Since 2012, we’ve partnered with world-class companies and groundbreaking research institutions to pursue our mission of improving the interaction between light and life. Along the way we’ve gathered indispensable data, made industryaltering discoveries, and gained a wealth of knowledge that’s just too valuable not to share.

Learn more from the leaders in cannabis lighting technology. Visit www.fluence.science/case-studies

Copyright 2021. Fluence Bioengineering,

SNOOK

By Mari-Len De Guzman

Many in the cannabis industry are awaiting the much-anticipated review of the Cannabis Act this fall, with a general sense of optimism about the changes it could potentially bring to the current industry landscape.

October 2021 will mark the beginning of the Cannabis Act review process and various industry sectors are already identifying aspects of the law that need changes or improvement. Understandably, different sectors and interest groups within the industry will have their own versions of what they would like to see in the review and the subsequent legislative amendements.

The past couple of years since adult-use recreational cannabis was legalized in Canada, the industry has gone through some major transformation that’s not without significant growing pains – mass layoffs, facility closures, and a series of lower than expected revenue reports for many LPs. But with growing pains come the “growing up” part, and that is always a positive outcome for both the industry and the market it serves.

Although still a relatively young industry, the cannabis sector is certainly maturing. Licensed producers are right-sizing their organization and implementing strat-

egies to efficiently streamline operations while optimizing profitability.

The review of the Cannabis Act could not have come at the right time. Much needed changes to the regulations will further strengthen the regulatory framework while allowing for an effective and reasonable oversight of the industry.

As the different sectors and interest groups start to flex some lobby muscles, it might be prudent to explore oppor-

Organizing into a single, united entity with buy-in from a good representation of the industry will be the ideal way to move forward.

tunities for collaboration and show somewhat of a united front. When an industry speaks in one strong voice, it’s easier to be heard.

Speaking as a united industry would allow for a cohesive expression of the most pressing regulatory issues that need to be addressed in the legislative review. From marketing and packaging to medical cannabis and taxation, the most important issues can be amplified before the federal regulators when presented in one voice.

But achieving a united front requires a lot of ground work for all concerned and

making sure all sectors within the industry and their respective concerns are considered. Licensed producers’ representation, for example, should not only reflect the big producers but also the smaller LPs – especially now when microcultivators and craft producers are emerging as a significant player in the cannabis market.

Full representation of the cannabis industry needs participation from a bigger chunk of the community and not just a handful of the major players. Organizing into a single, united entity with buyin from a good representation of the industry – macro and microcultivators, retailers, suppliers, etc. – will be the ideal way to move forward.

The start of the review in the fall is just the beginning of a long process that will likely take more than a year to complete. There’s plenty of time before then for the industry to come together in a genuine effort to instigate regulatory changes that can have a meaningful impact on the industry.

Part of the growing up process is learning to play well together. The cannabis industry is a highly competitive marketplace, but if the players work together to help create an even playing field, then the resulting successes – and failures – will be ultimately in the hands of those who come out to play.

May/June 2021

Vol. 5, No. 3 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Shawn Arul, Audience Development Manager

Tel: (416) 510-5181

Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Mari-Len De Guzman

mdeguzman@annexbusinessmedia.com

289-259-1408

ASSOCIATE EDITOR Jean Ko Din jkodin@annexbusinessmedia.com 437-990-1107

PUBLISHER Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR

Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175

MEDIA DESIGNER

Emily Sun

GROUP PUBLISHER/VP SALES

Martin McAnulty mmcanulty@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec):

1 year offers: Canada $25.50 + Tax USA $47.00 CDN FGN $53.50 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE

privacy@annexbusinessmedia.com Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Organigram Holdings Inc. announced that CEO Greg Engel has stepped down from his role in early May.

Engel will remain as a special advisor to the company’s board of directors through a transition period while current board chairman, Peter Amirault, serves as executive chair on an interim basis.

The board’s governance and nominating committee chair, Geoff Machum will serve as independent lead director.

“Greg has helped guide the company during a global pandemic and through period of significant change within our sector, one in which he is a recognized leader. We are pleased that he will continue to serve as special advisor to the board through this period of transition,” said Machum in a company statement.

“We are equally pleased that Peter Amirault will be leading Organigram as executive chair, while we begin a search process for a permanent CEO.”

The Ontario Cannabis Store (OCS) has introduced a new craft cannabis category on its website.

First announced during OCS Trade Day (Dec. 3), the Crown retailer now features hand-processed, small-batch flower products with a new digital badge. The badge appears on bulk craft, craft dried flower and craft pre-roll products.

The website defines craft cannabis as dried flower that’s been hang-dried, hand-trimmed, hand packaged and grown in a facility that produces less than 10,000 kilograms per year.

StratCann reports that OCS is looking to launch a new outdoor category later in the year.

Argentia Gold Corp. celebrated its grand opening on April 20.

Canopy Growth Corp. continues its recent acquisition spree with a $435-million deal to buy the Supreme Cannabis Company. The acquisition will see Supreme Cannabis’s 7Acres, Sugarleaf and Hi-way brands join Canopy’s roster, that already includes Tweed, Tokyo Smoke, Quatreau and Doja.

- THE CANADIAN PRESS

Located on a former WWII U.S. naval base in Argentia, N.L., the local cannabis producer pledges to put local consumers first, committing that online orders will be delivered to customers within a matter of days. The company’s range of cannabis products first launched on the CannabisNL

website in the beginning of April.

“As a local producer, our commitment is to the loyal consumers of this province,” said CEO Steve McNeill. “As we expand into packaged goods, we will introduce exciting new edibles, beverages and topicals to the Newfoundland and Labrador market before the rest of Canada.”

Cannabis Training Canada Inc. (CTC), an e-learning provider for cannabis retailers, announced a partnership with the Nova Scotia Liquor Corporation (NSLC) to provide an in-depth product knowledge education program to NSLC cannabis staff.

The company claims the Advanced Product Knowledge Program to be “the most comprehensive cannabis retail training program of its kind in Canada.” It will be used as “next level education” for employees who have completed NSLC’s Retail Certification Program and is primarily focused on Cannabis 2.0 and 3.0 products. The course is taken online and divided into eight modules, each with specific learning objectives and topics.

“As new products continue to hit the market and other scientific breakthroughs push the cannabis industry forward, these types of elevated education programs will become more important for retail staff,” said Zane Yassein, CTC co-founder.

The NSLC Retail Certification Program was custom-made by CTC and covers the basics of cannabis, cannabis-derived products, and responsible cannabis distribution. The Advanced Product Knowledge Program is meant to build on that foundation and teach staff to confidently discuss new and emerging product formats, how exactly they are manufactured, and the Canadian cannabis industry as a whole.

WeedMD Inc. has announced that Beth Carreon will be joining the company’s executive team as chief financial officer, effective May 3.

Carreon previously served as vice-president of finance at Tilray Canada, where she managed the company’s global treasury, shared services and financial planning teams, as well as mergers and acquisitions activities. Before Tilray, she worked for more than 12 years at Nestle Canada Inc. in a variety of finance leadership roles.

Carreon succeeded Lincold Greenridge, who stepped down from his position on April 30.

Tilray Inc. and Aphria Inc. say their merger deal has now closed after receiving approval from shareholders.

Tilray shareholders voted April 30 in favour of issuing stock to Aphria’s shareholders, but the Nanaimo, B.C.-based company has yet to reveal how many supported the proposal.

About 99 per cent of Aphria shareholders voted in favour of the deal in April.

The two cannabis companies announced in December they will merge under the Tilray name with Aphria CEO Irwin Simon at the helm and Tilray CEO Brendan Kennedy joining the board.

The new company is expected to have a pro forma revenue of $874 million and will control more than 17 per cent of the retail cannabis market –the largest share held by any Canadian licensed producer.

While Tilray shareholders supported the Aphria deal, they voted against increasing the company’s authorized capital stock from more than 743 million shares to 900 million shares.

- THE CANADIAN PRESS

First Nations communities in Saskatchewan say they are having to find their “own grey areas” when navigating the province’s gap-filled cannabis law.

In running four cannabis shops on their reserve lands southeast of the province, they are foregoing the provincially mandated permitting process. And the feds keep leaving the ball in the province’s court, saying it’s up to Saskatchewan to regulate, while seemingly not touching the on-reserve cannabis shop issues.

Yet the issue is black and white for two chiefs who spoke about their communities’ recently opened stores: As signatories to Treaty 4, Pheasant Rump Nakota Nation and Zagime (Sakimay) Anishinabeck have the sovereign right to do as they wish with business on their own lands.

Pheasant Rump Chief Ira McArthur views the provincial government as a “partner” and a “neighbour,” but says its authority has a clear endpoint.

He and Zagime Chief Lynn Acoose agree that Ottawa and the province are leaving the issue in a kind of political no-man’s land,

each government referencing the other when it comes to dealing with First Nations’ jurisdictional sovereignty.

Along with Pheasant Rump and Zagime, Muscowpetung Saulteaux Nation and Peepeekisis Cree Nation have opened cannabis shops on their lands. They remain, for now, the only bands to do so.

All of them are operating without a permit from the Saskatchewan Liquor and Gaming Authority (SLGA), which the province mandated when it created its Cannabis Control Act in 2018.

Former justice minister Don Morgan previously told the Regina Leader-Post that Ottawa ought to “control” Indigenous-run cannabis shops or send in the RCMP “to deal with it.”

Ministry spokesman Noel Busse said in an email the province’s position is “the federal Cannabis Act and the provincial Cannabis Control (Saskatchewan) Act apply across Saskatchewan.”

The two chiefs are now drafting documents and provisions for a safety standards association.

— EVAN RADFORD, REGINA LEADERPOST (LOCAL JOURNALISM INITIATIVE)

Easy to use • Consistent clean quality input

Traceability of all products • Growing support provided

CANNA is an established and serious partner for the Green Market. We provide solutions to growers of all sizes, including Canadian Licensed Producers. CANNA nutrients, additives and growing mediums are manufactured from the high quality source materials. We understand the importance of a clean, consistent and traceable input as well as keeping it simple.

CANNA loves to share its knowledge and experience, our team is there to support you.

By Jean Ko Din

The medical cannabis system is in need of an overhaul and Trina Fraser believes the industry needs to take the lead in bringing this change.

As the Cannabis Act undergoes its three-year legislation review this October, Fraser says the industry cannot leave behind the issues that most affect medical cannabis patients in the country.

Fraser was the keynote speaker at this year’s Virtual Grower Day on April 14. She shared her knowledge as cannabis lawyer and partner at Brazeau Seller Law, and board member of Medical Cannabis Canada to break down the history of challenges of the medical cannabis sector.

“We still have a whole lot of issues to deal with as medical patients,” she said. “We need to make sure that through this upcoming review of the legislation that the medical framework is not only protected but enhanced.”

Just before recreational legalization, Fraser said Canada showed a 350 per cent increase in patient registrations between 2016 and 2018. From 2018 to 2020, statistics show a mere nine per cent increase of new registrations.

“The way I look at this is that we still have too many barriers for medical patients, such that it is pushing the patients out of the medical framework into the recreational framework where they are self-medicating… because it’s just easier,” she said.

Diving further into Health Canada statistics, Fraser found significant slow downs in processing applications for personal production and designated grower licensing. Before the COVID-19 pandemic, more than 90 per cent of applications were being processed monthly. After April 2020, registration

numbers have plummeted anywhere from 10 to 12 per cent every month.

Excise duties on all products with more than 0.3 per cent THC will be a major point of advocacy for Medical Cannabis Canada during the Cannabis Act review, said Fraser. Duties compounded on a patient’s medical products is another barrier that is pushing patients to the recreational market, and perhaps even the illicit market.

“The rationale given at the time was they didn’t want to create incentives for people to fake their way into the medical framework, which is ridiculous because trust me, there’s enough hurdles already,” she said.

George Smitherman, president of Cannabis Council of Canada (C3), will also be participating in

the upcoming legislative reviews for the Cannabis Act. However, he hints that discussions at the review might not bring about the swift change the industry craves.

“I think some people believe the statutory review is going to fall this October and we’re off to the races. The thing about it is, that’s the beginning,” he explained during his on-demand presentation. “It could be two or three years before these amendments could possibly be voted on in the House of Commons and voted on by the Senate.”

Smitherman said C3’s priorities for the year are currently around building its member caucuses that address a number of regulatory topics, such as distributor taskforce with provinces, beverages caucus, its newest sustainability caucus, and a proposed caucus for the medical sector.

“I spent most of my life in politics and I have 10 pieces of legislation under my wing,” he said. “I think that for us, as an industry, it’s really going to behoove us to find the means of getting our challenges addressed that are most effective.”

Growing is no longer about relying on the grower’s intuition and “flying by the seat of your pants,” said CCI-Deloitte senior lead cultivation manager, Jayson Goodale.

Goodale offered his expertise in horticulture and commercial cannabis production during Virtual Grower Day on April 14. With so many automated environmental controls in a commercial facility, he honed in on some key performance indicators (KPIs) that growers need to make informed decisions about their standard operating procedures.

Selecting the proper genetics optimized to your particular growing method is the first step, said Goodale. He recommended monitoring the crop’s yield per square foot or square metre alongside its kilograms of Grade A vs. Grades B & C product per harvest.

Light intensity and environment controls can also be complex. “You can’t just increase your light and expect to get higher yields,” Goodale explained. “When you’re assessing your lighting program, your historical environment and your lighting environment play a very important role together.”

He said pay close attention to Day Light Integral (DLI) and Vapor pressure deficit (Vpd) as key factors in assessing your program.

In his presentation at Virtual Grower Day, Chef Don Gingrich offered some baking lessons with a special ingredient. Here’s the executive chef’s cannabis-infused cheesecake recipe.

• 1 1/2 cups graham cracker crumbs

• 1/2 cup melted, unsalted butter

• 1/2 cup sugar

• 1 and 1/3 tsp. infused cannabis oil/ butter (35 mg of THC/ml)

• 1 pkg. (250g) cream cheese at room temperature

• 2 eggs

• 2 tbsp. whipping cream

• 1 tsp. lemon zest

• 1 tsp. vanilla extract

• 1 tbsp. flour

Goodale warned attendees about getting complacent with routine sampling and testing programs, which will help determine the efficacy of your nutrient program and and integrated pest management program.

Suzanne Wainwright-Evans offered her own expertise as a horticultural entomologist. In her presentation, she shared economical and ecological best practices in maintaining a facility that is free of pests and diseases.

“There are many different challenges that depend on your growing method. This makes it hard to have one pest management answer to fit all,” she said.

Wainwright-Evans said identification is the most critical step in crafting a pest management program. Maintaining a regular schedule of scouting through plants and looking for small signs of common pests will be a grower’s best prevention strategy.

1. Pre-heat oven to 325 F. Line muffin tin with cupcake liners. Makes 12 cheesecakes each with 20 mg of THC.

2. Combine graham crumbs, butter,1/4 cup of sugar and cannabis oil in bowl. Press into bottom of cupcake liners. Bake on middle rack of oven for 10 minutes or until golden brown in colour.

3. In another bowl, mix cream cheese and the remaining 1/4 cup of sugar until creamy. Beat in eggs one at a time. Scrape down sides of bowl before mixing lemon zest, vanilla, whipping cream and flour.

4. Pull muffin tin out of oven, let cool slightly before carefully pouring the filling into the molds.

5. Bake on the middle rack for for 325 F for 15 minutes, then reduce heat to 300 F to cook for another 10 minutes. Turn off oven and allow cakes to rest in oven for two hours.

6. Cool to room temperature before refrigerating for another hour. Serve with fresh berries.

Watch Chef Don Gingrich’s cooking video, plus all sessions from Virtual Grower Day at: https://pheedloop.com/GrowerDay/ virtual/

By Gagandeep Singh Bhatoa and Mohyuddin Mirza

Gagandeep Singh Bhatoa is a plant health care specialist in Lethbridge, Alta. Email him at gaganagrico@gmail.com.

Mohyuddin Mirza, PhD, is an industry consultant in Edmonton, Alta. He can be reached at drmirzaconsultants@gmail.com.

When there are 16 essential nutrients cannabis needs to grow and prosper, it becomes a complex task to understand and interpret each nutrient and determine deficiencies or toxicity. Then, there is the task of how to adjust the nutrients to make corrections. Different analytical labs provide their own sufficiency ranges and present data in good, readable and visual formats where comparisons can easily be made. Most of the growers test their nutrients in the fertilizer solution when they see a symptom or many symptoms on their plants.

Whether you’re a grower, processor or retailer, it’s important to know the full nutritional profile of your products. Cannabis nutrient testing provides an accurate profile of your growing media, source waters and plant materials. Growers should submit multiple leaf samples to the lab over the course of a plant’s growth cycle in order to gauge its overall nutrient composition. This helps identify growth deficiencies before they become serious and irreversibly affect plant health. It is desirable to take weekly samples and thus, build a database for your facility.

Having an understanding of the plant’s essential nutrients is the starting point to interpret the results from the lab. Besides carbon, hydrogen and oxygen, which cannabis plants need during the food manufacturing process of photosynthesis, we need to supply essential minerals. The macro elements are nitrogen, phosphorus, potassium, calcium, magnesium and sulphur.

These are needed relatively in larger amounts, like above 50 mg/l, hence the term “macro” elements. Cannabis plants also need micro elements like iron, manganese, copper, zinc, boron and molyb -

Cannabis leaf tissue testing is the most common method for determining nutritional breakdown, known as foliar analysis.

denum in quantities ranging from 0.10 mg/l to about 3.0 mg/l. Gain knowledge of the role of each element and remember that any one of them can become the limiting factor in reducing the growth and thus affecting plant’s performance and energy balance.

Nitrogen, phosphorus, potassium, magnesium and sulfur are highly mobile elements. It means that these are stored in cell sap and can be moved by the plant if the upper leaves and shoots need it. As a result of this mobility, deficiency symptoms occur in the lower leaves.

On the other hand there are immobile elements which include calcium, boron, iron, manganese, copper and zinc. Thus, the deficiency symptoms first appear at the top of the cannabis plants. Some nutrients are more or less independent from each other and increase or decrease in the leaf tissue as the quantity is raised or lowered. Other nutrients operate in relation to each other and might not increase in the leaf tissue as the quantity is raised in the recipe.

Also, the pH of the root zone has a sig-

nificant effect on uptake patterns; most micronutrients are more available at lower pH and macronutrients are more available at higher pH.

Cannabis leaf tissue testing is the most common method for determining nutritional breakdown, also known as foliar analysis, and is a useful tool for managing the nutritional content. To test the nutrient content in cannabis, take samples from recently mature leaves, not the very young nor the older leaves (generally the fourth or fiftth leaf from the top of the plant). About 12 leaves may be required because labs dry them to determine the moisture content. Ask for total nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, sodium, iron, manganese, iron, copper, zinc, boron and molybdenum. These may be offered as a package. Silicon should also be included. We have seen aluminum is included by many labs as part of the package. If one takes older mature leaves, then calcium may appear to be very high.

It is recommended to send samples of your nutrient solutions when you are sending leaf samples to confirm a diagnosis of a deficiency or toxicity. Ask the lab for Nitrate nitrogen and ammoniacal nitrogen, phosphorus, potassium, calcium, magnesium, sodium, sulfur, iron, manganese, copper, zinc, boron and molybdenum. In addition, ask for chloride and silicon and bicarbon-

ates. Most labs offer standard packages for cannabis which may not include silicon and bicarbonates.

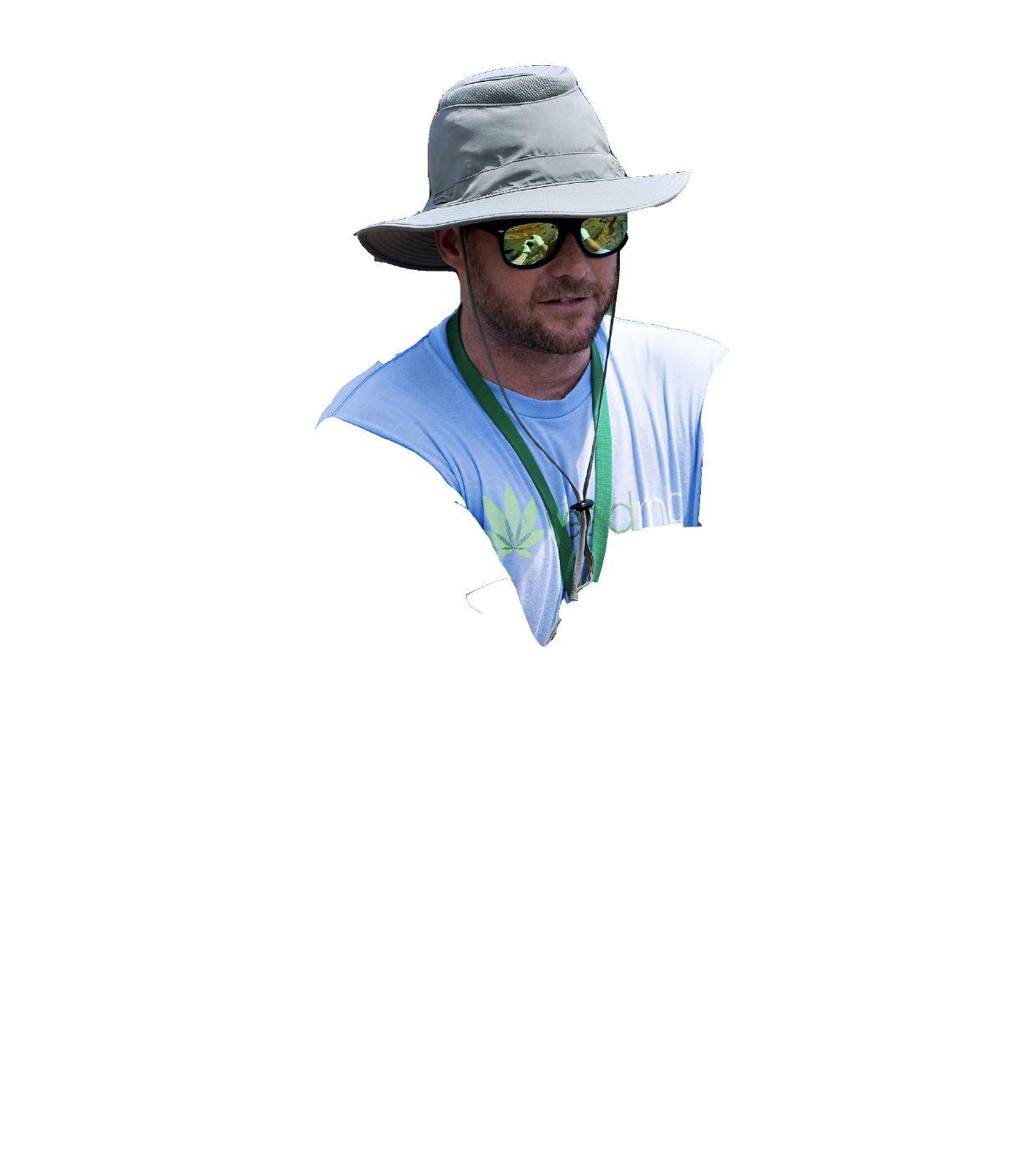

Analyzing lab reports

Tables 1 and 2 show cannabis leaf tissue lab test results showing the quantity of each nutrient present in the leaves. This indicates how your nutrient recipe should be adjusted. It is obvious that potassium in the cannabis leaves is above the sufficiency range, while iron is very high. Manganese is low. One can ask how these sufficiency ranges were established. It appears that the analytical labs have some information from literature and their own database and have come up with comparative data.

In Table 3, when we look at the two nutrient samples analysed, one can see the reason for a spike in iron contents. The level of iron is adequate in both samples but with the pH values of 5.2 and 5.4, iron uptake is several times higher than at pH values of between 5.8 and 6.2. A toxicity is possible and symptoms would appear as brown, necrotic spots on the edges and spread over the leaves as well. So pH correction is the first measure. Manganese is low and that is the reason as to lower tissue levels. High potassium is of no concern. Potential toxicity due to potassium is very rare. Cannabis is a high potassium user and it can be stored in cell sap. Molybdenum was not tested in the tissue samples and the levels in the feed solution are on the lower side.

Bicarbonates are on the low side. They are not a nutrient for cannabis but they are important to in providing pH buffering to the solution. The pH likely dropped that low because of lower levels of bicarbonates. A suggested level is to maintain between 50 to 60 mg/l in the solution. Another important point is that interpretation of results should be done based on the health of the plants as well.

Don’t be afraid to ask for help in interpreting the results. It is a complex process and all aspects should be examined to take corrective measures.

By David Brown

Outdoor production for a micro cultivator can be one of the most affordable ways to enter the cannabis industry but can also present some of the greatest challenges, when it comes to bringing products to the market.

The lack of an indoor growing facility can mean saving hundreds of thousands or even millions of dollars in construction costs. And relying on the sun for light, instead of powering a facility with lights and extensive heating and cooling systems means a much lower carbon footprint.

Some micro cultivators have been able to secure their licence for less than $20,000, assuming previous availability of land. An indoor micro facility, on the other hand, can often cost upwards of a million dollars.

However, these advantages also come with some serious downsides that any applicant should consider.

Cannabis can be a finicky plant. Sure, it’s “just a weed” and can grow in some incredible circumstances. But if you’re growing a crop for commercial production, you need a certain degree of reliability and replicability, not to mention the need to produce something that can pass all the required federal testing.

Incremental weather, a hail storm at the wrong time, an early frost or an especially wet spell right before harvest can wreak havoc on your cannabis flowers. A modest greenhouse

setup can offer some protection from some of these issues, but it can add to the cost of your facility, and can also present new problems to be addressed, like proper air circulation.

The market is flooded with large amounts of dried cannabis, especially from some of the large-scale producers. Even if your outdoor crop is unique, convincing buyers and ultimately, consumers of this will be a challenge and requires a considerable amount of pre-planning. Get a good understanding of current and future market factors before diving in.

Finding the right cultivator that can produce a high-quality product in Canada and will have buyers in the provincial market can be a challenge. Currently, many provinces still balk at cannabis much under 20 per cent THC, for example, and many outdoor crops in Canada are currently finding that their harvests are falling short of this threshold. This can mean either not finding a buyer at all, or being forced to take a much lower price than the grower may have planned on, sometimes well under $1 a gram wholesale.

Taking the time to find the right cultivar or variety that works for your specific location can be a matter of trial and error over several years. Planning for that beforehand can prepare you for some of those realities.

Despite some interest in a more environmentally friendly cannabis product, many consumers in Canada, right or wrong, have a perception of outdoor as being of a lower quality and potency than indoor. Even if you are knocking out some amazing outdoor product that is well over the

Where your outdoor farm is located and the choices you have in site selection can be a real factor in the success of your crop.

20 per cent THC threshold, and have passed all your relevant microbial testing, etc, you may still find yourself dealing with consumer (and therefore provincial buyer) biases that believe it’s inferior to indoor. This can arguably be combatted through some savvy marketing, but this requires a lot of pre-planning and coordination with retailers as well as some luck.

This can partly tie into the issues with weather, but where your outdoor farm is located and the choices you have in site selection can be a real factor in the success of your crop. Whereas indoor production will allow total control over the amount of light your plants receive, the amount of sunlight your outdoor plants receive can be limited by numerous environmental features. If a grower is growing in a location they are used to, they may have taken these issues

into consideration, but a new farmer in a new location may be surprised to discover some of these nuances in the first few years that can have a big impact on crop quality and yield.

Another issue can be the type of soil on your site, depending on your growing method. While most growers would recommend growing in raised beds or even pots, some may choose to grow directly in the ground. Taking the time to get all the necessary soil testing done beforehand can save you a lot of heartache later on. If your land isn’t well-drained, for example, or has pesticides in it from previous crops that could contaminate your cannabis.

None of this is to necessarily discourage anyone from getting an outdoor cultivation licence, micro or otherwise. The fact that costs for an outdoor producer are so low can more than make up for many of these shortcomings, especially if these are factors considered as part of a plan and mitigated against. As many growers are discovering, the legal cannabis industry is not just as simple as growing a crop, sticking it in a bag and selling it. Understanding the challenges of the market, both in terms of the layers of provincial and federal regulations, as well as consumer perceptions, will help ensure that you’ll be better prepared for these known issues with outdoor cultivation, as well as the many unknowns often lurking around the corner.

Licensed cultivators know that when it comes to controlling and monitoring their growing environment, a simple, flexible, sustainable control system is crucial. This is why proactive cultivators are turning to Reliable Controls. Our nationwide network of factory-certified

Authorized Dealers will design, install, and commission a comprehensive control system paired with an intuitive, custom-tailored graphical interface. Take command of your precisely controlled environment. Generate tracking reports and analytics. Reduce your carbon footprint while improving productivity, quality, and serviceability.

To learn more about this cost-effective, Canadian-made solution, please contact a Reliable Controls

Authorized Dealer near you.

By Peter C. Straszynski

Peter Straszynski is a partner with Torkin Manes LLP and a member of the firm’s Cannabis Law Group, assisting industry employers with all of their employment law needs. He can be reached at (416)7775447 or pstraszynski@torkinmanes.com.

With the distribution of the COVID-19 vaccine well underway, many Canadian employers are thinking about introducing vaccination policies into their workplace, raising the question “Are mandatory vaccination policies even legal?”

There is currently no federal or provincial legislation in Canada requiring mandatory COVID-19 vaccination for all employees, nor is any such legislation expected. Occupational health and safety legislation at both the federal and provincial levels, however, do require that employers protect their workers from health and safety risks in the workplace.

While Canadian employers are not legally required to mandate vaccination, it is not illegal for employers to introduce mandatory vaccination policies, subject to some important considerations and limitations.

Unions can challenge an employer’s right to introduce policies by filing a “grievance.” In these circumstances, an arbitrator has the power to determine whether the policy is a reasonable exercise of the employer’s management rights under the collective agreement.

While there has been no arbitration decision on mandatory COVID-19 vaccinations, arbitrators have, in the past found mandatory flu vaccines to not be reasonable in all circumstances. More recently, arbitrators have ruled that a mandatory testing policy was reasonable in a case that we recently argued, which may signal that arbitrators might be prepared to uphold reasonable vaccination policies.

Human rights legislation across Canada prohibits discrimination in employment on certain grounds, including disability, sex and religion, any of which could potentially justify an employee’s refusal to

vaccinate. Where a refusal is based on a justifiable human rights ground, the employer will be required to accommodate any such refusal to the point of “undue hardship.” Forms of accommodation could include working remotely from home or situation-specific masking, hygiene and distancing protocols in the workplace. A policy that does not address and offer accommodation will violate human rights legislation, resulting in the potential for litigation and resulting damages and costs.

Employees may offer medical evidence substantiating their refusal to vaccinate on the grounds that it would be harmful to their health due to a particular health circumstance or a medical condition. Enforcement of a mandatory vaccination policy in these circumstances could be either a wrongful dismissal or human rights violation (or both), resulting in the potential for litigation and related damages and costs.

A “constructive dismissal” occurs when an employer unilaterally changes fundamental terms of an employee’s employment, and it gives the employee the right to leave their employment and to claim damages for wrongful dismissal. Some employees may try to take the position that imposition of a mandatory vaccination policy amounts to a constructive dismissal.

Where an employee refuses to vaccinate for reasons other than a “protected” medical or human rights ground, the employer has the option of lawfully terminating employment. A refusal to vaccinate would not likely constitute “just cause,” however, and the employer would likely have to comply with its obligation to provide the employee with notice of termination or payments instead of notice. In the union context, the employer’s right to terminate employment might be further affected by the terms of the applicable collective agreement.

Employers in environments serving vulnerable persons will be the ones most likely to consider mandatory vaccination policies. Next would be employers in industries that are public-facing or involve large groups of people.

Implementation of any mandatory policy will have to be considered carefully and in the context of all of the above considerations.

Where an employer concludes that a mandatory vaccination requirement is either unnecessary or unreasonable in the circumstances, there continue to exist alternatives to mandatory vaccination, including recommended vaccination, masking and distancing protocols, and testing and self-isolation requirements.

Every business is different and not all businesses will need (or want) a mandatory vaccination policy. If your business is considering a vaccination policy, you first need to assess the transmission risks in your particular workplace and determine whether mandatory vaccination is a reasonable requirement, or otherwise, whether alternatives to mandatory vaccination would be adequate to protect the health and safety of your employees and the public.

By Treena Hein

The legal cannabis industry in Canada has evolved on all fronts, including in outdoor cultivation.

In August 2020, Health Canada stated that licensed outdoor growing capacity was almost three times that of indoor, reaching a whopping 59 million sq. ft. It’s scalable, perceived as natural and sustainable, and offers both low capital and operating costs – and while future prospects look bright, this type of cultivation must be done properly.

And it’s clearly not for everyone. For example, in December 2020, Canopy Growth announced the closure of its last outdoor facility in Saskatchewan, and at the end of March 2021, 48North followed suit, shutting down its Good Farm in Brant County in Ontario. Both companies listed profitability as a main reason.

“It seems a lot of growers rushed to outdoor growing because of the allure of a low-cost, high-margin product at scale, and many producers were focused on cheap biomass,” says Alex Rumi, co-founder and chief strategy officer at Good Buds in Salt Spring Island, B.C. “We started our company from the outset with craft outdoor (cultivation) in mind. We’ve seen that top-quality,

craft outdoor cannabis is possible through award-winning growers from California. We knew there was an opportunity to bring that quality to Canada, and Salt Spring Island is really the perfect place for it.”

Rumi notes that the island’s Mediterranean climate is the closest in Canada to California’s Humboldt County, where a large amount of award-winning cannabis has been grown – and that the terroir (soil type, climate, sunlight and so on) of a given location has a profound effect on cannabis quality and taste.

“In our early days, we enlisted the help of an ‘Emerald Cup’ organizer, Samantha Mikolajewski, who brought forward a lot of growing techniques and set us up to be a sustainable, organic-certified producer,” says Rumi. “Great weed doesn’t need to be grown indoors. Great wine isn’t grown in a warehouse, and I think we’ve seen that a high-tech facility doesn’t always mean that you’ll grow great weed. We believe craft outdoor cannabis is possible in Canada with the right terroir, genetics and growing methods.”

Overall, Rumi notes that growing outdoors comes with different variables like weather, risk of genetic contamination and THC level, but he and his team mitigate these risks through a lot of R&D and planning. “We’ve spent the past two

years hunting for the best phenotypes that will really deliver outdoors in our soils,” he says. “We’ve found some winners that are not only high THC but that feature alternative cannabinoids like CBG.”

Their ‘Gluerangutan’ strain achieved 28 per cent THC last year.

Nicco Dehaan, master grower and COO at Christina Lake Cannabis (CLC), also cites terroir, growing methods and genetics as keys to their success. However, during an online panel discussion in late April, he also credited team experience and hard work. Last year was its first harvest on 32 acres of licensed cultivation space in lower mainland B.C. near the U.S. border, which according to the leadership team went extremely well due to good growing conditions and the fact that all team members – some of them growers with 25 years outdoor experience – “gave it 110 per cent.”

The harvest topped 32,500 kg of dried cannabis, with plants reaching 10 ft. tall. All plants are clones propagated in the greenhouse. Of CLC’s more than 75 outdoor strains, the licensed producer is currently

growing eight.

“Genetics is everything outdoors,” explains another of CLC’s master growers, Steven Bowering. “A constant breeding program is necessary, testing new genetics every year.”

Drip irrigation is used at CLC, on potted plants grouped in zones by strain. Drones were used to monitor the crop as it grew in 2020, detecting at a very early stage if plants in a given zone were drying out faster than expected, with irrigation adjusted accordingly.

In Strathroy, Ont., WeedMD grew 27 acres of cannabis for the second year in 2020. Head of cultivation Curtis Wallace says their decision to do outdoor cultivation was definitely driven by its low costs, but he adds that “there is certainly a draw to cultivating the plant the way it was intended to grow, naturally.”

The company started outdoor cultivation in 2019 with over 35 strains, used eight last year and this year, may narrow that to six. Acreage outside will also shrink to some extent in 2021.

“Unlike other licensed producers, WeedMD has never been interested in maximizing our fields to grow copious amounts of

biomass,” Wallace says. “We tend to focus on growing quality biomass and cultivars that are recognized for their terpene profiles and cannabinoid content.”

The challenges faced by outdoor growers depend, to some extent, on their set-up and scale, but pests and disease are a threat that every operation must address. Wallace reports, however, that “for the most part, we’ve been quite fortunate in that we haven’t really seen diseases pop up outdoors. Powdery mildew is always something we look out for but in general, Mother Nature has taken care of pests and potential diseases for us… As the larger pests that are not particularly attracted to cannabis tend to feed on the smaller pests that are. Once again, Mother Nature is doing the heavy lifting.”

During the CLC panel, Dehaan explains that the use of UVN light keeps insect populations down indoors during the seedling stage. Outdoors, CLC staff worked with some biologists during 2020 to enhance aphid predators.

“We have a good native ladybug population and we introduced lacewings,” Dehaan says. “We distributed larvae throughout the field, and this year, we’re

Health

Plant

Quality Production Experts

Microbiological

Plant / Soil / Media

Disease Diagnostics

Water / Tissue / Soil

Residual Solvents

Edibles / Beverages /

Biologicals

Quality Production Experts

Seed-to-Sale Software

looking at planting companion plants around the plots as well.” These plants aim to boost the populations of these beneficial insects.

Rumi agrees that natural predators like frogs and ladybugs help with pest control, and for weed control, he uses cover crops like clover that outcompete them (and also fix nitrogen in the soil, making it available for cannabis plant use).

At CLC however, bud rot (Botrytis) and powdery mildew can pose problems. “Wet weather, humidity, morning dew will encourage bud rot,” says Bowering. “It mostly happens when plants are over ripe or exposed to excessive rain. Powdery mildew is encouraged by stagnant air and lack of sunlight (UV light kills the spores). We’ve built genetics that are mostly resistant to powdery mildew.”

Along with good genetics, and what Bowering calls “very good air flow” in the valley where the operation is located, no fungicides have yet had to be used.

The gigantic harvest at CLC poses a challenge in several ways. To handle the volume, strains were planted that reach maturity in a staggered fashion starting in August and ending in October. Dehaan explains during the panel that on-site testing was also really important to determine points of peak harvest.

“It was about two weeks earlier than we had thought,” he says. “It cuts cycle time and product is better. It was a huge win for us.” He adds that the small amount of root binding that results from growing in pots seems to trigger flowering earlier.

CLC has the capacity to dehumidify up to 6,000 kg of material a day. In the future, they may explore fresh-frozen harvesting methods. At Good Buds however, all outdoor cannabis is hung to dry because a slow cure “really locks in the terps,” says Rumi, “but… as you can imagine, fitting 13 acres’ worth of plants into drying rooms can be a tight squeeze. We’re continuing to add drying space to our site every year.”

However, finding enough people on the island to work the harvest is not easy, and Good Buds is committed to not using

migrant workers and to providing a living wage. Over time, they’ve become more proactive in finding seasonal staff.

To address its labour challenges, WeedMD has taken a multi-pronged approach. “With the hot, humid summer temperatures in southwestern Ontario, working outdoors in full sun can at times be gruelling, but we’re lucky in that the same crew voluntarily returns to work outdoors for us every year,” says Wallace. “But we now… know how to cycle our crews more efficiently. In fact, we used 60 per cent less labour in our second year over the first because we automated some of our cultivation practices by using an industrial planter.”

The degree of sustainability of outdoor versus indoor cannabis cultivation is complex to pin down, and greatly depends on individual practices. Sustainability can encompass everything from work conditions to use of recycled paper in the office.

All outdoor cannabis operations certainly use sunlight instead artificial light in a highly-controlled environment during the grow-out phase. This saves a large amount of energy.

Many operations are using beneficial insects for pest control, and all are continuously making breeding advances in terms of pest and disease resistance. Some operations like Good Buds are certified organic.

In terms of water use, irrigation/fertigation is required with the scale of outdoor growing, but rainfall can supplement irrigation to some extent, depending on the year. At Good Buds, rainwater is also captured for irrigation, and at WeedMD, irrigation is sourced from reclaimed water from its greenhouse operations (as well as onsite reservoirs).

Drying fresh plant material like cannabis is energy intensive, but smaller operations like Good Buds hang-dry their plants.

Looking forward, consumers will continue to expect the cannabis industry to show it’s making strides with sustainability, and they do with all other industries, and this will be easier for some outdoor – and indoor – operations than others.

By Jean Ko Din

Kevin Anderson doesn’t believe in shortcuts when growing top flower.

As head grower of craft medical cannabis producer, Broken Coast Cannabis, Anderson takes it upon himself to meticulously guide every stage of the production process.

Broken Coast operates a 44,000-sq.-ft. indoor cultivation facility in Duncan, B.C., on Vancouver Island. The company turned heads in the B.C. craft community when Aphria acquired Broken Coast for $230 million in 2018. While the facility has undergone significant expansions over the years, Anderson maintains that the company remains “craft by choice.”

Anderson oversees 30 hydroponic grow rooms with a total production capacity of about 5,000 kilograms per year. He likes to keep grow rooms small and dedicated to only one specific strain so that he can tailor the nutrition program and the environment controls to that cultivar.

Grow Opportunity took a virtual tour of Anderson’s grow rooms as he shared his small-batch philosophy for Broken Coast.

Grow Opportunity: Can you explain more about your philosophy of doing everything by hand?

Kevin Anderson: I really spend a lot of time making sure that every step of the process – the cannabis that’s being grown here that’s being trimmed – is really done to a high standard. We grow it with love, we trim it with love, we process it with love, we package it with love.

So you should be receiving really, really high-quality, pristine buds that have been really carefully looked after during that whole process.

GO: How did you train to be a master grower?

KA: I’d say it’s a combination of my educational background and passion for the cannabis industry. I have my diploma in electronic engineering and also studied to be an arborist. For those who don’t know, it’s the practice of arboriculture, which is the cultivation, management and study of horticulture. So I had a good skill set. I coupled that with a lot of hard work, dedication, love for the cannabis industry.

I’ve also grown a lot of weed and done a lot of personal research and development.

GO: Because your facility is fully hydroponic, how much time in your day is dedicated to monitoring these environmental controls? How much of it is automated?

KA: We’re looking at obviously the humidity, the temperature, the CO2 levels, the light levels of the room. But yeah, because we grow in a hydroponics system, we’re spending a lot of time monitoring the dryness of the rockwool block, as well as the EC (electrical conductivity) and the pH of that block, and using various techniques to keep all those parameters in the sweet spot.

And that does change between cultivars, like the nutrition of the plant does. Being able to replicate that in a large scale is very difficult and that’s why we’re so focused on the craft of growing cannabis, which is really, giving that plant the exact nutrition, the right watering in the right environment that it likes, to bring out the best of that plant.

We’re so focused on the craft of growing cannabis, which is really, giving that plant the exact nutrition, the right watering in the right environment that it likes, to bring out the best of that plant.

GO: In a virtual tour of your facility, you showed us a really interesting flower room where the bottom two-thirds of the plants have been pruned down. Why do you do that?

KA: We really like to prune a lot of the plants off so that we’re only growing the highest quality part of the plant. We think everyone that opens a bottle of Broken Coast product should really get a nice large bud, or at least a few nice-sized chunks. We don’t want people to be disappointed when they open our bottles, so we really only grow high-quality cannabis in all of our flower.

GO: Wouldn’t you be compromising yield by doing this?

KA: No one should be opening a bottle of Broken Coast product and be disappointed with the buds they got, because they were the low down buds on the plant. So, you know, we prune our plants very heavily, which we take a hit on yield for that. But it results in us only growing very high-quality cannabis. So that’s why the extracts that we have, and the dried flower that we have is only high-quality flower.

GO: Do you use the same methods for extracts?

KA: Yes, we don’t grow any differently for extract crops. We believe in quality and consistency – its’ at the forefront of everything we do, which is why we use the same approach. It’s important that every bottle has only high-quality buds in it and our extracts are made with the same flower, making them the highest quality.

GO: Is it different to grow for medical users than for recreational users?

KA: Good question. Not for us, because space is limited, we hold a specific amount for our medical and recreational products. Beyond that, everything is the same high-quality, consistency across the board.

GO: Do you have a favourite strain that you are growing right now?

KA: This is a crop of Pipe Dream, which is our newest release and something we’re really proud of. It took us a long, long time to bring this to market through a lot of pheno hunting for something that we felt was special. And then once we did, we had to grow it several times, we always do, just to really make sure that we were happy with it.

It’s really one I love to grow. It produces really nice, big tight buds. It’s got that really nice colouration, lots of purples and a real nice, frosty kind of colour to it. Smells amazing.

Another product we’re really excited for is the new genetics we have for our first wax products. Again, we are only putting the high-quality flower into the wax. There’s no small stuff to put in so it’s really just the stuff that you would get in a bottle. You’ll find that in the wax too.

That’s all high-quality flower that goes into making those vapes, as well, so you know it really gives you a much better experience with regard to flavour and that’s again, what it’s all about for us, is we really want to have really unique, flavourful cannabis that people really enjoy.

The most pressing security concerns in the cannabis industry

By Andrew Snook

When the Government of Canada decided to legalize the cannabis industry, there were many questions related to security and the potential criminal activity that would result from the production, transportation and sale of cannabis products.

“The degree of crime that was expected with the legalization of cannabis never materialized to the extent that the federal government predicted. However, this does not negate the fact that there’s an emerging risk of crime to the cannabis industry,” says Mike Soberal, senior director of corporate security at Aurora Cannabis, Inc.

Soberal notes there is an existing and growing risk of organized crime penetrating the inner workings of the cannabis industry.

“It’s certainly a difficult target to breach but through careful observation and by learning the processes at different cannabis companies, weak spots may be identified,” he says.

While current Canadian regulations don’t dictate the experience required to fulfill the position of head of security at a licensed cannabis producer facility, Soberal says it is crucial to have someone with a strong security background in this role.

“Whether that’s through a certification, such as the Certified Protection Professional (CPP) or previous law enforcement experience, having an extensive background in security is necessary to ensure your team is vigilant and able to prevent any opportunity for organized criminals to strike and infiltrate the industry,” he says.

Ken Doige, founder and CEO of ESRM

Solutions Inc. (Enterprise Security Risk Management), says cannabis producers and retailers need to understand the true value proposition from an internal security program and not focus on keeping upfront costs as low as possible.

“That’s no different than the battle I fought in my years in corporate security,” he says. “Security professionals are always trying to position themselves to show what the value proposition is that they’re bringing to the organization, and I think the cannabis sector still needs maturing in that respect as far as leadership is concerned – to understand the importance of a very integrated security program.”

Doige says retailers and licensed producers (LPs) need to understand the potential risks within their companies, which can be done by hiring security professionals who can identify those risks and offer solutions to help mitigate potential issues.

“I think, to a large extent, many of those requests are being shelved and are being met with, ‘Look, what’s the minimum we need to do to pass regulatory requirements?’ Organizationally, that’s the biggest hurdle,” he says. “It’s not just about being

compliant. If that was the case, then there wouldn’t be any security programs other than what is mandated by government. But having a risk-based approach to a security program is the key to success in organizations.”

One of the biggest areas of concern for LPs is internal theft, whether it’s theft of intellectual property, such as with genetics, or the theft of products.

Two ways to help mitigate some of the internal thefts are a focus on enforcement and being diligent with random searches, as well as doing security town hall meetings that require mandatory attendance for each employee.

“We would go through all of the responsibilities that every employee has in regard to securing the facilities and the product, and making sure it’s not diverted into the illicit market, which has always been a big concern for all of us,” Doige says. “That potential for internal theft, whether it’s just being used for personal use, or theft of genetic materials that can

Cali Pro 2-Part Nutrient Series is designed for growers who want a premium base nutrient that’s easy to use and guarantees professional results.

Cali Pro supplies all the essential elements in precise concentrations and ratios for vigorous growth and flowering throughout the crop life cycle.

Get everything your crops need to grow, flower and thrive - with Cali Pro.

quality. Maximum potential.

Emerald Harvest has partnered with growers around the world to help them achieve consistent, profitable crops every harvest.

Our premium base nutrients and supplements are made from the finest ingredients - so they run clean, test clean, and simply grow the highest quality product.

Home growers to commercial cultivators are enjoying incredible results with Emerald Harvest nutrients.

go to a competitor, those are certainly two areas of concern on the LP side.”

When it comes to the smaller retail shops, the owners typically do not have the assets of the larger corporations and do not have access to the same level of resources or security expertise.

“That’s where I think you’re going to see additional robberies and violent acts on the retail side of things,” Doige says. “I’m quite pleased to see that many jurisdictions have loosened the regulations on window coverings, for instance, because that was always a big issue for us as

security professionals in the cannabis industry on the retail side: giving somebody complete anonymity when they enter a store to lock the door and commit a robbery completely undetected because the windows are all covered. That was a big hurdle to overcome.”

While many LPs have tight security inside their production facilities, loss and theft of cannabis products during tranport pose a significant threat, Soberal states.

“It’s all over the map as far as the regulatory regime is concerned,” Doige adds. “There are such stringent procedures

and regulatory frameworks around the production, storage and sale of cannabis products, but anyone from Canada Post to Purolator to Pineapple Express is delivering this stuff. There are no security requirements around bulk transport.”

He says transport trucks delivering cannabis have been hijacked and there are no specific regulations around it to assist producers or transporters.

“I really think it puts the industry at jeopardy, as well as the transport folks. I’m not saying it needs to be all armoured because it’s just not practical with the amount of product that’s being moved, but I’m hoping that the review of the federal regs this year comes out with a little more consistency in respect to bulk transport of cannabis products,” Doige says.

Soberal also recommends keeping up to date on current regulated protocols and any new trends, regulations or changes within the industry.

“One way to do this is by networking with colleagues within the industry,” he says adding this will allow organizations to stay on top of best practices and global standards.

Doige says having the heads of security at your organization be part of a peer group can help with keeping a pulse on the latest threats.

Lorne Lipkus, founding partner of Toronto-based law firm Kestenberg Siegal Lipkus LLP, says counterfeit products are another security risk that the cannabis industry needs to

consider. Lipkus regularly litigates a wide variety of anti-counterfeiting cases including copyrights, trademarks, and industrial designs. He says the counterfeiting of cannabis packaging is an area of concern, as well as the government-required stamp on the package, which helps identify that it is authorized and legitimate product.

Lipkus says counterfeiting is showing up more and more on the edibles side of the cannabis industry, and it poses a serious risk to consumers.

“One of the problems police are having with edibles is that people are taking the edibles and putting fentanyl in them. What you think you’re getting, isn’t what you’re getting,” he says.

To help battle counterfeit packaging, Lipkus says a secure supply chain that people can rely on is important. He says the government needs to embrace using technologies on cannabis packaging to help show consumers that what’s inside is the real product, not unlike the technologies used to identify legitimate money and passports.

“The level of technology built into them is fantastic,” Lipkus says. “Overt, covert and forensic technologies are built into these labels, that’s what we’re talking about. It exists today, so there’s no reason that packaging can’t have that level of technology on it.”

Organized criminals could still counterfeit government stamps, and they will potentially fool some consumers, so it is important to educate the public on what to look for when purchasing cannabis products.

Exceptional

What’s Wrong with My Marijuana Plant? is the first problem-solving book for marijuana growers with an effective and easy-to-use visual diagnostic system pioneered by Deardorff and Wadsworth for identifying pest, disease, and environmental problems by symptom. This book contains all-organic solutions plus best growing practices to avoid problems before they start. Written in easily understandable, non-technical language and heavily illustrated with precise photography to allow rapid and accurate diagnosis, this is an essential resource for beginning and experienced growers alike.

Ovation Science Inc. has developed a patented skin delivery technology for topical Cannabis 2.0 products.

Backed with 20 years of the company’s own research and development, Invisicare was designed to ensure the product remains bound to the skin and resists wash-off or rub-off. The company said these new product formulations go through multiple checks and balances to verify the strength of CBD and/or THC in each formula and production batch.

“Not only do we believe our products are game changers in the topical cannabis industry; they are all protected by patents so no other company can duplicate our success,” said CEO Terry Howlett.

“Our health and wellness products in particular have been developed to have many ratios of CBD to THC, including 1:1, 1:2, 1:3, 1:10, and the reverse: 2:1, 3:1 and 10:1. These ratios have shown to have different therapeutic effects depending on the amount of CBD versus THC in the formulation.”

Ovation Science is a Nevada-based company that specializes in topical and transdermal consumer products, including its own brands, ASLO SBD Beauty and InVibe MD. It’s Canadian office is located in Vancouver. www.ovationscience.com

Process six pounds of dried flower per minute with GreenBroz Inc.’s newest processing system.

The U.S.-based cannabis harvesting manufacturer has introduced its newest system on the lineup, the Rise-N-Sort post-harvest processing system. It is designed to combine the Rise Conveyor, Precision Sorter and Sorter Table to consolidate a three-part system.

The system is designed to minimize human touch points in order to mitigate contamination risk. It is designed to operate gently without vibration and is constructed using food-grade stainless steel, surgical steel, polyurethane and ultra-highmolecular-weight polyethylene (UHMW).

The whole system is modular and can be combined with the GreenBroz Model M Dry Trimmer for an end-to-end process, from raw product to ready-for-packaging. Everything, including the motors, are designed to be washdown-ready for easy disinfection and maintenace. www.greenbroz.com

Pharma-tech company, Syqe Medical, has launched a new Health Canada-approved drug delivery technology that is designed to administer precise dosage for medical patients.

The Syqe Inhaler is the company’s first pharmaceutical grade system to deliver specific doses of cannabinoids with each inhalation to help relieve symptoms while avoiding adverse reactions.

“Finding the dose that provides a consistent result has been problematic for health-care professionals,” Dr. Peter M. Blecher, medical director of CPM Centres for Pain Management, said in Syqe’s press release. “It may now be possible to provide patients with relief without unwanted effects.”

Syqe Medical conducted a placebo-controlled, double blind study which found

that when THC is delivered with greater precision to the patient, lower doses are needed, resulting in greater overall efficacy and fewer side effects, such as potentially debilitating psychoactivity.

“We are proud of the extensive research that went into bringing the inhaler to Canada and the rigorous clinical evidence that supports its use,” said Michael Milloy, general manager. www.syqemedical.com

Purity-IQ is looking to set the global standard on cannabis product safety, quality and authentication.

“Cannabis Authenticity and Purity Standard,” or CAPS, is a 135-page document that outlines requirements for good manufacturing practices and good agricultural practices to establish prouct identity, authenticity and consistency. It details scientific standard operating procedures that are meant to help brands achieve its regulatory and risk-based objectives.

“Meeting CAPS requirements is the first step on a brand’s journey to guaranteeing consistently high-quality authentic products and differentiating itself in the marketplace with an evidence-based stamp of quality,” said Paul Vader, chief technical officer.

Valder hopes the document allows licensed growers and manufacturers to “walk before they run,” gaining third-party GMP/GAP site recognition before seeking specific product authenticity or consistency certification.

“As with other major industry sectors, the cannabis and hemp business will ultimately need to adopt proven voluntary safety and quality management systems, as they endeavour to do business with those major and recognized consumer brands, also wishing to protect their reputation,” he said. www.purity-iq.com

By Max Zavet

Max Zavet is the CEO and co-founder of BLLRDR. Working in collaboration with Grammy-nominated producer Noah ‘40’ Shebib and master grower Jef Tek, the BLLRDR team’s mission is to share their love and passion for cannabis with the entire world.

Arecent Statistics Canada report estimates that legal sales of recreational cannabis exceeded illicit sales for the very first time during the third quarter of 2020. What can this be attributed to?

As the CEO of BLLRDR, a Canadian brand specializing in the small-batch production of premium cannabis, I believe in the power of craft cannabis and its ability to improve the performance of the legal market. Right now, it’s very encouraging to see a number of smaller micro-cultivators in the marketplace developing fresh genetics and products that are superior to large-scale producers.

That said, these smaller producers continue to face difficulties in accessing the market due to provincial regulatory frameworks around distribution, combined with additional costs around packaging, taxes and logistics. In turn, this makes it difficult for those quality products to be sold directly to the consumer.

With the current situation in mind, here are three points to consider when discussing the role of craft cannabis in the future success of the Canadian legal market.

A major driving force behind Canada’s strong illicit market is the consumer demand for the best price. Craft offerings can impact purchasing decisions and support in con -

verting illegal sales to legal by providing cannabis consumers with well-made and wellpriced products that appeal to their preferences. We also know that cannabis users appreciate and value brands that offer transparency and tell a story, another advantage small producers have to major production facilities.

It should be mentioned that the term craft is not necessarily synonymous with high-quality cannabis. It can be used as a convenient term to mean that the cannabis was hand processed (trimming and packaging) and hung dried with more cannabis cover leaf. While those aspects are very important and generally lead to higher quality outcomes, it is only part of the process. Genetics, climate and other environmental conditions for growing, processing and curing/storage play a significant role.

While many factors go into the production-side of high-quality craft cannabis, I believe the best results come from a laser-focused, slow and steady process combined with

Brands that tell their story and connect to the consumer through shared values will also help in winning over the illicit market.

the best cannabis genetics by the best growers available. Brands that tell their story and connect to the consumer through shared values will also help in winning over the illicit market consumer and improve the legal market.

Business models like farmgate that allow producers to sell their fresh, sustainable products directly to consumers from their facility are the way of the future. Farm-gate can address the current access gap by providing the grower or purveyor with a convenient direct-to-consumer platform. This model also provides small producers with a unique opportunity to introduce the legal market to thousands of one-of-a-kind, high-demand genetics like Afghani Bullrider. Focusing on quality, not quan-

tity, this retail framework allows for small producers to have their own retail store where they can then sell fresh, farmto-table limited drops.

Another benefit of farm-gate is that it allows producers to introduce more varied offerings in different formats. An example of this is the next generation of fresh frozen hash concentrates that BLLRDR is currently working on. Once we are operational, we will be the first retail store in the country with in-house hash rosin production and will be able to deliver a fresh, superior, shelf-stable quality product at a more competitive price for the consumer at retail.

The impact of COVID-19 cannot be ignored. As retailers begin to welcome customers back in-store and more licensed shops open (especially in Ontario), consumers can explore their local dispensary and become more informed. This is necessary to introduce the new strains by micro cultivators that are available through regulated channels that deliver the best in flavour profile, terpenes and THC levels. Extending the retail experience and connecting to cannabis culture, music and fresh, exclusive cannabis products based on the best genetics will also connect and resonate with consumers and the experiences they desire.

The conversation must continue and there is still work to be done. While market-entry obstacles for small producers remain, the growing number of micro-cultivation licences in Canada is promising, as we work to create a thriving legal market.