AUTOMATE NOW Plus

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

DIGITAL SUPPLEMENT FOR FOOD & DRUG PACKAGERS AND THEIR OEM’S

ABB Robotics is a pioneer in industrial and collaborative robots and advanced digital services. We help our customers to improve flexibility, efficiency, safety and reliablity, while moving towards the connected and collaborative factory of the future.

For the most part, humans and robots don’t seem to get along together very well in science-fiction movies and literature—perennially engaging in some epic apocalyptic struggle for survival to determine who will inherit the planet.

While this constant conflict can make for great brainless entertainment, it also tends to negate the not entirely inconceivable notion that human-robot collaboration is not only possible in the modern world but also in fact highly desirable.

Whatever apprehensions many may harbor about the robotics’ potentially disruptive impact on future job markets, it is useful to refer to the initial “Three Ds” premise of what industrial robotics are all about—ditching jobs that are dirty, dangerous and dull.

Given that there are many more jobs out there like that than we would like to admit, should we not let off a collective sigh of “good riddance,” rather than bemoan the passing of hazardous and mind-numbing grindwork on to the machines that do it all better, faster, safer, and without hurting anyone’s feelings?

As human workers become freed up to focus on more value-added, creative and fulfilling tasks to fill their time at assembly plants the world over, we think it’s about time to put the old adage about a happier workplace being a more productive workplace to the test—made possible with the new humanlike collaborative robots made to work with humans side-by-side in pursuit of common goals.

That’s where the promise offered by the new generation of so-called collaborative robots (cobots) can be truly put to the test.

According to a recent white paper released by global industrial robotics giant ABB Inc., “The future of robotics and automation depends on humans and robots working together.”

Launched to rave reviews at last year’s PACK EXPO International 2016 packaging technologies extravaganza, ABB’s first generation YuMi collaborative robot—designed primarily for high-speed production of miniaturized mobile electronics—sets an early benchmark for the coming wave of further human-robot cobots not requiring safety caging and an array of safety sensors to stop operation.

Built to human-like dimensions but weighing only 35 kilograms, the robot’s magnesium skeleton is covered with a plastic casing wrapped in super-soft padding, so that any slight contact with a human co-worker stops the machine’s motion in milliseconds, no harm done.

According to Phil Crowther, ABB’s global product manager for small robots, the whole idea behind using a partner robot instead of a replacement robot is that humans are not as easy to automate as often thought.

“Humans have touch and motor control which allows us to handle delicate things with dexterity and precision, as well as judge how much force to use on a given component so we do not break it,” he explains.

“Humans can see where an item is, easily pick it up, and are able to handle an incredibly diverse variety of parts without pausing,” he adds. “Humans also have spatial awareness which allows us to interact closely and in harmony with our co-workers.”

Especially with co-workers like YuMi.

Thriving upstart granola bar processor raises its production efficiencies to a whole new level through thoughtful packaging automation and line integration

BY ANDREW JOSEPH, FEATURES EDITOR

PHOTOS BY NAOMI HILTZ

As one of the world’s most versatile breakfast and snack foods, granola offers food processors plenty of leeway for recipe innovation and experimentation. And for those companies who truly master it, the rewards can be massive. So massive, in fact, that producing enough to meet the red-hot market demand can become a real problem.

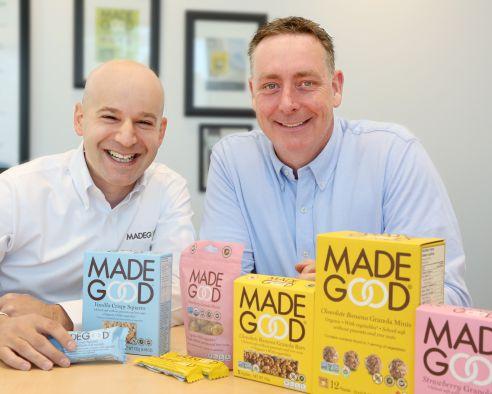

“Although that’s our Number One challenge right now, I must say that it’s a pretty good challenge to have,” says Nima Fotovat, president of the fast-growing granola processor Riverside Natural Foods Ltd. in Vaughan, Ont., located literally across the street from Toronto’s northern boundary along Steeles Avenue.

“To put it simply, we need to figure out how we can produce more product within the same more or less fixed parameters, such as available facility space or human resources,” Fotovat told Canadian Packaging on a recent visit to Riverside’s operations. Founded by Fotovat in 2013, Riverside has made lightning

fast progress in establishing itself as a promising new force in the highly competitive market segment with unique new recipes developed to turn granola’s popular perception of a healthy-but-boring blends of rolled oats and nuts right onto its head.

Drawing on his long experience in the Canadian nutrition-bar industry and a natural entrepreneurial knack for food innovation, Fotovat proceeded to create the unique new MadeGood line of granola bars and treats, fortified with real vegetables, at the company’s original Riverside’s 100-percent allergen- and nut-free facility in Vaughan.

where the peanut-free facility makes the MadeGood brand products.

According to Fotovat, the company’s rapid growth has been aided to some extent by the timely rise of the healthy organic, allergen-free, glutenfree and the portable food categories.

“But I also like to think that we have continued to achieve success in this competitive marketplace because we offer innovation, good service and, above all, a quality food product that the consumer finds highly appealing,” Fotovat proclaims.

Organic, school-safe and packing the same amount of nutrients as one serving of vegetables, the whole-grain MadeGood granola snacks—offered in standard-shaped and sized MadeGood Granola Bars and the bite-sized, ball-shaped MadeGood Granola Minis—are also low in sugar and vegan- and kosher-certified to boot.

According to Fotovat, the combination of flavors and healthy all-natural ingredients tapped a rich vein of growing demand by health-conscious Canadian consumers for an enjoyable and nutritious alternative to the multitude of sugar-packed nutrition bars already out in the market.

“We have enjoyed pretty good growth,” says Fotovat, explaining the company’s recent opening of a brand new 27,000-square-foot BRC (British Retail Council) food safety-certified plant that recently started up just across a parking lot driveway

“I do think that what sets us apart is the quality of our snack bars—not just from a taste sense, because it is very tasty, but also because of the life quality we bring to every unit produced here.

“We choose our ingredients very carefully,” Fotovat explains.

“We use dried fruits in our granola products because they not only have great taste and a naturally-long shelf-life, but also provide good nutritional value as a good source of fiber, vitamins, minerals and antioxidants to help provide a healthy immune and digestive system.”

Fotovat points out that Riverside only uses gluten-free, organic oats to add to the whole grains contained in the MadeGood product recipes.

“There’s only a few sources for oats like this in Canada, and just a handful more in the U.S.,” says Fotovat.

“We use pure organic, big flake oats and brown rice crisps—two whole grains that

contain healthy amounts of fiber, vitamins, minerals, antioxidants and disease-fighting phytochemicals,” he says.

According to Fotovat, all the products manufactured by Riverside use a pure, cold-pressed, high oleic sunflower oil that is high in unsaturated fat, low in saturated fat and has zero transfats, which are all highly sought-after product attributes in terms of combating the risk of heart attacks, strokes and heart disease.

In addition to producing the MadeGood brand, Riverside also does some private-label work for some leading store brands across Canada and the U.S., and the growing volume of work has not only prompted Riverside to start up a new plant last year, but also invest in some high-end packaging automation technologies at the second facility.

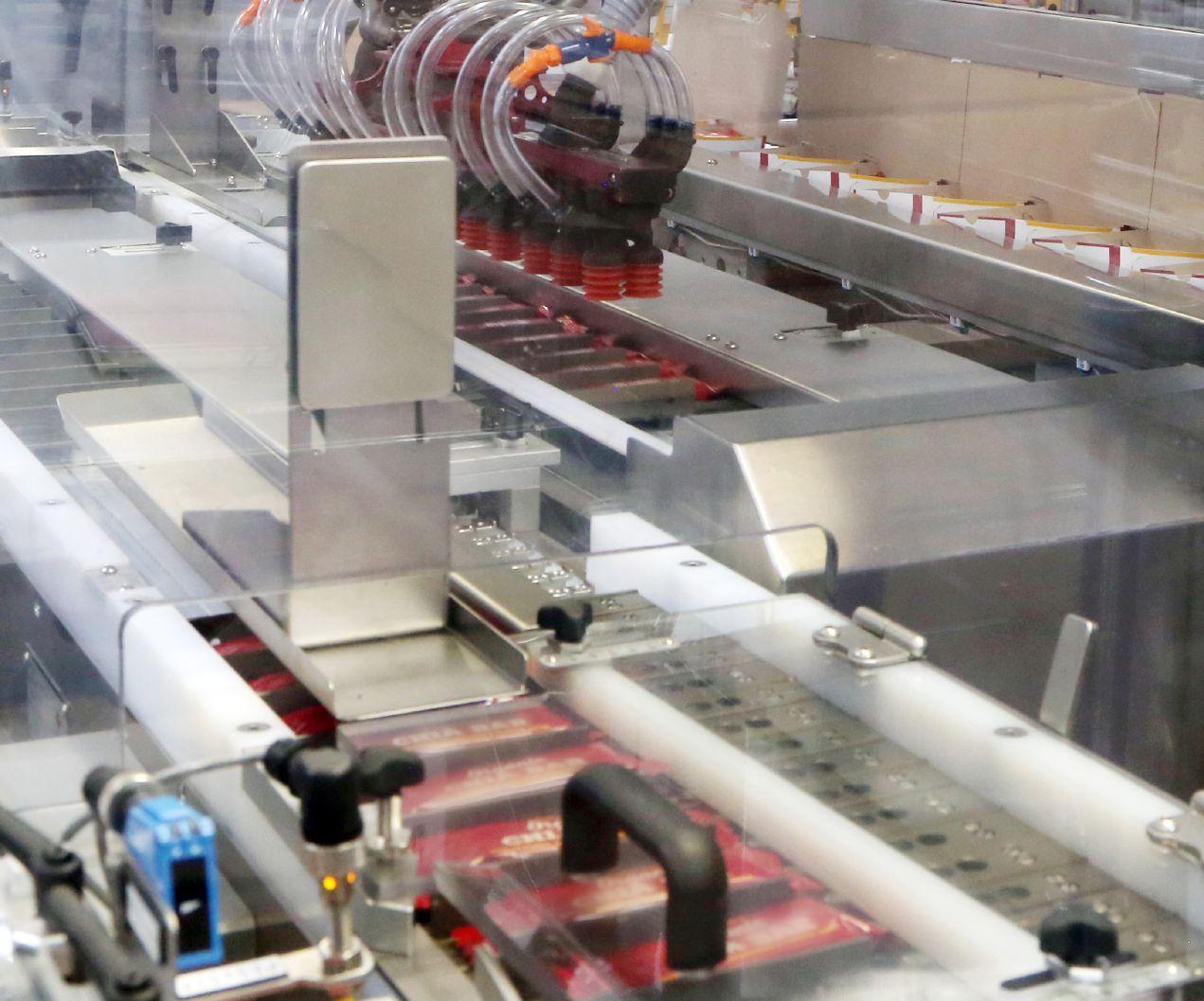

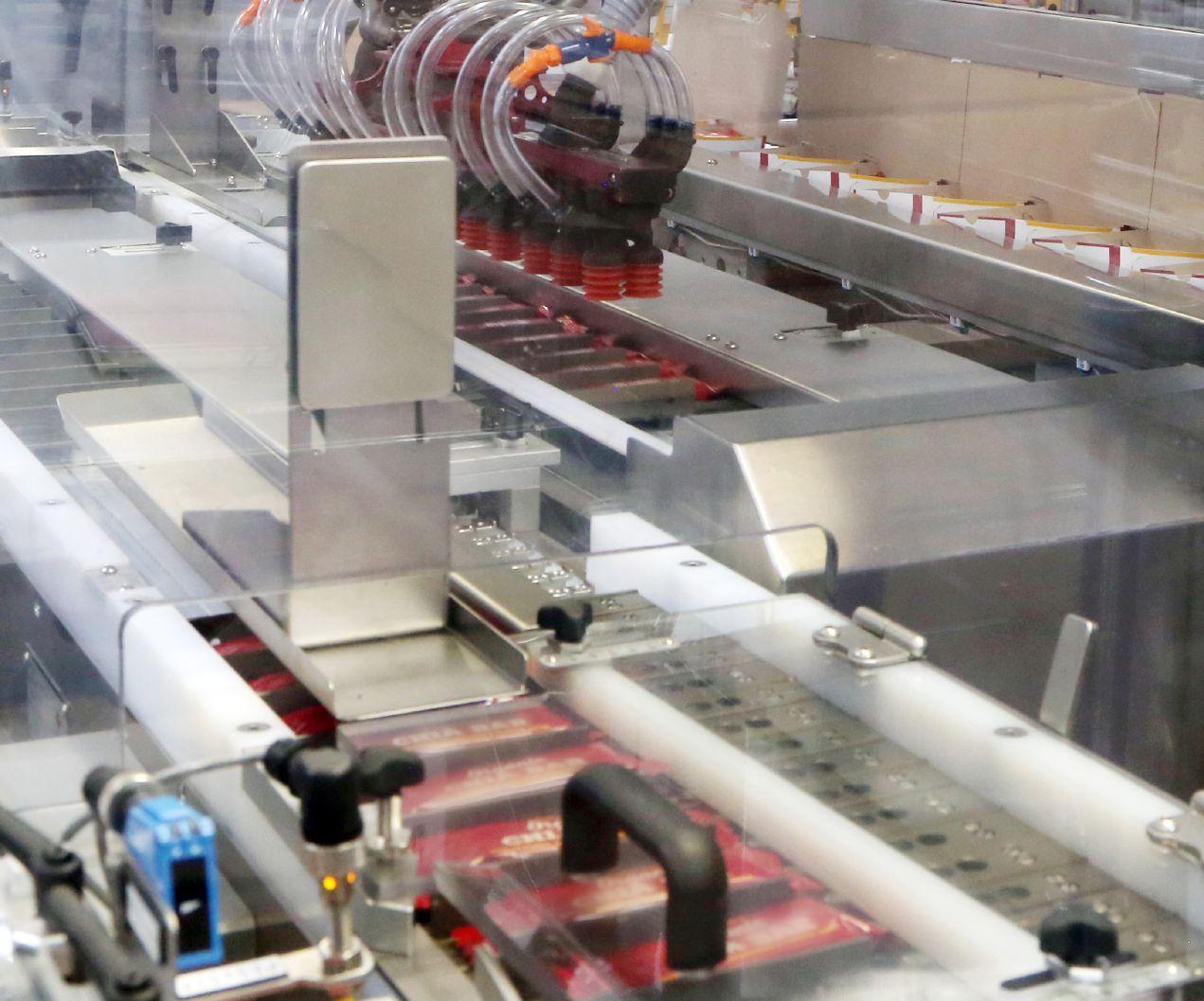

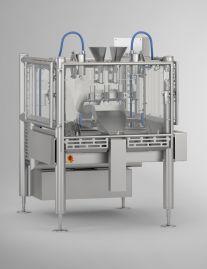

One of its more recent capital investments involved the instal-

lation of a dual robotic loader manufactured by leading robotics design and manufacturing company Propack, a prominent Canadian vendor and integrator of automation technology operating out of Beamsville, Ont.

“The LJ robotic pick-and-place machine picks 12 wrapped bars at time and feeds then into formed paperboard boxes,” Fotovat relates.

“By installing the LJ module, awe were able to move seven people from performing the same manual job over to other aspects of our production line to help remove bottlenecks.

“So it not only simplified our entire production process,” he extols, “but has helped us save money on labor too.”

Continuing, Fotovat is impressed with the LJ dual robotic loader: “It works through breaks taken by the employees—obvi-

A Videojet 3020 laser-coder applies best-before info and lot code data onto each carton formed by the Genesis carton former from Kliklok-Woodman, now part of the Bosch Group.

ously the machine doesn’t stop.”

With the plant’s production volumes now approaching seven metric tonnes of product per shift, according to Fotovat, “With the recent installation of the robotic product loader, new wrapping equipment, and a new carton former and closer, we have been able to triple the output of our production line.”

As Fotovat relates, the Propack team used its extensive experience and knowledge of packaging systems integration to fit seamlessly into the plant’s product equipment layout, comprising one processing line and two packaging lines.

After the granola ingredients are mixed, formed, cooled and shaped to appropriate product size, the product continues along the same conveying line towards two packaging lines, that are used at the same time before converging back into one line to proceed to case-packing.

As Propack owner and president Chris Follows explains: “We take freshly made product from one line and distribute product to two wrapping legs. Each wrapping leg receives a row of product, meters, and then turns the bars from long-side leading to shortside leading. There’s then an electronic inspection of the bars to ensure dimensional accuracy.

“The distribution line of each row is also inspected to ensure the presentation of the bar is correct for acceptance by each leg,” reveals Follows. In the event the leg is not acceptable, it is placed on an accumulation

Riverside Natural Foods president Nima Fotovat (left) and Propack president Chris Follows share a laugh with some finished retail packages of the MadeGood granola product.

conveyer so as to not disrupt the operation of the production line.

Fotovat says that getting the conveyor line’s timing to drop and raise took some clever software programming on Propack’s part to achieve equal product distribution along the two packaging lines.

In order to prevent the product sticking together along the conveyor belting, the plant uses an InFlight FT seamer from Benchmark Automation, featuring Rockwell Automation’s Allen-Bradley PanelView Plus 700 interface terminal—to move the product along short conveyors at different speeds.

A close-up view of one of many SEW-Eurodrive motors used at the new Riverside Natural Foods production facility to ensure smooth power distribution along the conveyor lines.

Each packaging line is equipped with the high-performance Revolution model flowwrapping system manufactured by Campbell Wrapper Corporation, with each machine’s precision-driven servomotors also controlled by an Allen-Bradley interface.

“The Campbell Revolution wrapper is designed to create an end seal and a cross-seal giving Riverside a perfectly hermetic package seal,” says Follows. As the film unwinds from the machine’s reel, a Domino V230i thermal-transfer printer swings into action to apply the best-before and lot-code information onto the plastic wrapping film before it is wrapped around the product.

“Because this Domino system has the ability to print the data in multiple languages,” notes Follows, “the processor can have the product shipped pretty much around the world to wherever it is required.”

Using pre-printed rollfed film supplied to the plant by Lynnpak Packaging Ltd., Bemis Flexible Packaging Canada Limited, and Alpha Poly Corporation, the Revolution wrapper uses the eye-marks registered into the film to wrap the bars precisely the way the customers and consumers can best see them on the bar.

To take care of its uncompromising food safety requirements, each packaging line is equipped with a high-accuracy Mettler-Toledo Safeline X-33 X-Ray inspection system—distributed in Canada by Shawpak Systems of Oakville—for thorough inspection of all products emerging from the flowwrapper. The robust high-speed X-Ray systems inspect every

single wrapped granola bar passing through it to detect the tiniest particles of foreign objects such as metal, glass, ceramics and pebbles, while also helping point out any product density issues.

“These Mettler-Toledo Safeline X-Ray units are a great technology that increases our food safety initiatives tremendously,” says Fotovat, praising the machine’s ability not to generate “false positives” because of the metal-foil wrapping used to package the bars.

Once the bars are wrapped and sealed, the product moves on to the Propack LJ dual robotic loader, which takes the bars exiting each Campbell flowwrapper into a fully-automated robotic cell—equipped with an ABB IRB FlexPicker pick-and-place robotic lift that picks pre-programmed quantities of products to place into open cartons.

“Using this flexible top-load technology to place product into the open cartons allows Riverside to add

coupons, to pack product varying in weight, and generally help create a very clean final package,” Follows states.

According to Follows, the robot’s 15-inch Allen-Bradley PanelView Plus HMI conveniently places all the important information required by the operator onto one page of the screen, eliminating the need to flip screens when searching for data.

“There’s even a special ‘Green’ icon indicating that all aspects of the machine are up and running optimally,” explains Follows. “If there was an issue, the screen would direct an operator to which area of the machine needs attention, with a fault notice coming up on the screen.

“As technology continues to improve, we work to ensure that operators are not left in the dark or are intimidated by the technology,” Follows remarks. “We want to ensure that every operator of automation technologies feels comfortable in using them.”

As Follows explains, the HMI on the Propack LJ dual robotic loader saves the parameters of carton changeovers—allowing the operator to quickly choose the required recipe via a simple touch of the screen—and also accumulates data such as how many bars per shift were placed within cartons to generate reports on efficiencies.

The cartons packed by the Propack LJ module are formed with the model Genesis carton manufactured by Kliklok-Woodman, part of the Bosch Group.

The Genesis series is part of Kliklok’s family of topload, lock-style carton forming machines developed to combine high-speed forming with ability to handle

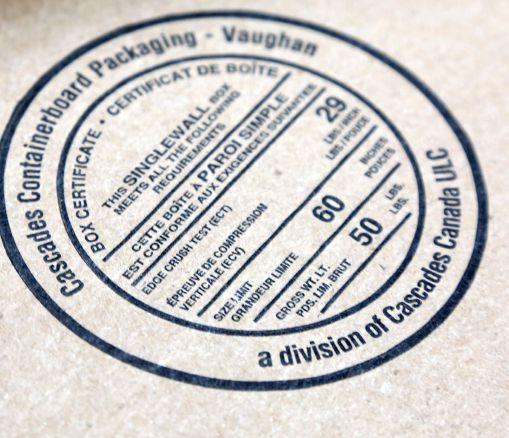

Corrugated master cases used to pack cartons of Riverside product are converted by the local Cascades Containerboard Packaging facility.

a wide range of carton sizes—the Genesis box former offers remarkably short changeover times of under 15 minutes, which is a major benefit for the busy Riverside plant.

“The Genesis is a very unique former that picks up the carton using a vacuum after forming through the cavity, in order to place it onto the conveyor,” Follows explains.

“With the lighter type cartons, you still get a positive placement on the conveyor—ensuring no jams occur on the empty carton transportation area.

“In my opinion, this Genesis is the best case former

manufactured by Bosch Kliklok.”

To close the loaded cartons, the plant employs a Bosch Kliklok Vari-Right carton closer that steadies the opentop cartons, folds the flaps to close the carton, and activates the Nordson ProBlue hot-melt adhesive applicating system to fully seal each box before it’s placed on a pallet.

“Like Genesis, the Vari-Right closer can accommodate very quick changeovers,” states Follows.

Adds Fotovat: “One of the things that I look for in vendors who might work with us, is their overall culture.

“It should be a service-oriented culture built on getting the job done without taking shortcuts—the same as Riverside.

“While Propack offered us a great piece of equipment that would create better production line efficiency,” he says, “they did much more than just sell us the hardware.

“They used their outstanding integration skills to tie all the machines into a single streamlined solution,” Fotovat states.

“We are very happy with the Propack solution,” he concludes, “which has provided us with a better way to further automate and improve our production process.”

See the video on the operation of the Propack LJ dual robotic loader at Riverside Natural Foods on Canadian Packaging TV at www.canadianpackaging.com.

IKEA did it and so can you… Green Ox Pallet Technology’s new assembly machine provides an in-house, real-time supply of strong, high-quality corrugated pallets

In 2012, IKEA made the bold move of implementing corrugated pallets across its worldwide supply chain, proving a new operational model that delivers considerable savings—both economically and environmentally.

Today, IKEA and its global suppliers utilize over 35 million corrugated pallets annually, which has helped the leading retailer save over one billion dollars as a result of the change.

Creating a business model centered on corrugated pallets wasn’t just a fantasy created by environmentalists and paper corrugators. It was a real-world business decision made by the world’s largest furniture retailer and a socially responsible “gamble” executed in more than 50 countries. And it paid off in a big way.

According to Adam Pener of ChangeThePallet.org, “The IKEA precedent demonstrates conclusively that corrugated cardboard pallets work, and create measurable, large-scale environmental and financial benefits to companies, states, and taxpayers.”

Green Ox Pallet Technology pallets can be manufactured and delivered anywhere and can be assembled inhouse on an as-needed basis by hand or via a new pallet assembly machine.

Green Ox and Edson Packaging Machinery—a Pro Mach brand and respected leader in end-of-line automation for multiple industries—have partnered to design and build a specialized and unique corrugated pallet assembly machine.

Although Green Ox pallets can be assembled quickly and easily by hand, the new pallet assembly machine provides greater efficiencies and economies of scale through automated pallet assembly for higher-volume pallet requirements.

The simple and modular ~650-square-foot pallet assembly machine, which features up to four stations, assembles 200- to 250-corrugated pallets per hour and offers real-time assembly for immediate use in the supply chain with end-of-line packaging functionality. Each station is loaded with corrugated blanks that are

transferred to the assembly section using vacuum cups where they are folded and glued. Two Nordson ProBlue units power the 59 spray nozzles that apply hot melt adhesive to the corrugated blanks to ensure rigidity. The pneumatically-controlled machine features one servo motor controlling the dispenser when transferring pallets along the assembly section. Due to the modular design, each dispenser uses cleated interlinked belts for accurate positioning. This entire system can be operated by one person and is controlled using a Rockwell Automation CompactLogix PLC and Panelview Plus Human Machine Interface. The machine accommodates standard size 48”x 40” pallets. Custom sizes can be assembled on future machines to adapt to customer requirements. The machine is sold and supported exclusively through Green Ox Pallet Technology; however, Edson is currently offering demonstrations at its corporate headquarters in Hamilton, Ont. These demonstrations will showcase the new pallet assembly machine and its real-time assembly of Green Ox corrugated pallets to companies that are interested in learning how to break free from the added costs, challenges, and inefficiencies of wood pallets. To schedule a demo of the pallet assembly machine, visit http://greenoxpallets.com/learn-more-pallet-assemblymachine/

Although corrugated pallets have been around since the 1970s, the newly-designed corrugated pallet system

from Green Ox Pallet Technology delivers on strength and reliability while providing an end-to-end global, and highly-sustainable, pallet system for companies that want to eliminate inconvenient, hazardous, and expensive-to-use wood pallets. So, how can corrugated pallets offer a safer, cost-effective, and viable alternative to wood pallets while making a positive impact on the bottom line and the environment? Compared to heavy, unsanitary, and expensive wood pallets (where the vast majority end up in landfills), Green Ox corrugated pallets offer multiple benefits across the supply chain, including:

• Lower transportation & fuel costs - It’s pretty simple: Green Ox corrugated pallets weigh 75 percent less than wood pallets, and less weight on trucks and planes equals lower fuel costs and fewer emissions.

• Increased product on trucks & planes - Because Green Ox corrugated pallets can be customized to fit any company’s product lines, more product can be shipped on a pallet, and more pallets can be placed on a truck or plane. IKEA reports 20-33 percent more product on each truck using corrugated pallets vs. wood pallets.

• ISPM exemption – Green Ox corrugated pallets are ISPM-15 exempt (no heat or chemical treatment required for shipping).This helps remove the cost and hassle of ensuring that export pallets are heat-treated. Additionally, corrugated pallets get through customs faster through this exemption, thereby speeding up inventory time-to-shelf.

• Food safety & sterility – Green Ox corrugated pallets are also 100 percent sterile and bear no risk of product contamination from chemicals (chlorine, pesticides or fertilizers), biohazards (feces or blood), or infection from e-coli, listeria, and other food-related diseases. The possibility of cross-contamination from multiple uses is also removed because Green Ox corrugated pallets are designed using a “one-way” model (albeit they can also be used multiple times in some closed supply chains).

• Space savings - Warehouse space isn’t cheap. Because corrugated pallets can be delivered and stored flat, then assembled when needed in-house with a Green Ox pallet assembly machine, they offer J-I-T (Just-In-Time) production. This allows you to free-up space for other needs and revenue opportunities.

• Reducing product damage and worker injury - Wood pallets contribute to product damage and worker’s compensation cases, negatively impacting a company’s bottom line. Green Ox corrugated pallets are free of protruding nails and splinters, weigh less, and have smooth surfaces—protecting both the product and people.

• Recyclability/sustainability – Green Ox corrugated pallets are partially made using recycled materials and are 100 percent recyclable, thereby increasing recycling revenue, removing the hassle of reverse logistics, and decreasing pallet recovery expenses—all while minimizing the environmental footprint. In addition, Green Ox pallets are the only USDA (United States Department of Agriculture)-certified Biobased pallet. This certification verifies that the amount of renewable based ingredients in Green Ox pallets meets or exceeds levels set by the USDA.

The influence of the increasing digitalization on the production of food is one of the central themes at Anuga FoodTec in Cologne from March 20-23, 2018—with a special look at smart sensors.

BY ANUGA FOODTEC

Smart factories are to be set up in practically all industries of the food industry, where the machines and products organize, steer and control themselves autonomously. Whether Greenfield or Brownfield: The course in the direction of Industry 4.0 is already being tread - now the task at hand is to solve the networking challenges. Smart sensors are the answer here. The unmistakable aroma that flows through the Nestlé factory in Schwerin, Germany arouses curiosity—no wonder because experiencing the production of coffee is something special. Seven production and packing lines on-site are in operation around the clock and these are to be expanded up to 12—with the planned final expansion stage, it will be able to produce two billion Dolce Gusto capsules a year via about a dozen different flavors. The Swiss company has invested €210 million (~CDN $308.6 million) and has equipped the facility state-of-the-art technology.

Each line produces up to 1,000 capsules per minute, while cutting-edge sensor and weighing technologies ensure the high-filling capacity.

The fact that the process and diagnosis data is passed on from the field level through to the management level is not actually new. Today, the machines are connected with each other in order to ensure the seamless traceability of the entire process chain. The next step is the direct communication between the individual system modules in real-time, known as M2M communication.

Static IT solutions quickly reach their limits here, because the intelligent factory comprises of decentralized production environments with different components, each of which have their own data sources.

Without Cloud computing, the growing amounts of data can no longer be processed and evaluated ad-hoc.

In the future, the data cloud is not just to be implemented at management level, but also in the machine room.

The central challenge here: Synchronizing the virtual representation of the production and the “real” production with the representation.

Even modern Greenfield factories like that of Nestlé don’t correspond with the understanding of Industry 4.0 in this aspect.

Also in the maintenance section, for instance for predictive maintenance, machines have to independently report back information on their operational state to the maintenance personnel. This is where intelligent sensor systems take on a key role.

In addition to values such as pressure, volumes and temperature, the artificial “sensory organs” also measure oscillations and vibrations. Based on this status data, the production is to monitor itself to a large extent.Yet this alone does not suffice.

Industry 4.0-compatible sensors—like those that will be exhibited at Anuga FoodTec also have a further interface in addition to outputs for the system control. This allows them to be linked up to Cloud services.

The inter-disciplinary research project Robofill 4.0 shows the course that the industry is taking.

The aim of the scientists from the Munich Technical University and from the Fraunhofer Institute for Tool Machines and Forming Technology is a flexible automation concept that allows drinks to be filled up to the batch size 1.

The companies Beckhoff, Krones, Proleit, Yaskawa, Siemens, Till and Zimmer as well as the German state brewery Weihenstephan are the partners of the project. The direct involvement of the consumer occurs via an online portal that enables the compilation of the drinks and the selection of the vessels. A direct inkjet imprint is foreseen for the individual design of the bottles. Stephan Birle is coordinating the project at the Munich Technical University.

For him, the focus lies on a decentralized control concept that is responsible for the

coordination of the system’s modules.

“At the moment there is no dynamic filling concept for medium-sized companies which would allow a format and batch size flexible production for a few bottles through to the unique specimen,” says Birle.

This is exactly where Robofill 4.0 comes into play—with the development of a filling system, where as cyber-physical systems all components communicate with each other as well as with the superimposed production planning using Cloud technologies.

The special feature: The product itself has a virtual representative that contacts the individual modules so that the bottles can independently control themselves through the filling process.

Machines and process that are equipped with artificial intelligence create the prerequisite for more flexibility in the production. In the case of an ideal typical Greenfield project like the coffee capsule factory in Schwerin, modern sensors can be applied from the very beginning.

In contrast to the highly-productive Greenfields in the food industry, the reality is very different in the case of many of the Brownfield factories.

In some cases their machines have been in operation for 15 years and rely on a totally different infrastructure than what is demanded in the smart factory. So that these can also produce competitively in the future, they have to be optimized in compliance with Industry 4.0. The integration of existing machines into smart processes using modern sensors and actuators will thus play a key role at Anuga FoodTec.

The visitors will be able to see how real the smart factory is and which challenges are involved in implementing the vision at the world’s most important supplier trade fair of the food and beverage industry.

The exhibitors will be presenting solution packages for Greenfield and Brownfield systems, which allow the processes to be digitalized in line with the requirements of Industry 4.0 at the Cologne fair grounds from March 20-23, 2018.

The show is organized by Koelnmesse, an international leader in organizing food fairs and events regarding food and beverage processing. Trade fairs such as the Anuga, ISM and Anuga FoodTec are established world leaders. Koelnmesse not only organizes food trade fairs in Cologne, Germany, but also in further growth markets around the globe, for example, in Brazil, China, India, Italy, Japan, Thailand, the U.S. and the United Arab Emirates, which have different focuses and contents. These global activities offer customers a network of events, which in turn grant access to different markets helping create a basis for sustainable and stable international business. Show information available at www.anugafoodtec.com.

Watch the VIDEO of Capmatic’s new $2.5 million investment in equipment that enables it to move all of its manufacturing in-house for builds of its leading capping, filling and labeling equipment

BY CANADIAN PACKAGING STAFF

Taking things to another level is all part of the daily routine for Montreal-based Capmatic, a leading North American destination for innovative liquid, tablet and powder (micro-dosage) packaging equipment.

Wanting to ensure it keeps its production area humming, Capmatic recently spent $2.5 million to improve its state-of-the-art “Area 51” workshop to take its work completely in-house.

“Quite frankly, the parts fabrication industry is highly competitive, and in order to keep up with the growing demands of our customers, we determined that having 100 percent of all manufactured parts done in-house at Capmatic will allows us to maintain top-tier control of our equipment and parts,” Capmatic president told Canadian Packaging magazine during a recent interview.

The manufacturer is well-known in the industry for its unique European designs offering customers a wide range of full turnkey

Watch the short VIDEO for a glimpse at the inner workings of Capmatic’s Area 51 manufacturing workshop.

packaging lines of unscramblers, sorters, fillers, cappers, labelers, as well as its line integration skills with cartoners, bundlers, and case packers.

The Capmatic investment consists of 10 state-ofthe-art CNC machines from Japan featuring the latest technological advances to better handle stainless steel construction of parts for its packaging equipment, as well as two dedicated machines for plastic materials.

The new equipment will enable Capmatic to manufacture robust frames, pistons, nozzles, conveyor frames, turrets, custom steel parts and much more.

“Now with production and parts manufacturing under our own roof within our workshop, Capmatic

has complete control of its internal procedures starting from engineering and design to actual part and equipment assembly,” he continues.

Bassani says that until recently, the majority of Capmatic’s parts suppliers also manufactured parts for the local giant manufacturer of plane and trains—Bombardier—which created complications for the packaging equipment manufacturer in getting its orders completed in the fast turnaround time it required.

“By now doing everything in-house, it allows us to provide a quick turnaround to our customers,” relates Bassani, “allowing us to be more productive while still maintaining our existing and exacting internal standards.”

The new ultra-compact DataMan 70 series fixed-mount barcode reader from Cognex Corporation, small enough to fit into the palm of one’s hand, is powerful enough to perform the most challenging label-based barcode reading applications at higher read rates for linear and 2D label-based barcodes than single-line and raster laser scanners, according to the company. With its flexible configuration enabling it to fit into the tightest spaces on production lines or inside machinery, the DataMan 70 reader employs advanced barcode reading algorithms, powerful image formation capabilities, and individually controlled LEDs to ensure continuously high read rates— even for damaged or distorted label-based codes. Cognex Corporation

Designed to facilitate fully-automatic packaging of tricky long-shaped food product like pretzels, the new product transfer system from Multipond (available from Abbey Packaging in Canada) features a fully-integrated six-axis articulated arm robot combined with a multihead weigher in an innovative configuration that enables the fully-programmable robotic arm to move freely in all directions. The systems uses its four-point tool to pick up two lots of two portions from the multihead weigher simultaneously and to pack them neatly into the provided trays. Capable of packing up to 60 pieces per minute, the self-cleaning transfer system employs an 3D camera integrated into the transfer system to send information about the position of the tray-sealer to the software, which in turn initiates the required action by the robotic arm. If the camera detects that a tray has been positioned incorrectly, or is not there at all, the four-point tool will not be filled at this position. Multipond America Inc. (In Canada: Abbey Packaging)

Distributed in Canada by PLAN Automation, the new RMI 400 X-ray inspection system from Eagle Product Inspection was designed specifically for demanding poultry processing applications with very strict sanitary and hygienic requirements. Unlike traditional X-Ray systems that employ protective curtains to ensure radiation emissions are kept to a safe level, the RMI 400 machine uses an innovative conveyor system designed to incline at a gradual angle on the infeed and discharge to create a curtain-free tunnel.

Featuring unobstructed sightlines, open and contoured surfaces that minimize potential contaminant harboring areas, while facilitating fast visual inspection, the entire machine can be disassembled by a single person in minutes for sanitation.

Eagle Product Inspection (In Canada: PLAN Automation)

The new fully-integrated TM300 FILLCAPP filler-capper from the Zalkin division of Pro Mach, Inc. is a single-head, stand-alone capper capable of automatically filling and capping up to 30- cpm (containers per minute), and up to 60- cpm for two-station models for smaller-volume containers ranging from energy drinks to mini-bottles of distilled spirits to travel-sized personal care products, extracts, condiments, oils, etc. Boasting a compact space-saving design that eliminates the need for a separate filler, conveyor and capper, the rugged machine offers multiple benefits of quick changeovers, fast CIP (clean-in-place) capabilities, and superior fill accuracy within 0.25 to 0.5-percent of volume for a wide range of light and semi-viscous products in the food, beverage, spirits, personal-care, homecare, automotive and chemical industries. Designed to apply screw, ROPP (roll-on pilfer-proof) and push-on caps, the TM300 FILLCAPP can fill both glass as well as plastic bottles with up to five-inch diameters, and it can also be easily integrated with other systems, such as induction sealing, for enhanced operational flexibility and versatility. Zalkin (Div. of PRO Mach, Inc.)