Quebec’s popcorn king upgrades its packaging line technology to pump up the volume Story on page 14

Backed by more than 40 years of continuous inkjet expertise, the latest Videojet CIJ printer is designed for uptime peace of mind and errorproof operation. The 1580 features the SIMPLICiTY™ user interface, CleanFlow™ technology, Dynamic Calibration, SmartCell™ components and optional VideojetConnect™ Remote Service to drive significant printer improvements through everyday operations.

SENIOR PUBLISHER

Stephen Dean • (416) 510-5198 SDean@canadianpackaging.com

EDITOR

George Guidoni • (416) 510-5227 GGuidoni@canadianpackaging.com

MEDIA DESIGNER

Brooke Shaw • (519) 428-3471 bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer • (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER

Anita Madden • (416) 510-5183 AMadden@annexbusinessmedia.com

COO Scott Jamieson

ANNEX BUSINESS MEDIA

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

CIRCULATION

Tel: 416-442-5600

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year, USA $138.00 US per year, Outside Canada $156.50 US per year, Single Copy Canada $10.00, Outside Canada $27.10. From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

ANNEX PRIVACY OFFICER

Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex

Never has there been a start to a new school season with so much at stake for Canada’s economic prospects, healthcare infrastructure and the education system at large, with the student population poised to play a key role in determining where we all go from here.

After the raging global COVID-19 pandemic laid waste to many high-school, university, college and other students’ last academic year, there is a lot of catching up for them in the months ahead to make up ground for school closures across the nation earlier this year, and it is essential they play their critical part in helping schools stay open as much as possible.

As such, proper social distancing protocols and personal protective gear like face masks must remain everyday features of the new normal reality in the academic world for as long as necessary, even permanently if required.

The good news, let’s hope, is that the Canadian students’ general propensity and instinct to do the right thing is often underestimated by the older segment sof the population.

At least until students thmselves take matters into their own hands.

Whereas the vast majority of Canadian students found themselves with too much time on their hands over the last six months, recent Sheridan College graduate Ramzy Ganady was self-isolating at the school’s Centre for Advanced Manufacturing and Design Technology in Brampton, Ont., manufacturing PPE (personal protective equipment) for frontline healthcare workers and protective shield panels for local businesses struggling to stay open during Phase 2 of the pandemic. (See Picture)

With financial support from Brampton-based soft-

drink bottler CocaCola Canada Bottling Limited, Ganady and Simon Heathcote, the centre’s mechanical and electrical engineering technology lab manager, were able to manufacture 200 countertop protective cashier shields—made of PETG and aluminum—that were distributed to local business operators.

“I want to thank Coca-Cola Canada for the protective shield and for the program,” says Dino’s Woodburning Pizza owner Dino Ari, the first of the 200 grateful Brampton businesses installing the shields.

“It has provided great protection for both my staff, and our customers.

“Securing our own protective shields would have been costly and taken much of my time away from running the business,” adds Ari, s”o having this assistance was very much appreciated.”

So while 200 shields may seem like the proverbial drop in a bucket in the larger ongoing struggle to contained the spread of COVID 19, this spur-ofthe-moment partnership between the city’s leading industrial employer and its biggest academic institution offer an inspiring example of true genuine partnership that can really help galvanize our youth to engage in further noble causes that will collectively make all of us proud and grateful in the challenging times ahead.

George Guidoni, Editor

While alcohol-free beer has been around for decades, non-alcoholic spirits are a fairly new product category that is nevertheless catching on like wildfire amongst Canadian consumers mindful of the adverse health and social behavior effects of excessive alcohol consumption.

Last month, this category has been expanded some more still with the Canadian launch of CEDER’s brand of premium non-alcoholic gins made with wild and rare South African botanicals and distilled with pristine water from Sweden to extract the finest flavors.

Handcrafted and bottled in Sweden by CEDER’S Drinks Ltd., company cofounders Craig Hutchinson and Maria Sehlstrom use an exclusive recipe, along with precise and unique distillation and extraction techniques, to ensure their production is carbon-neutral and environmentally sustainable.

“We created CEDER’S with the intention to offer an ‘escape’ from alcohol-based spirits, without compromising on taste, to answer the growing demand for nonalcoholic beverage options,” says Sehlstrom.

“We aim to provide consumers with more alternative choices of the highest quality without sacrificing a sophisticated drinking experience.”

Handcrafted and available in 500-ml bottles, the CEDER’S brand is distributed through Canada by marketing agency Dovetale Collections, which specializes in marketing of artisanal food from all corners of the world.

Available nationally through online retailers and at premium retailers in select Canadian provinces, the new alcohol-free gin is comprised of three flavors, including:

* CEDER’S Classic, akin to a classic gin, mostly juniper but with floral hints;

* CEDER’S Wild, juniper combined with ginger, clove and rooibos;

* CEDER’S Crisp, juniper combined with citrus, cucumber and camomile.

Each 500-ml glass bottle, designed as homage to the classic gin bottle, is decorated with a high-quality branding label created by U.K.-based independent designer Simon Kingston, according to Sehlstrom.

“The story behind the clean, elegant and beautiful label design is very personal, as we (Maria and Craig) used elements from our home countries and took inspiration from our wedding invitation when imagining the design,” Sehlstrom relates.

“The luckenbooth heart symbol above brand name, for example, has a protea flower as a crown on the heart and two twinflowers within the heart, which are the national flowers of South Africa and Sweden,” Sehlstrom explains, “while the botanicals of the wreath are illustrations of botanicals used in the product.”

PROBLEM: You want to use the latest automation technology. However, the complexity is overwhelming.

SOLUTION: MOVIKIT® software modules! They empower you to perform complex automation tasks easily and without experience. No more long hours. No more complex programming.

Simple is good... Fed up?

Positioning? Synchronization?

Torque sharing? Winders? Yes, and even more!

As an essential business in the retail supply chain, our network of manufacturing and fulfillment sites remain fully operational and productive, with available capacity to accommodate the rapidly evolving demands at retail.

Our skilled workforce and world-class automation allow us to meet the changing needs of our customers and their retail partners.

Menasha continues to implement proactive and controlled measures to combat the spread of COVID-19. The safety, health and wellbeing of our employees, their families, our suppliers, customers, and communities remains our number one priority. Partnering with your business as we

Our continued focus is to provide a clean, healthy, and safe work environment to ensure the seamless flow of products our customers and communities are counting on us to deliver.

Together we will ensure your business continuity by protecting, moving and promoting your products better than anyone else in these uncertain times. For further information please contact us at Menasha.Canada.Solutions@menasha.com

Jones Healthcare Group, London, Ont.-based supplier of pharmaceutical packaging and medical dispensing solutions, has completed installation of a new one-of-a-kind Aquaflex LX 2350 label printing and converting press to enable faster production of customized laser pharmacy labels.

Manufactured by F.L. Smithe Machine Company in Duncansville, Pa., the narrow-web Aquaflex LX 2350 features double-wide printing at 500 feet per minute through a series of five new-generation, high-precision flexo print stations— allowing for a range of color options and double-sided print capabilities using sustainable water-based inks.

With three die stations, the press can produce multiple

label configurations with dual web construction—including paper and self-adhesive labels.

“As the number of prescriptions dispensed to patients continues to rise, our pharmacy customers are looking for partners with near-shore manufacturing facilities who can supply laser labels for their prescription packaging with speed and efficiency,” says Stephen MacNeill, senior vice-president of the pharmacy market for Canada at Jones Healthcare.

“Our new equipment helps us continue to meet demand as a leading supplier within the unique Canadian pharmacy laser label market.”

As MacNeill points out, the new press includes a unique

Do you want SUPERIOR flexibility? You’ll love the range of packages that Reiser form/fill/seal machines can provide.

Do you want SUPERIOR production? You’ll love the speed.

Do you want SUPERIOR package seals? You’ll love not worrying about leakers and returns.

Reiser’s packaging technology and expertise are the powerful combination you need to produce a SUPERIOR package.

matrix extraction system to allow for continuous production runs— increasing efficiencies and reducing waste.

“With its unique double-wide capacity, the new Aquaflex press helps us produce a larger volume of customized, high-quality laser labels for pharmacies more quickly,” adds David Dembski, Jones senior vicepresident for cartons and labels.

“This is one of multiple equipment investments we are making over the next two years with a focus on enhancing operations and the client experience, while upholding the highest quality outputs for patients and consumers.”

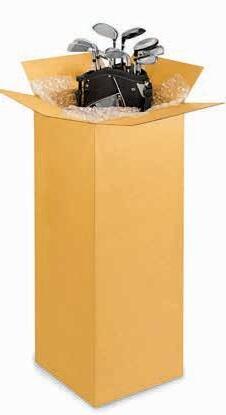

With online shopping becoming the new normal for many Canadian consumers, Kingsey Fall, Que.-based forest products group Cascades has launched a new line of packaging products deigned specifically for e -commerce distribution channels.

Grouped under the Cascades e-com packaging solutions banner, the new products and services were developed with a customer-centric approach to ensure that they meet the specific needs of this fast-growing market.

“We’ve worked extremely hard to provide our customers with a full range of solutions that go beyond traditional packaging or a simple product catalogue,” says Charles Malo, president of Cascades Containerboard Packaging

“By offering services, tools, laboratory tests and even innovative supply chain processes, our goal is to cover every angle with this new product offering.”

2020

Visit our virtual showroom at PACK EXPO Connects November 9-13, 2020

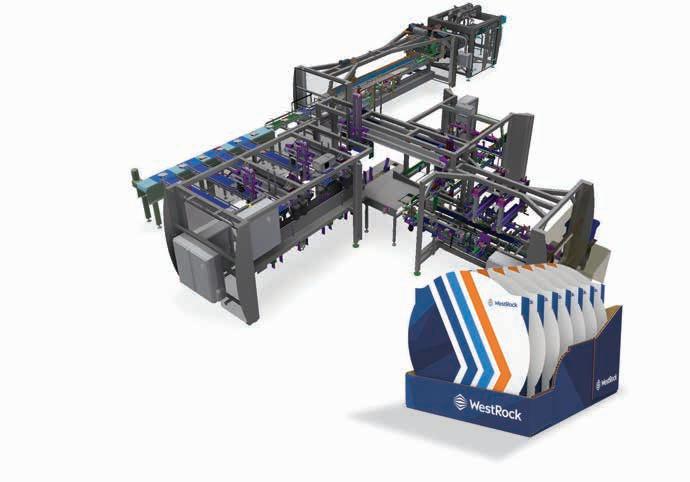

Introducing the CP eMerge™ Combo, WestRock’s newest automation technology for frozen food bowls that combines sustainable secondary and tertiary packaging into one system. The single-operator, end-of-line solution manages multiple SKUs and minimizes downtime by allowing for quick changeover between a range of bowls and trays. The integrated combo design is uniquely suitable for those with footprint constraints

Complexity, simplified.

westrock.com/automation

n Orangeville, Ont.-based automation systems integrator PLAN Automation has formed a strategic partnership with BlueMorph Health Systems for use of its proprietary COVID-19 UVC-based Virus Sanitization Technology. Critical for safe CPG (consumer packaged goods) manufacturing operations, BlueMorph’s FDA- and CDC -approved technology disinfects rooms, offices and vehicles in under 10 minutes using UVC (nonchemical ultraviolet C) light). The mobile automated units are easily operated and will provide PLAN Automation’s clients with the best solution for ensuring a COVID-free work environment for their employees. Tel. (416) 720-7875

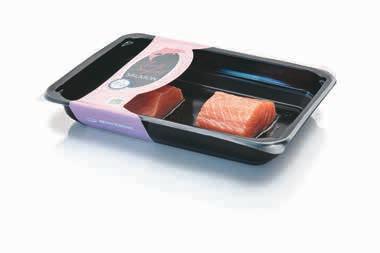

nGlobally operating plastic films manufacturer Klöckner Pentaplast (kp), headquartered in London, U.K., has announced plans to expand its post-consumer recycled PET extrusion capacity by 17,500 metric tonnes, which significantly increases its capacity for thermoformed recyclable protein trays in North America. The multimillion-dollar capacity expansion will be spread around among the eight North American locations that are best situated to serve its sustainable consumer and protein packaging customer base, according to kp, while meeting the increased consumer demand for curbside recyclable options, and supporting-closed loop packaging and the Circular Economy model. “As major brands announce robust sustainability initiatives that include post-consumer and recyclable packaging, kp will be positioned to service those market

1-piece, Film-lined Paperboard Tray for MAP and Vacuum Applications

Our Paperseal™ package from G. Mondini maintains a seal integrity equal to traditional plastic packaging, can suit any product, uses 80% less plastic, and provides easy separation of liner from paperboard for simple and efficient recycling. It uses less greenhouse gas, less energy, and meets all necessary food safety requirements.

Target market applications include: Whole Meat & Processed Protein, Produce, Deli Meat & Cheese, Meals, Sides and Seafood.

Contact Harpak-ULMA today to learn more about this exciting new environmentally-friendly package!

HARPAK-ULMA.COM

800-813-6644

Continuous fl ange for uninterrupted sealing surface

Options for various performance needs and appearance

Easy separation of liner from cardboard for recycling

Printing on all surfaces for excellent branding

Flat boards signifi cantly reduce storage and distribution costs

needs for the foreseeable future,” says kp’s chief executive officer Scott Tracey. “The extra capacity will also go a long way in supporting our company’s goals for product innovations and sustainability.” Founded in 1965, kp currently operates 32 plants in 18 countries, employing over 5,900 people.

nArdagh Group, Glass – North America, Indiannapolis, Ind.-based subsidiary of Luxembourg-headquartered gall and metal packaging products manufacturer Ardagh Group and the largest domestic manufacturer of glass bottles for the U.S. wine market, has announced that three of its customers were awarded PACK Design Awards at the seventh annual Wine Packaging Conference last month. The winning entries include:

* The classy, embossed glass wine bottle Ardagh manufactured for Ken Wright Cellars, whose Bonnie Jean Vineyard was awarded second place in the Best Luxury Package Design category.

* The customized gift set by A X R Napa Valley was awarded first place in the Best Assorted Set Design category, and The Debate, Cabernet Sauvignon - Elevate the Debate was awarded second place in this category. With bioth bottles manufactured by Ardagh, the wine sets, designed by Bellows Wine Consulting, were slected based upon the cohesiveness of the set, their visual appeal as a set and as individual pieces, design functionality and appropriateness for the price segment. “Unique embossing, stylish shapes and a variety of colors are just some of the intricate bottle design options wineries are able to achieve with glass packaging from Ardagh,” says John Shaddox, chief commercial officer for Ardagh’s North American Glass business unit. “Ardagh is proud to manufacture the award-winning glass wine bottles and to celebrate these brands for their commitment to innovation and for being leaders in wine packaging design.”

nBirmingham, Ala.-based Motion Industries, Inc., a leading distributor of maintenance, repair, and operation replacement parts and a wholly-owned

subsidiary of Genuine Parts Company, has completed the acquisition of Applied Machine and Motion Control, Inc. (AMMC), Kentucky-based supplier of motion control and automation products and services. Founded in 1995, the majority of AMMC’s business comprises the markets of Indiana, Kentucky, Michigan, Ohio, western Pennsylvania and West Virginia, with its customer base consisting primarily of OEMs (original equipment manufacturers). “As a premier supplier to the Ohio River Valley area and beyond, AMMC and its talented people will be instrumental in furthering our growth strategy geographically and in the automation arena,” says Motion Industries president Randy Breaux. “In addition to broadening our offerings to customers, their go-to-market approach and line card are very similar to our other Mi Automation Solutions Group divisions, to which AMMC will be a nice complement.”

nigus, German manufacturer of high-tech, low-cost and sustainably engineered plastics operating a wholly-owned North American subsidiary in Providence, R.I., has announced plans donate more than 220,000 face shields to schools in Rhode Island and Florida to help protect students and staff in the wake of the COVID-19 pandemic. “As business leaders and parents, we are thrilled to be able to donate igus face shields in an effort to provide additional protection against the spread of COVID-19 for the upcoming school year,’’ says Rick Abbate, vice-president of igus North America The shield includes an injection-molded, onesize-fits-all plastic strap that holds a replaceable sheet of plastic film that covers the face. Manufactured by igus at the company’s global headquarters in Cologne, the shields are not a substitute for a protective mask that covers the mouth, says Abatte, but they do provide additional protection, especially for the eyes, by guarding against the natural instinct for young people to touch their face and thus come into contact with the virus. “We are living in unprecedented times and the upcoming school

year is surrounded by much uncertainty regarding the safety of the children when they return to the classroom,’’ Abbate says. “It is our hope that these igus face shields will add greater protection for the students and provide more peace of mind for their parents, as we all do our best to protect our families and colleagues against the increased spread of the coronavirus.”

nSt. Louis, Mo.-headquartered rig packaging product group TricorBraun has reached an agreement to acquire Price Container and Packaging, a rigid packaging distributor primarily serving the industrial and

food markets. “Our acquisition of Price Container will significantly add to our robust range of packaging solutions by expanding our industrial presence,” said TricorBraun president and chief executive officer Court Carruthers, citing the company’s outstanding reputation and long-standing customer and supplier relationships. “As we continue to provide essential, quality packaging, we look forward to serving customers with their industrial and other market needs,” says Carruthers, adding that the company will continue to operate our of its existing locations in the Salt Lake City and southwest Washington areas under the banner of Price Container, a TricorBraun company.

Designed primarily for e -commerce packaging applications, the new SMAAK brand of vacuum-packing machinery from Korok Group o ers a diverse range of commercial and industrial tabletop single- and double-chamber vacuum sealers to suit the full range of small to large packaging requirements. Manufactured in North America to facilitate

easy replacement parts availability, the ergonomically designed machines are built from stainless steel to meet even the most stringent requirements for sanitation and food safety, the SMAAK machines are all equipped with Busch pumps, renowned for their reliability in running uninterrupted eight-hourplus production schedules.

Korok Group

Distributed in Canada by PLAN Automation, the new PTX poultry

technology from

Product Inspection can detect hardto- nd chicken and turkey bones below 2.0-mm, including fragmented rib, wish and fan bones. O ering a 99-percent accuracy rate and three to four times resolution improvement,

PTX uses advanced algorithms to deliver signi cant improvement in system performance and in the detection of poultry bones.

CARLO GAVAZZI Inc. has launched a new range of capacitive proximity sensors with integrated IO-Link communications. Building upon the company’s existing range of sensors, these new sensors are housed in durable AISI316L stainless-steel housings or PTFE Te on housings for high chemical resistance. Based on our fourth-generation TRIPLESHIELD sensors, the new CA18 and the CA30s series sensors represent the ideal solution for industrial automation equipment in applications where the sensing performance needs to be constantly and accurately monitored and logged. Besides the full range of technical features provided by the company’s capacitive sensor families, the IO-Link communication mode enables additional advanced functionalities such as: QoR (Quality of Run), QoT (Quality of Teach) and diagnostic parameters. With IO-Link, each sensor becomes fully programmable and customizable, according to the company, allowing for more than half a million setting combinations.

CARLO GAVAZZI Inc.

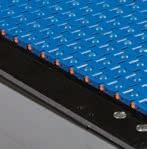

Designed to minimize the risk of bacterial contamination risks acroos food manufacturing environments, METTLER TOLEDO’s new washdown-resistant checkweighers can withstand the most rigorous cleaning procedures in food production, while ensuring weighing accuracy and upholding the highest hygiene standards. Ideal for processing and packaging applications involving meat, sh and seafood, baked goods, ready meals and other product where liquid product ingredients could spill over and contaminate conveyor belts or other parts of the machinery, the new Washdown Checkweighers series feature sloped surfaces to discourage liquid and debris collection, with their xonveyor belts removed quickly and easily for e cient cleaning. Comprising the C33 PlusLine and the C35 AdvancedLine models, the new checkweighers adhere to all the pertinent global weighing regulations and comply with all the regulations governing conveyor materials expected to come into contact with food.

METTLER TOLEDO Inc.

NOVA Chemicals Corporation has developed what the company calls a “transformative” high-density resin technology for the biaxially oriented polyethylene (BOPE) market to enable the manufacture of all-polyethylene, recyclable multilayer film structures with significantly improved physical performance compared to blown film.

According to the Calgary-headquartred company, a wholly-owned subsidiary of the Mubadala Investment Company of the Emirate of Abu Dhabi, United Arab Emirates—the new resin marks a major milestone in its accelerated pursuit of a plastics Circular Economy model.

Said to be exceptionally well-suited for use in food packaging, heavy-duty sacks, e -commerce and other demanding applications, the HD-BOPE was developed to help enable film manufacturers to realize the benefits of fully recyclable PE monomaterial structures without sacrificing stiffness and print clarity, according to NOVA Chmicals.

“Brand-owners and consumers are increasingly looking for easy-to-recycle packaging that prevents contamination and extends the shelf-life of their products,” says Alan Schrob, consumer and industrial films group manager for the company’s polyethylene business.

“Our HD-BOPE technology provides an additional building block for converters to make recyclable multilayer films that perform as well as traditional mixed-material structures,” says Schrob, pointing out that monomaterial film structures are critical to achieving brand owner commitments to make all plastic packaging 100-percent recyclable, reusable or compostable.

As Schrob explains, biaxially oriented films are stretched in both the machine and transverse direction, resulting in films that have enhanced

toughness, improved barrier performance, and exceptional optics.

BecauseeFilm structures that use the technology are commonly laminates, the HD-BOPE resins are designed for use in the print web and can then be laminated to a sealant film made with lower-density polyethylene.

The finished film also has high stiffness which enables downgauging and improved processability in converting steps copared to blown film alternatives, and lthe low tear properties needed for easy-open packaging.

Similar to films made from other biaxially-oriented technologies, BOPE films demonstrate excellent thickness uniformity and film flatness for high yield rates.

NOVA Chemicals has been working with Brückner Maschinenbau, the world’s leading stretching line manufacturer, to accelerate the development and commercialization of the technology. (Pictures above)

“We have been very pleased with the performance of NOVA Chemicals’ products on our equipment, and we are also getting positive feedback from the converters who are making film with it as well,” says Sebastian Ruhland, senior sales manager at Brückner

With our modular safety gate system you can build an individual safety gate solution optimally tailored to your application!

• Configurable safety controller PNOZmulti 2: Modular and compact solution as flexible as your application

• Safety gate system PSENslock: Safe position monitoring with process guarding in one system

• Pushbutton unit PITgatebox: Simple operation of your safety gate system

• Safety gate system PSENmlock: Safe interlock and guard-locking in one product with optional escape release

Modular safety gate system: Your gate. Our system. Your safety.

Maschinenbau.

“We believe this technology will open up completely new possibilities to provide PE films for 100-percent monomaterial packaging films as an answer to the recyclability challenges we are all facing today.”

According to Nova Chemicals’ public pledges earlier this year, the company is fully committed to its goal of enabling 100 per cent of plastic packaging recyclable of recoverable by 2030, and making sure that 100 per cent of plastic packaging is reused, recycled or recovered by 2040.

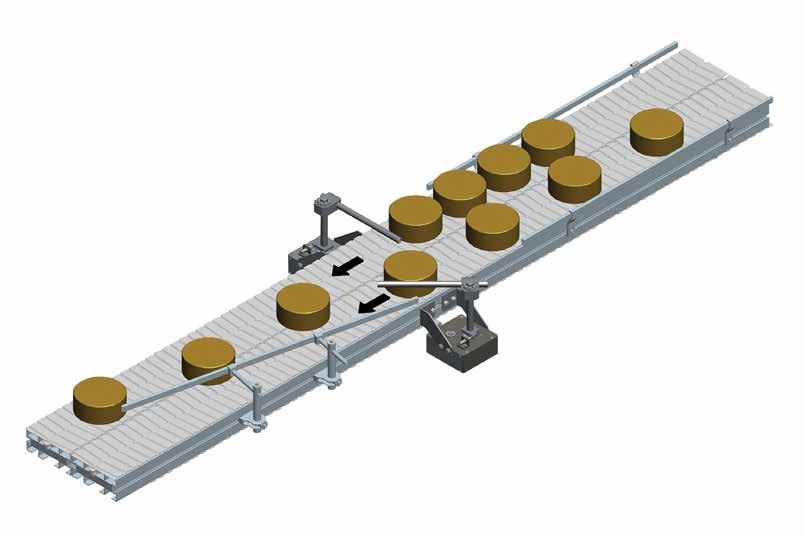

one integrated module could easily divert, transfer and sort multiple package types?

Very small packs? Polybags? Not a problem for ModSort transfer conveyor modules! The ModSort module can do left and right sorting on the fly for a wide range of package types and sizes. It is safe, quiet, versatile and cost effective.

Let our experts support you choosing the right system for your application or check it out at:

ModSort.com

Creating a better tomorrow™...

Quebec popcorn king breathing new shelf-life into its upscale snack favorites with sturdy and robust automatic bagging machinery

BY GEORGE GUIDONI, EDITOR PHOTOS BY PIERRE LONGTIN

With bland, generic and easily forgettable pop songs dominating the radio waves and Billboard charts these days, it is always a joy to be reminded that the heart of Rock-and-Roll is still beating out there at full volume—often in the least expected places.

Tucked away in a quite Montreal o -island suburb of Saint-Eustache, the 80,000-square-foot snack-food manufacturing Imperial Snacking facility looks pretty much like any other factory building, until you step through the front door.

Once inside, rst-time visitors may well feel like they have stepped inside a Graceland shrine celebrating all things Elvis—just as the company’s husband-and-wife team in charge, president and chief executive o cer Elvis Langevin and chairwoman of the board of directors Audrey Martel, always meant it to be from Day One.

Named in honor of the original King of Rock-and-Roll by his life-long Elvis Pres-

to the

remarkably e ortlessly for the

to

a room, immaculate pompadour hair straight out of the Grease movie set, stylish rockabilly attire, and con dent rock-star swagger to match Langevin’s high-tempo energy levels and keen business savvy.

For when it comes to the popcorn business, Langevin is literally the king of his domain any way you slice it.

“When he went to accept the Gold Medal Golden Eagle award that our company won at recent industry trade show in Cincinnati, everyone in attendance started yelling for him to sing on stage while accepting the award, and he was happy to oblige, like he always does,” recalls Imperial Snacking operations manager Robert Sylvestre, a long-time company employee and a family friend who has known Langevin for over 20 years.

“He loves to sing and entertain people,” Sylvestre told Canadian Packaging in a recent interview. “He is not shy: he genuinely loves being the life of the party and being in front of people.

“There is never a dull moment with Elvis around.”

Originally started up in Ottawa under the Imperial Concessions banner back in 1994, Imperial Snacking has been happily earning its bread-and-butter at the Saint-Eustache facility since 1997 by manufacturing home-quality popcorn, cotton candy, slush, and distributing other fun-oriented confectionery products often found at the concession stands at movie theaters, sports arenas, music halls, outdoor festivals and other mainstream entertainment venues.

Also operating a side distribution business to supply concession stand operators with popcorn poppers and dispensers, cotton candy machinery, hot-dog grills, slushie ice-beverage blenders and other portable food preparation equipment, the company’s relentless focus on both product and service quality has been rewarded with an extremely loyal client base and brand recognition in the Canadian markets, according to Sylvestre.

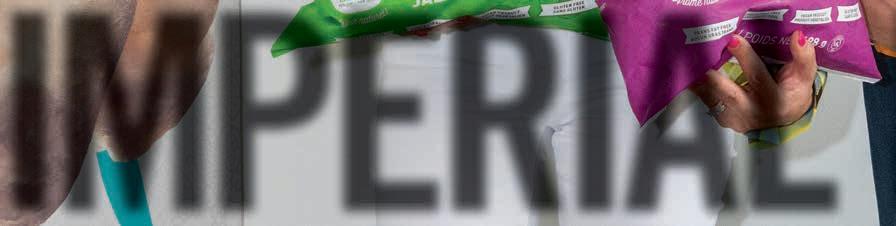

This success has also been well replicated in Canada’s grocery markets, with leading pharmacy chain Jean Coutu Group, supermarkets like Metro, Loblaws, Sobeys and Dollarama, and countless convenience stores and other established retailers happy to carry the company’s Maïs Sou é brand of multi avored readyto-eat popcorn in their snack aisles.

Featuring an iconic clown mascot and bright, childfriendly graphics on the surface of the transparent plastic pillow bags in several single-serve and family sizes, the company’s Maïs Sou é popcorn has been a popular snacking choice for many of the country’s kids for the last 20 years, according to Imperial Snacking.

But as market demand for healthier snacking alternatives for children and adults alike has continued to grow rapidly in the last several years, the company saw a unique opportunity to expand its customer base by extending its Maïs Sou é line-up with a new brand of premium gourmet-quality popcorn better suited to a more mature audience.

Inspired by music and dance themselves, Audrey and Elvis launched Imperial’s French Cancan brand as a tribute to the popular cabaret style chorus line dance still popular around France to this day.

Combining personally-driven product innovation with superior packaging execution, the deftly executed new product launch already appears set to raise the bar for the entire product category.

Currently retailing at Costco outlets in Quebec, Ontario and Maritimes in family-sized 360- to 698-gram bags, the French Cancan line comprises six innovative vegan avors—including the classic buttery Movie Style, Sweet & Salty, Cheddar and Green Onion, Jalapeño, Himalayan Pink Salt and Black Pepper & Lime—the gourmet-

Installed at the mezzanine level, the 14-bucket PrimoCombi automatic weighscale supplied to the Imperial Snacking plant by Paxiom Group delivers superior accuracy and weighing precision in delivering smooth and consistent ow of the lightweight uffy product to all of the system’s vibratory feeder pans and the stainless steel buckets that automatically dispense the precise quantity of product down to the bagging machines on the ground oor below.

fully-automatic

Featuring a built-in touchscreen HMI (human-machine interface) near the top of the electronic controls cabinet to provide easy programming and monitoring for machine operators, the WeighPack brand XPDIUS Elite vertical form- ll-seal machine uses specialty metallic foil bags to package the French Cancan line of premium-quality popcorn products at speeds of 10 to 12 bags per minute in perfectly-controlled continuous work ow that ensures nine-month shelf-life for the bagged popcorn.

quality popcorn is made exclusively from top-quality natural ingredients.

Expertly cooked in sun ower oil to produce a fullavor taste pro le, the transfat-, cholesterol- and glutenfree snack o ers consumers a tasty and satisfying lowcalorie alternative to potato chips, nachos, peanuts and most other traditional snack-foods.

“Popcorn is very much a growing business primarily because of the low-calorie content that both young and older people really appreciate nowadays,” says Sylvestre.

“We go through great lengths to secure only the bestquality grains we can for our products,” he says, “and that’s a very important part of the equation in a highly competitive product category like popcorn.”

Currently processing over three million pounds of popcorn annually, the Imperial Snacking plant runs a busy two-shift operation Monday to Friday, along with additional maintenance shifts for machine and facility cleaning as required by the plant’s HACCP (Hazardous Analysis Critical Control Points) compliance requirements for food safety.

Housing a total of ve packaging lines, the Saint-Eustache facility has to run like clockwork, Sylvestre contends, to accommodate time-sensitive packaging for a fast-cooking product—requiring less than four minutes of cooking per batch—in order to lock in all the avor and aroma inside the bags, which vary from 75- to 698gram volume sizes.

As for product shelf-life, Sylvestre cannot say enough good things about the new metallic foil bags that the company has recently started using for the family-size bags that Imperial Snacking currently supplies to the Costco stores.

Shipped in rollstock by a nearby Quebec-based supplier, the new foil bags literally breathed new life into the products by extending the best-before dates up to nine months, compared to 120 days for the polybags they replaced, without any gas- ushing during packaging.

“We realized that if we could not sell a product over a period of nine months then we had much bigger problems to address,” Sylvestre quips.

As it is, the family-size French Cancan bags have already become a brisk-selling product at Costco, Sylvestre con des, and the company is looking forward to then selling the smaller-sized 300-gram and 400-gram bags at other leading grocers across Canada before the year’s end.

Featuring upscale irtatious graphics and a glamorous cancan dancing girl out tted in a fancy dress with a popcorn kernel-shaped skirt, the new package design created by Blainville, Que.-based package design specialists Voyou Bou e has helped facilitate a highly successful new product launch.

As Sylvestre explains, the company’s recent investments in some state-of-the-art automatic weighing/ scaling equipment and vertical form/ ll/seal (VFFS) packaging machinery manufactured by the Montrealbased packaging systems specialists Paxiom Group have made Imperial Snacking uniquely quali ed to handle processing the bigger volumes required by the plant’s growing private-label business.

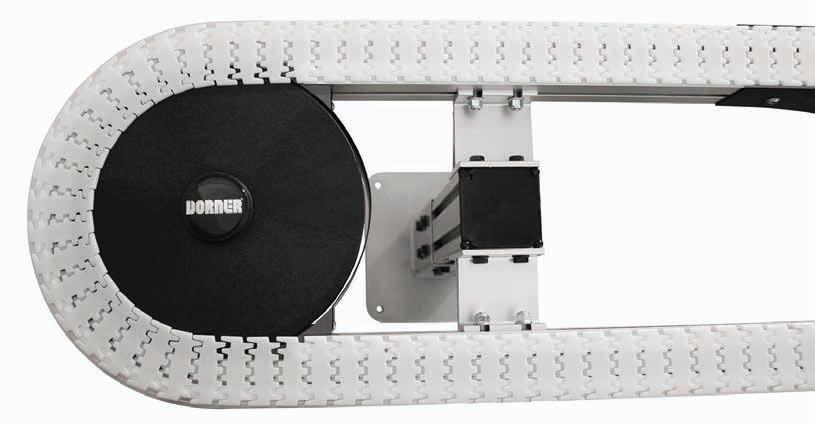

Installed over the last couple of years, this new equipment includes the PrimoCombi brand multihead combination scale—installed on the mezzanine level—and two high-speed XPDIUS Elite VFFS machines installed directly below the scale on the ground oor of the packaging area.

In operation, the bulk popcorn is moved up to the mezzanine level by an inclined bucket elevator convey-

for the brand to achieve vastly extended product shelf-life.

or, and laid on down on the smooth product transfer conveyor belt that directs the product ow to the center cone of the PrimoCombi weighscale.

Once lled, the loose popcorn vibrates from the center cone to 14 individual vibratory feeder pans that transport product to the individual weigh buckets— each one controlled by an individual load cell—to be weighed and measured to obtain precise desired quantity of product.

Once weighed, the PrimoCombi’s industrial PC determines which buckets equals a near-perfect match, locks the buckets, and then prompts all the lled buckets to release the product at the same time to the XPDIUS machines below for bagging and sealing.

Designed for high performance and speedy throughput, the XPDUIS vertical bagging machines include twin servomotors and drives for their pull belt assembly and horizontal seal jaws to ensure total control over acceleration, deceleration and positioning of the product, with capability of producing up to 100 bags per minute, depending on the product.

Due to the lightweight and u y nature of popcorn that makes it di cult to move and dispense at high speeds, the actual throughput rate for the XPDIUS machines at the SaintEustache plant currently ranges between 10 and 12 bags per minute, according to Sylvestre.

“We could go twice as fast if we were running heavier solid products through these machines,” Sylvestre acknowledges, “but we have to be patient with a tricky

product like popcorn due to its light weight, as running it at full speeds would end up having the loose popcorn y all over the place, creating unacceptable amounts of waste.

“Of course, minimizing product waste was one of the compelling reasons why we invested in Paxiom’s WeighPack brand of machinery to begin with.”

Says Sylvestre: “Back in the days when we used to ll the bags manually by hand, we would inevitably end up putting an extra 30 to 50 grams of extra popcorn into the bags just to ensure that we would not be short-changing the customer on the amount of product per bag.

“Having the CombiPrimo has enabled us to reduce this product giveaway down to a couple of grams of product per bag at the most,” he states. “It is a highly accurate, precise and versatile system that is a perfect match for our operation’s uncompromising emphasis on quality and customer satisfaction.”

As for the XPDIUS Elite VFFS bagging machines, Sylvestre says he highly values the equipment’s durable construction and reliability, along with general userfriendliness and ease of maintenance.

“We run these machines for up to 19 hours per day in a very challenging environment,” he says, “and so far they have proven to be exceptionally reliable.”

“We have maintained a very productive relationship with the Paxiom Group for several years,” says Sylvestre, adding that the horizontal form/ ll/seal machines used on the other packaging lines at the plant were also

supplied to Imperial Snacking by the Paxiom Group.

“Their local customer service manager Mark Conforti is an extremely knowledgeable guy who has provided great advice and service for us,” Sylvestre adds, “which give us a lot of con dence going forward to grow our popcorn business—both for our own brands and the new private-label business that we are working with to bring to our plant to really maximize our full potential.

Adds Conforti: “Working with the Team at Imperial Snacking has truly been a pleasure.

“We were able to work together as a team, and as a team we developed a packaging system that best suits Imperial Snacking’s speci c needs in order deliver a high-quality product and packaging to the marketplace.

“Upon arrival for the commissioning of the equipment at Imperials facility, everything was already in place and ready for us to hit the ground running,” Conforti recalls. “Within a couple of hours we had the system producing great quality-pouches ready be displayed at major grocery chains across Canada.”

As Sylvestre happily concurs:“Popcorn is a really fun and happy product to work with, and having a loyal, dedicated, skillful and happy workforce, using the best equipment we can get for them to work with, provides a happy work culture and environment to form a very strong foundation for all the future business growth to come.”

Visit our virtual showroom at PACK EXPO Connects November 9-13, 2020

WITH AUTOMATED SHELF-READY PACKAGING.

WestRock’s Meta® Duo o ers true multi-channel, in-house automation of one- and two-piece shelf-ready packaging designs and ships-in-own-container units. Utilizing our unique Meta® Systems precision-forming technology, Meta Duo e ciently transitions between 4-sided, 8-sided and half-slotted containers, helping you meet various retailer and e-tailer requirements from a single, small footprint machine.

Multiple channels. One solution.

westrock.com/metaduo

Explore it with Heidelberg and MK Masterwork. As the world’s largest supplier of machines for packaging printing, our portfolio is the most comprehensive in the industry. And one that offers complete confidence: MK Masterwork is the only supplier whose machines are all GS certified. Learn more at http://bit.ly/WorldofPackaging

BY GEORGE GUIDONI, EDITOR PHOTOS BY NAOMI HILTZ

If the company you keep is a valid re ection of what kind of a company you operate, then the people running Bellwyck deserve all the acclaim they can get for steering the Torontobased folding-carton converter into the upper tier of global market for the packaging for leading multinational cosmetic and pharmaceutical brands, while cementing its industry-wide reputation for superior product quality, exceptional customer service and leading-edge innovation.

With three state-of-the-art production facilities in Toronto, Owen Sound, Ont., and Langley, B.C., the privately-owned producer of upscale packaging and labeling solutions for some of the world’s biggest health-and-beauty, pharmaceutical and nutraceutical brand-owners may not be an overnight success story, but it o ers compelling proof that when it comes to world-class manufacturing, the Canadian

package converting industry is more than capable of holding its own.

The key, according to Bellwyck’s president John McVeigh, is having a sound business strategy and culture with relentless focus on quality and innovation, underpinned by continuous capital investment

in the latest cutting-edge printing and converting equipment and solutions available in the market.

“We meet each client where they are, and we always strive to provide innovative options as they evolve and grow,” McVeigh told the Canadian Packaging magazine in a recent interview from the company’s headquarters at Finchdene Square in northeastern Toronto.

“From helping drive e ciencies and quality to eco-friendly solutions and smart packaging options, our core focus is to meet and exceed the rigorous standards of our clients, while continually nding new ways to help them stand out in the marketplace.”

Bellwyck has successfully leveraged nearly a century of industry experience and know-how, according to McVeigh, to grow its customer base by excelling in its chosen market niche for production of upscale and luxury packaging, as well as CGMP

(Current Good Manufacturing Practice)-compliant pharma/healthcare cartons, for some of the world’s leading iconic brands.

According to Bellwyck, the company’s client base includes the majority of the world’s top 20 pharmaceutical companies.

“Bellwyck has evolved into an industry leader in the premium brand and pharma/healthcare space by providing unique, sustainable and turnkey packaging solutions for top global brands.

“To support Bellwyck’s industry-leading position, the company continues to make signi cant investments in technologies and systems that enable us to produce the most innovative, highest-quality packaging in the world, McVeigh adds.

“Our commitment to innovation and continually evolving solutions to embrace the ever-changing market is deeply embedded within Bellwyck’s DNA,” McVeigh asserts.

“Operating in a very demanding market space, we love meeting and exceeding our clients’ expectations,” McVeigh states, “which enabled us to become one of the largest players in the Canadian market space for printed packaging, serving Canada,

the U.S. and other clients around the world.

“We have created a culture of excellence in which we take great pride.”

This collective pride is enthusiastically shared by all employees working at the company’s three production facilities that include:

• The 170,000-square-foot Finchdene Square central manufacturing facility and headquarters in Toronto, where the company focuses on making packaging for high-end cosmetics and confectioneries, as well as premium liquor and personal care products.

• An 80,000-square-foot production facility in Owen Sound, specializing in producing pharmaceutical/nutraceutical/healthcare product packaging;

• A 40,000-square-foot West Coast operation just outside of Vancouver in Langley, manufacturing high-end label and exible packaging products. Between them, the company prints and converts over 250 million folding cartons, along with 65 million linear feet of labeling and exible packaging lm.

Running such high volumes consistently at the

highest quality levels is no easy task, McVeigh acknowledges, but being able to pull it o day-in and day-out is all part and parcel of the company’s unique value proposition to the marketplace.

Says McVeigh: “Our quality and on-time delivery are considered best-in-class.

“In one of our recent reviews with a major pharma client we scored 100 per cent in both categories.

“Moreover, we combine high quality and high customer service levels with our ability to drive innovation,” McVeigh says, “which is not an easy feat to pull o .

“When you are innovating in the market by constantly coming up with new and better ways of doing business, you’re pushing boundaries, running a risk that some other aspect of your business competencies will su er as a result.

“But having developed really high standards in customer excellence and quality at all of our plants actually helps to drive innovation,” says McVeigh, citing the company’s wealth of in-house expertise in all areas of the business, including structural design.

“Our innovation manifests itself in the nal product,” says McVeigh, relating the company’s in-house development of a unique new Spot Flocking tactile nishing technique used for high-end packaging for one of the top global cosmetic brands.

“The client’s vision was to create an exceptionally impactful product packaging look-and-feel with an intricately illustrated oral design and a uniquely tactile experience,” McVeigh relates.

“Our innovation team developed a creative solution that had never been attempted before in the cosmetic space—a Spot Flocking print that adds a tactile, furry e ect to an isolated element of the design.

“To achieve that,” he explains, “our die line and subsequent printing were considered to the minutest detail to ensure that the ocking in certain areas would stay on the board permanently.

“In the end, the nished printed design had a real ‘collectible’ quality to it, a real show-stopper, that made big waves with the client and in retail environments.”

As McVeigh notes, “The vast majority of our clients operate in a highly competitive marketplace, constantly requiring them to look for new opportunities to di erentiate themselves from their competitors.

“That’s why we continue to make signi cant capital investments to help our clients drive their efciencies, as well as make their product really stand out on the shelf.”

Over the last couple of years, a signi cant portion of Bellwyck’s capital investment activities have centered around installation of some truly cutting-edge, highly advanced printing press technologies manufactured in Germany by one of the world’s most famed press manufacturers Heidelberg (Heidelberger Druckmaschinen AG)

Operating in Canada through its Heidelberg Canada Graphic Equipment Ltd. subsidiary in Mississauga, Ont., the venerable global printing industry giant has helped Bellwyck carry out several major equipment installations involving some of its most advanced automated technologies the press manufacturer has commercialized to date, including:

* A Speedmaster CX 102-7+L Mixed Operation sheetfed o set press, which went into production at the Owen Sound plant about 16 months ago, along with a Heidelberg-made Diana Easy 115 foldergluer started up at the plant in May of this year.

“We also converted their prepress department to our Prepress Work ow Prinect, which allows for the integration and the ability to send digital information directly to the press,” says Ray Fagan, Heidelberg Canada’s sales specialist for sheetfed, postpress packaging and digital business segments.

* A one-of-a-kind Speedmaster CX 102-8+LY1+L UV press, which commenced production of high-end premium cosmetic product packaging at the Toronto facility earlier this summer.

As with the Owen Sound installation, the plant’s prepress operation was converted to Heidleberg’s Prepress Work ow Prinect for sending digital information directly to the press, according to Fagan.

“The two presses are very compatible,” notes Fagan, “which gives Bellwyck great production and scheduling exibility.”

For Bellwyck’s director of technical services and innovation Jerry Malfara, the installation of the

Speedmaster CX 102-8+LY-1+L UV press—expertly executed under extremely di cult circumstances stemming from the global COVID-19 pandemic— was a resounding con rmation of the very special business relationship that Bellwyck has cultivated with Heidelberg, and vice versa, over the years.

“It is a fantastic piece of equipment that has really changed the way we approach our production,” says Malfara, lauding the new press’s robust running speeds of up to 16,500 sheets per hour and expansive multicolor and nishing capabilities e ortlessly executed in one pass with stunning print quality and attractive value-added visual aesthetics.

Boasting nine printing and two coating stations, the custom-con gured Speedmaster CX 102-8+LY1+L UV press at the Toronto facility is the longest CX 102 printing press in Canada, according to Malfara.

“The speed, the accuracy and the consistency we get with this press has enabled us to signi cantly increase our print capacity and reduce our changeovers,” Malfara extols, “and it has an amazing color control system.

“It all adds up to signi cant savings,” Malfara explains, because it helps to lower your consumption of inks and consumables, the number of sheets you need to print to get the desired result, and the overall energy savings that the press provides with its highly e cient drying system.”

With its operator-friendly controls and operating software, the Heidelberg presses require just a twoperson crew to run the entire press at the Owen Sound location and, due to its sheer physical size, a three-person team for the 12-station Speedmaster CX 102-8+LY-1+L UV press in Toronto.

“It’s just not about the machine: it’s about transforming our work ow and our methodologies of realizing our vision of a ‘Smart Factory’ environment, whereby we’re using our people, software and all the other tools to create further process efciencies and optimizing the equipment time going forward,” says Malfara, who heads the company’s highly skilled innovation team.

Adds Bellwyck’s vice-president of operations April Burke: “The new press comes with at least 37 di erent data collection points that can be collected from the press to allow us to extrapolate that data.

“This helps us to better manage our work envi-

ronment as we go through our day-to-day tasks by identifying further opportunities for improvement.

“We have embarked on the transformational journey to a ‘Smart Factory’ model with signi cant capital investments,” notes Burke, “and this press will de nitely help us accelerate the process in our printing department by making real-time work ow adjustments to optimize the equipment uptime and availability.

“Moreover, it also has the ability to benchmark the collected data against some other similar-sized companies operating in this space,” she adds, “which allows us to see what kind of progress we’re making towards being the best-in-class operation.”

While Burke and Malfara admit that Bellwyck still has some work ahead of it to rightfully claiming that lofty status outright, the installation of the two new-generation Heidelberg presses in a relatively short time-frame has certainly laid down the required groundwork for getting there.

“Our Owen Sound plant has been running its Heidelberg press for over a year now,” says Malfara, “and that has certainly contributed to our understanding of how the machine supports the operator by using the data collected by the machine during all the jobs to improve our e ciencies and productivity.

“We look forward to drawing on our shared experiences between the two plants in the coming months as we get more familiar with all the possibilities o ered by this technology.

“We can actually move and exchange a lot of our calibrated work ow pre-sets back and forth between the two presses very seamlessly now,” he notes, “and having a shared prepress and shared equipment data also provides us with valuable back-up from a disaster recovery perspective, which is a very big thing for some of our larger clients.”

As Malfara points out, being able to bring the new press up to its maximum 16,500-sph (sheets per hour) running speeds is a resounding “testament to the high quality of training my team received from Heidelberg” and the sheer brilliance of Heidelberg’s proprietary Push to Stop process digitalization technology built into the new-generation presses.

Developed as an “autonomous printing mode” that enables operators to keep adding print jobs to the press with minimal intervention, the Push to Stop technology is designed “to free operators from the burden of routine tasks and to support them with

intelligent systems so that they can transform the technical potential of their machines into actual productivity,” according to Heidelberg.

“Whereas until now processes were actively started by the operator, in the future the press will do this itself, whereby the operator only interrupts the autonomously running process chain if necessary.

“This raises the e ectiveness of print production to previously unattainable levels by enabling better planning of processes and continuous process monitoring to lower the error rate.”

As Malfara concurs, “The Push to Stop technology has enabled a thorough work ow transformation at the two locations where we put in the new presses.

“While we still have some learning to do, we’re already starting to see its bene ts coming to fruition with the calibrated work ow.”

Says Malfara: “Our partnership with Heidelberg traces back more than 20 years ago starting with the Owen Sound plant, which installed their rst Heidelberg press back in 1998.

“This long-standing partnership provided us with all the support we needed to keep our latest installation moving along, even in these di cult times brought about by the COVID-19 outbreak.

“We worked very closely with their team to overcome this challenge,” he says, “and Heidelberg certainly has a very strong service team that supported us with the installation an day-to-day service.”

As Malfara relates, he was also very impressed by the professionalism and knowledgeable advice provided by Heidelberg Canada’s Ray Fagan throughout both Heidelberg press installations.

“He was an active and valuable participant through both projects,” Malfara recalls.

“He physically worked with us at both plants, diligently observing what we were doing to help validate the con guration of the presses.

“He gave us a lot of great guidance and advice that played a huge role in making our decision to go with Heidelberg equipment.”

For his part, Bellwyck’s president McVeigh says that adding the new Heidelberg presses to the company’s already extensive arsenal of high-performance production machinery will continue to push the company to new heights of packaging excellence and innovation.

“Because our customers range from top name brands to edgling start-ups, we are able to draw on a lot of di erent experiences,” McVeigh states.

“Each of them have di erent needs, some of them much more sophisticated than others, so we are constantly innovating to help them get better exposure in the market, stand out on the shelf, and to be as environmentally-friendly as possible, to help them grow to the next level.

“Knock on wood, we rarely lose a client once they come in—usually they’re a client for life,” McVeigh sums up.

“And as our signi cant capital investment in new Heidel-

berg presses and folder/gluer technologies shows,” McVeigh concludes, “our commitment to continuous innovation in this premium high-end market segment, as well as the pharma/ healthcare space, is second to none”

Hitachi’s UX Series continuous inkjet printers represent the pinnacle of innovation in marking and coding technology, all while showcasing Hitachi’s reputation for Reliability, Ef ciency, and Ease of Use.

East Coast entrepreneurs making good use of versatile vacuum-packing machinery and materials to help make their high-quality creations resonate in the marketplace

BY ANDREW SNOOK PHOTOS BY DALE PRESTON

For Luc Doiron, the lobster industry has been in his blood from a young age. Growing up in a family that worked in New Brunswick’s shing industry, he was excited to land his rst job working in a lobster plant when he was 16 years old.

“I was always in the lobster industry, even when I was young, doing summertime school jobs in the sh plants and lobster plants,” Doiron says. “That salty taste, you can’t get rid of it.”

After graduating high school, he attended New Brunswick Community College and graduated from NBCC’s business management program.

While in college, Doiron continued to work in the lobster industry during the summer months. When he graduated college, he continued to work in the industry—intimately learning all the many ins and outs of the business.

“I worked in another plant at di erent levels – learning the lines, learning purchasing, learning sales,” he says.

“I’ve pretty much been focused on lobster operation, since I graduated high school at di erent levels of the business.”

Even back in his college days, Doiron harbored big dreams of owning his own lobster processing plant one day.

In 2000, he created a business plan for buying an existing lobster processing plant as part of a course assignment. Ten years later, he made that dream a reality.

“I own that same plant now,” he says.

Proudly operating under the Suncoast Seafood corporate banner, the 35,000-square-foot lobster processing facility on the coast of the Northumberland Strait in Grand-Digue, N.B., specializes in freshly caught lobster for the wholesale market, as well as retail sales and the restaurant sector.

“It was a lobster processing plant that went up for sale that I purchased 10 years ago, and grew it from there,” Doiron says.

“At the time, hey were just doing front-end lobster meat extraction.

“Over time we developed di erent processing techniques, so that now we’re doing lobster tails, cooked lobster meat and whole cooks for a bunch of di erent SKUs (stock-keeping units).”

The majority of Suncoast’s products are sold to customers in the U.S., approximately 80 per cent, via the wholesale market. About 15 per cent of its sales come from a combination of Asian and European markets, and the company also does a small amount of business in Canada as well.

“We do mostly wholesale in Canada, but not a lot of retail,” Doiron says.

The company has an average production volume that ranges between seven and eight million pounds of live lobsters a year and produces upwards of 40 di erent SKUs of product.

“There’s a lot of di erent grading,” Doiron explains. “When we’re doing lobster tails they’re graded at different levels, six or seven.

“For cooked lobster meat we have 10 di erent SKUs, based on di erent mixes and products for the di erent customers.

“Although there’s only four edible components (tails, claws, knuckles and legs),” he says, “you can create a lot of di erent products.”

The busiest time for the plant is in the spring specically in May and June, with August and September also being the busier months of the year.

During the annual peak season, the company typically employs 180 people working a single eight- to 10-hour shift.

“When we rst started, we were probably at 80 employees,” Doiron says. “Today, we are generating six or seven times the annual sales we had since we rst started.”

With the plant being shut down over the winter months, Doiron takes the opportunity to take care of any serious maintenance issues and install new equipment without disrupting his operation.

As he relates, Doiron regularly searches the Internet and attends multiple trade shows to learn about the latest techniques and technologies for optimizing his operation.

Doiron says his favorite part of being involved in the industry is nding ways to ne-tune his business and improve product development and process ows inside the plant.

Doiron has looked at many automation opportunities for various aspects of the processing lines at his facility, but says he’s yet to see a machine outperform manual labor when it comes to lobster meat extraction and inspection.

“Most of the labor-intensive work is in the extraction,” he explains. “Every piece is a di erent size, every season a di erent shell—some harder shells, some softer shells,”

“A lot of people come in with new equipment, design it for the rst season, then the fall season comes, and the lobster grows and sheds its shell.

“The shells get harder as it gets colder.” say Doiron, explaining why manual inspections are more e ective than trying to automate that part of the process.

Packaging, on the other hand, is a di erent story.

Doiron says the packaging side of his operation is a very important aspect of the business, and one where the latest technologies can play a key role in assigning labor where it’s needed the most, while reducing production bottlenecks.

“I think packaging one of the easiest parts of the operation to automate,” says Doiron.,tured by VC999 Packaging Systems

As Doiron’s business grew over the years, so did his extraction workforce, which meant there was a lot more lobster meat that needed to be packaged.

After reviewing the di erent types of technologies available to improve his packaging lines, and speaking with other plant managers, Doiron decided to invest in a K7 conveyorized chamber vacuum packaging machine manufactured by VC999 Packaging Systems in Switzerland.

“We looked at it for two to three years, deciding whether we wanted to go that way, eventually making our decision in January of 2018, during our o -season, to have the system commissioned fro May of 2018.,” Doiron recalls.

“It was working ne, so we purchased a second one during the winter of 2019,” Doiron says.

“We didn’t eliminate much workforce, but we but doubled the throughput that we put through that machine, compared to the manual process.”

The installation, commissioning and ongoing maintenance of the K7 machines was thoroughly overseen by Carl-Michel Cloutier, sales manager for

Canada and distribution for VC999.

He says one of the most important aspects of his company’s technologies for Suncoast’s operations is that the K7 keeps the lobster meat free of humidity from the air when it seals the packaging.

“That keeps the lobster fresh.This means more moisture for the lobster meat and that it’s tastier for the consumers,” Cloutier says, adding that the K7 also o ers an e ective way to reduce labor costs.

Thanks to the automated conveyor belt, Cloutier says the K7 system only requires two employees loading the chamber.

That’ consideration is especially important for Suncoast’s operations because hiring local people has been extremely di cult, according to Doiron, who must rely on bringing in a lot of foreign workers, often at a high cost.

“We pay good wages and lots of good incentives are in place, but you have to like it to do it,” Doiron states. “This is very repetitive work [and] if they don’t like it, they don’t last.”

The lobster meat and tails are packaged using the high-barrier vacuum bags manufactured by VC999’s sister company XtraPlast, which are supplied locally through Al-Pack Enterprises of Moncton, N.B.

“Their service is great, their product is great,” Doiron says. “Where I was working before, I got to know them (Al-Pack) well, so I had that relationship going in when I took this plant over.”

The K7 system o ers a broad variety of key performance features that include features including bi-active sealing bars with electronic temperature control and precisely controlled contact pressure, along with highquality, quick and safe sealing with thick creases and two sealing height settings.

The control unit of the K7 has a high-resolution, eight-inch color display unit that can be operated from both sides in various languages, while o ering simple control and programming using soft keys, process visualization during the cycle, and remote maintenance via standard interfaces.

The conveyor belt features a quick-release attachment for cleaning with an optional pro led conveyor belt for small and round products. It also comes with additional perforation blades to process unusually long bags and optional trim removal.

As for future investments in the lobster plan, Doiron says he is planning on revamping the entire raw processing line next winter.

“It’s a fairly big project,” he states.

As VC999’s Cloutier relates, Doiron calls on him every year looking for new investment opportunities for his plant.

“He’s a really good guy, and we believe in his business,” Cloutier says.

“It’s really a genuine partnership that we developed with him, o ering great deals on nancing on our machines,” he explains.

“That helps smaller companies like Luc’s grow, with us supporting them any way we can.”

Although lobster is Doiron’s primary passion, he also has many other business interests—real estate among them

While looking into new investment properties a few years ago, he decided to purchase a rental property with a business partner, Remi Gautreau, located about 10 kilometers from the Suncoast plant.

There was a smokehouse on the property, but instead of tearing it down, Doiron and Gautreau decided to create a meat processing startup under the Joe’s Smokehouse corporate banner.

Started up as a niche beef jerky producer with one employee, Joe’s Smokehouse quickly expanded its operations to employ six-full-time sta making beef jerky, steaks, smoked sausage, chicken, ribs and bacon, which the company sells at farmers markets and delivers to convenience stores and local residences.

“We just started an online store this summer so that people can buy from us online,” he states, adding the company will deliver anywhere in southeastern New Brunswick.”

“We have plans to deliver all over the province eventually,” he adds.

Despite diversifying its product portfolio, beef jerky remains the single most popular product made by Joe’s Smokehouse.

In a busy week, the company produces about 5,000 packs of beef jerky, Doiron relates, along with about

1,000 packs of sausage.

“It’s all red meat that comes from directly from Prince Edward Island,” Gautreau explains.“It’s all Atlantic Blue Dot high-quality beef.

“The rest of the ingredients come from all over,” he says, “but we always try source as locally as we can.”

As the company grew and built a bigger smoker to produce more products, it experienced bottleneck issues at the packaging line, where the sealing machine had not yet been upgraded to accommodate the additional products.

To overcome this limitation, Gautreau and Doiron decided to invest in a VC999 model RS420c thermoforming machine, along with the XtraPlast non-forming and forming lms supplied by Al-Pack Enterprises. “Now it goes as fast as we can feed it,” Gautreau says. “You just need one employee to drop the stu in the

company has locations around the world, including a facility in Drummondville, Que., where they develop plastics for their equipment, and a manufacturing plant in Kansas City, where they produce the rollstock lm for packaging machines like the one at Joe’s Smokehouse.

“They bought a machine we already had in stock. [and] we just had to make the special mold for them, which took us about six weeks.

“The installation itself was very quick,” Cloutier says. Back at Suncoast Seafood, Doiron says he would like to see the company increase its retail sales in the future.

“We’re very limited in retail exposure, so we’d like to get a good portion of our sales into the retail market,” he reasons.

“ You’re more versatile and more exible when you have di erent markets for your products,” Doiron says.

“I could de nitely use the VC999 equipment for the retail market. There would need to be some add-ons, but it could be used to do retail packs.

“For example, the one being used at Joe Smokehouse could be used for frozen lobster tails,” he says.

As for the Joe’s Smokehouse operation, Gautreau says he would like to take the brand nationwide eventually after solidifying his current position in local markets.

“Right now, we’re going to try and expand all over the province,” he says.

“In the last six months, we worked hard and diversi ed, trying to tap into markets we didn’t think we could or would.

“But now with our steaks, we can seal and deliver them right to your door,” he says.

machine and the rest is done.

“It’s a big cost, but it’s worth the e ciency to push out that volume that we needed to do,” says Gautreau, praising the machine’s ability to customize the packaging for the beef jerky products.

“We’re packaging 60 grams of meat, and we wanted to make sure it that it was the right-sized package,” he relates. “So VC999 did the plates, customizing it to what we need.

“We wanted a tear strip on the side, “ he says, “and they customized it to exactly what we needed.

“We also wanted to put labels on the packs, and VC999 again with the design to provide us with the kind of stickers we wanted to put on.”

Gautreau says he highly appreciates the operational versatility of the VC999 RS420c system.

“You use di erent plates and forms with the ma-

chine,” he says. “Smaller plates for jerky, but our bacon or steaks are bigger, so we put bigger plates on.

“It adapts to what we need: it’s pretty versatile.”

Running on a PLC (programmable logic controller) platform, the RS420c features stainless-steel construction, quick-change tooling, heavy-duty 5/8-inch Pitch K-Transport Chains, an expandable design to meet future growth needs, and free life-time technical support, according to VC999.

“The RS420c is an entry-level machine, but very versatile for when you want to grow.,” Cloutier says.

“We can add a lot of con gurations,” says Cloutier, adding that VC999 created all the di erent moulds to cover all of Joe’s Smokehouse’s products, as well as provide the plastic lm designed to provide longer product shelf-life.

Although VC999’s head o ce is in Switzerland, the

“Last year wouldn’t have even thought of doing that, but the market has changed, so we’re trying to take advantage of the situation and change the way we look at things.”

As for what kind of products will be produced next, Gautreau says he is always looking to develop new, unique and innovative recipes.

“To say what’s next, I’m not really 100-percent sure,” Gautreau acknoweldges.

“But in the meantime, we’ll just ride the wave and gure out what’s next for us,” he concludes.

“We’re just going to try and keep going as well as we’re going right now.”

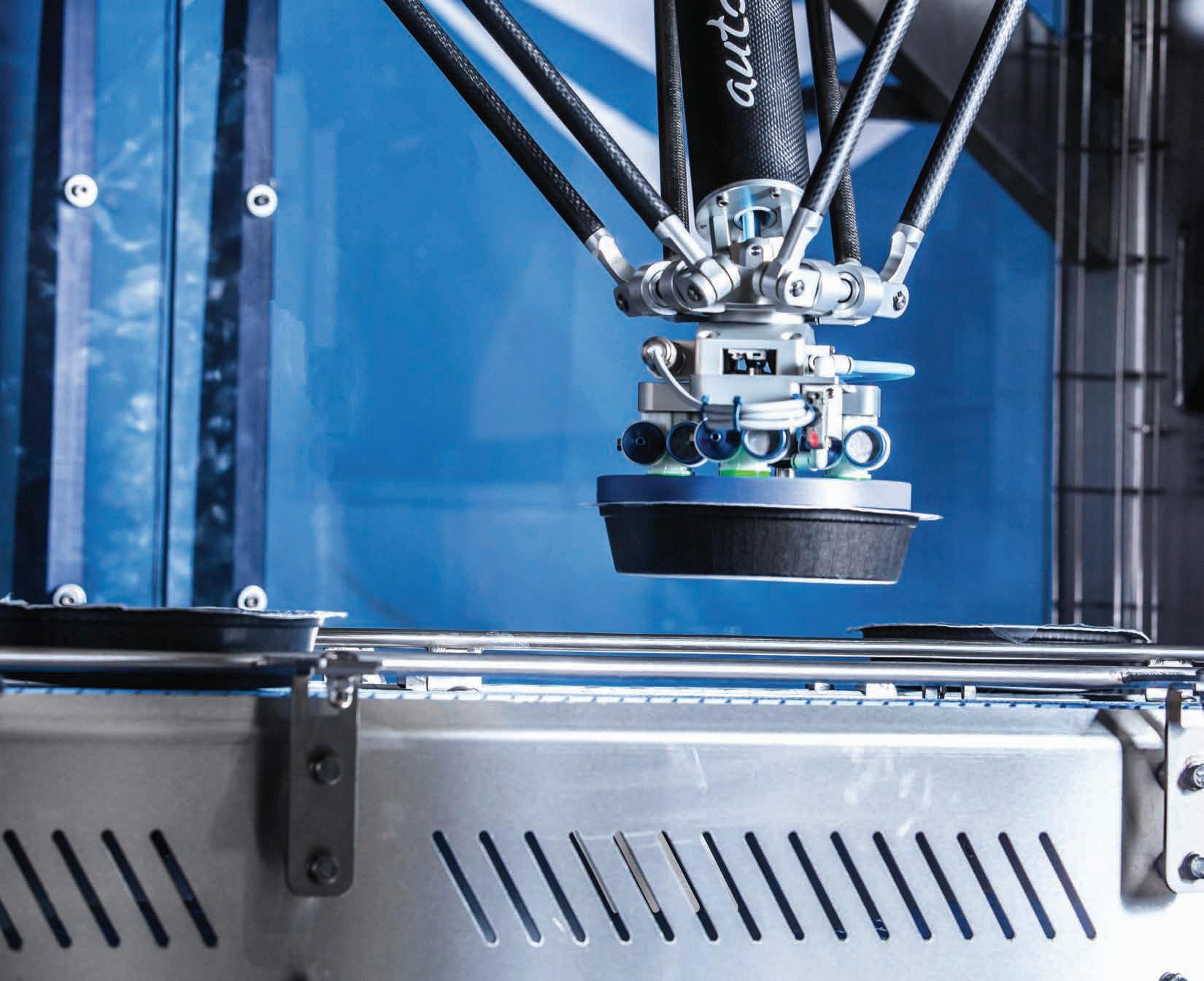

The lightline Pickerline consists of compact modules that are preconfigured and ready to use for standard packaging tasks. In this way the Pickerline is attractively priced and delivered in next to no time. With its individual robotic tools you will experience the benefits of the highest degree in flexibility with the innovative Schubert-Technology. www.schubert.group

LIGHTLINE PICKERLINE FOR PICKING AND PLACING PRODUCTS IN TRAYS

WestRock’s BoxSizer ® intelligent right-sizing technology is the only machine on the market that can right-size multiple preloaded box footprints arriving at random to the infeed without the need for changeovers. By ensuring optimal package size and eliminating void fill, this solution reduces labor, improves sustainability, and lowers your total cost.

Package variability. Solved.

Michigan craft brewer upgrades its IT infrastucture with leading-edge enterprise software to keep making big waves in the global marketplace

Headquartered in Grand Rapids, Mich., Founders Brewing Company is a globally recognized brewing enterprise that ranks as one of the 10 largest craft brewers in the U.S.

Considered to be one of the fast-growing breweries in the county, Founders Brewing has several beer brands listed in the Top 100 Beers of the World list, which is compiled each year by the global beer industry analysts at Beeradvocate.com

As the company continues its rapid growth, upgrading its IT (information technology) infrastructure up to demands of the new digital economy has become one of its top corporate priorities in recent years.

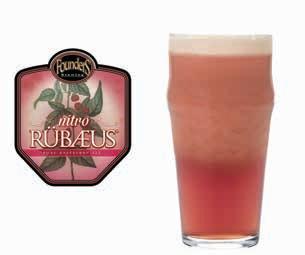

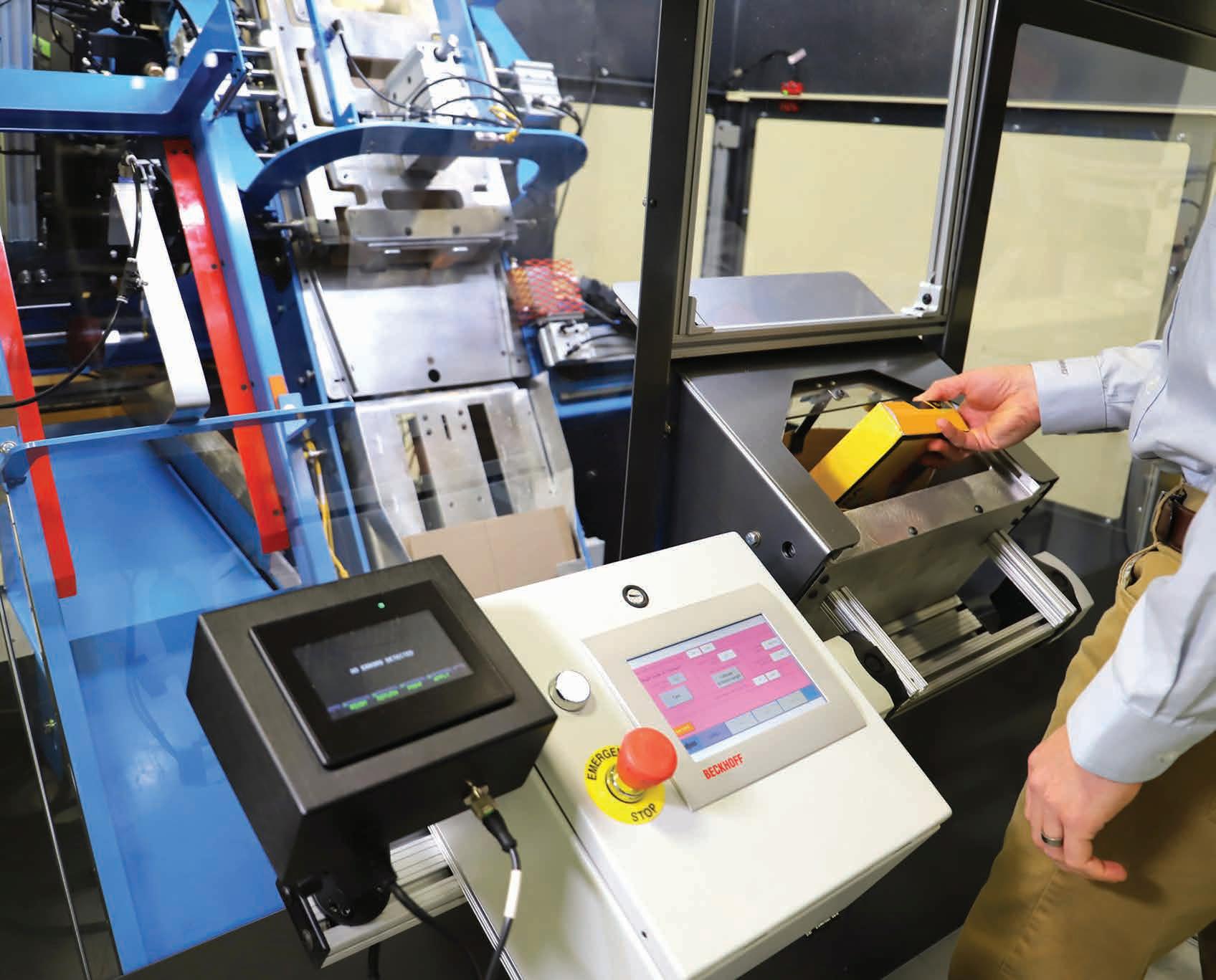

“As we grew and matured as a brewery, it was important for us to decrease our digital risk and increase the security and reliability of our most important software and network,” says vice-president of brewing operations Alec Mull, who turned to brewing automation experts at Process and Data Automation LLC, a Krones Group company, to carry out the required systems upgrades.

The project involved the integration of two isolated brewing control systems, referred to as “Gigantor” and “CombiCube,” which were operating at the facility.

While the Gigantor control system operated with a BOTEC F1 system license installed on two redundant servers and four clients, the CombiCube system was operating with a BOTEC Classic license installed on one server.

The upgrade would involve combining the two systems to allow an operator to control any portion, according to security credentials, from any HMI (humanmachine interface) terminal in the plant. According to Mull, this required merging the equipment and software currently used on the Gigantor process control system with that of the CombiCube control system.

To achieve this, it was necessary to create a system with two redundant virtual server pairs in separate locations with a virtual SQL server and several client machines. The still-ongoing project involves three phases, with the third to be completed in 2021, aiming at:

• Implementation of a virtualized system, BOTEC process data servers, and an SQL server to reduce risk.

• Upgrade from BOTEC Classic to BOTEC F1 and merge applications. In the past, the brewhouse has been running on BOTEC Classic, operating on an unsupported system without back-up.

By upgrading to BOTEC F1, which is in use at the company’s larger brewhouse,

Schubert North America has appointed Ana Pryor as new Director of Finance, effective July 6.

Previously, Ana worked at NorComp, Dhollandia and Groninger USA where she served as Controller and managed the finance and human resources departments. She will be replacing Schubert North America’s current CFO Sandra Chambers who will retire by the end of September. Sandra Chambers has played a crucial role in establishing Schubert North America in Charlotte and has significantly contributed to the company’s overall success.

e Schubert Group provides top-loading packaging machines that are easy to operate, flexible in terms of format conversion, high in performance and stable in function. e machines package products of all types in trays, cartons, boxes or flowwrap bags. e machines package products of all types in trays, cartons, boxes or flow-wrap bags. e business is headquartered in Crailsheim, Germany. e North America headquarters is Charlotte, North Carolina, USA.

schubert.group/en/schubert-north-america

and merging into one cohesive system, the brewer would able to control multiple areas of the facility, such as the 300-bbl (barrel) and 80-bbl brewhouses, or the cellar, from any of the server stations and/or client screens.

• Upgrade the visualization system (to be completed 2021) from Iltis V2 to Iltis WPF. The former is an older version of visualization and is not supported for new features on the BOTEC roadmap. In contrast, Iltis WPF uses open-format Windows standards and incorporates enhanced features related to trending, screen manipulation and troubleshooting issues.

Successful completion of the rst phase, focusing on migrating the process data server and SQL server to a virtual machine, provided several advantages, including:

• Reducing the time required the recover from hardware failures;

• Allowing periodic back-up of the virtual machines;

• Splitting the load across multiple servers to reduce redundancy;

• Creating a system that is controllable from any server location.