The aeroponics advantage

COLUMNS

Complying

Master the supply chain as a micro

“I will not comply” – In cannabis, you should 20 | Vantage Point

The state of cannabis tourism in Canada

DEPARTMENTS

FEATURES

14

COVER STORY

The aeroponics advantage How aeroponics is enabling Canadian growers to achieve premium results, and premium profits BY

TREENA HEIN

18

Developing genetics at Aurora Coast

Taking the industry’s R&D efforts to the next level BY

CATARINA MUIA

From the editor

By Catarina Muia

The importance of in-person networking

Ithink everyone can admit that while we didn’t have high expectations for 2022, we had some hope that things would start to slowly move back to normal.

I must say, it feels like the expectation to move back to normal is there but the dark days, cold weather, and restrictions are making it difficult to see the light at the end of the tunnel.

One thing to keep in mind is that it’s already February, which means spring is on its way (I write as I sit bundled in blankets…), and with it will come the sunshine, warmth, and the opportunity to meet again at the Grow Opportunity and Greenhouse Canada Grower Day 2022 event.

While last year the Grower Day event was run virtually, this year, we plan to host the event live and in-person at the Holiday Inn and Suites Conference Centre in St. Catharines, Ont. on June 21 and 22.

While I’m certainly excited to organize a number of interesting and educational sessions for growers across the country, what I’m looking most forward to is meeting with those of you I haven’t had a chance to connect with yet!

As the Canadian cannabis industry continues to develop, it’s important now more than ever for all of us within the industry to meet in person, have transparent conversations, and see what is available in the market in terms of

products, solutions, and new technologies that can be utilized to enhance cannabis cultivation and production.

Do you have a new product or solution that can help the industry’s growers achieve some of their cultivation, production, and post-harvest goals?

Be sure to check out the Grower Day exhibition application form, found at www. growerday.ca/apply-to-exhib -

As the industry continues to develop, it’s important now more than ever for all of us to meet in person and have transparent conversations.

it/, or reach out to Grow Opportunity publisher, Nashelle Barsky (nbarsky@annexbusinessmedia.com) to book a space on the event’s expo floor.

For those of you interested in contributing to our educational conference, we are beginning to develop our conference program and are looking for knowledgeable and experienced growers, researchers, health professionals, and cannabis business owners to discuss topics such as:

• Cultivation

• Disease and pest management

• Security and cybersecurity

• Insurance

• Supply chain challenges and solutions

• Genetics and breeding

• Industry best practices and lessons learned

• Lighting and packaging

• Market trends

• Post-harvest

• Quality and preservation

If you are looking to speak about one of these topics to help educate your peers and colleagues, please send me an email and we’ll be sure to get you involved.

As a grower within the Canadian cannabis industry, if there's an important topic you think should be addressed that you do not see listed above, drop me a line and let me know! I look to insight of our industry's experts to ensure Grower Day will educate our audience, and include something for everyone.

Be sure to check out the Grower Day website for new updates on topics, speakers, exhibitors, and sponsorship opportunities.

Within the Grow Opportunity magazine, if there is a topic you would like to learn more about, or would like to teach your community about, as always, free to send me an email at cmuia@annexbusinessmedia.com.

I would love to hear your feedback and get to know the members of our community. I’m looking forward to meeting and learning from each of you!

With that, I leave you to read, learn, and enjoy this issue of Grow Opportunity magazine.

Happy reading!

January/February 2022 Vol. 6, No. 1 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Shawn Arul, Audience Development Manager

Tel: (416) 510-5181

Fax: (416) 510-6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Catarina Muia

cmuia@annexbusinessmedia.com 519-410-0600

ASSOCIATE EDITOR Jean Ko Din jkodin@annexbusinessmedia.com 437-990-1107

PUBLISHER Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR

Mary Burnie mburnie@annexbusinessmedia.com 519-429-5175

MEDIA DESIGNER

Curtis Martin

GROUP PUBLISHER/VP SALES Martin McAnulty mmcanulty@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

1 year subscription (6 issues: Jan/Feb, Mar/Apr, May/Jun, Jul/Aug, Sep/Oct, Nov/Dec):

1 year offers: Canada $25.50 + Tax USA $47.00 CDN FGN $53.50 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Hexo receives warning from Nasdaq

Hexo Corp. says the Nasdaq Stock Market LLC has informed the Gatineau, Que.-based company that it is not in compliance with the minimum bid price requirements.

Hexo became non-compliant with the requirement when its closing bid price for common shares listed on the Nasdaq dropped below US$1 for 30 consecutive trading days.

The company’s shares closed Jan. 28 at 50 cents US a share, down from US$31 a share in April 2019.

Hexo says the Nasdaq notification has no immediate effect on its listing, but gives the company until July 25 to have its shares close at or above US$1 per share for a minimum of 10 days to become compliant again.

Hexo, which also has a Toronto Stock Exchange listing, parted ways with co-founder Sebastien St-Louis last year and quickly embarked on a new strategic plan to reduce expenses by about 30 per cent by the end of fiscal 2023.

- THE CANADIAN PRESS

Fire & Flower acquires Pineapple Express Delivery

Fire & Flower Holdings Corp. has completed the acquisition of delivery company, Pineapple Express Delivery Inc. (PED).

PED is one of the largest cannabis delivery services in the industry, boasting 40,000 deliveries per month across Canada.

As part of the purchase, Fire & Flower assumed and repaid CA$5.15 million in debt owed by PED.

“The acquisition of Pineapple Express Delivery marks the final step in building, what we believe to be, the cannabis industry’s first end-to-end consumer technology experience,” said Fire & Flower CEO Trevor Fencott.

$43.5B

The amount that the cannabis industry has boosted Canada’s gross domestic product, according to a study by Deloitte Canada and the Ontario Cannabis Store.

Cannabis companies face ‘crossroads’ selling off assets

West Blvd's first culinary cannabis facility

The new facility in Mount Pleasant, Vancouver is said to be the first of its kind in Canada. It will undertake research and development of new products in a state-of-the art test kitchen. It will also host on-site palatability testing for new product development and educational events.

Cannabis companies are listing cultivation facilities, retail shops and warehouses for sale as the industry tries to streamline production and better align its capabilities with demand.

Industry observers say there are so many cannabis assets available to buy because, while demand for cannabis is high, many companies have misjudged what consumers want and are cutting products and pivoting their businesses toward items more likely to fly off shelves.

“An increasing number of licensed cannabis businesses are coming to a crossroads where they’re having to look at the realities of their business, the industry, the market, the challenges, and the economics,” said David Hyde, CEO and co-founder of Hyde Advisory and Investments Inc., a cannabis-focused consultancy company in Toronto.

“They’re having to make a decision about whether they’re going to be able to continue on down the path and adjust themselves accordingly to the market, or whether there is a merger or sale that’s going to allow them to move forward in a better way.”

Those conversations and ensuing

urges to sell have ramped up over several years with companies as large as Canopy Growth Corp., Tilray Inc., and Aurora Cannabis Inc. letting go of assets.

But even more listings have materialized in recent months as companies saw the path to profitability wasn’t quick and easy to traverse, especially during the COVID-19 pandemic.

Some companies have experienced demand for particular products that is well below their expectations and have been left with a glut of cannabis to sell.

Others are struggling to stand out as the number of cannabis products for sale in the country swells, craft cannabis’ share of the market grows, and illicit sales remain mighty.

Hyde thinks the selloff won’t slow down soon. He predicts it will last another 18 months.

But he doesn’t believe the itch to sell means there are no cannabis opportunities. Micro and midsized companies will still find niches and ways to profit.

“There’s going to be a lane for them, but there’s not going to be a lane for everyone,” he said.

- TARA DESCHAMPS, THE CANADIAN

PRESS

Mohyuddin Mirza, PhD, is an industry consultant in Edmonton, Alta. He can be reached at drmirzaconsultants@gmail.com.

Gagandeep Singh Bhatoa is a scientific writer in Regina, Sask. Email him at gaganagrico@gmail.com

Complying with cannabis physiological rules and regulations

Part One:

Understanding the role of CO2 and stomata

Whether we grow indoors, in greenhouses, or outdoors in a field, growers are well aware of rules and regulations that we must comply with, and that we must keep all the records for audits. In the end, we get a sales licence.

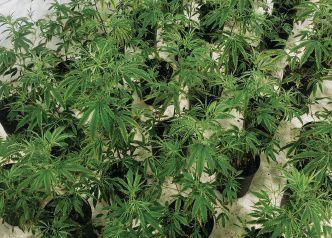

This article focuses on the cannabis plant’s own rules and regulations that must be complied with. A cannabis plant is totally dependent on the grower for its optimum performance. While a grower may look to prioritize these physiological rules, experience has shown this may not be the best way to proceed, as cannabis plants perform best based on a totally holistic or integrated approach.

If any one of the plant’s needed rules and regulations aren't followed, the plant’s performance is hindered and consequences will be serious.

Understanding photosynthesis

Cannabis, like other plants, is designed to fix light energy, (photons), in a biochemical form. To do so, the plant needs carbon dioxide and water. This is known as photosynthesis. Under cannabis rules, light, water, and carbon dioxide must

be provided in proper proportions, at the right time. For example, a grower tried to push the crop by providing CO2 evduring the dark/night period. It violated the principle of not using CO2 during the dark period, and plants suffered.

6CO2 + 6H2 O + light energy

= C6H12O6

+ 6O2

This formula's process is carried out in the leaves with green colour (the pigment chlorophyll), and several laws of physics, chemistry, and biology are involved. Inside the leaf there are chloroplasts, where all these reactions are carried out. Here are the key points to understand the above fundamental equation.

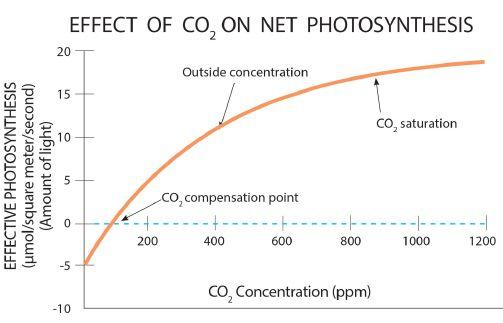

The importance of CO2 for photosynthesis

The rule of the plant is ensuring there's enough carbon dioxide surrounding the leaves. Cannabis uses CO2 in the presence of light, which is also critical for photosynthesis. Cannabis plants suffer if they don’t get at least a minimum amount of

CO2. Increasing the CO2 concentration beyond that, without increasing light intensity, doesn't result in a higher rate of photosynthesis. The cannabis plant cannot benefit from higher CO2 levels until the light intensity increases.

At a light intensity of 600 mol (4,600 fc) (49,310 lux), the photosynthesis rate increases as CO2 concentration is increased to 400 parts per million (ppm). However, the rate of increase declines a bit after that, but the photosynthesis rate continues to increase as CO2 levels reach 600 ppm.

The ambient air has around 400 ppm of carbon dioxide gas and when plants start using that, the level can drop rapidly to half of that rate in which state, plants will stop during the photosynthesis. The process of photosynthesis speeds up as the amount of CO2 in the air elevated, as long as there is enough light to power it.

Photosynthesis slows to a crawl and virtually stops at a CO2 concentration of around 200 ppm, as given in Figure 1. In an

outdoor situation, the ambient CO2 is not depleted because of constant air movement, however in greenhouses and indoor operations, additional CO2 has to be supplemented.

How much CO2 is enough?

How much CO2, is enough for your cannabis plant? At less than 100 ppm of CO2, photosynthesis does not take place and cannabis plants suffer a net loss of sugar due to respiration.

At 100 ppm CO2, respiration and photosynthesis are equal so there is no net loss or gain. At 400 ppm (the same as outside air) the photosynthesis rate increases quickly, as the CO2 levels rise.

The increase in photosynthesis is more moderate as the CO2 concentration climbs to 800 ppm. However, from 800 to 1,000 ppm, some growers think that more is better.

But, the plant’s rule is that over 1,000 ppm, the stomata may not fully open. Stomata on cannabis plants can be triggered to open as a direct response to adequate light so the plants can use the carbon dioxide during photosynthesis.

Safe CO2 for your cannabis plant

Is there a rule for where your cannabis plant’s CO2 should come from?

Yes, plants don’t respond well if open flames are burned inside a facility. Such CO2 burners have been seen in some facilities. These open burners can raise the temperature and could also add some

Figure 1

Dr. Mohyuddin Mirza and Gagandeep Singh Bhatoa

pollutants like carbon monoxide, nitrous oxide, and other combustion products. These pollutants go against the cannabis plant’s rules. Liquid CO2 is preferable.

The needs of a stomata

A cannabis plant’s stomata must be open to absorb CO2 inside the leaf, so it can be transported to the site of photosynthesis.

Keeping the stomata open requires proper water and potassium. Too much air movement isn’t good for the plants as well. For the CO2 to be diffused into the stomata, the air around the leaf has to be stationary.

The stomata openings are found mainly on the underside of the leaves must be kept open during the light period, and that depends on proper watering in the root zone and adequate transpiration from the leaves. Rules for stomatal opening are complex and contradictory demands are placed on

them during the growth cycle; growers must understand them for proper functioning of the cannabis plant. Stomata are the regulator of water status inside the leaves.

For example, when light is ‘on’ (daylight, LED, or HPS lights), it signals to the stomata that it should start opening. If irrigation isn't timed to coincide with the light, then the signal is not to open the stomata

because there isn't enough water.

Similarly, if the temperature is over 24 C or 25 C, the signal is to absorb and transport more water from the roots to the leaves, and the stomata will start closing to preserve the water inside the leaves.

Understanding the stomata is a fascinating aspect of production of cannabis, and it's important to its functioning.

Figure 2 shows a plant expriencing water stress and potassium deficiency. Yellow spotting can be seen on edges of all the plants, leaf edges rolling inward due to high relative humidity and over-supply of carbon dioxide from an open burner, which caused some pollutants to damage the leaves. Many rules and regulations of the plant were violated.

Future articles will discuss rules and regulations which relate to water, light, nutrients, and how they can make buds bigger and more bioactive compounds.

Figure 2

Micromanagement

By David Brown

David Brown is the founder of StratCann, a cannabis industry publication with a special focus on micros and nurseries. Prior to StratCann, David was a senior policy advisor to Health Canada’s cannabis branch from 2018 to 2020.

Master the supply chain as a micro

No licence holder is an island.

Many cannabis companies may seek to be fully, vertically integrated and own all aspects of the supply chain from seed-tosale. After all, who doesn’t want a chance to better control how their product is sold while taking home a bigger cut of the profits?

But in the cannabis industry, like many others, partnerships can be key when it comes to building a business that is viable in the long term.

Trying to operate all alone, especially as a micro producer, can be a difficult, if not an impossible feat in such a complex and highly regulated industry.

There are some — mostly very large — cannabis companies that do own most, if not all, of their own supply chain. But for small and midsized companies, figuring out

what you can do well and sticking to that — whether it’s cultivation, processing, packaging, marketing, or distribution and sales — can be a smart way to conserve resources and build towards a sustainable, profitable endeavour.

While there has been an increase of micro producers with all the appropriate sales licences and amendments required to sell their own products into provincial markets (around 20 as of publication), many of these companies are still finding it valuable

IIVO provides crop-specific smart technology for growers. A combination of smart software and state-of-the-art hardware. This truly unique system is capable of monitoring, controlling, and maintaining any type of growing environment.

Allowing you to grow more, at higher quality while using minimal resources. Whether you have experience in growing Cannabis or not. With self-learning controls and integrated security, you are ready for the future.

to work with others to navigate the supply chain.

This is especially important when it comes to entering provincial and territorial markets, most of which have a product procurement process and are not always accepting new suppliers. In those cases, producers need to partner with a company already approved in those provinces, even if they can — in terms of federal licensing — do so on their own.

To look at it another way, while a processing licence and sales amendment from Health Canada will, in theory, allow you to sell products into provincial markets, most of those provinces still want to first vet any new company selling into their system, and will also want to approve any new product that vetted company sells. While some provinces are open to new producers, many have stopped accepting new producers entirely.

In those cases, a new company has no other option but to work with those already approved by the province, if they wish to sell their products there.

But even in those instances where a province is accepting new producers and all the necessary licences are in place, partnerships with processors and distributors, and even marketing companies can be valuable for a micro.

Even if you are growing and then processing/packaging all your own products, selling into a province means taking on added costs like provincial recall insurance, federal and provincial taxes, and then marketing your products to

retailers so they are aware of who you are.

Although some attention or blame has been pointed at the federal government for a lack of sales amendments for micros, there have only been about 30 applications submitted by micros since the beginning of legalization (with two-thirds of them approved so far). This would imply that rather than a lack of licences issued, the reason is that few micros are even applying for them. This is likely to be, at least in part, to the above points — that no cultivator or processor is an island, that partnerships are paramount to survival.

And in my own discussions with many of micros who do have all those licences in place, many of them tell me that at this point, they still prefer to outsource at least some of those steps to companies that can do it more efficiently.

Having partnerships like this can allow them to focus on just growing great cannabis or, conversely, just focussing on processing or packaging; maybe making edibles or solventless extracts, and leaving the growing to those who are passionate and skilled on that side of things.

Therefore, it’s important to figure out what you really want to do and what you’re good at. Then, build partnerships with others who can help you fill in the gaps in order to get your products into provinces, in front of retailers and ultimately, consumers.

This industry isn’t going anywhere, and strong partnerships can last a lifetime.

By Matt Maurer

“I will not comply” – In cannabis, you should

Compliance is defined as the action or fact of complying with a wish or command. If you are working in the cannabis industry, compliance is a necessary fact of life. Federal licence holders must comply with a long list of rules and commands in order to become licensed. Retailers who are authorized to sell cannabis by a province or territory are in a similar boat. Although navigating the various rules can be a challenge, the overwhelming majority of companies are able to comply with the requirements in order to obtain a licence.

However, compliance does not end with licensing. In fact, many would argue that compliance only begins with licensing.

For federal licence holders, compliance is an ongoing part of doing business. Detailed rules pertaining to manufacturing, packaging and labelling, record keeping requirements, and promotion are just some examples of areas that require ongoing compliance from federal licence holders.

Observationally, it appears that the vast majority of federal licence holders struggle very little as it relates to compliance with the operations of their facilities.

PURE® COCO COIR GROW MEDIA FOR LARGE-SCALE CANNABIS GROWERS!

Problem Solving Features

• Proprietary design reduces algae and humidity inside grow rooms

• Power HP mix has great drainage and highest oxygen levels for roots

• pH buffered using patented organic process

• UV and Light blocking plastic stops algae and bacterial growth

• Lot numbers for traceability

• OMRI certified for organic growing

• Pre-cut Drainage slits

Many would argue that compliance only begins with licensing.

Perhaps this is due to the existence of standard operating procedures, or perhaps it is due to the routine and (what can be) repetitive nature of the operations within a facility.

Regardless of the cause, with some exceptions, it certainly seems that once licence holders are up and running they are able to effectively manage their operational compliance requirements. The same does not always appear to be true for non-operational compliance requirements.

Non-operational compliance requirements would include areas such as promotion and relation -

ships with other entities in the cannabis industry. Given space limitations, this article will discuss only promotion as an example of where licence holders appear to routinely struggle with non-compliance, innocently or intentionally.

We see this frequently when it comes to promotional activities. Despite the fact that the rules pertaining to promotion appear in the same place (the Cannabis Act) as those relating to operational compliance, and despite the fact that the promotional requirements are far shorter and more concise than operational requirements, licence holders appear to have a more difficult time adhering to the promotional rules than they do the operational rules.

There could be many different reasons for this. It is possible that significant attention is paid to the rules and compliance during the licensing process, given that compliance is critical to licensing. Similarly, ongoing operational compliance is critical to maintaining the licence, as well as selling products in a fashion that is acceptable to the provincial and territorial boards (i.e. meeting proper packaging requirements).

On the other hand, promotional rules are, to some extent, irrelevant during the licensing process and are detached from the day-to-day operations from the facilities.

This may mean that decision makers are not aware of the promotional rules in the same fashion as they are operational rules, or that they are not as familiar with how the promotional rules function.

Alternatively, it may be the case that licence holders are simply prepared to disregard promotional rules, or push the envelope with them, more than they are

prepared to do with operational rules. Monitoring and enforcement of promotional rules has been sporadic at best to date (although it has picked up significantly of late), and it may be the case that licence holders are prepared to accept the potential consequences of going offside the rules (warnings and possibly a fine) in light of the benefits that are gained (e.g. more brand awareness, more product sales).

Whatever the reasons may be, licence holders would be well served to follow non-operational rules with the same diligence as they do with operational rules. While enforcement has been sporadic to date, warning letters from Health Canada are showing up in mailboxes with much more frequent occurrence.

In addition to the risk of monetary penalties, there is a cost built in to having to deal with the regulator. Depending on the nature of the offence, the time and effort required to investigate what happened, devise a strategy, respond to the regulator, and ultimately work towards a satisfactory resolution with them, can be very extensive. If a licence holder decides to bring in counsel to help address the issue, there is a direct out-of-pocket cost now associated with non-compliance.

Even if the licence holder has in-house legal assistance, utilizing counsel to deal with compliance issues takes them away from their normal duties, which are likely focused tasks that are much more critical to the operations and growth of the business.

Non-compliance is an entirely avoidable activity that at best, leaves the licence holder potentially exposed to consequences from the regulator and at worst, puts the licence holder in a financial position that is far worse than if the licence holder would have just met their compliance obligations in the first instance.

While it is tempting to take short cuts here and there, by and large we find that those short cuts come back to haunt the licence holder, with the end result being that the consequences completely erode any benefit that was obtained by taking the short cut in the first place.

THE AEROPONICS ADVANTAGE

A close look at how aeroponics in currently enabling growers in Canada and beyond to achieve premium results and premium profits. By Treena

Hein

Aeroponics, as most know, is a growing method where fertilized water is misted or sprayed onto roots kept in darkened chambers. No soil means virtually no root pests or disease pressure. Nozzle clogging, a common historic problem due to the nutrients in the irrigation solution, has been solved through different nozzle designs and novel water pressure sensors.

Collectively, today’s entire aeroponics systems (sensors, precision nozzles, software, etc.) have higher capital costs than hydroponic systems, but lower operating costs. They also require more knowledge. The potential for massive root growth is high, for example, and must be closely monitored. A backup system, in case the fertigation pump fails, is critical, as plant root cells can only survive about 30 minutes without water. Water can be 100 per cent recycled within aeroponics systems, but growers need to carefully manage pH and mineral build-up. Some growers

discard their water periodically. This growing method itself, combined with the highly-precise nature of the technology and the advanced management skills required, enable production of higher quality cannabis compared to hydroponics, according to those Grow Opportunity spoke to in this story.

“Aeroponics is the highest level of efficiency for photosynthesis,” explains Phil Gibson, vice-president of marketing at aeroponics tech provider, AEssenseGrows in Sunnyvale, Calif. “Roots dangle in air with effectively infinite oxygen. Roots are not bound by soil and expand root surface area with abandon. The result is very high absorption and very efficient carbohydrate creation in the plant.”

Cannabis, says Gibson, “loves this infinite nutrient feed, so you can hit it with very high-intensity photosynthetic photon flux density at the canopy surface. The result is very fast growth, and potency is a result of this efficiency. Anecdotally, our customers are seeing five per cent to eight per cent lift in cannabinoid content from plants grown in aero-

ponics, versus the same strains grown in soil media.”

Grump Weed, Onyx Agronomics, and 420 Kingdom had mostly similar reasons for choosing this cultivation method, but all have unique perspectives and journeys. They all use AEssense tech, as does FarmaGrowers in South Africa, but its operations are still getting up and running.

Myriad of reasons

When Andrew Lange, the director of cultivation at Onyx Agronomics (and CEO of his own firm, Ascendant Management) was evaluating potential cultivation techniques five years ago with his team, some of their primary goals were consistency

in production and quality, and achieving very low thresholds for microbial levels. “Sustainability was also high on our priority list as well to reduce our environmental impact, and of course a competitive cost of production while achieving the above,” says Lange. “[With me] having experience in aeroponics already, it quickly went to the top of the list as the technology achieves all of these goals.”

The automated nature of the system has allowed him to achieve “incredible consistency” over the years since installation. In addition, they consistently achieve “extremely low” microbial levels (<1 CFU) in finished products. Lange says this is in large part because of the absence of grow-

ing media, which “therefore greatly reduces the risk of contaminants, either microbial or pest.”

From a sustainability perspective, no requirement for growing media means that no media waste is generated, and of course, water use in aero systems is always about 10 per cent of hydroponics. Lange adds that “with all those advantages, the price of production is naturally quite a bit lower than other growing technologies,” with “about 60 per cent less labour required per square foot to achieve the same results.”

He cautions however, that the learning curve is steep. “Small changes can elicit drastic changes quickly in the growth of the plant and that can be a negative in the

When Onyx Agronomics' director of cultivation Andrew Lange, looked into cultivation techniques five years ago, a primary goal was consistency in production and quality. With the automated nature of the aeroponics system, he has been able to achieve consistency over the years since installation.

beginning as much as it is a strength,” he explains.

And, in terms of the overall biggest difference in operating aeroponics and other grow methods, Lange pinpoints cleanliness. “You will often hear those who have

tried aero say ‘it was great for a few harvests then it just went downhill,’” he explains. “That’s most likely because their system wasn’t properly cleaned during or after each grow, resulting in pathogens taking hold.” Other than that, growers consid-

ering aeroponics should understand that vegetative growth is more rapid and schedules must therefore be adjusted accordingly. “We consistently grow plants from clone size six to seven inches to full-grown, ready to flip to flower 24 inches, in seven days,” he says. “Defoliation and training

“For us, using aeroponics has created a ‘market ocean’ we're swimming in alone. It’s the environmental story: no waste, less pesticides, recycling all the water. ” - Jeffrey Thorn, 420 Kingdom

Changed target market

Jeffrey Thorn chose aero cultivation from the start at his business 420 Kingdom in Bakersfield, Calif. in December 2020. He has 12,000 square-feet under production. His criteria for a growing method was first of all, lowest-cost production, followed by consistency and sustainability. Aero ticked all those boxes.

“Our labour costs are a lot lower than those of conventional growers, and we’re making profits where they are struggling,” Thorn explains. “The capital costs were high, but our margin is large. Our cost of production is US$150 to US$160 per pound (we use chillers and LED lights), and we’re selling at US$1,500 to US$1,600 a pound. We were getting over US$2,000 a pound, but the market is oversupplied right now. So, our return on investment (ROI) will be fast relative to the size of the capital investment, five or six years.”

A big part of the ROI story at 420 Kingdom is not just the low labour costs, however. Using aeroponics has also enabled at least one strain so far to achieve THC levels five per cent to seven per cent higher than competitors. This has enabled the 420 Kingdom brand to surge ahead, with much higher profits. Thorn explains that “my business plan was to produce about 90 per cent to wholesalers and sell 10 per cent as our products, moving all production to our brand by year two. But our brand has created so much buzz that we were able to stop wholesale at about six months. We started out testing 15 strains and lucked out upfront with our Watermelon Mamosa in terms of quality and yield.”

Thorn explains that most people don’t understand that many of the strains out there don’t do well under aero production. Most of the strains he has tried have produced a very low yield, but he has three other strains besides Watermelon Mamosa that are doing well, and he will keep going with trials to find at least two more.

Aeroponics has also created great interest in his brand from the sustainability angle. Thorn had always believed the positive environmental attributes of aero would be “a huge differentiator” in his primary marketplace of California, the U.S. state where environmental consciousness is likely highest of all states across the country. He believed it, even though he was told again and again that it would not be a differentiator, and he’s been proven right. “For us, using aeroponics has created a ‘market ocean’ that we are swimming in alone,” he explains. “It’s the environmental story: no waste (we compost our vegetative material), less pesticides, recycling all the water. It's also the high THC and better taste.”

Another part of Thorn’s success was the wise decision to shorten the learning curve significantly by hiring a consultant recommended by AEssense. And while 420 Kingdom is the only aeroponics grower in California that Thorn knows of, he’s hoping more will emerge.

He’s now sharing information with other growers interested in aeroponics, firstly because he’s happy to share information, but also because he believes that the more operations that use aeroponics, the more well-known and preferred ‘aero cannabis’ will become.

Developing genetics at Aurora Coast

Taking the industry’s R&D efforts to the next level.

By Catarina Muia

As the Canadian cannabis industry is still in its early stages of research and development (R&D), Aurora Cannabis looks to conduct its own R&D studies and produce new cultivars by opening its breeding facility, Aurora Coast.

In September 2021, the division released its first new cultivars under consumer brand, San Rafael ‘71. The cultivars include Driftwood Diesel, Stonefruit Sunset, and Lemon Rocket. Additionally, the Aurora Coast division looks to continue providing new cultivars under its newly-announced genetics licensing business unit, Occo.

In the most recent episode of ‘ Grow Opportunity: The Podcast’, Grow Opportunity had the chance to sit down with Greg Baute, senior director of breeding genetics, as well as Andrew Hand, director of cultivar development, both at Aurora Cannabis/Occo, who discussed the work currently being done at Occo, and the technologies at their disposal.

Grow Opportunity: How did Aurora Coast and Occo, come to be? What made Aurora Cannabis look to be a leader in the genetics and breeding space?

Greg Baute: I think everybody sees the need. Currently, there’s no central or public breeding programs for cannabis, due to its illicit status, up until 2018. Across the industry, everybody has some R&D efforts to some scale, but Aurora recognizes there's a place in the industry for a large dedicated research facility to fill that gap in a centralised way. The fa -

cility was first envisioned by Anandia, which was acquired by Aurora Cannabis.

GO: What separates Aurora Coast and Occo’s research and efforts from others?

GB: There are a couple of practical things, for example, the Aurora Coast facility is solely an R&D facility. We’re essentially unencumbered by some of the overhead that goes with being in a production facility. A lot of R&D is typically done in this sort of ‘back corner’ of a production facility, which is better than not doing it at all. But working in that space requires a very high level of SOPs and cleanliness, along with other variables that go along with the production facility. Our team also sets us apart. We have a dedicated team of people that have been solely focused on cannabis research for years, which builds in some real institutional knowledge to the processes we’re executing.

Andrew Hand: We also have access to an extremely large catalogue of exciting and interesting backgrounds for cannabis for us to breed with. When Aurora Cannabis acquired Anandia, MedReleaf, and CannaMed, they all had small breeding efforts,

or similar to what I was doing in our Markham facility just north of Toronto for about five to six years, which was producing a large number of different seeds and some crosses through the work I was doing there. Because of this, we have a very large catalogue of diverse strains and cultivars that have diverse aromas, looks, morphology, everything that gives us the tools we need to make the crosses that we believe will give us what we need for consumers and cultivators.

GO: What studies are currently being conducted at Aurora Coast and Occo?

GB: We have three broad areas of work. One, Andrew’s area, is the cultivar development pipeline. This is breeding photoperiod-sensitive, clonally-propagated, ultra-high-quality genetics or right now, having new things into the market as quickly as possible. The second band is a longer-term breeding effort to move to seed. We think eventually, the industry will move away from the mother and clone system, to all seed propagation. We’re investing early now to lead that. The earliest phase of that would be outdoor genetics grown from seed. Growing

Greg Baute, senior director of breeding and genetics at Occo/Aurora Cannabis.

Andrew Hand, director of cultivar development at Occo/Aurora Cannabis.

outdoors is generally at a larger scale, so seeds will make sense there, first.

The third band of work is ‘genetics’; super broad as it’s all technically genetics. But this is where we try to understand the underlying genetic basis of the traits that we care about. What makes a plant produce more THC? What makes it flower, earlier? What makes it produce more yield? Understanding the genes responsible for those traits will accelerate our breeding through marker-assisted selection (i.e. disease tolerance).

Our present focus is on powdery mildew resistance. A current project we’re carrying out with the Riesenberg Lab at the University of British Columbia (UBC), is focused on discovering which gene causes powdery mildew resistance, which will allow us to use markers instead of pathogen and disease tests.

GO: What new technologies are available for you to work with?

GB: I’m excited a technology that isn’t necessarily new to breeding, but is new to cannabis breeding. The project we’re working on with the Rieseberg Lab is focused on a set of technologies called ‘next generation sequencing’. We’re using high throughput DNA sequencing to sequence a huge library of unique cannabis cultivars. This will allow us to discover the markers and genes responsible for powdery mildew quicker than some of the older technologies we had access to 10 years ago. These tools are being applied to other crops, but applying them to cannabis for the first time, is the exciting part. AH: Again, this isn’t something that’s specifically new to cannabis, but the scale that we’re able to operate at here really allows us to find genotypes that check every single box for what cultivators our consumers want. When I did this work previously, it was in the type of room Greg described earlier. But what we’re able to do here is orders of magnitude larger in scale. The ability to use the technologies Greg discussed, then put it through a well thought-out pipeline that is high in throughput and really ensures to gather all the necessary data to make informed

selections, and also allows us to provide that that information to both cultivators and business-oriented people, really allows us to find products that can do well in the market, and can make a meaningful difference to production.

heavy soils conditioning improvement used in potting soil mixes

odorless mixes with peat moss

natural soil conditioner for lawns, gardens and plants improves soil aeration neutral PH

quantity and size available upon request

increases water and fertilizer retention in soil

preserves bulbs and roots

germinating seeds and rooting cuttings improves potting and transplanting

natural soil conditioner for lawns, gardens and plants improves soil aeration neutral PH

quantity and size available upon request

Vantage Point

By Jennifer Mason

The state of cannabis tourism in Canada

Cannabis tourism is an emerging industry in Canada. Travel agencies, tour companies, cannabis-friendly accommodations, consumption lounges, festivals, and more have all leveraged cannabis as a resource to draw in customers. But given the recency of cannabis legalization, little is known about who is interested in cannabis tourism, and where their interests lie.

Conducted by cannabis tourism experts New Heights Cannabis, and Susan Dupej, Ph.D., post-doctoral fellow at the University of Guelph. The Canadian Cannabis Tourism Research Study provides relevant insights about tourists’ interest in cannabis tourism in Canada.

Canna tourism 101

Cannabis tourism refers to recreational and leisure experiences that incorporate the purchase, consumption, usage, and education of cannabis. Traditional tourism staples (i.e. adventure tours, city tours, spas, attractions, cooking classes, outdoor recreation) have the potential to become cannabis tourism experiences in Canada.

The emerging supply of cannabis-related tourism activities and amenities in Canada aligns with a growing perception of normalization due to the pervasiveness of cannabis retail outlets in most communities across the country. Normalization is driving a new set of tourist attitudes, expectations, and demand for

unique experiences while on vacation.

In a time of recovery, tourism and hospitality businesses need to offer tourists more than what they can get at home.

Socialization as a reason to travel, now more than ever, will be a trigger to get people back out spending time and money in restaurants, bars, sporting venues, attractions and other activities that bring people together.

Cannabis can integrate into the existing tourism infrastructure as either a dedicated experience or an element of an activity. For example, offering cannabis-infused foods and beverages on par with alcoholic beverages is an element of a tourism experience, versus a dedicated tour of a cannabis facility and farmgate store.

There are infinite possibilities. However, there are only a limited number of cannabis tourism providers currently operating in Canada.

The lag in development is no doubt due to two factors: 1) the slow growth of retail cannabis – this barrier has now been removed; and 2) due to

the crushing effects the tourism industry has endured during the ongoing pandemic. Recovery will be a reality of the tourism industry for many years, but new packages and offerings can help. When travelling, many people want to do things they have never done before, making them an ideal target to offer a dedicated or side excursion involving cannabis.

One of the first cannabis tourism experiences established in Canada is Canopy Growth’s Tweed Visitor Centre in Smith Falls, Ont. The growth operation and visitor centre sit on the same patch of land that once housed the famous Hershey Chocolate Factory. While it’s temporarily closed due to the pandemic, the age-gated facility offers self-guided tours to see real grow rooms and highlights the fascinating history of cannabis, billing themselves as "your all-access pass to the past, present, and future of cannabis."

Aurora Cannabis also has a cannabis tourism play with their flagship store in West Edmonton Mall, Alberta’s top tourist destination which at-

tracts more than 30 million visitors a year. A separate event space in the store allows for experiences like musical shows, comedy evenings, movie nights, and more.

In addition to the opportunity to attract domestic tourists, responses to the research study included people from over 10 international countries who have expressed interest in visiting a cannabis tourism experience in Canada. This is a big opportunity for Canadian companies to design an experience that only a country with fully-legalized recreational cannabis can offer.

What do tourists want?

What are consumers looking for from canna tourism? Early results from the New Heights Cannabis Tourism research study indicate there are things we can learn from the wine tourism industry.

Like wine regions, a cannabis region can emerge from an area where there is a cluster of growers with quality product who are open and able to welcome tourists. Tourists can be invited to tour the grow area, touch the plant, try a sample, and make a purchase at the onsite store.

Another similarity is that cannabis can be incorporated into dining through curation by a specialty chef who can provide a very unique educational and entertaining tourism culinary experience.

What’s ahead?

As demonstrated in California, Colorado, and now Nevada, cannabis tourism is an

Jennifer Mason is responsible for driving cannabis tourism in Canada. She developed and hosted three New Heights Cannabis Tourism Summits in partnership with the Tourism Industry Association of Ontario (TIAO), and is the driving force behind the first Canadian Cannabis Tourism Research study.

economic driver and has the potential to be a much-needed stimulus to the Canadian economy as we emerge from the COVID-19 pandemic.

“We know the hospitality and tourism industries are on their knees. And anything that could bring people into those premises to stay longer and spend more, can only be a good thing right now,” says Chris Bloore, president and CEO of the Tourism Industry Association of Ontario (TIAO) about his desire to see legalization of the on-premise channel for infused cannabis foods and beverages.

There are many areas for growth in the cannabis tour-

ism sector, including farmgate stores and consumption lounges. As regulations stand, both farmgate stores and lounges face significant restrictions and regulatory hurdles. In

Ontario, while farmgate stores are now legal, the product must still go through the provincial supplier and lounges are primarily operating outdoors on private property. However,

these challenges don’t mean that there aren’t brands delivering innovative customer experiences.

We know that people are consuming billions of dollars of cannabis in Canada year over year since legalization in October 2018. At the moment, we continue to consume at home or in small intimate groups because the pandemic has forced us all to social distance. However, as recovery continues, people want to get out, socialize, and travel. Not only will they continue to purchase and consume cannabis, but they will want to do it when they are out having fun with their family and friends.

CANNABIS GROWER’S HANDBOOK

Ed Rosenthal’s Cannabis Grower’s Handbook is the definitive guide for all cultivators-from first-time home growers to experienced largescale commercial cannabis operators. The Grower’s Handbook breaks down the fundamentals of marijuana cultivation and demonstrates their practical applications in gardens of any size. Learn new techniques to maximize yield and efficiency and to grow bigger, more potent resinous buds!

With over 600 pages of full-color photos, this grower’s guide presents the latest science, tools, and methods to enable you to grow a cannabis garden of any size, anywhere-indoors or out.

$64.65 Item #1936807543

Suppliers’ Corner

Optimal lighting for vertical grows

P.L. Light Systems’ new VertiMax lighting system is designed to be a high-output LED delivered across the width and length of the grow rack.

With a photosynthetically active radiation (PAR) output of about 1,800 μmol/s and a system efficacy of 2.8 μmol/J, the 640W luminaire offers great performance and energy efficiency. An integrated driver reduces installation time and expense, as well as create a low-profile design with low radiant heat output.

The VertiMax system can be dimmable remotely. It offers a simple plug-and-play platform that is also daisy-chainable. www.pllight.com

RollPros launches new pre-roll machine

RollPros’ Blackbird Rolling System is designed to mimic “old-school hand-rolled results” through an automated machine.

In contrast to cone-filling machines, the company says the Blackbird’s rolling system uses sustainably sourced bobbins of paper and filter tips to radially compact flower in an even density pre-roll form.

It creates two uniformly dense joints every 9.5 seconds, or more than 750 joints per hour. Its fill accuracy is measured at +/- 0.03 grams.

Only one operator is needed to run the Blackbird which helps reduce labour costs, human touchpoints and risk of contamination or damage in the final product. www.rollpros.com