AUTOMATE NOW Plus

FSUCCESS STORY: YAMAMOTOYAMA

Bosch Rexroth ProBuilder helps a 326-year-old tea company move at a modern pace with VarioFlow plus

amily-owned and operated, Yamamotoyama was founded in Tokyo in 1690. Kahei Yamamoto II had a dream of introducing green tea to the general public, which at that time was only available to elite classes in Japan.

Yamamoto learned that steaming the tea leaves instead of brewing them, which was the accepted method at that time, resulted in a more delicious, sweet tasting tea that retained its nutrients. The tea was an instant sensation, making Yamamotoyama a household name.

Since that time the company has expanded its operations around the globe while staying current with modern manufacturing methods. Today, the company remains family-owned and continues to specialize in manufacturing green tea and nori (edible seaweed species).

EXPANDED PRODUCTION IN US REQUIRES CONVEYOR SYSTEM

Yamamotoyama of America was seeking to improve its Pomona, California production operations in order to achieve greater productivity and flexibility in producing multiple products.

The facility operates multiple IMA Group (of Italy) tea bag manufacturing and carton machines, each of which can produce 300 tea bags (aka 18 full cartons of tea bags) per minute. Once cartons are produced, the next step in the process is packing the full tea cartons into shipper cases, then labeling the cases and palletizing for shipment.

As management at Yamamotoyama planned to expand production, they needed to add more automated case packers, which in turn needed to be sourced from the tea cartoning machines.

A carton delivery conveyor system from the tea cartoners to the case packers was needed, with the ability to organize multiple flavors to the case pack-

PACKAGING WORLD AND PMMI

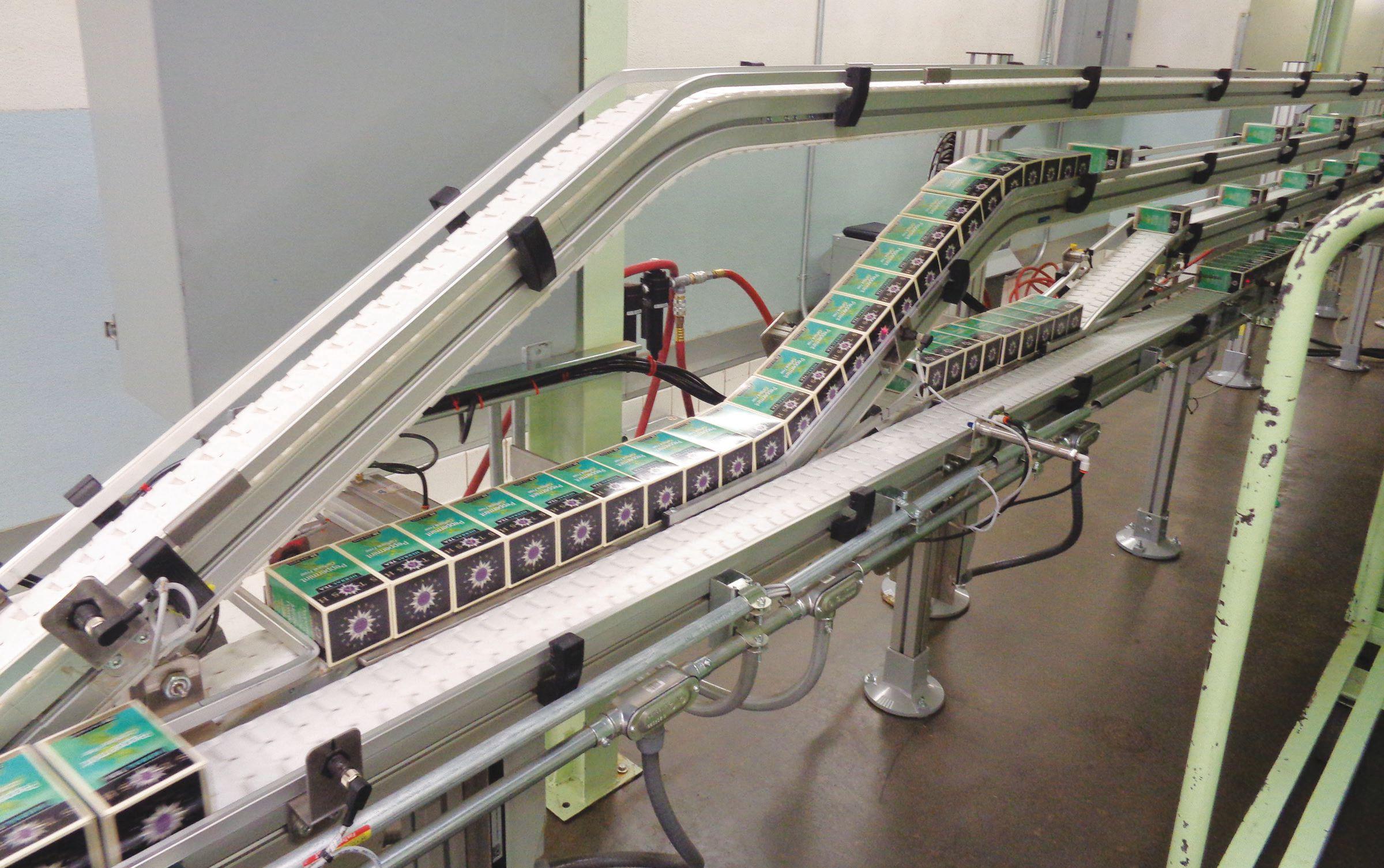

Rexroth’s VarioFlow plus allows Yamamotoyama to move products horizontally, vertically, on incline or decline, overhead, sub-floor, around obstacles and over long distances.

ers in the proper grouping of 12 cartons per flavor.

THE FLEXIBILITY OF VARIOFLOW PLUS IS A BIG PLUS FOR TEA-MAKER

VarioFlow plus from Bosch Rexroth is a flexible, modular plastic chain conveyor system used for moving high volume packaged goods and other consumer goods, such as packaged foods, pharmaceuticals and healthcare products.

It can be used to move products horizontally, vertically, on incline or decline, overhead, sub-floor, around obstacles and over long distances.Workpiece pallets can be used to convey products in applications where positioning or higher precision is needed.

VarioFlow plus is considered by many to be the quietest, most flexible, energy-efficient and easiest to assemble plastic chain conveyor available.

The management at Yamamotoyama were interested in VarioFlow plus because of its smooth running belt, low profile channel, tight radius curve wheel and ability to create a ‘stacked’ conveyor configuration with vertical curves, which is why they contacted Bosch Rexroth.

MULTIPLE FLAVORS INTO A SINGLE CASE PACKER

According toYamamotoyama of America chief operating officer Daniel Goldstein, “We needed the flexibility to source multiple flavors of tea product from multiple IMA cartoners into a single IMA case packer.We researched Bosch Rexroth products, and selected Bosch Rexroth Corporation due to their quality products.”

Each IMA machine can produce just one flavor of tea at any given time, however the Yamamotoyama plant is arranged such that the machines are located in groups, each producing 18 cartons per minute.

This meant that the conveyor system had to accommodate this volume of tea cartons per minute, and accurately merge/ induct groups of 12 cartons into the case packer, without error.

A second requirement was to protect the carton surface. The tea product is packaged in glossy, shelf ready cartons, and the appearance of the carton needed to remain neat and unscratched. Therefore, a smooth surface conveyor belt would be required.

The third challenge was one of space. The plant equipment spacing is very compact, with minimal lateral distance

between production equipment, so the conveyor system needed a very small footprint.

Rexroth’s VarioFlow plus increases productivity and flexibility to improve Yamamotoyama’s ability to produce multiple products.

PROBUILDER CREATES STACKED CONVEYOR CONFIGURATION

TransAutomation Technologies Inc., a Santa Ana, California-based member of the Bosch Rexroth ProBuilder network, was asked to complete the design and build of the system.

According to Goldstein, “We needed the system to be locally supported, and were confident in the fact that the system would be built and completely integrated by the local

Rexroth’s VarioFlow plus increases productivity and flexibility to improve Yamamotoyama’s ability to produce multiple products.

ProBuilder,TransAutomation Technologies.”

The mechanical design of the VarioFlow plus conveyor needed to be complemented with custom mechanical devices for controlling product groups of cartons, and further integrated with an electronic controls system.

Yamamotoyama system receives the output of the IMA cartoners onto individual take-away conveyor runs.

The Bosch Rexroth conveyor elevations were varied through the use of vertical inclines and lateral off-sets to achieve a stacked configuration, allowing for a very narrow footprint. At the terminus of the system, the product travels in a vertical incline onto the trunk conveyor through the use of Bosch Rexroth vertical curve declines.

Once product cartons approach the end of the Bosch Rexroth conveyors prior to the case packer, they stop and accumulate at the end of each of the conveyors. An electronic controls system counts the cartons in queue, and via a priority counting system, the control PLC (programmable logic control) establishes which conveyor lane is to be released onto the trunk line.

Once 12 cartons are accumulated on any given conveyor, that conveyor is ‘eligible’

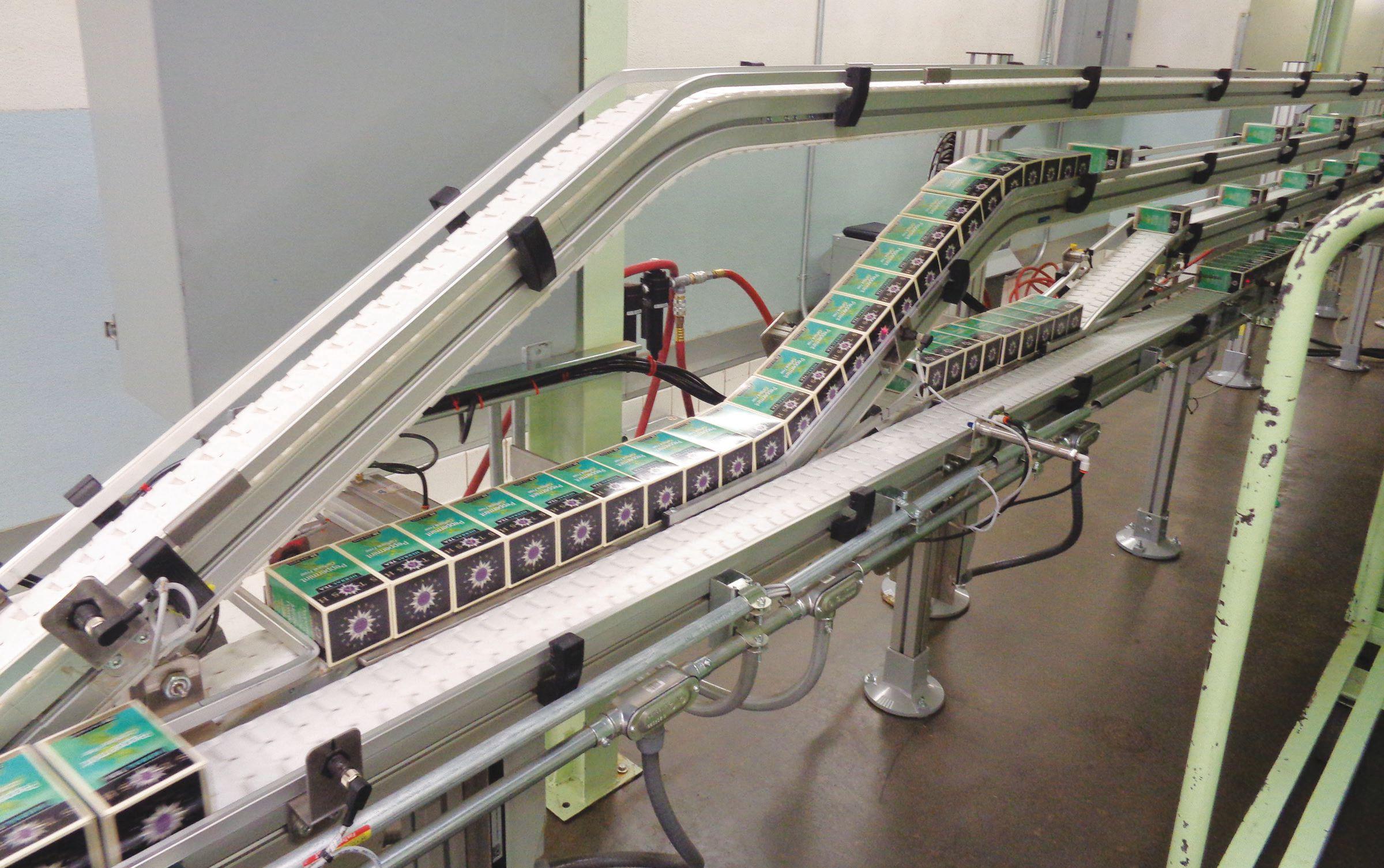

VarioFlow plus’ smooth conveyor belt allows Yamamotoyama to produce shelf ready cartons that remain neat and unscratched.

to release the slug of 12 cartons onto the trunk line. The slug release is accomplished through the use of pneumatic stops, escapements and right-angle pushers.

The shortest conveyor line with the least amount of accumulation capacity has the highest priority, then the second, and so on.

As a conveyor is signaled to release product, a custom right angle pusher activates and ejects the cartons six at a time onto the Bosch Rexroth trunk line.

Two pusher activations (2 x 6) are required to create a slug of 12 cartons, as required for the case packer.

All conveyor sections in the accumulation area are constantly monitored by the elec-

tronic controls system to keep the cycle repeating throughout the production run.

Once tea cartons enter the IMA case packer in groups of 12, two full shipper cases of six cartons each are produced and discharged from the case packer. Cartons are printed and then rotated upright, to be palletized by the robotic palletizer.

VarioFlow plus’ smooth conveyor belt allows Yamamotoyama to produce shelf ready cartons that remain neat and unscratched.

CASES SOLVED

The solution has been a huge success for the manufacturing facility, increasing the speed of production without damage to the prod-

ucts, all in a small footprint.

Goldstein says that “the project went very well from start to completion.”

BOSCH REXROTH PROBUILDER NETWORK

The ProBuilder network equips top-quality material handling professionals with all the resources they need to design, build, and commission superbly designed plastic chain conveyor solutions.

Members of the network enjoy unique advantages that include access to an array of design tools, expert application insight from Bosch Rexroth, training in best practices –all supporting VarioFlow plus conveyor solutions.

For information on the tea manufacturer, visit www.yamamotoyama.com.

For information on Bosch Rexroth, visit www.boschrexroth.ca.

Copyright 2018, PMMI Media Group. All rights reserved. This article from the April 2017 issue of Packaging World® (www.packworld. com) is reprinted by permission of PMMI Media Group. Packaging World® is a registered trademark of PMMI, The Association for Packaging and Processing Technologies (www.pmmi.org).

BETTER FLOW DOWN BY THE RIVERSIDE NATURAL FOODS

Organic snack manufacturer doubles packaging speeds with integrated turnkey solutions from tna

DALLAS, Texas—Riverside Natural Foods Ltd. has doubled its packaging speeds by installing new packaging systems from tna.

Based in Vaughan, Ont. just north of Toronto, Riverside Natural Foods is a leading manufacturer of healthy snacks, such as organic snack bars and granola minis, under its MadeGood brand. The company prides itself in the quality of its range of natural, allergen-free snacks and has seen a huge rise in the demand for its products since launching the brand back in 2013.

As a result of this immense growth, Riverside needed a partner that could deliver the high-performance packaging solutions and technical expertise to help them take their production volumes to the next level.

HEALTHY SNACKING ON THE RISE

Growing health-consciousness amongst consumers has driven the demand for small bags of healthy treats to new heights. According to the latest consumer surveys, over 79 per cent

of global consumers confirmed that health and nutrition was important to them when choosing which product to snack on, making it the second most important factor—after taste—to influence their food choices.

“The way we snack has definitely changed over the past few years and so have consumer expectations on the product itself,” comments tna sales manager Sekhar Chakkingal. “A lot of consumers are leading extremely busy lives and are looking for healthy, on-the-go snacks that deliver everything—taste, convenience and nutrition. This is good news for companies like Riverside which specialize in the manufacture of certified organic, highly nutritious snacks.Their range of Granola minis, for example, is ideal for consumers that need a quick nutrient boost that not only tastes great, but which is also able to fulfill their dietary needs.”

MEETING CONSUMER DEMAND

To help Riverside respond to the growing global demand for its 24 gram bags of granola minis, the company required a

packaging system that could increase production volumes, simplify the company’s processes and reduce downtime.

With previous packaging speeds ranging around 70-80 bags per minute, a highspeed bagging solution was at the top of the agenda for the snack manufacturer. At the same time, the system also needed to be hygienically-designed and easy-toclean to fulfill Riverside’s high sanitation standards and protect the allergen-free positioning of the company’s product portfolio.

HIGH-SPEED PACKAGING

The solution was the installation of two tna robag FX 3ci VFFS (vertical form, fill and seal) packaging systems (see image on previous page).

Renowned for its high speeds, the tna robag FX 3ci was able to offer both production flexibility and improved performance in a compact, easy-to-clean system. With its rotary double jaws, the new bagger was quickly able to deliver the company’s target speeds of 150 bags per minute, doubling the performance of the previous equipment and transforming Riverside’s production line efficiencies.

INTEGRATED SYSTEM SOLUTION

Featuring a small footprint to maximize the limited factory space available, the tna robag was delivered to Riverside as a completely integrated solution, which also incorporates tna’s intelli-weigh 0314 omega series of high-speed multi-head scales.

Capable of up to 200 weighs per minute, the tna intelli-weigh 0314 omega offers high accuracy, reducing product losses and

further improving the overall performance of the entire system.

As a result, Riverside can now easily meet the demand of its rapidly growing customer base, while keeping waste to an absolute minimum.

RELIABLE DATE CODE ACCURACY

A clearly printed and accurate date code is vital to communicate the freshness of

a product, meet regulatory requirements and avoid waste through rejected bags. Over the years, the bagging speeds of tna’s equipment have increased significantly to give manufacturers a competitive edge. However, operating at these high speeds can result in extremely high and rapid changes of film speeds, which in turn can affect the ability of some date coders to print a clear code.

MadeGood Minis 24 gram bags of natural granola from Riverside Natural Products.

By opting for tna’s simple, yet highly effective film path adjustment system, Riverside is able to accurately adjust and control the film path position so that printing takes place at a point where the film’s velocity is within the date coder’s printing capability.

As a result, Riverside is able to continuously achieve a clear and accurate date code print—even at 150 bags per minute.

QUALITY SEAL INTEGRITY

Riverside’s granola minis are packed with wholesome, certified organic ingredients, including a multitude of fine, particulate materials such as seeds, flakes and grains.

To prevent fines from affecting the seal integrity of the bags, tna installed cross feeders with integrated sifter to remove small particles from the line before the product reaches the bag.

In addition, tna’s product in seal detection (PISD) technology automatically triggers a reject mechanism if it detects product or particles in the seal area.

This means that Riverside is able to quickly remove bags from the line for further inspection before they enter the secondary packaging process. That way, Riverside is able to ensure that every bag meets the company’s high quality standards, while keeping waste to an absolute minimum and reducing downtime for a more continuous production process.

CUSTOMER SERVICE CULTURE

Commenting on the installation, Riverside vice-president of operations Justin Fluit says: “After reviewing all

MadeGood Minis brand of chocolate-banana goodness.

available options, we quickly realized that tna’s robag was the best solution for us to maximize our production capacities in the space available. No other vendor could deliver the speeds and offer options that also simplify operation and reduce downtime. The installation was smooth and we started hitting the target speeds shortly after setup. In fact,

we were so impressed with the performance of the two systems that we immediately ordered a third bagger.”

Fluit adds: “The culture of the team at tna was also a big advantage. We visited the team at their Dallas office, where we were able to experience tna’s values and commitment to its customers first hand.

“All in all, it’s been an outstanding experience to see everyone from tna jump in to ensure we were satisfied and everything was working to specification.”

ABOUT TNA

tna is a leading global supplier of integrated food processing and packaging solutions with 35 years of industry experience and over 14,000 systems installed across more than 120 countries. The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labeling, metal detection, verification and end of line solutions. tna also offers a variety of production line controls integration and SCADA (supervisory control and data acquisition) reporting options, project management and training. tna’s unique combination of innovative technologies, extensive project management experience and 24/7 global support ensures customers achieve faster, more reliable and flexible food products at the lowest cost of ownership. Company information available at www. tnasolutions.com.

For information on Riverside Natural Foods, visit http:// riversidenaturalfoods.com/.

FROM PLC EVOLUTION TO PACKAGING PROGRAMMING REVOLUTION

A look at cost-effective robotics systems that help companies not only quickly recapture their ROI, but exceed it

Gone are the days of deploying robots for the sole purpose of dealing with hot, heavy and hazardous applications. From beginning to end, robots are now being used to perform primary, secondary and tertiary applications in the food and consumer goods segment. While this uptick in robotic automation usage for material handling is greatly due to the availability of highquality, affordable robots that offer increased reliability, there is a paradigm shift in the way robot programming happens today that is impacting the market, creating a packaging programming revolution.

In an effort to save costs while simplifying production, end-users want the power to have a single source of control over in-house robotic applications without having to manage multiple processors or devices.

DEAN ELKINS

The robots are programmed through intuitive function blocks, which are programmable in Yaskawa’s MotionWorks IEC programming software

Traditionally, robots have required a separate proprietary programming language, but increased product changeover and the need to run a variety of packaging combinations on a single line has prompted manufacturers to seek a method of automation control that enables operators to oversee robots and their components in a standard well-known programming environment, where knowledge of specialized robotic programming language is not always required.

Whether it’s picking, packing or palletizing, operators should have the capability to exercise Singular Control over every component in their network, so Yaskawa Motoman engineered the MLX family of motion control integration solutions

for robots and programmable logic controllers (PLCs) and machine controllers, creating a user-friendly approach to automation implementation where:

• The robot does not require a separate programming language;

• An easy-to-use library of function blocks and sample programs are provided;

• A full set of HMI (human-machine interface) screens reduce the time and effort required to implement a system;

• A company’s prior investment in PLC staff is protected, and programmers may not need to learn the Yaskawa Motoman robot programming language (INFORM).

The MLX family provides interface options that enable the programming and control of Yaskawa Motoman industrial robots with the widely accepted Yaskawa motion controllers and the Rockwell Automation PLCs, giving end users of robotic automation the ability to deploy and support a broad range of Yaskawa Motoman robots to tackle complex applications intuitively and efficiently. The MLX100 and the MLX200 have paved the way for the MLX300, the next generation of integration for robots, machine controllers and PLCs.

The MLX300 software option is compatible with any DX200 material handling robot or YRC1000 GP-series handling robot, and a combination of up to four robots and positioners can be connected to a single MLX300 system. (A Functional Safety Unit (FSU) is available).

The use of Singular Control with MLX provides a well-integrated environment that leverages the knowledge and experience of the PLC programmer, while giving access to industry leading robot technology. Additionally, this approach simplifies safety design by eliminating re-

dundant electrical interfaces and consolidating hardware to optimize floorspace. The robots are programmed through intuitive function blocks, which are programmable in Yaskawa’s MotionWorks IEC programming software, or Add-On Instructions (AOIs) within the Rockwell Automation RSLogix 5000 environment. All program execution is performed by the motion controller or PLC; the motion control is handled by the superior kinematic algorithms of the Yaskawa robot controller.

No matter the material handling challenges you’re confronting, there is a solution tool to meet your unique objective. Taking a user-friendly approach to automation implementation with the use of MLX interface options can generate cost savings and improve production for the most complex applications.

For more information about Motoman, visit www.motoman.com.

Dean Elkins is Senior General Manager, Sales at Yaskawa America, Inc. – Motoman Robotics Division.

PINEBERRY MANUFACTURING’S

INSTAPRINT PACKING SLIP INSERTER

Pineberry Manufacturing Inc.’s InstaPrint prints, scans and inserts up to 200 pages per minute on demand, greatly reducing bottlenecks, labor costs and improving automated packing slip

order fulfillment

New to the Pineberry Manufacturing Inc. line of packaging products, the InstaPrint packing slip inserter uses a high quality drop-ondemand inkjet printer that has the ability to print on many flat materials, sizes and odd stocks, including paper, plastic and stock with an integrated label. With no consumables other than ink, the InstaPrint is cost-efficient proving a quick ROI (return on investment). Built with read and print software, packing slips are printed, folded and inserted into cartons at high speeds on demand; there is no need to

scan down the line.

“This is a very robust, economical solution with a small footprint used to automate packing slip order fulfillment for the packaging and e-commerce industry within material handling and supply chains,” states Pineberry Manufacturing president

David McCharles. “With an inkjet dropon-demand printer and no printer duty cycle, if a rare jam occurs it can be cleared in seconds, unlike a laser printer, making the InstaPrint the most reliable packing slip insertion automated system on the market.

“The InstaPrint is designed to increase capacity in distribution centers, reduce the

number of packing stations, reduce bottlenecks and labor costs, and improves the overall order fulfillment process,” concludes McCharles.

With 100 percent print, fold and insert accuracy, the InstaPrint has a small footprint measuring 32.56 inches wide and 59.50 inches long. The InstaPrint comes with an attached Pineberry HSF 12 friction feeder, Drop-On-Demand printer and a Pineberry Fold & Inserter on a vacuum conveyor that can be eas-

ily integrated next to packaging lines for seamless packaging and order fulfillment.

With an optional loader, the InstaPrint can hold up to 10,000 sheets. With an inkjet drop-on-demand print system, packing slips are scanned and printed in milliseconds for speedy order fulfillment. With an optional folding application, packing slips can be easily inserted into various sized cartons meeting multiple configuration requirements.

Pineberry Manufacturing can enlarge the InstaPrint with affixing and collating packaging lines, making the InstaPrint flexible to be altered according to job requirements.

To demonstrate the effectiveness of the InstaPrint, Pineberry shared an example of a customer’s happy solution.

CHALLENGE

The client, a multinational office supply retailing corporation, handles a variety

of package sizes and weights, with package contents ranging from lightweight items such as pens and staples to heavier items such as office desks and executive office chairs.

With the increase in online e-commerce orders and demand for same-day shipping caused an increase in bottlenecks, labor costs and order errors. The e-commerce orders packaged needed to include a packing slip with product descriptions, important collateral, like

warranty information, manuals, invoices, receipts and coupons.

With increasing minimum wages and labor costs, company profits were drifting further and further away affecting the bottom line. During peak order periods, costs per order increased as more labor was needed to fulfill orders.

On average, manually printing, scanning, folding and inserting order documentation requires 30 to 45 seconds per customer order. With 28,800 seconds in an eight-hour shift, one employee can manually print, scan, fold and insert order documentation to 640 to 960 cartons, without breaks or overtime. Furthermore, with the increase in labor and orders caused an increase in order errors and delays in shipping.

SOLUTION

Pineberry Manufacturing delivered the InstaPrint packing slip inserter. As companies strive to improve their bottom line, especially during peak order periods, integrating a fully automated pack station packing slip line is the quickest and easiest method to package orders that yields the lowest cost per order.

The InstaPrint packing slip inserter prints, scans, folds and inserts up to 200 pages per minute on demand, greatly reducing bottlenecks, labor costs and improving automated order fulfillment. As packaged contents come down the conveyor line to the pack station, the InstaPrint packing slip inserter prints, scans, folds and

inserts packing slips, invoices, receipts, warranty information, rebate offers and coupons. It’s a very robust, economical solution.

With an inkjet drop-on-demand printer and no printer duty cycle, if a rare jam occurs it can be cleared in seconds, making InstaPrint the most reliable pack station packing slip automated system on the market.

With no consumables other than ink, the InstaPrint packing slip inserter is cost-efficient proving a quick ROI. Built with read and print software, packing slips are printed, scanned, folded and inserted into cartons at high speeds on demand with 100 percent accuracy; there is no need to scan down the line. The InstaPrint packing slip inserter is designed to increase capacity in distribution centers, reduce the number of packing stations, reduce bottlenecks and labor costs, and improve the overall order fulfillment process.

RESULTS

Integrating the InstaPrint packing slip inserter decreased excess labor costs, order errors and bottlenecks, especially during peak order periods; efficiently getting orders out on time at less cost. Ultimately, automating the pack station packing slip system, costs per order drastically decreased, proving an attractive ROI.

In today’s demanding e-commerce world, every second counts during the packaging and shipping of orders. New and innovative technology allows for easy installation without having to change documents or

warehouse management software. Competitive corporations that integrate an automated packing slip pack station system for their order fulfillment lines reduce the number of pack stations in their distribution centers, increase pack station throughput, and improve profit per order. All compelling reasons to master peak order fulfillment.

ABOUT PINEBERRY MANUFACTURING

Since 1984, Pineberry Manufacturing has been developing high-quality friction feeding, printing, packaging and custom automation solutions for the plastic card, packaging, distribution, food and beverage, pharmaceutical, graphic arts, and mailing and fulfillment industries. Additionally, Pineberry specializes in integration, working with OEM’s (original equipment manufacturers) and providing customized solutions for the most demanding environments. Whether it is a standardized leaflet feeder, feeding and labeling bags, feeding cookies or an integrated custom solution, Pineberry has the expertise to provide exceptional products to make any project a success. Company information available at www.pineberryinc.com.

2018 GLOBAL WATER AWARDS

Schneider Electric NA shares nomination for Global Water Awards

Established in 2006 by Global Water Intelligence (GWI), the Global Water Awards recognize the most important achievements in the international water industry within several categories, and reward those initiatives in the water, wastewater and desalination sectors that are moving the industry forward through improved operating performance, innovative technology adoption and sustainable financial models.

Each year, the coveted awards are presented at the Global Water Summit, the major business conference for the water industry worldwide.

GWI is proud to announce the shortlisted entries for the 2018 Global Water Awards. Online voting will open on March 1, 2018 and the awards themselves will be presented at a dedicated ceremony to be held at the spectacular Pavillon d’Armenonville in Paris on April 16, in conjunction with the 2018 Global Water Summit: Transcending Boundaries.

The awards recognize excellence across the entire international water industry within several categories, and rewarding those initiatives in the water, wastewater, and desalination sectors that are moving the industry forward.

WATER COMPANY OF THE YEAR

• Aqualia

• Evoqua Water Technologies

• Orascom Construction

• Sabesp

DESALINATION COMPANY OF THE YEAR

• ACWA Power

• Metito

• Suez

SMART WATER COMPANY OF THE YEAR

• Aquatic Informatics

• Dubai Electricity and Water Authority (DEWA)

• Endress+Hauser

• Schneider Electric

WATER / WASTEWATER PROJECT OF THE YEAR

• Bishui wastewater treatment plant, China

• El Paso zero discharge plant, Texas

• Northern Treatment Plant, Colorado

• Ulu Pandan wastewater treatment pilot, Singapore

INDUSTRIAL WATER PROJECT OF THE YEAR

• ABF Ovaltine Effluent Treatment Plant, Thailand

• Arla Foods Milky Water Reuse, Denmark

• HAOR Wastewater Treatment Plant, Azerbaijan

• Paju Treated Sewage Effluent Reuse, Korea

BREAKTHROUGH WATER TECHNOLOGY COM -

PANY OF THE YEAR

• Claroty

• Drylet

• Moleaer

• Voltea

MUNICIPAL DESALINATION

PLANT OF THE YEAR

• H2Oaks Center BWRO plant, Texas

• Mirfa IWPP, Abu Dhabi

• Charles E. Meyer Desalination Plant, California

• Umm Al Houl IWPP, Qatar

INDUSTRIAL DESALINATION PLANT OF THE YEAR

• Dahej Refinery BWRO, India

• Jazan IGCC desalination plant, Saudi Arabia

• Kemapco desalination plant, Jordan

• Sarlux desalination plant, Italy

WATER

DEAL OF THE YEAR

• Hamilton biosolids financing, Canada

• Kigali Bulk Water Supply project financing, Rwanda

• Shoaiba 3 Expansion 2 financing, Saudi Arabia

• Umbulan Spring Water Project, Indonesia

WATER TECHNOLOGY COMPANY OF THE YEAR

• Fluence Corporation

• LG Water Solutions

• Royal HaskoningDHV

• Xylem

SMART WATER PROJECT OF THE YEAR

• Christchurch Pressurized Sewer Project, New Zealand

• Llanelli Water Project, Wales

• Mecca Smart Operations Project, Saudi Arabia

• Oum Mazza Drinking Water Treatment Plant, Morocco

WATER LEADERS AWARD

• Agua y Saneamientos Argentinos SA, Argentina

• Bangalore Water Supply and Sewerage Board, India

• Kaduna State Water Corporation, Nigeria

• Lagos Water Corporation, Nigeria

SAFE SPEED MONITOR PNOZ S30

The PNOZ s30 stand-alone speed monitor from Pilz ensures safe standstill in machines. The PNOZ s30 is suitable for safe monitoring of speed, standstill, position and direction of rotation, monitoring of a speed range and shearpin breakage of drives, for example. The configuration of the speed monitor is performed fast and simple with PNOZsigma Configurator or directly at the device via the illuminated display. The standards EN ISO 13849-1 up to PL e and EN IEC 62061 up to SIL CL 3 are met. The safety functions are implemented in accordance with EN 61800-5-2

MATROX IMAGING RELEASES MAJOR MIL 10 SOFTWARE UPDATE WITH DEEP LEARNING OFFER

MONTREAL—

Matrox Imaging has released the Matrox Imaging Library (MIL) 10 Processing Pack 3 software update featuring a CPU-based, image classification module which makes use of deep learning technology for machine vision applications. Processing Pack 3 also includes the addition of a photometric stereo tool to bring out hard to spot surface anomalies and a new dedicated tool to locate rectangular features.

DEEP LEARNING FOR IMAGE CLASSIFICATION

Leveraging convolutional neural network (CNN) technology, the Classification tool categorizes images of highly textured, naturally varying, and acceptably deformed goods. The inference is performed exclusively by Matrox Imaging-written code on a mainstream CPU, eliminating the dependence on third-party neural network libraries and the need for specialized GPU hardware. The intricate design

and training of a neural network is carried out by Matrox Imaging, taking advantage of the accumulated experience, knowledge, and skill of its machine learning and machine vision experts.

REGISTRATION TOOL SET GETS

PHOTOMETRIC STEREO

The photometric stereo technique is now available within the Registration module to produce a single image that emphasizes object surface irregularities such as embossed and engraved features, scratches and indentations. The composite image is computed from a series of images taken with light coming in from different directions as produced by illumination solutions based on the CCS Inc. Light Sequence

Switch (LSS ) or Smart Vision Lights LED Light Manager (LLM ).

SPEED MONITOR PNOZ S30 RELOADED – NEW FEATURES IN VERSION 3.0

The speed monitor PNOZ s30 has a configurable analogue output from Version 3.0. It passes on the safely measured speed to the controller as a proportional 0-20 or 4-20 mA signal. Thanks to the analogue output you do not need to use additional sensors for speed detection. The speed monitor PNOZ s30 also uses a safe output signal to indicate when values exceed or fall below defined warning thresholds. Up to three safety functions can be logically linked together using AND and OR connections. More information at www.pilz.com/ en-CA.

SHAPE-FINDING TOOL FOR RECTANGLES

Part of the Geometric Model Finder (GMF ) module, the Rectangle Finder tool is a faster, more flexible, and more robust option than generic geometric pattern matching. The tool is able to simultaneously search for multiple occurrences of rectangles with different scale and aspect ratios.

“Montreal is a hotbed of artificial intelligence development, and Matrox Imaging is perfectly situated to take full advantage of this growing knowhow,” says Matrox Imaging director of product management Pierantonio Boriero. “Combined with our long-standing and trusted expertise in the field of machine vision applications, we’ll be able to deliver the best solutions to our customers.”

To see these latest tools in action, visit Matrox

Imaging at The Vision Show in Boston (booth #1003; April 10-12, 2018).

The MIL 10 Processing Pack 3 update is now available to all registered MIL users with valid maintenance subscriptions through the software’s update service as well as those interested in evaluating the software.

ABOUT MATROX IMAGING

Matrox Imaging is an established and trusted supplier to top OEMs and integrators involved in machine vision, image analysis, and medical imaging industries. The components consist of smart cameras, vision controllers, I/O cards, and frame grabbers, all designed to provide optimum price-performance within a common software environment. For more information, visit www. matrox.com/imaging

EMERSON SAYS GO SWITCH

LOUISVILLE, Kentucky—Emerson Electric Co. has introduced its Topworx GO Switch Model 52M—a 12 mm proximity sensor designed specifically for applications in outdoor and challenging industrial environments.

The new sensor is well-suited for material handling, mobile equipment, industrial equipment, and food and beverage processing applications.

“The GO Switch 52M is highly durable, does not require power, and operates across a wide temperature range,” says GO Switch senior product manager Emill Melliz.

“Our proximity sensor is ideal for original equipment manufacturers (OEMs) desiring reduced maintenance and fewer equipment breakdowns. The GO Switch provides a much more rugged alternative to the inductive proximity sensor and is far more reliable than a reed switch,” Melliz states.

The Model 52M incorporates the GO Switch ’s unique dry contact proximity sensor technology that uses magnets to control a set of contacts.

This technology’s durability and reliability have been proven in over 60 years of service in the process industries. Its advantages include:

• No power requirement – provides application flexibility;

• High reliability – tested to five million cycles at full-rated load;

• Broad temperature range (-40°C to 100°C) – allows use across multiple applications;

• Simple contact arrangement – enables highly flexible wiring schemes

• Polarity insensitivity – eliminates need to specify NPN or PNP products;

• Weld-field immunity – for large magnet field applications;

• High and low current compatibility (5 mA to 2 A @ 24 VDC) – permits use with PLCs (programmable logic controllers) and relay-based control systems.

“The GO Switch 52M gives the end user greater flexibility in monitoring different types of equipment. One sensor can be used for a variety of applications, reducing part numbers and inventory,” says Melliz. “For OEMs, the GO Switch simplifies design complexity and eliminates the cost of workaround components.”

The new proximity sensor is backed by Emerson’s global support network. It is available for purchase from sales representatives and distributors.

For more information, contact 1-800867-9679 (or 1-502-969-8000, if outside of the US), or via e-mail at info.TopWorx@ Emerson.com, or visit www.emerson.com.

MAXOLUTION BY SEW-EURODRIVE

MAXOLUTION system solutions from SEWEurodrive supply all the necessary modules to create customized machinery and systems that ideally match your requirements.

They range from electromechanical drives, controllers, communication, visualization and contactless energy transfer systems to the varied service portfolio that provides you with fast and reliable support from experienced professionals.

The company’s system specialists form a core team that delivers industry-specific expertise and works closely with the sales and service staff you are already familiar with.

WELCOME TO INDUSTRY 4.0

One module that is part of SEW’s MAXOLUTION system solutions are automated guided vehicle systems (AGVs).

AGV’s ensure an automated in-house flow of materials, and are now used for assembly lines in many industrial sectors.

The MAXOLUTION AGVS system solutions consist of intelligent vehicles, contactless energy transfer systems and WLAN communication. It offers high flexibility and great practical benefits, including:

• ability to minimize downtime;

• ability to improve efficiency;

• 24 / 7 / 365 availability (AGV’s don’t sleep);

• improved safety of your facility;

• a scalable system that can reduce labor costs;

• an established platform for full automation;

• modular and adaptable to accommodate for future expansions.

AGVs are powered by SEW-Eurodrive’s contactless energy transfer system—MOVITRANS. MOVITRANS operates on the principle of inductive energy transfer. Electrical energy is transferred from a fixed conductor to one or more mobile consumers without contact. Timeconsuming, cumbersome drag-chain systems have become a thing of the past.

The electromagnetic connection is made via an air gap and is maintenance-free and wearfree. This contactless energy supply enables high speeds of more than 10 m/s. Line cables are routed under the floor where there are no longer any obstacles disrupting transverse traffic.

Other advantages of integrating a contactless energy transfer system are its ability to run emission-free—resulting in a healthier work environment. MOVITRANS is resistant to contamination and does not produce any noise emissions. These factors contribute to a better level of productivity, safety, and sustainable growth.

To discuss your next systems solution project, contact SEW-Eurodrive Canada technical sales Konrad Kurylo, P.Eng by telephone at 416-5757721, via e-mail at k.kurylo@sew-eurodrive.ca, or visit the website at https://www.sew-eurodrive.ca/ home.html.

BALLUFF INTROS NEW IO-LINK ANALOG HUB

New plug-n-play system avoids costly networks, with simple integration

Integrating analog signals is increasingly difficult and/or costly in networked control architectures.

Shielded outputs from analog devices must be handled outside the network and terminated to conventional analog I/O cards, or additional machinemounted network blocks must be added to ensure a sufficient number of analog ports are available. These difficulties are compounded by the variety of analog signal types encountered, such as voltage, current, and thermocouple.

Now Balluff, with the introduction of a new IO-Link analog hub, solves these challenges by making it as simple as plug-n-play.

“At Balluff, our focus is to simplify controls and integration of a variety of sensors and actuators by offering a unified interface for device-level connectivity. This new IO-Link analog hub is a major milestone along the way,” says Shishir Rege, marketing manager for networks and safety.

Balluff’s new eight-channel analog measurement hub utilizes IO-Link to bring all measurement data through an IO-Link master module and into the controller seamlessly. “The classical approaches to analog integration required

either purchasing expensive two- or four-channel analogto-digital converter modules compatible to the controller in use, or purchasing a specific network-dependent analog remote module. Balluff’s new IO-Link-based analog hub eliminates the disadvantages of both of these approaches,” Rege continues.

Working in concert with an IO-Link master block, the analog hub expands the already-substantial capabilities of the master to host multiple analog devices over a single IO-Link port, making the IO-Link-based architecture even more flexible and cost-effective.

“The analog hub offers our customers the choice to use either dedicated IO-Link sensors or conventional analog sensors to scale and fit their solution. This analog hub enhances Balluff’s extensive IO-Link portfolio and further enables building resilient modular control architectures for today’s complex automation,” says Rege. Features and benefits of the analog hub:

• each channel on the analog hub is fully configurable inputs for voltage, current, or temperature measurements, enabling a flexible integration approach;

• analog-to-digital conversion resolution can be configured per channel as 10-, 12-, 14- or 16-bits to

meet the demands of the application;

• software-based set-points can be assigned per channel, eliminating the need to physically teach set-points on the sensor, in turn reducing downtime during sensor replacement;

• eliminates long shielded-cable runs and expensive analog cards in the controls cabinet.

Company information available at www.balluff.ca.