9 minute read

tna Solutions

tna solutions: catering confectionery needs

tna solutions is a supplier of integrated food processing and packaging solutions with over 35 years of industry experience and 14,000 systems installed across more than 120 countries –Managing Director and CEO, Alf Taylor spoke with Kennedy’s about the evolution of tna from an initial Australian brand to the valued global brand it is today

Advertisement

Above: Alf Taylor, Managing Director and CEO, tna solutions Co-founded in 1982 by Alf and Nadia Taylor, tna solutions revolutionised the packaging industry with the world’s first high-speed, vertical form, fill, seal (VFFS) packaging machine; the tna robag® and in 1990, the Taylors made the decision to take the company global.

Managing Director and CEO, Alf Taylor, told Kennedy’s: “Nadia and I both had experience working in the food industry, Arnott’s Biscuits and Arnott’s Snack Food Divisions (Now Snack Brands). We were passionate about the industry. Together, we turned our dream, that literally started out as an idea on our kitchen table, into the reality it is today.”

The company provides a comprehensive range of products including materials handling, processing, cooling and freezing, coating, distribution, seasoning, weighing, packaging, inserting and labelling, metal detection, verification and end of line solutions. “My prime responsibility is to manage the aspirations of a global team that is the driving force behind tna’s success,” Alf continues. “Towards this, I am involved in developing the company’s global structure, developing new products and applications and ensuring that we continue to be a profitable enterprise.

“tna’s vision is a world where every individual has access to the basic human rights, they need to reach their full potential. With this vision in mind, we are focused on providing sustainable, empowering solutions in areas of education, healthcare, social welfare, emergency relief and more, to those less fortunate, especially children.”

Sussing the solution for confectionery

The challenge for the confectionery industry lies in keeping pace with everevolving consumer preferences, and delivering new, on-trend products to retailers’ shelves, as quickly as possible, to stand out in a crowded marketplace. From manufacturing to packaging, increasing flexibility and efficiency is essential to achieving the desired result.

“The confectionery industry is in a long, transitional phase with shifting consumer preferences,” says Alf. “The emphasis on

Above: The NID forté® mhp 3

low calorie, single-serve packs is driving the need for the packaging industry to deliver high speed solutions. As the pressure to maintain total kilogram output while reducing pack size creates increasing pressure on the industry to run small packs at ever increasing speeds; 300-400 bags per minute.

Since the acquisition of tna’s confectionery specialist and brand, NID, the company have been able to offer a complete line of confectionery solutions aligned with emerging trends in the industry - from high-speed moguls, starch conditioning systems to oiling and sugar-coating solutions, plus the company’s own flexible conveying and high-performance packaging technology.

Alf continues: “our ability to cater to the requirements of small to large scale food manufacturers, with innovative solutions, the ability to nurture our people and develop products and applications in keeping with evolving trends are some of the noteworthy aspects of our organisation.”

Predicting the sugar market

According to Alf, the general upswing predicted for global confectionery over coming years, almost 4% CAGR between 2016 and 2024, based on research from Mordor1 disguises a far more complex market than appears at first glance. On a global scale, chocolate continues to dominate, and so sugar confectioners are fully aware there is opportunity for growth not only within their own niches, but by attracting more consumers whose desires for indulgence, convenience and exciting eating experiences are currently being met by chocolate makers.

“Within sugar confectionery too, while sugar chewing gum sales are dropping almost universally, sugarfree variants are enjoying continued success,” he continues. “In addition, contrary to the early expectations of some observers, hard candy is holding its own thanks to several factors, most particularly nostalgia, the drive for clean labels and expanding vegetarianism.

“As consumer demands multiply, differentiation will become tougher as rivals fight for share of wallet. Individual, single-serve packs supporting low calorific value will be on the rise, driving demand for high-speed small packs.”

Future prospects

tna will continue to focus on developing products and expanding applications for the food processing industry aligned with emerging consumer trends. It is clear that the confectionery industry will also continue to play a significant role in tna’s future and its success. Alf concludes: “Innovation is at the core of tna’s business philosophy, which has led to the company’s evolution into a complete integrated systems solutions partner for the food processing and packaging industry globally. Whether it’s for building a new line, or upgrade a current production line, tna is the sought-after partner to provide the perfect solution.”

Footnote:

1. Mordor Intelligence: Candy Market - Growth, Trends, and Forecast (2020 - 2025) https://www.mordorintelligence.com/industry-reports/candy-market “tna’s vision is a world where every individual has access to the basic human rights, they need to reach their full potential. With this vision in mind, we are focused on providing sustainable, empowering solutions in areas of education, healthcare, social welfare, emergency relief and more, to those less fortunate, especially children…”

WDS: moulding mastery

Winkler und Dünnebier, WDS, is an international manufacturer of confectionery machines and well known for permanent development and innovation of its production plants – Head of Sales, Ralf Hübner, tells us about their greatest achievements as well as their forecast for the confectionery market and future prospects as a company

Above: Ralf Hübner, Head of Sales, Winkler und Dünnebier

WDS has more than 100 years in engineering confectionery machines known for their quality and flexible modular design. As a specialist for Moulding plants, the company are able to cover the entire spectrum of deposited sweets with different applications and throughputs.

Ralf Hübner told Kennedy’s about what his role as Head of Sales at WDS entails, “My main responsibilities include; ensuring the achievement of sales targets, disciplinary and professional leadership of the employees in sales, projecting and product innovation centre expansion of the sales organisation, observation of the markets and identification of future trends and technologies as well as development of strategic sales concepts.”

Product Innovation Centre

One year ago, WDS reacted to the significant increase in demand for high-quality confectionery production plants worldwide by building two new, ultramodern production halls with around 14,000 m² of additional production space.

The company’s technology lab, based at the WDS headquarters in Rengsdorf/Germany, is specialised in the development of new and optimisation of existing depositing processes as well as process engineering the production of confectionery - providing all services to transform a product idea into a successful product launch.

“Innovations usually start in our inhouse Product Innovation Centre - an excellent example is our new lab-depositor fully compliant with GMP guidelines for the production of functional gummies for marketing panels and product validation. Such a new depositor for a growing market with regards to OTCgummies triggers also new developments for the future.

“I think it is great to see our continuity in launching innovations across all our machine categories: chocolate, gummy moulding with the traditional starch bed as well starchless- moulding.”

Unique lines and solutions

WDS is known for its fleet of different Mogul lines – the Mogul type 660, for example, combines the latest demands from customers all in one machine. This means avoiding paint and using a stainless/ aluminium frame as well as the demand for a tray transport without chains, respectively the GuidedPusherSystem.

Ralf adds: “The Mogul 660 differentiates from others thanks to demoulding using a lateral extractable flat sieve and thanks to our rotary-valve depositors which can also be easily rolled into an offline position for fast cleaning without polluting the tray transport.”

With starch moulding, there is now a clear separation of moist starch and conditioned starch, i.e. a complete demarcation within the plant enables a 100% sieving. Only conditioned starch is used to fill the moulds. Although the Mogul 660 can optionally be operated with an external cyclone screener, this is not necessary in standard version due to the proven de-powdering with separating and cleaning sieves within the plant. The removable sieve station ensures easy access and quick, convenient maintenance.

WDS are also driven by serving the production of tomorrow´s chocolate products using their different technologies and ultimately focus on combining their moulding experience with the flexibility on the basis of a chain-driven mould transport. The result is the ConfecPRO for medium to large production capacities where all parts in direct contact with chocolate can be easily exchanged without tools.

“At WDS, we like to push current limits and to think about revolutionary solutions with regards to flexible mould transportation, speed for cleaning and change over,” Ralf continues. “With our ConfecVARIO we show how production of both chocolate and starchless products can be done avoiding chains in all segments and with complete new and more flexible line-configurations beyond the conventional rectangular racetrack.”

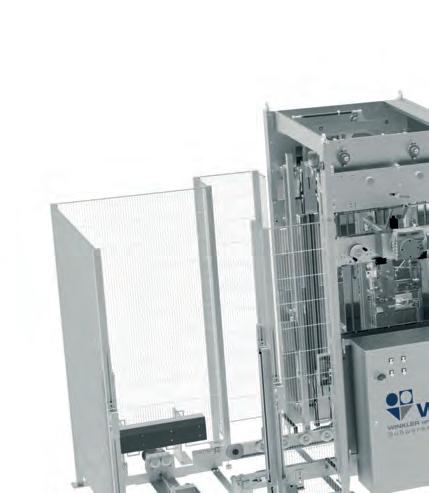

Below: The Mogul Plant type 660 is designed for the manufacture of all starch- moulded products

A constructive confectionery forecast

Today, it is difficult to develop an iconic confectionery product which shows huge sales growth over many years. The lifespan of a product has become much shorter and big food retailers are asking for seasonal innovation and this is directly linked to our machines. The demand has changed from large capacity lines for a dedicated product towards flexible lines which entertain multiple different products with a medium production capacity.

Ralf continues: “The number of confectionery products becoming sweets with health-promoting or biologically effective properties by adding various ingredients has been increasing for years. These products have a very large acceptance in the market e.g. as a nutritional supplement or nutraceutical, because consumers use them in many ways to support their individual health care. There is also great growth potential in the pharmaceutical sector for over-thecounter medicines.

Ralf Hübner, head of sales, WDS

“As a specialist in the development and manufacture of confectionery machines, we are one of the leading suppliers of technologies and machinery for the production of active OTC-sweets and cannabis products.”

Regarding the future prospects for WDS, Ralf concludes: “I am, firstly, looking forward to supporting our existing customers with our latest technologies.

Second, I hope sustainable global market for our machines although the political situation in some future markets is not easy.

Last but not least; I hope that new product trends will prosper so we can continue developing new technologies for a very sweet market.”