• FASTER ROOT DEVELOPMENT AND VEGETATIVE GROWTH

• INCREASED YIELD

• INCREASED PLANT HEALTH AND VITALITY

• COMPATIBLE WITH AUTOMATED FERTIGATION SYSTEMS

• COMPATIBLE WITH MOST ANTIMICROBIAL PRODUCTS

• HIGHLY EFFECTIVE WITH ALL NUTRIENT PROGRAMS AND GROWING MEDIA

• SPECIFIC FOR CANNABIS AND HEMP PRODUCTION

• CFIA REGISTERED & CERTIFIED ORGANIC

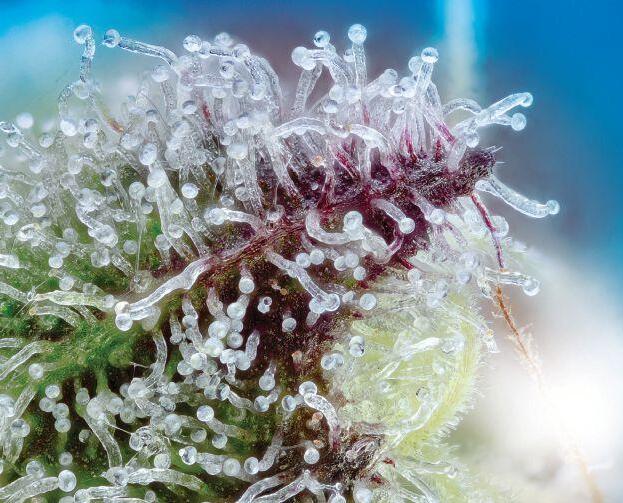

• INCREASED CANNABINOID LEVELS

• INCREASED TRICHOME DEVELOPMENT & RESIN PRODUCTION

• ENHANCED TERPENE PROFILE

• FASTER TRANSITION INTO FLOWERING

• ENHANCED FLOWERING AND BUD FORMATION

• PROMOTES TOLERANCE TO SALT, HEAT, AND DROUGHT

• COMPATIBLE WITH ALL NUTRIENT PROGRAMS AND GROWING MEDIA

• CFIA REGISTERED

08 | Cultivation

Part 3: are you compliant with a plant’s physiological rules?

12 | Micromanagement

Reducing industry red tape for micro-cultivators

14 | Legal Matters

The impact of white labelling on licensed producers

34 | Vantage Point

Industry optimism and urgency lies in Canada’s federal budget

04 | From the Editor 06 | In the News 36 | Suppliers’ Corner Featured products and services for the cannabis enterprise 38 | Under the Lights Q&A with David Hyde, Hyde Advisory & Investments

ON THE COVER Alexandre Gauthier, director of cultivation at Origine

interview with Alexandre on page 20.

Check out

20

COVER STORY

A passion for growing Alexandre Gauthier shares his thoughts on why he just wants growers to produce good cannabis for a good price BY PAUL GROSSINGER

26

The labour gap

A look into the talent shortage in Canada’s cannabis market, and what LPs can do about it BY TREENA HEIN

30 Innovation through collaboration

Product innovation is just one of the benefits of partnering with Canadian colleges on R&D BY ANDREW KASZOWSKI

32 Assuring cannabis quality

The C-45 Quality Association lists the changes they would like to see in the Cannabis Act BY TOM ULANOWSKI

By Paul Grossinger

Over the past few months. I have had the privilege to be the acting editor of Grow Opportunity.

This is not the first time I have held this title. When we launched the media brand back in the Fall of 2017, I played a similar role for our first 2 issues.

This time around, I followed a very similar path to my first go around as editor: speak to as many people in the cannabis industry as I can to learn about what is really going on in the market: how has the market changed over the past five years, who are some of the key players now, including in the growing micro-cultivator market, and what keeps cannabis professionals — both in the board room and the grow room — up at night.

In this information journey of mine, I had the pleasure to speak to many people, including: Mitchell Osak, Joshua Reynolds, David Hyde, Michaela Freedman, Tom Ulanowski, Mika Unterman, Jonathan Hiltz, Barry Davidson, George Smitherman, Av Singh, Jayson Goodale, Ika Washington, Bill MacDonald and Atiyyah Ferouz, just to name a few.

All of these knowledgeable people graciously gave me their time to share their wisdom, insights and opinions — strong ones too when it comes to big-picture industry themes, such as regulation, market

conditions and consolidation, the growth of retail, tax issues, and the barriers and shortfalls the industry has had to go through (some self-inflicted) over The Early Years of cannabis legalization in Canada.

After every Zoom call, email, phone interaction and LinkedIn chat with these people, I came away with one common theme: passion. Not surprising, passion was the theme of my first Editor’s

“There is a cannabis product for every type of price point and customer – it just takes effort, patience and passion to get there.”

Note back in our premier issue. Everyone I recently spoke too, probably like most people who call the Canadian cannabis market home, expressed their enthusiasm for this industry and what their plans are to help with its continued growth, evolution and normalization.

This passion definitely came across during my time spent with Alexandre Gauthier, the director of cultivation at Origine Nature in Quebec (see interview on page 20). In our way-too-brief call, Gauthier shared with me the emotion that came over him when The Cannabis Act came into law. He also explained to me the art and science behind growing, including the precise detail growers need to have when

cultivating cannabis and the teamwork every cannabis company toiling in today’s highly competitive and volatile market requires to survive.

In a short period of time, he opened my eyes to the difference between growing for medicinal markets versus recreational markets, the importance of growers understanding the entire cannabis space and not just cultivation factors, such as lighting and humidity, and that there is a cannabis product for every price point and customer — it just takes effort, patience and passion to get there.

But of course, Canada’s cannabis industry needs more than just passion to propel it forward. Attention to and execution of recognized and standard business and finanicial practices, principles and processes is one area where the industry needs maturation. Not to mention a more focused and concentrated plan to attract top talent to all jobs and careers in a cannabis operation, which will also go a long way toward continued industry growth, expansion and professionalism.

As previously mentioned, I am just a placeholder in the editor’s chair as, by the time you read the next issue of Grow Opportunity, a new editor should be in place — someone that will also display the passion that many of you possess, as well as be committed to telling stories that positively impact the cannabis market now and in the future.

May/June 2022

Vol. 6, No. 3 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Shawn Arul, Audience Development Manager

Tel: (416) 510-5181 Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

INTERIM EDITOR

Paul Grossinger pgrossinger@annexbusinessmedia.com

PUBLISHER

Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR

Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175

MEDIA DESIGNER

Curtis Martin

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES 1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec): 1 year offers: Canada $25.50 + Tax USA $47.00 CDN FGN $53.50 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Made possible with the support of

HEXO has announced it is closing its Belleville, Ont., facility and transitioning its operations to other sites to further streamline operations and capitalize on production efficiencies.

“After an extensive review of site capabilities, we have identified this operational closure and transition as an opportunity to further optimize our network,” said Charlie Bowman, HEXO’s acting COO. “Our decision is designed to leverage other sites with available infrastructure and capabilities to improve production outputs while significantly reducing costs across our entire network. This is a critical next step for HEXO as we continue to make strides towards becoming cash flow positive from operations.”

As part of the transition, all machinery and equipment currently located at HEXO’s Belleville facility will be transferred to other sites. Approximately 230 employees will be impacted by this announcement.

Kelowna, B.C.-based cannabis products manufacturer Valens Company Inc. has announced that its wholly-owned subsidiary Green Roads Inc. has entered into an agreement with Signifi Solutions Inc. to place cloud-managed smart kiosks in various major mall locations in the U.S. Initial locations are in New York, Florida, Arizona, Texas, and Colorado. The agreement includes the potential for an additional 60 mall locations in 2022. The first kiosk is expected to go live in June and will include a full assortment of Green Roads products.

“This partnership gives access to some of the largest mall locations in the U.S., thereby increasing overall brand awareness and opening a new revenue opportunity,” said Tyler Robson, Valens CEO and chair, in a written statement.

Webinars in The Cannabis Council of Canada's Shaping our Future – C45 Review Webinar Series. Watch them at growopportunity.ca

In a move that expands its store footprint in Northern Alberta, cannabis retailer High Tide Inc. has acquired Boreal Cannabis Co. for $2.2 million plus the wholesale value of inventory and cash on hand when the transaction finishes.

Under the terms of the deal, the Calgary-based High Tide will acquire two locations in Alberta: one location at Slave Lake and another one in St. Paul. The Slave Lake store was the first one to open in the municipality.

For the three months ended Jan. 31, 2022, High Tide said the two Boreal shops generated annualized

Leafreport.com has released a study reporting that 60 per cent of tested CBD, or cannabidiol, products currently marketed for sleep contained the wrong amounts of CBD, CBN, and/or melatonin.

Capsules performed the best out of any product category, with 50 per cent matching the label, followed by 40 per cent of gummies, and 30 per cent of tinctures.

revenue of $3.9 million and annualized adjusted earnings before interest, taxes, depreciation, and amortization of $600,000.

“This announcement is yet another example of how we continue to strategically advance our retail store footprint across Canada through organic growth and accretive acquisitions with a focus on regions where we are currently lighter on exposure, such as northern Alberta which has a dynamic economy that supports working families, a key consumer demographic for Canna Cabana,” said, Raj Grover, High tide CEO, in a written statement.

Cannabis technology developer and retail platform Fire & Flower Holdings Corp. has announced that its wholly-owned subsidiary Open Fields Distribution has entered into a one-year cannabis distribution agreement with Manitoba Liquor & Lotteries (MBLL).

Under the agreement, Open Fields will offer distribution of recreational cannabis products from licensed producers to retailers in the province of Manitoba at the direction of the MBLL. The move extends the existing Open Fields business, which offers wholesale and distribution services in Saskatch-

ewan, into a second province. “Open Fields was selected as part of a competitive RFP process to provide cross docking services in the province of Manitoba and we are delighted that MBLL has trusted our business to provide these services,” said Trevor Fencott, Fire & Flower CEO, in a press release. “Open Fields and Pineapple Express Delivery have significant experience in servicing retail customers in the provinces of Saskatchewan and Ontario and extending these services into an additional province creates scale and efficiency for the wholesale business segment.”

Find the latest grower-related news, stories, blogs and analysis from across Canada, and access to our forums . . . growopportunity.ca

Dr. Mohyuddin Mirza and Gagandeep Singh Bhatoa

Mohyuddin Mirza, PhD, is an industry consultant in Edmonton, Alta. He can be reached at drmirzaconsultants@gmail.com.

Gagandeep Singh Bhatoa is a scientific writer in Regina, Sask. He can be reached at gaganagrico@gmail.com.

When it comes to lighting, growers should understand that installing LED or other lights in a greenhouse is just the starting point.

The distribution of light above and within the plant canopy is important. Top installed light mostly provides adequate light within the upper one meter of the plant; it may be even less if the plant is more vegetative.

Recently, we took some measurements and found that 400 micromoles/m2/second at the top leaves and at the bottom the light varied from 200 to 100 micromoles, with lower leaves starting to turn yellow. As such, best practice is to place either side lights as shown in the picture below. Because many growers perform very drastic defoliation, which is not good practice, we believe that leaves should be removed only when they show the symptoms of lack of light or air movement needs to be improved in the canopy. The lack of light symptoms will show as loss of green colour and a yellowish colour may develop.

Daily Light Integral (DLI) is a measure of usable light plants receive over a day. It is measured in mol/m2/day. This measurement will be incomplete without the consideration photosynthetic photon flux density (PPFD) and its unit micromole (μmol). PPFD refers to the light intensity your plants receive or the amount of light photons that hit a surface (i.e., your plant canopy) in one second. It is measured in micromoles/sq. meter /second. Since PPFD numbers represent photons measured per second, in the course of one day you can end up with millions of micromoles. PPFD values will increase with decrease in distance from your LED grow light.

“The guiding rule is that keeping track of DLI is important and growers need to follow their own experiences, while sometime running the risk of light saturation.”

In general, DLI describes the number of photosynthetically active photons (individual particles of light in the 400-700 nm range) that are delivered to a specific area (1m2) over a 24-hour period. One micromole of light equals more than 62 quadrillion photons. It is calculated based on light intensity in micromoles/m2/ second multiplied by total number of hours the light is “ON” in indoor situations or in greenhouses natural light is available. In case you are wondering how many micromoles are in sunlight at noon, the estimates are around 2,000 micromoles/ m2/s and the moles for a 12-hour period will be 86.4. In Northern latitudes the sunlight in summer could be up to 18 hours and thus DLI would be 129.6 if we calculate based on noon time micromoles. This is an example of DLI in action. Actual values during the day will be less because of the

angle of the sun’s and diffusion through greenhouse glazing materials.

For optimal yield, cannabis plants need a minimum of 20 moles of light per day. However, growers aim for 40 moles, or 40,000,000 umol per day, to maximize their yield. Thus, the monitoring of DLI is imperative throughout the different stages of the cannabis life cycle. During the seedling stage, growers must ensure that the cannabis plants receive DLI of 13-19 mole each day at the range of 200-300 micromoles/m2/day for 18 hours. At this range, there’s a chance of better yields when your plant reaches the vegetation stage.

During the vegetative phase, growers need to provide 300 umol per second on cannabis canopy for 18 hours to achieve 20 moles of light per day, as recommended ranges from seedling to veg to bud do vary. During the cannabis flowering phase, growers need to deliver 462 umol per second for 12 hours straight in order to achieve 20 moles of light per day. If growers want to increase the amount of light from 20 to 40 moles per day, resulting in higher yields, they must double the numbers above 300 PPFD or umol per second to 600, during the vegetative phase, and 462 PPFD to 924 PPFD during the flowering phase.

The guiding rule is that keeping track of DLI is important and growers need to follow their own experiences, while sometime running the risk of light saturation. We have seen recommendations of using 1,000 micromoles with a DLI of 43.2 moles, which is in the high range, thus potentially leading to damage to the crop. It is important to understand that the desired DLI can be achieved by varying the light intensity and the duration of light.

Light is energy and is converted to heat. This applies to sunlight and the supplemental

Thermo Fisher Scientific does not support, encourage, or promote the use of its products or services in connection with any illegal use, cultivation, or trade of cannabis or cannabis products. Thermo Fisher Scientific products are intended to be used only in compliance with all applicable laws in a manner that promotes public safety and/or in connection with any lawful and approved scientific or medical research activities. This information is presented as an example of the capabilities of Thermo Fisher Scientific products.

lights as well, both High Pressure Sodium (HPS) and LED. When energy inputs in a greenhouse are examined, the following facts are worth noting:

• When sunlight falls on a greenhouse surface, 19 per cent is reflected back into the atmosphere, 12 per cent is absorbed by the glazing material and about 69 per cent is transmitted inside the greenhouse. The numbers may

vary based on the type of greenhouse glazing material and its colour.

• Inside the greenhouse, 14 per cent is reflected, 17 per cent given off as heat and 38 per cent is directly used for evapo-transpiration by the plants.

• Looking at the above numbers it means that during the day time in a greenhouse, heat gain could be higher than the heat loss and thus ventilation

• Proprietary design reduces algae and humidity inside grow rooms

• Power HP mix has great drainage and highest oxygen levels for roots

• pH buffered using patented organic process

• UV and Light blocking plastic stops algae and bacterial growth

• Lot numbers for traceability

• OMRI certified for organic growing

• Pre-cut Drainage slits

is required and at night time supplemental heat is required.

The table (left) provides a comparison of heat contribution from sunlight at four locations in Alberta. This illustrates that sunlight is a major factor in heating greenhouse spaces and could play a very significant role in achieving zero carbon foot print.

Most indoor cannabis facilities use HPS and/or LED lights for production. Growers should be aware of how much heat is produced by the lights being used, so the cooling system can be planned accordingly.

So, what does all of this mean for growers? Ultimately, they should understand the rules and regulations of light supplied to a cannabis plant from the beginning of the crop to the end. If every leaf can receive the same amount of light then yields are sure to be increased.

Easy to use • Consistent clean quality input

Traceability of all products • Growing support provided

CANNA is an established and serious partner for the Green Market. We provide solutions to growers of all sizes, including Canadian Licensed Producers.

CANNA nutrients, additives and growing mediums are manufactured from the highest quality source materials. We understand the importance of a clean, consistent and traceable input as well as keeping it simple.

CANNA loves to share its knowledge and experience, our team is there to support you.

By David Brown

Earlier this year, Health Canada announced it will begin issuing cannabis sales licences to all licensed processors. These changes signal a small, but not insignificant maturation of the industry, as well as creating more options for cultivators looking to enter the market, especially as some provinces are starting to allow processors to ship directly to retailers rather than through provincial warehouses.

Also this year, Health Canada announced a change in federal cannabis regulations, including licensed processors no longer needing to apply for a sales licence. Instead, these sales licences — required for sale into provincial and territorial markets — will be automatically issued upon receipt of a processing licence. As such, starting April 19, Health Canada began issuing all existing processors a sales licence, including for dried/fresh cannabis, cannabis extracts, edibles, and topicals.

In reality, the change isn’t that dramatic for most processors because applying for such a licence generally took a few months, and once a licence was issued, there was still a requirement for a 60-day waiting period following new product notification. This process is not part of the recent aforementioned changes. However, the change does free up time for licence holders already dealing with a significant amount of regulatory burden from all levels of government, not to mention provides some potential opportunities to streamline the market for cultivators and processors.

For cultivators, this change means they could see an increase in the number of potential processing partners they can choose from when finding a sales path.

On April 18, one day before the change came into effect, there were 266 processors, out of 496, with at least one form of

a sales licence. As this number increases, there should be well over 500 processors, all with sales licences, over the next few weeks. Not all processors will be looking to take on cultivation partnerships, but any increase in those who are looking to take that on can mean more options and leverage than a few years ago when there were only a handful of these processors with a sales licence to choose from.

And for those cultivators looking to also secure a processing licence to take part in any provincial farmgate programs, the automatic sales licence will mean that process will become much easier.

For processors, these changes mean having more time and resources to focus on the myriad of other regulatory burdens, along with every other aspect of their day-to-day activities. For many, simply securing the processing licence and starting commercial operations was enough of a challenge without then having to spend several months applying and waiting for a sales licence.

It also means that, as provinces begin allowing a more direct sales and/or farmgate model, more of these licence holders will be one step closer to being able to take advantage of those sales channels. Provinces such as Ontario, New Brunswick, and Prince Edward Island are currently allowing these farmgate sales, while British Columbia has similar plans later this year.

With Health Canada now automatically

awarding sales licences along with any processing licence, it further proves that the government is comfortable with the industry’s ability to manage such issues, rather than needing to gate-keep the process on a case-by-case basis.

Furthermore, it highlights a trajectory where, over time, a very strictly regulated industry can begin to become more streamlined. By taking on the task of being the first major nation to fully legalize and regulate cannabis, Canada took a very cautious approach — borrowing hard-learned lessons not only from places like Uruguay and various U.S. states in how they have managed cannabis, but also from the history of trying to reign in traditionally under-regulated vices, like alcohol or tobacco.

But this highly regulated approach doesn’t have to be, nor was it intended to be, always extant in its initial approach. It’s reasonable to expect that as the industry matures and there’s a less hovering political concern to ensure nothing goes sideways from a public health and safety perspective, governments will choose to create more regulatory efficiencies.

There is also the flipside to all of this: What this doesn’t mean for the industry. Well, this change doesn’t mean all these processors will now automatically be able to sell into the market. They will still need to be approved for sale in the different provinces and territories. Most of these jurisdictions also require each individual product to be approved for sale as well.

It also doesn’t mean every processor will want to deal directly with provinces. There are some processors with various sales licences who will still choose to partner with others and allow them to manage that aspect of sales. This is likely to continue. But as the industry continues to mature, these kinds of changes can make the industry somewhat more competitive and sustainable, and provide some hope for a highly regulated industry that there is at least slightly less red tape on the horizon.

bioavailable Si (like all other MSA products)

40% strength (like no other MSA products)

40% strength, pH neutral MSA is coming to Canada. Deliver more Si, with lower heavy metals, for much less* with GG.

Contact BioFloral or Quality Wholesale now for info and earlybird discounts on wholesale pre-order and commercial sizes.

*Than any commercially available silicon source including all leading brands. CDFA Reg:2022737A.

By Matt Maurer Legal Matters

Last summer, the Alcohol and Gaming Commission of Ontario (AGCO) launched a consultation with industry stakeholders regarding the existing Registrar’s Standards for Cannabis Retail Stores (i.e., Registrar’s Standards), and in particular standards that related to promotions and inducements.

In February, the AGCO released information on new rules that would come into effect as a result of the consultation. Many of the new rules were welcomed by those in the cannabis industry as they helped to clarify what were previously ambiguous rules, such as what constitutes a “material inducement.” However, when the new rules were announced, which are slated to come into effect on June 30, 2022, many noticed one prohibition in particular that seemed to be at odds with the AGCO’s objective of preventing federal license holders from improperly meddling in the affairs of retail stores.

The new rules provided that, generally speaking, retailers could not enter into agreements with licensed producers for items, benefits, payments or services, unless a specific exemption to the blanket prohibition so permitted. The guidance document went on to specifically list in-house brands or white label products as examples of prohibited activities. While the guidance document stated that retailers may con-

tinue to sell white label products that had already been produced, it also stated that retailers were expected to exit any current agreements and not enter into any new agreements with licensed producers once the updated Registrar’s Standards came into effect on June 30.

Many retail stores and chains have entered into contractual agreements with licensed producers for the manufacture and sale of products that are specifically branded for the retail stores. Many in the industry did not view these relationships as a vehicle by which licensed producers could inappropriately impact activities at the retail level. On the contrary, in my experience these types of relationships were sought out by the retailers themselves as a means to further differentiate themselves from their competitors and to build brand loyalty and awareness. Prohibiting a relationship that was sought out by retailers, primarily for the retailers’ benefit, did not seem to make logical sense. On top of this, the prohibition only applied to relationships with “licensed producer(s) or their representatives.” This meant

that store-branded accessories (e.g., manufactured by companies who do not hold a federal cannabis license), would be entirely permissible, but store-branded cannabis products would not be.

The response from stakeholders was swift and significant. Many contacted the AGCO to inquire as to why white-labelling arrangements were being prohibited and what objective the prohibition was meant to achieve. In a show of responsiveness not normally seen from cannabis regulators, the AGCO advised that it would look into the issue further and consider the feedback that was being received.

Less than two months after announcing the changes to the Registrar’s Standards that would come into effect on June 30, the AGCO backtracked on the white-labelling prohibition and announced that retailers would be permitted to enter into agreements with federal license holders for store brand or white label cannabis products.

The reversal is significant both from a regulatory and a business perspective. On the regulatory side, this marks one

of a few occasions where a Canadian cannabis regulator (federal, provincial or territorial) has backtracked on a potential rule change after receiving feedback from stakeholders. Such a reversal demonstrates the power of the industry’s voice when the industry is able to band together and mobilize collectively. Historic efforts at regulatory change generally arise in a fractured and disorganized fashion. While not every change that the industry hopes to achieve will necessarily come to fruition, the reversal on white labelling demonstrates that change is in fact possible and can be influenced.

On the business side, the reversal is obviously a boon to licence holders as it (re)opens a revenue stream that was about to be permanently closed. Shortly after the announcement of this reversal, the requests to begin (or resume) preparing commercial manufacturing agreements flooded our office (and certainly the offices of other cannabis lawyers across the country). Additionally, re-instating this type of product line gives retailers the ability to distinguish themselves from competitors in an industry that requires uniform packaging and an obligation for all retailers to choose from the same pool of products via the mandatory provincial wholesaler (e.g., the Ontario Cannabis Store).

All of this is a win for license holders, a win for retailers, a win for consumers, and a win for relationship building between the regulator and the industry.

From industry leader General Hydroponics ® comes a three-part, water-soluble fertilizer system specifically designed to feed high-value production plants. All three formulas are now available in cost-efficient 5 lb. and 25 lb. sizes. Look for updated packaging on the entire easy-to-use FloraPro line, along with new corresponding feed charts in additional languages.

By Joshua Reynolds

At the beginning of the 1948 California Gold Rush, the Unites States had no standard national banking regulations, let alone a national currency. Instead, regulations fell to individual states. In California’s case, state and corporate banks were prohibited under national constitutional law to finance gold. With no official means to exchange gold for tradable goods or currencies, prospectors turned to private individuals for their financing needs.

Since 2018, the Canadian cannabis industry has been going through its own “green rush.” With changing legislation, wider markets and the opened floodgates of Cannabis 2.0, everyone wants a slice — and they’re finding their angle in, no matter how financially risky cannabis remains. However, more access to the market, especially the ease of access, hasn’t necessarily caught up to legislation that makes it of equal ease to advance and grow capital. All of this makes one wonder if anyone really fully understood the duality behind declaring cannabis a “green rush” when the term was minted.

So, how can a licensed producer operate within this structure (i.e., a highly regulated cannabis market) and till enssure that growth is still viable?

While not a fix-all solution, effective accounts receivable (A/R) management can be the difference between success and death in this industry. Controlling and mitigating credit risk, to no surprise, is salient in such a high credit risk environment. Optimizing A/R processes within a company can effectively minimize the time it takes to get paid for invoices. Yet, incurring debt has been the go-to standard for producers selling the finished product to the provincial boards for distribution to retail. Payment delays are not a bug in the system; they’re a feature, required to mitigate risk up the producer-to-govern-

“Effective accounts receivable management can be the difference between success and death in this industry.”

ment-to-retail chain. Extending credit is a must to keep the chain afloat.

Forced to abide by this structure, LPs often see large reductions in cash, which, in turn, compounds and increases receivables down the chain. For larger companies, a sizeable index of receivables isn’t usually detrimental — due to their high liquidity—but the “cannabiz” is a different beast. It's estimated that in the two years following legalization, only one-fifth of cannabis production made it to shelves, amounting to more than $11 billion in cumulative losses. One publicly traded cannabis stock has “credit losses” amounting to 45 per cent of the outstanding A/R, aged 365 days before reflecting the “adjustment” in their current financials. Indeed, even giants of the industry can be a credit risk.

A/R monitoring is an effective tool for analyzing behavioural changes to assess whether buyers may become a credit risk. Here’s a case study: let’s say a micro-cultivator has noticed that its distributor, a larger LP, has dialed back on the volume of purchases of their product, or that the orders are smaller. These two clues may point towards issues with the distributor’s

cash flow, rather than a decline in interest or movement of the cultivator’s products. If this happens to be true, it doesn’t mean the distributor will go under, but that they could file for temporary protection from creditors, pushing payments for invoices even further down the line.

In this situation, anticipation is key, and high risk must be met with proactive responses and solutions. Measuring the performance of one’s current business affairs by targeting specific A/R KPIs, such as Days Sales Outstanding (DSO), Collection Effectiveness Index (CEI), and Average Days Delinquent (ADD), is necessary to properly assess risks, highlight fluctuations, and plan for due payments. Without effective A/R monitoring practices in place, these potential credit risks could go unnoticed, spelling destruction to no fault of the LP.

As much as a producer may implement effective A/R strategies, small to midsized companies are left to take the biggest hit with surmounting receivables. This forces the smaller players to weigh which expenses to pay in a cash crunch. Without the proper cash flow, any profits incurred on an invoice may have to go directly to paying off those late expenses (and the debt accrued) instead of reinvesting them. Seeking bank financing can be a tough sell, as many are averse to the industry’s high risk. Even if one were to secure this type of financing, banks require the receivables to be put up as collateral for a loan. Why take on more risk?

With banks almost entirely removed from the equation, LPs can look to an A/R financing service, referred to as factoring, for some help. Companies that specialize in this ulterior financing buy receivables at a discounted rate to deal directly with a company’s debtors. Seriously, it’s that simple. With more cash flow in hand, LPs can then focus on what’s most important: the growth of their business and taking advantage of the green rush that is still charging ahead.

Alexandre

By Paul Grossinger

Grow Opportunity: How and when did you begin your career in the cannabis industry?

Alexandre Gauthier: I've been in the cannabis industry for about 16 years now. In the early days, I focused a lot of my time on the medical use of cannabis. I knew a lot of badly injured workers, mostly from the construction industry, that required cannabis as a treatment, so I helped them get their licence and showed them how to grow their own cannabis.

My passion for this industry comes from trying to truly help people be more knowledgeable about cannabis. I've always been a big supporter of cannabis because it is a natural product and natural plant.

GO: Why so much passion for cannabis?

AG: In 2017, I entered the fully regulated side of cannabis, and the passion just exploded. We were the first country in the world to be in a position to help others move the entire industry forward, so it

was exciting to be part of this new adventure. Passion was a defining factor for the Canadian pioneers of the industry. A story I am fond of telling is that a lot of us, when we finally got the call that we were hired by a licensed producer, started crying and had to call our loved ones to share the news. We were so proud that we could finally help people with cannabis and be part of educating the world on this plant. I really want to try to help the industry evolve as I see the potential in the plant for both medical and recreational needs.

GO: Tell us about your time and current role at Origine Nature.

AG: I started with Origine Nature in March 2020. We’re lucky to have a true family and a team of passionate people. I was the master grower at Origine Nature, but now I am the director of cultivation, so I'm heavily involved in our entire operation. In this role, I conduct research and development, oversee the entire cultivation pro-

cess, from seed to sell, and the post-harvest processing. My role also includes growing a healthy industry, and not just an industry that is simply based on profit. Driving our business is our four core values: passion, family, social conscience, and street smarts. Everything we do revolves around these values. All business decisions and all R&D projects focus on moving our business and the cannabis industry itself forward.

Editor’s Note: Origine Nature was founded in 2017 and is located in Sainte-Agathe-desMonts, Que., in the heart of the Laurentians. The company is one of the founding members of the Association québécoise de l’Industrie du cannabis. Origine Nature was granted a standard cultivation license in March 2020 and a standard processing license in July 2020. The LPs first product was sold at the SQDC in October 2020.

GO: How has growing cannabis changed over the past several years?

AG: When legalization began, there was a

false idea that growing cannabis was very easy, and that people were just going to throw their money at license producers without regards of what is in the jar — as long as it had THC. There was a lack of understanding of the pre-established cannabis culture, and I would say for a product that was considered illegal, it had the strongest culture in the world. A lot of producers started as fast as possible without having a true regard for the quality of cannabis they were producing, so the first years were hard. Also, the black market was very well established, and the fact of the matter is that there are some excellent growers in the legacy market.

Now we're seeing a true shift from the black market to the legal market. Also, in the first year of legalization, the industry wasn’t really working properly because we didn’t understand what the true demand of cannabis was. There was no historical data on what cannabis consumers truly wanted. But over the years, we have evolved, and as recent as 2020, we truly saw good quality cannabis come to market at a scale that was unprecedented.

GO: Looking back, what are your thoughts on how legalization was handled in the early months and years?

AG: A lot of people were complaining about regulation and how it was established, but we need to understand that we were the first country to truly do this. Canada was the first one, so all eyes of the world were on us. When you are doing something like that, of course you need to start with harsher regulations to ensure that everybody is safe and that the industry is controlled in some way. Once we are more established, then we can relax our laws and move forward. I think we did it the right way and that the Canadian government did an amazing job. We need to crawl before

we can walk and run, and it was wise to take that time to do things properly. Today, we are really at that threshold where there's amazing quality cannabis in all the provinces at very good prices. To quote my good friend Jose Dominguez from Neptune, “There is no bad cannabis, only badly priced cannabis.”

GO: How important is it for growers to understand the entire LP operation, and not just the cultivation aspect of it?

AG: When you are simply growing, there are a lot of operational, market trends and industry issues that you might not understand. A lot of master growers are very well versed in cannabis, but they don't understand that when they're creating a product, they're not making it or marketing it for themselves. They're making it for whoever's buying it, which is not them, so being able to trace the entire chain, and fully understand the entire production and business is important. Knowing about the technology used, what goes into the costs of operation, how one action can produce something and how another action can cost too much are all vital to growers. In the end, there are certain ways of growing depending on what price segment you are growing for.

GO: What factors should LPs keep in mind before thinking of taking a product to market?

AG: When you are growing inside, you need to understand climatiza-

tion, humidification and dehumidification systems, air movement, lighting, energy management and how plants react to all of this. Every single parameter is critical. Every time there is something out of whack, whether it's pH, nutrients or climate, there is going to be an effect on the crop down the road. When it comes to growing, there is a lot of precision needed. There is also a real need to quantify and collect data to truly know what's going on with the cannabis plant itself. A lot of us basically did our education on our own, in a different context, but when producing on mass for the legal markets, there are so many variables to consider we’re growing cannabis.

GO: If we separate the markets now, recreational vs. medicinal, what is the difference from a cultivation perspective?

“When it comes to growing, there is a lot of precision needed... and the need to quantify and collect data to truly know what's going on with the cannabis plant.” - Alexandre Gauthier

AG: To understand the difference you actually need to talk about marketing and sales. When growing for recreational markets, we are thinking of an entire country, but when you are growing for the medicinal markets, clients have their own prescriptions, so you have to grow to their personal and unique needs. On the recreational side of things, you can just mass produce one strain and release that strain in stores, while for medicinal, you need to have multiple strain offerings and multiple product offerings to be sure that you can meet the demands of your client base. For medicinal grows, the production layout is different too as you are going to want more small flower rooms rather than big flower rooms. You're not going to want to do rooms that produce 200 kilos of the same strain; you're probably going to want rooms that create 30 to 40 kilos of the same strain, but with multiple rooms.

GO: How important is teamwork within a cannabis LP?

AG: It's absolutely everything. First off, when talking about master growers, your success is your team; you are only as good as your team, so having good unity is important. Passion is just as important. When you have the right team of people with true passion, you can overcome anything. At Origine Nature I'm part of the leadership team. They included me in this circle because they saw

the value of having me in it. One of the assets I bring to this team is my understanding of the entire chain within the cannabis market. There are no silos within our company. We have excellent communication, so when we do product launches or market studies, everyone shares their knowledge and we take everybody’s expertise into mind. The key is not focusing on one thing and being an expert on one thing; it's being able to draw expertise from multiple people and make connections to be able to create something even bigger, and that's what we do at Origine Nature.

GO: What skills and knowledge does a master grower need to possess to be successful?

AG: You need a deep understanding of all the different factors that can impact cannabis. Whether it's lighting, climate variations, or humidity, just to name a few, you need to start collecting data. What takes master growers to another level is being able to make sound decisions based on data, and based on your experience as a grower. Definitely having your own growing experiencing is a good first step, but then it's about letting passion drive what you do. You need to find the right fit at the company you are working for, including finding a company that fits your values. You also need to understand that there are a lot of regulations involved within Canada’s cannabis market, plus you have to be patient in that most master growers normally start off in entry level positions. In the end, it takes dedication, it takes passion and it takes knowledge. I would advise people to read true agricultural books that are done by scientists in order to truly master the craft. You need to start understanding the full chain of production of cannabis, and that every action a grower takes resonates throughout the entire company and all of its departments.

GO: Looking ahead, what is the short-term future of Canada’s cannabis industry?

AG: We're so early in the industry that at his point, I just want people to produce good cannabis for a good price. There is a need to stabilize our offerings and stabilize the level of quality per price segment before we can then move on to a more refined product where consumers can truly learn and respect what growers, including craft growers, are doing right now. I feel there is a lack of respect for craft growers today, but there's also no platform for them to tell their story and justify why, let's say, their product has a higher price point than another one. The consumer is pretty much just left with two products in front of him/her with two different price points without really truly understanding what goes behind one or the other.

When it comes to recruiting and retaining talent in today’s highly competitive cannabis industry, companies need to be organized, polished and efficient — not to mention willing and able to showcase its values on a daily basis.

By Treena Hein

At Tantalus Labs, in Maple Ridge, B.C., staff retention rates are a key metric used to measure success. It is why the cannabis company’s CEO, Dan Sutton, believes it stands above the crowd when it comes to recruiting talent in all of its areas of operation.

For Sutton, staff retention rates at Tantalus stand up very well against those of any young company in the world: “I’ve heard of companies our size, about 70 employees, hiring every week, week in, week out. That is definitely not the case for us.”

Before exploring specifics at Tantalus, it is important to dive into some broad observations of recruitment and retention in the Canadian cannabis industry. A few months ago, Mitchell Osak, CEO at Quanta Consulting, asked in a social media post: “Is there a war for talent in cannabis?”

He explained that he’d been hearing for quite some time about a ‘talent shortage’ from some of his clients, and observed that “clearly many companies have an issue finding and keeping the right people.” He added, “However, what I come to understand when I drill down is something quite different: This is not a war, but rather a self-inflicted wound.”

Today, Osak’s perceptions on the cannabis market’s labour situation are unchanged. For him, the talent sector gap is greatest at the managerial/executive level across all kinds of cannabis firms.

“This gap traces to the lack of an industry playbook and data, a limited pool of experienced managers, the ongoing stigma in the eyes of some workers, and the impression that cannabis is the ‘Wild West,’” explains the Toronto-based cannabis consultant. “Moreover, success in cannabis requires people to have strong soft skills and traits, such as an ability to learn quickly, cope in uncertain or dynamic situations and be entrepreneurial and change-ready.”

The ‘self-inflicted wound’ that Osak refers to is the poor recruiting practices at many cannabis companies. He notes that many operations have “no strategy or skills around recruiting” and seem oblivi-

ous to the need to be professional in this area. The fact that savvy candidates gauge potential employers by their recruiting processes (among other factors) is being completely ignored.

Instead, most industry recruitment effort in Osak’s view “has focused on quickly putting people in seats during rapid organizational scale-up and dealing with the high levels of industry turnover, where people leave for other cannabis jobs or exit the industry.”

Michaela Freedman, owner of Toronto-based MF Cannabis Consulting, believes hiring or onboarding the right applicant can also be hindered by a lack of communication and cohesion between departments at today’s cannabis firms.

“There are often situations where the head of sales describes a role, then the CEO

describes a completely different interpretation of it,” she explains. “This is not helpful for anyone. If there is a real need for new talent, it’s necessary to develop a clear job description and expectations with proper training and integration protocols.”

Freedman also mentions that more di-

“As our employees get more skilled, we aim for them to achieve three things: more autonomy, a strong sense of purpose and mastery. In terms of purpose, as they learn, they get increasingly excited about the goal of pushing the limits of cannabis quality, maximizing sustainability and so

on,” explains Sutton. “With mastery, we want them to be masters of Integrated Pest Management, of cultivation or whatever other area, and we make it happen. During earlier periods of training, sometimes we may move employees laterally to make a better fit or move them up. About

responsibilities. There’s a three-month period wherein new employees and Tantalus managers assess if it’s a good mutual fit, and coaching is provided from the start from the company’s multi-disciplinary leaders. After the probationary period, a thorough training program starts.

Contact AgSafe for online and on-site injury management resources to build a program that works for your workplace.

Preventing

Encouraging Worker Health & Wellbeing

90 per cent of our managers came through our training.”

“We’ve also had several people leave,” he adds, “to run their own facilities or run facilities in other parts of the world, having learned our processes. We make this very strong training investment in our employees, knowing that after a year or two or more years of training, they could leave. We’ve had a few affable departures where we’ve been really proud to see them go on to big things. But we believe you have to invest in people and take that risk.”

Beyond this strong willingness to invest in employees and see them succeed, there’s also a workplace ‘culture’ at Tantalus that makes people want to stay. However, Sutton defines the term perhaps differently than it is defined elsewhere.

“The word culture is thrown around a lot, whether you can bring your dog to work or

if there’s a place to do yoga, but for us, culture is about creating a fun and supportive place to work where you’re surrounded by passionate, intelligent and driven people,” he says. “You want to be one of them. There’s a drive here to make the cannabis better, to see our customers more excited, to achieve. Some of that is simply our people and some of it is because as an organization, we came from a place where we didn’t know if we were going to make it.”

Also, from the early days of operation, there’s been a genuine sense of deep familial caring at Tantalus. “We care about each other’s wellbeing,” says Sutton. “It just happened, but again, it’s because of our people. We pick up slack for each other when needed, we carpool or shovel each other’s driveways, we help when someone

gagement, of wanting to work as a team to achieve lofty goals, and people really respond to that. They want to stay. I hope we see more engagement and deeper reten -

IIVO provides crop-specific smart technology for growers. A combination of smart software and state-of-the-art hardware. This truly unique system is capable of monitoring, controlling, and maintaining any type of growing environment.

Allowing you to grow more, at higher quality while using minimal resources.

Whether you have experience in growing Cannabis or not. With self-learning controls and integrated security, you are ready for the future.

Location has also been a factor. Before

“This gap traces to the lack of an industry playbook and data, a limited pool of experienced managers, and the impression that cannabis is the ‘Wild West,’” says Mitchell Osak, Quanta Consulting

Tantalus was founded, Sutton and the rest of the leadership team deliberately situated it in a area that already had a large and suitable workforce. Specifically, this is in the lower mainland in B.C. (i.e., Fraser Valley), where there’s a large amount of people with greenhouse and cannabis experience here.

“We usually have 10 to 15 qualified candidates for every cultivation position when we do need to post a position,” says Sutton.

At Tantalus, cultivation employees are paid above the living wage for Maple Ridge. Sutton explains that “there are online living hourly wage calculators for B.C. and we are about 20 per cent higher. We also have benefits and other enhancements. If you have employees who aren’t able to afford to live a good life, who are worried or thinking about needing to get a second job, you aren’t going to retain them.”

Osak agrees that higher compensation would help recruit people in the cannabis sector, but solid company organization, as he’s described, is also a must. “The days of people joining the cannabis sector for the easy stock gains and big party are long gone,” he says. “It’s a tough industry now. Cannabis firms need to start resembling all of the other boring yet successful industries out there. The industry is getting there, but it’s a journey.”

Looking ahead, Osak expects job requirements across the Canadian cannabis industry to become more sophisticated and narrowly-defined as they are in other sectors, and that cannabis experience will become a standard requirement.

“I envision increased role specialization where employees focus on one specific business area such as retail or cultivation, and a function like sales or product management,” asserts Osak. “Employers are less willing to hire outside of these lanes, but given the nature of the industry, there should still be an emphasis on hiring people with soft skills. I would add to these skills, management ability, as many cannabis firms are on the path to maturity. When this happens, they will need to professionalize and focus more on people as opposed to growing product.”

By working with applied researchers at Canadian colleges, LPs can gain the competitive edge when developing new cannabis-based food and beverage products.

By Andrew Kaszowski

The growth of the cannabis 2.0 food and beverage market in Canada is marked with tremendous innovation to meet customer demand for new products.

Meeting the ongoing need to develop novel formulations through extraction requires research and development (R&D) support, which is often a costly undertaking for many small- to medium-sized licensed producers. Fortunately, there are several Canadian colleges with applied cannabis research licenses that offer a competitive advantage as they possess R&D expertise and funding capabilities that can help remove the barriers to growth.

Based in London, Ont., Fanshawe College’s Centre for Research and Innovation (CRI) aims to accelerate new product development, encourage knowledge sharing and technology transfer in the food processing sector and promote the develop -

ment of a network within the industry. The centre specializes in the development and enhancement of new and existing products through an in-house food innovation laboratory backed by a team of expert researchers. Further, CRI offers access to funding for eligible projects of up to $100,000 per year.

“Conducting innovation projects for R&D is a very expensive undertaking for many growing companies,” says Colin Yates, PhD, chair of research at research at CRI. “Most colleges are able to offer generous government funding that we already have available to eligible projects, which can de-risk the process of product development by partnering together to validate and develop exciting innovations. A college’s measure of success is helping the Canadian economy prosper, and we do that through innovative R&D.”

Each institution in Canada with a cannabis research licence tends to focus on

specific areas of R&D. For example, Fanshawe’s CRI has carved a niche in applied R&D for the processing industry by focusing on ultra-high purification and formulation of trace cannabinoids with potencies exceeding 99 per cent. CRI specializes in advanced chromatography and high shear micronization technologies for products in food, beverage, nutraceutical and pharmaceutical. The centre’s capabilities are mainly focused on processing: extraction, purification, analysis and processing, such as homogenization, spray-drying and encapsulation, are a few of the core competencies available.

“More industry awareness is needed about the intellectual resources available to conceptualize, execute, conclude and deliver on projects by Canada’s applied research institutions at colleges,” says CRI’s lead cannabis researcher and faculty member Sahar Samimi, PhD. “With expertise among college faculty, external researchers with

real hands-on industrial and global experience working in industry and an intellectual property-friendly approach to working with businesses, CRI has a winning combination to bring the ideas to fruition.”

The strength of college-assisted R&D is evident when looking at two recent industry projects that partnered with CRI. The first product was for Toronto-based Johnny Gold, which developed a novel CBD-coated coffee bean.

“I love good coffee and I was curious about combining CBD with coffee beans,” says John Filice, Johnny Gold’s founder. “When I learned that Fanshawe had a cannabis research licence I thought of reaching out to explore product development, and I’m happy to say we have produced something special. My hope is to commercialize it soon.”

Filice says that working with a college helped bridge the gap in scientific knowledge needed to make something truly innovative. “There’s an extraordinarily important scientific piece that went into my coffee-based product from the outset. I needed to find scientists who could help me develop this into something real, and the team at CRI worked with me hand-inhand all along the way with my vision. The experience of working with a research

team at a college made this all possible.”

The second project that the CRI team collaborated on was met with similar success. Nan Li is Founder of Lupos (Canada) Biotechnology Inc., Canada’s largest whitelabel standard processor of cannabis topicals. Lupos worked with CRI on advanced purification research during the past year.

“Working with a college research team was very beneficial from a time and cost perspective,” Li says. “CRI has incredible capabilities in the labs and with the scientists’ knowledge to develop our technologies further. Colleges build strong relationships with industry partners through the scientists and project managers who keep things on track.

“As a business, while we have these capabilities in-house,” Li adds, “we also collaborate with partners to accelerate technology advancement in a competitive environment - so having these resources available to us through the college was a huge help. Accessing the support helped us fast-track things, and the project managers really kept the project on track.”

By Tom Ulanowski

In March 2022, Health Canada announced several proposed changes to Canada’s Cannabis Act and Regulations.

Several of these changes, including modifying the dried cannabis equivalency for beverages, streamlining some aspects of non-therapeutic research on cannabis, and improvements to the analytical testing program were issues that the C-45 Quality Association Board of directors have raised and brought to the attention of Health Canada on behalf of our members.

While these proposed amendments represent only a small portion of the necessary regulatory improvements that our Association has been advocating for, these changes nonetheless represent a positive step forward for the industry and a willingness by the regulator to listen to stakeholders.

However, there are many other regulatory issues our membership continues to raise. Among those are concerns with how analytical testing is conducted,

simplifying or streamlining monthly reporting requirements, providing clarity and creating permanent flexibilities around packaging date requirements and authorizations for qualified staff, and moving to more of a risk-based model of control for cannabis products.

There has been ongoing concern expressed by our membership about the trend of “lab shopping” by some licence holders in seeking out testing labs that will provide more favourable results, especially when it comes to high THC levels. More oversight of licensed analytical testing laboratories—and sampling procedures by licence holders — is needed to ensure that sample preparation, reference

standards and analytical methodologies are appropriately validated for consistency between labs. For dried cannabis, moisture content analysis should be performed alongside cannabinoid testing to eliminate the potential for potency inflation from over-drying samples (since potency must be reported on an “as-is” moisture basis).

In addition, the C-45 Quality Association feels that inspections of analytical labs should be carried out by Health Canada officers who have the education, technical knowledge, and experience with the methods, reference materials used in validation and analytical instru

mentation they would be inspecting. Statistical analysis of cannabinoid potency results issued by testing labs is another very powerful tool that could be employed by the regulator to identify

anomalies and potential inter-lab bias.

We also believe that the requirement for pesticide testing should be eliminated for cannabis that is processed (i.e., extracted) for research and development purposes. Pesticide screening is expensive, and non-commercial products do not pose a risk to public health, as they are not intended for consumption.

The C-45 Quality Association would also like to see Health Canada move to riskbased controls for cannabis products rather than treating all products the same way. For example, a package of dried cannabis containing predominantly THCA (the non-intoxicating form of THC) requires the same child-resistant packaging as a cannabis extract or edible, which mostly contains THC. Packaging requirements for products should be proportional to risk.

In addition, we continue to urge Health Canada to consider dosage increases for edibles beyond the current 10 mg THC limit, or at least allow for more than 10 mg THC per package (while maintaining 10 mg maximum per unit).

Another regulatory improvement that we continue to advocate for is reforming the existing Notice of New Cannabis Products (NNCP) process. Currently, licence holders must provide detailed information on every new cannabis product SKU at least 60 days prior to selling the product. A new NNCP submission is required even if the name or net weight of a product is slightly modified after initial submission.

We believe that the NNCP process can be significantly improved by eliminating the requirement to submit a notice for standard product formats (dried cannabis or inhalable cannabis-only extracts) or product-line extensions for previously submitted products.

Currently, there is no guidance for “packaged on” dates (a required piece of information on every cannabis product), which is contributing to inconsistent

practices across the industry.

Some licence holders define it as the filling date, while others utilise the date when the final packaging is completed. Provincial wholesalers and consumers make purchasing decisions based on their own interpretation of the packaging date.

We believe that clarity to this labelling requirement is necessary. Further, our Association welcomes the recent extension to COVID-related packaging date flexibilities, and supports making those changes permanent.

Monthly cannabis reporting requirements are another area that can represent a significant regulatory burden for many in the industry, and one that our Association feels can be more reasonably streamlined while still ensuring the necessary information is provided to the regulator in a timely manner.

A few examples members have raised are the time-consuming inventory-type tracking within a facility, such as counting vegetative and flowering plants on a monthly basis. This is a very low-risk issue in terms of security compared to finished cannabis products, and has the opportunity to free up resources for licence holders.

The compliance requirements of onsite Security Clearance Holders (SCH) need provisions for operational redundancies and enabling supervised duties for remote working. The current responsibilities of an SCH can be incredibly onerous and time-consuming. Allowing QAPs, for example, to delegate some responsibility to qualified colleagues would mitigate burnout that many SCHs and Key Persons currently experience.

While the industry still has a way to go in terms of working as an efficiently regulated program, the C-45 Quality Association is pleased to see that Health Canada is listening to the concerns of industry, and is open to providing solutions based on stakeholder feedback.

Tom Ulanowski is the chair of the C-45 Quality Association (c45association.com).

By George Smitherman

Reactions to the recent federal budget (unveiled April 9, 2022) drew me back to the time when I participated in politics at a high level. Back then, I used to bristle when stakeholders would pass off what I thought were extraordinary efforts as a “good first step.”

Time will tell whether this year’s budget announcements—the co-packing and contract manufacturing changes to the Excise Tax Framework Act and the establishment of the Cannabis Industry Strategy Table — will amount to a “good first

step” or something more. What is certain is that these budget references, building on recent regulatory amendments fixing the cannabis beverage equivalency formula, have left some with a rare sense of optimism that there is an awakening at the Government of Canada about the challenges facing cannabis licence holders and the success of cannabis legalization.

To the outside observer it is odd to hear that the Government of Canada has projected an unsympathetic point of view to the nascent sector, with cannabis stigma well entrenched across government. I must confess I did some second guessing about being too positive. I know that for

many in our sector the times are so tough it’s hard to see incremental progress as a step at all. We cannot afford to lose sight of the fact that the licensed cannabis sector is facing huge risk of a contraction, job losses, facility closures and the resulting heart wrenching human toll on the combined contributions of workers, communities and investors.

The signs of struggle are everywhere, including at Health Canada where overdue regulatory fees from license holders increased tenfold year over year. Let’s face it, it can’t be an easy decision to leave fees you owe to your regulator unpaid. This is the urgency that drives our agenda.

It’s well known that the Legislative or Statutory Review of the Cannabis Act is to be initiated three years after the coming into force of the Act (October, 18, 2018), and that the review is six months overdue. Much has been written and said by those expecting the Legislative Review to be limited in scope or to directly echo the views put forward by Health Canada officials relying on a few specifically referenced items from section 151.1 (1) of the Cannabis Act. I’ve never accepted the idea that there can be a narrow or scoped review. I do not subscribe to a narrow interpretation of the Legislative Review language. Most of all, the urgency of the situation facing the sector dictates that we use any and all means before us to demand and to affect necessary change.

In partnership with Grow Opportunity, The Cannabis Council of Canada recently presented “Shaping our Future – The C45 Review Webinar Series,” in the hope of building momentum towards framing the “5 Big Asks” that our sector will be bringing to the attention of government decisionmakers in Ottawa during C3’s Grass on the Hill industry leadership conference and lobby day, set for May 30 and 31, 2022.

Grass on the Hill is based on the idea that regulated sectors need to invest time and energy in building relationships with elected MPs and other key influencers in Ottawa. The conference program is thought provoking and action inspiring. We hope to energize an informed community of cannabis sector advocates motivated to meet with their represent-

atives in Parliament.

Everybody has their idea of the changes needed if our sector is going to live up to its full potential, fulfill the public health and safety objectives of the Cannabis Act, and contribute to the broader social goals of cannabis legalization. The one thing everyone can agree upon is that achieving these goals and objectives is impossible without a viable legal cannabis sector. Here are our 5 Big Asks:

1. Financial viability. Whether one looks at the combined impact of taxes, fees, distributor mark ups and an unwieldy Excise stamp regime or focuses on an Excise Tax rate that is about three times greater than planned, all paths point to an urgent need for changes that would support the financial viability of licence holders.

2. Patient access to medical cannabis authorized by health care practitioners has lost focus since the legalization of adult-use recreational cannabis. Patient centered approaches to medical cannabis, like pharmacy prescribing, a medical cannabis specific research framework and, ending the injustice of taxing medical cannabis, will improve patient access. Patient access also means public funding for cannabis medicine as part of the recently announced Pharmacare expansion.

3. The illicit market continues to enjoy undue advantages in a variety of areas, and we need to see action that levels the playing field for licence holders. The public health and safety objectives of the Cannabis Act will never be

accomplished until all levels of government focus on eliminating the ongoing prominence of the illicit cannabis industry. This includes ensuring that Health Canada’s ACMP personal grow regulatory model functions as intended and that the illicit cannabis industry’s abuses of this system are ended.

4. The precautionary approach that governed the development of cannabis’ legal and regulatory framework has created an excessive regulatory burden for licence holders; C3 calls this burden the Red Tape or Nanny State. It is worth recalling that the precautionary approach “captures the idea that regulatory intervention may still be legitimate, even if the supporting evidence is incomplete or speculative and the economic costs of regulation are high," With three and half years of evidence

under the Cannabis Act and its regulations, the time has come to review the rules and resulting costs that distort the marketplace and make it impossible to achieve Canada’s public health and safety goals. One notable example of this regulatory distortion is the 10 milligrams of THC limit per package of cannabis edibles, which has the effect of conceding a significant market share ($200+ million) to the illicit market.

5. The inability of license holders to communicate with cannabis consumers in age-gated environments is a lost opportunity for a public health harm reduction approach to legal cannabis. The current Canadian cannabis consumer landscape has an undue reliance upon dry flower and pre rolls and a dramatic preference for exceedingly high THC products. This is a consequence of the inability of li-

cence holders to inform consumers about the products they are consuming. The lack of licence holder communication on product attributes and effect is short-changing the consumer and diminishing public health outcomes. One need only purchase cannabis from a legal dispensary in Ontario and listen to budtenders provide advice about effect and onset to consumers to appreciate the failures of the Cannabis Act’s prohibitions on promotion.

Success in bringing these “5 Big Asks” forward depends upon C3’s seeking alignment with our allies in the cannabis sector. Ultimately, we believe that building more relationships with sector partners is the path to growing and strengthening our community. We hope you join us on this journey.

The TriPlane luminaire LED horticultural lighting system by P.L. Light Systems offers controlled distribution, optimized efficiencies, thermal management, a light output of 2100 μmol/s and an efficacy of 3.2 μmol/J. The TriPlane’s LED modules can be adjusted independently in either direction, allowing for highly customed light distribution, depending on the application. Delivering optimum colour efficiencies, the TriPlane is available in two spectral recipes, which can be used in stand-alone LED applications, or in combination with HID luminaires for hybrid applications. www.pllight.com

The SPYDR 2h fixture by Fluence produces a photosynthetic photon flux (PPF) of 2,100 μmol/s, a 24 per cent increase over previous fixtures. Designed for indoor, multi-tier commercial cannabis cultivation environments, the fixture offers high-intensity lighting, precise uniformity, increased efficiencies and features Fluence’s PhysioSpec BROAD R4 indoor white spectrum with efficacy of 2.6 μmol/J at 277V AC. https://fluence.science/

Health Canada Lot Release Testing

Plant Sex ID Assay / Density

Quality Production Experts

Oils / Terpenes

Microbiological Environmental Testing

Plant / Soil / Media

Disease Diagnostics

Water / Tissue / Soil

Residual Solvents

Edibles / Beverages / Topicals

Biologicals

Quality Production Experts

Seed-to-Sale Software

What’s Wrong with My Marijuana Plant? is the first problem-solving book for marijuana growers with an effective and easy-to-use visual diagnostic system pioneered by Deardorff and Wadsworth for identifying pest, disease, and environmental problems by symptom. This book contains all-organic solutions plus best growing practices to avoid problems before they start. Written in easily understandable, non-technical language and heavily illustrated with precise photography to allow rapid and accurate diagnosis, this is an essential resource for beginning and experienced growers alike.

Since 2018, when the Government of Canada legalized cannabis from coast to coast, licensed producers have had to constantly navigate changing regulations, volatile markets and surges of mergers and acquisitions within the sector.

To learn more about the industry’s current and ongoing challenges, Grow Opportunity recently sat down with David Hyde, CEO of Hyde Advisory & Investments, a cannabis-focused business brokerage and strategic advisory firm. He is also co-founder of CannaNavigators, a global cannabis licensing, compliance and regulatory consultancy servicing cannabis companies, new market entrants, foreign/ local governments, cannabis startups and investment groups, with experience in 19 countries.

Grow Opportunity: Please tell us how you started in the industry, and how your position evolved to where you are today.

David Hyde: It’s been a really eclectic kind of journey. I didn't expect to be in the cannabis industry at all. I spent 20 years working for a very large corporation, ending up as a global director of security and risk management. So, a very business kind of background.

While I was security consulting, I was also doing a TV hit for CBC — I did quite a lot in the old days of national security, terrorism related news, news stories. The CEO, at the time, of Bedrocan, which was one of the first Canadian LPs, and a well-known global LP, saw me on the news and rang me up after and said, “Hey, I saw you talking about security. We need some security

specialists for this new cannabis regulated industry that's coming around. We want to be one of the first out of the gate, and we’d love to have you on board.” So, we met for a coffee, and he introduced me to cannabis, the science of cannabis and what’s behind it, including the medicinal qualities. From that point, I started to learn and read up on it. I jumped in with both feet.

GO: What are the biggest changes, both positive and negative, in the Canadian cannabis industry since its legalization?

DH: For me, the big changes that I’ve seen is of course medical cannabis regulation that came into place with the MMPR and then ACMPR. I really feel that the medicinal side of the industry has been left behind with recreational use coming out in October 2018. One of the things that I think can be improved is the focus on medical cannabis in this country. The education of doctors and patients is important for some medical patients don’t want to speak to a budtender. With all due respect, there are some great budtenders out there, but they're not medicinal professionals. We need a much better system where patients can get really good support, education, and be motivated to get medical cannabis through their insurance packages, and not taxed as well. Another change is in product development, which has evolved with competition. We’ve definitely seen some companies make bad decisions, like perhaps borrow too much money, or not have sound business fundamentals, and today they’re paying a price. We've also seen a lot of consolidation in the