The maintenance-friendly VarioFlow plus conveyor system creates optimal work conditions. Improved sliding characteristics and low-friction materials result in a quiet working atmosphere. Fewer joints and rolling friction in the horizontal curves ensure low wear and reduce downtimes.

▶ Quiet operation

▶ Maintenance-friendly conveyor system

▶ FDA compliant materials

▶ Short time to market

▶ Optimized sliding characteristics for the chains and slide rail

▶ Gliding surface does not require any machining

▶ Fewer joints and low-friction materials

▶ Decoupling of chain links using various materials

▶ Rolling friction for all track widths in the horizontal curves

Best-possible work conditions thanks to minimal operation noise

Longer service life

Reduced downtimes

DEPARTMENTS

NEWSPACK

6-7 Packaging news round-up. IMPACT

13 A monthly insight from PAC Packaging Consortium

40 By Myles Shane Joe Public speaks out on packaging hits and misses. 15 33 22

COLUMNS FROM THE EDITOR 4 George Guidoni Sustainable beauty well worth the price.

CHECKOUT

ISSN 1481 9287. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post

Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

COVER STORY

Alberta craft cannabis producer attains rapid productivity and throughput improvements with unique made-inCanada automatic pre-roll machinery. FEATURES

Renowned Montreal packaging machinebuilder leverages advanced automation controls to sharpen its competitive edge.

Canadian machine-builder and global automation controls giant team up to deliver a breakthrough produce packaging solution.

How Industry 4.0 is changing the name and nature of the game for metal detection users and suppliers.

A timely primer on Amazon’s Frustration-Free Packaging program compliance.

A sampling of exciting packaging technologies to be displayed at next month’s PACK EX Toronto exhibition at the Toronto Congress Centre, Nov. 9-11, 2021.

ON THE COVER

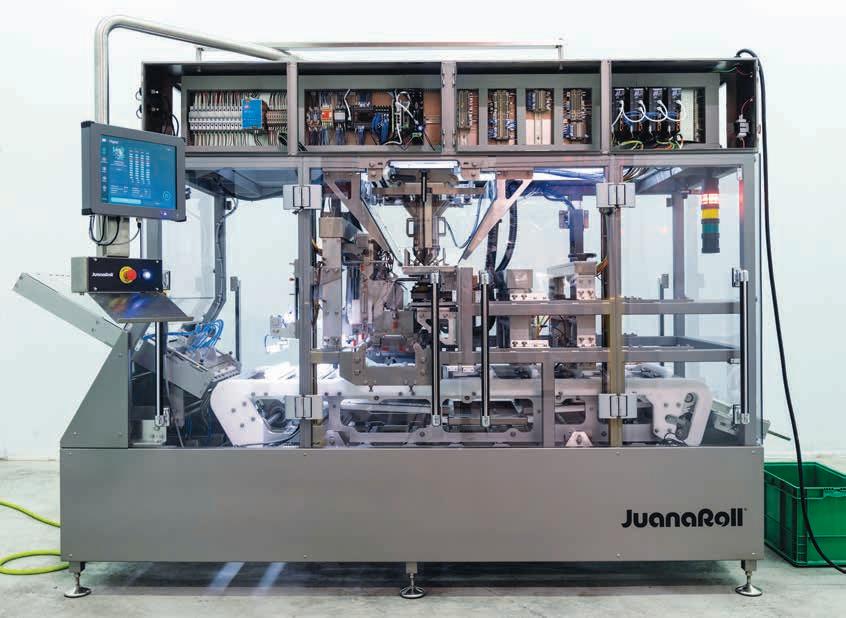

314 Pure Cannabis president and chief executive o cer Clayton Duguid stands alongside the JuanaRoll automatic pre-roll machine installed at the company’s processing facility in Crossfield, Alta.

After four years of being dismissed by higher powersthat-be as fake news and fear-mongering, global warming and climate change are once again at the of the priority list at the White House and around the western world in general, with past summer’s litany of epic record-setting heat waves, forest fires, hurricanes, floods and other natural calamities a grim reminder of the fatal dangers of wilfully ignoring worldwide environmental degradation.

And while it’s not something that the packaging industry, or any other for that matter, will resolve in isolation, most of us can agree that this is not the time to decelerate the considerable progress, fervor and zeal that many packaging industry leaders have displayed in years and months leading to the deadly global outbreak of the COVID-19 pandemic.

ethical obligation to make sure this does not happen, according to long-time industry insider Joe Cook, former executive director at Estee Lauder and vice-president of U.K.-based luxury packaging products group Delta Global

As Cook proclaims, “It is now perhaps more important than ever to remind the industry that this unexpected increase in plastics should not excuse businesses from obligations to sustainability.

“In fact, doing so would be a commercial and ethical disaster for the beauty industry,” Cook states.

“The beauty industry has made some important and impressive alterations to plastic packaging usage and, to put it bluntly, it had to.”

OCTOBER 2021 | VOLUME 74, NO. 10

Reader Service

Print and digital subscription inquiries or changes, please contact: Anita Madden, Audience Development Manager Tel: (416) 510-5183 | Fax: (416) 510-6875

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

120 BILLION

The nasty pandemic, currently manifesting itself in the fourth wave of outbreaks here at home and worldwide, has claimed millions of lives while doing enormous harm to the global economy, trade, travel and, notably, the considerable momentum towards making more sustainable packaging options available to the global CPG (consumer packaged goods) industries.

There is no denying the fact that the consumption of single-use plastics has soared during the coronavirus pandemic, driven by fears of contamination and widespread increase in PPE (personal protective equipment) usage.

While understandable as a temporary emergency response, it should not be taken as a carte blanche for CPG industries to return to their former ways of flooding the global market with single-use packaging products and components that have an uncanny inclination for escaping into the waterways and ending up washed on beaches all over the planet, while doing irreparable harm to marine life and fragile underwater ecosystems along the way.

That’s just not going to wash either with the consumer public nor the international regulatory authorities mandated to help bring the existential global pollution crisis under some semblance of control.

As one of the world’s bigger end-users of single-use plastic packaging, the global beauty industry has a profound social and

Citing statistics gathered by the U.N., Cook points out that beauty brands accounted for about 120 billion units of packaging in 2018, with a “generous estimation” that nine per cent of that packaging being recycled—leaving 12 per cent to be incinerated and the remaining 79 per cent put into landfill.

For Cook, such numbers are simply unacceptable in today’s global socioeconomic climate that is also experiencing a fundamental demographic shift that will have a profound impact on all major industries with a hefty carbon footprint.

Say Cook: “Several consumer reports have found that Millennials and Gen Z demand sustainable retail practices and are willing to pay more for it—in polar opposition to the consumer preferences of Baby Boomers.

“Significantly, that generation has recently entered the workforce en masse, meaning that for beauty brands, whose largest market is the 18 to 34 age category, it makes neither ethical nor business sense to avoid a coherent sustainability strategy.

“If the beauty industry is to provide what the new generation of customer expects, it must renew its eco-friendly commitments to packaging,” Cook asserts.

“Complete sustainability is where consumers and the market are heading,” he concludes, “and where the beauty industry must lead.”

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer

Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Business Media. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

Q: What do you get when you

Your One Stop Packaging Machinery Shop.

Syntegon is one of the leading suppliers of processing and packaging technology to the food and chocolate/confectionery industries. We offer a product portfolio ranging from entry-level machines to fully integrated systems. Our mission is simple: to support customers in creating sustainable solutions with market-leading technologies.

Start a conversation with us today connectwithus@syntegon.com +1 (770) 981-5200

www.syntegon.com/food

Syntegon. Formerly Bosch Packaging Technology.

Agropur is shaking up the fine cheese market with new high-end brand

While Canadians generally love their cheese and consume it in great quantities, relatively few of them are aware of how fine cheese is made and properly enjoyed in the right setting for optimal culinary reward.

But thanks to leading Canadian dairy co-op

Agropur, the mastermind behind the world-renowned OKA cheese brand, Canadian consumers have a new delicious way to elevate their knowledge of this beloved product in the tastiest way possible.

Launched across the grocery stores and cheese stores across Canada in late summer, Agropur’s new Monsieur Gustav brand of high-end authentic fine cheese products promises to demystify and democratize an important food category whose mass appeal has been held back in the past by its perceived snobbishness and elitism.

“Monsieur Gustav is a modern, unpretentious brand that breaks with the category’s established codes,” says Hubert Théorêt, Agropur’s marketing director for fine cheese.

“Its mission is to introduce new consumers

to the vast world of fine cheeses, to make cheese accessible and appealing to curious shoppers.

“It’s an innovative brand that will bring winds of change and renewal to the marketplace,” says Théorêt, likening the new brand to an old dear friend who drops by now and then with a few select gourmet cheeses for an impromptu evening of pleasant conversation and gustatory delight.

Théorêt says the Monsieur Gustav brand is the result of the expertise, know-how and passion of Agropur’s people, who are dedicated to the proposition that fine cheeses are for everyone.

“There is so much variety at the cheese counter that it can be daunting” says Pierre-Édouard Chomette, vice-president for the Fine Cheese business unit. “Monsieur Gustav will guide consumers and help them choose the right cheese for their taste, their planned use and the occasion,” he states.

“He will make life easier for consumers at the point-of-purchase by providing taste descriptions on the packaging and smaller formats that encourage shoppers to try new products and are practical for snacks or to serve to guests.”

”At every stage of the brand’s development, merchants and consumers were consulted, and we listened to what they had to say,” says Stéphane Le Gal, president for categories for Canada.

“With Monsieur Gustav, the world of fine cheese readily reveals all its charms.”

While each cheese is unique, Monsieur Gustav makes it easy for consumers to find their way around the cheese counter by organizing the brand’s 41 lovingly selected cheeses into eight categories, each with its own colour code, consumers to explore, try and enjoy.

Comprising a broad array of packaging sizes and styles—all featuring engaging cartoonish decorative graphics developed by Montreal-based creative agency Lg2—the Monsieur Gustav brand making a concerted e ort to meet the needs, tastes and desires of fine cheese neophytes with small formats for consumers who just want to try it at a ordable prices.

According to Agropur, 33 of the 41 cheeses in the Monsieur Gustav brand are exclusively made-in-Canada products—including Cheddar, Gouda, Harvati and Swiss varieties—made with the help of Canada’s leading packaging producers such as Cascades, Winpak, Labelink, Amcor and Innovaplast

“The packaging on Monsieur Gustav products is designed for visual consistency, to provide easy access to information and to facilitate choice,” explains Chomette. “It’s also eye-catching on store shelves.

“The visuals on each package also include a strip with additional information about the product’s specific taste to help consumers make an informed choice,” says Chomette, adding that the new packaging features embedded AR (augment reality) technology that consumers can activate with their smartphone to scan the on-pack QR (quick response) to learn innovative tips and ideas about the Monsieur Gustav cheeses.

“The augmented reality experience meets the latest standards in the field: no app to download, fast response time, and entertaining information to help shoppers make their choice,” Chomette relates.

“The content will be updated for every season and occasion,” says Chomette, noting that some of the new packaging also features on-pack ‘lactose-free” emblems for many of the brand’s lactose-free products.

As a highly diversified business, Saint-Lambert, Que.-based RICARDO Media Inc. has its finger in many di erent pies, including the retail food business.

With many of its popular ready-to-cook meal solutions retailing through out Quebec through the IGA grocery chain, which recently bought a majority stake in RICARDO, having a vibrant eye-catching packaging to attract consumers is naturally a top priority for a company that is also involved in magazine publishing, television production, online media, food and restaurant industries.

With so much on its plate, RICARDO is happy to rely on the packaging design expertise of leading Canadian design agency Pigeon Branding to help its delicious products connect with consumer on the shelf level.

This partnership has resulted in the recent launch of a stunning new look for the RICARDO food brands that perfectly reflects the RICARDO

brand personality.

“RICARDO is so much more than just a brand,” says RICARDO Media’s vice-president of operations Mireille Arteau.

“Behind it stands a man, a father, and one of Canada’s most recognized chefs.

“Our mission is to inspire, educate, and bring people together through cooking and at the dinner table,” Arteau explains. “Authenticity, family, and eating well are a big part of our brand values,” says Arteau, “and it’s important for us at RICARDO Media to reflect these attributes in the new packaging of our food products.”

After carrying out an in-depth design analysis of the current packaging and deciding that some of the products lacked the shelf impact they deserved, Pigeon worked to develop a bold new look to make the brand more visible on the grocery and refrigerator shelves to better reflect RICARDO’s personality, and generally making these products easier to locate at the store.

“One of the key the objectives of the redesign was to create a coherent platform from one category to the next, to better create interest and desire, as well as to generate attention and give people a taste for RICARDO products,” says Pigeon Branding’s vice-president of brand strategy Stéphane Crevier.

“The ultimate goal? Ending up on Canadians’ weekly grocery lists,” Crevier states.

“To achieve this we created appetizing imagery inspired by their dishes, and em-

ployed a lively palette of colors to ignite taste, while increasing visibility and contrast in all categories the products can be found.”

As Crevier explains, the Pigeon team made extensive use of the corn yellow, leek green and cranberry red colors associated with products created by the RICARDO team—highlighting their appetizing nature.

“The redesigned packaging stands out on the shelves and in the aisles, with a bright color palette to attract the eye, and connect with a warm and inviting spirit,” Crevier states.

“The new imagery will also add color to grocery baskets, giving consumers the inspiration to try other new RICARDO products.”

As a key part of the multi-show ADM Toronto exhibition at the Toronto Congress Centre next month, PACK EX Toronto is Canada’s only dedicated packaging event this year for packaging suppliers and buyers to discover innovation, engineer new technology, and build a better tomorrow.

Scheduled to run Nov. 9-11, 2021, this year’s PACK EX Toronto will o er an exceptional opportunity to hook up with the most innovative packaging suppliers, connect with experts on the latest food-and-beverage trends, and meet with the industry leaders providing cutting-edge design, process, materials and solutions to address today’s productivity challenges and mandates to cut packaging waste.

Here are some of the packaging technologies that will; be displayed at next month’s PACK EX Toronto exhibition:

Handtmann Canada Ltd. will unveil the full range of the company’s latest food processing innovations, including:

* The VF 828 S vacuum filler featuring the

technical advances of larger VF 800 models, including metal detectable non-metallic parts, a hygienic design with no microbial traps, and fast-drain external surfaces with simple controls and gram-accurate portioning at up to 1,200-ppm (pieces per minute)

* The SE442-1 rotary cutting solution for bakeries, featuring the precision of servo-driven dividing with better than +/-1% accuracy at up to 200-ppm, making it highly e cient for pizza and dough operations with ample flexibility to enable bakers to produce a range of premium products on one unit.

* The innovative FS525 all-in-one forming/

cutting system with a simple three-minute conversion from hole-plate 3D product forming to rotary cutting for di erent product cross-sections.

• The new FS552 valve-free return suction depositing system, designed to deliver excellent accuracy with smooth and chunky products at temperatures of up to 90°C.

* The award-winning INOTEC emulsifying design featuring a variety of performance, safety, and sanitation innovations, including a self-adjusting radial cutting set, advanced temperature control, and automated process monitoring. According to Handtmann, the automatic lNOTEC soft-start feature eliminates ‘running dry’ and extends blade life, while the cutting set self-adjusts every 15 seconds during operation to ensure consistent precision, simplify operation, and reduce parts costs.

Booth #1421

Full-service label printing provider AstroNova, Inc. will host live demonstrations of printing and labeling products that will include:

• The QuickLabel QL-120X premium

table-top color label printer o ering the industry’s best extended two-year warranty, extended printhead life, and extended life-time benefits of delivering high-quality labels at a lower total cost of ownership.

• The QuickLabel QL-300 Said to be the world’s first CMYK+White toner-based table-top printer that enables brand-owners to create high-quality labels with the utmost durability, ensure a competitive cost of ownership, and set their brand apart with vibrant, impactful product labels.

• The TrojanLabel T2-C , said to be first-ever high-capacity, high-volume table-top label press capable of delivering precision over long runs to produce consistent high-volumes in 24/7 production environment.

Busch Vacuum Technics Inc. will showcase the company’s new connected R5 PLUS series vacuum pump, deigned to bring the proven Busch rotary vane vacuum technology to the next level with Industry 4.0 connectivity and highly innovative features that include:

• Advanced control functionalities;

• Condition monitoring;

• Integration to any standard control system;

• Two operating modes: pressure control and constant speed;

• Large color touchscreen;

• Intuitive menu navigation. According to Busch, the pump’s integrated variable speed drive al -

lows adjustments of the motor frequency from 35 Hz to 70 H z, enabling energy savings of up to 50 per cent compared to unregulated vacuum pumps.

The pump’s di erent operating modes ensure that the R5 PLUS series vacuum pumps always run in optimal operating condition, while allowing for the maintenance intervals to be planned more precisely by permanently recording the condition of the components, the event history, and the running hours.

Booth #1335

Contaminant detection and product sorting technologies experts Sesotec Canada Ltd. will display the company’s leading-edge INTUITY metal detector and the RAYCON D+ X-ray product inspection system.

Equipped with the new INTUITY metal detection coil and multi-simultaneous-frequency technology, the INTUITY reaches a scanning sensitivity that is up to 50-percent higher than in other systems on the market, according to the company, while the INTUITY CONTROL user interface offers greatly improved ease of operation.

For its part, Sesotec’s RAYCON D+ X-ray inspection system surpasses the specifications of internationally applicable standards such as IFS and BRC in parts by up to 400 per cent, with and a rate of faulty detections of less than 0.01 per cent setting new standards in respect to detection accuracy, application flexibility, and ease of operation.

Booth #1445

Reiser (Canada) Ltd. will conduct live demonstrations of the company’s wide range of food

el on our brand new eti auro 33 large ormat in et printer to reate ibrant print on a wide range o rigid and flexible media up to 3.3 m wide. and ull automati .

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation. COMPLETE

info@heatandcontrol.com |

packaging equipment and processing-to-packaging solutions, with machines on display at the Reiser booth to be fully operational and running real or simulated products. The company’s vast exhibit will feature:

• Reiser horizontal form/fill/seal packaging systems to produce vacuum, modified-atmosphere (MAP) and vacuum-skin packages from flexible and semi-rigid materials. Compact configurations are available for lower production requirements, as well as high-performance machines capable of the industry’s fastest production speeds.

• Ross tray-sealers, designed to produce modified atmosphere, vacuum-skin and lid-only packages from pre-formed trays for the packaging of fresh, refrigerated and frozen food products at a full range of output rates, while ensuring superior seal integrity and extended shelf-life.

• Fabbri stretch film wrappers, designed to use stretch film to package fresh food in preformed trays and providing a “just packed” appearance.The Fabbri stretch film wrappers employ four-way stretch technology to produce tight, over-the-flange, wrinkle-free packages with securely sealed bottoms and superb case presentation.

• The Supervac range of automatic belt vacuum chamber packaging machines, shrink tanks, chill tanks and dryers, all

designed to produce attractive packages that feature two superior seals to eliminate leakers, rework and returns.

Booth #1203

Pilz Automation Safety Canada L.P. will showcase the PSENopt II Type 3 safety light curtains to obtain formal approval from the global test organizatio n Underwriters Laboratories (UL) to certify that they meet national safety standards in both Canada and the U.S.

Designed to ensure that it is safe to intervene in the production process, the PSENopt II safety light curtains provide optimal finger, hand and body protection in accordance with EN/IEC 61496- 1/-2 safety standard for electro-sensitive protective equipment, while o ering superior shock resistance for use in rugged industrial environments.

Ideal for use in robot applications, as well as on packaging machines and presses, the PSENopt II light curtains o er increased flexibility in terms of their point-of-use to provide a safe, economical and complete solution for all industries and application areas.

Booth #826

WeighPack Systems Inc., part of the Paxiom Group of companies, will showcase its brand

new Swifty Bagger Side Load automatic bagging machine o ering new value-added features for customers that require product orientation within a pre-made pouch.

This compact machine can load pillow and gusseted bags ranging in length from 150- to 350-mm and in width from 120- to 260-mm, either with zippers or without.

Additional options are available to provide a nitrogen gas flush for customers looking to increase product shelf-life, as well as a custom labeling configuration for printing expiration dates on the bags.

A perfect solution for products that are required to be standing up “soldier-style” within a pouch or single items, this automated solution can be used in food packaging consumer goods, healthcare, cosmetics, personal hygiene, hardware and many other such products.

According to WeighPack Systems, the Swifty Bagger Side Load bagging system is economical and easy-to-clean, while provides easy accessibility for cleanins and allowing the operator to monitor the entire filling process from the front of the machine.

Moreover, an accumulation table can be positioned prior to manual case-packing or, alternatively, its can also be fully integrated with complete end-of-line systems to include case erectors, pick-and-place case-packers, drop packers, case sealers and palletizers.

Booth #1215

Having recently joined FANUC’s Authorized System Integrator program, Harpak-ULMA Packaging, LLC will unveil the new TFS500 smart connected thermoforming machines incorporating FANUC brand robots for fully automated product loading and case-packing and Rockwell Automation’s flagship Allen-Bradley series controls, along with Vuforia and Thingworx software suites for Augmented Reality applications.

As part of the company’s new Customer Experience Centers (CXEs) program, the new IIoT-enabled solutions are the literal foundation of digital transformation in packaging operations, both in data acquisition and for contextualizing real-time operating information used to manage performance, according to the company.

“There is simply no more e ective way to convey what smart, connected packaging assets bring to the table,” says Harpack-ULMA’s chief executive o cer Kevin Roach.

“These are not pie-in-the-sky visions of what we could do—they are concrete, operational examples of what we already do,” Roach states. “No solution is an island unto itself [and] adding FANUC America, the leading supplier of robots and automation, to our CXEs puts an exclamation point on it for our customers.”

Both #1667

Inovadrum , a division of Technologie Inovaweld (Canada) specializing in the manufacturing of laser-welded stainless-steel drums and barrels for the food, chemical, cosmetic, and pharmaceutical industry applications, will exhibit its full range of bulk containers—o ered in more than 45 models with optimized and customizable designs—to accommodate volumes ranging from 16 to 210 gallons.

Boasting an ISO 9001 accreditation for its quality

management system and U.N.-rated accreditation for the transportation and storage of dangerous goods, the stainless-steel drums incorporate low-power laser technology to mark logos, identification numbers or barcodes to ensure the traceability of the barrels and their contents.

Booth #1139

VC999 Canada Ltd. will unveil a brand new R Series rollstock thermoform packaging machine that features many new breakthrough features to enhance packaging line productivity, while reducing labor and maintenance costs.

Incorporating a special lift design optimized to increase production speeds, advanced controls with faster processing speeds, and strategic placement of valvea to increase machine reaction speeds, the new machine features angled surfaces to eliminate pooling, washdown-rated igus bearings, and chain guides with nylon stando s for an exceptional hygienic design that can be customized to suit the end-users’ individual application needs and requirements.

Booth #1221

Food safety inspection systems experts METTLER TOLEDO Inc. will conduct live demonstrations of the company’s comprehensive range of product inspection systems, including checkweighers, metal detectors,vision systems and X-ray inspection systems,.

Designed to ensure brand protection, detect solid contaminants, confirm component content, inspect closures, measure fill levels and verify product weights, the METTLER TOLEDO systems o er optimal solutions to accelerating and automatingwork processes,improving product quality, increasing process e ciency, and supporting compliance with leading industry standards, regulations and legislations.

Booth #1013

The world and how we connect is changing rapidly. PAC is a trusted source, o ering Members valuable opportunities that transcend borders and location. As we continue down the path of international growth, we are committed to showcasing PAC Members to the world, and o ering quick-connect industry solutions.

*NEW * PAC ED: Golden Design Rules course for packaging professionals. Register for the November 10th workshop.

Canada Plastics Pact:

PAC is actively supporting Members through our ongoing collaboration and with your needs in mind.

PACKEX Toronto: November 9 – 11, 2021: 25% PAC Member discount on exhibition space

PIP360: A packaging assessment tool created by the industry, for the industry to help you meet your 2025 sustainability goals

PAC Global Awards and Summit: Showcase your work and compete against the best in the world.

Enter before October 28th.

Educational Webinars: Check weekly for the latest in relevant, insightful lunch-and-learn opportunities with PAC

PAC IOU: Inclusive Opportunities for Universal Packaging Design – making meaningful change for our industry. Join the movement.

PAC is a trusted source and collaborator in critical partnerships with government and other important industry stakeholders - allowing our Members to focus on doing what they do best, looking after their own bottom line. For a comprehensive overview on PAC Membership and the benefits to you, visit www.pac.global

Packaging automation helps enterprising craft cannabis producer respond to unfolding new market trends in real time

By George Guidoni, Editor

Photos By Asim Overstands

For a young and disruptive market like recreational cannabis, there are undoubtedly countless twists and turns to come before the nascent industry starts resembling other mainstream CPG (consumer packaged goods) sectors in terms of market maturity, pecking order and broader public acceptance.

But if the early trends are anything to go by, being an early bird in terms of product quality and manufacturing competence is a win-win recipe that has already helped companies like 314 Pure Cannabis put themselves on the map with supreme confidence and style well

befitting a $2.6-billion industry with enormous growth potential.

Started up in 2019 a short drive north of Calgary in Crossfield, Alta., the privately owned company is a licensed craft cannabis producer using proprietary hydroponic growing and cultivation methods to produce high-quality flower cannabis products retailed through government-approved cannabis dispensaries across western Canada and Ontario. Currently operating out of a custom-built, 42,500-square-foot facility designed to meet all the pertinent Health Canada regulations and to comply with the EU GMP (Good Manufacturing Practices) standards, the Crossfield operation houses five state-of-the-art flower rooms

to grow eight core strains of high-quality marijuana buds, with current capacity to produce 2,000 kilograms of finished product—retailed in flexible resealable pouches or as pre-rolled filtered cones (joints) that are sold individually or in multipacks of five or 10 cones per box.

“Our output is actually much higher than 2,000 kilograms, which means we still rely on many of our LP partners in the area for supply,” says 314 Pure president and chief executive o cer Clayton Duguid, a former building industry professional who was drawn to the budding cannabis business soon after the federal government announced its intention to

Clockwise from left Stand-up pouches with child-resistant closures used to package dry cannabis flower buds; the full turnkey bagging system anchored by WeighPack’s Swifty Bagger Mini bagging machine; bulk cannabis flower being dispensed into PrimoCombi scale buckets.

legalize cannabis for recreational use, which finally happened in the October of 2019.

“I think the cannabis market is maturing, and the products are quickly evolving in quality today,” says Duguid, one of three company co-founders at the helm of a group of about 50 private investors contributing the all-important start-up capital to get the venture o the ground.

“Like many other people I used to be sceptical about marijuana ever becoming completely legal in Canada.”

As Duguid explains, the recreational market has also matured quickly enough to become price-competitive, and in some instances less expensive, than cannabis sold on the black market—thereby delivering on one of the key arguments and justifications for the eventual passage of the historic Bill C-45 legislation in November of 2018.

“Like many other people I used to be sceptical about marijuana ever becoming completely legal in Canada,” Duguid remarks, “but once it became a key election promise and then a real government policy, it presents an attractive business opportunity for many people across the country, and especially here in Alberta.”

To di erentiate itself from the competition, the company worked with branding services group Blackwater Design and Marketing to incorporate the number 314 into the brand name as a playful nod to the molecular weight of the principal psychoactive cannabis ingredient THC (Tetrahydrocannabinol), which is technic-

A plant employee preparing to load pre-made pouches onto the Swifty Bagger Mini machine; machine operator loading pre-made paper cones onto the front end of the eight-channel JuanaRoll machine; rows of bulk Futurolla pre-made paper cones taken out of the box for loading the JuanaRoll machine.

ally defined as 314.469 g/mol

“We definitely wanted to use the word “pure” in our company name,” Duguid reflects, “but it was just too generic to stand up on its own, so adding 314 was a nice piece of branding to position ourselves as a craft cannabis producer.”

As Duguid explains, craft cannabis production di ers significantly from mass-scale harvesting by providing individual plants with much more physical space and time to reach full maturity and optimal THC content, resulting in superior buds.

“We grow 176 plants in a 2,600-quarefoot grow-room, whereas a typical largescale factory would grow 3,000 to 4,000 plants in similar space,” Duguid explains.

“Also we let our plant grow their full height of six to eight feet, and we monitor each plant all the time, letting them fully grow and flower in vegetative state until they’re ready to harvest.”

According to Duguid, this extra care, attention and patience results in

high-quality buds, of various targeted potencies, which the company markets under three main core brands, including:

• Poolboy, described as a fun value brand with 16- to 24 percent THC content;

• 314Pure Premium , a premium-quality product with 26- to 30-percent THC content;

• Dad Hash , high-purity cannabis extracts with 45- to 50-percent THC content.

With its product portfolio currently comprising 17 SKU (stock-keeping units), 314 Pure Cannabis is exceptionally well positioned to keep expanding in tune with the growing market for recreational cannabis, according to Duguid.

In fact, the company has recently commenced a 60,000-square-foot plant expansion at the 16-acre site that will eventually house another 270,000 square feet of production space—raising its annual manufacturing capacity to over 35,000 kilograms.

In the meantime, however, Duguid and his production team are focusing on optimizing and automating the company’s packaging operations in order to support the expected growth in volumes with a highly e cient process geared to ensure optimal product protection, consumer convenience, and high throughput speeds.

To achieve these goals, 314 Pure has formed a close business relationship with Montreal-based packaging machinery specialists WeighPack Systems Inc. and the Paxiom Group

In early 2020, WeighPack supplied the 314 Pure operation with a turnkey packaging solution—comprising a Swifty Bagger Mini bagging machine, a PrimoCombi multihead weighing scale, and an automatic WeightCheQ checkweigher—to completely automate the process of filling pre-made pouches with 3.5- and seven-gram portions of dried flower, which was at the time all done by hand. Designed specifically for processing compact bag sizes, the Swifty Bagger Mini stand-up pouch filling and sealing machine opens, fills and seals a variety of pre-made resalable stand-up pouches. Occupying less than 10 square feet of space, the Mini bagger is constructed

with stainless steel and is designed for easy service and maintenance.

Manufactured at WeighPack’s state-ofthe-art 70,000-square-foot production facility in Montreal, the machine’s adjustable bag magazine provides consistent bag feeding to ensure that the pre-made pouches enter the machine perfectly square—resulting in strong, high-quality seals.

The Swifty Bagger Mini installed at the Crossfield plan is integrated with the PrimoCombi multihead weigh scale positioned directly above the Mini bagger, dispensing precise amounts of dried

flower buds from its 14 0.5-liter buckets to the bagger below.

Once the PrimoCombi scale is filled with bulk product at the center, its starts to vibrate to loosen the buds from the center cone to the individual vibratory feeder pans. These feeder pans the transport product to the weigh buckets to be weighed and measured.

Once weighed, the PrimoCombi determines which buckets equal a near-perfect match, locks them in, and then triggers the buckets to dispense at the same time to the Swifty Bagger Mini machine below.

Accurate to within 0.01-gram of target

weight, as verified by the integrated WeightCheQ checkweigher positioned in the center of the bagger, the programmable PrimoCombi scale allows 314 Pure to use the same pre-made bags for packaging both 3.5-gram and seven-gram portions, simultaneously if required, to provide invaluable operational flexibility.

“The WeighPack machines have allowed us to package our product in 3.5and seven-gram bags flawlessly,” Duguid states. “It uses suction cups to open the bag and insert 3.5 grams of product inside, seal the bag and spit it out … all we have to do then is tax-stamp the bag.

Featuring a unique inline design, the eight-channel JuanaRoll installed at the Crossfield plant can produce up to 50 pre-rolled cones of uniform size and weight in one single pass whereby the machine automatically fills, compacts, tamps, twists, trims and ejects the finished pre-roll into the plastic basket below at the machine’s back end.

“We do approximately 15 bags a minute with this machine,” says Duguid. “Its very easy to use, it’s very interchangeable, and it’s easy to adapt.

“It’s built to do di erent things, so it can be easily scaled up for use on a bottling line, or for bigger-sized bags. It is very flexible.”

In similar vein, Duguid is quick to praise the exacting accuracy of the PrimoCombi’s scale, along with the real-time status report the system displays on three large screens via its HMI (human-machine interface) to ensure optimal filling accuracy each step of the way.

As Duguid explains: “The PrimoCombi uses three bright big digital screens: the digital mode, which displays the target weight that was just dispensed; the graphic mode that uses a color scheme to show the operator one status; and the camera mode, which displays the product coming through.”

Adds Duguid: “Another great feature of the PrimoCombi HMI is the Cycle History function, which displays the target weight, the actual weight dispensed, and how many (bucket) heads were used to complete the cycle.”

As Duguid points out, unerring weight accuracy is a vitally important pre-requisite for the 314 Pure operation, which also double-checks the weight of every 100th

bag coming o the bagging machine to ensure the weight falls within the five- or 10–percent tolerance limits as required by provincial and federal authorities.

While automating the plant’s bagging line was a massively important accomplishment for the 314 Pure Cannabis operation, it soon became apparent to company management that the recreational market has been rapidly changing in terms of growing consumer preference for pre-rolled, ready-to-smoke filtered cones (joints), at the expense of dry flower buds they would have to roll up themselves.

“When our company started out about 80 per cent of the product we were shipping out was dried flower,” Duguid relates.

“But we have seen rapid maturity in the market, with customers pushing for high-quality pre-rolls, and we needed respond to this trend quickly,” he explains.

“So we turned to Paxiom again to help us pivot a lot of our SKUs into the high-quality pre-rolled segment of the market, to see if they had a machine that could do it at large volumes.”

Also manufactured by WeighPack in Montreal, the highly innovative JuanaRoll automatic pre-roll machine turned out to be the perfect solution for 314 Pure, which took time to evaluate many other

pre-roll machine options available on the market.

Already in operation at many of the best-known cannabis brands in the world, several large LP producers across North America, the JuanaRoll was developed as an automated solution to replace manual hand-rolling, which is said to be one of the most labour-intensive and time-consuming manual processes keeping many LPs (licensed producers) from achieving adequate productivity levels they need to compete.

Available in four-, six- and eight-channel configurations, the high-speed JuanaRoll machine features an easy-to-load cone magazine, an integrated PreCheQ checkweigher, and special stations for compacting, tamping and twisting/trimming, along with value-added standard features such as no-cone/no-fill detection, cone-open camera vision system, and free online technical support.

For Duguid, who traveled to the WeighPack factory to see the machine in real-life demonstration, the speed and accuracy attributes o ered by the JuanaRoll machine far outweighed the significant cost of the initial investment.

“It really is the Rolls Royce of all the pre-roll machines out there,” says Duguid, adding the JuanaRoll machine has worked flawlessly at the 314 Pure plant since coming online this past January, producing tens of thousands of uniform half-gram pre-rolled cones with virtually negligible deviations in target weight.

“It has enabled us to reassign 20 people to other more productive tasks at the plant,” says Duguid, citing the machine’s high-end craftsmanship that enables it to work with bulk ground cannabis of di erent levels of moisture and stickiness.

“We can do 50 pre-rolls a minute on this machine,” Duguid extols, “which is just fantastic.

“But the really big thing for us is that we are able to use real flower that we grind down to desired size; we do not use any ‘shake’ product.

“Being able to put that sticky real flower product through the machine enables us to produce a higher-quality product for our customers,” Duguid says.

“There are many di erent strains of cannabis out there that all react di erently when being processed..

“There are also external factors, like temperature and humidity, which also have an e ect on the product composition.

“But we have found a way to make the JuanaRoll machine account for all these variables,” Duguid says, “and that was one of the key selling features for 314 Pure Cannabis.”

As Duguid recalls, “When we were investigating the pre-roll machines in the market we noticed that the definitely a

Clockwise from left

Pre-rolled cones undergo the final visual inception by 314 Pure Cannabis sta while being counted and grouped for packing inside rigid plastic containers containing fire of 10 cones each; Clayton Duguid checking up on the blossoming buds inside of the company’s five indoor grow-rooms; Duguid displays some of the company’s bestselling SKUs (stock-keeping units) produced at the Crossfield facility.

lot of a lot of supply out there.

“But when we got to WeighPack, we were really impressed by the quality of manufacturing that goes into their machines,” he says.

“Being all about product quality ourselves, that was enough for us to pull the trigger on buying this machine.”

Duguid says that adding the JuanaRoll machine has had a profound impact on the company’s product portfolio by making pre-rolled cones—sold individually on in five-pack and 10-pack rigid plastic containers—its bestselling product type by far.

“Pre-rolls now account for about 80 per cent of our production,” he says,

“with bags at about 10 per cent and extracts for the remaining 10 per cent.

“That is just the way the market is going right now: consumer want the onthe-go convenience and mobility that pre-rolls o er,” he states.

“An as the market continues to evolve in this direction,” he concludes, “we look forward to work with Paxiom to continue to grow and expand our brand s across Canada to become one of the leaders in the craft cannabis market.”

WeighPack Systems Inc. Paxiom Group

Please see a video of the WeighPack equipment in action at the 314 Pure Cannabis processing plant in Crossfield, Alta., on Canadian Packaging TV at: www.canadianpackaging.com

Leading-edge automation technologies help Canadian OEM set new benchmark for machine performance and equipment effectiveness

By Andrew Snook

Photos by Pierre Longtin

What sets a strong service-oriented company apart from a weak one?

If you ask Justin Taraborelli, vice-president of operations for Montreal-based WeighPack Systems Inc., it’s a complete supply chain.

“To be a strong service company and a strong people company, you also need a strong supply chain and that includes the way you treat your supply chain,” Taraborelli states.

“We choose partners, we don’t just buy from suppliers. We make sure they can support us so we can support our clients, and it’s a completely integrated chain,” he says.

Part of the globally operating Paxiom Group of companies, WeighPack is a renowned provider of automated primary packaging machines, including weighing, filling, bagging, wrapping, conveying and turnkey systems.

The company serves a variety of industries around the globe, predominantly related to consumer goods for the food and pharmaceutical sectors.

“Basically, anything you see when you walk through a grocery store or a pharmacy, we’ve got a machine for that,” Taraborelli says.

For WeighPack to o er high-precision packaging machines to clients around the world, they require a strong global supply chain, and one of the key components of that supply chain for the past 20 years has been Omron Automation Americas. Headquartered in the Americas out of

Above The automatic JuanaRoll pre-roll machine makes optimal use of Omron automation components, such as the AC servo drives to the right, to ensure virtually flawless precision and reliability.

Ho man Estates, Ill., with locations across Canada, Omron is a global leader in industrial automation technology. With a comprehensive portfolio spanning sensing, control, safety, vision, motion, and robotics they provide their customers with a complete automation solution backed by a strong service and support network.

“Based on the amount of volume and experience we’ve had with Omron, I can say that over the years, Omron products have been extremely reliable,” says Louis Taraborelli, founder of WeighPack Systems.

“I’ve never received customer complaints or anyone calling to say, ‘Hey, we’re getting a tremendous amount out of service calls due to the controls on our products.’

“They (Omron) have proven to be very reliable,” he adds.

“We have machines today still running, 20 or 25 years later, on older-generation PLCs (programmable logic controllers) from Omron that are still very functional today.”

Louis says the high level of service that Omron provides on a global scale has made them a key partner in the success of WeighPack’s business.

“Omron has been a super partner to work with from a global support perspective,” he says.

“If we do have a problem in the field, it doesn’t matter where the source of the Omron products came from, we can count on Omron tech support on a global level.”

“For example, Omron Canada will support you even if we buy from Omron in Italy or China,” adds Justin. “It’s really easy.

“You don’t have to go through some

terrible phone system and beg for support: You can always get a hold of someone.

“There’s a lot of value in that.”

Omron has also set itself up with a strong network by building a vlue-add distribution network.

“So it’s not just Omron directly; it’s the re-sellers that they’ve chosen to partner with as well,” Justin says.

“We’re have over 30,000 employees in 120 countries worldwide,” says Frank Pennimpede, regional sales manager for eastern Canada at Omron Automation Americas.

“We tell WeighPack whether they buy products here in Montreal, China or North Africa, wherever you may be, you’re going to get the same high level of support

worldwide.”

Over the years, Omron has supplied a diverse variety of automation technologies for WeighPack’s machinery.

In WeighPack’s SleekWrapper ValTara flow wrapper series, for example, Omron’s control technologies give the flow wrapper four axis of motion on the panel.

“Our function blocks in our PLCs for motion are pre-tested and help in reducing the programming needed,” Pennimpede says. “This helps them a lot.”

The first two are for the thin ceiling and front and rear ceiling of this machinery, he explains, while the third and fourth blocks are used for the tensioner and the unwinding of the film.

Omron also supplied two variable frequency drives (VFDs) used to lower and raise the ceiling jaws of the machine.

“All of it is connected through our EtherCAT network to the PLC to have everything connected,” Pennimpede points out.

“In there we have function blocks, and an instruction set that accelerates or decelerates the various points we have to attain for this machinery,” he explains.

Omron technologies also power WeighPack’s VerTek range of vertical bagging machinery.

“We have our Omron PLC from the CP1H family along with our temperature control card in there, which controls the top and rear jaws,” Pennimpede says.

“We have safety relays that secure this machinery from A to Z and another safety relay that controls our door switches on this unit in case of emergency.”

Motion applications are particularly important for automated bagging technologies like the VerTek machines.

Pennimpede says there are a few key factors that are important when it comes to bagging.

The first is having a marker to make sure the bag aligns properly, he explains, which is performed with sensors.

The second is ensuring speed and accuracy.

“In the bagger, through our instruction set, we were able to get the speed required, resolution required, and the precision required,” Pennimpede says.

“You’ll get bags that are consistantly filled out properly, so you won’t get waste, and also get high throughput as well.

“Those are the things that WeighPack looks for in their machines.”

For WeighPack’s SpinDexer filling machinery, Omron has supplied the CP1H series PLCs, along with safety relays, to control the opening and closing of the doors.

“It controls the 16 heads to rotate and have the non-liquid fill up the bottles at a certain level, doing 60 to 70 bottles per minute,” Pennimpede says.

“It’s a modular type of system. Our PLCs can go from four, eight, 12 or 16 bottles that you can program for.

“The other good thing is we don’t do is create overflow,” he says, “which is really important.

“The pre-test function blocks help tremendously, as the speed to fill up those bottles is pretty quick.

“We can do batches of four, eight or 16, so you get high throughput at a high speed.”

Over the past few years, Omron and WeighPack have been working together on building high-precision packaging machinery for an industry that blends in perfectly with the grocery and pharma-

ceutical sectors: the cannabis industry.

“The cannabis industry for us was rather organic,” Justin Taraborelli relates.

“We build high-precision packaging equipment that is a seamless fit into cannabis production

“Through our brand recognition and relationships we’ve built in cannabis, it created new opportunities for us.

“There was strong demand for packaging pre-rolls, and the JuanaRoll, which we developed with Omron as our partner, has been a tremendous success,” Taraborelli states.

“It’s a high-precision machine that is extremely technologically complex on the back end, but on the front end it’s rather seamless and intuitive—easy to use, easy to maintain, easy to operate, and allows for tool-less changeover.”

Justin says the JuanaRoll automated pre-roll machine has become an overnight success with cannabis producers.

“The thing we’re most proud about is that repeat sales are coming because our clients believe in the machine,” he ays,

Above

The Vertek vertical form-fill-seal machine manufactured by WeighPack Systems at the company’s state-of-the-art production facility in Montreal leverages high-end Omron automation components to achieve robust throughput speeds of 50 to 100 pouches per minute, depending on the size of the pouch and type of product being filled.

“If we do have a problem in the field, it doesn’t matter where the source of the Omron products came from, we can count on Omron tech support on a global level.”

Website:

Email:

Phone:

“It’s proven to perform what’s expected, and now the customers are coming back for second and third machines,” he says.

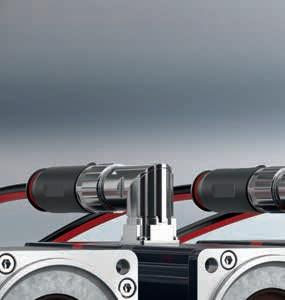

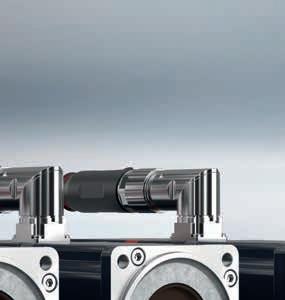

One the key components of the JuanaRoll machine is Omron’s Sysmac PLC automation platform, the compny’s latest machine automation platform from Omron with integration throughout: from controller to software.

According to Omron, the guiding principles behind the Sysmac automation platform are having one control for the entire machine or production cell; maintaining harmony between machine and people; and using open communication and open programming standards.

The automation platform features a new machine automation controller designed to integrate motion, sequencing, safety, networking and vision inspection; a new software (Sysmac Studio) that includes configuration, programming, simulation and monitoring; and a fast machine network (EtherCAT) to control motion, safety, vision, sensors and actuators.

Justin says that it’s the software that sets Omron apart from the competition.

“We really like Sysmac Studio software,” he states.

“It’s easy to use, it’s intuitive, it has an integration feature that we think is really smart, and it helps us managing our revisioning much better in collaborative programming,” he says.

“They (Omron) have also introduced some non-industrial standards that help us make fantastic, intuitive HMI (human-machine interface) terminal.

“This is a revolutionary terminal that is so quick that it can do five jobs in one.

“It can act like a PLC; it can support motion applications; it can support safety applications; it can support vision applications; and it can also support PC-type applications by working with SLU databases.

“It can do quite a bit,” Pennimpede says, “and it’s especially quick with motion applications.

“The response time to get the products from A to B, or on an indexing table, is really fast.

That’s why when we o er a kit with PLCs, HMIs and servos, OEMs get something that’s really valuable for what they’re paying.”

Also manufactured by WeighPack, the SpinDexer container filling machine on the right incorporates Omron’s Sysmac CP1H PLCs (programmable logic controllers) shown in the pictures below to fill up to 60 to 70 bottles per minute with various types of dry and powder products.

WeighPack also spec’d in the 1S Servo System package, whereby the first servo controls the compactor; the second controls the dampener; the third controls the twister; and the fourth the conveyor.

“All of this is connected through EtherCAT technology to the EtherCAT network. It goes to our PLC which controls all the I/O on the machinery,” Pennimpede says.

Justin says the servo package offers seamless integration with the rest of the Omron package.

“It’s been easy to use. It’s a reliable servo and it’s instrumental for the performance of the machine,” he says. “It’s really intuitive and it all works seamlessly together.”

Pennimpede worked with WeighPack on creation of the very first JuanaRoll machine.

“We’re starting to build more and more of these,” he says.

“This was one-of-a-kind, but since then, we’ve had other OEMs reach out and ask for some help,” he says, adding that reduction in labor costs and improvements in e ciencies are key drivers for the purchasing decisions of cannabis producers.

“Today with COVID restrictions and the goal of limiting human contact, the customer is always looking to automate their machines a much as possible, whether it’s by robots or automation systems.”

While quality, durable components and global-reaching high-level customer service and support have been key reasons for WeighPack’s long-standing relationship with Omron, cost has also been a deciding factor.

“As an OEM we’re cost-sensitive, and our clients are cost sensitive,” says Justin Taraborelli. “Omron’s PLCs are easy to use and they’re reliable.

Says Taraborelli: “For the amount of pressure were putting on the servos, we could use any brand.

“But for us, it is much more about the ease-of-use and programming. Omron has a really nice software suite that lays out a nice product roadmap for their studios.”

For his part, Pennimpede says Omron’s latest PLC system o ers quick response times, and that its servo-driven motion control system comes at a reasonable price point.

“We o er quality equipment and a good bang for your buck,” he says.

All in all, Louis Taraborelli sees a bright future for Omron and its partnership with WeighPack.

“We like the direction Omron is going in and I think their product life-cycle is going to be really rewarding—especially in non-industrial standards,” Taraborelli sums up. “For us, we really like building intuitive HMIs and better user experiences and Omron gives us that platform that allows us to segway into other technologies that we can piggyback on their platform.”

WeighPack Systems Inc.

Omron Automation Americas

ValTara SRL

Paxiom Group Inc.

Please see a video of running automatic WeighPack packaging machinery powered by Omron automation controls and software at the WeighPack Systems manufacturing facility in Montreal on Canadian Packaging TV at www.canadianpackaging.com

Bartel Machine is a 38-year-old company, based in Leamington, Ont., that designs and builds special-purpose automation equipment using the most advanced technologies from the automation industry’s major players.

Leamington has one of the largest concentrations of greenhouse growing in Canada, so greenhouse machinery is one of Bartel’s primary specialties. Although the city has a large population of seasonal workers, there are often not enough workers to cover the needs of the greenhouse industry.

To overcome this challenge, engineers at Bartel pitched the idea of creating a machine that automatically places greenhouse peppers in bags.

Because peppers come in a variety of shapes and can be prone to damage if not grasped along their unique contours, the bagging process is largely performed manually. However, if this task were to be successfully automated, greenhouse companies could save time, cut costs, and boost productivity.

Initially, Bartel created two machine prototypes using technologies from multiple automation solution providers.

This made it di cult to achieve the degree of flexibility the engineers were aiming for, since any modification would require extra e ort to make the di erent brands’ technologies sync.

Additionally, inconsistencies in their integration kept the overall e ciency from reaching its maximum possible level.

For this reason, Bartel decided to seek out an automation partner that could provide a complete end-to-end solution.

For the third version of the machine, which is now in production, Bartel worked with automation solution provider Omron Automation Americas

Since Omron products integrate well, Bartel could devote more energy to designing and manufacturing a modular machine that would scale up dramatically in response to changing application

needs.

To justify the cost of automation, the pepper-bagging machine also needed to work well for long periods of time without interruption, which Omron’s robotic technologies are also capable of doing.

Perhaps the most important benefit of implementing an Omron solution is the ability to change the motion profiles of various actuators with the utmost eciency.

Bartel was able to shave fractions of a second o each machine movement without destroying peppers or bags. These seemingly insignificant improvements are what make the system come

Omron’s Viper model six-axis articulated robot features specially designed grippers that self-adjust for the varying product sizes and contours.

alive, and they add up to a tremendous competitive advantage.

Bartel likens this strategy to race-car design, in which minuscule changes to aerodynamics at each point on the vehicle can work wonders for its speed over the course of a lap or an entire race.

Peppers, like any vegetable, are quite fragile and should not be tossed around in any automated application.

Compounding this challenge is the fact that each pepper possesses a di erent size and shape that necessitates a slightly di erent grip. If the system fails to grasp a pepper according to its unique shape, it could bruise or puncture the

- Clément Roy, Fermes Piscicoles Les Bobines

Clément’s company is a thriving trout farm and packaging operation in the beautiful Eastern Townships of Quebec.

Certi ed “Ocean Wise” and HACCP, Clément’s company operates at the highest aquaculture and environmental standards.

He recently allowed Canadian Packaging and EMBALLAGES magazines to visit his facility in East Hereford, head quarters for his growing business serving an expanding customer base that has necessitated an investment in production and packaging capabilities.

“I have read Canadian Packaging magazine for years, and continually nd it useful and informative. The in-plant stories are excellent, and we feel honoured to have our success story featured in the magazine,” maintains Clément Roy.

Do you have a customer who should be so featured? Let us know, we’ll be happy to shoot the pictures and tell the story of your next great Canadian packaging success story.

Ask us about shooting videos too.

Contact Stephen Dean at 416-510-5198 or at sdean@canadianpackaging.com

skin, rendering it unsellable.

Finally, the types of bags used today tend to be very thin, for cost reduction and sustainability purposes, making it essential for the system to delicately position peppers within the plastic film.

To ensure accuracy in picking peppers, Bartel developed a state-of-the-art gripper and mounted it on the end of an Omron articulated robotic arm. The gripper consists of a 3D-printed body with internal air passages and individually activated fingers that maintain a soft touch.

Since each finger works independently, the gripper’s hands can self-center on each individual pepper. One gripper uses six hands with four fingers each to pick six peppers at a time. On the robot, six grippers work simultaneously.

The machine’s conveyor contains plates that hold six peppers each. The robot uses the gripper, as described above, to grab the peppers.

The machine has a parallel bagging system that individualizes the bags, opens them, and seals them once the robot has placed the peppers inside. The sealing unit also deals with scrap plastic.

The bagging system is composed of linear actuators that use Omron’s 1S Series servomotors. A plethora of Omron sensors are used for part presence and to let the robot know that the plates have arrived. Together, one robot with two bagging systems, one on each side, represent a single module.

Scaling up the entire machine simply means adding more modules, each of which repurposes six or so workers who would otherwise be responsible solely for manual picking and bagging.

With fewer workers touching peppers before they go in the bag, the entire process is also much more hygienic.

One thing that is particularly special about this project is the high level of coordination between the Omron robot and servos. The servos stand out in a variety of ways, including size, controllability, ease-of-use, and ease-of-programming in tandem with robotics.

The latter benefit is largely thanks to the fact that the Omron NX102 machine automation controller with Sysmac Studio makes it possible to put everything together with a single platform, in one language, and on one screen. Making everything “shake hands” properly is easy with an Omron solution.

Bartel also appreciates the graphical interface of the Omron NA5 Series human-machine interface (HMI), which is easy to customize.

Since the engineers were able to connect the HMI to the robot, the sensors, and the servo drives in Sysmac Studi o, the new machine works well across all platforms. This is a significant advantage for a company that designs and builds a wide variety of automated machines.

With the NX102 machine automation

controller and Sysmac Studio covering the entire solution, there is only one phone call to make when help is required.

Given that peppers are non-linear, there will be events in which bags behave in unexpected ways and operators will need to enter the cell. In these rare but inevitable cases, the bagging line will need to be shut down.

“By creating a singlepackage solution, Bartel and Omron are at the forefront of what is likely to be a groundbreaking development.”

Bartel used Omron safety technologies, including F3SG-RE light curtains for the robot zone and multiple gate interlocks and emergency stop pushbuttons, to make sure that the line’s motion will automatically stop if a person needs to access the bagging area.

This is also the reason why each module contains a single robot with two separate bagging lines.

If one bagging line has an issue, the robot can continue to place peppers onto the second bagging line, while an operator safely troubleshoots the first.

This innovation helps ensure that production can continue to at least some degree even when challenging problems arise.

By creating a single-package solution for a task that has previously eluded such a high degree of automation, Bartel and Omron are at the forefront of what is likely to be a ground-breaking development for the greenhouse industry with key customer benefits by:

• Providing a fully integrated and scalable solution for pepper bagging;

• Accommodating variations in pepper shapes and sizes;

• Dramatically increasing e ciency by shaving time o every movement;

• Incorporating safety measures that keep parts of the line working;

• Improving hygiene by minimizing contact with fresh produce

In addition to freeing up workers to work on more creative and fulfilling tasks, such programming automation also improves the hygiene of sorted vegetables by reducing the amount of contact.

Complete with safety and seamless motion within a single platform, the new pepper bagging system sets the stage for more exciting machines to come.

SUPPLIERS

Omron Automation Americas

Eliminate and shrink control cabinets while expanding dynamic motion control: The AMP8000

Distributed Servo Drive System from Beckhoff integrates a servo drive directly into a servomotor. A unique benefit of the AMP8000 series is that servomotor power ratings* and installation sizes remain virtually unchanged. Proven One-Cable Automation in the EtherCAT P standard delivers real time communication and industrial power on one cable, and an innovative IP65-rated supply module powers multiple motors in the field. As such, the AMP8000 minimizes space requirements, installation effort, material costs and motion system footprint in a big way. sizes remain almost identical to standard AM8000 servomotors from Beckhoff no changes in existing machine designs required same high power ratings as before despite drive integration* TwinSAFE drive safety technology built into every servomotor

*Compared with a combination of servo drive and servomotor

For several years AI (artificial intelligence) and Industry 4.0 has been the subject of much hype, with the race to shorten production times, reduce costs and improve quality a continual focus. Following a year of pandemic disruption, today North American food factories are seeking practical technologies rather than unattainable solutions. As they set out on a new path, they want machines that can propel them forward, facilitate smarter decision-making and increase e ciency.

Step forward food safety specialist Fortress Technology.

With robust communication the starting point of any good digital transformation program, Toronto-based Fortress recently launched its new suite of connectivity software.

Adding to the existing turnkey packages like Contact Reporter—included as standard on all Stealth and Interceptor metal detector models— plus optional Contact Manager to facilitate the collection of data over a network, Fortress unveils the addition of communication adapters and Contact 4.0, software to give food factories complete choice in data retrieval technologies to support their Industry 4.0 journey.

New options include OPC/UA and Ethernet/IP communication to facilitate real-time end-to-end production visibility and enhanced maintenance, QA (quality assurance) and due diligence.

“Connectivity is key,” says Fortress Technology regional sales manager Eric Garr. “We are entering a new Internet of Things (IoT) era, where everything that can be connected will be connected.

“It’s all about knitting together the extraction of data and bridging the gap between machines and humans to help predict, rather than react, to all types of production scenarios,” Garr states.

Manually monitoring food inspection machine performance can be extremely labor-intensive and impact productivity. Even those that have upgraded legacy systems continue to gather data on a ma-

chine-by-machine basis, rather than integrating and analyzing information side-by-side and building up a full performance picture, suggests Garr.

For many manufacturing IT departments, selecting which Internet of Things (IoT) technology will add the greatest value can be deemed a minefield and create a sense of burden.

There’s a misperception that moving towards Industry 4.0 will require extensive investment, a dedicated team of developers, and slow or limited return on investment.

Garr explains: “Although many of Fortress customers express a strong interest in innovation and harnessing the power of data capture, some have been reticent to take the leap of faith.

“There is an underlying belief that they will not be able to connect new applications with existing legacy inspection machines,” Garr expands. “Humans can often get overwhelmed when there are too many options.

“As a result, data integration projects can stretch on for months, years, or never reach a decision.

“In such a fast-moving sector like food manufacturing, this has an immense impact on competitiveness,” Garr asserts.

To assist customers in gathering gather real-time data, Fortress digital conveyor, gravity, pipeline and combination metal detectors are equipped with optional machine sensors to run signals between everything from reject confirmation to bin doors, air pressure, infeed, encoders and more. Deploying more sensors naturally generates more intelligent machine, fault and process data.

Automated communication adapters can enable factories of all types and sizes to rapidly stream data within the firewall of their business network to support better decision-making.

All of this data can be viewed in Contact Reporter, notes Garr, resulting in a more fail-safe and smarter inspection system. Moreover, Contact 4.0 provides further features, including gathering data generated by multiple networked metal detectors within a fleet and automatically sending e-mail alerts when faults occur to production managers.

For any food plant making tentative steps into digital decision making, Contact Reporter provides a robust, easy-to-use event logging and record-keeping solution available as standard on Stealth and Interceptor metal detectors.

No complex integration is required: users simply install Contact Reporter onto their business PC, and all the timestamped data is extracted via USB on a machine-by-machine basis.

When uploaded onto the PC, Contact Reporter software converts this data into readable formats detailing contaminant events—ranging from rejects to machine setting changes and test results.

“This automated record-keeping of all events and performance verifications is essential for quality control and, ultimately, audits,” Garr points out.

“Additionally, the generated data can highlight any bottlenecks to the production manager,s and drill down to the machine’s performance flagging potential upstream processing issues.”

Rather than manually collecting and transferring data, Stealth and Interceptor users can opt for automated data extraction. Through an in-built Ethernet port, Contact Manager does all the legwork of polling the metal detectors over a network

When expanding your canning or bottling operations, there is much to consider. It can take many months to plan and procure new equipment prior to installation. Plus, it can take several months to get to producing saleable cans after you’ve installed new equipment. You know beer, we know conveyors – we can assist with design, consultation, installation, service and support during and after run-in. From conveying components, guide rail, speed reduces and bearings to Perceptiv™ diagnostic services, we can help you get new conveyors running smoothly and make the complex simple.

For more information, contact 800-626-2093 or PTSAppEng@regalbeloit.com.

regalbeloit.com/RunDry

Creating a better tomorrow™...

*Madtree

connection. This can lead to more consistent reporting and a more accurate data picture for each metal detector, as well as future-proofing the ‘Smart Factory’ automation projects.

Both Contact Reporter and Contact Manager maintain compliance with all international food safety standards, including HACCP, BRC and GFSI/SQF

“For food SMEs in particular, Fortress recognizes that digital fear remains prevalent,” states Garr. “Contact provides a transition step from manual, hard-copy data gathering to a digitized Food Quality Management system and begins to facilitate data use in a more sophisticated way,” states Garr.

Stressing that it’s never too soon to set the wheels in motion, Garr advises organizations of all sizes, but especially SMEs, to begin exploring established automation platforms to optimize productivity.