Vacuum skin packaging and meat smoking mastery an inspired recipe for upscale culinary finesse Story on page 16

Vacuum skin packaging and meat smoking mastery an inspired recipe for upscale culinary finesse Story on page 16

maintains freshness, flavor,

Our automated packaging solutions and performancebased container designs are optimized for speed and productivity. Protecting fragile foods as they travel from your field or greenhouse to the kitchen table, our packaging maintains freshness, flavor, and your place on the shelf.

Providing packaging from field to fork.

westrock.com/produce

Budding Quebec entrepreneurs strike the perfect balance between smoke-cooking perfection and skin-tight clear packaging for their high-end salmon sensations.

A new indoor marketplace installs next-generation refrigeration system employing leading-edge automation to set new benchmarks for energy e ciency.

Rural Ontario deli meats producer keeping its growth plans on track with timely investment in high-end vacuumpacking equipment.

Alberta producer of gourmet-quality chocolate bars adds automatic flow wrapping to its refined skillset repertoire.

Venerable Quebec pastries producer gets its co-packing business o to a flying start with turnkey packaging line automation.

6-7 Packaging news round-up.

& QUOTES

9 Noteworthy industry briefs.

11-12 New packaging solutions and technologies.

13 Sustainable packaging innovations.

A monthly insight from PAC Packaging Consortium

Marketplace and company updates.

Career moves in packaging world.

ISSN 1481 9287. Canadian Packaging is published 10 times per year by Annex Business Media. Canada Post

Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

Ontario manufacturer of protective face masks investing in packaging line automation to keep up with soaring production volumes and market demand.

COLUMNS

FROM THE EDITOR

4 George Guidoni

More than just a cog in the wheel.

CHECKOUT

44 Rhea Gordon Joe Public speaks out on packaging hits and misses.

ON THE COVER

Fumoirs Gosselin co-owners Charles and Samuel Gosselin holding up packages of smoked salmon produced on the Multivac R105 MF thermoform vacuum-packing machine (inset) installed last year.

Seeing a massive container ship lodged between the two banks of Suez Canal for six days last month was a startling reminder of the ever-present vulnerability of global supply chains to dramatic disruptions that, ultimately, may or may not be traced to human error.

$10 BILLION

The daily cost of Suez Canal shipping blockage

Frankly, such an outcome could on some level be more comforting than discovering the whole incident, costing the global trade US$10 billion per day, to be tied to mechanical or technological malfunction.

With the world on edge as it is, a technical failure with such far-reaching global impact would be truly alarming in the context of our increasing reliance on technology to get us through the ongoing COVID-19 crisis and into whatever the New Normal regime that follows it.

While the likelihood of this epic shipping bottleneck actually holding up life-saving COVID-19 vaccines from being delivered to those in need is thankfully remote, the fact remains that global supply chains can often come apart under the least likely circumstances.

As a magazine serving the professional packaging audience, we can only hope that the vast volumes of packaging materials, containers and systems used to and materials used to house, store, transport, protect, chill, cool, warm and otherwise comfort the billions of dollars worth of goods delayed from customer delivery by the Suez Canal incident did an adequate job to keep a significant portion of those goods—especially food products and other perishables—from turning to waste.

Like it or not, packaging is an essential, if often underrated, link in the modern supply chain, as noted in a recent position paper authored by Alicemarie Geo rion, vice-president of packaging operations at DHL Supply Chain North America

While Geo rion is happy to acknowledge the ongoing investment e orts by CPG (consumer packaged goods) and other manufacturers in nextgeneration digitalization technologies and all the complementary software, analytic tools and automation systems, the relative meager amounts of capital invested by these companies in their packaging functions is cumulatively a disservice to themselves, their customers and end consumers.

In other words the dreaded ‘Weak

Link, as Geo rion asserts in a timely think piece aptly titled How to Keep Packaging from Becoming the Weak Link in Supply Chain Digitalization.

“While many organizations are continuing to invest in warehousing and transportation digitalization, fewer are making similar investments in packaging,” Geo rion states.

“That disparity can create a digital divide that not only reduces packaging e ciency, but also creates a weak link in supply chain digitalization.”

As Geo rion explains, “Historically, packaging was viewed as something of a secondary operation within supply chain management and outsourced to o -site third-party packers who were largely disconnected from other supply chain operations.

“Today, many organizations have moved packaging operations into the warehouse to eliminate the unnecessary time and costs of shipping products.

“However, simply co-locating packaging with warehousing does not by itself put packaging operations on equal footing with warehousing and transportation in terms of digitalization,” Geo rion states.

“Supply chain managers need to think about packaging digitalization in the same way they already think about digitalization in transportation and warehousing.”

To do that, supply chain operations should invest in dedicated packaging software that will act as an engine for packaging digitalization, along the lines of WMS (Warehouse Management System) and TMS (Transportation Management System) software programs.

Says Geo rion: “Using sophisticated optimization algorithms combined with an on-demand approach to packaging, the right package can be produced at the right time for each shipment.

“With on-demand packaging,” Geo rion asserts, “right-sized packages are available at the packaging line when needed to enable lower transportation costs and reduced waste, while ensuring the product is protected.”

Which, in a nutshell, is what good packaging primarily all about, and always has been.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

APRIL 2021 | VOLUME 74, NO. 4

Reader Service

Print and digital subscription inquires or changes, please contact

Anita Madden, Audience Development Manager

Tel: (416) 510-5183

Fax: (416) 510-6875

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer

Privacy@annexbusinessmedia.com Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2020 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

n Fully automatic Ross IN inline tray sealer

n High-speed production of lid-only and modified atmosphere packages.

n Reliable, high-quality seals virtually eliminate leakers, extending product freshness and shelf life.

n Uses preformed trays of almost any size or shape.

n Fast, highly flexible, and extremely easy to operate.

n Contact us for sample packages.

Despite what its name suggests, sea cucumber is very much an animal and, moreover, a highly-prized and high-priced delicacy in China for more than 1,000 years.

And as Mother Nature would have it, some of the world’s largest populations of the phylum Echinodermata family of marine animals—containing over 1,250 di erent species—make their home on the ocean floor just o Nova Scotia’s Cape Breton peninsula.

Called Cucumaria Frondosa (C-Frondosa), the Canadian North Atlantic species are highly sought-after food items in the lucrative Chinese markets on the account of being packed with very potent nutrients that are preserved by the frigid temperatures of these northern waters.

For Hackett’s Cove, N.S.- based Atlantic Sea Cucumber Ltd., this geographic proximity to C-Frondosa has granted the 18-employee company a unique niche opportunity to process sea cucumber into a premium, high value-added health supplement retailing nationwide by leading health-food stores and grocers.

After the C-Frondosa is harvested from the ocean floor and brought to the plant, it is meticulously processed and dried into a

totally dehydrated chunks of bulk product that is eventually granulated into powder and formulated as easy-to-swallow 500-mg capsules, marketed under the Nova Sea Atlantic Sea Cucumber brand of natural health supplements distribute d by Halifax-based AKSO Biotech, Inc. (see picture)

According to AKSO, there is strong ongoing research taking place at many universities globally to investigate sea cucumber’s e cacy across a spectrum of various medical conditions, including heart disease, hypertension, inflammation and cancer.

As Atlantic Sea Cucumber’s general manager Lincoln Ellsworth explains, the company’s patient proprietary cooking and drying techniques enable the processed sea cucumber to retain all of the animal’s nutrients right through the encapsulation process, which is done at an AKSO Biotech facility in Toronto.

“Sea Cucumber is very laborious to prepare; it can take days,” says Ellsworth. “Our proprietary cook process locks in maximum nutrition, which makes us the supplier of choice for AKSO.

“Although sea cucumber is consumed around the world for its traditional health benefits,” says Ellsworth, “a capsule form is the only practical way of getting the benefits of sea cucumber on a daily basis.”

Packed 60 capsules to a bottle, the Nova Sea Atlantic is a registered Natural Health Product with Health Canada, with the approved claim of providing antioxidants to help fight/protect cells against oxidative damage caused by free radicals.

Packaged in impact-resistant HDPE (high-density polyethylene) plastic containers with a soft-touch finish, the innovative product picked up a Grand Prix New Product Award of the Retail Council of Canada last year in the competition’s Health Care category—impressing judges with exquisite package design and label graphics created by Wingz Marketing of Thornton, Ont., and expertly printed onto the wraparound foil labels by Premier Markings Inc. of Mississauga, Ont.

“Sea cucumber is very expensive to harvest, dry and encapsulate, which is why it carries a $99.99 price-point for a two-month supply,” says Wingz Marketing president James Staley.

“As a result, we needed the packaging to really reflect the premium nature of the product,” Staley says, “and we are delighted that AKSO Biotech was pleased with the final result.”

Since its launch in 2003, Scottish beer brand Innis & Gunn has grown to become one of the U.K. most successful international craft beer businesses. Some of the brand’s claims to fame include being the Number One craft lager in Scotland, one of three bestselling imported craft beers in Sweden and the U.S., and, above all, the Number One imported craft beer in Canada, according the Edinburgh-based brewer that claims to have sold over 21 million pints of beer in over 30 countries last year.

To build on its success in Canada so far, the company has recently launched an eye-catching new ‘fridge-pack’ beer case containing 10 440-ml cans of the company’s award-winning brands Innis & Gunn

The Original and Innis & Gunn Lager

Currently retailing in Alberta, the compact and attractive 10-pack cases will be rolling out across Ontario this spring, according to Innis & Gunn.

Fighting plastic waste at home one pod at a time Canada’s largest janitorial supplies company GreenLabs Chemical Solutions is bringing its innovative industrial secret to the kitchens and bathrooms of everyday Canadians through its revolutionary Green Seal-certified cleaning pods.

With plastic trash being a widespread global environmental problem, and water being heavy to transport, the new Earth Brand familu of home-cleaning prodcut tackles these problems by reusing existing bottles and taking the ‘just add water’ approach to the at-home cleaning process—replacing the need for single-use plastic containers and reducing transport-related carbon emissions by up to 95 per cent.

The Earth Brand’s completely sustainable cleaning solution

utilizes completely dissoluble pods can be used to refill and reuse any existing spray bottle.

Alternatively, the one-time purchase of a reusable Earth Brand bottle system will allow the consumer to simply add water to produce a powerful, earth-friendly cleaning solution.

By reusing existing plastic bottles, the Earth Brand products limit contributing to the overwhelming amount of plastic that currently exists in our environment.

By recycling the Earth Brand pouches that contain the pods, the system has a negative plastic footprint when reusing it a single-use plastic spray bottle.

The Earth Brand’s initial cleaning line-up o ers pretty much everything a consumer needs to keep their home clean, including a glass cleaner, a bathroom cleaner, kitchen clean and a disinfectant cleaner.

For ease-of-use, the dissoluble pods are all color-coded—creating a cleaning system that is simple and intuitive, with no specialized or complicated cleansers are needed.

To use the product, consumers simply drop the dissoluble cleaning

pods into tap water, give it a good shake, and they’re ready to spray and clean whatever surfaces they need.

With lower shipping costs and no need for repeat bottle purchases, this innovative cleaning solution comes in at 75 per cent of the cost of traditional, brand-name cleaning products,” according to GreenLabs, which developed the product last year after extensive testing and a rigorous certification process to obtain the international Green Seal certification for protecting human health and environments, while helping to conserve the planet’s resources.

“I am thrilled to introduce Earth Brand cleaning pods to the world,” says Nik Barey, who is spearheading the launch of Earth Brand products.

“As an environmentally-conscious buyer and new father, I am always looking for ways for our

family to be environmentally responsible, conveniently, without sacrificing quality or spending a fortune,” Barey states.

“We feel strongly that dissoluble cleaning pods are the future when it comes to household cleaning.

“We have all seen the adoption of pods for laundry and dishwashing, so it only makes sense for cleaning around the house,” says Barye, citing a recent Oceania group’s report showing that about 2.8 million tonnes of plastic waste ends up in Canadian landfills every year—the equivalent to the weight of 24 CN Towers.

“Earth Brand has a mission to remove single-use plastics from the cleaning routines of Canadians,” says Barey,” also citing the federal government’s recent legislation that will ban the use of 10 types common single-use plastic products after 2021.

“By implementing pod-based cleaning solutions,”Barey states, “the Canadian consumers are able to reduce the volumes of plastic waste introduced into the environment, reuse their favourite existing bottles, and recycle their plastic waste conscientiously.”

• Maximum output and precision

• Flexibility for your loading tasks

• Fast product changes

• Easy integration into existing lines

• Safe handling of products and packs T

Shawpak Systems Ltd., Oakville, Ont.-based distributor and integrator of product inspection, industrial hygiene equipment and automated packaging machinery, has been named as the national sales representative for the entire range of VFFS (vertical form/fill/seal) baggers, cartoners, combination weighers, bag-in-box and other packaging machinery manufactured by the Chicago-based Triangle Package Machinery Co. Founded in 1923, Triangle is one of the first companies in the world to manufacture VFFS bagging machinery, becoming a leading global single-source supplier of automatic bagging systems for a diverse range of packaging and other industrial applications. “Shawpak has been successfully providing solutions to the food-and-beverage, pharmaceutical

and industrial manufacturers since 1984, and we are well-positioned with knowledgeable sales representatives across Canada,” says Schawpak Systems president Nigel Turnpenny. “Our enhanced partnership with Triangle Package Machinery will allow both Triangle and Shawpak to serve all our customers more e ectively.”

Labeling and functional materials group Avery Dennison of Glendale, Ca., has reached an agreement for a US$24-million acquisition of JDC Solutions, Inc., a privately owned manufacturer of pressure-sensitive specialty tapes headquartered in Mount Juliet, Tenn. Currently employing 75 people and generating annual revenues of about US$30 million, JDC’s manufacturing operations and product portfolio— geared primarily at customers in the automotive, consumer appliance, and building and construction industries— will become part of Avery Dennison’s Performance Tapes North America business unit.

German plastic films manufacturer SÜDPACK Verpackungen GmbH &

Co. KG has completed the acquisition of LPF Flexible Packaging B.V.—producer of high-barrier films headquartered in Grootegast, The Netherlands—from the Clondalkin Group for an undisclosed amount. Founded in 1908, LPF is well-known in the global food packaging markets for the high-quality of its laminated films used in the food-and-beverage, confectionery, healthcare, animal feed, industrial and agricultural sectors. “We value LPF’s high level of development and market competence, and plan to establish the Grootegast site as a ‘Competence Center’ for high-performance laminates,” says SÜDPACK’s chief executive o icer Erik Bouts. “In doing so, we want to further expand SÜDPACK’s expertise and performance portfolio in the development and production of high-performance laminates in order to serve attractive emerging markets and to tap into new market opportunities.”

Irish-owned packaging products manufacturer and distributor Zeus Packaging has completed the acquisition of Austrian-based food packaging solutions business Petruzalek from Italian capital investment firm Sirap-Gema Group for an undisclosed amount. With annual revenues of approximately $80 million, the purchase of Petruzalek completes the seventh acquisition carried out by Zeus Packaging in the last 18 months, adding up to about $60 million in M&A activity. According to Zeus, which now employs about 670 people in 26 countries, the latest acquisition expands and strengthens the company’s geographic presence in western, central and eastern European markets, while boosting the group total annual revenues to about $300 million. “The purchase of Petruzalek significantly extends our reach into new markets, brings complementary diversification to our product range, and further enhances our client network,” says Zeus Packaging’s chief executive o icer Keith Ockenden. “Petruzalek’s product range utilizes low environmental impact renewable, recyclable and compostable materials, enabling us to further deepen our focus on sustainability in 2021.”

The new Sigpack TTMD cartoner from Syntegon Technology combines the company’s signature TTM secondary packaging technology platform with seamlessly integrated Delta robots for more flexibility in product feeding, processing of di erent products from several processes, and flexible product presentation enabled by choice of flat or on-edge carton loading. The system’s integrated Delta robots use camera-based vision control technology to detect products on the infeed belt, where they pick single or multiple products arriving in random order and place them precisely inside the cartons, trays or other containers at speeds of up to 120 products per minute. To enable additional packaging flexibility, the new top-load cartoner can also simultaneously pack di erent products from several infeed processes, while the system’s tool-less format changeover

technique enables a vertical restart after each format change. According to Syntegon, organizing the entire process around the ‘counterflow’ principle, whereby the cartons move in the opposite direction to the product, helps to reducs the reject rate and make sure that each carton is filled correctly. Syntegon Technology

Distributed in Canada by PLAN Automation, the Pack 430 PRO X-Ray inspection machine from Eagle Product Inspection is designed to deliver superior inspection of mid-sized packaged products by automatically detecting and rejecting a broad range of physical contaminants, including glass shards, metal fragments, mineral stone, calcified bone and some plastic and rubber compounds. In addition, the fully

integrated inline system further improves e iciencies and minimizes downtime on the line by simultaneously conducting automatic quality checks for mass measurement, component count and seal integrity, while its enhanced SimulTask PRO and TraceServer software that provide full on-screen diagnostics, advanced image analysis, quality assurance traceability, and enhanced data collection that can be shared and stored in a central database.

PLAN Automation

The new fully servo-driven HQ Series counting and dispensing machines from Cremer are designed to provide 100-percent accuracy for primary or secondary packaging of candy, confectionary and chocolate products, as well as as non-food items such as medical parts, hardware

and detergent pouches. Intended for use with unmixed, single-type or single-flavor products, the versatile machines feature mobile design that allows them to be placed directly atop a packaging machine for bag filling applications, or over a conveyor belt for precise positioning and discharge of product counts of common packaging platforms such as cartons, boxes, tubs or tins. Compatible with virtually all industrial packaging and cartoning machines, the HQ Series features a compact footprint of just 40 or 60 centimeters, FDA-compliant product parts for processing both food and non-food products, and streamlined tool-free disassembly for easy operation and cleaning. Available in HQ, HQF and HQI models, the versatile counting machines can be used for a wide variety of products—either in bulk quantities or single-piece discharge into any package—and they are fully scalable for varying production levels depending on product type and output, with available counting channel options of two, six, eight or 12 items, with typical output of up to 5,500 individual pieces or 175 units (discharges) per minute. Cremer

Industrial automation giant Siemens AG has expanded its Sinamics G120 drive series to include an option for wireless commissioning and service. The new Sinamics G120 Smart Access module enables wireless connectivity of mobile devices such as tablets, smartphones and laptops over Wi-Fi to Sinamics G120 and Sinamics G120C drives, with the module quickly set up in a few easy steps using a standard web browser and any standard operating system. Its built-in web server functionality eliminates the need to download additional software, and with its intuitive user interface and menu, the Smart Access module o ers users outstanding convenience, according to Siemens. The Sinamics G120 Smart Access Module is available for G120 drives with CU230P-2 and CU240E-2 control units, as well as

Sinamics G120C drives. Users are free to choose any web browser and any smartphone, tablet or laptop for drive commissioning, parameterization and maintenance, while the motors can even be tested in JOG mode. Warning signals and error messages are quickly detected over the wireless link, which can also be used to save or reset drive settings.

Siemens Canada

Designed to provide an alternative operating system for all of the latest Beckho Automation’s industrial PC (IPC) platforms, the TwinCAT/BSD combines the TwinCAT runtime with FreeBSD, an industrial-proven, Unix-compatible, and reliable open-source operating system. The FreeBSD system, as well as the TwinCAT/BSD, supports ARM CPUs up to Intel Xeon processors, providing

a scalable platform that combines the advantages of Windows CE—low cost and small footprint—with the numerous features of large Windows operating systems, thereby providing an alternative to Windows 7 or 10 in many applications. With the current minimum size of a basic image around 300 MB, with very small RAM consumption of less than 100 MB, these diverse machines and systems can leverage very compact controllers with TwinCAT/BSD and use all TwinCAT 3 runtime functions.

Beckho Automation

O ering detection range of up to 20 meters, the two new 21M series photoelectric sensors from Ballu Inc. o er a choice of three optical operations—combining the benefits of IO-Link technology with IP67 and IP69K protection ratings achieved with a newly-designed metal housing with improved sealing and plastic lens. Providing easy adjustments via a potentiometer, simple installation and reliable diagnostics, the di use version

can detect objects up to one meter; the retroreflective version up to eight meters; and the through-beam has up to a 20-meter range.

Ballu Canada Inc.

Designed to ensure tight reliable grip on big loads, the new OGVM suction cups from Festo Inc. feature special structure that enables them to absorb the highest transverse forces to provide energy-e icient handling solutions. According to Festo, the suction ergonomics ensure minimum suction times and absorption of extreme holding and transverse forces, including on oiled surfaces, making them ideal for workpieces with complex structures. The OGVM cups are available in a wide range of diameters from 30-mm to 125-mm. Festo Inc.

Control using any smart device with Wi-Fi

Nitro delivers 10 mm throw distance, long decap, and ink dry times under one second on most non-porous substrates, along with superior adhesion and rub resistance.

package.

From humble beginnings as a vendor in Seattle’s famous Pike Place Market more than 30 years ago, Cucina Fresca Gourmet Foods has steadfastly evolved into a leading U.S. producer of natural prepared pastas and sauces.

Inspired by fresh, high- quality ingredients like vine-ripened tomatoes, premium cheeses and garden-picked basil, the Cucina Fresca line of prepared foods has grown to more than 130 products that are available in more than 1,500 grocery stores, specialty shops and foodservice channels across the U.S.

Owned and operated by executive chef Brad Glaberson since 2005, Cucina Fresca strives to create great-tasting products while staying true to a philosophy of sustainability—a position that further endears the company and its products to a wide range of consumers.

According to Glaberson, “If we don’t do it at home, we don’t do it at work,” which means company initiatives include everything from composting food waste to choosing more sustainable packaging materials.

Fans of Cucina Fresca products and the company itself have come to appreciate this approach, so when the company started expanding its line of retail, hand-crafted pastas and sauces, some

began to express concerns that the products came in plastic packaging.

As company president Patrick Glingman recalls, “We were getting emails from some of our customers with concerns that our packaging was plastic.

“We knew we needed plastic MAP (modified atmosphere packaging) to keep the products fresh, but we also wanted to address their concerns,” says Glingman, who turned to the packaging experts at the Cryovac division of Sealed Air Corporation to answer the challenge.

“We’d been talking to Sealed Air about plantbased rollstock for some time,” Glingman relates, “but we weren’t sure it was right option for us.

“But once we understood how it took regular

Cut with the best for less.

Special promotion on G3/S3 digital cutting systems

Tailored to packaging and graphics applications – Completely modular, versatile, upgradable

plastic out of the equation it was a no-brainer.

According to Sealed Air, the CRYOVAC brand plant-based rollstock contains a barrier layer made from corn—a renewable crop that can be replenished by natural or other recurring processes in a reasonable amount of time. When added to plastics, such renewable materials help reduce dependence on petroleum-based resources, according to Sealed Air, while also reducing the carbon footprint of packaging.

While the packaging for the Fresca fresh pasta trays still uses traditional PET (polyethylene terephthalate) plastic for the exterior layers to retain optimal product safety, durability and thermoforming properties, the plant-based renewable barrier layer removes up to 24 per cent of fossil fuel-based plastic used to make each package.

The management team of Cucina Fresca is so enthusiastic about the packaging change that they proceeded to redesign the product labels to call out the use of CRYOVAC plant-based rollstock.

“We want to leave this world a better place, not just for us, but for our kids, our customers, and our customers’ kids,” states Glaberson.

“We want to make sure the plastic we use leaves the least environmental impact,” he concludes, “and that’s exactly what we’ve got with the CRYOVAC brand plant-based rollstock film.”

The PAC Packaging Certificate Program is the most flexible and comprehensive in North America, o ering maximum value. Delivered by industry experts, the program has been designed to meet the needs of all professionals in the packaging value chain, whether new to industry or tenured. Take all four classes, or just one!

COURSE 1

Packaging Essentials

COURSE 2

Explore the world of packaging, from development quality assurance and food preservation to smart packaging, prepress, print, and graphic design processes.

COURSE 3

Paper Packaging Plus

Learn about the combination of materials and structural choices available in constructing a package and how to evaluate the strength of packaging materials.

Complete Plastics Packaging

Get to know plastics from base elements to extrusion, injection and blow moulding, multi-laminates, design basics, and environmental interests.

COURSE 4

Packaging Circularity

Discover how to set up for success and deliver better packaging solutions by using circular economy approach from concept to next life.

For virtual and in-class o erings and dates, visit pac.ca/paced

PAC is a safe place for packaging leaders to collaborate, innovate, educate, and celebrate. For more information on how a PAC membership can benefit you and your organization, visit www.pac.ca

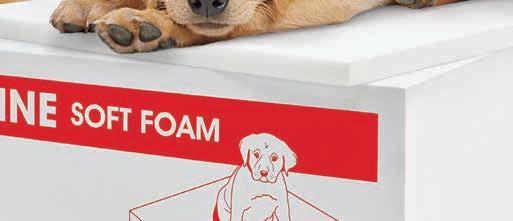

Providing meat packaging solutions to keep your operation running efficiently. It’s at the heart of what we do best.

Case-ready packaging minimizes handling and maximizes the shelf life of fresh food by enabling modified atmosphere, vacuum, and active or intelligent packaging techniques. It also allows for more precise control of product aging, enhancing the consumer eating experience. Add our wide variety of automation options to your primary packaging machine and create any packaging setup, up to a full product-to-pallet integrated line. Meat packaging covers an incredible gamut of options and solutions, and we can help with them all.

Any product. Any cut. Any style.

With consistent, professional and timely customer and technical service, our partnership starts at “hello” and extends well beyond your purchase.

Contact Harpak-ULMA today to learn more about our meat packaging solutions as well as options for poultry, produce, bakery, dairy, seafood, snacks, ready meals, medical and other non-food products!

Young Quebec entrepreneurs turn traditional family pastime into a fast-growing smoked salmon operation with lofty growth expectations

By Andrew Snook

Photos By Pierre Longtin

Brothers Samuel and Charles Gosselin grew up fully immersed in their family’s business. Their grandfather, Yvanhoe Gosselin, started up a small grocery store in Frelighsburg, Que., a small town close to the U.S. border crossing to the State of Vermont about 50 years ago. Over time, the store was passed on to their father, Francois Gosselin.

The two brothers would spend a great deal of their youths helping out at the store, acquiring the valuable hands-on experience that one day would help them start up the Fumoirs Gosselin smokehouse specializing in premium-quality smoked salmon products.

“Frelighsburg being a small town, a lot of

cottagers would come down during the summers, but not the winters,” says Samuel Gosselin.

“My father was always looking for ways to get people to come into the town to visit,” he recalls. “At that time, my father used to smoke trout with his friends as a past-time, so he decided to try out a bunch of products.

“About 15 years ago they ended up trying some salmon and came across a really good recipe that just stuck since then,” says Gosselin, co-owner of the family-owned Fumoirs Gosselin smokehouse operation located close to Frelighsburg in Cowansville, Que.

Although the company o cially opened in July 2019, smoked salmon is something Samuel and Charles have been involved in since a very young age.

“During the weekends when I was

(Clockwise)

Samuel Gosselin placing smoked fillets inside their packing trays; a finished skin-pack of smoked salmon being positioned for secondary packaging downstream; color-coded folding cartons used to di erentiate the di erent product recipes; the HMI (human-machine interface) touchscreen control panel provides full overview of the thermoform packaging machine’s operations in real time.

younger, my brother and I would smoke the fish, starting when we were 13 or 14 years old.

“As years passed by, the demand for our smoked fish kept growing and people were coming from further and further away, especially at Christmas time and other special occasions,” he continues.

“We saw the potential for starting up a business to commercialize the product,” he says, “which is now sold in grocery stores all over Quebec,” Samuel says.

While Charles continued to work with his father operating the family’s grocery store, Samuel went to work for another company and gained significant experience in operations management before re-joining the family business in 2018.

During the years when Samuel was away, Charles and their father began selling their smoked salmon to other local grocery stores.

In 2020, leading grocery chain operator Sobeys took notice of the family’s product on the shelves of a few grocery stores, and that’s when the smoked salmon operation blew up in a big way.

“When Sobeys saw what we were doing, they said they wanted our smoked salmon to be carried in all their stores across Quebec,” Samuel says.

With Sobeys ordering product for its

stores province-wide, the two brothers knew they would need to significantly expand their production capacity.

“For the first six months, we only had one product: our maple-smoked salmon,” Gosselin relates. “We used to have seven little smokers we had designed ourselves, which would smoke roughly 63 fillets, or 63 kilograms total per batch.

“Now we smoke at least 550 kilos per batch,” Samuel says. “When we first moved to Cowansville, it was four guys working in a 15,000-square-foot space.

“Now we are employing roughly 20 sta after just a year-and-a-half.”

Along with the increased production came a need for increased packaging capabilities.

“Being two little boys that grew up in a grocery store, we were familiar with a lot of things that are available on the market,” Gosselin states.

“We knew what a lot of companies were using, but we didn’t really understand the di erent types of packaging, the machines, or who would o er these types of packaging.

“So we started asking around, went to a couple of trade shows, and finally decided on what we wanted,” he relates.

The brothers reached out to Richard Tremblay, regional sales manager for Multivac Canada Inc. in Brampton, Ont., to help them find the optimal packaging solution for their operation.

“I was approached by Samuel and Charles, who were interested in investing in a skin-packaging machine.

“It’s a pretty specialized type of packaging,” Tremblay explains. “They explained to me that they have a family recipe of smoked salmon they’d like to put it on the shelves at a larger scale.”

When the brothers called Tremblay and told him they were considering purchasing a new packaging line, he immediately drove down and showed them Mutlivac’s various o erings.

Afterwards, Samuel and Charles drove to Mutlivac’s head o ce in Brampton and tried some of their products on Multivac machines set up in the

“We saw the potential for starting up a business to commercialize the product, which is now sold in grocery stores all over Quebec.”

company’s product demostration area.

“Right then, we knew that was the kind of product that we wanted,” says Samuel Gosselin, who ended up placing an order for Multivac’s R105 MF MultiFresh thermoforming packaging machine, along with the L310 Full Wrap Labeller and the MBS (Multivac Build System) 020 belt system.

“The feedback we got from a lot of people in the industry was that Multivac had the best machine for this type of packaging,” Gosselin recalls, “and we also knew Richard.

“He took care of us since we first started, he met with us in our little o ce in our grocery store, so we always felt

confident in what he was telling us.

“Those were two points that were critical to our decision,” Gosselin states.

“They wanted to have a high-end look to go along with their high-end product,” Tremblay relates. “Even before they processed the first piece of smoked salmon in their new facility, they decided to automate their packaging line.”

As Tremblay relates, the company’s investment in their new packaging line allowed them to automate the application of the labels in addition to the packaging of their smoked salmon fillets.

“Right now, they use a manual process only for loading the portions into the packaging machine,” Tremblay says,

“and the machine does the rest.

“The product goes in and is packaged in the full wrap labeler, the label is date coded, and then it is manually boxed,” Tremblay explains.

“It’s a vary nice line for a company like this one,” he says. “They will have this line for a very long time, doing approximately 20 to 24 packs per minute.

“It’s a very attractive product that they can e ectively di erentiate between different flavors by using di erent labels and folding cartons,” Tremblay states. “This gives them lots of flexibility to develop new recipes with the same high-quality packaging.

“At the end of day, the retail chains are looking for innovate, quality products that look good and attract consumers.”

Tremblay says that Fumoirs Gosselin still has plenty of packaging capacity available for expansion with this line.

“The full-wrap labeler is capable of doing 120 products per minute, so they could decide to use a bigger machine in front of it.

“They currently do about seven to eight cycles per minute on a three-up die—between 21 to 24 packs per minute—but the labeling machine could easily keep up to three to four times this volume,” he says.

That additional capacity will serve Fumoirs Gosselin well, as it’s always trying out new products.

“We’ve smoked a lot of things over the years, but before you bring a new product into the market there’s a lot of work

that goes into that,” Gosselin explains.

“We brought out a Natural smoked salmon brand, which was our easiest smoked salmon to cook.

“Then we found our Honey-smoked salmon worked really well, so we’ve brought that out.

“Since then, we’ve been growing a lot faster than we thought we would,” Gosselin confides. “Right now, we have a lot of di erent products we’re working on, and lots of new projects to come.

“We still have a lot of room to grow with the machine, and we are really happy about that,” he points out.

When Fumoirs Gosselin began to rapidly expand, they made sure not to allow the growth to a ect the quality of their product.

“When we decided to grow and transfer our smoking from the grocery store to a facility to supply across Quebec—and potentially all of Canada and into the U.S.—it was really important for us not to change our pre-smoking procedures.

“Our quality of brining, the way we do it, we’ve never changed it from dozens of fillets to thousands of fillets,” Gosselin states. “It’s the same process throughout.”

The brothers use their secret brining process on the salmon a day before placing it on the grill and then transferring it into the smokehouse.

After it cools down, it is transferred to a Marelec cutting machine that cuts the fillets into smaller pieces and feeds them into the Multivac thermoformer.

Investing in the packaging line to fulfill retail orders on a large commercial scale was vital for the company, since the COVID-19 pandemic had a significant impact on their sales.

“We’ve been doing this smoked salmon for 15 years and 90 per cent of all of our sales were from people who would invite people over for dinner, parties or other social events.

“When COVID-19 hit last year, our business dropped a lot for the first couple of weeks, because our product was associated with special occasions,”he says.

“But having Sobeys on our side helped us a lot,” he states. “They even tried to give us some specials a little more often to get our product out there in the public.

“They’re a really good company to have as a partner.”

As far as short-term goals go, Gosselin says would like to see the company begin o ering its products in Ontario. In the long-term, he would like to see his family’s smoked salmon on shelves at grocery stores in the U.S.

“We really like going to the U.S. because our family has a cottage in Vermont,” he explains. “We go there a lot.

“And when we go into grocery stores and see that nobody else there does what we do, so we see a lot of potential for us down the road.

“We’ve got our federal license, so that gives us the opportunity to sell outside of Quebec across Canada,” he says, “so now we just have to add on an international license to export to the U.S.,” he says.

Like with most fast-growing operations, there were some growing pains for the brothers that they had to overcome.

“My brother is 28 and I’m 30 years old,” says Gosselin. “We are two young guys who didn’t have any real experience in running production facility like ours, but we learned a lot in the last two years.

“The biggest challenge we had to overcome was getting through the first couple months of COVID and getting our name into the stores,” he concludes. “We’re working really hard for everybody to know who we are, and that we’re coming to their markets.”

Multivac Canada Ltd.

All finished packages of smoked salmon produced at the Fumoirs Gosselin facility pass through a Bizerba combination checkweigher and metal detector at the end of the line to ensure complete quality control and product safety for each individual package shipped to customers from the Cowansville production facility that produces a growing range of exciting flavors and recipes comprising its flagship branded smoked salmon product family.

(Left)

A Marelec Portio cutting machine producing perfect portions of salmon.

Please see a video of Multivac’s R105 MF MultiFresh thermoforming packaging machine in operation at the Fumoirs Gosselin facility on Canadian Packaging TV at www.canadianpackaging.com

Dave

a light moment at the entrance to the 1,600-square-foot cold room installed inside Your Farm Market building in Woodstock, where the cooler’s temperature is always maintained at 3°C by the Oxford LLP refrigeration system installed on the rooftop.

Schneider Electric intelligent automation platform helps upstart indoor market to yield dramatic energy savings with an innovative commercial refrigeration system

By George Guidoni, Editor

Photos By Haomi Hiltz

Expanding a business venture in the midst of a global pandemic crisis and punishing disruptions to daily commerce is a brave leap of faith.

But if there’s truth to the notion that fortune does in fact favor the brave, Bernia Wheaton provides a compelling case for trusting one’s entrepreneurial instincts when an opportunity knocks.

For Wheaton, one of three co-owners of the upstart Your Farm Market (YFM) marketplace in downtown Woodstock, Ont., that opportunity came a couple of years ago when she first heard aboutYFM being up for sale.

Previously operating as a seasonal fresh-produce vendor from an outdoor location during Ontario’s harvesting seasons, YFM already enjoyed a good loyal following in the local community, but Wheaton and her partners felt that the company had a lot of untapped potential to be unlocked by transforming it into a year-round enterprise.

To make it happen, the three partners

purchased a 7,000-square-foot former auto parts dealership and proceeded to refurbish it into a modern, bright, spacious and welcoming indoor market specializing in locally-grown produce, dairy, baked goods and meat products sourced from nearby farms and many smaller artisan-style food producers operating in and around the province’s Oxford County region.

Despite the devastating outbreak of the COVID-19 pandemic across Canada prompting long-term shutdowns of many smaller businesses across the province over the last year, YFM embraced its “essential business” designation to proceed with building renovation and upgrades— opening its doors to the public last July.

“We have been opened every day except for Christmas Day and New Year’s Day since then,” says Wheaton, who spent most of her previous working life focused on various segments of Ontario’s agricultural and agri-food industries.

As Wheaton relates, her deep-rooted respect and appreciation for the province’s hardworking independent farm enterprises played a big role in her decision to

(Clockwise from top)

The Magelis HMI (human-machine interface) terminal from Schneider Electric enables full control of the rooftop Oxford LPP refrigeration system from the ground level; Your Farm Market co-owner Bernia Wheaton shows o some of the locally-grown fresh produce shipped to the market by nearly 120 local suppliers keeping the market well-stocked throughout the year; the market’s large self-serve refrigerated display cases are also hooked up to the highly automated Oxford LLP refrigeration system for optimal temperature control and energy e iciency.

invest in YFM as a platform for expanding the vision of sustainable local farming to everyday life.

“I’m not just in the business of selling carrots: anyone can sell carrots,” Wheaton states.

“For us, the market is more about supporting local businesses and developing relationships with people running those businesses,” says Wheaton, citing a growing list of local produce and other food suppliers that now include about 120 Ontario-based farm operators and other related companies.

“We also put a high emphasis on providing the best-quality product available along with an exceptional customer service experience,” says Wheaton, citing steady foot tra c through the store even during the worst parts of the COVID-19 related lockdowns.

“We know many of our customers by name,” says Wheaton, adding that YFM highly values its loyal sta members that keep the store operating like clockwork seven-days-a-week.

“It’s all about the people for us, which I think is what separates us from traditional grocery stores,” Wheaton proclaims.

“People enjoy coming into the market because it’s not just an ordinary shopping experience,” she says. “They honestly enjoy the overall interaction that they experience here.

“Above all, they are really receptive to the way we do things by making it a priority to support local business by providing the highest-quality product that we can find.”

Says Wheaton: “During this year of COVID, people seem to want to know more than ever where their food comes from, what parts of the food chain it has been through, who has touched

it, and so on.

“We have regular conversations with our farmers and suppliers about how they’re keeping their sta healthy and their products safe,” she relates, “and we share that information with our customers to give them another level of confidence in the products they buy from us.”

Currently employing 23 people during the winter months, YFM expects to operate a sta of 42 at the height of the next summer’s harvest season, when nearly 100 per cent of all fresh fruit and vegetables sold at the store will be sourced from Ontario farms, according to Wheaton.

While YFM does import some of the more tropical fruit varieties from selected foreign growers during the winter, locally sourced foods still account for over 75 per cent of the store’s product volume even during the o -season months.

“There’s a lot of local food available all year long, much more than people may think,” Wheaton remarks.

“There’s apples, greenhouse vegetables like tomatoes, lettuce, cucumbers and peppers, root vegetables, sweet potatoes, rutabaga, onions, garlic ... there’s a lot we can o er,”Wheaton states.

“In addition, we specialize in a lot of locally-crafted meats and cheeses, as well as other locally-made grocery items like roasted co ee,

juices, breads, pies and many other great products to fill up your grocery cart with everything you need,” she states.

This unique product o ering has enabledYFM to attract an average of 800 customers per day over the last several weeks, according to Wheaten, who estimates the store’s full capacity at about 1,200 customers.

“We intentionally set up this building to have very wide aisles,” she points out, “so we can accommodate larger crowds while still remaining safe during COVID lockdowns.”

As Wheaton relates, the company’s preference for doing business locally has turned out to be very beneficial when it was time to install a new refrigeration system to operate the store’s 1,600-square-foot enclosed ‘cold room’ area with its own walk-in deep freezer.

In addition, this system would also have to provide optimal temperature control for the large deli section outside the cold room to ensure proper refrigeration for the cheeses, deli meats and other freshly made items displayed behind the glass counters.

With refrigeration systems often being one of the most capital-intensive investments in starting up a new grocery store, Wheaton had to make sure she picked the right supplier to provide a

(Clockwise from top)

The rooftop Oxford LLP refrigeration system; Oxford’s innovative Vapour Drive technology enabling oil-free operation; a close-up of a Schneider Electric power supply/UPS unit; several M172 series PLCs running Oxford Energy’s user-friendly Sensori Control software.

reliable and, critically, an energy-e cient system that would not cost a fortune to operate.

As it turned out, YFM’s ownership team made an exceptionally wise choice by approaching Oxford Energy Solutions Inc. to take care of the store’s refrigeration needs.

Also conveniently located in Woodstock since its founding in 2006, the privately-owned manufacturer has enjoyed rapid growth over the years through pioneering development of innovative, energy-ecient commercial refrigeration systems used in the agricultural, food processing and distribution, and healthcare industries.

“I have known about Oxford Energy from my previous work in the agri-food business,” says Wheaton, “and I was confident about engaging them to design and build a 1,600-square-foot cooler that would not just meet our current needs, but would be able to grow with us over the next decade.

“With them being a local company, they fit right into our mandate of supporting local businesses as much as we can,” Wheaton adds.

By securing Oxford Energy’s services, YFM has paired itself with a like-minded business enterprise aiming to a ect far-reaching changes in the way traditional commercial refrigeration systems are designed and serviced, according to the company’s president Ben Kungl.

“The commercial refrigeration market is dominated by few manufacturers whose product o ering is slow to adapt with

current available technologies.

“Our focus is on moving this industry forward to benefit the customer and the environment, instead of focusing on sales of replacement parts,” says Kungl.

Comparing the industry to the monolithic oil and gas business dominated by a few long-established players, “Oxford is looking to disrupt this hidden market,” says Kungl, explaining his company’s embrace of open-architecture control systems and intelligent control devices that can pinpoint the tiniest system problems and ine ciencies before they become major system failures requiring extensive repairs and overhaul.

“The core refrigeration design and control has gone unchanged for too long,” Kungl asserts. “Some systems are 50-years-old, with the compressors, valving, and integration remaining essentially unchanged.

“These refrigeration systems with conventional componentry are still dependent on pressure and oil,” Kungl explains, “whereas we have the ability of full integration with our Sensori Control platform, along with the oil-free, fully modulating Vapour Drive type of compressor.

Says Kungl: “When compressors fail, it is almost always caused by a separate issue in the system.

“Lack of information and diagnostics are really to blame in these systems,” says Kungl, “which hide the root problem.

“Technicians do not have all the information required to make proper assessments and therefore both the system and the owner su er.

“Secondary and third-tier problems such as electrical burn-ups, acids, high discharge temperatures, improper superheat, mass flow issues, etc. are usually evident and will forever plague these system as you go down this path,” Kungl asserts.

For Kungl, increasing component longevity, reducing breakdowns, increasing system e ciency can all be achieved with better control and vision built into the system from start, so it can be set up and assessed properly.

As he explains, the company’s Sensori Control platform o ers the required

scalability, repeatability, machine learning capabilities required for optimizing machine intelligence and energy e ciency, which Kungl, which he says are the key hallmarks of innovative new refrigeration technologies Oxford Solutions has brought to the market recently.

This includes, of course, the patent-pending Oxford LLP (Low-Pressure Platform) system installed at Your Farm Market last spring.

“It is arguably one of the highest-automated refrigeration platforms available on the market today,” Kungl states. “It’s a plug-and-play system; as soon you plug it in, it auto-loads and starts running.

“It’s also a connected system that is continuously pulling all the data and stores all the historical trends.

“If something goes wrong, it shuts o and we get a notification before anything detrimental could happen,” Kungl explains.

“By utilizing machine learning and adaptive predictability, we are now taking it to the next level by informing the customers what’s going wrong with the machine and how to fix it in the interim.

“Our key objective with every customer is to reduce service calls ans cost to customers, and the operating cost from maintenance standpoint, ” Kungl states.

“Energy reduction and lower hydro bill are all byproducts of that philosophy.”

Byproducts or not, Wheaton can’t say enough good things about the Oxford LLP system installed at her store location.

“It costs me about $300 per month to operate our Oxford refrigeration system,” Wheaton extols. “People are amazed when I tell them it costs me a fraction of the Hydro bill I pay monthly to heat and air-condition the rest of the store.”

According to Wheaton, the Oxford LLP system has operated flawlessly since startup, consistently keeping the cold-room chiller at 3°C temperature levels, while ensuring -20°C or lower temperatures inside the freezer, as need be.

“The large food area with refrigerated coolers, freezers, serving counters, process area, etc., has yet to exceed a peak of 20 KW of total energy for all refrigeration equipment, including all fans and defrost

heaters,” adds Kungl.

According to Kungl, the system’s remarkably low power consumption is in large part enabled by the system’s use of Oxford’s innovative Vapour Drive compressor technology, along with the new open-architecture Sensori Control software driven by advanced automation controls and devices supplied by global energy management and distribution systems giant Schneider Electric.

This powerful integrated package of automation hardware and software enables about a 50-percent reduction in the number of mechanical components in the systems’ design, including pressure safeties and pressure control hoses, while the use of smarter controls from Schneider Electric allows for a better-operating, lower-charged system with the least amount of connection points and gaskets.

All this adds up to reduced installation costs and start-up time, user-friendly benefits of pre-programmed, self-assessing and self-adjusting system architecture, along with self-programming EXV (electric expansion valve) controls.

As Kungl relates, collaborating with Schneider Electric in the design and integration of Oxford’s Sensori Control platform and Vapour Drive motor technology into the Oxford LPP system has been a rewarding experience on many levels.

“We share the same goals of energy resiliency, sustainability, reliability, adaptability, increasing e ciency and net-zero emissions,” he states. “We also have a shared vision of disrupting and improving the market by going against existing methods.”

Dave Mark, account manager for southwestern Ontario with the Industrial Automation Business unit of Schneider Electric in Cambridge, Ont., says the use of Schneider Electric’s M172 series PLCs (programmable logic controllers) aboard the Oxford Sensori Control panel has en-

abled the level of system integration over the full refrigeration platform that was difficult with any other system on the market because it was not open and flexible—enabling Oxford to apply a program control structure they have been trying to implement in this market for a very long time.

“Every compressor gets an M172 18-I/O PLC with set I/O configuration so they are all the same, every time, with all the case controls, condensing unit controllers, and dehumidifier controllers all having their own Modbus driver.

“The benefits of having all the M172’s functioning as individual devices with the same I/O allows us to auto-configure every device on the connected system automatically,” Mark explains, “like plugging an iPhone into a computer.

“The system already knows the associated I/O and where we want to direct the information,” Mark says.

“It’s a truly plug-and-play control platform, with no site programming, and where every device is fully independent of the others.”

All the information and commands generated by the M172 PLCs is displayed in real time on Schneider Electric’s Magelis industrial PC terminal mounted onto the refrigeration system’s control cabinet enclosure outside the cold room, which can only be accessed by Wheaton herself.

The rugged touchscreen Magelis terminal deploys Schneider Electric’s EcoStuxure Machine Scada Expert control technology to bring all the collected information to the user in a pre-defined set of screens.

“The final stage is the dashboard and server system for applying advanced analytics and machine learning,” Mark says.

“These solutions are protected by Schneider Electric EcoStuxure Secure Connect advisor, a strong cyber security solution for remote access to make for a

fully integrated solution,” says Mark, adding Schneider Electric also provided all the related hardware products including power supplies, switches, buttons, contactors, starters, humidity transducers, cables, sensors, motors, drives, etc.

“We have not experienced any failed components on-site yet and no hardware issues to this day,” Kungl states.

As Kungl explains, the Sensori Control platform running throughout the entire refrigeration platform utilizes the same pressure transducer and temperature sensor at every point in the system.

“Hence the inventory and replacement parts required for emergency stock are dramatically reduced,” Kungl points out.

“The ability to have total vision into a system or a stand alone device without any changes to system programming or set-up are key,” Kungl proclaims.

“The convenience of all devices communicating over a network LAN system makes integration and cross communication as easy as plugging in the cable.

“This is the design of the system as we saw it,” Kungl assets, “so that there would be no limitation to size or growth.”

Adds Your Farm Market’s Wheaton: “I’ve obviously learned a lot about what goes on with the system and what makes it unique, which is simply way out of my knowledge base.

“But although I didn’t know anything about refrigeration, I’ve been able to come up to speed thanks to all the great help I got from Oxford and Schneider Electric,” Wheaton states. “They’ve been great to work with and they have been exceptionally responsive and quick to answer any questions I may have.

“Moreover, it is a highly secure system that I can monitor virtually from anywhere,” says Wheaton, citing the system’s self-configuring Internet connection requiring no input from ITpersonnel.

“Security over the Internet is our biggest concern,” she states, “and this is one of the most secure systems on the market.

“The email set-up is as simple as typing in your address,” she says, “while everything else is automatic.

“All in all, this refrigeration system gives me a priceless peace of mind,” Wheaton concludes, “in addition to the fantastic savings in our electricity costs.

“And doing it while being able to create strong relationships with local businesses who are working to create a better and more sustainable environment is a great bonus for us and the community we all serve.”

SUPPLIERS

Schneider Electric Canada

(From left) Oxford Energy president Ben Kungl and Schneider Electric’s account manager Dave Mark have been collaborating on several joint projects over the years to help Oxford develop a new generation of energy-e icient commercial refrigeration systems for various industries.

Please see a video of the Oxford LLP refrigeration system, and the Schneider Electric automation controls used to operate it, on Canadian Packaging TV at www.canadianpackaging.com

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation. COMPLETE

info@heatandcontrol.com |

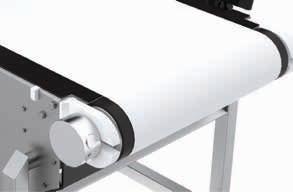

Artisanal deli meats producer making the most of its thermoform packaging investment with confident move into broader retail and online grocery channels

By Andrew Snook

Michael McKenzie has always had a passion for fine foods: salami and similar cured meats in particular. Whenever his work took him overseas, he took advantage of every opportunity presented to him to try meats from around the world.

“I was originally in the military and travelled around eating food everywhere,” McKenzie says. “I loved eating and making salami. I bought it everywhere I went—all over the West Coast in places like San Diego and Seattle, across Asia, and all over Europe.

In addition to tasting and enjoying different salamis, McKenzie would often sit down with butchers at the shops he visited around the globe and discuss the tech-

niques they used to make their creations— expanding his knowledge base and improving the salamis he was making back home, which became his passionate hobby about 15 years ago.

Upon leaving the military in 2010 to spend more time with his family in Sharbot Lake, Ont., McKenzie’s hobby quickly became his full-time business in 2010, which he named Seed To Sausage

“My son was being born and I was going to get deployed again, so I thought I should look at a new line of work,” he recalls.

Like many small businesses starting out, McKenzie tried to work out of his home, but this became impractical as the popularity of his cured meats quickly grew.

“My business started with chefs coming to my house and buying products from me, and soon I was selling to restaurants,” McKenzie recalls. “So I phoned Health

(Top to bottom)

A selection of cured sausages and other artisanal meat products produced by Seed To Sausage wrapped in airtight high-barrier plastic film packaging on the high-performance automatic Variovac Optimus HFFS machine installed at the facility about a year and a half ago.

Machine operator loading two salami sticks at a time inside the cavity pockets of the Variovac Optimus machine for making the salami twin-packs shown in the picture above.

Canada and let them know that I’m making salami in my garage and that I would like to have it inspected so I can make it out of my garage commercially.

“Someone came in and tried to help me turn my garage into a meat plant,” McKenzie recounts, “but it was impossible.”

Fortunately, a local economic development group heard about his cured meats and his need to expand the business.

They informed McKenzie that there was a local abattoir being o ered for sale, and he jumped at the opportunity to purchase the property.

“I was producing salami, writing my own regulations, delivering salamis and doing collections,” McKenzie recalls.

“I had originally started out with my father, who helped out on the bookkeeping side of things,” he says. “Even my mother would come to help out sometimes.”

Happily for the McKenzie family, all those early growing pains ultimately paid o in a big way.

These days, Seed to Sausage produces approximately 50 di erent types of cured meats, including seven di erent types of ready-to-eat sausage and, of course, a generous selection of di erent styles of salami—totalling about 250,000 kilograms of cured meats a year.

In addition to the production facility in Sharbot Lake, which employs upwards of 14 people during the plant’s busiest production periods, McKenzie also owns a retail store in Ottawa that employs another seven people.

Before the COVID-19 coronavirus pandemic was o cially declared last March, Seed To Sausage products were selling exceptionally well in many popular restaurants across Ontario.

“We sold to over 800 restaurants,” McKenzie says. “We were in almost every high-end restaurant in Ontario—like the Oliver & Bonacini restaurants.

“Our products were being served in the House of Commons and at the Governor General’s Awards banquet,” says McKenzie, citing a prestigious industry award as Canada’s top artisan food producer.

But the pandemic hitting the restaurants especially hard by forcing them to close in-room dining for the better part of 2020, McKenzie knew he had to develop a

new strategy for getting his products out.

After deciding to focus on online and retail sales, he began exploring options for acquiring the right packaging technologies for his high-end, hand-crafted artisanal products that would fit into the extremely small footprint of his processing facility.

“We only have 4,000 square feet to work with, along with an adjacent 1,000-squarefoot walk-in refrigerator,” he says.

Having been approached on several previous occasions by food packaging specialists at Reiser (Canada) Ltd. of Burlington, Ont., McKenzie decided to find out what Reiser could do to provide a practical solution for his needs.

“I’ve been calling on Mike since 2015,” says Reiser Canada’s sales representative

The Variovac Optimus machine is operated via a built-in seven-inch industrial PC touchscreen terminal displaying the machine’s operational status in real time.

Finished twin-packs of premium-quality salami sticks placed inside corrugated cases for shipping to customers.

Freshly-made salami packages exiting from the Variovac Optimus machine’s sealing unit at the system’s back end.

that—more e ective packaging.

“That’s what drove the sale,” says Kennedy, describing the recent installation of the highly robust and versatile Variovac Optimus horizontal form/fill/seal (HFFS) packaging machine delivered by Reiser Canada.

Je Kennedy.

“We’ve had a really good relationship over the years, talking about various technologies that Reiser o ers,” says Kennedy, admitting to being a fan of Seed to Sausage himself. “With the flavorings Mike puts in his sausages, he’s found a way to really differentiate his products.

“There’s nothing quite as unique like his products to be found in the larger supermarkets … he’s got a very loyal customer base.

“Considering where’s he’s located, he has built up a good following on the retail side,” Kennedy says, “but once Mike decided that he was going to do home delivery as well, we both agreed that he would need to have better packaging to do

“We had talked about thermoform packaging in the past,” recalls Kennedy, “and once Mike decided to switch gears he wanted to find out how he could implement it.”

As Kennedy explains, the Variovac Optimus system can process a broad variety of packaging styles and formats, including vacuum- and skin-packing, MAP (modified atmosphere packaging), shrink packaging or hot filling, o ering robust output rates of up to 13 cycles per minute.

Featuring stainless-steel construction and hygienic design for meeting the strictest sanitation requirements, the Variovac Optimus features the proprietary RapidAirSystem technology to ensure uniform, high-quality forming and sealing without the need for pre-heating film, according to Reiser.

McKenzie says that the installation and

Started up at the Seed To Sausage facility last November, the Variovac Optimus packaging machine installed by Reiser (Canada) Ltd. has provided owner Michael McKenzie (left) with the professional high-barrier film packaging that enabled the company to enter the more lucrative retail and online sales channels to make up for the lost restaurant business.

commissioning of the machine was not particularly challenging once he was able to find a home for it inside the facility.

“Typically, nobody has extra space just lying around that can be integrated into the flow of their production,” he says. “It took a long time to figure out where we were going to fit this machine.”

Around the same time that McKenzie was searching for a spot to place his new Variovac Optimus system, he was also starting to run out of space in his walk-in cooler. Deciding to kill two birds with one stone, he converted an old shipping bay into his new walk-in cooler and used the space from the old cooler to install the Variovac Optimus.

“We went from 600 square feet for our walk-in cooler to 1,000 square feet,” McKenzie notes. “Now even that room is getting too small.”

Adds Kennedy: “It took a rigging crew to get it inside.

“They have a very small facility, so they had to build an addition to the plant to install the machine,” Kennedy says. “It was a really big commitment on their end.”

The entire process of finding the necessary space, installing and commissioningof the new Variovac Optimus took about four months to complete, but by November 2020 everything was operational, and Seed To Sausage was back to filling orders for both the online and retail customers.

“Mike needed to figure out which products he wanted to package and what he wanted them to look like—things like pepperettes, bacon and sausages—and we came up with solutions that could package all those things,” Kennedy says.

The high-end, high-impact packaging produced on the Variovac Optimus machine was vital for getting the high-quality meats onto shelves at various retail locations, according to McKenzie.

“When the COVID-19 shutdown happened, we were not able to pack e ciently by volume to make up the sales we had in the restaurants,” McKenzie relates. “We were forced to go into retail sales, so we bought the Reiser Variovac for individual packaging and we’ve built our sales right back up.”

Despite only having his new Variovac Optimus operational for about half a year, McKenzie can’t picture life without it now.

“I couldn’t imagine not having the unit now,” he states. “It has increased the value of the company substantially.

“I really should have gotten it a long time ago.”

SUPPLIERS

Reiser (Canada) Ltd.

Please see a video of Reiser’s Variovac Optimus machine in action at the Seed To Sausage facility on Canadian Packaging TV at www.canadianpackaging.com

Premium-quality

Gourmet chocolate producer hits the packaging sweet spot with custom-designed horizontal flow wrapping system

By Andrew Snook

When Jacqueline Jacek took a hard look at her future career path, she couldn’t decide on whether she preferred to pursue a career in fashion or chocolate.Ulimtely, Jacek decided to have the best of both world by combining her pssion for both to become a cocoanista, a chocolate designer, by launching JACEK Chocolate Couture

“I started the business in our basement in December 2009 with a goal of combining fashion and chocolate,” Jacqueline told Canadian Packaging in a recent interview from her company’s head o ce in Sherwood Park, Alta.

“I decided to pursue the culinary arts and run the company on a fashion business model with collections launching seasonally.”

Already trained in the art of chocolate making, Jacqueline worked with her husband, Tim Jacek, and her father,Tom LaBerge, to convert a bedroom in the couple’s basement

The company’s award-winning chocolate bars are packaged on the high-speed Sinlon model SL-920HE horizontal flow wrapping machine (see below) that uses hermetic sealing to make air-tight packs that prevent the passage of air, oxygen or other gases that can adversely impact the product’s shelf-life.

into their first chocolate production space. Jacqueline’s model of producing beautiful, high-end chocolates with seasonal rollouts of new products was extremely successful, and the company has grown consistently every year since its inception.

In 2012, Jacqueline leased her first commercial space in Sherwood Park to expand production.