ABS EDGINGS WITH WALNUT DECOR

EDGINGS

MODERN, CLASSIC OR REFINED?

Walnut is a precious wood. Its rather vivid colour gradient, the natural grain and warm hue are currently in vogue in furniture and interior design. Furniture boards with walnut decor offer a resource-saving alternative to real wood or wood veneer. We provide the matching edgings.

SERVICE, DIVERSITY AND SPEED: THAT IS OSTERMANN.

For further information, go to www.ostermann.eu and type in #Walnut

Comment

The current turmoil on so many fronts is undoubtedly giving businesses numerous headaches and common to almost all in the furniture and joinery industry for some time has been rising energy and materials costs adding considerable incremental pressure to manufacturers. But talking to suppliers across the board, it seems the inimitable resolve of the furniture and joinery industry remains robust in the face of these difficulties. With numerous examples of businesses focused creating greater efficiencies into their business – and with the show season properly kicking back to gear from May, many will be feeling guardedly optimistic in the medium term despite these challenging times.

Naturally, from within these pages and across our website we regularly hear from businesses with positive stories of investment and progress – and whilst clearly not everyone is on top of things right now, these examples should be providing inspiration and encouragement to those who are having a rough time of it, as many undoubtedly will be.

In this issue, we have a wide range of content to inspire and encourage with features on dust extraction and wood waste management; joinery, window and door production; and storage and materials handling. Elsewhere we have Insight articles from Kenyon Group, TCM Capital and A L Dalton. Positioned between the News and Events page, we have added a Marketwatch section to highlight offers and deals from key suppliers – something always worth keeping abreast of! Another new feature is the Makers’ Gallery of manufacturers finished products – hopefully once again adding inspiration. Accompanying this issue is our annual CNC Supplement with a focused choice of detailed and informative reading for all those considering their CNC production options. Looking forward, alongside our June issue we will be publishing a special supplement focused on sustainable furniture and joinery manufacturing. So I’d like to sound a clarion call to all manufacturers who have made strides regards reducing their carbon footprint – even those who are in the early- or planning stages. I want to hear from you and listen to your experiences and how it is impacting your decision-making and how your business is adapting as you move forwards. Contact me for further details.

I hope you enjoy the issue.

John Legg, editorial director

Pushing the boundaries of Digitalization together to revive interiors

You drive quality. We have the technology. You customize. We maximize. You have the know-how. We enrich it. We pioneer. You lead.

We contribute to the Industry 4.0 revolution in the fashion, automotive and furniture markets with boldness and passion by providing best-in-class technologies. We offer industrial intelligence solutions – software, equipment, data and services – that facilitate your digital transformation.

Find out more at lectra.com

Biesse Fire Doors Days Event – discover how to improve fire door production

Biesse will open it’s doors once again from 21st-22nd March to demonstrate tailored solutions for fire door production.

The event will include live machinery and software demonstrations and where our experts will be available to help you find the best solutions help improve efficiency and overcome your production challenges. Machines on display include beam saws, sanders, edgebanders, CNC machines and vertical CNC’s.

Visitors will also see on Biesse’s CNCs how macro-driven variable programming can revolutionise fire door production and square cornered vision panels without the need for an aggregate. In addition, thos attending will see first hand how to machine frame parts on a vertical CNC including locks, rebates, plus hinge pockets on profiled frame parts (stop attached) including using a single tool, without breakout, that saves valuable processing time. Register at biesse.com/uk/wood/events/firedoors-days.

Keep downtimes low with Leitz’s CompleteCare Tool Management System

Leitz has taken the next step to providing their customers with a complete Tool Management package with CompleteCare. The system makes effective use of digital logistics software in order to help automate the ordering and monitoring process of tooling supplies.

“We are all well aware of the issues that machine downtime can have for our businesses,” said Simon Liddell, Managing Director at Leitz Tooling. “From lost efficiency and reduced throughput to complete factory shutdown, there’s a whole host of issues that can arise when a company’s tooling processes are improperly managed.

“There is a huge amount of work that goes into getting tooling parts where they need to be, when they need to be. Leitz’s CompleteCare package ensures that your machinery supply chain is expertly and efficiently managed, without the requirement to purchase tools

outright.” Ensuring that parts are where they need to be on time will significantly help to reduce downtimes and keep business’ manufacturing rates high.

CompleteCare provides a complete tool supply service from a single source, which makes it ideal for companies with large batch sizes. Invoicing is based on

agreed production figures, which means that pricing is adapted based on real-time costs and data.

As well as this, Leitz uses its expertise to make processes more productive and efficient, ensuring that your stock is managed effectively to minimise disruption.

Leitz has invested in developing a long-term partnership with

customers for mutual success.

Leitz also supports customers by advising on how they can begin to redesign their processes and adapt their production line to meet the demands of the future.

Learn more about Leitz and their range of Tool Management Systems at their website.

www.leitz.org/en-gb/

AMS works side-by-side with the HSE to update training regulations

AMS along with the Wadkin Bursgreen Training Academy work side-by-side with the HSE to update regulations and rules in the woodworking industry for the training courses and improve noise and vibration in their academy to protect their trainers and training attendants.

Scott from the HSE said: “We are very happy that companies like AMS works continually updating content to ensure the latest regulations and rules are reflected in their Woodworking Training Courses and Installations. Scott continues: “For many years, we have been working across many industrial sectors, and the tasks facing us will involve getting highprofile tooling manufacturers to work with us.

AMS has been providing woodworking training courses for more than 15 years with schools and colleges but since 2022, they opened their own training academy in Leicestershire with its own trainers, material and methods.

Phil, one of the trainers in the Wadkin Bursgreen Academy, said:

“Using our extensive industry experience and knowledge, we created our Woodworking Machinery Training Courses from scratch.

“We designed a specific manual for every machine unit, keeping in mind all the parts of each machine, its risks and its rules. We are very proud of our training method and materials.”

Phil continues: “We tailored every training course to our customers’ needs and our courses are 95% of the time at the machine, and 5% in the class. We believe the best method to teach them about woodworking machines is next to the own machine, and we see that most of the attendees prefer it too.”

Companies and individuals looking for training have the possibility to carry out the training in their own workshop or at the Wadkin Bursgreen Academy in Skeffington (Leicestershire). In February, AMS organised two training days in their academy with

different customers and it was a huge success.

Steve, director of training, said: “We had two days of training at our academy with over eight companies coming for chainsaw training courses and another four companies for planer moulder training courses. We launched it for the first time in February and it was a huge success so, we don’t know yet when the next training days in-house will be, but it will definitely be soon.”

Unfortunately today there is still a large number of accidents related to then use and operation of woodworking machines – bad accidents that they could avoid in 99% of the cases if those concerned had received the appropriate training.

Wadkin Bursgreen’s academy provides training courses for all woodworking machines from those used novice woodworkers to trainers.

“The most popular training courses are the general

woodworking machine training course, the refresher and novice training courses. Our cross-cutting chainsaw training course and our Profile Moulder Setting & Operator Training are becoming more and more popular in the industry,” says Steve.

“Our moulder and grinder courses are very popular with traditional moulders/high speed moulders and HSK moulder courses all available from AMS-Wadkin Bursgreen. Those attending can learn all about woodworking machines and chainsaws and ask the trainers – with more than 30 years in the industry– all their questions.”

To discuss training requirements, contact a member of the AMS team on training@advancedmachinery. co.uk and you will receive a formal quote in 24 hours.

Further information about the Wadkin Bursgreen Training Academy is available on the company’s website.

www.advancedmachinery.co.uk/ wb-training-courses

Sleepeezee donates £57k to children’s charity to help fund hospital helipad

A cheque of £57,000 has been presented to The Children’s Hospital Charity, the organisation that supports Sheffield Children’s NHS Foundation Trust, by mattress and bedding company, Sleepeezee and its brand ambassador, Dame Jessica EnnisHill, to help funding towards a new helipad for the trust.

Sheffield Children’s Hospital is a dedicated Major Trauma Centre (MTC) and is one of only five dedicated paediatric Major Trauma Centres in England. It is the only MTC in South Yorkshire and North Lincolnshire that receives children under 16 years of age and is open 24 hours a day, seven days a week and 365 days a year. The new helipad means the hospital can get critically ill or injured patients to the right place, with the right team and provide vital early care and management.

Young patients at the hospital enjoyed a visit from Sleepeezee ambassador, Dame Jessica who spent some time sharing her story with children on the wards and showcasing her Olympic medal while, Sleepeezee’s MD Steve Warren, received an insight into the working of the hospital including the wards and specialist services.

Athlete and London 2012 Olympic champion, Dame Jessica commented: “As a proud patron of The Children’s Hospital Charity and a Sleepeezee ambassador, it was a joy to visit the wards and present the impressive donation. Being able to contribute to a hospital that provides such an excellent level of care to both children and their families is an absolute pleasure and I am delighted the money is going towards the appeal to fund a much needed helipad on the hospital roof.’

The £57k donation was amassed via sales of Sleepeezee’s Jessica mattress range where £20 of each sale throughout the year is donated to The Children’s Hospital Charity. Now in its third year of fundraising, Sleepeezee has raised a total of £132k for the charity so far and plans to continue the initiative in 2023.

Steve Warren, MD at Sleepeezee, added: “Our partnership with Jessica and The Children’s Hospital Charity, which we know is incredibly close to her heart, continues to go from strength to strength and we’re thrilled to be back for another year. Seeing for ourselves the invaluable work that Sheffield Children’s carries out is an honour and we hope our donation from the Jessica Collection helps the hospital achieve its ambitions for the new helipad.’

Sheffield Children’s NHS Foundation Trust is a specialist centre for children’s health supporting children and young people from across the region, nationally and internationally. The Trust provides physical and mental health care in hospital, in the community, at home, in school

and even in the skies (through the Embrace transfer service) and is driving the future of children’s healthcare through pioneering paediatric trials and research across a wide portfolio of clinical specialties.

Tchad Western, business development manager and Chief fun officer at The Children’s Hospital Charity said: “This incredible donation from Sleepeezee will help with our current appeal to build a helipad on the roof of the hospital. We need to raise £6m in total and we’re currently over two-thirds of the way towards our target.

“At the moment, air ambulances land in a park across the road from the hospital, and patients have to be transported across the busy A57. This can attract a lot of attention, so a helipad will not only save vital minutes when every second counts, it will also provide families with privacy and dignity during a difficult time.

“This donation will make a huge difference in helping us to achieve our dream. On behalf of everyone at Sheffield Children’s and Charity, a big thank you to Sleepeezee and our patron Dame Jessica.”

Save £2000 on the smart new SCM Nova SI 300 panel saw

Spend £100 on Kenyon Group’s website and they will donate £10 to Guide Dogs

Guide Dogs is an amazing charity and a very worth cause to support. Since 2021 we have raised £49,070 and named/ sponsored five life changing pooches.

This European manufactured panel saw is a reliable workhorse that will form the backbone of your workshop.

The SCM Nova SI 300 features manual rise/fall/tilt adjustment, 3200mm sliding table, 1270mm saw to rip fence capacity, 7kW motor powering the 315mm diameter blade giving 100mm cutting depth, dedicated scoring

blade with 1.3kW motor and overhead crown guard with dust extraction port.

Supplied complete with scoring blade and main blade – was £10,400 + VAT, now £8,400 + VAT. For further information, contact the Daltons Wadkin team.

0115 986 5201

info@daltonswadkin.com

www.daltonswadkin.com

Visit the Kenyon Group website for Henkel adhesives, Tecbond glue sticks and glue guns, Tuskbond, Mitre Mate and many more products – it represents the complete adhesive package and your purchases will help raise crucial funds to support

Guide Dogs!

www.kenyon-group.co.uk

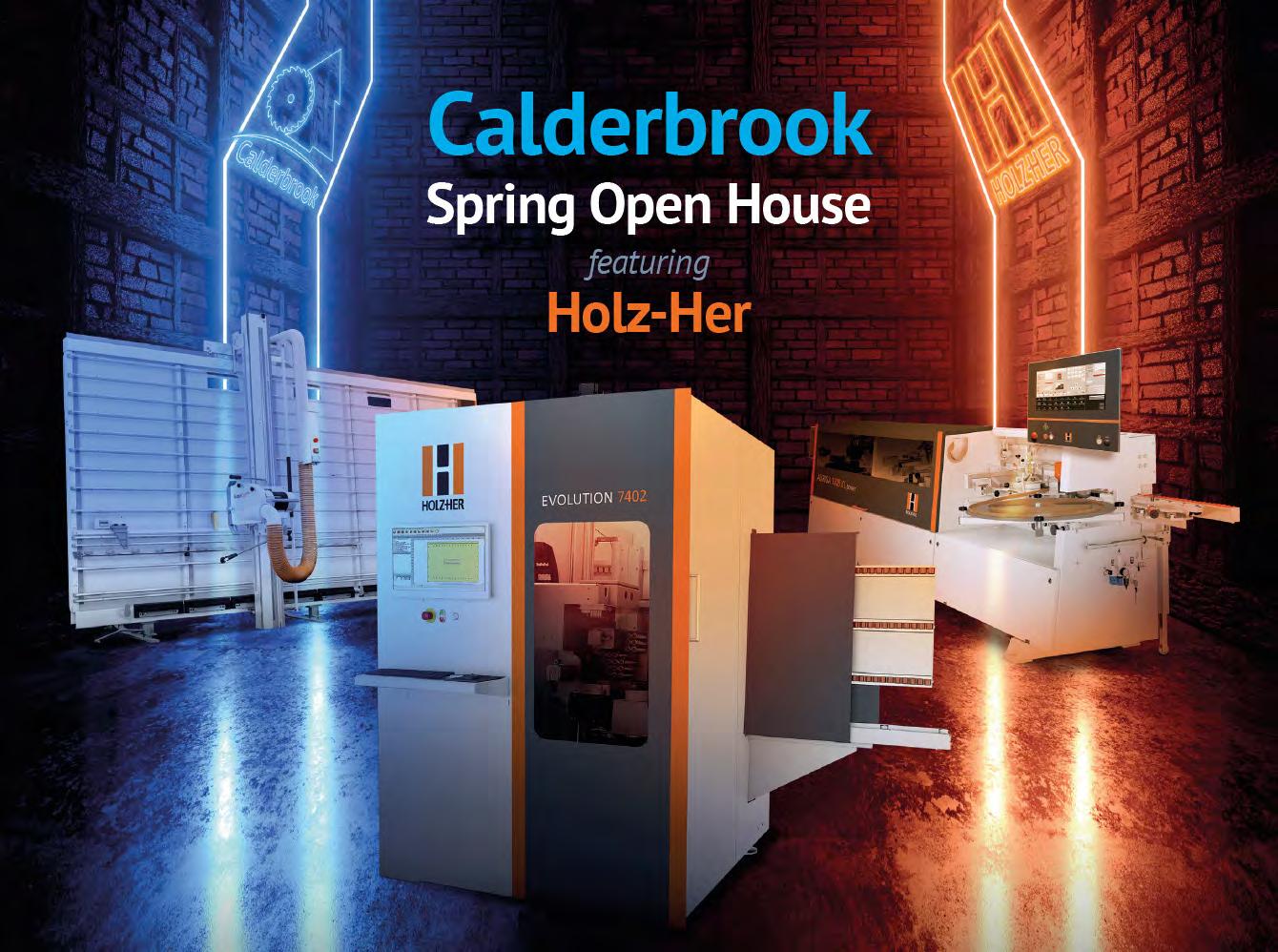

Holz-Her UK’s limited time offer

If you are looking to upgrade your production processes and capitalise on the wealth of benefits a CNC has to offer, there’s never been a better time to invest in a vertical CNC machine from Holz-Her. For a limited time only, the leading panel processing machinery manufacturer is offering an exclusive offer across its Evolution vertical CNC range. Available on Holz-Her’s brand new Evolution 7405 PinJet, Evolution 7402 and Evolution 7405, you could benefit from complete CNC machining

for less than £53k*. This also includes delivery, installation and training. Short on space? This isn’t a problem for an Evolution CNC user. Requiring just 5 sq m, the adaptable CNC range, which guarantees extremely short cycle times and maximum precision when processing solid wood and panels, offers flexible machining dimensions - working to virtually unlimited lengths whilst machining on all four edges of the work piece using their unique vacuum holding system. It also

features an integrated six-position tool-changer as standard and comes equipped with a userfriendly software package. Selected models also include automatic dowel insertion for streamlined production and come P-System and Peanut ready. So, isn’t it time you put the Evolution series to the test? To book your personalised machinery demonstration at Holz-Her UK.

01235 557600

www.holzher.co.uk

*Terms and Conditions apply

Hands-on with new designs at Panelco’s latest event

Furniture, kitchen designers and manufacturers gathered in number keen to see the new trends from two major brand partners at the second Innovation Event hosted by Panelco at the company’s head office in Stoke-on-Trent.

On show in the large welcoming open design studio, Saviola created multiple wall displays full of new designs and textures, inviting the customers to share their thoughts and opinions.

Feature display walls with standout designs were on show in large pieces with various authentic and elaborate wood designs. New textures featured heavily in the displays, and the unique finishes were received positively by everyone. Panelco has already committed to an ex-stock 18mm range of 29 colour-ways, including three carcase plain colours, to allow customers to achieve a 100% recycled kitchen unit as an option. Sustainability and an eco-ethical focus are at the core of Saviola’s design ethos, displayed in a visual

representation showing the whole process in specific stages, from old furniture, material cleaning, and separating waste to recycling which results in producing a pure material.

The idea behind displaying the new designs in this way was to include the customer in the review process and highlight décors they would benefit from and love; Panelco would then consider which new designs to add to their range using the feedback. Kronospan featured their new decorative collection in the design studio along the main display wall showing off an impactful array of colours, 42 unique designs were the highlight, and Panelco has committed to the complete new range.

‘Sustainability and an eco-ethical focus are at the core of Saviola’s design ethos, displayed in a visual representation showing the whole process in specific stages, from old furniture, material cleaning, and separating waste to recycling which results in producing a pure material’

Here it was easy to see the contemporary décors up close in the well-lit environment, the area was a hive of activity, and you could feel the buzz surrounding the new collection. Kronospan utilised the full use of the second design area where customers could move large samples around and get to grips with the latest designs and textures along with supporting assets to take away.

Presentations gave customers an insight into the collection’s origins and where the inspiration was derived. The recent range focused on four origin stories, each with a different look and feel, all very different in their own right; a

highlight was the new embossed texture that enhanced the new oak and chestnut designs on display, a real wow factor.

The new updated collection was met with positive feedback, and it was clear that the latest designs and textures were well received.

The entire collection is now in stock at Panelco and available for next-day delivery. The trends displayed from Saviola will now be used as part of a range review process, and the new designs will be reviewed shortly.

If you missed the chance to visit you can still see both collections on display at Panelco book your visit at www.panelco.com.

New look W Exhibition moves to May 2024

Organisers of W Exhibition, the UK’s flagship trade show for the furniture manufacturing and joinery industries, have announced that the event will return to the NEC from 19th-22nd May, 2024.

The announcement follows two key senior appointments to W Exhibition’s core event team within Montgomery Group. David Todd, formerly of Reed Exhibitions, joins as event director, alongside new commercial manager, Ranju Singh.

The pair have a combined 25 years experience, delivering awardwinning international trade shows across a range of industries. Alongside the team restructure, organisers have undertaken an extensive consultation period with stakeholders, including the associations, trade bodies, industry media and its visiting audience to redefine the show’s proposition. The reimagined format for the show will include a full repositioning of the brand.

With just over one year to go until the W Exhibition returns next May, event director David Todd said: “We’re excited to announce the new dateline for W Exhibition, which will commence with a full relaunch campaign this May as we count down to our return to the NEC from 19th-22nd May 2024.

“Our new team structure, combined with the thorough research process we have conducted of both the show and the markets we serve, all make

for a very exciting period ahead. We are on a very clear and defined path to ensure that W Exhibition makes a triumphant return next May.”

The W Exhibition brings together some of the world’s leading suppliers of woodworking machinery, materials, and tooling. The event, which has over 40 years of heritage, will return to the NEC in its new and reinvigorated format from May 19th-22nd, 2024. www.wexhibition.co.uk

Bridging the gap between EVA and PUR edgebanding adhesives

Over the last few years there has been much publicity about the most appropriate hotmelt adhesive to use for edgebanding and the bonding of various materials to wood-based panel products. Here Steve Morrow, Technical Sales South & UK Sales Manager at the Kenyon Group looks at EVA and PUR options.

It’s widely accepted that EVA based adhesives are the easiest of all to use and process. They are still as popular as ever and Henkel offer a full range from filled to unfilled to suit every application. However, EVAs come with disadvantages if the end product is likely to be subjected to steam, heat or moisture.

An alternative to EVA is PUR adhesives, which dominate the edgebanding market. Over the years PUR adhesives have been more accessible to customers who are edging and as technologies advance, PUR adhesives’ outstanding performance has become available to all edging customers delivering the finished goods to the highest standards.

If joints need exceptional water or heat resistance, then PUR adhesives are recommended as they have a significantly superior performance versus an EVA adhesive. On the flip side, PUR adhesives need more attention during processing, such as flushing the systems and cleaning.

According to Steve Morrow at the Kenyon Group, Henkel TECHNOMELT KS 922 Polyolefin based hot melt adhesive bridges the gap between EVA and PUR, by offering higher heat resistance and higher performance than an EVA with similar pricing levels.

TECHNOMELT KS 922 offers benefits of ultra-thin glue lines for superior edge aesthetics on all board types and colours and is a clean running adhesive with no stringing which leads to less down time for maintenance and cleaning. This in turn leads to increased production.

TECHNOMELT KS 922 can reduce your glue usage by up to 20% as polyolefin based adhesives have increased performance and therefore the coat weight per linear metre can be reduced. This can lead to cost savings.

Henkel TECHNOMELT KS 922 meets high requirements for state-of-the-art edgebanding and sets benchmarks in heat resistance and reduced cleaning efforts.

There’s edgebanding adhesives, and then there’s TECHNOMELT KS 922 – the next generation of edgebanding adhesives – it’s really that simple. Don’t underestimate it Technomelt KS 922 is a superior product at the right price with proven results – just ask anyone using Henkel edgebanding adhesives!

Remember PUR based adhesives will always outperform both EVA or PO adhesives for heat and moisture resistance! When deciding the right adhesive for your edging application, take a look at the Henkel range.

07960 047020 www.kenyon-group.co.uk

‘TECHNOMELT KS 922 offers benefits of ultra-thin glue lines for superior edge aesthetics on all board types and colours and is a clean running adhesive with no stringing which leads to less down time for maintenance and cleaning’Technomelt KS 922 bridges the gap between EVA and PUR Furniture and building component adhesives Technomelt KS 922 delivers the bond

R&D Tax Credits – an insight for manufacturers, creators and dream makers…

The R&D tax incentive was introduced in the year 2000, when the UK joined a number of other countries offering similar tax incentives to drive innovation across industries. The main aim was and still is, to incentivise and reward businesses for extending their capabilities and skillset when undertaking technically challenging projects each year, keeping the UK at the fore front of innovation, and stimulating growth in the economy.

Why was it introduced?

Businesses are often reluctant to take on projects that push them outside of their comfort zone and existing skillset, generally through fear of going over budget or time. This may ultimately even lead to them not delivering what the client wanted potentially losing valuable business in the future. Therefore, the government stepped in and introduced the proverbial carrot to change our appetite for risk and propel us towards innovation.

For qualifying projects, the benefit is equal to a portion of the costs invested in the form of a tax reduction or direct cash injection. These costs may involve staff time, subcontractors, agency workers, consumed materials and software licences. The rebates can be claimed retrospectively.

The benefit applies to both profit and lossmaking companies, something that’s often misunderstood. Another common misconception is that a project has to be “first of kind” in the industry to qualify, which I can understand as R&D evokes images of rocket scientists working on the next big breakthrough in science or space travel. To qualify, a project only needs to meet two fundamental criteria i) if you find yourself extending your capabilities above the baseline norm for your business ii) You have over come some kind of technical uncertainty in the work that’s being undertaken, then you’re likely to be able to recoup a % of those costs spent on that project.

The real litmus test is to determine if the work being undertaken qualifies as R&D. Did your project team face certain uncertain outcomes at the start of the project that involve new processes/methodologies of any kind? If so, it

means that your team did not know whether or not a certain outcome was achievable, this is a great indicator for R&D tax credits.

R&D starts with round table discussions, market research, early design mock ups, prototyping/small batch production and ends once the finished product is viable in a large-scale production.

Failed projects are also often overlooked for R&D purposes, you may have set out to launch a new product or seek to improve your processes, but due to complexities, funding, or a change in client requirement were unable to do so.

What’s in it for me?

The incentive is designed to reward small and large businesses for improving and innovating in their respective fields, eligible companies can claim between 13% and 33% of their staff, subcontractor, consumables, software and utility costs that can be attributed to qualifiable projects each year.

There are many businesses in the manufacturing and product development industry have yet to be told if they can qualify for R&D tax relief, so sadly they miss out on vital cash to the business each year.

The average claim size is around £30,000 to £40,000, however there is no maximum or minimum figure. In our experience successful claims usually come from businesses spending no less than £130,000 on staff salaries (including subcontractors) per annum.

How does it relate to my business?

Examples on the specific sub-sectors and R&D activities that could be eligible for a claim include: Manufacturing Furniture, Fixtures and Equipment: New product development, product improvement, internal efforts to become more efficient to reduce cost of manufacturing, efforts to implement automation.

Fabrication businesses: Working to tight tolerances, creating complex structures, making bespoke jigs and fixtures to improve efficiencies and develop new products.

Joinery: Bespoke design and creating complex structures, integrating electronic sensors/devices to turn into smart.

Textiles Development: Creating unique dyes or fabrics to increase longevity and fire resistance. The following may apply to some or all the respective subsectors:

Engineering efforts to adapt tooling/machinery, software design/development, sustainability efforts (moving from traditional materials to non-routine) and utilising exotic materials, improving efficiency/improving throughput of production, enhancing existing processes to improve productivity and reduce waste.

What do I do next?

If you’re interested in finding out if you’re eligible, the first step would be to have an informal chat to see how/if your business qualifies, taking no longer than 5-10 minutes. We look to understand your projects over the last 2 years and identify a few standout projects. If successful, your involvement is 2/3 hours of your time to offer up the information needed for us progress your claim.

Author Jack Nottingham 07497 159420 jnottingham@tcmcapital.co.ukCreative industries can claim tax credits for technically challenging work. Jack Nottingham from TCM Capital explains how your business could work towards and benefit from this.

Daltons Wadkin offers, arguably, the most diverse range of sawing technology in the UK and Ireland. We hear from managing director Alex Dalton who offers his insight on leading Dutch panel saw brand, Elcon, which forms part of Daltons Wadkin’s impressive range of saws and resaws.

Objective sawing advice from Daltons Wadkin

For over 120 years the family run business has specialised in supplying industrial woodworking machinery for processing solid wood, wood-based panels and composite material, always with a focus on quality and service. Band resaws, sliding table panel saws, dimension saws, vertical panel saws, circular saws and beam saws from Europe’s leading manufacturers can all be found in the extensive Daltons Wadkin machinery portfolio. Our complete offering of all types of panel saws gives us a unique perspective in the market. Most importantly, our customers can be sure of receiving unbiased advise when it comes to the best sawing solution for their needs. Each sawing method has its own advantages and disadvantages and we are always keen to discuss these in detail. In this article we focus on vertical panel saws (also known as wall saws).”

‘ Elcon vertical panel saws provide space saving panel sizing solutions that cater for all types, sizes and thicknesses of panels. With a cutting accuracy of 0.1mm/ mm, electronic digital scales, programmable setting and automatic cutting cycle’

Perhaps the most interesting and innovative sawing methods but often misunderstood, wrongly categorised as ‘agricultural’ or ‘inaccurate’. This could not be further from the truth. Elcon vertical panel saws provide space saving panel sizing solutions that cater for all types, sizes and thicknesses of panels. With a cutting accuracy of 0.1mm/mm, electronic digital scales, programmable setting and automatic cutting cycle, Elcon vertical panel saws can be tailored to suit the most exacting production requirements.

One of the key advantages of an Elcon vertical panel saw, is the optional ADVANCE handling system. Traditionally with wall saws panels are processed from the top down. First strips are cut horizontally, removed from the machine and stacked. Once the required number of strips have been cut they are loaded back on the machine for vertically cross-cutting to the finished component size. The disadvantage with this method is that

the operator must use their trailing hand or wedges to support the strip during the horizontal cut to stop it falling back onto the blade. This is not such a problem with smaller sheet sizes, but when working with large panels the weight and height can be awkward for the operator to handle.

Elcon’s ADVANCE system turns the cutting process on its head. Once the machine is loaded, two (or more) clamps descend and grab the panel(s) from above taking the full weight allowing the operator to work the material from the bottom up. Strip cuts sit on the base of the machine needing no additional support. Each strip can then be immediately cross-cut while the rest of the board remains in the clamps eliminating the need for wedges and repeat panel handling.

Need more? For ultimate productivity the Elcon QUADRA model takes ADVANCE clamping to the next level with the addition of a CNC controlled pusher system. Think of the QUADRA as a vertical beam saw. The CNC pusher positions each cut strip for cross-cutting. The whole

process is automated requiring the operator to only start each process with a single button press. Multiple cutting lists can be programmed directly at the machine or remotely from an office PC. In conjunction with optional optimising software components can be effectively nested prior to generating the cutting lists for maximum material yield.

Another important feature of Elcon saws is the patented and award-winning LIMPIO dust capture system. Greatly reducing dust emissions by simultaneously extracting waste from both the front and rear of the panel, the LIMPIO system keeps the saw blade running in an almost

completely enclosed area reducing dust emission values to less than 0.5mg/m3 – particularly advantageous when cutting large volumes of fibrous or cementitious material, minimising airborne waste entering the operating area.

Safety is a constant theme from Elcon. Vertical panel saws are generally considered one of the safest panel sizing methods available when used by trained operators. Elcon goes further still and includes a series of electronic safety systems that monitor the machine saw beam position and head tilt orientation – the machine will not start if it is not correctly set up with the beam locked/ unlocked and head positioned correctly for horizontal or vertical cutting.

Daltons Wadkin are the sole distributor for Elcon vertical panel saws in the UK and Ireland. The extensive Nottingham showroom gives customers the opportunity for live demonstrations, and the chance to directly compare Elcon vertical panel saws against more traditional sliding table panel saws from Altendorf and SCM.

For more information, or to arrange a visit, contact Daltons Wadkin on 0115 986 5201 or email info@daltonswadkin.com. www.daltonswadkin.com

‘Multiple cutting lists can be programmed directly at the machine or remotely from an office PC. In conjunction with optional optimising software components can be effectively nested prior to generating the cutting lists for maximum material yield’Elcon QUADRA – a vertical beam saw CNC pusher for panel positioning on the Elcon QUADRA

Faster and more efficient thanks to SCM

The eponymous German joinery business, Heiko Schmidt, has picked the Gabbiani S95 beam saw to make a huge leap in the production of furniture for homes and stores and now can offer with more confidence the challenges for the future.

‘Fit for future’ is the motto of the Heiko Schmidt joinery in Ladenburg, a German city in the Baden-Württemberg region. For this family company, this also means having a modern and efficient range of machinery, at the centre of which shines SCM’s latest entry, the Gabbiani S95 panel saw.

Daniel Briscoe, the leading carpenter and head of the furniture sector at the woodworking business, was enthusiastic about it right from the outset: “This beam saw makes our work so much easier. The work once done by two people in about four hours, can now be done in just 90 minutes by a single operator. This way, the new purchase has quickly paid its way in time and quality.”

The company’s machinery was fully replaced about twelve years ago. However, the company was also planning to move to a larger

headquarters and so began to think about how to optimise the production processes. As the owner, Heiko Schmidt, explained, it was not just a matter of understanding which machines to purchase: they would also need to have been compatible with one another.

The new Gabbiani S95 can be found at the centre of the large workshop and is not the only technical solution provided by SCM. The popular Morbidelli M200 CNC drilling-routing machining centre capable of resolving any kind of wood machining problem, and the state-of-the-artMorbidelli X200 nesting CNC machining centre, ideal for flexible and ‘batch 1’ production work alongside the Gabbiani in close synergy.

Directly above these four machines is a chaotic board store system which has a total of 14 storage areas. Not only does the warehouse autonomously sort the material stacks out but also loads the four machines below automatically, based on the orders inputted. As part of the work preparation procedure, during the night, the board store can prepare the panels needed for the next day in the right order, to ensure the work is done even faster.

Sat at his desk in the office, Daniel Briscoe needs to does no more than digitally send

an order to the board store system and the software launches the production order sent and finally the board store system informs the beam saw that the panel is in position and the machine can pick up the right sheet of material and start cutting the job sent explains Stefan Höhn, head of engineering and technical consulting at SCM. “Only when the pieces are finished, does the operator intervene.” This procedure is also applied to the routers and labellers.

Maximum comfort and efficiency

The Gabbiani S95 has a saw blade projection up to 90mm thick: “The machine can fully deal with loading several overlapping panels,” explains Höhn. “The panels can easily be moved either by the grippers or by the operator without having to make an effort to pick them up, and this is achieved by the air cushion tables which allows the panels to be easy moved around the bed of the machine ensuring an easy loading and moving process.”

The maximum cut length of this machine is 4.5m long and 2.2m wide minimum but can also be 4.5m x 4.5m if needed and 90mm thick blade projection, but also can be rotated easily on the table without any effort at all This beam saw can cut all kinds of wood-based products and guarantee a productivity of up to 30% more compared to a standard panel saw.

Another very important advantage is cleaning the work environment guaranteed by the machine structure and functional units. During the entire cutting process, specific curtains by section prevent shavings and dust dispersing into the environment. The machine is fitted with several extraction ports that remove the dust towards the centralised extraction at the woodworking workshop where they are collected and reused for heating. >>

A solution to the company’s growth projects

With the new SCM machines, the company has also found a solution to the problem of a lack of qualified manpower. “The enormous reduction in the workload made possible by the beam saw and other technologies purchased was definitely an important advantage in favour of this investment,” explains Heiko, who, despite this, is still looking to hire a total of 27 co-workers. Indeed, the company wants to continue to grow. Currently, the lion’s share of turnover still comes from the construction industry, but the aim is to increase the quota from the furniture industry by 50%, says sales director Heiko. That’s not all: thanks to the newly acquired technologies, it will also be possible to take part more regularly in important competitive bidding processes in the furniture and shop-fitting industry.

As well as expanding the furniture sector, there are also plans to build a showroom on the extensive land they own. In everything it does, this family-run business is always aiming to be more sustainable as a way of best preparing for the future. “This is something we care greatly

about” confirms Heiko. “We already use wood shavings for heat valorisation. The next step will be to install a solar power plant.”

Another important step will be the handing over of the company-control reins. Marek Schmidt is the owner’s son and is already learning the woodworking trade and has been identified as the person who will take over the business sooner or later. At that point, he will undoubtedly want to continue to pursue his father’s goal of ‘becoming a leader company in the industry in the Rhine-Neckar region’. www.scmgroup.com

Article by Camillo Kluge, courtesy of Holz- und Kunststoffverarbeitung www.hk-magazin.com

‘This beam saw makes our work so much easier. The work once done by two people in about four hours, can now be done in just 90 minutes by a single operator. This way, the new purchase has quickly paid its way in time and quality’The new Gabbiani S95 panel dividing saw accelerates production processes A crane positions a panel directly from the warehouse onto the Gabbiani S95 The panel is pushed into the right position with the grippers

Robotic Sanding by Mirka

Mirka® AIOS.

Designed by dedicated surface finishing professionals, this automated industrial orbital sander is easy to integrate and suits the requirements of different manufacturing industries.

For further information or to arrange a consultation, please contact Customer Services on 01908 866100.

CNC Creations invests in a beam saw and edge bander from HOMAG

Established in 2013, panel processing company CNC Creations has a turnover of £1.5m. Its panels and carpentry are manufactured in CNC Creations’ 17,000 sq ft facility in Northampton, with the business supplying a wide range of customers including Aston Martin, Nissan, Ibis Hotels, Aston University and McLaren. To help cope with a surge in demand, it recently invested in two new HOMAG woodworking machines –a SAWTEQ B-130 beam saw and an EDGETEQ S-300 edge bander.

“The pandemic was a challenging time for most businesses and we were no exception,” explains CNC Creations’ managing director, Paul Gristwood. He continues, “As the pandemic deepened and it became clear that it was going to be a long road to recovery, new opportunities began to emerge.

“Because people were unable to travel, they began to look at making home improvements. This led to a rise in demand for new kitchen, bedroom, bathroom and home office furniture. Local suppliers of this furniture turned to us

to provide the panels and carpentry needed to meet the growth in the market.

“This unexpected upturn meant we needed to improve both our throughput and the quality of our finished panel products. Our first thoughts were to explore the options to replace and upgrade our ageing wall saw.

Selecting the right beam saw and edge bander

“HOMAG has perhaps the best reputation in the market place for state-of-the-art woodworking machinery, so we began by studying the options

for HOMAG beam saws online. That led us to arrange a visit to their showroom in Castle Donington to see the saws in action. Whilst at HOMAG, we were shown the EDGETEQ S-300 edge bander, and were impressed with the speed, quality and ease of operation.

“We were also attracted to the interchangeable glue pots which offered a significant advantage for our manufacturing processes. These benefits swayed our decision and we decided to place an order for the EDGETEQ S-300 first.

“Before visiting HOMAG we had looked at a couple of other leading European suppliers of beam saws and edge banders. Overall though, the HOMAG machines came out on top; they are much more robust with a better build quality and a more aesthetic look. That may sound like a strange statement to make, but my dream is to have a workshop that looks as professional and efficient as a Formula One pit garage.

“Following the purchase of the EDGETEQ in February 2022, we returned to HOMAG to see the saws in action. That led us to place an order in June for the HOMAG SAWTEQ B-130 beam saw. The speed, accuracy and cut quality of this entry level saw is fantastic and it has since proven to be a great asset to the business, more than tripling the throughput.”

Game changers

”In terms of specifying the machines, we opted for the standard spec on the EDGETEQ with the

addition of an extra glue pot. The touch screen operation which comes as standard, is easy to use and foolproof. Since it was installed, it has doubled throughput compared to our previous edge bander.

“For the SAWTEQ we added a label printer which has helped improve throughput and traceability of cut panels. My only regret is that we didn’t invest in the larger SAWTEQ B-300 machine. Both the saw and the edge bander consistently deliver a quality finish giving our customers peace of mind and confidence in our products.

“Overall, we’re delighted with the performance of both machines. The beam saw in particular has been a game changer for us because of the way it processes panels. It’s more automated than our previous saw, enabling us to cut panels accurately, faster and with a much higher quality finish.”

Installation and training

“The installation of both machines went smoothly and the engineers who installed both

the saw and the edge bander carried out the training for our staff on site. It was a simple, painless process and our team were able to go live with production almost immediately.

“For the saw we had some additional training on the Magicut software. HOMAG’s trainer came to our offices to guide our staff through the necessary familiarisation and training which was very informative.

“The impact the SAWTEQ and EDGETEQ have had on the business has been tremendous. We’ve been able to take on larger jobs which previously we weren’t able to do because of restrictions with throughput and quality. Now, even with the faster processing capability, we don’t have to worry about finish quality or accuracy. The investments in HOMAG equipment have given us the confidence to take the business to the next level.” concludes Paul. For a demonstration or further information on HOMAG woodworking machinery or software, contact Adele Hunt at HOMAG UK on 01332 856424.

www.homag.com

‘Before visiting HOMAG we had looked at a couple of other leading European suppliers of beam saws and edge banders. Overall though, the HOMAG machines came out on top; they are much more robust with a better build quality and a more aesthetic look’

Let the crane take the strain

Chris Franklin, Managing Director of Ranheat Engineering Ltd, one of the UK’s leading manufacturers of wood-waste burning equipment, continues his series of articles exclusively for Furniture & Joinery Production. The location of a wood-fired industrial heating system is often dictated by the location of the dust extraction system. Generally, if installing an integrated dust extraction and industrial wood fired heating system you don’t want it at the front of your premises.

Often dust extraction systems are installed at the rear and sometimes access to this area is none-vehicular, particularly with a bag based dust extraction system. Individual bags can be carried through standard doors and put into a skip.

As companies expand and with the introduction of high speed CNC machines the changing of bags becomes a regular and messy operation. So, the solution to getting rid of the bags is to install the existing filter onto a new storage silo.

Ranheat modify the base of the filter and supply a new storage silo that the existing filter can sit on connected by a purpose made flanged upstand.

The silo is fitted with accredited burst panels on the dirty side of the filter. By using this method no expensive to run transfer fan is needed.

Obviously with no vehicular access to the rear of the site a large crane is needed. Specialist lifting contractors were used to provide a 200

the factory and to lift the existing modified filter onto the silo.

Finally the 300 kW Ranheat heater is lifted over the building Ranheat systems have a separate combustion system that either a warm air heater sits on or a boiler based system. The heater weighs in at just under 3 tonne and the base at 2.5 tonne, each is a separate lift.

All of the craning was complete in one days hire using specialist lifting contractors King Lifting.

Most makes of dust extraction filter systems can be modified and used in conjunction with Ranheat Silos. The existing hand loaded warm air space heater was also being replaced by a wood chipper to deal with off-cuts again saving time spent in loading the heater as well as the time spent in replacing bags on the extraction system.

For more information or a detailed site survey contact Ranheat Engineering. 01604 750005 sales@ranheat.com

tonne crane able to lift the new silo and other components to the rear ofWORLD’S FASTEST DUCTINGNOW EVEN FASTER!

Nordfab ducting is being used around the world for dust collection in woodshops, from one-person shops to large manufacturing plants. Because Nordfab’s Quick-Fit® duct is well-constructed, modular, and easy to put together or take apart, and because it is re-usable, it has become a standard for ducting in the woodworking industry.

Our 2-meter length duct makes it more efficient to install ducting, using less joins. In other words, the world’s fastest ducting just became even faster!

Easy & Fast to install

Because our ducting systems clip together, no rivets screws, or welding are needed. This cuts installation and downtime by more than 45% compared to flanged ductwork installation.

Re-Useable

Quick-Fit ducting is easy to uninstall and relocate as you move machinery or have other changes in work areas, providing one of the lowest life cycle cost of any ducting product.

2 meter DUCTING

Fits most applications

Quick-Fit ducting components are adaptable to existing ductwork and Quick-Fit has been used in a wide variety of applications, wherever dust collection or fine particulate transfer is required.

Fast Friendly Reliable

The world’s fastest ducting®

Out with the old… in with the new Extractly system

Extractly Ltd recently installed a complete dust extraction system at Unitech Oxon Ltd, including Ecogate energy-saving control technology, a new filter unit, and ductwork to replace an existing system which was now tired and insufficient for the company’s needs. Located on the outskirts of Banbury, with extensive factory and showroom facilities, Unitech is a long-established, family business, delivering bespoke kitchen and bedroom design, manufacture and installation to a discerning residential market. “Our goal has always been to provide our clientele with individually-designed kitchens and bedrooms – something we would be pleased to have in our own homes

‘As machines come on or offline, the Ecogate dampers open and close automatically and the greenBOX controller instantly instructs the Ecogate PowerMASTER variable speed drive unit to increase or decrease fan speed to exactly match extraction demand’

– manufactured to the highest quality and exacting requirements, yet competitively priced”, says founder and owner Kevin Crouch.

To help achieve this goal, Unitech has always embraced new ideas and technologies in order to streamline and enhance production methods and the business recently invested in cuttingedge CNC technology with the installation of

a high-performance Biesse ROVER B FT HD machining centre – only the second of its kind in the UK. “Although our ductwork system was installed only five years ago, it hadn’t given us the service we had expected”, Kevin explains. “It was getting to the point where we were going to have to make some expenditure on repairs or replacement, but then our decision to invest in

the new Biesse kit made the need to update our extraction system an essential requirement.”

Extractly sales engineer, Tom Firth, visited the factory to review Unitech’s dust extraction requirements, and also conducted a free energysaving survey. Extractly’s subsequent proposals for upgrading the company’s extraction included replacing the previous ducting with Nordfab ‘QF’ Quick-Fit clipped ductwork system throughout, along with a new externally-sited Nederman LBR SmartFilter with 55kW main fan and rotary valve discharge, together with a smaller 15kW transfer fan to convey filtered waste to the existing storage silo. As Tom Firth explains: “Unitech’s decision to install the new Biesse CNC equipment was something of a game-changer, and the previous extraction system just wasn’t designed to cope with the potential volumes of dust waste that could be generated with the factory in full production.”

Based on manufacturers’ data, Unitech’s collection of dust-producing machinery required a combined total extraction volume of around 38,000m3/hr. However, Extractly’s survey established that the installation would benefit significantly from the inclusion of Ecogate technology since, in common with most woodworking and joinery manufacturers, Unitech’s machines are never all in use at the same time. Typically, Unitech’s machine usage required a maximum extraction capacity of just 33,000m3/hr, and installing Ecogate would further reduce this requirement by around 15%. Without Ecogate’s energy-saving technology, the system would have required a filter unit with a capacity of around 40,000m3/hr with the main fan operating at full speed, all day, every day. But, with Ecogate’s ‘on-demand’ technology installed, the speed of the main fan will be continuously adjusted to provide optimum

extraction, in real-time, and only for machines that are operating at any given point in time. The new Nederman filter unit is designed to offer a total capacity of 33,500m3/hr which, with Ecogate controlling the main fan, still affords Unitech some spare capacity to accommodate additional machine installations, or to cope with possible future demand from high-speed replacement equipment.

At Unitech, Extractly installed an Ecogate greenBOX 12 control unit, which has the capacity to control extraction from up to 12 workstations, and motorised Ecogate dampers are integrated into the ductwork serving each machine. As machines come on or offline, the Ecogate dampers open and close automatically and the greenBOX controller instantly instructs the Ecogate PowerMASTER variable speed drive unit to increase or decrease fan speed to exactly match extraction demand. Directly controlling fan speed in this way not only reduces the filter capacity requirement, but also reduces the power required to run the fan, which in turn will significantly reduce electricity bills – typically cutting the cost of extraction by 50%, with a payback on the initial capital investment in under two years.

Extractly also incorporated several ‘Dust & Waste Clean-up Kits’ which simply connect to the extraction system with 100mm diameter flexible duct; each controlled by an Ecogate ‘Push-to-Run’ button. “We’re pleased with the system Extractly installed”, says Kevin Crouch in conclusion.

“The installation is neat and the extraction is very efficient – and a secondary benefit of incorporating Ecogate is that the factory is noticeably less noisy than it used to be!”

01924 520462

www.extractly.co.uk

Leitz technology tackles HSE dust and noise clampdown

Dust and noise has always been a chief concern within manufacturing industries. The Health and Safety Executive (HSE) is challenging businesses to look at ways to improve working practices as dust and noise are two of the leading causes of work-related illness. Simon Liddell, Managing Director of Leitz Tooling UK, talks about tackling the issues of dust and noise in manufacturing industries.

With the threat of fines, and in the worst cases: closure, businesses in the manufacturing sector must look at alternative solutions to these challenges. This is particularly relevant in all manufacturing processes. As employers, our duty of care to protect employees means we need to be taking steps to address those issues in our industry.

According to the National Society for Clean Air (NSCA) and Environment Protection, one million people in the UK are working in conditions that may damage their hearing unless precautions are taken.

Considered a silent killer, dust levels are notoriously difficult to visibly assess and harmful effects can take years to develop, excessive amounts can lead to such issues as skin irritation, respiratory problems and even lung cancer.

General principles of protection from the HSE’ state that:

• Where it is not reasonably practicable to prevent exposure to dust, a combination of engineering and process controls may be appropriate.

• Local exhaust ventilation (LEV) systems should be built into, and specially designed for, the machine or process that creates the dust. Remember that cross draughts and general air movements can all detract from their efficiency.

• For on-tool extraction, it is important to choose parts that are compatible and work together www.hse.gov.uk/pubns/cis69.htm

With these broad principles in place, it’s no wonder that factories are struggling to integrate solutions to avoid health and safety violations.

It’s this end-to-end approach that Leitz has focused on in tackling dust and noise on the factory floor.

It is typical to address these issues in isolation rather than looking for a combined solution, resulting in extra costs. By taking a holistic approach to reducing dust and noise, not only is it possible to solve both issues at the same time, but by focussing on improving process production, it provides an opportunity to increase productivity as part of the solution – leading to ongoing cost saving benefits.

Leitz Tooling UK has developed its Dust Flow Control® (DFC) technology – a tooling-toextraction system to reduce dust and noise that also delivers cost savings for manufacturers through significant productivity gains.

Our experience has taught us that dust hoods are an extremely effective solution and it’s necessary for our experts to get in the factory early to specify each DFC extraction hood to each machine.

Another solution to reduce vibration and therefore noise is to use more sophisticated

clamping systems on your machines. Whilst shanks reduce vibrations, using tighter clamping such as our Heat Shrink system produces greater balance on the tools, reducing both the wear and vibrations together.

Tool management is a critical but underutilised aspect of factory operations and good tool management also offers significant benefits for reducing noise. There are many tool management systems available on the market. At Leitz, we use transparent reporting so that our customers can see the entire servicing and replacement process. We send alerts when a tool needs replacing, or sent for sharpening, ensuring that replacement tooling is ordered in time, leading to minimal machinery downtime or impact on quality, avoiding up to a 25% drop off in productivity.

Optimised tools result in greater efficiency, less waste, less passes, and a reduction in dust. Because up-to-date tooling systems are designed to reduce noise, it makes sense that a fully optimised tool reduces noise pollution.

With the HSE clamping down on dust and noise levels in the workplace, our industry has to tackle these issues through end-to-end solutions that in turn save money and increase productivity. www.leitz.org

Vesta Space goes compact

Vesta Space Ltd isn’t your average wardrobe manufacturer. Over the last six years, Jon Meek and co-owner, Mark Davies have created a business model that sees them work extensively with housing developers, contractors, the trade and general public to provide an end to end service from tender to completion. Keen to build on its solid reputation and maintain growth, Jon has invested in a new Striebig Compact vertical panel saw and AL-KO Mobil Jet 160 dust extraction unit from TM Machinery.

“A vertical panel saw had always been on our radar,” begins Jon, Director of Vesta Space Ltd. “When we set-up the business six years ago, we purchased a sliding table saw. This was mainly because of the up-front cost of the machine but we quickly realised that there was much more to buying a machine than its price tag.”

Making the most of the company’s 4750 sq ft workshop was a huge factor behind the purchase of a Striebig vertical panel saw. “We follow a just-in-time production model, making sliding wardrobe doors on a short lead time. This is a really efficient way of working but, with limited floorspace available and our racking often reaching capacity, we needed to utilise every metre of space we had available to us. This meant investing in machines that allowed us to scale up without being restricted by space.”

With a sliding table saw taking up a large section of their workshop, Jon knew a Striebig vertical panel saw could offer him a fantastic space-saving solution and he was right.

Requiring just 7 sq m of working space – a third of the space required by an equivalent sliding table saw – the Striebig Compact not only offered Vesta Space a significantly smaller footprint, it offered quicker production times and increased output.

“When we originally purchased our sliding table saw, we were making 30 doors a day. We are now on course to make hundreds a week. Trying to handle sheets of MFC on a sliding

‘It’s also a much cleaner job thanks to the AL-KO dust extraction unit. There is no dust whatsoever, which makes for a clean and healthy working environment’Vesta Space has invested in a Striebig Compact vertical panel saw and AL-KO Mobil Jet 160 dust extraction unit from TM Machinery Jon Meek, MD of Vesta Space The compact nature of the AL-KO Mobil Jet 160 dust extraction unit suited Vesta’s requirements Vesta Space’s impressive output speaks for itself

table saw was challenging and required a lot of working space around the machine. Cutting panels was also a two-person job. Full size 8mm thick MFC sheets are not heavy but they are flexible, making them awkward to manoeuvre. On our old saw, the blade remained stationary so we had to manually position and feed the material through the blade. The pliability of the material made it difficult to hold in place, which ultimately had a knock-on effect on the accuracy of each cut and the time it took to machine.

“These problems simply don’t exist with a Striebig,” says Jon. Its moving saw head makes it a sleek one-person operation and its Swiss build quality and scoring blade guarantees a clean, precise cut within 0.1mm with no breakouts.

“The Striebig is not just for rough cuts,” he says. “It has dramatically speeded up the cutting process of our wardrobe interiors and makes light work of shelf towers that require six identical shelves in one design. It’s also a much cleaner job thanks to the AL-KO dust extraction unit. There is no dust whatsoever, which makes for a clean and healthy working environment.”

It’s also offered Vesta Space an opportunity to maximise production efficiencies and future proof its manufacturing: “Our door frameworks have a certain throat size. Before we had the Striebig, we were routing down the edges on a spindle moulder so they would go into the frame. With the Striebig, we are buying a different style of frame with a different size of

throat that accommodates our design without additional machining, slashing production time. This has allowed us to scale up and increase our current production by 25%, while still having the potential to increase our production capabilities by a further 30% in the next two years.”

The machine’s flexibility was also a selling point. Jon explains: “If our manufacturing requirements change, there are a number of retrofittable options available to us, including additional mitre capabilities and optimisation software. This meant we didn’t need to invest in extra cost options we were not sure we needed at the point of sale. Instead, we only opted for a 400mm strip-cutter for fuss-free repeat cuts and a scoring blade. Going forward, we can add certain things onto the machine instead of upgrading it completely. We found this to be unique to Striebig.”

It was this no-nonsense approach that made Jon want to buy from TM Machinery. “The sales

process was straightforward,” he says. “There wasn’t any flounce or over-selling. They sold us a machine that was right for us, with a dust extraction unit that worked effectively with the saw. The team clearly had a great knowledge of the Striebig range and understood us as a business.”

With the machine duo now being put to good use, there are new projects in the pipeline. “We have just secured a large contact in Birmingham that requires the design, manufacturer and install of over 800 sliding doors,” he confirms. “Instead of glass fronts, the contractors want wooden panels. This will certainly up-scale the volume of panels we are processing but we know we are in a position to be able to deliver to a high standard and on time. Looking ahead, it’s our goal to continue on this path and win more work. With the right machinery in place, we know this is achievable.”

‘Looking ahead, it’s our goal to continue on this path and win more work. With the right machinery in place, we know this is achievable’Close up of blade and motor The instinctive controls of Striebig Control Emptying the AL-KO is a simple process

A new criterion – NESTRO Dedusters

According to NESTRO® Lufttechnik GmbH the world-renowned extraction and filter technology specialists, the development of their new generation type – NE J – sets a new standard for the industry, citing that is the first series of clean air dedusters equipped with IE5 reluctance motors and frequency converters (both made by ABB).

Nestro says that users can save up to 22% energy costs compared to those using IE3 motors in workplaces with a variety of processing machines. In this way, the German company makes a significant contribution to climate protection.

The new range features the well-established performance classes 250, 300 and 350 with an operating air volume of up to 9500m³/h and is based on decades of company experience in woodworking, in device technology and in the technology of high efficient fans. The use of these dedusters for the extraction of various materials pays off cost-wise for companies in many industries. Nestro says the NE J verifiably saves:

• investment costs through indoor installation close to the machine using short pipeline routes only with overall low line resistances,

• operating costs thanks to the frequency controlled IE5 reluctance motor (efficiency above 90%),

• heating costs through circulating air operation with a guaranteed residual dust content of <0.1 mg/m³,

• maintenance costs through an intelligent, certified automatic fire extinguishing system –no water or dry chemicals needed – and

• installation and base costs as a mobile plug-and-play device (requires only power and compressed-air connection plus junction of the pipeline).

The new state-of-the-art design offers four different disposal options: mobile dust bins, 800l norm container, separator lock or briquetting press. The NESTRO-LOGIC control for automatic fan start recognises up to ten processing machines and controls the associated gate valves via potential-free contacts or spools. A wired control terminal gives the user optimal freedom of movement in terms of operation and data analysis. The deduster can be parameterized and operated in 16 languages via the 7 in colour touch panel. Thanks to WLAN, commissioning can even take place directly at the processing machines.

“The best business purchase we’ve ever made!”

A company that was recommended to purchase a wood waste heater from Wood Waste Technology is suggesting other companies investigate biomass heating solutions, based on its own positive experiences and the current energy crisis.

Image Displays UK Ltd, based in Leicester, manufactures display and shop fitting items, including point of sale. Director Andy Norton had already been recommended to look at a wood waste heater by one of the neighbouring businesses on the industrial estate, so started to do more research. When he discovered that the heater could burn many different types of wood waste, he contacted Wood Waste Technology who had supplied his neighbour’s heater, to find out more and get a quote.

Andy explains: “We recognised that purchasing a wood waste heater could solve our wood waste disposal problem, whilst also helping with our heating bills. We were using gas heaters in the manufacturing area to keep the space warm in winter, but realised a wood waste heater could make the gas heaters redundant, as we’d generate free heat from burning our waste wood!”

After speaking with Kurt Cockroft at Wood Waste Technology, the business ordered a WT10 heater that was installed by Wood Waste Technology’s experienced engineers. In addition, the company purchased a briquetting machine, to enable the sawdust generated from the extractors to be converted into briquettes that can be easily stored and used as fuel in the wood waste heater as required.

The investment has made many positive differences to the business. Andy explains: “The wood waste heater keeps the workshop warm, even on really cold days, and the business is also saving money on heating and waste disposal. We were spending around £600 a month on skips to dispose of

our waste wood, so that’s a huge saving to our business. We’re also no longer paying for gas to heat the production area, which is a further saving and a huge relief to be saving money on utilities at the moment with the current energy crisis! We’ve been so impressed with the heater, the service we’ve received and the benefits we’ve experienced that we’re very happy to recommend Wood Waste Technology and their products to others. It is, by far, the best business purchase we’ve ever made!”

Managing Director of Wood Waste Technology, Kurt Cockroft says: “We’re delighted that the wood waste heater is benefiting the business, helping Image Displays UK Ltd solve its waste disposal problem, plus get free heating in the workshop too.”

Wood Waste Technology’s years of expertise in wood waste solutions have helped many companies reduce their waste disposal and heating costs. As well as offering site survey, design, manufacture, installation and on-going maintenance for new

units, the company also services all types of wood waste heaters and supplies genuine spares up to 60% cheaper than other suppliers.

In addition, Wood Waste Technology is the UK official distributor for Gross Apparatebau GmbH, a German manufacturer of dependable, precision engineered shredders and briquetters, available in various size and specifications to suit all business applications.

01785 250400

www.woodwastetechnology.com

www.grossuk.co.uk

LEV solution for bespoke kitchen manufacturer

Expansion of a long-established bespoke kitchen manufacturer required relocation to larger production premises. As part of the move, Fercell were engaged to recommend a suitable local exhaust ventilation system, for the various production processes.

Through consultation, each production activity was assessed, with any process creating fumes or dust, requiring ventilation to comply with HSE laws and ultimately to ensure their workforce would be protected.

Fercell recommended a comprehensive suite of LEV systems to encompass both dust and spray extraction, as well as a programme of monitoring.

Subsequent meetings and designs, resulted in twin UF-Series dust extractors, a DB-Series spray booth and numerous LEV indicators.

Dust extraction for woodworking machinery

Twin UF3 dust extractors, inside the production area, are connected to all of their woodworking

machinery by a centralised system of steel duct work.

The UF-Series offer the perfect solution for high loading dust applications. They are designed to work with a range of fan sizes, in order to match the process materials, air speeds, and filtration velocity.

With a considerable collection capacity and a compact footprint, made the UF-Series ideal for this application.

Waste material is collected directly into, either, steel bins or collection sacks, located beneath the filter plenum. Easy release and lock rapid over centre toggle system, ensures minimum downtime.

The close-coupled MV-Series fan, used, is designed to withstand harsh industrial applications for the transportation of heavy dust laden air. The MV-Series are constructed from heavy-gauge steel plate, with fans transporting particulate materials, including dust, shavings and wood chips.

THE UK’S NUMBER ONE RANGE OF PROGRAMMABLE CROSSCUT SAWS

Cross cutting

OVER 350 SUCCESSFUL INSTALLATIONS IN THE UK & IRELAND

Stromab programmable cross cut saws are the proven machine of choice for companies who are looking to increase productivity, accuracy and safety.

Available in a wide range of configurations Stromab will have the machine to satisfy your production requirements and budget:

►

►

►

►

►

Matrix Programmable Push Fed Crosscut

Fast 500 High Speed Optimising / Defecting Crosscut

CT600 For Straight And Angled Cutting

Matrix/F & CT600/F For Crosscutting & Notching

Matrix HD Engineered Timber Crosscutting Saw

Furniture - Windows - Doors - Stair Parts - Garden Products

Timber Frame - I Beams / LVL - Packing Cases / Pallets FOR MORE INFORMATION CONTACT UK &

Spray extraction for product finishing

One of the product finishing services carried out onsite was wet spray painting. With exposure to paint fumes without adequate ventilation a potential hazard to health.

The DB-Series was selected to increase paint spraying extraction capacity. Available in a variety of dimensions, Fercell were able to configure the spray booth to match the clients’ exact requirements.

Paint, overspray, particles are drawn into the booth and filtered through a pleated paper filter, while the fumes are exhausted to atmosphere via a duct system, with an accelerator cap discharging above roof height.

LEV indication – keeping measure LEV indicators were fitted to every extraction port on the woodworking machinery, providing a visual indicator of the system performance. Whilst LEV testing must be carried out at least every 14 months, regular checks via the indicators will allow our customer to ensure the system is performing to its required levels and detect any service issues that arise to be dealt with efficiently.

Following the installation, LEV testing and commissioning was completed. The LEV system will allow our customer to carry out a variety of manufacturing processes, whilst ensuring best

working practices are followed and any exposure to airborne contaminants is reduced to meet the required standards.

Fercell have been successfully delivering industrial ventilation and recycling solutions for over four decades. With no customer the same,

Fercell provide bespoke solutions to meet your project requirements. From design, through to installation and servicing of LEV and recycling equipment, we provide complete solutions. 01622 791414 www.fercell.com

The Woodwork Dust Control Co Ltd

QUALITY PANEL SUPPLY

PRODUCTS

Wooden Edge Glued Panels

Worktops

TGV

Legs

Birch Ply

Wood veneered mdf

Wood edge banding

MDF MR

MDF MR Butt & Bead Primed

THICKNESSES

6/9/12/15/16/18/20/22/25/27/30/40mm

WIDTHS

300/600/620/915/1210/1220mm

LENGTHS

900 through to 4000mm

SPECIES

Oak, Ash, Pine, Knotless Pine, Tulipwood/Yellow Poplar, Beech, Iroko, Maple, Black Walnut and more

SERVICES

Cutting Service Available 24-72 hour delivery

National & European delivery available

Volume orders from stock

No minimum orders

Rubio Monocoat Supplier

01206 396725

sales@mlpanels.com

www.mlpanels.com

Follow us on social media @mlpanels

Products

Titus’ furniture hardware solutions have been improving homes around the world for decades. They increase the quality and facilitate assembly of furniture, giving a significant competitive advantage to manufacturers and improving the consumer experience.

The company’s most popular components are the T-type concealed hinge that has a tool-free 3Way snap-on mounting and the TeraBlack range that offers an attractive black matte hardware finish to enhance the appeal of cabinets.

T-type – the fastest hinge on the market Titus offers a comprehensive range of hinges for every door. The latest innovation, the T-type, enables time-savings at cabinet assembly and assures a lifelong consistent performance on a wide range of doors.

The T-type hinges with integrated soft closing assures above-average consistency of performance with no bounce effect and reliable closing at all closing speeds. A unique solution that works on doors of different dimensions and weights, with no rebounce.

The 3Way snap-on mounting system makes them exceptionally easy to install, with an intuitive hinge-to-plate mounting in three directions (from the front, the back and the top). Mounting cabinet doors – even on large heavy doors with multiple hinges - has never been this easy.

The range has recently been extended to include pie-cut (bi-fold) hinges for corner cabinets, which fit standard drilling patterns and feature convenient ‘double lock’ opening. This means users can either open just one door leaf to get excellent access into the cabinet interior or they can fully open the doors by locking the hinge cup and make the door leaves work as one.

T-type is a high-performance hinge that allows for misalignments of drilling patterns up to 0.6mm. Even in case of misalignment drillings, the hinge performs at its peak capabilities and always ensures smooth and perfect close in every cycle.

T-type with ConfidentClose, creates the consumer preferred way of damping, based on results of Titus research made in UK, Germany and Slovenia. It is characterised by fast closing, late start of deceleration action and quiet landing with SoftTouch. The damper is placed in the hinge cup with its positioning transversal to the hinge cup, and can be easily adjusted to suit different types of doors.