BRINGING HOME THE BACON

Gourmet meat processor leverages cutting-edge thermoform packaging technology to carve out a growing market share

Story on Page 17

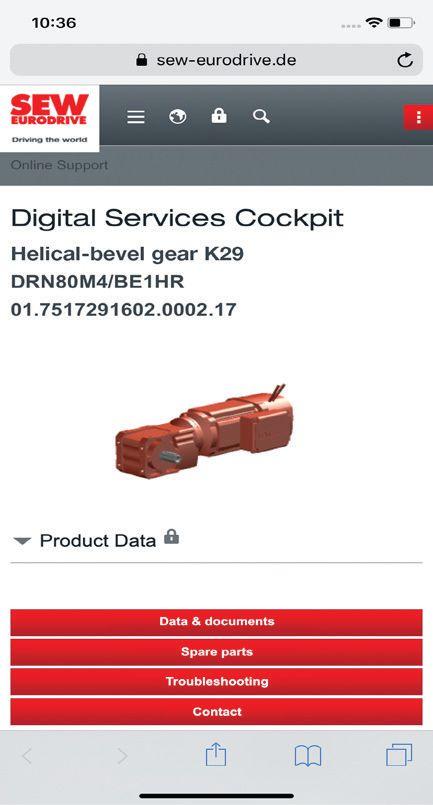

LEFT: JAY JAYAWARNA, GENERAL MANAGER, HERTEL MEATS

RIGHT: SAM NOSEK, REGIONAL SALES MANAGER, MULTIVAC CANADA

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

116 17

Videojet® 2380 large character printer

The mess-free way to print on cases and cartons

Maximize your coding efficiency with the Videojet 2380 inkjet printer. Designed for easy use, it integrates smoothly, requires minimal maintenance, and can be operated with simple training. Self-cleaning technology helps ensure crisp, high-resolution text, logos, and barcodes. Take advantage of the ability to code on multiple sides of cases and cartons with up to four printheads.

n

FROM THE EDITOR

4 George Guidoni

Cluching at straws to see any upside to sliding backwards.

CHECKOUT

44 Rhea Gordon Joe Public speaks out on packaging hits and misses.

17 HIGH OFF THE HOG

Vancouver Island-based pork processor raises its packaging game to a higher level following successful start-up of cutting-edge thermoforming packaging equipment.

FEATURES

12

Going for Gold

Leading independent Ontario paperboard packaging producer joins a select group of global manufacturing giants to have earned the EcoVadis Gold Medal certification for corporate sustainability.

22 The Upper Crust

Canada’s leading manufacturer of private-label frozen pizzas leveraging high-speed robotics technology to boost its production output without compromising the company’s stellar reputation for superior product quality and innovation.

28 Brotherly Bonds

A family-owned hog farming operation on Vancouver Island invests in state-ofthe-art vacuum-packing technology to support the stellar growth of its unique online meat distribution business.

33 Cut and Run

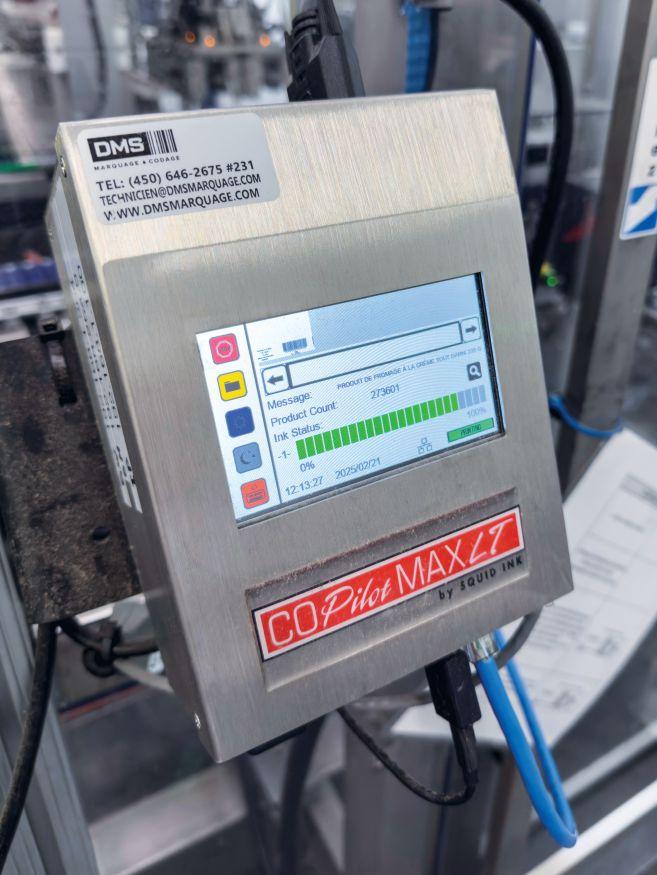

Rural Ontario meat processor reaping the rewards of its strategic investment in state-of-the-art slicing and flexible packaging machinery.

38 Going the Distance

Innovative Quebec dairy products manufacturer boosts its product identification and traceability capabilities with timely investment in advanced case-coding technology.

ISSN 0008-4654.

Hertel Meats general manager Jay Jayawarna and MULTIVAC Canada’s regional sales manager Sam Nosek cheerfully display a finished vacuum-pack of bacon coming off a MULTIVAC thermoformer at Hertel’s pork processing operation in Port Alberni, B.C.

Photo by Dave Buzzard

Clutching at straws in the ongoing battle against plastic waste

16 million

The number of plastic straws used in Canada daily in 2021

Packaging and politics rarely make for happy bedfellows at the best of times. So it is little wonder, in retrospect, to find packaging-related issues and controversies getting caught up in the political headwinds dominating the current new cycles.

As you may have heard, one of the first policy decisions announced by the new White House administration earlier this year—even before the trade tariffs—was to ban the federal government from buying drinking straws made from paper, reversing the eco-minded purchasing policy pursued by the previous administration.

With federal government being the biggest single purchaser of straws in the U.S.—being used in national parks, embassies, federal building, etc.—that early executive order may be far more consequential than it first appears.

With an estimated half a billion straws used in the U.S. every day, going back to the conventional plastic straws will only aggravate the growing global plastic pollution crisis that manifests itself daily in mountains of waste and littered beaches worldwide, along with the devastating impact on marine life and, potentially, irreversible contamination of the human food chain.

For all that, “I don’t think plastic is going to affect a shark much as they’re munching their way through the ocean,” U.S. president Donald Trump declared upon his return back to the Oval Office.

“We’re going back to plastic straws,” Trump told reporters before signing off on the executive order banning the paper straws.

“They (paper straws) don’t work. They break. They explode if something’s hot. They don’t last very long, like a matter of minutes, sometimes a matter of seconds. It’s a ridiculous situation.”

To be fair, this fixation with paper straws is not a one-off. A few weeks ago, the Progressive Conservative party leader Pierre Poilievre made a late pre-election pledge to scrap our federal government’s ban on single-use plastics and to bring back plastic straws and disposable grocery bags.

If that was a tactical move to regain some momentum heading into our federal election, it was either made too late in the game to have any impact or it was simply aimed at the wrong audience at the wrong time, as it turned out.

That said, it may be a good idea for the new Canadian government to acknowledge that the country’s single-use plastic ban, first announced on Oct. 7, 2020, may use some further reflection and refinement to address some serious concerns and misgivings voiced my many Canadian business leaders.

But getting bogged down in the pros and cons of paper straws hardly seems like the right place to start.

While the nationwide ban on single-use plastics like straws, checkout bags, cutlery and stir sticks is currently stuck in legal limbo—waiting for the federal court to make a final ruling on its constitutionality—many municipalities across the country have already moved ahead in enforcing at least some of its restrictions.

Rolling back that progress after having jumped through so many hoops would send out a lot of wrong signals at a time when the likelihood of future advances in environmental protection seems to be at its weakest point in years.

Numerous public opinion polls continue to show that most Canadians are willing to make reasonable sacrifices to their everyday convenience to help reduce the flow of discarded plastics into the Canadian environment, and phasing out plastic straws seems like one of the least painful sacrifices we could make to keep Canadians focused on the need for real progress on packaging sustainability going forward.

Having been thrust into the public spotlight when least expected, the humble plastic straw may yet turn out to be a powerful symbolic indicator of Canada’s long-term commitment to meaningful plastic waste reduction rooted in science, economic pragmatism and the greater common good.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

APRIL/MAY 2025 | VOLUME 78, NO. 3

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

Media Designer Alison Keba | (519) 429-5181 akeba@annexbusinessmedia.com

CEO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $80.07 per year,USA $183.09 (CDN) per year, Outside Canada $207.57 (CDN) per year, Single Copy Canada $10.00.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its affiliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

Rychiger Rychiger, Ree...hee...ger.

When it comes to automated packaging, we’ve got it down to a science. With over 125 years of combined expertise, Rychiger Canada delivers cutting-edge solutions for primary, secondary, and tertiary packaging.

Food & beverage? We’ve got you covered. Petfood? No problem. Personal care? Absolutely. If it needs to be packed with precision and speed, we make it happen. Because at Rychiger, performance isn’t just a promise—it’s what we do best.

Iconic ice cream shop chain launches new variety packs to celebrate freedom of choice

With warmer sunny days almost within our grasp, Canadian ice-cream lovers are in for a real cool treat this year, thanks to the Canadian launch of the first-ever Baskin-Robbins six-scoop Variety Pack boxes. Created specifically for ice-cream aficionados who have a hard time picking just one flavor, this grab-and-go pack features six of Baskin-Robbins’ most popular flavors in convenient, four-ounce pre-packs.

Launched in late February, the introductory selection includes perennial fan favorites like Jamoca Almond Fudge, Cookies and Cream, Mint Chocolate Chip, Gold Medal Ribbon, Pralines ‘n Cream and Mango Tango—perfect for sharing with family and friends, or simply indulging in variety. Since then, the Variety Pack offering has been expanded to include fourpack and eight-pack options.

Foreign Material Foreign Material

“The Variety Pack solves one of our customers’ biggest problems—choosing a flavor,” says Becky Felis, vice-president of international marketing at Inspire Brands.

“With pre-packs growing in popularity and new flavors launching regularly, this is a fun, convenient way for guests to take home a mix of their favorites,” Felis adds.

Currently available at participating Baskin-Robbins shops across Canada, the Variety Pack will soon be launching on the brand’s new digital and mobile ordering platforms, where customers will have the option to customize their flavor selections.

Founded in California in 1945, Baskin-Robbins is the world’s largest chain of ice cream specialty shops, with more than 7,700 retail shops in 33 global markets.

Celebrating 54 years in Canada this year, Baskin-Robbins operates 116 locations in Alberta, Ontario, Quebec, Manitoba and British Columbia.

Each year, more than 300 million people around the world visit Baskin-Robbins to enjoy some of the more than 1,400 flavors available in the brand’s ice cream library, according to the company.

Coca-Cola bringing back personal connections for the new generation

Having enjoyed overwhelmingly positive consumer response with its first-of-its-kind Share a Coke campaign back in 2011, Coca-Cola Canada is hoping to recapture the magic of personalized connection with a nationwide relaunch of the legendary promotion—allowing Canadians to find their names in place of the iconic brand logo on the bottles and cans of the bestselling soft-drink brand.

“The Share a Coke campaign honors personal connection and shared moments with friends and family,” says Solange Grimard, senior integrated manager at Coca-Cola Canada.

“For the return, we have expanded our name range to engage even more Canadians in these sharable moments of joy.”

As Grimard explains, the brand’s unique customization platform offers even more names to choose from, as well adding a unique personal touch via the Share a Coke Memory Maker online digital platform, accessible through the company’s website.

“Coca-Cola continues to lead through innovation and exciting new experiences that resonate with Canadian consumers,” says Phil Cox, general manager of Coca-Cola Canada. “By bringing back this beloved campaign, we’re inviting all Canadians to celebrate friendship and connections in a meaningful way.”

All the personalized Coca‑Cola bottles and cans used in the campaign are made, distributed and

Monomaterial PE bag a boost for planet and animal welfare

With recyclability and recycled content being two critically important cornerstones of the emerging Circular Economy, Austria’s leading packaging products manufacturer Mondi is doubling down on its efforts to ensure a bright green future for plastic packaging.

Launched last year, the company’s FlexiBag Reinforced is a new range of recyclable and cost-effective PE-based monomaterial packaging designed to offer ideal protection to a wide range of products with high barrier protection, improved mechanical properties, and seamless customization.

These benefits have already prompted family-owned German

pet-food producer mera to adopt the FlexiBag Reinforced packaging for packaging its Pure Green dry pet food range.

Having determined that the FlexiBag Reinforced packaging was perfectly suitable for its existing machinery, mera successfully intro-

duced FlexiBag Reinforced packaging—created with 35-percent PCR (post-consumer recycled) content—for its 10-kilogram packs of vegan dry dog food.

Says mera’s purchasing manager Enes Tajic: “We firmly believe that in nature, everything is interrelated.

“We are passionate about animal welfare—and part of that is a commitment to sustainability,” Tajic says.

“Working with our long-term, trusted partner Mondi meant that these new dog food products will be packed in a way that enables us to continue to create harmony between our furry friends and their environment.”

According to Mondi, improved mechanical properties make the bags superior to previous versions with better puncture resistance, stiffness and sealability.

Moreover, the level of barrier protection can be adjusted, providing medium to high barriers against fat, oxygen and moisture, while keeping the content fresh—making them ideal for the pet food industry.

Because the bags have been created inhouse by Mondi, leveraging its integrated value chain, the packaging can be tailored to different customers’ specific needs more cost-effectively, according to Dirk Gabriel, chief operating officer at Mondi’s Consumer Flexibles division.

“Mondi recognizes the increasing emphasis on PCR materials, driven by future regulative requirements, and as a market leader in sustainable pet food packaging, we are taking every effort to secure sufficient upstream supply of PCR material for our customers,” Gabriel states.

“By working closely with our partners along the value chain we can understand the unique requirements of each customer and adapt accordingly to material efficiency and recyclability,” he adds.

“With FlexiBag Reinforced, we are able to offer a solution that comes close to the material costs of conventional multimaterial laminates for certain structures, and at the same time offer recyclable packaging that gives our customers a competitive advantage in the market.”

According to Gabriel, being able to add a customized percentage of post-consumer recycled (PCR) content as required by end-user significantly reduces the use of virgin plastics, while promoting material efficiency by keeping materials in circulation.

GO WITH THE FLOW

The new generation of OEM-specific Dosimag and Dosimass flowmeters for filling applications from Endress+Hauser is designed for superior filling and batching performance, with high precision and repeatability, and exceptionally short filling cycles even for the tiniest quantities. The electromagnetic Dosimag provides quick volume measurement of conductive liquids and liquid foodstuffs in filling applications, while Dosimass, employing the Coriolis principle, ensure fast measurement of mass flow of conductive or non-conductive media. The new Dosimag and Dosimass flowmeters offer a choice of three different electronics—classic

pulse, integrating batching over Modbus RTU, and Intelligent pulse with IO-Link—each delivering their own distinct benefits. Classic pulse is easy and economical, while Integrated batching includes Dynamic Drip Correction and allows for integrated advanced filling control. For its part, the Intelligent pulse with IO-Link provides an even wider range of benefits. Boasting a compact design for ease of intallation, the Dosimag and Dosimass IO-Link versions are compatible with existing pulse filling flowmeters, allowing migration to take place in stages, whereby the IO-Link enables accelerated parametrization change for fast easy commissioning, remote zero-point adjustment, and optimized filling through real-time flow adjustment. According to the company, both of these next-generation filling flowmeters are designed to provide excellent measuring stability regardless of density and viscosity, and are both fully compliant with most application requirements in the food-and-beverage, pharmaceutical, chemical, personal care and other life sciences sectors.

Endress+Hauser

EAGLE EYES

Distributed in Canada by PLAN Automation, the new PXT (Photon-Counting X-Ray Technology) X-Ray detector from Eagle Product Inspection has been integrated with powerful SimulTask PRO image analysis software to set new standards in contaminant detection with superior precision, high-speed processing, and real-time data analysis for food manufacturers. According to the manufacturer, the PXT detector transforms traditional X-Ray inspection through advanced photon-counting technology by capturing individual photon energy measurements to produce razor-sharp, high-resolution images on the system’s HMI (human-machine inerface) touchscreen in real time. Originally developed to address unique needs of the poultry processing industry, this innovative solution now serves a broad spectrum of food products with outstanding performance. According to Eagle, the new state-of-the-art PXT X-Ray detector delivers industry-leading contaminant detection by identifying fragments as small as:

• 3-mm bone in beef rib;

• 1-mm bone in poultry;

• 0.5-mm bone in fish;

• 0.4-mm metal in packaged goods. Designed to transform the raw data captured by the PXT, the SimulTask PRO software processes information in real time— creating exceptionally detailed images with high clarity and contrast, even in the most challenging production environments.

The advanced software captures data from multiple diodes and applies advanced algorithms to generate the best possible image—all within a tenth of a second. Moreover, its auto-learn functionality also enables all Eagle X-ray inpection systems to quickly adapt to each unique application, even when processing parallel images on high-speed production lines.

PLAN Automation

FILL TO THRILL

Distributed by IMA Food North America, the new Hamba Flexline is a high-performance, fully servo-controlled fill-seal machine equipped with highly advanced sterilization technology and featuring hygienic stainless-steel construction for high-speed operation in aseptic production environments. Designed for clean, even filling and boasting peroxide sterilization capabilities proven to extend product shelf-life, the Hamba Flexline offers a highly effective packaging solution for high-speed packaging of yogurts, spreadable cheeses, puddings, baby foods, and a variety of other foodstuffs housed in cups. Aa a nod to increasingly eco-conscious packaging materials selection, the machine’s disinfection stations can be designed to accommodate a wide range of cup and lid substrates, including PET, PP and paper. The system’s ionization station removes potential static loads, while treating the insides with hydrogen peroxide, subsequently dried with sterile air. During this process, the cups are elevated to achieve satisfactory decontamination underneath the cup rim. For applications not requiring hydrogen peroxide, the system can also be designed to utilize UV and pulsed light technology. The highly versatile system can run from four to 12 cups per cycle in either single- or double-lane

PSENradar

set-ups—allowing the system to fill and seal as many as 57,600 cups per hour, while remaining flexible enough to handle cups up to 180-mm in diameter and 150-mm in height. Automatic format changes, simple push-button recipe control, and the ability to change lids without line stoppage further enhance the machine’s production efficiency.

IMA Food North America

METAL METTLE

Loma Systems has announced the North American lunch of the company’s next-generation IQ4M metal detector which combines Loma’s patented Variable Frequency technology with advanced multi-spectrum detection in a highly effective integration to deliver superior contaminant detection. According to Loma, this cutting-edge combination ensures exceptional performance across packaged meat and poultry, bakery, convenience food and metallized film products used in the snack and confectionery industries. Designed to enhance operational efficiency, it incorporates Dynamic Data Screen+ (DDS+) technology for

improved signal analysis, while its Quick Recovery feature reduces downtime by facilitating faster product switching and minimizing false rejects. To strengthen security and traceability, RFID security tags ensure controlled access, while its Industry 4.0-ready OPC-UA connectivity guarantees seamless data exchange with other systems.

Loma Systems

MAKING SENSE

Boasting an integrated LED bar graph and IO-Link communication, the new series of capacitive sensors from Carlo Gavazzi Automation are designed to provide exceptional sensing performance and simplified adjustments through their integrated LED bar, whereby the balance of green On/Off LEDs on either side of the yellow switching provides immediate feedback on signal stability and dust levels. Additionally, the LED bar offers real-time monitoring of dirt and dust accumulation, signaling when cleaning is necessary to ensure long-term reliability. With a heat tolerance of up to 120°C (248°F) on the sensing face, these sensors are well-suited for applications such as feeding systems, pellet burners, hoppers, blenders, or dryers in plastic molding equipment, where visualizing the setpoint simplifies sensor configu-

Long Range - Enhanced Flexibility

and Extended Detection up to 9m

ration. The CA18/30CB Series sensors are equipped with fourth-generation Tripleshield protection, offering outstanding reliability by shielding against magnetic and electrical disturbances, particularly from frequency drives.

Carlo Gavazzi Inc.

THE COOL LOOK

StaCool Industries, Inc. has upgraded its offering of protective vests with the new Premium Industrial model constructed of rip-stop fabric for longer service life. Designed to provide all-day cooling to keep workers comfortable and productive despite the summer heat, the lighter-weight, stain-resistant Premium Industrial vest features Velcro straps at the shoulders, chest and stomach to make them fully-adjustable to any body type and size for comfortable fit and unrestrained mobility, leveraging the advanced cooling technology of ThermoPaks to keep core body temperatures at safe levels for hours of use.

StaCool Industries, Inc.

Discover What’s Next in Packaging at the 2025 Disruptors Summit!

Date: June 10, 2025 ⏰ Time: 7:30 AM - 3:00 PM

Location: Humber Polytechnic, Toronto, Canada

The 2025 Disruptors Summit is a premier one-day event designed for packaging professionals across the value chain. Join us for a day of thought leadership, actionable solutions, and strategic networking. This is your opportunity to stay at the forefront of industry advancements, connect with key decision-makers, and gain insights into critical topics such as sustainable design, circular economies, AI, smart packaging, and material innovations. Don’t miss the chance to be part of a pivotal event shaping the future of packaging!

Claudio

Gemmiti

Senior Retail & Manufacturing Executive

Vlad Rebellon

Senior Director, Strategic Initiatives

Loblaw Companies Limited

Anthony Watanabe, Ph.D Chief Sustainability Officer

Indorama Ventures PLC

Visit the pac.global for tickets, the full lineup of featured Disruptors, participating table top showcase companies, and a detailed look at the value of attending.

From left

The Beneco Packaging team spearheading the company’s drive to earn the EcoVadis Gold Medal certification includes quality & sustainability specialist Nishant Thirupathi; production manager Shyam Sasidharan; technical expert (finishing) Dan Highway; printing specialist Jason Su; quality assurance manager Sachin Prajapati; and printing technical specialist Larry St Thomas.

GOING FOR GOLD

Ontario paperboard producer joins an elite group of global manufacturing stalwarts by earning the EcoVadis Gold level certification for corporate sustainability

By George Guidoni, Editor

Being good never seems to be good enough for companies like Beneco Packaging, a privately-owned Ontario-based paperboard converter with a stellar 20-year record of continuous growth and success in a fiercely competitive marketplace.

Founded in 2004 by the prolific company president Carol Jiang, the company’s rise from a virtual unknown to the top ranks of Canada’s folding-carton manufacturing industry is an inspiring example of bold entrepreneurship, ambition and customer service excellence propelling an industry newcomer to the top of the pack through hard work, proactive capital investment, relentless pursuit of manufacturing excellence, and unwavering commitment to quality and continuous

improvement.

Nowadays operating two state-ofthe-art production facilities in east-end Toronto (Scarborough) and Cobourg, Ont., the company offers true one-stopshop design, manufacturing and finishing capabilities for many high-profile CPG (consumer packaged goods) customers in the food, beverage and personal care industries, while also offering specialty and “short run” packaging products and services through its SoOPAK subsidiary’s online platform. Over the years, the company has made many significant capital investments to bolster its production capabilities, notably in the world-class printing and converting machinery manufactured by leading German printing press technologies stalwart Heidelberg Druckmaschinen AG, including:

• The Heidelberg Speedmaster CX102 6+L printing press with full automation and UV capabilities, and

output of 16,500 sheets per hour.

• The Heidelberg MK Promatrix 106 CS and 106 CSB die‑cutters, with output rates of 8,000 sheets per hour.

• The Heidelberg MK Diana Easy folder-gluer, boasting running speed of up to 350 meters per minute.

Combined with other big-ticket investments in state-of-the-art ESKO prepress equipment, advanced ERP (Enterprise Resource Planning) software technology, and a large on-site inventory of raw materials (paper rolls), Beneco is able to offer a complete range of services that includes structural and graphic design, prepress, offset printing, embossing, foil stamping, die-cutting, window patching, and folding and gluing.

Boasting an extensive product offering that includes straight-line, auto-bottom, four- and six-corner, and dozens of other box styles, Beneco also prides itself on exceptionally quick turnaround and delivery times measured in days rather than weeks, according to the company.

To validate its credentials to the marketplace, Beneco Packaging has also made considerable investments in achieving important, globally-recognized certifications for sustainability, food safety, product quality and other key hallmarks of a world-class graphics enterprise, including:

• FSC ‑ C19269 , validating commitment to the sourcing of raw materials from responsibly managed forests.

• IFS PACsecure, assurance of an established system in place for ensuring food and product safety.

• HACCP , an international standard defining the requirements for effective control of food safety.

• SGS & Co (aka GMI), validation of the company’s commitment to delivering packaging that consistently meets and exceeds customer expectations.

• G7 Master Facility Grayscale , validating demonstrated capability to accurately match brand colors across different printed products and technologies.

While each of these certifications is an important indicator of a company’s commitment to best-in-class practices in various aspects of the overall production process, Beneco’s management team decided to go one big step further by obtaining the highly prestigious global EcoVadis certification.

Launched in 2007, EcoVadis is a globally recognized assessment platform that rates businesses’ sustainability based on four key categories: environmental impact, labor and human rights standards, ethics, and procurement practices.

Consisting of 21 criteria for corporate sustainability, the EcoVadis certification process involves participating companies undertaking a self-assessment based on an extensive questionnaire, with many hundreds of questions, asking respondent to provide evidence

of their sustainability performance for each of the four categories.

The assessment is then externally verified by EcoVadis’ sustainability experts, who provide companies with a score from zero to 100, which is then used to create reliable industry rankings that let companies compare their sustainability positions to those of their industry peers.

With more that 90,000 companies rated across 155 countries to date, it is considered to be the world’s leading and most comprehensive ESG (environmental, social and governance) platform to date, counting leading multinational brands like Johnson & Johnson, L’Oréal, Nestlé, Schneider Electric and Michelin among its clients.

As Beneco’s quality assurance manager Sachin Prajapati explains, obtaining the EcoVadis certification became a strategic initiative for Beneco about two years ago, shortly after the company started up its massive, fully-refurbished 600,000-square-foot

A bird’s-eye view of the extensive array of best-inclass production and converting machinery assembled at Beneco Packaging’s vast 600,000-squarefoot folding-carton production facility in Cobourg, Ont.

Left

A high-performance Heidelberg MK Promatrix die-cutter at Beneco Packaging’s production facility in Scarborough is capable of reaching output speeds of 8,000 sheets per hour.

Above

Above A trophy wall inside the Cobourg plant displays the many prestigious plaques of recognition earned by Beneco Packaging over the years for product quality, sustainability and operational excellence.

Above right

A Heidelberg Promatrix MX flat-bed die-cutter in action at the Scarborough plant.

production facility in Cobourg.

Says Prajapati: “EcoVadis stands out because it’s not just about compliance: it’s about corporate social responsibility and continuous improvement across environmental, ethical and social areas.

“For us, it complements our other certifications by giving us a holistic view of sustainability.

“We pursued it to demonstrate our transparency and dedication to ESG principles,” Prajapati states. “We consider it one of our most strategic certifications, especially as more of our clients are evaluating supply chain partners through sustainability lenses.”

After being awarded the Silver Medal ranking in its first assessment in 2023, Beneco made a concerted effort to improve its performance and score the second time around last year.

“In our first year (2023), we focused

Beneco Packaging’s quality assurance manager Sachin Prajapati stands in front of a large inventory of paperboard rolls maintained at the company’s sprawling production facility in Cobourg, Ont., one of the company’s two state-of-the art manufacturing plants that now boast the global EcoVadis Gold Medal certification for corporate sustainability.

on showcasing the sustainability efforts we already had in place at our workplace,” Prajapati recalls. “After the evaluation, we set clear targets to improve our EcoVadis score for the next year.

“In 2024, we worked diligently to meet those targets by aligning sustainability practices across the entire company,” Prajapati relates.

“It was challenging,” he acknowledges, “but with dedicated effort from all departments, we made it happen.”

As Prajapati explains, pursuing EcoVadis certification is a fairly involved process requiring significant input and time investment across all of the organization’s departments.

“While our efforts toward sustainability, ethics and human rights are ongoing throughout the year, the specific process of completing the EcoVadis assess-

ment—which involved filling out the questionnaire, gathering documents, and uploading them—took around two months,” Prajapati relates.

“Internally, various departments, including Quality Assurance, HR, Health & Safety, Procurement, and Executive Leadership contributed by providing the relevant documentation to ensure we met the EcoVadis standards for sustainability.”

Says Prajapati: “The most tasking stage was the preparation—compiling and formatting policies, procedures, and evidence from multiple departments, while ensuring alignment with EcoVadis’ requirements.

“It required deep co-ordination,” he says, estimating it took Beneco about a month and a half to complete the preparation and documentation phase of the process.

Once done, it took another two weeks to complete and submit the comprehensive questionnaire online, according to Prajapati, followed by an eight-week review of the submitted material by EcoVadis analysts, who ultimately rewarded Beneco’s patience and efforts with the vaunted Gold Medal ranking.

“This places us in an exclusive group of companies that have achieved the Gold Medal in EcoVadis rankings,” Prajapati extols. “Globally, fewer than five per cent of companies assessed by EcoVadis earn the Gold Medal, so we are extremely proud.

“It validates the hard work our team has put into doing business responsibly,” says Prajapati, citing remarkably high scores earned by Beneco for:

• Environment. “We scored high due to our recycling initiatives, waste reduction programs, and use of sustainable materials in our operations,” Prajapati reveals.

• Labor and Human Rights . “Our strong focus on workplace safety, fair treatment of employees, and comprehensive employee training programs contributed to this high rating,” Prajapati says.

• Sustainable Procurement . “We were recognized for ensuring that our supply chain practices align with our commitment to sustainability and ethical sourcing.”

Says Prajapati: “These areas were particularly key to our Gold Medal achievement and underscore our commitment to not only meeting, but ex-

ceeding sustainability expectations.”

In addition to placing Beneco into the top one per cent of companied in the printing-related services globally, going through the exceptionally thorough and demanding EcoVadis certification process enabled Beneco to identify and address some new areas for improvement in its day-to-day operations, according to Prajapati.

“The EcoVadis certification process prompted us to enhance our documentation, formalize our supplier sustainability policies, and introduce more structured training around ethics and labor rights,” he relates.

“Additionally, it reinforced our commitment to operational sustainability, particularly as we work towards becoming zero-waste facilities.

“We have made significant strides in minimizing waste and improving recycling processes,” Prajapati continues, “making us more mindful of how each operational decision contributes to our overall sustainability goals.

“This effort to reduce waste is just one part of a larger initiative to align our daily operations with our long-term sustainability vision.”

Just as important, achieving Gold Medal certification gives Beneco a key edge in the highly competitive paperboard packaging marketplace, according to Prajapati.

“The Gold certification has already become a key differentiator in our industry,” he notes, “and we’ve already seen a surge in interest from prospective

clients.

“It is helping us attract new clients who prioritize sustainability, and it strengthens our relationships with existing partners.

“It also enhances our brand credibility and allows us to bid on opportunities where environmental and ethical compliance is a requirement,” says Prajapati, citing exceptionally positive impact this achievement has had on employee morale company-wide.

“Morale has noticeably improved, as employees feel more connected to a company with a strong sense of purpose,” he states. “Achieving a Gold Medal and being placed in the top one per cent globally within our industry was a proud milestone for the entire team.

“This recognition gives us a distinct competitive edge within our industry,” Prajapati concludes, “both locally and on a global scale.”

In addition to serving growing numbers of CPG manufacturing customers, Beneco Packaging has vastly extended its range of high-quality, sustainable paperboard packaging solutions for the foodservice sector in recent years.

Above

A sampling of the many different folding carton types produced by Beneco Packaging for customers in the food, beverage, personal care and other CPG industries.

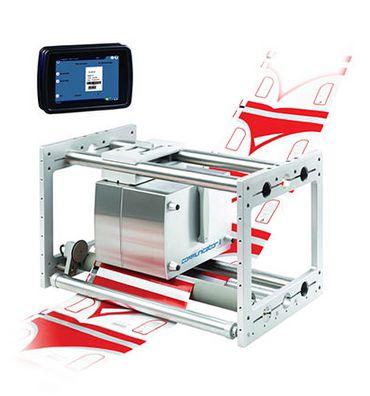

THE COPILOT MAX LT PRINTING SYSTEM

Squid Ink’s CoPilot® Max LT long throw printing system has redefined the hi-resolution industrial ink jet coding and marking industry with an unprecedented 12-14mm throw distance.

CoPilot Max LT utilizes Squid Ink’s revolutionary active ink system, allowing users the ability to tilt or rotate the printhead in any direction without making height adjustments to the ink supply

Hertel Meats general manager Jay Jayawarna (left) and MULTIVAC Canada’s regional sales manager Sam Nosek cheerfully display a finished package of premium quality Hertel’s brand bacon produced on the MULTIVAC R126 thermoforming packaging machine.

HIGH OFF THE HOG

Vancouver Island pork processor leveraging cutting-edge thermoforming packaging technology for a smooth switch to high-end flexible packaging

By George Guidoni, Editor

Photos by Dave Buzzard

In an industry driven by mass production and global distribution, Hertel Meats Ltd. stands apart as a proudly independent, family-owned processor committed to doing things differently.

Based in Port Alberni on Vancouver Island, Hertel Meats has spent over 60 years building a reputation for all-natural, preservative-free pork products that reflect a deep commitment to quality, transparency and community.

What began in 1963 as a small, locally focused operation run by founders Thomas and Helena Hertel has grown into one of British Columbia’s most trusted names in pork processing.

It is known especially for its traditional smoked sausages, nitrate-free bacon, and MSG-free seasonings.

In addition to establishing itself as a highly reputable wholesaler of fresh pork chops and other popular cuts for leading grocery retailers on Vancouver Island and British Columbia’s Lower Mainland region, the company’s flagship Hertel’s brand of sausages, bacon, ham and arti-

sanal salamis also gained strong traction among the region’s health-conscious consumers for their all-natural processing and composition.

While developing a new line of fresh sausages processed without wheat gluten, lactose (milk) products or artificial preservatives, Tom Hertel also created a line of naturally smoked bacon cured without the use of sodium nitrite, nitrate or other chemical preservatives, as well as pioneering the production of products seasoned without the use of MSG (monosodium glutamate).

These products have found a very receptive and loyal audience among the region’s leading grocery retailers and healthsavvy consumers, according to Hertel Meats general manager Jay Jayawarna. Today, Hertel Meats continues to serve a loyal customer base that values authenticity, ethical sourcing, and the kind of hands-on service that only a family-run business can provide.

Jayawarna notes that the company has remained committed to meeting evolving

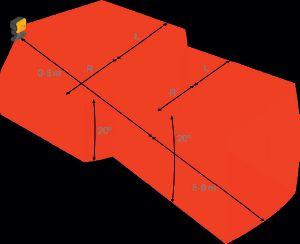

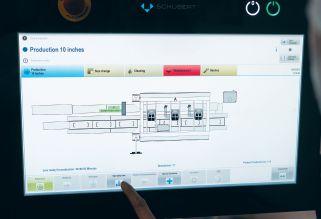

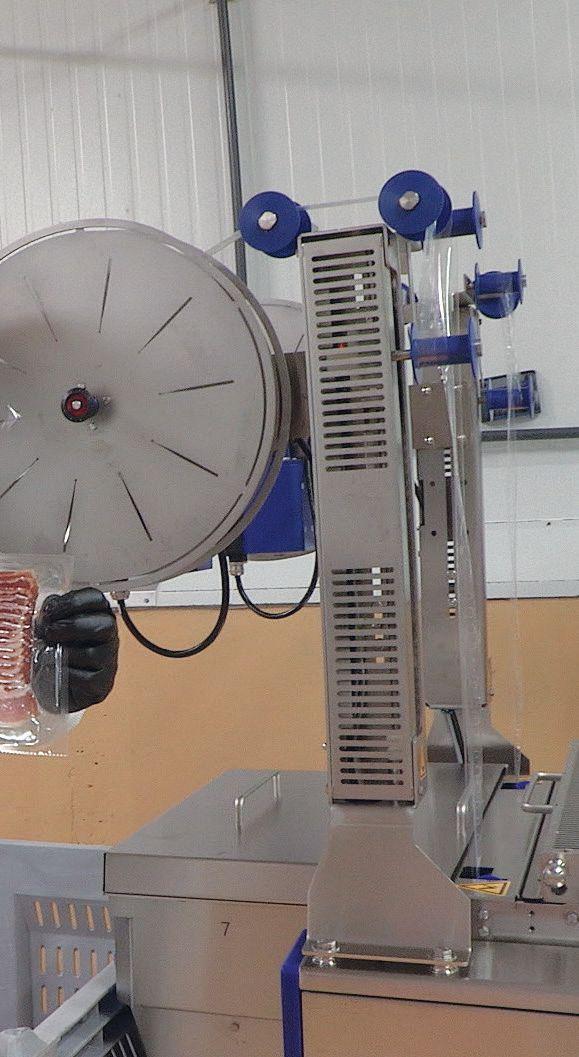

The MULTIVAC R126 thermoforming packaging machine (above) features highly hygienic stainless-steel construction, user-friendly operation and programmability enabled by the HMI 2.0 graphic user interface (inset), and large molds to accommodate the packaging of large-size products.

consumer expectations.

“Hertel Meats is well-known for its traditional, high-quality and preservative-free products,” he says.

“We specialize in high-quality ham, bacon, smoked sausages, and fresh sausages made using our unique processing methods that prioritize natural ingredients,” Jayawarna adds.

“We’ve built a strong reputation on Vancouver Island and beyond for our naturally smoked, locally-sourced pork products.”

“Being a small, family-run business really is our strength,” Jayawarna states.

“People connect with that.

“There is a high level of trust that comes from knowing who’s behind the product: it means we’re hands-on with everything we do, and that we genuinely care about what goes out the door.”

Jayawarna speaks with gratitude about the community that has supported Hertel over the decades.

“Vancouver Island shoppers are incred-

ibly loyal,” he says. “We’ve built real relationships with families and local businesses, some of them have been with us for generations.”

The company actively supports its community-focused brand through regular in-store tastings, product sampling, and promotional events.

“In today’s market, consumers expect brand interaction,” Jayawarna points out. “Experiential marketing, like in-store tastings, is key to boosting sales.

“Transparency and traceability are also increasingly important,” he adds. “Cus-

tomers want ethically-sourced, locally made products they can trust.”

Employing around 50 people working one shift, five days a week, the Port Alberni plant houses two production lines and two packaging lines.

Production is adjusted to meet the peak demand periods in the run-up to Easter, Christmas, and Thanksgiving holidays, as well as during the busy BBQ season in the summer months.

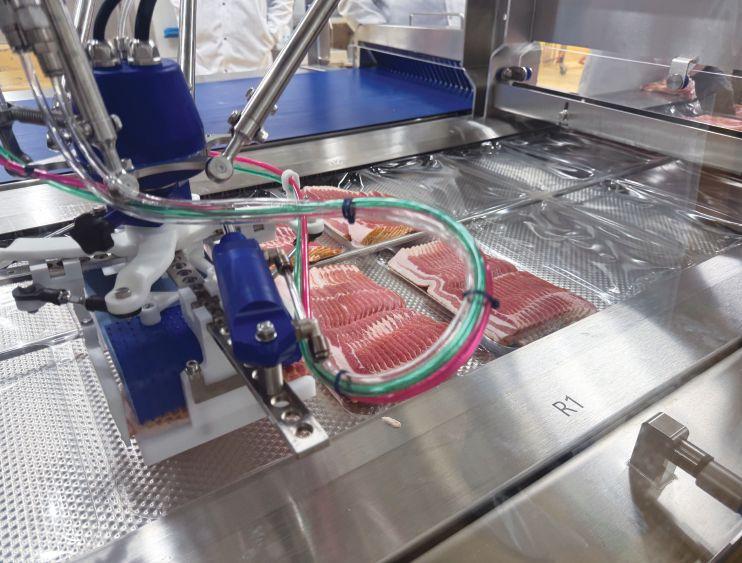

To meet increasing demand, Hertel Meats recently invested in two state-ofthe-art thermoforming packaging ma-

From top

Hertel Meats machine operator ensures proper tension levels for the pre-printed rollstock film used to package Hertel’s brand products on MULTIVAC thermoforming packaging machinery.

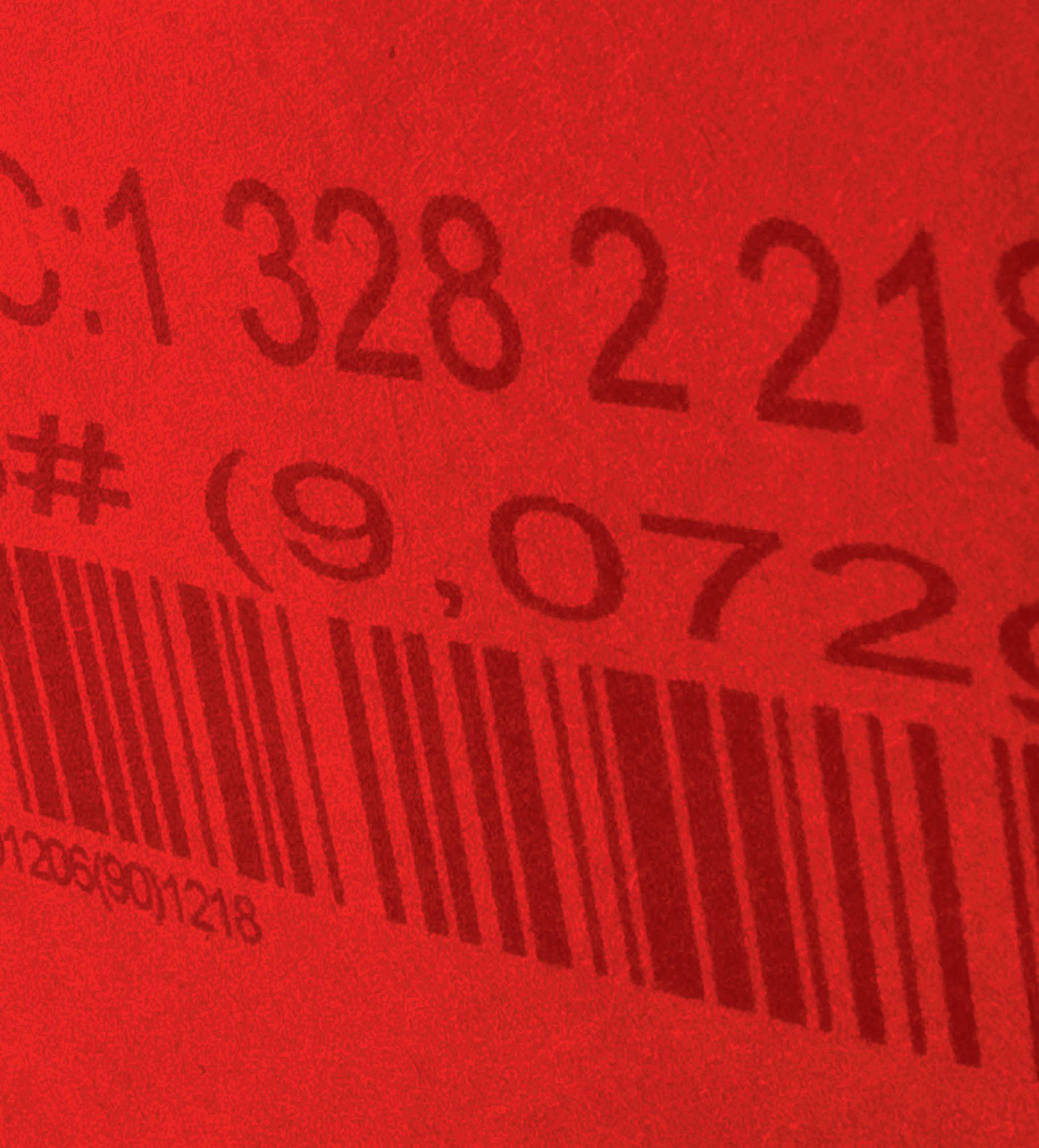

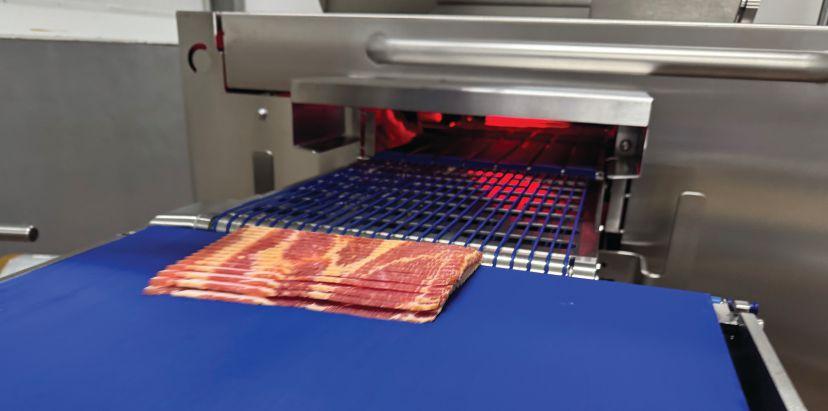

Close-up of the variable product information applied onto the pre-printed rollstock film, also supplied by MULTIVAC Canada, by a Bell-Mark thermal transfer printer. Finished packs of Hertel’s brand bacon coming off the MULTIVAC R105 thermoforming packaging machine.

chines, models R 105 and R 126, manufactured by the renowned German company MULTIVAC, and distributed in Canada by MULTIVAC Canada Inc., with locations in Brampton, Ont., and Richmond, B.C.

Featuring a compact design and modular construction for optimal flexibility, the MULTIVAC thermoforming packaging machines are designed to provide maximum productivity and highly efficient solutions for vacuum packaging, modified atmosphere packaging (MAP), or skin packaging.

Notably, the MULTIVAC thermoforming packaging machines are characterized by:

• High production output and pack quality;

• Robust and durable stainless-steel construction;

• Proprietary Hygienic Design for maximum hygiene and easy cleaning;

• Safe and ergonomic operation;

• IPC control with HMI 3.0 graphic user interface;

• Efficient use of film and energy.

“We wanted to get the best packaging solution we could find,” Jayawarna says, “and our market research revealed that MULTIVAC had a reputation for having the best packaging solutions for processing multiple products, in different SKUs (stock-keeping units), and in many different formats.

“The name MULTIVAC describes their machines perfectly!

“These machines have helped us significantly increase our packaging efficiency,” Jayawarna says. “They’ve also allowed us to reduce our plastic usage dramatically.”

Initially using semi-rigid MAP (modified atmosphere packaging) tray-packs, the company worked with MULTIVAC Canada’s regional sales manager for B.C., Sam Nosek, to transition to 100-percent

MULTIVAC Canada supplies all the high-quality flexible packaging film used to package the growing range of Hertel Meats’ innovative all-natural products on MULTIVAC’s high-performance thermoforming packaging machines at the pork processor’s production facility on Port Alberni, B.C. Below

Machine opeartor loading fresh-made raw sausages inside the cavities of the MULTIVAC R105 thermoformer prior to the next packaging cycle.

flexible film vacuum-packs in late 2023.

“One of MULTIVAC’s biggest strengths is providing ongoing support for the life of the equipment we manufacture,” says Nosek. “We can retrofit or modify MULTIVAC machines to help customers adapt to changing needs.

“In Hertel’s case, we helped them shift from rigid film (MAP) packaging to flexible film vacuum packaging,” says Nosek, noting the switch faciltated a more efficient use of materials, a longer shelf-life, and new branding opportunities.

A major advancement in the Hertel Meats project was the integration of BellMark’s EasyPrint MLP thermal-transfer printers onto both machines.

These printers allowed Hertel Meats to move away from manual labeling to printing key varible product information directly onto pre-printed top film, also supplied by MULTIVAC.

As Nosek explains, the new set-up allows for quick and easy printing of variable data like:

• product name;

• ingredients;

• weight;

• certification logos;

• nutritional data;

• date/lot codes;

Patrick McCarthy, MULTIVAC’s Film & Materials sales manager for Western Canada, adds: “This solution not only enhanced Hertel’s branding, but also prepared them for evolving labeling needs like front-of-pack (FOP) requirements and QR (quick response) codes for consumer engagement.”

Says McCarthy: The combination of the MULTIVAC thermoformers, MLP printers and MULTIVAC-certified film provided an effective solution for Hertel Meats to reduce packaging costs, reduce operational complexity, and elevate the brand value for their extensive line of market-trusted, emerging and innovative food products.”

According to Jayawarna, the packaging upgrades reduced plastics use by 69 per cent, increased throughput by 50 per cent, and lowered labour costs by 40 per cent,

Above

and throughput.

largely thanks to eliminating manual labeling.

“We’ve reduced packaging costs while delivering a more attractive product for our retail customers,” Jayawarna says, also citing notable improvement in the products’ shelf-life.

“Having all our packaging equipment, materials and expertise provided by a single partner like MULTIVAC has been a real advantage,” Jayawarna states. “Their support during installation and training was exceptional.

“We haven’t had any downtime with the machines so far, but even if we did, their service team is outstanding,” he says. “They’ll be here the next day.”

As Jayawarna concludes, “To succeed as an innovative food producer, you need a strong partner for processing and packaging, and for us, MULTIVAC Canada is that perfect partner for the long run.”

Please see a video of MULTIVAC’s thermoforming packaging machines in action at the Hertel Meats processing plant in Port Alberni, B.C., on Canadian Packaging TV at www. canadianpackaging.com

Below

Front entrance to the Hertel Meats processing plant in Port Alberni on the Vancouver Island.

Above Hertel Meats general manager Jay Jayawarna inspecting a new roll of pre-printed flexible film supplied by MULTIVAC Canada.

The MULTIVAC tooling on the R105 thermoforming packaging machine is designed to optimize the use of films and maximize efficiency, shelf-life

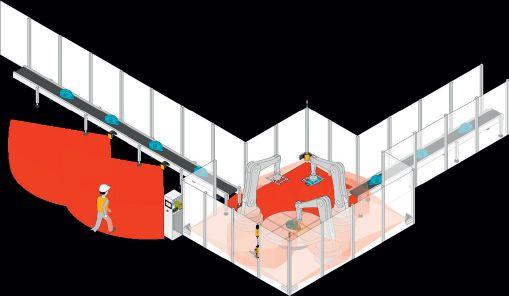

THE UPPER CRUST

Successful robotics integration paving

the

way for future automation investments at Canada’s leading frozen pizza manufacturer

By George Guidoni, Editor

Photos by Ahmad Sayed

Few comfort foods can rival the universal appeal, gastronomic versatility and the long-enduring popularity of pizza across the globe—in all its boundless recipe variations and ingredient innovations.

With a massive global market estimated at US$200 billion, according to Business Research Insights , and double-digit growth projected over the next eight years, pizza sales have become a highly profitable business for countless delivery services, restaurant chains, grocery retailers and other food vendors worldwide, including Canada.

With the average Canadian estimated to consume over 16 pounds of pizza annually—putting the country in the Top Five pizza-consuming nations year after year—the future certainly looks bright for companies like Molinaro’s Fine Italian Foods Ltd. of Mississauga, Ont.

Founded by Gino Molinaro in 1964, eight years after his arrival to Canada from Italy at the age of 16, the familyowned business has become a veritable powerhouse in the Canadian pizza industry over the years—currently ranking as the country’s largest producer of private-label frozen pizza brands.

Molinaro’s produces about 30 million pizzas each year at the company’s 105,000-square-foot pizza factory, which houses two large industrial ovens

and three fast-paced production lines.

The company boasts a highly diverse product portfolio comprising nearly 300 SKUs (stock-keeping units), while serving an elite retail client base that includes the likes of retail giants Costco, Metro and Walmart, among many others.

“Most of the products we produce are of upper- to mid-tier quality,” company president Vince Molinaro told Can adian Packaging during a recent visit to the Mississauga facility.

The plant employs approximately 300 people and operates on a three-shift schedule, five to six days a week, producing premium-quality, ready-to-heat frozen pizzas, DIY pizza kits, crusts, flatbreads, dough balls and other essential pizza ingredients in a variety of styles and sizes.

“We cover a wide spectrum of pizza products,” says Molinaro, one of several second- and third-generation Molinaro family members employed at the company in various management and administrative positions.

The close-knit family unit includes Vince’s younger brother Frank Molinaro, company vice-president in charge of operations; his son Joseph Molinaro (finance); Jake Molinaro (sales); and Luke and Nick Molinaro (distribution).

“A lot of our competitors only make deli or frozen pizzas,” Vince Molinaro

Molinaro’s Fine Italian Foods president Vince Molinaro (top picture) proudly displays some of the premium quality pizza products manufactured at the company’s busy pizza factory in Mississauga, Ont., for a broad range of retail, foodservice and private label customers.

relates, “and some of our competitors will only do crust, pizza kits or calzones (stuffed pizza pockets), whereas we do most of the spectrum.”

As Molinaro points out, the company enjoys industry-wide renown and respect for the high quality and variety of crusts it produces.

This acclaim is a point of special pride for the Molinaro family, as it emphatically validates the beloved company founder’s long-held belief that, “Every great pizza begins with a great crust.”

As his son Vince emphasizes, “We have always taken pride in crafting the best crust possible, and we have always made it a priority to use only the highest-quality tomatoes for our sauce.

“Those two things, the crust and the sauce, are the key elements to making a

great pizza because they’re what you taste first with every bite,” Molinaro explains.

“We have everything we need to make just about any crust style our customers need, whether it’s hand-stretched, fullypressed, partially-pressed, thin crust, or a hand-raised edge.

“Whatever the customer wants, we can make it happen.”

The lion’s share of the crusts are made from high-quality durum wheat primarily sourced from Alberta.

However, to meet the growing consumer demand for healthier pizza options, the company also offers a wide variety of alternatives, including gluten-free, whole wheat, multigrain, organic, cornmeal, GMO-free and all-natural dough.

Molinaro’s product range also includes the trending plant-based crusts made with cauliflower, zucchini, sweet potato and other specialty ingredients.

This abundance of choice is made possible with the remarkable flexibility of the plant’s production lines, which can accommodate both high-volume runs and smaller batch production with ease.

“We do all the Kirkland brand frozen cheese, pepperoni and gluten-free pizzas for all the Canadian-based Costco locations,” Molinaro states, “and we recently expanded into the production of special crust, made from fermented dough, for their in-store delis.

“It’ a fairly new process for us,” Molinaro reveals, “but it has already been well received by this very important client.”

Combined with the company’s focus on product authenticity and commitment to using only the highest-quality ingredients and toppings, this flexibility has positioned Molinaro’s as a onestop-shop of choice for the ever-growing base of its co-packing customers.

“We can pack our customers’ product right on-site in whatever format they choose: inside a box, shrinkwapped, with or without a label, shrinkwrapped and boxed, or even placed in boxes with see-through windows.

“Essentially, any format that you will find at supermarkets or at a deli,” Molinaro states.

A frequent finalist in the high-profile annual Canada’s Best Managed Companies awards program administered by leading business consulting firm Deloitte, Molinaro’s boasts multiple certifications for food safety and quality, including the GFSI BRC , Gluten free, Non GMO, Halal and Plant‑based accreditations.

These credentials, combined with the company’s commitment to excellence, continue to attract new clients and set

Molinaro’s apart in an increasingly competitive market.

“We like to call ourselves a custom producer,” says Molinaro, “whereby we work really close with our customers to develop new formulas and taste profiles.”

To meet growing market demand, Molinaro’s continuously invests in the latest processing and packaging technologies to boost output and productivity levels.

For example, the plant’s new topping line can achieve speeds of up to 240 pizzas per minute.

“We have spent about $10 million on various capital investments in automation over the last few years,” says Molinaro.

Close-up of the premium-quality Gino Bambino line of hand-stretched, stonebaked frozen pizza and pizza crusts developed to honor the rich legacy of the company’s beloved founder and family patriarch Gino Molinaro, who built the company from ground-up soon after arriving to Canada from his native Italy at the age of 16.

Molinaro’s plant engineer Dinesh Vasudevan (left) discussing the finer points of the Gino Bambino brand pizza crust packaging with the company president Vince Molinaro inside the Mississauga facility’s Test Kitchen area.

The company is also planning to install a brand new sheeting line at the Mississauga location by the end of this year, while commencing a 60,000-square-foot expansion of its distribution and warehousing facility in nearby Oakville, Ont.

“Our biggest challenge,” Molinaro remarks, “is ensuring that we do not compromise the product quality when we scale up production.”

Because of this relentless focus on quality, the Molinaro’s plant has to be selective about which parts of the production process it decides to automate, and which ones are better left largely manual.

“Our lines are mostly semi-automated because we need to maintain a certain level of flexibility to maintain our high quality standards,” Molinaro says.

“There are some parts of the process that you just can’t do with the machine to achieve the same quality, or the same final effect, that you would by doing it manually,” he says.

“Value-added tasks are a big part of our business,” Molinaro states, “so a lot of the hand-stretching of the dough, the placement of toppings, the folding of the calzones, to name a few, is still performed by human hands.”

This also applies to packaging. For example, the plant uses a lot of paper sleeves for products sold in delis that can only be opened and packed by hand.

“So our approach to automation is all about finding the low-hanging fruit where you can gain efficiencies through automation without impacting the final quality of the product, as well as the quality of packaging,” says Molinaro.

This pragmatic approach is delivering major daily benefits on the plant’s cold press line, where a trio of high-speed Shubert model F4 pick-and-place robots precisely place finished balls of dough into the center of each fast-moving pan before they’re pressed into their signature round pie shape.

As a global leader in packaging automation, Schubert brings decades of engineering expertise to solutions like this, helping manufacturers like Molinaro’s achieve greater consistency, speed and

After being coated with oil in the plant’s processing area, freshly-formed pizza dough balls are conveyed underneath the Schubert system’s enclosed vision system to verify each one meets the exacting product specs, displaying the captured images in real time on the system’s HMI (human-machine interface) touchscreen panel.

efficiency in their production lines.

“We used to have four people handling that task around the clock across three shifts,” Molinaro recalls. “Now, it’s down to just one person there per shift,” he says, citing the rapid return on investment delivered by Schubert’s high-precision robots.

Molinaro’s production line runs 10 different crust sizes using the same pan dimensions, each in a unique configuration. To ensure a consistent press, it is vital that each dough ball is placed precisely in the middle of each pan.

The automated system handles this task with unerring speed and accuracy, maintaining consistent product quality.

“That’s the key automation for us,” Molinaro states. “We definitely want to make sure we keep up with automation, but not at the expense of product quality.”

Since their installation and commissioning in late 2019, the Schubert system’s three F4 pick-and-place robots have delivered top-tier performance on Molinaro’s product line.

Equipped with scoop-shaped tools, they reliably pick up the moving dough balls and place them onto the pan with impressive precision.

Schubert’s pick-and-place machines are engineered to deliver unmatched speed, accuracy, and flexibility in automated packaging.

Built around the proven F4 robot— based on the SCARA (Selective Compli-

ance Articulated Robot Arm) principle— these systems are designed to handle delicate, high-speed applications with ease.

The four-axis F4 pick-and-place robot has proven itself over decades in many hundreds of picker lines worldwide, according to the manufacturer.

With reach speeds of up to 4.7 meters per second, the F4 is equipped with all the interchangeable tools that make it exceptionally flexible in operation, with terrific quick-changeover capabilities.

Offering a broad array of custom-designed grippers or suckers, it can pick up any conceivable product and place it gently into a tray, chain or onto a single belt.

According to Schubert, the F4 robot is particularly-well suited to wide and extra-wide product belts due to its large working area transverse to the running direction of the belt.

Whether it’s baked goods, confectionery, pharmaceuticals or consumer products, Schubert’s pick-and-place systems are tailored to meet the exacting needs of modern manufacturers.

The robots use interchangeable tools like suction cups, scoops, or mechanical grippers to gently and precisely pick up products and place them into trays, cartons, or flow-wrap chains.

With modular machine architecture, intelligent image recognition, and seamless integration with upstream and

The Molinaro’s plant employs three Schubert model F4 pick-and-place robots on its cold press line to position each passing dough ball into the center of moving pans before they are pressed into the signature round pizza pie shape further down the line.

downstream processes, Schubert’s pickand-place solutions are engineered to provide a future-ready answer to complex production challenges. From small batch runs to high-volume lines, these systems deliver reliable performance, reduced waste, and quick changeovers for maximum uptime and ROI.

Backed by advanced German engineering and decades of innovation, Schubert delivers cutting-edge packaging solutions that combine precision, reliability, and modular flexibility— trusted by manufacturers across the continent.

A well-established player in the North American food packaging business, Schubert runs its Canadian business operations through its Schubert

Packaging Automation subsidiary in Mississauga, Ont., part of the company’s Schubert North America subsidiary of Charlotte, N.C.

Being a first robotics installation in the Molinaro’s plant’s history, a successful and seamless start-up were essential to the project’s success and acceptance on the shop floor.

According to Molinaro’s plant engineer Dinesh Vasudevan, the smooth and quick installation process was expertly performed by a pair of Schubert technicians over single weekend, with no production downtime lost.

The high-quality frozen pizzas produced at the Molinaro’s production plant in Mississauga come in a broad ranges of sizes, shapes and recipe varieties to suit all of the company’s customer requirements for taste, quality, aesthetics and ease of preparation.

“The technicians that came in over the weekend were two exceptionally bright young people who just got their hands on all the hardware and proceeded to put everything together just right,” he recalls.

“We were just amazed at how talented they were,” remarks Vasudevan, who joined the company as a mechanical engineer in 2003, playing many instrumental roles in the company’s capital investment projects.

As the project lead for the Shubert installation, Vasudevan has high praise for exceptional customer service provided by Schubert Packaging Automation’s sales account manager Giorgio Calorio.

“We had a great introduction to robotics thanks to Giorgio and the whole Schubert organization,” Vasudevan says, pointing out that the previous

manual method of placing the dough ball onto pans all day long we a problematic task for various reasons.

“The employees were very hesitant to pick this dough balls because of the oil put on them in previous process steps,” he explains.

“We were getting lots of complaints about workers having their gloves, hands and uniforms completely drenched in oil by the end of the shift,” Vasudevan reveals, “but that has not been an issue since the robots took over that task.

“So we are really happy with this Schubert machine: there’s no doubt about it,” Vasudevan proclaims, adding the three rugged and well-enclosed robots have largely run trouble-free since the installation.

“It’s rare when one of the three robots may be misaligned out of reference due an accidental bump with a pan surface or if there’s some accidental contact,” he acknowledges, “but it only takes us 10 minutes to re-reference the machine and put it back online.

“In addition, Schubert has a 24/7 customer service you can contact online,” he adds, “to get great quick local service, provided by some great technicians they have working there.”

Like Vasudevan, Vincent Molinaro says he is keenly impressed with the productivity benefits of robotic packaging automation, as well as the solid business partnership and beneficial

Above: Installed by Schubert Packaging Automation, the F4 robotics line enabled the Mississauga plant’s cold press line to raise its throughput to 240 pizzas per minute. Left: Supplied by Reiser Canada, the VEMAG dough partitioner is used to form the pizza dough balls feeding Schubert’s pick-and-place system on the facility’s cold press line.

rapport that Molinaro’s has built up with Schubert since the installation.

“We see Georgio here a lot, it feels like he’s part of family sometimes,” Molinaro chuckles.

“But seriously, we are eager to implement more robotics in our operations in coming years,” he says, “and Schubert has been very helpful to us in identifying new opportunities and possibilities for future robotic installations.”

Adds Calorio: “At Schubert, we really believe in the importance of working with the customer as a team from Day One.

“This way we can share all the expertise we have in packaging, robotic and automation,” Clario states, “while the customer can do the same with their knowledge of the product, possible existing constraints, floorspace availability, and all the other key variables to be addressed during the project.

“Working in close partnership is the best way to ensuring the customer gets the best value from their investment,” Calorio asserts.

As Molinaro notes, “People often get nervous when they first start seeing robots going in because of fear over their jobs, but in the end, they are often thankful for robots eliminating certain tasks that nobody likes.

“Many of our employees were very happy to see us install robotics to pick up boxes full of product to eliminate manual box lifting and handling,” he points out, “so the jobs that robots do eliminate are not the jobs that anyone is going to miss.

“So all in all, our first experience with robotics has been a very positive one,” Molinaro concludes, “and as we continue to expand our operations in coming years, we look forward to having more success with robotic automation.”

A high-speed Mitsubishi Electric robot placing finished packs of frozen Cauliflower Crust Pizzas inside paperboard cartons prior to transferring them on to the palletizing area.

Above left: Loaded retail-ready display cases supplied by Cascades used for delivering stacks of Gino Bambino brand fresh pizza crusts to retail customers.

Above right: A Yaskawa palletizing robot used to load and stack filled corrugated carriers on top of shipping pallets in the plant’s end-of-line packaging area.

Left: Manual assembly and loading of the Molinaro’s pizza kits at the front end of the plant’s MULTIVAC R 535 thermoforming packaging machine.

BROTHERLY BONDS

Automatic vacuum-sealer helping enterprising hog farm operator scale up its fast-growing online meat distribution business

By George Guidoni, Editor

Photos by David Buzzard

Quality, taste and authenticity are timeless virtues in the modern meat business, especially for the smaller family-owned operators just starting to make a name for themselves.

Started up in 2014 on Vancouver Island just on the outskirts of British Columbia’s beautiful capital city Victoria, Berryman Brothers Meat Ltd. has done an outstanding job of making a name for itself all over the island for the past 10 years.

Founded by the company’s easy-going, 37-year-old president Justin Berryman— one of nine brothers and two sisters who have grown up alongside him on the

seven-acre family hog farm—the online meat retailer has built up a remarkably loyal customer base among the island’s residents keen to “buy local,” as well as leading nearby restaurants attracted by the gourmet quality, craftsmanship, variety and freshness defining the company’s diverse product portfolio.

“We operate primarily on a direct-to-consumer basis through our online platform to make it easy for customers to access our products directly from the comfort of their homes,” Berryman explains.

“We also have a farm store for in-person shopping and a B2B segment,” says Berryman, “whereby we supply local businesses with our high-quality products.

“This multi-channel approach allows

Reiser Canada’s British Columbia sales representative Alessandro Sestini (left) and Berryman Brothers Meat president Justin Berryman strike a cheerful pose in front of the brand new VEMAG HP1L vacuum filler recently delivered to the meat processor’s production facility located on the outskirts of Victoria, B.C.

us to reach a wide variety of customers and maintain a strong presence in both retail and wholesale markets.

“We have about 200 SKUs (stock-keeping units) available on our online platform at any given time,” says Berryman, who estimates that online sales, along with in-person sales at the company’s retail storefront, account for about 70 per cent of the company’s revenues, with grocery and foodservice customers for the remainder.

“Our facility is capable of producing up to two tonnes of product per day,” says Berryman, “allowing us to meet a variety of customer demands.

“Over the last decade, we’ve built a strong reputation for quality and efficiency,” Berryman adds, “with a focus on continuous improvement.”

Being located on a pig farm raising about 2,000 hogs per year, the company’s first product offerings were understandably mostly dominated by pork-based products, Berryman recalls, but as the company grew, so did the product variety.

“We offer a diverse range of products, including fresh cuts of meat, in-house made sausages, smoked items from our sausage kitchen, and even a compost soil program derived from our animals’ byproducts,” Berryman relates.

“This allows us to maximize the value of every aspect of our operation, ensuring sustainability and efficiency at every stage,” says Berryman, a professionally trained butcher who is also in charge of all the new product development and testing at Berryman Brothers.

“Our best sellers are fresh chicken and ground beef,” Berryman divulges, “both of which are in high demand due to their superior quality and competitive pricing.

“These products reflect our commitment to offering top-tier products at a very aggressive price-point,” says Berryman, noting that the company’s prices compare favorable to virtually all traditional butcher shops operating on the island, with no quality gap to speak of.

Says Berryman: “What really sets our products apart is our unwavering focus on quality: every item is carefully prepared and processed in-house to ensure it meets the highest standards.

“Combined with a highly competitive pricing structure, we offer our customers outstanding value for the money.”

As Berryman relates, the 8,000-squarefoot processing facility employs a dedicated team of 15 full-time and five parttime staff—many of them his brothers—to process and package the wide variety of fresh meat and livestock delivered to its doors daily from around the Vancouver Island and from mainland B.C., nowadays also including lamb, turkey, bison and seafood.

“We also do a lot of value-added work

with our smoke-house,” Berryman adds, citing products such as beef jerky, charcuterie sausages, meat pies, deli meats, stuffed chicken breasts, wieners, bone broth, dog treats, meat patties, breaded fish fillets, etc.

Growing up on a farm was a great learning experience for all the Berryman siblings in all aspects of the meat business, along with fostering deep appreciation for animal welfare and the environment.

As Berryman points out, “We are very serious that all the livestock and poultry we source is ethically raised, cage-free, free-run or free-range, no added hormones, no antibiotics … we pride ourselves on our products being as natural as they can possibly be.”

According to Berryman, the explosive

From top

The Berryman family’s farm raises about 2,000 hogs each year provide an adequate supply of locally-raised pork for the busy meat processing operation.

Supplied by Reiser Canada, the fully-automatic VARIOVAC

Optimus vacuum-sealing machine features stainless-steel construction and a hygienic design to ensure optimal food safety and sanitation for all products packaged on the high-performance system.

Locally-raised fresh chicken breasts are one of the Berryman Brothers Meat’s most popular products packaged on the VARIOVAC

Optimus vacuum sealing machine.

boom in e-commerce and online shopping during the last decade inspired him to adopt the e-commerce model for his fledgling business.

“Our main vision was to connect local consumers to local products,” he says.

“Before, if anyone wanted to buy some local farm-raised pork, they would have to buy at least a half or a whole hog from a farmer, and then wait for a half-year or more for delivery,” Berryman relates.

“What kind of service is that?

“There was no practical solution for people who wanted to eat locally on a regular basis,” he says, “and so our aim was to fill that void for them.

“The idea was to have enough inventory in stock to fill the orders as they come in online and have them shipped

out within a couple of days or so, depending on order size and complexity.”

All the packaged meats are immediately flash-frozen after packaging to maintain maximum freshness and flavor inside the package, and the plant’s staff pick and fill out the orders by hand by placing them in standard corrugated shipping boxes for customer delivery.

While the size of the orders vary from customer to customer, the average filled box contained roughly about $200 worth of meat, with eight to 10 different products, Berryman relates.

Depending on the location and order contents, the Berryman plant tries to deliver each customer’s box within one to four days of completing the order.

The company uses a small fleet of four refrigerated delivery vans to make home deliveries around the island on regular route schedules, or makes other suitable pick-up arrangements for customers, including on-site pick-up.

“We often have line-ups in front of the store when customers picking up their orders stop by the store to look at all the different delicious options we offer,” Berryman extols, “all of it local!”

As Berryman acknowledges, the online success did not happen overnight.

“It was very, very challenging at the beginning,” he says. “It was a difficult concept to implement quickly, being so unfamiliar to many people at first.

“But then the COVID pandemic hit, and that put us right on the map in no time,” Berryman states.

With demand for grocery online delivery services of all types exploding during the pandemic, the company was perfectly positioned to benefit from the massive shift to B2C retailing.

“There were many companies who started jumping on the train after the fact,” Berryman says, “but we already had the ball in motion.

“Our name was there, our shop was there, our delivery vans were there: we just ran with it, and we were very successful right out of the gate.”

With production runs quickly surging to over 2,000 products per day, Berryman realized the company urgently needed to bring in some automation to speed up the packaging process, while also ensuring optimal protection and shelf-life properties for the packaged product.

“We used to put products inside plastic bags by hand and then run them through a manual vacuum-sealer,” Berryman recalls, “but the volumes just got too crazy during COVID to keep up with the incoming orders.”

After coming across a recent Can adian Packaging issue featuring an article about a successful food packaging line installation by Reiser Canada, a leading Canadian packaging machinery distributor headquartered in Burlington, Ont., Berryman quickly contacted Reiser’s British Columbia sales representative Alessandro Sestini to find the right packaging solution for his plant’s unique requirements.

After taking stock of Berryman’s de-

Designed for quick and simple changeovers, the highly versatile VARIOVAC vacuum-sealing machine can accommodate various mold sizes and pocket depths to allow for processing of many different types and sizes of freshly processed meat products in true plug-and-play operation.