The new PONSSE BTS System increases standard fixed bunk loads by more than fifty per cent when compressing forest residues. Loads do not exceed the outer diameter of the forwarder bunks, saplings are saved enabling future growth.

Field tests have shown results in the 10-12-ton load capacity range allowing a semi trailer to be filled in about three loads – over 30 tons of biomass in total! The new PONSSE BTS bunk also handles round wood loads in a locked position.

The woody biomass industry presents huge potential for research, technology, and markets, Halifax biomass conference attendees learn. News and views from this, plus a visit to Nova Scotia co-gen pioneers Taylor Lumber.

Few jobs are too small, and now too big for Barrett Enterprises thanks to a duo of bush chippers and over 20 years in the biomass business. Trucking logistics, flexibility, multiple markets, and running a clean ship are all factors in long-term survival.

Despite running a single 26-in mill, Lauzon Recycled Wood Energy punches above its weight with this 35,000-ton plant in Papineauville, QC. Future expansion plans province-wide will increase this hardwood player’s role in the market.

This exhaustive round-up of biomass chippers and grinders is a handy “keeper” reference for anyone in, or thinking of getting into this side of the supply chain. It includes multiple models and approaches from 18 suppliers, all with distribution in North America.

There’s enough fibre, and nutrients, to go around.

ustainability means many things for biomass. First, there’s site sustainability, or the question of how much we can harvest, where, and how. This is the subject of a new column by Evelyne Thiffault of Natural Resources Canada, which she’ll address on page 8. We’re all learning as we go, including Evelyne, so I look forward to her keeping this topic on the front burner each issue. It’s only renewable energy if the forest is renewed.

There’s also economic sustainability – Can we get the biomass out of the bush cost-effectively? That’s where our other new columnist, Mark Ryans of FPInnovations (Feric), comes in. He’s been studying residual biomass harvesting, processing, and hauling for decades and has agreed to share his findings regularly with Canadian Biomass. His first column is on page 29.

biomass sector is developing in Canada, we may not need to argue. First, the bioenergy sector cannot afford to simply outbid traditional players for all its fibre. It must stay competitive with other energy sources, including hydro, coal, and wind/solar. Even when biomass is free, it’s hard to break even after the haul distance exceeds 150 km or so. Biomass will be part of a strong forest products sector for some time to come.

The way the biomass sector is actually developing should also quell concerns. The spotlight is on harvest residues that are not used by traditional industry. If anything, minimum top diameters have increased in recent years with poor lumber markets, leaving more in the woods, not less. In other areas, we’re talking about material that’s ill-suited for manufacturing, like beetle kill wood or off-species.

Volume 2

Editor/Group Publisher - Scott Jamieson (514) 457-2211 ext 24 sjamieson@forestcommunications.com

Field Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Western Editor - Jean Sorensen

Market Production Manager

Josée Crevier (514) 457-2211 ext 21 jcrevier@forestcommunications.com

National Sales Managers

Tim Tolton - ttolton@forestcommunications.com 450-458-4341

Guy Fortin - gfortin@forestcommunications.com 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8 Ph: (514) 457-2211 Fax: (514) 457-2558

Western Sales Manager Tim Shaddick - tootall1@shaw.ca 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Brooke Shaw

Canadian Biomass is published four times a year; March, June, September, and December. Published and printed by Annex Publishing & Printing Inc., and distributed as a supplement to Canadian Forest Industries and Canadian Wood Products magazines.

Printed in Canada ISSN 0318-4277

Circulation e-mail: cnixon@annexweb.com Tel: (514) 457-2211 Fax: (514) 457-2558

Mail: 90 Morgan Rd, Unit 14 Baie d’Urfé, Que H9X 3A8

Subscription Rates:

Finally, there’s the traditional forest products sector. Lately we’ve heard that the demand for biomass may threaten access to affordable fibre for existing players. Those at risk include panel plants using sawmill residuals and pulp mills using low-grade fibre. Change can be threatening, especially to those who’ve called the shots for decades when it comes to if, when, and at what price they’ll use lower-grade material. So industry associations like the US-based AF&PA are expressing concern about the growing biomass sector. There are worries about “distorting fibre markets,” as if the status quo were sacred, or about fibre being diverted to “lower value uses,” as if affordable heating were less important than paper for ad flyers.

It’s good dinner debate, but the way the

Finally, there are massive volumes of wood that aren’t being harvested simply because the traditional players are gone. In southeastern Ontario and New York, low-grade fibre used to go to the now closed Domtar pulp mill in Cornwall. Five pulp mills have closed in the part of New Brunswick now called the Dark Crescent, freeing over 1.6 million m3/yr, not counting harvest residuals. Large regions of Quebec and Ontario have seen permanent closures, as has most of Saskatchewan. These are vast potential supplies. They also show that in parts of Canada, the traditional forest sector has lost its right to lead. It’s time to follow, or get the hell out of the way. • Scott Jamieson, Editor/Group Publisher sjamieson@forestcommunications.com

Canada - 1 Yr $48; 2 Yr $85; 3 Yr $115 Single Copy - $6.00

(Canadian prices do not include applicable taxes) USA – 1 Yr $44 US; 2 Yr $75 US Foreign – 1 Yr $75 US

From time to time, we at Canadian Biomass make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianforestindustries.ca

Paramus, NJ - The increasing demand for ethanol that is made from nonfood sources has created growing interest in producing cellulosic ethanol from woody biomass. To meet this need, Raven Biofuels is poised to build two new cellulosic ethanol biorefineries on the west coast. Ground

breaking is planned for early 2009 in Washington State and late 2009 in British Columbia.

The feedstock for the Washington plant will come from construction wood waste supplied by a large construction aggregate. The plant in British Columbia will be built and owned in a joint

venture with Spectrum Energy of BC and will be supplied by pine beetle-infested wood from northern BC. Each plant will consume approximately 450 tonnes of wood per day, with an initial expected yearly capacity of 26 million litres of ethanol and 15 million litres of furfural chemicals

Vancouver, BC - The latest product development tests by Nexterra Energy Corp. indicate that the renewable synthesis gas, or “syngas,” produced by its directfire biomass gasification system can be used to replace 60–90% of the fossil fuels that are used in pulp mill lime kilns and up to 100% of those that are used in certain types of boilers. This could lead to substantial savings for industries such as forestry, mining, cement, and ethanol production by reducing the reliance

on increasingly costly fossil fuels and by decreasing greenhouse emissions and their associated carbon taxes.

Gasification is the energyefficient conversion of a carbonbased material such as woody biomass into a mixture of carbon monoxide and hydrogen; this syngas is then used as an energy source. Nexterra’s gasification system is coupled with a heat exchanger to generate hot water, steam, or hot air. Because of the new direct-fire application, syngas can be produced in one location and combusted elsewhere on site in the existing thermal

for further industrial uses. Potential expansions in capacity are planned for both sites.

Biomass supply for both plants will be managed by Price BIOstock, a seasoned biomass producer from the southern US represented in Canada by Ken Day.

process equipment. The “system is now ready for demonstration at commercial scale,” says Jonathan Rhone, Nexterra president and CEO. “Once proven at this scale, we plan a full commercial rollout for industries such as pulp and paper, wood products, mining, and others that want to reduce operating costs while lowering their carbon footprint.”

Nexterra Energy is a private company based in Vancouver that develops, designs, manufactures and delivers advanced gasification systems that convert waste fuels into clean, low cost heat and power.

Washington, DC - Several organizations have recently come out with studies warning of disruptions to the traditional fibre supply flow owing to the increasing interest in woody biomass. In mid September, an AF&PA workshop in Washington, DC concluded that bioenergy is a complex issue requiring better, and more comprehensive research and analysis for the US to realize the full potential that domestically produced bioen-

ergy can bring to fighting climate change and dependence on foreign energy without distorting traditional fibre markets.

RISI also released a report on the effects the demand for woody biomass and low grade wood may have on established players like pulp mills. It suggests that the extra demand will be close to 50 million tons in the near future, including an extra 3 million tons in eastern Canada and over

Is biomass friend or foe? To a large extent, that will depend if youʼre buying or selling, and where.

4 million tons in western Canada and counting.

Finally, Wood Markets September issue concludes that the emerging biomass markets will be both an opportunity and a threat to established forest industry companies. Opportunities abound for sawmills and other originators of

wood residues, as well as landowners with an abundance of lower grade material. Threats are seen especially for those using that lower end of the fibre spectrum – MDF, particleboard, and pulp plants.

Operations have been suspended temporarily at two Boralex Power Income Fund co-gen plants in Quebec because of difficulties in obtaining residue as a result of sawmill closures. The company plans to use this time to conserve and replenish its wood supplies to meet the demands of the peak power period between December and March.

In British Columbia, Canfor is building a new wood cogeneration plant at its Fort St. John sawmill to reduce operating costs. Construction should be completed by late spring 2009.

In Ontario, funding has been provided by the Ontario Forest Sector Prosperity Fund and Loan Guarantee Program to restart a sawmill in Harcourt and construct a four megawatt cogeneration plant to supply the mill.

As of press time, AbitibiBowater was set to start pressure testing on its $85-million, 45 MW biomass co-gen plant in Fort Frances, ON. The massive plant has been stockpiling hog fuel for almost a year in preparation for start-up.

Precision Husky announced at DEMO 2008 that Inland Kenworth (Parker Pacific) will sell and service all of the supplier’s equipment at the dealer’s locations across BC. Pictured left to right is Parker Pacific’s forestry equipment manager Tracey Russell with Precision’s VP engineering Billy Daniels at Precision’s DEMO site. The line includes 10 models of tub grinders and six horizontal grinders (100 to 1,100 hp). The company also makes sawmill chippers, knuckle boom loaders, and flail debarkers.

TurboSonic Technologies will be supplying pollution abatement equipment to control emissions from a new waste-to-energy biofuel plant in Canada.

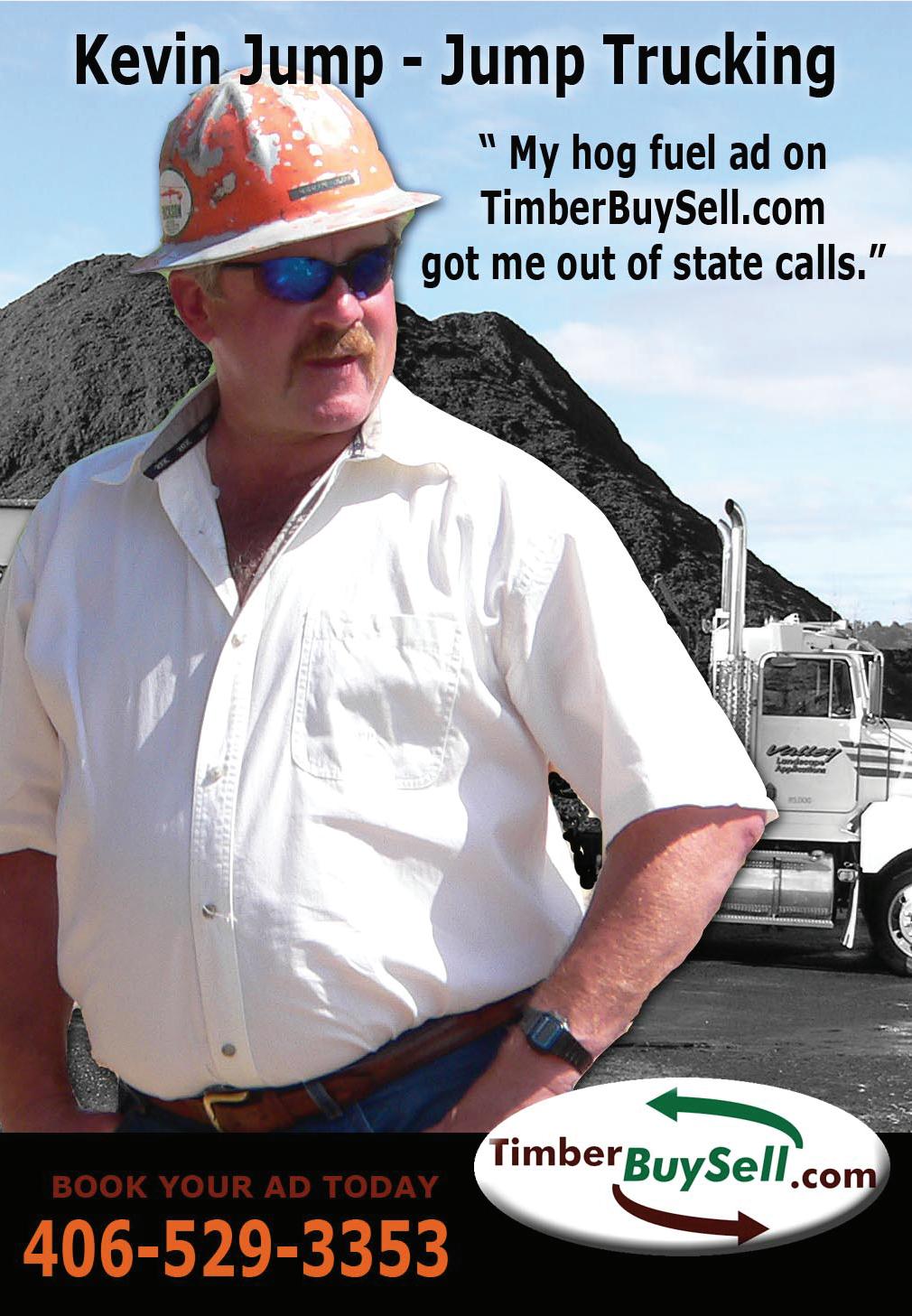

MARCH 25-27, 2009 • SMALL LOG CONFERENCE Coeur d’Alene, ID (406) 529-3352 www.timberbuysell.com

APRIL 1-3, 2009 • COUNCIL OF FOREST INDUSTRIES (COFI) AGM & CONVENTION Prince George, BC (604) 684-0211 www.cofi.org

APRIL 28-30, 2009 • INTERNATIONAL BIOMASS CONFERENCE & TRADE SHOW Portland, OR (719) 539-0300 www.biomassconference.com

MAY 13-15, 2009 • SMALLWOOD 2008 AND BIOENERGY & WOOD PRODUCTS JOINT CONFERENCE Madison, WI (217) 333-5900 www.forestprod.org

MAY 18-22, 2009 • LIGNA 2009 Hannover, Germany +49 511 89 32126 www.ligna.de

JUNE 3-6, 2009 • ELMIA WOOD 2009 Jonkoping, Sweden +46 (0) 36 15 22 34 www1.elmia.se/wood

AUGUST 31-SEPTEMBER 4, 2009 • BIOENERGY 2009 –SUSTAINABLE BIOENERGY BUSINESS CONFERENCE & EXHIBIT Jyvaskyla, Finland www.bioenergy2009.finbioenergy.fi

SEPTEMBER 10-12, 2009 • WOOD WEEK 09 - INTERSAW, LOGFOR, & DEMO FORET 2000 CONFERENCE Quebec City, (506) 658-0018 www.masterpromotions.ca

Forest biomass and ecological sustainability are the subject matter of this new column.

By Evelyne Thiffault

The forest bioenergy sector is developing rapidly across Canada, and great efforts are being devoted to the development of new technologies for converting forest biomass to energy. Wood waste from industrial processing is currently the major feedstock, but consideration is increasingly being given to harvesting slash. This “waste” is currently either piled at roadside in the case of whole-tree harvesting, or left in the stand in cut-to-length (CTL or stemonly) operations.

The harvest waste is a low-hanging fruit for the bioenergy sector, since it does not compete with existing industries. However, while we are getting better every day at the economics and the engineering of taking out the slash, as seen for example with Cyclofor in the last Canadian Biomass issue, it is relevant, and not just for (potentially) obnoxious forest ecologists like my-

Is this too much? A forest in southern Finland picked clean, stumps and all. How much to remove, and where is the topic of this regular column.

self, to wonder whether increased extraction of biomass from the forest is ecologically sustainable. This “‘waste” may in fact play a crucial role for the functioning of the forest ecosystem.

Historically, stem-only harvesting was typical in much of Canada, with trees manually felled, the stem delimbed where it fell, and branches and tops left behind. The stem was then hauled to the roadside using horses or oxen. The introduction of line skidders in the 1960s increased harvest productivity because stems could be

“Woodman, spare that tree! Touch not a single bough!”

- George Pope Morris.

hauled more efficiently. In the 1970s and 1980s, however, safety issues related to manual delimbing and a shortage of forest workers forced many forest companies to move to whole-tree harvesting. This was done by mechanizing delimbing using a slasher at the roadside. Although the more recent introduction of harvesters with efficient harvesting heads to delimb, buck and sort on site, as well as the use of forwarders, has increased the popularity of CTL operations in the 1990s, whole-tree harvesting remains the most common practice in large parts of Canada, and

one that may expand with the development of a market for slash.

Given the length of forest rotations under Canadian climatic conditions, whole tree removal is still fairly new. We may not have observed the full consequences of this practice on forest productivity yet. So, while this may sound overly dramatic, we may have caused unintended negative impacts on the functioning of the ecosystem, impacts that will appear before our eyes only in upcoming decades. Or maybe not. Still, here it is worth recalling that the whole idea of forest biomass for bioenergy being “carbonneutral”, as opposed to fossil fuels, assumes that the harvested stands will actually grow back and be as well-stocked and productive as they were before harvesting. If there’s a risk that increased biomass removal damages the ecosystem and hinders tree growth and carbon sequestration in future rotations, biomass utilization may not be so ‘neutral’ after all.

In Canada, concerns about the sustainability of intensive biomass removal were first voiced in the 1970s, when the oil crisis pushed prices of fossil fuels to record levels, and alternative sources of energy such as harvest slash were considered. Some studies were launched to investigate the impact of slash removal, and the Canadian Forest Service financed over many years the Energy from the Forest program (ENFOR), a part of which was aimed at developing tools to define sustainable levels of organic matter and nutrient removal. So we already have a moderately abundant ecological knowledge, from our Canadian research base and also from research done in countries with similar forest and climatic conditions. We know that in most cases, whole-tree harvesting slightly acidifies the soil and reduces soil nutrient reserves, especially calcium. We also know that for some site conditions and some tree species, it reduces tree productivity.

Why is this good news? By knowing which sites and species are sensitive to intensive biomass removal, we can avoid it in these areas. At the same time we can be a little more confident that this practice is probably sustainable for the remaining sites and species.

Of course, scientific knowledge is still incomplete. But the other good news is that the Canadian bioenergy sector is still nascent; although whole-tree harvesting is common, we are not yet intentionally chasing every twig and branch on a large scale in our forest to feed this industry. There is thus plenty of space to develop our understanding of ecological impacts, for

example by establishing legacy field trials comparing the effects of different intensities of biomass removal on various ecosystem processes over different sites. This information can then be used to adjust the list of ‘no-go’ sites as new data accumulate. This way the expansion of our bioenergy industry can be tailored to fit the ecological sustainability of forest ecosystems, always to the best of our knowledge.

Of course, this is all easier said then done. But as

they say, knowledge is power. That’s why in future columns we will discuss various issues related to the sustainability of forest biomass harvesting, and also have a look of what’s being done in other countries to tackle these issues. This will hopefully help draw the lines in grey areas, despite the uncertainties. •

Evelyne Thiffault of Natural Resources Canada writes this regular column on the sustainability of biomass harvesting for Canadian Biomass on behalf of the Canadian Research Group on Ecosystem Sustainability.

In cooperation with 3-6 JUNE 2009

JÖNKÖPING, SWEDEN

WWW.ELMIA.SE/WOOD

OUT IN THE FOREST· NEWS · MEETINGS

DEMO · MACHINES · TECHNOLOGY

Few jobs are too small, and now too big for Barrett Enterprises thanks to a duo of bush chippers and over 20 years in the biomass business.

By Scott Jamieson

operations are a little bit different,” admits Robin Barrett of Barrett Enterprises with a smile, as if the 22-year-old forwarder-mounted Bruks chipper working over his shoulder weren’t a clue enough. The second generation, family-run harvesting, firewood, biomass, and hauling business located just outside downtown Halifax certainly faces unique challenges.

“When we’re anywhere near houses, which is much of the time, we have to work around noise by-laws. We can’t start before 7:00 am and have to quit by 9:30 pm.”

So much for maximizing machine utilization. But proximity to Halifax does have advantages. A hungry urban firewood market right on the doorstep doesn’t hurt a business whose firewood processing yard will churn out 1,000 full cords and about the same amount of 8-ft firewood this year. A broad mix of local bioenergy clients that range from greenhouses to power generators and can handle the full range of wet to dry

biomass is also a help. And when you’re in the biomass salvage business, being at the heart of an expanding suburban market can’t hurt either. In fact, it makes a nice little business if you’re set up to handle it.

“Part of our expertise is to go to a site where they’re building a grocery store or other large building, and remove all the merchantable timber and then chip the rest. You have to be flexible and mobile, but that’s our business.”

Over the years Barrett Enterprises has built a team that includes a Ponsse Beaver-Caribou harvesting team, three chip trailers with Keith walking floors (two BWS 46-ft bought in 2000 and 2001, and one Manac 48 ft added in 2007), a Western Star tractor, three Rottne Rapid forwarders (1990, 1997, 2001), plus two service trucks.

But being flexible is really where the battle-scarred Bruks chipper comes in. Mounted on an 8WD Rottne forwarder, the old warhorse can be

brought in quickly to small lots, drives out to the slash itself, chips it, and then dumps it into one of Barrett’s three lie floor trailers.There may be better options for non-stop, high-volume roadside chipping, Barrett says, but then a massive grinder would look a little lost in a sub-development.

“Can you see a big grinder coming in here?” he asks, sweeping his arm across a small lot just beside the family sawmill that was the site of a demo for the Canadian Woodlands Forum/CanBio field tour last September. “Where would it set up, and how long could you keep it fed? We’re a bit of a niche market, and it’s feast or famine. One day we’re doing a large roadside chipping job, the next small jobs clearing everything, and we survive by being able to do it all, close to a city. We can send a guy in with a powersaw on small sites, then the chipper drives around cleaning up. It can also drive on the road from lot to lot.”

On larger jobs, Barrett might have a sub-contractor come in to log the site and process and sort out sawlogs, leaving the rest at roadside for the chipper. It’s on the larger-scale roadside jobs that the older Bruks chipper found its limitations. Bought in 1986 and still boasting the original operator Mike Barkhouse, it has brought home the bacon for 22 years, and still works on an as-needed basis. But at 250 hp, it lacks the muscle to compete on some of the larger jobs Barrett likes to bid on. To keep up, the company recently added a brand new 450-hp Bruks chipper mounted on a Ponsse Buffalo-King 18-tonne forwarder. The package came from dealer ALPA Equipment, and having one party take ownership of the unit was a deal breaker for Barrett. “It comes from two suppliers, but we wanted to have one company take responsibility for the whole thing working out. ALPA did, and so far there have been no serious issues.”

It joined the team this past August and has proven to be a real producer, Barrett says. While the original chipper brought out two 30-ton van loads per day (nine hours), the 450-hp unit was already topping three loads when Canadian Biomass was on site in mid-September. That 50%+ boost is all the difference.

“We need a wide range of work to survive, and the older chipper was having a hard time competing in the larger jobs. Now we can bid on those again, since the new one will keep up at roadside.”

Visitors to the Ponsse/ALPA booth at DEMO 2008 in Halifax this past September not only saw Barrett Enterprises’ newest Ponsse/ Bruks bush chipper in action, they were also treated to a first look at one of the Finnish-based supplier’s biomass solutions. The Bio Transportation System (BTS) is essentially a way to allow a conventional forwarder to maximize its payload of cumbersome slash to roadside. It’s all about moving less air and more wood, and Ponsse’s BTS does this by using sloped stakes to compress the slash as it moves through the block. It applies 10 tons of hydraulic compression through a 58-degree inward travel arc to more than double the weight of biomass removed per turn. Ponsse says field tests have shown payloads in the 10 to 12 ton range, as well as allowing the forwarder operator to keep a narrow profile through the stand to avoid damaging residuals or advanced growth. Efficiency can be improved by adding a brush grapple and fixed heel to the crane. When not moving slash,

At close to $900,000 with all options and materials, it had better. Still, it also brings improved fuel efficiency to the table, no small matter for today’s biomass producers. Barrett has long tracked fuel consumption as a core cost. In 2007, the old chipper averaged around 19 litres per bin for the forwarder and chipper combined, depending on the haul. That average means about 4 litres per green ton dumped in the live-floor trailers, or too much given current fuel costs Barrett explains.

“Best bets are that fuel per ton for hogs (grinders) is around 3 litres,

the forwarder can be used to move cut-to-length wood to roadside.

The system was developed by the company’s North American office as a way for contractors to use existing assets to get into the biomass game. It’s a common sense approach that many loggers, and competitors, at DEMO 2008 appreciated. Yet as long-time biomass contractor Robin Barrett says, cleanliness is next to godliness when it comes to biomass. He uses a makeshift extended bunk on his own modified forwarder to bring clean slash to his drum chipper, and while impressed with the BTS’ ability to haul a lot of slash at DEMO, he commented that he’d like to see a similar device added to future models. Ask and you shall receive: Ponsse’s technical support specialist Stacy Wagler told Canadian Biomass that the company has exactly that bunk extender available as an option for contractors that need extra-clean slash. It adds about a metre of support to the back end and is all part of Ponsse’s proactive approach to biomass harvesting, the forest machinery veteran adds.

“We’ve decided we’re going to be a player in the biomass sector. Our factory in Finland is working on solutions and has a biomass R&D program. But we’re also looking at bringing practical solutions now to our North American contractors, and the BTS is part of that. There will be more.” We look forward to it. •

The original warhorse 250-hp Bruks chipper dumps a load into one of three vans with Keith walking floors. The new Ponsse/Bruks chipper carries 21 m3 loose packed per trip versus 16 m3 in the older chipper. That 30% boost, along with the muscle that 450-hp provides, means some 50% more production.

while larger chippers are at 2 or a little more, so I figured we couldn’t compete head on with the older machine for long. It’ll be another couple of months before I know the total for the new machine, but let’s face it – a lot has changed in 22 years. I expect to be around 2.5 litres/ton for the total package, from the woods into the van.”

He puts this down to a combination of a much more efficient forwarder (literally the Mercedes of forwarders, as Ponsse is powered by

Mercedes engines), a new generation of hydraulics and controls, and the new Scania chipper engine. Efficient operators help too, and here he adds that the new unit includes many of the improvements and modifications his operator had put on his wish list during 22 years of running the older chipper.

“We went to Sweden to see the chipper before buying, and Mike had a list of over 20 improvements he wanted with the new chipper. They were all included on the new model. You add that to the new forwarder and big cab, and you have a happy operator.”

That, Barrett says, is probably more important than any gear when it comes to a successful bush chipping operation.

“An experienced, motivated staff is key - From the guy in the woods preparing the wood, to the forwarder operators bringing it to roadside, to the operator feeding the chipper. This chipper will make an excellent energy product, but the material has to be kept clean; that’s critical. It’s not garbage. Otherwise you’ll lose your shirt.”

While some chipper or grinder operations will scrape clean a chip “pad” at roadside, Barrett’s crew simply watches where they pile the wood, and tries to concentrate the fibre in higher piles to limit the material in contact with the ground. That, and a little care in loading the material makes all the difference. Also, when a forwarder is used to bring material to roadside, Barrett relies on a modified machine with a long, aluminum sub-frame that prevents the material from dragging along the ground.

“If there is one thing I can’t stress enough, it’s the need to keep the material clean through the entire process, right up to the chipper.” With that, he turns to watch his Ponsse/Bruks chipper work at DEMO. “I guess this means we’re at it for another 22 years at least,” he concludes. •

Many studies have examined the harvest of biomass (dead and nonmerchantable wood) for energy production or to reduce fire hazards, but few have included the lessons learned from the loggers. Researchers from the Institute for Agriculture and Trade Policy, the University of Wisconsin, and the University of Minnesota have done just that in their study Harvesting Fuel: Cutting Costs and Reducing Forest Fire Hazards through Biomass Harvest, released in June 2008. The study assessed economic and operational issues faced by the loggers, allowing specific recommendations to improve efficiency and reduce cost.

The selective biomass harvest took place in Superior National Forest, northeastern Minnesota, which comprises 1.2 million ha of multiuse forest. Excess fuel loads have accumulated in large areas of this forest and pose a serious fire risk. Instead of conventional fuel treatment methods in which biomass is crushed or piled and burned, would it be cost effective to harvest and sell the biomass?

To answer this, loggers harvested biomass in nine sites, and researchers monitored the pre- and post-harvest quantity of biomass and economic data on harvesting, forwarding, and processing. Because biomass harvest is new in

Minnesota, various harvest prescriptions and goals and harvesting and transportation systems were tested. Harvesting and transportation involved cutting and piling by hand or using machinery, forwarding of loose or bundled biomass, grinding, transporting by chip van or trailer, and in one case, biomass harvest was combined with some roundwood harvest. The loggers had little previous experience in biomass harvest.

The researchers found that biomass harvest was more cost effective than conventional fuel reduction in only one of nine sites. Optimization models showed that cost effectiveness could be achieved for additional sites, but varied with the equipment used and hauling distance (less than 160 km recommended).

There was huge variation in the removal of the prescribed biomass. The greatest harvest efficiency was 75% of stems less than 2.5 cm in diameter at breast height (dbh, 1.8 m above the ground) and 94% of stems greater than 2.5 cm dbh, but most harvests were much lower. Few dead standing trees, or snags, were removed, even when they were a harvest target.

The variation in biomass harvest was caused by two main factors. First, biomass was inacces-

Material size and visibility

• : Pile biomass so that it is visible among the trees

Material arrangement:

• Pile stems neatly parallel to each other and pointing toward the skid trail; shorten long stems

Site conditions:

• Avoid or use caution on rocky ground to minimize damage to machinery

Site demarcation:

• Remove previous flags and clearly flag harvest perimeter, stems to be protected

Seasonal factors:

• Snow and ice can increase the time required to locate and forward piled biomass

Accessibility:

• The site and hand-cut materials should be accessible by machinery

Machine size:

• Use small machines with a small or low harvesting head and long reach for greater visibility and manoeuvrability

Skid trails:

• Organize harvest and skid trails for efficient harvesting and forwarding; the harvester should consider that a bundler and/or forwarder will follow

Grinding:

• Prepare and sort material (remove rocks and stumps) for efficient use of grinder time

sible in many sites because of the topography or arrangement of overstory trees. Second, the removal or damage of large trees during biomass harvest could result in fines because of federal laws regarding timber harvest in National Forests. More flexible site prescriptions are recommended to address these issues.

Based on their experiences, the loggers had many suggestions to improve the efficiency of selective biomass harvesting. These were grouped into harvesting and delivery factors and planning and coordination factors, with tips found below. •

Picture source: Institute for Agriculture and Trade Policy

Landing:

• The area should be large enough to hold all harvested biomass for efficient grinding

Trucking:

• Combine bundles and roundwood to maximize truckloads

Site selection:

• Visit sites before harvesting to study site conditions, harvesting time, amount of biomass, and potential profit, and to plan the harvest in relation to machinery capabilities

Harvest prescriptions:

• Allow flexible, efficient biomass extraction; prescribe one diameter requirement for all species; discuss guidelines with forest managers at the start of harvest and work carefully; set prescriptions that minimize the chance of mistakes

Operator communications:

• Communicate operational requirements so that felling and piling maximizes bundling and forwarding efficiency

Payment:

• Payment should be based on effort, rather than quantity removed; biomass should be sold on a dry matter or energy content basis

By Heather Hager

Asthe costs of fossil fuels escalate and climate change policies come into force, the use of woody biomass for energy is becoming an increasingly attractive option. This was the topic at the pre-DEMO bioenergy conference held in Halifax, NS, in September by the Canadian Woodlands Forum and CanBio. The focus was largely on the Maritimes, and over 200 individuals from both national and international industry, government, and academia discussed the current status of the biomass industry both in Canada and abroad, including what biomass is available and what can be harvested, as well as techniques to obtain and transport biomass efficiently, and opportunities for emerging biomass markets. Ultimately, there seems to be a lot of potential for Canada to create its own unique identity in the biomass industry.

Biomass in Canada is currently produced mainly as a byproduct of the lumber industry or from the harvest of nonmerchantable timber. However, slumping lumber markets and sawmill closures have reduced the supply of sawmill residuals available. Thus, it may be necessary at times for the forest industry and policy makers to consider the harvest of forests for energy as a final product in itself.

It is difficult to estimate the current use of biomass for energy purposes because actual numbers are not always available, for example, the consumption of firewood by small woodlot owners or the internal use of sawdust and hog fuel by sawmills. However, David Palmer, general manager of the York-Sunbury-Charlotte Forest Products Marketing Board, estimates that the use of biomass to generate heat, steam, and electricity replaces at least 5.1 million barrels of oil annually in the Maritimes, and increases in the demand for firewood and the future planned construction of sawmill boilers and pellet mills will account for the replacement of another 1.3 million barrels. This may just be the tip of the iceberg.

The increasing and potential markets for woody biomass in lieu of fossil fuels seem a boon for the forest industry, but there are also a number of concerns within the industry. The chief concern is the lack of policies and guidelines regarding what can be harvested, from where, and how much. “We’ve only scratched the surface of what’s out there,” says forester Doug

This small co-gen plant in Sweden (near left) runs automatically at night and during weekends, using automated computer controls and alarm pagers. In Canada, it would require an engineer on site 24/7, much like Taylor Lumberʼs similar size plant in Nova Scotia (turbine shown at far left), creating a major hurdle to small-scale projects.

Prebble, and this seems to be the general consensus. The question is, what is sensible and practical to take, from both a commercial and an ecological viewpoint?

Trees are a renewable resource, so it makes good sense to ensure that forest ecosystems will continue to be viable. Biomass harvesting involves the additional removal of logging residues, or slash. “In biomass harvesting, we are taking more parts from the forest, so what is the effect of that?” asks Michael Main, research associate at Nova Scotia Agricultural College. In terms of nutrients, the whole tree can contain two to three times the amount of nutrients contained in the main stem alone because the foliage has a high proportion

of the total nitrogen, calcium, and other nutrients.

Cations such as calcium, magnesium, and potassium are important in the soil because they act as buffers to limit the solubility of iron and aluminium. Unchecked, these latter elements will increase soil acidity and can be toxic to plants at high concentrations. This soil buffering capacity differs with soil depth such that shallower soils are at greater risk of adverse harvesting effects.

Past studies that have examined nutrient flows indicate that the effects of biomass harvest on soils depend on various factors such as the underlying geology and soil thickness of the site, forest practices, acid and nitrogen deposition from the atmosphere, and the tree species. However, much more than just soil nutrients

Nova Scotia sawmill got into the co-gen game before the current energy price explosion and quest for renewable energy made it popular.

Taylor Lumber of Middle Musquodoboit, NS, has been dubbed a “Biomass Pioneer” by provincial utility Nova Scotia Power for good reason. The privately held sawmill, planing operation, chipping plant, and reman facility just outside Halifax added its 1.15 MW co-gen facility back in 1995. That’s long before $140 barrels of oil, and a full 13 years ahead of NS Power’s recent Request for Proposals (RFP) for 25 MW of additional biomass power.

While the move was only partly because of energy costs at the time, the end result has been the same – the co-gen plant is no doubt a key ingredient in Taylor’s ability to keep its 100 or so employees working through some of the toughest times the industry has faced. It also helped the mill meet a few other challenges at the time it was installed.

“We ran into a problem with our biomass here about 18 years ago,” explains company president Robert Taylor when asked during the CanBio/CWF conference field tour for the reasons behind the timely investment. “We were putting biomass into landfill and things like that. We saw the writing on the wall that it was going to be an environmental issue, and we knew there had to be better ways to use the material. We could also see our power consumption growing because of some expansions we had planned. It’s always hard to see the future in this business, but we based our power consumption estimates on our plans at the time, and it looked like we’d need more power. Altogether, the investment in co-gen looked like a good one.”

Also, like many other Maritime sawmillers at the time, Taylor was adding kiln drying capacity in the 1990s, so heat, steam, and power would all be welcome.

is affected by harvesting, stresses Dr. Evelyne Thiffault, researcher with the Ministry of Natural Resources.

It is imperative to consider other effects of the biomass harvest than simply that on soils when deciding what makes a sustainable harvest. Is the goal to sustain tree productivity, biodiversity, water quality, social values of forests, or perhaps all of these? Even looking to countries that have more experience in this matter such as Sweden, Finland, and the UK can only provide clues as to what makes a good indicator of site suitability for biomass harvest. The use of different indicators (soil depth, soil acidity) can produce completely different results.

This conundrum has created confusion for forest managers, who want to know what they are

to do in the meantime to maintain sustainable forest harvests until scientific knowledge can provide more robust answers. However, both Main and Thiffault stress that biomass extraction can proceed if it is managed intelligently. First, they recommend the avoidance of whole-tree harvests in sensitive sites; for the Maritimes, such sites might be those with shallow, coarse-grained soils. Second, it is generally a good idea to leave foliage and twigs behind after harvest. Thiffault recommends the use of common sense biomass extraction guidelines such as those used in Finland, where 30% of residues are left at the site. In most cases, it would be economically inefficient to collect this material anyway.

Third, Thiffault stresses the importance of monitoring real operations to obtain greatly needed

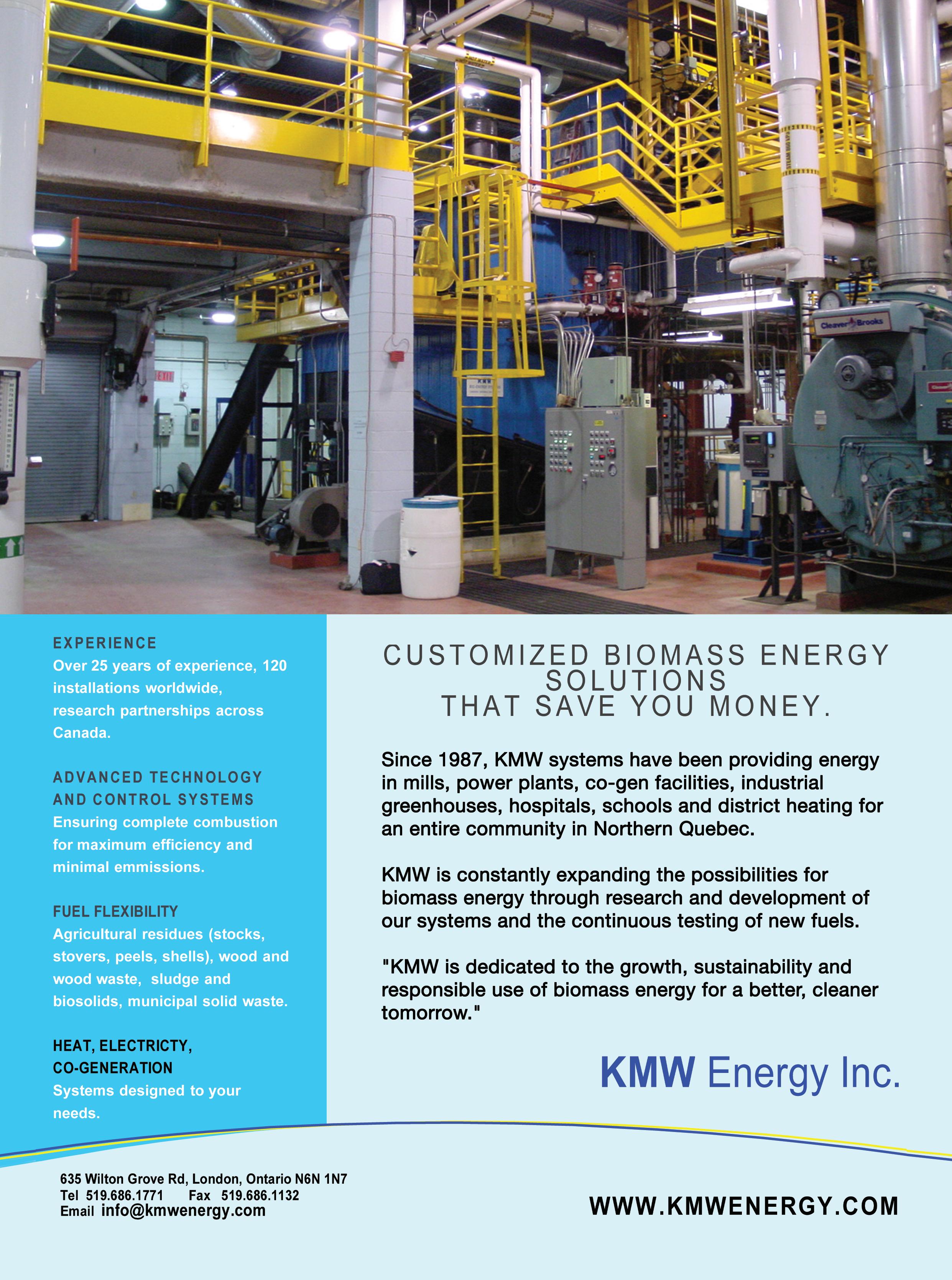

The result was a combination turnkey project for the boiler from KMW Energy Systems of London, ON, with what Taylor calls a “piecemeal project” for the rest. The boiler was chosen for its ability to handle a wide range of feed stocks, the majority of which are produced on site by the mill.

Hog (bark) constitutes 40% of the supply and is stored at the edge of the mill yard. Judging from the piles on site during our visit, both the size and quality of the hog fuel varies widely. Sawdust (40%) and shavings (20%) are stored inside, transported to the

information. Fourth, managers and policy makers should use adaptive management to evaluate and alter guidelines on a site-by-site basis depending on local knowledge and the availability and acquisition of appropriate data.

Of course, the harvest of biomass in the absence of market opportunities would not be economically sustainable. Biomass should compete for a piece of the energy pie that is currently occupied by fossil fuels, explains Jim Verboom, president of Verboom Grinders, a Truro-based biomass supplier and one of the largest in eastern Canada. The forest industry should look to expand current markets, including firewood, chips, hog

fuel, and wood pellets for heating, as well as to develop potential future markets for biomass and biomass products, including wood/coal co-firing to produce power, the co-generation of heat and power, and processes to further refine biomass such as gasification, pyrolysis, and torrefaction, and even carbon credits! Because Canadian biomass markets are in their infancy compared to those of Europe, particularly Scandinavia, there are many opportunities to get in on their development, including the development of industry policies.

Take the wood pellets industry, for example. According to John Swaan, executive director of the Wood Pellet Association of Canada, Canada produced approximately 1.5 million tons of wood pellets in 2007. Only 14%

appropriate sections of the warehouse by a simple, but effective, overhead conveyor with diverter gates. Shavings are stored separately and are bagged for the animal bedding market as required. In fact, an upcoming project is a more efficient bagging system for this hot market.

Feedstock is blended and brought to the KMW boiler via a drag chain conveyor. Here, moisture can be added if the blend is too dry, as was the case when Canadian Biomass was on site. Despite its small scale, the plant is manned 24/7 by a stationary engineer to meet provincial regulations (one of many that parties like CanBio are trying to get changed).

The wood residues are burnt and resulting gases re-burnt for maximum efficiency and minimal emissions. The entire process is controlled from an operator’s booth perched between boiler and turbine.

The mill generates 100% of its own power needs and sells power to the grid daily. Future plans for the shavings baling line, a pallet operation, and even aquaculture among others will reduce power available for sale, yet thanks to this 13-year-old investment, the power is there for the taking. This is far from always the case for rural sawmills in this part of the world.

“I think the industry has to look at a variety of energy sources down the road,” Taylor predicted a few years back in a NS Power video promoting bioenergy. “For us it’s something that worked out really well, and it will be a big part of our operation in the future.”

When asked why the 15 million bdft operation has managed to avoid the heavy downtime plaguing most of the industry, Taylor remained cagey. Luck is a big factor he said with a smile. Looking around the yard at the wide range of specialty products, niche marketing no doubt plays a role as well. Still before we climbed back on the tour bus, he admitted that the co-gen plant has been a factor.

of these were sold in Canada, with 32 and 54% going to the U.S. and overseas, respectively. The European Union nations in turn benefit from carbon credits that they receive from the use of pellets. Considering the increasing cost of ocean shipping and Canada’s commitment to the Kyoto Protocol, it would be advantageous to create and increase domestic uses for these pellets.

In other markets, the technology for energy and power generation that is currently commercially available for biomass is based on oxidative combustion. The greatest opportunity here seems to be in biomass co-firing, in which biomass is treated in some manner such as grinding and then used to replace some of the coal used in coal-fired power plants. This requires only slight modification of

existing plants to install biomass storage and feed systems. According to Fernando Preto of Natural Resources Canada, Ontario Power Generation has been conducting short co-firing tests using various types of biomass since March of 2006 at the Nanticoke plant, so these results are something to look for in the future. Canada should look to places like Finland, where co-firing is common, as a springboard to develop its own co-firing policies (Editor’s note: These tests have been successful, so OPG is expanding this project dramatically – see page 21).

Up-and-coming technologies include gasification and thermochemical conversion, or pyrolysis. Gasification ultimately results in the production of synthetic gas, which can be used as a fuel or further processed to make

“It’s been an aid, for sure. It’s just part of the equation now.”

While Taylor Lumber was the first independent sawmill to sell power to NS Power, it won’t be the last. The utility’s 2008 RFP calling for 25 MW of biomass power is looking for one big 20 MW project, but also a collection of smaller ones totalling 5 MW, all to replace the province’s heavy dependence on coal. Decisions will be made in mid-2009, so stay tuned. – Scott Jamieson

other products. Several North American companies have woody biomass gasification plants at the pilot and demonstration stages. The pyrolysis of biomass produces a corrosive and easily polymerized substance, requiring some modification of burners before the pyrolysis oil can be burned. Four companies in Canada currently produce pyrolysis oil, according to Preto.

One of the major barriers to the expansion of the biomass industry in Canada was noted by Bruce McCallum of the Canadian Bioenergy Association (CanBio) as the lack of bioenergy policy frameworks and inconsistencies in policies and programmes at all levels of government. Archaic requirements for 24/7 boiler engineers for the smallest co-gen plant is an example. There needs to be a push within and among governments to develop long-standing policies and programs for bioenergy that specifically address biomass as a form of energy. In addition, to facilitate markets and technology exchange, standards need to be

set or Canadian standards made compatible with European and U.S. standards when possible.

Another barrier to address is that of consumer confidence in product availability and maintenance. There is a need for the coordinated introduction of technology and resources, for example, pellet-burning residential furnaces and pellet supply. Policies should introduce incentives for people or organizations that want to convert from fossil fuel to biomass consumption. Addressing these barriers can only be advantageous: budgets will be reduced by switching public institutions to biomass heating, co-generation can reduce power and heating costs, Canadians will gain access to biomass forms of heating, price and supply should become more reliable and stable, and jobs will be created.

Given that biomass is available, can be harvested sustainably, and

Verboom Grindersʼ newest horizontal grinder, a Peterson 5710. With hourly costs in the $300 range, keeping such machines working is a key to biomass harvesting success.

there are market opportunities, the final major object of consideration is the efficient and economical transfer of biomass from the forest to the processing plant, and ultimately, its final destination.

According to Mark Ryans of FPInnovations’ Feric division, as well as several experienced producers, comminution and transportation are the most costly parts of the transfer chain. This makes sense because of the capital costs and fuel costs involved in operating the machinery.

Several recommendations were made regarding comminution and transportation. The main harvest and the recovery of biomass, e.g., pre-piling, should be integrated to reduce both costs and contamination of the biomass, the latter of which can increase machinery maintenance costs. Efforts should be made to minimize the amount of time that grinders and trucks are idle. Biomass should

be treated in a manner that minimizes the moisture content so that weight costs are for energy, rather than water content. Finally, efforts should be made to improve domestic markets, ultimately reducing shipping costs.

There are multiple ways to address each of these factors; the producer should take care to consider the whole production chain to determine which methods are most suitable for his or her particular operation and invest in equipment that will serve multiple purposes.

The final message to be taken from the bioenergy conference is that there is much to be done in the Canadian biomass industry. There are lots of opportunities to step in and become part of its development, from production, technology, and research to policy development. And there are lots of potential benefits to be had by becoming involved. •

Despite running a single 26-in mill, Lauzon Recycled Wood Energy punches above its weight with this 35,000-ton plant in Papineauville, QC.

By Scott Jamieson

Lauzon Recycled Wood Energy (RWE) was founded over 12 years ago, the pellet market was in its infancy in North America. There were few Canadian players, and markets were just forming. More than a response to a burgeoning market demand, Lauzon RWE was a way for the main business, Lauzon Flooring (now Lauzon International Inc. – LII), to solve a messy problem.

“The flooring plant down the hill was already creating the dry raw material a pellet mill needs,” explains sales and marketing director Stewart McIntosh. “This was a key, and they had an abundance of it at the time, which had to be land filled at a cost. There were few developed opportunities in the energy market at the time, so pellets were the way to go. Appliances to burn pellets were only coming on the market domestically, but we had a need here, so we went ahead.”

What started out as a $2.5 million investment in helping the company’s state-of-the-art hardwood flooring plant out of a jam has since developed into an environmentally-responsible business of its own, and one with a growing future. Demand has always been hard to predict in the young pellet market, but it too seems to be coming of age. For this coming season at least markets will not be an issue, not judging by the large storage yard adjacent to the mill. All but a tiny corner was empty when Canadian Biomass was on site in August. “It’s normally jammed this time of year, and we’re sold out of appliances this year too,” McIntosh adds of the Harman pellet stoves the company also represents.

What hasn’t changed since those early days is the direct flow of fibre from the successful flooring plant to the pellet company. The automated and optimized flooring plant has a host of machine centres producing dust and shavings, including chop saws, rip saws, and sanding lines. This fibre is collected by a dust collection system and blown up the hill to the pellet mill, making up 70% of the annual need. The other 30% comes in on truck from local wood products plants, and is dumped onto a screw infeed pad. The company runs upwards of 80 trucks to keep the flow of raw materials in and finished goods out.

Both fibre sources merge in two storage silos – 40 and 80 ton units. It is screened, sized in hammer mills, and then blown into a holding bin above the pellet mill. Material goes to the one and only pelletizer the plant runs – a warhorse that almost never stops, McIntosh

says. “We’re talking production efficiencies of 98%.”

It also runs 24/7, explaining the mill’s relatively high production numbers. From here, pellets drop down to a cooling system in the basement, and are brought back up to a 40-ton bin that feeds a Hamer automated bagging system. The company markets under three brand names, so product is bagged according to market. Bags then continue to a new robotic palletizing system supplied by Quebec-based Robovic. Canadian customers are supplied to the tune of 75 bags per pallet, while US clients get 50 per pallet, the latter largely to accommodate shipping restrictions between both countries. Shipping is via truck, with the plant located 45 minutes from Ottawa and an hour from Montreal.

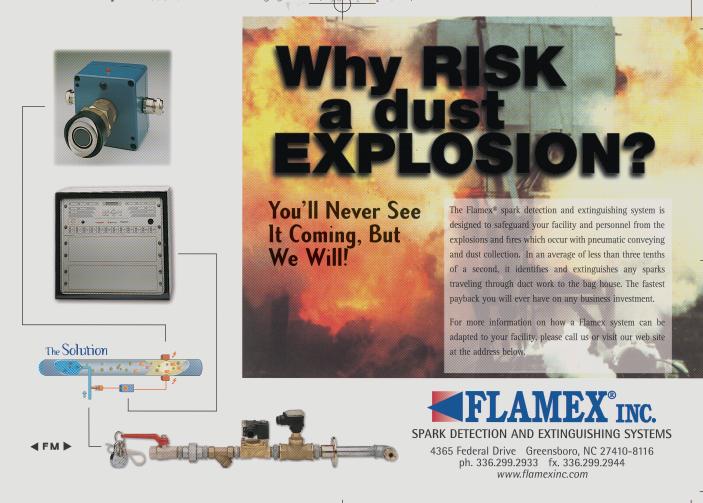

Safety has been a hot topic of late in the pellet sector, but Lauzon has been covered on this front since it opened in 1995. “We have a Flamex spark and fire detection system. If material goes through the hammer mill, and the system detects a spark, it’ll shut the system

down. If it detects heat, we have a flood gate that will flood the system.”

It’s a wise investment for any pellet plant to make. According to Flamex, the risk of dust fires and explosions is inherent in the pneumatic handling and air filtration processes found in any wood products manufacturing facilities, and wood pellets is no exception, as it involves processes such as drying and hammer milling which are particularly conducive to the generation of sparks and fire. The Flamex system as supplied to Lauzon by Rodrigue Metal detects airborne sparks traveling through a pneumatic duct, and suppresses them with water before they can reach cyclones, baghouses or dust bins where fires and even explosions could result. The water spray stops automatically when suppression has been achieved so production can continue and costly downtime can be avoided. Lauzon is certainly out front in taking such

risks seriously - In addition to the Papineauville and St. Paulin facilities, Rodrigue Metal has also supplied Flamex systems to Lauzon plants located in St. Norbert and Manawaki.

The Papineauville plant also runs a quality control room, where among other things, key QC parameters are verified every two hours. These include moisture content (target of 6%), ash content (0.4% or less depending on species), dust content and particle size.

Almost all production is sold in central Canada and the northeastern US, 98% of it in bags for residential heating in pellet stoves. While the company has tried selling in bulk to Europe, it found the risks outweighed the benefits. “We’ve learned from it. If we go back into Europe in the future, we’ll do things differently, but for now with our location and production, we can sell our products domestically (US and Canada).”

Lauzon Recycled Wood Energy has several projects in the works or in action to boost its annual pellet output, but where will these extra pellets end up? Sales and marketing director Stewart McIntosh sees incremental growth in the domestic market as fossil fuel costs rise over time. Still, it’s not likely to boom over night, he cautions, as North America lacks the residential heating appliances and delivery infrastructure required for pellet heating to go mainstream.

“You need the ease of use they have in Europe. The appliances and support are coming, and the drive is on to develop that market, but it will be a slow development.”

Aside from residential pellet stove heating, there is also potential for industrial and greenhouse heating, markets that are both growing. The latter especially has been all the talk at greenhouse industry meetings, as owners struggle with heating costs that have soared from 15% of overall costs to 40% or higher.

And then there are the really big potential players, like Ontario Power Generation (OPG). At the recent CANBIO annual conference in Ottawa this past October, Jane Todd of OPG’s fossil fuel division announced that its biomass co-firing trials have been exceeding all expectations. The goal is to replace all or a portion of the coal it currently uses for a large part of its power generation needs. OPG has been running co-firing trials at its four coal-fired plants, including four hours of using 100% biomass at its Atikokan facility, and various levels at North America’s largest coal-fired power plant in Nanticoke, ON. According to Todd, the trials have been much more successful than even OPG’s best-case expectations, with both power generation and emission standards more than acceptable. Building on this success, and an aggressive provincial policy to phase out coal by 2014, OPG plans to quickly ramp up biomass firing, and is talking of 100% conversion at Atikokan, which currently uses a lower-quality lignite coal and has direct rail access. The fuel of choice is wood pellets, as they allow the utility to use existing assets, such as pulverisers, with a minimum of modifications. The target announced at the meeting is 2.5 terawatts, which if our math is right (600,000 tons of pellets per TW) requires 1.5 million tons of high quality pellets. For an idea of the effect this power giant could have on the solid bioenergy market, Canada currently produces slightly more than 2 million tons/year. If the economics and politics work out, OPG could create a biomass support industry all its own. And Lauzon’s expansion plans, even if they all move forward, would be a drop in the bucket.

A solitary pellet mill makes the plantʼs 35,000 tons annually, and is maintained to run 24/7.

The Papineauville pellet operation runs with eight people in administration, although this group also shares some responsibility for the company’s other pellet mill in St. Paulin, east of Montreal. The Papineauville mill relies on 16 plant employees to run 24/7, while the St. Paulin plant adds two more administrators and 14 to 16 on the floor for another 25 tons/year or so. While the two plants have a combined capacity of close to 75,000 tons, they have more typically produced 60,000 tons/year. Like most pellet plants, inconsistent markets, supply shortages, and plant inefficiencies have combined to limit production well below capacity.

“Markets have been a year-to-year challenge. Compared to any other energy source, domestic pellet use and pricing have been a flat line with a few bumps. There’s lots of potential, but it’s still a young industry. We’ve had shortages in the past, which scares people just as they

start thinking of using pellets. There’s more talk of that this year again, even with the new plants coming on line. Then we’ll have a mild winter, and supply outstrips demand.”

Yet the company is currently planning on some sustained growth, and has recently been staffing up to prepare for it. For example, McIntosh had until recently been general manager, handling both sales and production. He now focuses 100% on sales, with Pierre Tremblay handling operations. Part of this growth is expected to come from the St. Paulin plant, which was shut down in April 08 for a major rebuild. It originally ran with three pellet mills – two small and one large. The two small units are being replaced with a larger one, for efficiency and added production.

“We started off with a two-phase project, and were going to do the first $750,000 phase this year. With the market, we’ve decided to do it all in one go, and are investing $1.5 million this year to bring it up to a state-of-the-art facility, with computer controls, fire suppression, automated packaging – the works.”

“It’s fair to say we see this as a growth market,” McIntosh concludes. •

exhaustive round-up of biomass chippers and grinders is a handy “keeper” reference for anyone in, or thinking of getting into this side of the supply chain. It is a mix of information from Timber Harvesting magazine (used with permission) and information collected by Canadian Biomass magazine, with all information provided by the equipment suppliers.

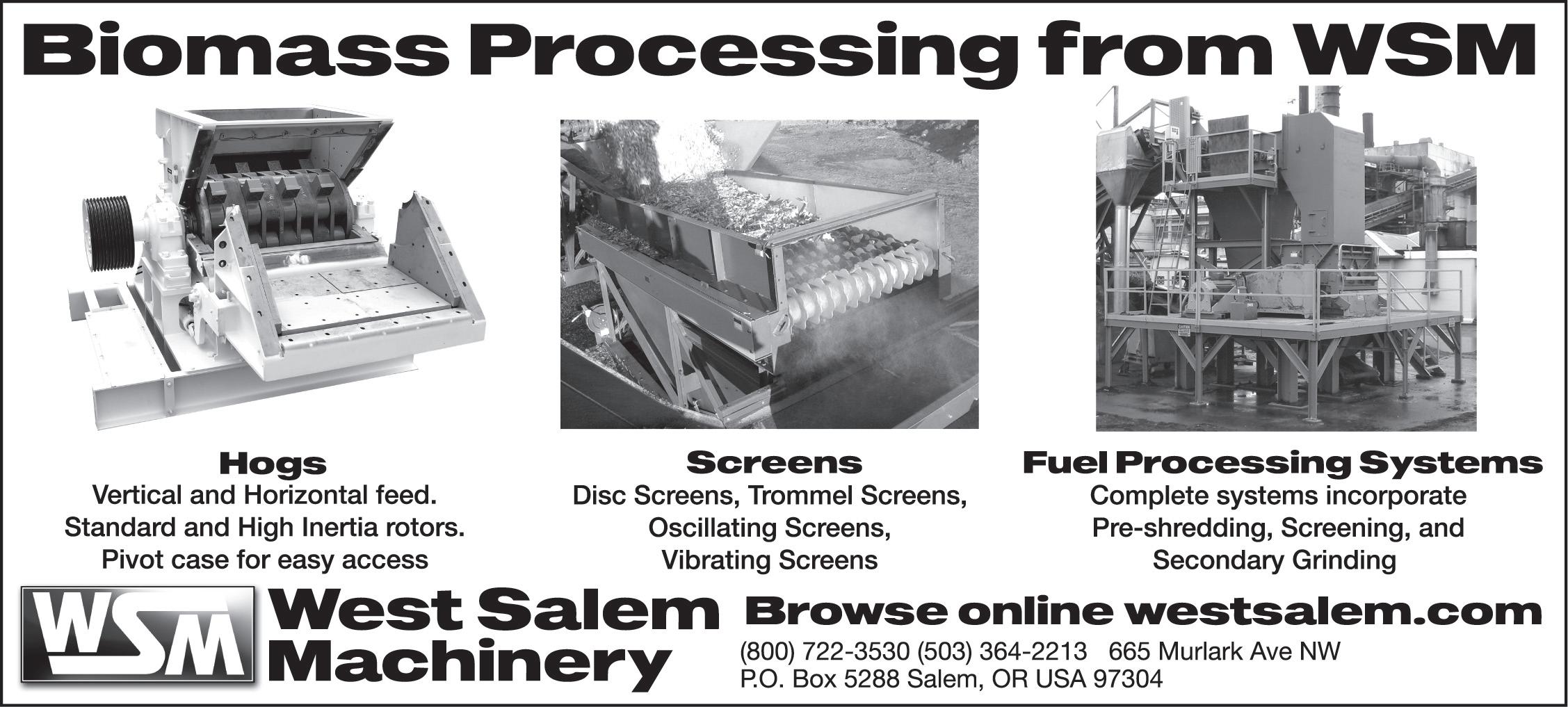

Regardless of the raw fuel source, the Acrowood DEAL Processor is an ideal choice for biomass fuel handling and can be used in either a recovery or main infeed center format accepting, classifying and cleaning the wood rich diet in a single step.

The coarse primary fraction, typically large wood chunks, stumps and logs, stay above the DEAL Processor rotor array where they are cleaned by the abrader tips and the intense tumbling action, while the secondary flow fraction is quickly expelled thru the rotor array interface opening to a collection conveyor.

The primary flow spills over an adjustable discharge gate, goes thru a reduction process, and onto the boiler fuel accepts conveyor.

Secondary stream is dependent upon the streamʼs composition. If the material is heavy to mineral, dirt and inorganic, then the stream may be composted to provide a soil supplement, used for landfill cover, returned to the forest floor, etc. Where the secondary stream has a high percentage of useable wood fiber with relatively low tramp materials, it can be directed past the chipper or hog and into the boiler accepts conveyor.

If the stream has a high percentage of useable fiber but is contaminated with tramp or mineral components, then it can be further refined by rotary deck screening and destoning to recover the useable wood fiber component.

Only the Acrowood DEAL Processor provides the classification and cleaning aspect as a single step process. Enhanced by a default metering function to ensure smooth delivery of coarse clean fibre to down stream processes, these heavy duty units provide long term performance with minimum maintenance requirements. www.acrowood.com

Anticipating an increase in demand for woody biomass, two years ago Bandit Industries began developing new products to expand its line of fuel wood harvesting machines.

The model 3090, a 24 in diameter capacity unit with a large 34 x 30 in opening, has a larger drum, larger chipper opening and a more powerful feed system that includes a drag chain infeed conveyor. With a 630 hp engine, this chipper can fill a 45 ft trailer in less than 20 minutes.

Models 3590 and 3590XL, our newest and largest whole tree chippers, were introduced in 2007. The 3590 is a 30 in diameter capacity unit with 700 hp. In

certain applications it will easily fill a 45 ft van in less than 10 minutes. The 3590XL is a 36 in diameter capacity machine with a 36 x 48 in chipper opening and an extremely powerful feed system. The 3590XL can fill a 45 ft van in about six minutes.

Any of Banditʼs Beast Recyclers can now be converted to a chipper to produce a conventional screened chip utilizing the patent-pending Beast Knife System.

As a whole tree chipper, the Beast will effectively chip large diameter material and is an excellent unit for logging slash and sawmill waste. In addition, the knife life in the Beast is actually better than the knife life in a whole tree chipper. If material is too contaminated to chip, you can simply switch to carbide cutting and grinding tools and then switch back to the knives in a cleaner material, lowering the fuel consumption and operating costs. www.banditchippers.com

Dumping into waiting containers is a key element to these systems in Sweden.

This forwarder mounted chipper turns logging residues to biomass where you need it. Logging slash can be piled up at the edge of the logging area, or for smaller jobs, the machine can go get it. The chipper is installed on a forwarder with crane for efficient feeding into the chipper. A spiked drum feeds the material to a chipper drum with two exchangeable knives, chipping the material against an anvil. The two chipping knives are changed daily.

The chipper drumʼs 1,000 rpm give a uniform infeed and high capacity. It is powered by a Scania 12 litre, 450 hp industrial engine. BRUKS manufactures about 40 mobile chippers per year, and today there are a total of some 150 professional forwarder mounted chippers operating in Sweden.

The computerised control system is making it easy to troubleshoot and follow up production, and is handled by the operator via a touch-screen in the forwarder cab. Wood chips are thrown out of the rotorʼs chip pockets to a chip accelerator and through the turnable chip tube into a chip bin. The chipper produces 30 to 50 tons/h of chips when used to its full capacity. In operation over a longer period of time, an average of some 20 ton/hr is realistic.

When the chip bin is full, the forwarder moves to a container waiting by the forest road to dump the chips into. These are picked up by a fleet of tractor trailers. These logistics are important for the efficient handling of chips. The trucks leave behind empty containers to allow hot logging operations to continue.

The chipping operation continues more or less day and night, all year round. The demand for fuel chips to produce power and heat in Sweden is steadily growing. www.bruks.com

Four swappable rotors may be just what todayʼs biomass contractor needs.

Who knows where the future of biomass contracting lies? Not us, and not CBI. Thatʼs why theyʼve made the Magnum Force 6400 to be what they call the worldʼ s most versatile grinder. With four different, field-swappable rotors (forged drum rotor; solid steel rotor; and two application specific drum chipper rotors), in a single day you can go from making mulch from trees and stumps, to chipping stem wood into 2-30 mm fiber length, to grinding highly contaminated C&D or railroad ties with the tie plates attached.

Features 765 – 1050 hp diesel or electric engine and is 2.99 meters wide to meet European standards. Track-mounted, wheel-mounted and stationary versions available. CBI has a revolutionary chipping process that can deliver uniform 3mm6mm micro-chips in a single pass. Traditionally, pellet manufacturers used sawdust when it was available. But as sawdust becomes scarce due to the popularity of this fuel, they have turned to whole tree chips (approximately 30mm in size) and they put them through a time-consuming and costly process of grinding in order to prepare the material for the pellet press. But CBI chippers like the Magnum Force 6400 and the Magnum Chipper 8400 yield uniform micro-chips that can bypass those processes and immediately be dried and milled into feed stock for the pellet press – saving up to 75% of the input power requirement while increasing the pellet press throughput. www.cbi-inc.com

Savings can be substantial with a grinder plugged into the grid.

As the cost of diesel fuel has increased, electric powered wood grinders have become the grinder of choice for an increasing number of grinding professionals.

In most cases, when using electric power, the savings will make your monthly grinder payment. CW has been manufacturing HogZilla brand electric & dieselpowered grinders for over 30 years. Industryʼs top professionals prefer HogZilla because of proven production, reliability, strength, durability, and solid value.

HogZilla grinders can be configured to suit your operation with top quality. The industryʼs best track-driven grinders as well as advanced trailer-mounted units with grapple loaders and many other unique process specific options are available including scrap-tire processing attachments.

If your operation can access electric power, let us show you how to revolutionize your operation as a private or municipal processor. We can provide you with machinery options that can save you so much money that you will wonder why you didnʼt make the change sooner.

If you are unable to access electric power due to location or mobility requirements, you need to become aware of the proven efficiency, reliability, and torque multiplying strength of Hogzillaʼs true torque converter drive that is the drive of choice in the top of the line HogZilla diesel powered units. Contact CW Mill to become fully aware of the benefits that go along with HogZillaʼs torque multiplying torque converter, and find out why we back them with a 5 year / 6,000 hour limited warranty. www.hogzilla.com

Diamond Z offers a broad range of tub and horizontal grinders and trommel screens designed to suit any application. From high-volume composting needs, to disaster cleanup, to stockpile tire disposal, to solid waste reduction, no grinder outperforms the Diamond Z.

The company has experienced steady growth since it was founded in 1989. It is recognized as a world-class manufacturer of high production tub and horizontal grinders. In 1996 Diamond Z introduced the worldʼ s first totally enclosed tub grinder to maximize safety in sensitive environments. The enclosed grinder processes a variety of materials at unparalleled production rates and is the best choice for operators in highly populated locations.

Diamond Z is committed to satisfying waste disposal needs of customers in a timely manner. This commitment is what makes the company a trusted grinding expert domestically and abroad. www.diamondz.com

ment for getting the job done right and on time. DuraTechʼs 3010T tub grinder was built to make your job easier. It was designed for ease of use, with features like a 6-function remote control and an engine compartment that has three doors per side to provide easy access for quick fixes and routine maintenance. The 3010T will also go where other grinders couldnʼt even position a conveyor, thanks to its unique track system.

The 3010T does not sacrifice power for the sake of being flexible and maneuverable. Itʼs powered by either a 475 hp or 540 hp C15 Caterpillar electronic diesel engine that meets Tier III standards. The engine sits protected from debris in a compartment designed to reduce noise levels.

Finally, you canʼt grind if you canʼt load. The compact stacking conveyor allows you to load the finished product into a truck or place it neatly onto an existing pile. DuraTech even offers an optional magnetic roller and aluminum chute to separate unwanted metal. www.duratechindustries.net

In recent years significant numbers of producers have chosen Dynamicʼs patented Cone-Head chipper to profitably enter the growing fuel wood market. The doublecone drum design has proven to be more fuel-efficient, producing more tons per litre and more tons per horsepower.

According to Charles Ledbetter of Antoine, AR, who is running a model 585 with a 440 hp Cat, the live infeed bed and the 34 x 22 in throat opening make for easy feeding of logging slash. The unique cutting angle of the Cone-Head drum makes a consistent high quality chip.

Sherwood Padgette in North Carolina has been running a model 570 with a 365 hp Cummins for over two years. He calls it “the most important machine I own” because it allows him to take more product off each jobsite and “it keeps me off the lowboy,” reducing costly moves. He chips eight to 12 loads per day and loves the smooth cutting action of the Cone-Head drum as well as the low fuel cost per ton.

Brad Hassek of Lufkin, TX is running a model 585 with a 500 hp John Deere engine and doing five to eight loads per day from delimber slash and wood refuse. He likes the high velocity discharge, which makes for tightly packed loads, and says he can feed his 585 material that other machines wouldnʼt take. The simplicity of maintenance and operation, mobility and durability are also features that attracted him to Dynamic. www.dynamicmfgcorp.com

The Chippo 500: This is a tractor driven drum chipper for processing whole wood trunks and branches. The robust design and the use of premium components make the drive rating of up to 500 hp possible. This means a throughput of up to 235 cubic yards per hour. The Chippo 500 offers the choice between “materialfriendly”, energy saving discharge via conveyor belt or conventional discharge via a blower featuring variable rotation speed. These two options let you create a stock pile or load out a truck with just the press of a button. Komptech will be offering three larger versions in 2009, the Chippo 5000, 6000, and 7000. Crambo 6000 Forest: The “Forest” model integrates a star screen unit into the discharge of the Crambo wood shredder. When the Crambo is shredding root stocks, green waste and forest residue containing soil and other residue, the fine fraction is effectively screened out in one operation. This is ideal for the customer looking to process co-gen in the forest in one pass. This unit is available on tracks, as well as semi trailer with grapple. Komptech provides three different power packages ranging from 340 hp to 600 hp. www.komptech.com

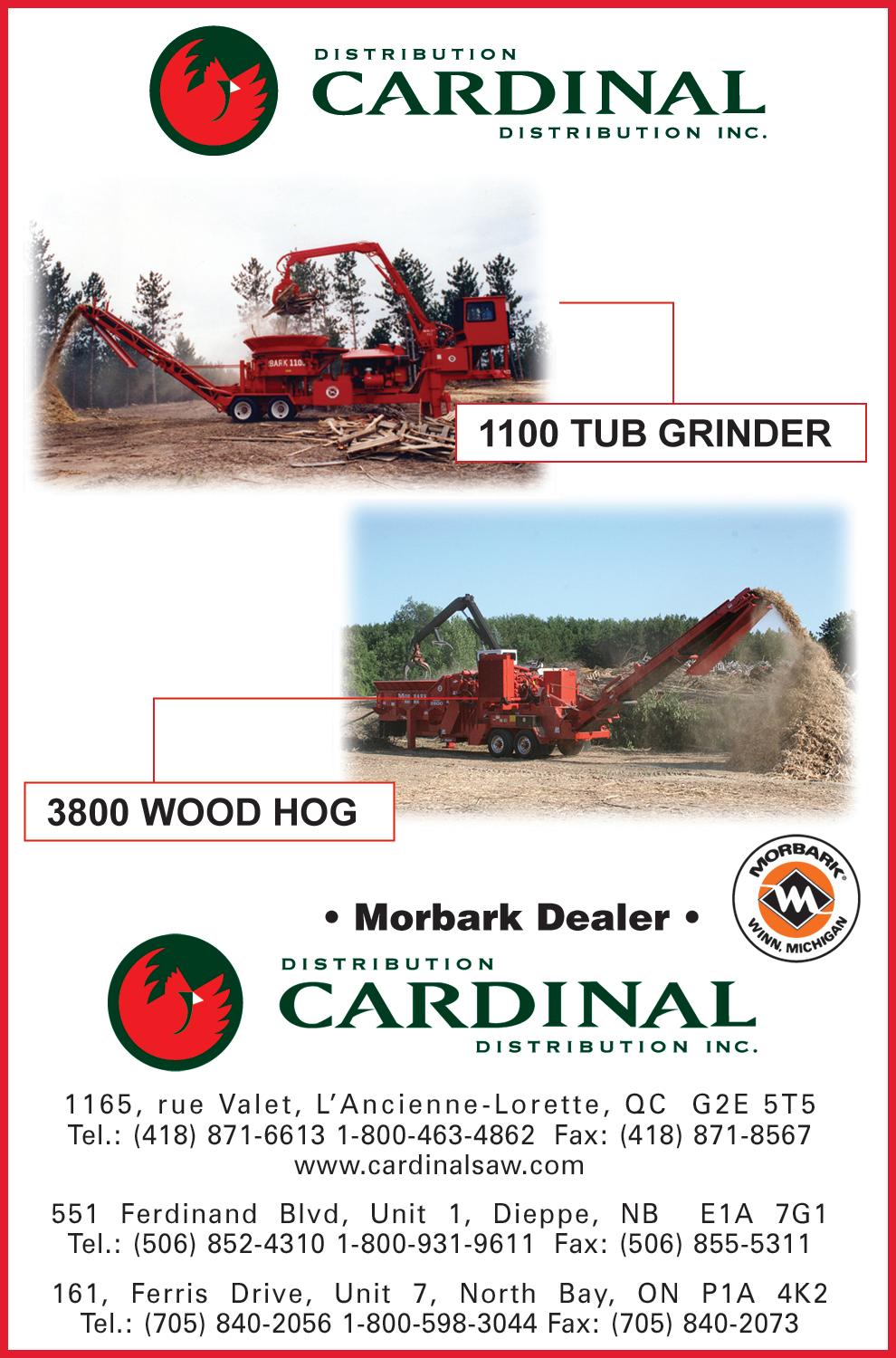

The 40/36 boasts the lowest fuel consumption per ton of chips according to Morbark.

Morbark has introduced the all-new model 40/36 whole tree chipper. Compact, affordable and productive, this drum chipper is specifically geared for the biomass industry and itʼs creating a buzz with medium to large fuel producers.

Equipped with the same internal drive perfected on Morbark horizontal grinders,

along with an extra wide feed opening, the 40/36 aggressively feeds brushy tops and limbs. This chipper effortlessly fills a chip van to maximum legal load capacity. This compact unit is easily transportable and requires no permits to move. The economical chipper also offers the “lowest fuel consumption per ton of chips produced.”

The 36x40 in. wide drum holds eight knives in a staggered configuration. Morbarkʼs unique IQAN system monitors engine parameters as well as hydraulic pressures and temperatures and allows for utilization of remote diagnostics. Power options are available up to 700 HP Cat or John Deere. Wireless remote control and four hydraulic stabilizers complete the package. www.morbark.com

The 5710C combines 1,050 hp with the ability to move quickly between jobs.

The 5710C is Petersonʼs latest generation of high production track grinders. Powered by the Caterpillar C27 or C32 engine at 1,050 hp, this grinder provides the highest power-to-weight ratio of any Peterson grinder. At approximately 83,000 lb, the 5710C was designed for operations requiring high production and frequent moves between jobs. With a feed opening of 60 x 44 in, combined with Petersonʼs high lift feed roll, the 5710C can readily reduce a wide range of materials including stumps.

The 5710C uses Petersonʼs new generation of Impact Release System that can be set in the detent mode to provide consistent product sizing or switched to the floating anvil mode for a primary reduction where accurate sizing is less critical. The floating anvil mode provides a high production primary reduction with more protection from contaminated feedstocks and reduced fuel consumption.

The 5710Cʼs new generation of controls includes a high production Adaptive Control System and a fully adjustable feed system that can be optimized for a wide range of materials. The new control panel provides self-diagnostics for faulty sensors and open circuits. Fault indicators make trouble shooting easy. An optional on-board modem permits remote diagnostics and monitoring of many machine parameters. The control panel features a large LCD display that provides the operator with the information needed to efficiently operate the unit. System pressure transducers and remote monitoring capability simplify setup and provide complete engine and system parameters.

The 5710C features a large grate area that enables it to produce materials to exact specifications. A quick-change multiple grate system makes it easy to customize grate configurations to produce a wide variety of finished materials.

Another major innovation included on the 5710C is the Impact Cushion System. Urethane cushions allow movement of the compression roll/anvil housing pivot shaft, cushioning impacts due to contaminants. Shear pins above the cushion and a sensing circuit that stop the engine help protect the shaft from catastrophic damage in the event of a severe impact. www.petersonpacific.com

ProGrind grinders can be converted to a chipper in very little time.

Precision Husky is now offering a chipper drum on all its ProGrind horizontal grinders, according to Billy Daniels, vice president of engineering. The cutting mechanism of the machine can be changed from grinder to chipper in a very short time. The first unit to be on demonstration this year will be the model H-3045. This option allows chips of any size to be made using standard adjustable chipper knives. Considering that the chips must pass through a screen plate before they are conveyed away, this makes it much easier to size the end product.

The grinder part of the new unit is engineered with a double cut hammermill that uses different hammer bodies. This feature reduces engine horsepower by cutting the wood with two different cutting diameters. Not only is this more efficient, the common problem of frequent jamming is also eliminated.