Poultry processor makes no bones about its uncompromising food safety and quality obsession

Story on page 14

As an essential business in the retail supply chain, our network of manufacturing and fulfillment sites remain fully operational and productive, with available capacity to accommodate the rapidly evolving demands at retail.

Our skilled workforce and world-class automation allow us to meet the changing needs of our customers and their retail partners.

Our continued focus is to provide a clean, healthy, and safe work environment to ensure the seamless flow of products our customers and communities are counting on us to deliver.

Menasha continues to implement proactive and controlled measures to combat the spread of COVID-19. The safety, health and wellbeing of our employees, their families, our suppliers, customers, and communities remains our number one priority.

Together we will ensure your business continuity by protecting, moving and promoting your products better than anyone else in these uncertain times. For further information please contact us at Menasha.Canada.Solutions@menasha.com

Predicting the future is usually about as useful as resisting the forces of science and Mother Nature.

pressures to meet demands related to shipping characteristics, smart automation, competitive costs, customer preferences and product value.”

DECEMBER 2020 | VOLUME 73, NO. 14

Reader Service

Print and digital subscription inquires or changes, please contact

Anita Madden, Audience Development Manager

Tel: (416) 510-5183

Fax: (416) 510-6875

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher

Stephen Dean | (416) 510-5198

SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227

GGuidoni@canadianpackaging.com

Account Coordinator

unfolding trends and market demands driving packaging development include safety/ security, delivery coding, customer unboxing, sustainability, reusable packaging, e-commerce and personalization.

But as the end of 2020 draws to a close with a long-awaited glimmer of hope sparked by development of COVID-19 vaccines, it’s time to lift the heavy veil of gloom that has made it such a year to forget, without ever forgetting the lessons it has taught us so cruelly.

With most wealthy economies around the world bound to remain stuck in their downward spirals at least until global vaccination e orts achieve the sort of herd immunity levels we need to return to some semblance of pre-COVID normalcy, focusing on the future at leasts o ers a much needed release valve for a year’s worth of sadness and anxiety many of us feel today.

And for the packaging and labeling industries, at least, the future looks much better than the present feels, according to a landmark new report released a few weeks ago by leading supply chain industry group MHI (Material Handling Industries)

Aptly tiled Transformation Age: ShapingYour Future, the comprehensive study is a must-read for all material handling, logistics and supply chain professionals of all stripes, and that includes the global packaging industry that suddenly finds itself at the center of global public and regulatory scrutiny on the account of its allegedly oversized environmental footprint.

And that’s perfectly okay with us. If one accepts the premise that no publicity is the worst publicity, the public’s misguided distrust in the inherently good and noble aims and purposes that packaging fulfils can and should be answered in the court of global public opinion in coming years, if for no other reason than just to show how far the role and function of packaging has evolved over the last decade, which has been nothing short of transformational.

“Over the last decade, packaging and labeling have shifted from being commodity elements to value-added products and solutions that serve key expectations from industrial, commercial and consumer customers,” the report states.

“The experience of package shipping, unloading, opening and disposal are now di erentiators in product and service delivery [and] innovation and growth in these solutions will escalate over the next 10 years.

“This growth will come with added

The report quotes Sealed Air Corporation’s presidentTed Doheny’s recent remarks about the profound impact that the unfolding digitalization and the Internet of Things have already had on the packaging supply chain that no one could foresee 10 years ago.

“How does a package communicate with people who want to know what is inside, when it was filled, how much it weighs, whether it was stolen, and whether the contents are nearing their expiration?”, says Doheny, urging companies to focus on development of new interfaces between packaging and technologies, such as blockchain.

“Packaging companies can use digital tools that note exactly when something went into a package,” he explains. “We can own that information and share it with customers, so they can trace the inputs and track the package.

“By providing that information, blockchain helps us add value,” says Doheny, noting that smart automation also requires new rules and practices for packaging to be addressed in di erent ways than those used in the past with a human workforce.

As Doheny points out, “A robot hand might not be as soft as a human hand, so what packaging is required?

“We may have to design for both robots and humans.”

There are multiple factors driving this growth and shaping sector innovation, according to MHI, including e-commerce, digitization, sustainability, margin pressures and customer preferences for convenience, customization, safety and security.

As the study asserts, “More retail packaged goods brands will emerge as leaders in sustainability, responding to customer demands and driving packaging and labeling innovations.

“Greater integration of this philosophy into design, sourcing, production, shipping and merchandising practices will mark this decade for significant progress in positive supply chain value.”

And on that upbeat note, Happy New Year to all!

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Media Designer

Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO

Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA

ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

Hershey raises its packaging game

As the popularity of video games continues to soar exponentially among today’s younger consumers—with an estimated 23 million Canadians openly identifying themselves as gamers—capturing their attention is no easy feat, even for the iconic Oh Henry! brand candy bar.

But that’s exactly what the 100-year-old brand did a few weeks ago with the launch of the new Oh Henry! Level Up bar aimed directly at gaming enthusiasts in need of a quick nutritional boost to raise their gaming

performance while they’re playing.

Featuring the time-tested sweet and chewy taste profile comprising the goodness of peanut butter, crunchy pretzels, peanuts, caramel and a chocolate coating, the new Oh Henry! addition has certainly raised the bar’s packaging game to a new level of excellence with a evergreen element of arcade graphics, specifically the pixel, and the authentic 8-bit infused typography with a twist on the Oh Henry! classic branding to convey the message that the Level Up bar is made specifically made for gamers.

While gaming and snacking typically go hand-in-hand to begin with, brand-owner Hershey Canada Inc. felt the brand needed an extra ‘Wow’ factor in its packaging to stand out on-shelf and to connect with the gaming

community’s collective consciousness.

Working with Australian-based package design specialists Anomaly, the Hershey marketing team developed an innovative promotion using special codes printed on the inside of Oh Henry! Level Up wrappers for an in-game “virtual” level boost for the popular NBA 2K21 basketball video game.

“The Oh Henry! bar has always been about conquering hunger, but now we’re helping Canadians conquer the court as well,” says Alejandro Mosquera, marketing manager for the Oh Henry! brand.

Beer holder adds joy to shower

Canadian craft brewer Steam WhistleBrewing has never been shy about using packaging and merchandising innovations to help grow the sales of its popular flagship Steam Whistle Premium Pilsner brand to mark special seasonal occasions, but this year the Toronto-based beermaker has arguably outdone itself by resolving the age-old mystery of enjoying an ice-cold beer while having a hot shower.

Called the Steam Whistle Shower Caddy, the fun and functional contraption removes the fear of having the beer watered down, being splashed with soap, or accidentally going down the drain by using its high-quality silicone construction to adhere to any smooth flat surface to hold a tall can of beer close by and out of harm’s way.

Sold for a limited time at LCBO (Liquor Control Board of Ontario) outlets with six-packs of 473-ml aluminum cans of Steam Whistle Pilsner, “The innovative Steam Whistle Shower Caddy solves a real problem for beer lovers,” says Tim McLaughlin, vice-president of marketing at Steam Whistle Brewing. “But Steam Whistle will not accept responsibility for people suddenly feeling the need to shower more often, spend more time in the shower, or convincing themselves that they are great singers.”

Located in rural southwestern Ontario, Elmira’s Own Tomatoes has supplied the local and surrounding communities with delicious, quality vegetables for many years the old-fashioned way. The company’s tomatoes are left to ripen on the vine—allowing for maximum flavor and nutrient content—and its natural growing practises include using bumblebees to pollinate the plants and introducing additional bugs to help balance the eco-system.

During last summer, Elmira’s Own took the next step along its sustainability journey by changing the conventional plastic packaging to adopt a renewable and compostable alternative—now packing its tomatoes in a compostable fiber pulp tray and wrapped in transparent NatureFlex NVS film from Futamura Chemical Company. Designed to run on existing fresh produce flowrap packaging lines, the NatureFlex NVS films are highly renewable, being manufactured from wood pulp sourced from sustainably managed plantations, while also meeting all the global standards for industrial composting and are certified to meet all the home composting standards for backyard composting.

Heat Sealing Packaging, Concord, Ont.-based supplier and distributor of leading packaging materials and equipment for the food processing industry, has announced the launch of a new company website (www.heatsealing.ca) and corporate logo (see image) to update the company’s continued commitment to innovation and sustainability. “We were equally inspired by the incredible commitment and e ort that the Canadian food processor industry made to continue the supply of fresh food in the face of a global pandemic,” says company vice-president Dan Margorian. “We believe our new look reflects Heat Sealing Packaging today and reflects our path forward, to emphasize the strength of our capabilities, delivering innovation with our collective commitment to servicing our clients as best we can. These are all key elements and will remain the cornerstones of Heat Sealing Packaging.”

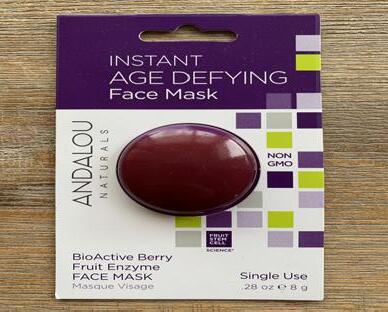

St. Louis, Mo.-headquartered rigid plastic packaging products group TricorBraun has been honored with four 2020 AmeriStar Packaging

Awards from the Institute of Packaging Professionals (IoPP) last month in recognition of innovation and excellence in packaging design. “At TricorBraun, everything we do starts and ends with our customers, so to receive this recognition for some of our innovative customer solutions is an incredible honor,” says TricorBraun president and chief executive o icer Court Carruthers. “Our team, the best team of packaging professionals in the world, is excited to be celebrated for our hard work, dedication and creativity.” The four AmeriStar award-winning entries include:

• A new delivery system for the FUNacho chili and cheese sauce sold in convenience stores, stadiums, and movie theaters around the world.

• A new refillable bottle for the for Truman’s line of household cleaning products, designed to evoks a beaker in a science lab, with the water fill line falling right where the bottle begins to angle outward.

• A redesigned hourglass-shaped the package for EcoClean Solutions’ Green Gobbler Drain Cleaner

• The new Sei Bella lipstick package featuring a custom-made over-shell cover and gift-box made from 100-percent recyclable cardboard material.

Chicago-based packaging products group Berlin Packaging has significantly increased its footprint in Canada following last month’s acquisition of Consolidate Bottle, venerable Toronto-headquartered manufacturer of consumer glass, plastic and metal packaging products founded in 1910. “Consolidated Bottle has an extraordinary history and shares our focus on quality, service and results for customers,” says Bill Hayes, chief executive o icer and president of Berlin Packaging. “We are extremely committed to the Canadian market and see tremendous growth opportunities for our employees, customers and suppliers,” says Hayes, noting that the new owners plan to continue operating Consolidated’s facilities in Toronto and Montreal with the existing workforce under the new Consolidated Bottle Corporation, a Berlin Packaging company, banner. “We are extremely committed to the Canadian market and see tremendous growth opportunities for our employees, customers and suppliers,” Hayes states. “We are thrilled to partner with Berlin Packaging for our next chapter,” adds Jonathan Rutman, chief executive o icer of Consolidated Bottle. “Our team and our customer base have enjoyed phenomenal growth over the past several years, and we are confident that our shared future is bright with Berlin Packaging.”

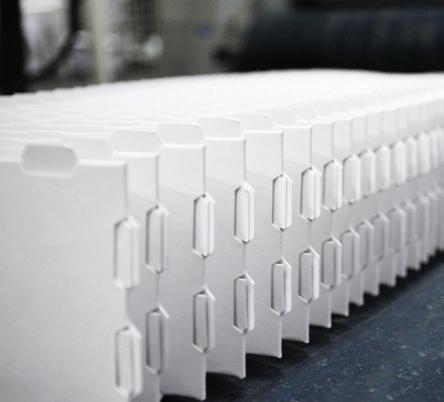

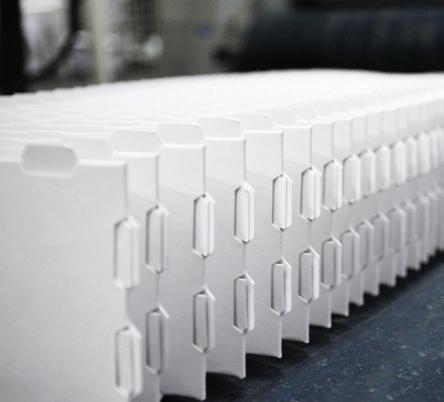

Camden, N.J.-headquartered folding carton producer Rondo-Pak, LLC has completed a major expansion of its production facilities in Camden and Juan, Puerto Rico, which included installation of a Koenig & Bauer

Iberica Optima 106 die-cutter capable of processing 8,000 sheets per hour, and a Bobst Expertfold 110 foldergluer. According to the company, the new equipment will enable it to meet growing market demand for specialty cartons incorporating value-added features such as child resistance, tamper evidence, crash-lock or auto-bottoms, and inner partitions. “We are continually striving to increase our capacity, e iciency and quality to meet and exceed the demands of our growing customer base,” says Rondo-Pak president and chief operating o icer Bob Reilley. “These purchases are critical towards achieving those objectives and supporting our continued growth and are important steps in our ongoing investment plans.”

Chicago-headquartered food processing and packaging equipment group Duravant LLC has reached a definitive agreement to acquire the assets of Cloud Packaging Solutions, Des Plaines, Ill.-based , manufacturer of high-speed horizontal flexible packaging equipment, including the patented rotary soluble pod equipment and ultra-high-speed packet, pouch, and sachet packaging machinery. According to Duravant, Cloud systems o er a perfect strategic fit for its own Mespack brand of stand-up pouch and stick-pack equipment technologies. “I couldn’t imagine a more complementary addition to the Duravant family of operating companies,” says Duravant president and chief executive o icer Mike Kachmer.

Trivium Packaging, globally-operating manufacturer of metal packaging products, was a multiple winner a last month’s 2020 Can of the Year awards, picking up a gold meal for the cutting-edge tinplate end with the EasyPeel aluminum membrane designed and produced by Trivium. Produced in collaboration with Amcor and Kezzler for global dairy producer Royal Friesland Campina, the project involved implementation of an optimal process for applying the metallic foil with a unique QR code for each product onto an EasyPeel lid at the company’s state-of-the-art nutrition plant in Hoogeveen in the Netherlands.

In addition, Trivium was also awarded:

* Silver medal for the 250-ml impactextruded aluminum bottle made for the U.S.-based Ste Michelle Wine Estates

* Bronze medals for the seven-ounce impact-extruded aluminum cans for Formulated Solutions Cutter Foaming Hand Sanitizer, andt he 10-oz (296-ml) impact-extruded aluminum bottle for Hand in Hand soap, produced at Trivium’s plant in Youngstown, Ohio, as

part of a project to convert personal care products into sustainable aluminum packaging.

“These awards represent our mission to deliver high quality, innovative, and sustainable packaging,” says Trivium’s chief growth o icer Rob Hu man.

“There is no greater accomplishment than working closely with our partners to deliver packaging solutions that exceed expectations in protecting and promoting their brand.”

The new vial table is part of Aphena’s new large-scale biologics packaging operation.

Aphena Pharma Solutions has announced that it now o ers cold chain storage and large-scale biologics packaging and distribution services at a new 500,000-square-foot facility in Cookeville, Tenn., that was specifically purpose-built for FDA-approved pharmaceutical and packaging operations. Built as part of the

company’s US$21-million capital upgrade project t at the company’s Solid Dose Division, the facility has dedicated 47,000 square feet to cold chain storage, accommodating 14,000 pallet spaces. According to Aphena, this space features 24-hour, state-ofthe-art security; redundant power supplies with a failover compressor; temperature mapping and monitoring; automatic alarm notification; and chilled storage and distribution with temperatures ranging from 2ºC to 8°C refrigerated and -10ºC to -18ºC frozen.

“This addition of cold chain storage, turnkey biologics packaging and distribution services establishes Aphena’s position as a top contender in the pharmaceutical contract service space,” says Aphena’s executive vice-president of sales Eric Allen.

Leading Austrian plastic packaging products manufacturer Greiner Packaging and German consumer products multinational Henkel have been honored the Green Packaging Award 2020 of the World Packaging Organisation (WPO) last month in recognition of the sustainability attributes of the combination cardboard-plastic packaging used by

Henkel for its Persil 4in1 Discs laundry pods, boasting 50-percent r-PP (recycled polypropylene) content. “Greiner Packaging has been producing sustainable solutions for many years, and the new Persil 4in1 Discs packaging solutions are an example of the ongoing collaboration between our companies in this area,” says Greiner’s, chief executive o icer Axel Kühner, citing 40-percent weight savings and 50-percent reduction in the use of virgin materials used to make the new package compared to the previous version. “We make the inside of the plastic container from white virgin material, which guarantees a high degree of color contrast with the colorful detergent discs,” explains Eduardo Celada, international packaging manager for laundry care at Henkel. “The packaging’s outer coating, meanwhile, contains recycled plastic obtained from end consumer households but this layer’s gray color does not impact the packaging’s look because it is wrapped in an attractively printed cardboard sleeve.”

Maximize the shelf life and eye-appeal of your perishable food products with Vacuum Skin Packaging from Reiser.

n Reiser form/fill/seal Vacuum Skin Packaging (VSP) provides nearly twice the shelf life of a traditional MAP package.

n Reiser VSP packaging wraps tightly around the product’s shape, acting as a second skin while removing all atmosphere from within the package.

n High-clarity, wrinkle-free, glossy skin film provides an attractive presentation that puts the focus on your product.

n Reiser VSP packaging machines are available in a range of model sizes to match specific application and output requirements.

The new Viper thermal inkjet (TIJ) printing system from Squid Ink Manufacturing, Inc. is designed to print superior quality hghi-resolution characters on porous and non-porous surfaces in high-speed product coding and marking applications with up to 0.5-inch (12.7-mm) of print height per printhead. The new Viper TIJ utilizes high-performance Funai no-mess ink cartridges to print up to 600-dpi high-resolution codes on wood, coated and non-coated stocks, polystyrene, films, foils and other substrates to print permanent marks that dry in seconds on glossy cartons, cases, trays, plastics at speeds up to 60 meters (197 feet) per minute at 300-dpi resolution. The Viper TIJ printing system features an 8.9- full-color touchscreen PC that gives users access to the printer’s internal messages and print functions, while allowing users to create and edit messages using Squid Ink’s intuitive Sirius PC software to print date codes, lot numbers, barcodes and other graphics needed for most coding and marking applications.

Squid Ink Manufacturing, Inc.

The new Sharp Packaging Systems MAX-PRO 24 continuous bagging system from Pregis LLC can handle a wide range of products and bag sizes to provide a cost-e ective and e icient solution for fulfillment operations with a broad e-commerce o ering product o ering. Simple to operate and integrate into current operations and processes, the MAX-PRO 24 has a number of features that contribute toward reducing packaging costs, including innovative web handling features that simplify operations, automated pass-through settings, an easy-touse bag threading system, and a user-friendly HMI (human-machine interface) control panel that

simplifies operation and guides troubleshooting. Accommodating bags up to 24-inches-wide and 36-inches-long, while handling products that weigh up to 10 pounds, the MAX-PRO 24 features a low-force jaw designed for safe and simple operations, according to Pregis.

Pregis LLC

The new Tu Stack Pro intermediate bulk container (IBC) from Elkhart Plastics, Inc. is an inner cylindrical tank positioned within a heavy-duty all-poly structural frame designed to fit a variety of applications and process uses. Available in 275- and 330-gallon sizes, the Tu Stack Pro o ers optional top lifting plates and is designed and tested for 1.9 SG (specific gravity) product weight, and its rotationally molded construction enables Tu Stack Pro to provide superior impact strength.

Elkhart Plastics, Inc.

The new Gawis 4D dimensional and thickness measurement system from Agr International, Inc. is an innovative light-based solution for non-contact thickness measurement of non-PET containers, including HDPE, PP and PE plastics. The patent-pending method incorporates a proprietary programmable spectrometer and utilizes an integrated method to analyze the signal level of multiple absorption bands within the entire NIR band width—allowing for highly colored bottles with low transparency to IR light to be measured for thickness. According to Agr, the new system is designed to provide highly accurate and repeatable dimensional gauging, as well as high-precision, non-contact thickness measurement over the entire bottle or preform, with robust throughput of less than twenty seconds per sample.

Agr International, Inc.

Leading Canadian meat processor Maple Leaf Foods is quickly emerging as one of the world’s most sustainable protein companies, according to the 2020 Coller FAIRR Protein Producer Index of Environmental, Social and Governance Performance list that ranks the company as the second-best among the world’s top 60 publicly-traded meat producers in terms of CSR (corporate social responsibility) performance metrics.

Coming justs days after Maple Leaf was globally certified as carbon neutral, its high ranking on the list—up from 7th place last year— also comes with a special ‘low risk investment’ recognition that only two other companies on the list have received.

“We are grateful that the meaningful progress we made on our sustainability journey throughout 2020 has been recognized,” says chief executive o cer Michael McCain. “At Maple Leaf Foods, we believe that real change results from meaningful action,” he states, noting Maple Leaf is one of only three animal protein companies in the world to adopt science-based greenhouse gas emissions targets.

The annual Coller FAIRR Protein Producer Index ranks the listed meat, dairy and aquaculture com-

panies by assigning scores to 10 key sustainability factors that include governance, greenhouse gas emissions; deforestation and biodiversity loss; water scarcity and use; waste and pollution; antibiotics; animal welfare; working conditions, food safety, and alternative proteins.

In fact, Maple Leaf Foods’ leadership in plant protein was a key factor contributing to itss rise in the global ranking. With the company aiming to reach $3 billion in annual sales of plant protein by 2029, Maple Leaf is already o to a

flying start in this category with a successful recent launch of the Maple Leaf 50/50 brand of socalled “fusion protein” products. Launched as a “direct response to rising consumer interest in flexitarian eating,” according to the company, “these products are made with 50-percent premium quality meat and 50-percent natural and plant-based protein for consumers who want to make sustainable pro tein choices for themselves, their family and the planet—without giving up meat entirely.”

When it comes to clip packaging solutions, there is no equivalent to TIPPER TIE. Since its founding in 1952, the company has introduced many welcome innovations in clippers and clip technology, starting with the Tipper Casing Tyer. Over the years, and thanks to the acquisition of TECHNOPACK GmbH and ALPINA GmbH, the product line has grown to address the needs of meat processors around the globe.

Today, TIPPER TIE and Pemberton provide application expertise, equipment and after-sale support to customers of all sizes – from the independent sausage maker and small butcher shop to multi-national Fortune 500 processors.

Expand your packaging knowledge with PAC’s comprehensive courses. Designed and lead by packaging experts to deliver essential skills and practical knowledge that builds a foundation for success.

Packaging Essentials

Explore the world of packaging, from development, smart packaging and food preservation to prepress, print and graphic design processes.

Paper Packaging Plus

Learn about the combination of materials and structural choices available in constructing a package and how to evaluate the strength of packaging materials.

Get to know polymers and plastics from their base elements to their most complex integrated applications. Complete Plastics Packaging

Packaging Circularity

Discover how to deliver better packaging solutions by using a life cycle approach and optimizing for the total value chain.

For more information and to register today, visit pac.ca/paced

PAC is a safe place for packaging leaders to collaborate, innovate, educate, and celebrate. For more information on how a PAC membership can benefit you and your organization, visit www.pac.ca

High-end poultry processor deploys new state-of-the-art X-Ray inspection technology to remove tiny bone particles and other contaminants from its new boneless chicken product line

By George Guidoni, Editor

Photos By Pierre Longtin

Waking up with the chickens may not be everyone’s ideal way to kick o a new day. But for the hardworking folks employed at the Giannone Poultry processing plant in Saint-Cuthbert, Que., being an early bird is all part and parcel of putting in a good day’s work.

Founded in 1989, the family-owned business has come a long way since shifting its focus from raising small-game birds to producing premium fresh chicken products for an ever-growing list of customers across Canada and New England, and it did not achieve this successful transformation by simply winging it.

Aside from being one of the first North American processors to use revolutionary new air-chilling methods to produce tastier and more wholesome meat, the pioneering company has also been a poster child for the virtues of humane animal treatment and welfare, headstrong in its belief that a happier chicken is always bound to be a better-tasting chicken.

As the company’s website proudly proclaims, “The Giannone method is based on ethical concerns for the welfare of animal and humane care, which results in a more tender, tastier product.

“We give our chickens the time to complete their normal growth cycle, making sure that they are grain-fed with corn, soy and wheat supplemented with natural vitamins and minerals.

“All our chickens are raised in barns to give them enough room for freedom of

movement.”

The company’s genuine animal welfare ethos—validated with the Antibiotic-Free Certified Humane certification—is in fact one of the several calling cards used by Giannone Poultry to grow its client base in the highly competitive poultry industry.

With capacity to slaughter and process up to 725,000 broilers per week, the 250,000-square-foot Saint-Cuthbert production facility has recently started a second production shift to keep up with soaring market demand for its products, boosted even further with Giannone obtaining the highest Halal certification for the Halal hand-slaughtered method.

Employing about 250 people, the busy plant houses a total of six production lines—each dedicated to a specific product type—to turn out a variety of products ranging from whole chicken to seasoned whole chicken and various primary and secondary cuts, which are shipped in bulk or vacuum-sealed inside air-tight skin packaging for retail sale.

“We are a high-end poultry processing plant that aims for nothing less than 100-percent quality and service levels,” says Giannone Poultry vice-president Bruno Giannone, citing the company’s unique air chilling process as one of several key competitive advantages in what he calls a “very tough” market segment.

“All our chickens are chilled in our exclusive air-chilling process with no water added,” Giannone explains.

“This ultra-modern system is greatly superior to the regular water-based method,” he says, “because air-chilled chicken conserves the meat’s natural juices, while also preserving its precious enzymes and proteins.

“Eliminating water from the process reduces bacterial contamination and significantly extends the product’s shelflife,” says Giannone, noting that Canada is the only country to have a supply management system for live chicken products.

“As a federally-inspected slaughterhouse we have many regulatory systems that we have to respect,” says Giannone, “and we have to plan all our slaughtering and marketing operations within this supply system, ensuring optimal safety and full compliance to regulations from plant level to the environmental impact.”

On the plant level, the company spares

no e ort to maintain a strict HACCP (Hazard Analysis of Critical Control Points)-compliant sanitation and hygiene environment as required by its SQF (Safe Quality Food) certification, one of the highest levels recognized worldwide under the GFSI (Global Food Safety Initiative) program, and its commitment to environmental protection is second to none, according to Giannone.

“We treat 100 per cent of all the water coming out of the plant operations,” he says, “and we also have an environmental certification that allows us to burn all the sludge that the processing plant produces, so there is no sludge sent to the landfill.”

As Giannone explains, the facility operates an on-site biomass combustion system using wood and the processed sludge to heat and create the steam required for production and plant needs— eliminating the use of diesel fuel and substantially reducing the company’s environmental footprint.

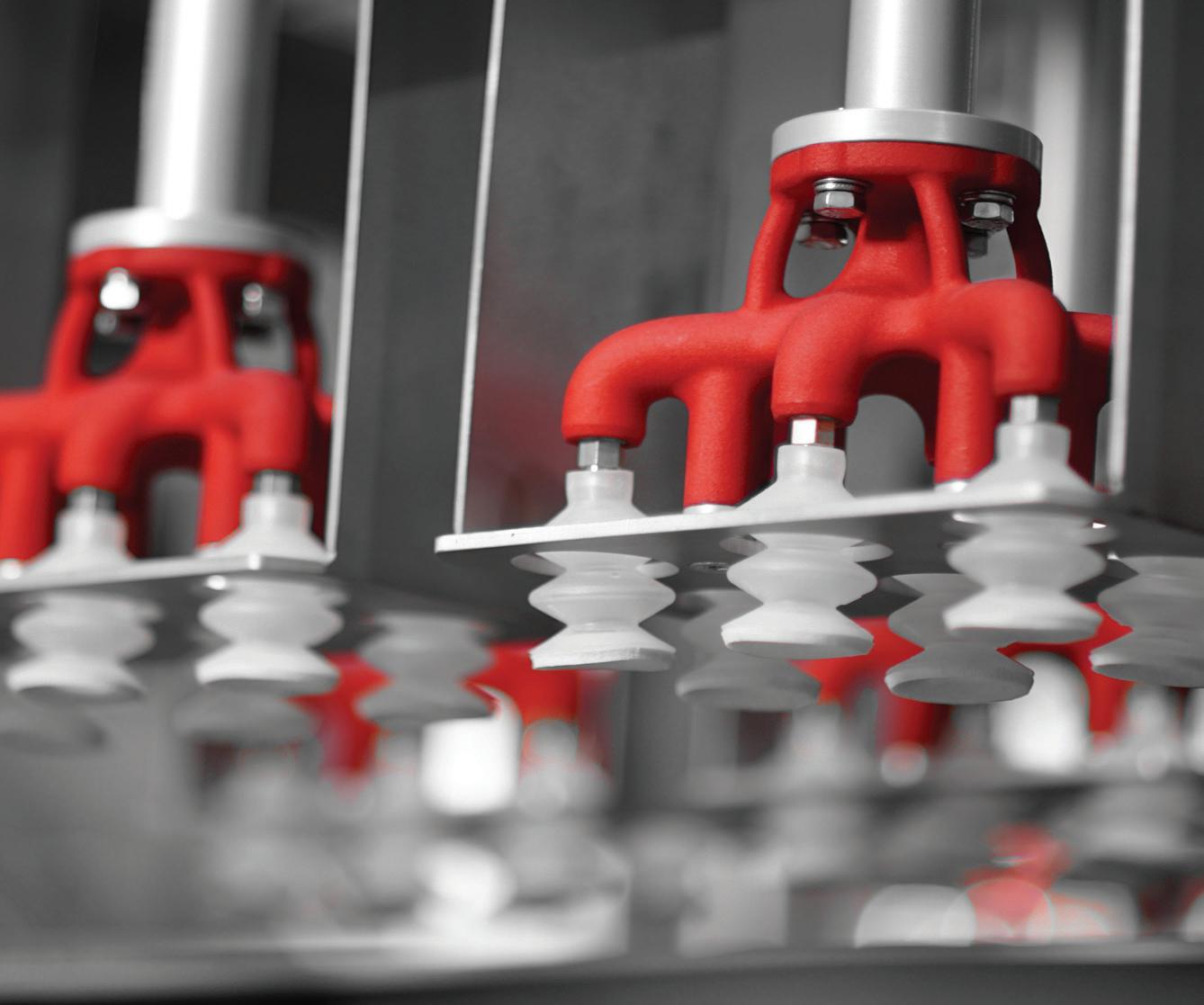

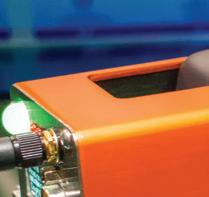

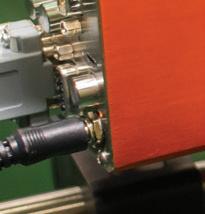

Naturally, the company’s focus on animal and environmental welfare is fittingly matched by its relentless focus on product and consumer safety, as evidenced by the two Eagle Pack 1000 Pro X-Ray inspection systems installed at the

plant in 2009 to detect tiny contaminants making their way into packed cases of bagged bulk chicken products coming o the plant’s production lines.

Both units were expertly installed by food safety and product quality-focused sta of PLAN Automation, Orangeville, Ont.-based packaging line integrators who are the largest packaging automation supplier in Canada.

Employing over 60 people and 11 technicians at o ces across Canada, PLAN Automation is in fact Canada’s exclusive distributor for the product inspection systems manufactured by Eagle Product Inspection of Tampa Ba, Fla., storing about $425,000 worth of spare X-Ray system parts at locations in Toronto, Montreal and British Columbia, along with a PXT demonstration system ready to be deployed for testing, trials, emergency product reclaim projects and rentals right across Canada.

The two Pack 1000 Pro X-Ray systems installed by PLAN Automation in 2009 have proven to be exceptionally good servants for the facility’s rigorous quality control process, according to Giannone.

But despite being great for inspecting large-sized cases or packages, the Pack 1000 Pro systems have their limitations

(from left) Outside of the Giannone Poultry processing facility in Saint-Cuthbert; the brand new Eagle RMI 400 PXT X-Ray detection system installed by PLAN Automation; chicken breasts pieces being sent back for rework; the new PXT technology provides poultry bone detection down to 1.0-mm.

“We are a high-end poultry plant that aims for nothing less than 100-percent quality levels.”

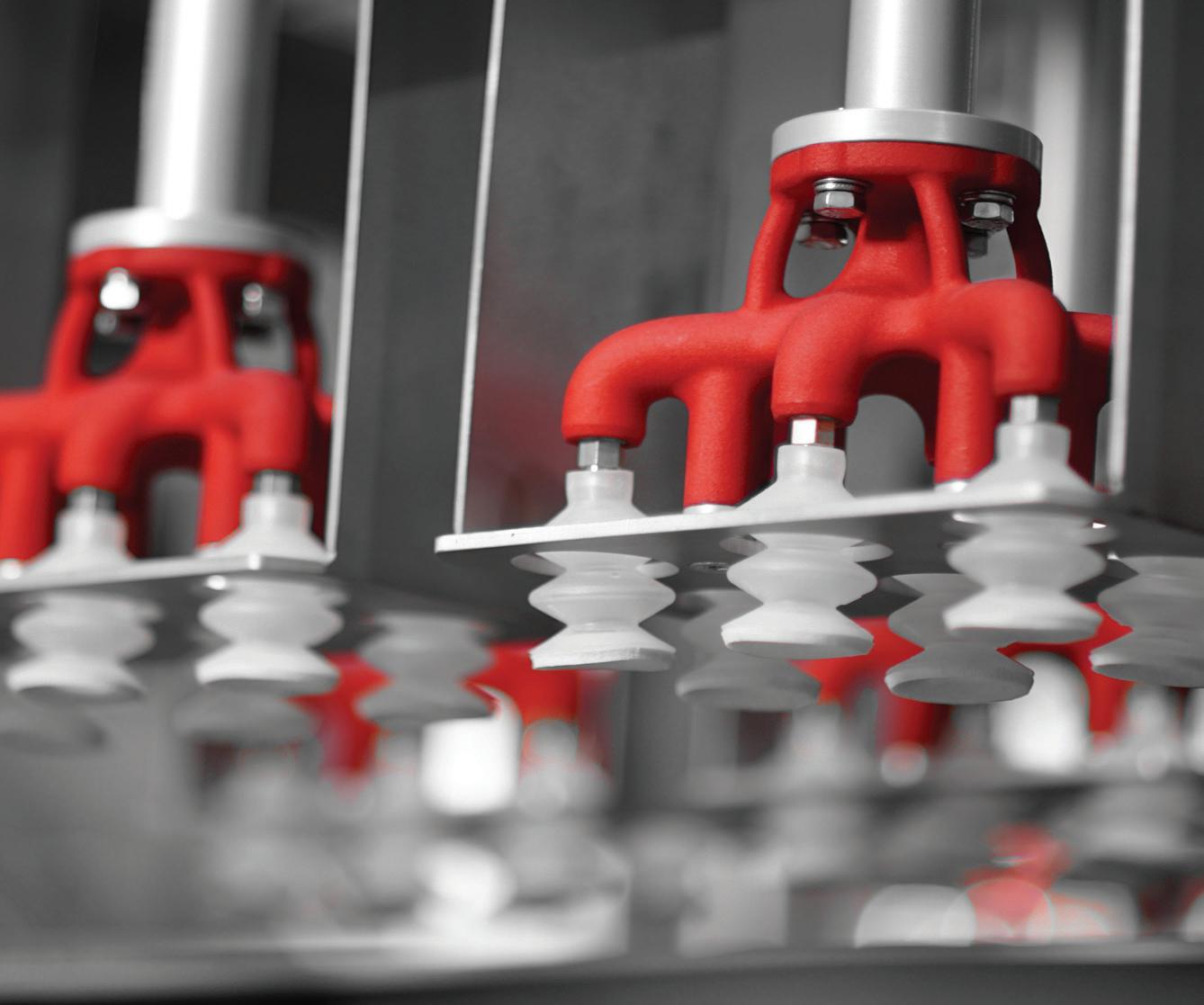

The Maralec weighing, grading and portioning system supplied to the plant by Reiser Canada; food-contact grade plastic conveyor belting and conponents used to transfer inspected pieces of bonessles chicken for placement inside plastic-lined bulk boxes; finished boneless and skinless chicken breasts inside retail skin-packs.

when inspecting individual chicken breasts, thighs and boneless whole-leg meat.

As a result, Giannone decided he would need even a more powerful X-Ray inspection solution to put to the test on a new production line dedicated to processing boneless chicken products—adding another promising value-added o ering to the company’s premium product portfolio.

After having installed a new automatic deboning line at the plant recently, Giannone realized the new process also resulted in generating many tiny bone fragments that would stay embedded in the meat—many of them being so tiny that the visual inspection method used by line operators would be ine ective due to their small size.

To resolve this new challenge, Giannone once again turned to PLAN Automation to come up with a suitable solution.

As it happened, Eagle Product Inspection had just introduced a brand new RMI 400 PXT (Performance X-Ray

Technology) X-Ray system capable of detecting small poultry calcified bone fragments as small as 1.0-mm or even smaller, compared to the minimum 3.0mm 5.00-mm particles that traditional X-Ray system are able to detect, due to their low density and the creation of cluttered images outside of the chicken’s breast area, such as thighs and trim.

Combined with an X-Ray infeed and reject system, the new poultry inspection solution was developed specifically to deliver superior inline contaminant and bone detection with reliable and consistent results to provide optimal brand protections.

Designed to NAMI standards and built with hygienic construction for the inline inspection of raw and unpackaged poultry products prior to further processing, the new system features unobstructed sightlines and contoured surfaces to minimize potential material harborage areas, while ensuring fast and convenient visual inspection during cleaning with a unique curtain-less design.

According to Eagle, the combination

of breakthrough PXT technology and SimulTask PRO image analysis software provides the industry’s highest level of inline automated bone detection available.

“SimulTask PRO analyzes the high-resolution images captured with PXT, allowing the application of multiple processing algorithms to work in parallel for every image—providing remarkably more accurate image analysis then ever before,” says Eagle.

“The ultra-high physical resolution of the detector run in a high-resolution mode, combined with the TDI (time delay integration) array, provides both low noise and high contrast.”

Suitable for both slaughterhouses and further processor of meat products, the system excels in the inspection of all forms of poultry—from fresh or frozen, bulk flow to retail, and from single- to multi-lane processing lines—to ensure extremely low FFR (false reject rate) performance to help minimize product rework, while maximizing uptime and improving throughput.

As the product is X-Rayed to detect bone fragments and other foreign body contamination caused by tiny bits of glass, aluminum, steel, stone and other standard foreign debris finding its way into the process, the X-Ray system’s contaminant detection sends a signal to the reject unit to activate the retractable belt, whereby the rejected product is dropped onto the reject return conveyor and delivered back to the operators for rework.

Using a lighted trim table, the operators can quickly access and rework the rejected product, which is placed onto a return chute that feeds the main line, while discarding any extra trim or waste into a nearby waste container.

Running at speeds of up to 240 pieces

per minute in dual-line configuration, the new RMI 400 PXT X-Ray inspection system was installed at the Saint-Cuthbert plant this past summer and, according to Giannone, has already proven to be an indispensable part of the new boneless chicken production line.

“The new X-Ray system has been resulted in a dramatic reduction of bones in our boneless products,” Giannone extols, “basically down to zero.

“By purchasing a dual-lane system, we were able to double our output, or do di erent products at the same time,” Giannone notes, “and we have had great customer feedback since the installation.”

Says Giannone: “We always update our facility on a yearly basis, and one of the most important investments in machinery and equipment we have made this year was purchasing this new X-Ray machine from PLAN Automation.

“Giannone Poultry prides itself on providing quality poultry product with 100-percent service level,” he says, “and adding this equipment to our production process is definitely helping us maintain the Giannone name in the market as a high-quality poultry processor.”

For PLAN Automation’s vice-president and chief operating o cer Mat Bédard, such customer feedback provides perfect validation for his long-term faith in the technological superiority of X-Ray inspection technologies developed by Eagle.

“This radically enhanced detector technology features smaller diodes with a smaller pitch, combined with a revolutionary dual-energy TDI detector to collect more detailed data about the product being inspected,” Bédard says.

“When analyzed with advanced image analysis software, this provides images with much higher resolution,” he adds.

“The breakthrough PXT allows poultry processors to find the smallest bone fragments, down to 1.0-mm, with high repeatability, low false rejects and less rework,” Bédard states.

“Moreover, the PXT can be deployed to suit a wide range of applications at any product control point, including chicken and turkey, intended for retail packs,” he says, “as well as incoming raw material bound for further processing and finished products like sausages, patties, nuggets, and even breaded fish fillets.

“This versatile technology is successful in detecting poultry bone and foreign contaminants in both fresh and frozen products, and it can handle thick products like turkey breasts or thinner products such as chicken tenderloins,” Bédard explains.

“The system can also e ectively detect poultry bone fragments in all types of cuts such as breast, thighs and trim meat,

as well as finished and cooked products in their final retail package.”

“From an operational standpoint,” Bédard points out, “processors can use X-Ray devices equipped with PXT in both single- and multi-lane set-ups either as stand-alone critical control points, or networked to other systems to enable full process optimization and efficiency analysis.”

Says Bédard: “Using an automatic deboning machine like they have at Giannone will always result in creation of smaller loose bone fragments that can go undetected at the rework table, where operators can only use visual detection.

“But with its ability to detect and pinpoint bones a small as 1.0-mm or even smaller, this new system really sets the gold standard for bone and contaminant detection that has never been seen before.

“I have personally seen this machine catch bones as small as 0.6-mm at the Giannone plant,” he says, “so there is no question in my mind that having this system in place will help Giannone remain one of the industry leaders, by applying state-of-the-art X-Ray technology to ensure they have the best-qual-

(Top)

Close-up of the Leeson SST motor from Regal Beloit used to power the takeaway conveyor transporting chicken pieces from the Eagle X-Ray inpection system down the line for packing.

(Bottom)

Air-chilled birds being lined up and prepared for a run on the Giannone plant’s new automatic deboning machine.

ity product available on the market.”

As Giannone reciprocates, “All I can say about PLAN Automation is that they have been a great partner for us to work with.

“They have a great team that provided full support from the purchase, delivery and installation of the new X-Ray machine,” Giannone states, “and they approach their business very much the way we do, providing the highest possible quality and safety to the end-use customer.

“We have some further new exciting projects planned for our facility in 2021,” Giannone concludes, “and PLAN Automation is definitely included in those plans.”

PLAN Automation

Eagle Product Inspection

Reiser Canada Ltd.

Regal Beloit Corporation

Please see the Eagle RMI 400 PXT X-Ray product inspection system in action at the Giannone Poultry processing plant on Canadian Packaging TV at www.canadianpackaging.com

Voltigeurs Farm’s director of planning and marketing Georges Jr. Martel (foreground) and Duropac’s senior packaging procurement representative Claude Ratelle display the perfectly vacuumpacked Duropac bags used to package the company’s premium organic chicken brand.

Organic chicken processor beefs up its packaging capabilities to cope with buoyant demand from leading grocery giants

By Andrew Snook

As manufacturing and processing operations grow, bottlenecks are almost always certain to occur at some point within the process.

Whether it’s at an infeed, a processing line, packaging, warehousing or shipping, upgrading various aspects of a plant to ensure its e ciency is a never-ending battle.

At Ferme des Voltigeurs Inc. (Voltigeurs Farm ), Drummondville, Que.based producer of high-quality organic and grain-fed poultry products supplying grocery stores across the country since 1958, that bottleneck was building up for

some time within its cut-up line and packaging department.

“With a process like this, when you start with a live bird, each time you increase the speed somewhere, there’s always a new bottleneck somewhere else,” explains Georges Jr. Martel, director of planning and marketing at Voltigeurs Farm.

“Packaging was over-saturated, but there was no more ability to increase the capacity or the speed of the line.”

To solve the company’s bottleneck issues, Voltigeurs Farm spent the past five years planning and investing in some of the latest packaging technologies, and those investments are paying o .

The processing plant is a continuous

line that starts with birds being slaughtered on-site at speeds of 2,500 to 3,000 birds per hour.

Demand for the company’s products is always increasing, with .Voltigeurs Farm currently producing approximately 75 di erent products to supply multiple brands.

One of its biggest clients is grocery store chain Metro , which co-branded with Voltigeurs Farm to supply 10 di erent poultry products for Metro’s Irresistibles store brand through its Naturalia and Organic products, including boneless grain-fed chickens, breasts, thighs, skinless thighs and drumsticks sold at Metro and Metro Plus store locations.

To keep up with increasing demand, the company has been planning out upgrades to all aspects of its production lines over the past five years, identifying the packaging line was one of the problematic areas that required immediate up-

(Above)

The Tipper Tie Rotamatic automatic rotary vacuum-packing system supplied by Pemberton & Associates.

(Right)

The RS 420 thermoform packaging machine manufactured by VC999.

“The shrink level is very good. It’s a brilliant and nicelooking bag that catches the eye.”

“When the birds go out of the air-chill line, we have to package at the same speed because we don’t want to slow down the killing line,” Martel explains, adding that the packaging department was preventing the production lines from meeting their peak e ciencies.

To improve the capacity of the packaging department, Voltigeurs Farm invested in several pieces of new technology over the past three years.

One of those investments was a Tipper Tie Rotamatic automatic rotary vacuum-packing system, manufactured by JBT FoodTech in the U.S. and distributed in Canada by Pemberton & Associates of Mississauga, Ont.

The unit was installed for the bagging of Voltigeurs Farm’s whole chickens and turkeys.

“It was quite a big investment, about $300,000 to do

the vacuum clipping, instead of having five or six machines with one person on each,” Martel explains.

“We installed it last year,” he relate. “The advantage is we need less people on the line and we increase the capacity of the line.

“Now we can increase orders and have three or four less workers [on that line].”

Éric Lechatelier, vice-president of sales for Pemberton & Associates, says that the Tipper Tie Rotamatic is a fairly straightforward machine to add to a processing plant.

“It’s a pretty standard machine that major operators in North grades.

(From top left)

Bagged chicken coming o the Tipper Tier

Rotomatic; top film layer applied to the packs of fresh chicken breasts on the RS 420 thermoformer; Videojet

DataFlex thermal-transfer printer; Georges Jr. Martel.

America use,” he says.

“It’s more or less a plug-and-play system, other than a few adjustments.

“It’s not a di cult machine to install,”adds Lechatelier. “It’s more about the organization of conveyors to feed that machine and the outfeed—putting everything in place around it.

“The machine itself is not really complex,” he adds. “Even if the operator needs a bit of training, in two days it’s a done deal.”

“Coupled to a continuous shrink tunnel, the system supplied by Pemberton & Associates produces

an airtight, aesthetically pleasing final package,” adds Patrick Colin, national sales manager for Pemberton & Associates.

After the Tipper Tie Rotamatic was installed, the line now only requires one or two employees to feed the machine and put the plates on each bag.

The bags for the unit are supplied by Duropac, Candiac, Que.-based supplier of vacuum pouches and modified atmospheric packaging (MAP) products for slaughterhouses, food processing plants, butchers, delicatessens and retailers.

“Ferme des Voltigeurs con -

tacted Duropac to find an alternative supplier for their poultry bags,” recalls Duropac’s chief executive o cer Jean-François Bourdeau, adding that the company was looking for increased flexibility from their supplier related to printing plate changes, lower minimum production runs, and more competitive pricing.

Bourdeau says his company’s bags are unique because they o er the lowest minimum product run for poultry bags in the Canadian marketplace, along with:

• the lowest printing plates costs that allow making graphical

changes at a lower cost;

• competitive price per bag;

• an inventory management program that includes warehousing and purchasing by Duropac;

• high-quality poultry bags for a product being manufactured in a BRC (British Retail Consortium)-certified plant.

“The shrink level is very good, and the appearance of the bags on store displays is very nice,” Martel says. “It’s a brilliant and nice-looking bag that cathes the eye.”

The other significant investment in the company’s packaging line was the purchase of a new VC999 RS 420 thermoform packaging machine and a new Videojet DataFlex thermal-transfer printer to take care of all the product traceability requirements.

“We had a VC999 thermoformer already, but we bought a larger one a few years ago,” Martel says, adding that it was a much-needed purchase to continue expanding his company’s processing operations.

“The Videojet DataFlex printer on the thermoformer increases our capacity because we some generic labels for four brands, and you don’t need to change the roll of labels each time,” he explains. “ The VC999 system and the Videojet coder are a good combination.”

The company also purchased a Sipromac shrink tunnel for its

whole-chicken line.

“After we package the birds into Duropac bags and clip them with the Tipper Tie, they then go through to shrink tunnel,” Martel explains. “Then once everything is put in the box, it goes to an automatic line scale to apply labels on the box.”

To continue growing and meeting future product demands, the company has another large project on the go—involving its refrigeration line and eviscerating department, according to Martel.

“Next year we will start construction of a new building and new automated eviscerating equipment that will increase our speed up to 4,000 birds per hour.

“Right now, we’re limited by our refrigeration line,” Martel says, adding that the transfers to the refrigeration line will be automated after the upgrades are complete.

“But it would not have been possible to think about this if we had not invested in the packaging and cut-up departments before,” he concludes.

“This is the reason why we invested so much capital in the packaging department—to be able to cope with the next big increase in volume.”

VC999 Canada Ltd.

Pemberton & Associates

JBT FoodTech

Videojet Technologies, inc.

Duropac

Sipromac

(from left)

Claude Ratelle of Duropac inside the plant’s on-site storefront; Georges Jr. Martel holds up freshly-bagged whole chickens; a close-up of air-tight packaging provided by the Duropac bags; thermoformed retail packages of premium chicken meat placed inside corrugated trays for shipment.

Throughout its 40-year history, Quebec label producer Imprimerie SteJulie has known how to elevate each printing technique to a point where it is an art mastered to perfection.

As leaders in this industry, the company is always looking for a way to do things better in order to give its customers a more comprehensive and contemporary range of products and services that includes labels, shrinkseleeves, flexible packaging, finishing processes and specialty services.

Proud of its progressive environmental mindset and corporate philosophy based on achieving the highest CSR (corporate social responsibility) performance in the label industry, Imprimerie Ste-Julie has recently become the first printer in Canada to o er Ravenwood’s new linerless labeling technology to replace traditional labeling methods.

Doing everything that the regular labels can do to provide e ective labeling solutions for food products such as fish and meat, fruits and vegetables, pastries, ready-to-eat foods, and pharmaceutical and cosmetic products, linerless labels do it all without the traditional support paper layer (liner)—meaning drastically less waste a the end of the process, along with considerable cost-savings and a notable reduction in the customers’ overall environmental footprint of their business.

The application of the linerless labels can be done manually or automatically, with the ideal scenario using the Nobac applications system for automatic linerless application.

This technology o ers about 10 di erent packaging options to help customers save time and to guarantee no application defects during the process.

Having recently become a certified ECOresponsible–Level 1 company, Ste-Julie is naturally very excited about the new business opportunities o ered by this certified recyclable, waste-free packaging solution that easily adapts to any product format.

To find more about this innovative new

labeling technique, the Canadian Packaging magazine recently reached out to the company’s Canadian linerless product manager Éric Thibault to explore the subject in further detail.

When did your company get into the linerless label business?

We purchased the equipment that allows us to manufacture this type of product in June 2019, and the installation at our plant was completed in January 2020.

How big of a business is linerless, in terms of market share, globally and in Canada?

The linerless technology, patented by Ravenwood Packaging in England, has been around for over 10 years.

It is currently the most widely used packaging technology in Europe, and Imprimerie Ste-Julie has been o ering it exclusively for Canada since last year.

Linerless labels are new in Canada, but they are already found on some packages in the displays of some products imported from the U.S.

Canada, despite its market being 10 times smaller than that of the U.S., will undoubtedly become a great consumer of linerless labels.

Food companies are starting to rethink their packaging philosophy, and they know full well that consumers are now demanding responsible, intelligent and recyclable packaging.

Linerless meets all these criteria, because it was developed with all of this in mind.

Linerless labels are said to be especially well-suited for the labeling of food products packaged in skin-pack retail pakaging formats.

What is your company’s market share in the linerless business?

Our company currently specializes in the printing of self-adhesive labels and shrinksleeves. We wanted to take a greener direction, while continuing to package products in our current niches.

We wanted to change the image of our industry by making it greener, because we believe that it is everyone’s business do to so.

Our company currently has annual sales of over $20 million, but we believe that it will be possible for us to significantly increase this number within 10 years with linerless labels alone.

What are the advantages of linerless labels versus lined labels?

Compared to other linerless labels known in Canada, where the back of the label is 100-percent covered with glue and silicone, the Ravenwood linerless labels we

A rendering of the many packaging formats suitable for the application of linerless labeling solutions.

o er use 80 per cent less glue and silicone, since only fine lines of glue and silicone are positioned in specific areas, depending on the packaging.

Compared to conventional labels, our linerless labels o er several advantages.

Having no support paper, they generate no manufacturing waste, and no waste after use.

As for roll diameter, we can reduce transportation costs and storage space by 40 per cent.

Linerless labels can be printed on both sides, therefore doubling the space available to communicate brand messaging to the consumers.

They easily come o the trays after use, allowing for recycling of the label and of the tray.

We can o er linerless in two ways: either on a roll, for automatic application by Ravenwood applicators; or on sheets for manual application.

The Nobac 5000 applicators are very versatile and e cient, but they do require an investment.

They are very easy to use, and some models allow you to apply up to 10 di erent types of labels.

The biggest challenge for customers is the desire to take an eco-responsible approach.

This technology requires a di erent way of thinking, both for operations and for administrative decisions.

This technology meets several criteria for government subsidies based on increasing productivity and reducing the carbon footprint.

How complicated is it for exi ing paaging lines to turn over to linerless solutions in their process?

Integrating the Nobac 5000 into current customer production lines is as easy as integrating a conventional labeler.

The machines are very compact, and they can be fitted with variable printheads and linked to electronic scales. They are versatile tools that simplify the work of users.

The compact machines and are often

placed between two conveyors. They are easy to install, and a few hours’ training is su cient for the operators.

The machine maintenance is simple, and most adjustments require no tools.

There are definitely many productivity gains enabled by this technology.

The optimization of your chain of operation is guaranteed, with applications possible at throughput speeds up to 150 -ppm (pieces per minute), with a minimal loss of only one to two labels per reel change, which itself only requires 60 seconds.

The Nobac 5000 applicators truly are reliable allies in linerless production.

How mu of your company’s business is now driven by the linerless label solutions?

Actually not much at the moment, because we only started to include linerless options in our production in January of 2020.

However, we recently acquired two new presses in order to meet the growing demand for our various products, as well as in anticipation of the take-o of linerless solutions in the market.

We are currently in contact with several big players, and the arrival of skin-pack packaging in Canada leaves no doubt that there will be strong growth in demand for our linerless recyclable zero-waste labels.

Who are the main end-users of linerless labels at the moment, and what new indu ries do you expe to join in the future?

Currently our customers are all in the food sector, including fish, meats (fresh and frozen), fruits and vegetables, and prepared meals.

We do expect to reach other sectors soon, such as the packaging of soap bars, bottles, etc.

We are aiming to extend this new range of labels, because they inevitably meet the expectations of consumers, who are looking for innovative and eco-responsible packaging.

What is the general market outlook for linerless labels in the future: globally, in Canada, and in terms of you company’s business?

There is no doubt that linerless labeling represents the future packaging solution for the food industry.

Currently in Europe, it is by far, the most widely used type of packaging. For Canada, the potential is enormous, as Canadian consumers are respectful of the environment, and all the big chain stores are looking for this type of packaging.

The good news is that linerless meets the demands of consumers and also o ers many production benefits for the users.

As for Imprimerie Ste-Julie, the acquisition of this technology corresponds in every way to our corporate values.

We believe that this product is ingenious, and our relationship with the Ravenwood team in the U.S. and U.K., as well as with our Ravenwood-certified equipment distributors in Toronto and Quebec, are strong.

We are very proud to be able to o er this line of labels to the Canadian market, and we see a bright future for what linerless labels can bring to businesses and consumers.

What is the value proposition that your company o ers to the market with your linerless solutions?

This product is designed for the food industry of fresh and frozen goods. It is a product that consumers are looking for, because it is attractive and recyclable.

This zero-waste product is easy to use and it allows users to record major productivity gains, while substantially reducing their carbon footprint.

This is what our linerless labels bring to the Canadian market, and anyone who is interested in benefiting from this technology can fully count on our support for easy and expert integration.

Imprimerie Ste-Julie Ravenwood Packaging

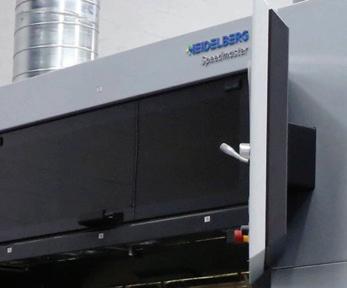

By Isidor Leiser

The global printing industry, packaging included, is under intense pressure to transform itself. Brandowners are upping the pace with many new and di erent requirements—meaning the industry has to be more competitive than ever to deliver the innovation that our brand-owner clients are looking for.

One very important aspect is sustainability. Printing, and especially packaging, is under huge pressure to improve its carbon footprint and to limit waste.

Today’s younger generation participates in regular demonstrations to put pressure on governments and brandowners. Although they often don’t know why packaging is important, many of them tend to assume that packaging is just somehow inherently evil.

Most don’t understand the benefits of packaging and look only at the waste it generates.

Even though there are many more sustainable solutions available today, a lot of them are not implemented simply because they are not yet economically viable.

Yes, everyone wants a better, cleaner planet, but nobody is prepared to pay for it. Packaging customers are out to cut cost, whatever it takes.

Our group has, for example, developed many new solutions and brought them to the market.

But even though Stratus Packaging is certified to both PEFC (Programme for the Endorsement of Forestry Certification) and FSC (Forest Stewardship Council) standards, with our process validated by Imprim’vert (Green Printing) carbon footprint analysis, our turnover from our “green” products is still very small.

Maybe we are not good enough in promoting or selling our solutions, but the resistance to change is also still very

strong—too strong in my view. I really hope to see more sustainable packaging materials coming through, along with more environmentally-friendly inks and printing presses able to print and process substrates in a more environmentally-friendly manner.

In the context of relentless consumer demand for more sustainability, better quality, shorter delivery times and reduced costs, all printing technologies are improving, with innovation often driving the transition of applications from one printing technology to another.

That said, it also important to avoid the hype of those who only believe in one printing technology (their own) and don’t appreciate the advantages of others.

I expect major changes to come for all printing processes as they need to improve e ciency, waste management and quality, while significantly reducing their environmental impact.

As the traditional print techniques are becoming more and more digital, with sensors all over the machines taking over time-consuming tasks from the operator, new digital set-up tools enable printers and converters to be more e cient by reducing the set-up time and increasing productivity.

The digitalization of our world and our lives is everywhere, and it is rapidly transforming the print and packaging industry.

While digital printing may be a competitor to the more established traditional processes, it can also be part of the solution for printers and converters to become e cient, to calculate their real costs more precisely, and to integrate

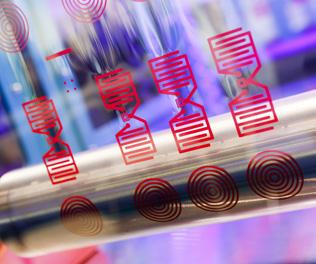

Product label manufacturers are expecting increased business opportuniies in coming years with growing demand for RFID tags and printed electronics to be applied to a vastly expanded range of branded consumer products.

physical products into the digital world using new technology such as AR (augmented reality), to give an example.

Moreover, applications like RFID (radio frequency identification) and printed electronics (see pictures) also o er great opportunities for the print industry to connect with the digital world.

Digital printing in general—incorporating prepress, printing and converting in one system—is in step with the rise with the automation of all the steps of the print workflow. Hence it is helping operators to optimize the entire production floor, rather than just the printing parts.

Moreover, it also links printers and converters better with their customers and suppliers with seamless integration into multichannel communications o ering personalization (individualization) capabilities.

It is time to start thinking beyond the printing press. Substrate innovations are going to be critical in the coming years. The digitalization and the automation of the entire workflow will change many organizations, and new technologies will require the hiring of new sta and development of new skills.

The way you will engage with your clients will change significantly as they are all soon going to be digital natives.

So rather than resist the changes, be ready to embrace them.

ISIDORE LEISER is chief executive o icer of Stratus Packaging, one of the leading European label converters using both conventional and digital technologies to transform the label industry.

Next-generation leadership performance

Hitachi’s UX Series continuous inkjet printers represent the pinnacle of innovation in marking and coding technology, all while showcasing Hitachi’s reputation for Reliability, Ef ciency, and Ease of Use. sales@harlund.com

Environmentally friendly while realizing a low running cost

High reliability, and reassured maintenance and service networks

Simple touch panel operation and maintainability

Digital process integration and optimized energy

efficiency hold key to a more sustainable global economy

By Jean-PascalTricoire

As we all continue to adapt to the ‘New Normal’ and learning new ways to live, we all see that digitalization as the solution to make remote and collaborative operations possible, while strengthening our resiliency by allowing us to better understand, anticipate and adapt to change with greater agility.

By enabling greater e ciency, at a much lower cost and with a much faster implementation, as well as better energy use and operational processes, it is also enabling a steep change in sustainability in everything we do.

Digitalization has disrupted the way we live together, and it is now disrupting the way we live with our environment—by enabling us to bridge progress and sustainability together.

Just as Internet had dramatically changed the way people live and work together, the new Internet of Things that connects machines to machines will completely disrupt our current notions of e ciency and sustainability.

Thanks to large data centers, we have a multiplication of Big Data and AI (artificial intelligence) that can be used to have machines training other machines digitally, with massive amounts of data generated through digitalization.

This creates a virtuous circle, where digitalization also lays foundation for managing a much more desirable future for all of us.

Just as cellphones became smart phones, buildings are becoming ‘smart buildings,’ the industry is moving to ‘smart’ manufacturing,’ and cities’ infrastructures are moving to the ‘smart city’ model.

And it seems intuitive that the world would be massively more electric, with

Schneider Electric’s chief execitive o icer Jean-Pascal Tricoire (right) deilvering a powerful keynote address at the company’s virtual forum on digital innovation last month, highlighting the company’s strong focus on process digitlization and energy e iciency.

the best example being this ongoing mass migration in the direction of electric cars in the next 10 years.

But the biggest migration for electricity down the road will be in buildings. In many countries around the world, building are still using fossil fuels for their heating functions, and it will take a massive e ort to see them moved to renewable electricity.

“We have seen a massive difference in the resilience levels of companies that had digitized their processes and those who have not”

Some would say that electricity is not a new technology, but it’s not about electricity as we know it.

It’s about renewable energy, especially solar energy.

It’s about decentralized micro-grid; it’s about the possibility to create net zero-carbon buildings; it’s about using solar panels or wind farms to power electric cars.

Saving energy resources is good for our planet and for our companies’ bottom lines, and if we can leverage digital eciency to achieve much better energy eciency in every building and every manufacturing plant out there, we can achieve new levels of e ciency at new building and manufacturing operations at much lower cost point, while increasing the rate of retrofits of existing installations.

The biggest problem is not new projects: it is the existing stock of buildings and manufacturing instillations that we need to digitize in order to become more energy-e cient in everything we do..

While living with COVID-19 has made things painful for all of us, it has forced us

to adapt to digital technologies faster than ever thought possible, and there is no going back.

Being able to do things remotely by using digital collaborative tools to design a construction site, to assist machine operators through augment reality, or completely train operators using virtual reality is priceless.

Throughout the COVID crisis, we have seen a massive di erence in the resilience levels of companies that had digitized their processes and those who had not, finding themselves in a real bind.

And one thing we have found is that resilience comes from the automation of processes that can keep going locally without human intervention through digital monitoring of system installations, because its puts you in a much better position to understand what’s going, and prevent any breakdowns.

Another thing we have learned about resilience is that you’re only as resilient as the weakest point in your process, which demands digital integration throughout the entire IT system.

The other thing that the COVID-19 has made clear is just how vulnerable we are to natural threats. Just as a virus can shut down a society and kill the economy, we need to tackle the biggest wave of all

coming at us, which is climate change.

At Schneider Electric , we are focused on o ering more and more services and education to our customers to keep progressing on sustainability, which is like a marathon without the finishing line.

We believe that the only true way to gain in sustainability, as well as economically, is to target a much higher level of energy e ciency through a much higher level of digital integration.

This means the integration of energy supply and automation; integration of every connected object on the shop floor or in the building; and integration of every end-point object connected into the loop up into the Cloud.

We’re talking a life-cycle integration, whereby your installation should be completely digitized from design stages into building and commissioning, with seamless integration into the world of the world of operation and maintenance.

We are proud that our ‘smart’ factory in Lexington, Ky., where 90 per cent of all processes are completely paperless, has been recognized by the World Economic Forum as one of the ‘lighthouse’ factories of the new smart manufacturing age.

Over the past 16 years, Schneider Electric has been working hard to build

up a unique portfolio of application software and artificial intelligence solutions to help customers optimize the way they design, build and operate their installations.

Using the Schneider portfolio to manage information better has enabled all project stakeholders—from the construction site to user, designer, architect and end-user—to test every available option for planning, scheduling, costing and materials in real time on the digital platform.

Our customer Walmart, who is very committed to sustainability, realizes that its environmental footprint is not just a byproduct of what they do, but also a byproduct of what its suppliers do.

By working with Walmart to digitize and integrate their supply chain, we have been able to save them over one million metric ton of carbon emission per year.

Schneider Electric’s new ExoStuxure suite of software systems is an an IoT-enabled digital platform consisting of connected products; edge control solutions; and apps, analytics software, and services designed to provide visibility and control across the enterprise via real-time monitoring, mobile insights, digital twin capabilities, and proactive risk mitigation.

We’ have worked with UPS to enable one of their major logistics centers to distribute more than 100,000 parcel every hour in a completely automated process running over 15 line of conveyor belts simultaneously.

We are committed to partnership in everything we do at Schneider to drive innovation forward.

In addition to developing our own technologies, we work daily with numerous technology start-ups in the areas of green energy and electric mobility.

We have a vast network of partners around the world, with more than 650,000 people working together with us with our technologies

We work with 45,000 system integrators around the world, and we have a close relationship with over 3,000 major utilities.

And we have created a digital platform for Schneider Electric Exchange to connect our network partners to come together on the web to cross all existing boundaries across many industries.

While we are currently living in very special times, but these are also very exciting times for implementing big disruptions in digitalization and electrification, whereby we can scale technology to resolve customer problems as we work to the end goal of making our world more sustainable and energy-e cient.

JEAN-PASCAL TRICOIRE is chairman and chief executive o icer of Schneider Electric, a leading multinational company providing energy and automation digital solutions for e iciency and sustainability in the construction, infrastructure and industrial markets worldwide. The above text is an edited and shortened version of Tricoire’s keynote address made at the company’s Digital Innovation Summit North America 2020 virtual forum last month.

one integrated module could easily divert, transfer and sort multiple package types?

Very small packs? Polybags? Not a problem for ModSort divert and transfer conveyor modules! The ModSort module can do left and right sorting on the fly for a wide range of package types and sizes. It is safe, quiet, versatile and cost effective.

Let our experts support you choosing the right system for your application or check it out at:

ModSort.com

Creating a better tomorrow™...

Global food industry needs united front to fight food waste with clear and cohesive expiration date marking standards

By Lee Metters

AFrench Agency for Food, Environmental and Occupational Health & Safety stating that ‘use by’ dates must be respected, with anything beyond that date “legally unfit for consumption, since it may represent a health risk for the consumer”.

In the U.S., the proposed Food Date Labeling Act of 2019 attempts to establish a similar dual-label system for food products in the US.

If passed, the act will require all manufacturers using a date label to indicate a food product’s quality to use the phrase “best if used by,” and all manufacturers using a date to indicate when a food should be discarded for safety reasons, to adopt “use by.” The act will also eliminate state laws that bar the sale or donation of food past the quality date.

According to Campden BRI, there are many forms of analysis used in order to determine date labeling for safety and quality purposes.