High-tech future

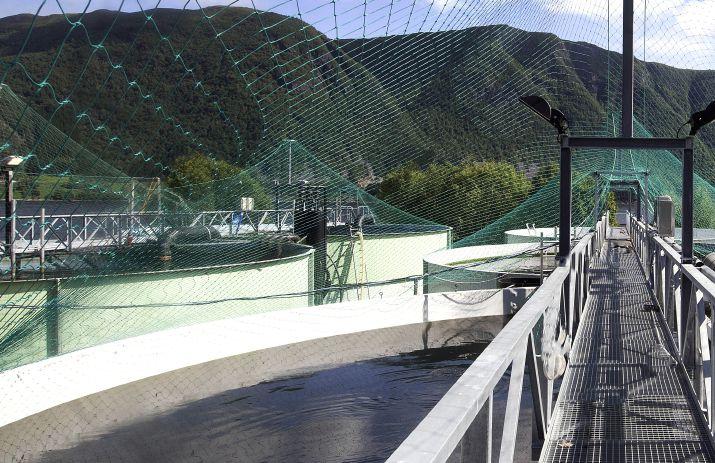

Disruptive technologies making their way to aquaculture farms

Aquaculture has exactly 10 years to meet the global seafood demand by 2030.

According to the Food and Agriculture Organization of the United Nations, the industry will need to supply two-thirds of the world’s seafood requirements or risk the world facing a seafood shortage of 50-80 million metric tons.

As we enter a new decade, there are technological pioneers in the industry that are helping drive aquaculture into the future.

DESIGNER FISH

As the industry looks to more sustainable ways to increase production, the Centre for Aquaculture Technologies Canada (CATC) is investing its resources on gene editing technology. Executive vice-president of research Debbie Plouffe says the future of aquaculture is in genetically-designed fish that are tolerant of warmer climates, disease-resistant and reproductively sterile.

“Different industries within the aquaculture industry probably fall somewhere in the continuum of genetic improvement but towards the most disruptive end of the continuum, is gene editing technology and that’s where

ISSUES

we spend a lot of time in R&D,” says Plouffe.

Plouffe is a molecular and cell biologist with a specialty in fish immunology and fish health. She has conducted leading research projects in the industry for 12 years. She currently oversees several new projects and collaborations from the CATC facility in Prince Edward Island, Canada.

Plouffe says gene editing of fish species offers several opportunities to increase high-quality production for farmers. In fact, many organizations are investing hundreds of thousands of dollars in gene editing tools that make fish species resistant to more pathogens.

The Centre is also collaborating on a new consortium funded by the Atlantic Canada Opportunities Agency looking to identify genetic markers in Atlantic salmon associated with tolerance to higher water temperatures. This also includes response to vaccinations and response to pathogens under these conditions.

continued on page 10

INDUSTRY VS ACTIVIST: Finding a middle ground

Hatchery expansion plans in Newfoundland, Canada, spark activist protest

BY MATT JONES

Conflict between environmental groups and the aquaculture industry is nothing new. The industry around the world is regularly met with harsh criticisms from activists over alleged environmental impacts. Is the aquaculture industry doing enough to address these concerns? And is there any common ground to be found with these groups, to work with them to address misinformation? Hatchery International spoke with representatives on both sides to find out.

This acrimony has been brought into sharp focus in Newfoundland this year, as activists have raised concern about MOWI operations, including pursuing legal action over a perceived incomplete environmental assessment process for the company’s Indian Head Hatchery expansion project, as well as the mortality of 2.6 million salmon at the company’s net pens in Fortune Bay.

THE CONTENTION

Dr. Stephen Sutton of the Atlantic Salmon Federation (ASF) points out the environmental assessment for the hatchery facility expansion itself is not the issue. The concern is the open-net pens where the additional fish will end up

Mark Lane, executive director of the Newfoundland

Industry Association, is

by how quickly the narrative

the

In late September, NAIA hosted 600 participants for the 2019 Cold Harvest conference and trade show. Days later, he found himself defending the industry from criticism following 2.6 million salmon mortalities at a MOWI farm.

Broodstock fed with a diet of dried krill and commercial feed produces more eggs and healthy fingerlings. (All Photos by Fisheries Production and Support Services Division, BFAR Region 2)

Green water

Filipino tilapia hatchery operator shows innovation is king

BY RUBY GONZALEZ

Green water technology and achieving sexreversal in a fifth of a time of the normal procedure are just some innovations practiced at JAVE Farms in the Philippines. And these have been attracting attention all over the country.

“JAVE Farm now serves as model aquaculture farm in Region 2 in [Northern Philippines]. Bureau of Fisheries and Aquatic Resources (BFAR) clients such as existing hatchery operators, interested fish farmers and students are usually referred to visit JAVE Farm to learn from the innovation and hatchery management of the owner, Mr. Vicente Lugagay,” Dr. Severina Bueno, BFAR Region 2 chief of fisheries production and support services division, tells Hatchery International

Other innovations developed by Lugagay include producing his own probiotics, cutting down feed costs and water pollution, designing and developing a special pump using the aeration principle, and using lambanog, a local nipa palm wine, instead of ethyl alcohol in preparing sex-reversal tilapia feeds. Lugagay, 55 years old, has owned and operated

VOLUME 21, ISSUE 1 | JANUARY/FEBRUARY 2020

Editor Mari-Len De Guzman, mdeguzman@annexbusinessmedia.com

Associate Editor Jean Ko Din, jkodin@annexbusinessmedia.com

Regular Contributors Nestor Arellano, Ruby Gonzalez, Ron Hill, Eric Ignatz, Matt Jones, Colin Ley, Liza Mayer, Bonnie Waycott, Vladislav Vorotnikov

Advertising Manager Jeremy Thain, jthain@annexbusinessmedia.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Circulation Manager Urszula Grzyb, ugrzyb@annexbusinessmedia.com

Production Brooke Shaw, bshaw@annexbusinessmedia.com

Group Publisher Todd Humber, thumber@annexbusinessmedia.com

COO Scott Jamieson, sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Hatchery International is published six times a year by Annex Business Media. The authority for statements and claims made in Hatchery International is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

A subscription to Hatchery International (six issues) is $37.00 within Canada, US$37.00 within North America, and US$47.50 outside North America. To subscribe visit our website at www.hatcheryinternational.com

Subscriptions Angie Potal, apotal@annexbusinessmedia.com

Tel: 416-410-5113 • Fax: 416-510-6875 or 416-442-2191

Printed in Canada. Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Hatchery International. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer privacy@annexbusinessmedia.com

Tel: 800-668-2374

ISSN 1922-4117

Next Ad Deadline

The advertising deadline for the March/April issue is January 15th. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the March/April issue is January 15th. Contact the Editor, Mari-Len De Guzman at mdeguzman@annexbusinessmedia. com, for details. Material should be submitted electronically with prior arrangement with the editor.

THE EDITOR

Minding the skills gap

If a recent Canadian labour market report is any indication, the aquaculture industry might be bracing for a shortage of skilled workers over the next 10 years, which could translate to millions of dollars in potential revenue loss.

The Canadian Agriculture Human Resource Council (CAHRC) has released its labor market report titled, “How Labour Challenges Will Shape the Future of Agriculture: Agriculture Forecast to 2029,” indicating an overall projection of labor shortages across the Canadian agriculture sector. For aquaculture, the report is anticipating a shortfall of nearly 500 jobs over the next 10 years, as 36 per cent of the aquaculture workforce is expected to retire during the same period.

Skills shortage challenges is not exclusive to the aquaculture sector, however. Over the last several years, alarm bells have been ringing across many industries as baby boomers – those born between 1946 and 1964 – enter retirement age. Analysts have projected baby boomers will be retiring at a rate of 10,000 per day over the next several years.

The consequences of a significant skills shortage can have to the company’s bottom-line is not negligible. In 2018, the aquaculture sector lost $34 million in sales as a consequence of labor shortages, according to the CAHRC.

Facing a labor shortage is one thing; a skills deficit is another matter. Particularly in the aquaculture sector –where specific expertise are required and can literally spell the difference between life and death for farmed species – increasing the number of the workforce alone will not be sufficient. Addressing the skills deficit challenge, ensuring that highly-skilled aquaculture workers are entering the labor market, is pivotal.

BY MARI-LEN DE GUZMAN

There is a treasure trove of knowledge and skills accumulated (and accumulating) in this relatively young aquaculture sector. Many of this sector’s pioneers are still in active duty, or at least, semi-active. Fish farming, particularly in the hatchery side, seems to be an attractive proposition for young professionals. There is a lot of knowledge that can be transferred to these young cohorts by their more senior counterparts.

Putting in place a formalized and systematic succession planning program across the organization will ensure that valuable production and operational knowledge are passed on appropriately and effectively. Mentorship of young workers will be key as well.

Skills shortage is a real phenomenon and it can have a negative impact on the overall productivity and revenue of the organization. Time to think about succession planning to ensure your continued success.

Have you got a story tip or a hatchery operation with a great story to tell? Send me an email at mdeguzman@annexbusinessmedia.com.

Aquaexcel2020 opens call for research

Aquaculture researchers now have the opportunity to apply for full European Commission-funded access to top-class research facilities through Aquaexcel2020.

Aquaexcel2020 is a project that invites proposals from European research groups for scientific research that use the facilities of any of the participating aquaculture research infrastructures.

The project unites major aquaculture research facilities with the capacity to undertake experimental trials on a selection of commercially important fish aquaculture species and system types.

The facilities available cover the entire range of production systems (cage, pond, recirculation, flowthrough, hatchery and disease challenge); environments (freshwater, marine, cold, temperate and warm water); scales (small, medium and industrial-scale); fish species (salmonids, cold and warm water marine fish, freshwater fish and artemia); and fields of expertise (nutrition, physiology, health and welfare, genetics, engineering, monitoring and management technologies).

These installations are made available to the research community for Transnational Access (TNA) with the support of the European Union’s Horizon 2020 Research and Innovation Programme.

Interested researchers can propose projects that involve visits of one or, in some cases, two people to the chosen research institution for periods of up to three months.

Access to the research infrastructures and associated travel and subsistence expenses will be paid for under the project. If you have an aquaculture project idea but need help to find the right facility, contact the orientation committee of Aquaexcel2020 at aquaexcel-OC@inra.fr.

CORPORATE NEWS

Mowi CEO steps down

Mowi ASA has appointed Ivan Vindheim as the company’s new chief executive officer, replacing Alf-Heige Aarskog, who has stepped down effective Nov. 12.

The announcement came days after Aarskog released a written apology on Nov. 7 to Newfoundland and Labrador Premier Dwight Ball and Fisheries Minister Gerry Byrne following the death of 2.6 million farmed salmon at Northern Harvest Seafarm’s facility.

“I am very pleased that Ivan takes over the helm and I would like to congratulate the Board on making an excellent hire. The recruitment of an internal candidate also ensures continuity and should reassure every- one associated with the company that the business is in the most

capable hands,” said Aarskog in a statement.

Vindheim has been Mowi’s CFO since 2012. Krisitan Ellingsen, group accounting director, will replace Vindheim as CFO.

“I am honoured to be given the opportunity to lead Mowi together with more than 14,500 highly competent colleagues. It is with humbleness I take on this task,” said Vindheim in a statement. “The board’s strategy for Mowi of being a leading integrated seafood provider remains unchanged, and together with the rest of the organization, I look forward to continuing to make Mowi a stronger company and execute on our strategy.”

FISH HEALTH

Canada approves all-natural fish health product

A company in Prince Edward Island, Canada, has obtained federal government approval for an all-natural product designed to produce healthier fish in aquaculture facilities.

RPS Biologiques Inc. received the green light for liquid and powdered versions of Supratect under the Low Risk Vet Health Product program. The efficacy of the product, which includes black tea in its list of ingredients, was tested on salmon and their ova during a three-year trial conducted at the Huntsman Marine Science Centre in Saint Andrews, New Brunswick.

Company president Dr. Subrata Chowdhury said the product is designed to improve fish health and prevent disease. It has been in development since 2015.

The company is currently ramping up to commercial production, thanks in part to over $86,000 in funding support from the federal and provincial governments. While testing has so far been concentrated on salmon, Chowdhury said the federal approval covers all finfish.

He said Supratect is the first natural fish health product to receive approval in Canada through the Veterinary Health Products notification program.

The company eventually hopes to introduce the

product in the US, Europe, Asia and Chile and discussions are underway with a number of potential partners, he said. A large commercial aquaculture firm in Canada that used the product as part of the field trial testing is now in the process of converting to largescale use of the product, Chowdhury added.

– Liza Mayer

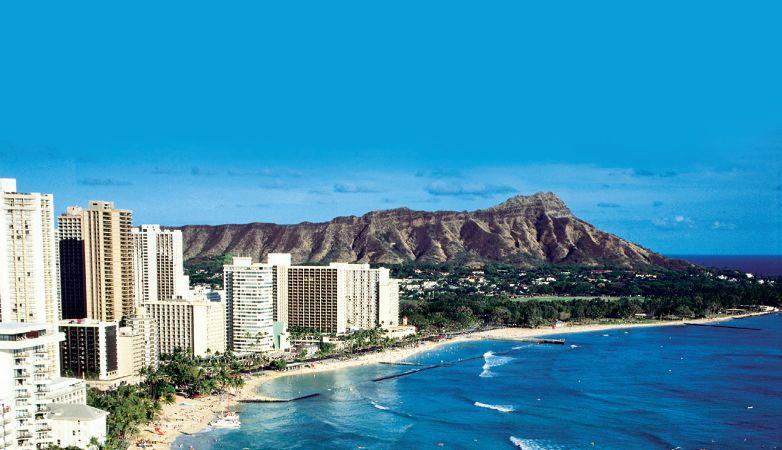

Dutch Yellowtail lands in Jonesport, Maine

Months of speculation were put to rest last November when Kingfish Zeeland finally announced that it intends to build a US$110 million land-based aquaculture facility in the town of Jonesport, in Washington County, Maine.

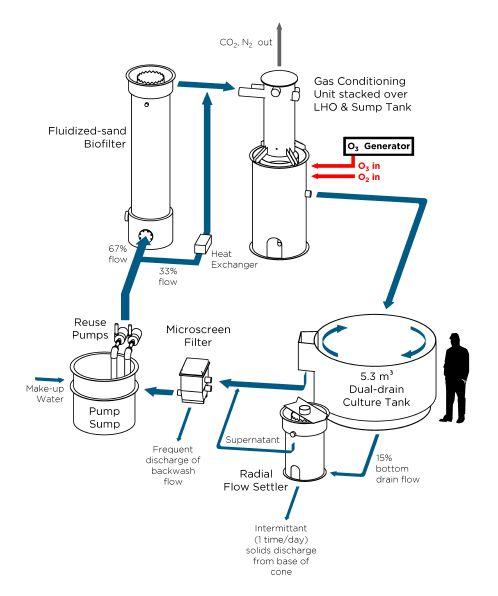

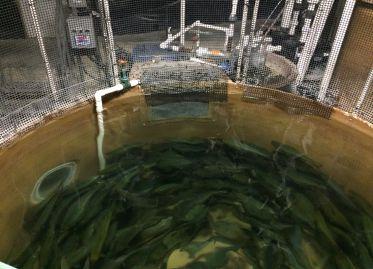

The Dutch company, which specializes in growing Dutch yellowtail (Seriola lalandi) for the European market, is the latest of several aquaculture businesses to invest in recirculating aquaculture system (RAS) facilities in Maine.

For some time now, there has been a number of theorizing as to where Kingfish Zeeland would be building its land-based aquaculture facility, according to a report from public information site MainPublic.org.

KingFish Zeeland said last spring that it plans to expand across the Atlantic Ocean. The company identified 22 sites along the East Coast, including two unspecified locations in Maine.

Jonesport is a lobster-fishing community of about 1,400 residents. Most of the work in the area is seasonal. The prospect of year-round jobs from a facility like the one Kingfish Zeeland is planning, is welcome news to the community.

The town felt “quite familiar to us,” MainePublic.org quoted Ohad Maiman, CEO of Kingfish Zeeland, as saying. He said lobster fishing history and the presence of aquaculture operations in the area appealed to his company.

Kingfish Zeeland intends to begin construction in early 2021. It will take 12 to 18 months to complete construction before the plant becomes operational, the company said.

The company plans to employ 70 people. Sixty of those employees will not need prior specialized experience to work at the plant, Maiman said.

The plant will initially produce 6,000 metric tons of fish per year. The company’s goal is to eventually hire more people and expand its facility.

– Nestor Arellano

New hatchery manager for Whole Oceans

Maine, USA-based Whole Oceans has chosen a person with more than 20 years of progressive experience in recirculating aquaculture systems (RAS) to manage its hatchery operations.

In a press release, Whole Oceans announced that Orfa Cabrera will be tasked with managing the development and improvement of raising Atlantic salmon (Salmo salar) for the company.

Cabrera will concentrate her efforts in the areas of incubation, first feeding and smolt.

“We are thrilled to bring Orfa Cabrera on the Whole Oceans team,” Jacob Bartlett, CEO of Whole Oceans, said.

Before joining the company, Cabrera served as a senior technical officer at Tassal Group Australia. The company built its first RAS in Tasmania in 2009.

Cabrera brings to Whole Oceans over 30 years of experience in the salmon farming industry. She has also worked in the RAS sector for about 20 years in Chile. Working in her native country, she took on responsibilities in planning, budgeting, personnel administration, equipment control and data analysis.

Cabrera’s main responsibility is to contribute her extensive knowledge and experience gained in Chile to the development and improvement of raising Atlantic salmon, the company said.

She also worked as a freshwater manager at Marine Harvest Chile. The hatchery produced 40 million fry using recirculating aquaculture systems.

Cabrera holds a degree in engineering fisheries management with Maximum Distinction from a Catholic university in Puerto Montt City, Chile. She also holds a marine technician degree from a Catholic university in Talcahuano, Chile.

– Nestor Arellano

RESOURCE

BC centre offers new genomic tools for salmon farmers

Salmon producers in British Columba, Canada, will now have access to innovative DNA sequencing at the British Columbia Centre of Aquatic Health Sciences (BCCAHS).

BC-CAHS and Elanco Animal Health Inc. has acquired a MinION Sequencer at the BC-CAHS laboratory in Campbell River, B.C.

This genome sequencing tool offers rapid pathogen detection and high-precision genome characterization of single organisms and complex samples. This testing will provide salmon farmers additional insight into pathogenicity, strain diversity, phylogenomic evolution and spatial distribution of microorganisms.

“The MinION sequencer allows BC-CAHS to quickly generate a high volume of valuable information to support Elanco Aqua’s global pathogen screening program and research efforts,” said Jose Rodrguez, global technical services manager at Elanco Aqua.

In the past, BC-CAHS’s limited resources resulted in high costs and extensive turnarounds to outsource genomic analysis for industry stakeholders. With the MinION Sequencer now fully validated and available at the Campbell River lab, BC-CAHS genomic analysis will be conducted in-house and at lower costs.

The MinION Sequencer was first developed at Oxford University in the United Kingdom. Its applications range from microbial identification, viral and bacterial phylogenomics, population genomics, metagenomics and monitoring of antibiotic resistance.

SKIN TEST DETERMINES GIANT GROUPER BROODSTOCK SEX

BY RUBY GONZALEZ

non-invasive method of determining sex of giant grouper (Epinephelus lanceolatus) broodstock has been developed by an international collaborative project between the Philippines, Vietnam and Australia. It only requires scraping off grouper skin mucus into a glass slide and determining the presence of a protein female marker, vitellogenin.

AGrouper are hermaphrodrites. The common method of sex determination among fish broodstock requires cannulation biopsy, which damages tissues and could lead to infection. Biopsy also requires skills which take time to develop and its accuracy mainly depends on the skill of the staff performing the biopsy, Peter Palma, researcher at SEAFDEC/AQD and one of the co-authors of the study, told Hatchery International

Another advantage of the non-invasive method is early detection. “Through immuno-detection of vitellogenin in skin mucus, ovarian development could be detected well in advance prior to observation of oocytes through biopsy,” he said.

This provides ample leeway for farmers to select maturing individuals starting to develop as females. “In existing spawning population, this method provides a more accurate estimate of females regardless of their gonadal stage, either spawning or resting, ensuring optimum sex ratio,” he explained.

“Hormonal treatment to induce early female maturation can take advantage of this method as a reliable measure of gonadal development. We have also observed that there is reduction in skin mucus vitellogenin level in giant grouper in response to androgen (methyltestosterone). Treatment, therefore, can be applied to monitor successful female to male sex reversal.”

The assay is capable of detecting vitellogenin in other grouper species such as the tiger grouper. It has also been applied for studying reproductive development of Eastern Atlantic bluefin tuna, Palma said.

The study, “Reproductive development of the threatened giant grouper Epinephelus lanceolatus,” was funded by the Australian Center for International Agriculture.

TRENDS

Labour shortage looms in Canada: report

A new report has revealed there will be 600 fewer people in the aquaculture workforce in Canada over the next 10 years, leaving 470 more jobs than the domestic workforce could fill. The Labor Market Forecast to 2029 released by the Canadian Agricultural Human Resource (CAHR) Council, said 36 percent of the current workforce are projected to retire during the period.

“Increases in innovation and technology would help close the labour gap and mitigate losses. On the other hand, retirements would work to make the gap wider. So when we consider the two opposing forces, it would be safe to say that the trend in lost sales would continue if the labor shortfall is not addressed,” said Debra Hauer, LMI Project Manager at CAHR.

Aquaculture has the most positive growth forecast of any in the Canadian agriculture sector – 3.9 percent annually compared to 2.1 percent for agriculture as a whole.

Roughly 90 percent of respondents expect employment at their farms to rise over the next five years to meet the strong market demand for seafood. But they are concerned the lack of workers will limit future growth by preventing or delaying expansion plans.

– Liza Mayer

Study shows faster growth rate for hatchery-grown mussels

BY MATT JONES

Greenshell mussels (Perna Canaliculus) reared in a hatchery can grow up to twice as fast as their wild counterparts. This was the conclusion of a multiyear breeding program conducted by Shellfish Production and Technology New Zealand (SPATnz), a research company in Nelson, New Zealand.

The study, the result of a seven-year partnership between SPATnz’s parent company Sanford, the Cawthron Institute, and New Zealand’s Ministry for Primary Industry, shows mussels taking an average of 16.7 months to grow from seed to harvest size, almost a year shorter than wild-caught.

Program manager Rodney Roberts said the mussels were raised in Marlborough, where most of the country’s mussels are grown, in order to experience typical production conditions.

“They were established across 10 sites in Marlborough, and the sites ranged from very poor to very good growing sites,” said Roberts. “The benefit of hatchery mussels was similar across all of the growing sites.”

Growth rates of three selectively bred hatchery mussel strains were compared to wild-caught from Golden Bay and Kaitaia. The quickest hatchery strain halved the growing time of Kaitaia mussels, which are the main source for the industry.

Assuming that mussels with less growing time would result in 35 percent more product being grown from existing space by 2026, business research firm BERL predicts the finding could result in a roughly $200 million windfall for the New Zealand economy.

“It shortens grow-out times markedly, especially compared to mussels from the predominant wild spat source in the Far North of New Zealand,” said Roberts. “Faster growth has other benefits that we didn’t anticipate, like an increase in crop per metre and less fouling on the shells.”

In a news release, Sanford CEO Volker Kuntzsch said the breeding program’s results would be a great step towards the New Zealand government’s ambitious goal of $3 billion in aquaculture sales by 2035. He also touted the environmental benefits of the research, saying that the program would help mitigate the impacts of climate change on the country’s aquaculture sector.

Roberts noted that the BERL estimate is based on the benefits of selectively bred mussels; it does not include the potential growth that would be unlocked by having a scalable spat supply.

Sanford is already distributing the mussels to the dozens of companies that supply them mussels for processing. Roberts said the company is not currently looking at selling either their spat or technology to overseas markets.

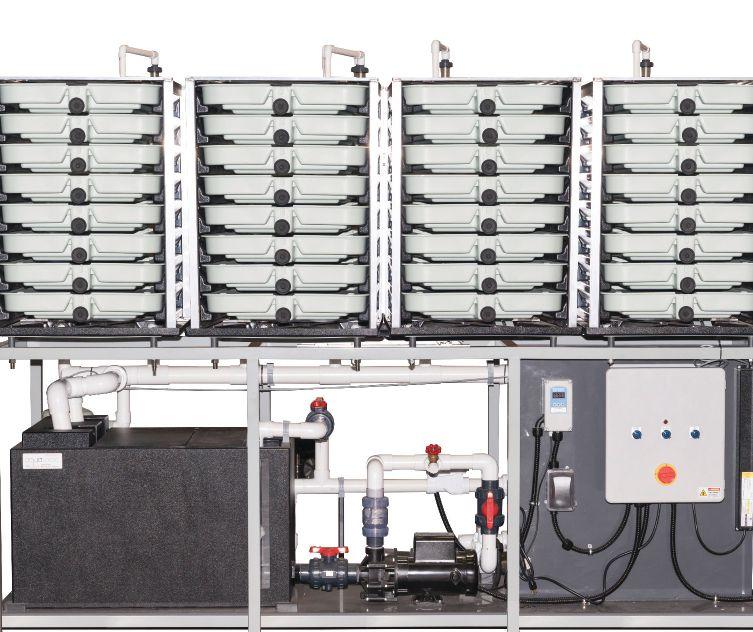

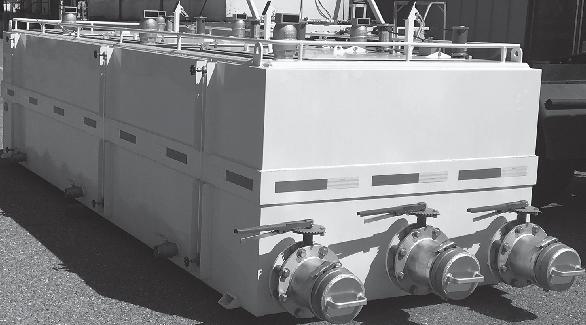

All-New HydroHatch Incubation System

Increased Survival Rate with Significantly Reduced Water Consumption

The all-new HydroHatch Incubation System from MariSource gives hatcheries increased efficiency. With recirculation, germicidal UV filter and a titanium heat exchanger, the HydroHatch delivers increased survival rate and significantly reduces water consumption.

Features and Benefits:

65 gallon sediment and recirculation tank

Requires only 150 gallons to completely fill the unit and reservoir

High-quality, long-life quartz germicidal UV filter

Complete isolation of eggs

Easily able to increase the dissolved oxygen content of the water

230 volt 30 amp control panel

Insulated titanium heat exchanger

Precise temperature control

Comes standard with four 8-stack incubators

Additional four 8-stack incubator option available

The new HydroHatch Incubation System is ideal for Salmon, Trout, Steelhead, Perch, Channel Cat Fish, Walleye, Eels, Shrimp and Muscles.

Customized for your needs “Best Fry” IncubationCost Effective and portable 503-791-9854 503-791-2533 http://reddzone.net/

Zone_NovDec19_SVA.indd 1 2019-09-18 10:27 AM

CANADA’S FIRST CLEANER FISH HATCHERY STARTS CONSTRUCTION IN 2020

BY ERIC IGNATZ

Innovation for land-based, sustainable aquaculture projects

The company that plans to build Canada’s first lumpfish (Cyclopterus lumpus) hatchery in Marystown, Newfoundland and Labrador, expects to commence construction by mid 2020, with lumpfish ready for first shipment by 2021.

Marbase unveiled its plans during the Newfoundland Aquaculture Industry Association (NAIA) Cold Harvest conference in September.

Marbase who also revealed that its sales agreement to purchase the Marystown shipyard for $1 million was finalized recently, intends to construct its new facility on the same footprint. The shipyard will be converted to an aquaculture service hub, providing the local industry a cluster of companies that can assist in the growth of the sector.

Plans have been in the works for at least a couple of years, and while some permitting still needs to be obtained, Marbase hopes to start construction by mid-2020.

“We will service the industry here [Newfoundland] and maybe further into the Maritimes. And as the biomass grows, the demand for cleaner fish will also grow,” said the owner of Marbase Paul Antle. “Our main product will be 25-gram to 60gram farmed cleaner fish, and we are looking at some other services to assist with keeping those fish in farms.”

At full operation, the facility will produce around three to five million lumpfish a year, he added.

Antle commented that Marbase is currently working closely with the staff at the Ocean Sciences Centre (OSC) through Memorial University. Members of the Dr. Joe Brown Aquatic Research Building at the OSC are already supplying the industry throughout the Maritimes with lumpfish but are unable to meet the growing demand.

Antle hopes this current relationship will build, stating, “Local research initiatives can be taken place locally with the brainpower that we have in the Ocean Sciences Centre. Together with industry we can work on a lot of different aspects of research locally, and obviously the education and training opportunities are enormous.”

Much remains unknown regarding lumpfish nutrition, genetics, and immune capabilities. Marbase intends to invest in these research areas to help develop tailored diets, implement broodstock programs and design vaccines as their facility becomes operational.

PHILIPPINES SEES NO RESPITE FROM SHORTAGE OF LOCAL MILKFISH FRY

BY RUBY GONZALEZ

he volume of fry produced by the Philippines milkfish (Chanos chanos) broodstock continues to lag behind demand, resulting in importation of as much as 70 percent of the national requirement.

T“The estimated Philippine milkfish fry requirement is between 2.5 to 3 billion pieces a year and local hatcheries can only produce 900 million a year,” said Alex Soriano, chairman of the Philippine Milkfish Group (PhilMIG). Gondol in Indonesia is the major source of imported fry.

The Bureau of Fisheries and Aquatic Resources (BFAR) is currently growing more broodstock, which takes five years to reach the spawning stage. The agency is also looking into a broodstock dispersal program for backyard hatcheries.

Increasing broodstock inventory is also in PhilMIG’s agenda. Soriano had looked into importing five-year old broodstock from Taiwan and Gondol, but transporting them over long distances increases the risk of stress and mortality.

Philippine fry costs between P0.33 to P0.41($0.0065 to $0.0081) per piece and has a survival rate of 60 to 70 percent. The 17-day old Gondol fry has a peak season landed price of P0.14 to 0.18 ($0.0027 to $0.0035) per piece and a survival rate of 30 to 35 percent.

The latter’s lower price compensates for the much lower

Class ‘A’ Philippine milkfish fry ready for shipment. Philippine hatcheries produce only about 30 percent of the

survival rate. The survival rate could increase if the fry is bigger but, as he explained, “Gondol hatchery owners prefer [selling] 17-day old fry because (it’s) economical and it’s cheaper to ship small fry.”

A BFAR official, in a news report, had suggested harvesting from the wild to augment the local fry supply. This option has disadvantages. Soriano said, “Based on our experience, we cannot rely on wild fry because supply is erratic and it’s only seasonal. At the same time, they have a very limited supply and price is horrendously high.

Estonia aims to return sturgeon to Baltic Sea

BY VLADISLAV VOROTNIKOV

The Estonian Environmental Center (EEC) has released the first batch of 20,000 sturgeon (Acipenser) fingerlings into the Narva River. This is the first step in an ambitious project aimed to revive sturgeon population in the Baltic Sea, said Meelis Tambex, a fish biologist with the EEC.

Sturgeon previously dwelled in the Baltic Sea, but had since gone extinct because of the cocktail of anthropogenic factors, Tambex said. The first batch of sturgeon fingerlings were purchased from a hatchery in Germany. Local environmentalists, however, hope that in the future local hatcheries in Estonia would also able to participate in the campaign to bring sturgeon back to Baltic.

The Estonian government has decided to focus on sturgeon enhancement as recent research has shown that the spawning ground for salmon (Salmo salar) had been destroyed by nearby hydro power plants. Breed-

Sometimes, price can reach Php1.10 ($0.022) per piece, which is very impractical.”

Some producers, particularly those with small-scale operations, cannot maximize their production because of the shortage of fry.

“They don’t have access to imported fry, or even if they import directly, they will have to pay cash. So they merely rely on the fry brokers for their requirements. But during peak fry stocking season, the priority of the brokers are those who pay in cash and with bulk orders,” he said.

ing salmon fingerlings for release into the Narva River would be a useless exercise as they would have no chance to grow and populate in the wild, according to Tambex.

“The spawning grounds of salmon and sturgeon are slightly different. Sturgeon can spawn in the Narva River, while salmon can’t, as its main spawning site has been destroyed. It is now a dry river bed,” Tambex said.

In a news report from Estonian news outlet ERR, a local fisherman expressed doubt that the sturgeon fingerlings released in the river would have a high chance of survival in the Narva River and make their way to the Baltic Sea.

“I think that most of these fingerlings in the end will be eaten by predators, because there is a lot of chub (Leuciscus cephalus). We catch it using gudgeon (Gobio) as bait, and it is exactly as small as the released fingerlings. You see, predators don’t care whether this is a sturgeon or not; everything will be gobbled up,” the local fisherman said.

OUTLOOK

High-tech future continued from cover

The consortium is made up of researchers from CATC, the University of Newfoundland, the University of Prince Edward Island, University of Guelph and the University of Waterloo.

Interest in gene editing is slowly growing in the industry, Plouffe says, because it offers the value of time. Targeting small permutations can make genetic gains in the stock in a shorter amount of time than through traditional selective breeding methods.

“This has only been in the last year or two, I would say, that regulatory agencies in different countries are starting to put some framework around how these types of gene editing technologies might be regulated differently from traditional transgenics,” says Plouffe. “I think we’re starting to see a regulatory shift which means that this technology may have a shorter path to market than previous technologies, like transgenesis, had. It took them 20 years to get to market.”

SUSTAINABLE FISH HEALTH STRATEGIES

Advancements in understanding the genomics, or genetic makeup, of fish species have huge opportunities in improving the sustainability of the industry. By studying a fish species’ genetic code, researchers can pinpoint the specific genetic traits that will lead to a bigger, better, stronger broodstock.

The University of Waterloo in Ontario, Canada, is making significant developments in this area. Associate professor Andrew Doxey is an expert in biological data mining, protein function prediction, and comparative and evolutionary genomics. He, along with research assistant Grant Cheng, recently developed an algorithm that powers a groundbreaking genome database.

“It searches all the genome data that’s out there and it looks for specific characteristics that look like antimicrobial peptides and what they found was at least 30 things that look like these that are not known to science at all,” says professor and colleague Brian Dixon. “In fact, some of these are not in the familiar families of antimicrobial peptides at all. They are completely novel.”

It was simple computer program but it opened up new possibilities of synthesizing two new antimicrobial peptides that could reduce the use of antibiotics in the industry.

In Canada alone, the aquaculture industry dumped about

150 tons of antibiotics into the ocean in the last year. Antibiotics are incorporated in fish feed as a common prescription to cure diseases in the stock.

This leads to antibiotic resistant pathogens in the environment that can be absorbed by fish (and humans). It becomes an endless cycle in which farmers introduce newer and stronger antibiotics to protect their fish from disease.

Dixon says harnessing antimicrobial peptides that naturally occur in all organisms might be the more sustainable alternative to treating the fish’s immune systems.

“The (genetic) sequences we’ve got are not just in fish genomes. They’re in pig genomes, they’re in human genomes, so it could potentially be a treatment for multiple classes of animals,” says Dixon.

The research team is looking to publish their research soon, but Dixon believes they have only scratched the surface on the potential uses of the genome database program in their research.

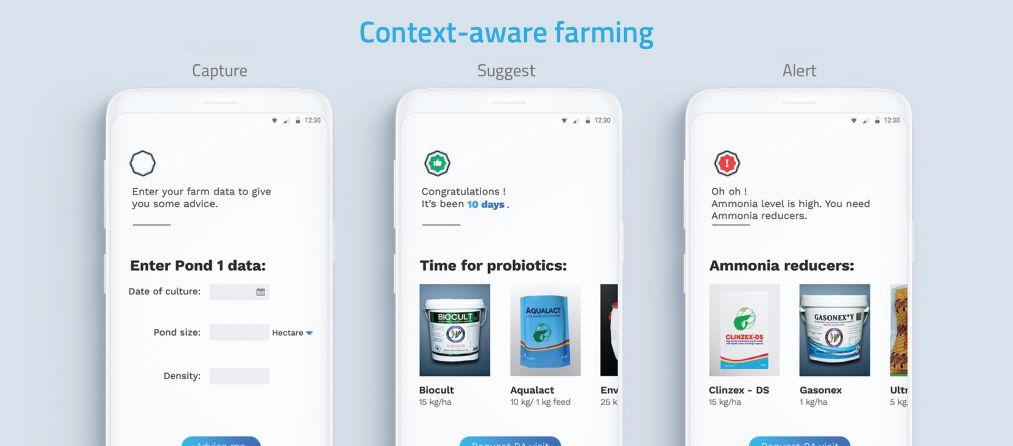

IMPROVING ACCESS TO TECHNOLOGY

New technological advancements are only useful to the aquaculture industry if people at the grassroots level have access to it. This is the revolution that Rajamanohar Somasun-

daram hopes to lead through his mobile app, FarmMOJO. Somasundaram’s background is in tech startups, not aquaculture. But it was during a serendipitous train ride back to his hometown of Chidambaram, India, in 2016, when he sat beside a rural shrimp farmer that he realized his opportunity to use his artificial intelligence (AI) and data computing skills to make a difference in one of India’s largest industries.

“In the West, huge capital investment has to go in, to manage an aquaculture farm operation. In India, it is all about small and medium farmers. About 80 per cent of production come from these small and medium farms,” says Somasundaram. “Typically, you will start doing aquaculture just by word of mouth. You will not have a scientific or professional knowledge about this business. It’s as simple as, your neighbor did it, he made good money, he bought a new car and a new house, so you want to get into this business.”

Sanjai Kumar, the shrimp farmer he met on the train, told Somasundaram about his struggles managing his “one or two-acre” farm. Even after 20 years of experience, the farmer was going broke because he couldn’t keep up with the high production costs, the disease outbreaks, managing water quality and all other operational aspects of running the farm.

After the train ride, Kumar took Somasundaram to his farm. They also looked at the neighboring farms and Somasundaram quickly understood that the solution was to automate more of the farms’ operations.

In 2017, Somasundaram, Kumar and Shanmuga Sundaram, a former banker turned entrepreneur, founded AquaConnect, an AI-enabled platform that can be accessed through its mobile app, FarmMOJO. This tool helps improve farm productivity and traceability by keeping track of pond water quality, feeding information, growth rate and other production data in one place.

FarmMOJO uses machine-learning technology to analyze data and generate predictive insights to improve productivity. The app also gives shrimp farmers access to a network of local technical service managers that can provide their expertise for every 20 farmers within their region.

AquaConnect’s full suite of products and services can be accessed through a pay-as-you-go model, which Somasundaram strongly believes, is why FarmMOJO has been adapted so widely in India’s aquaculture industry.

“The cost of the technology has to be proportional to the incentives of the product,” he says. “Most of the technologies that are built in the West, they are simply asking for thousands of dollars per license which can be the profit (margin) for the farmer in many cases. So, how can we expect the farmer in such technology? So, we have to bring in new, innovative pricing models.”

Somasundaram says AquaConnect is in the process of developing a new feature for FarmMOJO, which is a datadriven marketplace platform that hatcheries, feed producers, equipment manufacturers and other suppliers of the industry would pay to promote their products to the farmers.

AquaConnect is also working with banks and insurance companies which, Somasundaram says, are typically averse to investing in or doing business with small aquaculture farms.

“Since there is no reliable data, they (banks and insurers) are not able to assess the farmer’s credit worthiness and

potential,” explains Somasundaram. “How can we fill this gap through FarmMOJO? That is something that we are actively thinking about right now because we know what the farmer is doing at any given day. We can provide the information that can help create the framework for their credit worthiness.”

FarmMOJO is currently supporting more than 3,000 shrimp farms in coastal India, with pilot projects launching in Indonesia.

“I always understood that I won’t be able to make money through the technology solution that I’m providing,” says Somasundaram. “We work with farmers end-to-end… We have always created these products for them.”

COMMUNITY ENGAGEMENT

Bringing technology to the masses is not only beneficial for moving the industry and the economy better, it also facilitates better education for the consumer.

At the Norwegian University of Science and Technology, a small team in the IMTEL research group and lab is harnessing virtual reality (VR) and augmented reality (AR) technology to bring the story of aquaculture to the people.

Head of the IMTEL research group, Ekaterina PrasolovaFørland first presented a VR simulation at an aquaculture conference in 2015. Using an Oculus Rift device, the user can interact with a 3-D immersive experience of a salmon aquaculture farm.

Since then, Prasolova-Førland has been looking into other applications of VR and AR technology to increase professional training and public education about the industry. Her latest project is an AR program in collaboration with Master’s student Aslak Karlsen.

“It involves visualizing fish pens and their placements in the ocean, while also being able to see from inside the fish pen. The goal moving forward would be to work more towards use for education for people without knowledge of aquaculture, the life of the fish, the wellness of the fish,” says Karlsen.

He adds that his AR prototype has many applications. The simulation can be a useful tool to plan fish pen placements within a 3-D ocean layout. There can also be future applications in which farm managers can remotely examine a 3-D layout of each net pen without having to coordinate a diving expedition.

But more importantly, he hopes the program can provide interactive learning experiences for the general public to learn more about an industry that accounts for more than

Ekaterina Prasolova-Førland from the Norwegian University of Science and Technology is harnessing virtual reality and augmented reality technology for public education. (Photo credit: Ekaterina Prasolova-Førland)

NOK$64.6 billion or US$7 billion in export value.

There has been a recent push, even among Norwegian companies, to invite local high school groups and host community open houses to tour their facilities. However, even as a world leader in the industry, Prasolova-Førland says Norway still has a long way to go to raise public awareness about aquaculture.

“I mean, I’ve heard people say, ‘Is there salmon in Norway?’” she says. “It’s an important food source but people are not aware of where their food comes from… There are also prejudices about the industry about environmental challenges and antibiotics in the ocean.”

Aquaculture in Norway is only about 45 years old. But over the last 25 years, production of salmon and rainbow trout increased about 10 percent each year, according to Norway’s International Research Institute of Stavanger.

Prasolova-Førland says the Norwegian University’s Department of Education and Lifelong Learning has a special role to play in connecting this fast-growing industry to the consumer.

“Apart from some, the aquaculture industry is not seen as a relevant job prospect or career but after they have tried our programs, they gained some interest to explore more. For one of them, it even led to applying for a permanent position,” says Prasolova-Førland.

Liquid Diets (30% DW min)

NANNO GOLD

ISO GOLD

DHA GOLD

Dry Diets

M0 PLUS M 1 PLUS We select the best Marine Algae to produce innovative products We select the best Marine Algae to produce innovative products

Rotifer Culture

Rotifer Enrichment

Artemia Enrichment

Green Water Oysters Clams Fish Shrimp

Amazing Quality

Amazing Quality

Long Life Span

Long Life Span

Single Cells (2-20 microns)

Single Cells (2-20 microns)

Nutritional Superior (EPA, DHA, Omega 3) Competitive Prices

Nutritional Superior (EPA, DHA, Omega 3) Competitive Prices

INNOVATION

SPAWNING SNAPPER

BY MATT JONES

Earth Oceans Farms, part of the Cuna del Mar portfolio, was established in 2012 in La Paz, Mexico. The company’s mandate is to develop aquaculture for new species and, over the years, they have conducted research and development for high value marine species such as Totoaba macdonaldi and Pacific red snapper (Sebastes ruberrimus).

In 2013, the only marine finfish species available was totoaba, pioneered for aquaculture by Dr. Conal True of the Autonomous University of Baja California (UABC), says hatchery manager Fernando Guido Cavalin. Totoaba were once the subject of a lucrative wild fishery in Mexico, however, as the endangered vaquita marina porpoise was regularly being captured in totoaba nets, totoaba fishing was banned.

“But there’s been a lot of effort to develop aquaculture technology for the totoaba, which is an amazing species,” says Cavalin. “We’ve had growth rates of three to four kilos in one year, and a feed conversion rate of 1.3-1.5. It’s very disease resistant.”

Earth Ocean Farms purchased totoaba juveniles from UABC and set up their first grid of off-shore aquapods shortly thereafter. In 2013, the farm established its hatchery.

“The hatchery is basically full raft,” says Cavalin. “Rafts for group stock, for nursery, and partial rafts for larval rearing. Because conditions in the Baja are quite extreme, the water temperature, the amplitude is too high. It gets up to 30 degrees Celsius in the summertime and it’s quite cold in the winter, 19-20 degrees Celsius. So, in rafts, we have more control of water temperature.”

SELF-SUFFICIENT

Earth Oceans caught its first totoaba broodstock in 2014, had its first spawns in 2015, and reached a level of selfsufficiency in commercial production in 2016. However, Cavalin notes, the company knew that totoaba could not be the farm’s entire portfolio. For one thing, under the Commission for International Trade of Endangered Species (CITES), the export of either wild caught or farmed totoaba is banned, so the company can only sell that product to local markets. In order to produce totoaba at all, the company is required to release a certain number of fish back into the wild each year.

“The company always knew the uncertainties of the totoaba, so we always had R&D for the pacific red snapper on the back burner,” says Cavalin. “Our Mexican species is called huachinango. But it’s not easy. We’ve had broodstock since 2014, but it took us a while to control year-round spawns.

“We have three rooms of broodstock. First, we have to learn how to condition fish to spawn naturally year round. So each room is conditioned to spawn for three months. That was our major accomplishment with red snapper, controlling their spawning naturally by manipulating photothermal cycles.”

Cavalin’s team started to see good results for red snapper spawning around 2015. Prior to that, the survival rate was close to zero, but inched upwards over the following years. In 2018, the company saw a major breakthrough, and closed the year with a five percent survival rate.

“This year, we’re getting really good runs,” says Cavalin. “We’re getting runs of 10 percent, some up to a 13 percent survival. So, the company is pushing more towards the red snapper. We’re stocking more cages of red snapper. We started exporting red snapper this year to the US. And it’s been a major drive for us, developing commercial scale operations for the red snapper.”

SECRET TO SUCCESS

Cavalin says he can’t discuss the specifics of how they achieved those improvements (“You’re asking the silver bullet question,” he says with a laugh). But he points out that it involved dedicated, constant work with the species for years, and learning to control every aspect of the hatchery culture environment, including lights, air temperature and water temperature.

Cavalin acknowledges that someday Earth Oceans may look at licensing the technique to other operators, but for now, they will keep their operation in-house.

“I like to do an analogy to a chef,” says Cavalin. “A chef can disclose the recipe, ‘these are the ingredients,’ but it’s hard to replicate how a chef must cook, how he sets up his kitchen, the way he uses the stove, his timing. That’s what the company is trying to protect.”

This past April, the company broke ground on a new commercial hatchery, and expects to have fish and flowthrough systems in place by December, with full operation coming in June or July of 2020. This has been a long-term plan, as the current facility is only 1,600 square meters, meaning that totoaba production and red snapper R&D had to be conducted in very close proximity to each other.

“Since we started producing good numbers, the

company made the commitment, ‘let’s go ahead with a commercial hatchery so we can back up the extension of the farm and processing plant and sales.’ The facility is 7,000 square meters and we’re going to have large tanks for totoaba or perhaps a third species. Larger tanks for red snapper, full rafts. There is area and capacity for up to 10 million fingerlings. Our production right now is around a million fingerlings a year. And we need to just scale up to meet farm goals.”

The potential third species Cavalin mentioned has not yet been decided. There are several species with potential to be grown in the area, including Pacific snook and yellowfin tuna. Cavalin expects to see a market assessment and some R&D trials conducted in the next year, which will deter-

mine how the company proceeds.

“We need to see how the fish is going to do in the hatchery, get down our key production index, juvenile production, see how it grows in the farm, grow the feed conversion ratio,” says Cavalin. “But it’s in our back burner for now.”

Cavalin struggles to pinpoint the most challenging aspect of Earth Ocean Farm’s business model – everything has been a challenge, from learning to work with offshore aqua pods to the long R&D process. But one of the more consistent and unique challenges has been the weather, he says. The farm is located in a hurricane zone and August and September are generally very difficult months.

“We got hit by a hurricane in 2016,” says Cavalin. “It

tore the hatchery apart. It caused damages to the farm. So that’s very challenging. We could choose to do something easier closer to shore, but our operation is two and a half kilometers so it needs a lot of boats. The operation over there is not easy.”

The Baja Peninsula is becoming a hub for marine finfish aquaculture. Kampachi Farms, Pacifico Aquaculture and others are nearby, working on species such as striped bass and almaco jack.

“The new species industry is growing strong in Mexico,” says Cavalin. “The way Mexico is pushing for aquaculture, it’s attracting more investment and for people to come work here. At Earth Ocean Farms, we have people from all over the world.”

Since 1958, Faivre has been developing and manufacturing high quality equipments for the aquaculture industry

Saving the scallops

BY BONNIE WAYCOTT

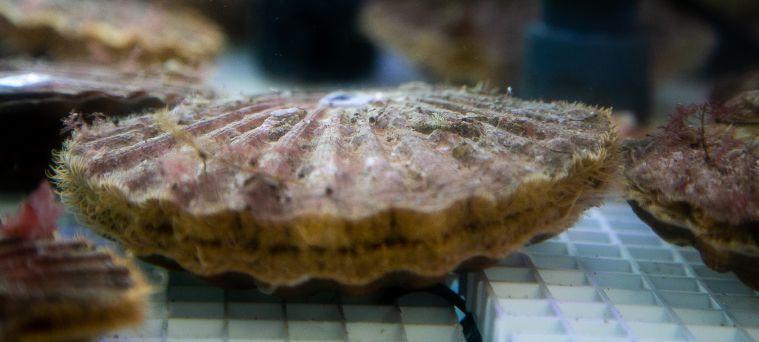

Anew scallop hatchery in Plymouth, U.K., is hoping to ease the pressure from commercial scallop fishing, which has caused significant strain on the ocean and the species that end up as bycatch.

To offer a sustainable alternative to wild-caught scallops, UK charity the Ocean Conservation Trust and Plymouth Marine Laboratory (PML) set up the scallop hatchery in Sutton Harbour, which supports around 600 jobs and sells over 6,000 metric tons of seafood products, including scallops, each year to local restaurants and fish markets.

“Our aim is to establish a local, sustainable fishery that consistently produces viable King scallop (Pecten maximus) seed that will contribute to the reduction of destructive fishing methods and conserve this valuable species,” says Jessica Harvey, hatchery technician at The Ocean Conservation Trust.

A variety of scallops live in UK waters, in particular off western Scotland where commercial scallop fishing took off in the 1930s. In England and Wales, it occurred on a smaller

scale until the 1970s, when landings increased thanks to the development of overseas markets. Today, many different scallops are widely sold by quality fishmongers.

However, scallops are mostly harvested by dredging, which results in severe ecological effects. Unless it’s managed effectively, the procedure can be extremely destructive due to problems such as bycatch and damage to the seabed. Bycatch include monkfish, dover sole, crabs and other benthic epifauna, while organisms can also be damaged from within the dredge bags due to abrasion from other organisms or debris. Despite efforts to return bycatch, those that are put back may die from physical damage, stress and vulnerability to predation.

NEW STEPS

The hatchery uses a small-scale recirculating aquaculture system with two broodstock conditioning tanks, six larval rearing vessels and two settlement tanks. There is also an algal culture facility containing around180 liters of live algae with a maximum capacity for approximately 200 liters.

“Ultimately, we’re aiming to produce as many scallops as we can support,” says Harvey. “Our settlement tanks can support a maximum of 480,000 settled spat, but at this stage we will not be stocking to our maximum capacity due to space restriction for grow-out. Additional space for early spat grow-out will be obtained if necessary.”

BROODSTOCK

Broodstock are above the minimum U.K. landing size of 100 millimetres. Divers collect them by hand within marine protected areas off Plymouth and surrounding Drake’s Island. Both locations are within close proximity to the hatchery. They’re held in natural filtered seawater at a minimum of 30 ppt.

Water is changed daily due to the high bio load within a recirculation system. In the morning, 50 percent of a mixed algae diet is given, followed by another 50 percent in the afternoon. Feed quantity varies between 4 x 109 to 8 x 109 cells per scallop per day, depending on the stage of the conditioning regime. Eighteen adults are held in a 240-liter tank, below maximum density to ensure minimum stress levels.

INITIAL GROWTH

Spawning is usually induced by a combination of thermal cycling, air exposure and the presence of fresh gametes in the water. Prior to spawning, natural conditions are mimicked through temperature and food increases, while staff are also looking closely at lighting regimes to mimic natural conditions even more.

Eggs are fertilized within a maximum of one hour of being expelled to ensure maximum

viability, with trochophore larvae usually observed around 24 hours post fertilization at temperatures between 16 and 17 degrees Celsius. Larvae culture occurs in six 60-liter conical vessels. Containers with a large bottom surface area are used for smaller scale spawning.

“Larvae densities within these will vary, with an initial maximum of ten larvae per ml,” Harvey explains. “This number will decrease as they develop through their life stage. At settlement, a maximum stocking density of five larvae per ml will be used. It takes between 25 and 30 days post fertilization for settlement to begin, and metamorphosis occurs between five and 15 days, depending on environmental conditions. Our aim is to rear the larvae without any antibiotic treatment.”

A mixed algal diet is offered as feed. Microalgae cell densities are maintained between 20 and 50 cells μl-1. The cell density of the larval vessels is calculated twice a day for assessment and readjusted when required. The scallops are given a nutrient-rich single species for their first feed, before a mixed diet is introduced within a few days of them developing into straight-hinged veligers.

“It’s possible to use a single algae species if it contains the correct nutritional values,” Harvey says. “But this can vary depending on the environmental conditions. We opt for a mixed species diet so that the key components are delivered in abundance and will be continuing our work to establish and research a suitable mixed algal diet.”

BIOSECURITY

A strict biosecurity protocol is also in place.

“The hatchery will use natural seawater, which is exposed to a four-stage filtration process before it reaches the hatchery system,” Harvey explains. “It’s drawn in from Plymouth Sound, passed through a sand filter, treated with ozone at 750 millivolts, passed through a UV system and held within our storage tank until it’s required for use. This process takes a minimum of four hours.”

The water is continuously treated within the recirculatory system once it reaches the hatchery. An astral sand filter, filled with TMC glass filter media, removes particulate matter down to 20 μm. A TMC P6 ultra violet sterilising unit, a 30-liter biological filter, a 25 and 10-μm cartridge filter and 5-μm filter socks are also part of the system.

To maximize biosecurity the hatchery implements rules and policies, such as restricted staff entry, sanitizing before entering the algal culture room and before handling all live stock, sterilizing equipment, biosecurity foot baths upon entry, using lab coats and gloves during all stages of algae and larvae handling, histological sample analyses, and using autoclaved seawater where possible for gamete storage and algal culture.

With the hatchery newly established and this year’s funding only for purposes of establishing successful culture protocols for the species, ongrowing methods haven’t yet been confirmed. But through the hatchery’s strong links to academic professors from Plymouth University, areas such as stocking density, location and ecological impacts will be addressed soon, says Harvey. Handling and processing will also be confirmed once the hatchery is reliably producing spat.

SUSTAINABLE FUTURE

Hatchery-reared

seafood sources, allowing people in Plymouth and elsewhere to purchase such seafood and enjoy it, knowing they have contributed to the conservation of a local species.

Within the next few months, the hatchery will be trialling new ways of conditioning and inducing spawning. Staff will also be investigating the scallops’ diet to ensure that all essential fatty acids are delivered during conditioning and larval development.

“We’re really excited for the year ahead,” says Harvey. “The hatchery has been up and running since May. Since then, we’ve managed to successfully fertilize eggs and rear larvae to 18 days post fertilization, where they developed

an eye spot and were getting close to settlement. Due to having an initial low number of eggs, 100 percent mortality occurred on Day 18. This is, to our knowledge, the furthest through their lifecycle that a hatchery has achieved in the UK. It was an enriching learning experience and we’re now well equipped for our next batch.”

“Aquaculture is developing rapidly and for a good cause,” says Melanie Kruger, communications officer at Ocean Conservation Trust. “It can allow natural populations to thrive while delivering a sustainable source of nutrient-rich food for an ever-growing population. I’m really looking forward to seeing the hatchery techniques develop.”

OPERATIONS

INVASIVE SPECIES

Pike proliferation threatens ecosystem around world’s oldest running trout hatchery

BY RUBY GONZALEZ

The Oughterard Trout Hatchery (OTH), located in its namesake town in Ireland, has been around for almost 120 years and has had its fair share of ups and downs. But nothing compares to what it is currently facing, according to hatchery manager John Gibbons.

“The most serious threat to the hatchery and its operation was the illegal introduction of Northern pike, Esox Lucius, to the Owenriff system circa 2008. It is an exact replica of the situation in South Central Alaska where Pacific salmon fisheries have been destroyed by pike,” Gibbons tells Hatchery International.

The 68 square-kilometer Owenriff system is a series of lakes interconnected by a river, which is a tributary of Lough Corrib.

The Oughterard Trout Hatchery is situated on the Owenriff river and hatchery brood stock are Owenriff spawned fish. According to Inland Fisheries Ireland (IFI), 15 percent of all Lough Corrib trout are spawned in the Owenriff system.

“The invasive pike population are systematically destroying a unique ecosystem that has existed since the last Ice Age. Atlantic salmon also spawn in the Owenriff system and have also been severely impacted by the pike introduction,” Gibbons says.

SPECIAL AREA OF CONSERVATION

“The Owenriff is a designated ‘special area of conservation’ (SAC) by the European Union Habitats Directive,” according to Gibbons. “The presence of pike is a contradiction to the conservation objectives of the SAC and therefore, we have petitioned the European Commission to force the Irish authorities to deal with invasive pike effectively.

In October 2017, a delegation of anglers representing Lough Corrib and the Owenriff went to Brussels, Belgium to meet with top officials from the European Commission’s Directorate-General for the Environment regarding the invasive pike issue.

FIRST IN ALGAE

“Our lobbying of European officials is continuing at this moment,” Gibbons says. Infestation has reached such a critical point that OTH, in a Facebook post, has begun to question the wisdom of having to release all the fry they produce in the Owenriff system, under its hatchery license from the IFI. They have documented evidence of the ecological damage caused by pike in the Owenriff system.

As a solution to the situation, the Oughterard Anglers and Boatmen Association (OABA) issued in June a four-point demand for IFI. This includes for “IFI to follow international best practice by issuing an immediate and unrestricted ‘catch and kill’ order for all invasive pike in the Owenriff system.” IFI has not commented on these demands as of press time, says a volunteer, who requested anonymity.

In the backdrop of all these, one thing has remained constant for OTH since its inception: keeping a tight production schedule.

Oughterard “is generally accepted as the greatest wild brown trout fishery in the world.” And it has a big role in maintaining such a stature.

A unique facet of the hatchery is that just as it collects broodstock at the start of every cycle, it also releases these back to Lough Corrib during the last stage, after stripping them of ova and milt. One hundred percent of the fry produced are released throughout the Owenriff system, contributing to a healthy trout population.

For the 2018/2019 cycle, 150 cock fish and 200 hen fish were kept for stripping, producing 250,000 fertilized eggs, which would give 180,000 fry in February.

VOLUNTEERS GATHER

In early October, volunteers gather at the hatchery and are marshalled by Gibbons to get the place ready for winter stripping and egg incubation. He has been the hatchery’s manager for over 30 years.

“For netting operations and fish stripping, we need about 20 core volunteers but more are welcome to help out at any stage. During the egg incubation period, less volunteers are required,” he says. There has never been a time when they were lacking in volunteers.

All who are interested are taken in. “Every Corrib angler who has an interest in wild salmonid sustainability is welcome to help out at any time, nobody is turned away,” he says.

He gained expertise in hatchery operations by “helping as a volunteer, like all Corrib anglers who give back with their time and effort during the angling off-season.” He was in his 20s when he started volunteering.

The group is in action for only four consecutive months every year but this period is packed, necessitating working through the holidays. Year in and year out, this cycle has been going on for generations with conservation in mind.

The Lough Corrib Angling Federation provides funding, which covers electricity costs, council rates and insurance. As everyone is a volunteer, there are no paid employees.

Conservation and hatchery are at the forefront of the association programs.

The hatchery has an interesting history that is worthy of several rounds of pints in a pub. The original location is the site of the world’s first commercial salmon hatchery, which was built in 1852. This is credited for “inspiring others throughout the world to commence what we now know as salmonid aquaculture.”

It became a trout hatchery in 1900, when the Department of Agriculture, on behalf of the Corrib Fisheries Association, redesigned and equipped a building. It was operational until the association was dissolved in 1925. The structures began deteriorating.

The current trout hatchery sprung from an initiative in 1938 of a group of anglers who, while seeking ways to improve trout fishing at Lough Corrib, decided to rebuild a new trout hatchery and raised funds.

A major refurbishment was done in the 1990s, resulting with new stands and pipework for the incubation trays. To prevent silting of fish trays, a filter unit was built. A new water supply was installed and laid upstream. Improving access even more, a concrete bridge was also constructed.

PACKED FOUR MONTHS

October to February hatchery operations are divided into four stages, starting with prepping the hatchery. This involves cleaning all pipework, cleaning the water filter tower, egg trays, and raking fish holding ponds and other general maintenance.

Next comes the collection of broodstock. “Net setting is done in the Owenriff River to trap a quota of cock and hen wild brown trout on their way to their spawning grounds from Lough Corrib,” the volunteer says.

After the completion of netting operations, the broodstock is brought to settle in the hatchery holding pond for two to three weeks with the cock and hen fish separated.

On two consecutive weekends in early to mid-November, the hen and cock are stripped of their ova and milt. The fertilized eggs are carefully spread out in various egg trays, which are kept in total darkness. All stripped fish are returned immediately to Lough Corrib.

This last stage requires the most intensive attention with the daily monitoring of developing eggs and removing any dead eggs with “great care.” This period runs until February, when the ova hatch. And even on Christmas Day, this has to be done.

Once all the ova are hatched, the fry are distributed throughout the Owenriff system by the same volunteers per the IFI license requirements. Fry are released when they still have their yolk sacs. This keeps their development as natural as possible.

Looking ahead, Gibbons says they have no improvement plans at this stage because the hatchery is run seasonally on a tight budget. There is minimal expenditure apart from general maintenance and utilities.

“However, considering the dire situation of the Owenriff with respect to invasive pike, we may start to rear Atlantic salmon again if we can obtain a license from IFI,” he says.

ISSUES

Industry vs activist: Finding a middle ground continued from cover

“I do not think that they fairly acknowledge the very significant improvements that have been made.”

– Tim Kennedy, president and CEO of the Canadian Aquaculture Industry Alliance, feels that the industry is still haunted by early mistakes that were made in the sector’s over 40-year history.

were not re-assessed for impacts from an increased number of fish.

Mark Lane, executive director of the Newfoundland Aquaculture Industry Association, disputes that interpretation.

Speaking hypothetically (as it involves a court case that he is not party to), Lane cites the environmental registration process that every new project has to file with the government, which is available publicly.

“These sites were already approved and went through rigorous and highlevel scrutiny,” says Lane. “They want an environmental assessment to be done on all your sites again and again and again, which makes no sense. It was already done and it’s available publicly.”

CITING SCIENCE

The ASF’s concerns about the aquaculture industry go far beyond these specific

CHANGE IN POLICY

Isituations, as evidenced by the group’s years of campaigning against it.

“The science is very clear now, every time somebody goes and looks they find more evidence of the impacts of aquaculture salmon on wild salmon,” says Sutton. “We know what the potential impacts are and we’ve seen it in places. There’s also growing concerns about issues of disease and the spread of disease from farms to wild salmon.”

Sutton cites a 2018 study by Brendan F. Wringe, et al, that linked farmed salmon escapes with “reports of population genetic change” and “potential negative consequences.”

Tim Kennedy, president and CEO of the Canadian Aquaculture Industry Alliance (CAIA), while not commenting on that specific study, describes trying to find a balance between negative and positive research as “a mug’s game.”

“Science doesn’t work in a democratic

n response to the controversy over the mortality of 2.6 million salmon at a MOWI farm, the government of Newfoundland introduced a bevy of amendments to its policies and procedures for the aquaculture industry.

The amendments include requiring more transparent public reporting of mortality events and sea lice abundance, the implementation of mitigation measures to prevent mortality events, the submission of biophysical data to various government departments and demonstrating that cage systems meet engineering standards, among many others.

While the policy amendments do nothing to strengthen potential consequences for companies that violate them, Mark Lane suggests that Fisheries and Land Resources Minister Gerry Byrne has demonstrated a willingness to impose punishments himself.

“The minister just suspended ten licences,” says Lane. “That’s unprecedented. I think that would far outweigh any type of penalty. These policies and procedures are attached to condition of licence.”

The ASF, however, is not satisfied, releasing a statement from Dr. Stephen Sutton stating that policies and procedures are not regulation or legislation, and that they do not see how these amendments would prevent a mass mortality event from occurring again.

“Better policy will hopefully lead to a more organized and transparent industry, but the changes do nothing to fundamentally address the issues of wild salmon interbreeding with escapes and the transmission of disease and parasites from aquaculture salmon to wild species,” Sutton says in the statement.

process,” says Kennedy. “It’s not a majority vote. One strong, well done conclusive story can outweigh a hundred bad studies. But we can’t authoritatively speak to the science. We refrain from saying there are this many studies that say this. We rely on the science to direct us and to inform our practices. And we will always say that if there is science that is clearly indicating that there are challenges, we’re going to change our practices.”

THE MIDDLE GROUND

Like Lane, Kennedy also refrained from commenting specifically on the Indian Head Hatchery expansion issue, however, he did state that the industry is constantly moving towards higher levels of transparency.

“We need clarity and certainty around the regulatory process,” says Kennedy. “Even if nothing wrong is happening, I think all of these processes need to be as clear and transparent as possible.”

Kennedy says that the industry needs to enhance its efforts to address concerns and engage with the public and environmental groups, citing the polarized landscape in British Columbia as evidence. He says that CAIA is interested in bringing national stakeholders together to have a dialogue on how to move forward on environmental issues.

“We want to have a constructive dialogue with constructive minded critics and environmentalists who want to see real improvements in the sector, who don’t want to destroy the sector,” says Kennedy. “Because you can’t really negotiate and discuss when someone wants to destroy you.”

Lane agrees, saying he has a

“I think the salmon angling community in Newfoundland has started to become more aware of the issues and the impacts on wild salmon.”

– Dr. Stephen Sutton, coordinator of community outreach and engagement for the Atlantic Salmon Federation.

great relationship with some activist groups, such as the Salmonid Preservation Association of Western Newfoundland. He describes having what he thought was a very productive meeting with members of the ASF, where they discussed finding common ground to work together to improve the industry and protect wild salmon. But he felt betrayed days later when the ASF resumed its attacks on the industry through social media.

“I’m willing to work with anybody who’s willing to work with us politely, professionally and cordially from a fact-based position,”

says Lane. “Some of these groups just don’t want to do that. They fundraise on the backs of farmers and they have a motive to kill the industry and put hardworking Atlantic Canadians out of work. I find it somewhat sad and pathetic.”

MOWI representatives did not respond to requests for comment as of press time. However, as of press time, the company’s CEO Alf-Helge Aarskog had sent a letter to Newfoundland and Labrador Premier Dwight Ball and Fisheries Minister Gerry Byrne committing to a variety of equipment upgrades and measures to increase transparency.

Green water

continued from cover

the three-hectare hatchery in Santiago City, Isabela, since 2005. He has a broodstock of 8,000. Monthly production varies from 700,000 to 1.5 million fingerlings, depending on whether it is hot or cool season.

Through his own tried-and-tested innovations, he has maximized the facility’s production capacity since day 1.

GREEN WATER

Lugagay uses different strains of tilapia to produce heat-tolerant fingerlings that can adapt to the changing climate.

Diet is an important aspect of conditioning the broodstock. A combination of dried krill and commercial feed produces more eggs and healthy fingerlings.

“Dried krill is high-nutrient, floats and is palatable to the fish. It only costs P600 (US$12) a kilo and that goes a long way,” he says.

Meanwhile, the breeding ponds are prepared starting with a pond-to-pond release of green water, which is filtered to keep out fingerlings and other small fish.

Chicken manure is scattered as a natural fertilizer.

Within a week, planktons and moena would be observed growing. Once there is enough growth, the broodstock are released.

With the natural food growing in the ponds, commercial feeds are no longer provided. Another advantage of this process is that since broodstock consume natural food through their gills, no egg is expelled during the mouth-brooding stage. “After 11 days, collection of fry begins,” he says.

Coming up with the concept of green water technology came from his experience at the first hatchery he owned and operated. He has trained himself to notice and observe what is happening with a researcher’s eye and mindset.

At 15 years old, in 1979, he was hired as one of the day laborers to work on the construction of a prawn hatchery, located in Negros Occidental, by one of the biggest multinational corporations in the Philippines. He went to night school just to finish high school. By the next year, he was promoted as a hatchery assistant. In this new environment, he was surrounded with aquaculture graduates and professionals from state

universities and became conversant with industry and scientific jargons. “Every day, they would give me tasks to do and explain to me the process,” he recalls.

In 1997, following years of steady downsizing because of the collapse of the Philippine prawn industry, he was assigned to the company’s tilapia hatchery in Calauan, Laguna. By 1998, he was the team leader who ensured quality of fingerlings. In 2000, he was qualified for retirement and opted for it. He then set up his own tilapia hatchery in the nearby town of Bay.

“When I still had a tilapia hatchery in Bay, there were backyard hatchery operators and the water they used would pass through neighborhood districts and was very green. This needed to be filtered before being directed to flow into the breeding ponds. I observed that after a week, zooplanktons started growing and that the fish ate it,” he says.

He tweaked and fine-tuned this into the green water technology he now uses.

FOUR-DAY SEX-REVERSAL

After the fry collection comes the sex-reversal process, which he has been able to shorten from the usual 21 to only four days. An experience from his early days served as one of the foundations for this innovation.

“When I was still a hatchery assistant, I assisted a student who was doing his thesis on egg to fry development and sex development,” he explains. One of the basic facts Lugagay learned was that tilapia have no determined sex

THE WORLD OF AQUACULTURE

when they hatch and the fry develop sex after one week. For the sex-reversal process, he has tanks for 100,000 fry equipped with an aeration system that he designed and developed himself. This produces a high dissolved oxygen level that increases vigor of the fry. “Feeding is done ad libitum,” he says. “They just keep on eating.” Hormone-treated commercial feeds are provided roundthe-clock.