DECADES

EXPERIENCE

MULTIPLE

DECADES

EXPERIENCE

MULTIPLE

BY JEAN KO DIN

Another year has come and gone for the hatchery industry. As we look at the challenges that continue to face us – rising operational costs, supply shortages, climate change – it sometimes feels like we’re fighting an uphill battle in our work.

Whether you raise fish for food production, for sport fishing, or for enhanching local populations, I can understand the pressures you must face in the pursuit of a healthy and productive season. But, as we come down from the holiday season and start to look ahead at the work still to be done, we must also take some time to look back. This is a friendly reminder to celebrate the wins, no matter how small or insignificant we may think they are.

This is especially important in front of the young people that you work with.

The Skillwork Forum says that one of the most concerning skilled trade shortage statistics is the ratio of Baby Boomers retiring to Millennials and Gen Z entering the trades. For every five Baby Boomers that retire, only two candidates of the younger generations are coming behind to replace them. Though the statistics are drawn from U.S. workforce data, I’m sure similarities can be seen around the world.

The hatchery industry talks all the time about the looming knowledge and skills gap as seasoned professionals start to retire. I’ve even heard of many that have been called out of retirement because of this huge need to pass on that hard-earned expertise onto the next generation.

At the same time, many companies can’t wait for grads or trainees to fill their labour demands. There is so much work to be done and there are not enough highly skilled people to do it.

So, for those of you who are reading these pages, let me propose your resolution for 2025. If you are an older professional that

work with younger staff members, I urge you to be be a part of injecting a growth mindset for those who are in your network.

Remind the next generation that their work is part of a bigger picture. They need to know that their day-to-day work contributes to feeding the world, or preserving a natural ecosystem, or even continuing a sports tradition that have endured for millennia.

Having someone in your corner can make all the difference between someone who is there for the paycheque and someone who is there to make a difference.

I think the young staff also need to see that their supervisors and their mentors still carry the same passion that they did at the beginning. The thing that has motivated you for decades can become the thing that also inspires others to fuel their own decades-long careers, long after you’ve left the workforce.

Encourage them to grow in their roles, learn new skills, listen to them pitch new ideas, and engage in new responsibilities that will help them feel challenged, but fulfilled. Hire them, promote them, and let them take up new spaces around the decision-making table. Just because it was not what was done before, does not mean that it is the wrong way to do it. Experimentation has always been the origin of establishing new standards.

And while we’re at it, we hope you share Hatchery International with your network too. Let it be our goal to help in that sharing of research, expertise, and also just good ol’ fashioned farming stories that celebrate professionals and their work. We want to model the kind of growth mindset that we need to sustain a legacy industry like this one.

And as always, if our team ever misses the mark, please don’t hesitate to reach out and give your two cents. As I always like to say, my email inbox is always open at jkodin@ annexbusinessmedia.com. | HI

Hatchery International’s Editorial Advisory Board: Ryan Couture I Ron Hill I Alpa Pansuriya I Noelia Rodriguez I Jesse Trushenski

VOLUME 26, ISSUE 1 | JANUARY/FEBRUARY 2025

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon smoritiwon@annexbusinessmedia.com

Contributors Bob Atwiine, Curtis Crouse, John Davidson, Lynn Fantom, Ruby Gonzalez, Chris Good, Nicole Kirchhoff, Christine Lepine, John Mosig, Magida Tabbara, Vlad Vorotnikov

Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com +1-416-606-6964

Account Coordinator Catherine Giles cgiles@annexbusinessmedia.com

Media Designer Svetlana Avrutin savrutin@annexbusinessmedia.com

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

Group Publisher Anne Beswick abeswick@annexbusinessmedia.com 416-410-5248

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

To subscribe visit our website at www.hatcheryinternational.com

Printed in Canada ISSN 1922-4117

Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Hatchery International are copyright ©2025 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the Mar/Apr issue is Jan. 14. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our advertising department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the Mar/Apr issue is Jan. 13. Contact Jean Ko Din at jkodin@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

Oceanic Institute releases 300 juvenile yellow tang to aid Hawaiian reef restoration

The Oceanic Institute (OI) of Hawai’i Pacific University (HPU) has released over 300 farmed juvenile yellow tang (lau’īpala) into the waters of Oahu.

This project—carried out together with Georgia Aquarium and Disney’s Aulani Resort—was the first documented release of fish in Hawai’i aimed at preserving Hawai’i’s coral reefs rather than food production. With a focus on ecosystem health, the initiative showed a new model for reef restoration efforts in Hawai’i, a press release from Hawai’i Pacific University states. Researchers performed extensive trials. They first succeeded in producing fertilized eggs in captivity, and after a decade of study, identified the specific plankton needed to sustain baby yellow tang through their juvenile stages. This approach provided an alternative to wild-caught yellow tang for the aquarium trade. With financial support from Georgia Aquarium, OI partnered with Disney’s Aulani Resort Rainbow Reef Aquarium to harvest and transport fertilized eggs from their exhibit tanks to OI’s facilities.

A biologist from the Hawai’i State Department of Land and Natural Resources (DLNR) inspected the fish for pathogens shortly before the release on Nov. 2.

“The release of these iconic coral reef fish into our nearshore waters represented a historic, watershed moment for OI, HPU, and the State of Hawai’i. This represents a tremendous opportunity to add another important tool in our collective toolbox to protect our coral reefs for future generations,” said Shaun Moss, executive director at Oceanic Institute.

Hawai’i’s coral reefs have an estimated US$33 billion in value and contribute about $800 million annually to the local economy. Despite this, threats from climate change, pol-

lution, and invasive species have increasingly jeopardized their survival.

“The fish in Aulani Resort’s Rainbow Reef essentially act as ambassadors to Hawai‘i. Every day, they help educate our visitors about their fragile reef environment and the actions we can take to protect them. Through this program, we are happy to be playing a role in continuing their sustainability message beyond Aulani Resort, into other aquariums, and now back into the ocean,” said Rafael Jacinto, animal and water sciences operations manager at Aulani.

According to Hawai’i Pacific University, the release demonstrates how aquaculture can directly support reef health and serves as a model for future restoration efforts across Hawai’i.

The recently concluded 15th Aquaculture Association of Southern Africa (AASA) Conference, held in Stellenbosch, South Africa was a key event for the region’s aquaculture industry.

The conference was held under the theme “sustainable development of aquaculture in Southern Africa, a critical issue as the global demand for seafood continues to rise while traditional fishing industries face environmental and economic challenges”.

In partnership with All Atlantic Ocean Sustainable, Profitable & Resilient Aquaculture (ASTRAL), the event brought together industry leaders, experts, researchers and students from around Africa with a major focus on advancing aquaculture in Southern Africa through sustainable practices, new technologies and research-driven solutions.

The sessions emphasized how the region can leverage its aquatic resources to position itself as a significant player in global aquaculture while ensuring sustainability.

Key discussions explored enhancing production capacity, improving fish health management, and protecting the environment.

Industry leaders, along with delegates from South Africa’s Department of Forestry, Fisheries, and Environment (DFFE), engaged in important conversations that support sustainable aquaculture growth.

One of the most highlighted concepts during the event was Integrated Multitrophic Aquaculture (IMTA), a system that involves farming multiple species at different trophic levels in the same ecosystem. IMTA is seen as a solution for balancing production with environmental health. It allows for a symbiotic relationship between species such as fish, seaweed, and shellfish, where one species’ waste becomes a resource for another.

The ASTRAL project focused on the implementation of IMTA to boost production while minimizing the environmental impact of traditional aquaculture practices.

Industry experts also shared insights on how to overcome the region’s challenges, such as limited infrastructure, capital access, market access and regulatory hurdles.

Companies like Sea Harvest Group presented their aquaculture graduate program to students at the conference and associations such as Tilapia Farmers Association of South Africa presented the state of the tilapia sector and challenges faced by farmers in the field.

The conference underscored the need for stronger collaboration between government bodies and the private sector to create policies that enable growth in the aquaculture industry.

The delegates also called for the urgent need for investment in research and infrastructure to help small-scale fish farmers scale their operations sustainably.

– Bob Atwiine

Uzgen Fish Farm, a state-owned farm in Kyrgyzstan, has launched production of carp fish and broodstock in fish-and-rice farms, the Agricultural Ministry said in a statement on its website.

The farm breeds common carp (Cyprinus carpio), silver carp (Hypophthalmichthys molitri), and grass carp (Ctenopharyngodon idella) in several ponds, the Ministry reported.

In recent years, Kyrgyzstan, a

small state in Central Asia between Kazakhstan, Uzbekistan and China, has been experiencing an aquacultural boom. Fish production in the land-locked country more than tripled since 2011, reaching 33,600 tonnes in 2023.

The rapid growth turned Kyrgyzstan into a net fish exporter, with sales to foreign customers standing at 5,600 tonnes in 2023 according to official information.

Kyrgyzstan is a pioneer in the post-Soviet space in establishing fish-and-rice farms, a practice popular in the countries of Southeast Asia.

The ministry said such production technology boasts several advantages. “In search of food, fish loosen the soil and break up the biological film on the water’s surface. Fish also kill the larvae of the rice mosquito, the main pest of rice,” the ministry explained, adding that fish excrement and feed serve as fertilizer.

As a result, the rice yields grow by eight to 10 centners per hectare, the ministry said, describing the approach as particularly profitable.

The Kyrgyzstan Agricultural Ministry also described operational and environmental challenges farmers who want to run fish-andrice farms must brace for.

This is only one example of the effort the Kyrgyzstan government makes to give further development impetus to aquaculture. In July 2024, the authorities facilitated the establishment of a consortium between a group of local companies and the Korean aquacultural firm King Salmon. The consortium aims to construct the national aquacultural centre for 50 million soms (US$600,000). This centre, which

will run its own hatchery, will serve as a hub for aquaculture research, education, and production, and is expected to significantly contribute to the growth of the industry in Kyrgyzstan.

– Vlad Vorotnikov

The Belarussian government has commissioned work on new aquacultural law, hoping the legal framework will propel growth in the promising industry.

Olga Boreisha, head of the livestock and aquacultural department of the Belarussian Agricultural Ministry, said the idea of developing the law originated from joint projects with Russia, where similar legislation is already in force.

A similar law was passed in 2023 in Kazakhstan, where it is intended to facilitate a nearly tenfold growth in production by the end of the decade.

“Our legislation has such a concept as “fish farming”, but not such as “aquaculture,” Boreisha said, explaining that this legal gap leaves farmers breeding seafood in the grey zone. Among other things, they cannot count on state aid for which fish farmers are eligible.

“The main message of the draft law’s developers is to consolidate the understanding of aquaculture in the business environment and among the population and to expand its prospects,” Boreisha added.

In general, Boreisha said that the future of Belarussian aquaculture is associated with RAS technologies.

Over the past few years, Belarus has emerged as a prominent fish feed and broodstock producer in the Eurasia Economic Union, a trade bloc of five post-Soviet countries.

Belarus exports significant quantities of trout (Salmo gairdneri) fry and broodstock of the herbivorous fish species to Russia, where aquaculture has been grappling with the impact of Western sanctions. In the meantime, Boreisha admitted that fish farming in the country has yet

to unlock its potential. The country remains largely dependent on fish imports from Russia and other countries.

The work on the draft bill is scheduled to be finished by June 2025, after which it will be passed to Belarussian lawmakers for approval.

– Vlad Vorotnikov

South African firm develops digital tools to help African fish farmers using AI Dominion Solutions, a South African aquaculture firm, has developed digital tools and systems that can help African fish farmers monitor fish behaviour using artificial intelligence (AI) and ensure efficient utilization of fish feeds.

Shongwe Thembeka, the founder and CEO of Dominion Solutions says she started the consultancy company after observing a big gap

within South African aquaculture which she says is still behind compared to the rest of the world.

According to Thembeka, the aquaculture sector in South Africa is still underdeveloped, which she attributes to a lack of access to land and sea space, a small pool of skills and knowledge, limited access to funding and investment, and limited extension support.

“I started Dominion Solutions because I saw the need for further

development of the South African aquaculture sector in terms of sustainable aquaculture management, training and skills development, knowledge transfer and business support to small-scale farmers,” said Thembeka.

She revealed that “South Africa despite being one of the most developed countries in Africa, the country is only contributing 0.08 per cent to the global aquaculture sector, which disheartened me and I found myself looking at how I can make an impact on the sector.”

An aquaculture consultant, and marine biologist, Thembeka says her work is to bridge the industry gaps that fish farmers face by addressing challenges such as limited funding, outdated practices and underutilized resources.

Under this strategy, Dominion Solutions has developed a precision aquaculture tool to address the challenge of high fish feed

costs and excessive feed waste in water systems.

AquaBrain Net is an artificial intelligence-powered tool that optimizes fish feeding by monitoring fish behaviour and generates optimized feeding schedules ensuring that feed is distributed efficiently.

“As we all know fish feed is the highest operational cost in a fish farm production, so smallscale farmers struggle to keep up with increasing feed prices. This tool helps farmers reduce waste which indirectly reduces their feed cost,” Thembeka told Hatchery International.

She further noted that there are other benefits of the tool which her team of scientists is currently researching, adding that they are very excited at the prospect of AquaBrain Net alleviating feed cost pressure on small-scale farmers in South Africa. | HI

– Bob Atwiine

nutrients for improved health and fast growth. Optimum conditions for survival for both larvae and fry.

Low mortality and uniform fish stocks with tailored feeds without compromise result in no deformities and uniform fish stocks.

Optimal environmental conditions and water quality are paramount for successful transitioning from yolk-sac to external feeding.

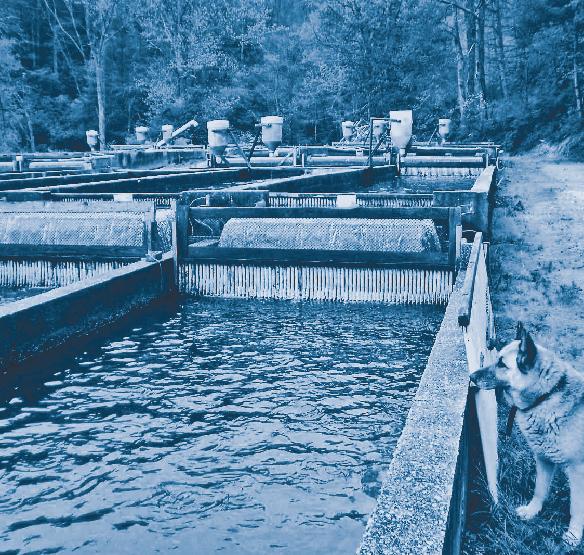

Ontario’s Community Hatchery Program relies on passionate volunteers for fish stocking

By Seyitan Moritiwon

Alan Sutter has spent the past 15 years raising brown and rainbow trout in a community hatchery that existed before his birth.

He spends about four hours a week at the Bruce Peninsula Sportsmen’s Association (BPSA) Fish Hatchery feeding fish and cleaning their tanks. But at certain times in the year, during egg-collection and hatching, he’s there every day. He did this for about 10 years but knew he wanted to help out in a greater capacity. Soon enough, the role of hatchery manager at the Bruce Peninsula Sportsmen’s Association hatchery was passed down to him.

He describes raising fish in the community hatchery as “very rewarding. I enjoy it so much. More than just the joy of raising the fish and then getting to stock them for people to catch.”

“We get to run some kids’ fishing days and community living fishing days, and see people come in from the community and catch fish there, and see our hatchery. And to me, that’s the best part of it is getting to promote all this to the community. And a lot of times it’s people that have lived in our community for their whole lives and don’t realize that we’re doing this,” he added.

The Bruce Peninsula Sportsmen’s Association—which comprises about 50 other dedicated volunteers—is one of over 40 community hatcheries supported by the Community Hatchery Program (CHP).

The Community Hatchery Program started in 2013 after the Ontario Federation of Anglers and Hunters (OFAH) launched the partnership with the Ontario Government. On behalf of the Ministry of Natural Resources, Ontario (MNR), the CHP provides funding to eligible community hatcheries and supports Ontario’s community fish culture and stocking efforts.

In 2024, the OFAH and the MNR entered into a three-year transfer payment agreement where the MNR will provide C$1,045,500 (US$743,523) over the term of the agreement and the OFAH will administer the CHP on their behalf. CHP provides about C$175,000 (US$124,453) each year in reimbursement to these hatcheries to help with their operating expenses and capital improvement projects.

“We also share through workshops, meetings and small training protocols that we do, with the groups for different aspects of the hatchery depending on the time of year or the need. So anything from fish health testing— that’s a big one for us—and biosecurity, ensuring that our fish are healthy going into natural waters,” said Matt Burley, Community Hatchery Program coordinator at the OFAH.

With the help of over 2,300 volunteers who give 50,203 hours annually—which translates to about C$1.25 million (US$ 888,956) in-kind—these hatcheries have stocked over 76 million fish into Ontario lakes and rivers since 2013.

“The volunteers are tremendous and often, I would say, in most of the communities, people, anglers, people in the community are probably not really aware of the investment that people are putting into their local ecosystems,” said Burley.

With the slogan, public fish for public waters in Ontario, the volunteers give their all to raise fish for their communities.

One of those hatcheries is the Almaguin Community Hatchery Program, formerly known as the Almaguin Fish Improvement Association.

It has been going on for over 35 years, but the Ministry of Natural Resources shut it down in 2007 after a biologist in the Parry Sound office concluded that the volunteers’ work

wasn’t impacting local fish stock in the Magnetawan River system.

The hatchery restarted in 2011 and has been with the CHP since it started in 2013.

In 2020, Jerry Brandt, vice president, of the Almaguin Community Hatchery Program and two members, sat down over a cup of coffee, and on a piece of paper, drew up a plan to transform their hatchery into a mobile one. So, they got a trailer and started the mobile hatchery in 2020, during COVID-19. While wearing masks and protecting themselves, they were able to produce their first batch of walleye.

“No one expected to turn the light switch on and have the hatchery run and run unbelievably, right away, without any complications, but we were able to start the hatchery up, have it run, and we produced 1.6 million fry that year out of our 2 million quota,” said Brandt.

They produced about the same number in the second year. The numbers have fallen to 900,000 due to water quality, and Mother Nature.

Brandt said he noticed walleye populations were going downhill. When he was younger and used to go fishing with his grandpa and father, they’d get a good feed.

“You catch four or five and catch your limit in a day. And as time went on and I got older and kept on fishing, well, instead of five or six, you’re catching maybe two,” he said, adding that it was

why he started volunteering at the hatchery.

Thanks to their hatchery, “Now people are catching fish off their docks.”

One of Brandt’s highlights of volunteering is he did something nobody else has done.

Many people have used pineapple juice to de-stick fish eggs.

“Guess what, we’re the first to do in walleye, and it was 100 per cent success. Two failures, because you gotta get the mixture right, and then 200 per cent successes, and we hatch 350,000 on pineapple juice,” he said. “That’s my biggest accomplishment,”

added Brandt, although he said he needs credibility and more testing from universities.

The Almaguin Community Hatchery Program also educates kids about responsible hatchery practices, conservation and ecology both at the riverside and in the classroom. Brandt said his motivation to keep volunteering comes from seeing the smiles on the children’s faces as they help in the hatchery while listening.

Burley said the total annual operating budget is close to half a million dollars each year. Because

the CHP only has $175,000 to give these hatcheries yearly, some of them face the challenge of fundraising.

So they do a lot of additional fundraising dinners and often get support from the communities and local businesses to keep these hatcheries running. “And it’s not going down. It’s definitely going up. And with the inflation, it’s been just absolutely astronomical,” said Burley.

Nick Alfano, the chairman of the Georgian Triangle Anglers Association’s (GTAA) Community Hatchery, said funding is one of the challenges his hatchery

www.oxyguard.com

“I try to dedicate as much time as I can to that and I hope I can do it for a lot of years. I hope that it continues on, and I can do this well into my retired years.”

faces. Whatever the CHP is unable to cover, gets funded by the GTAA.

The Georgian Triangle Anglers Association’s Community Hatchery raises 50,000 rainbow trout, 30,000 brown trout, and 10,000 brook trout yearly. But roughly 70 per cent of them are put into the lake.

The hatchery has been in operation for more than 30 years, although Alfano has only been volunteering there for six years.

Alfano went into a store to get some bait to go fishing and met the president of the Georgian Triangle Anglers Association who asked if he’d be interested in volunteering at the hatchery. He’s been going ever since, feeding fish, and doing other chores that need to be done. “I like the idea, and gives me something to do. And it supports the community by putting fish back into the environment.”

“I also volunteer at a golf course. So, it’s fulfilling. It gives some purpose and reason to get up and go and do something. And depending on what it is, you feel some fulfillment. We raise 90,000 fish. So that’s a very important contribution to the environment,” Alfano added.

Sutter believes he’s going to be volunteering for as long as he can. “I try to dedicate as much time as I can to that and I hope I can do it for a lot of years. I hope that it continues on, and I can do this well into my retired years,” he said.

He said he knows a lot of other clubs are struggling with getting younger people involved in volunteering. “I’m very lucky to get in there and work while these guys (seniors) still want to be there and able to be there and pass this knowledge along to our generation and get some kind of a plan going.”

As a middle-aged man, Sutter tries to get his kids involved in feeding fish, cleaning tanks, grading fish, fin clipping, stocking fish and helping at their community events.

“As do some of the other people that are in there that are in around my age. We love getting the kids there and getting the kids involved at a young age, and hope that they do keep interest in this as well,” he added.

Burley shares these thoughts. Although there’s a need for more volunteers, he’s also happy to see more people coming out to volunteer regardless of their background. “They generally want to see good things happen within their community and their ecosystems and benefit the local waters that they enjoy and fish in,” he said.

“There’s also a lot of influx of different people from multicultural aspects, women, lots of children, teenagers volunteering. So it’s a great opportunity for us and for those groups, to start getting that next generation into those hatcheries, as the core group of volunteers that will become professionals,” Burley added. | HI

Industry outlook from hatcheries around the world

Although this is not a complete overview of the current events in the global hatchery industry, our editorial team at Hatchery International attempts to provide a general overview of what to expect for the new year. Hatcheries are an important cog in the larger fisheries and aquaculture machine. We continue to work towards providing our readers with as many different perspectives as possible.

Public sentiment and government intervention have become critical in North American aquaculture, both breathing new life into the industry and, at times, sounding the death knell.

Last September, NOAA Fisheries issued a National Seafood Strategy Implementation Plan that indicates more support for U.S. marine aquaculture. Currently, aquaculture for food fish is dominated by freshwater catfish raised in the southeastern region.

But improved regulatory efficiency and science-based support will be prioritized for U.S. marine aquaculture, according to the new report. This includes oyster breeding programs on the East and West coasts, as well as Alaska.

With much fanfare, the Northeast Oyster Breeding Center opened last year with the commitment to supply commercial

hatcheries with seed—free of charge—that is better adapted to regional growing conditions and more resilient to climate change.

Communication and outreach are also key goals that are critical in light of pockets of anti-aquaculture sentiment. The tide has been turning as more young people, including women, are pursuing careers to build a new “Blue Economy” not only with shellfish but also seaweed farming, which is the fastest-growing aquaculture sector in the U.S.

The country’s largest seaweed producer, Atlantic Sea Farms, has a robust hatchery in Maine that produces seed which is given free to its independent farmers, who are primarily lobstermen. Atlantic Sea Farms harvested a record-breaking 1.3 million pounds of farmed seaweed in 2024.

Despite these positive signs, overall social acceptability presents significant challenges

in North America, along with climate change, new ocean uses, labour shortages, and aging infrastructure, particularly for hatcheries.

In British Columbia, Canada, the government is mandating a move from open net pens to closed containment aquaculture by 2029 – a timeframe which the B.C. Salmon Farmers Association calls “unrealistic” and “unachievable.” It remains unclear how this action will affect hatcheries.

On the other hand, enthusiasm – and funding – remain high throughout North America for hatchery operations devoted to sports fishing and the enhancement of wild populations. Last October, the Biden-Harris Administration awarded US$240 million in federal funding to modernize tribal hatcheries in the Pacific Northwest.

– Lynn Fantom

Broodstock production in the European Union (EU) likely remains stagnant, and things are not expected to improve in the foreseeable future without a dramatic legislation change, according to sources.

The European Mollusc Producers Association (EMPA) has publicly appealed to European policymakers, calling for a new set of rules to reinvigorate the sector plagued by multiple crises.

The business organization revived the idea of developing a “Common Aquaculture Policy” – a long-discussed analogue of the E.U. Common Agricultural Policy, which involves a system of generous subsidies and support measures.

The EMPA appeal echoes the complaints that have been expressed by European fish farmers during the last few years.

For example, Javier Ojeda, general secretary of the Federation of European Aquacultural Producers, admitted that the industry lacked growth in recent years owing to excessive regulations strangling business and competition with imports from outside the E.U.

Broodstock production follows the same dynamics as the aquacultural industry as a whole. However, Ojeda said his organization lacks data to confidentially say how

this segment was impacted by the general turbulence.

The outlook for the European aquaculture and broodstock sector has not changed much during the past year, Emam Waseem, founder and head of the think tank, Ethical Seafood Research, commented. The economic shocks of the last few years, starting with the COVID-19 pandemic, dealt a blow to consumer spending on seafood products.

According to Waseem, the general outlook for European aquaculture remains somewhat gloomy, though there are some opportunities on the table.

In the meantime, the prospects of adopting the Common Aquaculture Policy look vague. The idea has been brewing in the European Commission for some time, but there are no signs of concrete results on the horizon.

Aside from the legal battles, European fish farmers also face a growing threat of climate change, as revealed by Anna SwachaPola ń ska, office manager with the Polish Trout Breeders Association. Specifically, in Poland, this factor already directly affects rearing conditions, as water occasionally turns too warm. In this context, the industry is switching to RAS farms, and this trend could accelerate in the coming years.

– Vladislav Vorotnikov

The future of Africa’s fish hatchery industry 2025 is poised to continue growing significantly owing to an ever-increasing demand for protein from fish and many sector lifechanging initiatives aimed at revolutionizing fish farming across the continent.

Presently, there are several thousands of improved/modern hatcheries distributed across the vast continent with production capacity of at least 1.5 million metric tons of fingerlings annually. They culture species mainly catfish, tilapia and trout.

As companies continue to make a killing from the lucrative fish business, the 2025 could see hatchery farms, like Rwanda’s High Tech Gishanda Hatchery, with the ability to produce about two million tilapia fingerlings annually. Kenya’s Moon Hatchery operated by Victory Farms, Ghalioun Sea Hatchery from Tunisia, Al-Madinah Hatcheries from Egypt, are among others scaling up production to meet the growing demand.

Companies are also likely to improve technology in order to improve survival rates and overcome disease outbreaks. Year 2025 might see hatchery firms – like Atlantic Shrimpers Ltd., a shrimp farm in Badagry, Lagos in Nigeria and recently, Jonkershoek fly fish farm operated by South Africa’s Stellen Bosch university – explore new trends like diversification to new species, such as shrimp and mass production of trout which are still very scarce on African fish market but with increasing demand by new consumers.

The year 2025 is also projected to see major companies integrate hatchery operations with processing and distribution to enhance value chains as seen at Egypt’s Al Fayrouz fish farming project located in Port Said.

The year could also see new hatchery farms like Novation a Swiss owned company

which recently established the first land based closed system shrimp farm to tap into global demand for aquaculture products, create more job opportunities and enhance food security for the continent and its nutritional goals.

However, it is a prayer for both small scale farmers and large corporations that 2025 sees governments and private insurers developing specialized insurance products to mitigate industry risks. This is because major credit institutions in Africa are not willing to stake their money in aquaculture business because they don’t know how the business works or farmers lack security for loans.

That said, other threats like effects of climate change including rising temperatures and changing water patterns, disease outbreaks in hatcheries, feed costs and availability, imported cheap species from countries like Malaysia, China and other Asian countries have haunted African hatchery owners in the past because big cage fish farming companies prefer importing genetically improved fingerlings that grow faster than those cultured locally in Africa. 2025 may not be exceptional.

Now, this calls for the industry stakeholders and governments to develop robust strategies and good regulatory frameworks to support African hatchery industry also to thrive.

African hatchery companies must also embrace change and invest in modern technology like adopting Recirculating Aquaculture Systems, more research on improving genetics, Integrated Multitrophic Aquaculture (IMTA), a revolutionary solution for balancing production with environmental health for symbiotic relationship between species such as fish, seaweed, and shellfish, where one species’ waste becomes a resource for another.

Therefore, 2025 and beyond will likely observe much needed significant growth and development if governments and stakeholders address these challenges and leverage on the opportunities for Africa’s fish hatchery . – Bob Atwiine

Three of the powerhouses of the Southeast Asian aquaculture industry

Enter 2025 with the backdrop of rising operational costs, biosecurity problems and environmental issues. Collaborations extended by the government, non-governmental organizations and private sector are providing farmers relief and even hope.

Vietnam’s shrimp exports face stiff competition from country producers selling at much lower prices. Despite this, the US$10 billion target will be delivered by year-end, according to Vietnam Sustainable Shrimp Alliance secretary general, Le Dinh Huyn, in an interview with Vietnam Investment Review.

The Vietnam Association of Seafood Exporters and Producers projected a 2024 year-end revenue of almost $4 billion. Credit is being given to the Mekong Delta organic shrimp farming program to contribute to the 2025 target. Participating farmers are provided with scientific know-how, quality seeds, and global standard protocols, among others. The programme addresses social, environmental and economic aspects. By growing shrimp in the mangrove, protecting the forest is done at the same time. The practices, together with the narrative, upgrade it to a premium product that puts it in a higher tier than the cheaper shrimps.

The organic shrimp farming is a beneficiary of an initiative of the Australian government on climate change adaptation in the Mekong Delta region.

By the time Thai Fish Project ends in May 2025, the cooperative project with the Japan International Corporation Agency would have established protocols for sustainable aquaculture in Thailand.

The project’s research initiatives include efforts to develop disease-resistant and fast-growing traits through molecular breeding in order to create resilient family lines.

The six-year project aims to develop a sustainable aquaculture system for native Thai fish and shrimp species. It focuses on Asian seabass and banana shrimp, “relatively highend,” restaurant and hotel-quality products, that appeal to the international market.

The Philippine aquaculture industry is getting additional guidance towards global competitiveness with the National Aquaculture Development and Management Plan (ADMP) 2025-2030.

An initiative of the Bureau of Fisheries and Aquatic Resources, ADMP zeroes in on sustainability, productivity, socio-economic factors and environmental impacts.

Among the key goals identified is ensuring an adequate supply of good quality seed stock.

The shortage of Philippine-produced milkfish fry is still very much of a concern. A tripartite agreement among Philippine government agencies is seeking to ease this through a hatchery automation project, HATCH, which will culminate in June 2025. Protocols produce a conducive year-round breeding environment for broodstock, assuring uninterrupted fry supply.

– Ruby Gonzalez

The El Niño Southern Oscillation (ENSO) cycle, coupled with a positive Indian Ocean Dipole (IOD) over the previous 12 months has brought severe dry conditions to much of southern and southwestern Australia. Soil moisture levels in some areas are as dry as they’ve ever been recorded.

At the time of writing, The Bureau of Meteorology (BoM) is cautious. Its current data indicates neutral conditions, but it is tracking temperature movements, that should they continue at their present rate, they warn, would lead to mild La Niña

and negative Indian Ocean Dipole (IOD) conditions.

Moreover, the Bureau warns that global sea surface temperatures (SST) remain at near-record levels, and that temperatures since July have been well above all observations since 1854, and just below the record levels of 2023. The sustained nature of this global ocean heat suggests that customary climate indicators may not behave or evolve as expected in the past.

Hatcheries across the various sectors have experienced climatic extremes, particularly over the last 25 years, and they are well prepared for adverse climate eventualities. Their economic risk lies with their client base.

While cooler, wetter conditions suit the southern regions, storm events in the warm temperate, subtropical and tropical northern aquaculture zones can be catastrophic for open pond growers. This group includes barramundi, prawns, and jade and silver perch farmers.

Apart from the risk of pond flooding and the associated infrastructure problems, excessive silt and freshwater surges

compromise water exchange in fish and prawn ponds. Estuarine oyster growers are particularly vulnerable.

Southern oyster growers are more likely situated in shallow bays and inlets, and less likely to suffer to the same degree from excessive rainfall. Extreme summer heat, however, can wreak havoc, and they will be hoping the indications of cooler conditions prove to be accurate.

Tasmania’s climate is influenced by the East Australia Current and the upper reach of the Antarctic Circumpolar Current. The East Australia Current is a global oceanic hotspot and salmon growers welcome the cooler conditions brought about by a La Niña cycle. They don’t expect any downturn in seedstock requirements, or for that matter hatchery production.

Overall, the Australian hatchery sector itself is well prepared for adverse weather conditions and are confident they will be able to cover the seedstock requirements of their relative domestic growout sectors and, for those who export to overseas’ markets, their export orders. | HI –

John Mosig

BY MAGIDA TABBARA

Aquaculture successfully produced 94.4 million tonnes of aquatic animals in 2022, surpassing capture fisheries by 3.4 tonnes. For the first time, 51 per cent of the aquatic animals obtained were cultured rather than fished for.

The success of aquaculture activities so far has been driven by years and years of efforts. The increase in production is a fruit of increasing culture areas, intensifying culture conditions – which started over 50 years ago – in addition to fertilizing ponds and improving aeration techniques. However, aquaculture activities are not complete without having properly fed animals.

Research on determining the nutritional requirements of aquatic animals didn’t really start until the 1980s. But since then, there has been a significant development in the diets of commercially important species, and even further development in feed manufacturing.

With the development of extruders and extruding techniques, feed manufacturing companies are nowadays able to produce feed with particle size as small and fine as less than 50μm. But the small size feed does not tackle the challenge of feeding fish larvae, which is still an overlooked area of research with a lot of difficulties.

When we think of successful aquaculture operations, the first factors we think about tend to be the advances in

practices, such as the ones mentioned above (aeration, intensification, etc). Reality is, if the fish are not well-fed and have an almost perfect welfare in the early development stages, it’s almost guaranteed that the fish batch raised will not be of great quality. Nutrition is a vital element in animal welfare.

Without proper feeding, the animals will not grow properly, and their quality in terms of filet yield, texture, odor, etc will not reach an appropriate level for consumer satisfaction. Accordingly, investing in raising quality fish will result in high returns, which is what every farmer desires.

Feeding fish at the early stages of life is a challenging process, and it is still difficult and overlooked in terms of studies. The nutritional physiology of larvae and early juveniles has been studied. But the process offering larvae commercial feed from the moment they lose their yolk sac is still complicated, especially in the case of marine fish.

An astonishing piece of information derived from a meta-analysis about the use of manufactured feed for freshwater fish larvae can increase their probability of dying by 2.5 times compared to when offered live feed. Such a conclusion disregards the optimism about further improving the development of commercial larvae feed, especially with the complications of marine species.

The small size of marine fish larvae mouth forces hatcheries to rely on live feed. That further increases production expenses, especially with the need for a live feed production unit among the hatchery to be able to feed those larvae. Additionally, the expenses come with the variation in live feed quality among batches.

Research has shown that the nutritional composition of Artemia tends to vary, and so does their availability and price on the market. That opens up a new nutritional and economic challenge, especially if the hatchery decides to invest in enriching the nutrition of their Artemia prior to feeding them to the larvae.

To skip the enrichment step, hatcheries could invest in formulated feed for their Artemia, but that does not eliminate the added cost.

Despite the challenges mentioned above, the production of common carp and Atlantic salmon was successfully achieved with the use of manufactured feed solely. Such production succeeded through applying the understanding of larval physiology and nutrient assimilation.

For instance, Atlantic salmon and catfish develop true stomachs even at the larva stage. That allows for feed storage in the stomach and mixing with digestive enzymes, which at the level of stomach acidity results in proper digestion. Therefore, such fish are able to directly feed on manufactured feed. But the question of whether all

of their nutritional requirements are met is yet to be answered by science.

Larvae are constantly in the process of growing, which by itself necessitates a lot of energy. Efforts were made to try to establish the nutritional requirements of certain commercially important fish species at the larval stages. Unfortunately, such efforts were not very successful for a variety of reasons.

The main experimental design by which a nutritional requirement can be determined is formulating feed with a incremental levels of the nutrient in question, starting with a basal deficient diet. With juvenile fish, a difference in growth performance can be observed, which after statistical modeling, can elucidate in which ballpark falls the nutrient requirement. Larvae are in a constant state of fast growth, which necessitates a big amount of energy.

In such a case, regardless of the level of nutrient in the feed, the larvae require so much energy that their metabolism would even use all nutrients as energy source. Therefore, no accurate level of nutrient will be determined. Additionally, the rate by which larvae grow is fast. With that, their digestive system grows, which further changes their nutritional requirements. Furthermore, even when formulating feed that are presumed to provide essential nutrients for the larvae at adequate levels, there is no guarantee that the animals will efficiently benefit from all of them. Majority of the components of larval manufactured feed are water-soluble and have low molecular weights. Additionally, larval feed is manufactured to be in such small particles that there is an increased chance nutrients will leach out in the water. That makes the feed less nutritious, and decreases its benefits to the larvae.

We discussed some of the challenges of feeding larvae. But we must not forget that good quality larvae also come from good quality parents. Similar to the case of larvae, broodstock nutrition is one of the least studied aspects of aquatic animal nutrition. The difficulty stands in the necessary infrastructure to perform scientifically sound experiments that will result in reliable data.

Fish broodstock necessitate high-quality feed to produce high-quality gametes and hence, larvae. But unfortunately, there are some limitations to determining the nutritional requirements of broodstock, especially during breeding season. It is generally advised to provide good quality feed composed of high protein, lipid, and energy levels, in addition to Vitamins E, C, and B6. Such necessities in tandem with not knowing precise levels of nutrient requirements makes it challenging to provide good feed that is at the same time cost-effective.

Aquaculture production is increasing every year, and so is the need for optimizing practices to obtain good quality fish in the most cost-effective manner. It all starts at the hatchery, and efforts are being made to try to shift away from live feed and focus more on nutritious and well manufactured commercial feed. Finding a solution to this difficult challenge will open doors for further use of sustainable and less costly feed ingredients. Meanwhile, the best that can be done is to pay close attention to broodstock feeding. Investing a bit more in high quality feed for broodstock would pay back with healthy larvae that would grow big and healthy to satisfy consumers. | HI

BY JOHN DAVIDSON, CURTIS CROUSE, CHRISTINE LEPINE, AND CHRISTOPHER GOOD; FRESHWATER INSTITUTE

Recirculating aquaculture systems (RAS) are designed to maintain water quality that matches the biological requirements of fish. However, when RAS are operated with limited water exchange, harmful compounds can accumulate in the water.

Over the last 15 years, the Freshwater Institute (FI) has characterized RAS water quality under different operating conditions while evaluating effects on fish growth, health, and welfare. Early studies identified accumulating nitrate, dissolved copper, and potassium as compounds that could negatively affect salmonids in RAS (Davidson et al., 2009; 2011).

Of these parameters, nitrate was deemed the most likely to cause chronic fish health and welfare responses. Therefore, nitrate, expressed here as nitrate-nitrogen (NO3-N), became the focus of subsequent studies with rainbow trout (Davidson et al., 2014) and, more recently, Atlantic salmon (Davidson et al., 2017; 2024).

This article centers on research with large post-smolt Atlantic salmon, which are now frequently grown in RAS to 0.5-1 kg before transfer to commercial net pens or, alternatively, cultured to market size in land-based RAS facilities. Two studies utilizing the same experimental freshwater RAS were conducted to assess nitrate’s effect.

During the first experiment, FI researchers found that salmon performance, health, and welfare were unaffected by 99 vs. 10 mg/L NO3-N as the fish grew from 0.10 kg to 1.2 kg (Davidson et al., 2017). These findings generally established a safe NO3-N range for Atlantic salmon cultured under similar conditions; however, the upper limit at which this species is negatively affected remained unknown. Therefore, a second study was recently conducted to evaluate the impact of higher NO3-N levels (Davidson et al., 2024).

During this trial, traditional assessments of Atlantic salmon health and performance, including blood chemistry, growth, and feed conversion ratio (FCR), were complemented with continuous heart rate measurements provided by Star-Oddi bio-loggers.

Before the study commenced, FI researchers aimed to establish standard procedures for implanting the bio-loggers. A custom surgery table was assembled with a pump that recirculated oxygenated water with a mild sedative to sustain the salmon.

Next, the FI team practiced and became proficient with the surgical method (Figure 1), and a pilot study was conducted to determine the required fish recovery period. Following these preliminary steps, 36 diploid all-female Atlantic salmon were implanted with bio-loggers.

After a one-month recovery period, these fish were divided equally among six replicated RAS along with a base population of comingled all-female diploid and triploid salmon. In total, 227 fish with an initial average weight of 0.35 kg were stocked in each system.

Three weeks later, water flushing rates were reduced to allow NO3-N levels resulting from nitrification to gradually increase to 50–100 mg/L in all six RAS (Phase 1). Peristaltic pumps were then used to continuously dose sodium nitrate in three RAS,

facilitating a steady increase to 150 mg/L NO3-N (Phase 2), followed by a subsequent climb to 200–250 mg/L NO3-N (Phase 3). Sodium sulfate was continuously added to the low-nitrate systems to balance conductivity and dissolved sodium concentrations between treatments.

These conditions established the basis for comparing the effects of 50–100 mg/L NO3-N vs. 100–250 mg/L NO3-N on postsmolt Atlantic salmon cultured in six identical 9.5 m3 RAS (N=3).

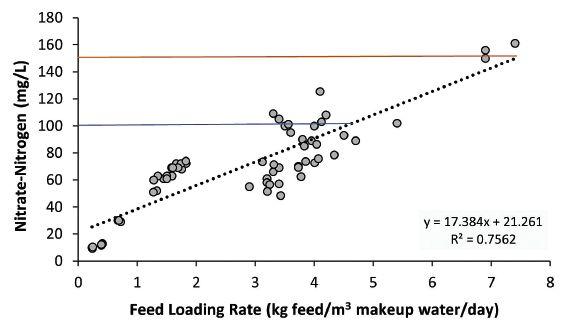

Over the six-month study, target NO3-N levels were maintained within the prescribed treatment concentrations. Nitrate-nitrogen gradually increased or remained stable during each study phase, except for a notable spike during Phase 3 in the high NO3-N treatment (Figure 2).

Overall, the results indicated that Atlantic salmon growth, FCR, and welfare metrics, including fin and cataract scores, were unaffected by the tested NO3-N levels, including separate comparisons of all-female diploid and triploid fish (P > 0.05). At the end of the study, salmon cultured in the high and low NO3-N RAS weighed 1.84 ± 0.05 and 1.91 ± 0.02 kg, respectively. However, subtle effects on salmon physiology, including significantly higher plasma hematocrit and hemoglobin levels, were measured after the fish were exposed to 150–250 mg/L NO3-N.

Along the same timeline, heart rate measurements began to separate, with consistently faster rates measured in salmon from the high NO3-N treatment (Figure 2). These effects overlapped with a subtle, albeit non-significant, dip in growth and a slight increase in FCR, which may have been related. Cumulatively, these findings mirrored a classic compensatory response to a stressor.

In conclusion, this research suggests that post-smolt Atlantic salmon can be safely cultured at <150 mg/L NO3-N under similar conditions, including freshwater production of the same Atlantic salmon strain provided by Benchmark Genetics.

However, additional research evaluating longer exposure times and the effects of naturally

produced nitrate would be useful in establishing a definitive NO3-N threshold. Apart from verifying optimal conditions for Atlantic salmon culture, this research also provided valuable information about water use requirements for land-based salmon RAS facilities.

Figure 3 demonstrates a strong linear correlation between the feed loading rate and coinciding NO3-N levels while culturing salmonids in the same replicated RAS.

When considering this relationship, it becomes evident that safely maintaining higher NO3-N levels results in substantial water savings. For example, operating RAS with 100 mg/L NO3-N requires approximately 4 kg feed/m3 makeup water/day or 278 L of makeup water/kg feed/day.

Alternatively, maintaining 150 mg/L NO3-N requires 7 kg feed/m3 makeup water/ day or 143 L of makeup water/kg feed/day (Figure 3). Thus, safely increasing the NO3-N limit by 50 mg/L reduces the required water use by about 50 per cent.

A diminished water requirement ultimately allows more fish production per unit of available water and could expand locations where salmon RAS facilities are sited to include water-limited areas near major seafood markets. A possible tradeoff is the production of higher nitrogen concentrations in the effluent, albeit within a smaller outflow.

Nevertheless, this concentrated wastewater could be effectively treated using decoupled denitrification technologies such as woodchip or membrane biological reactors or nitrogen uptake options, including constructed wetlands or aquaponics, or other preferred alternatives. | HI

This research

by

Institute’s Institutional Animal Care and Use Committee.

Davidson, J., Good, C., Welsh, C., Brazil, B., Summerfelt, S. 2009. Heavy metal and waste metabolite accumulation and their potential effect on rainbow trout performance in a replicated water reuse system operated at low or high system flushing rates. Aquacultural Engineering 31,136–145.

Davidson, J., Good, C., Welsh, C., Summerfelt, S.T. 2011. Abnormal swimming behavior and increased deformities in rainbow trout Oncorhynchus mykiss cultured in low exchange water recirculating aquaculture systems. Aquacultural Engineering 45, 109–117.

Davidson, J., Good, C., Welsh, C., Summerfelt, S.T. 2014. Comparing the effects of high vs. low nitrate on the health, performance, and welfare of juvenile rainbow trout Oncorhynchus mykiss within water recirculating aquaculture systems. Aquacultural Engineering 59, 30–40.

Davidson, J., Good, C., Williams, C., Summerfelt, S. 2017. Evaluating the chronic effects of nitrate on the health and performance of post-smolt Atlantic salmon Salmo salar in freshwater recirculation aquaculture systems. Aquacultural Engineering 79, 1–8.

Davidson, J., Crouse, C., Lepine, C., Good, C. 2024. Evaluating the suitability of nitrate-nitrogen levels for post-smolt Atlantic salmon Salmo salar production in RAS with assistance from heart rate bio-loggers. Aquacultural Engineering 107, 102461. For more information, the full research article can be accessed at: https://doi.org/10.1016/j. aquaeng.2024.102461

Specialists in corrosion-resistant, reliable and stable propeller pumps, with high uptime and low energy consumption- for a healthy and sustainable aquaculture.

Fermentation technology company Norwegian Mycelium (NoMy) has announced its entry into the Japanese market, with a subsidiary, NoMy Japan KK.

NoMy Japan has partnered with industrial actors like Nippon Beet Sugar Manufacturing Co. Ltd and Hokuren to expand the reach of its core fermentation technologies utilizing food industry sidestreams. The company said more partnerships will be announced later.

The partnership with Nippon will pursue feeds including aquaculture and food applications.

“Our goal is to create a new industry utilizing sugar beets, which have high carbon dioxide absorption capacity. NoMy’s technology, which utilizes the byproduct of the sugar manufacturing process to produce filamentous fungal protein as a food resource, has great potential to produce feed and food substitutes for animal protein. We believe that this technology will help to promote agriculture and solve food problems,” said Dr. Shu Ishikuri, president of Nippon Beet Sugar Manufacturing Co. Ltd.

NoMy is also launching an upcycling service,

called MycoPrime, that is said to combine the power of data science, fermentation technology and artificial intelligence. MycoPrime aims to help NoMy Japan’s partners find the optimal utilization of sidestreams, minimize waste and CO2 emissions, maximize water recycling, and design co-located production facilities for the manufacture of sustainable fungi-based products.

“There is a massive need and opportunity to de-risk the development of sustainable upcycling solutions and bring them to life. With NoMy’s technology and MycoPrime, the food industry now has a reliable, end-to-end partner to create value instead of waste, and become a pioneer in food system transformation,” said David Andrew Quist, NoMy’s co-founder and chief explorer.

Aker QRILL Company, a new company spun out of Aker BioMarine, has been launched.

The company, which will focus on providing marine ingredients for the aquaculture, animal feed, and nutraceutical industries, is owned by American Industrial Partners (AIP) and Aker Capital.

“While our name may be new, our commitment to excellence remains unwavering,” said Webjørn Barstad, CEO of Aker QRILL Company. “We’re building upon years of expertise and innovation developed as part of Aker BioMarine, and we’re excited to now chart our own course in delivering sustainable, superior krill ingredients with the highest quality standards.”

Krill is one of the largest biomasses in the ocean and is a valuable ingredient in aquaculture feed due to its nutrient-dense properties.

Aker BioMarine said it will remain the same company but without the feed division. It will be more focused on human health products, while Aker QRILL will focus on the animal side..

Barstad said Aker QRILL’s first goal is to improve on its operational excellence, working with people with industry background to do so. It’s been two and a half months since the new ownership took over.

So alongside rebranding and renaming, they’re working on getting their customers and vendors to learn about the new company and its new focus. The company is also working on market strategies and looking to move its products to new markets in addition to expanding in existing markets.

“Aker is excited to be a part of this journey. This venture is an important component in our industrial portfolio and we are committed to support the management as we move into the next phase of growth and innovation,” said

Øyvind Eriksen, president and CEO of Aker ASA. Barstad added that he’s proud of the employees of the company who have actually taken this challenge head on.

“It’s been an awesome job that everybody has put down. So, I’m really pleased to see how people are grasping this new opportunity and just running together with the new structure,” he said.

Research from BioMar’s R&D department has shown that many of the new feed ingredients are delivering good sustainability metrics, maintaining growth performance and showing positive effects on robustness, welfare and health to aquatic species.

Simon Wadsworth, BioMar’s global R&D director, said that the long-term reduction in the use of marine ingredients decreased the level of essential Omega-3 fatty acids such as EPA and DHA in aquafeeds. But the recent provision of algal oils has allowed these key fatty acids to be supplemented in over four million tons of BioMar feeds.

Single cell proteins offer potential in terms of future volumes and raw material flexibility. Research by BioMar and research partners has shown that these proteins are performing well for both growth and robustness in different aquaculture species.

“The novel ingredients also offer exciting synergies with existing raw materials. Single cell proteins incubated with soybean meals can reduce the presence of anti-nutrients as well as significantly increase overall protein levels. This technology opens other opportunities with a range of other existing, high-volume raw materials,” said Wadsworth during his presentation at the Global Seafood Conference in Scotland.

The effects of feeding insect meals also show growth performance at higher levels of inclusion as well as maintaining robustness, welfare and health. As volumes increase, these raw materials are being successfully deployed with customers in commercial operations.

Elin Kvamme, global aqua director from Innovafeed shared findings from their recent research on insect meal in shrimp feeds.

“The inclusion of insect meal can help shrimp better resist common bacterial infections like vibriosis and viral diseases such as white spot syndrome virus which is a significant concern in shrimp farming. The combination of antimicrobial peptides, chitin, and lauric acid in insect meals contributes to these health benefits by enhancing immune function, improving gut health, and providing anti-inflammatory effects,” said Kvamme.

According to BioMar, as the aquaculture industry continues to grow, the demand for both existing and novel raw materials will increase. These new nutrients sources are not only essential but are proving to be beneficial in supporting the health, welfare and robustness of aquatic species.

Voda IQ, a fisheries conservation technology company, has appointed Armando Piccinini as its new European sales director.

Piccinini, who has over two decades of experience in aquatic conservation and the European market, will begin his role to lead the expansion of Voda IQ’s presence in Europe, on Oct. 1

He most recently served as an aqua conservation specialist at MSD Animal Health. He has spearheaded sales initiatives, managed cross-functional teams, and implemented effective marketing strategies.

“His expertise in PIT (Passive Integrated Transponders) tag technology and his deep understanding of the European aquaculture and wildlife markets make him a perfect fit for this role,” a press release from the company states.

Piccinini’s new role will foster relationships with key stakeholders, enhance brand visibility, and expand the company’s footprint in the European market.

“Armando’s comprehensive experience and dedication to conservation are exactly what Voda IQ needs as we continue to grow and innovate. We are confident that his leadership will greatly enhance our operations in Europe and help us achieve our strategic goals,” said Brian Beckley, president of Voda IQ.

BY NICOLE KIRCHHOFF

Are we ever prepared enough?

That is the question I have been asking myself lately especially as I reflect on this past year, my first year as a writer for Hatchery International How can I describe Hatchery Hacks in such a rapidly changing world? Let me explain.

Nearly weekly, we hear about a new unprecedented natural disaster hitting somewhere in the world – record breaking floods, heatwaves, blizzards/cold, and hurricanes/ tsunamis. Many disasters are occurring in new locations, breaking all historic records for strength, and causing massive utility and/ or infrastructure collapse.

Here in Florida, for example, we experienced two extremely devastating, late-season hurricanes within only weeks of each other in September and October 2024.

The first, Hurricane Helene, sent a storm surge higher than any 100-year level through the clam aquaculture capital of Florida and the third largest in the USA, causing near complete destruction. The second, Hurricane Milton, spawned a record-breaking 45+ tornadoes throughout the state.

One of these, an EF1 tornado, started at our hatchery door, sucking the door off our broodstock conditioning room, causing a mass electrical surge that zapped equipment, caused our automatic generator transfer switch to malfunction, and put a live electrical line down in our driveway. Only a few hours later, a massive EF3 tornado touched down within a mile of the farm and killed six people.

While we have been through hurricanes, two with near-direct eye hits on my farm, this one caused us a new level of stress and concern. As fellow farmer, Jane Davis of Evans Farms, said, “Every storm gives us new challenges.” And it made us completely rethink our disaster plan.

First, we will be investing even further in the latest alarms, virtual switches, and a tertiary set of backup equipment so that no one will ever have to stay at the farm during a natural disaster again. This time, instead of physically being at the farm during the tornadoes, we watched in real-time with our Starlink internet, Ring cameras, and iSocket alarms the tornado’s impact and backup generator

“Every storm gives us new challenges.” And it made us completely rethink our disaster plan.

engaging, well not properly engaging. But a few friends only a few miles down the road were at their farms and it was a wake-up call.

We were reminded our lives are more important than our businesses, especially when there is accessible and affordable technology that doesn’t require us to be there. Now that we know we can maintain the internet during a storm, even on backup power, we will be investing in more virtual switches so we can turn on and off secondary and even tertiary backup gear. We need even more real-time monitors so we can ensure fish wellbeing while also maintaining our safety.

Second, we will rethink the “vital” equipment for our backup power. Hurricanes, like so many other natural disasters, are not short-term events. Long after the eye of the storm passes, you must have special passes to be on the roads, and power crews cannot start working to restore power until the winds drop below gale force.

As the storm raged, we, fortunately, had a neighbour carefully walk into the farm, past the live, down power line, to manually engage our surge-malfunctioned generator. With the number of tornadoes and widespread deviation of this storm, we were looking at record-breaking power outages and an unknown amount of time before it was restored. As good friend, Eric Wagner of ProAquatix, put it, “This job is hard enough when we do have power.”

As the days marched on, the concerns grew. When sizing backup power, one prioritizes and limits power-hungry electronics. For example, blowers and water circulation pumps take priority, while lights, finer stage filtration, and temperature control may be able to wait until power returns.

But as the hours turned to days and an unknown end in sight, we couldn’t hold back feed from the fish anymore, which meant we needed lights and filtration. Equipment we didn’t think was vital for our aquatic animals suddenly became increasingly important to

their life support. In an era of increasingly devastating natural disasters, our backup power plans must start to consider situations when power may be out for an indefinite period.

Finally, we learned our community can be more important than our disaster planning. Very soon after the storms, the texts from fellow farmers started rolling in. “Are you okay?” “Do you have power?” “What do you need?”

Government, farm service agents, even utility workers are not the first responders to our farms in disasters, it is our fellow farmers. We are the ones on the ground, working to keep our animals and farms alive every second of the storm and immediately after the storm passes. We run to each other’s farms to loan spare blowers, and pumps, cut fallen trees out of access roads orhelp replace/repair broken vital equipment. We loan generators when a fellow farmer’s generator was crippled beyond repair. Give each other advice on what fish to prioritize or how to maintain them as best as possible as power outages rage on. We give each other a shoulder to cry on, to vent, an ear of understanding to the level of stress we are facing, knowing we aren’t alone.

Even after the storm, as fellow farmers were short on labour because their staff lost homes or transport, those of us awake for days needed a break, we were there for each other. This community became our lifeblood. And in so many ways was just as or more important than our disaster plans. And for this reason, cultivating a community near and far is something we will continue to foster and invest in. I highly encourage you to do the same.

This past year of writing for this magazine has been a wonderful gift. It has made me critically evaluate things I/we do around our farm on autopilot without thought and put them into words and practice. It has made me evaluate how we can do things better. And encouraged me to learn about all the new innovations in our field.

While aquaculture and its many techniques are not new, farming in the modern world is and I look forward to continuing to bring the latesthatchery concepts and techniques to my readers. | HI

High quality fish farming equipment

Designer & Manufacturer Since 1958

One Supplier, all your solutions and equipment for your RAS

FAIVRE Group has developed its activity in industrial equipment design dedicated to aquaculture. With more than 60 years of experience, this French structure has developed its technological success thanks to its family history. Today Faivre is a world leader in its field and offers complete solutions from water treatment to fish farming equipment.

Fish pumps

Grading

Fish graders