PRESSING THE POINT

Corrugated packaging stalwart leaps into the digital age Story on Page 17

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Oct. 23-25, 2023 Booth 2925

McCormick Place, South Hall Chicago, IL USA

info@heatandcontrol.com | heatandcontrol.com

Compact & Affordable Robotic Automation

COLUMNS

FROM THE EDITOR

6-8 Packaging news round-up.

&

10-11 Noteworthy industry briefs.

Sustainable packaging innovations.

15 A monthly insight from PAC Global

42 Upcoming industry functions.

42 Career moves in the packaging world.

ISSN 0008-4654. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2023 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada. DEPARTMENTS

COVER STORY

17 ABOVE BOARD

A new production-scale digital printing press enables venerable Toronto corrugated packaging producer to continue its trailblazing ways with commanding technological leadership.

FEATURES

25 Form and Function

West Coast manufacturer of tray forming equipment leverages advanced servo control technology for optimized machine flexibility and throughput.

31 The Future of Fiber

How paperboard packaging fits into the accelerating global shift towards the Circular Economy business model.

35 What Happened in Vega s

Recapping some of the most memorable highlights and talking points of the recent PACK EXPO Las Vegas packaging extravaganza.

4 George Guidoni

Why hammer policies are a wrong path to meaningful plastics reduction.

CHECKOUT

44 Julie Saunders

Joe Public speaks out on packaging hits and misses.

38 Show and Tell

A brief preview of the upcoming biennial PAC EX Toronto exhibition at the Toronto Congress Centre next month.

ON THE COVER

Anthony Memme, Andrew Tucker and Adam Pauwels of Atlantic Packaging Products strike a confident group pose in the reception area of the company’s Tiffield Road retail packaging plant in Toronto’s east end. Cover photo by Naomi Hiltz.

Why hammer policies to reduce plastic waste may be a waste of time

WEstimated share of the total volume of fresh produce sold in Canada that is pre-packed in plastic

ith demonization of all things plastic seemingly becoming a full-time occupation for public figures in government and activist circles, saying anything in defence of the one-time miracle material defense runs the risk of being branded a heretic or a climate change denier. That does not seem to bother Martin Gooch, chief executive officer of the Value Chain Management International (VCMI) think-tank in Oakville, Ont.

Well-known in industry circles for producing several authoritative reports on the economic and social impact of global food waste, VCMI’s fundamental position on the need for a cautious and largely voluntary approach to reducing plastic packaging solution may not be on-trend with the prevailing public opinion, but it does not mean that it should be ignored on principle outright.

Published in response to the latest consultation paper released by the Environment and Climate Change Canada Environment (ECCC) on August 1, 2023, as a starting point for a concerted reduction in the use or plastics for primary food packaging, VCMI’s long list of objections to the government’s appetite for heavy-handed regulation suggests that the journey to the Circular Economy for plastics in Canada will be anything but a stroll in the park.

In fact, the subtitle of VCMI’s Benefiting the Environment and Ecologies by Reducing Plastics Pollution position paper sternly proclaims that, “Plastic packaging hammer policies are not the answer.”

As the VCMI report argues from the outset, “One of the greatest risks facing industry today is well-intended though poorly conceived policies.

“Poorly conceived policies and the mechanisms required for their execution have the potential to worsen the issue(s) that they seek to address,” VCMI states.

While VCMI agrees with the overall aims outlined in the ECCC document, the devil is always in the details.

“In our opinion, detailed objectives published by ECCC in April and August 2023, particularly the latter, are unachievable and will lead to widespread unintended consequences,”VCMI proclaims,

warning about the dangers of exploiting the public’s newfound environmental awareness as a political ploy to boost the federal Liberal government’s sagging popularity.

“The challenge facing industry and consumers is that activists find hammer policies and regulations appealing because they create a false sense of effective action, for which they claim credit,” VCMI states.

“Due to the true cost of implementation and enforcement, and the expected benefits of implementing hammer policies and legislation rarely materializing, hammer policies and their regulatory mechanisms become a dead-weight loss on the national economy.”

To tone down the expected wrangling and strong-arming,VCMI calls for a more compromising discussion that takes into account some key principles:

• Policies must recognize the scale of the conflated relationships that exist between plastic pollution and GHG (greenhouse gas) emissions.

• ECCC urgently needs to establish constructive dialogue with industry on addressing plastic pollution, or else risk losing its credibility as an authoritative government body.

• The topic of plastic pollution cannot be viewed in isolation. Doing so will lead to widespread unintended consequences.

• The need for negotiated agreements is particularly critical in Canada’s federated system, where provinces and municipal governments can impede change initiatives by having implemented conflicting regulations and misaligned systems.

• Industry must be the driving force for change, with visionary leaders committing to achieve and be accountable for bold targets, and investing in the creation of harmonious pre-competitive solutions to address plastic pollution.

• Government-implemented policies, regulations and programs need to incentivize and assist industry to address barriers that have historically inhibited formation of circular packaging economies.

Your move, Ottawa, let’s hear it.

OCTOBER 2023 | VOLUME 76, NO. 8

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

President/COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2023 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

With MULTIPOND’s specialized approach our customer always gets the right MULTIHEAD WEIGHER customized for their specific product requirements. Whether your weighing confectionery, vegetables, frozen foods, fresh products such as cheese or meat, mixtures or non-food products, the Abbey Equipment team will make every effort to work with you to find tailored and optimized solutions.

New Coca-Cola creation offers a positive spin on the AI-powered future

While most of North American public is still processing how the rapid growth and deployment of AI (artificial intelligence) technology will affect their everyday lives, consumer brand-owners like soft-drink giant Coca-Cola are already using this highly disruptive high-tech to make their packaging and labeling more futuristic on every level.

Launched across Canada last month, the new limited-edition Coca-Cola Y3000 Zero Sugar

beverage is said to be the first futuristic flavor co-created with human and artificial intelligence in what the Atlanta-headquartered beverage producer calls a “celebration of an optimistic future through the connections we make.”

Available in individual 500-ml and eight-packs of 300-ml bottles, the new beverage features embedded AI-powered experience that will give fans an exciting perspective on what the year 3000 could look like by scanning the label.

Produced and packaged in Canada by Coca-Cola Canada

Bottling Limited, the new Y3000 Zero Sugar is the sixth limited-edition Coca-Cola flavor developed as part of company’s ongoing Coca-Cola Creations product development campaign, with the full-sugar version of the drink expected to be launched into the market later this year.

“Our ambition for Coca-Cola Creations is to create unexpected and magical moments for our fans,” says Oana Vlad, senior director of global strategy at The Coca-Cola Company

“Inspired by the timelessness of Coca-Cola, we want to celebrate everyone’s idea of what the future might look like,” Vlad says.

According to Vlad, Coca-Cola created the Y3000 experience by tapping into human and artificial intelligence to understand how fans envision the future through emotions, aspirations, colors and flavors, combining the fans’ perspectives from around the world with insights from AI to create the distinct taste of Y3000 beverage.

The new Creation features a futuristic packaging design

combining including light and optimistic, a Coca-Cola Creations logo composed of effervescent bubbles, and the Coca-Cola Spencerian Script font-face, with fluid dot clusters that merge to represent the human connections of our future planet.

As The Coca-Cola Company’s integrated marketing manager Solange Grimard relates, “After the label design was created by our global team and their partners, our design team in Canada worked on localizing it to reflect all local rules and regulations that we need to follow while keeping it light and fresh to stand out on shelf.

“To capture the futuristic feel and taste of Coca-Cola Y3000 Zero Sugar, the packaging showcases liquid in a morphing, evolving state, communicated through the silver base with light and optimistic tones including violet, magenta and cyan,” Grimard explains.

“Also, the Coca-Cola wordmark features a connected dot matrix with fluid dot clusters that merge to represent the human connections of our future planet.”

23_006941_CN_PCKG_OCT_CN Mod: September 6, 2023 9:16 AM Print: 09/13/23 page 1 v2.5

THE COPILOT GEMINI PRINTING SYSTEM

WIDE RANGE OF SUBSTRATES

The CoPilot Gemini utilizes oilbased, solvent-based, or UV curable inks for printing on a wide range of porous or non-porous substrates.

MORE PRINT HEIGHT

With a massive 5.6” of print height and print speeds up to 220 ft/min, the CoPilot Gemini provides a cost effective solution for making your mark on a wide variety of products and substrates.

HI-RESOLUTION

PRINTING

Squid Ink’s proven inks and fluids print hi-resolution characters, razor-sharp text, scannable bar codes and great looking logos at up to 360 dpi. A coding and marking leader for over 25 years, Squid Ink printers and inks are made in the USA and are designed to keep your production line up and running day after day. For more information, visit www.squidink.com or call 1-800-877-5658 for an Authorized Squid Ink Distributor in your area.

packaging operations and optimizing efficiency,” says John Ashby, president of London, Ont.-headquartered Crawford Packaging. “The Automation Experience Centre will empower our customers to witness firsthand how these technologies can revolutionize their businesses and provide them with a competitive edge in the market.”

During their visit, invited customers eagerly took advantage of the opportunity to spend quality me with Crawford’s Packaging experts, engaging in insightful discussions and receiving personalized recommendations on how to enhance their business.

A new packaging facility to help tackle plastic waste

Taking direct aim at plastic packaging pollution, the federal government made a strategic $3.7-million investment earlier this year to enable Guelph, Ont.-based Omnia to purchase new equipment to make 100-percent compostable and recyclable paper trays, as well as 100-percent recyclable plastic trays, for the Canadian food industry. This substantial investment was fittingly showcased last month with the grand opening of Omnia Packaging’s brand new production facility, marking a significant milestone for Omnia’s Italian-based parent

Says Omnia Packaging’s chief executive officer Paolo Sunino: “We are committed to leading the way in innovative, sustainable

AstroNova unveiling a range of new digital printing solutions at Printing United Expo

By Mohit Bhushan

AstroNova, Inc. (NASDAQ: A LOT), will showcase an array of new digital printer products at the upcoming Printing United Expo in Atlanta, Georgia, October 18-20. The company offers a range of digital label printers, compact presses, and direct-to-package printing equipment under its flagship product brands –QuickLabel® and TrojanLabel®. It also offers a variety of blank label materials through its GetLabels® brand under its total solution approach to cater to the needs of brand-owners and print shops for in-house label production. The company also provides custom design and manufacturing solutions for a range of well-known envelope and label printer brands active in the printing industry.

QuickLabel QL-900

QL-900 is a rugged desktop inkjet label printer designed for full-color labeling applications. Manufactured

at the company’s newly acquired facility in Chicago using proven inkjet technology, the QL-900 enhances AstroNova’s expertise in providing the total printing solution, including supplies such as exclusive supply purchase programs, ongoing technical support, and a variety of label materials and substrates. The QL-900 provides a step up in usability and flexibility in the desktop QuickLabel range, featuring a built-in touchscreen interface, which includes a built-in job library, support for external RIP solution, and visual status of the printer locally (without needing an additional s/w utility installed on the host). The stand-alone capabilities offered through its touchscreen interface and internal job library enable users to manage printer setup and print operation easily.

TrojanLabel T2-PRO

The all-new T2-PRO is the company’s latest addition to its TrojanLabel brand of compact

digital label presses targeted toward industrial and professional printing segments. It incorporates Memjet’s Duraflex technology to offer a print width of 12.75” (324 mm) with a high print resolution of 1600x1600 dpi using highly durable aqueous CMYK pigment inks. Its compact footprint (under 40” wide and 59” long) makes it an ideal roll to roll machine for any size print shop and label converters. It can print on a continuous or pre die-cut media and handle industrial-size label rolls (330 mm wide with 600 mm OD). Setting up is quick and easy; a short media path and long-lasting printheads result in a much superior cost of ownership across all available aqueous inkjet technologies in the market. A high-capacity data pipeline supports real-time variable data printing to support serialization and customization needs.

TrojanLabel T3-PRO

T3-PRO is a compact CMYK digital print module, directed toward OEMs looking to easily integrate a print station into conveyors or transports to offer fullcolor digital printing solutions for envelopes, corrugated or paperboard printing segments. Using Memjet’s DuraFlex inkjet technology, it offers the capability to print as wide as 12.75” (324 mm) in full color at a top speed of 30 ips (46 m/min).

VF-280 Commercial Vacuum feeder

VF-280 is a high-speed commercial vacuum friction feeder, designed to handle a variety of materials like bags, envelopes, heavy card stocks, corrugated cardboard, jewel cases, calendars, and sheet stocks. At Printing United, AstroNova will showcase the VF-280 integrated with the TrojanLabel T3-OPX, a modular direct-to-package postprinting system that enables highquality, full-color printing directly onto materials with ink-receptive surfaces. The T3-OPX and VF-280 combination boosts the benefits of digital CMYK printing with flexibility, accelerated time to market, and waste reduction on sustainable and popular paperbased packaging substrates.

AstroNova will be exhibiting these products, alongside their broad range of digital label printers, envelope printers, and direct-topackage printing solutions at Printing United Expo in Atlanta, GA, October 18-20. Stop by booth B19045, for a live demonstration and more information. Visit www. astronovaproductid.com or contact your sales representative for more information.

London, Ont.-based packaging distributor Crawford Packaging has entered into a partnership with the U.K.-based labeling technologies innovator Ravenwood Packaging Ltd for the distribution of Ravenwood’s Nobac range of linerless label applicators and linerless labels through Crawford’s its product lin-eup. According to the companies, “This strategic partnership provides businesses with access to advanced linerless label technology, improving their packaging operations while promoting sustainability.” Engineered to run a wide range of formats and trays on a single machine, the high-speed linerless applicators use linerless labels with no release liner—resulting in substantial reduction in environmental impact, while accommodating up to 40 per cent more labels per roll than with

traditional labels. “We are delighted to bring Nobac label applicators and linerless labels to the Canadian market through our partnership with Ravenwood Packaging,” says Crawford Packaging president John Ashby.

“The linerless label technology offers tremendous benefits for a broad range of applications, providing efficient labeling solutions while reducing waste and improving sustainability efforts.”

The new Endress+Hauser Customer Experience Centre facility in Burlington, Ont., officially opened up last year, has added the vaunted global LEED (Leadership in Energy and Environmental Design) Gold certification to its growing list of achievements and accolades as a pace-setter for new sustainable design and construction. Housing a full-scale Process Training Unit (PTU), state-of-the-art Factory Acceptance

testing and calibration labs, and multi-purpose training and office areas, the 47,000-squar-foot facility had earlier attained ZCB Certification in 2022 for achieving zero carbon operations. According to Endress+Hauser, a global leader in measurement instrumentation, services and solutions for industrial process engineering, the building generates more energy than it consumes, with surpluses delivered to the Burlington Hydro grid. “Within the global Endress+Hauser Group, the Customer Experience Centre stands out as a shining example of what industry can achieve in green facility design and operation,” says Anthony Varga, general manager of Endress+Hauser Canada. “We were encouraged by the senior leadership of Endress+Hauser to set very ambitious sustainability goals for this project to set an example for others, inside and outside the company, to emulate.”

Industrial automation technologies supplier Emerson has completed the acquisition of Afag Holding AG, a prominent Swiss-based global supplier

of electric linear motion, feeding and handling automation solutions for industrial application in industries such as packaging, electronics, pharmaceutical and battery manufacturing. According to St. Louis, Mo.-headquartered Emerson, the acquisition will significantly enhance its factory automation portfolio by combining Afag’s electric linear motion solutions with Emerson’s pneumatic motion technology. “Afag brings exciting technology that will enable Emerson to accelerate growth in our existing US$900-million factory automation business,” says Emerson’s chief operating officer Ram Krishnan. “As discrete and hybrid customers continue to accelerate electrification across their manufacturing processes, Afag’s technology is ideally suited to provide improved energy efficiency and performance gains.”

San Francisco, Ca.-based OSARO, developer of machine-learningenabled robotics for e-commerce, has formed a partnership with leading robotics manufacturer FANUC America to expand the capabilities of FANUC’s robotic automation solutions

Conveyor Models

optimized for warehousing and e-commerce fulfillment. The two companies will collaborate on go-to-market strategies, commencing with the installation of an advanced piece-picking demonstration robot at FANUC’s Innovation Center in Rochester Hills, Mich. According to OSARO’s chief executive officer Derik Pridmore, “By collaborating on engineering and business development, FANUC and OSARO will be able to deliver the industry’s most advanced robotic automation solutions across the e-commerce fulfillment center—from incoming inventory depalletizing to outbound kitting and bagging. We look forward to expanding the market in collaboration with FANUC’s experienced team.”

Hantsport, N.S.-headquartered sustainable packaging group CKF Inc. has unveiled a new production line at the company’s manufacturing facility in Langley, B.C., dedicated to production of the award-winning Earthcycle range of certified homecompostable and recyclable food packaging made from thermoformed molded pulp. (See bottom picture)Equipped with advanced servo-actuation technology, the new Earthcycle production line will create 20 new full-time jobs at the Langley factory, which currently employs 325 of the company’s 1,100 employees at eight plants, six of which are located in Canada. “Earthcycle’s expansion in Langley is driven by rising demands for packaging that reduces carbon footprints, aligns with recycling streams, and satisfies consumers’ desire for sustainable options,” says CKF president Ian Anderson. “Langley’s strategic location near major markets in California, the Pacific northwest and western Canada, coupled with access to global trade routes, strengthens our

production capabilities and also serves as a hub for further Earthcycle innovation—expanding the product line into new market applications.”

Durst Group, global manufacturer of large-format digital printing and production solutions, has acquired Aleph SrL, Italian-based pioneer in sustainable digital solutions and consumables for textiles and interior and exterior decorations. According to Durst, the acquisition further enhances the company’s position in water-based and sustainable printing technologies, while serving as a strategic bridge to Como, acknowledged as Italy’s epicenter for textile design and high-quality decorative applications. “We are delighted to welcome Aleph into the Durst family,” says Durst Group’s chief executive officer Christoph Gamper. “Their expertise in sustainable, water-based applications, their software for high-end textiles, and their creative solutions for water-based poster printing align perfectly with our vision of pushing the boundaries of digital printing technology,” Gamper states. “Together, we will strengthen our market position, expand our product portfolio, and enhance value for our global customers.”

Swedish-based labeling equipment group Evolabel AB has commenced operations of its new Evolabel Inc subsidiary in Atlanta, Ga., to expand the company’s advanced print-andapply labeling solutions into the North American market. “We’re incredibly excited about this new venture,” says Mattias Ackers, chief executive officer of Evolabel AB. “Establishing Evolabel Inc is a testament to our unwavering commitment to availability and satisfaction,” Ackders states. “With a team of experts in place and a full suite of resources at our disposal, we will be able to provide innovative labeling solutions that align with the unique needs of North American businesses.”

produce it, process it, pack it or move

finance it. Partner with the only lender 100% invested in Canadian food. And that includes businesses like yours. Let’s talk and see how we can keep you moving forward.

Closing in on closures

Greener

closures enabling global brands to achieve sustainability targets and unlock growth

potential

By Raphael Grange

Packaging is an integral part of every brand’s success. Along with product formulation and brand equity, functional packaging helps consumers connect with brands and create unique product preferences.

Creating innovative dispensing closures to help brands stand out, reshape market categories and deliver on consumers’ convenience and safety has been Aptar Closures’ history for more than 75 years.

During the last decade, we have been thoroughly investing in building deeper expertise and partnerships to stay ahead of the increasing demands for sustainable solutions and address the current and upcoming sustainability standards and legislation in every region of the world.

With that, our goal is to provide brands with ongoing and distinct opportunities to transform markets with breakthrough sustainable packaging solutions.

We collaborate with multiple industry partners and with many of the leading sustainability-focused organizations, such as the Ellen MacArthur Foundation, to create dispensing closure solutions that integrate world-class sustainability principles. This, in turn, helps advance our collective progress toward building a safer, healthier, more sustainable future.

Two critical goals we share with many global Consumer Packaged Goods (CPG) brands are to achieve fully recyclable packaging and to incorporate recycled content in packaging by 2025.

To that end, as a company, at Aptar we are committed to bringing to market 100-percent of solutions that are reusable, recyclable or compostable, and to achieving 10-percent recycled content for our dispensing solutions by 2025 within the personal care, beauty, home care, food and beverage markets.

A critical facilitator of sustainability efforts is staying ahead of and up to date with trends in materials – both sourcing and the creation of the most effective materials for

the manufacturing of our closures.

This includes proactively removing unnecessary materials from the manufacturing process; using recyclable and recycled materials where possible; staying abreast of the latest recycling, composting and waste management trends, and more.

Our product sustainability experts and product developers are continuously working to refine our material selection process to ensure we are using the best materials and the most sustainable manufacturing approach possible—a landscape that is changing daily.

Our goal is to ensure that our customers worldwide can continuously rely on us as a partner for solutions that meet their current and upcoming needs.

We rely on a team of highly skilled experts to prioritize solutions that enhance plastic circularity and meet the demands of convenience, safety, shelf appeal and a superior consumer experience.

One of our notable efforts towards sustainability is our SimpliCycle recyclable flow control valve.Made from a low-density material (density<1), the valve floats during the recycling sorting process, allowing it to be easily separated from the polyethylene terephthalate (PET) stream and then recycled right along with the polypropylene (PP) and polyethylene (PE) olefin stream.

When assembled into an Aptar closure, SimpliCycle creates a fully recyclable solution for use with PET, PE or PP containers, enabling brands to achieve their fully recyclable packaging goals.

The SimpliCycle recyclable valve has received two prestigious awards: the Best CSR/Sustainability Initiative by the World Food Innovation Awards (WFIA) in 2021, and a Packaging Innovation award by the World Packaging Associ-

ation (WPO) in 2022.

It also received Critical Guidance Recognition from the Association of Plastic Recyclers (APR) in North America, a recognition that acknowledges technologies or packaging components that aim to solve long-standing problems in sustainable package design.

Moreover, SimpliCycle has been assessed by third parties in Europe, such as Cyclos and RecyClass, confirming its compatibility with the readily available sorting and recycling sectors in the region.

All of Aptar’s products are designed with the people and our planet in mind, including Maestro, a dispensing closure developed for the edible oil market. The Maestro is a fully recyclable solution, with a tethered cap and a non-detachable tamper evidence system to increase the likelihood that all parts remain together through the recycling stream. It is a lightweight and recyclable solution that is mono material when paired with HDPE tubes, helping brands reach their goal of fully recyclable packaging.

We are continuously looking for ways to reduce

weight and eliminate or minimize the use of additional materials that contribute to plastic waste, such as liners and shrink wrappers. Slide, our newest linerless development for the sauces and condiments market, features a non-detachable tamper evidence system which allowed us to eliminate the need for a non-recyclable foil liner.

With Slide, the consumer can access their product with one opening gesture, delivering a convenient and memorable packaging experience while still protecting product shelflife and reducing the potential for product tampering.

As a result of the expertise and creativity of our engineers and product managers, we have been able to deliver highly innovative solutions to the market.

For example, Aptar Closures and Unilever have recently partnered with Ecological Group, a Brazilian waste management and recovery company, to collect and recycle biaxially-oriented polypropylene (BOPP), a flexible plastic film material, and turn it into a post-consumer recycled resin that can be used to manufacture PP closures. These materials, that would previously have been sent to landfills, can now be collected and directed to a resin supplier, who applies the processing steps of grinding, washing, gas extraction and more to create a novel type of plastic resin pellets. These pellets are now used by Aptar Closures to produce closures for TRESemmé hair-care product lines.

The world has recently seen a major push to increase plastic circularity coming from brands, consumers and legislators worldwide, sustainable innovation is by no means a new focus for Aptar.

We have historically focused on leveraging innovation to create solutions that improve convenience and safety while keeping the people and our planet in mind.

In 2019 we partnered with Ecover, the European market leader in sustainable formulations for household cleaning products, to launch the first dispensing closure in Europe made from 50-percent post-consumer recycled (PCR) resin.

The launch of the custom flip-top closure in PCR resin for Washing Up Liquid products made it one of the first major brands to use PCR resin in its bottles and dispensing closures in Europe.

Since that important milestone was achieved, we have been serving multiple personal and home-care brands with PCR closures in the region.

RAPHAEL GRANGE is president of global market development at Aptar Closures in Crystal Lake, Ill.

February 5 & 6, 2024

New York City

Don’t miss this intimate, prestigious gathering that spotlights Futures Edge global leaders and best practices in package design and innovation.

Summit highlights:

Design Intelligence, Dawn of a New Era: Dive into the fascinating world of Artificial Intelligence with Adobe and four global design agencies.

Co-Creation with Brands: Explore the power of collaboration between brands and technology experts to co-create digital customized printing solutions that resonate with consumers on a personal level.

ESG and Philanthropy: Gain insights from European leader Kellogg’s as they share their ESG strategies and philanthropic approach.

Packaging that Tells a Story: Journey with iconic brands Colgate and Hello as they reveal how package design can be a compelling storytelling tool.

Celebrating Student Design Excellence: Be inspired by the future of packaging accessible design as we celebrate the talented winners of an international student package brand design competition, sponsored by Kellogg’s. Witness their creativity and innovation firsthand!

PAC Global Awards Celebration: This event will feature the celebration of the worlds best package design, innovation, sustainability and accessibility. The PAC Global Awards recognize and honor the trailblazers of the industry.

Networking: Don't miss this opportunity to network with industry experts, gain invaluable insights, and celebrate excellence in packaging design.

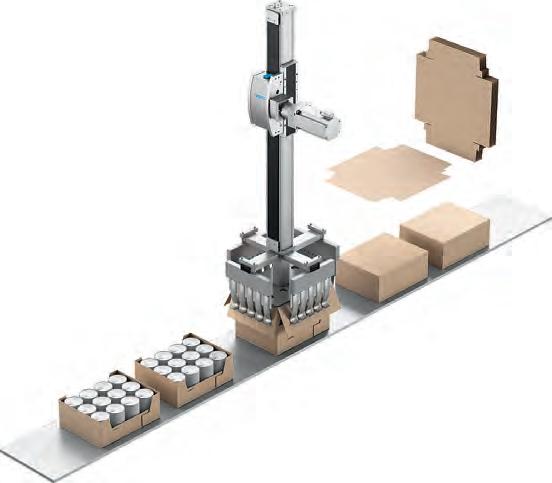

Profiting by upgrading old case packer designs with electric automation

Breathing new life into an old case packer has never been easier, from both a dollar and good sense perspective. Almost every process in an older design from formatting through loading and palletizing can be upgraded using the latest electric automation (EA) technology. It can be done incrementally and cost-effectively, adding productivity-enhancing functionality or simplifying a task for greater reliability with less wear and tear, even potential labor and energy savings.

For OEMs, giving a dated model a makeover can launch a new variant or options with a relatively small engineering investment.

Upgrades can be offered as retrofit packages for machines in the field. Case packers are meant to last for decades. The role of boxboard and corrugated packaging isn’t about to change. For many end users, targeted retrofitting is a better economic move than buying a new machine to keep fulfilling the same orders.

Over the last decade, EA technology has continued to improve while its inflation adjusted cost has declined, making incremental upgrading a better proposition than it might have been in the past. Upgrading can automate manual functions or substitute more capable EA tech for old pneumatic or electromechanical systems. Instant format changes are possible, often just a one-touch recipe on the HMI. A retrofit also can deliver greater throughput or eliminate low-value uses of staff overseeing the streaming of boxes and product for loading. Auto -

mation is an elegant workaround for labor shortages and can make small-batch production or just-in-time order turnaround truly feasible.

Manual reformatting a case packer for container or product changes is time-consuming and error prone. And much of the tribal knowledge of experienced hands is going with them into retirement. Employing the latest compact, low-energy servo technology like Festo’s CMMT drives with incremental encoder and EMMT motors to replace hand cranks and manual adjustment wheels assures exponentially faster changeovers with consistently accurate positioning. Festo’s inexpensive, easy-to-commission Simplified Motion Series actuators are ideal for single lanes requiring constant width changes or for marshalling box and product streams.

For other processes, substituting the latest EA for pneumatics can increase throughput and reliability, with fewer positional or time-based errors. Compared to pneumatics, Festo EA solutions can boost cycle times, and improve reliability. They require less maintenance, run more smoothly and provide higher dynamic performance.

For case/carton/tray erecting, an all-EA process is faster than pneumatics or the difficult-to-synchronize combinations or electrical, pneumatic and mechanical system often employed in older designs. EA increases reliability and is easier to maintain. For the loading function, 2D or 3D gantries like Festo’s EXCT perform as well as Delta or articulated robots and are clearly cheaper for small and medium-sized loads in particular. For the closing, sealing and

compression functions, EA solutions can cost a bit more than pneumatics, but offer a faster payback, measured in greater uptime and flexibility – like faster format changes – and potentially faster line speeds with lower air consumption.

For loading and palletizing, an articulated or Delta robot often proves to be an over-investment. The right Cartesian gantry – correlating with payload and safety requirements – is easier to size correctly and commission. A single, compact Festo CPX-E controller can control the interpolating motion performed by multiple gantries, as opposed to the larger controllers needed to manage multiple articulated robots.

All functions in an old case packer can be improved using EA technology. Festo’s e-book “Power Up with Electric Automation Solutions; Upgrading case packer designs through incremental change”, will help you identify and evaluate these and other upgrade opportunities, stage by stage, with the optimal solutions from Festo’s extensive EA portfolio. scan here to download the free eBook

Upgrade your case

left: Atlantic Packaging’s Adam Pauwels, Vice-President of Sales, Corrugated Division, Ontario; Anthony Memme, Digital Print Manager; Andrew Tucker, Vice-President, Specialty Group, in the reception area of the company’s Tiffield Road plant.

ACROSS THE BOARD

Venerable corrugated packaging manufacturer setting a high bar for digital printing excellence with new cutting-edge press technology

By George Guidoni, Editor

Photos by Naomi Hiltz

With digital printing press technology improving in leaps and bounds at a relentless pace, making

a massive capital investment in current state-of-the-art digital printing technology is always fraught with the risk that it can become obsolete long before its anticipated best-before date—making a meaningful ROI (return-on-investment) a highly elusive target.

And as more and more paper packaging producers and converters are swayed to invest in digital printing by

customers’ demands for more customized, personalized and higher-quality packaging graphics and more sustainable products, it is a challenge faced by a growing number of packaging suppliers, with corrugated boxboard producers no exception.

Happily for the Toronto-based Atlantic Packaging Products Ltd., astute capital investment and keen understanding of the customers’ needs and market trends are very much near the top of the many core competencies that the privately-owned corrugated packaging producer has skillfully mastered over the last 78 years to become a major player in the North American market for corrugated boxes, trays, re-

From

tail-ready packaging, merchandising displays and many other paper packaging solutions demanded by a growing base of brands and CPG (consumer packaged goods) producers looking to improve their sustainability profiles and credentials.

Nowadays operating 22 manufacturing and converting facilities in Canada and the U.S., the company has recently reaffirmed its long-standing credentials as the corrugated industry’s technology leader with the arrival of a gigantic

six-color Delta SPC 130 digital printing press manufactured in Austria by Koenig & Bauer Durst GmbH—a joint-venture company formed in 2019 by Koenig & Bauer , the world’s second-largest printing press manufacturer, and Durst Group , a leading global supplier of digital printing technologies.

Skillfully combining the advanced, best-of-breed technological capabilities and attributes of both joint-venture partners, the new Delta SPC 130 digital

Clockwise

A look inisde the hybrid drying section of the Delta SPC 130 digital press commissioned by Atlantic Packaging; a close-up of the freshly printed corrugated sheets passing through the drying station; manufactured at a Durst factory in Austria, the six-color Delta SPC 130 digital press measures about 50 meters in length.

press has been quickly fulfilling its promise as the proverbial industry “game-changer” since being commissioned at the company’s Tiffield Road retail packaging facility in Toronto’s east end in June of this year.

Measuring about 50 meters in length, the new Delta SPC 130 is the first six-color digital corrugated printing press installed anywhere in Canada, according to Adam Pauwels, vice-president of sales at Atlantic’s Ontario Corrugated Division, and only one of four such presses currently operating in North America.

“We expect this new press to become a real workhorse for us going forward,” Pauwels told Canadian Packaging on a recent visit to the Tiffield Road plant.

“We did this for our customers so that they had a cost-effective way to get new products to market without costly printing plates and the need to commit to labels or pre-print rolls which leads to obsolescence,” Pauwels states.

“Our customers needed a quicker way to market, and digital was the solution.”

As Pauwels reveals, “Right now we are still focused on educating many of our customers to understand the full bene-

fits of this press.

“Being a truly disruptive technology, it will take time for the market to fully embrace it,” he acknowledges, “but based on the jobs we have run on it so far, we know our customers will be open to moving more and more of their jobs onto this press once they realize all the possibilities it opens up that were not available before with the traditional printing processes.”

As Pauwels remarks, “Digital printing has become more and more commonplace in Europe, where they tend to be early adopters of digital technologies of all kinds, but we are convinced that once the Canadian market fully understands it, it will grow in a big way in Canada as well.”

While earlier generations of digital press technologies have provided an adequate alternative for creating packaging prototypes and handling smallrun production by offering unprecedented levels of graphic design flexibility—notably in label and folding-carton production—the new Delta SPC 130 press represents a profound technological leap by combining superior print quality of up to 800-dpi (dotsper-inch) resolution with commercial-scale running speeds of up to 120 meters per minute, making it a perfect fit for the vast multitude of medium-volume production runs (up to 20,000 sheets) accounting for a large part of the company’s orders.

Considering the significant capital investment involved in acquiring and installing such a sophisticated piece of machinery, Atlantic Packaging spent

Clockwise from top right

The SPC 130 digital press employs high-precision Durst Quadro Array printheads equipped with hundreds of tiny spray nozzles to print in up to 800-dpi resolution.

Overhead views of the Delta SPC 130 six-color press that can run up to 150 meters per

about four years carefully evaluating the available technologies in the marketplace before settling on the Durst six-color press, according to the company’s digital print manager Anthony Memme.

“We really put the suppliers through the wringer with all the graphics trials, production trials and visits to their customers,” Memme recalls, “but we found that most of the existing technologies at the time were better-suited for making displays rather than retail or food packaging.

“The print quality wasn’t quite up there, the speeds were too slow, and getting the thicker corrugated boards from one end of the press to the other in

one smooth pass seemed to be a real challenge.

“So we waited a little for the technology to catch up,” Memme says, “and luckily for us there have been some significant gains made in both quality and speed in the last couple of years to justify our large investment in digital corrugated printing.

“The mechanics have improved greatly, along with big advancements in software, the feeding section, inspection, defect rejection and so on,’ he says, “but the big thing for us is the modular design of this Durst press.

“It’s not just one long, hulking piece of metal,” Memme states. “Being modular allows us to upgrade the press in step

Right

The Delta Control Station for the Delta SPC 130 digital press features a large worktable to help facilitate optimal quality control and proofing for the press operators for any size of sheet.

with whatever future technological advancements come down the line by replacing the print section, for example, or updating the primer section, or enhancing the feed section.”

For Atlantic Packaging, which prides itself on its sustainability track record, being able to user water-based inks on the SPC 130 press was also a major factor and selling point in its final equipment selection.

“Water-based inks is one of the biggest things to happen in the market for digital printing,” says Memme, “because the absorption and the drying of waterbased inks on corrugated boards is a fairly complex process at high speeds.”

Adds Pauwels: “Using water-based inks enables us to live up to our environmental goals and standards, as well as to ensure safe food contact and no odor.

“Moreover, the digital printing press does not use any printing plates, so there is no need for any cleaning chemicals or wastewater from cleaning the plates, which is all bad for the environment.”

In addition to widening the traditional CMYK color gamut with the addition of orange and violet, the SPC 130 press also includes an additional inline primer section to create ultra-vibrant colors directly onto uncoated corrugated in smooth single-pass process.

According to Durst, the SPC 130 press combines a well-engineered mechanical

Top Left

A stack of finshed produce trays featuring fullboard, high-definition graphics created on the Delta SPC 130 digital press.

Top right Memme, Tucker and Pauwels assessing the finishing quality of a freshly printed corrugated sheet.

design with easily accessible sub-assemblies and selected components to guarantee durable quality, high performance and reliability, along with Durst’s dropon-demand printhead technology, a non-hazardous ink system, and an efficient IR/UV drying process designed for high productivity.

Configurable with up to six colors, the press can print any length of corrugated cardboard up to 110-inches (2,794-mm) wide or paper media of up to 12-mm in thickness, while offering optimal versatility, low maintenance requirements and 24/7 dependability.

The Delta SPC 130 is equipped with recirculating Durst Quadro Array printheads and water-based, odor-free WT inks for production of high-quality,

indelible, glossy and non-fading end products in a single-pass process.

The production process on SPC 130 begins at the feeder section, which is a fully-automatic, non-stop feeder with integrated cleaning station, built-in detection of damaged sheets, and automatic sheet ejection.

Once inside, the sheets move through the priming section for optional digital pre-treatment of coated or uncoated material and on to the hybrid dryer, which combines thermal drying with IR (infrared) and hot air to ensure durable high adhesion on coated fiber-based materials without pre- treatment, whereby the thin coating layer and high adhesive friction of the ink surface prevent the stack from shifting.

“Using water-based inks enables us to live up to our environmental goals and standards, as well as ensure safe food contact and no odor.”

After passing through the single-pass printer section, where thousands of tiny inkjet dispensing nozzles deposit tiny droplets of water-based inks onto the surface, the boards move on through the quality inspection station to inspect any errors in the printing process, and on to the cooling station, before arriving at the fully automatic stacker at the end of the line, featuring integrated ejection of waste sheets from the final stack.

The entire process is centrally controlled and monitored from an elevated, ergonomically-designed Delta Control Station platform equipped with all the state-of-the-art features and accessories required for simple, clear, comfortable and central operation of the digital Durst single-pass printing line, including:

• Worktable for a 280X130 centimeters sheet size for quality assessment, profiling and color checking;

• Camera server for clear monitoring of the printing line;

• Two 55-inch monitors for quality control, workflow monitoring, camera view, and ERP (Enterprise Resource Planning) system networking;

• One 32-inch touchscreen control terminal;

• Matrix screen control for customer-specific, freely selectable assignment of the monitors;

• Pull-out leather seat arm for machine operators;

• Additional interface for color

measuring devices for profiling and color checking;

• Six lockable compartments for machine operators, including the cellphone charging option;

• A signal lamp to display the printer status.

All in all, the SPC 130 press offers all the main advantages of the digital print press process in terms of design flexibility and variability, exceptionally fast changeovers, color stability, onthe-fly adjustments and design changes, and a virtually zero-waste, zero-scrap process that is totally in line with Atlantic Packaging’s sustainability mindset, according to Memme.

“Our customers not only love the print quality we get with this machine,” he states, “but also the consistency of it, whereby we can digitally trap that color consistency from sheet to sheet.

“The big advantage for our customers with digital is that if they want to do a run of seasonal or promotional packaging, we can just add a pop of color of some different graphics on the selected sheets and insert it the middle for a regular production run, without interrupting the process.

“It allows for the level of customization and individualization that was just too cost-prohibitive before,” Memme says. “Hence it opens up a whole host of opportunities that were not available with earlier digital print technologies.

“For someone who has been

Adam Pauwels cheerfully shows off the vibrant colorful graphics created by the Delta SPC 130 digital printing press on corrugated board fresh produce trays using food-safe water-based inks.

MORE THAN YOUR AVERAGE PAPERBOARD

UP TO

REDUCED WEIGHT VS. CONVENTIONAL ALTERNATIVES

MetsäBoard Pro FBB Bright is up to 35% lighter than conventional paperboards, while retaining the same quality and rigidity.

metsagroup.com/metsaboard

A freshly printed stack of corrugated sheets coming off the Delta SPC 130 digital press is ready for pick-up and delivery to customer.

living in print for most of my working life, I never thought that digital printing for corrugated would arrive as quickly as it has,” Memme acknowledges.

“So the fact that the quality that we can get off this press, at the speed that we can get it off this press on a corrugated sheet, is really mind-blowing, really unbelievable,” he remarks.

“For me, the biggest ‘Wow factor’ about digital printing is how quickly the technology has caught up with our requirements in the relatively short time since we started out on our digital journey,” Memme remarks.

To maximize its digital investment, Atlantic Packaging has invested significant time and money to train its operators and maintenance staff on the machine, with Durst supplying much of that training right on-site at the facility.

“The technology itself is fairly user-friendly,” says Memme, “with a pretty intuitive workflow and user-interface.

“Of course, it is different from regular printing with a flexo press, let’s say, where you need to set up the tooling and the pressure levels, while constantly monitoring and adjusting all your ink levels with mechanical knobs.

“Everything on this press is done through a computer interface,” he points out, “so it requires a somewhat different mentality for our operators.

“They need to be really computer-efficient to run and troubleshoot this press properly.”

For Andrew Tucker, vice-president of the company’s Specialty Group business, the successful commissioning of the SPC 130 digital press is a very gratifying outcome of a lengthy equipment evaluation process in which he played an instrumental part during the earlier stages.

“When digital became the big new buzzword several years ago, everyone wanted to get in on it right away, with customers demanding the flexibility, the

The reception area of Atlantic Packaging’s Tiffield Road plant features a graphic historical retrospective of the multiple memorable milestones and accomplishments achieved by the family-owned company over its 75-year history.

quick response time, the quick turnaround time, and all the other cool features promised by digital printing,” he recalls.

However, the technology available at the time was not suited for cost-effective continuous processing of corrugated board, according to Tucker, and thus it was mostly limited to the production of merchandising displays.

“So we expect this press to become a real workhorse for us, ultimately capable of processing up to 100 million square feet a year over a three-shift schedule.

As Tucker concludes, “It really hits the sweet spot by combining high productivity and really good graphic while using water-based inks—enabling us to provide our customers with truly sustainable corrugated packaging solutions.”

“But some time about two years ago we started seeing new offerings from the like of Durst, and other press manufacturers, that had really closed the quality gap to provide superb print quality with high productivity,” Tucker says.

A Siemens Simatic HMI (human-machine interface) terminal displays all the critical feeder station information to the press operator in real time.

Watch a video of the Delta SPC 130 digital press in action at Atlantic Packaging’s Tiffield Road plant in east-end Toronto on Canadian Packaging TV.

FORM AND FUNCTION

West Coast end-of-line packaging OEM hits its stride with servo control technology to raise machine performance to the next level of operational excellence and reliability

By George Guidoni, Editor

Photos by Dave Buzzard

Founded in 1977 in Richmond, B.C., Wexxar Packaging Inc. is a proud and renowned Canadian packaging equipment manufacture specializing in building automatic, sturdy, high-speed end-of-line packaging machines such as case erectors, case sealers and tray formers used to make the corrugated shipping containers for transporting fresh produce, agricultural products, meat, beverages, packaged foods, household goods and many other types of everyday CPG (consumer packaged goods) to grocers, retailers and food wholesalers across North America.

With a Wexxar machine available for forming or sealing anything from a basic “brown box” to complex specialty trays in the company’s comprehensive product

portfolio, Wexxar equipment has been installed in over 40 countries to date, according to the company, which has been operating as part of the ProMach group of companies, headquartered in Cincinnati, Ohio, since 2005.

Prior to that, the company operated under the updated Wexxar Bel moniker following its 2000 acquisition of competing case forming and sealing machinery manufacturer Belcor to significantly boost its product offering, which was further expanded in 2009 with ProMach’s acquisition of the Richmond-based tray forming equipment builder IPAK, subsequently integrated into the renamed Wexxar Bel business.

Despite the changing names and owners, the Wexxar brand name continues to be synonymous with productivity and reliability in packaging industry

Bosch Rexroth Canada account development manager Christopher McGregor (left) joins IPAK engineering manager Davis Huang (center) and IPAK product manager Christopher Parkinson to display the high-quality, sturdy corrugated produce trays coming off the TF385 model tray former at the Wexxar Packaging manufacturing facility in Richmond, B.C.

Top

Stacks of corrugated lined up behind the TF series tray forming machine, awaiting their turn to be shaped into final shipping trays.

Bottom

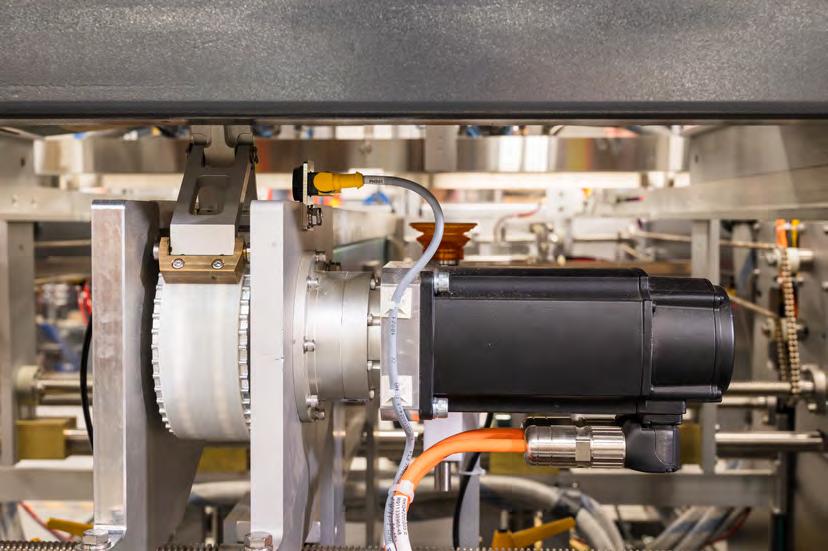

A close-up of the Rexroth IndraDrive servo motor installed at the blank advance station of the IPAK TF385 tray forming machine.

circles, with some of the Wexxar Bel machinery reported to have been operating for over 30 years at some locations.

Priding itself on its “solution-based engineering” philosophy, Wexxar had centralized all its manufacturing operations under the roof of a newly-built 100,000-square-foot factory in Richmond in 2014, thereby providing opportunities for greater synergies between the company’s major brands.

One of the brands that has greatly benefited from these opportunities is the IPAK range of tray formers, which have been continuously enhanced in the last couple of years with improved design features and incorporation of advanced servomotor technology to enable the machines to form a variety of tray styles suitable for virtually any industry.

Officially launched in the spring of 2022, the updated IPAK line of tray formers—comprising models TF385 , TF485 and TF486—features multiple design upgrades that allow users greater accessibility for faster, easier, and safer changeovers than ever before, according to IPAK product manager Mike “Parky” Parkinson.

“The big story with our new IPAK tray formers is that we made it much easier to do adjustments in the machine, which allows the operator to safely get it back up and running quicker—thereby really increasing the overall efficiency of the entire packing line, says Parky.

“At Wexxar Bel, we constantly listen to our customers and continuously strive to improve our machinery to best meet their needs.”

As Parky relates, updates to the new IPAK tray formers include redesigning the guard doors and other new guarding components to provide better access into the machine for faster adjustments and changeovers.

Additionally, the number of adjustments needed for changeovers has also been reduced—making it easier for employees with varying skill levels to operate, while reducing the amount of required training and shortening the learning curve.

As Parky notes, “Simplifying the design and improving machine access also aids maintenance crews by troubleshooting and servicing the machine more effi-

“We constantly listen to our customers and continuously strive to improve our machinery to best meet their needs.”

Clockwise from top

A close-up of the Rexroth IndraDerive servo drive and motor instlled at the mandrel of the IPAK TF 385 tray former; close-up of the corrugated blanks being moved through their paces at high speeds inside the TF385 tray former; finished corrugated trays coming out of the TF385 tray froming machine.

ciently—minimizing downtime.”

As part of this machine streamlining, the coalescing filter/ regulator unit on the redesigned IPAK tray former was relocated outside the machine—enhancing ease of accessibility when pneumatic adjustments are required.

The relocation has also made pneumatic connections more direct and efficient, reducing the chance of air leakage and making for a more energy-efficient operation with an overall lower cost of ownership.

Other changes include reinforcing materials on the overall machine and, notably, reinforced guarding and door hinges to increase overall operator safety and product life.

“With these design improvements all centered around simplifying operation, IPAK really allows employees to take ownership of the machine,” Parkinson said. “Our goal was to build an even safer, more reliable tray former that expedites the changeover process, and we’ve done that with our new tray former.”

The new IPAK automatic tray formers can create a broad variety of tray styles—including four-corner, six-corner, rollover, self-lock triangular corner, etc.—at robust throughput speeds of 15 to over 40 trays per minute, depending on tray type.

According to Wexxar, the TF series tray formers utilize reliable and precise technology to form a perfectly square tray— ensuring the perfect aesthetic look and, more importantly, superior product protection.

Featuring an active compression section, servo-driven blank advance and self-cleaning vacuums, IPAK trays incorporate a user-centric, intuitive design to reduce the amount of time required to learn, operate and maintain the machine.

Equipped with a large 10-inch touchscreen HMI (human machine interface) for user-friendly control and large doors to allow easy access to changeover and maintenance points, the tray formers allow for quick and tool-free size changeovers in under 20 minutes.

Moreover, relocating the FRC to a centralized position on the machine has streamlined the entire pneumatic system and, according to Wexxar, reduced the overall energy costs while increasing machine reliability.

One of the most impactful new machine performance features, according to Parky, was the installation of two IndraDrive HCS01 servo drives along with the IndraDyn MSK motor at the machine’s blank advance station and at the mandrel—to ensure superior speed, reliability and repeatability.

Supplied by Wexxar’s long-time automation partner Bosch Rexroth Canada, the high-performance combination servomotors enable the TF series tray formers to handle a broader variety of tray styles, according to Parky, while also speeding up the process.

“Once the tray enters into the compression station from the loaded hopper, the mandrel is going to come down and form that tray from the blank sheet of corrugated,” Parky explains.

“With the two servos on this machine, giving us the ability to run up to 40 trays plus per minute, with the Bosch Rexroth servo advancing the blank through the machine with consistent performance, reliability and repeatability,” Parky states. “At the end of the day, that’s really what the customers are looking for.”

Adds IPAK engineering manager Davis Huang: “For the last 15 years, we

The IPAK TF385 model tray forming machine from Wexxar Packaging incorporates the signature-blue Nordson ProBlue Flex adhesive applicator for highly precise and repeatable application of hot-melt adhesive onto the corrugated surface to ensure reliable construction, performance and durability of each shipping tray coming out of the high-speed machine.

“Simplifying the design and improving machine access also aids maintenance crews by troubleshooting and servicing the machine more efficiently—minimizing downtime.”

have been very proud building the most compact machines that fit into most applications, thereby providing and forming the best possible trays for our customers.

“With this project, the goal was to make flexible machines that our customers can adapt to make multiple styles of trays, and the Bosch Rexroth servo system is providing us that capability to do that.

“The Ethernet-connected HMI on the machine allows us full control of the servo drive and the motor, while enabling customers to have less machines doing more work.

“We chose to work with Bosch Rexroth servomotors because they make the machine more efficient and provide better control, with greater reliability, while improving efficiency,” Huang states, describing Bosch Rexroth as “a great partner for us to work with, especially at the product development stage.”

Says Huang: “When we started trying to find solutions to move from our traditional control system to the more modern system, they (Bosch Rexroth) came in, introduced the available technology, and did a comparison of all options.

“They then came in with their technical team to help us develop the product we wanted in a very short period of time.

“We are very happy with the support we get from Bosch Rexroth,” Huang states. “We are happy with the products they supply,” he says, “and the level of collaborative interaction between us is always beyond expectation.

“So when it comes to control auto-

From left Close-up view of the touchscreen HMI (human-machine interface) terminal used for operator-friendly operation and recipe management of the IPAK tray forming machines.

An IPAK TF series tray former being prepped for shipment to customer inside state-of-the-art, 100,000-squarefoot Wexxar Packaging manufacturing facility located just outside of Vancouver in Richmond, B.C.

mation,” he sums up, “they are always the first ones up for consideration as a partner.”

Such feedback is a priceless compliment for Bosch Rexroth’s account manager Christopher McGregor, who was directly involved in the project from the start.

“Our scalable servo drive and control range is flexible enough to handle any of Wexxar’s needs,” says McGregor, noting that Bosch Rexroth has been supplying Wexxar with automation components for over 10 years.

“We act as a single source supplier for Wexxar—not only offering linear mechanical components but also all the drives and controls,” McGregor adds.

“The partnership allows for increased efficiencies between both parties, as well as application-specific knowledge sharing within each other’s technology group.”

As McGregor points out, “Bosch Rexroth leads the market in research and development of motion control—allowing our customers to equip their machines with the latest in drive and motor technology, while still maintaining support of their legacy products.

“As an example, we are currently supporting Wexxar as they transition to

Bosch Rexroth’s newest servo motors that are smaller, lighter, and have impressive torque accuracy,” he says.

“The global network of Rexroth engineering and our desire to be a market leader in automation requires us to work closely with our customers and develop new technologies to meet their application demands,” states McGregor.

“Rexroth leads the market in R&D with new products like ctrlx (automation software), linear smart function kits and flex effectors, which are all disrupting our market and leading the way in industry advancements.”

As Wexxar’s Parky sums up, “We’re best in class than what we do, and we look forward to showcasing our new improved equipment to our customers in coming years.

“We are always working to meet the customers’ needs,” he concludes, “so we can grow with our customers as a trusted partner.

“And as we look ahead, we look forward to Bosch Rexroth being therefor us to take care of all our drives and other automation needs.”

SUPPLIERS

Wexxar Packaging Inc.

Bosch Rexroth Canada

Watch a video of Wexxar’s model TF385 tray former, equipped with Bosch Rexroth servo motors and controls, in action at the company’s manufacturing facility in Richmond, B.C., on Canadian Packaging TV.

THE FUTURE OF FIBER

Why fiber-based packaging is poised for long-term growth in global shift to the Circular Economy business model

By Nate Pajka

In a world with steady population growth and urbanization, the need for packaging is constantly growing. At the same time, packaging requirements are becoming more numerous, with environmental sustainability emerging as a common denominator.

To succeed in the packaging industry, nearly every idea a company invests in must consider how it will reduce a product’s environmental impact.

Sustainability can no longer be considered “just a trend,” as it was when the concept was first popularized. Consumers demand it on a global scale and our planet relies on its comprehensive implementation so it can operate naturally.

Understanding the appropriate path forward for fiber-based packaging—in our quest to minimize the industry’s impact on the planet—must start on a macro level before homing in on specific actions that can be undertaken thoughtfully, but with due urgency.

As with nearly any industry, the paperboard packaging market is impacted by both global and local trends. Globalization, and the ease and speed at which consumers digest information, has forced companies to think about more than what is directly related to paperboard.

According to Mintel’s PESTEL analysis in their Global Packaging Trends 2023 report, there are several categories of global trends that we can monitor, including political/legal, economic, social, and technological.

The most notable recent political event that affects this industry is Russia’s attack on Ukraine and the ensuing war.

The war has soured international relationships, negatively affecting trade, as sanctions were placed on Russia and its

allies by countries in neighboring Europe and around the globe.

Before the war, Russia, Ukraine and Belarus were supplying close to 25 per cent of Europe’s timber and forest product needs, with that percentage since dropping to essentially zero. Not only has this created a shortage of fiber in general, but it has also forced suppliers to change their fiber mix without access to certain tree species.

Russia was also a major supplier of energy to the EU (European Union) and the rest of the world, and without their contributions energy costs skyrocketed—resulting in increased production costs that get shuffled down the value chain to the consumer.

Political polarization has been rampant since the height of the COVID-19 pandemic, creating divisions amongst consumers and a volatile purchasing environment. Today, every company seems to be one public relations nightmare away from a full-scale boycott of their products.

Produced by the Finnish-based paperboard packaging manufacturer Metsä Board Oyj, MetsäBoard Prime FBB EB is a dispersion-coated, lightweight barrier paperboard incorporating a medium barrier for protection against grease and moisture.

The upcoming U.S. election should exacerbate divisiveness, as campaign promises and subsequent conversations echo through living rooms across America. Because legislators believe they can make change through enacting new laws, we should expect to see a strict and dynamic regulatory environment moving forward.

A principal issue in the packaging industry is centered on dealing with plastic waste, so we can expect investments in recycling infrastructure, deposit return schemes, more widespread extended producer responsibility legislation, and closer attention to the PFAS ‘forever’ chemicals.

From an economic perspective, the report discusses the following trends directly affect the packaging industry: economic uncertainty, the rising cost of goods, supply chain challenges, labor shortages, the threat of a global recession, and inflation.

As a result, a premium has been placed on value-based options. Industry

members need to consider how their packaging can help consumers stretch a budget without compromising quality, safety, sustainability, convenience, or freshness.

Considering social factors is incredibly important in an era where information travels expeditiously across the globe via different media channels.

Consumers today trust companies, governments and institutions less than ever, and as such they believe they bear the obligation to act responsibly.

Now that consumers are a few clicks away from company and product information, transparency is key.

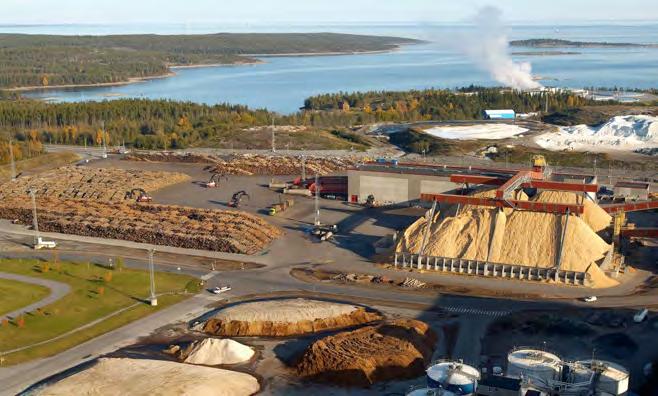

Pristine and well-managed Scandinavian forestlands provide ample raw materials for the Metsä Board mill in Husum, Sweden, where high-quality paperboard is produced mostly with mostly fossil-free energy, and much of the volume is sent to the Americas.

vast impressionable audiences.

For all the misery it caused, COVID -19 did accelerate many technological advances. One of them is the adaptation of the so-called ‘smart labeling,’ whereby a QR code can be used to communicate product details left off-pack.

Narrowing our focus to corrugated packaging, we see some notable trends. The market is continuing to grow, but the proportion of fiber-based packaging is actually decreasing. This is due to higher growth rates in production and usage of other fiber-based products, coupled with lightweighting of the board itself.

In 2023, factors such as inflation, destocking, near-recession conditions, and poor agricultural conditions are shrinking current demand, but it is expected to bounce back in 2024.

In the long-term, corrugated packaging will remain a valuable product in high demand—primarily because consumer purchasing has been transitioning to online ordering and home delivery. From a sustainability perspective, corrugated board is becoming more lighter-weight as producers are using different combinations of liners to reduce board-specific carbon footprints and material use. Moreover, corrugated board is widely recycled, while often being made from 100-percent renewable raw materials.

Consumer attitudes about sustainable packaging are constantly changing.

Leading global management consultancy McKinsey & Company has published results from studies in two new reports —titled Sustainability in Packaging: U.S. Survey Insights and Sustainability in Packaging 2023: Inside the Minds of Global Consumers—which help us understand these attitudes.

The studies found that the top buying criteria for packaging are price, quality, and convenience. Over two-thirds of consumers cite inflation as their top concern, as the price criteria has increased in importance by 11-per cent since the onset of COVID

This can be done through clear, thirdparty verified on-pack labeling that communicates the company’s purpose. This will also require being honest about challenges the company faces and how they will be addressed.

Consumers will also buy from brands that hold similar values, so they pay attention to how a brand responds to controversial topics.

With consumers spend more time on line than ever before, there has been a strong push towards enhancing digital experiences. Influencers have influence, so companies must be ready to respond when emerging trends are broadcast to

The studies also show that environmental considerations depend heavily on demographics, whereby Millennials, Gen Z and folks living in urban areas tend to care more about environmental considerations than do those in older generations, or people living in rural areas.

In terms of packaging characteristics, the studies found that hygiene and food safety are highest-rated attributes, but they have also become less important to consumers since the height of COVID

Nearly 40 per cent of the survey respondents said that environmental impacts were either very or extremely important, which is down four per cent

since 2020. This is likely due to the price increases causing consumers to prioritize other characteristics, but as the global economy normalizes, we should expect to see environmental impact regain significance to the consumer.

Identifying a sustainable packaging type is difficult for most consumers, but compostable and plant-based packaging types tend to indicate to consumers that the package is sustainable, according to the study. Conversely, aluminum foil and multi-material packaging are seen as the least sustainable options.

These studies also showed that consumers are willing to pay more for sustainable packaging.