is at 520 tons per year, but the company plans to grow that capacity to 1,000 tons this year, and to 4,000 tons by 2020.

To ensure consistent supply of quality eggs, Kingfish Zeeland built two hatcheries – one dedicated for production and the other for R&D purposes, mainly for broodstock selection and feed production.

continued on page 25

Saving Japan’s wild salmon population

Exploring ways for hatcheries to give species a fighting chance for survival

BY BONNIE WAYCOTT

The mass release of farm-hatched fish to supplement wild populations and increase harvest has been practiced across the world. In Japan, the northernmost island of Hokkaido has been home to Pacific salmon (Oncorhynchus spp.) hatchery programs since the late 19th century. Between the late 1970s to the end of the 1980s, chum salmon (O. keta) populations increased exponentially, coinciding with enhanced hatchery technology and improvements in marine survival due to favorable climate and ocean conditions.

In the 1990s, hatchery populations contributed up to 50 percent of total returns of chum salmon in the Pacific. Today, some commercial fisheries in Hokkaido, such as the Hokkaido Island Chum Salmon Fishery, rely almost exclusively on hatchery production to meet their catch targets.

Global RAS professionals to gather in D.C. at RAStech 2019

eading RAS experts from around the world are speaking at RAStech 2019, the premier conference for recirculating aquaculture systems happening on May 13 and 14 in Washington, D.C.

LFormerly the International Conference on Recirculating Aquaculture, RAStech 2019 features a line-up of education sessions designed to provide the latest in RAS research, technology development, best practices and implementation.

“Whether you are a current user of RAS technology or considering implementing a RAS project, or even thinking about investing in this market, you will find this event very relevant to you,” says David Kuhn, associate professor in the aquaculture research and extension programs, department of food science and technology at Virginia Tech.

continued on page 3

WHOOPS! WE MADE A MISTAKE ON OUR 2019 CALENDAR. !

Due to a production and editing error, our 2019 calendar included incorrect dates for December 2019 so we've included a new calendar with this issue to replace it. We regret any inconvenience this has caused. If you’ve already marked up your existing 2019 calendar, may we suggest that you simply cut out the month of December from the new correct calendar and glue it on top of December on the old one. Being creative hatchery professionals, we know you probably have already thought of this, but just in case you haven’t had your morning coffee yet.

< Professor Masahide Kaeriyama of the Arctic Research Center at Hokkaido University

•

VOLUME 20, ISSUE 2 | MARCH/APRIL 2019

Editor Mari-Len De Guzman, mdeguzman@annexbusinessmedia.com

Associate Editor Tamar Atik, tatik@annexbusinessmedia.com

Regular Contributors Matt Jones, Ruby Gonzalez, Bonnie Waycott, Tom Walker, Vladislav Vorotnikov, Ron Hill, Colin Ley

Advertising Manager Jeremy Thain, jthain@annexbusinessmedia.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Circulation Manager Barbara Adelt, badelt@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3546

Production Svetlana Avrutin, savrutin@annexbusinessmedia.com

Group Publisher - Scott Jamieson, sjamieson@annexbusinessmedia.com

President & CEO – Mike Fredericks

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Hatchery International is published six times a year by Annex Business Media The authority for statements and claims made in Hatchery International is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

A subscription to Hatchery International (six issues) is $37.00 within Canada, $37.00 US within North America and $47.50 US outside North America. To subscribe visit our website at www.hatcheryinternational.com

Subscriptions Angie Potal, apotal@annexbusinessmedia.com

Tel: 416-410-5113 • Fax: 416-510-6875 or 416-442-2191

Printed in Canada. Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Hatchery International. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com

Tel: 800-668-2374

ISSN 1922-4117

Next Ad Deadline

The advertising deadline for the May/June issue is March 10th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the May/June issue is March 10th. Contact the Editor, Mari-Len De Guzman at mdeguzman@annexbusinessmedia. com for details. Material should be submitted electronically with prior arrangement with the editor.

NEWS BRIEFS

POLICY

Canadian government makes move to improve aquaculture industry

The Canadian government announced a number of initiatives in late 2018 to improve the country’s aquaculture sector and further protect threatened wild salmon populations.

A key initiative includes a study on the alternative technologies for aquaculture, including land and sea-based closed containment technology. The study will help determine gaps that limit commercial readiness and help to inform future technology development efforts, according to a release, and will be conducted in partnership with Sustainable Development Technology Canada and the Province of British Columbia.

Another key focus is moving towards an area-based approach to aquaculture management – to ensure that environmental, social and economic factors are taken into consideration when identifying potential areas for aquaculture development – including considerations relating to migration pathways for wild salmon. The British Columbia Salmon Restoration and Innovation Fund will also be receiving more than $100 million in federal funding over six years, with provincial funding still to be announced.

Another key initiative is developing a framework for aquaculture risk management, based on the precautionary approach, which will ensure the sustainable management of aquaculture, and will be the overarching framework for future policies.

The government also plans to create a single comprehensive set of regulations – the General Aquaculture Regulations – which it says will bring more clarity for industry, stakeholders and the Canadian public about how aquaculture is managed for responsible growth in Canada.

"The Government of Canada is committed to making

aquaculture more effective, efficient and environmentally sustainable,” stated Jonathan Wilkinson, Minister of Fisheries, Oceans and the Canadian Coast Guard. “Together, with Indigenous, environmental and industry partners, we will lead the way towards a more prosperous and sustainable aquaculture industry."

The initiatives follow a meeting of the Canadian Council for Fisheries and Aquaculture Ministers in St. John's, Newfoundland, where ministers agreed to the development of a federal Aquaculture Act.

Environmental advocacy group SeaChoice has come out in support of this new initiative.

A new Aquaculture Act should properly price the ecosystem services that open-net pen aquaculture takes from the ocean, SeaChoice said in a release.

“Appropriate and escalating licensing fees can be used to spur investment in cleaner technology,” says Shannon Arnold, SeaChoice representative from the Ecology Action Centre.

RAStech is jointly hosted by Annex Business Media, publishers of Hatchery International and RAStech magazine, and Virginia Tech. Oxygen Solutions and Veolia Water Technologies are the platinum sponsors.

“We are working with different associations and organizations in the aquaculture industry to develop the education sessions and ensure that we continue to provide a high-quality education conference for our attendees,” Kuhn added.

Innovation is vital to the growth and success of recirculating aquaculture systems.

RAStech 2019 features education sessions that highlight the latest innovations and case studies in RAS engineering, aquaponics, fish health management,

biosecurity, and energy management. Plus, some great sessions on raising marine species in RAS environments, RAS feeds management and much more.

The event also features a tradeshow of the latest in RAS products and services, providing attendees a first-hand look at new technologies that can help boost their RAS projects.

With two full days of learning and networking, RAStech 2019 is one international aquaculture conference you cannot miss. Save big on hotel and registration by signing up before the early bird deadline of March 8th. Registration is limited to just 250 attendees, so don’t delay.

continued from cover

David Kuhn

NEWS UPDATES

Oregon research shows no negative impact from hatchery steelhead on wild populations

BY MATT JONES

New research out of Oregon, U.S.A, has found no negative impacts on wild steelhead (Oncorhynchus mykiss) populations from interactions with hatchery fish in the upper Clackamas River.

The American Fisheries Society published a scientific review headed by Fisheries Scientist Ian Courter of Mt. Hood

Environmental, who studied 59 years of summer hatchery and winter wild steelhead runs.

Courter’s research utilized a detailed and accurate dataset where fish were individually enumerated at the North Fork Dam. By analyzing abundance data, he was able to quantify various environmental impacts

on wild steelhead production, but did not find any significant negative impacts from interactions with hatchery steelhead.

“What we found was there was actually a slight positive association between hatchery fish abundance and natural fish abundance,” says Courter. “That’s counter to what the conventional theory might be about hatchery fish effects. It wasn’t really strong, but it was definitely on the positive side. We suspect that’s because both hatchery and natural origin fish share a common environment – it’s not really surprising that they would both be going up and down together somewhat.”

That conventional theory about negative impacts from interactions between wild and hatchery populations was the basis for the closure of the summer steelhead program in 1999. And, Courter notes, the theoretical basis for the idea that there would be negative impacts from those interactions is solid – there have been a number of studies that have demonstrated differences between the two types of fish, but it is not yet well known whether that actually results in a negative impact on wild fish production.

“It seems to us there’s somewhat of a one-sized perspective on this and a poor grasp on some of the differences between hatchery programs that have substantial impacts on whether one should assume that the hatchery fish has a negative effect or not,” says Courter. “For example, if you integrate your broodstock with natural origin fish, then the genetic risk to the domestication factor that could potentially be translated to the natural origin population goes way down. The type of program being implemented is extremely important and needs to be part of the explanation of why in one instance you may observe a negative impact from hatchery fish and in another you don’t. It’s not a one-size fits all conclusion.”

As for how these findings should be handled or whether the stocking program should be re-instated, Courter declines to comment on that aspect. As a scientist, his aim is to ensure the best information is available – nothing more.

“I don’t have an agenda to see hatchery programs restarted in the Clackamas

or anything like that. My aim is just to continue this line of research and identify more opportunities to evaluate the impacts of hatchery fish. Policy makers at the state agencies and policy makers will decide what the most appropriate next step is.”

Courter cautions against using their findings to form broad assumptions about hatchery and wild interactions in general. However, he does hope that their findings in the Clackamas will inspire further research into other water bodies in other jurisdictions.

“As I dove into this topic, I was struck by the lack of direct evidence for negative effects at the population scale. If you begin to understand that and not get drawn into the policy debate, but focus on what is the real material evidence for a direct negative impact from hatchery fish, that would be important because it will drive how the folks that are engaged in hatchery fish production perceive the available science. It’s important because it’s going to drive research going forward which is going to drive management decisions. That will dictate how important hatcheries are in the future.”

Fisheries scientist Ian Courter holds a winter steelhead in Oregon’s Sandy River. The researcher found no evidence of negative impacts on wild productions from interaction with hatchery steelhead. In fact, the research found a small positive association.

NEWS UPDATES

Nordic Aquafarms company Sashimi Royal becomes ASC-certified

A sister company to Nordic Aquafarms Inc., which is planning to build a world-class, land-based salmon farm in Belfast, Maine, in the U.S. has received certification from Aquaculture Stewardship Council (ASC) as a sustainable and quality seafood producer.

Sashimi Royal of Hanstholm, Denmark is the largest, land-based facility in the EU that produces Yellowtail Kingfish, a delicate and much sought-after seafood product.

Aquaculture Awards judging panel announced

As the announcement of the winners of the 2019 Aquaculture Awards draws near, award organizers have revealed the composition of the judging panel.

The award judges include: Alex Adrian, aquaculture operations manager of Crown Estate Scotland; Martin Gill, head of aquaculture and fisheries at Lloyds Register; Rob Fletcher, senior editor of The Fish Site; Nicki Holmyard, head of corporate communications for Offshore Shellfish Ltd; Professor Dave Little, head of research at the Institute of Aquaculture at the University of Stirling; and event organiser Susan Tinch.

“ASC certification is the gold standard for fish farming and represents a major commitment to best practices and sustainability,” said Erik Heim, president of Nordic Aquafarms Inc., the U.S. subsidiary of Nordic Aquafarms. “We also will seek ASC certification for our U.S. operations, which means we will adhere to the highest standards in the industry and be subject to audits from independent, third-party quality assurance organizations."

Sashimi Royal received its ASC certification on Dec. 13, 2018, after an extensive audit process that verified sustainable practices to minimize impact on the environment, stringent limits on the use of antibiotics and chemicals, measures to prevent fish escape, sustainable feed sourcing, and more. Sashimi Royal’s certification was overseen by DNV GL, a global quality assurance and risk management company.

The Aquaculture Stewardship Council is an independent, international, non-profit organization that promotes the best environmental and social choices when buying seafood and manages the world’s leading certification and labelling program for responsible aquaculture. According to its website, ASC’s mission is “to transform aquaculture towards environmental sustainability and social responsibility using efficient market mechanisms that create value across the chain.”

“As we proceed with the development of our land-based facility in Maine, the community and all of our stakeholders can be assured that this important certification achieved by Sashimi Royal is just the first step in a commitment to environmental sustainability and accountability that exists throughout our company,” Heim said.

The awards will be presented on May 29 at a formal event in Edinburgh, Scotland. They “showcase the great innovators and most exciting developments taking place in the world’s fastest growing protein production sector,” Aquaculture UK stated in a release.

The awards are open to anyone involved in aquaculture and feature categories on applied research, animal welfare, international impact and more. The judges have been selected for their “breadth of knowledge of the international aquaculture sector and includes well-known figures from industry and academia,” the release stated.

When examining the individual entries, the judges will consider the criteria identified for each category. Following consideration of all entries, the judging panel will identify shortlists for each category, from which the winners will be selected, Aquaculture UK stated.

Award nominations are open to both commercial and research sectors from around the world.

The shortlist of candidates will be announced in early April. This will be followed by the awards presentation dinner to be held at Dynamic Earth, Edinburgh, on May 29.

Sashimi Royal facility in Denmark (Photo: Nordic Aquafarms)

NEWS UPDATES

Nostril navigation

Researchers from Oregon, U.S.A., help Chinook salmon find way home

BY MATT JONES

In an effort to find ways to prevent hatchery fish from straying, Oregon State University researcher Maryam Kamran has been working with the Oregon Hatchery Research Center to study salmon responses to various scent stimuli. In recent years, Chinook salmon (Oncorhynchus tshawytscha) in the area are not homing as well as they once were, Kamran says.

“With salmon homing, they go out to the ocean and they come back after a few years and they come back to their natal tributary – where they were born and that’s where they mate,” says Kamran. “They only get one chance to do this and so they have to get it right. Research has shown that more and more fish weren’t coming back to the areas that they were supposed to.”

When returning home, the scent of the natal tributary is very important in the homing process.

Technically known as olfactory imprinting, familiar scents can act as a landmark to help guide the salmon, which Kamran compares to billboards or road signs. Her research project focused specifically on the Elk River Hatchery, which has had significant problems with straying in the past.

a template for similar efforts in other jurisdictions.

Kamran and her collaborators have been testing artificial odors which could be used at the hatchery to give a distinct odor which the fish will recognize – one which would be safe for release into the water, cost effective, able to persist in the environment, and can be detected by a salmon’s nose. An important distinction, she notes, is that the odor must not be an attractive or aversive odor. The goal is to find an odor which does not induce a behavioral response – which could impact other species – but rather one that can simply be detected. They are also testing to find the best timing for the use of effective imprinting.

“Primarily, the most robust response we saw were with a combination of amino acids,” says Kamran.

The information gathering and testing phases of the research are nearly complete. Their research is specific to the conditions in the Elk River, however, Kamran hopes their model could be used as a template for similar research projects in other areas.

“It will be specific to what’s already in the water there in terms of the chemical cues available, the species, the run timings – all these different things will have to be factored in.”

Renovations aim to update Sterling Springs Fish Hatchery’s aging infrastructure BY

GEOFFREY RABINOVICH

The Sterling Springs Fish Hatchery (SSH) in Sedona, Arizona, U.S.A., is currently undergoing a US$3.3. million dollar rehabilitation to modernize its facilities. Construction commenced in early December 2018 and expected to be completed by June 2019.

SSH is the smallest facility owned and operated by the Arizona Game and Fish Department hatchery program. This hatchery has a very important role in the hatchery program. Each year SSH produces and supplies hundreds of thousands of trout fingerlings to Page Springs Hatchery – the largest trout hatchery in Arizona – to be raised to catchable size prior to being stocked.

This renovation project was identified in the State of Arizona Fish Hatchery Report. The hatchery management is grateful that the commissioners, the Governor’s office

Oregon State University researcher Maryam Kamran is leading a research effort to find scents that could be used to help salmon find their way back home to their native tributaries. She hopes the research will provide

< Field station for collected water samples from Elk and Sixes river help determine what was in the water (dissolved organic carbon, dissolved organic matter- amino acids etc.)

Amanda Pollock, faculty research assistant, collects Amino Acid samples.

< Michelle Scalan (far left), faculty research assistant at Oregon State University and Dr. Marc Johnson (back, left) filtering water samples using a bicycle pump, while Amanda Pollock (standing), faculty research assistant at OSU, and Dr. Singer (right) look on.

and the Arizona Game and Fish Department executive staff recognize the importance of the fish hatcheries for the state of Arizona.

It is all about ensuring that successful hatchery operations at Sterling Springs continue for years to come. Hatcheries play a vital role in maintaining the quality of sport fishing in Arizona. Planning for the future is necessary to maintain and increase current production in order to meet current and future demands of sport fish in the state. According to the Economic Impact of Fishing in Arizona, annual recreational sport fishing produces US$1.47 billion in economic benefits for the state of Arizona.

RENOVATIONS

Sterling Springs Hatchery is having some problems. The current infrastructure is aging. Some of the piping is over 70 years old. Most of the infrastructure have been in use since 1971, and some of the piping, valves and concrete raceways are in dire need of replacement.

The pipe delivery is full of holes from corrosion. The raceways are falling apart. With decreasing water supplies, it is going to become necessary to be able to operate the hatchery with less water.

We are hoping that with a more secured water source and cleared inflow pipes coming from the springs, we may possibly have an increase in water flow which would help with production. The current pipes are a steel welded eightinch and six-inch boiler pipe that is approximately more than 70 years old. It is rusted out in spots and definitely leaking, allowing foreign materials into the incoming water flows.

The nearly US$3.3 million project will involve the reha bilitation of the water inflow pipes leading to the hatchery, as well as various spring/control boxes along the pipelines. In addition, the outside concrete raceways and water pipe lines will be replaced. The project includes a cover canopy and fence around raceways, a new storage building and a partial recirculation system among other improvements.

This pipe will be lined with a cured-in-place pipe liner to keep from disturbing the wilderness setting in which the pipes are laid.

Because of low water flow of approximately 240 gallons/ minute, we will not be able to use circular tanks. We also evaluated the use of dual drain circular tanks, but with the limitation of water and the small area of the facility, it was not feasible to use circular tanks without incurring an as tronomical cost in recirculation equipment and operations.

The hatchery will continue to use 11 rectangular concrete raceways, which will hold 6,358 cubic feet each.

FUTURE PLANS

Once the project is completed, SSH hopes to be able to continue with a stable, healthy production that the hatchery has already been noted for, which is approximately 700,000 to 900,000 fingerlings per year. On average 850,000 rainbow trout and approximately 70,000 browns are raised at SSH per year.

Rainbow trout eggs will continue to be sourced from the Ennis National Fish Hatchery in Montana and Troutlodge in Washinton state.

The hatchery hopes to raise Gila trout and Apache trout in the future as well, which they plan to source from

the Mora National Fish Hatchery in New Mexico and Williams Creek National Fish Hatchery in White River, Arizona, respectively.

The sport fisherman in the local area will likely notice the impact of the rehabilitation project. The SSH has made arrangements with its other facilities to temporarily cover Sterling Springs Hatchery production.

Geoffrey Rabinovich is the statewide hatchery program manager for the Arizona Game and Fish Department, in Arizona, U.S.A.

Planning for the future, the SSH renovation will include the installation of a partial recirculation system that will help the facility during the heavy production months. The recirculation system will consist of a sump at the bottom of the facility near the outflow, where the hatchery effluent water will run through a drum filter and UV light. The water will then be pumped back to the top of the facility to an aeration tower to later to be diverted to the raceways that need the extra flow for cleaning or production.

LINN.eu

New hatchery under construction in Sakhalin, Russia

Russian company Salmo Plus has started building a new hatchery to produce Siberian salmon (Oncorhynchus keta) fry, the company said in a statement. With the overall investment cost of Rub380 million (US$6 million), the hatchery will be producing 73 million fry per year beginning in 2020.

The fish will be released in the local waters to be caught several years after, said Stanislav Fyodorov, general director of Salmo Plus.

Under the common approach investors establish a complete reproduction cycle at a hatchery of that kind, which means that all production stages from egg incubation up to release of the fry to the water are taking place within one production unit, according to Fyodorov. Salmo Plus will transfer fry almost immediately after hatching to “the breeding ground” – the artificial reservoirs near the spawning rivers. This approach reduces the investments necessary to

build a hatchery and also takes down the production costs, Fyodorov estimated.

“We expect to release the fish Siberian salmon into the local waters in 2020. The full-grown fish will return only in 2023. This means that the company will have to operate with almost zero revenue for several years. The residency in the Vladivostok free port, with tax and other preferences associated with it, will help the company to endure in this most complicated period of its development,” Fyodorov said.

Sakhalin hatcheries release fish fry to catch full-grown fish several years later.

Sakhalin has seen the volume of salmon production reducing in the past few years.

The residency in the Vladivostok free port is an operational regime that the local government in the Russian Far East grant to some investors whose projects are considered to be important for the local economy. This regime involves numerous tax breaks and several other bonuses.

With 73 million units of fry released to the local rivers, it was estimated that 3,000 tonnes of full-grown fish could return. Giving the current prices for Siberian salmon on the local market, Salmo Plus believes the payback period on the project will be limited to eight years.

Alexey Belik, deputy chairman of the Sakhalin Island government, commented

that the Siberian salmon produced by Salmo Plus in future could be found all over Russia. Belik continued that the fishing industry is very important for Sakhalin, and its further development requires new projects in the reproduction area.

In 2017, the fisheries of the Sakhalin caught 27,000 tonnes of humpback salmon (Oncorhunchus gorbusha). This was one of the lowest figures in the past few decades. The local scientists repeatedly claim that population of salmon species in the local waters have been constantly falling due to continuous poaching and several other factors.

- Vladislav Vorotnikov

Uzbekistan allows duty-free broodstock imports

New measures aim to develop local aquaculture industry

Aquaculture producers in Uzbekistan are getting some relief with the announcement by President Shavkat Mirziyoyev of tax-free broodstock import over the next two years. This measure is part of a large-scale development program for the domestic aquaculture industry and to support the fish farming sector until it is completely self-sufficient on broodstock.

Mirziyoyev has also temporarily cancelled import duties on equipment and feed for the aquaculture industry. Uzbekistan currently does not produce any equipment for the aquaculture industry. This measure would support the construction of new hatcheries in the country, the explanatory note to the bill said.

In 2018, seven hatcheries were built in Uzbekistan with total production capacity of 350 million units of fish fry. In 2019, 10 new hatcheries are slated to be built with total production capacity of 530 million units, the government forecasted. It is expected that Uzbekistan would become self-sufficient on broodstock by 2023.

The new hatcheries could be an impetus for the development of aquaculture in Uzbekistan. In 2018, the country produced 150,000 tonnes of fish. This year, the figure is projected to grow to 201,500 tonnes. The Uzbekistan government plans to allocate US$50 million for new aquaculture projects in the next two years, plus grant additional US$15 million per year to support the operation of existing farms.

In addition, all fish farms with actual production above 50 tonnes per year would be exempted from all taxes and fees for three years. The ultimate goal is to establish a complete aquaculture industry in the country, with hatcheries, fish farms and fish processing capabilities, the national government said in a statement.

In 2018, the Uzbekistan government said five new hatcheries are slated to be built in the next three years through joint ventures between Uzbekistan companies and foreign investors, including from the European Union.

- Vladislav Vorotnikov

All-New HydroHatch Incubation System

Increased Survival Rate with Significantly Reduced Water Consumption

The all-new HydroHatch Incubation System from MariSource gives hatcheries increased efficiency. With recirculation, germicidal UV filter and a titanium heat exchanger, the HydroHatch delivers increased survival rate and significantly reduces water consumption.

Features and Benefits:

65 gallon sediment and recirculation tank

Requires only 150 gallons to completely fill the unit and reservoir

High-quality, long-life quartz germicidal UV filter

Complete isolation of eggs

Easily able to increase the dissolved oxygen content of the water

230 volt 30 amp control panel

Insulated titanium heat exchanger

Precise temperature control

Comes standard with four 8-stack incubators

Additional four 8-stack incubator option available

The new HydroHatch Incubation System is ideal for Salmon, Trout, Steelhead, Perch, Channel Cat Fish, Walleye, Eels, Shrimp and Muscles.

Uzbekizstan plans to expand the domestic aquaculture industry in the coming years.

Uzbekistan fish farmers get some financial relief

NEWS GLOBAL

Aquaculture boom increasing demand for broodstock in Crimeria

BY VLADISLAV

The demand for broodstock is on the rise in Crimea in light of efforts by Russian authorities to develop the local aquaculture industry and to mitigate the negative impact on the environment resulting from the construction of the Crimean Bridge.

The aquaculture industry in Crimea is experiencing a real investment boom, with production volume increasing from 800 tonnes in 2016 to 1,799 tonnes in 2017. There are dozens of new aquaculture projects on the pipeline, according to a statement published in the Russian Gazette, the official publication of the Russian government.

In 2017, local authorities granted Rub30 million (US$500,000) to reimburse part of the investment costs on new projects, as well as to subsidize the cost of acquiring broodstock for the local aquaculture producers.

The development of fisheries and aquaculture are among the top priorities in the economic growth policy for Sevastopol, the capital of Crimea, said Natalia Goncharuyk, chairman of the agricultural department of the Sevastopol government. Currently, local farms are importing most of the broodstock from the Russian southern regions – Krasnodar Krai and Stavropol Krai.

AQUACULTURE CHALLENGES

In total, there are 30 aquaculture farms in Crimea, and 60 percent of all production is European carp (Cyprinus carpio), silver carp (Hypophthalmichthys) and Chinese carp (Ctenopharyngodon idella). The lack of fresh water is the biggest challenge for the local aquaculture industry.

After the Russian annexation of Crimea during the 2014 Crimean crisis, Ukrainian authorities cut the volume of water flowing into Crimea through the North Crimean canal, citing a huge outstanding debt on water supplies owed by the peninsula. The North Crimean canal was the main source of fresh water supply for Crimea and the region has been experiencing shortage of fresh water in the past few years.

Despite the problem, some foreign investors are considering some fish farming projects in Crimea. A big project,

Better aquaculture management rewards Malaysia’s fish farmers

New study identifies most important factors influencing livelihood of small-scale fish farmers in Malaysia

Ain particular is currently under consideration by a Chinese company, according to Sergey Aksenov, the head of the Crimean government. So far, no additional information about this company or the project has been provided.

Over the past four years, non-Russian companies were refraining from investing in Crimea because the peninsula has been subjected to international sanctions by the U.S. and the European Union, which includes prohibitions to conduct any business on the territory.

CRIMEAN BRIDGE ISSUE

The additional demand for broodstock in Crimea is also associated with the implementation of the Crimean Bridge’s ecological program. Under the program, 500,000

recent study finds that brackish-water fish farmers in Malaysia earn more than freshwater fish farmers.

Small-scale fish farmers in Malaysia earn 2.5 times more farming in brackishwater, compared to freshwater, according to a study in the Pertanika Journal of Social Sciences & Humanities

Aquaculture is a common source of income in Malaysia and Roslina Kamaruddin, a researcher from Universiti Utara Malaysia, wanted to understand why some fish farmers are more successful than others.

Kamaruddin queried 216 small-scale freshwater and brackish-water pond fish farmers from the state of Kedah about their assets, such as education and investment capital, fishing strategies, and household income.

Overall, higher education level and experience, as well as higher investment and operating costs positively correlated with higher levels of best management practices and household income.

Russian sturgeon (Acipenser gueldenstaedti) fingerlings were released into the local waters in 2018, and 500,000 more are slated to be released in 2019. There is a possibility that this program could be expanded in the future.

Ukraine environmentalists have been repeatedly claiming that the recently constructed Crimean Bridge, which is spanning the peninsula with mainland Russia, negatively affects the population of some fish species in the Kerch Strait and Azov Sea – although no research in this regard has been made so far. Russian authorities argue that the sound barrier installed across the bridge protects fish from sound impact.

The Crimean Bridge ecological program is needed to restore the population of the Russian sturgeon that was affected by poaching, authorities said.

The highest incomes were among brackish-water fish farmers – in part because brackish-water species generate higher profits, but also because brackish-water farmers are more likely to use best management practices than freshwater farmers, the study said. Brackish-water species require intensive care, so farmers use best management practices, such as pond preparation and fish health management, to help ensure high survival rate and best quality produce.

“Good management is crucial for sustainable aquaculture and this study showed that fish farmers need more training and financial support to implement best practices,” Kamaruddin said. While brackish-water species generate more profit, they also require high investment, operating costs and technical knowledge. More brackish-water farmers are financed by banks and agencies, whereas freshwater farmers are more likely to use personal financial resources. Freshwater fish farmers often supplement their income with other sources, such as agriculture.

Not all aspects are better for brackish-water farmers, however. The study shows they experience higher levels of stress, worry and anxiety when their underwater farms were adversely affected. In addition, brackish-water farms had a higher impact on the environment as they used more fertilisers and antibiotics.

Measures to boost education, training and financial investment should be prioritized to improve fish farmers’ livelihood, the study noted. For example, credit institutions could provide credits or loans which cater to small-scale farmers. Training for best aquaculture practices should also be readily available.

Other policies could include differentiating between aquaculture products from farms with good management versus poor management, or penalizing farmers who do not follow best practice standards.

Several hatcheries work in Crimea to produce fish fry for local needs.

Russian authorities give money to hatcheries to produce fish fry to be released in Crimea.

Ecological campaign in Crimea may be expanded soon.

VOROTNIKOV

Philippines BFAR eyes country's first yellowfin tuna farming project

BY RUBY GONZALEZ

The Philippine Bureau of Fisheries and Aquatic Resources (BFAR) is pushing for the country’s first yellowfin tuna (Thunnus albacares) farming. It will be a private-public partnership, with the BFAR and Japan International Cooperative Agency (JICA) as catalysts.

Juvenile yellowfin tuna will be gathered from the municipal waters, located within 15 kilometers from the shoreline, and then fattened in 30- to 50-meter-diameter submersible sea cages in open waters, BFAR Regional Director Juan Albaladejo told Hatchery International.

Sites have been identified in Eastern and Northern Samar provinces, located some 840 kilometers southeast of Manila. The waters face the Pacific Ocean and are along the path of tuna, where they chase and feed on pelagic fish.

There are several ways to gather juvenile tuna. Citing a method practised in Australia, Albaladejo said, “They usually collect them using seine net, enclose them and drag the net to their marine cages. The dragging usually takes around 24 to 48 hours.

“But for our purpose, where the yellowfin tuna is within the municipal waters, we plan to use a fish-aggregating device (FAD), called payao, and use a ring net to

enclose the fish and drag the net to our marine cages in the vicinity.”

Payao is a Philippine traditional FAD – a floating and anchored bamboo raft. Because it provides shelter, it attracts freeschooling tuna and small pelagics.

“For transferring to a marine cage, just like in Australia, both the transport net and cage have openings that you could tie together,” he said. The fish would then be herded from the transport net to the cage.

He stressed that he needed to establish the feasibility of these ideas during his scheduled talks with experts in Japan.

Shortly after his interview with HI, Albaladejo went to Japan to meet Nitto Seimo executives in Kyushu to finalize project details.

Nitto Seimo has been identified as the provider of technology and submersible cages. Philippine company Feedmix Specialist has also indicated interest. Another Philippine company, Inca Plastics Philippines might also come in.

Nitto Seimo has a substantial global market share in knotless nets and demonstrated its success in tuna farming.

Albaladejo said the most critical part of the tuna farming process is transporting the juvenile, explaining that it could turn

fatal if they get into contact with the net.

In this project’s case, it is an advantage, then, that the length of time required to transport the juvenile is relatively short.

Citing the Japanese method, he said juvenile yellowfin tuna is gathered at 20 kilos and then fattened up for five to six months. “The good thing here is that since they are in cages with regular feeding, they will develop fat that is marbled with meat, just like Kobe beef,” he said.

The daily fish feed would be 10 percent of the body weight.

Since 1958, Faivre has been developing and manufacturing high quality equipments for the aquaculture industry

In Samar, a kilo of yellowfin tuna sells at P250 a kilo. He said the cultured variety could command double the price. Circular fish cages are ideal for tuna because its gives them a perception of endless space. The grow-out cages would be positioned five kilometers, at the most, from the shoreline. The location is along the Philippine Trench. Since they face the opens seas, the provinces often get battered by strong waves, winds and typhoons. Submersible fish cages could make the fish farming operations typhoon-resistant, he said.

BFAR Regional Director Juan Albaladejo. (Photos: BFAR Region 8)

Juvenile tuna bound for the market. The plan is to catch them live for farming.

Multispecies hatchery opens in India

India has launched two hatcheries in the latter half of 2018, which will serve to help support the industry in a variety of fashions.

In December, the Marine Products Export Development Authority opened a multispecies hatchery in the state of Kerala, which will also serve neighboring states Karnataka and Tamil Nadu.

At capacity, the hatchery will produce 20 million post-larval black tiger shrimp (Penaeus monodon), as well as over a million fin fish fingerlings and significant numbers of mud crablets (Scylla serrata). The facility’s fin fish offerings will include cobia (Rachycentron canadum), Asian sea bass (Lates calcarifer), silver pompano (Trachinotus blochii) and tilapia (Oreochromis niloticus).

India’s The Hindu newspaper reports that the facility will feature significant bio-security measures, including a quarantine facility, an effluent treatment system and the use of a high-density polythene lining on nurseries meant for diversified fish and shellfish species. The article also notes that the facility’s proximity to an international airport will add the benefit of faster transportation of seeds.

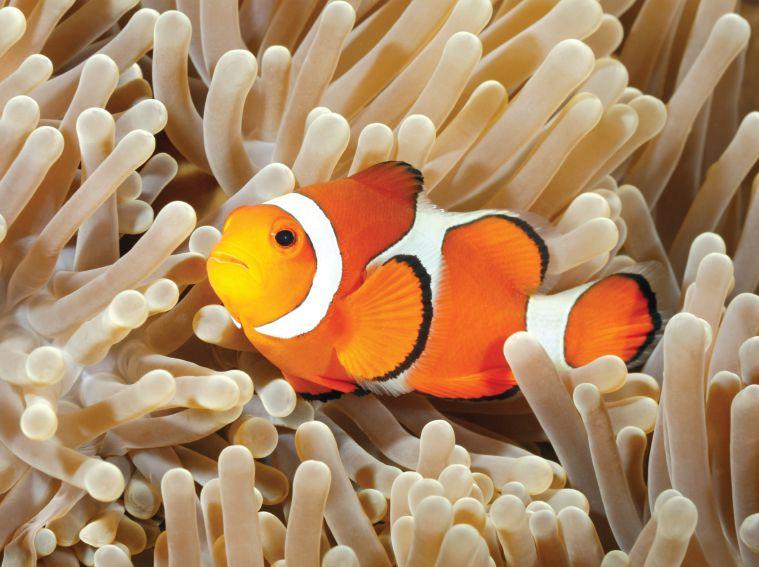

Around the same time, the State Mangrove Cell in Mumbai launched a hatchery for grooming clownfish (Amphiprioninae Pomacentridae) at a coastal and marine biodiversity center in Airoli. The hatchery houses 57 tanks, with almost half of those holding broodstock pairs. The remaining tanks are used for acclimatization of sea anemones.

“Since the Mumbai creek water requires repeated filtration as compared to the sea water of Alibaugh, therefore the decision was taken,” chief conservator of forests N. Vasudevan told the Free Press Journal about why the facility sources water from various locations on the Mandva coast. “Scientists of the National Bureau of Fish Genetic Resources has suggested to use the water of Mandva as it has a better water quality suitable for the hatchery. The recommendation was made based on the research and sample testing done by their scientists.”

When the clownfish pairs produce babies, they will be distributed to beneficiaries representing nearly 50 villages on the Konkan coastal belt. The aim of the hatchery is to provide a foray into the ornamental fish industry.

-Matt Jones

Peruvian community to benefit from $2M funding boost for local trout farming

Singapore and Japan-based aquaculture technology company Umitron has been approved for a US$2 million project funding to improve aquaculture productivity in Lake Titicaca, Peru.

The project, in partnership with rainbow trout producer Piscis and Peruvian credit union Abaco, is being funded by IDB Lab, the innovation laboratory of the InterAmerican Development Bank (IDB) Group. The goal is to improve the local trout farming industry’s economic and environmental sustainability.

“Right now, a lot of trout is being sold locally in Peru or Bolivia,” Andy Davison, product manager of Umitron in Tokyo, tells Hatchery International. “Piscis, our partner in this project, is exporting to many different foreign markets and this side of the business has the potential to grow and bring more money into the local economy around Lake Titicaca.”

The local Peruvian industry is growing, with 100,000 tons of production in 2016 projected to grow to 221,000 tons by 2030. This follows the trend of a growing aquaculture industry in Latin America and the Caribbean, where The Food and Agriculture Organization of the United Nations (FAO) estimates that fish production through aquaculture will grow from 2.7 million tons in 2016 to 4.0 million tons in 2030.

IDB first approached Umitron to gauge its interest in collaborating on a project in Latin America and connected the company with Piscis. After a couple of trips to Japan and Peru, the collaboration took form. Umitron’s feeding technology using artificial intelligence (AI) reduces the need for farmers to visit each individual cage every day for feeding and observation. Instead, fish can be remotely monitored and fed. The automated feeder also has the capability to reduce overfeeding and improve overall feed use efficiency.

In addition to making grow-out cage feeding more efficient, Umitron is also looking at how its system can be adapted to feed fish during all life stages, including in the hatchery, Davison explains.

“In general, we are interested in using data analytics, machine learning, and IoT technology to solve bottlenecks and problems for all parts of the aquaculture industry,” he said adding, “If hatchery operators have suggestions for how connected devices, data gathering, or data analytics can help their operations, we would love to hear from them.”

Through a variety of technology tests and training with local producers, the end goal for the project is to implement real-time data-driven aquaculture feeding technology for farmers in both Peru and eventually all of Latin America.

This project is the first step in Umitron’s long term plans to support and develop technology for Latin American aquaculture producers. Through impact investment, Umitron is looking for similar public private partnerships where they can assist aquaculture producers to increase their ability to deliver high-quality, sustainably grown products in both Latin America and abroad, the company said.

The complete nutrition for all lifestages of zebrafish

GEMMA Micro is a unique, patented diet that offers complete nutrition for every lifestage of zebrafish. Integration of GEMMA Micro to the zebrafish feeding regime requires no Artemia and can reduce feed frequency to only one feeding event per day for adult fish. Smaller pellet sizes allow for earlier transition to microdiet from live feed.

www.skretting.us

Top three modules of the modular reef that were sampled and immediately returned to the same location. From

Location, modular reef design show promising results for shellfish restoration efforts

The success of an eastern oyster (Crassostrea virginica) and hooked mussel (Ischadium recurvum) restoration effort in Chesapeake Bay has been credited to the “complex architectural design of a concrete modular reef” and its location.

Made of rebar-reinforced concrete, the artificial reef was composed of five modules stacked on each other. Each module had a total surface area of 75 square meters. It was designed by Ret. Capt. Robert Jensen with the intention of providing suitable substrate of eastern oyster in a highflow, low-siltation habitat.

“This modular reef is one of the most successful artificial reefs for eastern oyster and hooked mussel restoration, and details features that are conducive for successful settlement, growth and survival in subtidal habitats,” said authors Romuald N. Lipcius and Russell P. Burke, who are affiliated with the Virginia Institute of Marine Science, College of William & Mary.

It was deployed subtidally at a seven-meter depth near the mouth of the Rappahannock River, a western-shore tributary of Chesapeake Bay, where strong currents delivered food and larvae.

“The key findings of our study, which we believe is one of the most thorough evaluations of subtidal artificial oyster reefs, relate to reef features that are most conducive for successful settlement, growth and survival of the eastern oyster and hooked mussel in subtidal habitats,” the authors cited.

The five-year study documented “density, abundance, biomass and size structure of the eastern oyster and hooked mussel as a function of various features of the artificial reef, which can serve as a model for the use, performance and monitoring of artificial reefs in restoration efforts.”

The densities translated to 1,085 oysters and 8,617 mussels per square meter river bottom, which researchers said are the highest recorded for artificial oyster reefs.

Size structure of oysters reflected four year classes. About 40 percent of the oysters were spats and the re-

maining were reproductive age.

The study was completed in May 2005. A research article was published in October 2018 in PLOS ONE.

“Oyster densities of spat and adults on the modular reef were comparable to those on the most successful restored shell reefs for the eastern oyster, which averaged 683 adults and 344 spat m-2, and higher than those on other successful restoration shell reefs for eastern oyster,” the authors said.

The densities were also comparable to or higher than those on natural, unharvested subtidal reefs in Louisiana and Texas.

The modular reef’s design proved an “extremely effective structure” for restoring eastern oyster and hooked mussel populations because it “provided suitable habitat for another suspension-feeding bivalve, thereby augmenting ecosystem services of the reef.”

More on the density, they said, “We also suggest that mussel density was highest on the top face, not only due to the strong currents, but also due to the protection afforded by crevices within oyster clusters.”

left: Captain R. Jensen, R. Lipcius, and K. Knick. (Photo credit: L. Latane)

BY RUBY GONZALEZ

Muscles for Philippines mussel industry

BY RUBY GONZALEZ

he Philippine government bats to address the challenges impeding the growth of the Philippine mussel industry with the Mussel Industry Strategic S&T Program.

TUnder this initiative by the Philippines Council for Agriculture, Aquatic, and Natural Resources Research and Development of the Department of Science and Technology (PCAARRD- DOST), hatchery and nursery protocols/techniques were introduced to delve into concerns such as low production of mussels and insufficient and unstable seed stock.

“The mussel industry in the Philippines is still dependent on collection of wild spats,” Dr. Carlos Baylon, a professor at the University of the Philippines – Visayas (UPV) and the chair of the First Philippine Mussel Conference, told Hatchery International. “The supply from the wild should be supported by production from the hatchery.”

The Philippines produces green mussel (Perna viridis) Along with P. canaliculus, green mussels account for 10 percent of global mussel production. The rest are blue mussels, Mytilus edulis and M. galloprovincialis

Spat supply is affected by both human activities and nature.

“The deterioration of the culture/spawning sites are due to anthropogenic perturbations, occurrence of natural calamities – flood, landslide, typhoon – and inadequate number of mussel broodstock left in the traditional mussel growing areas due to overharvesting,” said Dr. Mary Jane Amar, a mussel expert at UPV.

Mussel production in the country uses stake and longline methods.

“According to the PCAARRD-funded Ex-Ante analysis for the mussel spat requirement, the country needs about 679 million and 151 million spats per year for the stake and longline method, respectively,” Amar said.

This was estimated based on the 900-hectare area available for culture.

To work on these issues, including spat production and quality, UP-Visayas launched in 2014 the Mussel Hatchery and Nursery Program with funding support from the PCAARRD- DOST.

Year 2014 coincided with the second consecutive year of dip in Philippine mussel production. From 25,660 metric tons in 2012, production in 2014 fell to 18,762 metric tons. The fall continued until 2015 before bouncing back in 2016. In 2017, production was 19,209 metric tons.

At the congress, held in October 2018, Amar presented the program results.

In the abstract, she cited, “This is a recent work on the development of larval rearing techniques for the green mussel, P. viridis in the country. P. viridis larval survival from D-hinged to pediveliger stage was about 50 percent, and from D-hinged to early spat stage (1mm) was 4.4 per-

cent. In the nursery phase, survival from early spat to spat (1cm) was 94 percent,” she said.

The hatchery-produced P. viridis spats were transported to different culture sites as far as the northern tip of the Philippines located some 1,250 km from the site, and attained high survival of up to 100 percent.

Aside from reliable and quality spat, farmer behavior

and technology are also holding back industry productivity, industry leaders told The Daily Guardian on the sidelines of the congress.

DOST Sec. Fortunato dela Peña said the “non-entrepreneurial character deters higher productivity.”

Baylon cited “very primitive methods” still being used by the farmers.

Green mussel harvest (Photos: Mussels Philippines)

Breeders from the wild at the hatchery developed by the University of the Philippines – Visayas

Slow and steady

Sturgeon breeding success continues for ‘crazy’ German pioneer

BY COLIN LEY

Brothers Peter and Udo Gross have been farming sturgeon (Acipenseridae) at their Fischtucht Rhönforelle farm in central Germany for 29 years, working their way through an initial cost-only decade before settling into a pattern of progressive production which continues today.

Currently working with eight different sturgeon species, five of which are reproducing nicely while the other three remain ‘in development’ in breeding terms, the brothers’ sturgeon adventure has never been boring or, for that matter, particularly easy. It has, however, always been exciting and rewarding, at least after the first 10 years of investment was completed.

ROOTS

Fischtucht Rhönforelle, which is a flow-through freshwater pond located near Gersfeld, in the heart of the country’s Rhön region, has been in the family since 1882 when it was established by the present owners’ greatgrandfather, Eligeus Gross.

He initially used the farm to produce brown trout, a fish which at the time were considered a delicacy in Germany, creating a demand for his product which he transported to customers by horse and cart in water-filled barrels. Although the business has kept pace with changing production and market demands over the years, the sale of trout for consumption remained the core of the business throughout its first 100 years.

That was before Peter, aged 20 at the time, returned in 1990 from a period of fish farming experience in the U.S.A., which included a brief work placement with a major trout producer in Idaho.

What really grabbed his attention, however, wasn’t the potential of farming trout for a living but the more exciting appeal of raising sturgeon, which he also saw during his time in Idaho.

The ultimate aim was to produce caviar, a goal which was finally achieved last year, 28 years after Peter’s return from the U.S. His sturgeon story is much bigger, however, than just the production of 10 kilograms of homeproduced Rhönforelle caviar in 2018.

BUSINESS BUILDING

For the last 19 years, in fact, Peter and Udo have slowly but steadily developed a sturgeon breeding operation, based on five different breed species, from which they produce one million eggs a year for sale to customers around the world. They also supply sturgeon fingerlings to on-growers throughout Germany.

Before starting to earn money from sturgeon, however, the brothers had to endure 10 years of investment and learning, alongside a large amount of breeding trial and error.

“That first decade was really all about costs and not much about income,” says Peter, whose enthusiasm for the idea of breeding sturgeon in the harsh winter conditions of the Rhön region somehow got him through the difficulties of the start-up period.

“The main reaction I got when I arrived back from the USA talking about sturgeon was that I was crazy to even think about farming the species in Germany,” he says. “It wasn’t much better a few months later when I met representatives of a major Soviet Union company, Sofrybflot, who were promoting their high-quality caviar at Germany’s massive ANUGA food trade fair, held in Cologne.

“When I told them I wanted to buy fertilized sturgeon eggs from them, not caviar, they said it wasn’t really their thing but if I wanted to travel to Russia to see their farming operation, I was welcome. Two months later, along with a good friend, I drove to their farm in Konakowo, which is about 200 kilometres from Moscow to take a look.”

Actually, it was a bit more than a look, as Peter and his companion, ar-

Some of the earlier sturgeon broodstock at the Fischtucht Rhönforelle farm are nearly 30 years old and weigh up to 150 kg.

rived with a pick-up, fully equipped with empty fish tank and a full oxygen cylinder. Having already negotiated the legal requirements to enable him to return to Germany with live fish, his Russian hosts eventually responded by providing him with a starting consignment of 1,000 fingerlings. Pre-sale discussions took about two days but when he left Russia, it was with a full fish tank and an ondemand oxygen cylinder.

“This was quite a breakthrough,” Peter says. “We became one of the fish farms in West Germany (as it was until 1990) to be allowed to bring live sturgeon into the country. Egg imports into the EU from the former Soviet Union had been possible before then, arriving in France in the 1980s, for example, but not live fish.”

SLOWLY BUT SURELY

Having established that live sturgeon and fertilized eggs could be moved safely and legally from Russia to their Fischtucht Rhönforelle location, Peter and Udo turned their focus on how to make their breeding operation successful.

“One of the first things we had to do was to introduce heat into our former trout hatchery to create the warmer water which sturgeon require to achieve acceptable growth rates,” says Peter.

“During those first years we depended wholly on obtaining new supplies from Russia, although we didn’t travel to collect live fish any more, being happy to progress with imported fertilized eggs.”

With sturgeon females taking anything between nine and 14 years to reach sexual maturity, and then only spawning once every two to three years, the start-up period for the new unit was inevitably slow. As a result, it was the year 2000 before Fischtucht Rhönforelle was ready to start producing its own eggs.

“Although it was a long 10 years of development to go through, the good news is that our sturgeon operation, when it began, was successful,” says Peter. “Unfortunately, having convinced my father that farming the species was a good idea, we initially found ourselves in 1991 and 1992 with 20,000 fingerlings but with nobody wanting to buy them.

“There was no idea among other fish farmers at the time that rearing sturgeon might be a good idea. There seemed to be plenty of caviar available from traditional wild sources to keep the market happy.

“Later, around 1996 - 1998, sturgeon started to appear on the endangered species list, prompting many people to start thinking about the potential of producing caviar from farmed sturgeon. So, while our first years were very hard, the work we’d done from 1990 to 1998 paid off in that we were ready and able to provide high quality fertilized eggs to many customers when demand began to build.”

After a strong growth and income period for the farm, driven largely by the knock-on effect on the world market of China’s sturgeon investments, Peter and Udo’s business today is based on a solid home-grown broodstock base, with some of their earliest fish now nearing 30 years of age and weighing up to 150 kg.

While the fertilized egg market isn’t as dramatic as it was 20 years ago, the brothers are still selling successfully into several European countries, exporting to South and North America, plus sending smaller consignments to Vietnam, Kazakhstan and one or two other countries.

“While the original aim, back in 1990, was to produce caviar, we’re very happy with where we are with our sturgeon breeding enterprise today,” says Peter. “Our breeding program

developed naturally in tune with the cold winter climate in which we have to operate, leading us to concentrate on fertilized egg production and the raising of fingerlings.

“Having started from scratch with our own young fish and relatively small stock numbers, it didn’t make sense for us to kill any of our fish in order to harvest caviar, as would have been necessary under German regulations. Producers here aren’t allowed to use ovulated eggs for caviar. It’s allowed in other countries but not here, which is why we’re still only producing a very small amount of caviar from our stock.

“Alongside this, however, we have a strong breeding base for sturgeon in Germany, 29 years after being told it crazy to attempt such a thing.”

COMPETENCE INNOVATIVE PROFESSIONAL

Fischtucht Rhönforelle has been steadily developing a sturgeon breeding program for nearly two decades.

like to use, and get feedback from our fish culturists,” says Boucher. “We wanted to collect some data so we have some information to say, ‘Ok, after a couple of seasons trying it, here’s what we can expect out the other end.’”

FIRST TRIAL

The first test used the Norwegian designed Alvestad Easy Hatch substrate mat. “I like this one because the bottom is perforated. You are going to be getting good gas flow and water exchange,” says Boucher. “I like that it’s rigid, but also the space between the fingers for our relatively small egg size was good.”

The hatchery built a quadrant shelf to fit in a threefoot, 1,200-liter combi tank and lined the bottom with the substrate mat. The control was a stack of standard heath trays.

Some 5,600 spawned eggs were reared in an up-welling MacDonalds style jar until they were eyed. Half went into the substrate shelf and half into heath stacks. Both were reared at 10 degrees Celsius on the same well water and in the same facility.

“This was all done at production densities right on the production floor with the fish culturalist helping,” Boucher explains. “That to me was the most meaningful way to do this, so we did actually see what we can expect in a real honest to goodness situation.”

“Then we had to sample them,” says Boucher. “We wanted to know if there were any growth gains? Are we going to be saving any time?”

The team defined performance by looking at growth in both length and weight. They wanted to know size at ponding (first feeding) and the time it takes to get to half-gram and time to one gram. They also looked at survival rates.

During incubation, the fish were sampled every three days, 90 fish per treatment, looking at length and weight. Once they were ponded, samples were taken every week. “We proved these fish out all the way to one gram,” adds Boucher.

At ponding, substrate fish were 12 percent larger, says Boucher. “That is significant because these fish are at 10 degrees and have only been rearing in the substrate about 20 days.”

“We also observed, but did not quantify, that the substrate fish appeared to be moving a lot less,” Boucher adds. “And the substrate fish really showed good emergence behavior. Both sample groups were ponded into combi tanks. Size difference continued to increase throughout the evaluation, with those fish from the substrate continuing to grow larger. Fish from the substrate group reached a half gram 10 days earlier than the control group, notes Boucher. “Remember they had the same temperature, same loading density, same feed rate. We even checked that velocity and oxygen was controlled for,” he adds. “So, what we are seeing here is definitely the effect of the substrate.”

“We saw that we got fish to one gram 14 days earlier,” says Boucher. It was 54 days after they came out of the substrate.

SECOND TRIAL

Boucher says they do most of the incubation in heath stacks. They wanted to adapt the substrate into the rearing trays. Substrate mats were cut to fit and adhered into the heath stack. “We just removed the bottom PVC screen and it held together really well.”

This was a much smaller version of the first trial. It was conducted only until the eggs would have been ponded. “The goal was to say, ‘OK, we got pretty good results from the first trial. Are these trays going to hold together? Are they going to be effective,’” Boucher recalls. “And would we be interested in using these again?”

The eggs were again reared to eye stage in up-welling jars and loaded in equal density into three substrate modified trays and three regular heath trays again at 10 degrees. Trays were alternated in the stack. Fungus was controlled by a parasite S drip system.

“Again, we got 12 percent larger fish at ponding,” says Boucher. “It was interesting seeing pretty consistent results.” The alevin also appeared to move less in the substrate. Fungus in the trays was negligible.

There were no difference in losses in either of the tests, Boucher says.

“We know from the literature that complexity in early rearing is a really good thing,” says Boucher. “Even this early in early rearing, complexity leads to increases in brain volume and increases in swimming performance.”

Using substrate in early rearing raises larger fish in less time. “What we are talking about is a higher quality product at the end.”

PRODUCT DEVELOPMENT

Incubation systems provider MariSource confirms they installed the substrate that Boucher used in their rearing trays and are now working on a permanent solution. “We

are working to design it so that we can injection mold the substrate into the bottom of the tray all in one piece,” says Mike Fudge MariSource sales manager.

Fudge says the substrate would replace the PVC mesh screen that is currently used to line the bottom of the trays. “Those screens have to be cleaned very carefully,” he points out. “They also have to be replaced every couple of years.”

The injection molded unit could be cleaned with a pressure washer. While it will come at a price premium, it will save on the PVC screen maintenance.

It enables the up-welling and flow-through design of the tray to continue to function. “It’s a good concept, it makes the eggs feel like they are in the bottom of a river bed,” says Fudge. “And you are getting a much better fish at the end.”

HATCHERY FEEDING SYSTEM (HFS)

Complete feeding solutions for aquatic hatcheries

• Microdiets

• Weaning Diets

• Micro Algae

• Live Feeds

Collaboration boosts South American breeding programs

BY COLIN LEY

Ross Houston, and his genetics group, with the aim of helping to develop a new set of breeding tools for use in the improvement of native fish species in Brazil.

The key focus of the collaboration was Piaractus mesopotamicus, a Brazilian freshwater species which is popularly known in South America as ‘Pacu,’ a name best translated as ‘fast eater fish'.

One of the most important freshwater species in the region, mainly because of its size, reaching up to 40 inches long and weighing up to 40 lbs., Pacu has become a victim of over-fishing in recent years. This has, in turn, prompted an increased requirement for aquaculture to supply animal protein to the population in a sustainable and profitable way, and to play a part in helping to restore species numbers.

Due to a lack of biological information relating to Pacu, coupled with little understanding of the species’ susceptibility to bacteria under stressful conditions and immunity factors when cultured in intensive production systems, farming Pacu has so far resulted in high mortality rates. This was largely due to bacterial diseases, such as aeromoniosis.

BETTER GENES

Almost as important as the mortality issue, the task of farming Pacu successfully also involved the marked use of antibiotics or bactericides, a requirement which it’s hoped the genetic improvement of the species can reduce.

Filho’s time at Roslin was spent seeking to apply the genetics knowledge and expertise, already developed by Houston and his group, to the farming problems surrounding Pacu. A particular focus was on applying modern genomic tools to the species, especially as they relate to resistance against bacterial infections.

These tools, which were already developed and well understood at Roslin, relate to how to acquire genomic knowledge about the immune system of an individual species and how to apply such immunity factors within future breeding programs.

To address the circumstances surrounding Pacu, in particular, the joint Brazil/Scotland study was designed to genetically characterize the species according to its resistance to the bacteria Aeromonas hydrophila.

This involved the characterization of immune system genes of both susceptible and resistant individuals which were challenged with A. hydrophila infection. Work was also done to identify regions of the Pacu’s genome associated with resistance to A. hydrophila, also known as QTL (Quantitative Trait Locus) analysis.

This was the context in which Filho worked with Roslin’s Dr. Carolina Peñaloza, Dr. Diego Robledo and Dr. Alejandro Gutierrez, seeking to generate a genomic profile of the host response to A. hydrophila infection in Pacu. The ultimate aim was to establish genetic markers for use in the development of future breeding programs which specifically tackle disease issues surrounding the species.

This was the first research of its type to be performed on a Brazilian native fish species and, as such, could become the cornerstone for the development of genomic resources for other South American species, potentially leading to the integration of genomic tools to improve selective breeding across Brazilian aquaculture.

“The accomplishment of our analyses will generate results that can be applied in the development of Brazilian native species production,” said Filho. “This is particularly the case in issues related to fish mortality in aquaculture.”

Houston was similarly positive, adding that the collaboration has helped Roslin's genetics group to develop a set of genomic tools and techniques that could potentially be used to study the genetics of new aquaculture species.

Vito Mastrochirico (left, seated) and Ross Houston (center, standing) with the research team at Roslin Institute in Edinburgh, Scotland.

Changing the conversation

Conference highlights successes in land-based farming, sustainable production systems

BY MARI-LEN DE GUZMAN

MIAMI, Fla. – It's time for the aquaculture industry to realize its potential for sustainable food production to answer the growing demand for food of an increasing world population.

This was the overarching message from some of aquaculture's most avid advocates in the food industry during the two-day Aquaculture Innovation Workshop (AIW) in Miami, Florida, U.S.A., hosted by The Conservation Fund's Freshwater Institute.

"Seafood bears the albatross of being guilty before proven innocent," said executive chef and sustainability advocate Barton Seaver, in his keynote address at the AIW. He points out the lack of public education about aquaculture and the bad reputation the industry has endured over the years, do not do justice to the potential of aquaculture to help solve the world's food supply challenges in a more sustainable way.

Barton commends the innovations transpiring in the aquaculture industry, particularly the movement toward more sustainable seafood farming practices, saying this needs to be front and centre in public messaging.

"We are sitting in a room where a new food production system is being invented; it's technology, it's innovation... it can happen in cities, it can happen in the ocean, it's hip," Barton said of recent innovations in sustainable aquaculture production systems.

Barton, who founded Coastal Culinary Academy in

Portland, Maine, U.S.A., also called for more content around seafood in culinary education, saying chefs and cooks are not being educated enough on seafood and aquaculture. With statistics indicating that two out of three meals a day are eaten outside the home, Barton says chefs are the "perfect pathway by which we accomplish our goal of increasing seafood use across demographics."

"We should portray seafood and its production as a principal catalyst by which we create food systems designed to make people thrive, and aquaculture is the key to this," he added. "My challenge to you is to envision seafood not as a product category but as a frontier for sustainability; our means to fix people and fix food systems."

today's seafood products are not being sold in a way that speaks to the consumers and responds to their needs.

"First, it needs to taste good. All of the potential of aquaculture is unrealized if people don't eat it," Claudia said.

PRICE OF SUSTAINABILITY

Pricing for sustainably farmed seafood is also a challenge if the industry were to promote increased consumption of seafood. Seafood farmed in land-based production systems or in ways that reduce its environmental footprint has a premium attached to it and that, according to Claudia, can spell the difference in consumers' buying choices.

One food industry executive echoed Barton's call for the aquaculture industry to take control of the messaging around seafood and seafood production.

"(Seafood does) not have an awareness problem in the U.S., at least; it's a product and placement problem," said Jacqueline Claudia, CEO and founder of frozen seafood brand Love The Wild. "Most people, when they go to the grocery store, don't even go to the seafood section."

Love The Wild promotes sustainably farmed seafood through its off-the-shelf packaged products. Claudia says

"We need to be competitive (with pricing). Unless we can really address the cost of growing fish we are going to have a really nice niche business, but we are not really here to create a niche business," Claudia said.

She added, "I understand putting a premium on price of seafood, but premiums have got to go away. We have to be competitive with other animal proteins."

Perhaps, this might be happening soon. Industry observers believe as companies with sustainable systems increase production capacity overtime, premium pricing will go away. Producing Atlantic salmon on land at higher volumes, for example, might help with the pricing challenge.

Jacqueline Claudia, CEO, Love The Wild

All eyes in the industry are on Atlantic Sapphire, as the company ramps up construction of a massive landbased, RAS salmon farm in Miami, Florida (see page 23).

The project is being done in three phases, with phase one bringing the company's production capacity to 10,000 metric tons by third quarter of 2020, and will scale to more than 60,000 metric tons by 2026.