1 minute read

Commercial Vehicle eMobility –lubrication solutions

This is our final article in a series of three looking at eMobility and the accelerating Commercial Vehicle (CV) development, the challenges slowing this down, and the expected pace and direction of electrification. Highlighting how the latest dedicated Electric Vehicle (EV) lubricant technologies can help manage the divergent hardware designs that are emerging and maximise reliability and efficiency.

OEM investment in electrified CVs is proceeding quickly; while only a few models are in production so far, these are being closely followed by a range of prototypes and customer trials based on various forms of electrification.

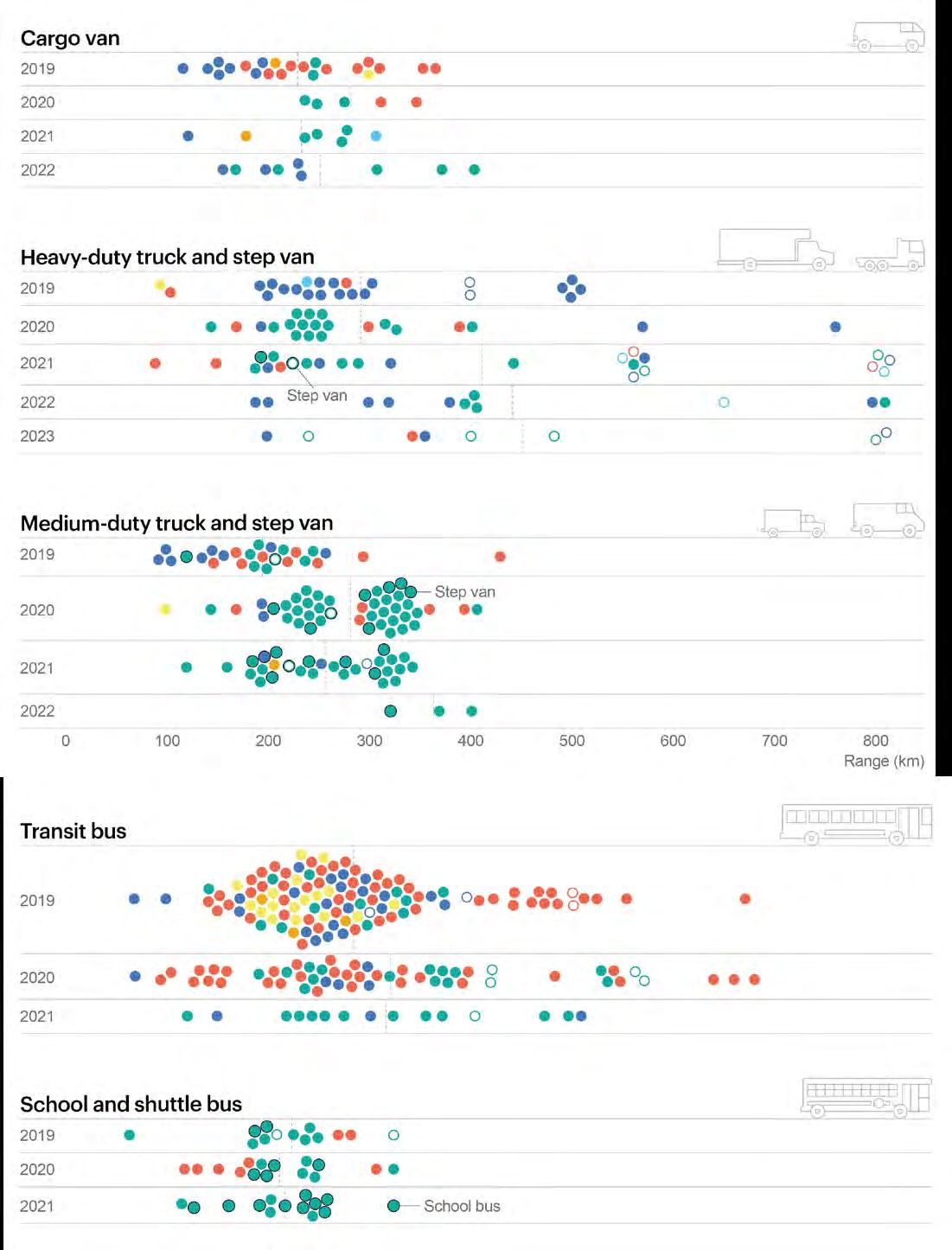

Types of zero-emission HDVs (Heavy Duty Vehicles) expand, and driving range lengthens

Current and announced zero emissions commercial vehicle models by type, release date and range, 2019 - 2023

Notes: Electric HDVs data were provided by CALSTART from their Global Drive to Zero’s Zero Emission Technology Inventory (ZETI) database, which is regularly updated and offers a detailed glimpse of announced OEM production model timelines. ZETI data are meant to support fleet operators and policy makers and should not be construed as representative of the entire vehicle market. Inductive solutions are further from commercialisation and face challenges to deliver sufficient power to trucks operating at highway speeds.

Source: IEA (2022), Global EV Outlook 2022, IEA, Paris www.iea.org/ reports/global-ev-outlook-2022/trends-in-electric-heavy-duty-vehicles Licensed under CC BY-SA 4.0. All rights reserved.

Commercial vehicles come in all shapes and sizes, with a diverse set of tasks and drive cycles. With such a broad range of applications to cover, electrified drivetrain configurations for CVs are already more varied and complex than for passenger cars. This has implications for the selection of ECV (Electric Commercial Vehicle) lubricants.

Hybrids already have clear SAE definitions for P0, 1, 2, 3, and 4 layouts, however EV layout descriptions are not standardised. Many variants are being explored, developed and evaluated for BECVs and the final layout will depend on many factors, most importantly vehicle usage and efficiency. Interim considerations, such as the ease of integration into existing vehicle architecture and supply chains, may also influence the choice of many OEMs.

© 2022. Afton Chemical Corporation is a wholly owned subsidiary of NewMarket Corporation (NYSE:NEU). 10/22. The information in this bulletin is, to our best knowledge, sure and accurate, but all recommendations or suggestions are made without guarantee since the conditions of use are beyond our control. Afton Chemical Corporation and its affiliates disclaim any liability incurred in connection with the use of these data or suggestions. Furthermore, nothing contained herein shall be construed as a recommendation to use any product in conflict with existing patents covering any material or its use.