Okanagan Valley cheesemaker blends product innovation with advanced vacuum-packing machinery to maintain its winning edge Story on Page 13 Show Preview Sept. 29- Oct. 1, 2025 Starts Page 33

PIONEERING INNOVATION SINCE 1950

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

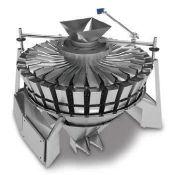

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Sep. 29-Oct. 1, 2025

Booth W-2506

Las Vegas, NV USA

• Controls and information systems info@heatandcontrol.com |

Las Vegas Convention Center

The Videojet 7920 UV laser marking system is engineered to optimize your operations with innovative Videojet SmartFocusTM technology, helping to reduce manual intervention while maintaining packaging integrity.

See how you can achieve your automation goals with the Videojet 7920 UV Laser and SmartFocus™ technology.

Food and beverage manufacturers continue to focus on sourcing more reliable products that require minimal service to keep up with the industry’s growing demands.

Regal Rexnord is the ONE partner that can deliver component solutions designed to deliver increased, sustainable productivity - whether by designing more efficient solutions or simply sending more product out the door, quicker. We have united engineering expertise and best-in-class brands to provide both standard and customized end-to-end powertrain solutions that are widely used in the most challenging applications and conveyor lines. Learn how our products come together seamlessly to create efficient and reliable solution that can help you reach your business goals and upgrade your packaging line efficiency.

Regal Rexnord can help your business achieve your unique goals within these fast-moving industries.

Okanagan Valley-based cheese products manufacturer cooks up a winning recipe for sustained marketplace success with best-in-class vacuum-sealing technology and continuous product innovation.

Iconic family-owned rotisserie chicken restaurant chain makes a promising move into the local retail market with high-impact paperboard packaging.

Montreal-based manufacturer of antiseptic and disinfectant solutions for the healthcare industry leverages leading-edge product coding and marking technologies to sustain its strong market momentum.

How automation and artificial intelligence are driving the swift adoption of smart manufacturing technologies in the packaging industry.

Leveraging the lure of exciting automation technologies to attract the next generation of young talent into the packaging industry.

Our preview of the exciting new technologies awaiting their unveiling at the upcoming PACK EXPO Las Vegas 2025 exhibition.

analog and dairy cheese products packaged on high-end vacuum-sealing machinery supplied to their Okanagan Valley plant by Reiser Canada Inc. Cover photo by Dave Buzzard

As one of the country’s biggest economic growth drivers, the Canadian meat processing industry has a lot going for it these days—tariff wars notwithstanding—but the sector’s long-term prosperity is far from a done deal, according to The Conference Board of Canada.

adian meat processors like Cargill and JBS Foods Canada are making progress in adopting smart technologies, this adoption has been driven largely by an appetite for quick fixes in productivity and process efficiency, rather than as part of a comprehensive sustainability strategy addressing critical environmental and social issues impacting the industry’s value chain.

SEPTEMBER 2025 | VOLUME 78, NO. 6

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Meat processing sector’s share of all food processing sales last year 25.3%

With estimated sales of $43.8 billion last year, accounting for 25.3 per cent of total food processing sales, Canadian meat processors play a massive role in the country’s economic well-being—supporting more that 81,000 full-time jobs and nearly 1,000 businesses. But for an industry so reliant on trade with the U.S. and other international markets—with an estimated 51 per cent of all beef and cattle production exported in 2022—maintaining its status as a major player in the increasingly competitive global meat business will require a major upgrade of the industry’s manufacturing, workforce training and sustainability strategies.

As the new Conference Board report on the Canadian meat industry proclaims, “Sustainability underpins the future of meat. Consumers, especially in high-income countries, are increasingly conscious of the environmental and social impacts associated with meat consumption,” says the report, aptly titled From Knives to Knobs: Advancing Sustainability in the Meat Value Chain with Smart Manufacturing

“The [Canadian] meat industry should confront these issues to safeguard its social licence and remain competitive,” the report’s authors assert, suggesting that the industry’s current skillset is quickly becoming outdated in terms of downsizing its environmental footprint, while simultaneously adopting key “smart manufacturing” technologies such as robotics, automation and digitization.

“For meat processors to harness smart manufacturing, their workers need the right skills,” the study points out, citing a serious “skill mismatch” in the Canadian meat processing sector, especially in the beef segment.

For example, Canada ranks last among all G7 countries in terms of using robotics in the production and packaging of meat products, according to the report, which attributes this shortcoming to the industry’s inability to recruit enough skilled workers to operate them properly.

And while some of the largest Can-

“While the meat processing industry plays a crucial role in global food security and nutrition, the meat value chain also faces serious sustainability challenges,” the report proclaims. “For instance, beef production is the leading cause of tropical deforestation globally.

“In Canada, beef production uses 74 per cent of the crop and pastureland that wildlife relies on for reproduction,” the study notes, “[while] over 30 per cent of global methane emissions are from livestock farming.”

With methane emissions considered to be at least 28 times more harmful than carbon-dioxide in terms of global warming, tackling the sector’s environmental footprint will require new creative and collaborative approaches to production, packaging and distribution by meat processors, retailers and foodservice operators alike.

“Meat processors tend to assess smart manufacturing technologies in terms of their ability to address specific company needs,” the report’s authors point out, “but this inward focus is too narrow.

“Smart manufacturing technologies should be assessed using a value chain perspective.

“Given their common sustainability priorities, which smart manufacturing can address, processors should engage grocery and foodservice retailers to leverage capital, share risks, and collaborate on product positioning strategies for the value chain,” the study concludes.

“Pilots could be rolled out to test these strategies, which would help to innovate new technologies and reduce risks.”

Maintaining a healthy, vibrant and sustainable Canadian meat industry is in everyone’s best interests—from farmers to processors and consumers alike—and given its critical contribution to the country’s economic well-being, failure is not an option.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Alison Keba | (519) 429-5181 akeba@annexbusinessmedia.com

CEO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $80.07 per year,USA $183.09 (CDN) per year, Outside Canada $207.57 (CDN) per year, Single Copy Canada $10.00.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

Watch live demonstrations of our vacuum chamber packaging machines

n Superior vacuum packaging extends product freshness and shelf life

n High-pressure sealing system provides two superior seals to every bag, eliminating leakers

n Expansion Cushion reduces evacuation times by up to 30% for increased production

n Full range of machines, including hot water shrink tanks, cooling tanks, and drying tunnels

Sept. 29 – Oct. 1, 2025

Las Vegas, NV – Booth SL-13048

October 21-23, 2025

Toronto, ON – Booth 1701

Oct. 28-30, 2025

Chicago, IL – Booth 2812

Leading Canadian bottling giant making major upgrades to its western Canadian operations

Coke Canada Bottling has capped off a $12.55-million capital upgrade at its manufacturing facility in Richmond, B.C., with the official unveiling of a new state-of-the-art canning line last month.

According to the company, the new line will significantly expand local production capacity at the facility—designated as the local CocaCola brands bottler for the Lower Mainland

region—while enhancing supply chain resilience across western Canada and reducing reliance on third-party manufacturers.

“As a family-owned Canadian business, we make, move and sell the most-loved beverages that Canadians enjoy—many of which are made local in Richmond,” says Tony Chow, president of Coke Canada Bottling. “We’re thrilled to officially open our new can line and get even more product into the hands of our customers and, ultimately, the consumers.

“This investment reinforces our commit-

METTLER TOLEDO finished goods re-inspection services support processors with on-hold inventory to manage foreign material incidents. We provide equipment to inspect suspect finished goods and provide detailed test reports to help processors make informed decisions to reclaim their product.

PXT™ Photon-Counting technologies enable the detection of most standard foreign materials in packaged food and beverage at below 1mm, including a wide range of plastics, rubbers, stones, and glass to support clearing your on-hold finished production as quickly as possible.

Learn more today by visiting www.xrayreclaim.com or calling (844) 972-9911

ment to producing locally and supporting our growth in Canada.”

Since becoming an independent, familyowned business in 2018, Coke Canada Bottling has invested approximately $65 million in its Richmond manufacturing and distribution operations.

In 2024, the company opened a brand-new, 230,000-square-foot sales, warehouse and distribution center there to streamline its logistics to better meet customer needs.

Today, Richmond is home to nearly 500 Coke Canada Bottling employees, including 150 at the manufacturing facility and 350 at the distribution centre. Both facilities operate 24-hours a day, five to seven days per week, depending on the season, producing a wide range of popular beverage brands such as Coca-Cola, Coke Zero, Diet Coke, Sprite, Fanta, Dasani, Monster and A&W. According to the company, Coke Canada Bottling contributes approximately $132 million annually to the Lower Mainland economy through local suppliers and partners.

Also last year, Coke Canada Bottling commenced construction of a new $70-million distribution center just outside of Calgary, Alta., which is scheduled for completion before the end of this year.

The new 60,000-square-foot, high-density warehouse will enable the company to bring western Canadian logistic operation in-house— instead of relying on third-party warehouse operators—and it represents the company’s largest single Canadian investment since 2018.

The new facility will house the company’s first automated storage and retrieval system(AS/RS)—along with a digital inventory management system—to store up to 19,000 pallets of beverages.

As the official high-protein yogurt of the NHL (National Hockey League), the Oikos PRO brand of Greek-style is undoubtedly one of the rising stars of fast-growing product category ringing up $3.2 billion in sales in Canada last year, with projected annual growth of 4.5 per cent through 2035.

With increased health awareness and the shift towards functional foods driving brisk sales of high-protein, probiotic, and plant-based yogurt across the country, the made-inCanada Oikos PRO yogurt—available in 650-gram tub for at-home use and in 300-ml drinkable bottle formats—is fast becoming a go-to

texture and a generous protein boost of up to 24 grams per serving.

Made and packaged at Danone Canada’s dairy processing plant in Boucherville, Que., Oikos PRO is widely available in most major grocery and retail chains across Canada—including Loblaws, Walmart, Metro and others—now boasting updated new packaging graphics designed for the brand by leading Canadian branding services provider Pigeon Brands Inc.

Introduced last February as part of the new Oikos PRO collection launch, the new design was created to visually communicate the brand’s high-performance nutrition.

Featuring bold, modern graphics and clear callouts such as “18–24gram Protein,” “No Added Sugar”

product benefits while reinforcing the brand’s energetic identity.

“As the official high-protein yogurt of the NHL and a brand built on purpose, Oikos PRO is here to fuel consistency and celebrate commitment,” says Aurélie Goffinet, senior brand manager at Oikos

“Instead of making athletes choose between gym time and game time, we brought both worlds together with a highenergy, playoff-worthy gym takeover that honors their discipline,” adds Goffinet, citing the brand’s close marketing partnership with the Edmonton Oilers hockey team during its nearly successful run at the Stanley Cup during last season’s NHL playoffs.

Canadians feed their strength with high protein content and no added sugar—without compromising on taste,” Goffinet points out.

“The visual identity projects strength, consistency, and trust, using simple, impactful design and nutrient-forward messaging,” says Goffinet, lauding the product’s 100-percent Canadian origins.

As Goffinet explains, “The new packaging was designed to reflect a high protein, high-performance lifestyle while remaining approach-

“It’s a point of pride that the product is crafted here in Canada to support the nutritional needs of Canadian consumers.”

Says Goffinet. “The on-pack claims like ‘High in Protein’ and ‘No Added Sugar’ make the product’s purpose clear: it’s fuel for people who take their nutrition seriously, whether they’re training at the gym, recovering from a workout, or simply powering through a busy day. However, it was also developed to appeal to a wider group: think

Single-serve rice dishes offer tasty convenience for any meal occasion

A trusted staple in North American kitchens for over 75 years, the Ben’s Original family of parboiled seasoned rice mixes is expanding its portfolio with the launch of new Ben’s Original single-serve cups and

rice dishes—introduced last year—has been expanded to include two new exciting flavors: Ben’s Original Street Food Honey BBQ Flavored Rice with Chicken; and Ben’s Original Street Food Teriyaki Style Rice with Chicken. Ready in 90 seconds, each 255-gram bowl is packed with up

mushrooms into a new era of

Enhance quality assurance with the ICON Combination System. Designed for efficiency, this compact unit integrates robust X-ray inspection with precision checkweighing, delivering contaminant detection and accurate weight verification in a single, space-saving solution.

Leading Canadian paper products group Kruger Products Inc. has inaugurated its new LDC (light dry crepe) tissue plant in Sherbrooke, Que., following completion of large-scale $377.5-million expansion project. Constructed on a site adjacent to its TAD (through-airdried) plant, the new building houses a state-of-the-art and a facial tissue converting line, with another new bathroom tissue line also installed at the TAD plant as part of the multi-year expansion that commenced in 2020. According to Kruger, the project created 205 new direct jobs at the Sherbrooke Operational Centre, with the company’s total investment in the region exceeding $1 billion sine 2018. With annual capacity of 60,000 metric tonnes, the new LDC machine more than doubles the Sherbrooke Operational Centre’s production capacity to more than 130,000 metric tonnes per year. “This second plant fulfills our vision to make Sherbrooke a major manufacturing hub in North America of premium-quality tissue products,” says Michel Manseau, Kruger’s senior vice-president and general manager for the consumer business. “The fact that two large-scale projects were completed in just six years is a clear indicator of

outstanding success and a testament to stellar teamwork.”

Leading Canadian corrugated and tissue products manufacturer Cascades Inc. has announced a $5.3-million investment at the company’s tissue manufacturing plant in Granby, Que., aimed at increasing the capacity of two strategic production lines and enhancing product quality. As part of the investment, the plant will add a new packer and a higherperformance case-packer to the machine that produces bathroom tissue for the Cascades PRO

Away-from-Home product line— increasing production capacity by an estimated 20 per cent. “These enhancement at our Granby tissue plant will expand our ability to meet the needs of our current and future customers,” says Cascades president and chief executive officer Hugues Simon. “This investment is part of an ongoing effort to optimize our operations and consolidate our growth path.”

Montreal-based private equity fund

MontClerc Capital has made a significant strategic investment in Polykar, a leading Canadian

manufacturer of sustainable flexible packaging solutions, by acquiring a minority stake to support the company’s growth in North America. According to Polykar, the investment will enable the compny to expand its production capacity and accelerate the development of innovative, environmentally-friendly packaging solutions at its manufacturing plants in Montreal in Edmonton. “This collaboration reaffirms Polykar’s leadership in the field of sustainable packaging,” says Polykar president and chief executive officer Amir Karim. “Over the last 35 years, we have built a resilient company founded on innovation and operational excellence,” Karim adds. “This investment underscores confidence in our business model and growth potential.”

Kingsville, Ont.-based greenhouse operator Red Sun Farms has picked up the coveted the People Choice Hottest Tomato award in the annual 2025 Greenhouse Competition, for the company’s Empress Purple

Tomato brand, along with being awarded the Best Bite Size Tomato top prize for the company’s Sweetpops brand tomatoes. “It’s an honor to have our work celebrated by a community that shares our passion for greenhouse excellence,” says Red Sun Farms chief executive officer Carlos Visconti. “At Red Sun Farms, we’re driven by innovation and committed to sustainable growing practices, [and] these awards reflect the dedication of our entire team and the strength of our values.” Ranking as one of North America’s largest vertically-integrated greenhouse growers, Red Sun Farms operates state-of-the-art greenhouses across Canada, Mexico and the U.S.

With packaging play-

ing a critical role in protecting both the environment and consumers, designers and engineers at Graphic Packaging International have developed innovative new laundry detergent packaging that accomplishes both: a recyclable paperboard carton that protects laundry detergent pods or other cleaning products from moisture, outfitted with a unique child-resistant closure.

Until recently, U.S. brands and retailers who needed child-resistant packaging for laundry detergent pods had few options beyond plastic—until Graphic Packaging addressed this gap earlier this year.

Developed in collaboration with Radienz Living, one of North America’s leading private-label laundry detergent pod manufacturers, the new CleanClose paperboard laundry detergent packaging features a patent-pending ChildBlock closure, recently certified for child-resistance according to the

U.S. 16 CFR 1700.20 specifications.

According to Graphic Packaging, this innovative solution significantly reduces the amount of plastic in product packagingand prioritizes child safety, while also delivering significant consumer safety benefits and supply chain efficiencies.

The CleanClose with ChildBlock packaging is engineered to be intuitive for adults to open, yet difficult for children, and is designed to generate an audible “click” to les consumers know when it has been properly closed.

“Securing certification under 16 CFR 1700.20 is a milestone for Graphic Packaging, and CleanClose with Child Block is one of the most significant packaging innovations of my career,” says Chuck Tarlton, new business development director at Graphic Packaging.

“Requirements for child resistance pushed our team to explore countless design variables,” Tarlon relates.

“We had to meet stringent child safety requirements while also delivering cost-effectiveness, recyclability,

supply chain and manufacturing efficiency, and an outstanding consumer experience.

“We were excited to work with our partners at Radienz Living to bring this groundbreaking packaging system to consumers.”

According to Radienz Living, the highly customizable CleanClose pack can holds up to 160 laundry detergent pods to accommodate many different pack-size requirements.

Delivered flat for filling, the solution also improves warehouse and transport efficiency, with the number of filled packs per pallet determined to be at least 10 per cent higher than for plastic pouches.

Moreover, the pack has been designed to withstand 400 pounds of top-load compression—enabling self-palletization and supporting majority of Club Store supply chain operations.

Made from paperboard with 50-percent recycled fiber content, CleanClose is recyclable in curbside paper waste streams and is pre-qualified as Widely Recyclable under the

In recent years, sustainable packaging has become the expected packaging for all sorts of companies claiming their products to be a better choice for the planet and consumer health.

Formed in 2021 in Hockenheim, Germany, Vetain GmbH is a rapidly growing start-up company that manufactures vegan protein powder and supplements, includes protein powder, protein bars, nut butters and various toppings.

Founded by young entrepreneur athletes Luca Gruber and Philipp Riedl, who were on the lookout for a vegan and tasty alternative to protein powder, the company is driven by relentless commitment to ensuring

that its products fully align with its three core values of quality, transparency and sustainability.

These laudable principles have stuck a very responsive chord in the European markets, with the company’s client base now comprising about 200,000 customers.

Today employing 23 people full-

How2Recycle program in the U.S.

“We are deeply focused on delivering products that protect children and support environmental stewardship,” says Tom McLenithan, vice-president of research and development at Radienz Living.

“We are proud to have partnered with Graphic Packaging in the creation of an innovation that delivers against so many of our goals and our mission to create customer partnerships for life.

“This innovation offers customers a packaging solution made from paperboard that provides safety for children by meeting strict child resistance requirements,” McLenithan adds. “At the same time, it delivers reliability, efficiency and cost optimization across the supply chain.”

Says co-founder Riedl: “As former athletes, it was clear to us when launching Vetain that we wanted to offer a high-quality and great tasting alternative to the additive-packed products already on the market.

time, Vetain is already achieving an annual turnover of about $32 million.

As part of its sustainability agenda, the company has recently switched the packaging for its protein powders to Sonoco’s GreenCan containers with a paper end—replacing rigid paper containers with metal ends it used earlier. Made with at least 96-percent paper content, the Sonoco solution serves up a more recyclable and circular format, according to Vetain.

Now available in the German markets, Sonoco’s GreenCan with paper end is fully approved for full recyclability within the paper stream, meeting all the pertinent European recycling requirements.

“Being able to use fully recyclable packaging for our protein powders supports our brand perception, and many of our customers have praised our new paper-based packaging.”

For Sonoco, the partnership demonstrates its commitment to working with brands looking for highly sustainable packaging.

“Vetain is a great example of young entrepreneurs looking to make a meaningful difference with its brand and packaging,” says Oliver Kock, senior sales manager for Sonoco Consumer Europe. “After starting out using GreenCan with a metal end, Vetain team expressed its clear commitment to keeping its ecological footprint as small as possible, and using the GreenCan with a paper-end ensure that its customers can recycle the entire can.”

With the launch of PAC Digital Imaging , members gain more learning, more networking, and more global connections — plus access to PAC Global’s full suite of programs: PAC Awards , PAC IOU , PAC ED , and PAC NEXT .

Behind-the-scenes strategic and administrative support.

Expanded access to PAC Global certification and education.

Opportunities to engage with global brands and their creative p artners. A larger, cross-industry platform to connect, learn, and lead. NOW

Famed for its abundant fruit orchards, vineyards and beautiful natural landscapes with lakes and mountains, British Columbia’s Okanagan Valley region is also home to hundreds of smaller independent businesses specializing in production of high-quality, artisanal food products reflecting the area’s many natural charms and the entrepreneurial spirit of its inhabitants.

Located about a 15-minute drive east of Vernon, B.C., the village of Lumby is home to a number of thriving business enterprises playing a key role in the ongoing diversification of local economy, including the family-owned cheese products manufacturer Castle Cheese

Founded by Bill Boyko in 1997, the company started out as a wholesale cheese operation in Vernon, driven by the idea of providing Canadians with high-quality and attainable cheese prod-

ucts on a year-round basis.

The company enjoyed several years of slow but steady growth at its original 6,000-square-foot facility in Vernon, with Bill’s son, Paul. and daughter Ashley working to keep the business growing. By 2004, however, the company began looking for a new home after outgrowing the confines of its Vernon facility. Happily, the family did not have to look very far.

“The Village of Lumby welcomed us with opened arms in 2004 and found us a beautiful parcel of land,” recalls Castle Cheese president Paul Boyko.

“We moved into our purpose built facility in 2005 and have just celebrated 20 years here in Lumby,” says Boyko, who played and instrumental part in transforming Castle Cheese from a wholesale business into a bona fide manufacturing enterprise since assuming the company’s leadership.

Nowadays operating out of a modern 40,000-square-foot manufacturing plant

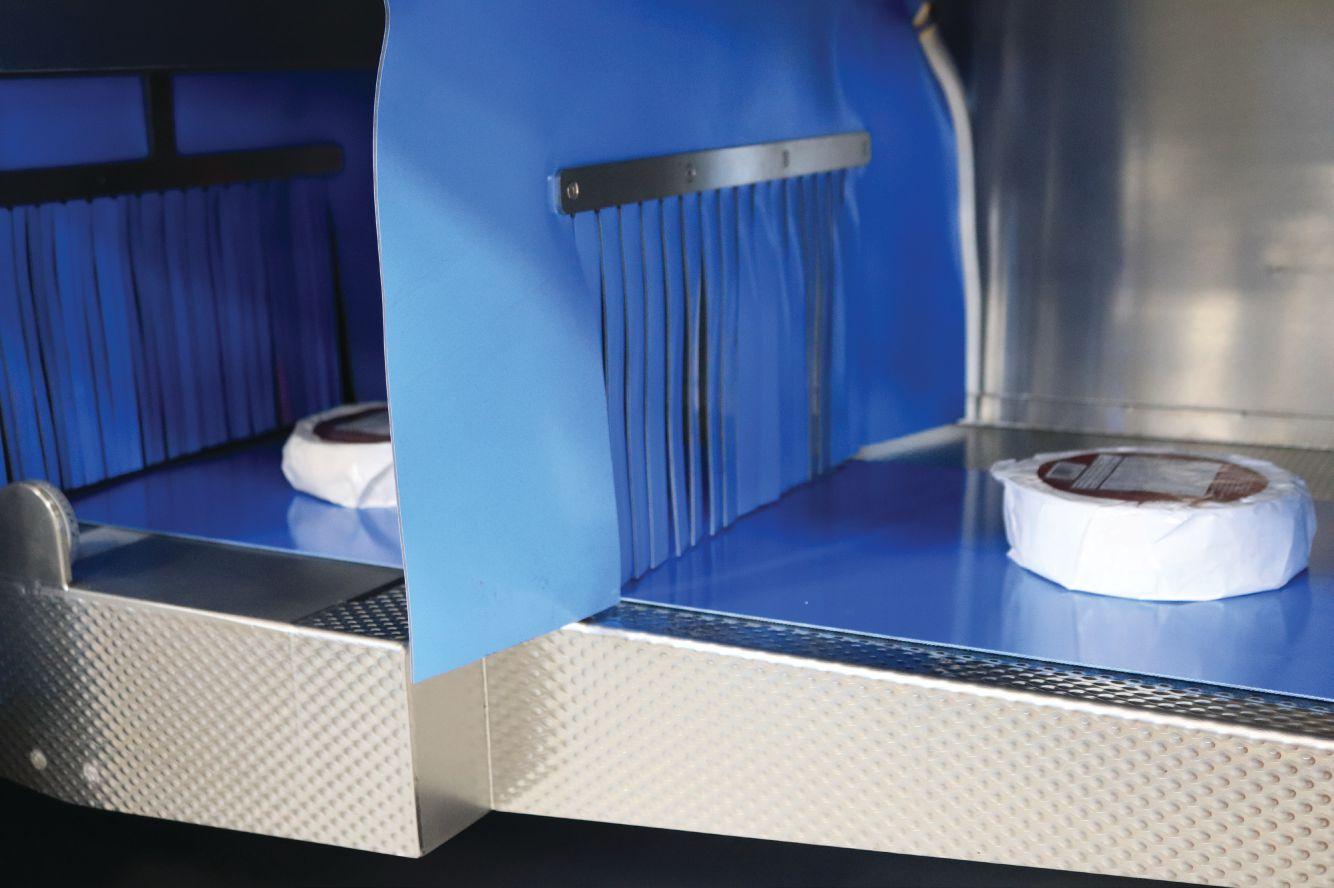

(Above)

Castle Cheese production manager Michael Moore tends to setting up one the Lumby plant’s three VARIOVAC Optimus vacuum-packing machines for the next production run.

A varied selection of packaging formats and sizes produced at the Castle Cheese manufacturing plant in

Uniform bricks of cheese loaded into the cavities of the VARIOVAC Optimus machine in preparation for the next packaging run.

employing about 50 full-time people, Castle Cheese has achieved significant success in the Canadian cheese industry circles—in large part through astute selection of promising niche market segments and continuous refinement of its manufacturing capabilities to support robust growth in those segments.

“We offer high-quality custom blends of dairy products and analog cheese at affordable prices,” Boyko told the Canadian Packaging magazine in a recent interview.

“We are uniquely situated in the Canadian dairy market to help our customers keep their ever-increasing food costs in line.

“We accomplish this by crafting custom blends of cheese products with our own proprietary recipes that meet or exceed our customers’ requirements,” Boyko continues. “We sell our products from coast to coast across Canada.

“Our major customers are food service providers who sell to restaurants, institutions and food industry processors,” Boyko says, adding that all of the company’s products are Halal-certified.

According to Boyko, the majority of the plant’s output is distributed to food-

(Right)

Close-up of the easy-peel package opening feature formed on-pack by the VARIOVAC Optimus packaging machinery.

(Right) The 4,000-liter still at the All or Nothing Brewhouse facility in Oshawa has been put to extensive use since early March to produce 65-percent enthanol hand sanitizing solution.

service companies across Canada in shredded, sliced, cubed and block formats.

The balance is used for the production of the company’s retail brands such as Castle Cheese , Okanagan’s Choice Cheese, Okanagan Soya Co and Pacific Coast, which can be found on the shelves of leading grocery chains like Loblaws, Save-On-Foods, Co-op, Sobeys and at most independent grocers across British Columbia.

“Our food safety record and consistent customer satisfaction reflect our commitment to quality.”

Housing a total of six production/ packaging lines, the Lumby plant is not a highly automated operation, Boyko

acknowledges, “due to the nature of working with cheese.

“We need to have human employees to handle and operate cutters and run the packing machines,” he says, “as well as to box and palletize the finished products.”

As Boyko explains, one of the plant’s lines is used for blending the raw ingredients—sources from across North America—and forming them into big uniforms blocks of cheese.

The other five lines are then used to process those blocks into shreds, dices, slices or cubes that go inside the gasflushed packages made from the high-quality barrier film supplied by FoodPak Ltd., Richmond, B.C.-based

Side view of the Lumby plant’s production area dedicated to the processing of loose shredded and cubed cheese products, which employs bucket elevators and automatic multihead weighscales to produce pre-measured portions of cheese product that is then packaged in large-sized, gas-flushed bags made from high-barrier film supplied by FoodPak.

division of Duropac specializing in flexible packaging products for food industry applications.

“FoodPak is one of our key packaging partners,” Boyko states.

“They supply all our packaging needs and work with us to help deliver film and supplies in a timely and cost-effective manner.

“They even go above and beyond for us by storing film in one of their warehouses in B.C., as we are always tight for space.”

As Boyko asserts, “Because we primarily sell to the foodservice market, packaging integrity and production efficiency plays the biggest role in our success as we move forward into the future.”

Machine operator loading up the pockets of the VARIOVAC Optimus machine with large blocks of cheese just prior to packaging.

As part of the company’s continuous efforts to secure a prosperous future for Castle Cheese products, the company has in recent years built a strong relationship and rapport with Reiser (Canada) Ltd., a leading supplier of food processing and packaging equipment headquartered in Burlington, Ont., with a big presence in British Columbia.

“We attribute a lot of our success to working with key partners such as Reiser,” sates Boyko.

“They have helped us diversify our products and packaging ranges to keep up with other larger and more diverse competitors, such as allowing us to offer new and improved packaging or diversifying our cubed and dice lines of cheese.”

Close-up of the blocks of cheese placed inside the Variovac Optimus machine’s cavities lined with the high-barrier packaging film supplied to Castle Cheese by FoodPak.

As Boyko relates, much of this diversification and packaging enhancement can be attributed directly to the purchase and installation of three state-ofthe-art VARIOVAC Optimus vacuum-packing machines purchased from Reiser over the last few years.

“We first met the team at Reiser at the PACK EXPO Las Vegas show in 2018 after seeing their advertisement in the Canadian Packaging magazine,” Boyko recalls, “and we had a great experience working with Reiser on the purchase of our first VARIOVAC.

“It was so much better than our old packaging machines!

“We found we had much less downtime due to fast die changes and film changes,” he continues, “with little of and little to no loss of time due to errors in packaging.

“Moreover, the whole team at Reiser was very professional,” Boyko adds, “from Alessandro Sestini (B.C. sales rep) working with me on the purchasing end to Eric Deschamps (technician) on the installing side, with his vast knowledge of the machinery.

“We enjoyed the process so much that we budgeted over the next two years to replace all outdated and aging packaging machines to VARIOVAC Optimus,” Boyko extols, “and so we now have three of them.

“From what I hear, there are not very many food manufacturers in Canada to have three VARIOVAC Optimus machines in operation,” says Boyko, “and we could not be happier about having them at our Lumby facility.”

In fact, the positive experience that Castle Cheese has enjoyed through its partnership with Reiser so far also prompted the company to purchase another piece of equipment from Reiser earlier this year—the Holac Cubixx 100 dicer—to improve the consistency and uniformity of its cubed cheese products.

“It’s a beautiful machine that operates really efficiently, is easy to clean, and has made our diced cheese far more consistent in terms of the cubing structure.

“The machine is actually a gamechanger for us,” he enthuses, “providing a nice perfect cube every time, so that we have a perfect finished product for our customers in every pack.

“We had also, years prior, purchased a Vemag cheese block former from Reiser, which we use for extruding some of our cheese products into bricks,” Boyko adds, “and it also works really well for us.”

Designed as an all-purpose machine for cost-effective and automatic packaging for food products, the VARIOVAC Optimus is engineered to provide exceptional vacuum, MAP (modified atmosphere packaging), skin and shrink packaging, and hot-filling performance through many cutting-edge performance features.

The deep-drawing machines are equipped with the proprietary VARIOVAC RapidAirSystem that guarantees optimum formation of the packaging and a high packaging output, reaching speeds of up to 12 cycles per minute for shallow vacuum-packs, with superior film distribution in the corners and precise forming of the package.

Boasting all-stainless-steel construction, the washdown-compatible machine features almost no plastic parts, with all the color-coded tubing housed in a designated frame inside machine, with easy access for cleaning.

Featuring easy three-button operation (start, stop, reset) and an E-stop, the compact three-meter machine is controlled via a full-color 10-inch touchscreen HMI (human-machine interface) for fully flexible programmability, recipe management storage and optional remote diagnostics.

“These machines filled our needs in all the areas that we wanted insofar as higher speeds, a wide array of pocket formations, and the ease-of-use.

“The side panels of the machine easily come apart so that we can access all the internal components,” he continues, “and because most of the parts are not proprietary, we can easily order them right off-the-shelf, should the need occur.

“We really enjoy how efficient, fast and reliable these machines are,” Boyko says.

“After we saw how well our first VARIOVAC worked for us, we knew that we could safely invest our money into more of these machines.”

Castle Cheese production manager Michael Moore fully concurs, lauding the VARIOVAC machines’ user-friendly operation.

“The interactive display panel (HMI) is very simple and intuitive for our people to control the running speed,” he says, “and it displays all the key parts of the machine right on the screen with a simple touch of the icon.

“It also allows us to store up to 100 different recipes,” Moore points out.

“We currently have 19 pre-programmed recipes,” Moore notes, “and it’s very easy to switch over from one to another: very simple and straightforward.”

Boyko adds that he is fond of the exceptionally quick product and die

changeovers enabled by the VARIOVAC Optimus machines.

“We often need to change the pockets two to three times a day to package different items,” he notes, “and it can all be done within 10 to 15 minutes with very little use of any tools.”

Adds Boyko: “What we also really like about Reiser’s VARIOVACs is their reliability, so that when we turn them on in the morning, they’re going to be ready to run all day, without the worry of potential downtime or sensor issues.

“There is also a big advantage in having your processing and packaging machinery coming from one supplier,” Boyko states, “because you only have to make one phone call to get new parts or to have a service technician come over.”

Says Boyko: “We find the Canadian dairy sector to be a highly competitive industry with many strong and innovative competitors, and we attribute a lot of our success to working with key partners such as Reiser.

“We have noticed a lot of new interest in customers looking for Canadian-made products in the last six months,” Boyko notes.

“With the threat of potential tariffs and boycott of many American-made products, we are definitely seeing an uptick the in sales of our products made here in Canada,” he reveals.

“I have had many new customers make the effort to reach out to us looking to move from ordering similar products from the U.S. to our products,

Stacks of the Okanagan’s Choice retail brand of Aged Cheddar cheese immaculately packaged inside the FoodPak high-barrier clear film on one of the Lumby plant’s three VARIOVAC Optimus vacuum-packing machines.

A freshly formed block of cheese is prepped for dicing on top of the Holac Cubixx 1oo fully-automatic dicing machine, also supplied by Reiser, that enables production of consistently uniform cheese cubes of virtually any size with virtually no size deviation.

“We find the Canadian dairy sector to be a highly competitive industry with many strong and innovative competitors, and we attribute a lot of our success to working with key partners such as Reiser.”

made here in Canada.”

As Boyko sums up, “We plan to keep moving forward, diversifying, and continuing to grow to meet customer demands.

“And we’re looking forward to partnering with Reiser again in the future to help us meet those goals.”

Iconic restaurant chain spreading its wings in the retail markets with high-impact brand packaging

By Andrew Snook

For 65 years, Benny & Co. has been feeding hungry Quebecers with its famous chicken and rib products.

With 83 locations across La Belle Province, the fourth-generation family business has a footprint throughout almost all of Quebec in the restaurant sector.

While this level success is impressive, the leadership of Benny & Co. have continued to challenge itself to grow the brand

In 2021, the company decided to enter the hypercompetitive grocery retail space and launched five products in grocery store aisles, including Chick’N Tenders, Winnin’ Wings, Bits O’ Chicken, Veggie Fingers, and the restaurant’s famous Benny & Co. BBQ Sauce.

This was a particularly challenging task, since the company does not own any production facilities.

“We always wanted to get our flavors, our products, into the retail division side, but how would it be possible since we don’t have a plant?

“We don’t produce our own products to sell in retail,” says Benny & Co. director of purchasing and retail Vincent Samuel Cabana, who has worked for Benny & Co. for 20 years, starting out at the company’s restaurant in Joliette at 16 years of age.

Since Cabana was director of procurement at the company, he has a large number of suppliers he could reach out to for discussions about entering the grocery retail space.

So when the challenge was presented to find a way to break into the sector, The

Cabana embraced the opportunity.

In June 2021, Benny & Co. launched its first five products with Sobeys under an exclusivity agreement, which is set to expire in the near future.

Since then, the company has been ramping up its product offerings in preparation for a larger expansion into Quebec’s grocery retail sector.

“We now have 15 products,” Cabana says. “Being at the end of the exclusivity agreement, we’re definitely looking at other markets.”

While the exclusive Sobey’s agreement forbids Benny & Co. from disclosing its future locations and markets at this point, “In a few months, we’re going to be in other big markets in Quebec,” Cabana reveals.

Benny & Co. currently works with six co-packing manufacturers—including Novo Poultry , Lesters and a few others—for the production of its chicken and ribs.

“This has worked for us because it makes us more flexible to create new products, because each co-packing manufacturer has their own specialties,” Cabana explains.

“So, we can choose which one we want to work with when the market wants something specific.”

For the packaging heading to the grocery store shelves, Benny & Co. works regularly with LMi Packaging, based in St-Eustache, Que. to help ensure their products catch the eyes of potential customers.

The relationship between the two companies started out as neighboring businesses.

“We were neighbors, but we moved to Blainville, and LMi Packaging moved to St-Eustache,” Cabana recalls.

“At the time we were not working together, but then Gerry Bonneau, coowner of LMi Packaging, said, ‘Hey, come visit us, just to see what we can do for you.

‘I know you’re working with others company for your packaging in retail, but

I’m sure I can do something better for your needs.’

“So It all started there,” Cabana states.

Two years ago, Benny & Co. management decided to visit LMi Packaging’s 54,000-square-foot facility in St-Eustache to learn more about the printing technologies the company was utilizing.

“It was nice to visit them. They have state-of-the-art equipment for all of their printing, so we decided to do a little test with them,” Cabana says.

Benny & Co. was very impressed with the quick production turnaround times and competitive pricing.

“The speed of execution really stood out. It took about two weeks to complete the order, and usually it took other suppliers eight to 12 weeks to get our packaging,” Cabana says.

“We said, ‘It’s probably because they want the business, so we tried another test, but it was the same outcome.

“They (LMi) are really efficient because they have new equipment and do more just-in-time production.

“Sometimes they can even do an order in one week if the graphics are perfect.,” Cabana adds. “So we really like to work with them.”

Another reason Benny & Co. enjoys

working with LMi Packaging is the company’s reputation as for sustainable production.

As Cabana points out, LMi Packaging boasts the vaunted FSC (Forest Stewardship Council) certification and ECOPRINT accreditation, validating that the company has a low environmental impact with its printing processes.

In addition to sustainable practices such as the use of recycled cardboard and paper, vegetable inks and waterbased varnishes, the company also utilizes two Komori H-UV presses in its print operations.

The highly efficient Komori H-UV presses offer significantly lower energy consumption compared to traditional UV printers, while delivering robust throughput speeds of up to 18,000 sheets per hour.

“The ECO-PRINT accreditation is an aspect we like because it helps us become more environmentally sustainable,” Cabana says.

The quality of the final printed products was another key selling point for Benny & Co.

“In retail there are tens of thousands of products in the grocery stores,” Cabana points out. “We need to have really nice

Vincent Samuel Cabana proudly shows off some of the company’s more prestigious industry awards.

graphics on our packaging, and because LMi Packaging has new equipment, the quality of the printing is really nice.

“It’s a high-end product,” Cabana says, “but it’s still competitive with the pricing. That’s why we like to work with them.”

Gerry Bonneau, co-owner of LMi Packaging, says he enjoys working with Benny & Co. because of the similar values the two companies share.

“We have a nice way of working together because they have the same values that we do,” he says. “We a both a family business, so we often work the same way.”

Bonneau says the design and production process with Benny & Co. runs extremely smooth.

“They’re easy boxes. What they needed from us is to know what kind of board to use, what kind of finishing to put on it to go in the freezers.

“That’s the expertise we have,” he says.

“We guided them on what board to use, how to do it, and then we just clicked.

“They recently got a big order from a customer, requiring them to put products on the market for the Super Bowl at the last minute.

“It was a big success,” Bonneau recalls. “We managed to do the job in 10 days, which normally would have taken five weeks.”

One of the ways Benny & Co. have used its packaging to help showcase its product portfolio since entering the grocery retail sector is through the use of different colors for each product, with otherwise identical packaging.

Under this color-coding scheme, The Chick’N Tenders come in a red box; Winnin’ Wings in orange; Bits O’ Chicken in yellow; and Veggie Fingers in green.

“In 2021, it was not common to see different colors for different portions,” Cabana recalls.

“At this time, we didn’t have the graphics, so we worked with our communication partners to develop that.

“It was really new in the business to have different colors for your packaging, and we wanted to have the Benny & Co. logo the biggest size possible for people to recognize the brand easily.”

Because LMi Packaging offer just-intime production for its packaging products, companies like Benny & Co. can maintain better cash-flow by not having to purchase large quantities all the time— allowing for more flexibility in products offerings and design changes.

“We’re really changing the market,” Bonneau states. “Instead of stocking big quantities, companies are keeping a good cash-flow with us being just-in-time.

“I think it’s the way to go right nowadays.”

For companies like Benny & Co. that require freezer board for its products, LMi Packaging’s Komori H-UV presses offer significant advantages.

“When you use freezer board, you need a protector you put on the sheets that you have to buy from the mill.

“The good thing about having my Komori H-UV presses is I can buy regular board, take the H-UV food grade that goes in the freezer, and put it in my machines,” Bonneau explains.

While acknowledging that the grocery retail sector is an incredibly competitive space, Cabana says Benny & Co.’s flexibility and brand recognition across Quebec gives the company a big advan-

(Left)The glass still case is part of the spirit distilling equipment relocated by All or Nothing from the former Oakville facility and put to use in the production of hand sanitizer.

tage over some competitors.

“We have a strong brand that resonates for a lot for Quebec consumers. Benny & Co. is synonymous for them with quality and unique flavor,” Cabana says.

“I think this is one of our strengths, along with our credibility—not only with the consumers, but also our reputation with suppliers.

“We have past success with them with our restaurants, so they they know we can do good business with them.”

For the moment, Benny & Co. want to focus on utilizing its brand recognition in Quebec to grow its footprint in the province.

Gilles Benny, the youngest of the eight Benny brothers, is credited with developing the exclusive three-hour slow roasting technique that put the company on the map, with the boardroom at the company’s headquarter (inset) named in the honor of his legacy.

“We did a Leger survey, and we have 88-per-cent name recognition all around Quebec, including markets where we do not operate, so it’s pretty big for us,” Cabana says.

While the company has impressive brand recognition in Quebec, it does have plans to expand its restaurants and grocery retail products throughout the rest of Canada.

“We think our flavors are good for more markets than just Quebec,” Cabana says.

Benny & Co. started from humble beginnings with eight Benny brothers

operating a grain mill and working as chicken farmers in the 1940s and 1950s in St-Félix-de-Valois, about a 50-minute drive north of Montreal.

“They were selling their chickens to grocery stores and restaurants in Montreal,” Cabana says.

Since they were a big family that enjoyed getting together for Sunday dinners, the brothers decided to build a rotisserie for slow-roasting chickens to feed their families in the late 1950s.

“They started to think, ‘Maybe it would be a good idea to have our own restaurant’,” Cabana says.

In 1960, the brothers decided to open their first restaurant in Joliette, Que., north of Montreal.

“They thought it could be fun, because they could develop their own flavors, their own spices, for the chicken, for the coleslaw, for the sauce,” Cabana says.

The restaurant found great success in Joliette, so the brothers decided to sell off their chicken farm and grain mill to focus entirely on the restaurant business.

To that end, the brothers all moved to different regions of the province to open up restaurants and replicate the success they found in Joliette.

Moving to locations in the Outaouais Region, Quebec City area, and the South Shore in Montreal, each brother operated their restaurant independently from each other, with a few key similarities.

“They each had their own names because in the 1960s, the chain restaurant was not a common model,” Cabana explains. “But they all had the same flavors,

The brothers eventually turned their businesses over to the second generation of the Benny family in the 1980s, who grew the family business to over 40 restaurants during the 1980s and 1990s.

Eventually, the company started to struggle somewhat in the early 2000s

(Above)

The classic Volkswagen Beetle that was one part of the company’s original delivery fleet.

(Right)

Vincent Samuel Cabana, Vanessa Pinho-Giguère, and Marc-Antoine Benny having an animated chat about the high-impact retail boxes produced for Benny & Co. by LMi Packaging.

due to increased competition.

“In the 2000s it was a bit hard, because fast-food chain restaurants were growing, and it was more common to have them in your town,” Cabana says.

Fortunately, Jean Benny, a member of the second generation, along with his brothers, had a plan to counter the momentum of their competitors.

In 2006, the Benny family decided to build the Benny & Co. brand.

Between 2006 and 2012, the family’s various restaurants came together and took on the new brand and began getting some of the same advantages as large fast-food chains.

“They were bigger and had better brand recognition by consumers,” Cabana says.

The Benny family still own all 83 restaurants across Quebec, with multiple generations active in the business. Between the head office and 83 restau-

rants, Benny & Co. employs approximately 2,500 people across the province.

“It’s a really big family business, and each Benny & Co. are still owned by our Benny family members.

“Now there is the third generation, and also the fourth generation, who are now working in the restaurant,” Cabana says. “We have 35 Benny family members in the business.”

With the increasing demand for Benny & Co.’s chicken and rib products, the company has decided to return to its roots by looking to purchase a chicken production plant, making it more vertically integrated,”

“It’s part of the plan for the coming next years,” Cabana says, “because we want to do more production for our restaurants and retail sites.

“So, that is something we’ll be seriously looking at over the next few years.”

KemiTM liners, Metsä Board’s premium white top kraftliners, have played a significant role in the evolution of corrugated packaging in the Americas. Known for their superior printing surface and high performance, KemiTM liners are a coated white top kraftliner that revolutionized the corrugated packaging industry by combining performance with visual branding.

KemiTM liners, then known as Kemiart, were launched in the American market in 1991. Innovation continued introducing double coated white kraftliner in 2011. Most recently, in 2023, the Kemi mill underwent further developments to increase its capacity to 465,000 tons, while enhancing energy and water e ciency.

At 465,000 tons, our facility is now the world's largest

Growth, with a future

production plant for coated white-top kraftliner. Customers worldwide specifically request "Kemi" when they mean our first-class white kraftliners such as MetsäBoard Classic WKL, MetsäBoard Pro WKL and MetsäBoard Prime WKL.

With a legacy spanning over five decades, Metsä Board will continue to help set the standard for excellence in packaging, allowing every box to tell a story of quality and sustainability.

By George Guidoni, Editor

There is no such thing as too much quality control in the healthcare and pharmaceutical industries, where a slightest miscue on production or packaging lines can have lethal consequences for manufacturers of any size or stature.

But for companies who get it right at all times, like the Saint-Laurent, Que.based Lernapharm (Loris) Inc. , the rewards are often well worth the effort and expense of ensuring optimal efficacy and safety of the products they bring to market.

Founded in 2001 by president and chief executive officer Razmik Margoosian, the family-owned company is testament to the virtues of relentless focus on product quality and innovation as a platform for continuous success in the domestic and international markets.

From humble beginning as a small start-up manufacturer of alcohol prep pads, Lernapharm has quickly evolved into a world-class supplier of medical devices, antiseptics and disinfectants for use in personal and healthcare sectors.

Today, the company operates two manufacturing plants in Montreal’s second-largest borough, with over 120,000 square feet of production and packaging space, cleanrooms, laboratories and administrative offices.

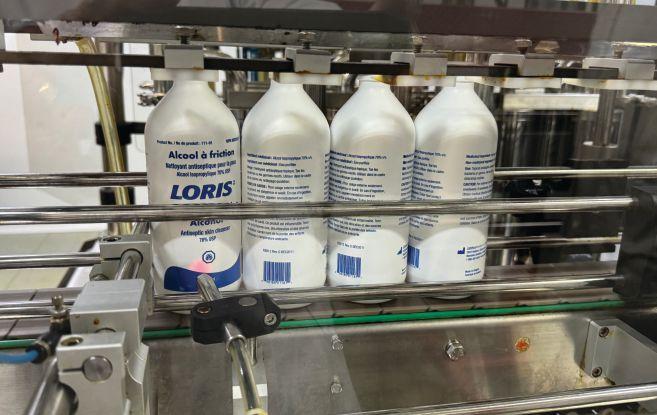

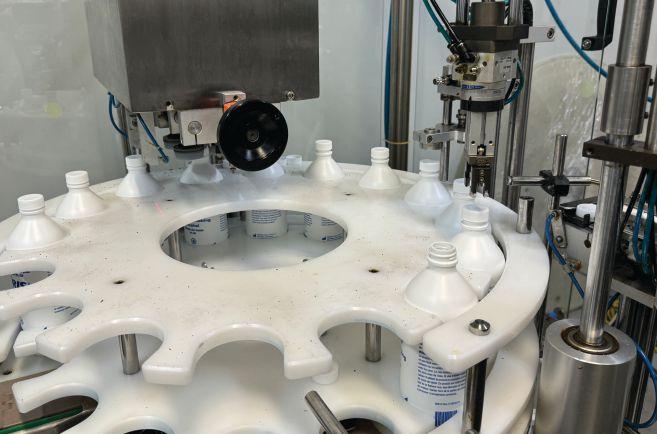

Employing 110 full-time staff to manufacture a diverse product line comprising antiseptic and disinfectant pouches, wipes, bottles, applicators, sponges and swabs, Lernapharm currently operates nearly 50 packaging lines, including vertical, horizonal, liquid filling, bottling and thermoform packaging

lines.

Marketed under the brand names Loris , Lerna and Saninta , Lernapharm’s products offering revolves mainly around five active ingredients including Povidone Iodine and Chlorhexidine Gluconate, among others.

In addition to being a major player in the Canadian market for antiseptic and disinfectant solutions, Lernapharm products are also sold in the U.S., European and other international markets, according to the company’s director of operations Viken Afarian.

“Our products are distinguished with their consistent quality,” Afarian states. “Made in Canada, they are available to the market at internationally competitive prices—allowing Lernapharm to bring Canadian know-how and quality to the end-users.

“Our product are predominantly used in healthcare setting for various indications and various patient groups,” Afarian adds.

According to Afarian, the company’s competitive edge stems in large part from its deep-rooted commitment to continuous R&D (research-and-development) and manufacturing excellence.

“Every business needs to understand its competitive edge,” Afarian states, “and Lernapharm has long ago decided

(Above) Lernapharm founder, president and chief executive officer Razmik Margoosian proudly displays the diverse variety of medical antiseptic and disinfectant solutions produced at the company’s two manufacturing facilities in Saint-Laurent, Que., for use in the personal and healthcare sectors across Canada, the U.S. and other global markets.

to concentrate on its core competencies, which are product development and manufacturing.”

As Afarian relates, “Lernapharm is well-known for its forward-looking R&D efforts in bringing new delivery solutions to the market of topical antiseptics and hospital care products.

“Focused and well-organized internal processes allow for these solutions to be cost-effective and of high quality,” he states.

“Lernapharm’s agility and its capabilities in engineering production lines enable it to bring new, cost-effective and quality to products to market,” says Afarian, citing the company’s core values that include

• Integrity;

• Trust;

• Customer focus;

• Teamwork;

• Innovation;

• Continuous improvement;

• Social responsibility.

As Afarian relates, the company’s multistage production process comprises packaging and raw material receipt, testing, and quality release; manufacture of bulk solutions in mixing tanks; filling of the bulk solutions into individual units; and final product testing and quality release.

To execute all these steps in efficient

Supplied to the Lernapharm plant by Redemac, the LEIBINGER model Jet2 NEO model inkjet coder and the older model Jet2 SE coder incorporate proprietary SEALTRONIC automatic nozzle-cleaning technology to ensure consistently flawless code printability and legibility on all Lernapharm packaging.

and cost-effective manner, the company leverages various leading-edge automation technologies throughout its production process, Afarian explains.

“Different lines have different levels of automation,” he says, “and most of our current automation capabilities is deployed in the line feeding processes— descramblers, spider robots, etc.

“However, we are now implementing automation on the final packaging side to increase the consistency and efficiency of our production lines.”

In addition to boosting the company’s productivity and line efficiencies, automation also plays a key role in maintaining a safe and sound work environment for its dedicated staff, Afarian notes.

“As a family-owned business, Lernapharm is conscious of people’s desires to balance their work and their personal life, which is why we have a two-week summer shutdown every summer, as well as about 10 days off for Christmas and New Year,” Afarian relates.

“At the present time we operate on a single shift, which allows us the flexibility of doing overtime or requesting people to work a second shift if and when necessary,” he continues.

“In our business the workflow is usually forecastable, which allows us time to recruit and train new employees.

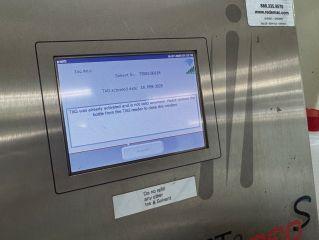

With user-friendly operation enabled by the slim profile and intuitive graphic displays of all key operational data on the touchscreen HMI (human-machine interface) panels, the LEIBINGER continuous inkjet (CIJ) coders enable crisp, durable and highly legible product coding across a broad range of packaging containers and other packaging formats used for ensuring full regulatory compliance and product traceability for all product made at the two Lernapharm production facilities in Saint-Laurent, Que.

“As a pharmaceutical company we operate under strict GMP (Good Manufacturing Practices) requirements—therefore we only recruit permanent employees.”

As Afarian reiterates, “Lernapharm cannot thrive without the contribution and devotion of its employees, be it those who have been with us from Day One to those who have joined us in our journey recently.”

In addition to following the GMP protocols and being registered with Health Canada under a Drug Establishment License and a Natural Health Product Site License , Lernapharm also has to maintain strict compliance with multiple stringent international quality management standards and certifications to continue exporting its products.

As such, both of its ISO (International Organization for Standardization) -certified plants are holders of an Establishment Registration, an ISO 13485 MDSAP certificate, a CE registration, and various other drugs,

natural health product, and medical device registrations in Canada, the U.S, the EU and many other jurisdictions.

“The pharma industry is continuously evolving worldwide,” says Afarian, “resulting in increased harmonization between countries as far as regulatory requirements are concerned.

“However, this harmonization has not led to the lowering of barriers.

“Because each jurisdiction requires formal registration with its regulators, with all their local twists, regulatory knowledge for each country is an indispensable asset,” Afarian says.

“But with all the certifications we have earned to date, as well as our reputation of supplying quality products, we can compete on the global stage with multinational and local corporations.”

Says Afarian: “Our multiple certifications are a testament to the company’s dedication to ensure its compliance with the cGMP requirements through robust and efficient design of its premises, equipment, supplier manage-

With over 800 user-friendly functions, the new LEIBINGER model JET3 SE inkjet coder ensures superior non-contact marking capabilities at speeds of 403 meters per minute, with ability to print up to five lines of text. (Right)

A side view of the Lernapharm plant’s processing area housing an expansive tank farm, home to hulking stainless-steel blending, filtering, storage and other vessels.

ment,quality control, and quality assurance elements.

“Lernapharm processes are routinely audited internally and inspected by regulatory agencies,” Afarian points out, “which directs the company’s ongoing efforts for continuous improvement.”

As part of the company’s regulatory compliance requirements, full product traceability and serialization capabilities have to meet the highest levels of regulatory scrutiny and quality assurance— making it imperative that the company’s product coding, marking and labeling systems are the highest-performing product identification technologies available in the marketplace.

To ensure that, Lernapharm has effectively leveraged its close partnership with leading local product coding systems supplier Redemac, Inc., a highly reputable supplier of complete solutions for marking, coding and labeling in industrial, packaging, production and distribution applications.

Founded in 1987, Redemac is an offi-

cial Canadian distributed for the full range of advanced product coding technologies and solutions manufactured by the renowned manufacturer LEIBINGER , a global specialist in coding and marking systems headquartered in Tuttlingen, Germany.

Founded in 1948, the third-generation family-run company has attained worldwide renown and acclaim for its innovative, leading-edge CIJ (continuous inkjet) systems designed for flawless, high-precision, user-friendly, time-saving coding and marking systems designed for peak productivity and exceptional print quality.

Incorporating the company’s one-ofa-kind, fully-automatic SEALTRONIC nozzle sealing system, LEIBINGER’s inkjet coders are widely considered to be the golden standard for product coding and marking excellence, with its diverse and extensive customer base spanning more than 150 countries worldwide.

At Lernapharm, the LEIBIN-

Above Close-up of the LEIBINGER inkjet coder’s 60-micron nozzle printhead in action.

Left

The rotary bottle filling and capping system used to package various types of Lernapharm’s well-known and reputed liquid disinfectant solutions.

GER-made inkjet coders supplied through Redemac over the years have proven to be an outstanding capital investment on every level, according to Afarian.

“We have been working with Redemac since 2008, when we acquired our first LEIBINGER printer,” Afarian recalls.

“Since then, we have acquired over 50 more printers—all from Redemac and all made by LEIBINGER.

“The LEIBINGER printers that we have sourced from Redemac are ideally suited for our fast production lines—en-

(Above)

Redemac managing director Italo Ruggiero and Lernapharm founder Razmik Margoosian share a light moment inside the boardroom (left) and on the plant floor.

(Left)

Lernapharm’s director of operations Viken Afarian checking out the quality of product codes applied to the Saninta brand antiseptic wipes packaged inside sachet twin-packs.

(Bottom) Close-up of the production lot and expiration codes applied into the side margins of the Loris brand sachets containing single-use disinfectant wipes.

abling us to rely on them for fast and accurate printing of our lots and expiry dates, which are required in all our products.”

The extensive arsenal of LEIBINGER CIJ coders employed on multiple Lernapharm packaging lines includes the older model Jet2SE units with 60-micron nozzles; the newer model Jet2 Neo coders with 60-micron nozzles; and the more recent Jet3 SE models with 60-micron nozzles.

“These state-of-the-art printers are used for coding various antiseptic topical skin cleanser packed on the FFS (form-fillseal) seal equipment, along with the HDPE (high-density polyethylene bottles) plastic bottles of various cleansing solutions right after filling and capping,” says Redemac’s managing director Italo Ruggiero.

“Their patented SEALTRONIC nozzle seal, clean start-up and shutdown, low consumption of fluids, and service maintenance every 9,000 hours make LEIBINGER’s equipment the CIJ systems of choice, with the lowest cost-of-ownership,” Ruggiero states.

For his part, Afarian fully agrees.

“We have found Redemac to be a highly reliable and knowledgeable supplier, whose after-sales service, technical knowhow and knowledge have helped us greatly over these many years,” Afarian states, complimenting the entire Redemac team for its outstanding professionalism, superior customer service and timely technical support.

“Every relationship we develop is developed for the long term, be that with our suppliers or customers,” Afarian asserts.

“Our equipment suppliers, such as Redemac, our packaging suppliers, and our raw materials suppliers are all considered strategic suppliers,” he continues.

“That is why Lernapharm’s business model is based on creating lasting relationships with suppliers like Redemac, as well as with distributors who bring our product offering to the end-user.”

For Afarian, maintaining this rapport and goodwill with Redemac and other business partners will become even more critical in coming years, as the company continues to develop more sustainable packaging for its products.

“Considering Lernapharm’s continuous efforts in developing new products and delivery systems, the availability of sustainable and product-compatible packaging alternatives is imperative for our continued growth in this sector,” Afarian states.

“We expect to see more optimized packaging solutions in this space in the near future,” he concludes, “and automation, including advanced product coding and marking technologies, will play a significant role in the growth of this sector.”

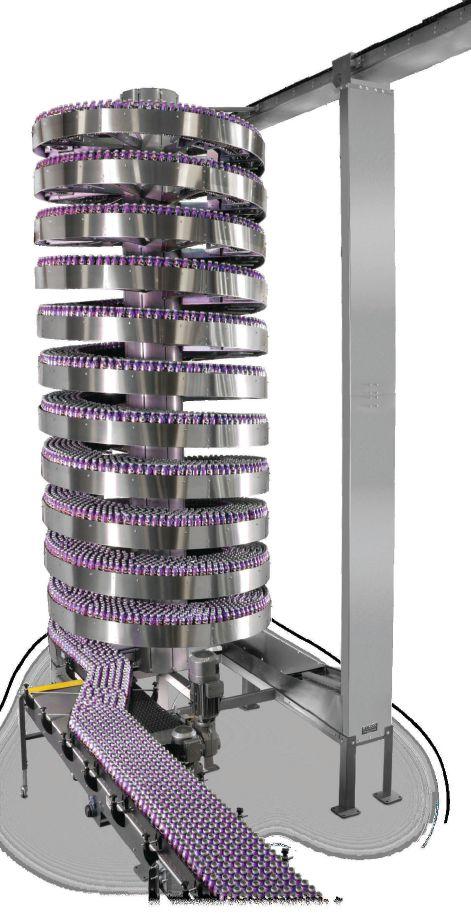

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2,000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 220 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Our Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. They are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

They can be configured with multiple inlets or outlets that can be controlled individually. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, or stainless-steel for wet environments.

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit www.ryson.com .

Visit us at Pack Expo | Booth W-3570. Ask us to see a maintenance demonstration.

www.ryson.com (757) 898-1530

Booth # W-3350

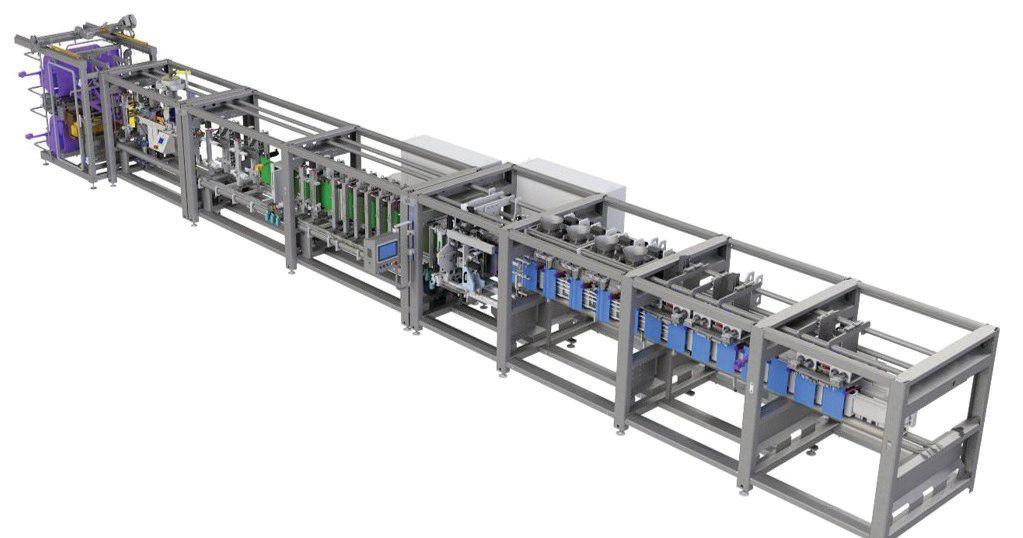

As an innovator in end-of-line automation, RYCHIGER offers advanced solutions that streamline every phase of your packaging process from filling and sealing to cartoning, case packing, tray packing, and palletizing. Our precision-engineered systems are designed to maximize throughput, optimize automation, and enhance overall efficiency. With a strong focus on customization, we tailor each solution to meet your specific needs, ensuring optimal performance, reliability, and seamless integration into your existing line. Whether you need a single machine or a complete end-of-line solution, we guarantee unmatched precision and performance at every step of your process.

Visit us at PackExpo Las Vegas, Sept. 29–Oct. 1, Booth # W-3350 for live demos of our VRC-60 Cartoner and Cobot Palletizer, and discover how our innovations can streamline your packaging process.

Scan to learn how our solutions can streamline your end-of-line process

Automation and AI offer the promise of a smarter path forward for the global packaging industry

By Tom Egan

n the not-so-distant past, automation in the packaging industry meant conveyor belts, shrinkwrap tunnels, and fixed-path robotic arms—mechanical reliability at the cost of flexibility.

IToday, artificial intelligence (AI) is reshaping that definition. From machine vision and predictive maintenance to connected worker platforms and generative code assistants, AI is ushering in a new era—one that promises to enhance productivity, mitigate labor shortages, and pave the way for the factories of the future.

This transformation, however, is not without its growing pains. Even the most innovation-forward companies must balance technological potential with cultural shifts, workforce training, infrastructure limitations, and return-on-investment scrutiny.

Nonetheless, as The AI Advantage in Equipment: Boosting Performance and Bridging Skills Gap white paper from PMMI, The Association for Packaging and Processing Technologies, makes clear, AI isn’t just the next step—it’s also a necessary one.

For companies willing to take that step now, there is no better place to begin their research and preparation than by attending the upcoming PACK EXPO Las Vegas 2025 exhibition at the Las Vegas Convention Center, also produced by the PMMI.

Running from Sept. 29 to Oct. 1, North America’s largest packaging and processing industry event of the year will provide a compelling next step for industry stakeholders to explore new AI innovations first-hand.

With over 2,300 exhibitors across more than one million net square feet of exhibit space, along with over 100 educational sessions, the show is a proving ground for next-gen automation, and a beacon for companies navigating the complexities of workforce shortages, legacy constraints,

and cost pressures.

The leap from traditional automation to AI-enhanced systems is not simply a matter of replacing humans with machines. AI-infused technologies provide something older systems cannot: adaptability.

Take machine vision systems, for instance. Whereas rule-based inspection systems falter under inconsistent product shapes, AI-powered vision excels. Companies like Yango Robotics use AI to determine optimal palletizing and depalletizing strategies using real-time camera input, according to the PMMI’s white paper.

Its system can identify, segment and manipulate tens of thousands of SKUs (stock-keeping units) without requiring pre-programmed scripts—handling unpredictability with unprecedented efficiency.

The result? A 42-percent reduction in cost per pick and a doubling of operational speed.

This leap in functionality also extends to digital twins—virtual simulations of

The PACK EXPO Las Vegas 2025 exhibition will showcase a multitude of leading-edge automation and artificial solutions, including AI-assisted robotics, to help user in the new era of smart packaging line processes to raise productivity and efficiency standards across the industry.

physical machinery or systems.

As highlighted in PMMI’s white paper, Siemens’ recent collaboration with Sollas on AI-driven wrapping machines boosted throughput by 33 per cent— from 120 to 160 boxes per minute—by leveraging reinforcement learning models to optimize conveyor layout and mitigate downtime due to material inconsistencies.

Perhaps AI’s most profound impact is its role in addressing the industry’s chronic workforce issues. As seasoned machine operators and technicians retire, the gap left behind is not easily filled—especially in some sectors such as baking, where both artisanal knowledge and operational consistency are essential.

In today’s manufacturing landscape, AI doesn’t seek to replace labor, but rather to empower it.

As the PMMI white paper points out, connected worker platforms like Augmentir exemplify this shift.

Recently deployed at a global paper and packaging manufacturer, the AI-powered system helped guide less-experienced employees through complex tasks—reduced downtime by 21 per cent—and cutting on-boarding time for new hires by a staggering 72 per cent.

Similarly, according to the PMMI white paper, predictive maintenance tools from companies like Senseye help leverage AI to monitor operational data and detect failures before they happen.