Everything new comes from something old. With this in mind, we want to take you on a journey in this anniversary book through the development of Witteveen+Bos.

We will do this using our colleagues’ experiences as the starting point. They are the people who give a face to our consultancy and engineering firm every day – whose efforts put into practice the values of expertise, collaboration and entrepreneurship present in our DNA – and help write the continuing story of Witteveen+Bos.

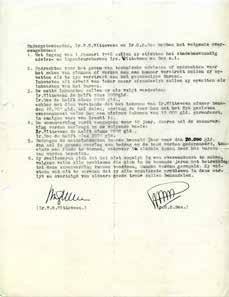

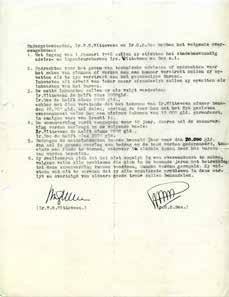

That story began 75 years ago on an ordinary sheet of paper. On this A4 sheet, Willem Witteveen and Goosen Bos drew up their very first plans. It was an act based on trust, and it is heartening to see that 75 years later trust still plays an important role in our company.

The stories and projects included in this anniversary publication are, of course, only a selection. There are so many more great stories to tell. The ones told here nevertheless offer a good sense of the worldwide contribution we make in our fields of operation: water, infrastructure, the built environment and construction. They also shed light on how we value personal growth and ambition.

In this digital age, we have consciously chosen for a responsibly produced physical book. In doing so, we continue a fine tradition of books published by Witteveen+Bos.

We wish to thank everyone who shared a personal story and contributed to the creation of this book, and we hope that you enjoy reading it.

Wouter Bijman Eveline Buter Stephan van der Biezen

75 years of Witteveen+Bos

Foreword

Expertise Collaboration

‘Our responsibility towards the society of which we are a part’ 19 ‘Witteveen+Bos is unique in its cross-pollination of top expertise and entrepreneurship’ 25 Experts on social challenges 33 ‘Milestone is a wonderful example of collaborating on innovations’ 51 Collaborating is in our DNA 57 Sharing knowledge internally and innovating 63

75 years of Witteveen+Bos

Entrepreneurship

Entrepreneurship leads to worldwide growth 83 Responsibility and autonomy 87 ‘There are lots of possibilities, but you have to go after them yourself’ 91 The Witteveen+Bos story will never be finished 97

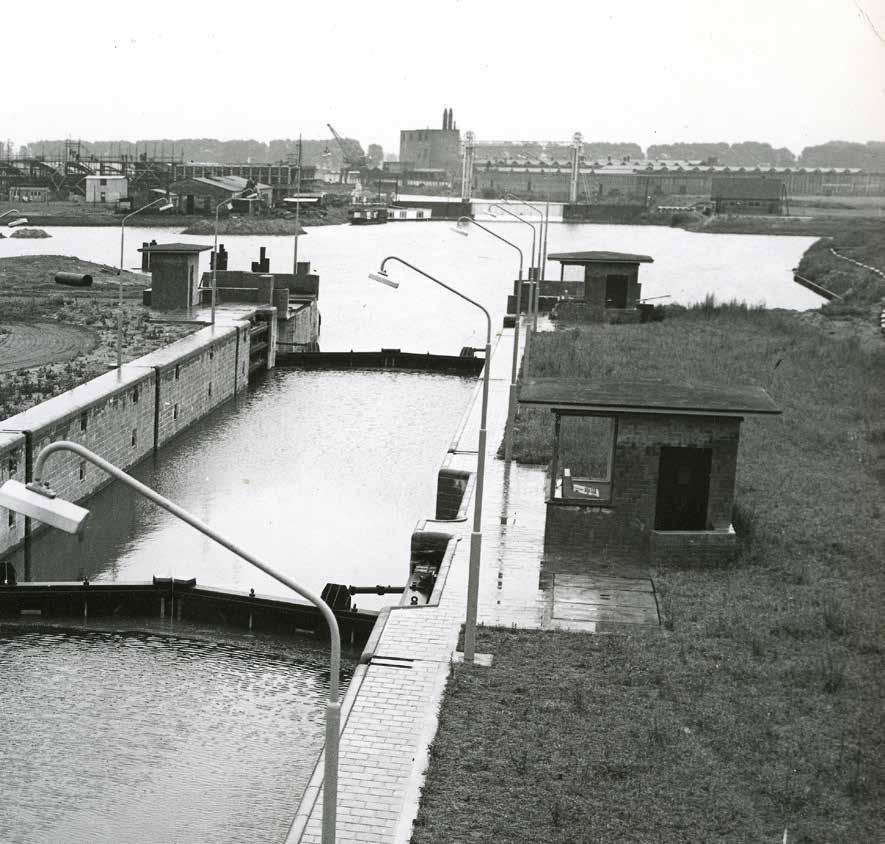

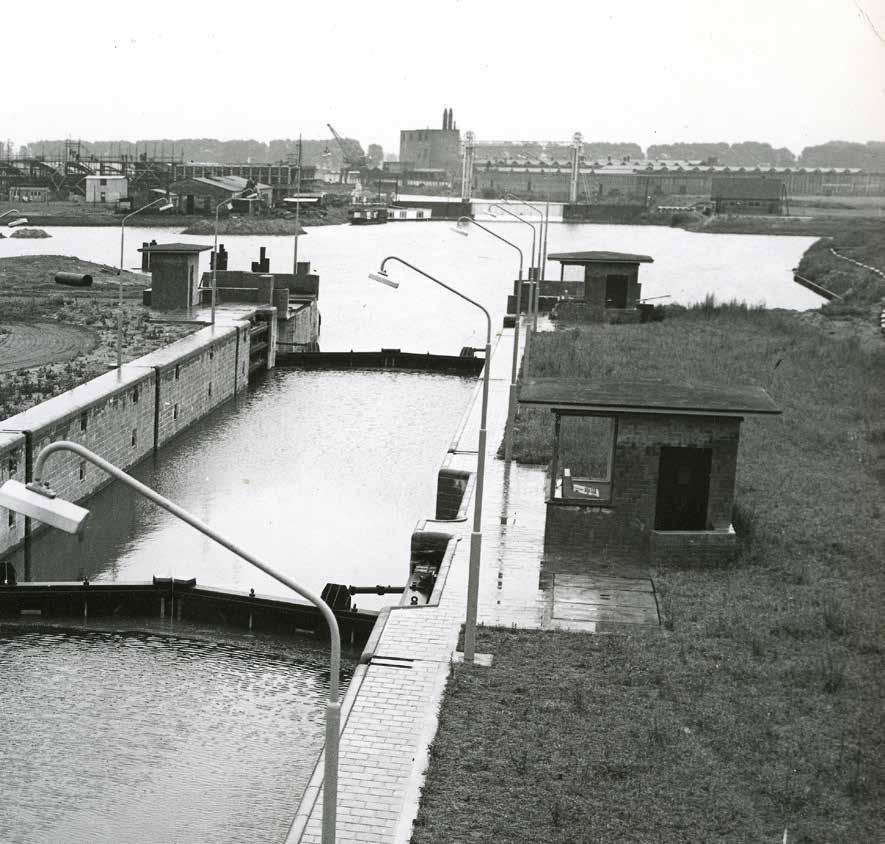

The A4 sheet on which Bos and Witteveen confirmed their collaboration agreement..

75 years of Witteveen+Bos

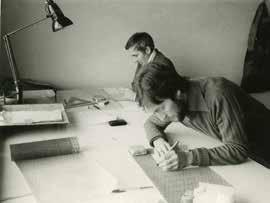

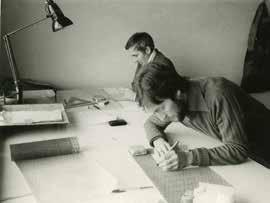

In the company’s first few years, all the characteristics of the postwar pioneering phase were present. Drawings were done on drawing boards and we used slide rules for calculations. Supervisors rode their bicycles from project to project. It was a phase in which projects literally were ‘awarded’ to the expert engineers and consultants of Witteveen and Bos because they were good at their jobs. In the years that followed, we rode the wave of progress in the Netherlands and experienced a strong period of growth. Witteveen and Bos grasped the available opportunities for other types of projects with both hands. To this very day, developments in society can be seen in the expertise and specialist knowledge within the organisation.

75 years of Witteveen+Bos Expertise

‘Our responsibility towards the society of which we are a part’

‘Witteveen+Bos is unique in its cross-pollination of top expertise and entrepreneurship’

Experts on social challenges

Marker Wadden – Wouter Roosen

Marker Wadden – Wouter Roosen

75 years of Witteveen+Bos

In the company’s first few years, all the characteristics of the postwar pioneering phase were present. Drawings were done on drawing boards and we used slide rules for calculations. Supervisors rode their bicycles from project to project. It was a phase in which projects literally were ‘awarded’ to the expert engineers and consultants of Witteveen and Bos because they were good at their jobs. In the years that followed, we rode the wave of progress in the Netherlands and experienced a strong period of growth. Witteveen and Bos grasped the available opportunities for other types of projects with both hands. To this very day, developments in society can be seen in the expertise and specialist knowledge within the organisation.

In 1946, Willem Witteveen and Goosen

Bos founded the company which has grown into today’s Witteveen+Bos, a global network of over 1,400 experts.

Building on our strong foundation, our DNA, our corporate objectives and our strategy, we want to continue to grow as a globally integrated company with a sustainable and innovative profile. In the coming decades, our aim is to remain an engaged and appealing employer, contractor and project partner for the solution of social challenges.

75 years of Witteveen+Bos

In the company’s first few years, all the characteristics of the postwar pioneering phase were present. Drawings were done on drawing boards and we used slide rules for calculations. Supervisors rode their bicycles from project to project. It was a phase in which projects literally were ‘awarded’ to the expert engineers and consultants of Witteveen and Bos because they were good at their jobs. In the years that followed, we rode the wave of progress in the Netherlands and experienced a strong period of growth. Witteveen and Bos grasped the available opportunities for other types of projects with both hands. To this very day, developments in society can be seen in the expertise and specialist knowledge within the organisation.

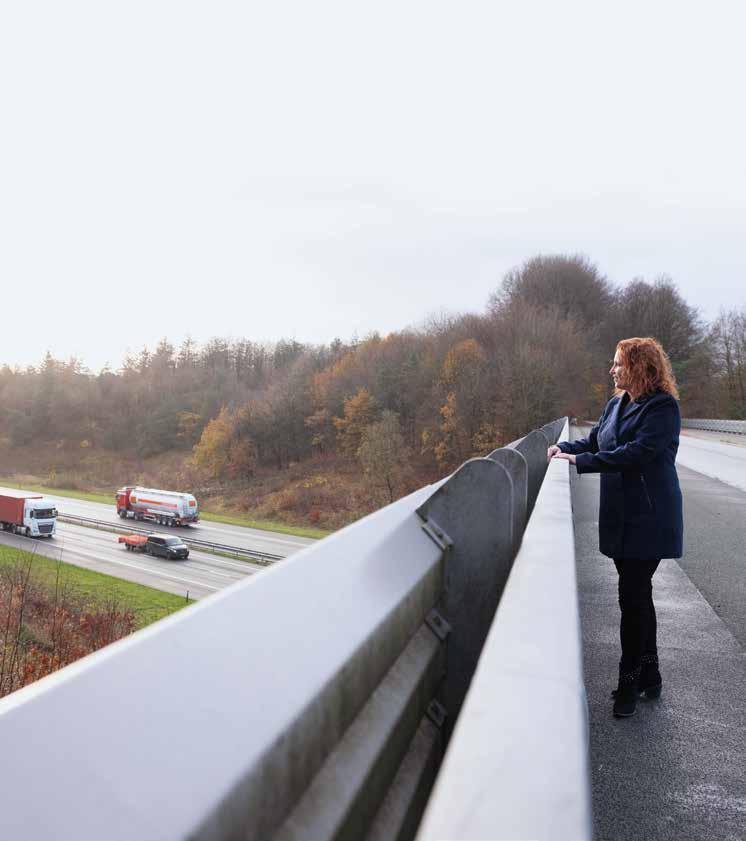

Utrecht STP – Manca Petek

Utrecht STP – Manca Petek

‘Being allowed to contribute to the reinforcement of the Afsluitdijk – specifically, the design of the discharge sluices – makes me proud. Climate change means that sea levels are rising, heavier rainfalls are expected and our rivers’ peak discharges are increasing. To meet these challenges, the dyke and all its civil engineering structures are being reinforced and its discharge capacity increased. The Afsluitdijk is an icon. It’s fascinating to be given an insight into the design of its discharge sluices. Tackling today’s challenges makes you more aware of how ingenious Cornelis Lely's, a Dutch civil engineer, ninety-year-old design is.’ In many respects, the way hydraulic engineer Huig de Waardt describes his work on the Afsluitdijk resembles the ambition and engagement of our founders, Willem Witteveen and Goosen Bos.

19

‘Our responsibility towards the society of which we are a part’

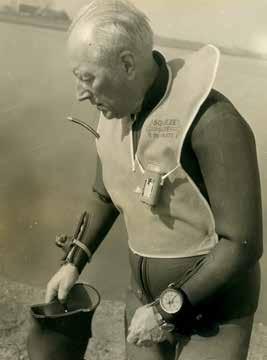

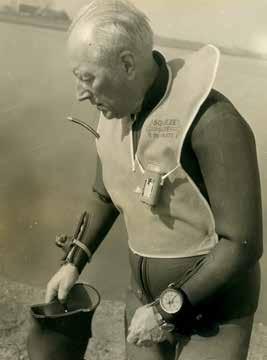

Goosen Bos – founder of Witteveen+Bos

75 years of Witteveen+Bos

Changing social challenges

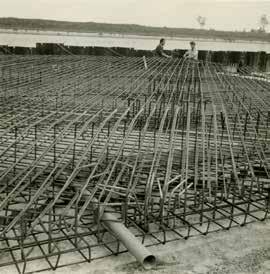

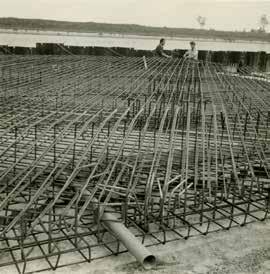

Witteveen+Bos’s development is a reflection of society’s evolving challenges. In the early years, immediately following the Second World War, most of the work involved repairing and expanding Dutch infrastructure. In the 1960s, the booming economy led to further industrialisation, the growth of cities, and increased mobility in the Netherlands. The negative effects of this growth, however, soon became visible: the pollution of surface water, soil and air. Witteveen+Bos became involved in a range of complex projects: large pipelines for transporting waste water, movable bridges, viaducts and sewage treatment plants. At the same time, social tension increased around large (expansion) projects. Ed Koster, who joined the Board of Directors in 1968, gave the engineers’ work an extra dimension: new insights were needed to meet the new challenges, disciplines other than civil engineering were required, and an integrated approach had to be developed.

Expansion of projects

Following the introduction in 1969 of legislation on surface water pollution, the demand for sewage treatment plants (STPs) increased. So as to be able to design an STP in its entirety, expertise on purification technology was built up and later developed further for designing drinking water treatment plants. Expertise on

20

They began in 1946 full of confidence and, according to Bos, with the mission to ‘work in order to help people live safely.’ Bos felt that he was a technician ‘working in a domain situated between two responsibilities: towards the client and towards the society of which we are a part.’

surface water quality and geohydrology was also developed in this period. When the first major soil contamination was discovered in Lekkerkerk in the late 1970s, the first environmental experts joined Witteveen+Bos from Wageningen University.

Integrated approach and introduction of environmental impact assessments

The addition of these new disciplines also saw the introduction of integrated design, not only for environmental projects but in almost all fields. The basic principle was that engineering firms needed to adopt an integrated approach to projects and also take environmental consequences into consideration. In the United States, environmental impact assessments (EIAs) had been introduced to ensure that effects on the environment were considered in large projects. The approach was received positively in the Netherlands and, in advance of legislation on the subject, six EIAs were conducted as a pilot in the late 1970s.

In 1977, one of these pilot projects was awarded to Witteveen+Bos: an EIA for the proposed site of the sewage treatment plant in Tiel. In the early 1980s, three EIA pilots were also carried out in Indonesia. There, too, Witteveen+Bos was responsible for one of them: an EIA for the expansion of the Dumai oil refinery on Sumatra. The EIA remains an important component of the services we offer. It involves more than just writing environmental impact reports; here, too, it is about an integrated approach to the issues at stake and about viewing projects in their larger contexts. In 2002, a product-market combination (PMC) was established for preparing environmental assessments and permit applications. Technical designs, landscape integration and environmental impact have since been integrated across the whole company.

The creation of the Ecology PMC

Ecology is now an indispensable PMC. Begun as a department consisting of two aquatic ecology employees in the 1990s, it has since developed into a fully

21 75 years of Witteveen+Bos

‘In ten years’ time, the core of the design process in our projects will be formed by liveability, sustainability, health and biodiversity. They’ll no longer be just a nice touch or an added bonus. As a result, environmental and local area impact assessments will be valued core instruments in the planning process, not an afterthought.’

Anke Springer-Rouwette – Group Leader, Planning Studies and EIAs in Urban Living Environments

fledged PMC as a result of effective entrepreneurship. It all started with the manipulation of water systems. The idea was that shallow, turbid water filled with algae could once again be made clear and plant-filled by intervening in the fish population. Map Grimm, then head of the Integrated Water Management Sector, proclaimed: ‘I’m going to create that market.’ The first major project then followed, involving the intervention in fish stocks in the Wolderwijd, one of four bordering lakes near the forest-rich Veluwe area.

Ecologist Marcel Klinge: ‘Especially in the early years, the company’s success didn’t depend on ecologists. This has now been completely reversed: ecology is at the heart of the company. Ecological support is requested in almost all our projects. Further development in The Netherlands is currently on hold. First nature has to be put back in order – only then can we start building again. Government policy has made ecology a prerequisite. We’ve got the wind at our backs in that sense, including from a legislation perspective.’

New types of expertise

Over the years, projects have increasingly demanded a multidisciplinary approach. For this reason, new types of expertise have been brought into the company and we now also provide advice, for example, on innovative contract forms and permits and tenders; we conduct social cost-benefit analyses; and we support clients in communicating with their local community, including via digital tools. As a result of this, as well as the professionalisation of our business operations, more and more non-engineers have joined the ranks, including lawyers, industrial designers, environmental managers, software engineers, (landscape) architects, soil experts, geologists, data analysts, HR advisers, communications specialists and marketers.

A social development currently in progress is the global energy transition. How can we bring together new, sustainable energy solutions – from production and distribution to use – in one integrated system? Using our expertise, we

22

‘My heart lies in permits, especially the content. Legislation is constantly changing. By staying on top of new developments, I’m able to effectively advise and support clients.’

Jolanda Overbosch – Environmental Lawyer

help clients over the entire value chain of generation, storage, distribution and energy use. What started as a modest group in 2014 has now grown into three PMCs, and the real work is yet to begin.

From national to international

In the post-war years, Witteveen and Bos had their hands full with projects in the Netherlands, mostly involving infrastructure. By bringing in new disciplines and developing leading expertise and a healthy growth ambition, boundaries were pushed. Although, from the 1950s, projects in other countries were occasionally carried out, in the mid-1970s Witteveen+Bos was still a regional engineering firm whose employees came from Deventer and the surrounding area. This changed with the acquisition of the Nedeco office in Jakarta in 1978, which meant that, for the first time in the company’s history, we had an office outside the Netherlands. From that point on, the number of projects steadily increased worldwide. In 2021, we have home markets in Belgium and Kazakhstan as well as the Netherlands and Indonesia. From these home markets, we collaborate with smaller ‘front offices’ in Dubai, Ghana, Latvia, Panama, Singapore, the United Kingdom and Vietnam.

23

‘We have the important job of solving large problems today and in the future. Innovation, inclusivity and international growth are needed to create maximum impact worldwide. Only then can we realise our full potential.’

Wouter Bijman – Managing Director

75

years of Witteveen+Bos

3D concrete printing, Eindhoven (Milestone) – Marijn Bruurs

3D concrete printing, Eindhoven (Milestone) – Marijn Bruurs

‘Turning lines of research into practical applications, into concrete projects – that’s what I was hired for in 2001 and it’s still an important and incredibly enjoyable part of my work. Witteveen+Bos is unique in its cross-pollination of top expertise and entrepreneurship. For me, the challenge remains to establish new long-term goals together with clients and partners, and to achieve them.’ Twenty years ago, Arjen van Nieuwenhuijzen was awarded a PhD in the physico-chemical pretreatment of waste water. His doctorate sowed the seed for the innovative purification concept of the LIFE Water Factory in Wilp.

25

‘Witteveen+Bos is unique in its cross-pollination of top expertise and entrepreneurship’

Arjen van Nieuwenhuijzen – Consultant, Circular and Bio-based Solutions

75 years of Witteveen+Bos

‘We’ve now demonstrated that it works and that was a great team performance. At the Vallei en Veluwe Water Authority’s sewage treatment plant, a pilot was conducted from May 2019 to June 2020. By separating sewage, valuable raw materials are extracted from it – a physico-chemical treatment process that doesn’t release any greenhouse gases.’

Alongside his work for Witteveen+Bos, Arjen is a principal investigator at the Amsterdam Institute for Advanced Metropolitan Solutions and Associate Professor of Circular Urban Resources at Wageningen University & Research. In these roles, he is concerned with bringing the business community, the government and the academic world together to solve pressing circular challenges for the urban environment.

Applying the latest knowledge from universities and colleges

Witteveen+Bos utilises the latest knowledge from universities, colleges and other research institutes in a range of ways. Various Witteveen+Bos employees are conducting PhD research and combining this with their jobs. Also, many employees are or have been active as teachers – for example, in the field of structural design, ports and waterways, virtual reality/3D, and contracting and tendering. Collaboration with universities even led to the opening of a Witteveen+Bos office on the Wageningen campus and – in the year of our 75th anniversary – to a pop-up office at EnTranCe, the centre of expertise on energy at the Hanze University of Applied Sciences in Groningen.

Together with Antwerp’s Institute of Tropical Medicine and local universities, Witteveen+Bos Belgium has committed to two projects in Africa aimed at combating malaria. ‘In both cases, it concerns strong population growth towards a river valley – precisely where mosquitoes deposit their larvae. There’s currently a malaria epidemic in the residential areas of Jimma, Ethiopia,’ explains Sofie Depauw, leader of the Coasts, Rivers and Cities PMC. ‘We’re

26

‘We’ve got to change our traditional way of thinking. We’re working on a large project for the Belgian coast with an initial rise of three metres in the sea level. With almost all the other firms, we’re looking for alternative forms of sea wall protection: Where will we draw the line in the future between land and water? We’re really being challenged.’

Sofie Depauw – PMC Leader, Coasts, Rivers and Cities

investigating the relationship between the centre of the problem and the hydrographic system. How can we contain the epidemic? Does the city need to develop differently or can we responsibly adjust the water system?’

Creating public value

If a researching engineer or consultant can add value and knowledge to the organisation by completing a PhD, it is a win-win situation. It increases the level of knowledge and experience of both Witteveen+Bos and the employee. Leonie Koops obtained her PhD from TU Delft in 2017 for her thesis, ‘Creating public value. Optimizing cooperation between public and private partners in infrastructure projects’. Leonie: ‘During various infrastructure projects, I noticed that I needed more knowledge about public and private partners and the relationship between the two. My experience had taught me that collaboration between public and private project partners could be drastically improved. This led to a PhD course of study. For my thesis, I studied the organisational side of collaboration between project partners, with the aim of delivering more projects on time, within budget and with satisfied stakeholders.’

‘During my research, I noticed that I was immediately able to apply new insights at Witteveen+Bos – such as how clients view projects. These insights ended up being applied both within the organisation and outside it – for example, in the construction team models used by Rijkswaterstaat. On the other hand, I also really enjoy passing the practical experience I’ve built up on to students.’ Leonie still has a connection with TU Delft as a lecturer and as Chair of Public Commissioning.

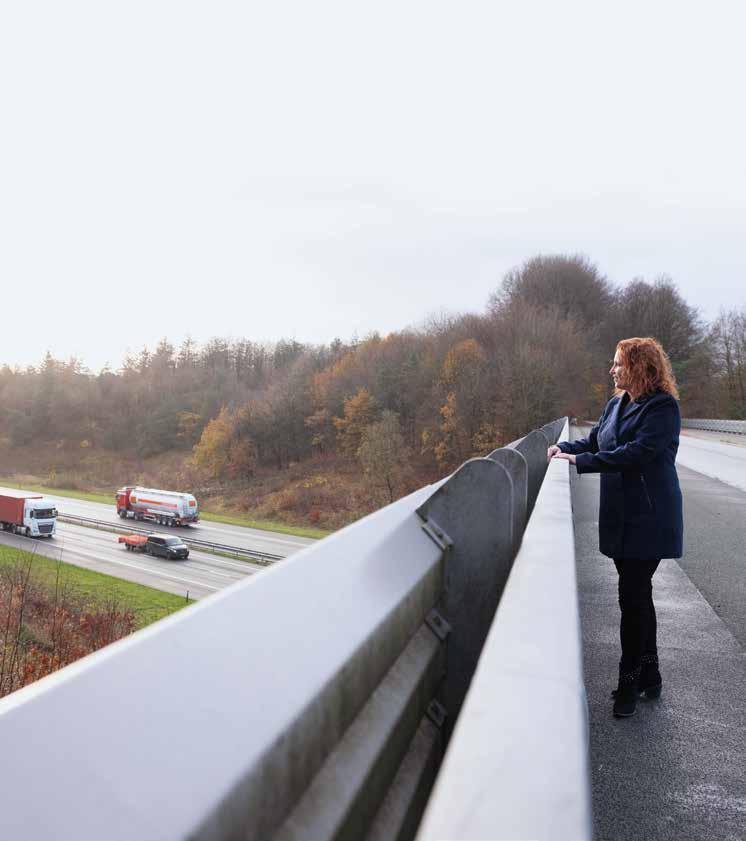

‘Over the coming years, a lot will change in the field of mobility’

The ambition to lead the pack in terms of knowledge and contribute to solving social issues was an important reason for Aries van Beinum, Traffic and Roads PMC leader, to work for Witteveen+Bos – and to complete a PhD. He

27 75 years of Witteveen+Bos

‘Every year, a really special assignment comes along, like the design of the Netherlands Pavilion at the World Expo in Dubai not too long ago. You have to recognise it and seize the opportunity to be a part of something special.’

Maarten Veerman – Group Leader, Building Physics

has developed into an authority on traffic and is the ambassador for mobility at Koninklijke NLingenieurs, the Dutch trade association for consultancy, management and engineering firms. In 2021, as a result of the corona pandemic, mobility has become a social issue. Aries: ‘We already knew that a ten-per-cent reduction in traffic would eliminate all traffic jams as well as crammed trains. We’ve now seen this in practice, in 2020 and 2021, as a result of corona. We’ve also seen new means of transport emerge, such as the speed pedelec, and authorities are contemplating whether fewer or no cars at all should be permitted in inner city areas. As a result of this, a lot will change in the field of mobility in the coming years. It’s fantastic – and very interesting – that Witteveen+Bos is involved in the development of these changes. This is reflected in our recommendations regarding, for example, use and safety, capacity and costs, and spatial suitability, the environment and liveability.’

‘We felt a bored tunnel was feasible’

In projects, too, knowledge is heavily invested in. Frank Kaalberg is a PMC leader and an expert in tunnel design and underground structures, and he was one of the technical leads on the North/South Line project in Amsterdam. ‘We felt that a bored tunnel was feasible and offered greater social value because it wouldn’t involve demolishing historical houses and would require less concrete. It was also groundbreaking, because before 1994 no such tunnel had been constructed in the Netherlands. With young engineers determined to master this field of knowledge, and with the help of firms overseas, we acquired the necessary knowledge and made it applicable to the situation in the Netherlands. This allowed us to build up knowledge and expertise.’

Amsterdam’s soft ground meant that the overseas knowledge had to be tailored to local conditions. To achieve this, a programme of six large practical trials was set up at a cost of more than EUR 15 million. The knowledge and insights gained were immediately integrated into the design of the North/South Line. As a result of this research and the way its results were applied, we developed

28

‘We’re very similar to a family business, because we own our own shares. I don’t know if that’s why we always want to be the best – that we’re very driven in terms of content – but it definitely contributes to it.’

Eric Holtrop – Group Leader, Space and Mobility

75 years of Witteveen+Bos

the ‘design by testing’ philosophy in collaboration with TU Delft. The North/ South Line is an example of how Witteveen+Bos develops knowledge, shares it, and deploys it in projects. Techniques developed during the North/South Line project were applied, for example, to the Sluiskil Tunnel in Terneuzen, the Spoorzone in Delft, the Hubertus Tunnel in The Hague, the Baan Tunnel in Rotterdam, and the Oosterweel Link in Antwerp.

Frank: ‘It gives me real satisfaction that our work has an impact. That’s why we do it. Different committees make use of it, for example, and it’s applied to new guidelines on underground construction so that tunnels are better and more sustainable. We’ve shared the knowledge we gained with fellow specialists across the globe, so who knows how many people have since made use of it.’

The groundbreaking design of the North/South Line’s bored tunnels received the Schreuders Prize in 2013 and the prestigious Ground Engineering Award in 2014.

Unique: odour laboratory

At Witteveen+Bos, we are always searching for knowledge that is new, knowledge that we do not yet possess, and knowledge that we can use to make our projects even better. Take, for example, the Odour Lab, established and developed in the 1980s following complaints about the smell at sewage treatment plants. Our odour lab in Deventer and its olfactometers (‘odour meters’) were developed by Witteveen+Bos, and its measurement methods are fully accredited. The lab is quite unique: there are only two other accredited odour labs in the Netherlands. Our experience measuring air quality and odour led, in 2020, to us starting a centre of expertise on barn emissions together with Wageningen University & Research for the purpose of tackling the enormous task of reducing emissions of ammonia, odorants and particulates in the Dutch livestock sector in the coming years. ‘Our measurement technicians are participating in the measurement campaign’, explains Environment, Health and Habitat PMC leader Hannie Dierx. ‘Witteveen+Bos also designed, fit out and developed the data platform.’

29

‘We’re constantly challenging people to learn, to develop expertise. I’m proud of the enormous dedication and commitment of our people – to the company, to projects and to the results they achieve.’

Eveline Buter – Director

Establishment of centre of expertise on PFASs

In 2012, Witteveen+Bos was one of the initiators of a centre of expertise on PFASs. According to scientific findings, emerging contaminants such as PFOA and PFOS are extremely harmful for the soil-and-water system, ultimately impacting on human health too. The centre of expertise collects and shares knowledge and information about this. Back when most people in the Netherlands had never heard of per- and polyfluoroalkyl compounds, environmental chemical engineer Martijn van Houten was already viewing them as among the top ten substances worth keeping an eye on. This realisation was shared by others at TTE Consultants and Arcadis and resulted in the joint establishment of the centre of expertise. In 2021, there is a broad awareness of the topic and a shared sense of urgency about tackling PFASs.

‘We’re involved in various technical solutions for removing PFASs from soil. We do this both at the request of our clients and on our own initiative,’ explains Martijn. ‘But we’re also looking beyond this: How can we deal with nonstandardised substances in soil and water? We’re doing this with the POPUP project. In this project, a consortium is working together with end users – such as provinces, water authorities, municipalities and environmental services – to create roadmaps for guiding the actions to be taken when a non-standardised substance or new contamination arises. Rijkswaterstaat and the Ministry of Infrastructure and Water Management are also collaborating on the project. These roadmaps are one of the results of ten years’ thinking about PFASs. This will help prevent problems, such as those surrounding PFASs, in the future; and I think it's important that we, as a company, contribute to this. As an engineer, I get a lot of satisfaction from that: we really are making a positive impact.’

30

‘Being an expert also means seeing the bigger picture. Hydrogen is part of the broader sustainability story. I want to support clients as a ‘tour guide’ in taking the energy transition further.’

Fenna van de Watering – Group Leader, Innovation, Hydrogen and CO₂

31

75 years of Witteveen+Bos

‘Twenty years ago, we were traditional consultants and engineers with knowledge of a certain domain. Witteveen+Bos employees are now challenged to contribute to solving social issues. That’s explicitly asked of our company and is also related to our own intrinsic motivation. My motivation is to contribute to creating future-proof cities.’

Matthew Marshall – PMC Leader, Area Development

Windplanblauw Wind Farm – Jimme Zoete

Windplanblauw Wind Farm – Jimme Zoete

75 years of Witteveen+Bos

Experts on social challenges

Our clients face major challenges – for example, in their efforts surrounding liveable and safe cities that are easily accessible and possess sufficient clean drinking water and a sustainable energy supply. Cities and villages where it is pleasant to live and work, and where companies produce sustainably. Witteveen+Bos provides advice and assists clients in making the right choices. Our seven sustainable design principles help in this and ensure, for example, efficient and sustainable use of materials, protection of the environment and biodiversity, and promotion of chain management and (public) participation. They allow us to have the most possible impact and make the biggest possible contribution to solving the issues relevant to us.

33

Working together to create social value

‘We don’t just copy what already exists, and we never take anything for granted. We’re always looking to be constructively critical,’ says Jacobiene Ritsema, expert in social and environmental impact assessments and adviser on sustainability. ‘We’re a collection of experts who always look beyond the fields we’re experts in. I come from the world of non-governmental organisations. When I started at Witteveen+Bos twelve years ago, I thought: ‘Wait a minute. Is this all just about making money?’ Over the years, I’ve come to look at it in a much more nuanced way. I have the freedom here to think whatever I want. For example, I believe we should connect the technical and social domains to an even greater extent. As engineers, we need to think more about an integrated approach to the organisation of our society. For a broader view, it’s important to examine where we can make a difference and seek out unusual collaborations.’

Ten years ago, Jacobiene helped to initiate the sustainable design principles together with a number of young sustainability enthusiasts. ‘This took on such a significant form that, after a while, I recommended creating a CSR team. That exists now too. Due to our becoming increasingly professional in the field of corporate social responsibility (CSR) and the sustainable design principles becoming a serious topic, there was a need for an overarching corporate vision. That arrived, in part as a result of the Sustainable Development Goals (SDGs) published by the United Nations (UN) in 2015.’

‘An engineer can build a home for humanity’

‘We read the SDGs – agreements made by member countries of the UN, including the Netherlands – and recognised many themes that occupy us all day long at Witteveen+Bos,’ explains Karin Sluis, managing director from 2013 to 2020. ‘Clean drinking water and sanitation for all, the development of safe and sustainable cities, responsible production and consumption, developing resilient infrastructure, tackling climate change, and protecting life on land and in the water: this is the core of what we do.

34

We decided, therefore, to make a maximum contribution to the SDGs. This has been made more concrete with the help of the seven sustainable design principles (SDPs). Our purpose is beautifully expressed by Daniel Manenga, an artist from Congo: ‘An engineer can build a home for humanity.’ That’s what we’ve been put on this earth to do.’ The seven SDPs are social design, trias, participatory design, multifunctional design, circular design, flexible design, and designing with nature. By designing with these SDPs, we create an impact with all our projects and are really able to make a difference.

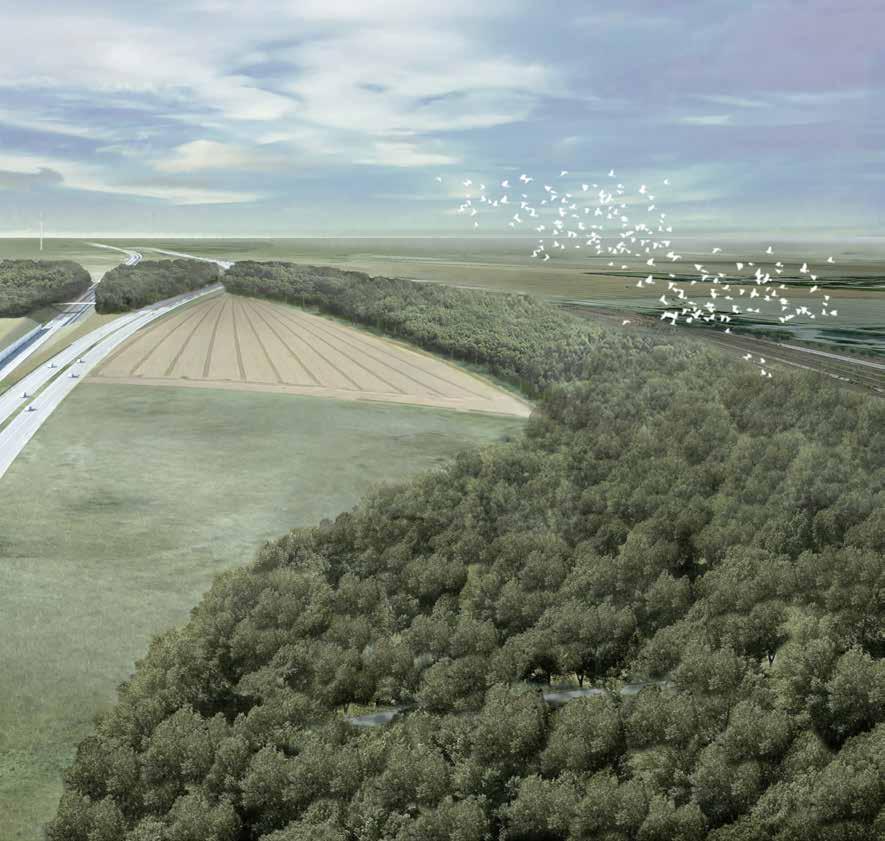

Designing and building with nature

One of the sustainable design principles is designing with nature. Since 2008, we have been developing expertise on this topic as part of EcoShape. EcoShape is a consortium of government authorities, research institutes and companies in the Netherlands which develops knowledge on designing and building with nature for coastal construction projects. Following a four-year knowledge programme, pilot projects were established in which applications were implemented and monitored. In each case, the ecosystem is the starting point, which leads to more sustainable solutions.

Tom Wilms, an expert in nature-based solutions for integrated coastal management, was involved on behalf of Witteveen+Bos in a pilot project involving small semipermeable dams in Demak, Indonesia in 2015. Tom: ‘70,000 people in the Demak region are vulnerable in terms of livelihood and housing. That’s because the coastline has moved up to three kilometres inland due to mangrove forests being cleared for fish ponds and the construction of infrastructure. A total of 3,000 villages are threatened. Along the twentykilometre coastline of Demak, a pilot project has been established in which civil engineering and socio-economic measures are combined. It’s a publicprivate collaboration between the Indonesian and Dutch governments, in which Witteveen+Bos is working together with knowledge institutes and the business community.'

35 75 years of Witteveen+Bos

‘You find the nature-based solutions concept all over the world now. Everyone wants to use it. To have a real impact, we need to connect the climate world with the engineering world.’

Henk Nieboer – Director 2006-2017

The civil component consists of developing semipermeable dams which retain sediment and allow the mangroves to grow back. At the same time, the local population is taught how to conduct sustainable fishing at the Coastal Field School.

Tom: 'Involving the local community greatly increases the results of the project. It will prevent the future felling of mangroves and allow the economy to benefit optimally form nature.'

Nature-based solutions have since been embraced as a promising and sustainable approach to hydraulic engineering and coastal management, and we have applied the concept in many projects in the Netherlands too, including the Sand Motor in South Holland, the Marker Wadden in the Markermeer, and Koehool-Lauwersmeer on the Wadden Sea coast in Friesland.

Multifunctional design

Another sustainable design principle is multifunctional design. Multifunctional design is a way of looking for the best possible combination of functions that you facilitate with the design. ‘The crux is to surprise stakeholders with one or more extra functions and thereby extra social value, often by relatively minor adjustment to the design. This principle has been successfully applied in projects such as the energy corridor near the A58 motorway, area development for the Floriade, and even the Afsluitdijk,’ explains Ingrid Bolier, specialist in value engineering. ‘What you do is increase the value of goods, services or products. There are two ways in which it can be done: by reducing costs or by adding functionality. To achieve the latter, the functions – not the solutions –are explored in sessions with the stakeholders. We want to avoid the pitfall of choosing the most obvious solution. To do this, you create a setting in which all stakeholders feel comfortable enough to come up with as many ideas as possible. It’s most efficient to do that at the start of a project. That’s when you have the most opportunities to define a situation that everyone wants.’

36

‘Solutions we develop in Europe can also be applied here. The entire international engineering community is here in Dubai. If we collaborate well, we can have a big impact on sustainability.’

Daniël Dusseljee – Head of Office, Dubai

Digital design tools make designing with the local area possible

Digital design tools have given participatory design, one of the sustainable design principles, an added dimension. Participatory design means not designing for the local community but together with it. As a result, the design will be more in line with the community’s wishes and support for the project will be greater. ‘Participatory design isn’t new. However, digital design tools offer the possibility of involving all stakeholders – residents, civil servants, administrators and entrepreneurs – in projects and making use of their feedback right away. Take the traditional design drawing: that’s not designed for or tailored to the end user. With the help of virtual and augmented reality, we can make the content of projects and the consequences for end users clearly visible’, explains Pieter-Bas de Visser.

In 2015, Pieter-Bas was the first industrial designer at Witteveen+Bos. ‘Industrial designers look to – and begin with – the end user, and that’s a perfect match for digital participation.’ Pieter-Bas helped develop the InBeeld participation platform. ‘This online platform enables stakeholders, in an accessible way, to share their opinions, concerns or suggestions about projects that affect their personal living conditions.’ According to Pieter-Bas, InBeeld is just the beginning of the digital approach and the possibilities which will allow users to really contribute to the design of their own living environments.

‘Practise what you preach’

We strive for maximum sustainability not only in our projects, but also in our business operations. At the end of March 2018, we moved into our sustainably renovated office on Leeuwenbrug in Deventer. Our seven sustainable design principles were, of course, applied to the design of the renovation.

Martijn Engelberts, Project Manager, Facilities Department: ‘The energy measures, the use of sustainable materials, the use of nature inside and

37 75 years of Witteveen+Bos

outside the building – it all contributes to our desire to operate as sustainably as possible. With the biodiverse roof, we hope to bring more life to the city by attracting insects and other living creatures. At the same time, we’ve made the transition to electric cars and have reduced our paper use even further. All this fits in with our thinking on corporate social responsibility. Yes, we believe in practising what you preach.’

‘We’re constantly thinking about which issues we want to work on’

‘Witteveen+Bos’s sustainability ambitions aren’t new; it’s just that now the time seems ripe – both socially and among clients – to make a difference,’ explains CSR team chairperson Ruud Bouw. ‘People are responsible for changing the climate and polluting our planet – for example, with plastic and PFASs – and for the extreme reduction in biodiversity. As well as this, throughout history we’ve shown ourselves to be incapable of fairly distributing resources. It’s my opinion that since this is the result of people’s actions, it’s up to us to make amends. We should be much more concerned with the question of whether it’s right and desirable to do something in a certain way – or to do it at all. And we, Witteveen+Bos employees, can and should also be taking a critical look at ourselves. If you ask an engineer whether something can be done, the answer is actually always: Yes, it can.’

The CSR team functions as Witteveen+Bos’s social antennae. For some projects and clients, for example, the question is asked whether we should have anything to do with them at all. Projects related to cruise missiles in the 1980s and nowadays the fossil fuel industry are examples. Funnily enough, according to Ruud, making money is not of crucial importance: ‘There’s enough other work available to not have to take on certain projects.’ Why, then, does Witteveen+Bos end up working on projects that generate debate? ‘We often take the approach that our contribution will make the projects better. That doesn’t mean that all projects are taken on without further thought; there’s a

38

‘Entrepreneurship isn’t just about chasing money but about finding where you can make a difference.’

Jacobiene Ritsema – Consultant, Social and Environmental Impact Assessments

lot of intense internal debate. That also leads to awareness. Learning from the ethical dilemmas we’ve encountered in practice, we put together a handbook for our project managers. We’re also constantly thinking about which issues we want to work on. At the moment, we’re drafting a company-wide policy on this topic. We’re right in the middle of a fundamental process.’

39 75 years of Witteveen+Bos

‘Contributing to society is also part of specialist knowledge: making the world a slightly better and nicer place.’

Aries van Beinum – PMC Leader, Traffic and Roads

75 years of Witteveen+Bos

75 years of Witteveen+Bos

Sharing knowledge and innovating is also being given a lot of attention within Witteveen+Bos. This is needed to be able to properly guide the changes taking place in our company, from strong growth and the broadening of expertise to the digital transition.

Collaboration

‘Milestone is a wonderful example of collaborating on innovations’

Collaborating is in our DNA

Sharing knowledge internally and innovating

Antwerp Water Plan – Sofie Depauw

75 years of Witteveen+Bos

Sharing knowledge and innovating is also being given a lot of attention within Witteveen+Bos. This is needed to be able to properly guide the changes taking place in our company, from strong growth and the broadening of expertise to the digital transition.

Each year, we work on more than 4,000 projects in four fields of operation: Built Environment; Deltas, Coasts and Rivers; Energy, Water and Environment; and Infrastructure and Mobility. These often involve complex issues that require an integrated project approach incorporating a wide range of perspectives, and knowledge development. Collaboration and innovations are essential to achieving sustainable solutions. Not only within the chain but also outside it. We aim to be a flexible team player, aware of what is needed to form the strongest possible collective with the other parties involved. Central to this aim are collaborating, and developing and sharing knowledge in order to come to the best possible solutions for today’s challenges – together.

75 years of Witteveen+Bos

Sharing knowledge and innovating is also being given a lot of attention within Witteveen+Bos. This is needed to be able to properly guide the changes taking place in our company, from strong growth and the broadening of expertise to the digital transition.

Inspection of civil infrastructure – Danny den Boef

Inspection of civil infrastructure – Danny den Boef

‘Milestone is a wonderful example of bringing research institutes, government authorities and companies together for the purpose of developing new techniques – techniques which lead to faster construction. This is urgently needed, because we’re faced with the enormous task of building around a million new houses in the Netherlands by 2030.’ Structural engineer Marijn Bruurs, involved with Milestone from the start in Eindhoven, lauds the importance and potential of digitalisation in the construction industry. Partly because of his contribution to Milestone, Marijn was named Young Talent of 2020 by Cobouw. In 2018, the Milestone plans were presented: five boulder-shaped houses to be built with a 3D concrete printer for a leafy development site in the Eindhoven neighbourhood of Bosrijk. In April 2021, the first house was completed and the tenants received the key.

51

‘Milestone is a wonderful example of collaborating on innovations’

of Witteveen+Bos

Marijn Bruurs – Consultant, Digital Construction

75 years

Golden triangle

The ‘golden triangle’ collaboration of research institutes, government and the business community is characteristic of Milestone, but also city campus De Kien in Deventer, the hydrogen hub and the Smart Zwolle alliance. The Municipality of Eindhoven was a co-initiator and facilitated the project, Eindhoven University of Technology (TU/e) conducted research, and Witteveen+Bos worked on models which made the printing possible. The Saint-Gobain Weber Beamix company developed the special concrete mixes needed for 3D printing and – together with TU/e – developed the printing technology itself. Witteveen+Bos worked on the building technology and structural aspects. Construction company Van Wijnen led the project and built the house. The property is owned by Vesteda, which rents it out to private individuals.

‘Beautiful things make you happy, don’t they?’

Theo Salet was a PMC leader and consultant at Witteveen+Bos and, in addition, led the research as a professor at TU/e: ‘I happened to fall in love with concrete printing but that’s not the end goal. For me, it’s about the digital transition in the construction industry, and printing is a way of working digitally. The printer eliminates the paper phase between design and construction, enabling the BIM design to be realised in an automated manner. This makes a huge difference in costs due to error and material use. It’s a bit strange, isn’t it, that we’re still required to reduce those incredibly complex BIM designs to paper drawings before we can start building? In my opinion, digitalising the construction industry has three significant benefits: economically (productivity in construction is increased), in terms of sustainability (far fewer materials are needed, for example), and socially. In terms of the social benefits, digitalisation has consequences for aesthetics in construction. It allows us to make things which are more beautiful. Houses that create an experience for people and, as a result, have an impact on their well-being – even though that may sound a bit soft. Beautiful things make you happy, don’t they? With digitalisation, we

52

can provide custom solutions at an industrial level and create designs to meet human needs. Digital construction is undergoing huge developments. A lot of work is being done on 3D concrete printing projects in the Netherlands, Dubai and Singapore.’

‘We see a challenge and we go for it’

‘At Witteveen+Bos, we have our own manner of developing initiatives,’ explains managing director Wouter Bijman. ‘We see a challenge – it could be technical or social in nature – and then we look for one or more parties willing to tackle that challenge with us, and then we go for it. The market is not what directs us in these cases but our ambition. Frequently, there’s no business model to begin with.’ The 3D concrete printer’s development is an example of this, as are the centre of expertise on PFASs and the ANT platform.

Wouter: ‘The 3D concrete printer wasn’t a request from a client, but rather a development which we think will help us in the construction industry and in society. We hadn’t yet developed a business plan. The ANT interactive online platform – which has already been used for several complex projects, including the Blankenburg Link, Oosterweel and ViA15 – is another initiative realised in this way.’

Flexibility, speed and oversight in complex projects

Rinze Herrema, leader of the Infrastructural Engineering PMC: ‘A few years ago, we developed a plan for using an online database platform to automate the process of infrastructure design. We found a partner in CollaborAll, with whom we developed ANT together. Designers, geotechnicians, structural engineers and consultants can continue working in their own design packages while exchanging shared data through ANT. It offers flexibility, speed and helps maintain an overview in complex projects with high time pressure.’

53 75 years of Witteveen+Bos

‘The technical side of a project is only one part of the whole. Make sure that the contractual and relational sides are also in order. Listen carefully to your client and be sure you understand what they want.’

Jan Coppes – Director 1987-2002

Further developing digital construction

As part of our ambition to digitalise and automate the construction industry, Witteveen+Bos has a 3D concrete printing laboratory in Singapore, and a webbased platform is being developed to manage both design and construction processes online. This platform, the Integrated Building Information System (IBIS), is part of a larger initiative in Singapore to develop a digitalised and partially automated construction system. This involves employing automated construction cranes and tracking systems for visualising and managing the progress of construction and logistic processes. IBIS is at the core of this system. The initiative is being led by Singapore’s Nanyang Technology University – one of the two biggest universities in the country – and is being developed for and under contract to the Housing and Development Board.

Jordy Vos, leader of the Digital Construction Group in Singapore: ‘What makes IBIS unique is the integration in a single platform of the entire workflow for a building, from design right up to construction; whereas currently, you often have to employ several individual solutions simultaneously. By managing data intelligently, changes can be tracked and visualised in IBIS. This allows us, for example, to see which construction elements are new or have been changed or removed, and to follow the progress of construction in 3D. The information is sent live from the construction site.’ With the help of this integrated solution, parties in the construction chain are better able, together, to ensure that construction projects are completed on time and within budget. Witteveen+Bos employees in the Singapore and Dutch offices worked together on the development of IBIS.

Collaborating on hydrogen production

Another example of how we collaborate and develop and share knowledge when entering new markets and knowledge areas is GROHW (green oxygen, hydrogen and waste heat). ‘We need to improve our systems of energy storage. I first had this thought seven years ago,’ explains Raphaël van der Velde,

54 75 years of Witteveen+Bos

‘Working with driven professionals is incredibly stimulating. We look for complex projects which we can come up with innovative solutions for.’

Leonie Koops – Head of Sector, Infrastructure and Mobility

leader of the Energy Systems PMC. ‘I came into contact with Elestor, a start-up working on the development of a hydrogen bromide flow battery. There was a need for cheap energy and their battery was capable of meeting it. The idea of a hydrogen bromide battery, incidentally, wasn’t new. It had originally been conceived by NASA but never realised. Over the past seven years, I’ve seen an increased interest in the development of hydrogen as an energy carrier. This is why we went looking for partners to produce green hydrogen with. We wanted to just get out there and do it – and show that it can be safe. In 2020, we began a collaboration with businesses and institutes in Deventer for the purpose of developing a hydrogen system. The intended result of GROHW is a scalable design that can be applied in other industrial contexts.’

55

‘We don’t work together just for the sake of it; We do it to learn from each other, to exchange knowledge, and to come up with better solutions. That’s a good thing.’

Aries van Beinum – PMC Leader, Traffic and Roads

The Wolderwijd – Marcel Klinge

The Wolderwijd – Marcel Klinge

Collaborating is in our DNA

Besides innovations, we also frequently collaborate on projects. Collaborations are undertaken with other firms, nongovernmental organisations and parties in the construction chain. Our belief in doing this is that collaboration always leads to better solutions – for our clients and for society. Sometimes a long-term collaboration is formed, such as in Tunnel Engineering Consultants (TEC). TEC was founded in 1988 with immersed tunnels as its area of expertise. This led to many tunnel projects outside the Netherlands, including the Øresund Link (the tunnel-bridge connection between Denmark and Sweden), the Fehmarn Belt Fixed Link (between Germany and Denmark), the Busan-Geoje Link in South Korea, and the connections between Hong Kong, Macau and the mainland of China. TEC’s expertise covers not only the construction of new tunnels but also the maintenance, renovation and modernisation of existing tunnels.

57 75 years of Witteveen+Bos

Piet Barten, Witteveen+Bos employee for more than three decades: ‘On my first day at Witteveen+Bos, we were treated to cake because the Tunnel De Noord project had been assigned to us. That was a TEC project, at the time still an organisation starting up.’ With his structural engineering background, Piet initially worked for TEC on control calculations for bridges at Schiphol Airport, where the aircraft were becoming increasingly heavier. In 1993, he was asked to go to Denmark for the tunnel in the Øresund Link. Piet: ‘I was surprised that they asked me to do it – I didn’t know anything about tunnels. The person from TEC who was already there said: ‘Have you ever driven through a tunnel? Then you already know more than the Danes!’ It began with drafting the project documents, and knowledge was then gradually built up. Remember that there was very little knowledge at the time – the building regulations in Europe, Denmark and the Netherlands weren’t really suitable for tunnels. In the Netherlands, this has now been rectified by guidelines from Rijkswaterstaat, which we also contributed to. At TEC and Witteveen+Bos, our knowledge of immersed tunnels really is world-class. It’s a niche in which we have a lot of experience and a strong position; I think, worldwide, we’re involved in two-thirds of these kinds of projects in some form or another.’

Strategic European Expertise Network

In the first 25 years of Witteveen+Bos’s work outside the Netherlands, our revenue model was primarily based on selling and exporting knowledge. In 2002, Jan Coppes – director at the time – decided to investigate whether we could acquire knowledge outside the Netherlands that could be marketed at home. Jan: ‘This initiative was based on positive experiences with Montgomery Watson. Knowing that Scandinavian countries possessed high-quality knowledge, we sought contact with the engineering firms NIRAS in Denmark and Tyréns in Sweden. There was an immediate click and the advantages of exchanging knowledge to strengthen each other’s positions in home

58 75 years of Witteveen+Bos

‘A niche in which we have a lot of experience and a strong position’

‘We form a hub for other firms wanting to enter the Latvian market. We assist them. In that respect, we’re truly unique. Instead of seeing each other as competitors, our solution is to tackle issues together.’

Oskars Zivtiņš – Head of Office, Latvia

markets were obvious.’ The French firm Sogreah (now Artelia) also joined the collaboration after a few years and SEEN (Strategic European Expertise Network) was born. NIRAS has since been succeeded as a member of SEEN by the Spanish company Typsa. Among other things, the firms assign employees to each other’s projects – for example, Danish fire safety experts on the North/ South Line and Dutch water experts at a Swedish water treatment plant. Regular meetings to exchange knowledge and experiences also take place in the areas of financial management, ICT, personnel management and acquisition. It is also interesting for the firms’ young employees to get in touch with their peers from the SEEN network and exchange experiences and expertise.

Collaborating with NGOs

In several projects, we work together with non-governmental organisations (NGOs). Since 2015, for example, we have collaborated with the development organisation Simavi. At first glance, NGOs do not appear to be the most likely partners. As it has turned out, however, the ‘money-grubbers’ at Witteveen+Bos – as the business community is sometimes characterised by NGOs – and Simavi’s ‘sandal-wearing longhairs’ work very well together. Fred de Bruijn, leader of the Drinking and Process Water PMC and one of the collaboration’s initiators: ‘We have the same motivations and dreams – namely, giving poor people access to (clean) drinking water. And we complement each other well. Witteveen+Bos has the knowledge on drinking water and Simavi knows the country and the people and is in contact with the various communities. The collaboration has resulted, among other things, in the creation of water and sanitation facilities in Ghana and Tanzania. Projects have also been carried out in Congo, Rwanda and Bangladesh.’

As part of the Ghana-Netherlands WASH Programme, an initiative of the respective national governments, toilet blocks were constructed at about one hundred schools in Accra and in the vicinity of Cape Coast. The project also provided 140,000 residents with access to clean drinking water. Educational

59

‘Our former director Wim Slijkhuis once told me: ‘It’s better to have two half projects than one whole project, because you always learn new things from collaborating with others.’ I totally agree with him.’

Karin Sluis – Managing Director 2013-2020

activities have also been carried out in the fields of water, sanitation and hygiene were also carried out. In collaboration with the relevant municipalities, master plans were developed for public facilities for drinking, waste and surface water and the treatment of solid waste.

Construction teams: contributing to better collaboration in the construction industry

‘At its core, it’s about knowledge and collaboration: forming the best team with the right knowledge and the right partners to meet our challenges in a sustainable way’, explains Jaap de Koning, contracting and tendering specialist.

Jaap is one of the creators of the Modelovereenkomst Bouwteam DG 2020, a model agreement for construction teams in which knowledge sharing and collaboration based on a shared goal are the starting points. At the centre of this is the mutual effort on the part of the client, designers and builder to pool all knowledge during the design phase (construction team phase) and arrive at a good design. This results in avoiding ‘hassle’ during the implementation phase as much as possible. ‘An optimal design requires a lively, open discussion in the construction team, in which the client actively participates,’ explains Jaap. ‘And in which designers have a fully-fledged, independent position, without underlying interests. And the contractor needs to be able to contribute freely and fully, without complicating his responsibility for the implementation. If all parties work in the interest of the common project goals, they will be achieved smoothly, efficiently and at acceptable cost.’

The concept of a construction team is not new. In the Reconstruction years following the Second World War, it was applied on a large scale for the construction of houses. Its application subsequently diminished, and most projects were carried out using the traditional method of building to specifications. In recent years, the construction team has been undergoing a revival.

60 75 years of Witteveen+Bos

‘Entrepreneurship is about looking beyond the borders of your discipline, making unlikely connections and working together.’

Heleen de Fooij – Consultant, Water and Raw Materials

61

‘Witteveen+Bos always starts with the content, and from there we look to collaborate with enthusiastic, skilled people and parties to solve complex problems together. In my opinion, you have to want each other to succeed in order to share success and work together enjoyably.’

Jaap de Koning – Contracts and Tendering Specialist

Reception desk, Amsterdam – Sorita Pronk

Reception desk, Amsterdam – Sorita Pronk

Sharing knowledge internally and innovating

Sharing knowledge naturally forms part of Witteveen+Bos’s informal and trust-based corporate culture. A colleague’s success is also your success, we always tell new employees. Knowledge is shared in all sorts of ways, from casual conversations at the coffee machine to lunch lectures and professional meetings. Our Technical Contact Meeting (TKB), begun in the 1960s, also has its roots in the sharing of knowledge. Shared knowledge fuels new knowledge and innovations, such as those developed in our innovation programmes.

63

75 years of Witteveen+Bos

‘The innovations that make use of digital possibilities also make demands of our ICT department. In the past, we’d make sure the network functioned and that everyone had a laptop; now we’re also closely involved in what’s happening in the PMCs and the market. That gives our work a new dimension. As a department, we make decisions together with the PMCs, and that makes the work even more interesting and

75 years of Witteveen+Bos

History: Technical Contact Meeting

In the 1960s, the need to share knowledge internally grew and, as a result, the Technical Contact Meeting (TKB) was created. Begun as a means of keeping the increasing number of Witteveen+Bos employees abreast of new developments in the field, it has since grown into a biannual internal network meeting. The meetings are devoted to developments in the company as well as our fields of work, and to social developments affecting Witteveen+Bos. As it is customary to conclude with a buffet, the TKB is also a good opportunity for colleagues to get to know each other better in an informal context. Nowadays, the TKB is streamed live, including live translation, so that it can be followed worldwide – or watched later.

The Plus+ Innovation Programme

Many good, innovative ideas exist within Witteveen+Bos. In order to collect these and give them the chance to mature, the internal Plus+ Innovation Programme is launched in 2017. The aim of the innovation programme was to generate ideas and innovations, develop new products and services, stimulate entrepreneurship, and enthuse our employees regarding the latest (digital) developments. The programme generated a wave of new energy and can be seen as the starting point for the digital transition at Witteveen+Bos.

The seed for the programme was sown by a question from the Municipality of Eindhoven about its inner ring road. Otto Schepers – Head of Sector, Digital Acceleration and Support: ‘The difficulty was that nobody knew what the inner ring road would look like – how it would work. We simulated this in virtual reality (VR) so that everyone could experience it. We built a model for a quarter of the project area – the most interesting part, because that’s the most useful. That was the ‘Beleef de Vestdijk’ project about experiencing the Vestdijk. We showed the simulation during a committee meeting. The council member for participation – someone with a great affinity for innovation – was given the chance to ‘experience’ it and after thirty seconds, his reaction was: ‘Wow, this is

64

enjoyable.’

Gerrit Jan Werler – Head of Department, ICT

cool.’ VR was a bit of a gimmick to get a foot in the door, but it became the start of a broader participation platform.’

The success of this simulation provided an incredible boost and Otto wondered how he could share his experience and expertise in digital innovation with colleagues and increase their knowledge of the topic. ‘There’s no shortage of ideas at the company – there are plenty of them – but how do we bring them to the attention of clients and the market? Around that time, I was at an innovation meeting held by a software manufacturer and saw a good example of how you can approach it. That provided the impetus for our own innovation programme.’ So far, there have been three editions of the Plus+ Innovation Programme.

‘Digitalisation

Collaboration between the different offices worldwide is intensifying and, accordingly, the exchange of knowledge is too. Jaïr Smits – Head of Office, Singapore: ‘Employees of the offices in Singapore, Indonesia and Belgium regularly work together on projects and share their knowledge. The same goes for colleagues in Dubai and Kazakhstan. We could organise and professionalise that even further.’

Nurisa, leader of the Design and Visualisations Group in Jakarta, agrees. According to her, the flow of knowledge can be improved and digitalisation makes this easier. ‘Knowledge sharing is an ongoing process. My group works on projects worldwide, together with colleagues at the offices in Singapore, Dubai, Belgium, Kazakhstan and the Netherlands. I hope we can develop that even further.’

‘In recent years, we’ve updated our intranet and made it interactive. Employees worldwide see all our internal news: about projects, policies or internal vacancies. In knowledge groups, colleagues exchange ideas, experiences or tips. Or they collaborate on a company-wide focal point. There’s a reason it’s called W+B Connect.’

65

makes sharing knowledge worldwide easier’

Nathalie Eimers – Head of Department, Communications

1946

Start of Witteveen+Bos

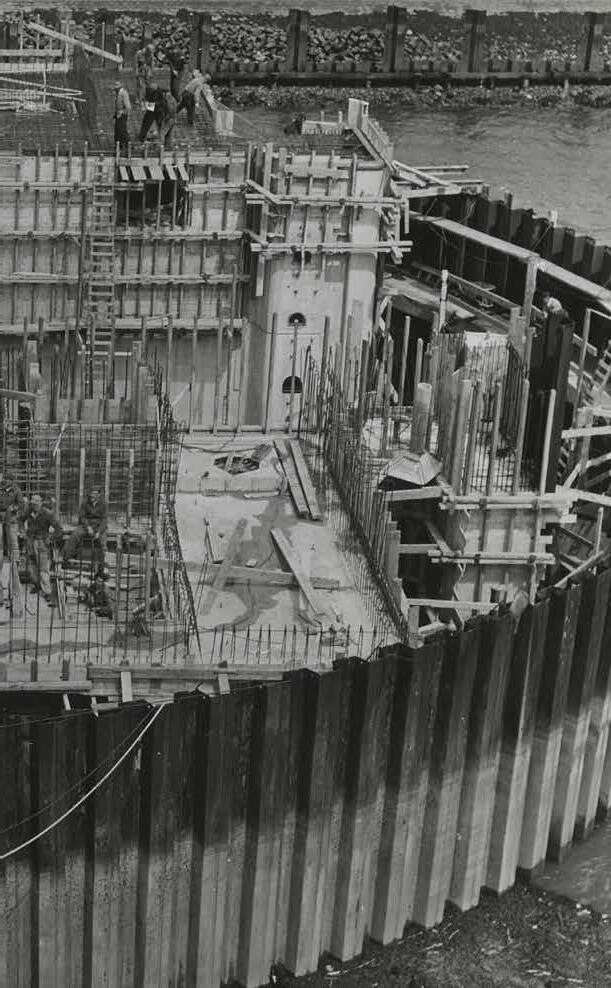

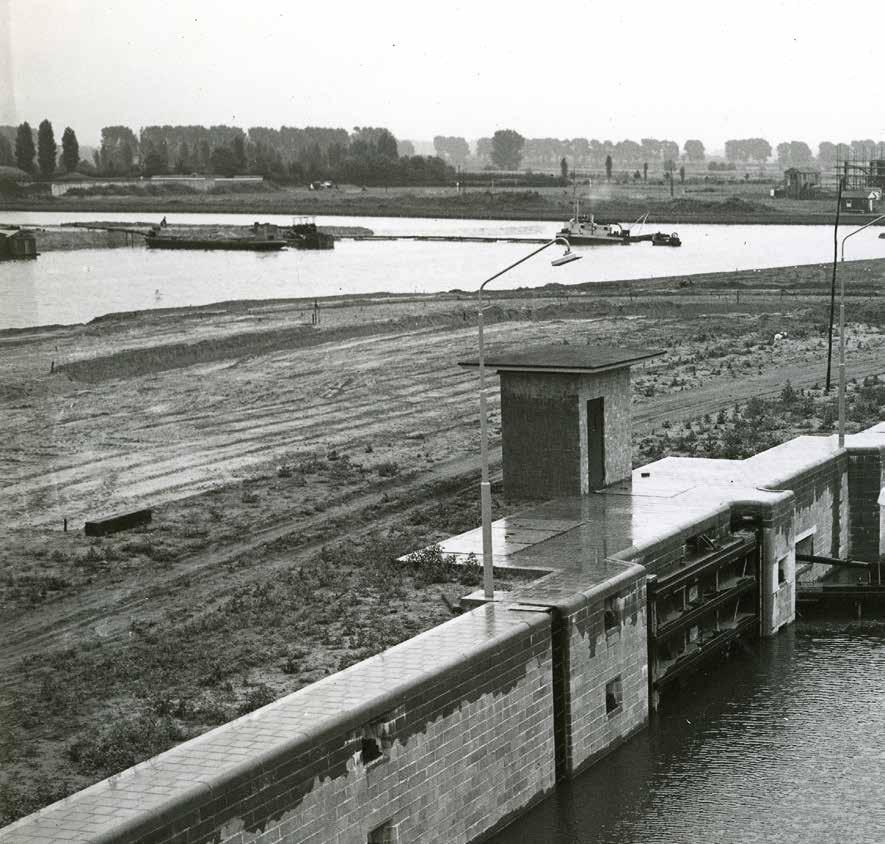

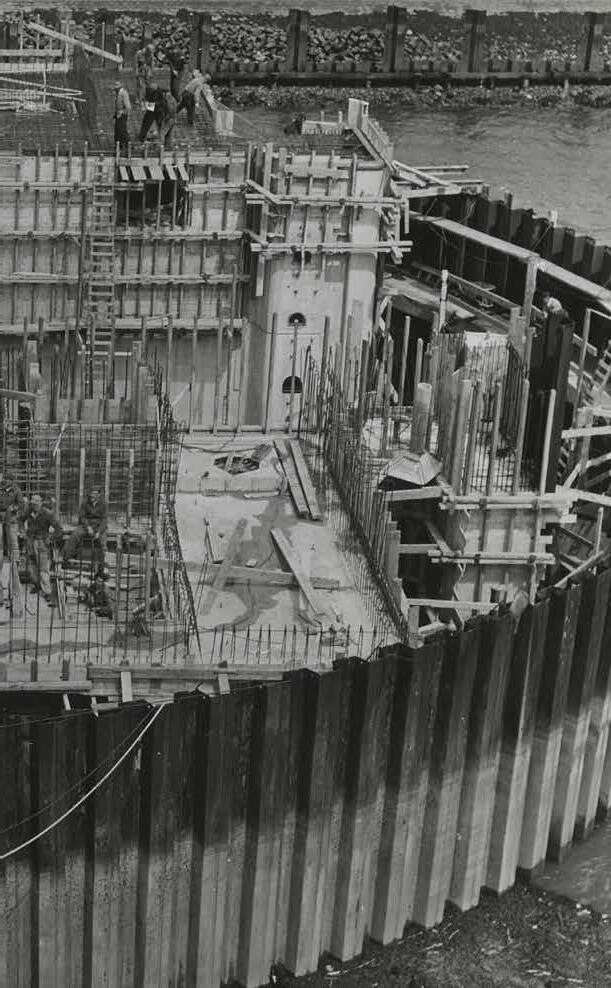

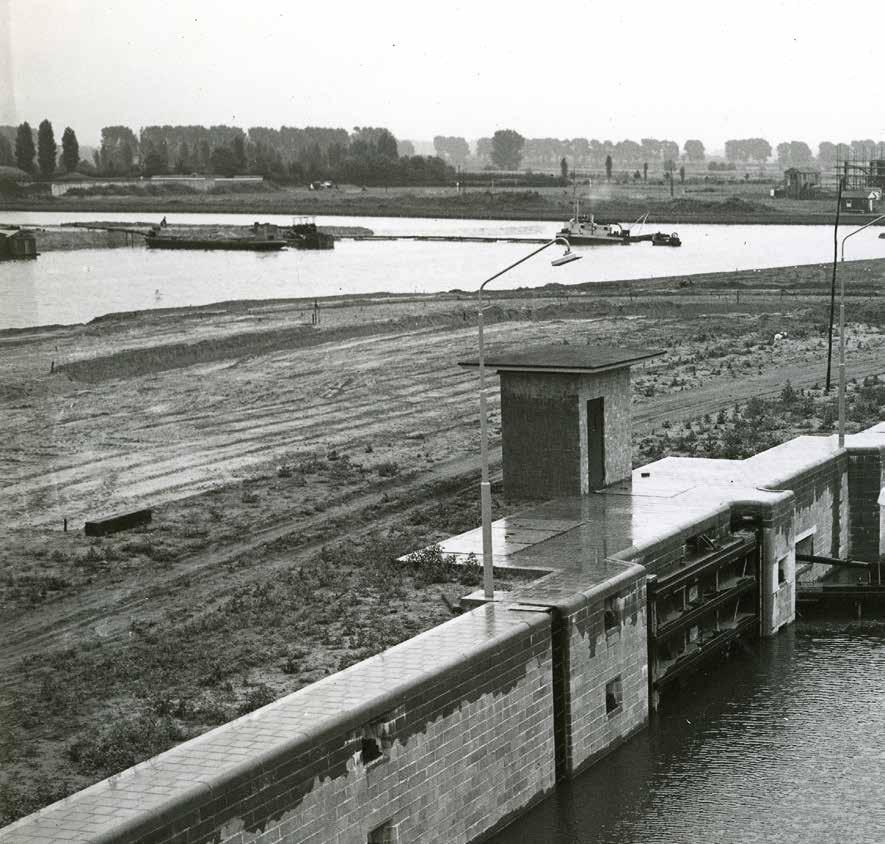

On 1 January 1946, ‘Stedebouwkundig adviesen ingenieursbureau Witteveen en Bos c.i.’ is founded by engineers Willem Gerrit Witteveen (1891-1979) and Goosen Siger Bos (19082004).

1947

First project: Prince Bernhard Lock, Deventer

The design of the Prince Bernhard Lock in Deventer is the partnership’s first project. It is also why they choose to establish their office in that city.

1951

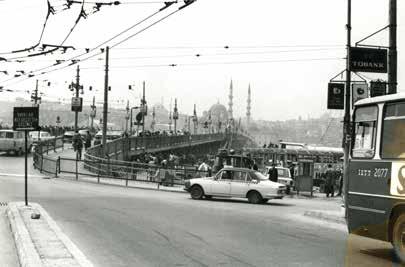

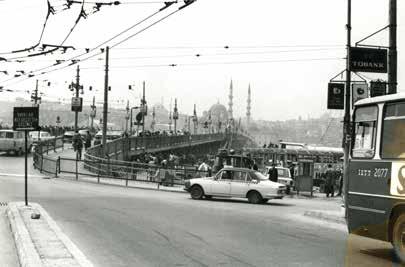

First overseas project

The first project abroad is a feasibility study for a metro system in Istanbul.

1955

Construction of sewage treatment plant (STP) in Alkmaar

In 2021, our work in waste water encompasses the entire development process of transport and treatment systems, from study through to realisation and operation. We have extensive knowledge and experience in the biological treatment of waste water and sludge and in the purification of waste water. The STP in Alkmaar is the first large treatment plant designed by Witteveen+Bos.

1963

Witteveen+Bos has 50 employees

1966

First Technical Contact Meeting (TKB)

The TKB is initially intended to inform employees about new developments in the field. It has since grown into a biannual internal network meeting at which developments at the company and in our fields of work are highlighted alongside social developments affecting Witteveen+Bos.

1970

Witteveen+Bos passes the 100-employee mark

1972

Goosen Bos: professor at TU Delft

In March 1972, Bos starts as Professor of General Civil Engineering at TU Delft. He is the first professor affiliated with Witteveen+Bos. Other employees who become professors include Gerd Scherpbier (constructions), Jaap van der Graaf (waste water treatment), François Clemens (sewerage) and Theo Salet (structural design).

1973

Design and commissioning of Zimpro installation at Nieuwveer STP

Witteveen+Bos designs the Zimpro installation for the Nieuwveer in Breda-North. It is the first energy factory design completed for a water authority. Forty years later, in 2013, it is replaced by a new installation capable of sludge digestion and dewatering. This, too, is designed by Witteveen+Bos.

1975

Plus sign is added to Witteveen+Bos name

1976

Zierikzee office opened – first outside Deventer

Zierikzee is the first office outside Deventer. An office is also opened in Enschede later that year. In 2021, Witteveen+Bos operates from eight offices in the Netherlands: Amsterdam, Breda, Deventer, Groningen, The Hague, Heerenveen, Rotterdam, Utrecht and Wageningen.

1977

First environmental impact assessment in the Netherlands: Tiel STP The environmental impact assessment (EIA) for the proposed location of the Tiel STP is one of the first EIA projects in the Netherlands. EIAs remain an important component of the services Witteveen+Bos offers.

1978

Indonesia office opened – first outside the Netherlands

An organisational change at Nedeco in 1978 leads, in that same year, to Witteveen+Bos being able to take over its Indonesian office and several port, dredging and land reclamation projects. In 2021, we operate from fourteen offices outside the Netherlands, in ten countries: Belgium, Dubai, Ghana, Indonesia, Kazakhstan, Latvia, Panama, Singapore, the United Kingdom and Vietnam.

1985

Odour laboratory initiative

In the 1980s, following complaints about the smell at STPs, we investigate how odours originate and how they can be measured. This leads to the creation of the odour lab. In 2021, Witteveen+Bos’s lab is one of three accredited odour labs in the Netherlands.

1986

Witteveen+Bos has 300 employees

1988

Introduction of PMC structure

The PMC structure is one of the success factors of Witteveen+Bos. The product-market combinations (PMCs) are small, independently operating cells. They grow when the market is good, merge when necessary and split when they get too big.

1988

Foundation of Tunnel Engineering Consultants (TEC)

In TEC, Royal HaskoningDHV and Witteveen+Bos combine their knowledge of tunnels. In the years that follow, TEC carries out a number of high-profile projects, including the Hong Kong-Zhuhai-Macau Bridge.

1990

Land development in Kapuk Naga, Indonesia

Since 1987, Witteveen+Bos has been involved in developing a series of ten artificial islands off the coast of Jakarta. The plan also includes reclaiming land along the coast. The reclamation of 800 hectares of fish ponds in Pantai Indah Kapuk starts in 1990, and construction of the first offshore island begins in 2013.

1991

Office opened in Latvia Witteveen+Bos acquires the Tebodin office in Riga, Latvia.

1992

From partnership to company; introduction of employee participation

From its inception, Witteveen+Bos’s ownership structure had been a partnership. In 1992, the eleven partners of the time convert it into a company. Since then, employees have been able to participate in the ownership of the company by acquiring shares.

1993

Start of preparations for ultrafiltration plant in Heemskerk

The world’s first large-scale ultrafiltration plant is to be built in Heemskerk. Its surface water treatment installations are the first not to employ chemical disinfection. The factory is completed in 1998.

1995 Engineering contract for North/South Line

In 1995, Witteveen+Bos, as main contractor, is awarded the engineering contract for the North/ South Line in Amsterdam. Construction begins in 2003 and the metro line is officially opened in 2018.

1996

Foundation of Transport Consultants and Engineers (TCE)

TCE is founded: a collaboration for the railway market between DE-Consult and Witteveen+Bos, and later with Deutsche Bahn and Royal HaskoningDHV, too. Its first project is the ‘Iron Rhine’. In 2009, TCE is renamed Railinfra Solutions (RIS). In 2016, the collaboration ends.

1997

Water barrier at Kampen

The Kampen water barrier is an example of a project in which significant attention is paid to local participation. Not least because the water barrier literally runs through the homes of Kampen residents in some places.

1997

Design of artificial islands in Caspian Sea

Since 1997, Witteveen+Bos has been involved in the design and construction of artificial islands, wave and ice protection measures, and harbour facilities for the discovery, production and processing of oil in the Northern Caspian Sea. Artificial islands and ice protection structures are being designed for twelve locations in the Kashagan Field.

1998

First 'Room for the River' projects

Witteveen+Bos is awarded one of the first ‘Room for the River’ projects: the Hondsbroeksche Pleij near Arnhem. Many others follow later, including the Border Meuse and IJssel projects.

1998

Framework agreement for Vinex location in Haarlemmermeer

Witteveen+Bos concludes a framework agreement with the Municipality of Haarlemmermeer for the Vinex location Floriande, a newly constructed neighbourhood with about 6,500 houses and an area of 200 hectares. We work on several aspects, including drawing up specifications for 25 bridges and preparing various locations for construction and habitation, including landscaping and public lighting.

2001

Office opened in Aktau – first in Kazakhstan Since 2001, Witteveen+Bos has operated from an office in Aktau, on the Caspian Sea. A second Kazakh office follows in 2003 in Atyrau, and in 2007 we open a third office in Almaty.

2001 Remediation of Volgermeer Polder, Amsterdam

The Volgermeer Polder remediation is one of the largest and most complex remediation and nature development projects in the Netherlands. In 1980, tens of thousands of drums of chemical waste were discovered there. In 2001, Witteveen+Bos conducts a successful trial investigating the remediation measures’ feasibility. In 2011, the remediated Polder is opened.

2002

First Witteveen+Bos Art+Technology Award

In 2002, the first Art+Technology Award is handed out. The Art+Technology Award, an oeuvre prize, is awarded each year to an artist who unites art and technology in his or her work in an exceptional way. In 2021, the twentieth and final award is presented and the collaboration with artists is continued in a different form.

2004

Witteveen+Bos has 700 employees

2006

FishFlow Innovations launched FishFlow Innovations, a partnership between Gerard Manshanden and Witteveen+Bos, develops a concept for a passageway intended to prevent high levels of fish mortality at pumping stations. Following six years of fruitful collaboration, on 1 January 2012 Witteveen+Bos’s stake in the partnership is transferred to Manshanden.

2006

Drinking water treatment plant in Kwanyako, Ghana

The robust drinking water treatment plant in Kwanyako is one of the first overseas treatment plants designed by Witteveen+Bos.

2007

Office opened in Saint Petersburg, Russia

From our Saint Petersburg office, we work on the restoration of canal walls and port projects. Due to a worsening business climate in Russia – owing in part to political and social tensions between Russia and Europe – the decision is made in 2020 to close the office.

2007

Carbon footprint published

In 2008, for the first time, we calculate and publish the carbon footprint of Witteveen+Bos’s operations. The CO₂ emissions in 2007 amounted to the equivalent of around 5.72 tonnes per FTE. In 2021, we still measure our progress based on 2007. We have been able to reduce CO₂ emissions by more than 60 % since that time.

2008

Construction of Maasvlakte II begins in Rotterdam

Witteveen+Bos is responsible for the project planning, geotechnics and hydraulic engineering for the construction of Maasvlakte II, the largest hydraulic engineering project since the Delta Works. The Port of Rotterdam is expanded by 2,000 hectares – an increase of 20 %. Maasvlakte II officially begins operations in 2013.

2008

EcoShape launched

EcoShape is a consortium of government authorities, research institutes and companies in the Netherlands – including Witteveen+Bos –which invests in the development of knowledge on building with nature for coastal construction projects. One of the projects carried out is the mangrove restoration project in Demak, Java, which wins the ‘De Vernufteling’ engineering prize in 2016.

2009

Office opened in Antwerp, Belgium

In 2009, Witteveen+Bos opens an office in Antwerp. In 2015, our presence in Belgium is strengthened by the acquisition of environmental consultants MAVA. Witteveen+Bos now has offices in Antwerp, Steenokkerzeel and Ghent and provides advice to government and port authorities, industries, project developers, and contractors.

2009

Design of Fehmarn Belt Fixed Link

Since 2009, TEC has worked on the design of the world’s longest immersed tunnel. The 18.5 km-long tunnel is intended as a future road and rail link between the islands of Fehmarn (Germany) and Lolland (Denmark).

2010

Ultra-Pure Water Factory opened in Emmen

The Ultra-Pure Water Factory in Emmen, designed by Witteveen+Bos, is opened by Prince Willem Alexander. The plant purifies sewage water to such an extent that it becomes pure water for industrial use. The choice of source, the scale of production and the innovative combination of purification techniques make the plant unlike any other in the world.

2010

Office opened in Vietnam

Witteveen+Bos opens an office in Ho Chi Minh City, Vietnam. In 2021, we carry out water management projects in Vietnam in the broadest sense of the term: industrial waste water, hydraulic engineering infrastructure, flood protection, groundwater and surface water.

2012

Redevelopment and transformation of area around Utrecht station

For the transformation of the area around Utrecht’s central station, Witteveen+Bos develops the plan for restructuring and reorganising the Van Sijpesteijnkade and Mineurslaan streets, as well as for the public transport interchange (buses and light rail). Later, we also carry out transport studies and create the architectural design for the viaduct, among other things.

2012

Oosterweel Link, Antwerp

Together with Sweco, work is being done in Antwerp on one of the biggest European infrastructure projects: the Oosterweel Link. It is intended to close the R1 ring road around Antwerp and improve traffic flow. It is an important part of Antwerp’s 2020 Master Plan.

2012

Centre of expertise on PFASs launched Witteveen+Bos is one of the initiators of the centre of expertise on PFASs. Emerging contaminants such as PFOA and PFOS form part of a group of more than 6,000 substances which are extremely harmful for the soil-andwater system, ultimately impacting on people, too. The centre of expertise shares knowledge and information about this.

2013 Zuidas, Amsterdam

Since 2013 Witteveen+Bos has worked with Arcadis on an integrated design for the construction of a tunnel for the A10 motorway. The tunnel will run under the Zuidas to maximise the accessibility of the area without impeding on valuable building space or natural areas.

2014

Project office opened in Accra, Ghana

In 2014, an office is opened in Accra for the Ghana-Netherlands WASH Programme. The programme focuses on the realisation of urban water and sanitation facilities. Due to an insufficient amount of subsequent projects, the local staff are let go in 2019. Local registration is still in place and projects are being carried out from other offices.

2014

Offices opened in Dubai, Singapore and London

The Dubai office focuses on water purification, hydraulic engineering and landscape architecture, and the Singapore office on the built environment and digital construction. In 2016, the opening of an office in the United Kingdom follows which focuses on topics including active travel.

2015

Witteveen+Bos passes the 1,000-employee mark

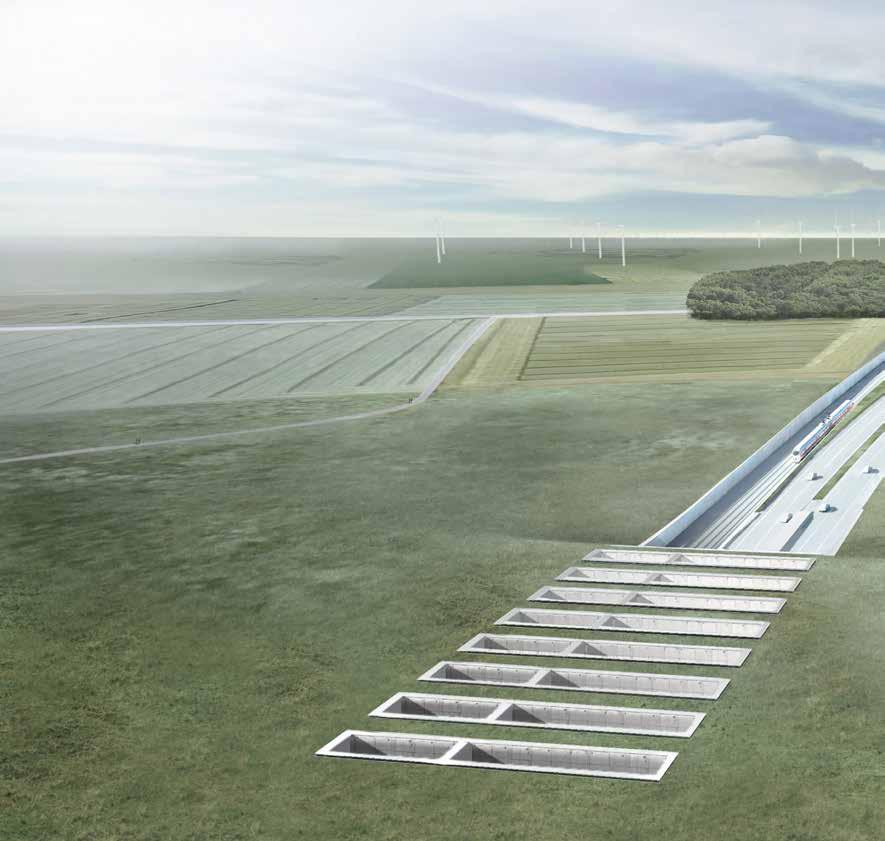

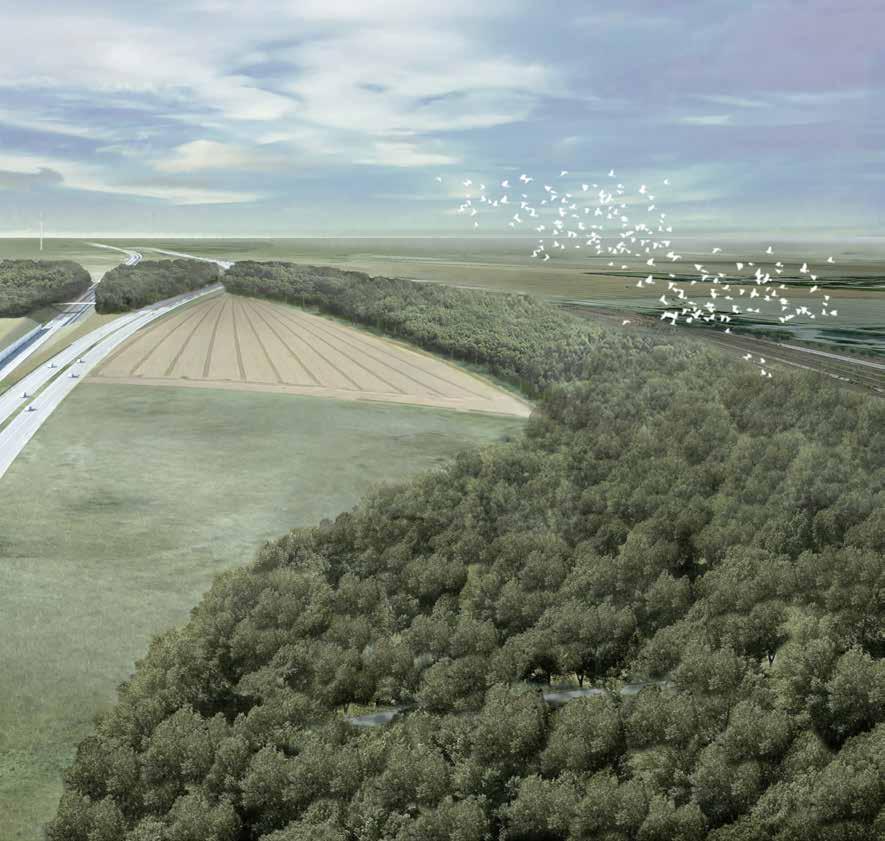

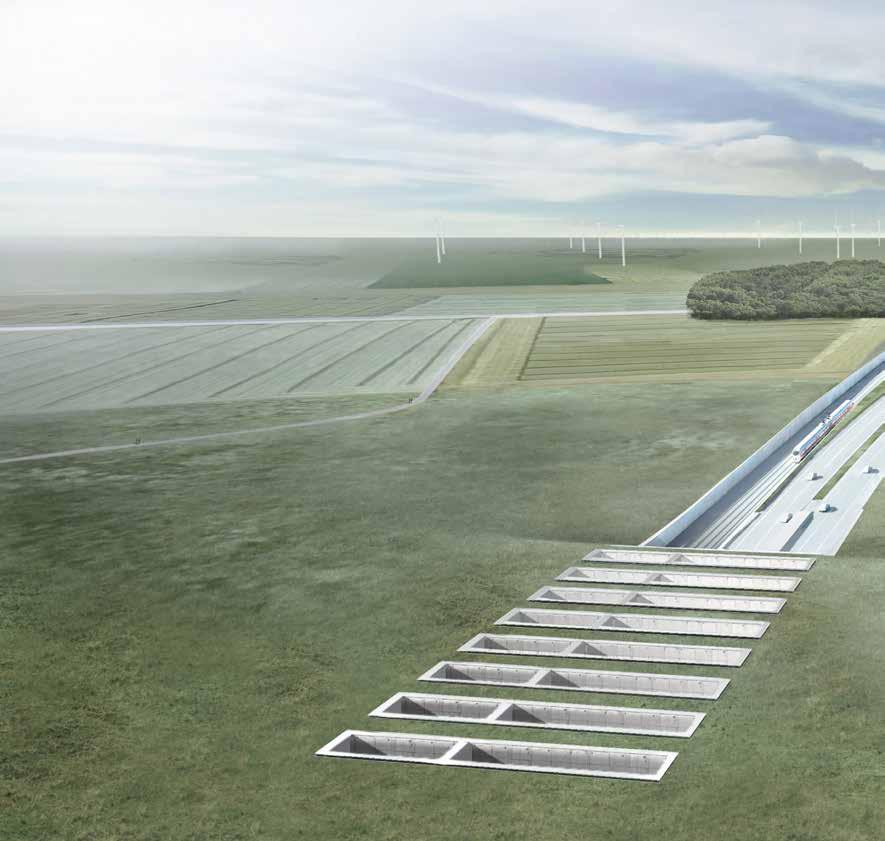

2015-2016

Windplanblauw launched Windplanblauw is a wind farm north of Lelystad. 74 existing wind turbines will be replaced by 61 larger ones. To determine the effects on the landscape, living environment and nature, we conduct an environmental impact assessment (EIA). We also carry out investigations for the EIA and the permits, and we contribute to the environmental process. This was successful: the environmental permits have since been granted and the SDE+ subsidy has been received. Construction of the park is planned to start in 2021.

2016

Establishment of sustainable design principles (SDPs)

The SDPs were developed by Witteveen+Bos to help realise sustainability ambitions in projects. The seven SDPs are designing with nature, flexible design, circular design, multifunctional design, participatory design, trias and social design. In 2016, we decide to apply the SDPs to all our projects.

2017