6 minute read

ASPHALT & MANUFACTURING

FROM OUR PLANTS TO OUR

2020 has been a challenging year. Along with the inherent challenges of operating and We have also had some upgrades and personnel changes at some of the plants. maintaining a hot plant, we have had to deal with Plant 7 in Largo is currently working on the the Covid-19 pandemic. Even with these challenges construction of a new control house for the we have been able to keep all of our plants open plant. It will be finished in 2021. The silos and operating throughout the year. This required at plant 4 have been installed and will be operators and employees to work at multiple plants fully operational by early January 2021. We at times to keep them operating. also have a new lab building at plant 4 and it should be done in early 2021. In October 2020, we began the site construction for our new plant facility in Lake Wales. Clay Cross, the Area Manager from Area 4 has been instrumental in managing the site construction for the plant. We are excited to open this new area in early 2021 with a new Astec plant. We look forward to working and supplying asphalt in this new market. There have been some personnel changes at the plants and we are excited to see employees within the company taking on new responsibilities.

Photos from the addition of silos at Plant 4. We are excited that having six silos at Plant 4 will allow us to better supply our many customers and their needs.

View from the top of Plant 1 sent in by Safety Manager, Bob Kern Myrtis Harrison studying for Asphalt II.

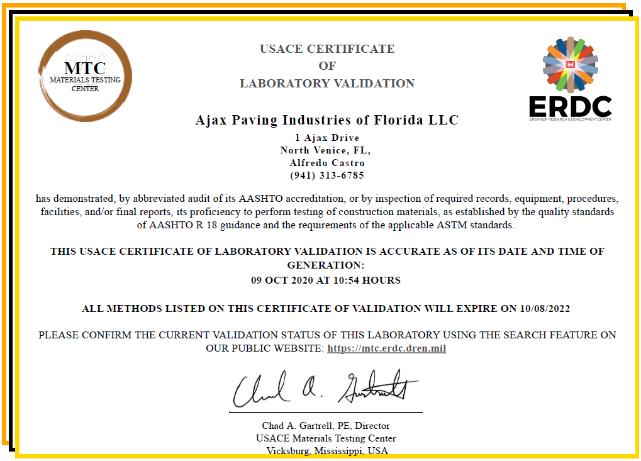

Leo Steen, an Operator at Plant 6, has been transferred to Plant 7 in Largo to manage that facility. Matt Vogel came from construction in 2020 and began his plant training at Plant 5 Odessa and has now moved to Plant 3 in Palmetto to be a plant operator. Joshua Ketnor, a new employee hired as a Loader Operator in 2020 is now training as a Plant Operator at Plant 6. Jasen Starks started as a Groundsman in 2015 at Plant 5 in Odessa and is now training to be a Plant Operator at Plant 5. Myrtis Harrison transferred from construction this year to the asphalt lab in Venice and is being trained as a Lab Technician. Alfredo Castro has become a member of the Committee of Asphalt Research and Technology (CART). Alfredo also received the Army Corp of Engineers and The American Association of State Highway and Transportation Officials certifications for his lab. Congratulations to Alfredo. This is a big accomplishment and very few labs get these certifications.

I would like to give a special shout out to our great employees and their dedication, flexibility and hard work. Each plant employee performs a vital role in the success of the plants, and in turn, Ajax Paving.

Mickey Cox, General Manager of Plants

Bill Van Houten working on a repair at Plant 1.

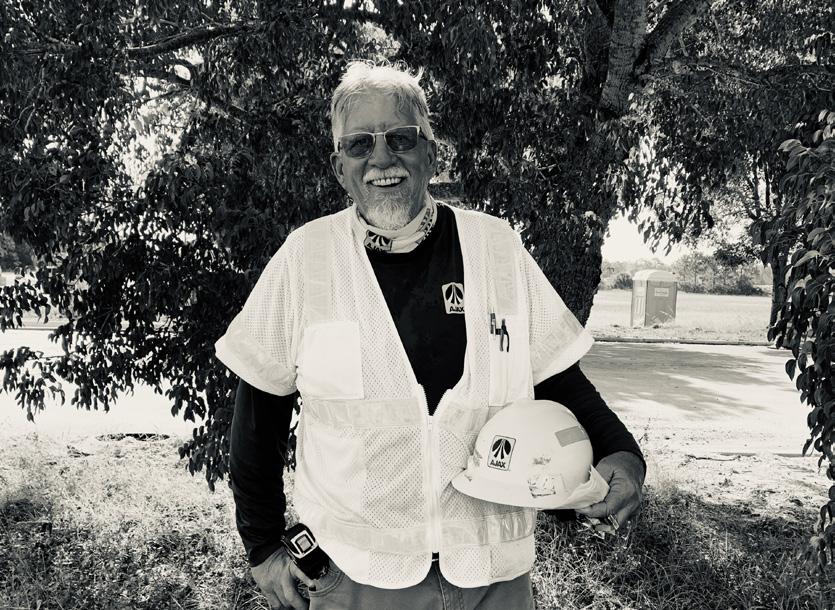

Mark Slomski, Ajax’s Field QC Technician, takes a break from testing to smile for the camera!

Kyle Watkins completing daily maintenance on the plants to keep everything running in top shape.

PLANT 8 UPDATE

IN October 2020, Plant 8 officially broke ground. Our newest facility will service Central Florida and the Heartland. In addition to servicing a new batch of customers, Plant 8 will be the foundation for kicking off a new area office – Area 4. We are excited to have an opportunity to develop new markets, develop and grow new employees, establish new customers, and create new relationships in the market place. Scott Gilliard has moved from Area 1 to Area 4. Steve Francis, Superintendent, was hired in October 2020. We are all looking forward to the challenges and opportunities this area will bring for Ajax in 2021. Special thanks to Tim Smith (A2), Vinnie Ferrone (A1), Cody Dahlberg (A2), Wes Moore (A1), Pheneathius Brown (A1), and Charlie Prince (A1). These gentlemen have spent the last 3 months away from their homes to help us get the plant site ready. Clay Cross, Area Manager

UPDATE ON AJAX MIX DESIGN & PERFORMANCE TESTING LAB CERTIFICATIONS

FOR a couple of years now, all new mix designs and revisions of mixes that go through our plants have been done by Ajax in house with its own Mix Design lab. Our lab also has performance testing capabilities to analyze and predict mix performance in great detail. Due to our expanded testing capabilities, we have been involved in several studies and task forces with NCAT, FDOT, and private institutions.

For 2020, we set out to take a new important leap in quality assurance for our Mix Design lab, that would be of great benefit for us and also for our customers. We decided to get our Mix Design lab certified through the strictest and most respected national agencies.

The first we got was the AASHTO accreditation for our mix design lab procedures, which was finalized in August. The approval and certification process involved a thorough review of our lab policies, procedures, and performance of all the test methods that are done. It finalized with a full assessment that lasted three days in which more than 30 test methods for asphalt and aggregates were evaluated. This certification is also being constantly updated through periodic revisions, evaluations on performance of different samples that are sent for testing. As long as we are AASHTO certified, it will mean that our lab is currently up to par with the best standards out there. We also received in October the certification from the US Army Corps of Engineers (USACE). The USACE has their own certification process, and the certification process involved similar reviews as the one for AASHTO. There are currently very few labs in the region certified for mix designs from both of these agencies, and Ajax is one of those.

Through these certifications we are expecting to offer an added level of confidence in the quality of the mixes that are designed and produced at Ajax. It will also make it easier for us to be involved in projects with different agencies where the specs require the mix designs to be developed only on certified laboratories.