UPROOTED

Unearthing the potential of aeroponics in cannabis cultivation

CannaPro.........................................265

Cannasupplies ................................453

Canncas ..........................................455

CannDelta Cannabis Consulting .....353

Canntab Therapeutics Inc. .............255

CannTx Life Sciences Inc. ..............507

Cantel (Canada) Inc ........................264

CCR Canada.....................................652

Cedarlane ........................................713

Ceres Greenhouse Solutions ..........248

CFN Media Group ............................161

Circle Of Growth..............................136

Coast 2 Coast Branding Inc. ...........605

Commissionaires ............................649

Contempo Specialty Packaging .....252

Cowan Insurance Group .................442

Crop King Seeds .............................603

Dalynn Biologicals Inc. ...................716

Delta 9 Pak ......................................569

Avigilon Corporation .......................111

AXSource Infotech Inc. ...................135 Bassetti Americas...........................754 Beleave ...........................................167

BelTri Inc. ........................................340 Berger .............................................623

Black & McDonald Limited .............257

Black Swallow Soil .........................144

Blade Filters ....................................250

BlueSky Organics Corp ..................339

Boss Promotions.............................217

Boulder Botanicals & Bioscience Labs ..........................101

Boveda Inc ......................................343

Braingrid Corporation.....................366

Brass Monkey Installations Ltd......247

Bulldog Fire and Security ...............668

Bundy Baking Solutions/ Chicago Metallic .............................545

CALA Inc. .........................................206

Caliber Communications ................109

California Lightworks .....................243

Canadian Cannabis Industry

Directory (Contact Canada) ............707

Canadian Cannabis Packaging Services ..........................................342

Canadian IPG...................................157

Cannabis and Coffee.......................561

Cannabis Compliance Inc...............221

Cannabis License Experts ..............617

CannabisNewsWire ........................755

Cannamation Corp. .........................557

CannaMedTech Innovations Ltd. ....120

Design Systems Canada Ltd...........553

Detonate Group ...............................332

dicentra Cannabis Consulting ........433

Dino-Lite Scopes ............................542

DMLIFT INC. .....................................142

Dope Automation ............................550

Durafest Label Company ................708

Environmental Systems Corp .........239

ERB and ERB Insurance Brokers ...139

ESET Canada Inc. ............................153

Eurofins Experchem Laboratories .607

Fabco Plastics ................................627

Form-Tech Scientific Inc. ..............140

FUTUROLA USA ................................229

Gallagher Security ..........................263

GardaWorld .....................................314

GardaWorld .....................................355

Green Coat LLC ...............................640

Green Zone Therapy /

Canadian Craft Growers .................747

Greenshield .....................................355

Grow Opportunity ............................225

GrowerIQ .........................................664

GrowLegally ....................................710

GTAGSM LTD ....................................355

Headset Inc. ....................................368

High Canada ....................................168

High North Inc. ................................117

Higher Environments ......................619

Hikvision Canada ............................759

Hill Street Beverage Company Inc. 316

Hubert Company .............................208

Huplaso ...........................................609

Illumitex ..........................................249

IMSM Canada LtdISO Specialists ................................202

Inaxsys Security Systems Inc. .......452

IndicaOnline ....................................441

Indiva ..............................................207

Inmar ...............................................752

IQVIA ................................................647

JRoss Retail Recruiters ..................666 Juiceworks .....................................715

Kanata Earth ...................................154

Keyline Safety .................................613

KGK Science Inc. ............................447

Kingspan .........................................352

Koppert Biological Systems ...........746

Kush Oil ...........................................642

L2Brands .........................................141

Lab Society .....................................213

Laporte Engineering Inc. ................138

LDRLY Games..................................137

LeKAC Sourcing Ltd. .......................233

Lexaria Bioscience Corp ................555

Linnaeus Lighting ...........................629

Longhill Energy ...............................750 M & L Testing Equipment ...............105

Mabre ..............................................723

Mandel Scientific Company Inc. ....348

Markem-imaje.com .......................655

MAZ..................................................549

MediPharm Labs Inc. .....................204

Metro/Imaginex...............................149

Micron Waste Technologies ...........151

Montel Inc. ......................................501

Motorleaf .........................................107

Shenzhen

Soil

Storz

Strainprint

Structural

Sun

TELUS

Thar

Worldwide

Zef

Zenith

Zortech

DO YOU KNOW A CANNABIS GROWER WHO:

• Shows deep understanding and knowledge of cannabis cultivation

• Demonstrates a strong work ethic

• Demonstrates an ability to lead and innovate

• Shows a strong passion and commitment to production of high-quality cannabis products

• Commits to the highest standards of cannabis growing practices

If you or someone you know exemplifies the above qualities, we would like to hear from you.

ELIGIBILITY:

All nominees must be currently working at a licensed cannabis facility within Canada. Nominations will close June 28. Winners will be announced and featured in the September/October 2019 issue of Grow Opportunity.

JUDGING

It’s not a popularity contest. Nominees will be evaluated by an esteemed panel of judges who are leaders and influencers in the Canadian cannabis industry. Visit canadastopgrowers.com to see who our judges are.

SPONSOR

For sponsorship opportunities contact Adam Szpakowski ASzpakowski@annexbusinessmedia.com

By Mari-Len De Guzman

When Grow Opportunity was launched in the fall of 2017, it was with the intention to serve as a resource for Canadian licensed producers. The mandate of Grow Opportunity is to help cannabis producers grow and manage their business and help propel the Canadian cannabis industry. From growing and cultivation to business management and operations, our content aims to engage our audience from multiple fronts: print, online and events. In this issue we are announcing a new initiative that will bring to the forefront the unsung heroes of the cannabis industry.

Behind every successful LP is one or several masterful growers, who are passionate about the plant. These growers and master growers are the soul of every cannabis enterprise, ensuring that every bud that blooms from each plant conforms to the company’s high quality standards.

The growers are the closest to the plant and have the most influence on the production outcome. They are the most critical part of a licensed producer’s operations and yet, they typically remain in the background, usually content to be in the company of the plants.

I think it’s time to change that. I am happy to announce the launch of the first-ever

Canada’s Top Growers Award, presented by Grow Opportunity.

As the name implies, this program recognizes exceptional cannabis growers across Canada.

We are proud to be recognizing outstanding cannabis growers who are responsible

leadership and innovation.

We are choosing from a pool of nominees from across Canada and recognizing the most exceptional ones.

This is where you, our readers, come into the picture. Are you or someone you know an exceptional cannabis

Are you or someone you know an exceptional cannabis grower? Nominate them for Canada’s Top Growers Award, presented by Grow Opportunity.

for nurturing some of the best quality cannabis in the country. We want to shine a spotlight on these individuals who exemplify integrity, innovation, leadership and ethical standards in cannabis cultivation.

This is not a popularity contest. Winners will be evaluated based on their demonstrated abilities and knowledge of cannabis cultivation. We have assembled a group of industry leaders with significant knowledge on cannabis culture, who will independently evaluate our nominees based on the following criteria: exceptional skills, knowledge of growing practices, ethical principles,

March/April 2019 Vol. 3, No. 2 growopportunity.ca

EDITOR

Mari-Len De Guzman mdeguzman@annexbusinessmedia.com 289-259-1408

ASSOCIATE EDITOR Tamar Atik tatik@annexbusinessmedia.com 416-510-5211

ASSOCIATE PUBLISHER Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR

Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175 888-599-2228 ext 234

CIRCULATION MANAGER

Barbara Adelt badelt@annexbusinessmedia.com 416-442-5600 ext.3546

MEDIA DESIGNER

Emily Sun

GROUP PUBLISHER

Martin McAnulty mmcanulty@annexbusinessmedia.com

grower? Nominate them for Canada’s Top Growers Award, by telling us why they deserve to be recognized as one of Canada’s Top Growers.

Nomination is simple. We have an online nomination form where you can tell us all the wonderful things about the grower you are nominating. Once nominations are closed, our esteemed judges will evaluate all the submissions and, based on a set judging criteria, select the best candidates who will be named the 2019 Canada’s Top Growers. The winners will be announced in the September/ October 2019 issue of Grow Opportunity.

Nominations are now open and will close June 25th. To find out more about this program, including the identity of our judging panel, visit www.canadastopgrowers. com.

One of Canada’s Top Growers could be someone you know.

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES 1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec):

1 year offers: Canada $25.50 + Tax USA $36.00 USD FGN $41.00 USD GST # 867172652RT0001

SUBSCRIPTIONS

Roshni Thava rthava@annexbusinessmedia.com Tel: 416-442-5600, ext. 3555 Fax 416-510-6875 or 416.442-2191 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com

Tel: 800.668.2374

ISSN: 2561-3987 (Print)

ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

We recognize the support of the Government of Ontario

100,000

Kelowna, B.C. – SunPure Industries Ltd., an advanced stage Canadian cannabis company, has been granted a multi-year Industrial Hemp Licence from Health Canada.

The company said it plans to expedite its entry into the cannabis market by selectively growing hemp for Cannabidiol (CBD) for high return on investment per acre. “Our hemp licence allows us to capture hemp-derived CBD market share securing future growth,” the company said.

Hemp-derived CBD is expected to be a significant market and represents an unprecedented growth opportunity for SunPure. The demand for non-intoxicating hemp-derived CBD products and products such as hemp-derived CBD oils for the nutraceutical and food industries is strong and growing, SunPure said.

SunPure Industries is partnering with local farmers to expand acreage and production potential.

Up Cannabis Inc., a wholly-owned subsidiary of Newstrike Brands, has entered into an agreement with Cannabis NB to supply the government-run retail outlet with cannabis.

“Being among the select group of licensed producers that will supply cannabis to the New Brunswick marketplace is a privilege, and we look forward to helping Cannabis NB achieve its goals of providing safe, reliable product to adult-use consumers,” said Jay Wilgar, CEO of both Newstrike and Up Cannabis.

With this announcement, Up Cannabis becomes one of only eight licensed producers to have a supply agreement with Cannabis NB.

New Brunswick marks the eighth Canadian province with which Up Cannabis has announced distribution agreement.

For the first time, the U.S. Food and Drug Administration is moving forward with proposed regulation to legalize CBD-infused food and drinks. The agency has set the first public hearing on May 31st .

Vaughan, Ont.-based licensed producer CannTrust has announced plans for 200 acres of outdoor cultivation to add an additional annual production capacity of between 100,000 and 200,000 kilograms by 2020. As of this writing, the company has acquired the first 81 acres in British Columbia.

In a conference call reporting financial results for the fourth quarter of 2018, CannTrust CEO Peter Aceto said the company has entered into Letters of Intent to secure some 200 acres of land, through purchase and lease agreements. This move will further enhance CannTrust’s capacity for extraction-based products, he said.

“In combination with our Phase 3 expansion, we estimate our annual production capacity target to be between 200,000kg and 300,000kg,” Aceto said.

CannTrust has reported revenue of $16.2 million, a 132 per cent increase from the $7-million reported revenue in the fourth quarter of 2017. The company posted a fourth-quarter net loss of

$25.5 million, compared to a $6.3 million profit in the same period in 2017. CannTrust’s patient base rose to 58,000 by the end of 2018, a nearly 60 per cent increase from 37,000 patients in 2017.

“We expect the trajectory of revenue growth to continue in 2019 as we bring additional capacity online through our Phase 2 expansion, realize the potential of investments we have made into training and crop yield optimization, implement targeted price increases and distribute our products to more and more consumers,” Aceto said.

CannTrust also plans to become “an early-mover” in vaporization products and plans to forge more partnerships to “bring innovative products to market.”

“The company continues to invest in people, process, technology and marketing, and is developing innovative products for the expected legalization of the edibles market in Canada later in 2019. These products include vape pens, beverages and confectionaries,” the company said.

PRO-MIX® BX BIOSTIMULANT™ + MYCORRHIZAE™ is a solution for growers seeking to benefit from both the nutrient retention ability of vermiculite and a perlite content providing limited but proper drainage capacities. Combined with high-quality fibrous peat moss, this formulation is ideal for growers looking for a general purpose medium which creates a well-balanced growing environment.

Neptune Wellness Solutions Inc. has completed initial commercial production and is now shipping cannabis extracts from its licensed, GPP facility in Sherbrooke, Que. Neptune received its standard processing licence from Health Canada in January 2019, and has since completed required testing and commissioning of its Phase 1 (CO2based) extraction installation, after which it produced its first lots of cannabis extract. Upon successful analysis and testing, the products are now being shipped and invoiced, the company said.

“The quality of the extracts in Neptune’s first production runs at our state-of-theart facility has been terrific, and we are proud to begin deliveries. This marks an important step forward in the execution of our vision to lever our decades of extraction and wellness industry experience towards becoming the world’s leader in the extraction, purification and formulation of value-added, differentiated cannabis products,” said Jim Hamilton, president and CEO of Neptune.

The completion of investments for installation of Phase 2 ethanol-based extraction equipment was expected in March 2019, with operations planned to ramp up progressively towards a total annual processing capacity of 200,000 kg by July 2019, pending regulatory approvals.

As the global market for cannabinoid products grows rapidly and the Canadian market readies itself for new, extract-based product categories slated for legalization in October 2019, Neptune has also initiated planning for the third phase of its capacity expansion investments, which will bring its total extraction capacity to 6,000,000kg by retrofitting equipment already installed in its facility..

Canadian cannabis branding firm Origin House, formerly CannaRoyalty, is poised to be acquired by U.S. cannabis producer Cresco Labs Inc. in a $1.1 billion deal. Origin House has more than 50 brands in its portfolio that are distributed to more than 500 dispensaries in California.

One out of five Canadian adults are expected to be cannabis consumers by the year 2025. This is according to new analysis from financial services firm EY Canada. Consumers are projected to spend an average of $1,652 on cannabis products annually.

“There’s an argument that as legal cannabis prices increase so is spending in the illicit market, and that’s not completely true,” said Zachary Pendley, EY Canada cannabis real estate and valuation leader.

“The reality is that retail and distribution frameworks across Canada have been implemented much slower than anticipated, pushing many consumers to look for alternatives. As the industry matures, access to product eases and higher margin derivatives come online, we’ll see a rise in consumer spending on legal cannabis.”

EY analysis indicates that if current and planned facility expansions of more than 14 million square feet are completed and licensed in a timely manner, the supply of cannabis in Canada will outpace demand in less than five years. This will increase

competition and drive down commodity prices, resulting in the average wholesale price for dried flower to likely be between $4 and $5 by 2025. However, EY cautioned, achieving this level of supply requires significant capital investment, which can be more than $250/sq. ft.

Research shows that the Canadian direct cannabis market will grow 50 per cent to $11 billion by 2025. Consumption will mostly be split between dried flower (46 per cent) and extracts (37 per cent), with a small percentage to edibles (12 per cent) and non-edible derivatives (5 per cent).

“Despite projected growth, Canadian licensed producers still face a lot of uncertainty as they navigate an immature and undefined market,” said Pendley.

“Unclear regulations around edibles, for example, make long-term capital allocation decisions a challenging task. Managing these unknowns, coupled with rising competition, is putting more pressure on producers to maximize output in the most cost-effective and efficient ways.”

Edmonton, Alta.-based Aurora Cannabis has announced that it has appointed Nelson Peltz as a strategic advisor.

“Nelson is a globally recognized business visionary with a strong track record of constructive engagement to generate accelerated, profitable growth and shareholder value across many industry verticals that are of great interest to us,” said Aurora CEO Terry Booth.

Peltz is CEO and founding partner of multi-billion-dollar investment management firm Trian Fund Management LP.

Aurora said he will work collaboratively and strategically with the company to explore potential partnerships that would be the optimal strategic fit for successful entry into each of Aurora’s contemplated market segments. Peltz will also advise on the company’s global expansion strategy.

“I believe Aurora has a solid execution track record, is strongly differentiated from its peers, has achieved integration throughout the value chain and is poised to go to the next level across a range of industry verticals,” Peltz said.

The NHL Alumni Association recently announced it would participate in a clinical research partnership with NEEKA Health Canada and the Canopy Growth Corporation. The yearlong study will test if canna bis-based therapies can help reduce the severity of neurological issues among former pro hockey players and improve their quality of life.

About 100 former players will take part in a random ized double-blind study. It will include those who have developed impairments as a result of past concussions, including depression, post-traumatic stress disorders, and progressive dementia from chronic traumatic encephalopathy. Specifics on the financial capital required for this study weren’t released. A Canopy Growth communications manager did not provide a dollar figure but said the investment would be “con siderable.” The study is expected to begin this summer.

— BY GREGORY STRONG, THE CANADIAN PRESS

Insulating your floors with Insta-PanelsTM will save you up to 25% on energy cost annually

Insulating and heating your floors with Insta-PanelsTM will save you up to 45% on energy costs annually

cost installation of panels for in-floor insulation range from $25,000 - $35,000 per acre

Koppert has developed multiple products to control aphids at all levels of infestation.

ERVIPAR™ parasitic wasps and CHRYSOPA™ lacewings are effective as preventative and control measures.

ww w.koppert .ca

By Mohyuddin Mirza Cultivation

Dr. Mohyuddin Mirza is an industry consultant with more than 37 years of experience in crop development, production and marketing. He specializes in the technical aspects of hydroponics and systems for plant production.

Ihad the privilege of making a presentation at the Cannabis Tech Conference in January in Abbotsford, B.C., on the topic of cannabis quality and nutrient management. I had a chance to meet a large number of growers, scientists and specialists. How to produce quality cannabis product consistently and repeatedly was the subject of discussion with these participants. In my opinion, we should grow seedlings that are happier and the criterion is that it makes you happy.

There is no one starting point for quality. There are multiple touch points growers should understand. I am finding that sometimes quality control specialists don’t understand that good quality starts much earlier than the end product. One must understand the business of the cannabis plant right from the beginning to maintain good quality.

I always tell growers that the key business of the plant is not making money for you but to fix light energy in a useable form so that it can produce the chemical compounds you need – and that is the photosynthesis.

So the starting point is that the plants are able to trap light effectively and the leaves are the major parts of the plant that need that light.

In indoor situations the only light is top light. Once the plants start growing upward, the lower leaves don’t get enough light and start turning

yellow. That is not a good way to maintain optimum photosynthesis.

Good optimum light is essential to have good quality plants, and the most commonly asked question is, ‘How much light and what spectrum?’ I will write more on this subject, light for cannabis, in another issue. Let me go back to the starting points for good quality.

The choice of good quality seeds and clones is key. The picture shown here is of a well-rooted clone, wellbranched, and good root-toshoot ratios. They appear to be free of diseases and insects. When you look at such seedlings, it gives you a feeling of pleasure and happiness. This seedling was exposed to optimum light from all sides, top, bottom and sides.

This seedling was also provided optimum nutrients to establish good quality. A proper pH and EC was maintained. That is why we have those standard operating procedures. Growers should have that knowledge of optimum nutrient management, use of pH and EC meters, above all.

Notice how beautiful the root hair are? This means that there is good oxygen dynamics in the root zone and these roots can absorb all the nutrients properly.

White colour is another indication of good quality, as well as good branching, properly elongated and green leaves. All indications are that this seedling is of good quality and ready to make a good quality “adult” plant. The

One must understand the business of the cannabis plant right from the beginning to maintain good quality.

foundation of quality is the good seedlings.

Looking after the early “childhood” phase for cannabis is important for quality later on. It is very important to let the plant establish itself before we prepare for the buds. Let the plant build its proper structure and symmetry for which it is designed. Too tight a spacing, where plants are growing into each other, is a sure recipe for lower quality plants and buds.

Build a plant with 4 to 6 side branches, not 10 to 12 side shoots. For quality, maximize light penetration down to the lower leaves. Once they start turning yellow, it means all the energy the plant puts into those leaves are wasted.

Everything the cannabis plant does is based on costs and benefits. A good example: if the plant itself has to transpire lots of water to keep itself cool because the cooling sys-

tem of the grow operation cannot keep up with the heat generated by the light, then the bud quality is going to suffer because energy is used differently.

Water and watering practices must be understood in the con text of ultimate quality. Canna bis plants, like other plants, are designed to transport water from roots to top. Nutrients are retained in the cells and water is lost through stomata. Transport of this water requires quite a bit of energy and we must balance this with energy uses.

Nutrient management also has a very important role in determining quality. As the plants grow, optimum nutri ents are to be supplied in right amounts and at the proper time. Too much nitrogen will result in a very vegetative plant and will result in poor quality buds. This will also cause the plants to be more susceptible to diseases like grey mold and powdery mildew.

Climate control, which means proper temperature –day and night, 24 hours aver age, day to night ramping and night to day ramping, and relative humidity – all have an important role in determining quality.

Proper drying and post har vest handling also affects bud characteristics and thus, quality.

The point is made that qual ity has to start right at the planning stage, and all aspects of management will determine the quality of the plants and the quality of the end product. This translates to your reputation in the marketplace.

By Matt Maurer and Yale Hertzman

In December 2018, Health Canada released its proposed regulations to amend the Cannabis Act and Cannabis Regulations to authorize the legal sale of three new cannabis products: edible cannabis, cannabis extracts and cannabis topicals (collectively, the “new products”).

The proposed regulations, which are in draft only and are not yet in force, were subject to a public consultation process that launched on Dec. 22, 2018 and closed on Feb. 22, 2019. Health Canada is considering the feedback from the public consultation and the final regulations will be released no later than Oct. 17, 2019, one year following the coming into force of the Cannabis Act.

This article provides an overview of the proposed regulations and several of the main proposals in the areas of THC limits, product composition and ingredients, packaging and labelling and good production practices.

Currently, the Cannabis Act authorizes, among other things, the legal sale of dried cannabis, fresh cannabis, cannabis plants, cannabis plant seeds and cannabis oil. Further to the federal government’s policy objective of offering a broader variety of cannabis products to displace the illegal market, it has proposed authorizing three new classes of cannabis for legal sale by federal license holders and provincially and territorially authorized

distributors and retailers: (i) edible cannabis; (ii) cannabis extracts, which are products produced using extraction processing methods or by synthesizing phytocannabinoids; and (iii) cannabis topicals, which are products containing cannabis that are intended to be used on external body surfaces. According to the proposed regulations, a cannabis processing licence (standard or micro) would be required to produce the new products, and no additional licence would be required.

One of the proposals that has received a significant amount of attention is the proposed THC limits on the new products, which are as follows:

• Edible cannabis: Not more than 10 mg of THC per discrete unit and package;

• Cannabis extracts: Not more than 10 mg of THC per discrete unit that is intended to be ingested, such as a

capsule, and not more than 1,000 mg of THC in a single package; and

• Cannabis topicals: Not more than 1,000 mg of THC per package.

The THC limits in edible cannabis are intended to re duce the risk of overconsump tion (which may be higher in jurisdictions where THC lim its are based on serving sizes, therefore making it easier for users to consume more THC than intended). However, a number of parties and indus try stakeholders have raised concerns that these limits will require excessive packaging, resulting in increased costs for licensed producers and potential environmental impact. It remains to be seen whether the final regulations will contain any modifications to the proposed limits.

certain other restrictions.

The proposed regulations include restrictions on the use of

It is proposed that the plain packaging and labelling requirements that currently apply to all cannabis products, including the standardized cannabis symbol, health warning messages and child-resistant packaging, would apply to the new products, with certain additions and modifications. For example, labels for edible

Light cycles. Growth cycles. Business cycles. We craft lighting solutions to improve all three. With expert lighting calculations, custom designs tailored to your environment, and post-installation performance testing, Gavita has what you need to reach your cultivation goals.

cannabis products would need to include, among other things, a list of ingredients, a list of allergens or glutens and a cannabis-specific nutrition facts table. For cannabis topicals, the intended use of the product and directions for use would also need to be on the label.

The proposed regulations provide that cannabis products cannot be represented as having a health benefit or as being suitable for persons with dietary restrictions. Representations that would associate a cannabis product (including its brand element) with an alcoholic beverage would also be prohibited. For cannabis extracts, it is proposed to prohibit representations of certain flavours that are appealing to youth, such as dessert or confectionary flavours.

The proposed regulations include strict manufacturing controls for the production of edible cannabis to reduce the risk of food-borne illness. For example, there

“The THC limits in edible cannabis are intended to reduce the risk of overconsumption.”

are certain prohibitions on producing edible cannabis and conventional food in the same facility, unless the edible cannabis is produced in a separate building.

There are a number of additional proposals and reference should be made to the proposed regulations for further detail. Given that Health Canada is currently reviewing feedback from the public consultation, there may be changes between the proposed regulations and the final regulations, which will be published no later than Oct. 17, 2019.

For more information, please contact the Cannabis Law Group at Torkin Manes LLP at cannabis-law.ca.

A constructed wetland for treatment of greenhouse irrigation leachate & process water.

Our sub-surface, vertical flow constructed wetland consists of sand & gravel beds planted with moisture tolerant plant species. There is no open or standing water & the system is designed to operate winter & summer.

Ontario Regulation 63/09 classifies all process & irrigation leachate water leaving a greenhouse as industrial sewage. Therefore this water requires an Environmental Compliance Approval (ECA) prior to discharge. In addition to sanitary sewage from toilets etc. this industrial sewage is defined as water with added nutrients

• water that has been used for irrigation & washing of crops

• recycled water

• water carried through floor drains inside the greenhouse operation, including water that mixes with storm water (www.ontario.ca/page/rules-greenhouse-operators#section)

Recent projects include:

1) Treatment & re-use of greenhouse irrigation leachate/process water, Niagara & Haldimand counties;

2) Treatment of sanitary sewage combined with greenhouse process water (cannabis) in Niagara & Norfolk;

3) Treatment of winery/brewery process water at numerous sites in Niagara.

We provide turn key systems, including design, permitting (required for discharge) & installation or will partner with your chosen consulting/engineering company.

Contact: Lloyd Rozema at 905-327-4571 or lrozema@aqua-tt.com

Aqua Treatment Technologies Inc. 4250 Fly Road, Campden, Ontario, Canada, L0R 1G0 www.aqua-tt.com

Canada’s legalization of cannabis creates a conflict with a U.S. federal law that prohibits the export, import, sale or transportation of items deemed to be drug paraphernalia.

The law reaches broadly to items for the production, harvesting, packaging, distribution and use of marijuana, potentially inhibiting companies focused on cannabis production and processing activities. The precise reach of the law is ambiguous and lacking clear definition, but there are a few measures companies can take to ensure compliance with the paraphernalia statute and to avoid seizures and penalties of merchandise.

First, companies focused on the cannabis sector should review their product offerings to determine which ones are safe and which ones could be deemed prohibited paraphernalia. The reach of the law is broad. Congress originally enacted the statute to give U.S. enforcement authorities the ability to seize not just controlled substances, but also items primarily intended or designed for a variety of drug-related activities, such as production, manufacturing, preparing and ingesting controlled substances. The U.S. Supreme Court has interpreted the phrase “designed for” to mean items principally used with illegal drugs by virtue of design features are paraphernalia under U.S. law.

An otherwise standard pair of scissors, for example, is not transformed into drug paraphernalia just because it can be used to trim a cannabis plant. Such items can be freely sent across the U.S.-Canada border. Where an item might arguably be prohibited paraphernalia, companies should proactively en-

gage U.S. Customs and Border Protection (CBP) to find out the status of that item under the statute.

The cannabis industry can gain clarity on what is prohibited paraphernalia by asking CBP to issue a prospective ruling.

Second, the cannabis industry can gain clarity on what is prohibited paraphernalia by asking CBP to issue a prospective ruling. CBP rulings will provide certainty as to the status of each item subject to such a request and, ultimately, CBP’s determination controls with respect to an import or export. This step should be taken prior to any transaction that is questionable under the paraphernalia statute to avoid seizure and potential criminal penalties. CBP has legal authority to inspect all U.S. imports and exports for potential violation of federal law. If CBP considers something to be prohibited drug paraphernalia, CBP can seize the items, initiate forfeiture proceedings and initiate criminal penalty proceedings against the parties involved in the transaction.

The CBP rulings issued to date suggest that parties can influence CBP’s decision by producing evidence showing that an item is not primarily for cannabis applications.

Third, recent trends suggest that the scope of what falls outside of the paraphernalia statute may be

significant. In particular, legalization of a broader scope of cannabis derived products under federal law suggest many production- and process-related products fall outside of the statute.

Recent changes to U.S. federal law that permit increased hemp production also raise questions as to the scope of permissible and impermissible cannabis production and processing activities. For example, if a product is designed specifically for harvesting a cannabis plant, is that product in a safe harbour under the new law or does it remain prohibited drug paraphernalia?

CBP has taken the position that U.S. state-law developments in permitting wider use of marijuana products have not changed the scope of the federal paraphernalia statute. CBP maintains that the U.S. Constitution, under the Supremacy Clause, displaces state laws that would otherwise authorize transactions relating to drug paraphernalia.

Until CBP provides greater clarity however, companies would be wise to take a risk averse approach, and only proceed with cross-border transactions for items that clearly fall outside the ambit of the paraphernalia statute.

By Jordan Whitehouse

It’s been over a dozen years now since Nathan Woodworth started growing legal cannabis for himself as a way to deal with chronic migraines.

It was a good move.

Not only did those early buds help relieve the throbbing headaches he had been having 98 per cent of the time, but they led to a now-fruitful deep-dive into how to best grow the stuff.

By the time home-growing was infamously outlawed in 2013, Woodworth, his wife and his brother had tried almost every cultivation method currently being used (and a few that aren’t).

Eventually, though, they landed on aeroponics, a futuristic-like method that uses no medium for the roots. The reason they liked it most, says Woodworth, is because it does one of the best jobs of solving — at least partially — what they call “the data problem”.

“Within a plant system, you can’t see and measure everything that’s going on. There are hidden variables, like what’s going on in the substrate. Aeroponics unlocks that next-level data, however. All of a sudden, we can look past the substrate and we can see what the plant is actually doing within the system,” Woodworth explains.

For the aeroponically uninitiated, picture this: On top of a grow table, flats of tightly-spaced cannabis plants. Under the table, dangling tentacles of white roots being misted with re-used nutrients and water. Nearby is a reservoir where that water is stored and tested.

The method has been around since the 1920s, but it’s really been refined and popularized since the 1990s, when NASA funded a number of aeroponics projects aboard the space shuttle and International Space Station. Today, it’s being used to grow a variety of plants, including vegetables like leafy greens, carrots, lettuce and others.

This method is more popular with cannabis growers south of the border, but it is catching on in Canada,

particularly with medical marijuana producers. In October, for instance, Just Kush announced that it had completed the first construction phase of a facility in the Okanagan Valley in British Columbia that, pending ACMPR approval, would include an aeroponic system. Saskatchewan’s Agro-Greens is also reportedly using aeroponics, as does Alberta’s RMMI Corp., which thinks it will start producing 8,200 kilograms of aeroponically-grown dry product and 1,800 litres of oil annually by the time this issue is published.

The biggest player, though, is Woodworth’s company, James E. Wagner Cultivation (JWC), a licensed producer based in Kitchener, Ont. The company’s first facility has seven grow rooms and produces around

All of a sudden, we can look past the substrate and we can see what the plant is actually doing within the system.

especially root rot pathogens, says Dr. Youbin Zheng, an associate professor at the University of Guelph’s School of Environmental Sciences.

“Research has shown that if plants are grown with substrates, they can have lower dissolved oxygen levels than those grown with aeroponics,” he says. “Lower dissolved oxygen levels, especially those below five parts per million, correspond to higher rates of disease. With typical aeroponics systems, if the root zone is at 25 degrees Celsius, the dissolved oxygen level should be around 8.5 parts per million.”

At RMMI Corp., they’ve decided to use an aeroponic system developed by California-based AEssenceGrows (the other major one being used in the industry is made by Avid Growing Systems in Niagara Falls, Ont.). Based on their initial testing and research, RMMI has found that the AEssenceGrows system could give them higher yields in shorter growth cycles, meaning they could squeeze in one or two additional harvests annually.

Their system also uses about 98 per cent less water than traditional methods because the water is recycled throughout the system. Plus, the set-up allows them to stack their racks. “So even though our facility is about 30,000 square feet, all blown out, it’s the equivalent of 330,000 square feet,” says George Jurcic, the company’s director of corporate development.

As for the economics, Jurcic says that more capital cost was needed up front to pay for the system relative pots and soils, but that they believe payback will be fairly quick. They’re also confident they’ll be able to get their cash cost per gram well under the $2 industry average — likely under $1, in fact.

1,500 kilograms of medical marijuana per year. Its second facility, which is expected for completion by the end of 2019, will have over 140 grow rooms and produce about 28,500 kilograms per year.

There are a few reasons why these Canadian LPs are banking so heavily on aeroponics, and one of the big ones is risk reduction. When you don’t use soil, where a large percentage of contaminants like pests and mold enter a grow operation, that contamination risk is severely mitigated.

Another advantage related to this method is that with aeroponics, plants are less prone to pathogens,

Woodworth also sees those economic benefits, and believes that the proprietary aeroponics system they developed at JWC, called GrowthStorm, “can produce the best quality at the lowest cost, no question.”

GrowthStorm was engineered specifically for cannabis, Woodworth says. Most traditional aeroponic systems aren’t designed for the total root volume and mass of plant that can accumulate over the total lifecycle of a cannabis plant. This one has been, and has also been built in a way that more easily allows growers to deal with plants on an individual basis, adds Woodworth.

If you were to walk into one of JWC’s grow rooms, you’d see two plants grouped together on a single tray in their own separate enclosures. There’d be two trays to a table, and all of the tables would be completely

mobile so that staff can move them and rotate them in order to completely assess the health of the system.

“It’s the difference between your normal street car and a Formula One race car,” says Woodworth. “Cannabis needs to be treated in a particular way in order to perform to its maximum extent, and this system does that.”

If we keep the Formula One metaphor going, like a race car, cannabis also needs high-grade inputs. This is especially true for aeroponically-grown cannabis because one of the biggest challenges is maintaining proper root culture.

In a traditional soil culture, roots naturally decompose and return to the soil. With aeroponics, there’s nothing to mediate that exchange. Plus, roots produce a mucilage that doesn’t interfere with things when using a substrate but can when using aeroponics alone. Thus, aeroponic growers need to use a highly complex nutrient solution to ensure the long-term efficacy of a system.

This is why JWC has spent a lot of time and money developing a unique dual droplet system wherein they’ve de-streamed their nutrient solution into two different chemistries. That solution is delivered into a single root mass using two different droplet sizes.

“This creates a unique environment and a unique interchange of chemistry with the root mass,” says Woodworth. “Root health is vastly improved, as are all plant health metrics across the board. We’re seeing growth which is unprecedented.”

Another challenge related to that nutrient solution is how to avoid the spread of disease, says university professor Zheng. Though this isn’t necessarily a challenge unique to aeroponics, it is more pronounced since all aeroponic systems re-use the nutrient solution. If one plant has a disease, and the nutrient solution it was misted with was also used to mist the other plants, those other plants could also get that disease. Avoiding this comes down to using advanced water treatment practices.

Proper water treatment is also key to avoiding the particles that can clog the nozzles that mist the roots, adds Zheng.

“If you have a small-scale set-up, it’s not a problem because you can quickly see that a nozzle is clogged by debris and change it. But nowadays, with people producing acres of cannabis, how often would they check? If they don’t check enough, the plant won’t get the water it needs.”

Aeroponics is one of the more complex ways to grow cannabis, but the advantages far outweigh those challenges. And not only is this method here to stay, but more producers will likely be exploring and using it in the years ahead – not just for cannabis.

“The total efficiency of [aeroponics] is so great that its impact on the environment, on the world we live in, is the most minimal of any agricultural practice available,” says Woodworth. “In the cannabis industry, it’s one of the most powerful tools at our disposal. But it’s complicated and difficult to understand, so the more we talk about it, the more we write about it, the easier it will be to see its value.”

Jordan Whitehouse is a freelance writer based in Vancouver.

And where there’s mold, there’s crop loss.

Unlike condensing technologies that can actually grow and distribute mold, Agam’s liquid desiccant dehumidification technology captures & neutralizes fungal spores, continuously cleaning the air.And since we use a salt solution, not refrigerants, we’re also helping make plant cultivation a lot greener.

Visit EnvirotechCultivation.com/agam to watch Agam VLHC in action. Plants, People, Passion

LEARN MORE AND REGISTER ONLINE AT:

JUNE 18TH

Flourishing in the technological age

Topics include:

• Biofungicides: Microbe vs. microbe

• Managing pests in the digital age

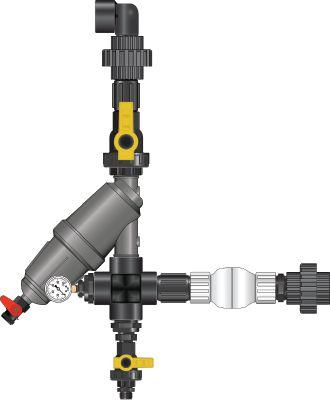

• Clean water: Filter by design

• Grounds for a DIY mix

• Software solutions for greenhouse automation

• The payback on mechanization: A tale of two growers

• Lighting & plant science: A deep dive into using smart LED lighting

• How to co-exist with your cannabisgrowing neighbour

JUNE 19TH

Cultivating your cannabis enterprise

Topics include:

• Innovation in cannabis cultivation

• Safety in cannabis product

• Going organic

• The business case for outdoor grow

• All about hemp

• Procedures and protocols

• Business briefs

• Product packaging

• KEYNOTE: Security and Risk Management for your Cannabis Business

By Tamar Atik

Dr. Ramesh Zacharias has been prescribing medical cannabis for more than a decade.

As the medical director of the Michael G. DeGroote Pain Clinic and co-chair of the Physician Advisory Group at the Michael G. DeGroote Centre for Medicinal Cannabis Research (CMCR) at McMaster University in Hamilton, Ont., Zacharias works with a motivated team that wants to bring more cannabis knowledge to the forefront.

A growing number of licensed producers (LPs) are recognizing the importance of working with the research community to produce more peer-reviewed results. The more science-backed information becomes available, the more physicians might begin prescribing cannabis-based products. And isn’t that the goal for producers in this competitive and rapidly changing industry?

The medical benefits of cannabis have been shown in some studies to date, but as both researchers and LPs tell Grow Opportunity, those studies are few and far between.

Two heads are better than one Studies can be expensive and Zacharias says LPs should know they need not contribute monetarily in order to make a difference. At McMaster’s pain clinic, trial costs are covered by the clinic and products are the most valuable contribution LPs can provide.

The pain clinic has partnered with Vaughan, Ont.-based medical cannabis producer CannTrust to conduct a randomized, double-blind, placebo controlled clinical trial on the efficacy of its proprietary cannabis oil capsules for managing chronic, non-cancer pain.

“We are hoping that our proprietary cannabis oil capsules will reduce dependence on much stronger and dangerous medications, such as opioids,” says Ilana Platt, vice-president of innovation and global regulatory affairs at CannTrust.

CannTrust is providing two products for the clinical trial – a CBD oil capsule and a combination CBD/ THC oil capsule – that will be randomized to participants. A third group of patients will receive placebo capsules that do not contain CBD or THC. The trial will be comprised of 309 participants split randomly be -

tween two phases. In phase one, both the patient and the prescriber will know what treatment is being prescribed. And in phase two, neither party will know what has been prescribed until the end.

The patients will be monitored over 12 weeks to see whether either product has reduced their pain or improved their overall quality of life. Zacharias says the end goal is to get clarity on both the benefits and potential harms of cannabis, including whether there is a difference between those two products as it affects pain, sleep, mood and anxiety.

He says there are about half a

dozen research projects that LPs have been involved with at the clinic, each with a different set of researchers depending on the topic and the interest of the LP for their product.

“We don’t only work with CannTrust, but when we decided to look at the study, it made sense to approach CannTrust to do the study, but it could have been anybody,” Zacharias explains. “They’ve been absolutely wonderful to work with, very cooperative and they have a very professional team.”

McMaster’s main criteria for engaging with an LP to do research involves reserving the right to publish

the study findings regardless of the results. “We are an academic institution at McMaster. We are neither pro-cannabis nor anti-cannabis; we’re simply pro-evidence,” says Dr. Jason Busse, associate director at the CMCR.

CannTrust is also partnered on another university trial with Australia’s Gold Coast University Hospital. It’s a clinical trial to determine the effectiveness of CannTrust’s CBD oil in delaying the progression of ALS or motor neuron disease.

“Our research will help educate physicians and the public surrounding the use of cannabis,” Platt says. “This is our way of building the data

for the physicians to gain their trust and also their acceptance for prescribing cannabis to their patients.”

Randomized control trials are the gold standard of evidence in the health-care system, says Busse. “This is what (LPs) are going to be asked for to support indications for their different products.”

Health Canada currently has more than 350,000 patients registered to use medicinal cannabis, including 10,000 veterans. And the numbers rise every year.

“We have a standing meeting once a week and I can’t remember the last one where we did not have a licensed

McMaster University’s new Science of Cannabis program is one of the first post-secondary programs in Canada focused on the scientific study of cannabis and its therapeutic applications, risks and harms. In partnership with the Peter Boris Centre for Addictions Research and the Michael G. DeGroote Centre for Medicinal Cannabis Research, the program offers an evidence-based approach to understanding the science behind the substance. As a three-course academic certificate of completion, the program can be taken entirely online through McMaster Continuing Education and will be available to interested persons working in the health, education, public service, and social and community services sectors across the country.

producer come to be part of that meeting,” Busse notes. He says more LPs are becoming interested in working with researchers because they recognize that there’s an information gap.

“There’s a lot of clinicians that are simply hesitant to authorize medicinal cannabis at all because of their limited experience and limited knowledge about the evidence out there,” he explains.

As a physician who later entered the medical cannabis space, Dr. Peter Blecher, understands the issue.

“I think there is a social responsibility for all LPs to be involved and focused on clinical research,” says Blecher, who is the chief medical officer at Toronto, Ont.-based cannabis licensed producer Starseed Medicinal Inc. “I think all the data ultimately will

help everyone.”

Starseed has dedicated resources and funds to do its own studies that investigate both condition outcomes and displacement of opioids and other medications using cannabinoids. The LP works with the Laborers’ International Union of North America (LiUNA), Canada’s largest construction labour union, where overuse of opioids for pain is prevalent among workers.

Construction workers over index for chronic pain, and possibly medication use, as a result of their work, Blecher explains. A recent study in Massachusetts found that one in four opioid deaths involved construction workers, an industry in which some 15 per cent have a substance abuse disorder – twice the national average.

“If cannabinoids can help displace that, I believe that we can actually create a safer workplace with less absenteeism, less pre-

senteeism and hopefully show improved safety records and reduced accidents,” Blecher says.

Through LiUNA, Starseed also works with Seasons Retirement Homes owned by the union. The producer is partnering with the organization to study the benefits of cannabis in managing delirium, and potentially dementia, in the elderly population.

Blecher explains that the average retirement home resident is on a dozen or more medications, many of which are sedatives for mood disorders, anxiety or pain. The cumulative effect of this medication burden can lead to delirium, and in turn to increased falls and fractures – and that, he explains, could result in extended bedrest that leads to strokes and heart attacks.

“We want to see whether cannabis can help displace a number of these drugs,” explains Blecher. “If we can do that using CBD

We focus on the automation of indoor farming

So you have full control over the growth of your cannabis plants

Hoogendoorn’s next generation iSii monitors and controls all climate,irrigation and energy equipment in all types of facilities such as greenhouses and buildings. The iSii is equipped with advanced controls that work according to the principles of Plant Empowerment. This way light, temperature, humidity and CO2 are aligned with each other for a maximum photosynthesis. In addition, to prevent water stress, irrigation is driven by the evaporation energy and water balance of the crop. With the iSii process computer, you set the base for high quality production.

info@hoogendoorn.ca | www.hoogendoorn.ca

with a small amount of controlled THC, then there’s a lot of emerging data to suggest that many of these elderly patients actually have a vastly improved quality of life.”

Canadian producers aren’t the only ones focused on improving quality of life. Although the U.S. hasn’t federally legalized marijuana yet, the states that have are busy making their own advancements.

Take Jason Cranford, founder of the Flowering HOPE Foundation (FHF) in Colorado. He is funding the first U.S. clinical study on the benefits of medical cannabis in partnership with Clover Leaf University in Denver.

FHF is a non-profit organization that supports the medicinal use of plant-derived cannabinoids, called phytocannabinoids. The organization was one of the first li-

“We want to educate the neurologists through this research so they know there’s another option.”

cences issued for hemp cultivation and partnered with Clover Leaf to comply with federal law that requires all hemp cultivators in the U.S. to be involved in research studies with an institution of higher learning. FHF is paying for the research with the $40,000 it raised at a golf tournament.

“The three things we wanted to study were autism and cannabinoids, epilepsy and traumatic brain injuries [TBI],” Cranford explains, adding that NFL players suffer from the latter and take pharmaceuticals that

make it worse. His team applied for all three studies through the Institutional Review Board (IRB) and were approved for all three, but the TBI study is being rolled out first.

“We have the first cannabinoid TBI study that’s approved through an IRB in the United States,” Cranford says. “We think that’s going to be a much more impactful study because there’s nothing that precedes it.”

FHF wants to pave a new path for TBI treatment. “We want to educate the neurologists through this research so that they

know there’s another option,” Cranford says. He understands there’s much more give than take in the work he is doing, but he believes in the wider benefits that could result from his investments in research.

Those benefits are not limited to North America. European patient numbers are predicted to surge from 130,000 to 225,000 in 2019 in the region’s three largest markets (Italy, Germany and The Netherlands), according to a recent report by legal cannabis expert Prohibition Partners. The forecasted increase is due to both legislative change and increased awareness of the potential health benefits of cannabis products.

Cranford says more peer-reviewed research papers will reverse the stigma on cannabis. “The reefer madness stigma has gone on for almost 100 years. The only thing that’s going to change that stigma is reversing it. The only way to reverse it is to produce

science. It’s peer-reviewed research that shows the effectiveness of cannabinoids.”

‘Only scratched the surface’

It may be too soon to tell what the future of the medical cannabis sphere will look like, but Busse says the research needs to be strong enough to stand up to scrutiny from the most intense critics.

FHF’s Cranford believes cannabis is slowly transcending its dark past. “I think now we’re crossing over that line between the black market and legitimate businesses,” he says. “Eventually, we’re going to have pharmaceutical grade cannabis products that are backed by people with PhDs behind their last name. That’s the direction it’s heading.”

For certain medical conditions, the evidence is strong, notes CMCR’s Zacharias. “The bottom line is we have some research and some evidence that is relatively strong

for certain conditions: seizures in pediatric patients, patients who have spasticity disorders like MS and moderate evidence for patients with chronic pain.

“There’s still a lot of evidence to gain in nociceptive pain, PTSD, depression, sleep, anxiety and inflammatory problems.”

Zacharias encourages a cautiously optimistic approach. “Where our optimism can grow is by doing well-controlled trials,” he says. “One of the things that people don’t understand is that cannabis is not a single product; it’s a very complex product. There are hundreds of different chemicals within the cannabis plant. We have only studied two. We’ve only scratched the surface on the potential of the cannabis plant.”

Tamar Atik is the associate editor of Grow Opportunity. Email her at tatik@annexbusinessmedia.com.

Mari-Len

One of Canada’s first large-scale outdoor farms is prepped for primetime

By Mari-Len De Guzman

About an hour and a half west of Toronto in Brant County, a 100-acre organic farm is getting ready to receive its first batch of cannabis seeds. Surrounded by 5,800 meters of perimeter fencing and several state-of-the-art security cameras, The Good Farm is expected to produce about 40,000 kilograms of dried cannabis once cultivation gets underway.

When Health Canada announced last year that it will allow the cultivation of cannabis outdoors, Jeannette VanderMarel and her team at Good & Green, a subsidiary of 48North Cannabis Corp., immediately began the work to apply for a Health Canada licence for outdoor grow.

“I have always believed that cannabis belonged outdoors,” the president and cofounder of Good & Green and co-CEO at 48North tells Grow Opportunity. “It only moved indoors because of its illegality.”

Just days after the Cannabis Act came into force on Oct. 17th, the Brantford, Ont.based licensed producer applied for an outdoor cultivation licence with Health Canada. As of this writing, the application is still pending, but VanderMarel hopes that long-awaited go signal will come in time for spring planting. The company did, however, get its processing licence for its Brantford site, where it will bring harvest from the outdoor farm for extraction and processing.

There are three types of Health Canada licences for outdoor cultivation: nursery, micro and standard cultivation. There is no limitation on the type of cannabis that will be permitted, and no THC limitations as well.

Outdoor growing is far from a novel approach for cannabis cultivation. California produces an estimated 326 million grams of

outdoor-grown cannabis annually, according to data from the U.S. Department of Agriculture. Kentucky and Tennessee are also big producers of sun-grown cannabis. The warmer climate in certain states south of the border certainly makes them ideal locations for outdoor cultivation. However, VanderMarel says Ontario’s southwestern region – jokingly referred to as the banana belt – is one of only a few places in Canada where cannabis can really grow outdoors.

“If you look at crop heat units, it really is an ideal area to grow fantastic cannabis outdoor. It’s basically southwestern Ontario and a little tiny part of lower B.C. where you really have the units and the season to grow good, quality outdoor cannabis,” says VanderMarel, who happens to know a thing or two about crop growing.

Coming from a family of Dutch immigrants, farming is in VanderMarel’s DNA. Her family is one of the larger apple producers in Ontario. Even as she pursued a career in health care in her early adult life – as a registered nurse and then as a certified critical care nurse specialist – fate had another plan.

“My daughter, Breanne, was born in 1994. Unfortunately, she had Dravet syndrome. The worst symptom is uncontrollable epilepsy,” VanderMarel recounts.

“Despite her being on over 20 drugs, she never stopped her seizures and her development slowed, with the constant seizures and the toll that the drugs were taking on her body. She never had cannabis, I did not know about it then, despite me working in a teaching hospital.”

Breanne passed away in 2003. Carrying

Top quality analytical standards for analysis of Phytocannabinoids, Terpenes, Pesticides, Residual Solvents, and Mycotoxins.

Available as single standards or multi-component mixtures.

Guaranteed authentic quality control microbial strains for licensed testing labs, provided in a convenient frozen format –Just open, plate, and go!

Cannabis plant culture cultivation kits and reagents including dry powder media, pre-poured media, plant growth regulators, growth vessels, and bioreactors.

• Plant tissue culture reagents (regulators, antimicrobials, etc.)

• Sample labelling, packaging

• Sample extraction, cleanup

• DNA / RNA / Protein analysis

• Microbiology QC Strains

to discuss your project and how shopping with Cedarlane will save your lab time & money. Reference code GROWOPP19 to receive 10% off your first order PLUS a complimentary wall poster for your lab: A guide to the biosynthesis, naming, and numbering of phytocannabinoids

• Biochemicals/ Buffers

• HPLC / MS consumables (Filters, Columns, Resins, etc.)

• Analytical standards (compounds/chemicals)

• Industrial vacuum sealers, stackable drying racks

on her work at the hospital, VanderMarel eventually came to hear about and have seen families using cannabis to manage epilepsy. That sparked her interest.

“If you’ve ever watched your child have seizures, turn blue and stop breathing, you would cut off your arm to do anything to help,” she says. This led her to explore the possibility of conducting clinical trials on the health benefits of cannabis, but was informed by Health Canada that she needed a research and development licence and would have to grow the cannabis herself.

That started her journey to becoming one of the pioneering women leaders in the Canadian cannabis industry, co-founding and self-funding The Green Organic Dutchman (TGOD) with her husband, Scott Skinner, in 2012. TGOD has since been sold to another entity but the husband-and-wife team still remains as significant shareholders in the company, VanderMarel says.

Organic cannabis farming is the foundation of VanderMarel’s cannabis play and corporate social responsibility her operational standard. “Failing miserably” at retirement after selling controlling equity of TGOD, VanderMarel eventually founded a new cannabis company – Good & Green ¬ aiming to fill what she found lacking in the developing cannabis industry.

“I looked at the industry and I saw that there were still gaps... around women (representation), obviously... but as a developing industry it was very ‘stock promoty’ momentum play. There weren’t any real metrics… no one seemed focused on profitability, diversity, corporate social responsibility, ethics – all those things that I think a good corporation needs.”

Good & Green was later acquired by another female-led corporation, 48North. VanderMarel now shares the CEO role at the newly merged companies with 48North’s Alison Gordon, a structure that capitalizes on each woman’s unique leadership strengths. VanderMarel is focused on the operational management of the 46,000-sq-ft. Brantford facility, the 100-acre outdoor farm, as well as 48North’s 40,000-sq-ft. indoor cultivation and processing operations in Kirkland Lake, Ont. She also looks after government relations and human resources. Gordon, mean-

while, is focused on sales, marketing and investor relations.

The 100-acre farm will be 100 per cent organic, says VanderMarel. Most of the cannabis crop that will be produced from The Good Farm will be destined for extraction to produce 48North’s next generation of products in the health and wellness consumer space.

In the Brantford facility, dozens of large bags of organic soil are sitting in the warehouse, waiting to be placed on the ground once cultivation commences.

“We’re basically doing it like field tomatoes,” VanderMarel explains. “We will be laying rows of plastic mulch on the ground with dripped irrigation underneath. We’ve done hundreds of soil tests. We bought all our organic soil amendments that we’re going to be putting on the farm. The soil has the fertilizers and nutrients right in it so when the plants go in, they simply draw what they need.”

The farm will use watering ponds and existing wells for irrigation. Except for water, nothing else goes in the plants, the 48North executive says. “It’s a pretty simple method of growing. It’s our first year of growing so we want to make sure we are using standard growing methods. The farm across the road is growing tomatoes in the exact same method.”

As with its indoor cultivation, beneficial

insects, such as mites and nematodes, will be used to prevent the influx of pests in the farm, and they will be placed on the soil during the early stages of planting.

The growers will also be relying on nature to help nurture the plants. “Plants in general release terpenes and essential oils, and they do that on purpose to deter pests and insects and other rodents,” the farmerturned-CEO explains. “Cannabis releases a lot of terpenes. Plants have evolved that way to protect themselves.”

The sun also makes a formidable ally for outdoor farms. Cannabis plants are exposed to endless amounts of natural ultraviolet (UV) light that combats pests, pathogens and mould.

“A lot of indoor growers actually use UV light to try to mitigate pests; we have it naturally outdoor,” VanderMarel happily notes.

More than a pest buster, the sun also helps the cannabis grow larger than they would ever do indoors, where they are only exposed to artificial lights and light penetration into the plant can be limited. “The sun penetrates all the way through.”

The company is anticipating two growing cycles within a year. Seeding will begin indoors at the Brantford site. The plants will then be planted on the farm during late May or early June. Two varieties of cannabis will be planted outdoors. First are autoflowers of the ruderalis phenotype. These types are not dependent on light cycle, according to

VanderMarel, and generally grow to maturity in 10 weeks or under.

“It will flower under longer periods of light. As you know, we get a lot of light in the summer time,” she says. “We hope to actually get two crops of that plant.” Planting in late May or early June will allow for harvesting by end of July. A second batch of seeding will begin in mid-July and will be planted on the farm immediately after the first harvest. The second harvest will be done at the end of September.

The second variety will be cannabis strains that are known to be ideal phenotypes for outdoor growing, the 48North executive says. “Those ones are more dependent on the light cycles.”

Using outdoor farms for low-cost, large volume quality cannabis production not

only makes sense economically, but environmentally as well. The cost of producing cannabis in a large-scale indoor facility is between $1 and $3 per gram, according to estimates by cannabis consulting firm Cannabis Compliance on its website. Outdoor farming, on the other hand, could bring production costs to below 0.20 cents per gram, the company notes.

“It just does not make sense to grow it indoors,” VanderMarel states. “Growing cannabis indoors does create good, quality products but it’s not environmentally friendly.

“I think consumers really do care about whether their products are grown appropriately and sustainably. I would really like to be a carbon-negative company.”

If the latest report from Nielsen is any indication, sustainable production practices are increasingly becoming the norm.

“Looking for a better lifestyle, consumers are searching for options that are healthier for them and for their homes,” Nielsen states in a November 2018 article, “Sustainable shoppers buy the change they wish to see in the world.”

More than 80 per cent of consumers globally feel strongly that companies should do their part to help improve the environment. The same global survey says 41 per cent of consumers are willing to open their wallets for products that are organic, and 38 per cent are willing to spend more on products made with sustainable materials.

With the impending changes to the Cannabis Act to allow for the legal production and sale of cannabis-infused products such as edibles, extracts and topicals, the cannabis industry is poised to expand its consumer base to non-traditional cannabis users. As the cannabis market opens up to

Your fire. Our fuel. We put the brands that matter, in your hands, when you need them. With 6,000+ skus in stock across 11 North American distribution centers, Hawthorne is built to accelerate your growth.

a wider consumer population, the case for corporate social responsibility and environmental sustainability gets even stronger.

48North currently operates two indoor cultivation facilities: the DelShen Therapeutics production facility in Kirkland, Ont., and Good & Green in Brantford, with a combined annual production capacity of 5,000 kilograms.

“We have two indoor facilities that we try to manage as well as we can using LED lights and glycol-based HVAC so we’re not putting a huge strain on the environment,” VanderMarel says. “The bulk of our products, pending Health Canada approval, will come from the outdoor grow. And the electricity needs and the infrastructure needs are minimal compared to what we need for an indoor grow.”

ucts coming from the organization all-natural and organically grown. The indoor production facility in Brantford is already growing cannabis organically. VanderMarel is currently leading the charge in transitioning the DelShen indoor grow to full organic cultivation.

VanderMarel is no stranger to organic certification, having gone through the process with her first “baby” TGOD for Ecocert certification.

“I think it’s important as a market differentiator, but also for our target consumers,” she says. “We know that the organic shopping basket is getting bigger weekly. Also, consumers are getting more aware of what they put in or on their bodies.”

GH_AndyLang_June2016 copy.pdf 1 2017-10-17 9:45 AM

48North, and VanderMarel in particular, is on the path to making all cannabis prod-

One of the biggest infrastructure investments in outdoor cultivation is the secur-

ity system. 48North spared no expense in ensuring that its farm is equipped with the latest security systems to protect its crops from any type of breach.

“Under Health Canada, we have to be aware of any actual or attempted intrusions. Whether it be at our other sites or our farms, we can detect someone before they even approach the fence,” VanderMarel says.

“On top of that we have everything from infrared sensors, vibration sensors, invisible lasers. There’s a lot of security infrastructure that we’ve put in place in there that we feel exceeds the expectations of Health Canada.”

The company also recently hired a new head of security; a retired local police officer from Brantford who also runs a security company.

A large security force will be present at the farm, especially during harvest time, VanderMarel adds.

Lower labor, fertilizer and water costs while acheiving higher yields and better quality crops. Growlink precision nutrient injection systems provide a quick return on investment by providing plants with only what they need, when they need it.

Program up to 32 di erent recipes and feed your entire farm from a single system. Works with both in-line and diluted tank applications.

By Damon Bosetti

Fueled by an increase in hightech “vertical farming” and cannabis cultivation centres, lighting for indoor agriculture is one of the fastest growing load categories for many electric utilities in Canada and the U.S.

A U.S. Department of Agriculture report by Navigant Consulting in late 2017 pegged the annual electricity consumption of horticultural lighting installations at 5.9 terawatt-hours (equal to the annual electricity production of a gigawatt-class Canadian hydro station), and estimated that consumption will increase between 15 and 25 per cent per year, as more indoor agricultural operations come on line. Similar increases can be expected in Canada – perhaps even more so, since the colder climate pushes more cultivation indoors.

While rising electricity usage for grow lights impacts farmers’ bottom lines, on a large scale it also has the potential to stretch the limits of energy efficiency and greenhouse gas emission reduction targets set by various government entities.

The good news is that technology available right now can reduce growers’ energy costs, while making them pioneers in a new area of efficient production. The same Navigant Consulting, Inc. report cited above found that switching all U.S. agricultural lighting to light emitting diode (LED) technology could reduce the sector’s annual electricity consumption by 40 per cent, a savings of approximately $240 million. As LED technology continues to improve in efficiency, this savings potential will only increase.

Against this backdrop, the DesignLights Consortium (DLC), an NGO that helps utilities define and incentivize high performance lighting products, announced late last year a first-of-its kind performance standard for horticultural fixtures.