1 minute read

Filling single file

from Industry guide AMCAS

by AmbaFlex

Liquid containers are usually transported single file, especially in applications such as winemaking, dairy, distilled, sports drinks and sodas. These containers are made from carton packs, PET, HDPE or glass. The shape can be cylindrical, rectangular, reverse tapered or irregularly curved.

Preventing mass flow is a trend, as it requires a great deal of space in the re-single lining of the flow. It is also the preferred method if the right handling solutions are available. Many single file flows remain on ground level. Height differences require long lengths due to instability, but usually there is no floor space available for this.

Instability or sensitive handling also requires special options, but good solutions for elevation, accumulation or buffering have not been available in the past. AmbaFlex enjoys taking on special challenges such as belt lubrication, glass breakage and hot filling. We offer an extensive range of elevation and accumulation solutions.

Watch video >

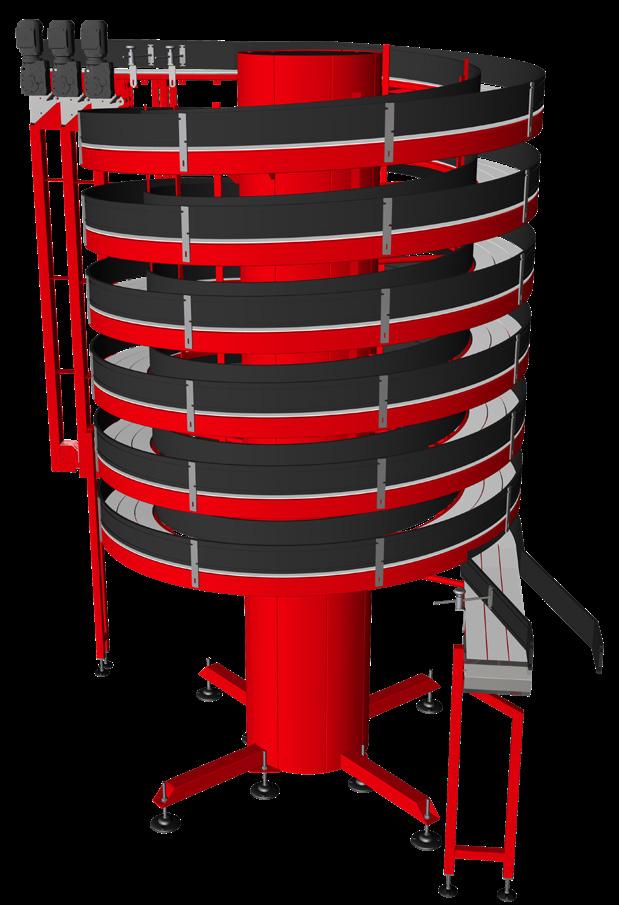

The SpiralVeyor BottleLift is a configuration spiral conveyor that is used to elevate or store flows of Liquid Container items of all kinds. For example filled and empty bottles, cans, cartonbriks, cups and jars.

Distinctive features:

• Ultra flat, high friction

• CR coating

• Stainless steel chain

• Banking

• Slimline design

• Continuous flow

Filling mass flow

Handling the mass flow of bottles and cans presents some well-known challenges in filling line layouts.

Mass flow accumulation tables and single liners take up a lot of space and can become problematic when operators need to move efficiently along multiple filling, labeling and packing stations.

Making use of the 3rd dimension, or using multiple stories in a mass fill line, has been impossible for a very long time. Even lowering empty cans or bottles down from a depalletizer presented a difficult challenge.

However, AmbaFlex’s development of the first spiral conveyor that was able to handle mass flow products opened up many new possibilities in the efficient use of space in liquid container handling.

Example solution for Mass Flow: SpiralVeyor MassFlowLift HD

Watch video >

The SpiralVeyor MassFlowLift HD is used to bring bottles and cans to the desired level. It can cope with particularly high requirements such as extreme loads or height overcoming. It contains all functions for a pressureless product handling.

Distinctive features:

• Tip support

• Ultra flat, high friction

• Stainless steel chain

• Multi chain option

• Glass contamination package