XYLOLOGIAE ZVOLEN VEDECKÝ ČASOPIS SCIENTIFIC JOURNAL 65 1/2023

ACTA FACULTATIS

Vedecký časopis Acta Facultatis Xylologiae Zvolen uverejňuje pôvodné recenzované vedecké práce z oblastí: štruktúra a vlastnosti dreva, procesy spracovania, obrábania, sušenia, modifikácie a ochrany dreva, termickej stability, horenia a protipožiarnej ochrany lignocelu-lózových materiálov, konštrukcie a dizajnu nábytku, drevených stavebných konštrukcií, ekonomiky a manažmentu drevospracujúceho priemyslu. Poskytuje priestor aj na prezentáciu názorov formou správ a recenzií kníh domácich a zahraničných autorov.

Scientific journal Acta Facultatis Xylologiae Zvolen publishes peer-reviewed scientific papers covering the fields of wood: structure and properties, wood processing, machining and drying, wood modification and preservation, thermal stability, burning and fire protection of lignocellulosic materials, furniture design and construction, wooden constructions, economics and management in wood processing industry. The journal is a platform for presenting reports and reviews of books of domestic and foreign authors.

VEDECKÝ

ČASOPIS DREVÁRSKEJ FAKULTY, TECHNICKEJ UNIVERZITY

VO ZVOLENE 65 1/2023

SCIENTIFIC JOURNAL OF THE FACULTY OF WOOD SCIENCES AND TECHNOLOGY, TECHNICAL UNIVERSITY IN ZVOLEN 65 1/2023

Redakcia (Publisher and Editor’s Office):

Technická univerzity vo Zvolene (Technical university in Zvolen); TUZVO

Drevárska fakulta (Faculty of Wood Sciences and Technology)

T. G. Masaryka 2117/24, SK-960 01 Zvolen, Slovakia

Redakčná rada (Editorial Board):

Predseda (Chairman): prof. Ing. Ján Sedliačik, PhD., TUZVO (SK)

Vedecký redaktor (Editor-in-Chief): prof. Ing. Ladislav Dzurenda, PhD., TUZVO (SK)

Členovia (Members): prof. RNDr. František Kačík, DrSc., TUZVO (SK) prof. RNDr. Danica Kačíková, MSc. PhD., TUZVO (SK) prof. Ing. Jozef Kúdela, CSc., TUZVO (SK) prof. Ing. Ladislav Reinprecht, CSc., TUZVO (SK) prof. Ing. Mariana Sedliačiková, PhD., TUZVO (SK) prof. Ing. Jozef Štefko. CSc., TUZVO (SK) doc. Ing. Hubert Paluš, PhD., TUZVO (SK)

Jazykový editor (Proofreader): Mgr. Žaneta Balážová, PhD.

Technický redaktor (Production Editor): Ing. Michal Dudiak, PhD.

Medzinárodný poradný zbor (International Advisory Editorial Board):

Bekhta Pavlo (Ukrainian Natl Forestry Univ, Ukraine), Deliiski Nencho (University of Forestry, Bulgaria), Jelačić Denis (Univ Zagreb, Croatia), Kasal Bohumi (Tech Univ Carolo Wilhelmina Braunschweig, Germany), Marchal Remy (Arts & Metiers ParisTech, France), Németh Róbert (Univ Sopron, Hungary), Niemz Peter (Bern Univ Appl Sci, Architecture Wood & Civil Engn, Switzerland), Orlowski Kazimierz A. (Gdansk Univ Technol, Poland), Pohleven Franc (Univ Ljubljana, Slovenia), Potůček František † (Univ Pardubice, Czech Republic), Teischinger Alfréd (Univ Nat Resources & Life Sci, BOKU, Austria), Smardzewski Jerzy (Poznan Univ Life Sci, Poland), Šupín Mikuláš (Technical University Zvolen, Slovakia), Vlosky Richard P. (Louisiana State Univ, USA), Wimmer Rupert (Univ Nat Resources & Life Sci, Austria).

Vydala (Published by): Technická univerzita vo Zvolene, T. G. Masaryka 2117/24, 960 01 Zvolen, IČO 00397440, 2023

Náklad (Circulation) 150 výtlačkov, Rozsah (Pages) 164 strán, 14,09 AH, 14,29 VH

Tlač (Printed by): Vydavateľstvo Technickej univerzity vo Zvolene

Vydanie I. – jún 2023

Periodikum s periodicitou dvakrát ročne

Evidenčné číslo: 3860/09

Acta Facultatis Xylologiae Zvolen je registrovaný v databázach (Indexed in): Web of Science, SCOPUS, ProQuest, AGRICOLA, Scientific Electronic Library (Russian Federation), China National Knowledge Infrastructure (CNKI)

Za vedeckú úroveň tejto publikácie zodpovedajú autori a recenzenti. Rukopis neprešiel jazykovou úpravou

Všetky práva vyhradené. Nijaká časť textu ani ilustrácie nemôžu byť použité na ďalšie šírenie akoukoľvek formou bez predchádzajúceho súhlasu autorov alebo vydavateľa.

© Copyright by Technical University in Zvolen, Slovak Republic.

ISSN 1336–3824

CONTENTS

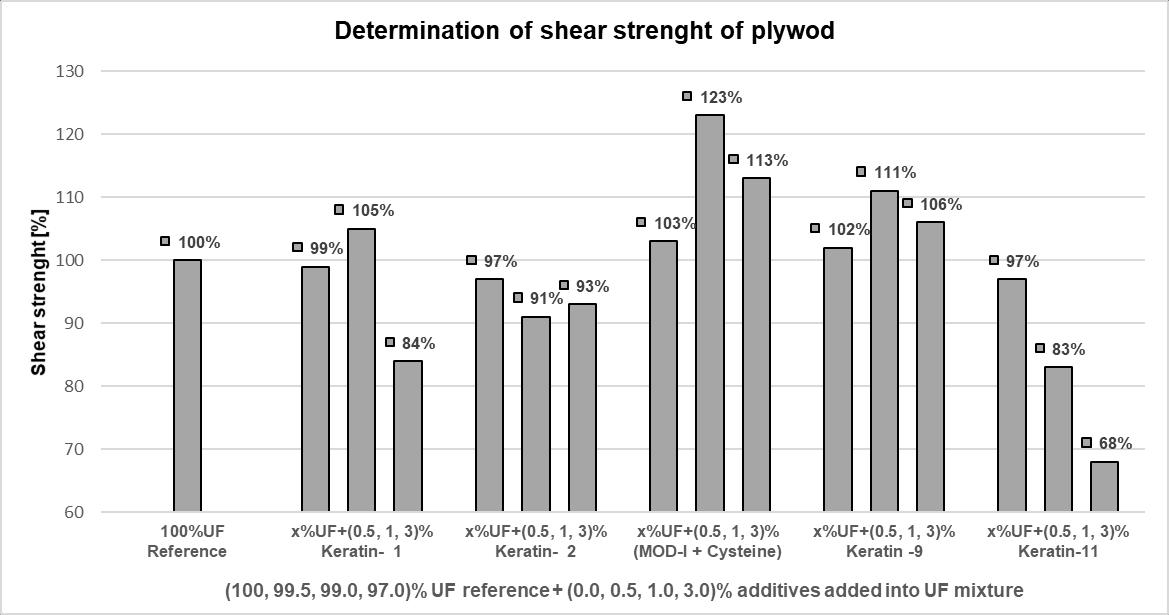

01. MARIYA PYLYPCHUK – VOLODYMYR MAYEVSKYY – VASYL TARAS – MYKHAILO BURDIAK – ZOYA KOPYNETS: PATTERNS OF CHANGES IN TECHNOLOGICAL ACCURACY OF PLANOMILLING MACHINES DURING THE PERIOD OF THE CUTTING TOOL WEAR RESISTANCE ........................................................................ 5 02. ZUZANA VIDHOLDOVÁ – MILOŠ PÁNEK – LADISLAV REINPRECHT: THE EFFECT OF OUTDOOR WEATHERING OF THERMALLY MODIFIED SPRUCE AND PINE WOODS ON THEIR SURFACE PROPERTIES 23 03. MICHAL DUDIAK – LADISLAV DZURENDA: THE EFFECT OF SUNLIGHT ON THE COLOR CHANGE OF STEAMED BIRCH WOOD 35 04. GABRIELA SLABEJOVÁ – ZUZANA VIDHOLDOVÁ – MÁRIA ŠMIDRIAKOVÁ: CHANGE IN THE COLOUR OF TRANSPARENT SURFACE FINISH ON HYDROTHERMALLY TREATED WOOD 45 05. JÁN SEDLIAČIK – JÁN MATYAŠOVSKÝ – PETER DUCHOVIČ –IGOR NOVÁK – PETER JURKOVIČ: KERATIN AS A FORMALDEHYDE SCAVENGER FOR ENVIRONMENTALLY FRIENDLY WOOD-BASED PANELS 57 06. LARYSA YAREMCHUK – LILIYA HOGABOAM – GABRIELA SLABEJOVÁ – JÁN SEDLIAČIK: COMPARATIVE ANALYSIS OF THE QUALITY PROPERTIES OF OIL-BASED AND ALKYD COATING MATERIALS FOR WOOD ........................................................ 63 07. LUKÁŠ ADAMČÍK – RICHARD KMINIAK – JARMILA SCHMIDTOVÁ: MEASUREMENT OF THE ROUGHNESS OF THE SANDED SURFACE OF BEECH WOOD WITH THE PROFILE MEASUREMENT SOFTWARE OF THE KEYENCE VHX-7000 MICROSCOPE ....................................................................................................... 73 08. SERGEI KAZITSIN - ALEKSEY NAMYATOV - MIKHAIL BAYANDIN - NINA GROTSKAYA: DEEP IMPREGNATION OF BINDER-FREE, LOW-DENSITY WOOD BOARDS WITH FLAME RETARDANTS .............................................................................................. 87 09. LADISLAV DZURENDA – ADRIÁN BANSKI: MODEL OF THE INFLUENCE OF THE CLIMATIC CONDITIONS OF THE SLOVAK TERRITORY ON THE CONSUMPTION OF FIREWOOD AND THE PRODUCTION OF EMISSIONS DURING THE HEATING OF BUILDINGS .................................................................................................. 105 10. MÁRIA OSVALDOVÁ – MAREK POTKÁNY – NIKOLAY NEYKOV: CONVENTIONAL VS. INNOVATIVE METHODOLOGICAL COSTING PROCEDURE FOR THE PRODUCT MANUFACTURE FULFILLING THE PRINCIPLES OF THE CIRCULAR ECONOMY 111

HUBERT PALUŠ – NIKOLA SLAŠŤANOVÁ – JÁN PAROBEK –RASTISLAV ČEREŠŇA: PROPOSAL OF A MODEL FOR THE IMPLEMANTATION OF ENVIRONMENTALLY SUSTAINABLE PURCHASING IN WOOD PROCESSING INDUSTRY ....................... 125

MILOŠ HITKA – SILVIA LORINCOVÁ – LENKA LIŽBETINOVÁ –PAVLA VRABCOVÁ – HANA URBANCOVÁ – MARTINA LIPOLDOVÁ: THE EFFECT OF THE COVID-19 CRISIS ON EMPLOYEE MOTIVATION IN THE ENTERPRISES IN FORESTBASED SECTOR IN SLOVAKIA 135 13. ERIKA LOUČANOVÁ – MIRIAM OLŠIAKOVÁ – MARTINA NOSÁĽOVÁ – HUBERT PALUŠ: PERCEPTION OF SELECTED TYPES OF FAMILY HOUSES WITH REGARD TO WOOD-BASED STRUCTURES 147 14. LADISLAV REINPRECHT: LAUDATIO FOR LADISLAV REINPRECHT Professor, Ing. CSc. ............................................................... 161 15. MIKULÁŠ SIKLIENKA: LAUDATIO FOR MIKULÁŠ SIKLIENKA Professor, Ing. PhD. ................................................................................... 163

11.

12.

ACTA FACULTATIS XYLOLOGIAE

ZVOLEN, 65(1): 5 21, 2023

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2023.65.1.01

PATTERNS OF CHANGES IN TECHNOLOGICAL ACCURACY OF PLANO-MILLING MACHINES DURING THE PERIOD OF THE CUTTING TOOL WEAR RESISTANCE

ABSTRACT

Polynomial patterns of changes in the technological accuracy of the machine tool over the period of the cutting tool wear resistance were established. The software, which makes it possible to show regression models of the average value and the scattering field of the size of the manufactured parts depending on the degree of the tool wear, was developed. Based on the results of experimental studies of changes in the machining accuracy on six planomilling machines during the wear resistance period of the cutting tool (ρ = 5 − 50 μm), regression models in the form of third-order polynomials were obtained. It was found that to ensure the machining accuracy within the tolerance (± 0.1 mm), the wear resistance period of the cutting tool should not exceed ρ = 30 μm, and the technical specification of the machine should correspond to an exceptionally high accuracy class.

Keywords: regression model, accuracy, machining, machine tool, part.

INTRODUCTION

Wood blanks after machining on plano-milling machines must have the appropriate shape, size accuracy and surface roughness (Kiryk 2006). The quality of machining is affected by a number of factors: the characteristics of the material being processed, the parameters of the cutting tool and the cutting mode (Chladil et al , 2019, Bendikiene and Keturakis 2017, Mazur et al., 2011, Vančo et al., 2020, Warcholinski and Gilewicz 2022). The determining indicator of the quality of machining on machine tools is the accuracy of the dimensions of the manufactured parts, compliance with which ensures: interchangeability of parts during the assembly of products; manufacturing accuracy of the whole product; economic efficiency of the entire production. Increased requirements for machining accuracy (±0.1 mm) primarily relate to the manufacture of bar parts on planomilling machines. Compliance with these requirements is currently ensured by performing technological operations for calibrating individual parts or prefabricated products (window and door units), which requires additional raw materials and energy costs.

The source of errors in the dimensions of the parts produced in the cutting process is the dynamic system "machine-cutting tool-workpiece" (McTW) (Pylypchuk 2021, Vukov et al., 2021),whichcontains alargenumberoffactors thathaveboth asystematicandarandom nature of influence on the accuracy of machining. The main indicator of the efficiency of a woodworking machine is its technological accuracy which gradually

5

Mariya Pylypchuk – Volodymyr Mayevskyy – Vasyl Taras –Mykhailo Burdiak – Zoya Kopynets

decreases duringtheoperationofthemachine. The technological accuracyofmachinetools is partially restored due to their periodic adjustment and repair, as well as timely resharpening of the cutting tool. That is, maintaining the required level of machining accuracy on machines requires the development of specific practical solutions to improve or restore the technological accuracy of the machine, and this, in turn, requires conducting research to find the patterns of changes in accuracy.

In the process of operation, the machine tools lose their initial technological accuracy and therefore require timely taking measures to prevent the appearance of defective parts. Accordingtothemanufacturers,theinitialtechnologicalaccuracyofplano-millingmachines corresponds to a particularly high class, which ensures machining accuracy according to IT10-11 qualities (ISO 286-2). During the operation of the machine tool, various types of energy are acting, which causes the occurrence of processes in the components and parts of the machine that change the initial characteristics (Hernande and Fernando de Moura 2002, Kanarchuk et al., 2003). Such processes may be reversible or irreversible. The reversible processes temporarily change the parameters of machine parts and its units within certain limits, for example, elastic and thermal deformations of machine parts and cutting tools. The irreversible processes lead to a gradual loss of machine performance and the onset of parametric failures. Some authors (Pylypchuk et al., 2021) developed a parametric machine failure model based on the accuracy criterion, which makes it possible to determine the duration of the interregulating periods of machine operation.

Theprocessesin themachinesalso differin theirspeed (fast, medium-speed and slow), which affects the change in the initial parameters of the machine (Pylypchuk 2021). Medium-speed irreversible processes that occur during continuous operation of the machine and last for several hours include the process of gradual wear and bluntness of the cutter blade (Dobryansky and Malafieiev 2020; Zatulenko and Zaiets 2019), which is of typical character (Fig. 1a). The period of a cutting tool resistance to wear T is determined by the operating time before critical blunting of the cutter blade, during which three stages can be distinguished: I – running in; ІІ – gradual wear; ІІІ – critical (emergency) wear. During roughing, the operation is conducted in zones I and II, that is, according to the criterion of maximum total stability of the cutter blade. When finishing on milling machines, the period of the cutting tool wear resistance is determined by the technological criterion – ensuring the specified quality of machining.

The authors (Kiryk and Hryhoriev 2013) note that the cutting tool after sharpening has a radius of curvature of the cutting edge of 6 4 0 = μm (Fig. 1b). The cutting ability of the tool is gradually lost and becomes critical when the radius of curvature of the cutting edges reaches 60 50 = max μm. The cutting tool period of wear resistance can range from a few minutes to 400 hours of continuous operation, depending on the material of the blade, the properties of the wood and the modes of cutting.

6

Gradual failure of the cutting tool due to the loss of machining accuracy occurs when deviations in the size of the manufactured parts reach the tolerance field limit (Bustos et al., 2010, Nadolny et al., 2020, Pylypchuk 2021). The main determinant of machining accuracy on plano-milling machines is the actual location of the cutting plane passing through the center of the circle inscribed in the cutting edge of the blade (Fig. 1b). During the process of milling, the blades gradually wear out; accordingly, the radius of the inscribed circle increases, and its center moves along the bisector of the sharpening angle. Therefore, the machining surface is shifted by an amount of d:

where:

0 – the radius of rounding of the cutting edge of the initially sharpened tool;

0e

relative residual deformation under the cutting surface of wood.

Exceeding the average period of tool life leads to a discrepancy between the dimensions of theworkpieces andthenominalsizes. Inordertopreventtheappearanceofdefectiveworkpieces, itisnecessarytousetheefficientcuttingtoollifeaccordingtothecriterionofmachiningaccuracy, forthedeterminationofwhichfurther researchconducting is necessary.

According to the study results (Vitchev 2019, Vitchev and Gochev 2019), the surface quality of Scots pine wood samples is influenced by the rotation frequency of the cutting tool, the feed rate, and the characteristics of the milling cutter. In the work (Keturakis and Juodeikienė 2007) the influence of the blunting radius of the cutter blades as well as the feed rates and cutting speeds on the surface roughness during longitudinal milling of birch wood was investigated. It was found that the roughness of the machined surface increases as the radius of rounding of the milling cutter blades increases. In the work (Atanasov 2021), based on the results of experimental studies, determined was the dependence of the cutting force on the feed rate and the thickness of the cut chips during longitudinal milling of oak wood, tropical species – meranti, koto, as well as composite materials – medium-density fiberboard and plywood.

In order to obtain high machining accuracy during the cutting tool wear resistance period, it is necessary to prevent the occurrence of excessive vibrations of the "machinecutting tool-workpiece" system, which is confirmed by studies (Kovatchev and Atanasov 2021) of the influence of feed rate and milling area on vibration resistance. The authors (Chunmei et al., 2020) investigated the influence of different shapes of milling tool blades on cutting forces, vibration during cutting, change in chip shape at different feed rates, as

7 a b

Fig. 1 Wear and bluntness of wood-cutting tool blades: a – the nature of the cutting tool blade wear during operation (Dobryansky and Malafieiev 2020); b – changes in the rounding radius of the blades during the cutting tool wear resistance period (Kiryk and Hryhoriev 2013).

( ) ( ) 0 0 0 0 = e d e d d max max (1)

–

well as on the roughness of the machined surface. It was found that the feed rate has a significant effect on the roughness of the machined surface, with an increase in this rate, the roughness increases, and no studies have been conducted regarding the machining accuracy. The work (Li et al., 2022) also investigated the influence of the following factors on the roughness of the machined surface and the cutting power in the process of helical milling of pine wood: the helical angle of the cutter, the rotation speed of the main shaft, and the depth of milling. The influence of the input variables and the quantitative relationship between the input data and the change in the assessment indicators were clearly identified. The results obtained are useful for selecting the mode parameters of helical milling in order to improve the quality of the machined surface and save power consumption.

In the work (Djurković et al., 2019), the influence of the cutting tool blade wear on cutting power and the quality of the machined surface is investigated. The tests were carried out on samples of beech wood of the same density and moisture content and without visible wood defects. It was found that the wear of the tool blades significantly affects the cutting power and the quality of the machined surface, which is important in determining the cutting mode and the period duration of the tool wear resistance. The authors (Bendikiene and Keturakis 2016) also investigated the effect of the cutting tool blade wear on the surface roughness of birch wood blanks in the planing process. It was found that after a cutting length of 3,200 m, a change in the geometry of the tool cutting edge leads to an increase in the surface roughness.

The authors (Skliarov and Prykhodai 2021) note that the introduction of automation tools and the use of robotic systems can improve the productivity and machining accuracy, but these measures cannot exclude the influence of factors such as the cutting tool wear, temperature, elastic and contact deformation of the technological machine systems on the accuracy of manufactured parts. To do this, the machines use active control systems, means of controlling the elastic movements of the machine-cutting tool-workpiece system and automaticadjustment systems, whichprovides anincreasein machining accuracy, sincethey allow periodically adjusting the position of the cutting tool relative to the workpiece and can be used on milling machines. In order to obtain the required productivity, product quality, and energy saving, the authors (Rudenko et al. 2012) proposed using a new automated combined system for controlling the mechanisms of plano-milling machines with the introduction of regulators for the tool drive start-up process, the interaction of the main drive and the feed drive, and the regulator of roughness of the machined surface.

So, based on the analysis of the results of well-known studies on the quality indicators of the cutting process on plano-milling machines, it should be noted that in most works, the roughness of the machined surface and the effect on its value of the main operation factors: cutting speed and feed rate, wood species, area of the cut layer, as well as structural differences of the milling tool and the degree of its bluntness are considered as a quality indicator of processing. Few works are concerned with the study of changes in machining accuracy during the period of the cutting tool wear resistance, when due to the gradual blunting of the tool, a parametric failure according to the criterion of machining accuracy occurs, as a result of which there is a need to restore the working condition of the cutting tool. Therefore, we consider it necessary to conduct scientific research aimed at finding the patterns of changes in the technological accuracy of the machine during the period of the cutting tool wear resistance and developing measures to ensure modern requirements for machining accuracy indicators.

8

MATERIAL AND METHODS

During the process of machining a batch of parts on a woodworking machine, the dimensions of the manufactured parts are scattered, which is described by a field of scattering of machining errors (Pylypchuk and Burdjak 2009). The scattering field does not remain constant during the production time of a batch of parts, but gradually changes in magnitude and, accordingly, its average value changes. The basis of the methodology for studying changes in the technological accuracy of the machine during the period of manufacturing a batch of parts, which is equal to the period of the cutting tool wear resistance, is the method of instantaneous sampling (Pylypchuk 2010). It was preliminarily found out that ten instantaneous samples of parts in a group, 10 / N n n = , characterize quite accurately the batch of manufactured parts.

The dimensional inaccuracy of the manufactured batch of parts is characterized by the parameters ofthe scattering field and dimensional setting X (Fig. 2). Inmost woodworking machines,themachining accuracyis graduallyreduced during theproduction timeof abatch of parts. Based on the results of studies on changes in sawing accuracy during the period of the cutting tool wear resistance on circular saws (Pylypchuk 2020), it can be argued that it is necessary to apply a polynomial model that takes the form:

where: 0C – the coefficient characterizing the initial value of the evaluation parameter; n ...C C1 – coefficients that characterize the nature of changes in the parameter during the period of the cutting tool wear resistance.

Taking into account the polynomial model (2), the changes in the average size j X and the scattering field j are described by the equations:

9

( ) ( ) ( ) 0 1 1 1 C x C x C x C x Y n n n n n + + + + = (2)

Fig. 2 Model of the polynomial pattern of changing the technological accuracy of the machine during the period of the cutting tool wear resistance.

( ) ( ) ( ) 0 1 1 1 X t B t B t B t X n n n n j + + + + = (3) ( ) ( ) ( ) 0 1 1 1 + + + + = t C ... t C t C t n n n n j (4)

where: 0 0 , X

the initial values of the average size and the scattering field of the part sizes;

t – the time of production of a batch of parts during the period of the cutting tool wear resistance;

n n ...C C , ...B B 1 1 –coefficients that determine the nature of changes in the average size of parts and the scattering field of part sizes during the period of the cutting-tool wear resistance.

The quantitative characteristic of the cutting tool wear is the degree of blunting of the cutter blades, which is determined by the radius of rounding of the main cutting edge ( µm). During the cutting process, the blunting of the blades of tool cutters is constantly increasing and according to data (Kiryk and Hryhoriev 2013), the value that describes the wear resistance period of milling knives is within ( 50 5 = µm).

To process experimental data from studies of changes in the technological accuracy of the machine tool, the DynToch program has been developed by the authors. It is used to obtain the mathematical dependencies describing the change in machining accuracy indicators over the characteristic periods of machine operation, using a regression equation – a polynomial of the nth degreeandin graphical form.

The program provides the following steps in a logical sequence: input data; calculation of statistical indicators and indicators of changes in the average value and scattering field; obtaining a regression equation based on linear and polynomial models and constructing graphical dependencies ofchanges intheaveragevalueandthescattering field ofthemachining error. The input data table allows processing arrays of ten samples, each of which contains ten measurements of the parts. All the samples are entered into the program in the sequence of their obtaining during the experimental studies. Calculations are performed automatically at all stages of the program, and all calculation results and their graphical representation are also automatically recalculated when each of the input data values is changed. The value of statistical indicators is also determined automatically for each of the samples after entering the input data.

The determined pattern makes it possible to analyze and predict changes in the accuracy of parts machining on any machine. In addition, by knowing the pattern, the state of technological accuracy of woodworking machines during a certain period of their operation can be monitored and the appearance of defective parts can be prevented. The developed technique can be used both to establish the pattern of changes in the technological accuracy of various types of woodworking machine structures, and to predict the machining accuracy on woodworking machines under production conditions over the period of the cutting tool wear resistance.

Determination oftheactual technological accuracyoffour-sideplano-millingmachines

The actual technological accuracy of four-side plano-milling machines was determined on the basis of experimental studies of machining accuracy in the case of eight types of machines operated in woodworking enterprises in Ukraine: Unimat 500, Profimat 23, Unimat 23 EL, Hydromat 1000, Hydromat 2000 from the Weinig company; QMB 620 GH from the Quality Greation Maker company; RMM 623 from the Reignmac company.

The experimental studies were carried out under the following conditions: wood – oak (Quercus); moisture content of the wood – 7–9%; feed rate – 20–25 m/min; spindle rotation speed – 6,000–8,000 min-1; the number of milling cutters – 4 pcs.; the degree of the knives wear ( 50 45 = μm); the number of part size measurements in one sample is

10

–

100 (10 parts with 10 width and thickness measurements on each part). The results of the sample data processing and main indicators are shown in Table 1.

Tab. 1. Main indicators of the actual technological accuracy of four-side plano-milling machines

Basedon the analysis oftheresults obtained(Table 1),it is worth notingthe following: under conditions of critical wear of milling knives ( 50 45 = μm), machining errors in all themachines,bothinwidthandthicknessoftheparts,exceeduptotwotimesthepermissible values both during preliminary calibration of workpieces (± 0.2 mm) and during finishing (± 0.1 mm). The largest machining error was observed in the case of the machines of the Chinese manufacturers QMB 620 GH (Quality Greation Maker) and RMM 623 (Reignmac), which in terms of the thickness of the dimensions of the parts exceed the permissible values by 3.7 and 3.3 times,respectively. Thehighest machiningaccuracy (within ± 0.14–0.19mm) was provided by the Weinig machines: Unimat 23, Unimat 23 EL, Unimat 500, Hydromat 1000Hydromat2000,however,allthemachinesdidnotmeetthetechnologicalrequirements for dimensional accuracy (± 0.1 mm), which necessitates conducting further research and development of measures to improve the accuracy of machining in these machines.

Bychecking thehypotheses about thelawofmachining errordistribution, it was found that the distribution does not correspond to the normal law, and the Hnidenko-Weibull law more accurately describes this dependence. The discrepancy between various distributions (which can be used as input flows in the simulation modeling of wood machining processes) and the normal law is typical for such a natural material as wood, in particular, the work (Mysyk et al., 2017)describedthedistributionsofthelengthofdefect-freeareas fordifferent species. To adequately describe such distributions of lengths of defect-free sections, it is more appropriate to use the Log-Logistic and Burr laws. In

11

Machine brand, (year of manufacture) The dimensions of the blanks, ( h b ) mm Tolerance for blank size deviations, = mm Indicators of the

of

dimensions

parts Processing quality, ІТ10–18, (ISO 286-2) Machining accuracy class (1, 2, 3, 4)* Average size value, h / b mm Scatteringfield, = 2 , h / b mm Machine tools of the manufacturing companies - China QMB 620 GH ( year 2017 ) 53.0 × 31.0 Calibration, ± 0.2 45.4 / 23.3 ± 0.23 / ± 0.37 13 /14 2 / 3 RMM 623 (year 2017) 94.0 × 22.0 Calibration, ± 0.2 90.3 / 18.4 ± 0.21 / ± 0.33 13 /14 2 / 3 Weinig machine tools (Germany) Profimat 23 (year 2003) 68.0 × 33.0 Calibration, ± 0.2 59.4 / 31.5 ± 0.22 / ± 0.24 12 / 13 2 Unimat 500 (year 2006) 44.0 × 35.0 Calibration, ± 0.2 40.0 / 27.7 ± 0.21 / ± 0.23 12 / 13 2 Unimat 23 (year 2003) 46.0 × 46.0 Finishing ± 0.1 43.3 / 39.4 ± 0.16 / ± 0.16 12 2 Unimat 23 ЕL (year 2005) 41.0 × 28.0 Finishing ± 0.1 40.5 /27.6 ± 0.16 / ± 0.18 12 2 Hydromat 1000 (year 2014) 76.0 × 32.0 Finishing ± 0.1 71.2 / 28.1 ± 0.17 / ± 0.19 12 2 Hydromat 2000 (year 2017) 80.0 × 30.0 Finishing ± 0.1 72.3 / 22.3 ± 0.14 / ± 0.17 11 / 12 1/2 Note * 1 – particularly high; 2 – high; 3 – medium; 4 – normal.

accuracy

the

of the manufactured

addition, the distribution of this error according to the Weibull law confirms the presence ofadominant factorinfluencing adecreasein accuracyandtheshift in theaveragesizevalue towards an increase. It means that there is a factor with a systematic nature of the impact, which is the blunting of the cutter blades leading to a decrease in machining accuracy and an increase in the size of the parts.

Thus, according to the results of statistical processing of the experimental studies on the technological accuracy of machines, it can be concluded that the accuracy of surface machining of workpieces using the machine tools is low (within ± 0.14–0.37 mm) and does not meet the technological requirements (± 0.1 mm), which is explained by the long-term operation of machine tools and the maximum wear of knives ( 50 = max μm).

The study of changes in machining accuracy during the period of the cutting tool wear resistance

According to the developed methodology, experimental studies on the influence of the degree of knife wear on the accuracy of milling bar workpieces in production conditions on six machines were performed (Fig. 3).

12

Unimat 500, Weinig company

Profimat 23, Weinig company

Unimat 23, Weinig company

Hydromat 2000, Weinig company

The experimental studies on the technological accuracy of four-side plano-milling machines operating in woodworking enterprises in Ukraine for 5–18 years were carried out under the following conditions: wood – oak; the wood moisture content – 5–7%; workpiece dimensions: length – 730 mm; cross-section – 50 × 50 mm; feed rate – 20 m/min; period of resistance of knives to wear ( 50 5 = µm); layer removal thickness 2.0–4.0 mm, the speed of rotation of the spindles – 6,000 min-1 .

The cutting tools – cylindrical assembled cutters with insert knives (Fig. 4 a, b) with a diameterof125

260mm,thenumberofmilling cutterknives –4pcs; thepermissibledegree of knife wear ( 50 µm). Technical specifications of the milling cutters: for horizontal spindles (Fig. 4 a): the manufacturer – Leitz, serial number – 100249971, dimensions –143×150×40 mm, = max n 9,000 min-1, HM 200-2-05, MEC S35; for vertical spindles (Fig. 4 b): UNIMERCO, dimensions – 145×80×40 mm, = max n 9,000 min-1

The radius of rounding of the cutting edge, which was periodically measured after performing a given cutting path, was used to quantitatively assess the wear of the blade of the milling cutter. The milling cutter was removed from the machine, the top of the knife was photographed under the object-micrometer OMP No. 652295 with a division value of 0.01 mm (Fig. 5 a, b) and re-installed on the machine for further milling. Simultaneously with photographing the knife blade, a microline was photographed, the distance between divisions being 0.01 mm, which makes it possible to determine the dimensions of the cutter knife with an accuracy of 10 μm. The wear of the cutter knife blade was measured from the obtained photo using the AutoCad computer program.

13

QMB 620 GH, Quality Greation Maker company (China)

RMM 623, Reignmac company (China)

Fig. 3 Four-side plano-milling machines operating at woodworking enterprises of Ukraine.

–

a b

Fig. 4 Assembled shell-milling cutters that were used on the plano-milling machines during the experimental studies: a - on horizontal spindles; b - on vertical spindles.

Measurementsofthedimensionsofthemanufacturedpartsoneachofthemachines weremadebytheirwidthandthickness,andsamplesof100valueswereobtained(10parts with5widthandthicknessmeasurementsoneach).

Indicatorsofmachiningaccuracyonplano-millingmachinesaretheaveragevalueand scatteringfieldofthesizeofthemanufacturedparts,whichisequaltomm.The criterionforevaluatingtheaccuracyofmachiningisthemagnitudeofdeviationoftheactual sizeofthemanufacturedpartsfromthepermissiblevalueofthesizeerror.Sizetolerances ofmanufacturedbarpartsonplano-millingmachineshavethefollowingvalues:preliminary calibrationmm;finishing(final)machiningmm.

Onthebasisofprocessingtheresultsoftheexperimentwiththehelpofthedeveloped program"DynToch",theregressionequationsofthechangeintheaveragevalueandthe scatteringfieldofthethicknessofthepartswereobtainedintheformofthird-order polynomialsforsixmachines,whichtakethefollowingform:

14

a b

Fig.5Measurementoftheradiusofroundingofthebladesofthemillingcutterknivesatheknifeof themillingcutter;bthetopoftheexperimentalknifeofthemillingcutterunderthemicroscope.

theQMB620GHmachinetool (5) (6) theRMM623machinetool (7) (8) theProfimat23machinetool (9) (10) theUnimat500machinetool (11) (12) theUnimat23machinetool (13) (14) the (15) (16)

All the regression equations (5-16) of the average value and the scattering field of the size of the manufactured parts describe the increasing dynamics of the growth of machining accuracy indicators during the period of the tool wear resistance. The graphs of the polynomial models of the change in the average value (Fig. 6) and the scattering field (Fig. 7) for six machines show that the empirical dependences of the change in milling accuracy during the period of the tool wear resistance are approximated with high accuracy (R2 = 0.95–0.98) by polynomials of the third degree.

15

Fig. 6 Рolynomial models of changes in the average size of manufactured parts on the machine tools.

Thus, the obtained regression models in the form of a polynomial of the third degree, which describe the increasing dynamics of the average value and the scattering field of the size of manufactured parts on machines of the following brands: QMB 620 GH, RMM 623, Profimat 23, Unimat 500, Unimat 23 and Hydromat 2000 during the period of knife wear resistance ( 50 5 = µm), allow analyzing and predicting changes in the accuracy of machined parts on each of the machines and identifying the maximum duration of cutting tool wear resistance periods according to the criterion of machining accuracy

16

Fig. 7 Polynomial models of changes in the scattering field of the size of manufactured parts on machine tools.

RESULTS AND DISCUSSION

On the basis of the graphs of regression models (Figs. 6–7), for each of the machines, the characteristic phases of the milling cutter knife wear resistance period were determined: initial, sharp knives ( 5 = µm); medium degree of wear of knives ( 30 = µm); critical, maximum wear of knives ( 50 = µm). Based on this, diagrams of the magnitude of the scattering field and the average value of the size of parts for three characteristic values of the periods of the cutter knives wear resistance on each of the six machines were constructed (Figs. 8a, b).

Based on the results of the analysis of changes in machining accuracy in the case of the Unimat 500 and Profimat 23 machines (Fig. 8 a), it was found that the scattering field of the size of the manufactured parts increases three times ( 24 0 08 0 = mm) during the entire period ofknifewearresistance,andthemillingaccuracywithinthetolerance(±0.1mm)isprovidedonly at the initial and middle phases of the knife wear resistance period, i.e. under the condition of 30 µm. On the Unimat 23 and Hydromat 2000 machines, the cutting accuracy during the knife wear resistance period ( 50 µm) is also reduced by 2.4 times ( 17 0 07 0 = mm), but slower compared to the Unimat 500 and Profimat 23 machines. The tolerance of machining accuracy (±0.1 mm) on these machines is provided under the condition of 40 µm, which confirms thehighgeometricaccuracyandstiffness of machinestructures.

ItwasfoundthatthemachiningerroronthemachinesQMB620GH,RMM623ofChinese manufacturers (Fig. 8 a) duringthe periodof wear resistanceof the knives increases most rapidly ( 38 0 13 0 = mm), that is, by 3.7 times, and the tolerance requirements (±0.1 mm ) are not provided even in the initial phase of the milling period ( 0.16 0.13 = mm). On these machines,duringtheperiodofkniveswearresistance 30 µm,machiningaccuracyisensured within ± 0.2 mm, which meets the requirements only for the preliminary calibration of the workpiecesandconfirmsthenon-complianceofthemachinespecificationwithaparticularlyhigh class ofaccuracy.

Theaveragevalueofthesizeerrorofmanufactured partsinthecaseofallthemachines during the period of knife wear resistance (Fig. 8b) also increases in accordance with the increase in the scattering field of the size of the parts. On the Weinig machines, during the middle phase of the knife wear resistance period 30 µm, the average value of the part size changes within 19 0 09 0 . . h = mm, i.e. the thickness of the parts increases by 0.1 mm, and with the maximum wear of the knives ( 50 = µm) 28 0 09 0 h = mm, i.e. the size increases to 0.2 mm. Thus, the Unimat 500, Profimat 23, Unimat 23, and Hydromat 2000 machines will ensure machining accuracy according to two criteria during the middle phase of the knife wear resistance period ( 30 µm): the average value of up to 0.1 mm and the scattering field (± 0.1 mm).

17

On the Chinese-made QMB 620 GH, RMM 623 machines, during the period of wear resistance of the knives ( 50 5 μm), the average value of the thickness of the parts changes within the range of 65 0 23 0 h = mm, that is, the size increases by 0.42 mm. A significant increase in the size of the parts indicates insufficient rigidity of the "machinecutting tool-workpiece" system and the need for additional dimensional adjustment of the machine before the beginning of the critical phase of wear resistance of knives ( 50 30 μm).

Based on the results of the analysis, it was found that in order to ensure machining accuracy in plano-milling machines within the tolerance (± 0.1 mm), the wear of the cutter knives should not exceed 30 = μm, and the technical specification of the machine should correspond to a particularly high accuracy class.

CONCLUSIONS

On the basis of experimental studies in the production conditions of Ukrainian enterprises, the indicators of the actual technological accuracy of plano-milling machines of various manufacturers were determined and it was found that under the conditions of maximum wear of milling knives ( 50 = µm), the size errors of the manufactured parts in the case of all the machines exceed the permissible values (± 0.1 mm) by up to four times, which makes it necessary to establish a pattern of changes in machining accuracy during the period of the cutting tool wear resistance.

The algorithm for mathematical prediction of changes in machining accuracy in machine tools over the period of tool wear resistance was improved. Software that makes it possible to obtain regression models of the change in the average value and the scattering field of the size of manufactured parts in the form of polynomials of the n-th degree and to predict the change in the accuracy of machining on the machine during a certain period of operation was developed. Moreover, it can be used to establish the allowable duration of the period of the wear resistance of the cutting tool according to the criterion of machining accuracy and to prevent the appearance of defective parts.

18

а b

Fig. 8 Machining accuracy for characteristic phases of the wear resistance period of the milling knives: a – by the scattering field; b – according to the average value.

According to the results of experimental studies of changes in the accuracy of machining on machine tools during the period of tool wear resistance ( 50 5 = μm), regression models in the form of polynomials of the third degree were obtained. These models describe the change in machining accuracy on machine tools during the period of the cutting tool wear resistance with accuracy 0.95 2 R . It was found that in order to ensure the machining accuracy within the tolerance (±0.1 mm), the period of the cutting tool wear resistance should not exceed 30 = µm, and the technical specification of the machine should correspond to a particularly high accuracy class.

The proposed mathematical model for predicting the change in machining accuracy during the cutting tool wear resistance period makes it possible to determine the duration of the cutting tool wear resistance period, which ensures the required accuracy of machining. The developed methodology and the obtained results are the basis for further research on the implementation of systems of active control over the size of manufactured parts and the development of systems for automatic dimensional adjustment of machine tools.

REFERENCES

Atanasov, V. 2021. Experimental research on the cutting force during longitudinal milling of solid wood and wood-based composites. Acta Facultatis Xylologiae Zvolen. Vol. 63(2), pp. 73−84.

https://doi.org/10.17423/afx.2021.63.2.06

Bendikiene, R., Keturakis, G. 2016. The effect of tool wear and planning parameters on birch wood surface roughness. Wood Research. Vol. 61 (5), pp. 791-798.

Bendikiene, R., Keturakis, G., 2017. The influence of technical characteristics of wood milling tools on its wear performance. Journal of Wood Science, Vol. 63, pp. 606-614.

https://doi.org/10.1007/s10086-017-1656-x

Bustos, C., Moya, C, Lisperguer, J., Viveros, E. 2010. Effect of Knife Wear on the Gluability of Planed Surfaces of Radiata Pine, Wood and Fiber Science: Journal of the Society of Wood Science and Technology. Vol. 42(2), pp. 185-191.

Chladil, J., Sedlák, J., Rybářová, E., Kučera, M., Dado, M. 2019. Cutting conditions and tool wear when machining wood-based materials. BioResources. Vol. 14(2), pp. 3495-3505.

https://doi.org/10.15376/biores.14.2.3495-3505

Chunmei, Y., Qingwei, L., Ting, J., Mingliang, S., Yan, M., & Jiuqing, L. 2020. Test analysis and verification of the influence of milling cutter blade shape on wood milling. In Wood Research. Vol. 65(2), pp. 313-322. https://doi.org/10.37763/wr.1336-4561/65.2.313322

Djurković, M., Miric Milosavljević, M., Mihailović V., Danon, G. 2019. Tool wear impacts on cutting power and surface quality in peripheral wood milling. In International Journal – Wood, Design & Technology. Vol. 8, no. 1, pp. 9-17.

Dobrianskyi, S.S., Malafieiev, Yu.M. 2020. Technological foundations of mechanical engineering: text book. Kyiv: Igor Sikorsky Kyiv Polytechnic Institute. 379 p.

Hernande, R., Fernando de Moura, L. 2002. Effects of knife jointing and wear on the planed surface quality of northern red oak wood, Wood and Fiber Science: Journal of the Society of Wood Science and Technology. Vol. 34(4), pp. 540-552.

ISO 286-2:1988 ISO system of limits and fits – Part 2: Tables of standard tolerance grades and limit deviations for holes and shafts.

Kanarchuk, V.Ie., Polianskyi, S.K., Dmytriiev, M.M. 2003. Machine reliability: text book. Kyiv: Lybid. 424 p.

Keturakis, G., Juodeikienė, I. 2007. Investigation of milled wood surface roughness. In Materials science (Medžiagotyra). Vol. 13, No. 1: pp. 47-51.

Kiryk, M.D., Hryhoriev, A.S. 2013. Preparation of wood-cutting tools for work and their operation. Lviv: UNFU. 342 p. ISBN 978-966-96826-8-0.

Kiryk, M.D. 2006. Mechanical processing of wood and wood materials: text book. Lviv : KN. 412 p. ISBN 966-8800-07-9.

19

Kovatchev, G., Atanasov,V. 2021. Determination of vibration during longitudinal milling of woodbased materials. Acta Facultatis Xylologiae Zvolen. Vol. 63(1), pp. 85−92. https://doi.org/10.17423/afx.2021.63.1.08

Li, R., Yang, F., Wang, X. 2022. Modeling and predicting the machined surface roughness and milling power in scot’s pine helical milling process. Machines. Vol. 10, 331, pp. 1-13. https://doi.org/10.3390/machines10050331

Mazur, M.P., Vnukov Yu.M., Dobroskok V.L.,Zaloha V.O., Novosolov Yu.K.,Yakubov F.Ia. 2011. Fundamentals of the theory of cutting materials: text book. Lviv: Novyi svit-2000, 2nd Edition. 422 p.

Mysyk, M., Matsyshyn, Ya., Mayevskyy, V., Ray, Ch., Kurka, R., Sopushynskyy, I. 2017. Identification of the length distribution of lumber defect-free areas. In Wood and Fiber Science. The Sustainable Natural Materials Journal – Published quarterly by The Sheridan Press Hanover, Pennsylvania. Vol. 49, no 4, pp. 396–406

Nadolny, K., Kapłonek, W., Sutowska, M., Sutowski, P., Myśliński, P., Gilewicz, A. 2020. Experimental Studies on Durability of PVD-Based CrCN/CrN-Coated Cutting Blade of Planer Knives Used in the Pine Wood Planing Process. Materials. Vol. 13(10), 2398, https://doi.org/10.3390/ma13102398

Pylypchuk, M.I., Burdjak, М.P. 2009. Exactness sawing research method of logs on "JasenBarakuda" roundsaw machine-tool. In Scientific bulletin of UNFU. Vol. 19(8), pp. 156-161.

Pylypchuk, M., Dziuba, L., Rebezniuk, I., Chmyr, O., Burdiak, M. 2021. Modeling parametric failuresofwoodworkingmachinesaccordingtothetechnological precisioncriterion.Inselected papers from the 3rd Grabchenko’s International Conference on Advanced Manufacturing Processes. InterPartner-2021, LNME, pp. 119-126. https://doi.org/10.1007/978-3-030-913274_12

Pylypchuk, M.I. 2010. Development of the research methodology of technological accuracy of woodworking machines. Agricultural machines: Coll. of sci. art. Lutsk: LNTU. Vol. 20: pp. 259-265.

Pylypchuk, M.I. 2020. Methodology for studying the dynamics of technological accuracy of woodworking machines. Proceedings of the 4th International science-practice conference, April 1

3, Ivano-Frankivsk, Academy of Technical Sciences of Ukraine. Ivano-Frankivsk: Vasyl Stefanyk Prykarpattia National University. Vol. 1: pp. 70-71.

Pylypchuk, M.I. 2021. Development of scientific and technical bases for ensuring the accuracy of woodworking on machines. Doctoral dissertation, Ukranian National Forestry University, Lviv, Ukraine.

Rudenko, T.H., Ermolaev, Yu.O., Shalimov, V.O. 2012. Development of an automated control system for wood machining on plano-milling machines. In Technology in agricultural production, industrial machine building, automation. Vol. 25, part 2: pp. 272-275.

Skliarov, R.A., Prykhodai, D.A. 2021. Methods for increasing the machining accuracy of metal cutting machines In Book of abstracts of the X International scientific and practical conference of young researchers and students "Current issues in modern technologies", November 24-25. Ternopil: TNTU, p. 56.

Vančo, M., Korčok, M., Barcík, Š., Koleda, P., Gochev, Zh. 2020. Analysis of Factors Effecting on Qualitative Parameters of Surface when Planar Milling Heat-treated Oak Wood, Scientific Journal „Innovation in Woodworking Industry and Engineering Design“, Vol. 2 (18), pp. 1528.

Vitchev, P. 2019. Evaluation of the surface quality of the processed wood material depending on the constructionofthewoodmillingtool.ActaFacultatisXylologiaeZvolen.Vol.61(2),pp.81−90. https://doi.org/10.17423/afx.2019.61.2.08

Vitchev, P., Gochev, Zh. 2019. Influence of the cutting mode on the surface quality during longitudinal plane milling of articles from Scot pine, Science journal "Innovations in Woodworking Industry and Engineering Design". Vol. 8, № 2, pp. 66-72.

Vukov, G., Slavov, V., Vitchev, P., Gochev, Zh., 2021. Forced Spatial Vibrations of a Wood Shaper, caused by the Wear of the Cutting Tool, Scientific Journal "Innovation in Woodworking Industry and Engineering Design", Vol. 10, № 2, pp. 51-62.

20

–

Warcholinski, B., Gilewicz, A. 2022. Surface Engineering of Woodworking Tools, Applied Science, 2022, Vol. 12 (20), 10389. https://doi.org/10.3390/app122010389

Zatulenko, A.S., Zaiets, S.S. 2019. The influence of the process of wear of the cutting tool on the accuracyofmachining. Proceedings of the XIIAll-Ukrainian scientific and practical conference of students, postgraduates and young scientists "Looking into the future of instrument engineering", May 15-16. Kyiv: Ihor Sikorsky Kyiv Polytechnic Institute. pp. 152-154.

AUTHORS’ ADDRESS

Mariya Pylypchuk Doktor of Technical Sciences, Associate Professor

https://orcid.org/0000-0002-7684-1821, Volodymyr Mayevskyy Doktor of Technical Sciences, Professor

https://orcid.org/0000-0001-5820-9454

Vasyl Taras PhD in Technical Sciences

https://orcid.org/0000-0001-5159-998X, Mykhailo Burdiak PhD in Technical Sciences

https://orcid.org/0000-0002-9669-1680, Zoya Kopynets PhD in Technical Sciences

https://orcid.org/0000-0001-8977-6953, 79057, 103, Gen. Chuprynky St., Lviv

Ukraine

21

22

ACTA FACULTATIS XYLOLOGIAE

ZVOLEN, 65(1): 23 34, 2023

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2023.65.1.02

THE EFFECT OF OUTDOOR WEATHERING OF THERMALLY MODIFIED SPRUCE AND PINE WOODS ON THEIR SURFACE PROPERTIES

Vidholdová – Miloš Pánek – Ladislav Reinprecht

ABSTRACT

Products from thermally modified wood used outdoors should be stable against sun, rain, wind, and biological agents. The effect of 1- to 24-month outdoor weathering of the Norway spruce (Picea abies) and Scots pine (Pinus sylvestris) thermally modified woods “ThermoD produced in Oy Lunawood Ltd Finland” (TWs) on their selected surface properties –colour, gloss, roughness, and mould resistance is analysed in the paper. With prolonged weathering, the surfaces of both Thermo-D wood samples lost their original yellow-red shadow. They continuously turned greyer – in the CIE L* a *b* colour system, they obtained greener and bluer colours, together with the logarithmic increase in the total colour difference Δ��∗���� Surfaces of both Thermo-D wood samples within the first four months of outdoor weathering turned much lighter with a higher gloss. However, they got darker and matter due to adsorbing soot and dirt. Similar changes, i.e., as in the lightness and gloss, occurred in the roughness of weathered Thermo-D woods, which firstly decreased and subsequently increased with further prolongation of weathering. Moulds Aspergillus niger and Penicillium brevicompactum, in all cases, intensively attacked spruce and pine wood –natural wood, Thermo-D wood, weathered natural wood, weathered Thermo-D wood.

Keywords: spruce, pine, thermowood, weathering, colour, gloss, roughness, mould resistance

INTRODUCTION

Weathering is one of the most common degradation processes observed outdoors above ground, directly effecting surfaces of wood or other materials. Weathering of wood generally includes a cascade of events that follow photochemical degradation and water leaching of wood components and lead to changes in its surfaces – discoloration, increased roughness, and checking (Meyer and Kellogg,1982; Evans et al., 2008; Kúdela and Ihracký, 2014; Pánek and Reinprecht, 2014; Niklewski et al., 2022). Solar radiation, it means ultraviolet (UV) rays and, to a lesser extent, also visible light rays, cause photochemical damage, especially in lignin and some extractives are more susceptible (Hon and Chang, 1984; Feist, 1990; Pandey, 2005). Photo-damages of the cell wall constituents of wood and following water-leaching of the decomposed products often result in exposing other wood constituents that, in turn, become subject to new degradation from solar radiation. Weathering is an important issuefor all woodproducts exposedoutdoorsas it affects their appearance, service life, and wood-coating performance (Jirouš-Rajković and Miklečić, 2021). Weathering of

23

Zuzana

woodis not to beconfusedwith wooddecay caused bybrown-rot,white-rot,orsoft-rotfungi acting in the presence of excess moisture and a certain proportion of air for an extended period, when the wood can be biodeteriorated rapidly, mainly due to enzymatic reactions in its all volume. Practice and experiments showed that products from softwood and hardwood species primarily treated at high temperatures above 180 °C (TWs – thermowoods) better resist to decaying fungi as products from the same natural wood species (Ahola et al., 2002; Reinprecht and Vidholdová, 2008; Reinprecht and Repák, 2022). On the contrary, the weathering resistance of thermowood is not always higher compared to natural wood.

The popularity of thermally modified claddings for new buildings is increasing fast. The material is seen as native, organic, and aesthetic, and it is also marketed as long-lasting and maintenance-free option. Compared to natural – unmodified wood, thermally modified wood has altered characteristics. Its chemical composition is changed by degrading mainly the hemicelluloses and extractives in the wood cells. The level of change in the wood cell walls depends on the wood species, the type of heat treatment – in air, oils, etc., the time and temperature at treatment, at which the temperature and the absence of oxygen play an important role (Hill, 2006). As a result of changes in the chemical and anatomical structure ofwoodit has changed acidity, wettability,surface free energy, andmechanical and physical properties (Reinprecht, 2016; Sandberg et al., 2021).

The colour and gloss stability of the thermally modified wood is important for the interior and mainly for outdoor exposures connected with its intensive weathering. For example, Ayadi et al., (2003) found that thermally modified ash, beech, maritime pine, and heartwood of poplar showed much less discoloration in comparison to unmodified wood species after UV-exposure. It was speculated that the more stable colour was partly caused byincreasedphenolcontentandhigherstabilityofthecondensedlignin.Baysal et al ,(2014) reached a similar conclusion for thermally modified Scots pine and noted that a longer thermal modification time resulted in a more colour-stable surface. Nuopponen et al., (2004) reported that the lignin content of thermally modified Scots pine wood samples was higher than the lignin content of unmodified samples after 7 years of natural weathering. Also, weathering products of lignin were easily leached out with water from the unmodified wood, whereas in the heat-treated wood they were largely unleachable. Deka et al. (2008) found that colourchanges ofheat-treatedsprucewood werelowerthan untreatedspruce woodafter long-term artificial UV light exposure. It could be due to an increase in lignin stability by its condensation at the time of the heat treatment process at 210 °C. Tomak et al., (2018) have also reported a less negative effect of natural outdoor weathering over four years on the colour stability of thermally modified ash, iroko, Scots pine and spruce wood species. On the contrary, some of studies showed that thermal modification of wood decreases its resistance to weathering. Jämsä et al , (2000) stated extensive greying, increased surface roughness and cracking after a five-year weathering trial of thermally modified pine and spruce boards. Yildiz et al., (2011) reported that thermal modification of alder delayed/decreased the rate of colour change caused by weathering factors but did not completely prevent it. Srinivas and Pandey (2012) also stated that the thermal modification of rubberwood was ineffective in restricting colour changes and suggested that the condensed structures formed in thermal modification were more susceptible to UV-induced degradation. Ahola et al., (2002) reported that thermal treatment had no influence on mould and blue stain growth on coated thermally modified spruce and pine wood during outdoor weathering.However,themoisturecontentofthermallymodifiedwoodwaslowercompared to unmodified wood.

The aim of this experiment was to determine effects of the natural outdoor weathering of spruce and pine thermowood on their selected surface properties – stability of colour and gloss, change of roughness, and mould resistance.

24

MATERIALS AND METHODS

Wood

Samples from the thermally modified Norway spruce wood (Picea abies L. Karst.) (signed – spruce TW) and the thermally modified Scots pine wood (Pinus sylvestris L.) (signed – pine TW), marked with the class Thermo–D – as the selected representatives of softwood with different contents of extractives, were used in the experiment. Four test samples with a dimension of 378 × 78 × 20 mm3 were prepared from each type of solid tongue-and-groove boards (Oy Lunawood Ltd., Iisalmi, Finland) recommended for outdoor use – i.e., from spruce TW and pine TW, as well. The surfaces of test samples were before weathering sanded with the sandpaper grit of 80.

Natural outdoor weathering of wood

Exposure of all test samples in the exterior was carried out according to the standard EN 927–3 (2006) in frames facing south at an angle of 45° and placed approximately 1 m above the ground for 1, 2, 3, 4, 6, 12, and 24 months from November 11, 2015, to November 11, 2017, at Suchdol, Prague (50° 07′49,68″N; 14° 22′13,87″ E, elevation above sea level 285 m). The climatic conditions at the exposure site were as follows: average daily temperature: 10.17 °C (daily extremes 36 °C, −15.70 °C), average daily precipitation 1.52 mm, and average daily incident solar energy 10 899 kJ.m 2. The weathered samples were stabilized at 20±2 °C and 65% relative humidity in the laboratory before the measurements. Tab. 1 shows an overview of the climatic conditions during 24 months of weathering.

Note: Based on data from the meteostation at the Czech University of Life Sciences http://meteostanice.agrobiologie.cz/)

Colour evaluation

The colour characteristics of the wood surfaces were measured using a spectrophotometer CM-600d (Konica Minolta, Japan). The equipment was configured to a D65 light source and observation angle of 10°. Parameters L* , a * and b* were measured at 8 points (Fig. 1) on each test sample over the tangential surface at the beginning of the experiment and after 1, 2, 3, 4, 6, 12, and 24 months of weathering. The colorimetric parameters of each wood sample were analysed according to the CIE L* a *b* system (ISO 7724-3: 1984).

= 90 mm

B = 70 mm

C = 48 mm

25

Average climatic parameter Months of exposure 0-1 1-2 2-3 3-4 4-6 6-12 12-24 0-24 Temperature (°C) 5.86 3.50 2.60 3.01 8.49 15.70 9.81 10.17 Humidity (%) 78.38 82.69 77.12 76.92 65.02 69.24 71.39 71.57 Total precipitation (mm) 45.20 15.20 20.70 47.40 45.10 389.20 550.30 1 112.40 Global solar rad. (kJ.m-2) 2 838 2 081 3 381 5 443 13 523 14 592 11 073 10 899

Tab. 1 Overview of the air climatic conditions in the exposure site during outoor weathering.

Fig. 1 Measurement points on samples for the analysis of the colour, gloss, and roughness.

A positive value of L* , a *, or b* means a lighter, redder, or yellower colour, respectively. From the relative colour changes ΔL*, Δa*, and Δb*, namely differences between chromaticity coordinates of the weathered thermally modified wood sample and the thermally modified wood sample, the total colour difference ΔE* ab was calculated for each point in the tested sample by the equation (1):

Gloss evaluation

The gloss of the wood surfaces was measured with an MG268-F2 glossmeter (KSJ, Quanzhou, China) at an angle of 60° according to EN ISO 2813 (2015). Gloss was measured at 8 points (Fig. 1) on each sample over the tangential surface at the beginning of the experiment and after 1, 2, 3, 4, 12, and 24 months of weathering.

Surface roughness evaluation

The surface roughness of wood samples was determined as its average value Ra (µm) according to EN ISO 4287:1998/AC and EN ISO 4288 (1997) using the profilometer Form Talysurf Series Intra 2 (Taylor-Hobson, UK). The measurement parameters were set in accordance with the standard – a base length was 15 mm. Parameters Ra were measured at 8 points (Fig. 1) traversing lengths oriented perpendicularly to the length of the samples over the tangential surface at the beginning of the experiment and after 1, 2, 3, 4, and 24 months of weathering.

Mould resistance evaluation

For the mould growth activity (MGA) test, there from the nonweathered and 24-month weathered natural spruce and pine wood samples, and also from the nonweathered and 24month weathered TW spruce and TW pine samples, all with a dimension of 378 × 78 × 20 mm3, were prepared specimens with a dimension of 50 ×10 × 5 mm3 . Specimens were exposed to moulds in accordance with the standard ČSN 49 0604 (1980). The natural and thermally modified Norway spruce and Scots pine specimens included the top surface: (I.) without weathering “Reference”, (II.) with two-year /24-month/ weathering “Original surface”, and (III.) with two-year /24-month/ weathering and following brushing “Brushed surface”. The specimens sterilized with UV-light were placed into Petri dishes with a diameter of 120 mm on a 3 to 4 mm-thick layer of 4.9 wt.% Czapek–Dox agar medium (HiMedia Ltd., Mumbai, India) and inoculated with a spore suspension of the microscopic fungus Aspergillus niger Tiegh. (strain BAM 122; Bundesanstalt für Materialforschung und -prüfung, Berlin), and the microscopic fungus Penicillium brevicompactum, respectively. Both spore suspensions were prepared in sterile redistilled water in 106 to 107 spores/ml concentrations. The incubation of the inoculated test specimens lasted 28 days at a temperatureof28 °C ± 2°C andaRHof90%to 95%. Themouldresistance ofthe specimens was determined by the MGA values (from 0 to 4) using these criteria: 0 = no mould growth on the top surface; 1 ≤10%; 2 >10% but ≤25%; 3 >25% but ≤50%; 4 >50%.

Statistical analyses

Statistical analyses were performed with MS Excel 2016, using mean value - average (Avg.), standard deviation (SD), and points graphs. The effect of increased exposure time of weathering (Time → t) from 1 to 24 months on selected surface parameters of wood was analysed using correlations “y = f(t)” and their coefficients of determination “r2”. The statistical software STATISTICA 12 was used to evaluate Duncan’s tests to measure

26

Δ��∗���� = √Δ��∗2 + Δ��∗2 + Δ��∗2 (1)

differences between average parameters of colour (L* , a *, b*, ΔE* ab), gloss (GU), and roughness (Ra) of spruce and pine TWs.

RESULTS AND DISCUSSION

Colour and gloss of weathered thermowood

The most well-known effect of exposing unprotected wood to outdoor weathering, including periods of sun and rain, is a change in colour of its surface. Tab. 2 and Fig. 2 show the average values of chromaticity coordinates L* , a *, and b* for spruce and pine TWs at the beginning and after 1, 2, 3, 4, 6, 12, and 24 months of natural outdoor weathering. With prolonged weathering, the surfaces of both TWs lost their original yellow-red shades and continuously obtained more grey shades defined in the CIE L* a *b* colour system with the observation of greener and bluer colours (Fig. 1a and b). During the first months of weathering (in the wintertime – from November 2015 to March 2016), the wood surfaces become lighter – after 4th month of exposure, lighter maxima L* were observed, i.e., 61.97 for spruce TW and 58.70 for pine TW, at which only then they got darker due adsorbed soot and dirt.

Note: Individual mean value – average (Avg.) and standard deviation (SD) were determined from 32 values (8 values per sample).

Changes in the chromaticity coordinates a* and b* show the performance of outdoor weathered wood surfaces and can be correlated with the wood greying. Experiments showed a trend that both TWs became after weathering less red (a* lower and closer to zero

see Fig. 2a and Tab. 2) and less yellow (b* lower and closer to zero – see Fig. 2b and Tab. 2). The yellow colour changed 2.4 times faster than the red colour (Fig. 2c). Both chromaticity coordinates a* and b* showed a systematic trend to decreasing values with prolongation of exposure time (Tab. 2), and their exponential decrease was described by the following

27

Time L* (-) a * (-) b* (-) Wood Species (Months) Avg. SD Avg. SD Avg. SD Norway spruce - Thermo-D 0 49.94 0.92 10.75 0.16 25.07 0.18 1 57.43 1.11 8.73 0.09 23.39 0.41 2 59.44 1.15 8.20 0.15 20.90 0.71 3 61.20 0.95 7.33 0.21 18.50 0.81 4 61.97 1.86 6.74 0.27 16.94 0.77 6 58.24 3.58 2.84 0.97 8.21 1.20 12 44.33 3.71 1.42 0.25 3.22 0.94 24 39.55 1.86 1.04 0.06 1.72 0.16 Correlation “y=f(t)” – a * = 8.718·e-0.104·t b* = 24.472·e-0.122·t Determination coefficient “r2” r2 = 0.914 r2 = 0.949 Scots pine - Thermo-D 0 50.13 1.37 10.75 0.42 25.32 1.28 1 57.87 1.45 8.65 0.13 25.17 1.22 2 57.83 2.54 7.85 0.23 22.25 1.16 3 58.20 1.47 6.62 0.48 19.01 0.25 4 58.70 1.12 5.60 0.32 16.18 0.43 6 54.01 0.98 1.97 0.19 5.53 0.53 12 45.99 1.38 1.20 0.08 2.42 0.21 24 35.41 1.63 1.01 0.07 1.54 0.14 Correlation “y=f(t)” – a * = 7.848·e-0.104·t b* = 23.003·e-0.130·t Determination coefficient “r2” r2 = 0.886 r2 = 0.920

Tab. 2 The colour parameters (y = L* , a *, b*) of the Norway spruce and Scots pine TWs after their outdoor weathering from 0 to 24 months.

–

equations: for spruce TW: a * = 8.718·e-0.104·t with r2 = 0.914; b* = 24.472·e-0.122·t with r2 = 0.949, and for pine TW: a * = 7.848·e-0.104·t with r2 = 0.886; b* = 23.003·e-0.130·t with r2 = 0.920.

c)

Fig. 2 Correlations between coordinates of the CIE L* a *b* colour system for weathered Norway spruce and Scots pine thermally modified woods (TWs).

a) The chromaticity coordinate a* and the lightness (L*); b) The chromaticity coordinate b* and the lightness (L*); c) The chromaticity coordinate b* and the chromaticity coordinate a*

A similar tendency of lightening and darkening for pine and spruce TWs, treated at 212 °C for 90 min, was at natural outdoor weathering from October 2011 to October 2015 reported in the study of Tomak et al. (2018). They also found that the dark colour of thermally modified samples lightened during the first six months of weathering. Based on the FTIR analyse, the considerable decrease in lignin, mainly in the aromatic ring of syringyl and guaiacyl lignin and asymmetric bending in CH3 in the first weathering exposure period were found. Also, Kucuktuvek et al. (2017) investigated colour changes of Scots pine thermally modified at 210, 220, and 230 °C/1, 2 or 3h, after weathering from May 2016 to October 2016. They found that after weathering all the pine TWs becomes lighter However, the un-heated pine wood become darker. Ugovšek et al. (2019) evaluated the weathering performance of wooden windows and façade elements made from thermally modified and unmodified Norway spruce wood – performed field tests in Žiri (Slovenia), Ljubljana (Slovenia), Hannover (Germany), Skellefteå (Sweden), and Madrid (Spain) from October 2015 until September 2016. They noticed that the colour changes depended on specific locations and weather conditions, where the amount of precipitation played an important role.

Similar colour changes were demonstrated in the case of spruce and pine TWs. The total colour difference (ΔE* ab) showed a systematic trend to increase values with a longer duration of exposure time (Fig. 3). Logarithmic increases of ΔE* ab were described by these

28

a) b)

equations: for spruce TW: ΔE* ab = 7.027 + 6.687·ln(t) with r2 = 0.953, and for pine TW:

ΔE* ab = 5.266 + 7.690·ln(t) with r2 = 0.904.

Spruce TW: ΔE* ab = 7.027 + 6.687·ln(t); r2 = 0.953

Pine TW: ΔE* ab = 5.266 + 7.690·ln(t); r2 = 0.904

a) b) Spruce TW Pine TW

Fig. 3 a) Logarithmic correlations between the total colour difference ΔE* ab of spruce and pine TWs and the time (t) of their weathering

b) Final grey colour and roughness structure of TWs after 24-months of their weathering.

After 24-months, at the end of weathering, the silver-grey surface was visible on both TW surfaces. However, according to Duncan’s test for the total colour difference ΔE* ab, significant contrast was occurred between the weathered spruce TW and pine TW (p-value was 0.004 – see Tab. 3). Kržišnik et al. (2018) found that at weathering the unmodified Norway spruce wood underwent a greater colour change than the thermally modified wood. In outdoors, water rain leaches photo-degradation products from wood surfaces, and a grey surface composed of partially degraded cellulose, some portion of hemicelluloses, and only low lignin content is left (Feist, 1990; Tomak et al., 2018; Kropat et al., 2020). In contrast, the blue-stain fungi acting in exterior darken the wood (Zink and Fengel, 1989; Kržišnik et al., 2018).

Tab. 3. Duncan's multiple range tests for comparison the changes of colour (L* , a *, b*, ΔE* ab), gloss (GU), and roughness (Ra) between the naturally weathered Norway spruce and Scots pine TWs.

Note a-d = indexes of statistical significance (p-value): a very significant difference at the 99.9% level; b significant difference at the 99% level; c less significant difference at the 95% level; and d insignificant difference at the <95% level.

Along with colour, gloss is another important aesthetic property of wood, particularly in terms of user's preferences. The average surface gloss of the Norway spruce and Scots pine TWs at their natural outdoor weathering is shown in Fig. 4. Initially, before weathering,

29

Exposure time (Months) L* (–) a * (–) b* (–) ΔE* ab (–) GU (–) Ra (µm) 0 0.883 d 0.975 d 0.595 d – 0.255 d 0.489 d 1 0.739 d 0.651 d 0.265 d 0.854 d 0.024 c 0.595 d 2 0.065 d 0.038 d 0,003 b 0.005 b 0.000 a 0.002 b 3 0.034 c 0.000 a 0.526 d 0.000 a 0.000 a 0.000 a 4 0.042 c 0.001 b 0.093 d 0.003 b 0.000 a –6 0.022 c 0.081 d 0.091 d 0.076 d – –12 0.184 d 0.196 d 0.076 d 0.123 d 0.037 d –24 0.001 b 0.847 d 0.683 d 0.004 b 0.808 d 0.000 a

the TW surfaces had a gloss value of less than 10, which means that the surfaces were matte. The surfaces during the first 4 months of weathering acquired a higher gloss, meaning that the surfaces were semi-matte (GU values were between 10 and 35), but then became matte again and even more matte due to adsorbed soot and impurities. According to Duncan’s test for the gloss, there after 24 months of weathering, an insignificant difference occurred between the spruce and pine TW (p-value was 0.808 – see Tab. 3). Kucuktuvek et al. (2017) also notedthat asurface gloss oftheScots pinemodifiedbyhigh temperatures was increased after natural half-year weathering from May 2016 to October 2016.

Roughness of weathered thermowood

Surface roughness of spruce and pine TWs at the beginning and after 1, 2, 3, 4, 6, 12, and 24 months of natural weathering is shown in Fig. 4. During the first four months, the trend of the change in roughness was for both wood species evidently different. However, at the end of weathering period, both surfaces became rougher. After 24 months, a higher roughness was found – about 121% for spruce TW, and about 40% for pine TW (Fig. 5). According to Duncan’s test for the roughness after 24 months of weathering, significant difference occurred between the weathered spruce and pine TWs (p-value was 0.000 – see Tab. 3). The increase in surface roughness may be related to the photo-degradation of wood lignin and hemicelluloses, the water-leaching of depolymerized polar substances from wood surfaces by rain, fog or dew, and the spatial release of cellulose fibrils (Nuopponen et al., 2004; Reinprecht 2016; Tomak et al., 2018).

Mould resistance of weathered thermowood

Mould growth on wood surfaces is a very important factor which can negatively affect thevisual appearanceand healthparameters of woodproducts exposedin outdoors(Kržišnik

30

Fig. 4 The gloss (GU) of the Norway spruce and Scots pine TWs during natural weathering.

Fig. 5 Roughness (Ra) of the Norway spruce and Scots pine TWs during natural weathering.

et al., 2018). In our experiment the moulds Aspergillus niger and Penicillium brevicompactum always intensively attacked spruce and pine woods – natural wood, Thermo-D wood, weathered natural wood, weathered Thermo-D wood (Tab. 4, Fig. 6).

Tab. 4 The mould growth activity (MGA) of two microscopic fungi evaluated after 28 days on the top surfaces of the Norway spruce and Scots pine thermowood “TWs” as well as natural wood

types I., II., and III.

Generally, the thermal modification processes usually did not have an influence on develop the moulds and blue stain fungi on wood surfaces during wood exposure to laboratory and field trials (Ahola et al., 2002; Reinprecht and Vidholdová, 2008; Kržišnik et al., 2018). According to study of Ugovšek et al. (2019), the mould growth on wooden surfaces in the field test also may depend on the specific location and weather conditions – so if the precipitation was higher, the mould growth on wooden surfaces was also higher.

31

–

Wood species Mould growth activity (MGA) (0-4) A. niger P. brevicompactum Thermowood - TW Natural wood Thermowood - TW Natural wood Norway spruce I – Without weathering “Reference” 4 4 4 4 II. – 24-month weathered “Original surface” 4 4 4 4 III – 24-month weathered “Brushed surface” 4 4 4 4 Scots pine I. – Without weathering “Reference” 4 4 4 4 II – 24-month weathered “Original surface” 3 – 4 4 4 4 III – 24-month weathered “Brushed surface” 4 4 4 4

P.

Norway spruce TW – Natural wood Scots pine TW – Natural wood Norway spruce TW – Natural wood Scots pine TW – Natural wood

A. niger

brevicompactum

I. Without weathering – Reference

II. 24-month weathering “Original surface”

III. 24-month weathering “Brushed surface”

Fig. 6. The mould growth activity (MGA) of two microscopic fungi evaluated after 4 days on the top surfaces of the Norway spruce and Scots pine TWs and natural wood.

Note: In each Petri dish is one TW specimen (in left) and one natural wood specimen (in right).

Based on the analysis of the 1- to 24-month natural outdoor weathering effect of the thermally modified Norway spruce (Picea abies) and Scots pine (Pinus sylvestris) wood “Thermo-D” – TWs, the following conclusions can be drawn:

• with prolonging of weathering, the surfaces of both thermally modified woods –spruce and pine TWs – lost their original yellow-red shadows, continuously obtained more grey shadow defined in the CIE L* a *b* colour system by bluing and greening, and the total colour difference ΔE* ab increased logarithmically with a weathering time;

• during the first 4-months of weathering, the surfaces of both TWs turned lighter with a higher gloss, and only then they got darker and matter due to adsorbed soot and dirt;

• during the first 4-months of weathering, the surfaces of both TWs obtained a lower roughness and only then they got rougher due to the leaching of polar by sun rays depolymerized phenolic and saccharide substances from wood surfaces by following action of rain, fog or dew;

• during the first 4-months of weathering, the surface of the Norway spruce TW was more susceptible to the temporary change in the lightness, gloss, and roughness than the surface of the Scots pine TW;

• at the end of weathering, the colour evidently changed for the surfaces of both TWs and they obtained silver-grey shadows;

• at the end of weathering, the roughness of TWs surfaces increased for both wood species; however, the Norway spruce TW had a significantly higher roughness than the Scots pine TW.

• The moulds Aspergillus niger and Penicillium brevicompactum in laboratory conditions always intensively attacked the Norway spruce and Scots pine wood –natural wood, Thermo-D wood, weathered natural wood, weathered Thermo-D wood.

REFERENCES

Ahola, P., Jämsä, S., Viitanen, H., Viitaniemi, P., 2002. Mould and blue stain on heat treated wood. Proceedings of Cost Action 18 Meeting, Portugal, 4 April 2002.

Ayadi, N., Lejeune, F., Charrier, B., Merlin, A., 2003. Color stability of heat-treated wood during artificial weathering. Holz als Roh - und Werkstoff 61, 221–226.

https://doi.org/10.1007/s00107-003-0389-2

Baysal, E.,Degirmentepe, S., Şimşek, H.,2014. Somesurfaceproperties of thermally modifiedScots pine after artificial weathering. Maderas. Ciencia y tecnología 16, 355–364.

https://doi.org/10.4067/S0718-221X2014005000028

ČSN 49 0604: 1980. Ochrana dřeva. Metody stanovení biocidních vlastností ochranných prostředků na dřevo. Úřad pro normalizaci a měření: Praha, Česká republika,1980

Deka, M., Humar, M., Rep, G., Kričej, B. Šentjurc, M., Petrič, M., 2008. Effects of UV light irradiation on colour stability of thermally modified. copper ethanolamine treated and nonmodified wood: EPR and DRIFT spectroscopic studies. Wood Science and Technology 42(1), 5

20. https://doi.org/10.1007/s00226-007-0147-4

Evans, P.D., Urban, K., Chowdhury, M.J.A., 2008. Surface checking of wood is increased by photodegradation caused by ultraviolet and visible light. Wood Science and Technology 42(3), 251

265. https://doi.org/10.1007/s00226-007-0175-0

32

CONCLUSION

–

–

EN 927–3: 2006 Paints and varnishes - Coating materials and coating systems for exterior woodPart 3: Natural weathering test. European Committee for Standardization: Brussels, Belgium, 2006.

EN ISO 2813:2015 Paints and Varnishes, Determination of Gloss Value at 20°, 60° and 85°; European Committee for Standardization: Brussels, Belgium, 2015.

EN ISO 4287:1998/AC. Geometrical product specifications (GPS). Surface texture. Profile method. Terms, definitions and surface texture parameters. European Committee for Standardization: Brussels, Belgium, 1998

EN ISO 4288:1997 Geometrical product specifications (GPS) - Surface texture: Profile methodRules and procedures for the assessment of surface texture European Committee for Standardization: Brussels, Belgium, 1997

Feist, W.C., 1990. Outdoor wood weathering and protection. In: Rowell, R.M., Barbour, J.R. (eds) Archaeological wood properties. chemistry. and preservation. Adv Chem Ser 225. Am Chem Soc. Washington. DC. USA.

Hill, C.A.S., 2006. Wood modification: Chemical, thermal and other processes. John Wiley & Sons. Chichester. UK.

Hon,D.N.S.,Chang,S.T.,1984.Surfacedegradationofwoodbyultravioletlight.Journal ofPolymer Science: Polymer Chemistry Edition 22(9), 2227–2241. https://doi.org/10.1002/pol.1984.170220923