Cultivation: Effective post-harvest techniques for incredible weed p.8

growopportunity.ca

Cultivation: Effective post-harvest techniques for incredible weed p.8

growopportunity.ca

OGEN and Distinkt Cannabis lead untamed and immersive cultivation tours P.12

p.16

The key to incredible weed lies in effective post-harvest technique

Evolving the law of trade-dress in a digital world 20 | Vantage Point

Competition Bureau’s industry recommendations just the tip of the iceberg

& CEO, Oceanic Releaf

12

Calgary LPs shine bright in Canada’s Wild West

Relish the cultivation experience of OGEN and Distinkt Cannabis BY

HALEY NAGASAKI

16

Cultural appropriation in psychedelics

When ancient tradition meets modern medicine, who gains? BY

DEVON SCOBLE

Into the sweet grass

Muskoka grown weeds

Let’s talk cultivation with three LPs who favour the expression of hydroponics and living soil BY

MATT JONES

By Haley Nagasaki

B.C. to Ontario, the Maritimes and now Alberta – with each new edition we offer a look at operations from across our nation. This issue includes a glimpse inside two Calgary-based LPs, stacked with an additional story sourcing three other producers. As we showcase five LPs of varying sizes, spanning three separate provinces just in time for the harvest, we at Grow Opportunity are pleased to say we’ve reconnected with our cultivation roots.

It has now been five years since adult-use cannabis became federally regulated in Canada. Despite difficult growing pains, this industry is not going anywhere, and as such, producers have had the opportunity to readjust business practices while those still emerging onto the scene employ their recent findings.

Regardless, the global cannabis conversation that Canada lit on fire is worthy of celebrating, especially the international expansion, while we continue to adapt to change.

This September/October issue also brings new topics outside the realm of industry into consideration, by the deepening of introspection brought about by waning daylight. This season, with its crisp air and warm hues, inspires us to get back into reflection before ramping back up for the holidays and the changing calendar year.

As a preliminary introduction to psychedelics in the magazine, we embark on a journey beyond Canadian confines and into the Amazon rainforest. We move beyond mere business and into the tapestry of origins and identity.

As more producers are granted dealer’s licences, the elephant in the room remains the acknowledgment of the complex issue of cultural appropriation.

The global cannabis conversation that Canada lit on fire is worthy of celebrating, especially the international growth, while we continue to adapt to change.

Journalist Devon Scoble shares two perspectives on this issue in her latest feature for Grow Opportunity, urging non-Indigenous users of traditional medicines to respect Indigenous authority in psychedelics. The use of theses sacred plant medicines – ayahuasca, psilocybin and peyote in particular – is a space that still warrants gatekeeping, rather than being blown open strictly for profit.

But below the ethereal world brought on by the psychedelic experience is the density of our day-to-day affairs, which, in this trade pub, surrounds the cannabis marketplace.

Inside you’ll find the nuts and bolts of digital marketing

and trade-dress in an informative Legal Matters column written by two members of Torkin Manes LLP. Denis Gertler’s Vantage Point column reads between the lines of the Competition Bureau’s recommendations comprising regulatory information in need of consistent monitoring, and our latest Cultivation column by Jim Strain breaks down his most effective post-harvest techniques.

We’re also pleased to present a Q&A with Oceanic Releaf CEO Taylor Giovannini anchoring the back of this issue, whose task of supplying cannabis to Newfoundland consumers through nearly a quarter of the province’s retail locations serves as a reminder of what this industry is working towards. While Oceanic is an effective vertical business model of retail and cultivation, Giovannini finds the most meaning in the task of shared health and wellbeing between herself and her community.

As we celebrate five years of cannabis legalization, we reflect on the remarkable progress made, the lessons learned and the milestones yet to come.

Here at Grow Opportunity , we look forward to announcing the two winners of Canada’s Top Grower Award gracing the cover of our final issue of 2023, and, as always, we look forward to continue working alongside those at the helm of the mighty Canadian cannabis enterprise.

Until next time.

September/October 2023 Vol. 7, No. 4 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Services Administrator Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Haley Nagasaki hnagasaki@annexbusinessmedia.com 519-410-0600

PUBLISHER

Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175

MEDIA DESIGNER

Curtis Martin

AUDIENCE DEVELOPMENT MANAGER

Shawn Arul sarul@annexbusinessmedia.com

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

PRESIDENT/COO

Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec):

1 year offers: Canada $25.50 + Tax USA $47.00 CDN FGN $53.50 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Made possible with the support of

EASY-TO-USE | CLEAN & QUALITY INPUTS

TRACEABILITY OF ALL PRODUCTS | TECHNICAL GROWING SUPPORT

CANNA is the pioneer and global market leader of plant nutrients and growing mediums for the cultivation of fast growing crops. All CANNA products are manufactured from the highest quality materials, as a known partner of the Green Market. We understand the importance of clean, consistent, traceable inputs, as well as keeping it simple!

1. Cannabis research advancements: Advancements in cannabis research explore its potential in medical and therapeutic treatments, helping to further destigmatize the plant and expand its applications.

2. International cannabis trade: Canadian companies are expanding their footprints into international markets resulting in increased partnerships, exports and collaborations.

3. Cannabis retail innovation: Retail innovations include the cannabis delivery services, online ordering and tech integration to enhance the shopping experience.

4. Focus on quality and education: As the market matures, there is a growing emphasis on quality control and consumer education as seen in investments and smart marketing.

5. Evolving regulations: There were recent shifts in packaging requirements, retail window coverings and advertising policies. More changes are needed at the federal level before industry can balance growth and development.

Germany’s Cabinet approved a plan to liberalize rules on cannabis, setting the scene for the European Union’s most populous member to decriminalize possession of limited amounts and allow members of “cannabis clubs” to buy the substance for rec purposes. The bill, which government hopes will take effect at the end of this year, foresees legalizing possession of up to 25 grams and allow individuals to grow up to three plants on their own. — Geir Moulson, The Associated Press

Too many cannabis shops, too much production Rising competition has depressed in-store prices, which fell by more than half. Monthly store sales now average $96,000 and the estimate margins $24,000, making it tough to pay the bills.

– Michael Armstrong, The Globe and Mail

$269 MILLION

The anticipated revenue for the government of Ontario from the federal cannabis excise duty for FY2023-24.

A decision this year by the OCS to lower its price markups and fix its price structure has cannabis industry players hopeful the move will provide a much needed boon amidst a difficult financial environment and continuing competition with the illicit market.

Changes to the price structure by the Ontario Cannabis Store will lower profit margins for the government and put dollars back into industry producers and retailers. Currently, the pricing is based on a uniform markup rate of 50 per cent on the wholesale price. However, this system has led to inconsistent pricing and limited profitability for retailers.

The new pricing strategy aims to introduce a tiered approach that considers the price of the product. This means that lower-priced cannabis products would have a higher markup percentage, while higher-priced products would have a lower markup.

This change is intended to address concerns from retailers who have been struggling to compete with the illicit market due to pricing disparities.

These new prices changes will take effect September 11, 2023, and aims to create a fairer and more competitive market for cannabis retailers and producers. – Jake Hribljan, Grow Opportunity

AI powered pest & disease detection for increased profitability.

Croptimus™ automatically scouts for Aphids, Spider Mites, Thrips, Powdery Mildew, Bud Rot (Botrytis), Mosaic, nutrient issues, general plant health, both mechanical and pest damage, and more. Croptimus™ dramaticaly reduces scouting costs, pesticide/chemical usage, and crop losses, increasing the efficiency and profitability of

By James Strain Cultivation

James Strain is the director of cultivation and master grower at Dycar Pharmaceuticals, home to up-and-coming cannabis brands like J.R. Strain, Lamplighter & Legend Chocolates. With 33 years of experience, Jim delights customers by blending time-honoured techniques with the latest in genetics, science and technology.

Harvest time is a critical moment for any cannabis grower. You have invested a lot of time, effort and money into your crop, so you want to make sure you do it justice. One of the worst things you can do is rush the finishing process. It reminds me of the old days in the early ’90s when I was involved in the black market. We would harvest a large grow, trim it on the spot, and hang it in a hot room to dry it in three days. We just wanted to get rid of it as soon as possible, which I guess makes sense when you are risking your freedom. But then I discovered the secret to much better weed.

If you want to enjoy the best quality of your cannabis crop, you need to pay attention to how you dry and cure it. In this article, I will show you the seven simple steps to achieve a smooth, tasty and potent product.

One week before harvest, start flushing your plants with pure water. This means no nutrients or additives. This will remove any excess salts or chemicals from the plant tissues, giving you a cleaner burn and a better flavour.

2.

During the last week, lower the temperature of your grow room and water system, especially at night. This will bring out the

At harvest, cut down whole plants and hang them upside down in a dry room. Don’t trim any leaves or branches, this will allow the plant to die slowly and evenly, keeping more moisture and flavour.

natural colours of your plants and increase the production of terpenes and cannabinoids. I love seeing the plants go purple, greens of all shades, yellows, blues and reds. Autumn indoors!

3. Going dark

One or two days before harvest, I typically turn off the lights and let the plants rest in darkness. This will boost resin production and preserve the terpenes. It will also prevent the plants from producing more chlorophyll, which can make the weed taste harsher.

Whole plant harvesting

When it’s time to harvest, cut down whole plants and hang them upside down in a dry room. Don’t trim any leaves or branches. This will allow the plant to die slowly and evenly, keeping more moisture and flavour.

5. Drying

For the first day of the drying process, I set the temperature to 22°C (72°F) and the relative

humidity (RH) to 50 per cent, with some fans and air movement. This helps to remove some of the initial water content more quickly. After that, lower the temperature to 18°C (64°F) and raise the RH to 60 per cent. Reduce the air movement to a gentle breeze. This will set you up for a 12-to-14day drying cycle.

To check if the buds are dry enough for trimming, I use a water activity meter or check the branches (keep this number at 0.55 to 0.65 water activity). If you don’t have a water meter, the old-school technique is that it’s ready for trimming when the thinnest branches near the bottom have a snap when bent. The leaves should be dry and crispy, but the main stems should still be a bit pliable.

Your buds should be looking nice and frosty, with a spongy texture and a fantastic smell. Trim the buds by hand or by

machine. I prefer hand trimming because it preserves more trichomes and gives a better appearance. Appreciate your trimmers because trimming is a hard and tedious process. A pro trimmer can do the work of four amateurs – at least! Try to maintain the same environment in the trim room as in the dry room: 18°C (64°F) to 20°C (68°F) temperature and 55 per cent to 60 per cent RH.

It’s good to store your buds in sealed containers for several weeks or months. This will let them mature and develop their full potential in terms of flavour, aroma and potency. I use barrels that can hold five to eight kg (11 to 18 lbs) of weed each. I open and burp them regularly. I also monitor their moisture level and smell. I give them a spin and toss them gently to prevent mould formation. After about four weeks, they are ready to enjoy!

As you can see, harvesting, drying and curing your cannabis is not a complicated process, but it requires some patience and attention to detail. After about four weeks, your cheeba is ready to enjoy! It should have a great smell, taste, burn and effect. Get the most out of your crop without compromising its safety or quality. You will be rewarded with a smooth, tasty and potent product that you can be proud of. Happy harvesting!

By Roland Hung & Matt Maurer Legal Matters

Roland Hung: As Counsel in Torkin Manes’ Business Law and Technology, Privacy & Data Management Groups, Roland Hung’s practice encompasses all aspects of corporate law, with emphasis on technology, privacy compliance, cybersecurity and data management.

The federal Cannabis Act places significant limitations on the way that cannabis companies, and licensed producers in particular, can market and promote their products. As such, cannabis companies are constantly looking for creative ways to disperse unique customer experiences to boost brand identity and loyalty.

There is a growing need to protect the design and other distinguishing elements incorporated into the appearance of products and services, as well as online customer experiences. Collectively, these features are known as the trade-dress, or the look and feel of the brand. An example of tradedress protection was illustrated in a recent federal court case, where it protected Skittles’ trade-dress against three John Does who marketed and sold THC-infused products in Skittles lookalike packaging.

In Canada, there is no separate process for registered tradedress. Previously, trade-dress could be protected by registration under the Trademarks Act as a “distinguishing guise,” defined as the packaging, containers or wrapping of “wares.” This provision was repealed in 2014. Currently, trade-dress can be registered as a trademark or industrial design.

In Canada, trademark registration is not required for trademark rights to subsist. However, trademark registration offers both national protection and statutory enforcement mechanisms that are not available for unregistered marks.

Unregistered trade-dress established by ordinary commercial use can be protected under s. 10 of the Act, which codifies the common law tort of passing-off. Broadly, s. 10 requires unregistered trademark owners to produce evidence demonstrating how the mark is associated with the goods or services in the minds of consumers.

For the trade-dress to be registrable as a trademark, the trade-dress must be: (a) distinctive; and (b) not primarily functional. The Canadian Intellectual Property Office (CIPO) categorizes trade-dress categories, such as colour or threedimensional shapes, as non-traditional trademarks, to be inherently non-distinctive.

However, trade-dress can be protected in conjunction with a trademark if the mark itself is distinctive. Section 2 of the Act defines distinctive as a trademark “that actually distinguishes the goods or services in association with which it is used by its owner from the goods or services of others or that is adapted so to distinguish them.”

The trademark becomes distinctive through use and CIPO can require the applicant to submit evidence demonstrating the trademark acquired distinctiveness as of the filing date.

A significant limitation on the registration of trade-dress is the functional features. Section 12(2) of the Act prohibits tradedress protection by registering as a trademark if its features primarily have a utilitarian function, such as if the trademark’s features are essential to the use or purpose of either the goods or services, and its registration may grant a monopoly on those features. In Kirkbi AG v Ritvik Holdings Inc., the Supreme

Court of Canada held that the unique features of the LEGO bricks that allows them to snap together could not be protected as trade-dress as it is primarily a functional characteristic.

In Mars Canada Inc. v. John Doe #1 (King Tuts Cannabis), the Court found that the packaging layout and design of Skittles to be unique amongst confectionary products. The defendant Flash Buds was found to have sold the infringing product in packaging that was nearly identical to the Skittles marks and trade-dress.

Blaze Pizza, LLC v. Carbone Restaurant Group Ltd., however, demonstrates that similar packaging of goods is not enough to warrant trade-dress infringement. Blaze Pizza asserted that the Carbone Restaurant Group operated and marketed its business in association with Blaze Pizza’s trade-dress by using the Blaze Flame Design, the phrase FAST-FIRE’D and a white-on-orange colour scheme.[6] While the branding context is considered in a passing off action, the central issue of a registered trademark is the trademark itself and not the effect another mark has when they appear together. The Trademark Opposition Board did not find the use of a red-orange colour referencing fire, or the use of a flame in a mark with the words “FAST FIRE’D,” to be a distinctive design feature.[7] Consequently, Blaze Pizza’s trade-dress was found to not have been infringed.

The Industrial Design Act protects elements of trade-dress, such as shape, pattern, configuration or ornament that “appeal to and are judged solely by the eye.” Similar to trademarks, a design cannot be registered if the feature is primarily a utilitarian function. Industrial design differs from trademark because an owner can assert a claim without the owner being required to show that the design acquired distinctiveness.

Industrial design registration requires that the design must: (a) be novel; (b) be created by the applicant or the applicant’s predecessor in title; (c) not primarily consist of utilitarian functions; and (d) not be contrary to public morality or order. A novel design cannot be the same or a substantially similar design that was disclosed to the public for more than 12 months

before the applicant’s priority date or disclosed before the applicant’s priority date by any other person.

There is considerably more trade-dress litigation in the U.S. than in Canada, particularly regarding the look and feel of websites. In today’s world of technology, U.S. courts are granting trade-dress protection for digital properties like social media and mobile apps.

Recently, the Southern District Court of New York affirmed the viability of protecting the trade-dress of websites and other digital properties. The plaintiff OffWhite claimed that the defendant Off-White caused thousands of X (formerly Twitter) users to write hashtags in connection with the defendant’s company rather than the plaintiff’s company.

The U.S. differs from Canada because the Lanham Act allows trade-dress to be registered with the U.S. Patent and Trademark Office. In the U.S., trade-dress infringement claims must allege that: the trade-dress is distinctive and identifies the source of the product; there is a likelihood of confusion between the parties’ goods or services; and, the trade-dress has acquired secondary meaning. In demonstrating these three elements, it is the plaintiff’s responsibility to “articulate the specific elements that comprise its distinct dress.” Further, trade-dress can still be protected despite not being formally registered.

As sales and consumer interaction continue to expand in the technology sphere, cannabis businesses need to be vigilant about protecting their brand identities and tradedress. Understanding the legal landscape is a critical first step in that regard.

By Haley Nagasaki

As the cannabis industry continues to progress, either holding fast as a drought-resistant cacti or behaving more like a voracious Venus flytrap, it’s important to celebrate the producers who are adapting to the shifting tides.

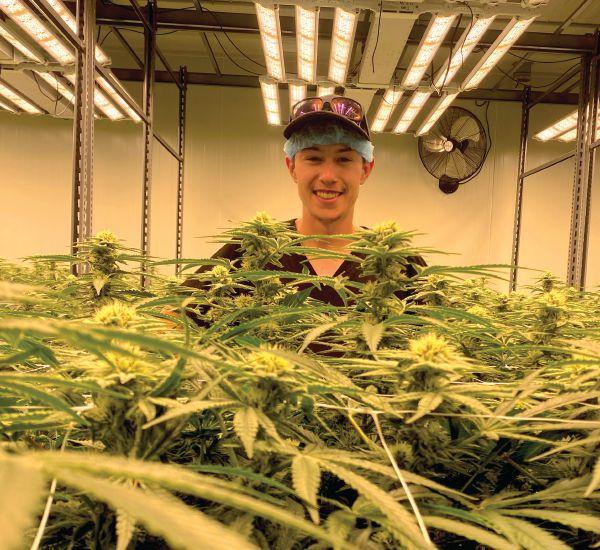

This past July, Grow Opportunity ventured to wild rose country and toured two very different LPs –OGEN and Distinkt – showcasing the superior cultivation practices they hold in common.

The Calgary-based producers, while friendly competitors, have entirely different strategies spanning grow technique, marketing tactics, staffing and fields of influence. OGEN’s team of leaders, with their scientifically driven backgrounds coupled with their passion for growth, development and the industry at large, informs their culture-forward approach to operations. While Distinkt, now also expanding into psychedelics, prefers more of the legacy ethos when coming to market. Both approaches hold water, so to speak, though one in rock wool and the other in coco.

OGEN obtained their cultivation license in 2018 and underwent an expansion phase to increase their operations’ capacity. December 2019, they achieved occupancy and by mid 2020 they expanded their workforce from a dozen to over one hundred individuals, ramping up production and offering specially curated cultivars to the recreational market. Currently, OGEN distributes their products in Alberta, Manitoba, Saskatchewan,

Ontario, New Brunswick and Newfoundland, while working to establish presence in provinces in which they are not yet active.

The LP also recently received its extraction license and formed a partnership with Simply Solventless, allowing them to offer a diverse range of products combining craft flower with Solventless’ bubble hash and live rosin. In general, the LP is keen to explore mutually beneficial partnerships catering to quality and consumer taste that is the hallmark of their brand.

The faces behind the flower are led by three passionate individuals who are invested and proficient in their areas of expertise: cultivation manager Justin “JC” Creencia, post cultivation manager Carson Stewart, and irrigation and environmental manager Baker. Joining the OGEN team near the beginning as technicians, these three have grown in their proficiency as leaders of an equally passionate cultivating team now tending the quality of cannabis they grow today.

Having experienced the technician’s highs and lows, the three managers work not only to maintain and increase the quality of OGEN’s flower but to increase the

quality of life for their staff – the entire team prides themselves on a rotating phenohunt series within an indoor cultivation space of approximately 55,000 sq ft.

Their delicious, best-selling strain Peach Chauffeur #15 checks a lot of boxes and has been very well received in market. Velvet Apples #12 is another favourite, balancing both flavour and potency. While the guys at OGEN recognize the reality that “you can hurt yourself with too much variety,” says operations manager James Brophy, still the team is always on the lookout for something new with bag appeal.

OGEN also emphasizes smart marketing and a culture-forward approach. The thriving Calgary tourism industry enables the LP to position itself as a must-visit destination for local budtenders, enthusiasts and curious tourists with the goal of ending stigma against both the plant and the industry.

“I don’t think you need to be an expert to get excited about seeing how something is made,” says Luke Dickson, OGEN’s brand manager. “It is a staple part of some vacations to check out local breweries or wineries, like

The thriving Calgary tourism industry enables the LP to position itself as a must-visit destination for local budtenders, enthusiasts and curious tourists with the goal of ending stigma against both the plant and the industry.

Heineken or Steam Whistle, without having to be a buff. That’s why we offer open tours that can be booked by anyone of legal age in Alberta. It helps to remove stigma and break down the barriers of education,” he says.

With each province that Grow Opportunity visits, seeking cannabis stories to share nationwide, comes the search for differentiation. Whether it’s Manitoba’s intense UV and cool evenings, the water quality of the Pacific Northwest, Quebec’s affordable electricity or the agricultural fecundity of the Niagara region, each province boasts a unique cultivation quality regardless of whether crops are grown indoors or out.

For Alberta, cannabis growers take full advantage of the region’s drier climate and better humidity control compared to the regions with excess moisture. Post-harvest and drying processes can make or break a crop, so it’s possible that Alberta has a leg up in this department. At their indoor facility, the entire cultivation team takes pride in their work and their approach to testing, experimentation and hands on learning while incorporating

lessons learned into their operations and business values.

“It’s so easy to cut corners in a lot of small ways, which leads to quality ultimately being compromised,” says Stewart. “We are always watching to make sure our crops are not dying a death by 1,000 cuts. Each area of production has to hold themselves to an extremely high standard.”

The cultivation process also consists of multiple harvests each week and the careful handling of plants to prevent quality degradation. During harvest, “each plant is carefully chopped, extricated from its neighbours and draped over racks for storage,” says Brophy. Rolling harvested plants down the halls on racks rather than carrying them by hand or dropping them into totes helps mitigate trichome damage. Before, during and after harvest, the sanitation team also plays a vital role at the LP by maintaining a sterile work environment. “They do a great job; this room is spotless when they’re done,” says Brophy. “All of this debris will be gone and that’s something that I think people don't understand – every piece of plant material has to exit this room – it’s a daunting task when you first look at it. That amount of sanitation really is the cornerstone of everything that we do here.”

The sanitation team also helps during post-harvest in the curing process. Taking only a couple hours in the morning to complete

a harvest and sanitize a room, the LP has quickly streamlined operations by employing knowledgeable people with good chemistry. “We’re familiar with how testing and experimentation goes on,” says Brophy. “Our QA has a master of chemistry. They’ve helped run all of those changes and experiments for us to really dial in consistency and quality; that’s the main driver for us.”

Though the managers had no previous cannabis experience, and each began with an entry-level position, they’ve all grown in the same way the company has – through research and hands on experience. “These guys have so much passion that they bring to the table,” says Dickson, “and none of this would have happened if they weren’t like that,” which is a fact that helps bolster the producer’s unique imprint on the Canadian cannabis space.

Mark Corrigan, founder and president of Distinkt Cannabis and previous golf pro founded the company in 2017 and received their production license in early 2021. With a total of 22 employees all who wear many hats, and a second location Distinkt 2 coming online in the coming months, the Calgary-based LP is poised for expansion when the time is right. Having a lean, versatile team “is the way to get through this nightmare price reduction, compression, but at some point, prices will have to go up,” says Corrigan. While the LP is looking to expand into psychedelics, mainly psilocybin production, they heed caution knowing “there’s no reason to be the first one to the party,” says Corrigan, who intends on waiting until he feels the market is viable.

The same is to be said with the live rosin category, though the entire rosin market in Alberta is only valued at $600,000. Distinkt will wait for an increase in consumer demand before exerting further time and resources into rosin production. Currently, the provinces that carry their products include Alberta, Yukon, Saskatchewan, Manitoba and Ontario.

The producer also grows their own phenohunted genetics and some of their own breeding as well. Corrigan sees this production technique as one of the markers for success, because “anything

you bring to market, no one else is going to have.”

A tour of the LP revealed primarily the cultivation of Monaco Octane and Lemon Razz – a solid cultivar that continues to come in at 26-30 per cent THC and over three per cent terpenes.

Head of cultivation, Jacob “JD” D’eath studied cannabis production at Olds College and was previously employed as a grower at OGEN. “Before that I grew black market and before that I worked at a garden centre,” he says. “One day I found a seed in my weed, so I bought a grow light and it snowballed from there.”

Within six grow rooms, D’eath experiments regularly, specifically surrounding defoliation variations and high-stress training of the canopy to increase both yield and quality. In a room of Lemon Razz one week into flower, D’eath demonstrates the training method he’s employed by bending and almost breaking the stem, which stunts the plants and makes the tissue harden up to create a more even canopy.

Corrigan also explains the motive behind the facility’s construction, previously a meat packing plant, by taking “black market sized rooms and growing commercially,” he says. “The biggest room is 850 sq ft – we keep it tight and controllable so we can have consistent product.”

They’re also working with a known breeder called TK, experimenting with different cuts to see about bringing them to market in partnership. “Some people can grow but they don’t have the bandwidth for sales, boards and marketing,” says Corrigan. “TK has a good name in the black market and from a breeding perspective, it’s something we’d look at bringing in.”

The facility uses a semi-automatic fertigation system now with valves that can be opened and closed using apps connected to the teams’ smart phones. Each of the rooms also has its own HVAC system so that if something goes down, it only affects one room.

They’ve been fortunate to keep down pest pressure, “but you know,” says Corrigan, “everyone’s got their own challenges. I think what’s kept us alive is we’re small enough to keep nimble, our operating expenses aren’t crazy, and we still produce consistent product and we continue to tell our story.”

Distinkt 2 is already built out, “and we’ll turn the machine on when we see a larger market,” Corrigan says, leaning into an extraction lab mainly for rosin and additional square footage for the cultivation of psilocybin or other types of fungus or cacti. Distinkt houses a driven team full of proponents of the therapeutic benefits of psychedelic therapy, but still, “we’re not there yet,” he says.

Corrigan looks forward to opening the second facility, located 15 minutes away, that will be EUGMP-certified and seamlessly operated by a crew of 50. Until then, the national company has capitalized off their learning experiences, taking pride in what they’ve so far accomplished. “We’re proud of what we do here,” says Corrigan; “we’re proud of making great products.”

Disclaimer: Devon Scoble is a British-descended Canadian writer living and working on the traditional lands of the Mississaugas of the Credit, Anishnabeg, Chippewa, Haudenosaunee and Wendat peoples. She is grateful for the Indigenous knowledges reflected in this piece and acknowledges any misconstrual of those perspectives as entirely her own.

When ancient tradition meets modern medicine, who gains?

By Devon Scoble

Alot can change in eight years. For Sapha, a Persian-Canadian Vancouver Islander who goes by his first name, it’s the difference between days focused on scoring and using alcohol, opiates and stimulants and days devoted to helping others overcome their addictions to those same substances.

“In the throes of addiction” for 16 years, he no longer takes what he calls hard drugs or alcohol. But he does credit the psychedelic drug ayahuasca as a medicine in his healing journey, even though it wasn’t offered at any of the early recovery programs he attended.

“Being a recovering addict and working with psychedelics is very controversial. Most 12-step fellowships and self-help groups are abstinent-based and see psychedelics – even with a therapist – as using drugs,” he says. But in 2015, a conversation with a counsellor at a holistic recovery centre in Saskatchewan gave Sapha the courage to explore an intuition.

“I told her how I viewed plant medicines as sacred tools for going deeper,” he says. “And she said, ‘Whatever you do when you leave here, don’t let anybody tell you that that’s wrong. If you’re working with psyche-

delics in your recovery and doing it with care and guidance and the proper people in your corner supporting you, then there’s nothing wrong with that. Just check in with yourself and your intentions and go forward with that in a good way.’ And so, that’s what I did.”

His recovery journey would lead him through a degree in social work, and, eventually, to becoming a co-founder of Sacred Rebels Recovery, an ayahuasca-assisted addiction recovery retreat in Iquitos, Peru.

Humans have understood the transformative power of psychedelics for centuries, but Western clinical practitioners largely

ignored the predominantly Indigenous plant medicines until the last century. Stories like Sapha’s are increasingly gaining the attention of the mainstream, and across the world, hundreds of clinical trials are underway, studying various psychedelic compounds’ potential to treat depression, PTSD and addiction, fibromyalgia, migraines and more.

The future of psychedelic medicine is exciting, but history is often obscured in the rush to understand these drugs and their clinical applications. It’s a familiar story in Indigenous communities and begs some questions. When traditional healing meets modern, for-profit medicine, who benefits? And who should benefit?

Truth and reconciliation in Canada has been a bumpy road, and for many non-Indigenous people, a process of unlearning whitewashed histories and reconceptualizing their role in the lands they call home.

Evidence of unmarked graves in Canadian residential schools is “changing the narrative that most people grew up learning about,” says N’alaga, a Haida and Kwakwaka’wakw land-based cultural empowerment facilitator and the founder of N’alaga Consulting. “A lot of people are learning about ongoing impacts of colonial genocide, residential school abuses and missing and murdered Indigenous women for the first time, and they’re quite horrified this was not part of what they learned in Western education systems.”

N’alaga runs and develops allyship workshops for non-Indigenous folks and landbased, culturally-rooted healing programs for Indigenous people. Psychedelics aren’t part of her offerings, but she uses them for her own healing. She has a personal understanding of their potential, and professional advice for anyone who wants to work with them.

“Ayahuasca, peyote and psilocybin are medicines that grow in Indigenous territories,” she says. “For the people who belong in these territories, it’s part of their culture, way of life and connection to the land. If you’re a non-Indigenous person engaging in these practices, the most important thing is to be guided by someone whose culture it belongs to.”

Since access to Indigenously-centred psychedelic healing can be hard to come by – especially in legal, clinical settings – at the very least, she’d like to see reciprocity from anyone who consumes traditionally-In digenous medicines or their chemical ana logues, and especially from anyone who re searches or profits from them.

“If I could send a message to anyone in that realm, it would be, ‘How are you giving back to the communities that medicine comes from?’”

coaching and mentorship for Sacred Rebels Recovery participants. A practising curandero, which loosely translates as shaman or medicine man, Sapha also prepares them for ayahuasca ceremonies. He doesn’t work alone. Maestro Ricardo Amaringo is a Shipibo curandero master, and Sapha’s mentor. Maestro Ricardo taught Sapha how to ask the ayahuasca for guidance, and he blesses and supports Sapha’s continued work with Shipibo traditions on Shipibo land.

Sapha is mindful that his efforts benefit the local community. He also volunteers at the centre’s permaculture program, which provides local employment and food share programs and nurtures Shipibo medicinal plants, especially ones facing extinction. He also encourages participants who can afford treatment to pay it forward and donate so that a local in need can also attend ceremonies.

“What Sapha and his team are doing is

appropriate,” says N’alaga. “They’ve been guided and taught and invited by people whose culture these traditions belong to.”

Sapha and N’alaga give the same advice to non-Indigenous people interested in psychedelic medicine: ask your practitioners how they were trained, if they received blessings from the medicine’s Indigenous communities of origin and what they are doing to give back to those communities.

Grodan-Ad-GROW-4.6875x4.75.pdf 1 6/23/23 12:24 PM

“Whether it’s done in a Western tradition or South American or any other tradition, at the end of the day what comes first is the ability of the person suffering to experience relief and to experience qualified help and support,” says Sapha. “So I think it’s really up to practitioners to acknowledge the history of the plants, whether it’s psilocybin or ayahuasca or any other medicine, and be part of educating the patient on its origins and history and how they’re working with it in integrity.”

Back in Iquitos, Sapha offers recovery

Let’s talk cultivation in three different provinces showcasing hydroponics and living soil

By Matt Jones

There are a variety of different approaches that licensed producers can take towards cultivating their products. Those techniques can vary depending on the purpose of the product. This past summer, Grow Opportunity spoke with three Canadian LPs about how they employ cultivation techniques for their purposes.

Muskoka Grown has a goal of being the top independent supplier of flower and prerolls in Ontario. “I think when you have good people, you focus on happy customers and you focus on consistency, you can be successful,” says John Fowler, president of Muskoka Grown. “That’s what’s allowed us over the last two years to go from being a bankrupt company to a profitable company, from being, quite frankly, a pretty crummy grower to, I think, one of the best growers in the country. And to go from being a

nothing in Ontario to a top-30 brand and a top five private company in the province.”

Fowler says that the company thinks of themselves as being in the craft flower business and as manufacturers. One of the first things they did in service of that goal was to increase the company’s transparency.

“The second thing we did, in that idea of being a manufacturer, we actually got rid of the title of master grower,” says Fowler. “We have horticulturalists that are wonderful, we have consultants that are wonderful, we have experts, but day to day, we try to run on a procedural basis.

Ram Davloor, Muskoka Grown’s general manager, says that the specific cultivation techniques the company employs have broadly remained the same – a hydroponics system with climate controls. However, the lessons learned over the last several years regarding management practices and using data to guide decision making have paid off.

“Our average yields have increased two

times, our average THC is over 30 per cent and our sales increased almost four times over the last year,” says Davloor. “Today, when I walk into a cannabis store, I’m proud to say I work at Muskoka Grown.”

B.C.'s Sweet Grass Cannabis

British Columbia-based Sweetgrass Cannabis focus on an organic approach, growing cannabis in living soil. Master grower Julien Leclair describes their approach as being like a farmer in his field, adding nutrients to the soil and letting them break down.

“Most people would apply lime in their field or adjust pH or calcium,” says Leclair. “It’s the same idea here, what we add to the soil takes a while to be available but once it’s in balance, the plants can choose what they like instead of being forced to take it.”

While it would be tempting to say that Sweetgrass Cannabis’ approach is one taken for ideological reasons, Leclair notes that is not necessarily the case.

“We’re in the middle of a very rural area, and we have very good, pure water from the ground,” says Leclair. “There could be some runoff if people used fertilizers. We don’t want to pollute the environment we’re in.

Leclair says the company grows their product in a large room with 14-inch-tall, four-foot-wide and 24-foot-long flower beds. Those beds are filled with living soil that the soil then needs time to ‘cook,’ to allow the worms and other bacteria to break down the nutrients and make them available.

Cloning is done first in a smaller ‘veg space,’ before the plants are brought to the larger beds. “We call that the flower room, but they’re still going to veg in there for a few weeks, then we transition into flower,” says Leclair. “We brew compost tea throughout veg and early flower. We also do the top dressing every two weeks and we add dry amendments to the surface.”

Another company taking the living soil approach is Into the Weeds, formerly known as Rusktic Greens after c0-owner Brian Rusk. The Alberta-based small craft grower has been in production for about a year.

“It actually started when Chanttelle [Rusk’s wife and business partner] was in a car wreck years back,” says Rusk. “She wound up being on a pile of pain medication and a neurologist told her, ‘why don’t you try cannabis instead of these pain pills?’ She did and it worked great, and she was able to get off all the pain pills eventually.”

Chanttelle found securing a consistent supply to be difficult and expensive, so Rusk started growing at home for her. “A core of our cultivation process is that we use living soil,” says Rusk. “We use more of a compost base in our soil and then we’re adding dry amendments to keep the soil at a sufficient range and the microbes in the soil deliver

Serving the cannabis industry with complete testing and agronomic support.

production services

that to the plant. We feel we can get a fuller expression on the plant by allowing the natural process to deliver what it needs.”

Rusk says that their use of the living soil approach and other general low-tech aspects of their operation are both because they benefit the plants but also due to an interest in more sustainable practices.

“In my experience, the best cannabis I’ve had is grown this way,” says Rusk. “Not to say that there can’t be really great cannabis grown other ways, but we really feel that you’re able to hit a more fuller flavour expression and terpene profile with the living soil.”

Into the Weeds’ production is decidedly low-tech – they use drip irrigation and other simple techniques. They utilize soil testing to ensure that the soil is feeding the plants exactly what they need. Their biggest challenge, however, has been scaling-up their operation and the labour costs associated with that.

By Denis Gertler

In the fall 2022, Canada’s Competition Bureau began to assess competition in the cannabis industry to address Health Canada’s mandated review of the Cannabis Act. Its recommendations were released in late May this year, and while sensible, do not go far enough to address what ails the industry, or most importantly, point the way forward.

The advice to streamline and reduce the cost of licensing processes, “consider adjusting” THC limits on edibles, and to ease restrictions on packaging, labelling and product promotion are fine as far as these suggestions go. Industry players have raised similar concerns. I’d expected more from the Bureau, given its objectives of gaining a deeper understanding of industry’s competitive dynamics, gauging how the Act may be “impeding competition, innovation and choice,” and recommending measures to strengthen competition and industry innovation while reducing illicit sales.

The Bureau notes that the scope of its review is limited to matters directly regulated by Health Canada, which excludes fiscal policy and transportation safety, as well as the provinces’ role in retailing, and municipal responsibilities for policing and planning. It also rules out industry shortcomings.

To its credit, the Bureau does address the federal excise tax on recreational and medical cannabis. As others have previously noted, the excise tax rate is a massive problem which heavily bonuses the illegal market. It’s a key factor reducing LPs’ profitability due to its hit on topline revenues. And the tax clearly inhibits the government’s goal of reducing illegal sales, particularly to young persons. While federal agencies

The main problem with the discourse about competitiveness of our cannabis industry is its focus is mainly short-term. That’s understandable to some extent. When the ship is on fire, you’re reaching for the firehose not course correcting.

typically refrain from commenting on federal tax policy and its administration, the Bureau does discuss the excise tax’s dysfunction, noting unpaid excise duties have climbed over 2,000 per cent since 2020 as the average price per gram of dried flower dove from $12 in 2019 to $5 this year.

The report cites a lack of industry standardization as another barrier, although I think it’s referencing the in-

compatible requirements across provinces and levels of government. Again, not something that Health Canada can fix on its own but certainly an initiative the federal government could lead were it so inclined. Interestingly, there is no mention of the sparse uptake on Agriculture and Agri-Food Canada’s multi-billion-dollar Canadian Agricultural Partnership, despite cannabis’ eligibility for many of its programs.

This last example points up the main problem with the discourse about competitiveness of our cannabis industry: its focus is mainly short-term. That’s understandable to some extent. When the ship

is on fire, you’re reaching for the firehose not course correcting.

You’d expect the federal government who established and oversee the industry’s regulatory framework, to take responsibility and change policies and practices based on outdated or faulty assumptions. They’ve had almost five years to observe the consequences of early decisions. Comments contributed to the Cannabis Act review could certainly help if the federal government took these to heart. Some under-realized opportunities include tapping available funds to improve crop and product quality; further developing wellness markets; and reducing cannabis’s heavy carbon footprint while addressing climate change.

We also have much to learn from other business sectors. Craft cannabis deserves a more careful look, whether that involves research on genetics to drive quality and

refine classifications, or to detect tainted and fraudulent products as with wine, honey and olive oil. The premium wine model offers a way to step out from the ‘race to the bottom’ as well as the slavish celebration of high THC content to sell products.

We should be studying the Emerald Triangle’s appellation system which is based on delineating terroir, regional branding, and product quality. B.C.’s Kootenays and Vancouver Island might pursue a similar approach, but so could Ontario’s Niagara peninsula and other Canadian regions.

If Canada hopes to eventually export cannabis – to tourists, medical markets and as a premium recreational product – we’ll need to establish appellations, as well as stronger supply chain certification and product standards. Defensively, we need to pay heed to the

health front. I see mainstream media devoting more attention to cannabis smoke toxicity and respiratory effects. Unlike tobacco, there’s a medicinal side to our business but also a lack of medical research. Tobacco research eventually sparked public disapproval, but cannabis has had to establish itself while dealing with pre-existing social stigma.

In truth, the federal government did not consider competitiveness as a key issue when it legalized recreational cannabis and is still limited by its single focus on health issues. This situation goes way beyond Health Canada’s mandate, and therein lies the problem: it’s not the agency’s job to nurture a new industry. But if the feds are serious about refocusing their agenda on economic matters, here’s a sector of great opportunity! There’s still time for governments and businesses to raise their sights.

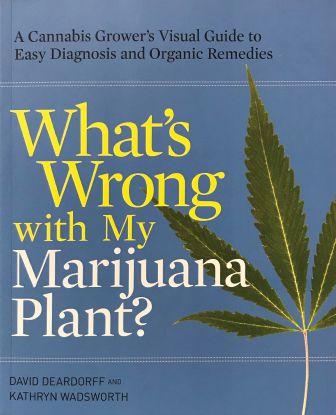

What’sWrong with My Marijuana Plant? is the first problem-solving book for marijuana growers with an effective and easy-to-use visual diagnostic system pioneered by Deardorff and Wadsworth for identifying pest, disease, and environmental problems by symptom. This book contains all-organic solutions (vitally important to protect your health, the health of your plants, and the environment) plus best growing practices to avoid problems before they start. Written in easily understandable, non-technical language and heavily illustrated with precise photography to allow rapid and accurate diagnosis, this is an essential resource for beginning and experienced growers alike.

After wrapping St. John, Newfoundland’s George Street Festival this summer as the only cannabis company on site, promoting the launch of their new app and sharing information about their nine retail locations representing nearly a quarter of cannabis retailers in the province, Oceanic Releaf owner and CEO Taylor Giovannini reflects on the remarkable growth of her company as it occurred in tandem with the plant’s transformative impact on her own life.

GO: Why was Oceanic created?

TG: Oceanic was created because everyone in the world understands the ocean as healing. It was founded organically and accidentally through helping a family member on his journey, which I wasn’t aware was actually my own. I made a batch of brownies for my husband’s grandfather and really helped alleviate his pain. It was an ‘aha moment’ for me, born out of medical need and the dream of helping as many people as possible.

GO: How did you work inclusivity into your branding?

TG: Oceanic evolved by leaning into the recreational side of things and having the opportunity here in Newfoundland to open up stores. I understood very quickly that there was a stigma, and that the stigma would hinder anyone who really needed the plant because of what they’ve been taught. So, I focused wholly and truly on creating a space and an atmosphere that was comfortable and stripped of stigma. That’s what Oceanic represents – it’s this brand of acceptance and education.

GO: What other methods are you using for differentiation?

TG: From my own experience, I didn’t want to ask stupid questions when I went into a store, so I was trying to figure out how to strip this completely down. How do we do that? We sell coffee! We sell coffee to differentiate ourselves from cannabis and to educate people. And then we also had the first drive-through in Canada. I have been super keen on that from day one; for parents. At the time cannabis became legal, my son was two and he’s literally attached to my hip. I thought, how do I physically go in stores when I can’t leave my baby?

GO: Was there any pushback from the community when you began operations?

TG: I’ve never seen any pushback whatsoever. I believe people listened to me because I don’t look like the stigma and because I’m very upfront and transparent about learning about this plant. Even though I’m the CEO and owner of Oceanic, I’m on the same beginner journey as everyone else. I engage with the communities and they’re more than happy to have safe and responsible cannabis rather than their local drug dealer.

GO: Can you describe more of your retail landscape?

TG: We have nine stores, and the ninth will open likely in August. There are four tiers in Newfoundland and all our stores are tier one, which are standalone stores that only sell cannabis. Three of our nine have drive-throughs and we’re working on a fourth. We also sell coffee from a local roaster in all of our stores and

cannabis apparel and accessories. Of course, the number one question we get is asked is “is your coffee infused?”

We have a little meme that says: Our coffee is plain Jane, not Mary Jane.

GO: Were you cultivating before retail? What brands have you sold?

TG: No, actually we opened up the stores first while we were in the process of getting our license. Our store opened first and then we got our cultivation license and then our sales license. We hold 60 per cent of our shelf space with our three in-house brands: Oceanic, our homegrown flower and pre-rolls, Seaweed is our curated brand from other craft growers in Canada, and Booty is our value brand. Then we also have partnership brands. Higgs is an L.A. brand that is super cool – we just launched it. Of course cannabis can’t cross borders, but brands can! Then the other 40 per cent of shelf space are carefully selected partners like Organigram, Delta 9, and Aqualitas. We’re also already in the German medical market and, I mean, I want to be global.

GO: How has the personal journey of Oceanic changed your life?

TG: I believe in Oceanic and what it’s capable of doing. I’ve also learned that this is a lifestyle. It’s a complete lifestyle change in so many aspects of my life, and I’m a better everything because of cannabis. Now I’m a better mother, I exercise, I meditate; I use it for everything and it elevates my life in all aspects.

We’ve got a long way to go still to be, what I would consider, successful, but I think the groundwork has been laid, especially with the partners that we have in place.

I focused wholly and truly on creating a space and an atmosphere that was comfortable and stripped of stigma. That’s what Oceanic represents — it’s this brand of acceptance and education.