32 minute read

South East Asia

Keppel’s Tuas Shipyard with the Liza unity on the left hand side of the repair jetty

New vision for Keppel

Advertisement

During January this year, Singapore’s Keppel Corporation announced that, amidst the global energy transition and major disruptions facing the oil industry, it will carry out a comprehensive transformation of its wholly-owned subsidiary, Keppel Offshore & Marine, to better align it to Keppel’s Vision 2030. This is part of Keppel’s strategic review of its offshore and marine business, with the goal of creating a slimmer, and more competitive Keppel O&M that is well-placed to support the energy transition, even as Keppel continues to explore inorganic options.

Reflecting Keppel’s commitment to sustainability and combating climate change, Keppel O&M will exit the offshore rig building business, after completing the existing rigs under construction. In line with the Group’s more disciplined approach towards capital allocation, Keppel O&M will be selective in undertaking cashflow neutral projects. It will also progressively exit low value-adding repairs and other activities with low bottom line contribution, and focus on higher value-adding work such as being a developer and integrator of offshore energy and infrastructure assets. These would include FPSO, FLNG, FSRU and FSO conversion projects as well as newbuilding projects in the marine industry.

This is highlighted by a current newbuilding project involving Brazil’s Petrobras, which is developing the Buzios field offshore Brazil, the second largest field in this area. Keppel is in advanced discussions with Petrobras for the P-78 FPSO, which if awarded, will involve various yards with final assembly in Singapore at Keppel.

Keppel O&M currently has a total of six vessel conversion projects underway – four FPSOs, two FSRUs and one FLNG. The FPSO projects include two for SBM Offshore – the Liza Unity and the Prosperity.

During March this year, the topsides lifting campaign for the Liza Unity FPSO was completed and a major project milestone was achieved. Over 26,000 tonnes of topsides were safely lifted in position at Keppel O&M, since the vessel came out of drydock in October of last year (2020).

The FPSO Liza Unity represents SBM Offshore’s first Fast4Ward design, benefitting from standardisation of the project`s execution plan and using a fully completed and commissioned MPF hull, which sets the benchmark for future FPSO projects. The project continues to target first oil in 2022 in line with client planning. The unit is due for delivery in June this year (2021).

The second SBM Offshore project involves topsides and integration work on the Prosperity FPSO for end-client ExxonMobil. She will be stationed offshore Guyana as part of the Payara development. The FPSO will utilise a design that largely replicates the design of the Liza UnityFPSO.

The other two FPSO projects involve contracts from BW Offshore and Modec – the BW Opportunity and the Miamte (MV34). The BW Opportunity is the former Petrobras FPSO Cidade de Sao Mateus, which suffered extensive fire damage a few years ago. Keppel is rebuilding the FPSO, which includes a new aft section and superstructure.

Meanwhile, the Miamte (MV34) will be deployed in the Offshore Area 1 some 10 kms offshore Mexico at a water depth approximately 32 m. The project involves the conversion of a suezmax tanker to FPSO, the initial work carried out at China’s Cosco Shipyard. The unit then arrived in Keppel during January this year for completion and testing. This project is expected to be completed in the third quarter of 2021.

The FPSO will be capable of processing 90,000 bbls of crude oil/day, 75m ft3 of gas/day, 120,000 bbls of water injection per day and have a storage capacity of 900,000 bbls of crude oil. The first oil production by the FPSO is planned for later in 2021.

The two FSRU projects involve BW Offshore – the BW Tatiana, the former Shell-owned LNG tanker Galliana, and an upgrade and repair of a FSRU from Japan’s Mitsui OSK.

The BW Tatiana will be used on a LNG to power project in El Salvador and the Mitsui OSK project is for the Hong Kong Offshore LNG Terminal Project, which will be located in the southern waters of Hong Kong and to the east of the Soko Islands.

The FLNG project involves Golar’s LNG tanker Gimi, which has already been in the shipyard for a number of months. This conversion is very similar to Keppel previous project for this owner involving the

LNG tanker Hilli. The unit, which will be utilised offshore Mauretania, is expected to be delivered during 2023.

Keppel O&M has also won the contract from Holland’s Royal Boskalis Westminster to carry out jumbolisation work on-board its TSHD Oranje. Meanwhile, In alignment with Keppel O&M’s pivot to renewables, Keppel O&M has also secured a contract for the modification and upgrade of wind turbine installation vessel Brave Tern, owned by Norway’s Fred Olsen Windcarrier’s, work involving the installation of a new 1,600 tonne capacity crane.

Keppel is also one of the world’s leading locations for LNG tanker repairs, especially Japanese-owned tonnage. So far this year, Keppel has completed some 11 LNG tanker repairs, including six such vessels in Keppel’s Benoi Shipyard simultaneously during April. LNG tanker repairs completed this year include three vessels from Japan’s NYK LNG, two from Japan’s MOL LNG, two from Singapore’s Eaglestar Management, and one each from Greece’s Maran Gas, Exmar Singapore, Norway’s Hoegh LNG and Singapore’s Sinokor Ship Management.

The six in the Benoi Shipyard simultaneously were four from MOL LNG – the Energy Liberty, Energy Navigator, LNG Saturn and LNG Vesta, Maran Gas’ Maran Gas Achilles, and NYK LNG’s Grace Dahlia.

Keppel has repaired five VLCCs so far this year, two from Greece’s Maran Tankers – the Maran Antares and the Maran Thaleia, Kyoei Tanker’s Gen-ei, K Line’s Tedorigawa and Athenian Sea Carriers’ Athenian Freedom.

Keppel has also repaired a similar number of containerships this year – two from Malaysia’s Shin Yang Shipping – the Danum 160 and the Danum 175, Technomar Shipping’s Tina 1, MOL Ship Management’s One Motivator and CMA Ships’ APL Danube .

Keppel is also heavily involved in BWM system and scrubber installations – nine BWM installations carried out this year and six scrubber installations. Clients include Maran Tankers (two BWM), and a BWM system installation on-board ships from Greece’s Chandris (Hellas), Japan’s Nippon Steel Engineering, Singapore’s Green Wave Shipping , UK’s NYK LNG, Shipmanagement (UK) and Norway’s Wilhelmsen Shipmanagement.

Greece’s Maran Tankers has also utilised Keppel for the installation of scrubber systems on-board two vessels with Chandris (Hellas), and using Keppel for one vessel each were Japan’s Kyoei Tankers, France’s CMA Ships and Japan’s K Line.

First containership bunkered by Keppel’s LNG vessel

The first ship-to-containership LNG bunkering operation in Asia was undertaken recently by CMA CGM and FueLNG, a joint venture between Keppel O&M and Shell Eastern Petroleum, and MPA. A containership, CMA CGM Scandola, has been fuelled with 7,100 m3 of LNG from FueLNG Bellina, Singapore’s first LNG bunkering vessel, built by Keppel. The CMA CGM Scandola is the first of six new 15,000 teu LNG-powered containerships which CMA CGM Group has lined-up to be bunkered in Singapore this year. These ships will be deployed on CMA CGM’s MEX 1 service between Asia and the Mediterranean.

It is also the first vessel in Asia to conduct simultaneous container loading and discharging operations alongside LNG bunkering operations, shortening port stay time. From Singapore, she will set sail with over 14,800 teu, comprising household goods, electronic items, machinery and personal protection equipment for the Mediterranean.

This is also the first ship-to-ship operation for FueLNG Bellina. Designed and built by Keppel O&M, the 7,500 m3 FueLNG Bellina provides more options for shipowners and operators to bunker LNG in Singapore. FueLNG aims to provide a total of about 30 to 50 ship-to-ship LNG bunkering operations in 2021, extending its track record of over 300 truck-to-ship LNG bunkering operations so far.

FueLNG Bellina is also the world’s first bunkering vessel with Smart Notation for its suite of digital services. Equipped with Keppel O&M’s proprietary VesselCare solutions, these smart functions enable remote monitoring and real-time support of vessel operations.

For achieving a perfect safety record and zero lost-time incidents, Keppel O&M was also awarded a safety bonus by FueLNG.

ABS’ digital technologies on-board FueLNG Bellina

ABS and Singapore’s Keppel O&M are continuing their pioneering application of digital technologies by integrating Smart functions into the world’s first smart LNG bunkering vessel – FueLNG Bellina, equipped with Keppel O&M’s proprietary AssetCare Digital Solution.

ABS was selected by FueLNG, to class the vessel, which will feature notations for Smart Infrastructure (Smart INF) and Crew Assistance and Augmentation (Smart CAA). Obtaining these notations form an integral part of the digital tools tailored by AssetCare to support FueLNG in enabling remote monitoring and real-time support of vessel operations, as well as predictive maintenance, which increases the vessel performance and efficiency.

The digital innovation has also extended to the construction and commissioning process for this vessel. One example is the use of Smart glasses for remote inspection, which increase yard efficiency while improving workforce safety throughout the inspection process especially during the COVID-19 pandemic.

The 7,500 m3 LNG bunkering vessel will be owned and operated by FueLNG Pte Ltd. The vessel, which will be Singapore’s first LNG bunkering vessel, will supply large ocean-going LNG-fuelled vessels throughout the region.

The FueLNG Bellina

Sustainability award for Sembcorp Marine

Singapore’s Sembcorp Marine today won the Sustainability Award at the Singapore International Maritime Awards (IMA) 2021, a biennial event organised by the Maritime and Port Authority of Singapore to celebrate outstanding achievements and contributions to the local port, shipping and marine industries.

The Award, presented for the first time, lauds Sembcorp Marine’s steadfast commitment to sustainability, which is integrated into the Group’s business strategy and embedded into its operations. Sembcorp Marine’s pursuit of sustainability extends beyond energy and resource conservation, waste minimisation, process efficiency enhancement, use of renewable resource to the provision of innovative engineering products and solutions with a focus on sustainability for the marine, offshore and energy industries.

Notably, the Group has developed a suite of comprehensive Gas Value Chain solutions which helped it secure a contract to build a 12,000 m3 LNG bunkering vessel for Japan’s Mitsui O.S.K. Once completed, this vessel will be the largest LNG bunkering vessel built in Singapore, complementing Singapore’s advocacy for decarbonisation and augmenting the development of Singapore’s ecosystem and infrastructure to support LNG bunkering.

Sembcorp Marine’s enhanced capabilities in sustainable solutions have also enabled the Group to make inroads into the renewable energy market. In March 2021, the Group, in collaboration with GE Renewables Grid Solutions, secured a contract to supply the High Voltage Direct Current transmission system for RWE Renewables’ Sofia Offshore Wind Farm. One of the largest wind farms in the world once it is completed, Sofia will supply electricity to nearly 1.2m homes in the UK. For this project, Sembcorp Marine will be building the world’s most remote offshore converter platform, located some 220 kms offshore.

In 2020, despite operational challenges posed by the COVID-19 pandemic, the Group completed 34 BWM system retrofit projects and 16 scrubber projects. Innovation is a core enabler at Sembcorp Marine, driving the Group’s transformation and Sustainability push. To boost innovation development, the Group collaborates with government agencies, research institutions, classification societies and other stakeholders to develop its engineering bench strength. Recent collaborations include: • Signing a Master Research Collaboration Agreement with the Agency for Science, Technology and Research to set up a Joint Lab @TBY to facilitate test-bedding and commercialisation of Digital Design and Advanced Manufacturing capabilities and other Industry 4.0 technologies • Development of large-scale maritime hydrogen fuel cell systems for the international market • Development of commercially viable carbon capture solutions for maritime transport, offshore discharge, floating storage and CO2 injection for permanent storage in subsea reservoirs.

The Group has also invested in building its Tuas Boulevard Yard (TBY), a ‘smart’ yard equipped with Industry 4.0 technologies and environmentally friendly features that support sustainable operations. In particular, the Group replaced over 5GWh of grid-supplied electricity with clean energy harnessed from a solar-panelled roof located above its steel fabrication workshop. This amount of solar-generated electricity – enough to power about 1,100 four-room flats for one full year – enabled Sembcorp Marine to reduce carbon emissions by over 2,100 tonnes, equivalent to taking 684 cars off the road for a year. Sembcorp Marine will progressively scale up its solar power output at TBY in the coming years.

During mid-March, Sembcorp Marine’s Admiralty Yard delivered a FSRU to Turkey’s KARMOL ahead of its deployment to Senegal. The 125,000 m3 vessel, KARMOL’s first FSRU, will bring cleaner LNG-powered electricity to locations where domestic gas production or infrastructure are not yet available. The FSRU is the former LNG tanker Dwiputra.

Currently under conversion at Sembcorp Marine are a number of other FPSO/FSO projects. The first involves the FPSO conversion under a contract with Shapoorji Pallonji and Bumi Armada, to convert the 2000-built VLCC Ariake, into a FPSO unit for deployment on the east coast of India. The vessel will produce up to 90,000 bbls of oil/day (BOPD) and have a 1.3m barrel storage facility. The project includes hull repairs and upgrading as well as fabrication of at least three topside modules which Sembcorp Marine will install on the vessel. The work will be completed at TBY, with delivery scheduled in the second half of this year (2021).

Also in this yard is the LNG Flora, now renamed Torman II. She is being converted to a 127,000 m3 FSU for Gasfin Developments. During December last year, the upgrading work on the 173,400 m3 FSRU BW Magna for Singapore’s BW LNG was completed. Also completed in the first quarter of this year (20210 were the major upgrades of FPSO Ningaloo Vision, which is now back offshore Australia, and FPSO Tantawan, which is now offshore Thailand.

Sembcorp Marine has also recently completed the major upgrade of 50,228 gt heavy-lift vessel Aegir for Rotterdam’s Heerema Marine Contractors prior deployment to the Changhua Offshore Wind Project in Taiwan.

In addition to the many general repair contracts covering all types of ships, Sembcorp Marine specialises in two particular markets – cruiseship refits and repairs and general repairs to LNG tankers (Sembcorp has been the world’s leading LNG tanker repair yard for the past number of years).

This year, among the 10 cruiseships refitted during the first quarter of 2021, in the two Sembcorp Marine yards have included Paul Gauguin Cruises’ 19,170 gt 1997-built Paul Gauguin, Noble Caledonia’s 4,200 gt 1991 expedition vessel Caledonian Sky, P&O Cruises Australia’s 108,977 gt 2002-built Pacific Encounter (ex Star Princess), and two ships from Costa Cruises – the 85,619 gt 2003-built Costa Mediterranea and the 85,619 gt 2000-built Costa Atlantica, which arrived from layup in Manila.

Meanwhile, LNG tankers recently repaired include the 173,400

The VLCC Ariake under conversion at TBY

Solar panels (left) on the roof of the steel fabrication workshop at Tuas Boulevard Yard provide clean energy for up to 30% of maximum production capacity

m3, 2016-built Creole Spirit, which is owned by Teekay LNG Partners and on charter to Cheniere Marketing. This vessel is Teekay’s first M-type, electronically-controlled gas injection (MEGI) powered LNG tanker. Other LNG tankers in the yards have included Northwest Shipping’s 125,042 m3 Northwest Sandpiper and GasLog’s 154,948 m3 GasLog Singapore .

Sembcorp Marine, Shell and Penguin to develop hydrogen as a marine fuel

Sembcorp Marine, Shell and Penguin International have signed a MoU to jointly develop hydrogen as a marine fuel - a first for Singapore as it champions decarbonisation in the marine industry.

The collaboration will see Sembcorp Marine designing, fabricating and integrating a hydrogen fuel cell system onto a ro/ro vessel. Shell will supply the hydrogen fuel and is the charterer of the trial vessel. The ro/ro vessel is owned and operated by Penguin International.

As the world pivots towards cleaner and greener energy sources, interest in hydrogen as an alternative fuel has increased in recent years. The lightest element in the Periodic Table and most abundant chemical substance in the universe, hydrogen produces zero emission when used as a power source, making it an ideal and sustainable fuel. However, while widely produced, hydrogen is still untested as a marine fuel due to the low technological maturity for hydrogen-based engines.

This project will be a pilot to test hydrogen fuel cell and also the first step in establishing the feasibility of hydrogen as a marine fuel. If successful, the project not only paves the way for zero-emission shipping, but also reinforces Singapore’s reputation as a world class marine and offshore engineering centre.

Sembcorp Marine received the Sustainability Award at the Singapore International Maritime Awards for its steadfast commitment to Sustainability, which is integrated into the Group’s business strategy and embedded into its operations.

The signing of the MoU (from left to right) James Tham (Penguin International), Aw Kah Peng (Shell) and Simon Kuik (Sembcorp Marine)

In addition to augmenting Sembcorp Marine’s Sustainability credentials, this latest collaboration highlights Sembcorp Marine’s technological bench strength to undertake complex and cutting-edge projects. The Group continuously boosts its capabilities by investing in human capital, making strategic acquisitions and collaborating with best-in-class partners.

Notably, the Group has embraced Industry 4.0 technologies such as additive manufacturing (or 3D printing) and the Industrial Internet of Things (IIoT). In 2019, Sembcorp Marine received certifications qualifying its 3D printing procedures for making and restoring parts used in construction and repair projects and completed the proof of concept for applying IIOT to improve the precision of steel-plate tracking at its steel fabrication facility.

Mr Wong added, “The global transition towards cleaner, greener and renewable energy is underpinned by multiple complex social, political and economic factors. There is a push for businesses to embrace digitalisation, alternative propulsion technologies and fuels, and Industry 4.0 applications. To remain relevant, the maritime community must continuously invest in innovation and remain flexible and agile to futureproof the industry for current and future generations.”

Silverstream work on-board LNG tanker refitting in Sembcorp Marine

UK’s Silverstream Technologies has announced that its pioneering air lubrication system, the Silverstream System, has delivered significant fuel and emissions savings during testing on the Shell-chartered 170,000 m3 LNG tanker Methane Patricia Camila . Following operational testing of the retrofitted technology, Silverstream and Shell’s engineers demonstrated 6.6% net savings generated by the Silverstream System. The technology was tested at various vessel speeds during the Methane Patricia Camila’s normal operations, to calculate fuel and emissions savings.

The Silverstream System enables fuel and emissions efficiencies through its unique design. The innovative technology produces a thin layer of micro-bubbles along the full flat bottom of the vessel, reducing frictional resistance between the water and the hull. The System was successfully retrofitted on the 2010-built vessel during its October 2020 planned drydocking at Sembcorp Marine’s Admiralty Shipyard. The project was installed within the planned drydocking period, and was delivered on budget. From design through to installation the System was reviewed and approved by ABS in accordance with their guidance note for Air Lubrication Technology.

Commenting on the announcement, Noah Silberschmidt, Founder & CEO, Silverstream Technologies, said, “It is great to announce that retrofitting the Silverstream System on-board the Methane Patricia Camila has already had a significant positive impact on fuel consumption and emissions, with 6.6% savings verified during initial testing. We’d like to thank our colleagues and partners at Shell for their confidence in our technology, and also for their vision and commitment to pioneer proven clean technologies within shipping.”

SCHOTTEL supplies Sembcorp Marine

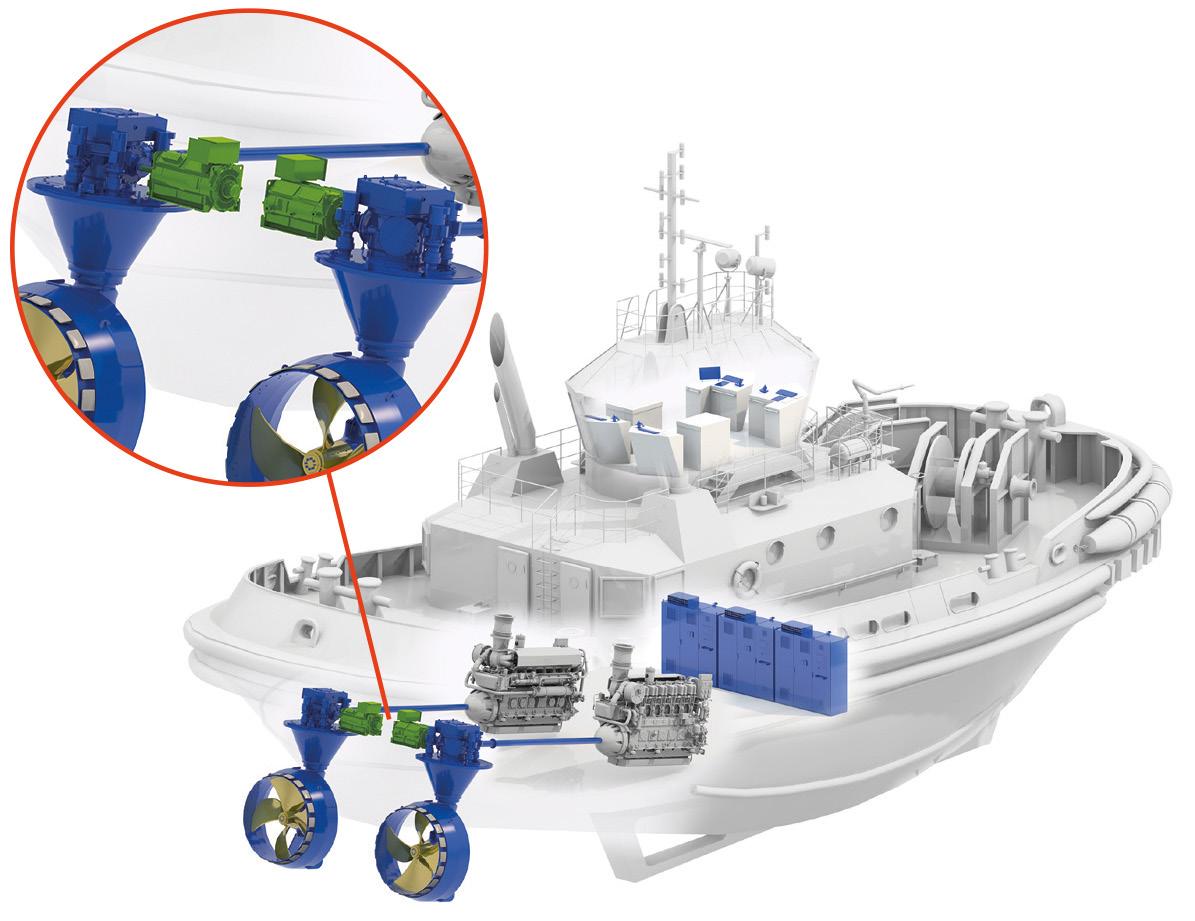

Sembcorp Marine relies on SCHOTTEL’s azimuthal hybrid drive system SYDRIVE-E for the world’s first LNG hybrid tug. With this first in a series of 12 vessels, Sembcorp Marine will build the world’s first hybrid LNG-fuelled tug fleet that will replace its existing diesel-powered tugs. The vessel is designed by LMG Marin, a wholly owned Sembcorp Marine subsidiary, and a leading naval architecture design house in Bergen, Norway, which provides energy efficient solutions.

The tug’s future operation profile in the harbours of Singapore will demand highly variable power ranges. Depending on the desired operating mode and the required propulsion power, the hybrid drive system activates the appropriate power source or both together. The LNGfuelled main engines and the electrical motors are both coupled to the SYDRIVE system and always operate efficiently within their optimal load ranges, thereby reducing fuel consumption and emissions and supporting Sembcorp Marine’s efforts in environmental protection.

In terms of thruster integration, each upper gearbox offers two power input positions with an offset angle of +/- 90° for two power sources. An option with a +/- 135° offset angle is also available allowing even more design flexibility.

Sembcorp Marine’s hybridised SCHOTTEL RudderPropellers type SRP 430 will have a power intake capacity of about 2,000 kW each which will be fed by zero emissions electrical motors and/or low-emissions LNG main engines. The 360o steerable SRPs combine maximum manoeuvrability and a high bollard pull as harbour operations require.

The SCHOTTEL SYDRIVE-E azimuth thrusters are engineered and manufactured in Germany. Commissioning and After Sales Service will be provided by SCHOTTEL Far East, Singapore. Sembcorp Marine’s hybridised fleet will be operated by its subsidiary Jurong Marine Services

The Methane Patricia Camila

The SCHOTTEL SYDRIVE-E system on-board the Sembcorp Marine’s fleet of tugs

for services in Singapore’s harbours with operations scheduled to start in late 2021.

Royston combines with FELZ Marine

UK’s Royston Marine has completed work with Singapore’s FELZ Marine to provide new electronic fuel management systems for two newbuild vessels. The work involved the supply and commissioning of enginei systems, featuring on-board HMI (human machine interface) and a specially configured remote platform, for the new 28 m length fast crew and surfer vessels.

Constructed in Singapore, these vessels are being delivered in the first quarter of 2021 before heading to Nigeria, West Africa, where they will be used to support the operations of offshore oil and gas exploration and production companies.

Offering comprehensive, easy-to-understand fuel data analysis and reporting options, enginei is an advanced Real Time Fuel Monitoring System. It can be installed as part of a comprehensive suite of digital marine technologies, delivering long-term operational efficiency and performance.

Following installation of an enginei system in its utility vessel Joshuua in 2017, FELZ Marine has continued to invest in the online technology to ensure compliance with customer specifications for electronic fuel management systems, which help to improve fleet operations.

The new systems have been overseen by Royston’s Singapore-based operation, which is seeing strong demand from Asia Pacific-based vessel owners and operators for easy-to-use and flexible technology with accurate measurement, control and analysis of fuel consumption data capabilities.

The new FELZ Marine work takes the number of vessels deploying enginei to more than 350 world-wide, including OSVs such as anchor handlers, jack-ups, PSVs and crew boats, operating in West Africa, the North Sea, Asia, Egypt, Mexico and Brazil.

At the heart of the system is expanded on-board flowmeter and sensor technology. This gives the advanced system the ability to acquire comprehensive real time engine and vessel performance measurements beyond the usual RPM, GPS and fuel inputs to take in a wide range of other engine control unit outputs.

The data is displayed live through a touch screen bridge display and transmitted remotely to the enginei web portal where the state-of-the-art interface enables the rapid production of intuitive online reports and trending graphs, as well as providing alerts and map dashboard tracking with weather overlays, showing a detailed operational profile for a vessel.

FELZ Marine is using Royston’s enginei EFMS

AET recognised with SRS Ship Owner of the Year

During mid-April, AET won the SRS (Singapore Registry of Ships) Ship Owner of the Year Award presented at the Singapore International Maritime Awards (IMA) ceremony. The SRS Award recognises an outstanding owner of quality Singapore registered ships and takes account of fleet size, growth, operational excellence, sustainable contribution to human capital development both ashore and at sea. This year, special emphasis was placed on the owner who has been able to demonstrate resilience by adapting its business activities and operations even amidst the global pandemic challenges.

The IMA ceremony was held as one of the key anchor events of the Singapore Maritime Week organised by the Maritime and Port Authority of Singapore (MPA). The biennial Singapore IMA seeks to recognise individuals and companies for their contributions to Singapore’s development as a premier global port hub and an international maritime centre.

Receiving the Award on behalf of AET, President & CEO, Capt Rajalingam Subramaniam said, “Being named SRS Ship Owner of the Year for the first time is a great recognition for AET and the entire MISC Group. I would like to thank the MPA for its steadfast support to the maritime community and their distinguished panel of judges for recognising AET and the work that we do as a team.

“This Award reflects on our commitment and contributions to the entire maritime ecosystem as a global company with Asian roots and as a leading player of responsible and sustainable shipping. I am honoured to accept this Award on behalf of all my colleagues at AET and the MISC Group, at sea and ashore, and I thank them for their hard work and dedication particularly during these challenging times. I would also like

Capt. Rajalingam Subramaniam (right), President & CEO of AET, receiving the Award from Chee Hong Tat, Senior Minister of State for Ministry of Foreign Affairs and Transport.

An artist’s impression of the 42 m FCB Maritec’s new advanced bunker testing allows ship operators to identify the root cause of a marine engine’s fuel-related problems

to express our appreciation to all stakeholders of AET for their continued support as always.”

Synergy Group wins award

Synergy Group’s contribution to Singapore’s development as an international maritime hub was recognised earlier this week during the Singapore International Maritime Awards (IMA) 2021 event. Synergy Group won the ‘Maritime Service Provider Award 2021’ at IMA.

Synergy was established in Singapore by Captain Unni in 2006. After starting out with just a handful of ships, the fleet is now almost 400 vessels strong and includes some of the world’s most complex LNG tankers. As well as ship management, Synergy also offers shipbuilding, crew management, training, husbandry, forwarding and travel services.

Synergy is a major customer of Singapore’s ports and shipyards as well as a key component of the Singapore maritime cluster. In November, for example, Synergy completed the successful conversion of a 1992-built, 126,000 m3 LNG tanker into a FSU at Sembcorp Marine’s Admiralty Yard in Singapore.

“The business philosophy for Synergy Group from the beginning was to offer ship owners better productivity and service by investing in human capital to become a thought partner to clients,” said Captain Unni. “Singapore was the perfect location due to the high quality of education and maritime training, plus its world-renowned port and shipyard facilities.” Meanwhile, Strategic Marine has secured a contract to build two 42 m Fast Crew Boats (FCB) for Centus Marine Sdn Bhd. This is the fifth and sixth vessel built by Strategic Marine for Centus Marine and follows the delivery of a 40 m FCB in February 2021. Both FCBs are scheduled for completion in second Quarter 2021 and fourth Quarter 2021 respectively. This design is a customised solution developed in close collaboration with Centus Marine to meet their operational needs.

Propelled by three Cummins KTA50 engines, the 42 m FCB will cruise at 30 knots, and can reach top speed of over 31 knots. The design incorporates the robust engineering of hulls proven in tough commercial marine environment and is fully compliant to Petronas’ requirements.

Crew comfort and safety is another major consideration for Centus Marine which is reflected in the interior arrangement of the vessels. The accommodation area features 12 berths in seven cabins and can comfortably accommodate up to 100 personnel on-board. It offers spacious business class recliner seats, dedicated luggage racks, a large incorporated deck storage and wide, efficient walkways to facilitate crew transfer amid demanding offshore conditions.

Maritec introduces a new fuel service

Singapore’s Maritec has introduced a suite of new fuel testing and analysis services aimed at mitigating the risk of bunkering off-spec fuel. The Maritec Enhanced Analysis Package (MEAP) is an upgraded testing programme developed to complement the existing ISO8217 fuel testing standard.

As part of the overall MEAP, three additional testing services are available depending on the level of detailed analysis required. Testing services include the analysis of fuel for deleterious materials, chemical contamination by GCMS – screening, stability by P-values sediment, and asphaltenes.

As an option, MEAP includes a Compatibility Package allowing ship operators to determine the compatibility of ROB and new bunker of three blending ratios (10:90, 50:50, and 90:10). The analysis is based on a Total Sediment Potential (TSP) test as recommended by the International Council on Combustion Engines (CIMAC).

Engine problems relating to fuel stability can also be prevented with a MEAP Stability Package. Fuel with low stability exhibits a higher potential for asphaltenes, resulting in higher volumes of sludge causing various engine operational problems. The Stability Package analyses the fuel for Total Sediment Accelerate (TSA), Total Sediment Existent (TSE) and Total Sediment Potential (TSP), with further tests carried out to assess P-value and

Zen Hong Oh, Regional Service Manager for Southeast Asia, Ecochlor

asphaltene content.

If Phenol is detected in bunker fuel, Maritec advises to carefully observe the fuel system and conduct further Gas Chromatography/Mass Spectrometry (GCMS) testing to detect other higher boiling point phenolic compounds and Estonian shale oil (alkyl 1.3-benzenediol derivatives).

New Manager for Ecochlor South East Asia

US-based Ecochlor has announced the appointment of Zen Hong Oh as Regional Service Manager for South East Asia. Mr. Oh has more than 11 years of involvement in the maritime industry both in shipbuilding and in project management of vessel repairs and retrofits. Prior to Ecochlor, he was Field Service Manager at Emerson Process Management Marine Solutions. He also acted as Assistant Manager of Green Technologies for Singapore’s Sembcorp Marine with responsibilities that included the technical review of retrofits.

“We are expanding our Singapore Services Hub with increased chemical storage capabilities, engineering service support and spare parts network,” said Michael Madely, VP, Global Service. “Situated in Singapore, Mr. Oh is crucial to our growth in this area along with developing strong relationships with our service partners in Japan and Korea. He has a wealth of managerial and technical experience in BWM system project management, which is central to the support of our teams and customers in Southeast Asia.”

Mr. Oh added, “My background in both shipyard retrofits and in project management of BWM system installations will be of great assistance to both our service engineers and in providing a real-time response to our clients. I am excited to bring my experience to this ‘best in class’ service support team!”

Mr. Oh has a Masters in Offshore Technology with Subsea Engineering and a Bachelor of Mechanical Engineering from the National University of Singapore.

Large offshore contract for MMHE

Malaysia Marine and Heavy Engineering Sdn Bhd (MMHE), a wholly owned subsidiary of Malaysia Marine and Heavy Engineering Holdings Berhad (MHB), has secured a contract from SapuraOMV Upstream (Sarawak) to undertake the engineering, procurement, construction, transportation & installation, and hook-up & commissioning services (EPCIC) for the SK408W Jerun Development Project, offshore Sarawak.

This EPCIC contract comprises the construction of an approximately 15,000 tonnes topside, 10,000 tonnes jacket and 5,000 tonnes piles of Central Processing Platform (CPP). It also includes the design engineering of a 30-inch (762 mm) carbon steel pipeline with a length equivalent to 80 kms distance from this CPP to the existing E11R-B platform to commingle with the existing trunkline to Petronas Malaysia LNG Plant in Bintulu, Sarawak.

Upon completion, the facilities will be installed in Jerun gas field, which lies in the SK408W Block located offshore Bintulu, Sarawak. SapuraOMV Upstream (Sarawak) Inc. is the Operator of SK408W Block, with Sarawak Shell Berhad and Petronas Carigali holding 30% equity interest, each.

For the start of this year, the on-going projects in the yard for the Heavy Engineering segment include EPCIC work for the Kasawari Gas Development Project and EPCIC of BEDP-A and BEDP-B WHP for Bekok Oil Project.

For the three months period, the Marine repair segment completed the repair and maintenance of some 29 vessels of various categories, of which one was for a repair work on an LNG tanker. During February this year, MMHE opened its new 350 m x 80 m large graving dock at its Pasir Gudang shipyard. This facility has been specifically designed for the repair of LNG tankers. However, the first ship to use the drydock was Zodiac Maritime’s containership CSAV Toconao.

Since the opening of the drydock, LNG tankers to use the facility have included BW Gas’ 142,988 m3 LNG Benue, Exmar’s 63,993 m3 Lerici and MISC’s 134,833 m3 Puteri Nilam Satu .

BV classes hybrid-powered ship

Bureau Veritas (BV) has certified and classed Singapore’s first hybridpowered ship. Built, owned and operated by Singapore-based Penguin Shipyard International, a subsidiary of Penguin International Limited, Penguin Tenaga is a 15 m, 12-passenger aluminium pilot boat capable of entirely running in electric mode at five knots for more than 30 mins, and in conventional diesel mode can reach a maximum speed of

The new graving dock at MMHE

The Penguin Tenaga

24 knots. The vessel design is based on the same hull form as two of Penguin’s existing monohull pilot boats that are currently operating for Shell Eastern Petroleum in Singapore.

The Penguin Tenaga is classed under BV with the notation Electric Hybrid and Zero Emission (‘ZE’) mode. This notation provides operational and environmental benefits. It helps to ensure the systems operate safely and efficiently, as well as reduce fuel consumption, local air emissions and noise when in proximity to centres of population. BV assisted Penguin by providing guidance on the BV rules and advice to Sea Forrest Power Solutions Pte Ltd (a subsidiary of BH Global Corporation Limited) towards certification of the equipment on-board, such as the hybrid electric propulsion systems installed on the vessel.

In addition, solar panels installed on the roof of Penguin Tenaga provide electrical energy that is used to recharge mobile devices on-board and supplement the vessel’s ‘hotel load’.

Singapore, one of the world’s largest and busiest ports, has pledged to reduce greenhouse emissions by 36% by 2030, when compared to 2005 levels. This shipbuilding project is an important step towards Singapore’s environmentally sustainable future and meeting its own green targets.

In a bid to reduce emissions, Singapore is taking a lead in developing hybrid-electric propulsion technology for offshore support and harbour vessels. Currently, there are limited applications for pure electric vessels in Singapore due to the lack of charging infrastructure. However, this could change in coming years as the country electrifies its maritime eco-system to meet the IMO sustainability targets as well as its own sustainability goals. BV has also created comprehensive guidelines and rules to help the ship owners and builders move towards sustainability powered vessels.

This landmark project is a collaboration of Penguin, Danfoss Power Solutions, Durapower Technology (Singapore), ZF Asia Pacific, BH Global Corporation and BV.

Foundation Det Norske Veritas teams up with MPA

Foundation Det Norske Veritas, which owns DNV Group, has teamed up with MPA and five other industry leaders to establish a maritime decarbonisation centre in Singapore. The centre’s stated mission is to catalyse and facilitate decarbonisation in the maritime sector and will be supported by contributions from the founding members totalling S$120m. Its creation follows the release of a recommendation by the International Advisory Panel (IAP) – a Singapore Maritime Foundation initiative – on maritime decarbonisation to set up a decarbonisation centre in Singapore. The Memorandum of Co-operation was signed on 21st April in the presence of Chee Hong Tat, Singapore’s Senior Minister of State for Transport and Foreign Affairs.

Foundation Det Norske Veritas has committed S$10m – a figure matched by partners BW Group, Eastern Pacific Shipping, Ocean Network Express, Sembcorp Marine, and BHP with the MPA adding S$60m to the contributions.

“The Foundation Det Norske Veritas is driven by a desire to help society tackle major global transformations,” said Remi Eriksen, Chief Executive Officer of the Foundation Det Norske Veritas and DNV. “Transforming the world energy system is one of the biggest challenges currently confronting society, and shipping must play its part. But doing this cannot be achieved without industry wide collaboration. That is why we have taken the decision to become a founding member of the Singapore decarbonisation centre.

“We believe the deep expertise behind the Foundation complements Singapore’s status as a world-leading maritime ecosystem for sustainable energy and climate change. Working together, I am confident the Centre will deliver a global impact on decarbonisation while further bolstering the Foundation’s purpose of safeguarding life, property and the environment.”

Quah Ley Hoon, Chief Executive of MPA, added, “Maritime decarbonisation is a global challenge requiring a collective responsibility from all stakeholders involved. It is crucial to have strong public-private sector partnerships. We thank like-minded partners like the Foundation Det Norske Veritas that have responded strongly to our call for collaboration. The agreement signed today is a first step, which we hope will catalyse a larger, much needed momentum to make international shipping more sustainable.

“Collaboration is key to progress on the decarbonisation pathway. At DNV, we are pleased to widen the scope of our longstanding co-operation with MPA by sharing our technical competence and industry knowledge in this maritime decarbonisation centre. Together with leading shipping firms in the region, we look forward to supporting the adoption of new low- and zero-carbon solutions which will help to reach IMO’s greenhouse gas reduction targets,” said Cristina Saenz de Santa Maria, Regional Manager South East Asia, Pacific & India, Maritime at DNV, who signed the Memorandum of Co-operation on behalf of the Foundation Det Norske Veritas.

Spanning a five-year period, Foundation Det Norske Veritas’s contribution will support research and technology development projects in the areas of greenhouse gas emissions reduction, and collaborations with higher education institutes and research bodies.

Remi Eriksen