FUEL for growth

Ale Eboli reveals the supply chain changes underway at Conagra Brands, which aim to deliver $1bn of cost savings

Digital transformation

The key to building faster, flexible, and traceable supply chains

Logistics

To gain the most value, data has to be correctly collected and analyzed

Sustainability

3 emissions

Vol 9 - Issue 11 - 2022

What to look for when tackling challenging Scope

INDUSTRIAL INTERNET OF THINGS

The future of automation is digital and connected. As your automation partner, we support you step by step to smart factory solutions. Together with Balluff you are ready for the IloT.

www.balluff.com

#B_IIoT

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Director Tom Vince Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Daniel Baksi, Alex Caesari, Danielle Champ

Editorial Administrator Amy Gilks

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork Administrator Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors Philip Monument, Joy Francesconi Head of Content Management Adam Blanch

Client Sales Executives Chloe Allman, Mark Cawston

Project Managers Lewis Bush, Jo-Ann Jeffery, Lauren Proulx, Ben Richell, Basil Sharpe

Content Managers Mark Cowles, Valentina Forero, Jeff Goldenberg, James Page, Richard Saunders, Tarjinder Kaur De Silva

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

US Office

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Hello and welcome to the November issue of Supply Chain World. This month we cover a variety of topics including Sustainability, Artificial Intelligence, Digital Transformation and Scope 3 Emissions. Our authors point out trends and offer their opinions into the best way forward for supply chain leaders. In these challenging times, I hope you find a useful look into a potential approach or a suggestion that triggers an idea – do let me know if you are inspired!

I would also love your input for next year. I am now planning the content for 2023, so please do get in touch if there are any subjects that you would like to see in our pages.

Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such

Logistics To gain the most value, data has to be correctly collected and analyzed Digital transformation The key to building faster, flexible, and traceable supply chains Sustainability tackling challenging Scope emissions FUEL for growth Ale Eboli reveals the supply chain changes underway at Conagra Brands, which aim to deliver $1bn of cost savings

information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of

Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Finelight

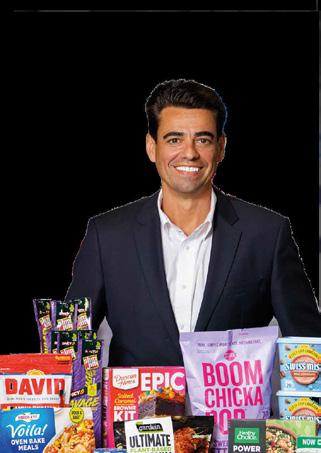

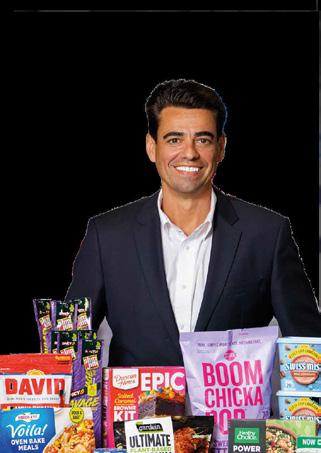

Our cover story this issue gains insights from Alexandre ‘Ale’ Eboli,

and Chief Supply Chain Officer at Conagra Brands. The business has a range of supply chain initiatives underway – plus Ale reveals what makes him

up happy each morning.’ Turn to

to learn more.

Executive Vice President

‘wake

page 42

lh@finelightmediagroup.com

@SCWmag supply-chain-world-magazine Follow supply chain world at Welcome scw-mag.com 1

Libbie Hammond, Editor

2 8 Inside this issue News Logistics 3D Printing Sustainability Technology Manufacturing Strategies Summit Supply Chain Strategies Summit 10 16 24 12 28 20 32 6 Digital Transformation Sustainability Contents

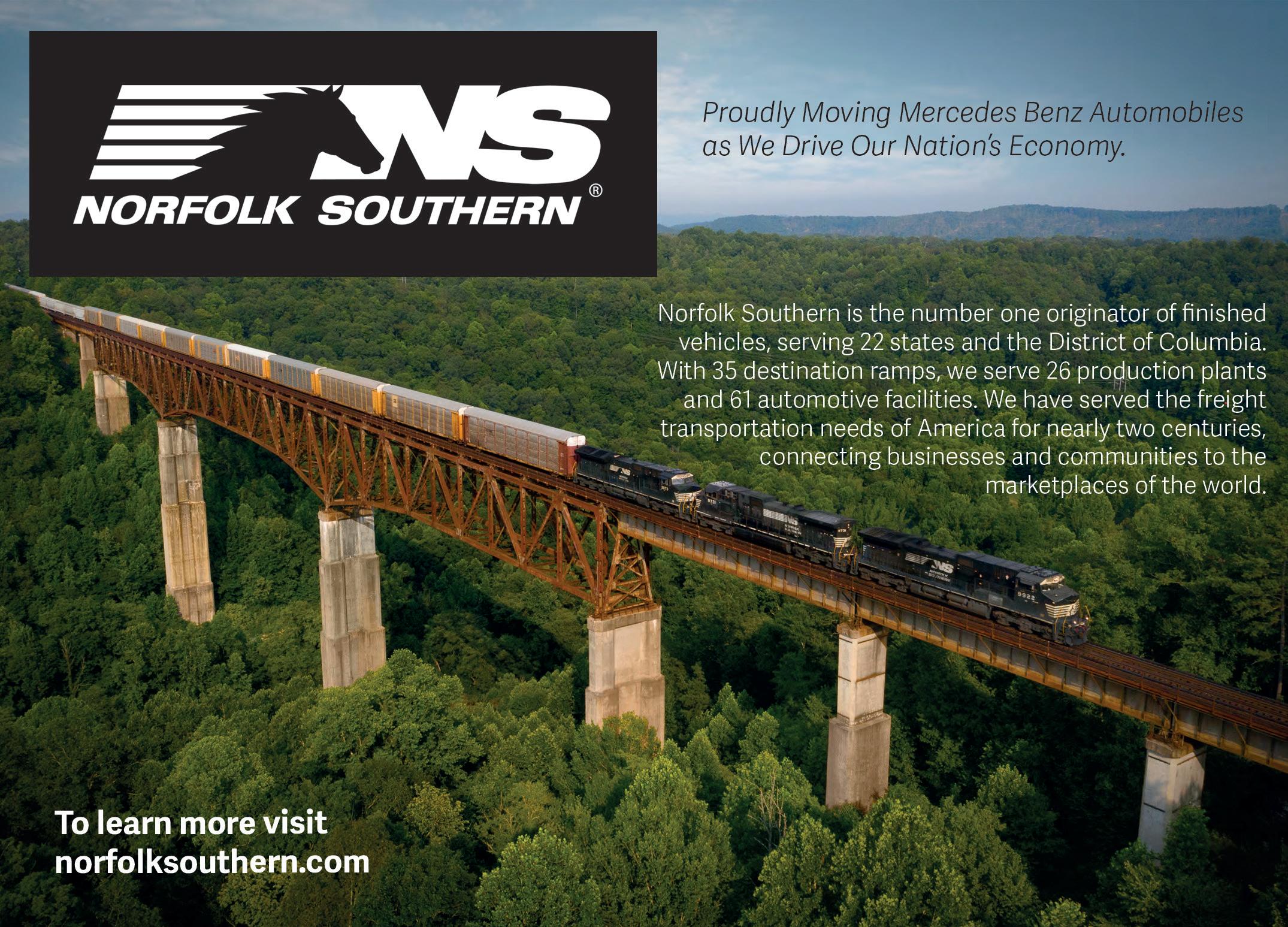

scw-mag.com 3 DHL LLP Conagra Brands Exclusive Feature Cover Story Cardinal Health American Welding & Gas Abercrombie & Fitch Co. 42 38 72 58 62 Mercedes-Benz USA 80 supply chain world

4 Northwell Health Power & Tel 116 104 128

Lubrizol

92

98 Contents

Day Kimball Healthcare

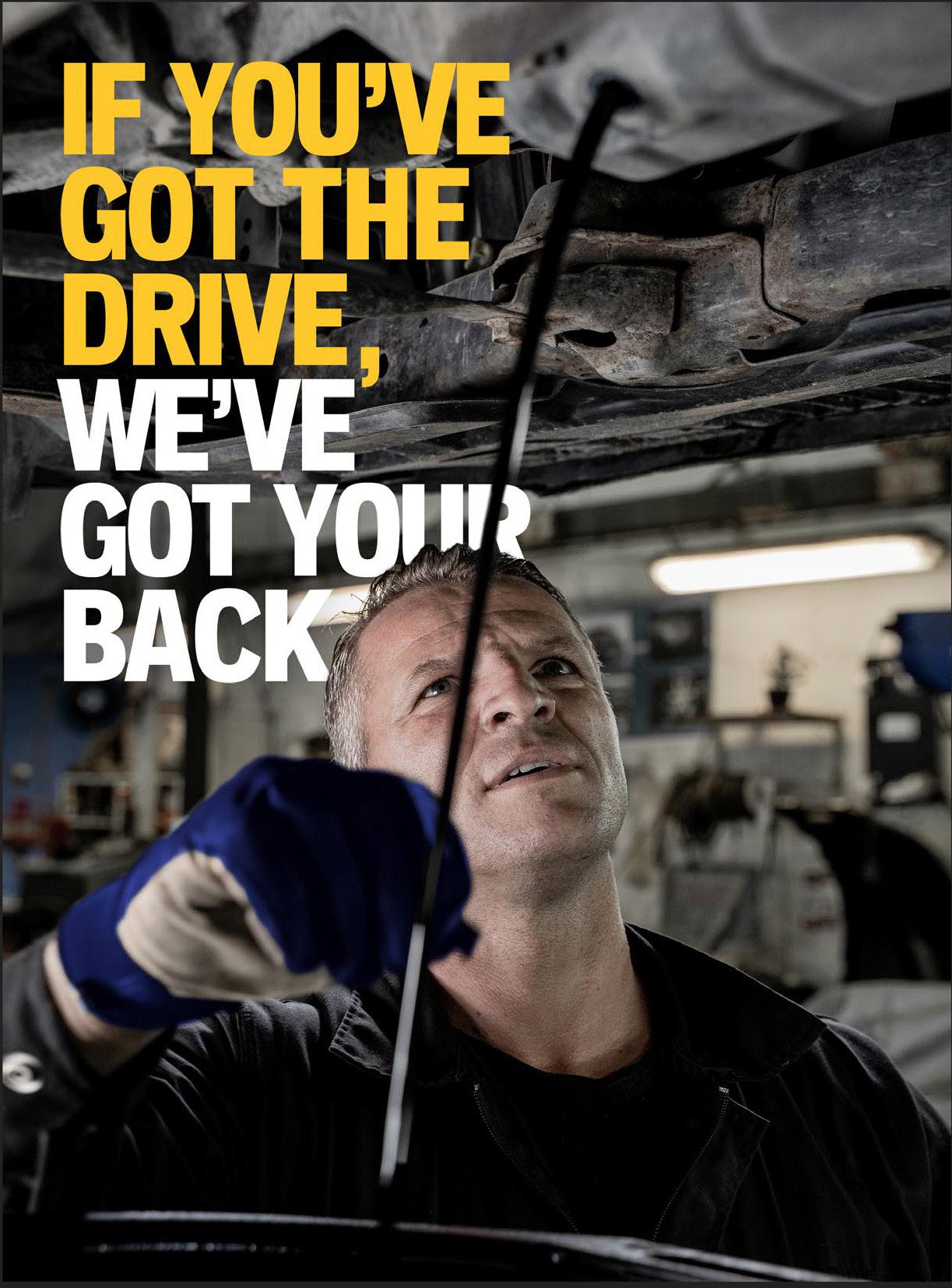

Driven Brands

From Conversion Systems to Spare Parts, DRT has you covered. Why limit yourself to one? Now produce DRT’s Beaded EOE, DRT’s New Depress Panel EOE, or both. Innovation: Now available only from DRT, a new design that produces 10% more tabs per ton of aluminum than the next commercially available tab. Contact us today to learn more! From Conversion Systems to Spare Parts, DRT has you covered Discover more at www.drtmfgco.com METAL PACKAGING CAPABILITIES FOOD AND BEVERAGE END CONVERSION SYSTEMS • EASY-OPEN END PRECISION TOOLING PRODUCT DEVELOPMENT AND INNOVATION • SERVICE AND TRAINING • STOLLE OEM TOOLING

European Manufacturing Strategies Summit

Industry experts gathered in Berlin for a packed program of industry insights at the 18th annual European Manufacturing Strategies Summit

The 18th annual European Manufacturing Strategies (EMS) Summit took place from 7th to 9th November at the Maritim proArte Hotel in Berlin. The annual summit provided an international forum for manufacturing leaders to share and discuss strategies for the best way forward in this new world.

EMS is the only strategic manufacturing conference and networking event to reveal best practice and highlight the latest solutions in preparing for an upturn over the next 12 months. Manufacturers in the industry shared case studies and insights on how the world has irrevocably changed in the aftermath of recent and ongoing geopolitical events.

Boasting a packed three-day, threestreamed schedule of 51 engaging and informative sessions, attendees enjoyed a wealth of industry experience and expertise. The summit offered workable and relatable case studies from the past couple of years,

presentations from active senior industry professionals and plenty of networking opportunities. Now a CPD-accredited event, attendees were able to expand their knowledge and gain a certificate of attendance that counts towards professional development.

The summit’s key themes explored maintaining an effective and functional workforce, highlighting the key parameters in switching to Net Zero, and transferring digital thread and technology capabilities.

There were several keynote presentations from notable heads of industry. Marc Winkelman, Global Director of Manufacturing Innovation Capability at Proctor & Gamble discussed the seven actions leadership needs to accelerate the operational excellence journey and deliver its results. Widely-regarded as an industry leader, Marc extrapolated the capabilities that have helped P&G experience a yearon-year program of cost-saving, inventory

6

reduction, service improvements and employee satisfaction.

In another exciting scheduled keynote presentation, Frank Polky, Head of OT Security at Mars discussed finding the balance between trust and zero trust. Having experienced a cyber-attack five years ago, Frank talked through the Mars journey from onboarding stakeholders to staff training in their global defense, and the resulting impact on productivity.

Delegates were also invited to attend a range of panel discussions. Topics included a framework for smarter manufacturing, growth pressure points and tailoring the customer experience to create a customercentric supply chain. Additionally, case studies covered a range of industry insights. From the Internet of Things (IoT) and technology to advanced production and strategic operations, heads of industry explored subject matter pertinent to modern manufacturing.

Delegates were also able to enhance their learning by attending networking brunches, one-to-one meetings and solution spotlight sessions. The summit was delighted to welcome heads of business from industry leaders, such as Staedtler, Electrolux and MTU Aero Engines, alongside esteemed academics from the University of Warwick, UK and the Institute of Mechanical Engineering of the School of Engineering of EPFL, Switzerland to this year’s advisory board. ■

European Manufacturing Strategies Summit

Dates: 7th to 9th November 2022

Location: Maritim proArte Berlin, Friedrichstraße 151, 10117 Berlin, Germany Website: www.ems-summit.com

7 scw-mag.com

European Manufacturing Strategies Summit

Supply Chain Strategies Summit

Heads of industry shared their strategy expertise surrounding the changing world of supply chain management

The Supply Chain Management Strategies (SCMS) 6th annual European Summit was held from 7th to 9th November in Berlin at the Maritim proArte Hotel on Friedrichstraße.

The European SCMS Summit provided an international forum for industry leaders to share and discuss the best way to face the many new challenges facing the industry. Delegates were joined in Berlin by industry experts, who offered an unparalleled range of senior leadership case studies and solutions for the sector.

A packed, three-day program of engaging and informative sessions offered attendees a wealth of industry experience and expertise. Delegates were able to experience workable and relatable case studies from the past couple of years, presentations from active senior industry professionals and plenty of networking opportunities.

The summit is now classed as a CPDaccredited event, and as such, attendees gained a certificate of attendance that counts towards professional development.

The key topics for the 2022 summit included food supply chain challenges, the current chip shortage, and discussions surrounding potential ways to create agility to avoid disruption. Additionally, experts discussed workforce disruption, the training of new staff and the adoption of remote auditing as a regular part of the supply chain management process in light of the global new normal.

There were several keynote presentations from notable heads of industry, focused on a range of topics. From advocating for the circular economy to the benefits of developing a strong relationship with customers, delegates had the opportunity to join leaders from across the globe to learn about the latest technologies and strategies.

8

Holger Langbein, VP Logistics, Robert Bosch GmbH, discussed a new strategy to include internal and external partners into processes and data flow. A special focus of the presentation was on the inbound side of logistics at Bosch and the value of seamless information and data flow between the organization and its suppliers.

Torsten Becker, Head of Study Program Supply Chain Management, SHR Berlin University of Applied Sciences spoke about the current supply chain climate. As the pandemic, the war, bottlenecks in transport and production, and limitations for travel have impacted the business world, many companies have been forced to adapt their supply chain strategies to the increased Volatility, Uncertainty, Complexity und Ambiguity (VUCA). Based on strategy projects from various industries, he highlighted new approaches, strategies and possible solutions.

Delegates were also able to attend a range of panel discussions. Notable industry heavyweights, such as HP Deutschland, Matsmart, Infineon Technologies and IBM, joined the panel to deliver case studies that imparted a breadth of industry experience and invaluable insight.

Additionally, delegates could enhance their learning by attending networking brunches, one-to-one meetings and solution spotlight sessions. ■

European Supply Chain Management Strategies Summit

Dates: 7th to 9th November 2022

Location: Maritim proArte Berlin, Friedrichstraße 151, 10117 Berlin, Germany Website: www.scms-summit.com

Supply Chain Management Strategies Summit 9 scw-mag.com

European

Corporate supply chain tool

Watershed has launched Watershed Supply Chain. The solution produces a Scope 3 emissions footprint using privately and publicly disclosed financial and climate data, plus granular insights into individual supplier emissions. It then overlays the customer supply chain footprint against suppliers’ existing climate programs and commitments, helping customers prioritize engagement with the suppliers that are best positioned to drive maximum climate impact.

Massive investment in US

The US Department of Transportation has announced more than $703 million to fund 41 projects in 22 states and one territory that will improve port facilities through the Maritime Administration’s Port Infrastructure Development Program. The funding, made possible by the Bipartisan Infrastructure Law and additional Congressional appropriations, will benefit coastal seaports, Great Lakes ports, and inland river ports, helping improve supply chain reliability and offering new workforce opportunities.

Safe patient tracking

SATO has partnered with Solid Solutions en Identification SA (Solid), to enable Swiss Clinic MV Santé to monitor patients in its wards using SATO’s RAIN RFID wristband.

The SATO RAIN RFID wristband, which helps reduce risk of infection while providing real-time data on a patient’s location in a hospital ward, is configured to work seamlessly with the SATO CT4-LX printer and its UHF RFID module.

The integrated solution enables automatic and accurate identification when patients are moving from one area to another.

Flexible solutions from KWE

Kintetsu World Express, Inc. (KWE) is an international freight forwarding and logistics company headquartered in Japan. As a subsidiary of the Kintetsu Group, KWE was officially established in 1970, gradually expanding its overseas network until five regional groups were formed: Japan; East Asia; Southeast Asia & Oceania; Americas; and Europe, Middle East & Africa. In 2015, KWE completed the acquisition of APL Logistics to further complement its extensive offerings with greater support and specialized services.

Today, KWE and its subsidiaries operate across 688 locations within 298 cities and 46 countries, with a warehousing footprint over 2,000,000 square meters and a workforce of more than 17,000 cargo specialists, brokerage experts, and supply chain architects. Its dedicated teams offer an array of flexible and localized solutions for aerospace, automotive, chemicals, electronics, healthcare, industrial, and retail sectors.

Industry News 10

Times change. Our commitments don’t

For more information, visit us at www.kwe.com

.

Four key steps

Purchased goods and services: addressing the most challenging Scope 3 emissions.

By Anuj Saush

The phrase ‘Purchased goods and services’ may seem innocuous, but sustainability executives know better.

Corporate emissions originate from various sources, which are grouped into ‘scopes’. Scope 1 refers to direct emissions from owned or operated assets e.g., emissions from the burning of diesel fuel in company trucks. Scope 2 refers to indirect emissions from purchased energy used in the company’s own operations, e.g., electricity used in company facilities. Scope 3 refers to indirect emissions originating from all other sources in the upstream and downstream parts of the reporting company’s value chain, e.g., processing and production of raw material and emissions coming from employee commuting.

Across industries, ‘purchased goods and services’ usually represent supply chains’ highest source of ‘Scope 3’ emissions. Inherently data-intensive, this can be one of the most difficult to handle categories of Scope 3 emissions, as they require extensive supplier engagement and collaboration and potentially the innovation of and reformulation of existing products and processes.

Actionable strategies are emerging, however. The Conference Board, a global think tank providing businesses

with trusted insights for what’s ahead, has developed a realistic sustainability pathway for executives to reduce their companies’ purchased-goods-andservices emissions. There are four key steps to an effective Scope 3 emissions reduction strategy: screen and prioritize; acquire data; refine supplier base; and, finally, set targets, monitor, and audit.

Emissions screening and prioritization

Prioritizing data collection efforts requires ranking Scope 3 emissions and then focusing on the most significant categories. One way to rank Scope 3 categories is based on the activities’ relative financial significance. However, spending and revenue do not always correlate well with emissions and actual environmental impact. Instead, companies must work toward using actual data – unit of measure of a product in dollars, kilograms, tonnage, and the associated emissions factor – to accurately quantify Scope 3 emissions. While the required data may be incomplete, for efficient and reliable monitoring of Scope 3 emissions in the future, companies should create robust quality-controlled master data management systems.

12

Sustainability scw-mag.com 13

Acquire data and explore potential

Companies typically use databases such as the Evoinvent and Gabi TS for materials and products emission factors or information from CDP supplier databases and Ecovadis ratings to prepare their emissions inventory. Although these cover a wide range of materials, products, and services, companies may not be able to find all emissions factors they need to have a complete inventory of greenhouse gases. It would, of course, be ideal if suppliers provided the specific data, but not all suppliers will be able to support such requests. It is most likely that a company will have to use a hybrid approach: a combination of a spending-based method (using financial data to calculate estimated emissions, for example), an average data method (converting volume of purchased goods to emissions estimates), and supplier-specific method (using actual life cycle analysis to calculate emissions, for example). While this hybrid method may not be fully accurate, it helps to identify the biggest sources of upstream value chain emissions with sufficient accuracy to start engaging in the joint management of emissions reductions.

Refine supplier base

Companies should identify the suppliers with the greatest estimated potential to reduce emissions. They are the first targets to engage, and the easiest wins occur when the company has a strong buying position – lots of influence, in other words – and the supplier has strong emissions reduction potential. Where the company’s influence is high but the potential for the supplier to actually effect reductions is low, it can begin joint initiatives to reduce and replace the input materials or services in question. Where there is low influence over the supplier and low potential of reduction, switching suppliers and/or redesigning the product might be the right move. Where there is high potential for the supplier to reduce emissions, but the company has little influence over the supplier, it may want to collaborate with other customers to improve sustainability. Of course, when forging these alliances, all parties must be careful to avoid any potential competition law breach. Once a company has mapped out and prioritized suppliers, it should engage with them to receive primary data.

14

Agree on targets and evaluate

Once the reporting company has calculated its Scope 3 emissions footprint and reduction potential, it should create a specific plan to achieve them. While setting their targets, companies must balance ‘ambitious’ and ‘achievable’ and need to be transparent about their underlying assumptions. Additionally, companies should set both shortterm and long-term targets. The former allows them to continuously monitor progress and incremental reductions as well as alert when adjustments due to changed circumstances are required.

Monitoring progress requires a system that can provide frequent Scope 3 emission calculations, enabling companies to detect deviations and quickly course correct. It can help to encourage such data collection efforts within the company by showing immediate results to all managers involved.

The transition to a low-carbon economy requires companies to review their entire value chain. For

some companies, e.g., re-sellers, the only way to reduce Scope 3 emissions is to have their suppliers reduce theirs. Addressing Scope 3 emissions is a significant undertaking. The right prioritization, however, will allow enterprises to achieve it in a reasonable timeframe, thus help create a more resilient supply chain. ■

For a list of the sources used in this article, please contact the editor.

Anuj Saush www.conference-board.org

Anuj Saush is Center Leader, European Governance & Sustainability Center at The Conference Board, the memberdriven think tank that delivers trusted insights for what’s ahead. Founded in 1916, it is a non-partisan, not-for-profit entity holding 501 (c) (3) tax-exempt status in the United States.

scw-mag.com 15 Sustainability

People data

Logistics’ employee safety and its role in digital transformations

Logistics organizations are under unprecedented pressure to improve not only efficiency, but also employee safety. The Covid-19-inspired spike in demand has highlighted endemic performance problems and created new workplace challenges; how can companies recruit and retain staff in a highly competitive market when the transport and storage industry exhibits a higher rate of injury at all levels of severity compared to other sectors?

Digital transformation provides a chance to improve efficiency, reduce costs and enhance responsiveness to customers, and transform the dayto-day experience for employees. This can only be achieved, however, if organizations get the right data

collection and analysis solutions in place that quickly and effectively deliver new insight to logistics teams, explain Peter Ruffley, CEO, Zizo, and Ian Brown, CEO, Excelpoint.

Data capture challenge

While there are many technologies associated with digital transformation, in essence it is about data; using data to both automate processes and gain better understanding to drive business improvement.

For many organizations, however, that simple statement is the stumbling point. What data is required? Where is it located? How is it accessed? Can it be used in combination with other sources? Is there any contextual information? How often does it change?

16

The first question, of course, is: how can data be collected? For warehouse operations still reliant upon many manual, even paper-based processes, data collection is complex and time consuming. It can require significant effort to entice any insight from systems – information which is then out of date in this fast moving environment. Inefficiencies remain unchecked and safety risks ignored.

Extracting value

Achieving fast, effective data capture is a priority. No-code automation software that can be configured into a range of solutions for businesscritical processes can quickly improve access to information, eliminating the need for multiple inputs across numerous systems. Such software helps businesses to streamline the way they manage people, systems and information, in turn, improving the workforce’s welfare, achieving flexibility and significant cost savings.

For example, from a safety perspective, simple, automated solutions for logging, recording and

resolving incidents can both ensure Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR) compliance and provide vital insight to ensure the incident is not repeated in the future; while automated safety audits create a structured process where information driven insights support employee safety while meeting compliance regulations.

In addition, the deployment of sensors or wearable devices, connecting to an Industrial Internet of Things (IIoT) platform or at the edge, can very quickly deliver new business insights. For example, data from smart controls, such as loading docks, blind intersections and door openings can be used for operational improvements, as well as ensuring employees are safe and following protocols.

Employee safety

With a holistic overview of operations, logistics managers gain confidence to make better decisions regarding both performance and

Logistics scw-mag.com 17

employee well-being. Workforces can identify areas where incidents could happen, highlighting risks before an accident occurs. In addition, information gathered from wearable devices can pick up an individual’s lifting techniques, body temperatures, heart rate or distance travelled in the workplace – providing managers with the ability to intervene in any unsafe practices in real-time.

This insight also creates a unified picture of what is happening across the factory or warehouse by highlighting patterns of behavior that previously may have been undetectable, information that can be used within a feedback loop to drive continual improvements. For example, employees can be offered specific interactive and data-driven training – which will not only enhance employee wellbeing, but also improve employee productivity, in turn, increasing their satisfaction.

This is crucial as, according to the Health and Safety Executive, ‘training helps people acquire the skills, knowledge and attitudes to make them competent in the health and safety aspects of their work.’ Such programs, driven by data-insight, can ensure that individuals performing a task have the competence to do so without putting the health and safety of others or themselves at risk.

Conclusion

Good employees are hard to find right now. For an industry experiencing a significantly higher number of safety incidents - for example forklift accidents account for approximately 85 deaths and 34,900 serious injuries each year - more must be done to both improve the operational risk

18

environment and create tailored employee training and education.

Furthermore, employee safety is a great place to kick off a digital transformation program. With wearables and no-code solutions, the process is simple and creates zero disruption; and the insight is both immediate and accessible for logistics staff. Critically, it builds confidence in the value of data amongst logistics teams, accelerating their commitment to transformation and helping to create an appetite for data driven change.

Once businesses realize the benefits and can see the impact, such as better employee safety, warehouse managers will begin to question what else they can do. What else can be improved? What else can be changed for the better? And this is the foundation to driving the digital transformation. ■

For a list of the sources used in this article, please contact the editor.

Peter Ruffley is CEO, Zizo, and Ian Brown is CEO, Excelpoint. With state-of-the-art patented technology and value driven service, Zizo® helps organizations, of all sizes, identify and access their most valuable data; enabling them to rapidly become data driven. An end to end platform, comprising of an edge database, graphical data engineering capability and data visualisation, each solution was conceived to meet the challenges of data analytics at both the edge and at the cloud, meaning Zizo® is truly unique.

Peter Ruffley www.zizo.co.uk

scw-mag.com 19 Logistics

Unlimited possibilities

What is required to unlock the next stage of supply chain evolution?

By Sateesh Seetharamiah

Fragmenting demand, rising supply chain complexities, and the need for resilience and responsiveness in the face of disruption are catalyzing a shift in the fabric of the global supply chain. The Covid-led disruption in 2020 was unprecedented for global supply chains, especially for retailers and consumer goods manufacturers; the stakes have altered considerably.

Surveys from several consulting firms show that the preference for online shopping is here to stay. This has led to an unparalleled fragmentation of demand where the demand signal comes from each customer’s doorstep. Moreover, even next-day delivery comes too late in the age of instant gratification. For manufacturers, not clued into their real-time supply chains means frequent out-of-stock situations, losing business to competition, and suboptimal inventory management. For instance, during the Covid crisis, 72 percent of retailers experienced multiple stock-outs for fast-moving products. We all remember the toilet roll runs! Fittingly, the top priorities for supply chain digitalization have become demand planning (74 percent), supply planning (69 percent), and inventory optimization (58 percent).

The key to building faster, flexible, and traceable supply chains

While manufacturers are adapting to these shifts, Gartner found that 70 percent of supply chain leaders have not been able to align strategy with operational execution. One of the reasons is the lack of end-to-end visibility and intelligent solutions that help real-time action. To make effective decisions regarding product stocking, holding, recall, and other operations, you need to know what is happening at every point in your supply chain. That kind of granular visibility and traceability – beyond Tier 1 and Tier 2 suppliers – at the SKU level goes a long way in building resilience. According to a McKinsey survey, companies with end-to-end supply chain visibility were two times as likely to report having no challenges from 2022 disruptions.

20

It’s also obviously good for business. For instance, by improving supply chain visibility, a premier international brewer was able to reduce stock-out scenarios at distributor locations by 15-20 percent. In another example, a global leader in confectionery, pet food, and food products was able to standardize its hold and release process with a unified view of its supply chain. Harmonizing data from multiple enterprise resource planning (ERP) and warehouse management systems, it could track where the finished goods were at any given moment and hold or recall them if needed.

Unfortunately, these success stories are outliers. Even today, despite accelerated

digitalization efforts, a large part of supply chains, especially in the emerging markets, rely on antiquated tracking methods such as spreadsheets or disparate and disconnected systems. Mining and harmonizing data to glean insights from across the supply chain from these siloed collection methods is effort and cost intensive.

The industry needs a new approach that allows more visibility across the partner network and more collaboration that leads to order fulfillment. An approach that goes further than digitalization and uses integrated solutions to gather, extract, and share information with multiple stakeholders, creating a truly connected supply chain.

transformation 21 scw-mag.com

Digital

Achieve market dominance with a cognitive, connected supply chain

Supply chains can no longer afford to follow a linear model and must transform into connected multi-vendor ecosystems that are scalable, rapidly customizable, agile, and ‘always-on’. Competitive differentiation depends on being able to leverage data collected from these connections in real time to coordinate and harmonize functions across people, processes, technology, and networks.

A connected supply chain rests on three pillars - building cognitive operations, exploiting the power of value networks, and amplifying human potential (see fig). This involves:

■ Digitizing processes and documents to unlock hidden insights faster

■ Connecting all supply chain stakeholders and facilitating an exchange of data and information in near real-time

■ Automating processes and systems to remove inefficiencies

■ Leveraging AI/ML to augment human decision making

By coupling high levels of AI, Automation and Machine Learning with seamless data visibility across the entire value chain, the connected systems get smarter as they scale. For instance, a global sports merchandise giant augmented its network with 325 new distributors using an intelligent supply chain platform with automated sales data acquisition. Access to this data across 32,000+ stores and 30+ countries increased its demand visibility by 60 percent, improving demand planning, speed to market, and customer engagement.

Digitize Processes and documents Connect

Parties and customer journeys

Exchange

Data and information Automate Processes and systems

Augment

Human decision making

Committing to the next-gen supply chain

Today’s massive, complex supply chains are living, breathing organisms. Keeping them alive is a concentrated effort of multiple, interconnected, interdependent systems that run seamlessly without the need for manual intervention. Building a connected supply chain is like creating a central nervous system for this organism. In this system, every tiny cell can send signals about what

22

Amplifying

it needs to a control mechanism that activates appropriate responses to meet those needs. This level of connectivity, insight and intelligent automation will be essential in unlocking the next stage of supply chain evolution to drive hyper-personalization and true reconciliation of humanmachine capabilities.

For a list of the sources used in this article, please contact the editor.

Operations Unlock new business models Improved org resilience Enhanced customer experience Industry leading process efficiency Increased productivity & predictability Sateesh Seetharamiah www.edgeverve.com Sateesh Seetharamiah is the CEO of Edge Platforms, EdgeVerve Systems Limited (An Infosys Company), and a board member and

Director at EdgeVerve. EdgeVerve Systems

subsidiary

Infosys, is

global leader

platforms, assisting clients

unlimited

Human Potential Value Networks Cognitive

Whole-time

Limited, a wholly-owned

of

a

in developing digital

to unlock

possibilities in their digital transformation journey.

Digital transformation 23 scw-mag.com

The missing link?

Bridging the gap for a resilient supply chain.

By Dr. Henrike Wonneberger

24

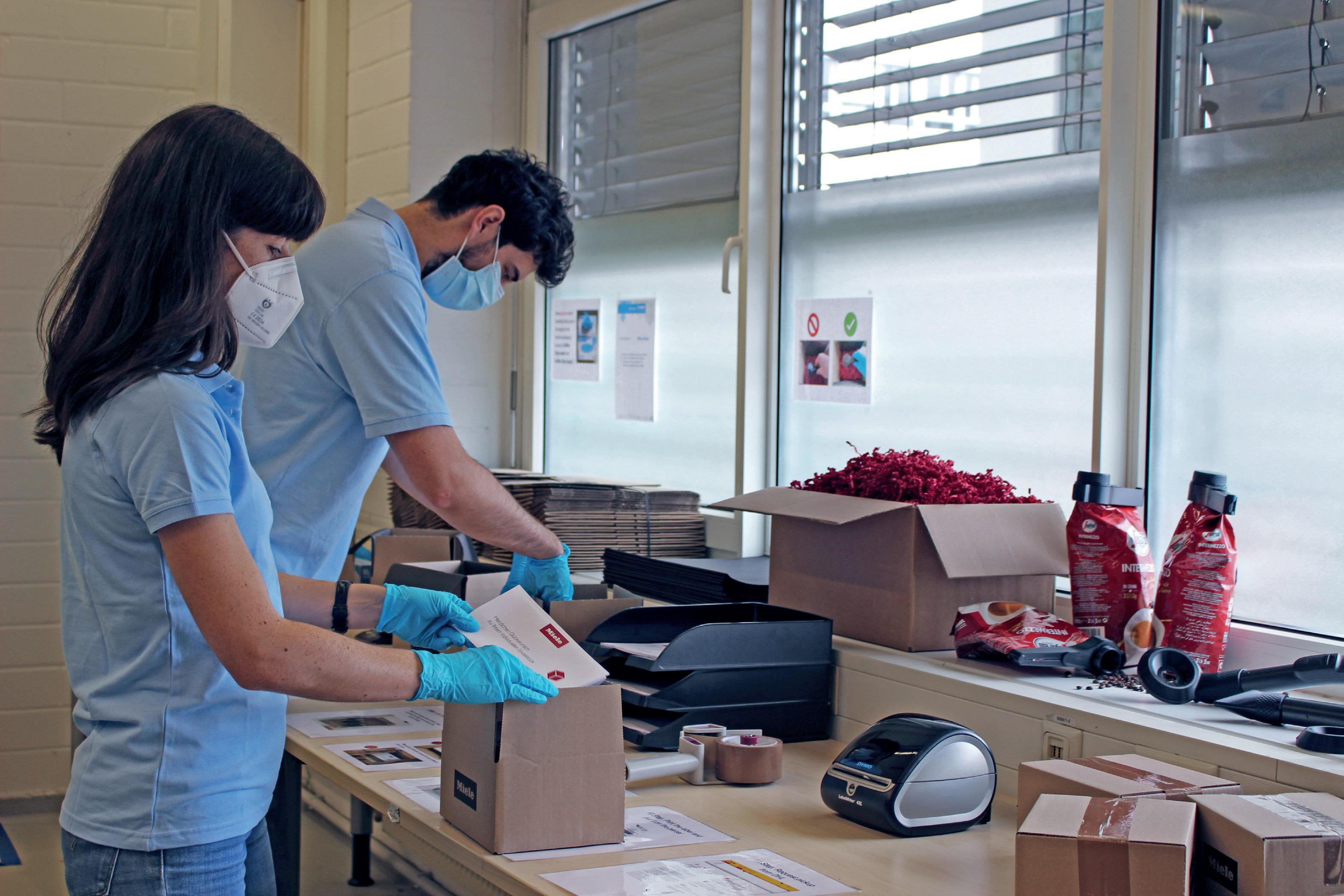

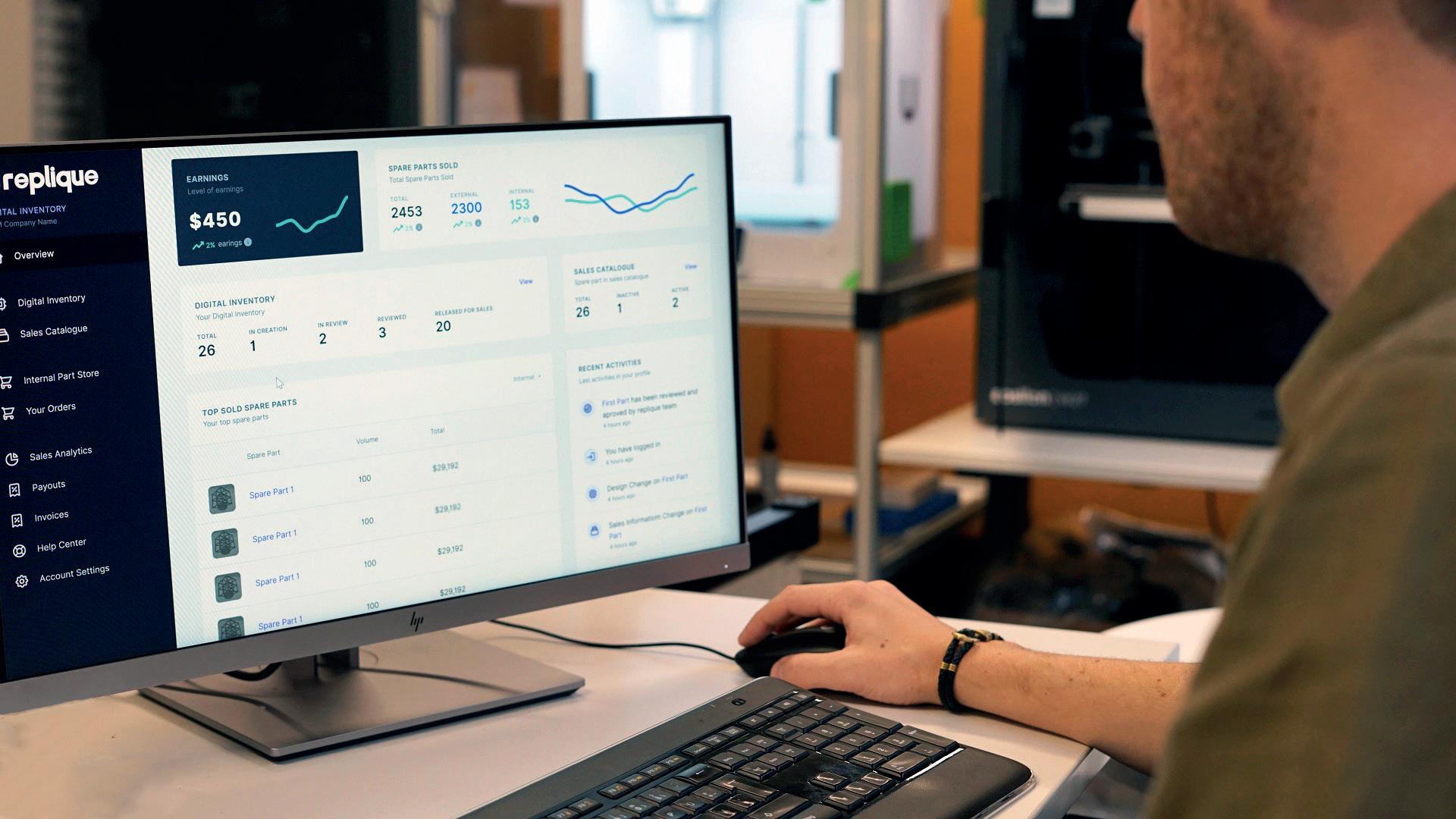

Optimizing the supply chain contains huge potential for OEMs to increase profitability. Reducing inventory costs with punctual delivery has been, for many years, the focus of supply chain management. Over the years, supply chains have been optimized to perfection, using algorithms and digital tools, but they are balanced on a knife’s edge. Covid 19 and the subsequent closing of borders have revealed the limits of planning and the fragility of supply chains to suppliers, OEMs, and end customers.

Ways to mitigate supply chain risks

When a part is needed urgently, every hour can cost manufacturers hundreds and thousands of dollars with the cost of the spare part itself often negligible compared to the economic and reputational damage caused by its absence. Increasing the buffer in warehouses could minimize the risk of supply gaps, but counteracts previous efforts to reduce inventory and increases tied up capital, warehousing costs and obsolescence.

Another option is to source from several suppliers in multiple locations; should one supplier fail, others can cover the demand. However, interconnected global supply chains are often dependent upon a few suppliers of basic materials. Subsequently, for specific parts or components, all worldwide suppliers might be affected by the material shortage. A better solution is not only supplier diversification, but also in material alternatives.

A third way to improve the resilience of the supply chain is to

return to localized manufacturing –as witnessed at the beginning of the Covid-19 pandemic. This saw many manufacturers 3D print critical parts needed to fight Covid-19 – such as face shields or valves for respiratory devices. This manufacturing philosophy, named bridge manufacturing, can be used as a blueprint to generally improve supply chain resilience.

Essentially, bridge manufacturing means having a technically viable alternative to bridge a gap. This gap can be economic if other technologies are too expensive, or an availability gap, if parts produced in another manufacturing technology are unavailable.

Bridge manufacturing requires a manufacturing alternative for the part that allows on-demand, decentralized production. This ensures the part can easily be made available anywhere globally in the event of a sudden unexpected shortage. Consequently, should supply chains be disrupted, the OEM or supplier has alternative options, potentially saving money and reputation. As a concept, bridge manufacturing comprises three different types: provisional solution, equivalent manufacturing solution, and ramp-up/phase-out bridging.

Provisional solutions

Well known in dentistry, this is where a transitional prosthesis –using a different material and a different technology – is provided as a makeshift solution while the actual prosthesis is manufactured. Requirements for a makeshift solution are often lesser than for the original, making bridge manufacturing a second-best alternative from a technological standpoint.

3D printing scw-mag.com 25

Whether a part is used as a stop-gap until the ‘original’ spare part is delivered, or until it breaks down and is replaced by the ‘original’ spare part, bridge manufacturing of the part takes place in parallel to ordering a standard ‘original’ spare part. Like this, the machine downtime is reduced in the same way, saving the OEM money and reputation.

Equivalent manufacturing

However, bridge manufacturing can meet all requirements and specifications of the ‘original’ part. In this case, bridge manufacturing might be more expensive

in a regular supply chain situation, making it inappropriate for standard production, but it might have certain advantages when other constraints occur. For example, a polymer part could be manufactured at low cost per part in large quantities in a central location.

In the event of a global supply chain disruption and the part is needed overseas, this can be bridged by localized 3D printing close to where it’s needed in the required (probably low) quantity. If the manufacturing alternative was set up conforming to specifications, a part produced correspondingly might last as

26

Few manufacturing technologies meet these criteria; injection molding, requires high tooling investments and ramp-up-time before production can start. Milling can be very expensive and material-intense, and is limited regarding geometries and complex structures.

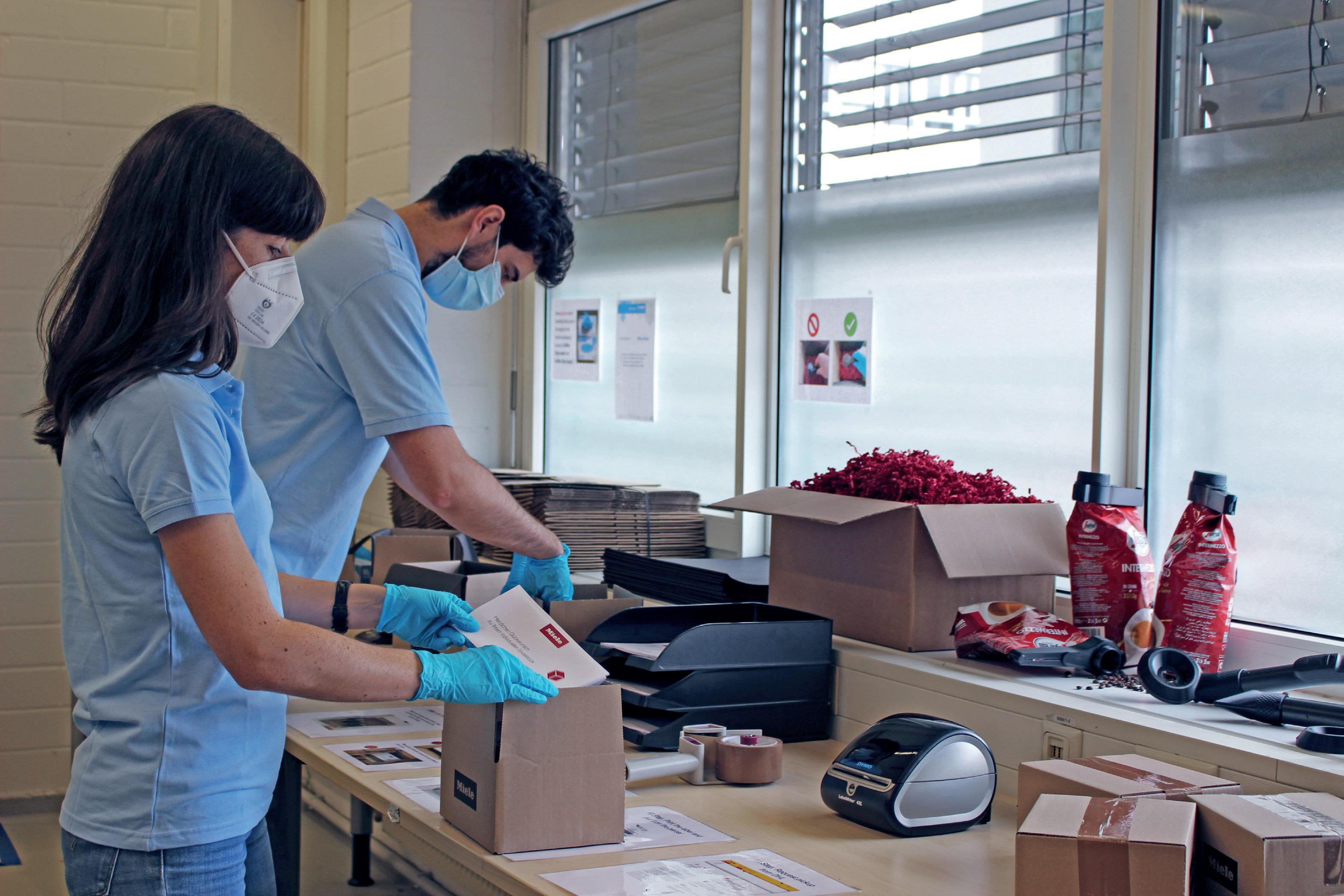

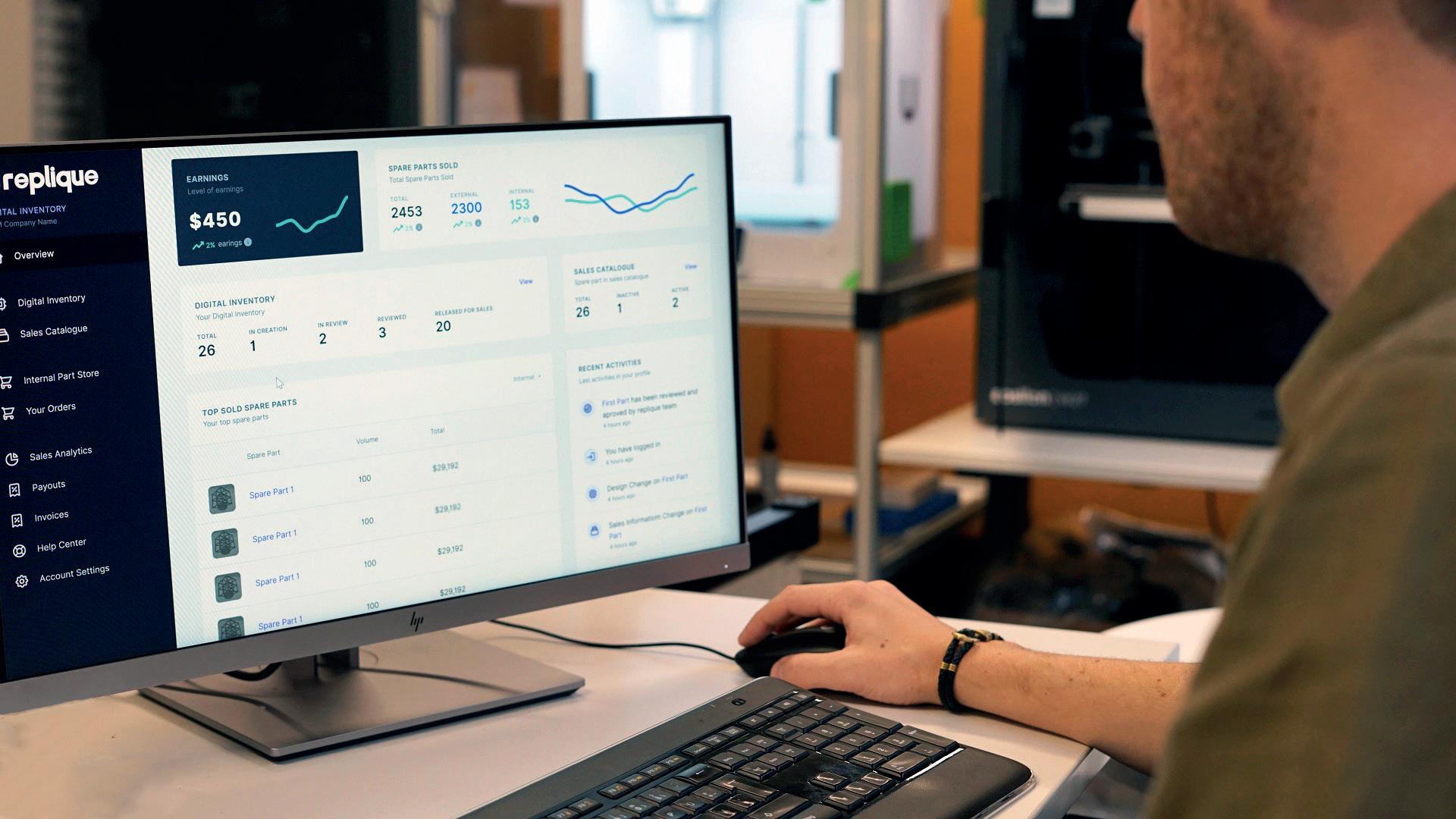

Adding value with additive manufacturing

The most viable option for bridging is additive manufacturing and in the last years 3D printing has become increasingly popular, especially for industrial applications.

Once a part is qualified and print parameters are set, it does not need any ramp up but can simply be sent securely to a 3D print service bureau for fast, cost-effective production. That’s to say, exactly where the part is needed, when

it is needed and in the precise quantity needed – even a lot size of just one. It is these basic principles of 3D printing that continue to make it an agile and benefit-enhancing option for low-volume manufacturing requirements among OEMs large and small. ■

Replique replique.io

Dr. Henrike Wonneberger is COO and Co-Founder of BASF-owned, Replique, which offers an industrial 3D printing platform that enables OEMs to provide parts on-demand anytime and anywhere to their customers through a global, decentralized and secured 3D printing network.

3D printing scw-mag.com 27

An intelligent approach

Two years of constant disruption show the value of integrating AI in the supply chain.

By Polly Mitchell-Guthrie

By Polly Mitchell-Guthrie

28

Unprecedented and continued supply chain disruption has become a major business problem that places huge demands on organizational resilience and agility. Many industries face significant upheaval from the spike in energy prices, war in eastern Europe, skills shortages, commodity and shipping cost inflation, port delays, congestion, container shortages and Chinese Covid-19 lockdowns. The seemingly never-ending problems represent disruption to the point of disorientation.

The consequences are visible in poorly-stocked shelves and warehouses, drops in manufacturing output, delays in on-time delivery to customers, and loss of revenue. As organizations attempt to satisfy demand they may feel forced to engage in heavy expenditures on expedites like air freight, adding to their cost pressures (and carbon footprint, a growing area of pressure for companies).

While there is no way of preventing unexpected events, integrating AI into supply chain systems can help improve supply chain efficiency and resilience, enabling organizations to manage the disruption far more effectively.

For example, by automating mundane tasks so planners focus on the complex exceptions, their productivity can be increased. Additionally, they can use AI to predict demand, increasing the accuracy of the signal that kicks off the rest of the supply chain planning steps. AI can also be fused with optimization

and custom heuristics to address supply allocation, such as maximizing revenue from existing inventory by determining what could be built with the least additional budget.

Organizations integrating AI and advanced analytics have advanced warning of likely events and can respond far more quickly. Take demand-sensing, for example, which uses AI to enhance shortterm forecasting by incorporating external signals along with the usual sales history inputs. These external signals could include data from the downstream supply chain, market information, social media and commodity price indices. To give one example of how this works – planners with these inputs can act fast to secure raw materials that become available at a smaller increase in price before the rest of the market piles in.

In a control tower approach, an AI application will monitor disruption signals and prescribe recommendations based on what it has learned from the efficacy of previous interventions.

AI provides a variety of techniques to deal with a wide range of events. A machine learning approach called clustering, for example, will aggregate sales patterns into groups used to adjust forecasts. These clusters offer guidance on how to order and replenish.

As the significant gains AI delivers become better understood, adoption has increased. The MHI Annual Industry Report for 2021 showed an increase in AI adoption from 12 percent to 17 percent, with almost another quarter (24 percent) of respondents expecting to implement AI within a couple of years.

Technology scw-mag.com 29

The steps businesses require to maximize the immense potential of AI integration

Integration of AI into existing supply chain management systems does, however, involve many careful steps and wider considerations.

One of the main areas of attention is data. AI needs large amounts of data to make predictions, and while supply chains typically have no shortage of data, it needs to be accessible, prepared for analysis, and attention paid to increasing its quality. AI-adopting businesses also need to ensure they have good processes behind decision-making, overhauling

them in preparation. They should also address the data literacy of their workforce, so they can use the technology to best effect.

The human element remains vital. AI research progresses daily, but even as systems become smarter, human input is needed. AI applications and skilled employees should complement each other, rather than create what some call a ‘lights out’ or fully autonomous supply chain that replaces the human. We know AI can find patterns in massive amounts of data beyond the cognitive capacity of homo sapiens, but it lacks the three C’s: it cannot derive meaning from context, collaborate by building

30

and maintaining relationships, or provide a conscience. The goal should be to focus planner domain expertise on situations with high volatility and complexity that we cannot predict, much like the last couple of years.

Human supervision is also necessary as ESG (environmental, social and governance) requirements become more urgent. AI will do what we program it to do, but it has no conscience interested in avoiding modern slavery and deforestation or opting for the most environmentallyfriendly use of energy. It needs a guiding hand to address these important challenges.

The implementation of AI should also focus on transparency so it is not a mysterious and threatening black box solution. AI models typically trade precision for interpretability, which means they may be more accurate but with no explanation as to how the results were derived. Planners need AI accompanied with tools to increase interpretability, so they have choices about the decisions organizations make. And they need democratization in the form of new developments such as automated machine learning that can deliver AI to people without data expertise but who can interact with tools that generate insights for them to use.

In conclusion we can say that the last two years have demonstrated how traditional spreadsheet approaches to supply chain planning and operations struggle when one set of severe and unforeseen disruptions follows another. Businesses need AI so they can see ahead, respond faster

and more effectively, equipping their supply chain leaders to make the right decisions and seize opportunities more quickly than competitors. The world is changing fast, and businesses with complex supply chains must adapt. ■

For a list of the sources used in this article, please contact the editor.

Kinaxis www.Kinaxis.com

Polly Mitchell-Guthrie is VP of Industry Outreach and Thought Leadership at Kinaxis. Everyday volatility and uncertainty demand quick action. Kinaxis® delivers the agility to make fast, confident decisions across integrated business planning and the digital supply chain. People can plan better, live better and change the world. Trusted by innovative brands, the company combines human intelligence with AI and concurrent planning to help companies plan for any future, monitor risks and opportunities and respond at the pace of change. Powered by an extensible, cloudbased platform, Kinaxis delivers industry-proven applications so everyone can know sooner, act faster and remove waste.

“ “

The human element remains vital. AI research progresses daily, but even as systems become smarter, human input is needed Technology scw-mag.com 31

“ “

Time to get ready

Sustainable supply chains: How to turn regulations into opportunity.

By Dr.Madhav Durbha

By Dr.Madhav Durbha

32

Amultitude of events

over the past two years have caused worldwide disruptions and put supply chains in the spotlight. For a couple of decades, businesses have centered their supply chain design around ‘just-in-time’ delivery, but the past few years have forced them to re-evaluate their approach.

Despite ongoing disruptions, this refreshed focus on supply chain networks has provided companies with an opportunity to assess and improve their networks, not only from an efficiency standpoint, but also from an environment, social and governance (ESG) perspective.

The rising focus on ESG

Although some leaders may still fail to recognize the term as more than a buzzword to their own detriment, ESG is becoming a vital regulatory requirement and a key business priority – especially for those who are focusing on a purpose beyond generating profits.

It’s not only because it’s the right thing to do but because of pressure driven by customers and investors. There’s also growing regulatory pressure from governments on companies to meet ESG objectives, with the introduction of new laws that push businesses to act on reducing their carbon emissions and prevent environmental degradation or ethical misconduct. This is not only

within their operations but also with direct and n-tier suppliers, as well as subcontractors throughout their supply chain. Companies that fail to comply with these regulations will face stiff penalties.

One example of new regulation is Germany’s Supply Chain Due Diligence Act. Starting January 2023, it will require large businesses operating in the country to monitor their supply chain for human rights violations and compliance with environmental standards – otherwise they’ll be met with hefty fines. In the US, the Securities and Exchange Commission (SEC) has proposed the introduction of ESG reporting rules and requirements. This would also require companies to disclose certain information about climate-related risks and emissions.

However, the regulatory trend shouldn’t be viewed as a burden. It’s an opportunity for companies to have a positive impact on the world and begin the process of assessing and improving their supply chains – a perfect time to push forward their ESG priorities. Especially as social and governance standards are typically well established in large western companies already, yet their supply chains often generate far greater emissions than the company’s direct emissions. For any business that has the goal of achieving ‘net zero’, the sustainability of their supply chain is vital.

Sustainability 33 scw-mag.com

Pushing forward with ESG

But are companies committed to meeting their ESG priorities and if so, what challenges are they facing? Insights from research conducted by Coupa discovered that most enterprises do care about ESG concerns and they’re committed to their objectives. For example, globally 91 percent of businesses stated that reducing emissions is important to them and 89 percent said the same about eliminating modern slavery.

Looking at the US data, it’s aligned with the global statistics, with 89 percent responding that both are important.

Nevertheless, many companies are suffering from major blind spots in their supply chains, making it impossible for them to make meaningful progress toward their ESG objectives. Specifically, 61 percent of US companies cannot tell if their

closest supply chain partners are meeting any kind of ESG standards. Additionally, 53 percent admit to not having an effective risk management system in place to accurately assess ESG integrity in their supply chains. Given the large number of companies that may need to comply with Germany’s Supply Chain Act, this could be a major challenge.

Diving deeper into the blind spots, US companies need to become faster and more agile to replace supply chain partners which fail to meet ESG standards too. Only 18 percent can do it within a couple of days, whilst 43 percent would need a couple of months or longer, if possible. What’s more, when asked about how they assess the ESG risk and compliance of their supply chain partners, 61 percent find their current solution inadequate.

34

Next steps to improve your supply chain

Businesses need to pay closer attention to their supply chains so they can meet their ESG objectives and comply with legislation. But how can they do that with several major blind spots?

First thing first, businesses must invest in their people, processes, and technology to meet legislative requirements, such as implementing effective third-party risk management solutions.

Secondly, they need to look at their supply chains and implement better tools for designing and planning them. A great example of this is digital twin technology which uses Artificial Intelligence (AI) to create virtual models of a company’s supply chain which can help improve resilience. Companies can use it for scenario planning and stress testing to discover if, and where, there are weak links and to assess the potential operational and financial impact from risky suppliers. This technology can deliver sustainability benefits too, such as helping to plan more fuel-efficient routes for the transportation of goods or reducing wastage by optimizing inventories and capacities.

Lastly, companies must engage in industry-wide collaboration and data sharing on suppliers’ ESG credentials. All the US companies surveyed agreed that this would be useful information to have. Collaboration would save the duplication of work, as well as ensure that it’s collected efficiently and in the hands of decision-makers when they need it.

Modern technology platforms can make such data sharing easy, secure, and automated. They can feed realtime, third-party data to customers

from organizations that monitor suppliers for ethical malpractice or environmental damage. For instance, if a supplier has committed an offence, it can automatically flag this to customers working with the supplier. Such high levels of transparency inform businesses if they’re working with a company that represents an ESG risk.

“

Many businesses have already spent time assessing, reevaluating, and fine-tuning as they navigate the disruptions they’ve faced. However, businesses that want to have a resilient supply chain must pay close attention to their ESG standards, especially if they want to be ready for the incoming regulations. ■

For a list of the sources used in this article, please contact the editor.

Dr. Madhav Durbha is VP of Supply Chain strategy at Coupa. Coupa is the cloud-based Business Spend Management (BSM) platform that unifies processes across supply chain, procurement, and finance functions. Coupa empowers organizations around the world to maximize value and operationalize purpose through their business spend.

Coupa www.coupa.com

Coupa www.coupa.com

“ “

Modern technology platforms can make such data sharing easy, secure, and automated.

“

Sustainability 35 scw-mag.com

Towering

ABOVE the competition

In the realm of lead logistics providers, DHL’s global network of control towers puts the business firmly at the fore

In the first two instalments of our series exploring DHL LLP (DHL), we have delved into the ways that digitization is shaping the landscape of global supply chain logistics and why more businesses are employing the expertise of Lead Logistics Providers (LLP). In this conclusive edition, we are seeking a deeper understanding of how DHL utilizes its strategically placed control towers around the globe to provide greater supply chain visibility for its customers.

These control towers stand as information exchanges, where global intuition meets local knowledge to provide a clearer path for goods and services, and greater visibility of the global network. As Adam Ruff, Vice President of LLP North America, details further: “The control towers offer our customers greater control over their supply chains and logistics networks, which is why we also use the term ‘center of excellence’ to describe them. They house experts

38 Exclusive Feature

DHL LLP scw-mag.com 39

in logistics engineering, sourcing and procurement of transportation service providers, and operations and financial specialists, who vow to not only find solutions but uncover the best practices available for our customer base. These all align with the implementation of the three pillars of the DHL strategy: centralization, standardization and value creation.”

Bart Van Holsbeeke, Managing Director of LLP Europe, adds: “Through the grouping together of experts, we have a crosspollination of knowledge from multiple industries – some common practices in one may be huge innovations in another.”

Through utilizing this shared information, the control towers develop contingency plans for customer supply chains, reinforcing DHL’s proactive approach to customer service.

“There has been an increase in customers with multiple presences around the world, who rely on a global network for their supply chain management,” Bart continues. “We have built a virtual network between our control towers, with Istanbul being the most critical for Europe. Our international reach allows us to be connected to a multitude of local markets and their counterparts simultaneously. With this presence comes invaluable knowledge of regional authorities, legislation and the general protocol of expediting goods. This helps us anticipate issues, for example, relating to missing paperwork or information that would lead to delays.”

DHL works together with its customers to solve potential issues by running analyses and providing expert opinions. With reference to the company’s mentality towards proactivity, Adam expands: “In terms of risk incident

monitoring; in supporting a manufacturer with an international inbound supply chain from Asia Pacific to North America, there are multiple control towers involved. We will advise the customer of any instances that may impact their production, by monitoring the 5000 parts from the 500 suppliers in the network.

“The shipping status and requirement of each part is cross-sectionally analyzed against their inventory to help protect plant-operations so that, in case of any serious delays, we can look to implement a contingency plan,” he continues. “This may be to divert stock from elsewhere or alter their production schedule to keep the plants running. Incidents can range from strikes or port delays to bad weather or even just a local holiday, of which they’re unaware, given that they’re based 2000 miles away.”

A prime example of its expertise in action was during the onslaught of Hurricane Ian. As the hurricane crossed the Gulf of Mexico, DHL ran numerous scenarios regarding the paths Ian could have taken. Once forecast, it started working with its affected customers’ planning teams to divert inventory, alter schedules or notify customers of potential delays. This deployment saved customers many hours of manual look-ups in legacy systems to ascertain the location and shipping status of parts. DHL’s automated system handled this process, allowing for the focus to be on problem-solving and implementing contingency plans.

When the business cannot find appropriate third-party technology, it simply develops its own, and although it looks to integrate different layers of technology, it still relies on human application to make the difference. One of the primary technologies incorporated in the

“ “

In times of uncertainty, DHL undoubtedly has the requisite solutions to bring clarity to the global stage 40

“ “ Exclusive Feature

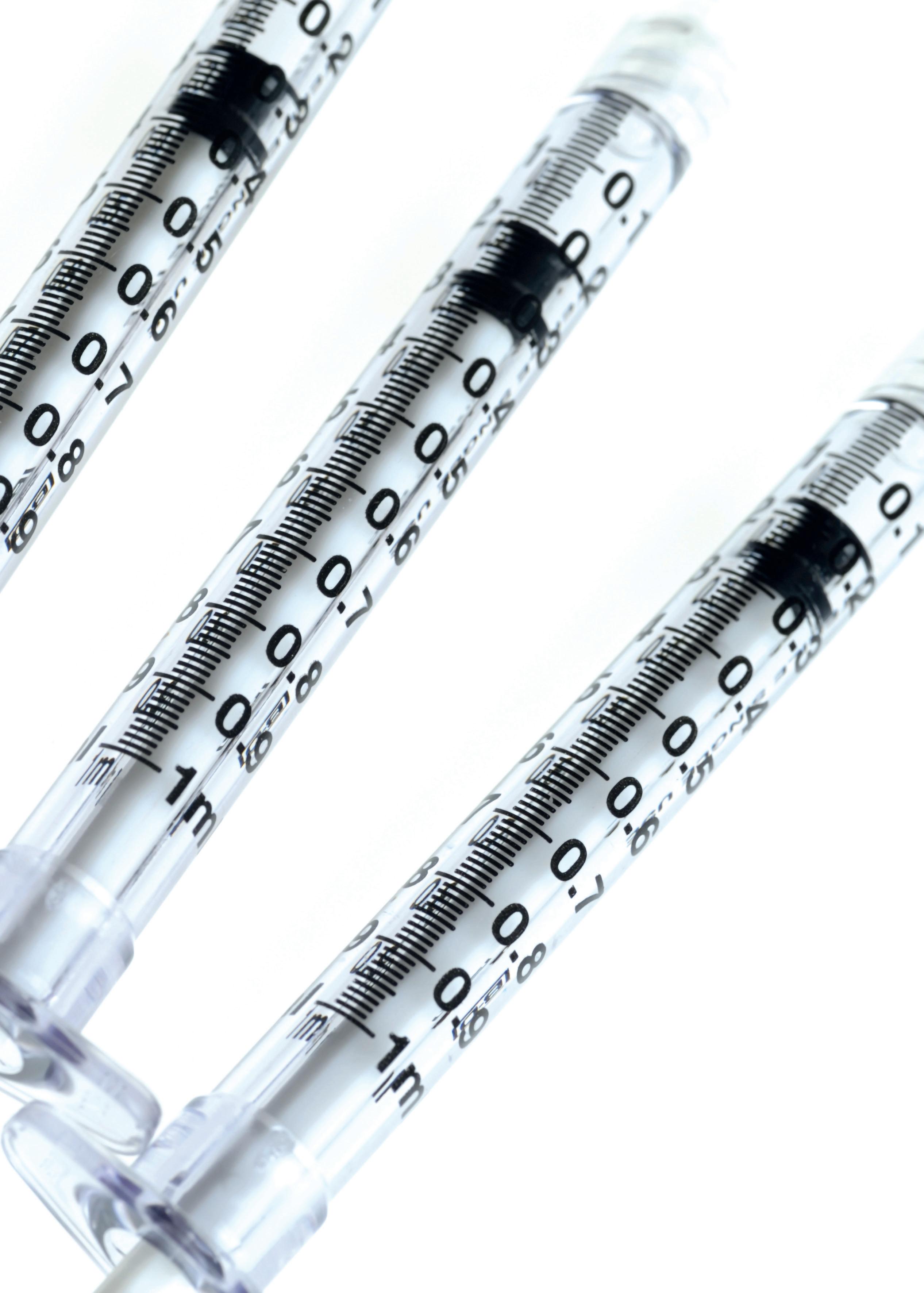

control towers is the transport management system, which offers supplementary solutions beyond those of its competitors.

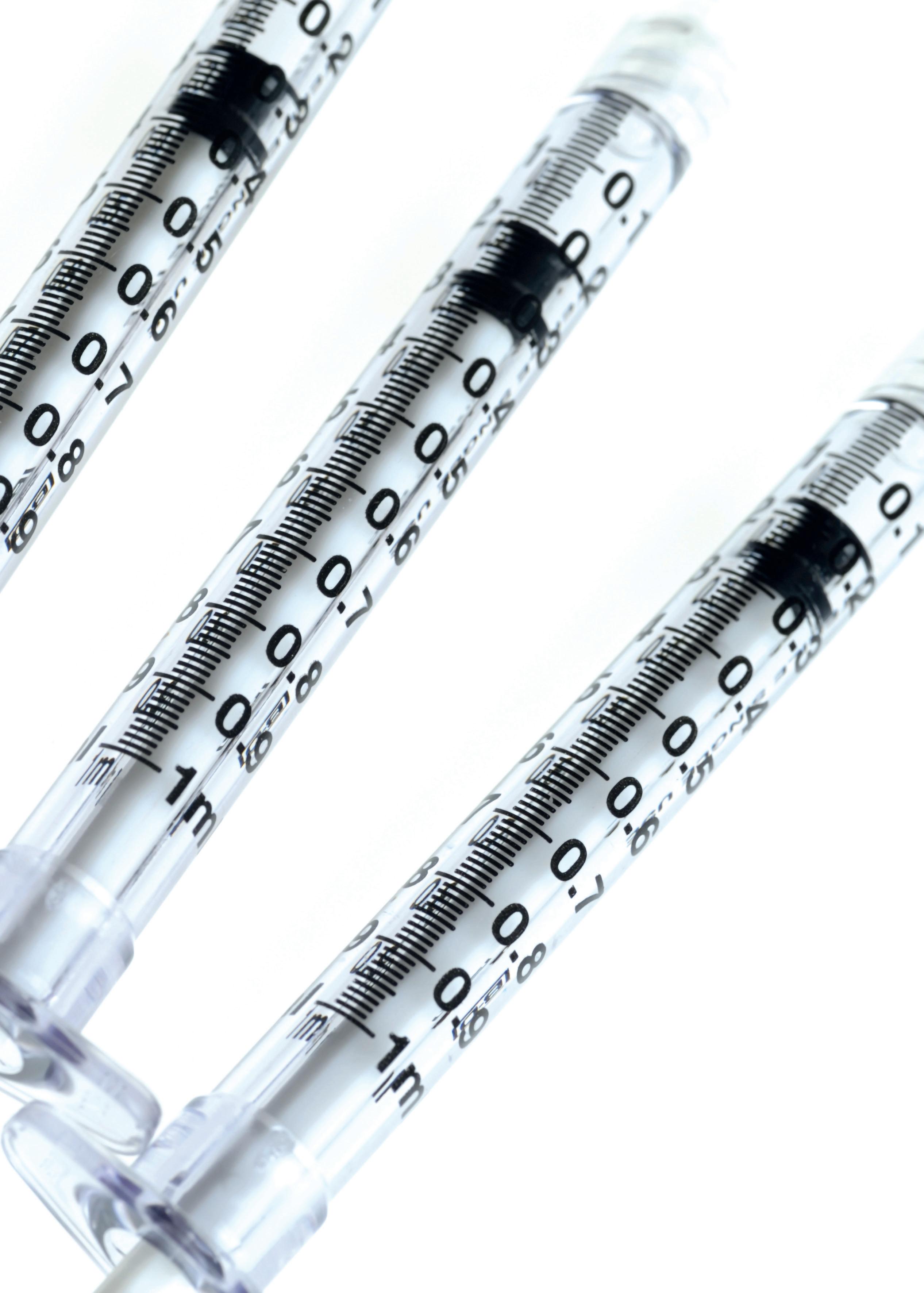

As Adam explains: “We have the capability to capture supply chain events, particularly those of our parcel carriers. We conducted a very important program for a large pharmaceutical provider in the delivery of Covid-19 vaccinations, which allowed incredibly precise visibility of each and every product.” Additionally, the business offers supply chain risk, and instant monitoring tools. Indeed, DHL pilot-tests many new technologies for start-ups, and on average, will integrate at least one in every four into its own platform.

In times of uncertainty, DHL undoubtedly has the requisite solutions to bring clarity to the global stage. The gentlemen conclude that it’s about providing insights, engineered by the talented experts in the team. These specialists understand customer networks, and can pinpoint the best practices to propose when it comes to resolving supply chain issues. ■

www.dhl.com

DHL LLP scw-mag.com 41

Fuel for growth

Ihave been in the consumer goods industry for almost three decades,” begins Alexandre ‘Ale’ Eboli, Executive Vice President and Chief Supply Chain Officer at Conagra. “My career began back in my home country of Brazil, then Latin America and Europe, until I arrived in the US and joined Conagra. I have spent the last 27 years working and travelling across different geographies.

“The beauty of Conagra is that we are a highly focused company in terms of our portfolio,” he goes on. “By concentrating on the North American market and consumer brands, we have created a strong sense of team spirit and commercial agility, allowing our employees to collaborate in an inventive way. We do things quickly, both in terms of connecting to customers as well as expanding and maintaining the brands they love.”

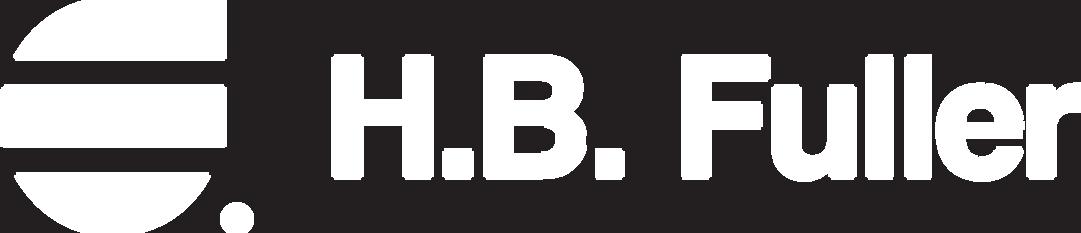

Conagra is the manufacturing force behind household brands such as Birds Eye, Slim Jim, Gardein, Duncan Hines, Healthy Choice, Earth Balance, Reddi-wip, and Orville Redenbacher’s – just to name a few. In the last 15 years, Conagra has made a concerted effort to modernize its portfolio, creating fresh products – and revitalizing iconic ones – to reflect the needs of customers and consumers alike.

In today’s highly competitive marketplace, it has never been more important to stay relevant and up-to-date with the latest trends. Consequently, as Ale details, the food giant has grown even bigger in stature, garnering substantial returns for its shareholders and investing back into the business and its portfolio of iconic brands.

Why supply chain is the beating heart of any organization, according to Conagra Brands

Cover Story 42

scw-mag.com 43

“ “

“Simply put, our intent is to continue to serve our customers and consumers with high quality food and innovative products – each and every day,” says Ale. “Our products fall into three main categories. First is our frozen food, which has gone through a resurgence in recent years as we’ve introduced new products into the frozen aisle that are more aligned with consumer preferences. By premiumizing our frozen portfolio, we’ve been able to offer consumers convenience, affordability and nutrition, and also a means of reducing their waste through the use of sustainable packaging.”

Fresh food spoils. That is not new. With frozen food, we take out what we need when we need it, and the rest is saved until another day. Less ends up in the bin. But Conagra is taking this aspect of sustainability and waste reduction one step further. Evol, a Conagra-owned brand focused on making tangible steps towards the protection of the environment, recently became the first manufacturer to introduce Carbonfree Certified Carbon Neutral frozen meals. In addition, these products are produced in a TRUE certified Zero Waste facility.

To earn this accolade, plants must have diverted an average of 90 percent or greater waste from landfills or made other equivalent waste reductions in the last 12 months. The eco-friendlier range, which includes the all-new Five Cheese Alfredo Mac with Chicken

We are the metaphorical heart of the company

“ “

Cover Story 44

as well as eight other certified singleserve offerings, utilizes fully recyclable paperboard cartons and paper bowls to slash the carbon footprint of packaging across the line.

Small changes make big environmental savings. Indeed, across its Healthy Choice Power Bowls range, a significant carbon saving has been made by Conagra. By using plant-based fibers instead of plastic, the carbon footprint of manufacturing select product lines has been reduced by up to 70 percent, helping to decrease the company’s overall carbon footprint by 34,117 metric tons – the equivalent to avoiding greenhouse gas (GHG) emissions produced by driving 84 million miles.

Ale continues his overview of Conagra’s three distinct product

categories: “The second is snacks, so we produce meat sticks, popcorn, sunflower seeds, puddings, and more. We continue to innovate in places that see new or growing consumer demands. If you think about it, a popular meat stick like Slim Jim is free from carbohydrates, and that is really well-received by consumers. Similarly, popcorn offers a healthier option than, say, regular potato chips. These snacks form what we like to call an ‘acceptable indulgence’ for our consumers, and we are growing quite a lot in that space.

Another example is keto-friendly cake mixes from Duncan Hines, a versatile option for those following a ketogenic diet but wanting to still get that sweet fix. Addressing this particular consumer need has stimulated significant growth for us.

Cover Story 46

YOUR ADHESIVES SOLUTIONS PARTNER Indirect Supplier of the Year 2022 Award Recipient by Conagra Brands PROUDLY SERVING CONAGRA Driving innovation Facilitating sustainability Prioritizing service Since 1887, H.B. Fuller has provided adhesives, coatings, and tapes to packaging makers and CPG brands. hbfuller.com/packaging

“Finally, we have our staples category, which are ingredients and enhancers, and shelf-stable meals and sides,” he goes on. “This portion of the business is all about keeping brands available, profitable, and serving consumers according to their evolving needs. It is always imperative to identify and match changing trends: ten percent of turnover comes from innovation and delivering products that directly respond to market analysis. It is a core component of our strategy,” asserts Ale.

Beneath the brands, however, is a rigorous supply chain strategy and program that keeps the wheels turning at Conagra. Without it,

particularly in these current times of geopolitical and economic turmoil, names like Slim Jim and Birds Eye might not be available on grocery store shelves.

To prevent that, Ale spearheads a robust supply chain division that focuses on building from a strong base with an experienced and capable team to ultimately drive gross margin and customer service through an aggressive end-to-end productivity agenda. According to Ale, investments in people, assets, and technology make that happen.

Driving forward with an agile and resilient end-to-end supply chain is part of Conagra’s ambition

48 Cover Story

of delivering $1 billion in cost savings over the next three years and becoming the best supplier in the food industry. Yet, for Ale at least, it goes much deeper than that. “There are two things in supply chain that allow me to wake up happy each morning,” he reveals. “The first is that we are responsible for the livelihoods of 15,000 people across a total of 42 factories in the US, Canada, and Mexico. These factories are responsible for approximately 80 percent of the food that we sell; the rest is produced by core manufacturers that operate as an extension of our manufacturing footprint. We ship products from 21 distribution centers across the entire country.

“If, on average, each one of those 15,000 employees has a family of four, then you can imagine the number of people we are impacting – and that is not counting suppliers, their workers, and their workers’ families,” he aptly points out. “We are one of – if not

Devro

Devro is a leading global supplier of edible collagen casings and gels for the food industry. We have over 1000 customers in over 100 countries, including many of the top meat snack and sausage companies in the world, and we are particularly proud to count Conagra Brands among them. We boast a modern manufacturing footprint that includes operations in six countries across four continents. Our wide product portfolio enables productivity enhancements and provides sausage products with the superb bite and texture consumers love. Our 85-plus-year history of unparalleled service and operations creates and maintains outstanding relationships with our customers.

Devro is a leading global manufacturer of Edible Collagen Casings and Gels, supplying a wide array of products and providing technical expertise to many of the top sausage and meat snack companies around the world.

Devro, Inc / North America Customer Service Toll free (United States and Canada): 1 800 637 5343

FOR

EXPERIENCE THE DEVRO DIFFERENCE FOR YOURSELF!

devro

Delivering the Added Layer of Value

OVER 25 YEARS AS A PROUD PARTNER WITH CONAGRA BRANDS

www

com

Conagra Brands scw-mag.com 49

the – biggest employer in this wider network of communities; thus, we see it as our duty to conduct business in a responsible way and also give back to the communities. We treat people with respect as we truly have a tangible impact upon their lives.

“The next special aspect of supply chain management is how it relates to and interacts with the wider business,” he says. “We are the metaphorical heart of the company; we make the blood pump through the system every day, despite the challenges and obstacles that are bound to arise. This is particularly special here at Conagra because we have a uniquely strong partnership with sales, marketing, and finance – all of whom are driven to find creative solutions. Indeed, we approach the supply chain holistically

as an orchestrator of specialties, meaning our network of suppliers depends on us to open commercial channels and facilitate the flow of imaginative ideas.”

To expedite that process, Conagra has reorganized its supply chain management, leveraging the integration of end-to-end

Sonoco

Sonoco is a proud partner of Conagra Brands, and together, we work to improve the quality of products for people worldwide. Sonoco has a rich history of helping brands achieve their sustainable packaging goals, and our solutions, services, and programs support our corporate purpose of better packaging, better life.

50 Cover Story

scw-mag.com 51

52

procurement, manufacturing, logistics, product quality, and service. Suppliers become intertwined with the customer as part of that network.

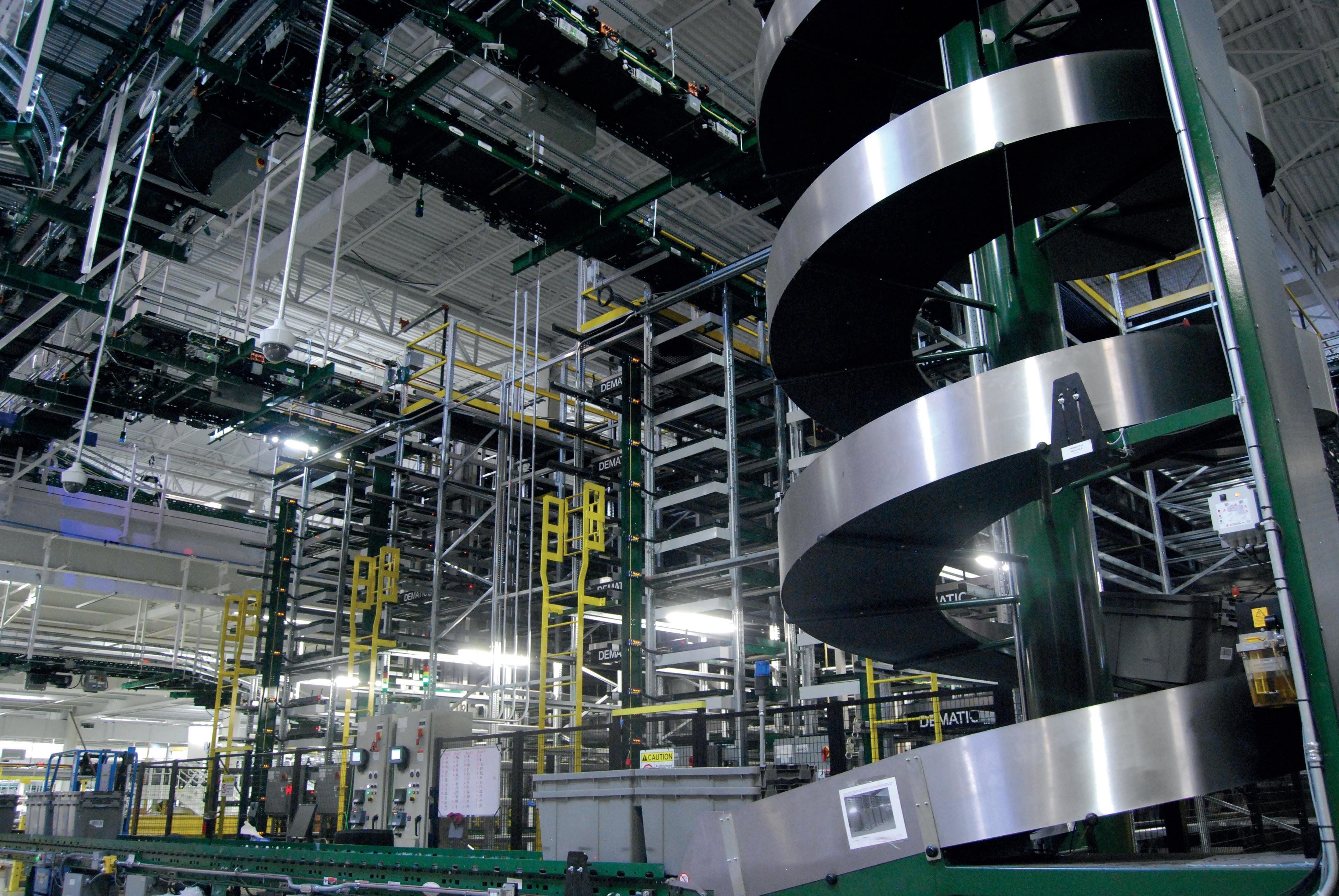

Key to Conagra’s strategy is its Fuel for Growth program. Ale explains: “The Fuel for Growth program is made up of five pillars and one core, foundational element. The first pillar is Network Optimization, which is not just limited to logistics. In that area, we are centralizing our network and expect to reduce 50 percent of shipping locations within the next three years. Regarding the manufacturing side, we are reviewing opportunities for either

Burd & Fletcher

Burd & Fletcher continues to meet the food packaging needs of Conagra. For well over a century, Conagra has counted on us for speed-tomarket, package quality, plant efficiency and process improvement. As integrators of its packaging needs, we’re honored to make Conagra’s products stand out on store shelves. From concept to consumer, our role is to protect the company’s brand and supply chain through innovation and continuous process innovation.

Conagra Brands scw-mag.com 53

consolidation or outsourcing (if they are needed), and finding new capabilities that we can leverage.

“The second pillar is Integrated Margin Management, which is basically our productivity program,” he adds. “The focus, here, is on identifying opportunities on mostly a cost basis across the entire supply chain, so we have a strong team of people always looking at how we can optimize formulations, integrate better, reduce waste, increasingly automate, and digitize our supply chain. All this is part of a wider company effort to be more efficient and lean in our manufacturing and distribution processes.

“The third concerns End-to-End Planning and the retooling of related processes,” comments Ale. “This area is utilizing data science and has successfully implemented artificial intelligence to aid that reconfiguration; consequently, thousands upon thousands of models have been created to find the right weekly location for item combinations. Another concrete example we have used to bolster this pillar is a tool called Blue Yonder – a software that allows us to be much more agile in terms of supply and long-term capacity planning.

“Finally, we have pillars four and five,” he notes. “Talent Management is a pillar that reflects how we attract, maintain, and develop our people and offer them a pathway to a successful future, and the final pillar is Sustainability, which can be broadly summarized by improving our operations through five areas of priority: decarbonization, packaging, agriculture, waste, and water. For each of these, we are building programs that mirror our commitment to the environment.”

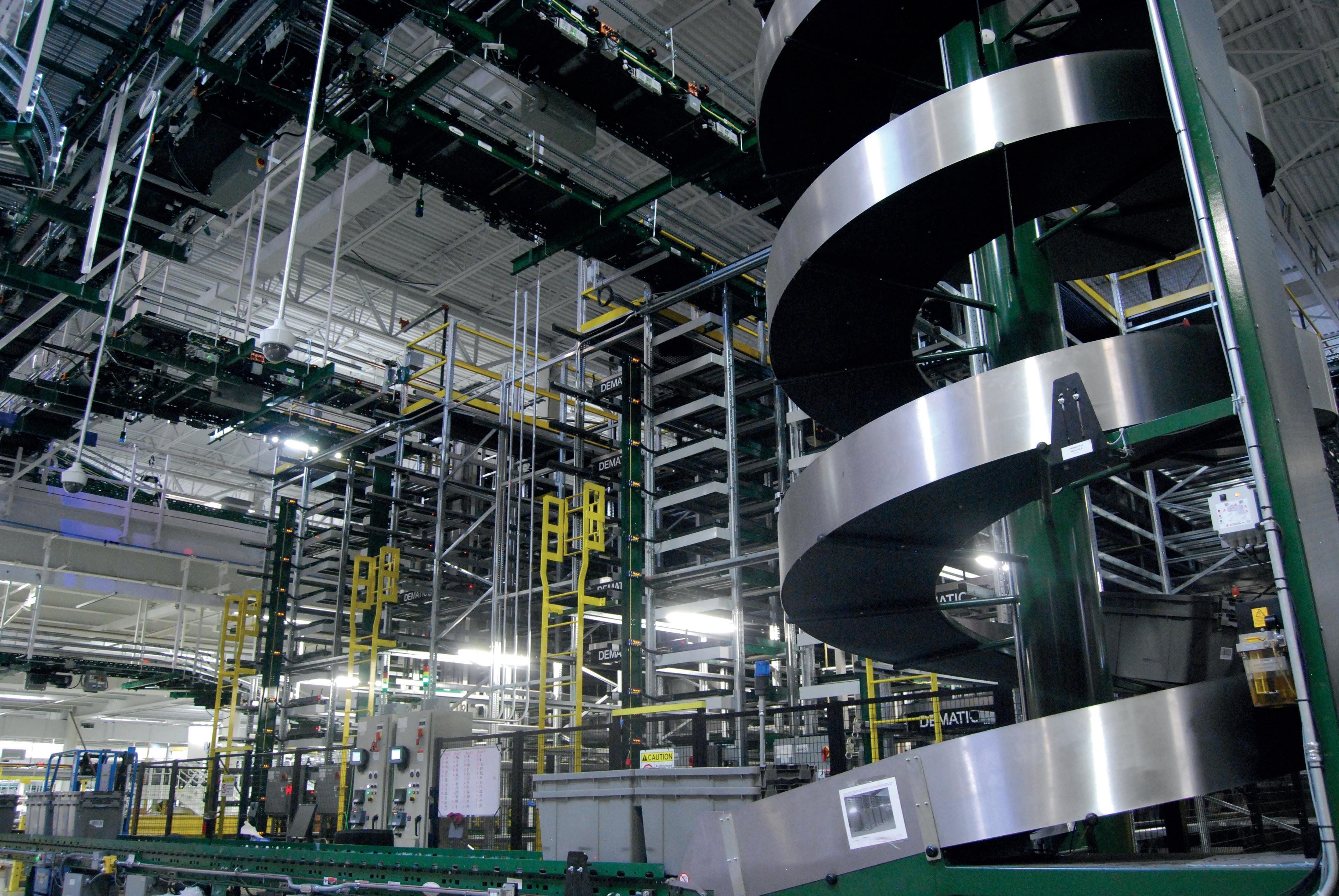

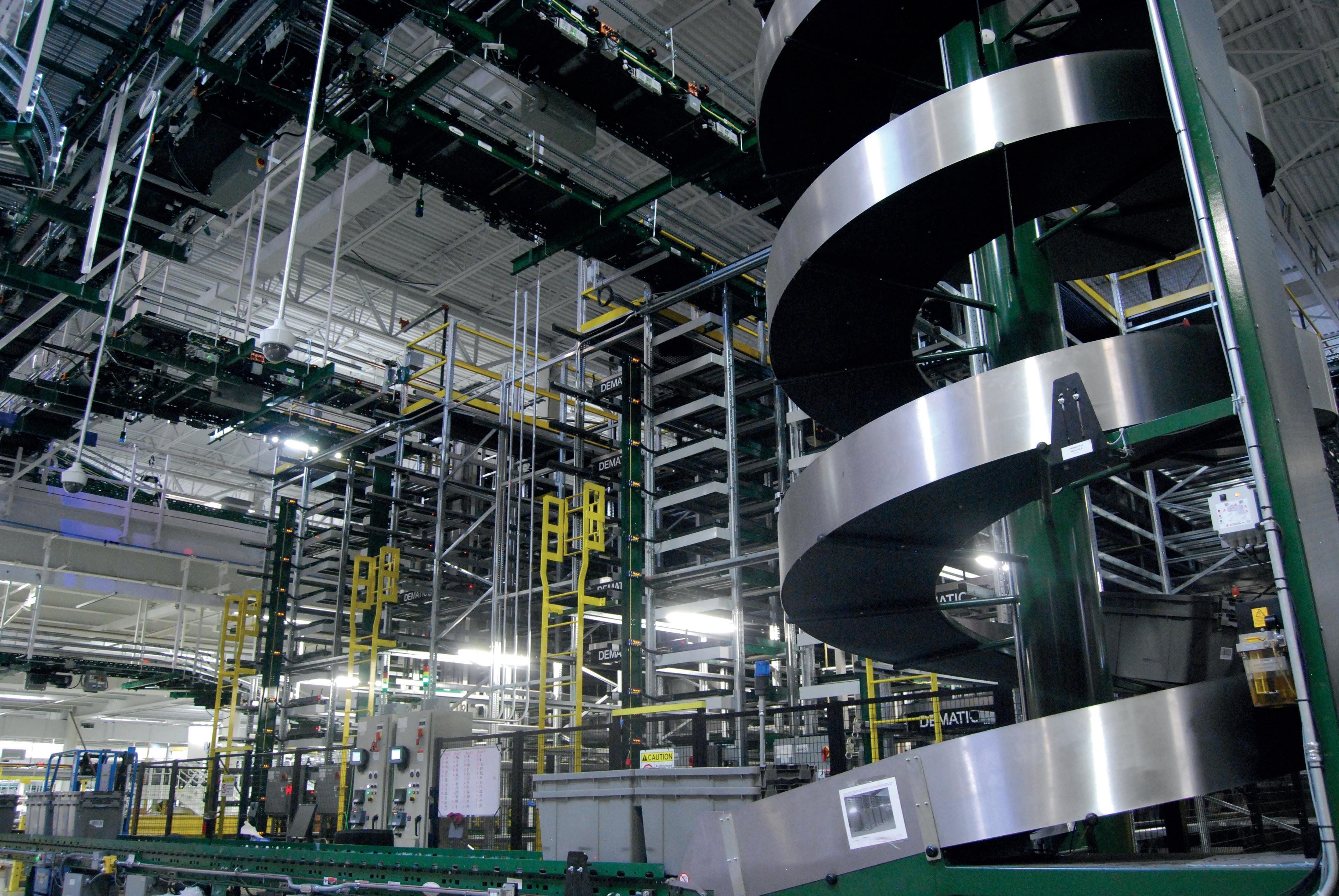

Ultimately, each pillar underpinning the Fuel for Growth program is sustained by a core element: Conagra’s continued investment in technology. This includes, for instance, Connected Shop Floor, an innovative program that will neatly digitize and standardize all of the food giant’s manufacturing sites, and Oracle Transportation Management (OTM), a logistics service used to upscale a range of execution capabilities.

On a larger scale, Conagra has also recently opened a new, 245,000-square-foot vegetable processing plant in Waseca, Minnesota. The state-of-the-art facility processes fresh vegetables – taking them from harvest to frozen in just five hours – to support Conagra’s frozen division and Birds Eye brand. The

Cover Story 54

Waseca site was built to the company’s own specification, maximizing automation to generate greater operating efficiencies and enhance food safety measures. Water usage per pound of product produced will be cut by upwards of 25 percent and Conagra will operate with a 20 percent higher throughput capacity, leading to a better overall yield.

It is worth pausing on the sustainability aspect of Conagra’s operations once more. Reduced water usage is an important factor across plant processing sites; however, the company aims to embed more

environmentally-friendly methods across its entire supply chain.

Indeed, supply chain sustainability initiatives have not only reduced Conagra’s carbon footprint by 215,000 metric tons and waste by 122,700 tons, but also saved the company $280 million since 2009. Environmentallyminded moves such as this are driven by Conagra’s overarching green agenda: the food company has committed to reducing Scope 1 and 2 GHG emissions by 25 percent by 2030 and will slash Scope 3 emissions from purchased goods and services by up to 20 percent per metric ton of material sourced within that same timeframe.

Conagra Brands scw-mag.com 55

As mentioned previously, Conagra has already begun to implement plant-based serving bowls across select product lines, which have avoided an estimated 23 million pounds of plastic, while also driving $1 billion in sales. Another example Ale is keen to highlight is the transformation of Swiss Miss’ Coco Powder packaging.

“We were the first major hot cocoa brand to move to a cubical shape instead of the conventional cylindrical one,” he says. “The shape of a product affects everything – how you build and stack pallets, space utilization in transport, and the amount of stock that can be stacked on shelves. By altering the shape of the packaging, we managed to completely change the carbon footprint of the product, making Swiss Miss better for the environment and more profitable.”

The new Swiss Miss easy-to-grip container is made of recyclable plastic and features a space-efficient cube design that is said to reduce the carbon footprint associated with manufacturing and transportation by 15 percent – the same as avoiding emissions expelled by driving 243,176 miles.

“Each sustainability initiative makes sense for both the planet and the business,” concludes Ale. “That interconnection is powerful, and we will continue to invest in this dynamic space going forward. But we will also continue to play the game we are currently winning, and that means continuing to innovate, grow, and listen to consumer demand. Everything comes down to digitizing and improving operations across the supply chain.” ■ www.conagrabrands.com

56 Cover Story

World-class service

Headquartered in Raleigh, North Carolina, American Welding & Gas, Inc. (AWG) is one of the largest independent, fullservice suppliers of industrial, medical, beverage and specialty gases, propane, safety supplies, and welding supplies. A family-owned company, AWG traces its history to Valley Welding Supply in Billings, Montana, and Scott-Gross Company in Lexington, Kentucky – both of which began operations in 1949.

Today, over 600 employees work across AWG’s 70 retail locations and 18 gas fill plants. It’s a footprint that spans Montana, across the upper Midwest and Great Lakes to Pennsylvania, and down through Texas and Florida. Underpinning AWG’s operations is a fleet of more than 300 trucks and trailers, used to pick up and distribute products across the country. Palletized cylinder trucks make up the bulk of this fleet, used specifically

to deliver compressed gas and welding supplies to AWG’s customers. Cryogenic transports, meanwhile, deliver bulk quantities of medical and industrial oxygen, food grade and industrial carbon dioxide, nitrogen, and argon, while the company’s tube trailers transport bulk quantities of compressed nitrogen, helium, and hydrogen.

According to Stuart Williams, AWG’s Vice President of Supply Chain & Product Management, this range of products is a “key differentiator” for the company. He comments: “We have the capability to produce and deliver packaged gases and bulk gases for almost any customer need, and have the flexibility to identify new and safe ways to do so – for example, bulk delivery of liquid argon, nitrogen, or oxygen to bulk tanks at customer sites, EPA protocols for research applications, beverage CO2 or argon-CO2 75/25

American Welding & Gas is a supplier with a difference

58

American Welding & Gas scw-mag.com 59

twelve-pack cradles for metal fabrication. As for welding supplies, we distribute filler metals for all types of fabrication, welding consumables, plasma consumables, abrasives, safety supplies, welding machines and various industrial supplies from a variety of leading brands, as part of an inventory that’s regularly refreshed in line with customer demand.”

Much of AWG’s success comes down to an ethic of continuous improvement. “Our most recent investment includes the introduction of smartphones, as an alternative to