Profes si onals make informed decisions...

Biopiracy in the era of climate chaos

Why saving cannabis from a genetic monopoly lends itself to a more resilient species BY AV SINGH

STORY Stewart Farms profile Tour the small, but mighty, Maritime LP that’s making waves across the country BY

HALEY NAGASAKI

How producers attempt to mitigate climate impacts, with more uncertainty on the forecast BY MATT JONES

From the editor

By Haley Nagasaki

Maritimes, sustainably minded

Last month I visited Stewart Farms in St. Stephen, N.B., for a full tour of its veg, flower and mother rooms, as well as its wellness product and fish farm aquaponics facilities.

My guides — Tanner Stewart, Genevieve Newton, and Catrina Jackson — were great hosts, and I would like to thank the whole team for welcoming me so openly, in true East Coast fashion.

What attracted me to Stewart Farms was some of its previous projects I’d coincidentally encountered over the years, such as automated vertical farming, along with a powerful (pun intended) documentary film entitled “The Need to Grow,” which I recently discovered Stewart helped produce.

The 2018 film had a lasting impression on me. It revolves around this concept of harnessing free energy in specially designed “Green Power Houses,” using algae production and biochar to power greenhouses and other structures, while also sequestering carbon and producing regenerative soil amendments.

These are the kinds of projects that keep me excited and passionate about Canada’s cannabis industry, and beyond. Specifically, about creating a closed loop system for our consumption patterns, while embracing a more cyclical, partnership model for our operations, where systems are interconnected rather than independent.

As the summer begins to wind down, we’d usually be prepping ourselves for sweater weather and the highly anticipated “Croptober,” especially for outdoor growers. However, the number of these brave outdoor LPs appears to be dwindling, and perhaps for obvious reasons. Though at this time of year, ever more it seems summer stretches on, and as Canadians, we may find this an appealing phenomenon, but one can’t help but wonder what is causing this shift.

Using algae & biochar to power greenhouses, while sequestering carbon & producing soil amendments.

For those climate change deniers out there, I would say this: climate change has now occurred. It has permeated each of our timelines — past, present and future —because the climate has in fact, already changed. In all fairness, environmental issues are mostly responsible for my interest in journalism to begin with.

Of course, we can all be somewhat hypocritical on this subject, as mostly indulgent Westerners (myself included), but the topic is none the less pressing on the greater social consciousness.

This brings me to Dr. Vandana Shiva (an expert featured in the aforementioned “The Need to Grow” film). Shiva has become the unofficial leader and one of the most important activists on

the topic of ecological justice. Her message may be rooted in Av Singh’s feature this month, speaking out against biopiracy and the patenting of modified plant genetics, the risk of which has made its way to the cannabis market. Singh prefaces this by providing the example of RiceTec’s attempt at monopolizing rice exports in South Asia through a modified strain of rice.

I’d now like to welcome cannabis consultant Michaela Freedman to the roster of Grow Opportunity columnists. She contributed to this conversation by touching upon the lack of options for plant disposal in the industry, as well as the overuse of plastics.

During my conversation with Trina Fraser last month, regarding CBD recommendations, I asked her to speculate where we will source CBD, and if hemp would be considered. Perhaps this might open the door to other uses of plant matter in this industry, as an alternative material source for biomass, fibre, etc.

All this to say that rather than looking for channels to capitalize off the changing climate by examining market potential (e.g., growing figs and olives in the Okanagan), my hope is that through awareness, and a great deal of motivation, we may find solutions today. Although we may never reverse the damage done, perhaps we might help soften the blow and salvage our future for precious generations to come, and traditional plant species to thrive.

September/October 2022 Vol. 6, No. 5 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Services Administrator Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Haley Nagasaki hnagasaki@annexbusinessmedia.com 519-410-0600

PUBLISHER

Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175

MEDIA DESIGNER

Curtis Martin

AUDIENCE DEVELOPMENT MANAGER Shawn Arul sarul@annexbusinessmedia.com

GROUP PUBLISHER Paul Grossinger pgrossinger@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES 1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec):

1 year offers: Canada $25.50 + Tax USA $47.00 CDN FGN $53.50 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Made possible with the support of

Industry lawyer addresses Health Canada's CBD report

Cannabis attorney Trina Fraser, partner at Brazeau Seller Law, recently weighed in on the recommendations by Health Canada’s Science Advisory Committee.

“Many are watching this category very, very closely, but you have to keep a realistic frame of mind about the timeline that is still ahead of us,” she says. “Do not get locked into anything at this point because the recommendations in the report are just that: recommendations. They’re not necessarily going to be accepted. by government.”

Fraser addresses glaring questions following the report, including what kind of promotion and packaging regulations will be required for Cannabis Health Products (CHPs). This query stands in relation to marketing, as well as the health claims that can be made and/or printed on the package.

Other questions include whether CHPs will be treated the same as regulated cannabis products when it comes to the rules on use of colours and graphics. Will products be permitted to represent glamorous or trendy lifestyle brands?

Fraser also evaluates the timeline before industry will see draft regulations.

“I don’t think these are products that are going to launch in 2023. We’re looking into 2024 to see these products, and potentially longer if there is a whole new infrastructure that has to be created.

“And when it comes to the sale of CHPs,” Fraser adds, “if the federal government says it’s appropriate to only sell these products in pharmacies, pharmacies are regulated provincially. So, the provinces may need to adjust their regulatory scheme.”

Another pressing question for Fraser is

the source of the CBD itself.

Will these extracts be taken from federally licensed producers of cannabis, or will they extend the category to include hemp growers as well? What licensing will enable producers to create these products, and at what standards?

Fraser affirms that this is a similar situation as initial cannabis legalization, but on a smaller scale.

She encourages everyone who has an interest in the development of CHP licensing and infrastructure to seize the consultation and make submissions.

“Put your position forward because now’s the chance,” she advises. “This is your opportunity to be heard. It is not clear how much room for change there will be once draft regulations are published.”

Facility Design

Legal

Matters

By Matt Maurer

Turbulent times from the perspective of civil litigation

Ispent the first decade or so of my legal career practicing exclusively in the field of civil litigation. Today, I still maintain a busy civil litigation practice, but have been focusing heavily on cannabis law for the last six years.

The experience of spending over 15 years caught between feuding parties over sizable sums of money has provided me a unique perspective on the way matters go awry in business, as well as what people can do to best protect themselves from their relationships heading south. This is especially relevant now during an era of looming recession and tough economic times.

It is often said that good paper makes good relationships, and I could not agree more.

No one likes spending money on legal fee and so many business owners feel that they are capable of drafting their own agreements, or worse, they feel as though a written agreement is not required because they “trust” the other party. This is, of course, troubling because every business deal is consummated when the parties are on good terms.

The problem is that at some point in time, many, if not most business relationships deteriorate from the honeymoon phase. And you should count yourself exceptionally lucky if this has not yet happened.

Perhaps your supplier begins turning their attention elsewhere to a larger customer at your expense. Or perhaps your customer who is overextended on credit terms suddenly finds themselves in a financial pinch and are unable to pay their accounts. Maybe the person you’re in business with is simply unscrupulous and attempts to work you over in any way possible.

Many are shocked and appalled when they experience terrible business behaviours from people they thought they knew. However, ask any lawyer who has practiced civil litigation for more than a couple of years and they will certainly inform you that some simply show no remorse in the face of personal gains.

Oftentimes it is a balancing act evaluating the strength of the existing relationship vs. the exposure you are taking on for your own business.

Actions to take to protect yourself against law suits

The first lesson is to make sure you have the proper written agreements in place at the outset of the arrangement. The cost of putting these agreements in place is nominal compared to the cost of litigating, which is astronomical even for modest sums of money. And even with the proper agreements in place, it is prudent to constantly monitor and evaluate the ongoing business relationships you have.

For example, when push comes to shove, if your defendant has no assets to collect on, you are going to be left holding the bag.

Next, ask yourself this — has your supplier begun delivering late, here and there, and/or is the quality of what you are receiving slipping?

If so, it is always best to address these issues (in writing whenever possible) as soon as they arise. Doing so ensures that everything is properly documented in the event that you need to go to court, and just as importantly, it allows you to begin obtaining feedback on where the relationship may be headed in the future.

Ideal business partners will immediately apologize and remedy the wrongs moving forward. If your partner apologizes but the pattern continues to repeat, this is often a sure sign of trouble on the horizon.

Unsuspecting behaviours to watch out for

Are you monitoring your accounts receivable? Are your customers taking longer than usual to pay? Address this as soon as you can. Most clients will have an explanation (often a legitimate one) as to why they have been a bit tardy remitting payment. It is possible to be sympathetic to their situation while at the same time making it clear that if the situation persists, then the ability to provide credit terms will be impacted.

Most people do not want to take a hard line with good customers who have long standing relationships. However, great customers will understand and appreciate your need to look out for your own interests, as their conduct impacts your business and your employees as well.

In fact, the largest debts are often owed by a business’ “best” customers because they are given excessive credit and leeway in terms of repayment, which they take advantage of because their own business is struggling. They may have the best intentions of paying it back once business turns around, but the problem remains that business does not always turn around.

No one is saying that you must suddenly eliminate your best customers’ ability to buy on credit, or dramatically alter the existing relationship. Oftentimes it is a balancing act evaluating the strength of the existing relationship vs. the exposure you are taking on for your own business.

Remember to always be mindful of where, and to what degree your exposure lies, because it is often your oldest and best customers that may leave you holding the bag.

Trust me, I’ve seen it, many times over.

Matt Maurer is a partner and co-chair of the Cannabis Law Group at Torkin Manes LLP in Toronto, Ont.

One less thing to worry about.

Easy to use • Consistent clean quality input

Traceability of all products • Growing support provided

CANNA is an established and serious partner for the Green Market. We provide solutions to growers of all sizes, including Canadian Licensed Producers.

CANNA nutrients, additives and growing mediums are manufactured from the highest quality source materials. We understand the importance of a clean, consistent and traceable input as well as keeping it simple.

CANNA loves to share its knowledge and experience, our team is there to support you.

Cultivation

By Dr. Mohyuddin Mirza & Gagandeep Singh Bhatoa

Dr. Mohyuddin Mirza, PhD, is an industry consultant in Edmonton, Alta. He can be reached at drmirzaconsultants@gmail.com.

Gagandeep Singh Bhatoa is a scientific writer in Regina, Sask. He can be reached at gaganagrico@gmailcom.

Quality post-harvest practices for cannabis

Undeniably, growing cannabis is a tedious yet rewarding process. All cannabis crop management practices affect the post-harvest quality, which determines the product outcome. Post-harvest quality parameters will also vary with the end use of the cannabis flower. One of the most important aspects of growing quality cannabis comes when you are ready to harvest your plant.

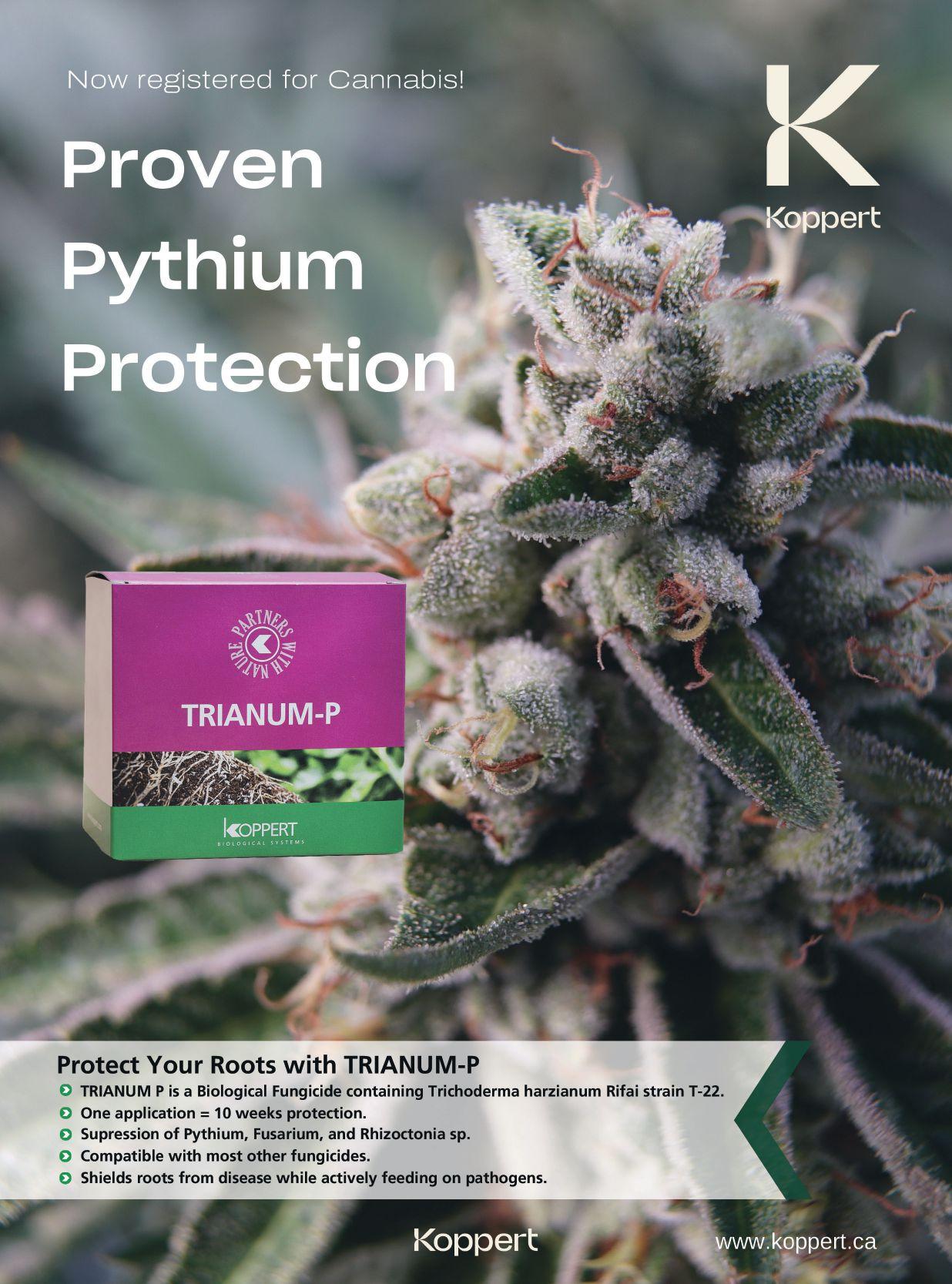

When is the best time to harvest?

The image (right) shows an example of a ripe bud where pistils have turned amber in colour and trichomes are no longer translucent. The number of days in flower will vary by strain. Typically, indica plants will be ready for harvest in approximately 50 to 60 days, and sativa usually between 60 and 70 days.

Harvesting plants too early or too late can affect potency and yield, potentially lessening the flower’s quality. The number of days from flower to harvest will also influence the way plants are grown, vegetatively or generatively.

Should growers harvest fresh buds or hang branches to dry?

Growers follow three main practices while gathering buds for drying and processing:

1. Harvest the entire plant and hang it up, then harvest the buds when they’re dry.

2. Remove the branches with the buds intact, hang them and then harvest the buds after drying.

3. Remove the buds from the stem to save space, and dry buds in boxes or on trays. When the entire plant is hung up, usually it takes longer to dry. During handling, the dried leaves and buds may fall or crumble.

Processing your cannabis buds

Drying: Several factors such as microbial activity, moisture content, room temperature, and duration of light, affect the

post-harvest quality and sustainability of cannabis. Drying is the most effective technique for controlling microbial activity and enabling long-term storage while maintaining potency, taste, and medicinal properties.

Several drying methods have been used to dry the flowers, including hot air drying, oven drying, vacuum freeze-drying, atmospheric freeze-drying, and microwave-assisted drying.

While carrying out the drying process, keep the following points in mind:

• If you are drying the entire plant, then ensure that everything is set up prior to harvest — racks are properly placed and disinfected in advance;

• Don’t overcrowd the drying rooms. Keep the dry rooms well-ventilated with proper air flow to maintain ideal temperatures and humidity levels, which decreases the chances of mould and mildew;

• Some growers use higher temperatures for the first three to five days to get rid of moisture quickly, and then drop to lower temperatures;

• We recommend using Vapor Pressure Deficit (VPD) as a guideline rather than temperature and humidity independently. VPD indicates the difference of water activity inside the buds as compared to outside of them;

• A good range for proper loss of water from buds is suggested to be between seven to

nine millibars. Temperature and RH adjusted to achieve proper VPD will help to avoid condensation and mould;

• Measuring the moisture content of cannabis buds determines the effectiveness of drying and curing techniques, which also affect the terpene concentration and chemical profile of the finished product;

• The moisture content of adequately cured cannabis flower should be less than 13 per cent.

Curing: Curing is essentially a process of “ripening the buds” where dried buds are placed into airtight containers and stored in a dark environment between 15.5 to 20 degrees, with around 60 per cent humidity. Measuring water activity (aW) in cannabis buds helps determine how vulnerable the product is to microbial contamination. Mitigating water activity reduces the chance of microbial growth and allows the product to be stored for extended periods.

Growers often mistakenly assume that higher moisture content in the flower means a higher water activity but that’s not always correct. It is possible to have low moisture content in the product and still have water activity that is more than 0.65 aW. It is recommended that dried cannabis be stored in sealed containers with water activity below 0.65aW.

Storing the product with poor drying conditions under high humidity encourages the formation of microbial spores and harmful microbial toxins such as aflatoxin, as well as powdery mildew and botrytis, which causes the deterioration of cannabis.

The therapeutic potential of cannabis products depends heavily on the initial quality of the plant material, as influenced by the harvesting time, harvesting technique, and post-harvesting technologies. This also helps to determine the chemical composition and quality of the buds.

Safety has been the biggest concern, however, since no proper standardised procedures are present, it’s difficult to enforce. Thus, having controlled processing systems in place, in alignment with the scientific evidence, is essential.

LIKE PEANUT BUTTER AND JELLY -

IIVO provides crop-specific smart technology for growers. A combination of smart software and state-of-the-art hardware. This truly unique system is capable of monitoring, controlling, and maintaining any type of growing environment.

Allowing you to grow more, at higher quality while using minimal resources. Whether you have experience in growing Cannabis or not. With self-learning controls and integrated security, you are ready for the future.

Cannabis biopiracy in the era of climate chaos

Genetic autonomy breeds plant resiliency.

By Av Singh

Thinking of having Indian food tonight? You can probably conjure the fragrant aroma of Basmati rice.

Well, about 25 years ago, a Texas-based company, RiceTec, received a patent affording it control over all production and import of Basmati rice into the U.S. market. If upheld, the legislation would have devastated many South Asian countries that prospered from rice exports.

What was their “novel” trait so worthy of such a broad patent? RiceTec plant breeders crossed a Basmati rice cultivar with a long grain rice from Texas. Yet crossbreeding has been done for millennia; it is hardly new.

Most WTO (World Trade Organizations) countries exclude plant variety protection from patentability, but not the U.S.

In the U.S., plant breeders can gain exclusive rights to “new” varieties, thereby forcing farmers to pay royalties, stop them from saving seed, or even keep them from breeding or growing certain cultivars.

The Indian government claimed patenting plants was theft of traditional knowledge belonging to generations of Indigenous farmers of varying regions — calling it biopiracy.

Biopiracy, or bioprospecting, can be defined as the appropriation of knowledge, biodiversity, and genetic resources

claimed for patent or exploitation for profit without permission or compensation to those communities that have traditionally nurtured those resources.

Demonstrating that generations of farmers had been crossing several rice varieties in a specific region of India to create ‘Basmati,’ meant the patent was successfully overturned.

As for the question on whether biopiracy could happen in cannabis. Well, It already has.

There are well over a dozen U.S. plant patents on cannabis, including some held by Canadian companies. Arguably, the most famous strain to be patented is that of Charlotte’s Web by the Stanley Brothers. However, the first strain to be patented was a simple ‘sativa-dominant’

strain crossed with an ‘indica-dominant’ strain, dubbed an “Ecuadorian sativa.”

Recently, the “owners” of this strain were quick to promote claims that it had high levels of CBGA, shortly after reports suggesting that this cannabinoid could have merit in fighting COVID-19.

The notion of “owning” Nature or creating “novelty” from something that has been cultivated and traded amongst humans for thousands of years, is a debate for another time.

Cannabis breeders like SubCool, DJ Short, Arjan Roskam, Ben Dronkers, Top Dawg, Simon Smit, Josey Wales, Vic High, and so many others, took great risks during prohibition times and deserve compensation for their art of breeding and phenohunting.

Flooded rice fields in India assist with the growth of plants and help to control weeds and pests.

Av Singh, PhD, PAg serves as an independent cannabis consultant with Flemming & Singh Cannabis Inc., as well as QAP for several LPs, and volunteers with Veterans for Healing; Cannabis Quality Assurance; Régénération Canada; and Canadian Organic Growers.

But this is different from “owning” a plant.

For instance, many of these breeders would consider their efforts to be art, and they may make claims to their artwork, but would never attempt to own all art-making materials.

That being said, the elephant in the room remains this: who will address the notion that many of these breeders’ strains have their foundations from landraces such as Hindu Kush, Afghani, Durban Poison, Congo Red, Colombian Gold, Thai Stick, Acapulco Gold, Jamaican Lamb’s Bread, and many others? And why have there been no concrete efforts to retain these genetics as part of the commons, or discussions about compensating the countries of origin?

How can Canadian cannabis leaders help?

As a global industry, the cannabis sector must collectively ensure that countries of origin do not become further exploited. Perhaps it should even go as far as to look at the means of supporting efforts for financial retribution, working towards decriminalization, legalization, cannabis genetic preservation, and further education.

As nations increasingly legalize cannabis cultivation, especially in the global South, there will be concomitant increase in sun-grown cannabis. Primarily because outdoor cultivation is the most cost-effective, most environmentally sustainable, and the flower or concentrate might make the most robust medicine with diverse flavonoids, terpenes, and other medicinal constituents.

The challenge arising is that climate chaotic events like droughts, extreme temperature fluctuations, wildfires, flooding, etc., are making the growing season unpredictable and, at times, causing severe field losses.

Moreover, the increased presence of the plant worldwide, coupled with temperature increases, are introducing a host of new pests and pathogens, adding cannabis to their menu. However, within the domesticated genome of this millennia-old plant, there are genes that may potentially offer unique traits to combat these new and upcoming selection pressures.

Traits that confer minor cannabinoids and medicinal molecules are one thing, but traits that can produce a more resilient cannabis in times of climate chaos are important genetics that must be treated as part of the commons to be shared amongst current and future breeders.

Current research interests focus primarily on human health properties, but as legalization continues to expand globally, research will include more plant genetics, physiology, and agronomy.

Increased understanding of the cannabis plant genome will help better explain the power of the plant, affording insight into how it can be better manipulated for disease and insect resistance, drought tolerance, shorter flowering times, increased secondary metabolite synthesis, etc.

At the end of the day, efforts to keep the genomic library public is in our best interest, as it provides freedom for the plant to meet the needs of a dynamic and ever-changing climate.

Stewart Farms: From seed to suds

Stewart's most striking quality is the spirited authenticity and pride with which the entire team works and interacts with one another.

By Haley Nagasaki

In August, Grow Opportunity ventured to the historic East Coast of Canada to visit a small, but mighty, cannabis company called Stewart Farms, located in the unique border town of St. Stephen, New Brunswick, which sits adjacent to The Bay of Fundy.

It’s here that a team of passionate cannabis enthusiasts cultivates a robust variety of cannabis genetics in a living soil, aquaponic combo system, while manufacturing a line of wellness products, including bath bombs, magnesium-rich bath salts, and pain balms.

CEO and founder, Tanner Stewart, originally hailing from Miramichi, N.B., captains this operation with a crew of talented women at his side — cultivation director Genevieve Newton; COO and director of product development, Catrina Jackson; Ashley Hamilton, operations manager; and Megan Roy, QAP and regulatory compliance coordinator.

From construction, vertical farming, and documentary film production to aquaponic cannabis and infused wellness products, the skillset of Tanner Stewart has made waves across the nation, now extending to the tubs of lifestyle enthusiasts from coast-to-coast.

Stewart Farms bares a unique signature as a company that employs a large group of neurodivergent staff, while several of

their key management also hold backgrounds in social services.

“These boxes are how we ended up working with the vocational centre,” says Catrina Jackson, while standing amongst a team boxing and labeling bath bombs.

“When we first started, we had all our boxes shipped to us, but they all came in separate pieces that needed to be assembled. We’d be packaging, and then the team would have to stop to go prep boxes.”

“My background, before coming here, was in human services and job coaching people with special needs. So, I looked at it, and I thought: this is an awesome opportunity for someone with potentially limited physical mobility, different skillsets, or neurodivergence.”

“So now we take our boxes to the vocational centre, they prep them, and that keeps our production line running smoothly,” says Jackson.

Tanner Stewart, Catrina Jackson, and Genevieve Newton sit with the entire team at Stewart Farms behind them, assembled for a photoshoot and lunch duo as a team-building and story telling exercise.

The art of creating sensual experiences

The wellness products produced at Stewart Farms include infused bath bombs, pain and healing salves, as well as bath salts, such as Seaweed OG, containing real seaweed from The Bay of Fundy.

Jackson explains that the salts were “also designed with different function enhancers, like tremella extract, which is snow mushroom.”

“When we started developing these,” she says, “I tried some of the infused salts on the market and they were literally just Epsom salts mixed with isolates; they settle on the bottom of the tub and then

they go down the drain. So that was a wasteful product to me. The snow mushroom works as a natural absorption enhancer so you’re getting the most out of the cannabinoids. They’re also loaded with moisturizing mango butter.”

All the products are handmade using pure essential oils. There are no synthetics used in the process, avoiding potential sensitivities and reactions in users.

“I couldn’t imagine subjecting our team members to synthetic perfumes all day. These are all natural ingredients, like the absorption enhancers use geraniol, derived from geranium essential oil.”

The products at Stewart Farms are medicinally designed even before stacking them with cannabinoids.

Jackson and her team blend botanical essential oils into their products, encouraging an entourage effect.

Moving freely about the facility

The next room was reminiscent of an apothecary where team members mix and make bath bombs, listening to tunes and relishing the scent of terpene-rich essential oils and cannabinoids.

“I had a lot of training in aromatherapy before working in human services — I worked in botanical product development.” Jackson explains.

“When we first launched the bath bombs, they had no cannabis. The whole purpose was to use the bath bombs to educate people that terpenes are not just in cannabis; terpenes are a main compound in the oils already used in many wellness products.”

In a typical workday, staff might spend half the day completing bath bomb production, followed by a half day of pre-roll production or packaging, after lunch. They are trained in all departments of the operation and are dedicated to their work — a hallmark of Stewart's operation.

“In our interview questions, I always ask: what’s your relationship with cannabis? You don’t have to be a user, but you need to be an ally. You need to understand what we’re doing, and why. Every person who works here has incredible respect for the plant and what we do; it’s a requirement.”

“Now,

onto the weed!” — Tanner Stewart

Within the storage room, amongst racks of curing bath bombs and boxes of salts, stands a white fridge padlocked with a chain. Inside is what Tanner Stewart refers to as the genetic library:

“There’s about 20 thousand seeds and 500 genetics in there, with 30 to 50 to 100 seeds each, of some of the best genetics from breeders on the west coast of California and all over the world.”

“This genetic library,” says cultivation director Genevieve Newton, “is what brought me here to the East Coast — it’s a fridge full of unicorns.”

Newton has been cultivating cannabis for eight years, and professionally since 2018. She completed a six-month production course in Olds, Alta., after transitioning from non-profit work to cannabis.

“When I first got here, the very first week, I dropped 300 seeds. The most stressful thing

A look inside the high-energy bath bomb production space.

a grower can do is propagate seeds, and we had a 98 per cent success rate out of this fridge.”

Newton then revealed a room where two tables displayed perfectly green, vegetative plants, with their leaves reaching for the lights.

“Currently this table is holding 111 genetics from our genetic library. Usually, we have two copies of everything. And these are all going to become mothers,” she points out.

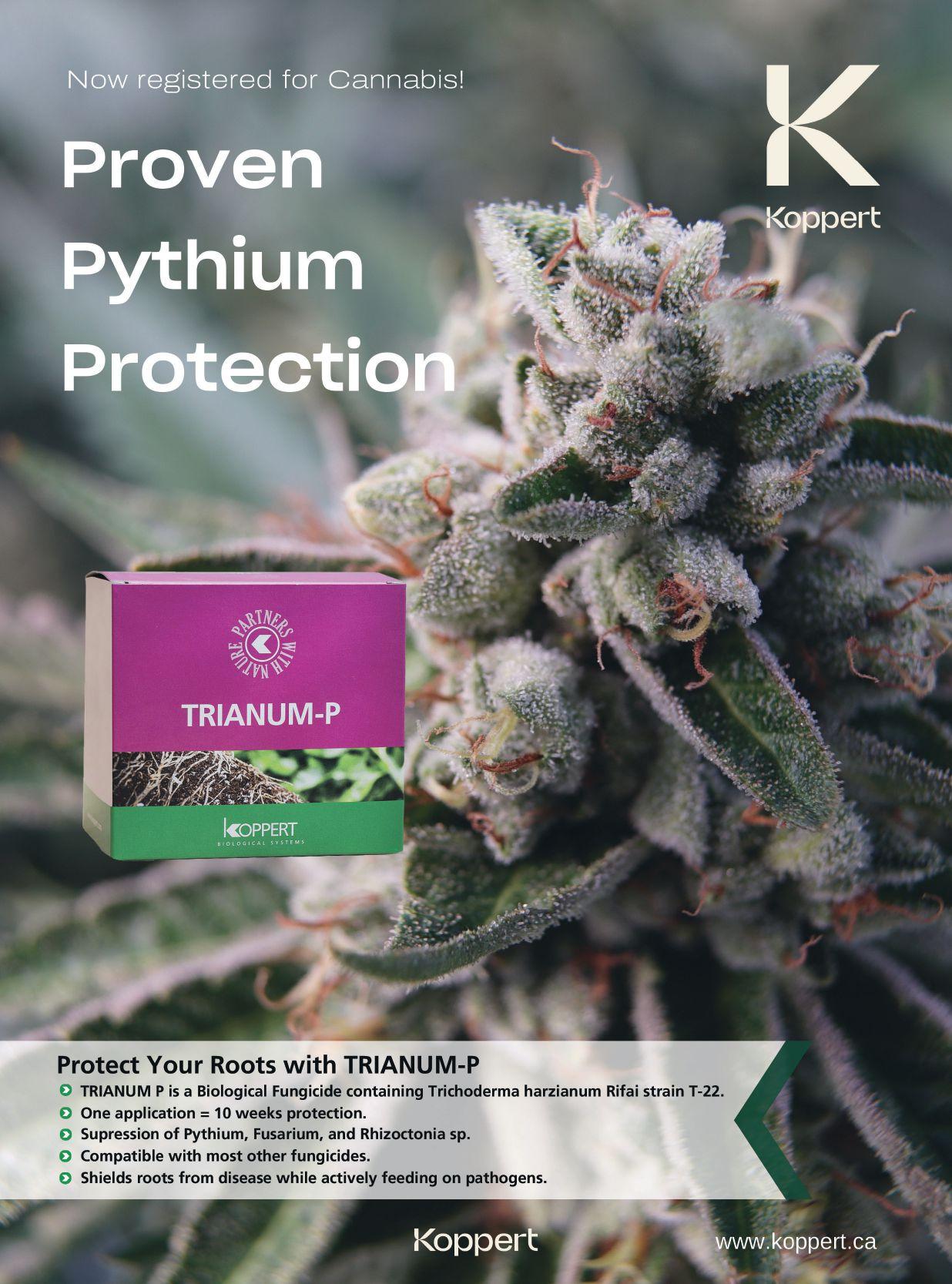

Newton uses Koppert biological controls against pests, such as thrips and gnats, and everything at the farm is hand watered.

“I call this the teen mom room,” she says, laughing.

“We’ll show you the little baby room next, and then we’ll take you into the seven and 10 gallon [pot] room, where some of these veg plants go after they’ve been trained. There are moms bigger than you in there!”

The rest of the cultivation team were found in the nursery — or Veg room 2 — where clones of Stewart’s soon-to-be-released Grape strain were being potted into four-inch pots.

“They’re getting basically 100 per cent success rate on rooting these clones,” Stewart smiles.

“We’ve got quality down,” he says. “Now we’re going to ramp up yield.”

“We have proven, without a doubt, that living soil organics can hit cannabinoid numbers the same if not better than hydro. Now, we’re focused on matching or beating salt grown yields.

“Growing in hydroponics is like you’re driving a speedboat; you can make quick turns as you go. With organics, you’re sailing the Titanic — you have to start

turning way ahead of where you want to land later.”

“In living soil, the rhythm and timing of potting-up are critical. That’s your momentum that leads to yield.

“So, if you pot-up too late, then you lose a lot of vigor. You’ve got to hit it within a roughly three-day range. Start in the smallest pot then, boom, you go up to the one gallon, boom, you hit the four gal, and then you’ve got this beautiful biological momentum happening.”

Big mamas and sticky flowers

The two largest Grape plants tower in the mother room. All the oldest mother plants at the facility have provided at least two generations of clones, and the smaller mothers in the room still have another pot size to move into.

“I’ve worked in other facilities where the mothers are neglected, and I’m so proud of these ones,” exclaims Newton.

“Another thing that my team is all over,” says Stewart, “is energy consumption! The mothers need less light, so I’m saving 50 per cent energy in this room because they’ve gone and turned off every second LED while keeping the light on the canopy even.”

“What we have here, is a group of people that pay 100 per cent attention to everything,” says Stewart, proudly.

Newton proceeded to lead the group into the hang dry and curing room, feasting their eyes on a room full of tasty buds.

The tour then concluded with a look at the onsite fish farm consisting of two tanks of about 300 Black Nile Tilapia. The fish provide their nutrient and microbial-rich wastewater as a supplemental tea to enhance the performance of the living soil-grown cannabis.

Upon completion of the facility tour, evidently Stewart Farms is an LP operating with a high level of integrity, directed by the spirited, well-informed staff that Tanner Stewart seldom forgets to thank for their efforts.

The LP has become a model farm, demonstrating dedication to an important cause, all while creating meaningful medicine and core memories for many.

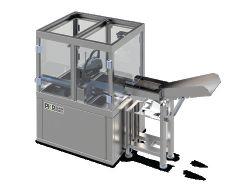

Grow as you

performance pre-roll machine used around the world

Expandable from 1 channel to 8 channels as your business grows

1 channel up to 3,500 / shift 2 channel up to 7,000 / shift 4 channel up to 14,000 / shift 8 channel up to 28,000 / shift (3, 5, 6 & 7 channels available)

How cannabis producers address climate impacts

The changing climate is a matter of concern for all, and although it particularly impacts those involved in agriculture, cannabis producers are no exception.

By Matt Jones

Intensifying weather conditions mpact how crops are grown and harvested, regardless of whether their production is indoor, outdoor or in a greenhouse. At the same time, cannabis producers also grapple with their own contributions to climate change and how best to mitigate those impacts through sustainable practices and more efficient technologies.

Agriculture and Agri-Food Canada’s website notes that climate change impacts, such as droughts or intense heatwaves, can cause crop failure and barren pastures. Annual and seasonal mean temperatures across Canada have increased, particularly in the winter.

Climate change has also increased the likelihood of extreme weather events, such as wildfires, flooding, hailstorms, and tornadoes. Droughts and soil moisture deficits are projected to become more frequent and intense in the coming years.

While all those factors can impact cannabis producers, there may also be direct impacts specific to the cannabis plant. The report “Photosynthetic response of Cannabis sativa L. to variations in photosynthetic photon flux densities, temperature and CO2 conditions,” published in the journal

Physiology and Molecular Biology of Plants, found that the rate of water use and photosynthesis in cannabis plants benefit in warmer weather, but once temperatures pass the threshold of 30 degrees C, the impacts become negative for both. Here are three examples of Canadian LPs looking at the impact of climate change on their business, and what they are doing to mitigate the risks.

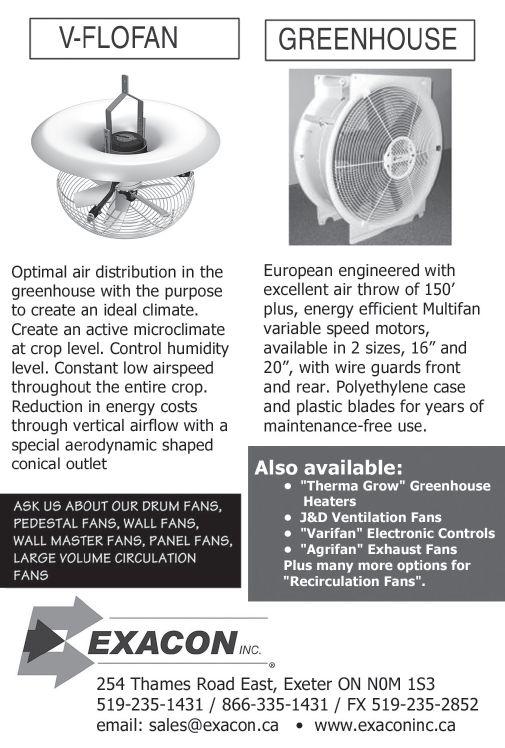

DYKSTRA GREENHOUSES

Southern Ontario-based Dykstra Greenhouses has a 100,000 square-foot facility, which includes their growing operations as well as processing, storage, and other uses. Production manager and master grower, Bart Brouwer, stipulates that he’s far from an expert on climate change, but reckons that underlying climate issues have likely impacted the logistics of their operation. While winter is the best time to grow crops in a greenhouse, it’s also the most expensive time due to heating and lighting requirements.

“In the summertime, we’re not shutting down, but we’ve decided to grow bigger plants,” says Brouwer. “We’re not flowering out in the summertime. We’re just growing a natural crop; they’re going to flower naturally so we don’t have to

heat or cool. In a vegetative state, they can handle the heat. They still don’t like the heat, but it doesn’t affect the flower because it’s not flowering. So, we’re now growing all big plants that are going to be harvested in October.”

The other impact with hotter summer temperatures that Brouwer has observed is a significant increase in the number of bugs they have to deal with.

“The bad bugs are, I would say, almost uncontrollable in the summertime,” says Brouwer. “The biological bugs that we use to fight the bugs when they flower like the heat a lot less than the aphids and what not. They thrive in the high heat and the biologicals don’t.”

In terms of efforts to reduce their overall climate footprint, Dykstra Greenhouses only use soil, avoiding rock wool, which creates more waste. The company also keeps electricity costs low using more efficient LED lights. Brouwer advises other producers that while some sustainable practices do come at a high cost, others can serve to save a great deal of money in the long run by reducing energy consumption.

“We do a lot of research on how we can save our money, but at the same time, use less energy because that’s saving money in the long run as well,” says Brouwer.

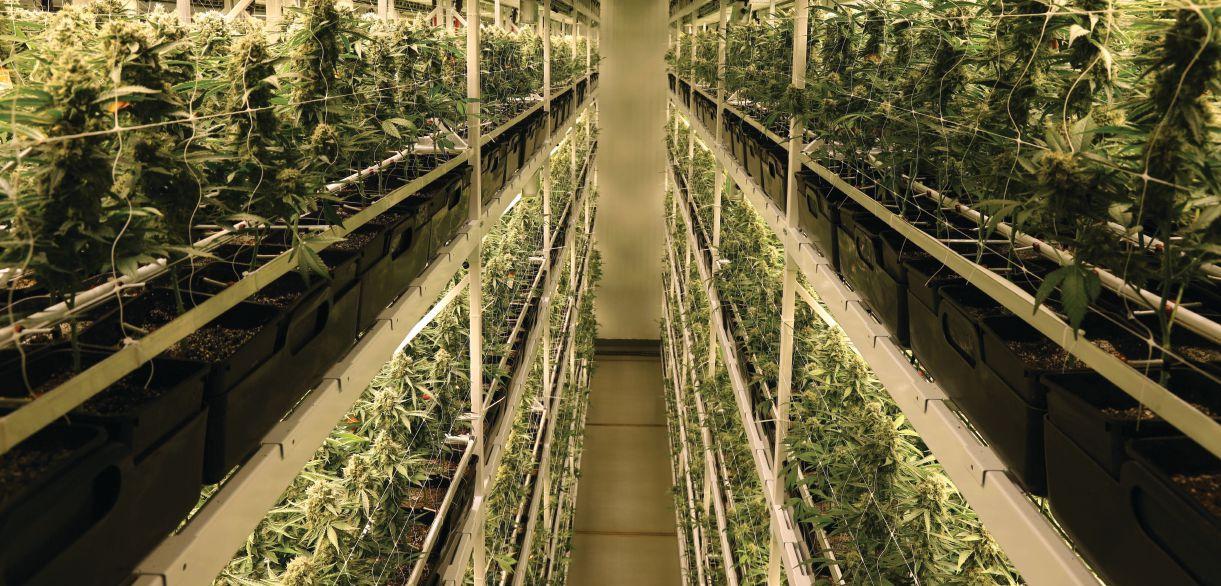

Greenseal Cannabis focuses on keeping a low climate footprint. Rather than ‘cost per gram,’ the company uses the measurement ‘grams per watt' — how many grams of product are produced per watt of power usage.

GREENSEAL CANNABIS

Ontario’s Greenseal Cannabis Co. is an indoor grower known for their high-density vertical growing, with a high yield per square foot. And while an indoor grower will not experience as many direct impacts as an outdoor grower or a greenhouse, Phil Niles, executive vice president of Greenseal, feels that many people would be surprised by how many impacts there are on indoor growers.

“There’s no such thing as a 100 per cent weather tight building,” says Niles. “We’ve even noticed a seasonality in our harvests with respect to drying. As you get more extreme temperatures, and especially more extreme humidity, we definitely see a difference in how fast the product dries.”

Niles adds that the humidity has had an impact even at night, which has led the company to increase their heating, ventilation, and air conditioning capacity in their drying rooms. But even if the direct impacts are limited, the indirect impacts can be quite pronounced. Niles says that he can always tell when conditions are hotter because Greenseal starts receiving more calls from their wholesale customers, looking to replace lost crops to fill orders.

With climate and sustainability issues in mind, Greenseal designed their operations with several efficiencies, such as employing the use of digital electricity.

“We’re actually able to change the wattage that goes to the light. You can just throttle it up and down,” which minimizes ballasts and heat sources, reducing the need for HVAC. They are also using beneficials for pest control rather than pesticides, etc.

Niles says the company is regularly examining ways to alter their practices to improve sustainability. While many companies discuss their ‘cost per gram,’ Greenseal deals in ‘grams per watt’ — how many grams of product are produced per watt of power usage. However, Niles recognizes that in an industry that often has thin profit margins, such efforts may be beyond the ability of many LPs.

“It’s an awkward and uncomfortable conversation for the industry right now,” admits Niles. “Most cannabis companies do not have spare dollars left over at the end of the month to spend on this stuff.

So even if they wanted to do it, if the choice is keep the lights on, properly pay staff or invest in some solar panels for my roof, we know where most people are going to put their money.”

THE MICRO COLLECTIVE

Alberta-based The Micro Collective (TMC) has three indoor micro cultivation facilities with 2,150 square feet of canopy each, growing in a potting soil mix. They use hand watering and all artificial lighting. CEO Ed Wilson says that while their most difficult climate impact (to date) was from the imposition of the carbon tax, they are seeing a lot of indirect impacts.

“We’re finding that we’re using a lot more air conditioning through the summer here to keep the climate in check,” says Wilson. “Here in Alberta, 30-degree days used to be the rarity but we’re seeing that a lot more consistently these days; it’s really taxing on the infrastructure.”

The unpredictability of the changing climate was a significant factor leading to the decision to grow indoors.

“In Alberta, we have a very short growing season to begin with,” says chief growth officer, Kailey Parkin. “The financial aspect of it, and trying to be profitable, it just made more sense than to attempt outdoors.”

Wilson observes that catastrophic weather events seem to be occurring much more frequently, citing hail, tornadoes, large damaging thunderstorms, and extremely high winds.

“Two years ago, we had a tornado touchdown behind our facility,” adds Parkin. “Last week there was the largest hailstone ever recorded in Canada about a half hour north of us. It’s too much risk to try and have an outdoor crop.”

Parkin says one of their more conscious decisions was to use horse manure for the destruction of waste products. Yet she feels that between the impacts of climate change, and the pressures of utility costs and the carbon tax, producers may have to become more creative in their methodology to find a profitable balance.

Matt Jones is a freelance writer and journalist who specializes in trade publications. He lives with a cat named Bowie in Fredericton, New Brunswick.

The Business Section

By Michaela Freedman

Three lessons learned from Canada’s legalization rollout

Canada was the first country to federally legalize recreational cannabis, making it accessible to adults of legal age. Besides Uruguay and a few U.S. states, Canada did not have many leadership examples to follow when developing its legal system, so naturally, the system has some flaws.

The strict nature of the Cannabis Act, which came into force on October 17, 2018,

was crafted through a public health lens, aiming to accomplish three goals: keep profits out of the pockets of criminals; prevent underage use; and provide adults safe access to legal cannabis.

In the four years since legalization, the Canadian market has seen considerable expansion and growth, yet this has been at the expense of the industry and the businesses driving it.

to compete with the legacy market due to inflated fees and tight margins.

On top of the legacy operators deflecting taxes, they also have no restrictions on potency or types of products they can manufacture.

Legal operators are subject to intense regulatory and tax structures, making it difficult

Meanwhile, legal operators have been calling upon government to address cannabis taxes and THC limits on packaged edibles and are still waiting for Health Canada to conduct its mandatory three-year review of the 2018 legislation.

The Canadian government, specifically the federal Department of Innovation, Science and Economic Development, proposed a new cannabis strategy table that would involve collaborating with industry stakeholders to foster economic growth.

That the cannabis industry must work separately with different departments (which has yet to happen) is a perfect example of the failure of government agencies’ ability to work in tandem.

Plant

Quality

Plant / Soil / Media

Disease Diagnostics

Water / Tissue / Soil

Residual Solvents

Microbiological Environmental

Edibles / Beverages / Topicals

Biologicals

Quality Production Experts

At the same time beyond Canada’s borders, cannabis liberalization is growing.

Other governments are taking more pragmatic approaches to developing systems that better integrates and fosters industry — Switzerland and the Netherlands are two examples of this.

Both countries are carrying out recreational pilot trials to better understand the effects of controlled access to cannabis. As cannabis reform becomes a global phenomenon, a lot can be learned from Canada’s legalization rollout.

Beyond the burdensome taxes and fees, there are additional factors that must be prioritized if governments want to achieve cannabis reform while fostering economic growth. Here are three facets that international policymakers should implement from the get-go:

Prioritize medical cannabis

Health Canada has chosen not to distinguish between medical and recreational cannabis.

Medical cannabis is subject to the same excise duty and sales taxes as recreational products, and this has disincentivized patients to renew their prescriptions. As a result, licensed producers have shifted their focus away from medical.

In Europe, even when recreational legalization happens, the medical market will still have huge market potential. For example, in Germany and Italy, many patients receive insurance coverage and access their cannabis medication from pharmacies, as opposed to canna-clinics.

The wider adoption of medical cannabis is a huge benefit to legal producers who are more likely to have repeat buyers with higher average order values.

Cracking down on illegal sales

Legalization has helped reduce illicit sales somewhat, but it’s still very easy to access non-legal cannabis products from illegal dispensaries and providers.

The lack of law enforcement not only hurts legal businesses, but also allows for unsafe products to get into the hands of consumers, which is exactly what Canadian policymakers wanted to avoid.

It’s imperative for governments to develop robust enforcement protocols for cannabis, like they do with alcohol, in order to benefit public and economic health.

Increase environmental sustainability

Despite Health Canada’s commitment to public health, it has made no consideration to the environmental impacts of cannabis production.

Canada has granted more than 850 licenses to produce and sell cannabis to a country with a population of under 40 million. Our market is oversupplied with a surplus of unsold product.

In December 2021, Health Canada reported the total inventory of packaged units of dried cannabis represented 3.7 times the total sales. This doesn't even include unpackaged units!

To make matters worse, there is no prescribed method for cannabis disposal, resulting in a lot of unsafe waste. Capping licenses may be problematic, but cannabis packaging is a more addressable problem.

Health Canada mandates that cannabis packaging be child-resistant, include a security seal, and be large enough to accommodate a label with the proposed requirements.

Environmentally friendly options are limited and costly, forcing most producers to use low-cost plastic packaging.

If governments do not address the environmental costs of cannabis production, the industry is well on track to becoming a major contributor to climate change — the biggest threat to humanity.

Despite Canada’s shortfalls, we are still leading the global cannabis industry, and have inspired many countries. Yet the Canadian government has failed to collaborate with cannabis firms — a vital step in creating a sustainable, viable industry.

As other jurisdictions move closer to legalization, they could learn from Canada’s regulatory oversights, and create a framework that can out-compete the entrenched legacy market while also prioritizing and facilitating public, economic, social, and environmental health.

Q&A with Atiyyah Ferouz, CEO, AgCann

n this interview, Atiyyah Ferouz addresses her background in consulting, post-harvest practices for growers, and new Canadian market prediction insights.

GO: Attiyah, what did you study in school?

AF: I did my master’s degree in plant biotechnology and genetic engineering, and I had always wanted to eventually go into the agricultural space. When cannabis legalized in Canada, I thought it was a really good opportunity to transition over and work in a fast paced and exciting industry, but to also use all the knowledge that I gathered during my graduate degree.

GO: When did you start your consulting business?

AF: I started my consulting business in November 2020 because I felt there were so many processes I was seeing that were not really optimized from a plant health perspective and a commercial perspective; a manufacturing perspective. My first client was in Leamington, Ont., and now the majority of my clients are international, mostly based in Europe.

GO: What are the most common tips you offer growers to save money and increase profit?

AF: One of the things that I do is look for nutrient brands that are specific to cannabis. In Canada, there are so many options for you to get mixes of your fertilizer from agricultural suppliers, which will save you have a very large chunk of money.

The other thing is to really invest

in somebody who knows IPM. Having an IPM specialist on your team, or at least an IPM consultant, is ideal because integrated pest management is very important. It’s important to deploy strategies that will help you reduce your production costs and increase the general strategy of data driven implementation.

A client might say to me: “We need to change the air filters here; we want to upgrade the filters.” And I’ll ask why? And they’ll say because the air isn’t clean. And I’ll say: well, how do you know that?

I do a lot of the changes that I implement. I don’t really like to spend additional money unless there’s really good backing for it.

What we found is that cannabis companies can sometimes go a bit overkill for things that aren’t really necessary. So, I’m there to help sort out what’s needed from both a plant health perspective and a regulatory perspective.

GO: What are some of the major no-no’s you’ve been seeing when it comes to growing cannabis?

AF: A lot of the major no-no’s that I see are actually in the drying and the curing process.

There hasn’t really been a ton of data gathering on the topic. There are textbooks — there are things going on — but the big issue is that everybody’s dry is specific to them. There is no standard on how to build a cannabis dry room.

Everyone designs their own, or they buy chambers and dry down their product. We see a lot of product loss on that end, and we see a lot of people not being able to achieve consistent drying through-

out the batch, which again leads to potential mould issues, but also problems with product consistency.

That’s actually one of the largest areas that I consult in: post-harvest processing.

Nailing down the trimming pro cess so you’re not abusing the trichomes and nailing down the drying process so you’re ensuring consistency throughout the prod ucts, a lower level of water activity, and a good quality finished bud.

GO: How are people staying com petitive in the cannabis market, and what do you think the future holds for Canadian LPs?

AF: I think it’s going to be tumultu ous for the foreseeable future, and the reason is the Canadian cannabis consumer is not that well educated or well versed in product options.

I think a large part of that is the restrictions and the regulations, which don’t really allow their main contact (budtenders) to give them any real information — they’re very limited on what they can say.

Licensed producers are very lim ited on what they can advertise and put out into the media. And, un fortunately, what’s provided by the government is very, very minimal.

So, there’s a lot of confusion about what products to buy, what products to use, how to use the products, and what some of the options are.

I also feel like this whole obses sion with over 20 per cent THC is really just a lack of consumer educa tion and maturity in the market, which to be honest, I don’t foresee miraculously changing overnight.

But I really hope in the next two to three years, with more educa tion exposure, we can start to see a bit of that change in the market. And I think that the driving reason for the volatile market is definitely consumers. And the second is oversupply.