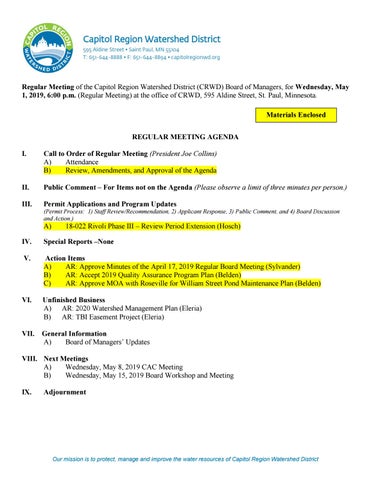

Regular Meeting of the Capitol Region Watershed District (CRWD) Board of Managers, for Wednesday, May 1, 2019, 6:00 p.m. (Regular Meeting) at the office of CRWD, 595 Aldine Street, St. Paul, Minnesota. Materials Enclosed REGULAR MEETING AGENDA I.

Call to Order of Regular Meeting (President Joe Collins) A) Attendance B) Review, Amendments, and Approval of the Agenda

II.

Public Comment – For Items not on the Agenda (Please observe a limit of three minutes per person.)

III.

Permit Applications and Program Updates (Permit Process: 1) Staff Review/Recommendation, 2) Applicant Response, 3) Public Comment, and 4) Board Discussion and Action.)

A)

18-022 Rivoli Phase III – Review Period Extension (Hosch)

IV.

Special Reports –None

V.

Action Items A) AR: Approve Minutes of the April 17, 2019 Regular Board Meeting (Sylvander) B) AR: Accept 2019 Quality Assurance Program Plan (Belden) C) AR: Approve MOA with Roseville for William Street Pond Maintenance Plan (Belden)

VI.

Unfinished Business A) AR: 2020 Watershed Management Plan (Eleria) B) AR: TBI Easement Project (Eleria)

VII.

General Information A) Board of Managers’ Updates

VIII. Next Meetings A) Wednesday, May 8, 2019 CAC Meeting B) Wednesday, May 15, 2019 Board Workshop and Meeting IX.

Adjournment

Our mission is to protect, manage and improve the water resources of Capitol Region Watershed District

May 1, 2019 III. Permits A.) 18-022 Rivoli Phase III 2nd Review Extension Request (Hosch)

DATE: TO: FROM: RE:

April 25, 2019 CRWD Board of Managers Elizabeth Hosch Second 60-day Review Period Extension for Permit 18-022

Background The current review period for Permit 18-022 Rivoli Phase III will expire on 5-2-19. Issues The applicant requested a second extension to the 60-day review period prior to the expiration. Additional time is still needed to resolve how the applicant will meet CRWD Rule requirements. Requested Action Approve 60-day review period extension for permit 18-022 Rivoli Phase III to expire July 1, 2019.

W:\07 Programs\Permitting\2018\18-022, Village on Rivoli\Brd Memo 2nd Extension request, 18-022 Rivoli III.docx

Our Mission is to protect, manage and improve the water resources of Capitol Region Watershed District.

May 1, 2019 Board Meeting V. Action Item A) Approve Minutes of April 17, 2019 Regular Board Meeting (Sylvander)

Regular Meeting of the Capitol Region Watershed District (CRWD) Board of Managers, for Wednesday, April 17, 2019, 6:00 p.m. at the office of CRWD, 595 Aldine Street, St. Paul, Minnesota. REGULAR MEETING MINUTES I.

A)

Call to Order of Regular Meeting (President Joe Collins)

Managers Joe Collins Seitu Jones Shirley Reider Rick Sanders Mary Texer

B)

Staff Present Public Attendees Jessica Bromelkamp, CRWD Mark Doneux, CRWD Anna Eleria, CRWD Bob Fossum, CRWD Elizabeth Hosch, CRWD Forrest Kelley, CRWD Michelle Sylvander, CRWD Nate Zwonitzer, CRWD James Mogen, Ramsey County Attorney

Review, Amendments and Approval of the Agenda. – website update added

Motion 19-050: Approve the Agenda of April 17, 2019. Reider/Texer Unanimously Approved II.

Public Comment – For Items not on the Agenda

No comments were made. III.

Permit Applications and Program Updates A) Permit 19-009 University of St. Thomas Residence Hall/Iversen Center (Hosch)

Ms. Hosch reviewed permit #19-009 University of St. Thomas Residence Hall/Iversen Center. The applicant, University of St. Thomas is planning construction of new student housing and expansion of the existing chapel. The applicable rules are Stormwater Management (Rule C), Flood Control (Rule D), and Erosion and Sediment Control (Rule F). The disturbed area of this project is 5 acres with 2.6 acres’ impervious surface.

Motion 19-051: Approve permit #19-009 McCarrons Hill with seven conditions: 1. Receipt of $13,500 surety. Surety has increased $400 since first submittal (dated 2/2/19) because paving plan (rcvd. 4/1/19) indicates an increase in 3,486 sf of impervious cover. 2. Receipt of documentation of maintenance agreement recorded with Ramsey County. 3. Provide a copy of the NPDES permit. 4. Provide a site-specific maintenance plan that includes items a.-d. in the April 12, 2019 permit report. 5. Revise plans to address items a.-b. in the April 12, 2019 permit report. 6. Clarify underground infiltration system type. Plan indicates a 66” diameter Contech CMP system, but the HydroCAD storage indicates a 60” dimeter ADS system. Additionally, sheet C6.02A indicates 6 rows of 126 ft pipe and 3 rows of 77 ft pipe, whereas the Contech detail on Sheet C9.02 indicates 5 rows of the longer pipe and 3 rows of the shorter pipe with a header row. 7. Submit XPSWMM model to verify input and output parameters with the plans. The submitted XPSWMM screenshots could not be cross-referenced with the design plans. Consider submitting the electronic model(s) with drainage areas maps and /or site plan as the background image. Reider/Jones Unanimously approved B) Permit 19-011 Summit Ave Bridge Reconstruction (Hosch) Ms. Hosch reviewed permit #19-011 Summit Avenue Bridge Reconstruction. The applicant, St. Paul Public Works is planning bridge and roadway reconstruction. The applicable rules are Stormwater Management (Rule C), and Erosion and Sediment Control (Rule F). The disturbed area of this project is 3.99 acres with 1.51 acres’ impervious surface. Motion 19-052: Approve permit #19-011 Summit Ave. Bridge Reconstruction with three conditions: 1. Provide a copy of the NPDES permit. 2. Revise plans to address conditions a.-d. on the April 11, 2019 permit report. 3. Provide filtration volume calculation. Volume presented in the stormwater narrative cannot be verified in the plans. Consider providing the footprint of the top and bottom of the course filter aggregate. Sheet C55 shows an approximate BMP footprint of 5,900 sf. Assuming that this is the average footprint of the coarse filter aggregate layer, the rock voids provide approximately 8,260 cf of storage (5,900 sf x 3.5’ depth x 0.4 void ratio = 8,260 cf) which is less than what is stated in the narrative (395 cy x 27 cf/cy = 10,665 cf). Manger Texer asked if there was a relationship between this project and the Ayd Mill resurfacing. Ms. Hosch did not know if there was a relationship with the projects. Reider/Jones Unanimously approved

IV.

Special Reports No Special Report

V.

Action Items A)

AR:

Approve Minutes of the April 3, 2019 Regular Board Meeting (Sylvander).

Motion 19-053: Approve the Meeting Minutes of the April 3, 2019 Regular Board Meeting. Jones/Reider Unanimously approved B)

AR:

Approve March 2019 Accounts Payable/Receivable (Sylvander)

Motion 19-054: Approve March 2019 Accounts Payable/Receivable and March Budget Report, direct Treasure and Board President to endorse and disperse checks for these payments. Reider/Texer Unanimously approved C) AR: (Doneux)

Authorize Staff Positions for Regulatory and Water Resource Technician

Administrator Doneux reviewed that the 2019 Work Plan and Budget includes five full time employees for new positions within each of the five divisions at CRWD. The budget also includes two seasonal technicians, one for the Monitoring and one for the Regulatory Division. At the January 16, 2019 Board meeting the Managers approved the Urban BMP Technician, Administrative Assistant and Communication Associate positions. These positions are all entry level at Grade 6 with a salary range of $37,800 to $56,800. Diversity Plan elements that are included in this round include updates to the position description that reflect our intentions for diversity and inclusion in hiring. Staff will incorporate an external panelist for interviews. All interview panelists will undergo implicit biased training. Motion 19-055: Approve new staff positions for Water Resource Technician and BMP Inspector and authorize staff to advertise and fill these positions. Reider/Sanders Unanimously approved D)

AR:

Approve Annual Report (Bromelkamp)

Ms. Bromelkamp reviewed that all metropolitan watershed management organizations are required by Minnesota Statute 103.B to submit an annual Activity Report, Financial Report and Financial audit to the Minnesota Board of Water and Soil Resources (BWSR).

Ms. Bromelkamp will be taking feedback till the end of this week. Staff have requested feedback from the Citizen Advisory Committee (CAC) about the general format and contents of the report as well as how best to share this information with residents by April 19, 2019. Manager Reider asked for a photo of the CAC group to be more clearly identified, the picture is located close to an engineering groups photo. Manager Texer asked for clarification on other projects that were started in prior years. Administrator Doneux replied that he would address projects in the opening letter. Overall the Managers were pleased with the report and felt it was easy to read with so many pictures helping tell the project stories. Motion 19-056:

Approve the 2018 Annual Report for submission to BWSR.

Texer/Jones Unanimously approved E)

AR:

Authorize Solicitation of RFQs for Professional Services (Zwonitzer)

Mr. Zwonitzer shared the policy adopted to solicit professional services. The last time CRWD staff have solicited qualifications from consultants was in early 2017 for the 2017-2018 consultant pool. As part of CRWD’s diversity and equity initiative, staff identified approximately 90 Minnesota businesses that meet WBE (women-owned) or MBE (minority-owned) certifications through MNUCP (Federal/State database) and/or CERT (Metro database administered by St. Paul). The RFQ will be sent to those firms in addition to firms on the pervious RFQ distribution list (143 firms total). Expanding search for consultants. By May 17th. Motion 19-057: 2019-2020.

Authorize solicitation of qualifications for professional services contracting for

Texer/Reider Unanimously approved F)

AR:

Approve Contract with Kidzibits for Interactive Water Exhibit (Eleria)

Ms. Eleria shared with the Board of Managers a final concept rendering of the water feature for CRWD’s pocket park. The pocket park will have three distinct areas – an interactive water exhibit, stream and shallow pond. The elements of the park tie into the 2010 Watershed Management Goal of “Brining Water Back” to the community. Ms. Eleria reviewed how the exhibit has been designed to represent a small-scale urban watershed that utilizes rainwater from the CRWD cistern. The exhibit will encourage visitors to decide where rainwater should be directed into an urban landscape or down a storm drain without removal of pollutants. Visitors will be able to control who the water flows. When the visitor selects the option to flow water thru the exhibit, they will be able to see water passing thru the display and move butterflies in the exhibit. The exhibit has been designed with a 10 year old in mind. Manager Texer shared concerns about the exhibit being removed for winter storage. Ms. Eleria shared that the exhibit was designed to be kept outdoors, the materials used to build the exhibit were selected so that it can be kept outdoors. Manager Reider asked about any signage to explain the exhibit. Ms. Eleria

replied that there would be signage. Administrator Doneux added that the signage would illustrate the desired path, Manager Jones recommended that the image of the exhibit be used in educational materials. Manager Jones also recommended adding a human image into the exhibit plan to help with the scale of the model. Motion 19-058: park.

Approve contract with Kidzibits for interactive water exhibit in CRWD’s pocket

Reider/Sanders Unanimously approved G)

AR: Authoirze Solicitation of RFQs for Operation and Maintenance Services at Snelling Midway Redevelopment Site (Kelley)

Mr. Kelley reviewed that CRWD and the City of St. Paul are currently drafting a cooperative agreement for operation and maintenance of the rainwater harvesting and reuse system constructed as part of the Allianz Field redevelopment. The agreement states that CRWD will be reimbursed for all staff and contractor costs associated with managing the system. Mr. Kelley shared a Request for Qualifications (RFQ) that summarizes the anticipated work and level of effort to operate with components of the rainwater treatment system. The timeframe for transferring ownership of public infrastructure from Mortenson Construction to the City of St. Paul, and coordinating trainings for operation of the system, results in the accelerated schedule to have the maintenance firm selected in May. Staff feel it is important that the RFQ be reviewed by city staff prior to distribution. Motion 19-059: Authorize Distribution of Request for Qualifications to provide Operation and Maintenance Services for Rainwater Reuse System at the Snelling-Midway Redevelopment. Reider/Jones Unanimously approved H)

AR:

Authorize Purchase of District Vehicle (Sylvander)

Ms. Sylvander asked the board for authorization to purchase an additional vehicle. The Regulatory & PPG divisions have budgeted funding for an additional vehicle. Staff are requesting the purchase of a 2019 Ford Fusion from Midway Ford. President Collins asked about the charging stations. Manager Jones asked if anyone could use the charging stations. Administrator Doneux replied that the changing station can be programmed to only operate during business hours. Motion 19-060: Authorize Administrator to purchase a 2019 Ford Fusion Titanium from Midway Ford for an amount not to exceed $31,000. Reider/Sanders Unanimously approved

VI.

Unfinished Business A) Como Park BMPs Design Update (Kelley)

Mr. Kelley provided an update on the Como Park BMP. There will be 2 BMPs, one will be adjacent to the Zoo near the Polar Bear exhibit. The other will be located near the golf course pond. Meetings are scheduled with the golf course about shutting down parts of the course and setting up temporary holes. Manager Jones inquired about building up the area around the pond making sense for future plans for the golf course. Mr. Kelley replied that this would save money for the project and would keep the gold course functional. No was action was taken. Information provided as an update. B) Watershed Management Plan Update (Eleria) Ms. Eleria shared that the first phase of soliciting feedback is starting. Resource materials have been completed. Four events have been planned in May & early June. Ms. Eleria shared a flyer with the managers with the dates and locations listed. A survey of 10 questions related to plan is available online. A shortened version of the survey has been made available for community events. President Collins suggested contacting council person Amy Brendmoen, she puts out a monthly newsletter and could possibly include this information. Manger Texer asked to have the flyer sent to her as a PDF for sharing. Ms. Eleria will be sending the Board Managers an email requesting three members to attend the technical advisory meeting. For the week of May 20th. No action was taken, information shared as an update. C) Website Updates (Bromelkamp) Ms. Bromelkamp provided the Board of Managers an overview of the website, demonstrating the pages and drop-down menus. Ms. Bromelkamp demonstrated how the site projects can be viewed thru a map or list. Each project includes a description of the location, problem, solution, and the results. Mr. Zwonitzer helped with designing maps for the site. The website includes many pictures, not all projects were included on the site. A large variety of projects were highlighted. Information has been connected to the website such as board meeting minutes and permitting applications. The monitoring & research tabs allows viewers to search information and view customizable data. Maps show the numerous monitoring stations. The “Act Now Page” directs residents on how to get involved and what they can do. Viewers of the site can visit the “News & Events” tab to see upcoming events and read articles about past events. Managers were very pleased with the new website. No action was taken, information provided as an update for the managers. VII. A)

General Information

Board of Managers Updates

Mangers Texer, Reider, and Collins attended the Moos Family Lecture. Administrator Doneux will send the managers a link. Administrator Doneux shared that the solar panels are installed and just need to be connected.

VIII. Next Meetings A) B)

Wednesday, April 24, 2019 CAC Meeting, 7:00 PM, Wednesday, May 1, 2019 Board Meeting

IX.

Adjournment

Motion 19-061: Adjournment of the April 17, 2019 Regular Board Meeting at 7:22 p.m. Reider/Sanders Unanimously Approved Respectfully submitted, Michelle Sylvander

May 1, 2019 Board Meeting

DATE: TO: FROM: RE:

April 25, 2019 CRWD Board of Managers Britta Belden, Water Resource Project Manager 2019 Quality Assurance Program Plan (QAPP)

V.B. Accept 2019 Quality Assurance Program Plan (Belden)

Background In 2016, CRWD staff developed and implemented a Quality Assurance and Program Plan (QAPP) to guide the CRWD monitoring program. The QAPP guides the CRWD monitoring program by: a) defining data quality assurance goals and procedures; and b) summarizing the program design, sampling methods, analytical procedures, and data review protocols. The contents of a QAPP ensure that quality assurance objectives and regulatory needs are being met. Monitoring data collected using an approved QAPP have strong credibility with outside parties and allow the District to confidently utilize the data to make regulatory decisions. The first version of the CRWD QAPP was presented at the September 7, 2016 meeting and accepted by the Board of Managers. The QAPP is updated annually to reflect any changes that have been made to the CRWD monitoring program as it relates to staffing, monitoring stations, monitoring procedures, and laboratory protocols. Issues The revised CRWD QAPP (enclosed) was updated to reflect changes that have been made to the monitoring program since the last update of the QAPP in 2018. CRWD staff are requesting acceptance of 2019 QAPP by the Board of Managers to formally endorse its use in the CRWD Monitoring Program. If you would like a printed copy of the 2019 QAPP please contact the CRWD office staff. Requested Action Accept the 2019 Quality Assurance Program Plan. enc:

CRWD Quality Assurance and Program Plan, draft dated 04/25/2019 (Digital Only)

"W:\07 Programs\Monitoring & Data Acquisition\Monitoring Protocols\Quality Assurance Program Plan (QAPP)\2019 QAPP\Board Meeting\Board Memo_QAPP Update_04-25-19.docx"

Monitoring Quality Assurance Program Plan Capitol Region Watershed District – St. Paul, Minnesota

Approved: September 2016 Updated: April 25, 2019

By my signature below, I attest that I am familiar with the requirements of this document and agree to fulfill the responsibilities specified herein.

_____________________________________________ Bob Fossum, CRWD Monitoring Program Division Manager

____________________ Date

_____________________________________________ Britta Belden, CRWD Water Resource Project Manager

____________________ Date

1

Table of Contents 1.0 Introduction ............................................................................................................................................. 5 1.1 Program Background .................................................................................................................. 5 1.2

Program Description ................................................................................................................... 6

1.3 Quality Objectives and Criteria ....................................................................................................... 1 1.4 Monitoring Variables and Frequency.............................................................................................. 1 2.0 Program Organization and Responsibilities ............................................................................................ 3 2.1 Capitol Region Watershed District Responsibilities ................................................................... 3 2.2 2.3

Laboratory Service Responsibilities ........................................................................................... 4 Stakeholders, Partners, and Agencies Responsibilities ............................................................... 4

2.4 Relationship of QAPP to Other Guidance Documents ................................................................... 4 3.0 Field Measurement Equipment ............................................................................................................... 5 3.1 ISCO 6712 Automated Sampler ................................................................................................. 5 3.2 ISCO 2100 Flow Modules .......................................................................................................... 6 3.3 ISCO Model 750 ............................................................................................................................. 7 3.4 Field Equipment Maintenance and Calibration ............................................................................... 7 4.0 Field Sampling Methods ......................................................................................................................... 8 4.1 Field Activity Preparation and Field Decisions .......................................................................... 8 4.2

Sampling Procedures .................................................................................................................. 8 4.2.1 Flow-Weighted Composite Sampling Procedure ........................................................... 9 4.2.2

4.3

4.4

Grab Sampling Procedures .......................................................................................... 10

Sample Bottle Preparation and Equipment Cleaning ................................................................ 12 4.3.1 4.3.2

ISCO Sampler Bottles and Equipment Cleaning ......................................................... 12 MCES Laboratory Submission Containers and Preservatives ..................................... 13

4.3.3

Private Laboratory Submission Containers and Preservatives..................................... 13

QA/QC Sampling Methods ....................................................................................................... 13 4.4.1 4.4.2

Equipment Blank Sampling Method ............................................................................ 14 Composite Duplicate Sampling Method ...................................................................... 14

4.4.3 Grab Replicate Sampling Method.................................................................................... 15 5.0 Quality Assurance Objectives ............................................................................................................... 16 5.1 Precision.................................................................................................................................... 17 5.2

Accuracy ................................................................................................................................... 18

5.3

Completeness ............................................................................................................................ 18

5.4

Sensitivity ................................................................................................................................. 19

5.5

Comparability ........................................................................................................................... 19

5.6

Representativeness .................................................................................................................... 19

6.0 Field and Sample Custody Documentation ........................................................................................... 21 6.1 Field Forms ............................................................................................................................... 21 6.2

Analytical Data Review ............................................................................................................ 22 2

6.3

Sample Identification ................................................................................................................ 22

6.4 6.5

Chain of Custody ...................................................................................................................... 23 Sample Handling and Transport ............................................................................................... 23

7.0 Quality Assurance Procedures .............................................................................................................. 24 7.1 Laboratory Quality Assurance Procedures ............................................................................... 24 7.2 CRWD Quality Assurance Procedures ........................................................................................ 24

7.3

7.2.1

Data Management ........................................................................................................ 24

7.2.2

Data Review and Validation ........................................................................................ 25

Corrective Action ...................................................................................................................... 29

8.0 Data Assessment and Reporting ........................................................................................................... 29 8.1 Internal Quality Assessments .................................................................................................... 30 8.2

Electronic Data Reporting......................................................................................................... 30

8.3

Annual Reporting of Monitoring Data ...................................................................................... 30

9.0 References ............................................................................................................................................. 31

3

List of Tables Table 1

2019 CRWD Monitoring Station Locations

Table 2

Monitoring Parameters, Minimum Frequencies, and Typical Frequencies.

Table 3

2019 CRWD Monitoring Personnel

Table 4

Types of Equipment Blanks Performed by CRWD

Table 5

2019 Duplicate and Replicate Naming Conventions for CRWD Full Water Quality sites

Table 6

QA/QC Methods Employed to Reach QAOs

Table 7

Laboratory Sample Parameters, Analytical Method, and Holding Times

Table 8

WISKI Quality Codes and Standard Remarks

Table 9

Steps for various flow data editing scenarios in WISKI List of Figures

Figure 1

2019 CRWD Monitoring Station Location Map

Figure 2

Flow chart of monitoring seasons, flow event types, and sample collection methods

List of Attachments Appendix A

CRWD Organizational Chart

Appendix B

Field Standard Operating Procedures

Appendix C

Sample Chain of Custody

Appendix D

Laboratory Quality Assurance Manual and Standard Operating Procedures Distribution List

Name

Title/Organization

Mark Doneux

Administrator, CRWD

Bob Fossum

MRM Division Manager, CRWD

Britta Belden

Monitoring Coordinator, CRWD

Joe Sellner

Water Resource Specialist, CRWD

Sarah Wein

Water Resource Technician, CRWD

Mark Houle

Water Resource Technician, CRWD Planning, Projects, and Grants Program Manager CRWD Regulatory Division Manager, CRWD

Anna Eleria Forrest Kelley

Address 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104 595 Aldine Street, St. Paul, MN 55104

4

E-mail mark@capitolregionwd.org bob@capitolregionwd.org britta@capitolregionwd.org joe@capitolregionwd.org sarah@capitolregionwd.org mhoule@capitolregionwd.org anna@capitolregionwd.org forrest@capitolregionwd.org

1.0 Introduction This Monitoring Quality Assurance Program Plan (QAPP) guides water quality and quantity monitoring for the Capitol Region Watershed District (CRWD). It outlines sample collection and analysis procedures.

1.1

Program Background

CRWD is a special purpose unit of government in Ramsey County, Minnesota that manages and protects water resources within its watershed boundaries. CRWD is a 41-square mile watershed nested in the Upper Mississippi River basin that contains portions of five cities, including Falcon Heights, Lauderdale, Maplewood, Roseville, and Saint Paul. CRWD is highly urbanized with a population of 245,000 and 42% impervious surface coverage. All runoff from CRWD eventually discharges to the Mississippi River from 42 outfall locations along a 13-mile reach. The water resources within the District (streams, lakes, wetlands, and stormwater) are monitored by CRWD in addition to other partnering entities. CRWD monitors streams, stormwater, and best management practices (BMPs) within the District. Lakes water quality monitoring is completed by Ramsey County Public Works (RCPW).

The Mississippi River is monitored by Metropolitan

Council Environmental Services (MCES), the United States Geological Survey (USGS), the Army Corps of Engineers, and the Minnesota Pollution Control Agency (MPCA). The City of St. Paul also monitors stormwater water quality and BMP performance at several locations throughout the District. The primary objectives of the CRWD monitoring program are to identify water quality problems, quantify the subwatershed runoff pollutant loadings to the Mississippi River or other receiving water bodies, evaluate the effectiveness of BMPs, provide data for the calibration of hydrologic, hydraulic, and water quality models, and promote understanding of District water resources and water quality. CRWD also conducts stormwater monitoring to assist the City of St. Paul in meeting the monitoring requirements for the Phase I Municipal Separate Storm Sewer System (MS4) Permit (MPCA, 2016).

5

1.2

Program Description

CRWD operates several monitoring stations to collect data that helps meet the goals of the monitoring program. Each monitoring station is strategically located throughout the District to gather meaningful data needed to meet the monitoring program goals. Data collected may also be needed to support a specific CRWD project. The types of data CRWD gathers includes: 1) Continuous flow data in storm sewers, stream channels, and BMPs; 2) Water quality data in storm sewers, streams, BMPs lakes, and wetlands; 3) Continuous level data in lakes, stormwater ponds, and BMPs; and, 4) Precipitation data from rain gauges. Table 1 and Figure 1 show all monitoring station locations operated by CRWD in 2019. Stations categorized as “Full Water Quality” indicate that both flow (continuous) and water quality samples are measured and that the station is located in either a storm sewer, stream channel, or BMP. Stations listed as “Flow Loggers” measure the volume of water continuously flowing through a system. The “Level Logger” stations are measuring continuous water level in a lake, stormwater pond, or BMP. The “Rain Gauges” are measuring precipitation data from either (or both) manual or automated rain gauges during non-winter months. The “Grab Sample” stations are locations where only a water quality grab sample is taken during a targeted hydrologic event. In 2019, the CRWD monitoring program includes 19 full water quality monitoring stations (Table 1; Figure 1). At full water quality stations, flow is conveyed as either event flow (stormwater, snowmelt, or illicit discharge) or baseflow through either a storm sewer, stream channel, or BMP. The majority of the full water quality stations monitored in 2019 are located in storm sewers. Baseflow, or dry weather flow, is present in storm sewers at many full water quality monitoring stations. Baseflow at these stations is constant with continuous flow throughout the entire year and is generally driven by groundwater and surface water connections. At all full water quality monitoring stations, flow data (level, velocity, discharge) is collected for both event flow and baseflow. Stations with baseflow are monitored year-round whereas stations that do not have baseflow are monitored seasonally from April to November when active runoff from precipitation is occurring. Water quality samples are also taken at these stations during both event flow and baseflow periods (if baseflow is present) via automated samplers and/or grab sample methods. Samples are analyzed for a suite of water quality parameters by an analytical laboratory. The sample results are utilized in conjunction with the flow data to calculate loads of various 6

pollutants, such as total phosphorus (TP) and total suspended solids (TSS). Data are summarized and analyzed in an annual monitoring report and online in the CRWD Water Data Portal. Flow logger stations are installed at 12 locations in 2019 to record water discharging through a storm sewer or from a surface water (Table 1; Figure 1). At these stations, continuous flow data (level, velocity, discharge) is measured and recorded seasonally from April to November. From the measured flow data, a volume of water discharged is calculated. Water quality samples are not taken at these locations. Continuous water level data is collected at 26 level logger stations in 2019 (Table 1; Figure 1). Level loggers measure and record 15-minute data to observe water level fluctuations in lakes, stormwater ponds, and BMPs. Level logger stations are installed seasonally from April to November during open water periods. Water quality samples are not taken at these locations. Precipitation stations measure rainfall amount and intensity using manual and automatic rain gauges at 7 locations in CRWD (Table 1; Figure 1). Precipitation stations are distributed across CRWD in order to capture the spatial variation in rainfall across the District. Rainfall is measured seasonally from April through November. Winter snowfall data is not collected by CRWD precipitation stations and is instead supplemented by external climate observation groups. Water quality grab samples are taken at 15 stations in 2019 generally within 24 hours of a rain event (Table 1; Figure 1). The stations listed in Table 1 for grab samples each have a unique monitoring plan that requires a water quality grab sample to fulfill the requirements of the program or project in question. Grab samples may also be taken at stations that have an automated sampler installed during the monitoring season if the sampler is either not working or is not installed. Baseflow and event flow grab sampling procedures are described in Section 4.2.2. Continuous dissolved oxygen data is measured at 1 station in 2019 (Table 1, Figure 1). At this station, a floating DO sensor will be situated at the deepest point in a wet pond. The DO logger will be installed seasonally from April to November during open water periods. Water quality samples are not taken at this location.

7

Table 1: 2019 CRWD Monitoring Station Locations. CRWD 2019 Monitoring Stations Flow Loggers Full Water Quality a, b

St. Anthony Park

Hidden Falls Outlet East Kittsondale Phalen Creek

a, b

a, b

a, b

Trout Brook Outlet

a, b

Trout Brook-East Branch a, b Trout Brook-West Branch Villa Park Outlet Villa Park Inlet

a, b

b

b

Como 3 a Como 7 a Midway Office Inlet

a

North Como 3 a

Level Loggers

Grab Sample

AHUG Inlet

AHUG Level

CRWD Office

GC Clubhouse Pond

Como Outlet

Alameda Pond

MMCD Office

GC Parking Lot Pond

Hidden Falls 30" Pipe

Arlington-Jackson

St Paul Firestation

MOW - Central Deep

McCarrons Outlet

Como Lake Level

TBEB

MOW - Central Shallow

TBNS - Magnolia

Crosby Lake

Villa Park

MOW - East Deep

TBNS - Jenks

GC Clubhouse Pond

Western District Police

MOW - East Shallow

TBNS - Rose Overflow

GC East Pond

Firestation 18

MOW - West Deep

TBO - SP Tunnel

GC Parking Lot Pond

MOW - West Shallow

Upper Villa Bypass

Golf Course Pond

Sims-Agate Outlet

VP - Out Overflow Channel McMurray Well

Upper Villa Cistern

VP - In Overflow Channel

Midway Office Piezometer

Upper Villa Pipe Gallery

TBNS - Lift Station

Lake McCarrons

Upper Villa-West

Loeb Lake

Upper Villa-Center

Sims-Agate

Upper Villa-East

Victoria Park Pond

William St. Pond

TBNS-Rose a TBNS-Stream Upper Villa Inlet

Precipitation

a

Dissolved Oxygen Villa Park Wet Pond

Westminster-Mississippi

Parkview Center School 1 a

William Street Pond

Parkview Center School 2 a

Albert SWP - EAST

Parkview Center School 3 a

Aldine SWP Griggs SWP - NORTH Marion RG - NORTHWEST Oxford SWP - SOUTH Pillsbury RG - NORTH Syndicate RG Lexington Tree Trench Western Tree Trench 19

a

Station location is in a storm sewer

b

Station location observes continuous baseflow

12

26

0

7

15

1

Figure 1: 2019 CRWD Monitoring Station Location Map.

0

1.3 Quality Objectives and Criteria The primary goal of this QAPP is to define the data quality assurance goals and quality assurance procedures that are applicable to the CRWD monitoring program. The CRWD monitoring program strives to produce consistent and reliable data; however, non-routine situations may arise for rapid response monitoring (e.g. illicit discharge detection and elimination (IDDE)) or monitoring a new location. This plan includes best practices that can be applied to both routine and non-routine monitoring circumstances. Water quality sample results collected through this monitoring program may indicate environmental and/or human health concerns that require corrective actions and/or long-term management decisions. Therefore, sampling and analysis must meet specified quality assurance and quality control objectives to accurately characterize the conditions within the district. This QAPP reflects the need for data of acceptable quality, while recognizing financial and technical constraints. The detailed data quality assurance objectives are discussed later in this plan.

1.4 Monitoring Variables and Frequency The types of water quality samples collected by the CRWD monitoring program are determined by the time of year, the flow event type, and the method of sample collection (automated versus grab) (Figure 2). At “full water quality� stations, automated samplers are installed for the duration of the field season, roughly April to November. Event samples are collected by the automated samplers during and/or after storm events, either as flow-weighted composite samples or as grab samples. At full water quality stations that have continuous baseflow, the automated samplers are programmed to take baseflow samples on a monthly basis during the field season as conditions allow. At these stations, baseflow samples are also taken during winter months (December-March) as grab samples because the automated samplers are not deployed during that time. Snowmelt grab samples are also taken at all full water quality stations if there are two consecutive days above freezing, and flow is entering the storm sewer. The suite of water quality parameters that samples are tested for under the CRWD monitoring program are listed in Table 2. Water quality samples are analyzed for specific parameters generally at a minimum frequency defined in the City of St. Paul’s MS4 Permit. Parameter analysis is also dependent on the amount of time that has passed since the sample was collected (holding time), the total sample volume, and the specific water quality concerns or sampling plan for a station. 1

Composite, after event Event flow Grab, during event

Field Season (April- November)

Winter

Baseflow (baseflow sites only)

Composite, monthly

Baseflow (baseflow sites only)

Grab, monthly

Snowmelt

Grab, as available

(December-March)

Figure 2: Flow chart of monitoring seasons, flow event types, and sample collection methods.

Table 2: Monitoring Parameters, Minimum Frequencies, and Typical Frequencies. Parameter

Frequency (required by

Sample Type

Ammonia Nitrogen

Composite

BOD - Carbonaceous 5-day Cadmium Chloride Chromium Copper

Composite Composite Composite Composite Composite

E. coli Flow (from level and velocity)

Grab Measurement

Fluoride Hardness Lead Nickel

Composite Composite Composite Composite

Nitrite Plus Nitrate, Total (as N) Ortho Phosphate pH

MS4 permit)

Typical Frequency

Quarterly

35 per year

Grab Grab Grab Grab Grab

Quarterly Not Required 15 per year Not required Monthly

Quarterly 35 per year 35 per year 35 per year 35 per year 22 per year Every 15 minutes w/ sampler

Grab Grab Grab Grab

Quarterly Every 15 minutes w/ sampler Not Required Monthly Monthly Not Required

Composite Composite Composite or Grab

15 per year Quarterly Quarterly

35 per year Quarterly Quarterly

Potassium

Composite or Grab

Not Required

4 per year (For illicit discharge)

Sulfate Surfactants Total Dissolved Solids Total Kjeldahl Nitrogen Total Phosphorus Total Suspended Solids

Composite or Grab Composite or Grab Composite Composite Composite Composite

2 per Year Not Required Quarterly 15 per year 15 per year 15 per year

Quarterly 4 per year (For illicit discharge) 35 per year 35 per year 35 per year 35 per year

Volatile Suspended Solids Zinc

Composite Composite or Grab

15 per year Monthly

35 per year 35 per year

or or or or or

or or or or

2

4 per year (For illicit discharge) 35 per year 35 per year 35 per year

2.0 Program Organization and Responsibilities Personnel associated with the CRWD monitoring program and their contact information are presented in Table 3. Monitoring is overseen by the Program Manager and Monitoring Coordinator. Water Resource Technicians are responsible for the majority of the field work, with occasional help from other CRWD staff. Technicians are also responsible for reviewing data and assessing the QA/QC practices outlined in Section 4.4. The complete CRWD organizational chart can be found in Appendix A.

Table 3: 2019 CRWD Monitoring Personnel. Position

Name*

Organization

Phone Number

Program Manager

Bob Fossum

CRWD

651-644-8888

Monitoring Coordinator

Britta Belden

CRWD

651-644-8888

Quality Assurance Manager

Anna Eleria

CRWD

651-644-8888

Water Resource Specialist

Joe Sellner

CRWD

651-644-8888

Water Resource Technician

Sarah Wein

CRWD

651-644-8888

Water Resource Technician

Mark Houle

CRWD

651-644-8888

Water Resource Intern

Tanner Johnson

CRWD

651-644-8888

* Staff are subject to change

2.1

Capitol Region Watershed District Responsibilities

CRWD staff are responsible for coordinating and conducting field operations for the monitoring program and meeting the quality assurance objectives outlined by the QAPP. District staff install, operate, and maintain monitoring equipment at each of the monitoring stations, collect water quality samples, download hydrologic data, select new stations for monitoring, and remove stations no longer needed. District staff are also responsible for reviewing analytical laboratory and hydrologic (level, flow, and discharge) data for quality assurance. CRWD staff are responsible for preparing annual work plans and scoping documents, filling out laboratory sample chain of custody (COC) documents, preparing annual reports, and submitting data to the City of St. Paul, and other partners and stakeholders. 3

2.2

Laboratory Service Responsibilities

Water quality samples are currently submitted to Metropolitan Council Environmental Services (MCES) for analysis. The analytical laboratory is responsible for receiving samples from CRWD, receiving and processing chain of custody documents, analyzing samples based on the method specification, and providing sample results. The analytical laboratory is also responsible for ensuring all QA/QC procedures are in place and followed for all laboratory functions. The analytical laboratory’s QA/QC procedures, including organizational structure, laboratory procedures and qualifications, can be referenced in the Laboratory Quality Assurance Management Plan (QAM) in Appendix C. Other qualified analytical laboratories may be contracted to perform the routine analytical work or work beyond the scope of this QAPP. Prior to contracting with other laboratories for analytical services, CRWD staff will review their Quality Assurance Manual and ensure it is consistent with the CRWD QAPP. Laboratory reports containing results of submitted water quality samples are accessed by CRWD from the MCES online database once per month. Records of laboratory results are saved electronically to the CRWD server and are imported into the WISKI database.

2.3

Stakeholders, Partners, and Agencies Responsibilities

CRWD’s Board of Managers, Citizen Advisory Committee, other District staff, and the general public provide input on CRWD monitoring activities. Other units of government and consultants can suggest possible areas of collaboration or express areas of environmental concern, which also helps direct the CRWD monitoring program. Citizen groups, neighborhood groups, and city councils have historically been sources of direction for monitoring priorities. The MPCA, research institutions (e.g. the University of Minnesota), and MCES review annual reports and data. The cities of St. Paul, Falcon Heights, Roseville, Lauderdale, and Maplewood review annual reports as well.

2.4 Relationship of QAPP to Other Guidance Documents This QAPP is one of several documents that guide the CRWD monitoring program. Contained in this QAPP are summaries of the program design, sampling methods, analytical procedures, and data review protocols. The CRWD monitoring program Standard Operating Procedures (SOPs) provide a 4

more in-depth description of sampling procedures, field analysis laboratory analysis, and data review (Appendix B). This QAPP and the CRWD monitoring program SOPs are available to staff for electronic review on the CRWD server and in printed form. SOPs are compiled annually into a printed handbook and are available to staff in monitoring trucks and the shop area.

3.0 Field Measurement Equipment This section outlines the field measurement equipment used in CRWD’s monitoring program. At each monitoring station, equipment is either housed in a steel box enclosure above-ground or hung in a manhole by a suspension bracket. Each full water quality monitoring station consists of an automated sampler with intake tubing and sieve, a flow logger with a sensor, and a power source (i.e. deep-cycle battery, 6-volt batteries, or a solar panel). CRWD uses two different sizes of ISCO 6712 automated samplers: compact and full-sized. For measuring and recording level and flow data, ISCO 2150 flow modules or ISCO 750 flow modules are used. At each station, level and velocity are measured by the sensor that is mounted on a plate in the center of the channel or pipe and then recorded by the flow logger in 5 or 15-minute intervals. From the level and velocity measurements, discharge (Q) is calculated by multiplying the water level by the channel shape or pipe diameter using Equation 1: �� = �� × ��

(Equation 1)

Other standard equipment for each monitoring station includes a power source (12-volt marine battery or solar setup) and connection cables for ISCO 6712 units. Periodic inspections of field measurement equipment and their components will be performed to assure their use as specified in their respective manuals and this QAPP.

3.1

ISCO 6712 Automated Sampler

ISCO 6712 automated samplers are used to collect flow-weighted composite samples during the monitoring season. Discrete 200-mL samples are extracted by the automated sampler at a preprogrammed flow-paced rate into a 24 bottle carousel and then combined into one composite sample to be submitted for analysis. Sample volume calibrations are done when the sampler is

5

installed, and as needed (Section 3.4). The procedure for flow-weighted composite sampling is described in Section 4.2.1. Two different sizes of ISCO 6712 automated samplers are used: •

ISCO 6712 Full-Size Portable Sampler: 24 1000-mL ISCO sampler bottles. Collects four 200-ml samples per bottle, for a total of 96 discrete samples.

•

ISCO 6712c Compact Portable Sampler: 24 500-mL ISCO sampler bottles. Collects two 200-ml samples per bottle, for a total of 48 discrete samples.

Each automated sampler has internal desiccant packets placed inside the electronic control panel to absorb moisture. The ISCO 6712 sampler instruction manual is available in the CRWD office and online and provides directions for operating, maintaining, and calibrating samplers (ISCO, 2015).

3.2

ISCO 2100 Flow Modules

ISCO 2100 area-velocity sensors and 2150 flow modules are programmed to continuously measure water level and velocity at 15-minute intervals. During events with increased flow, measurements are taken at 5-minute intervals. Most stations with the ISCO 2100 setup are equipped with a series of modules, including the ISCO 2150, 2105, and 2191 modules. ISCO 2150 modules log flow data measured by an area-velocity (AV) sensor that is mounted in the center of the channel or pipe. Water levels are measured by the AV sensor using a pressure transducer and velocity is detected by the sensor transmitting a continuous ultrasonic wave, and then measuring the frequency shift of returned echoes reflected by air bubbles or particles in the flow. The ISCO 2105 modules interface between the ISCO 6712 sampler and the 2150 area velocity module, triggering the sampler to collect samples based on a pre-programmed water level, velocity, or flow threshold as measured by the sensor. ISCO 2191 modules house battery units to power the all of the 2100 modules. Each module has internal an desiccant cartridge to prevent moisture inside. Desiccant indicators located inside the ISCO 2150, 2105, and 2191 modules are inspected regularly and exchanged as needed. The ISCO 2150 module instruction manual is available in the CRWD office and online and provides directions for operation, maintenance, and calibration (ISCO, 2012a & ISCO 2012b).

6

3.3 ISCO Model 750 ISCO area-velocity sensors and 750 flow modules are programmed to continuously measure water level and velocity at 15-minute intervals. Flow is measured using submerged sensors that are mounted in the flow stream. ISCO 750 modules have no temperature coefficient calibration. Water levels are measured by the AV sensor using a pressure transducer and velocity is detected by the sensor transmitting a continuous ultrasonic wave, and then measure the frequency shift of returned echoes reflected by air bubbles or particles in the flow. The ISCO 750 modules have an internal desiccant cartridge to prevent moisture inside. Desiccant cartridges are inspected at each site visit, and exchanged as needed. The ISCO Model 750 instruction manual is available in the office and online and provides directions for operation, maintenance, and calibration (ISCO, 2013).

3.4 Field Equipment Maintenance and Calibration CRWD staff monitor the performance of equipment and instruments in the field during routine site visits. CRWD staff will work to resolve deficiencies as they are discovered, and replace components as needed. If necessary, equipment can be tested in the CRWD shop using a controlled level testing apparatus and/or a velocity testing flume. Equipment may be sent back to the manufacturer if deficiencies cannot be resolved by CRWD staff. The Monitoring Coordinator will provide the final decision on the usability of damaged equipment. ISCO 6712 samplers require frequent attention to assure their intended use. Intake tubing is replaced annually to prevent sample contamination. Pump tubing is replaced after 1,000,000 turns of the sampler pump or if wear or damage is visible. ISCO 6712 samplers and attached flow modules and AV sensors need to record accurate level measurements and pump precise sample volumes. To ensure accuracy, these mechanisms must be calibrated at the time of installation and as needed throughout the field season. To calibrate sample volumes, the sampler is manually triggered to pump a set volume (typically 200-mL). The pumped volume is measured in a graduated cylinder. The process is repeated until the desired sample volume is attained. ISCO AV sensors are calibrated once per month while installed. To calibrate the level, a reference stage is manually measured in the flow in front of the sensor with a ruler. This is compared against the real-time measurement logged by the 2150 module. If the module measurement and the reference measurement differ by more than 0.1 foot, the difference is noted in the field notes to be 7

later adjusted during the database QA/QC data editing process in the WISKI database. No adjustments should be made to the instrument in the field.

4.0 Field Sampling Methods This section defines procedures to be used for collecting and handling water quality samples. Unforeseen circumstances may require deviations from these procedures. Such deviations will be approved by the Monitoring Coordinator prior to sampling. If prior approval cannot be obtained, deviations from the established procedures will be recorded and the need for resampling will be evaluated at that time.

4.1

Field Activity Preparation and Field Decisions

Upon arrival at each monitoring location, field conditions are noted in the electronic field form. Any unusual condition will be recorded on the electronic field form. Conditions that may interfere with obtaining representative analytical results will be rectified before sampling proceeds and noted in the field form. Minor changes to the field protocol can be made by the field technicians if prior approval cannot be obtained. Changes will be reviewed with the Monitoring Coordinator retroactively to decide whether or not locations need to be re-sampled. For significant changes to this protocol, approval will be obtained in advance from the Monitoring Coordinator. The Monitoring Coordinator will review any changes to the protocol that may adversely affect results before proceeding. Any deviations, minor or significant, are reviewed by the Monitoring Coordinator during the writing of the annual report.

4.2

Sampling Procedures

CRWD collects two different types of samples: flow-weighted composite samples and instantaneous discrete grab samples. Composite samples can only be taken by automated samplers and are generally taken for baseflow, storm, and illicit discharge events during the monitoring season while samplers are installed (April-November). Grab samples are taken when automated samplers are not

8

installed or if they are malfunctioning during the monitoring season. E. coli samples are always taken as grab samples. 4.2.1

Flow-Weighted Composite Sampling Procedure

Composite sampling by an automated sampler is conducted to collect a representative sample of a baseflow, storm, or illicit discharge event. The following equipment is used to collect composite samples: •

ISCO 6712 Full Size Portable Sampler or 6712c Compact Portable Sampler

•

24 sterilized 1000-mL or 500-mL plastic ISCO sampler bottles and caps arranged in a ISCO carousel configuration

•

8-L or 14-Liter churn, clean

•

Clean, labeled, 4-Liter laboratory submission container, or various laboratory submission containers with preservatives for private laboratory (if needed)

•

Cooler

The automated samplers are programmed to collect a discrete sub-sample for a given volume of water that passes through a channel at a flow-paced rate. Discrete 200-mL sub-samples are collected into 500-mL ISCO sampler bottles in compact samplers (48 sub-samples maximum per sampler), and into 1000-mL ISCO sampler bottles in standard samplers (96 sub-samples maximum per sampler). To collect storm composites, samplers are programmed with a trigger and a pacing to collect discrete sub-samples of the event. Trigger and pacing values may vary throughout the season, depending on flow conditions, antecedent moisture conditions, expected rainfall amounts, and other factors. If an illicit discharge is suspected, a sampler can be programmed with an adjusted trigger and pacing in an attempt to collect a representative sample of that event. Technicians retrieve full or partially full carousels from sites with automated samplers following a sampling event. Staff place ISCO sampler bottle caps on each sample bottle and transport them to the CRWD office to be composited in a churn. A churn is used to composite discrete samples from individual bottles into one homogenous sample. To composite, each ISCO sampler bottle in a carousel is vigorously shaken to agitate any sediment 9

that has settled out. The contents of each bottle are dumped into an 8-L or 14- L churn and then mixed for 30 seconds using the agitator. While being continuously mixed, the now composited sample is poured into a 4-L laboratory sample container. Composited samples are labeled by station name and sample date/time and then placed in a refrigerator at about 4 degrees Celsius. Within 24 hours of compositing, samples are placed in coolers, and transported to the analytical laboratory for analysis with a chain of custody accompanying each sample. If a carousel of samples exceeds the 14-L churn volume, sample bottles are divided into two sample sets. The above process is followed for each sample set; but, only 2,000 mL of each composited sample sets are distributed into the 4,000 mL submission containers. Base composite samples are collected monthly while ISCO samplers are installed during the field season. Sampler programs are paced in order to collect a full carousel (24 bottles) in approximately 24 hours at base flow levels. Samples are collected after the 24-hour cycle and taken back to the CRWD office to be composited using the same procedures for compositing storm samples. 4.2.2

Grab Sampling Procedures

Grab sampling is done in conjunction with composite sampling or as a standalone procedure. The following equipment is used to collect grab samples: •

Sampling bucket and rope, clean

•

Clean, labeled, 4-Liter laboratory sample container, or various laboratory sample containers with preservatives for private laboratory (as needed)

•

ISCO 6712 Full Size Portable Sampler or 6712c Compact Portable Sampler pump, or other external pump (Pump Collection method only)

•

Cooler and ice

If no composite sample is taken during an event due to equipment failure, a grab sample can be taken instead. At stations without an ISCO 6712 sampler installed, grab samples are collected. Outside of the monitoring season, base grab samples are taken once per month. Snowmelt grab sampling and illicit discharge grab sampling are also conducted when possible. E. coli grab sampling is conducted once per month during base grabs or as needed during storm or snowmelt events.

10

Grab samplers are taken from the middle of the flow to collect well-mixed, representative samples. The sample is then poured directly into a clean laboratory sample container. The container is capped, stored in a cooler, and sent directly to the lab for analysis. Alternatively, samples can be transported back to CRWD, placed in the refrigerator, and brought to the lab within 24 hours for analysis (depending on the holding time of the parameter being analyzed). Three variations of full water quality grab sampling and one version of E. coli grab sampling methods are discussed below. 4.2.2.1

Bucket and Rope Sampling

Bucket and rope sampling is the most common way to collect full water quality grab samples, since many sites are below ground and most easily accessed from the surface. A sampling bucket with rope is lowered from the surface and triple-rinsed with the water being sampled. Following the triple rinse, a sample can be collected and poured directly into clean laboratory sample containers. Sample containers are labeled by station name and sample date/time. 4.2.2.2

Direct Grab Sampling

Samples are occasionally collected directly from the water source if the water body is at the surface or staff has used confined space entry to access an underground storm sewer. Similar to bucket and rope sampling, the sampling bucket should be triple-rinsed and poured into the clean laboratory sample containers. If taken from a stream, samples should be taken facing upstream, from the center, while ensuring that the stream bottom is not disturbed in the process. If taken from a pond, samples should be taken from a consistent location, slightly below the surface, with floating vegetation moved away, and while ensuring no pond bottom debris is disturbed in the process. If taken from an outlet structure, samples should be taken as they flow over the outlet structure. Occasionally, the laboratory sample container may be filled directly from the outlet structure. In this instance, the sample can be collected directly into the laboratory sample container; no triple-rinse is required. 4.2.2.3

Pump Collection

If the above grab sampling methods are not possible, a grab sample can be collected using the ISCO 6712 pump or other external pump. To use this method, the sampler is set to pump in reverse and the sampling line is purged for 30 seconds. Then, the sampler is set to pump forward for 30 seconds before filling a laboratory sample container. This method is often employed at East Kittsondale and the exfiltration monitoring sites.

11

4.2.2.4

E. coli Grab Sampling

E. coli grab samples are taken in conjunction with base composites, base grabs, storm composites, storm grabs, snowmelt grabs, and illicit discharge samples. The following equipment is used to collect E. coli grab samples: •

E. coli Sampler and Rope

•

NASCO Whirl-Pak® Sample Bags, or other E. coli laboratory submission containers

•

Small cooler with ice pack

A sealed, sterile, 18-ounce NASCO Whirl-Pak® is opened on-site and placed in a sampler. Care is taken to ensure the Whirl-Pak® is not contaminated by field staff fingers, sewer side walls, or other contaminants. In some circumstances, the Whirl-Pack® can be filled without the sampler. If this is the case, the Whirl-Pak® is directly filled with sample water while being held at the tabs, with care taken to ensure it is not contaminated by field staff fingers or other contaminants. The sample must be taken directly from the water source. The sample is put in a small cooler with ice packs immediately and transported to the laboratory within 6 hours.

4.3 4.3.1

Sample Bottle Preparation and Equipment Cleaning ISCO Sampler Bottles and Equipment Cleaning

Flow-weighted composite samples are collected into either 500-mL or 1000-mL ISCO automated sampler carousel bottles. To decontaminate used bottles, they are washed in a Liqui-Nox and hot water solution, scrubbed with a nylon brush, rinsed with hot water, and loaded into the dishwasher for sterilization. Unused bottles that shared a carousel with bottles containing samples are also loaded into a dishwasher for sterilization, but do not require the Liqui-Nox and hot water pre-wash. Bottle caps are also dunked in a Liqui-Nox and hot water solution. They are then placed in the dishwasher in silverware containers, not to be more than ¾ full. The shop dishwasher is run without soap on the “Pots and Pans” cycle to sterilize the bottles. Once all bottles have been removed from the sampler carousel bases, the bases are rinsed with tap water, scrubbed (if needed), and placed out to air dry. Clean bottles are loaded into carousels and stored on a shelf in the CRWD equipment shop. Clean caps are separated by size and stored in clean containers. 12

Churns may be reused between the compositing of multiple sample carousels. Between each composite, churn components are triple-rinsed in hot tap water after each sample is composited. After all samples have been composited for the day, churns are washed with Liqui-Nox and hot water, rinsed, and loaded into the dishwasher. The dishwasher is run without soap on the “Pots and Pans” setting to sterilize the churns. 4.3.2

MCES Laboratory Submission Containers and Preservatives

Composited samples and grab samples are filled in 4-Liter containers to be submitted to Metropolitan Council Environmental Services (MCES) laboratory. MCES neither requires CRWD to preserve samples nor to transport samples on ice (with the exception of E. coli samples). Prior to delivery, samples may be stored in a refrigerator at approximately 4 degrees Celsius for up to 24 hours. At the laboratory, MCES preserves some samples in order to process certain parameters. The MCES Quality Assurance Manual (QAM) includes specific procedures for the following: laboratory submission container cleaning, testing, labeling and storage, and preparation (Appendix D). 4.3.3

Private Laboratory Submission Containers and Preservatives

CRWD primarily uses the MCES laboratory for sample analysis; however, private laboratories may be used periodically for various sample analyses. Private labs may be used for the following reasons: •

CRWD intent to investigate alternative labs

•

Need for specialized sampling parameters for which MCES is not equipped to perform analysis

•

MCES is temporarily unable to process samples due to logistical constraints

The private laboratory QAM shall include specific procedures for the following: sample container cleaning, testing, labeling and storage, preparation, and addition of preservatives. All chemical preservatives added to containers in the laboratory will meet the criteria of the laboratory’s QA/QC program as reflected in the QAM.

4.4

QA/QC Sampling Methods

This section defines specific quality control samples that will be collected in the field. Equipment blanks, field blanks, and field duplicate samples are submitted to the analytical laboratories to provide the means to assess the quality of the data resulting from the field sampling procedures. 13

How these samples are used to meet the quality assurance objectives is discussed further in Section 5.0. 4.4.1

Equipment Blank Sampling Method

Equipment blanks verify the effectiveness of the equipment decontamination procedures. Equipment blanks are conducted after various pieces of equipment used by the CRWD monitoring staff are cleaned. To collect an equipment blank, analyte-free, deionized water is poured into or through the container or equipment in question. Information regarding the types of blanks, associated frequency, and when the blank will be conducted can be found in Table 4. Blank samples must account for 10% of all samples submitted, which equates to the frequencies listed in Table 4 for an average sampling year. Equipment blank samples will be identified according to a table of aliases listed in the “Equipment Blank SOP,” which can be found in Appendix B.

Table 4: Types of Equipment Blanks Performed by CRWD. Blank Type

Frequency

When to Complete

ISCO Sampler Blank

3 sites,3 times/year

Grab Sampler Blank

5 times/year

During level calibrations In the field after a suite of grab samples, after a triple rinse of DI water

Churn Blank

10 times/year

In the shop after triple rinse of tap water

Sampler Bottle Blank

10 times/year

After cleaning process and dishwashing cycle

MCES Bottle Blank

10 times/year

Anytime

Equipment blanks are analyzed for the target parameters in Table 4. Blank laboratory sample containers will be identical to the 4,000 mL sample containers used for general sample analysis for these parameter groups. All containers shall be pre-cleaned within the laboratory’s QA/QC program in the same manner as primary sample bottles for laboratory submission. Equipment blank results greater than the reporting limit for a parameter will be flagged for blank contamination. Field notes and sampling procedures will be reviewed to determine possible sources for contamination. 4.4.2

Composite Duplicate Sampling Method

Composite duplicate samples are samples collected in order to evaluate the sampling procedure and laboratory precision. Duplicate samples should theoretically represent the parameter(s) of interest at a given point in space and time equally. Duplicate samples are collected from the same sampling device and split into two separate laboratory sample containers. Duplicate samples will be submitted to the laboratory as blind or masked samples using a sample alias name (see Table 5 for naming 14

conventions). The true identity of the sample will be recorded in the field form. Field duplicate samples will be collected and submitted at the minimum 10% of total samples per year (approximately one per composite sampling trip).

Table 5: 2019 Duplicate and Replicate Naming Conventions for CRWD Full Water Quality stations. Site

Duplicate Alias

Replicate Alias

St. Anthony Park

CRWD100

CRWD200

Hidden Falls Outlet

CRWD101

CRWD201

East Kittsondale

CRWD102

CRWD202

Phalen Creek

CRWD103

CRWD203

Trout Brook Outlet

CRWD104

CRWD204

Trout Brook-East Branch

CRWD105

CRWD205

Trout Brook-West Branch

CRWD106

CRWD206

Villa Park Outlet

CRWD107

CRWD207

Villa Park Inlet

CRWD108

CRWD208

Upper Villa Inlet

CRWD109

CRWD209

Como 3

CRWD110

CRWD210

Como 7

CRWD111

CRWD211

AHUG Inlet

CRWD112

CRWD212

TBNS-Rose

CRWD113

CRWD213

TBNS-Stream

CRWD114

CRWD214

Midway Office Inlet

CRWD118

CRWD218

North Como 3

CRWD119

CRWD219

4.4.3 Grab Replicate Sampling Method Grab replicates are defined as independent samples collected as close as possible to the same point in space and time as another scheduled grab sample. Grab sampling equipment is used to extract two separate samples from the same source. Replicate samples are stored in individual laboratory sample containers and are analyzed independently. Field replicate samples will be collected and submitted at the minimum frequency of 10% of samples throughout the sampling season (approximately one per grab sampling event). Replicate sample labels will be masked with an alias (Table 5) on both laboratory sample container labels and COCs, with the true identity noted in the field forms.

15

5.0 Quality Assurance Objectives The overall objectives of the CRWD QAPP is to develop and implement procedures for sample collection, laboratory analyses, and data reporting that will provide a high level of data. Six specific Quality Assurance Objectives (QAOs) are defined below. This section provides goals to meet the QAO of precision, accuracy, representatives, completeness, comparability, and analytical sensitivity, along with the means by which they are measured. Table 6 lists all QA/QC methods employed by CRWD and the MCES laboratory to ensure that QAOs are being met.

Table 6: QA/QC Methods Employed to Reach QAOs. Sample Type

Description

Function

Method Blank

Reagent-grade water carried through sample preparation and analytical procedural method

To assess contamination from the laboratory preparation and analytical procedure

Laboratory Control Sample

Reagent-grade water spiked with known concentrations of analytes of interest

To determine the accuracy and consistency of instrument calibration

Quality Control Sample

A second source sample evaluated for analytes of interest

To verify purity and preparation of the calibration standards

Matrix Spike/Spike Duplicate

Separate aliquot of sample spike with known concentrations of the analytes

To determine the ability to recover the known analyte or compound in that sample matrix

Surrogate Spikes

Analytes, similar to those being evaluated, added at known concentration (organic analysis only)

To measure the performance of the analysis and to measure any matrix interferences

Internal Standards

Analyte, similar to those being evaluated, added to a sample at a constant concentration

To measure the relative responses of other method analytes and surrogates in the solution

Equipment Blank

Reagent-grade de-ionized water subject to sample collection, processing, and analysis

To evaluate contamination resulting from successive use of sampling equipment

Composite Duplicate

Duplicate of event sampling procedures

To estimate laboratory and sampling procedure precision

Grab Replicate

Two discrete samples taken concurrently from the same source

To estimate laboratory and sampling procedure precision

16

5.1

Precision

Precision measures the reproducibility of measurements under a given set of conditions. Laboratory precision is determined by replicate analysis on a single sample, such as laboratory blank samples, laboratory spiked samples, field samples, or spiked field samples. Laboratory precision frequency is dictated by the laboratory’s QAM. Total precision, which combines both laboratory precision and field precision, is measured using masked field duplicate samples. Field duplicate samples provide precision information for the entire measurement system, including sample acquisition, handling, shipping, storage, preparation, and analysis. Relative percent differences (%RPD) will be calculated for each pair of duplicate samples (laboratory replicates or field duplicate samples). When both values are reported as detected values, Equation 2 is used to determine precision:

% RPD = Where:

S-D x 100 (S + D) / 2

(Equation 2)

S = First sample value D = Second sample value

CRWD upholds a target RPD value of 20%. If this threshold is exceeded, data will be flagged for that particular parameter.

17

5.2

Accuracy

Accuracy measures the bias in a measurement system. Laboratory accuracy is measured using the analytical results of matrix spike/matrix spike duplicates (MS/MSD), laboratory control samples/laboratory control sample duplicates (LCS/LCSD), as well as by instrument and method blank samples. To analyze MS/MSD samples, CRWD water samples are spiked with a known concentration of the analyte and compared against base levels in the original water sample. LCS/LCSD utilizes the same process, but instead uses spiked pure water rather than sample water. The percent recovery (%R) will be calculated using Equation 3:

%R = Where:

A-B x 100 C

(Equation 3)

A = the analyte concentration determined from the spiked sample B = the native sample concentration of the unspiked sample C = the concentration of the spike added

Field accuracy is assessed conducting equipment blank samples. These samples are used to assess possible contamination in the sample collection procedures or sample bottle preparation processes. If samples are found to be contaminated, additional blank samples may be taken to identify the source of contamination.

5.3

Completeness

Completeness is a measure of the amount of valid data obtained from a measurement system compared to the amount expected to be obtained under normal conditions. For laboratory completeness, it is expected that the contracted laboratory will provide useable and acceptable data for at least 95 percent of all samples collected using the specified analytical method. Field completeness is calculated using Equation 4 from the number of samples required by the city of Saint Paul’s permit and CRWD project goals in a calendar year. đ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??śđ??ś =

đ?‘Łđ?‘Łđ?‘Łđ?‘Łđ?‘Łđ?‘Łđ?‘Łđ?‘Łđ?‘Łđ?‘Ł đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘Žđ?‘Ž đ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œđ?‘œ đ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ąđ?‘Ą đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘‘đ?‘‘ đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’đ?‘’

18

(Equation 4)

All full water quality stations should have at least 12 storm samples submitted per year as well. The goal for stations with baseflow is 20 samples per year. Continuously recorded level, velocity, and temperature data should be collected at 15-minute increments for the duration of the monitoring season, approximately 260 days. CRWD upholds a target field completeness goal of 95%.

5.4

Sensitivity

The achievement of reporting limits depends on instrument sensitivity and matrix effects. Instrument sensitivity will be monitored by the laboratory. It is expected that the laboratory will meet the sensitivities as required by the sample matrix and composition. To ensure that the analytical data are useful, the reporting limit for a given analyte should be well below the lowest expected ambient environmental concentrations or below any applicable regulatory action levels. The laboratory target reporting limits and methods of the monitored parameters are presented in Table 7. The actual reporting limits achieved may depend on available sample volume, sample matrix interferences, and target and non-target parameter concentrations.

5.5

Comparability