Issue 206 - 2022

transparency

visibility across the supply chain

battery manufacturing

the worst and treat cybersecurity

a priority

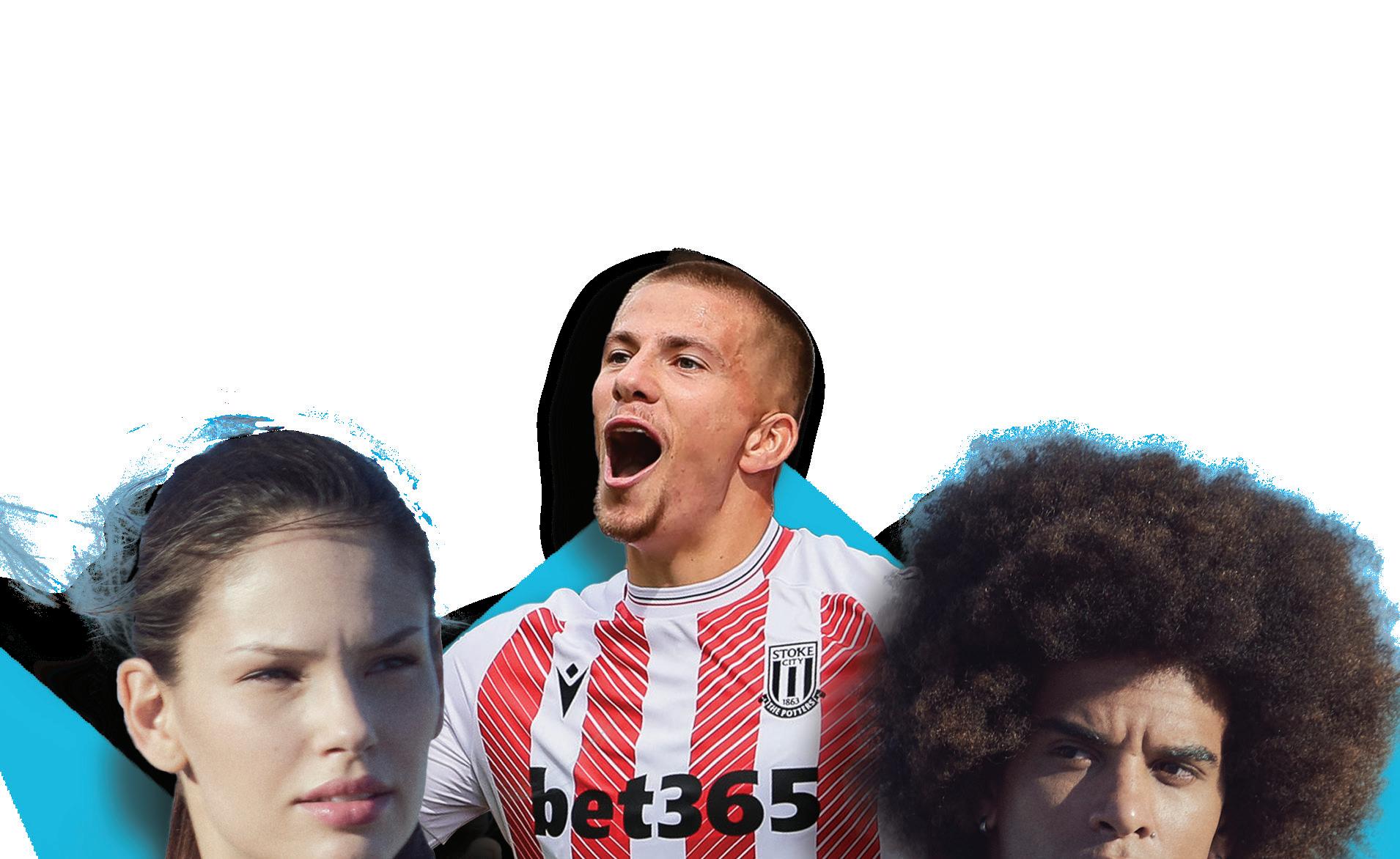

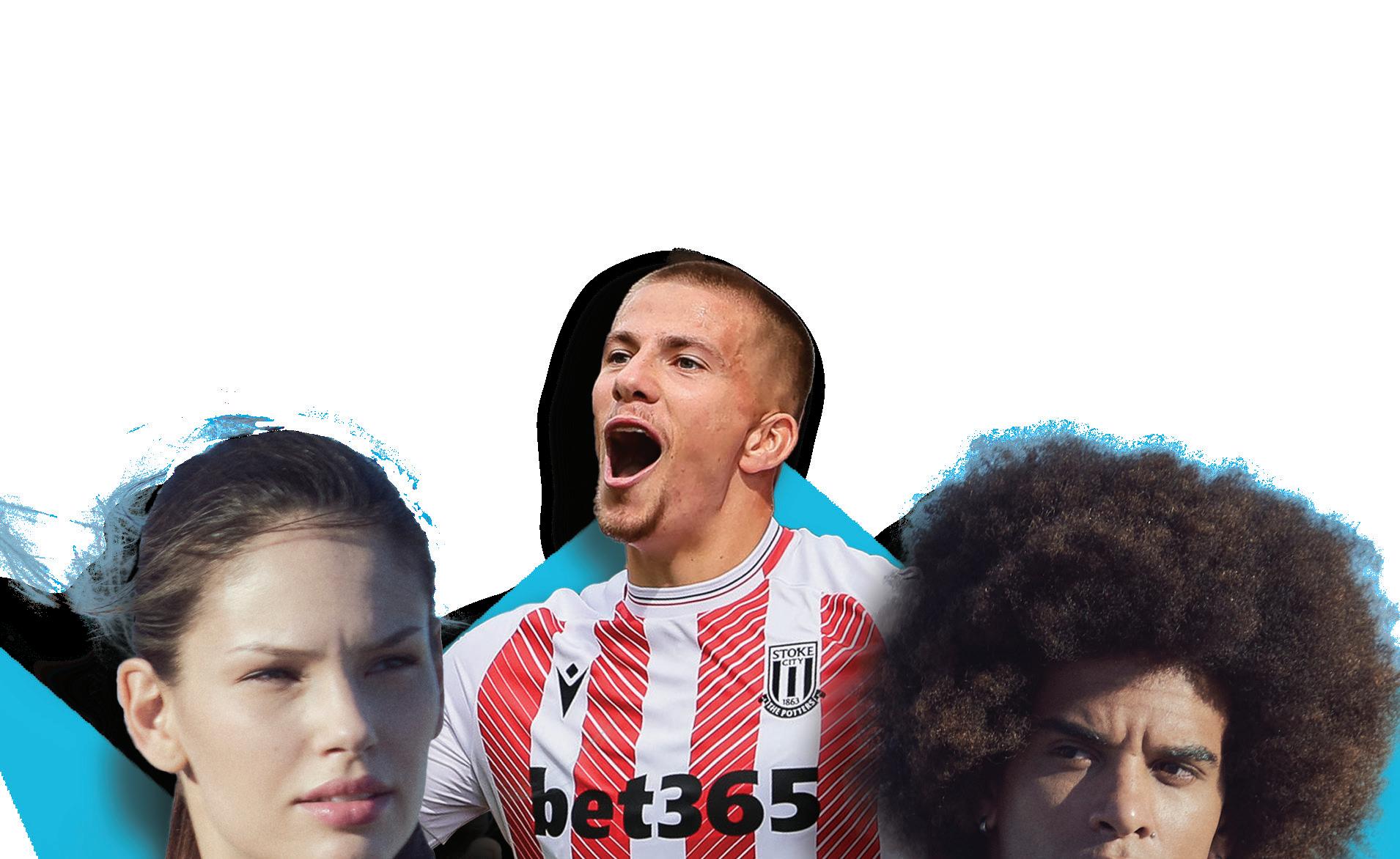

Macron is bringing its A game to the field of sportswear and accessories design, manufacture and distribution

PLAY

Supply chain Building trust,

and

Intellectual property Protecting IP as opportunities in

increase Cybersecurity The need to plan for

as

How

WORK HARD.

HARDER.

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Director Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Daniel Baksi, Alex Caesari, Danielle Champ

Editorial Administrator Amy Gilks

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork Administrator Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors Philip Monument, Joy Francesconi

Head of Content Management Adam Blanch

Client Sales Executives

Chloe Allman, Mark Cawston

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell, Laura Thompson

Content Managers Johanna Bailey, Mark Cowles, James Fuller, Jeff Goldenberg, Melanie Joyce, James Page, Wendy Russell, Richard Saunders

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Hello and welcome to the November issue of Manufacturing Today. Are you protecting your intellectual property? Our feature from Dustin Bauer of Reddie & Grose LLP takes a look at this area, with a focus on battery manufacturing. The recent rise in EV production has resulted in massive growth in demand for batteries and given the combination of increasing demand and new competition, the value of intellectual property in this field will continue to grow.

We also look at another form of protection – this time in terms of cybersecurity. Author Ross Brewer believes that manufacturers must adapt to an ‘assume breach’ mindset of when, rather than if, an attack will happen. It might sound an overreaction - but would you be prepared for the worst?

LH@finelightmediagroup.com

experts Macron. COO, Paolo Guizzardi, reveals why its products stand out from the crowd. Turn to page 34 to learn more.

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130 www.manufacturing-today.com

US Office 2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Supply chain Building trust, Intellectual property Protecting IP as Cybersecurity The need to plan for How Macron is bringing its A game to the field of sportswear and accessories design, manufacture and distribution WORK HARD. PLAY HARDER. Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Our cover story this month gains insights from technical sportswear

Follow manufacturing today at @mfgtodaymag manufacturingtodaymagazine

Libbie Hammond, Editor

Welcome manufacturing-today.com 1

Inside this issue Supply chain News Intellectual property Cybersecurity 8 12 18 16 Contents 2

Macron JR Automation GYS Cover story Exclusive feature Exclusive feature SLM Solutions 40 28 22 34 manufacturing today manufacturing-today.com 3

are not new to any of this, either. We have demonstrated an enthusiasm for the product – and the company as a whole – and between us have clocked up many decades at NCMT.”

“Indeed, it has not been a typical buyout, where someone just walks into the business and decides to make a load of changes,” adds Ian. “There is still the history of the company here; our idea is to maintain what NCMT has done for its customers in the past, while also taking the business forward. We have our own fresh ideas and approaches to various tasks, so it will be

machines. Between the two technically superior brands, NCMT has every customer covered when it comes to metal cutting and grinding processes.

“From an automation point of view, the build and quality of these machines is integral,” explains Ian. “If a machine is going to be running 24-hours-a-day in a production environment, then it needs to be reliable. Fortunately, the machines manufactured by Okuma and Makino that we stock are the best in the industry.

The former range includes turning

The former range includes turning

3 52

C&A

ASD Lighting PLC Kingsdown

NCMT Onboard Corrugated Ltd

Tool

46 66 60 80 72 Contents 4

Zerhusen Kartonagen

Safestyle Moonpig Group Tomburn Rayner Jones Sign Company Fibrant 112 106 90 86 100 94 manufacturing today manufacturing-today.com 5

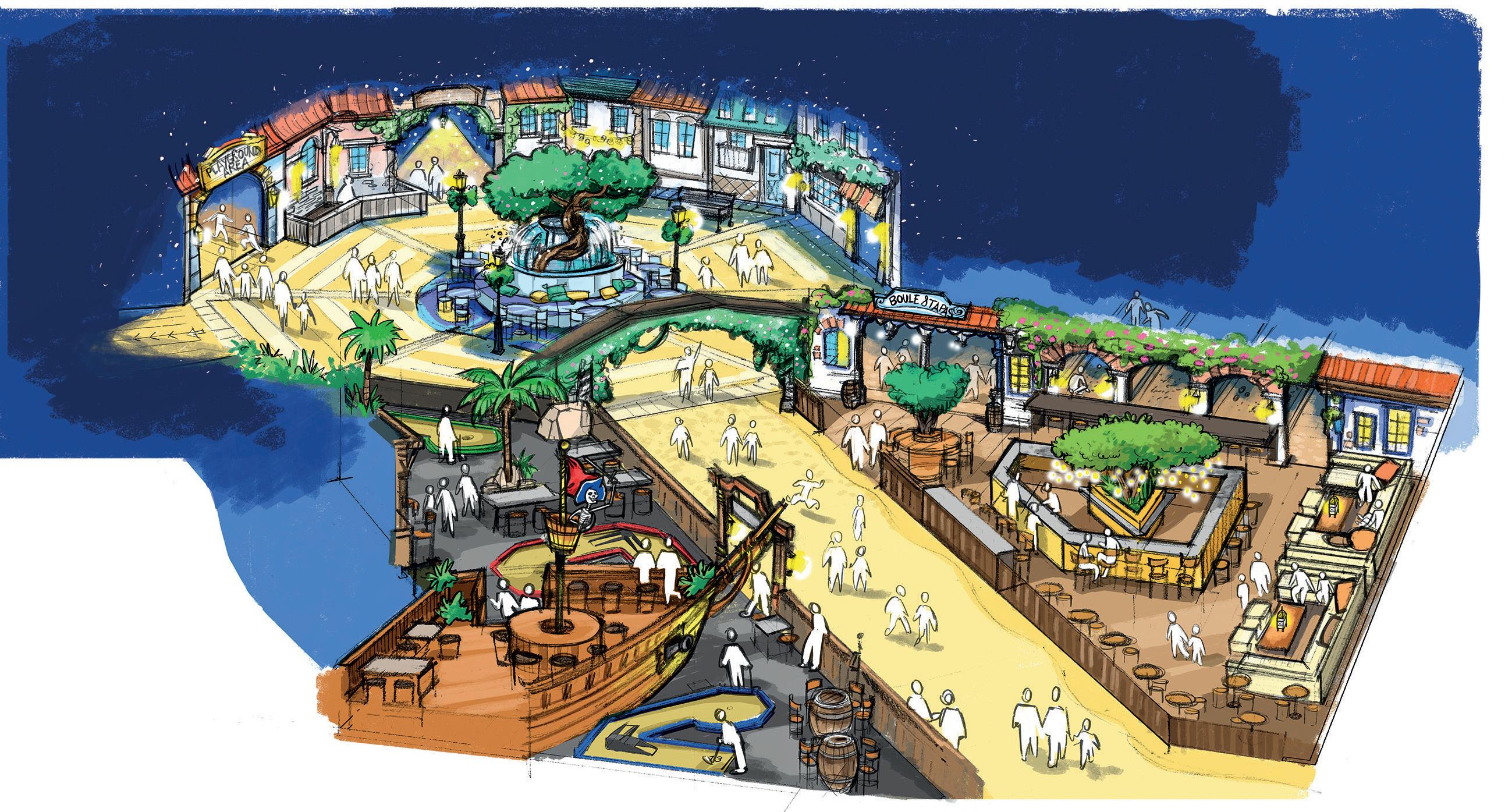

122 Fabulosa Vendors Exchange Rieke Office Interiors Green Bay Packaging Sugden Ltd & Baldwin Technical Services SPI Global Play 128 142 132 118 138 Contents 6

ADDED VALUE

8

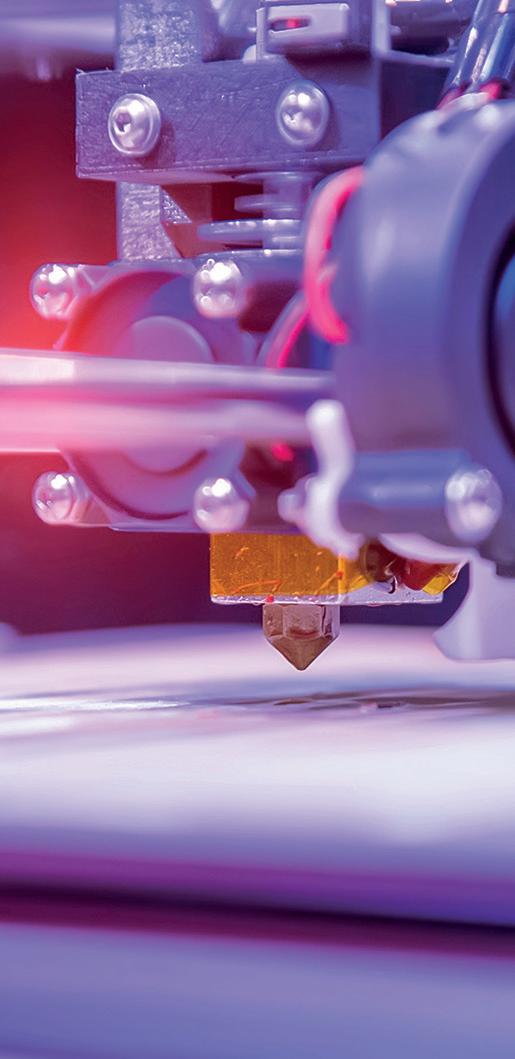

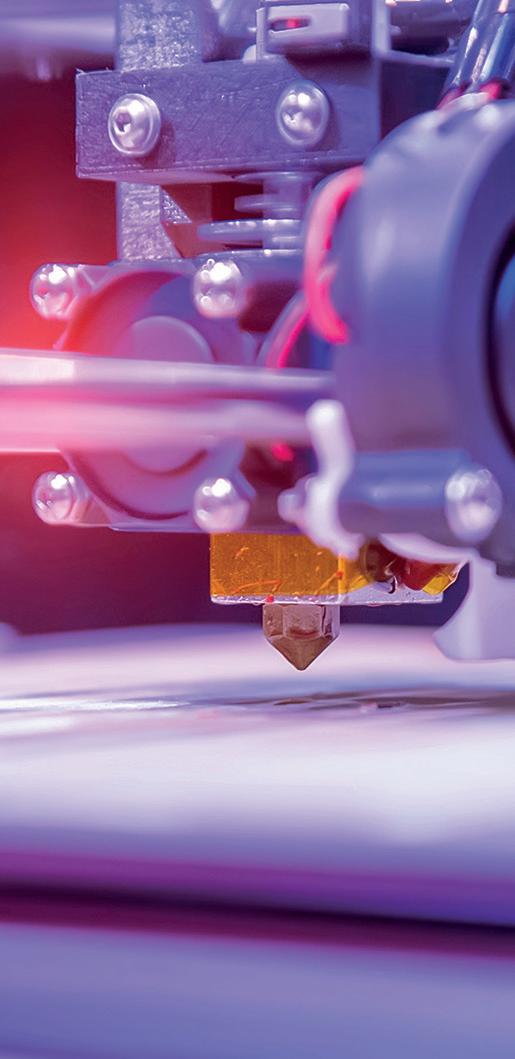

Innovations in battery manufacturing and their drivers

By Dustin Bauer

The rapid adoption of electric vehicles is reinforcing massive growth in battery manufacturing. For example, global demand for Lithium-Ion Batteries (LIBs) is set to grow from 360 GWh in 2021 to 3100 GWh in 2030, caused mostly by rising demand from the passenger and commercial vehicle sector.

OEMs in the automotive industry have demonstrated an increasing interest in vertical integration of the manufacture of not only battery packs and battery cells, but also battery materials. Recently, this has also extended to the equipment for battery cell and battery pack manufacture. This is in part caused by a lack of supply of manufacturing

equipment. Increasing demand for LIBs and additional competition underlines the importance of protecting innovations in this field.

Various trends have persisted in battery manufacturing in recent years, particularly those seeking to make manufacturing more sustainable and more efficient. In electrode manufacturing, recovering solvents used for electrode coating may improve sustainability and also reduce costs. Dry coating of electrodes, on the other hand, seeks to eradicate the need for these solvents entirely.

On the cell and battery pack side, recent developments include Tesla’s ‘tabless’ cells, manufacturing of mixed chemistry packs, and improved pouch cell degassing.

Intellectual property 9 manufacturing-today.com

Patenting activity illustrates R&D trends in LIB manufacturing

Perhaps unsurprisingly, over the past decade, the number of patents and patent applications being published related to the manufacture of electrodes (Cooperative Patent Classification CPC H01M4/04) and to electrode manufacturing involving compressing or compaction (CPC H01M4/043) such as dry coating, has increased significantly (see Figure 1). Publications relating to the manufacture of electrodes generally have increased from about 1000 in 2012 to about 1500 in 2021. In the same time period, publications relating to manufacturing involving compressing or compacting (including dry coating) have risen sharply from about 130 to over 600.

Similarly, the number of patent publications in CPC H01M10/04, related to manufacture of secondary batteries, has risen from about 230 in 2012 to nearly 1800 in 2021.

The increase in patent publications may be explained in part by new players entering the market. For example, automotive OEMs and battery start-ups and scale-ups are getting involved in battery cell and pack manufacture, as well as seeking to make their own equipment for manufacturing electrodes, battery cells, and battery packs. With increasing commercial opportunity and competition, protecting intellectual property in this field becomes ever more relevant.

Most patent publications in battery manufacturing are filed by the ‘usual subjects’ –large manufacturers such as LG, Samsung, Toyota, CATL, and Murata. However, when looking at the most recent publications (relating to inventions for which a patent application was first filed in 2020), automotive giants such as Volkswagen, and newer companies such as Prime Planet Energy & Solutions, Clever, and SVOLT, appear more frequently. It remains to be seen if this trend will continue.

▲ Figure 1 10

Recycling

“ “

Material supply limitations and mineral price volatility are of increasing concern. In line with the End of Life Vehicle Directive, 95 percent of a vehicle by weight must be re-used, recycled or recovered. Although this Directive is not designed for electric vehicles, this is clearly the direction of travel and so revised requirements for electric vehicles appear inevitable. Achieving similar levels of sustainability for electric vehicles will require increased investment in reuse, recycling and recovery of LIBs.

Battery recycling poses many technical challenges, including different cell chemistries, and varying levels of cell degradation. One strategy for addressing some of these technical challenges is to build-in ‘recyclability’ at the point of manufacture, to facilitate recycling and recovery at end-of-life.

Soaring interest in battery recycling is borne out by a significant increase in the number of patent publications (see in Figure 1) related to reclaiming serviceable parts of accumulators (CPC H01M10/54), rising from below 200 in 2012 to nearly 2000 in 2021. Mining companies such as Sumimoto Metal Mining and JX Nippon Mining & Metals are the top filers, highlighting the importance of LIB recycling to materials suppliers. However, specialized companies such as Aqua Metals and Guangdong Brunp Recycling Technology (owned by CATL) are also well-represented.

Given increasing vertical integration of automotive OEMs and growing interest in built-in ‘recyclability’, one might expect

automotive OEMs and battery manufacturers to increasingly appear on patent publications in this field.

Final thoughts

Manufacturing methods and machines are at the heart

of enhanced battery cell and pack performance, increased manufacturing efficiency, and improved recyclability. With growing demand for battery manufacturing equipment, and limited supply, the impetus for OEMs and battery makers to manufacture their own manufacturing equipment will only increase. Given the combination of increasing demand and new competition, the value of intellectual property in this field will continue to grow. ■

a list of the sources used in this article, please contact the editor.

Dustin Bauer www.reddie.co.uk

Dustin Bauer is an Associate at Reddie & Grose LLP, an internationally renowned firm of European and United Kingdom patent, trade mark and design attorneys.

Its experienced team of nearly 80 IP professionals based in London, Cambridge, Munich and The Hague includes specialists in a wide range of technical disciplines. They handle the full range of IP rights for a global client base ranging from SMEs starting to consider IP through to large corporations with rights in over 100 countries.

For

“ “

Intellectual property 11 manufacturing-today.com

95 percent of a vehicle by weight must be re-used, recycled or recovered. Although this Directive is not designed for electric vehicles

12

Aiming for

Over the past two years, global supply chains have quite literally weathered storms, battled an ongoing pandemic, and worked tirelessly to maintain supply of core components, including semiconductors. The agility and resiliency of supply chains are now a main topic in the boardroom and beyond.

Recent events have forced almost every business that relies on the smooth and predictable flow of goods to re-evaluate their supply chain. Legacy supply chain models were considered streamlined, with a justin-time and low-profile approach that worked when conditions were

just right. However, as crises and disruptions challenge the system, these supply chains have seen higher prices, longer delivery times, and in some instances no supply at all.

A critical component of business continuity and security is being able to trust in your supply chain’s agility and resilience. Rather than focusing exclusively on cost and supposed efficiency, premium brands are now prioritizing agility and resiliency within their supply chains to help them manage the current supply challenges. This is not a simple shift, but when done right it can allow your business to pivot and continue operating at scale in the face of unforeseen challenges.

Supply chain 13 manufacturing-today.com

Lynn Torrel offers her expert guidance on building trust in your supply chain

transparency

Here, I’ll share some of the best practices learned over the past few years to protect supply chains and secure the trust of global premium brands.

Unlocking supply chain transparency

Trust begins when a supply chain partner can anticipate delays and swiftly implement mitigation plans. This instils confidence and builds trust between suppliers, companies, and customers.

As consumer demand fluctuates in response to economic, social and geopolitical shifts, it is increasingly important for global brands and their partners to have efficient and transparent supply chains to manage dynamic demand. This includes removing obstacles that can hinder visibility such as inaccurate data, poor information systems and lack of visibility upstream.

If supply chain managers can’t relay precise and timely information, companies will make decisions based on faulty or incomplete data. This can cause problems further down the line and lead to shortages, surplus stock or product shipment delays that impact the bottom line.

Visibility can help build trust at every stage of the supply chain. Ultimately it can benefit the end user, who is now more conscious of each purchase and expects full availability, traceability, and accountability. For the customer, being able to get a product in time can be a source of differentiation. Branding, price, and product innovation apart, suppliers and distributors can be the vital component in meeting and exceeding customer expectations while competing brands struggle with their supply chains.

We work closely with clients to identify their preferred suppliers. A dedicated supply chain team uses a proprietary software-based collaboration tool that offers extraordinary levels of real time insight into highly complex,

The value of visibility in decision-making

14

...the Flex Pulse, has helped our team quickly size and scope supply shortfalls and identified regional factory shutdowns... “ “ “ “

globally distributed supply chains to reduce risk and improve the efficiency of that specific value chain.

Highly focused visibility into the global supply chain empowers teams to optimize decision-making, with the response to Covid-19 serving as an example of the value of supply chain transparency. Our system, the Flex Pulse, has helped our team quickly size and scope supply shortfalls and identified regional factory shutdowns to minimize disruptions to our clients.

With the right tools and the experience of supply chain professionals, datadriven and informed decisions that took into account the downstream effect of shortages and plant closures could be made. It’s not an understatement to say that transparency with tier-1 suppliers was vital in helping clients weather an unprecedented year of disruption and remain competitive.

Aligning through open communication

Supply chain transparency is often challenging to achieve for organizational reasons rather than technical ones. Many companies grow through acquisitions and must coordinate their operations and systems to create visibility for the supply chain team. In addition, good communication is key to avoiding misalignments and misunderstandings which can manifest into significant issues and disruptions if unattended.

Increasing transparency and visibility provides all parties with the necessary information to collaborate and act with purpose. By sharing accurate and real-time information, including tracking and inventory levels at various locations, you can build trust in the supply chain operation. Moreover, partnerships built on trust enable

companies to better empathize with their counterparts by operating at more than just a basic transactional level.

Building a trusted supply chain

As new technologies emerge and the business and economic landscape evolves, the opportunity to build agility and reliability into supply chains has become a necessity. There’s a finite number of competitors, materials, and demand within every product category, from consumer electronics to automobiles. Deep visibility into your supply chain gives you insights that help you identify risks and opportunities to create realistic manufacturing and delivery timelines for businesses. Complete transparency is nearly impossible, but that shouldn’t dissuade supply chain professionals from striving to improve. The ability to gain a comprehensive and real-time understanding of component inventory, pricing, and location, is critical to achieve a globally distributed supply chain. Once that information is captured, having a system in place to share actionable data with stakeholders and partners is the key to long-term resiliency, business continuity and trust. ■

Lynn Torrel www.flex.com

Lynn Torrel is Chief Procurement & Supply Chain Officer at Flex. A pioneer in modern product design, advanced manufacturing, supply chain and after-market services Flex is an international organization trusted by a diverse customer base to build products that make the world a better place - drawing on the expertise of a global workforce of 160,000 people spanning 30 countries.

15 manufacturing-today.com Supply chain

Actions and consequences

The cyber fraud industry that rapidly grew during the pandemic is showing no signs of slowing down.

Around a third (31 percent) of UK businesses experience cyber-attacks or breaches at least once a week, according to new figures published in the government’s Cyber Security Breaches Survey 2022 report. Manufacturing companies now account for nearly a quarter of all ransomware attacks. In recent years, damaging cyberincidents like the 2021 Colonial Pipeline attack have highlighted the need for manufacturers to treat cybersecurity as a critical operational priority.

At $4.4m, the Colonial Pipeline ransom payout was one of the largest in history, but the collateral damage inflicted was even greater, with President Biden saying the US Government took ‘extraordinary measures’ to mitigate the physical effects of the temporary oil shortage. Financial loss, reputational damage and customer mistrust are just a few of the effects a successful breach can have on a business.

At board level, the chief of a $1.2tn oil fund in Norway recently stated that cybersecurity was a bigger concern than market movements. For organizations to fulfill their financial potential in 2023, mitigating cyber-risk at all levels of their operations should be prioritized, but real change often comes from the top.

The evolving industrial CISO

As of 2022, just 12 percent of Chief Information Security Officers (CISOs) sit on their company’s board. Although growing awareness of cyberrisk has seen organizations investing more in cybersecurity, nearly half of all manufacturers in the UK have been or are currently falling victim to cyber-crime according to MAKE, the industry trade body, ranking the sector in the top five most prone to successful cyber-attacks.

Gone are the days of manufacturing CISOs managing solely tangible assets in a physical environment. Digital transformation has ushered in a brave new world, not just for CISOs, but for the directors they answer to, with nearly half of manufacturers in the UK

Prioritizing cybersecurity should be top of your New Year resolutions list says Ross Brewer

16

now prospering from the advanced stages of digital transformation. Done effectively, digital transformation married with effective cybersecurity can drive commercial results.

Reporting is a crucial indicator of cybersecurity posture, but in this new technological age it is no longer about what you think you know, but rather what you can prove to an auditor, regulator or board member. Organizations utilizing performance-based data in cybersecurity reporting means CISOs can compete with Chief Technology Officers (CTOs), or Chief Financial Officers (CFOs) when reporting to their board with visceral data on how well their program is performing. However, attacks on infrastructure come in many guises, which makes it imperative for businesses to stay one step ahead of the adversary.

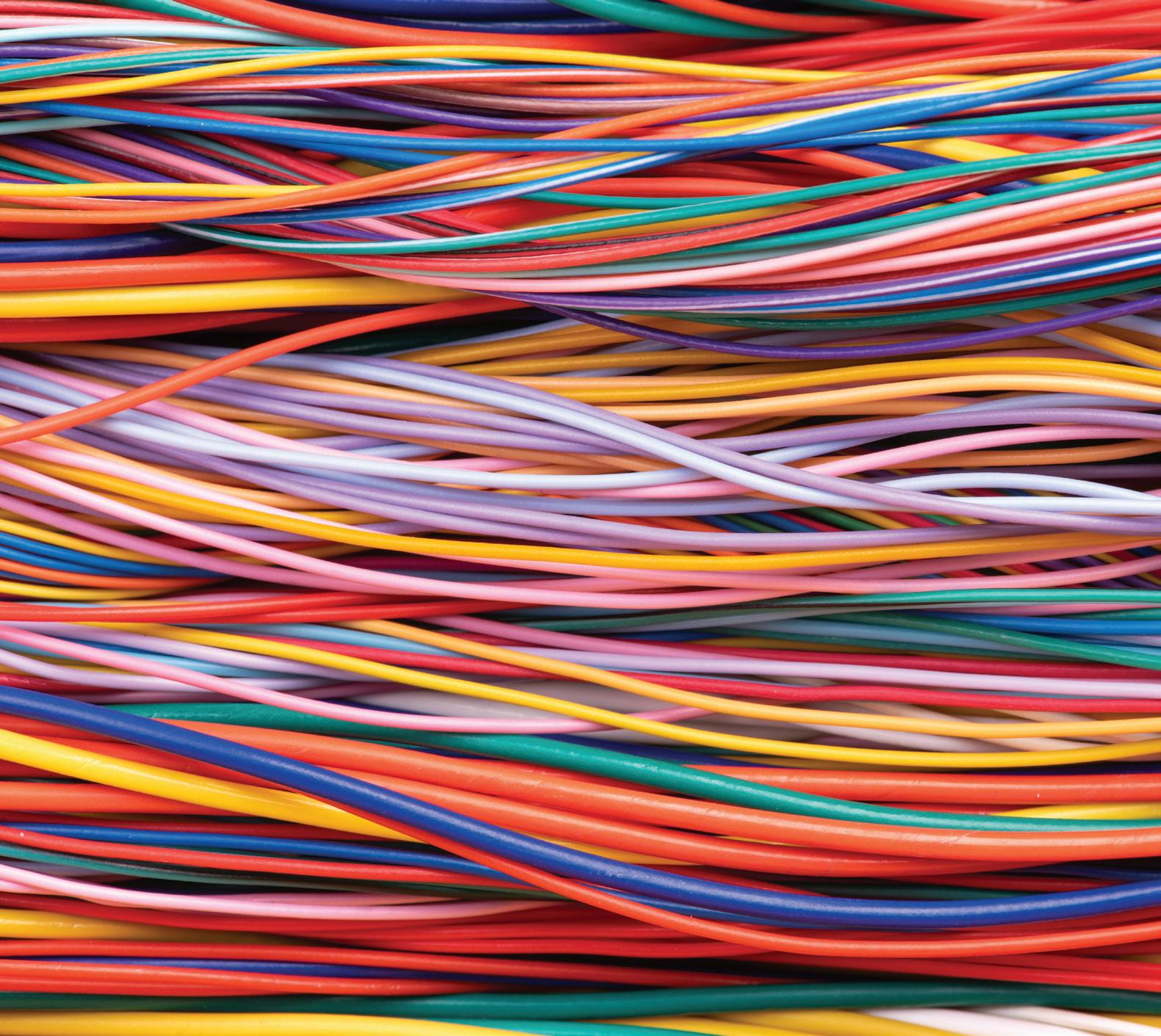

Methods of attack in 2023

An advanced digital infrastructure means an increased attack surface, providing more pathways for adversaries intent on infiltrating systems and stealing sensitive data. The abundance of intellectual property present in the manufacturing sector also means firms often rely on technical software packages that can be hard to patch against recent exploits, making them vulnerable to increasingly sophisticated cyber-threats. If a system is smart, it is vulnerable.

In 2023, however, social engineering attack methods such as phishing will be as damaging as highly sophisticated attacks targeting key assets. Employing zero-trust models and automation in cybersecurity environments can counter these known threats by authenticating, authorizing and continuously validating internal and external users.

The International Data Corporation (IDC) this year stated that cybersecurity is now a ‘priority business investment’, with automation acting as a ‘force multiplier by taking routine tasks off the plate of cybersecurity, allowing specialists to focus their effort on adding higher-level value to the organization’.

Automated Breach-and-Attack Simulation (BAS) helps cybersecurity teams continuously stress test and validate their people, processes, and technologies. By moving away from episodic, point-in-time, manual testing methods, organizations can realize both team productivity improvements and cost savings. According to IDC, BAS capabilities can help cybersecurity teams discover and remediate gaps in their security posture, delivering key security outcomes such as strengthening cyber defense and helping IT and security teams do their jobs better and faster.

To meet the needs of a modern threat landscape, manufacturers must adapt to an ‘assume-breach’ mindset of when, rather than if, an attack will happen, and utilize an ‘evidence based security’ method of making informed decisions about their cybersecurity program. An organization’s board needs to be kept informed of their cybersecurity posture with performance data-driven insight, rather than box checking exercises. By enhancing visibility within their cybersecurity program, manufacturers won’t be entering 2023 blindfolded. ■

For a list of the sources used in this article, please contact the editor.

Ross Brewer www.attackiq.com

Ross Brewer is Vice President of EMEA and APJ for Cybersecurity firm AttackIQ, the leading independent vendor of breach and attack simulation solutions. AttackIQ built the industry’s first Security Optimization Platform for continuous security control validation and improving security program effectiveness and efficiency. AttackIQ is trusted by leading organizations worldwide to plan security improvements and verify that cyber defenses work as expected, aligned with the MITRE ATT&CK framework.

manufacturing-today.com 17 Cybersecurity

News in Brief Try before you buy

Scientific strides

SambaNova Systems is delivering its DataScale® system to the US Department of Energy’s Argonne National Laboratory. DataScale® is a fully integrated hardware-software system that enables organizations to reimagine their approach to AI.

“With the rollout, we’re seeing scientists use novel AI architectures for pioneering research in areas ranging from climate predictions to neutrino physics,” says Rick Stevens, Argonne’s Associate Laboratory Director for Computing, Environment and Life Sciences.

The new system will be made available to the scientific community via the ALCF AI Testbed, a growing collection of some of the world’s most advanced AI accelerators.

Driving tomorrow

Renault Group and Google have announced the expansion of their partnership. The ‘Software Defined Vehicle’ will bring together the best of the automotive and digital worlds to allow for new on-demand services and continuous upgrades.

This will build on the existing Android Automotive Operating System and Google Cloud technology collaboration, accelerating their partnership to develop the vehicle of tomorrow.

Google has also become Renault Group’s preferred cloud supplier. The collaboration, initiated in 2018, will be extended as part of its digital transformation.

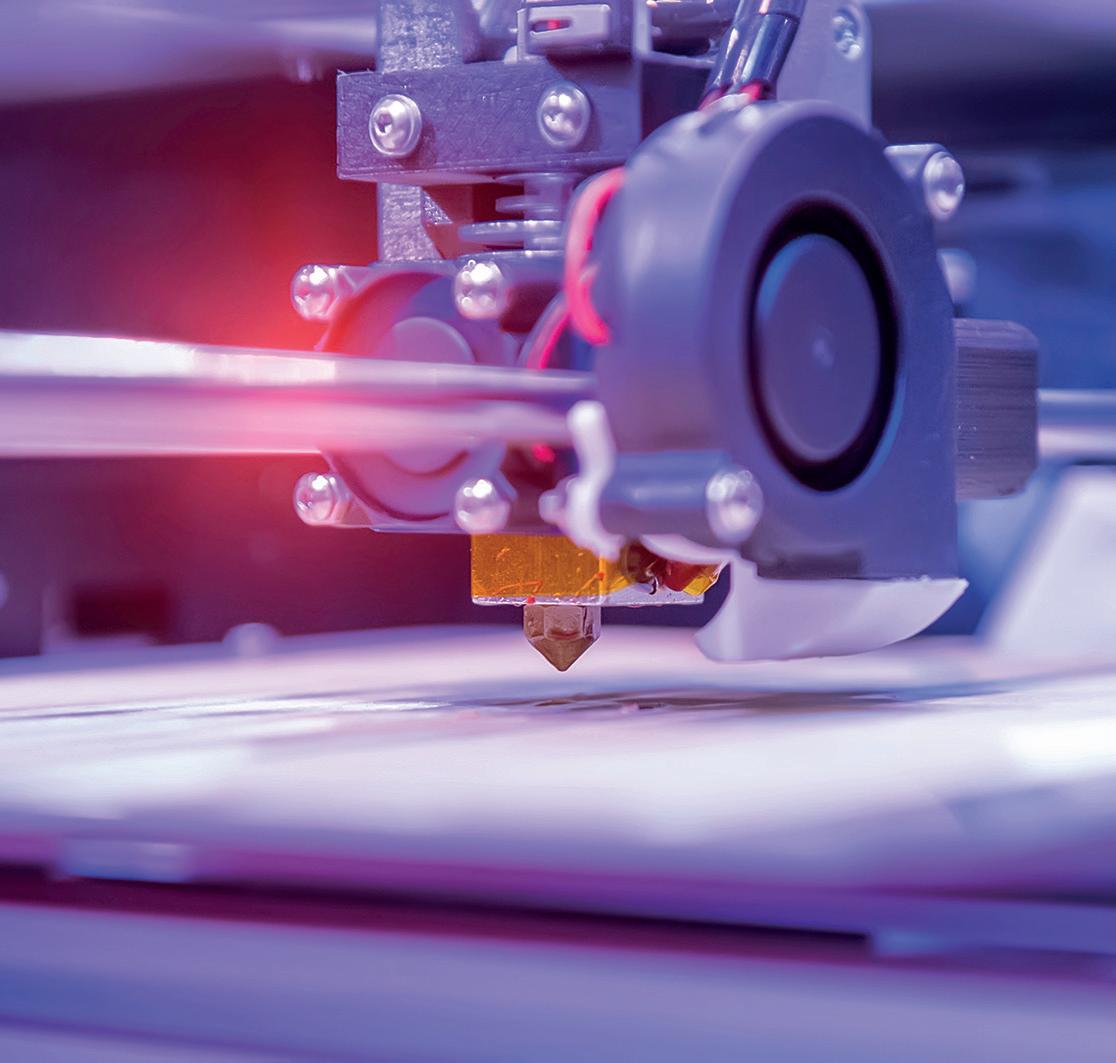

Hexagon is partnering with Research Institutes of Sweden (RISE) to provide software that will advance the use of Additive Manufacturing (AM) technologies and accelerate the adoption of innovative and sustainable processes in European industry. Established by RISE to increase the accessibility of AM across industrial sectors, the new Application Center for Additive Manufacturing will be overseen by a consortium of industry leaders. It will provide an independent and risk-free environment where manufacturers can ‘test before they invest’ with the center’s state-of-the-art facilities.

Manufacturers such as Volvo, Siemens Energy, and Ericsson will use the centre to evaluate and validate entire AM ecosystems through collaboration with researchers, scientists, industry experts, and partners. Mathieu Pérennou, AM Solutions Director at Hexagon’s Manufacturing Intelligence division, says: “This collaboration offers a win for the entire industry, with the partnership combining our years of expertise in driving 3D printing innovation with access to the most cutting-edge tools and R&D teams.”

18

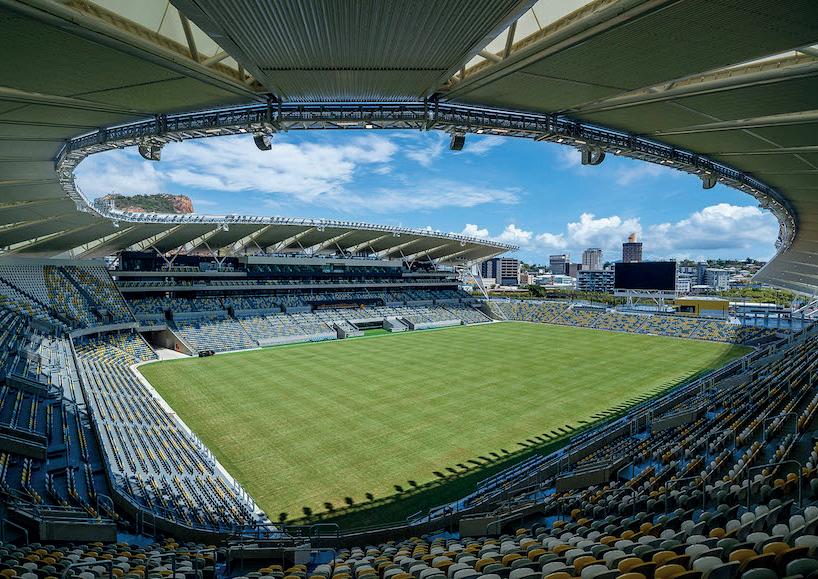

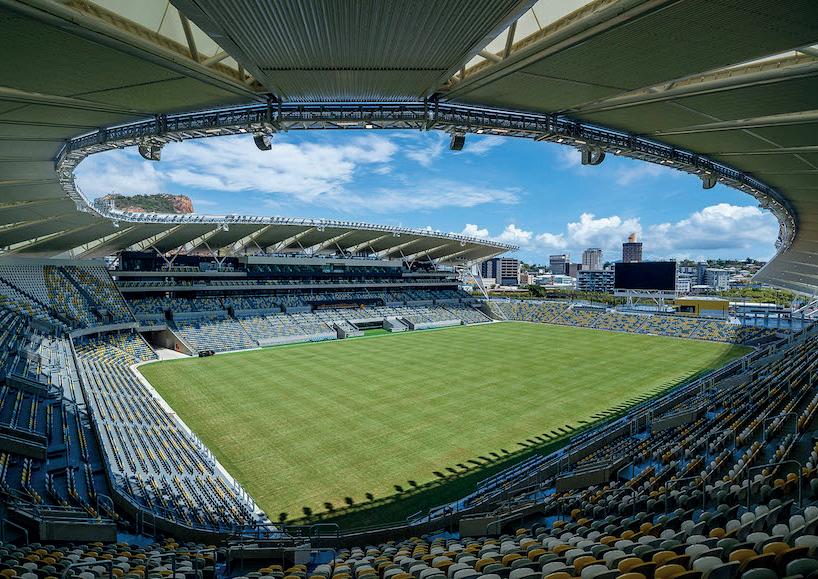

Take a seat

Infor®, the industry cloud company, announces that Camatic Seating, a leading supplier and manufacturer of ergonomic seating solutions for stadiums, cinemas, educational institutions and transit areas, is using its integrated AI solution to help improve customer satisfaction, increase revenues and optimize the vendor selection process.

Melbourne, Australia-based Camatic Seating has developed innovative seating solutions for some of the most iconic venues in the world. With Infor Coleman® AI, it anticipates increasing its saleswin rates by five percent, which would translate into ten-to-15 million dollars in new revenue.

“With AI applied to key business processes, we now have the confidence to tell our customers we can deliver their seating on time,” says Jamarl Scase, Planning and Production Control Manager at Camatic Seating.

“We weren’t really analyzing data in a consistent manner,” Jamarl says. “It led to sometimes making the incorrect supply selection. Now, by applying AI to our historical data, more accurate and consistent information is available at the touch of a button.”

Industry News manufacturing-today.com 19

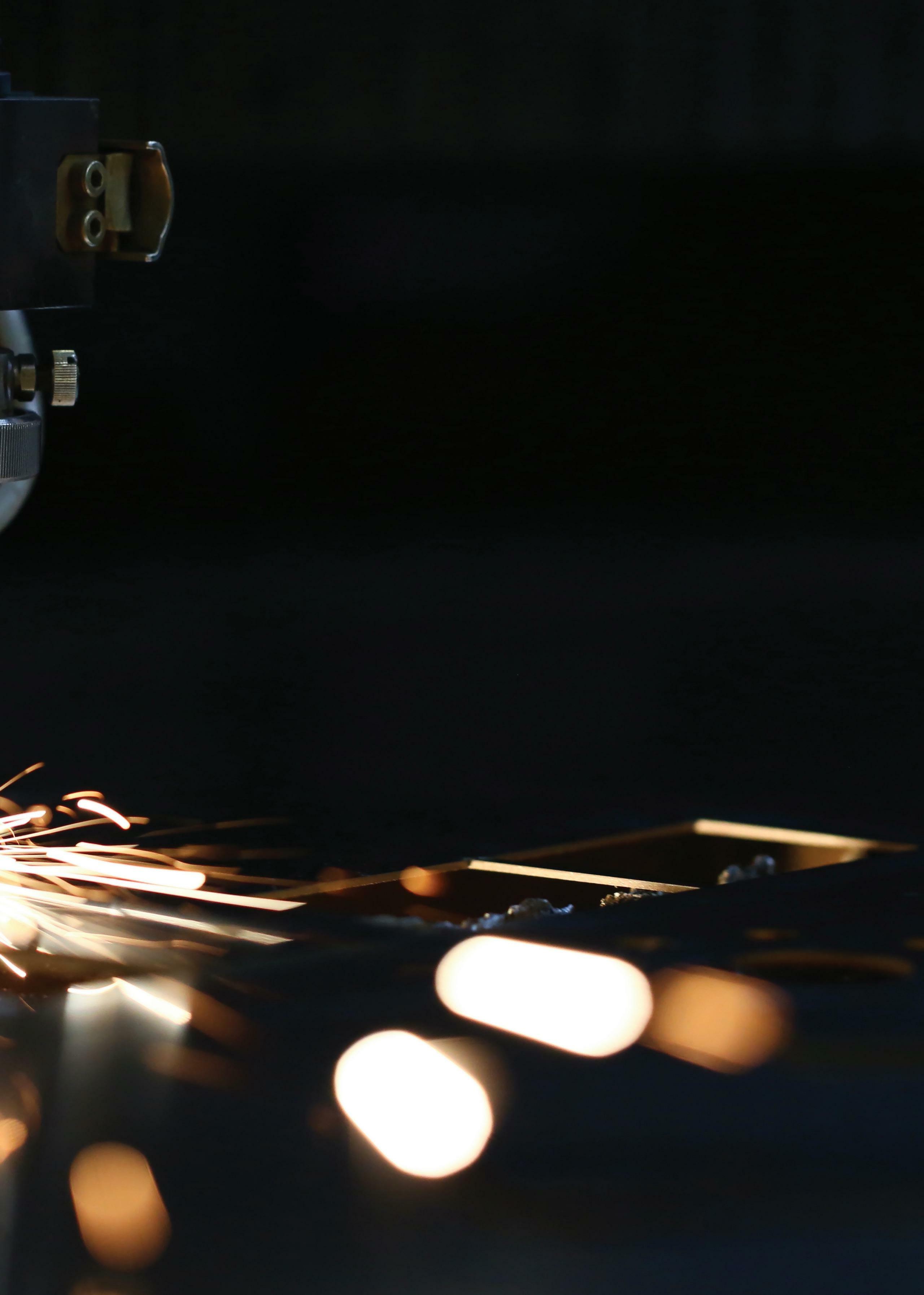

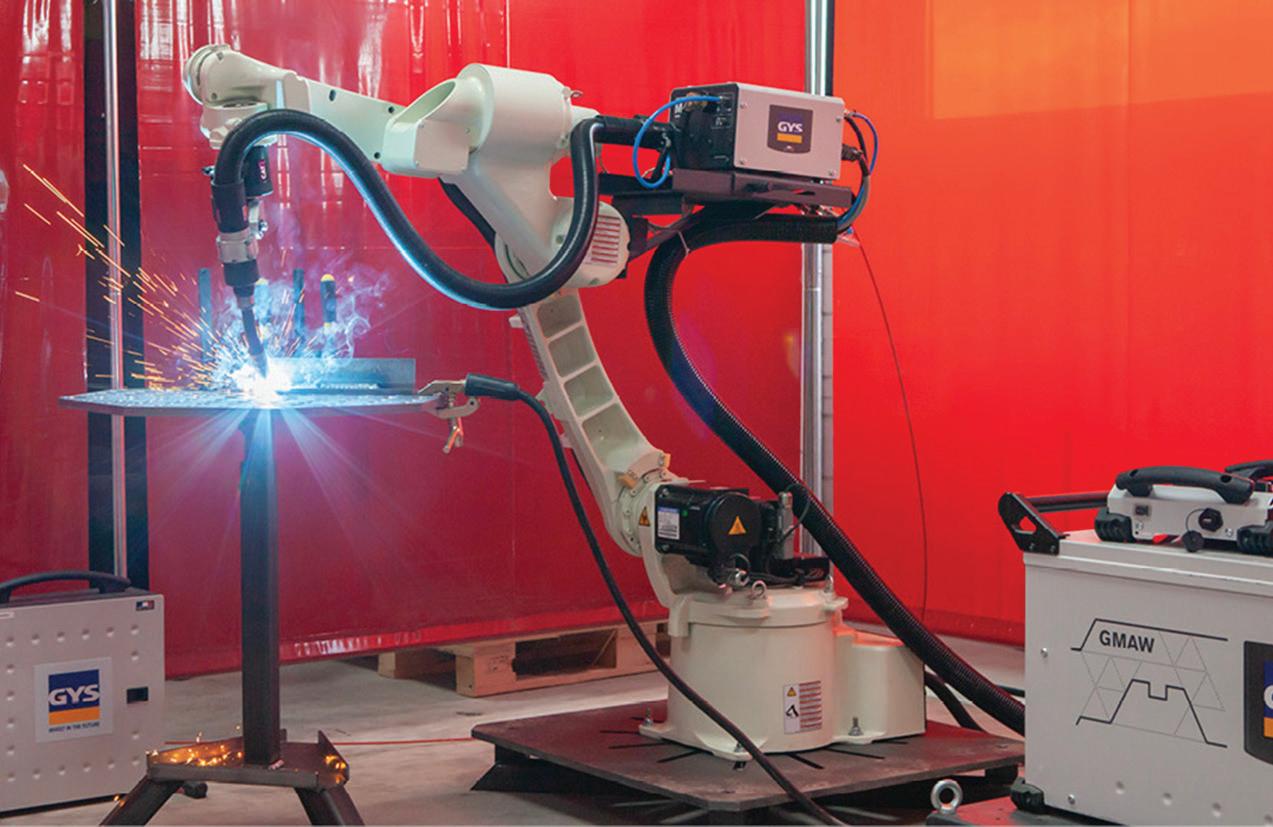

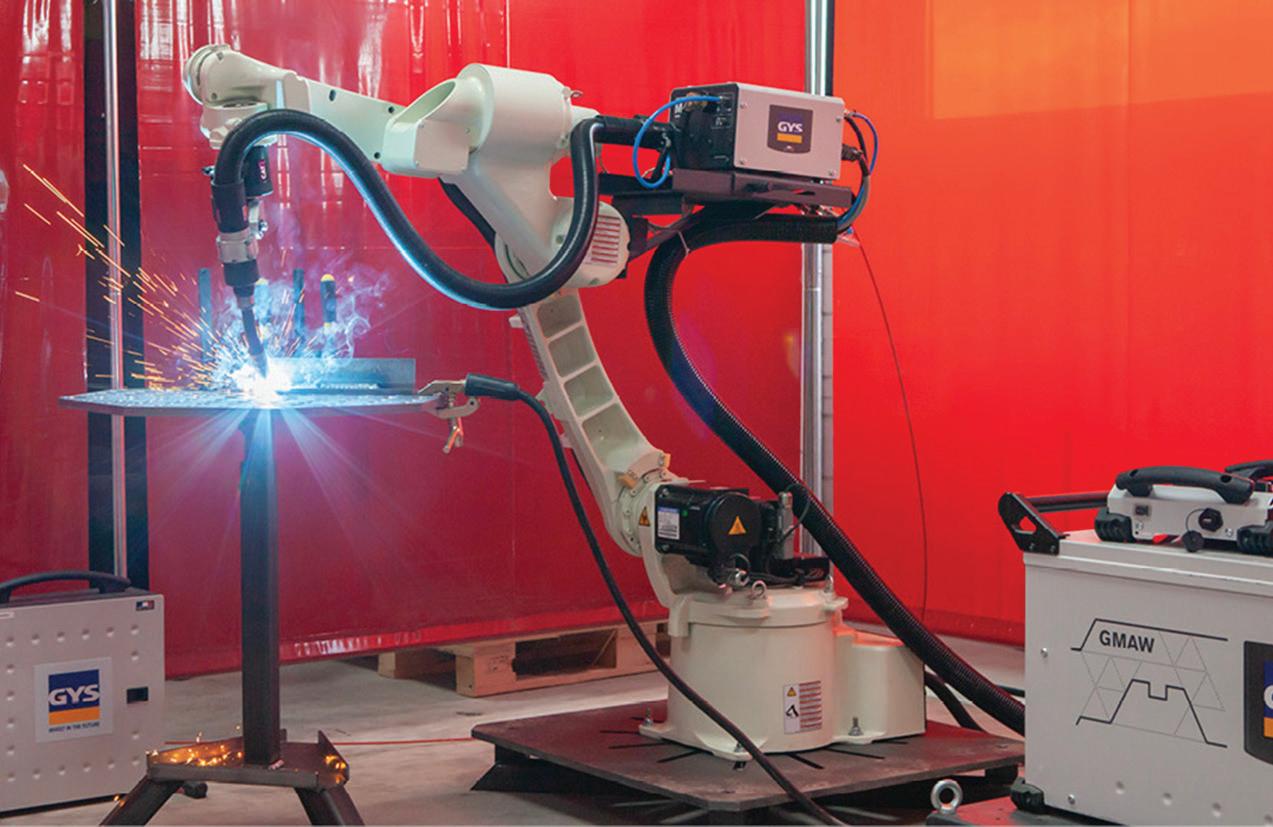

Invest in the FUTURE

GYS is a family-owned business, heralded as an industry leader in the design and manufacture of welding equipment, battery chargers and vehicle body repair systems. Although its headquarters are based in Laval, France, it has locations across the UK, Italy, Germany, China and now, Spain. It was founded in 1964, but the year 2020 marked a significant turning point in a 25-year endeavor into Research and Development (R&D) – a timeline with correlative links to an exponential period of growth that the company has seen since 1997.

“ “

There is no better descriptor to set the tone for a discussion on GYS, than that delivered by Neil Pulsford, Managing Director: “GYS is a challenger. The last four

years have been extremely important for the world of welding. The industry is a vast entity, with a multitude of players and products around the globe. To give you an idea of the breadth of these products, at GYS we produce a huge range from lowcost, simple technologies, priced around €150, up to high-end, software-driven machines, which sell for thousands. Today, our most advanced machines contain in excess of one million different lines of software. GYS’ strapline ‘invest in the future,’ reflects the company’s modus operandi and speaks for the immense journey into R&D that we have undertaken throughout the last few decades to ensure that our product range can offer clients the maximum possible from the technology available.”

“ “

GYS has challenged its way to the top of its industry, but is only just getting started

GYS’ strapline ‘invest in the future,’ reflects the company’s modus operandi

22 Exclusive Feature

GYS manufacturing-today.com 23

24

“ “

At the beginning of this exploration, the company ran with a modest range of smaller, less complex machines. The constant R&D investment has steadily increased the range to over 100 different welding machines in the latest catalog. Neil cites 2020 and 2021 as being milestone years in terms of the company’s product development timeline. “It’s only in the last four-to-five years that we have completed our product range with the introduction of advanced 400A+ MIG/MAG and TIG machines,” he reflects. “We are among maybe six or seven global brands in the market who are capable of the design, engineering and manufacture of products of this caliber: products that draw from developments in technology to improve the functionality and performance for the final user. So, we have arrived in terms of welding, after 20 plus years of serious investment into the French R&D team.

“Internally, I would refer to us as the new tier one welding supplier,” he continues. “From a product and technical point of view, we’re definitely there, but in terms of awareness and recognition, we are not yet so well-known externally; we have a lot to do in this area. Progressively we are making friends in the industry, gaining customers and spreading the word. The major center of the organization’s

gravity is well vested in Europe. From our base in France we have strong sales, marketing and support subsidiaries in Germany, the UK, Italy and since earlier this year, Spain. These are the major markets for GYS in Europe, however we have established distribution and importers catering to all of the European markets. Overall, GYS is now a team of 900 people internationally, with 600 located in France.”

The constant investment by the company has seen 1997’s team of 30 being expanded to the 900 we see today. As Neil states: “GYS is an organization that is designed for growth, we have managed to grow every single year for the last 24.” Using great foresight, industry knowledge and, to some extent, its global reach, GYS managed to evade numerous complications during the pandemic.

“ “

As Bruno Bouygues, Chief Executive Officer, details: “Just before the world stopped, when Covid hit, we made the correct predictions with regards to the disruptions that we were going to be facing. We forecasted that as computers, iPads, Wi-Fi, 4G and 5G technologies were suddenly in huge demand, there was going to be an international shortage of semiconductors. To give you an idea of our reliance on these components – we manufacture

GYS

manufacturing-today.com 25

I want to change my industry by providing a new ease to connectivity

between 2000 and 3000 machines every day, some of which use as many semi-conductors as a car. Average car factories only produce maybe 300 to 400 cars per day, so in terms of the volume of consumption, we are one of the largest in France. One of the good decisions we made, was to purchase two years’ worth of stock to see us through the pandemic. This has enabled the continuation of our steady growth throughout the last few years and also meant that our customers were not affected by delays.

“Besides our use of initiative, we had the opportunity to learn from our counterparts in China, who shut down first and then reopened before us, which gave us time to plan and acquire the necessary PPE,” Bruno adds. “As a group, we have always made limiting disruption a top priority, so in some ways we were prepared for such a huge occurrence. We operate out of a very large warehouse, so when the factory closed, we were still able to ship pallets for quite some time. This helped us to win over new clientele, as we’ve established

more distributors during the last three years than in the entire prior history of the company. On top of all this, we signed into a new capped energy contract at the start of 2020. This means that none of our operations or costs have been affected by the recent changes and we haven’t had to pass any price increases onto our customers. It has all been very positive of late.”

Problem solver

Alongside its expertise in welding equipment, GYS is the largest player in the professional automotive sector for battery chargers. The company has gained extensive knowledge on battery charging through continued R&D, which it is now applying to new markets across different industries. As Neil explains: “We have 50 years of experience in producing battery charging equipment, mostly for the automotive sector. As the technology in your vehicle has outgrown its traditional 12-volt battery, car manufacturers have been presented with a number of new challenges,

26 Exclusive Feature

concerning production, servicing and aftercare. For example, a small family car from 20 years ago would have required the most basic four-amp charger, whereas today’s cars require between 120 and 150 amps to protect the array of complex electronic systems in play. Through our newly advanced technology, GYS’ engineers are able to extract chargerelated data to understand how different applications respond to the charging process itself. In doing so, we are able to program chargers to improve their performance for any battery metallurgy required.”

From batteries to bots, GYS has its eyes set firmly on the future, with the next development in welding, for Robots and Cobots, already well underway. Part of this includes the development of an automation platform: Smart Automation Machine (SAM.) The idea being that SAM will simplify the difficulties surrounding

automation, specifically in terms of machine recognition. Bruno elaborates: “I want to change my industry by providing a new ease to connectivity. SAM will enable automatic recognition to connect machine to machine, the same way you would your printer and computer.”

GYS is a challenger by definition: from barely existing 25 years ago to now challenging the top competition of each new market it enters. It challenges how things are currently done and how they can be improved – a process in which it invites its staff to collaborate. “It’s a positive characteristic in a growing company,” Neil concludes. “I believe ‘challenger’ is the perfect term to encapsulate our style of organization, and a very healthy environment to be in.” ■

www.gys.fr

manufacturing-today.com 27 GYS

Exclusive Feature

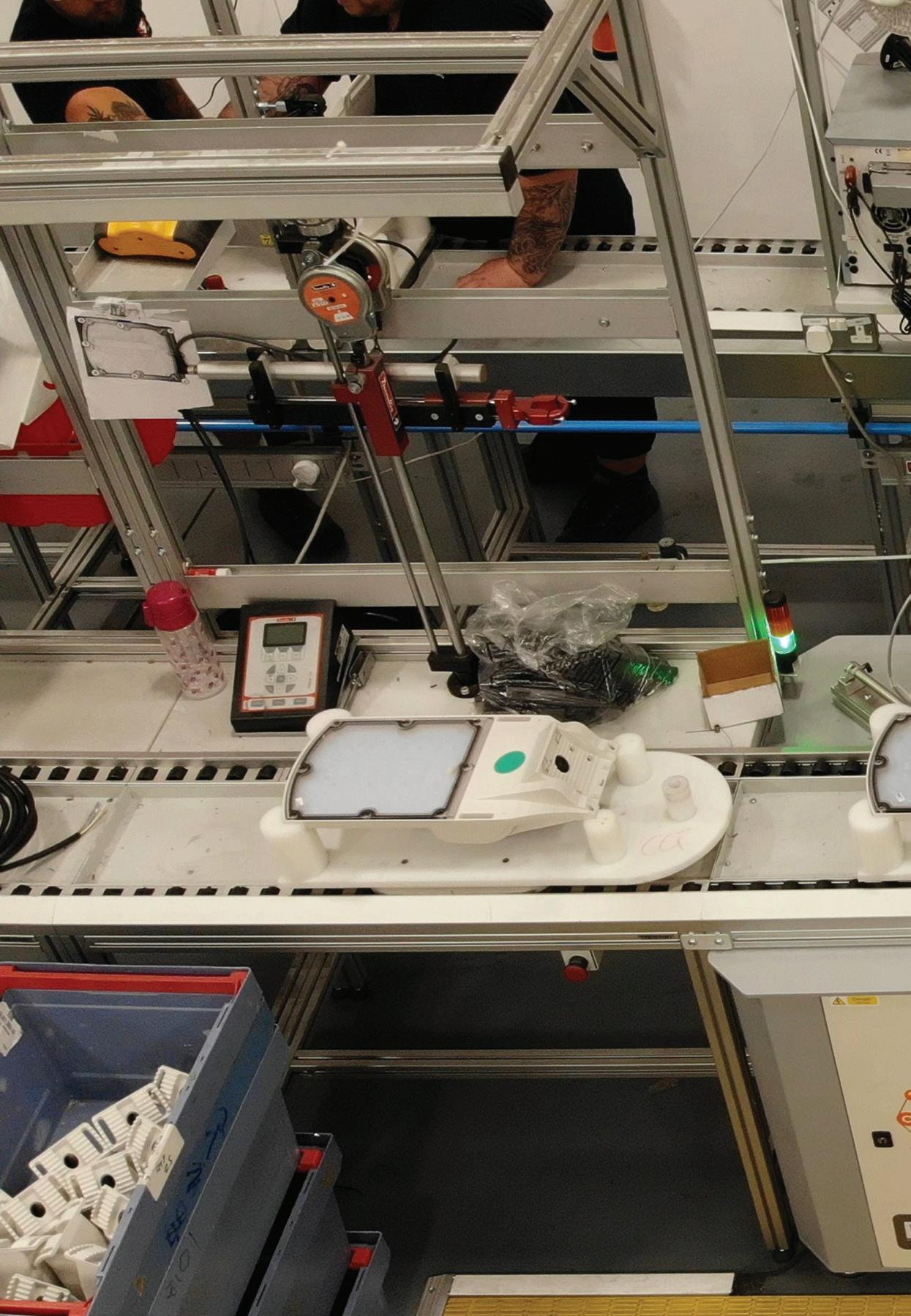

Seamless solutions

How JR Automation positions itself as the partner for success

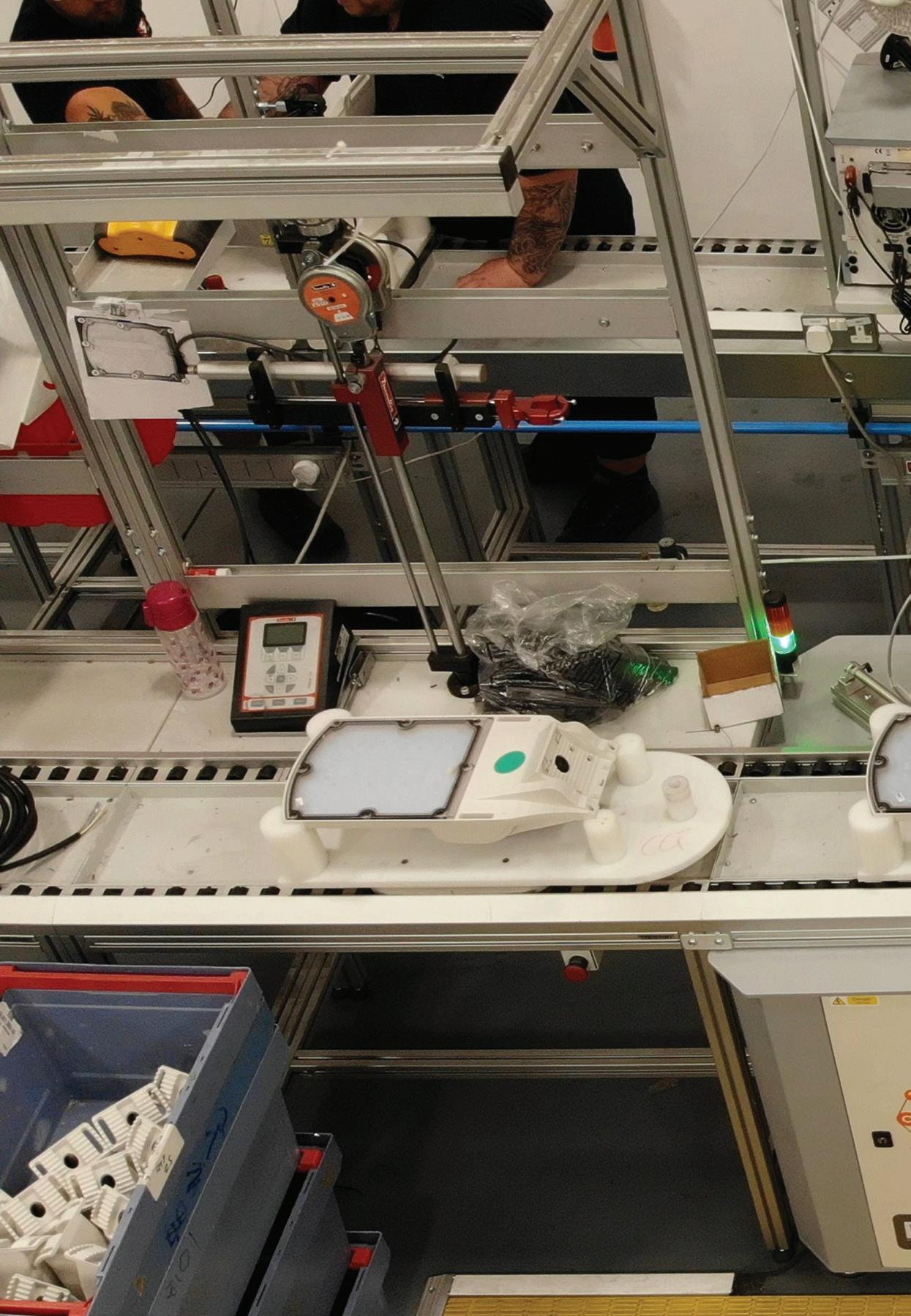

Founded in 1980, JR Automation has evolved over the years to provide intelligent automated manufacturing and distribution technology solutions that transform the way the world’s leading manufacturers make and distribute products.

As a consequence of strategic acquisitions and organic growth, the business boasts more than 1,700,000 square feet of automation and engineering space around the world. Acquired by Hitachi, Ltd. in 2019, JR Automation is now able to accomplish even more for its customers by combining its expertise in robotic system integration with Hitachi’s deep skill sets in artificial intelligence and IoT technologies for manufacturing.

Uniting its five divisional brands in 2021, JR Automation is able to offer more innovative solutions and areas of expertise than any other company, providing customers with seamless services and connecting the entire value chain with data to achieve total optimization.

“We are a large automation integrator with a wide variety of expertise,” explains Craig Ulrich, CEO. “With specialty divisions in different geographic regions, we are able to feel more relevant, local and personal to our customers while simultaneously, being able to leverage the breadth of expertise afforded by our scale. This local feel, combined with our geographical reach and extensive knowledge base help to set us apart from the competition.”

Manufacturing plants tend to have separate Operational Technology (OT) and Information Technology (IT) divisions. The former denotes systems that monitor and govern physical equipment, whereas the latter encompasses digital information and infrastructure. As Craig suggests: “It’s very rare that a company can provide both capabilities to their customer base. Again, I think our size and ability to adapt allows us to do that. In fact, we try to no longer differentiate between the two. Our approach bridges the divide to create a fully integrated smart solution.”

manufacturing-today.com 29 JR Automation

that is occurring in manufacturing. Industry 4.0 represents the adoption of smart and autonomous systems that are fuelled by data and machine-learning.

INGENOVA360™ is JR Automation’s suite of software that fully connects equipment to an intelligent planning and control system, delivering the information needed to make strategic decisions on every business level.

“We integrate our equipment into our customers’ Enterprise Resource Planning (ERP) systems to enable automatic scheduling. While many companies are capable of building the automation equipment, we are able to both provide and seamlessly integrate it as a onestop service offering,” Craig enthuses.

Senior Vice President of Sales & Marketing, Thomas Rozema, agrees: “I think it’s an unmet need in the industry and we are uniquely positioned with the support of the powerhouse that is Hitachi to deliver not only the automation but the additional value of the digital solution too.”

discussed, and potentially understood, in terms of concrete representation however, it’s still early days, and many customers are unsure how the technology actually functions in real terms. Communicative systems need to be in the hands of those with the knowledge and support to implement them.

Thomas explains: “We are able to put a Warehouse Execution System (WES) in place that can talk to multiple machines at the same time. On completion of one operation, the next machine will pick up the work flow without any human interaction.

Software drives the process, thereby optimizing work flow and production.

While JR Automation has been building logic into its offering for some time, customers were never necessarily aware of its inherent value. Today’s increased emphasis on streamlining however, and practical evidence of the technology’s benefits in action have helped to get the ball rolling.”

30

Software drives the process, thereby optimizing work flow and production “ “

Exclusive Feature

“ “

Holistic solutions

Vice President of Digital Solutions, Mike Lashbrook, adds: “I would say a further consideration is the human factor, and understanding that now we have all this data at our fingertips, it’s crucial to make sure we are using it properly, and sharing it at the right level. Ultimately, decisions need to be made on the manufacturing floor. To enable team leaders to make the correct decisions and implement continuous improvement activities, information needs to be accessible to the right people. It’s not simply a case of providing management with graphs and charts. Empowering the workforce to make decisions based on available data is intrinsic for growth. It takes an organizational level of training and leadership to ensure automation solutions are exploited to their full potential.

“When data and equipment is implemented, it’s crucial to know how to use it in a way to actually improve business. We like to understand what problem our clients are trying to solve. From productivity improvement to quality enhancement, understanding a client’s motivation provides better transparency when it comes to how the operator

works with the equipment. This enables us to use the data to better resolve the issue in a collaborative manner.”

Indeed, it would seem the business is uniquely positioned to develop partialautomation as a key area of opportunity. For example, as Mike elaborates: “The general assembly lines we supply for automotive makers haven’t changed dramatically in decades, and are not likely to. We have tried to automate more and more, but we will never remove the people aspect from the general assembly process of an automotive plant, and there are many other manufacturing processes that are similar. The more we can incorporate that element into the bigger picture, the better we’re able to offer more holistic solutions.”

By understanding and responding to key operational drivers, JR Automation seeks to not only deliver its core offering of robotic automation, but moving forward, to also make sure it integrates software and systems as a seamless solution, for every client, from day one.

As Mike explains: “This approach really requires a greater understanding of our clients. Instead of being just an automation solution provider, we need to co-develop

manufacturing-today.com 31 JR Automation

partnerships with our customers to understand the root of what they are asking us to solve. We can then uncover the necessary data, and integrate solutions from day one that can be maintained and supported for years to come. A life-cycle management approach drives continuous improvement. While we don’t want breakdowns to occur, if we can better predict when they’re likely to, we can help our clients to better manage occurrences, alleviate the effects, and mitigate against them with preventative maintenance.”

Looking to the future, the team at JR Automation places considerable emphasis on company culture and how that filters through to customer service. Craig highlights: “We need to make sure we are functioning well locally and that we are a cohesive team in the regions in which we work. Through our visions and values, we act as a global organization but with a local focus. We do that by various means. For example, each area has a community care fund through which charitable giving is fed back to the good of the local community. This helps to embed the organization in the local community which is good not only for our people, but for our customers too.

“Our people are key to everything we do. We take care of them and in turn, they take care of our customers. From a customer perspective, that is why a local feel is important to us. We don’t want to present ourselves as a faceless conglomerate. Our customers

need to feel reassured that the person they worked with on a previous job is going to be the same one they work with on the next job, and the next. They can count on us to produce what they need to run their business in a timely manner. This relationship encourages repeat custom, and in effect, we become an extension of their business. Our success is as a result of our customers’ success.”

Tom reiterates: “While buying habits have traditionally veered towards low cost, I think we are seeing a trend in the industry where customers are really valuing the strategic partnerships we offer. We have about a dozen very large customers that bring repeat revenue on a yearly basis. It’s extremely beneficial; we talk the same language when designing automation, enabling our teams to execute systems with enhanced efficiency and particularly so, from a life cycle management perspective. Not only are we providing new solutions, we’re servicing and supporting those solutions for the long haul.”

Today JR Automation is roughly an 800-million-dollar business. With 28 manufacturing facilities and over 2000 dedicated teammates across the globe, the business continues to grow and evolve to help its customers succeed. As Craig shares: “Our total seamless solutions stand us in good stead for sustained success moving forward.” ■

JR Automation

www.jrautomation.com

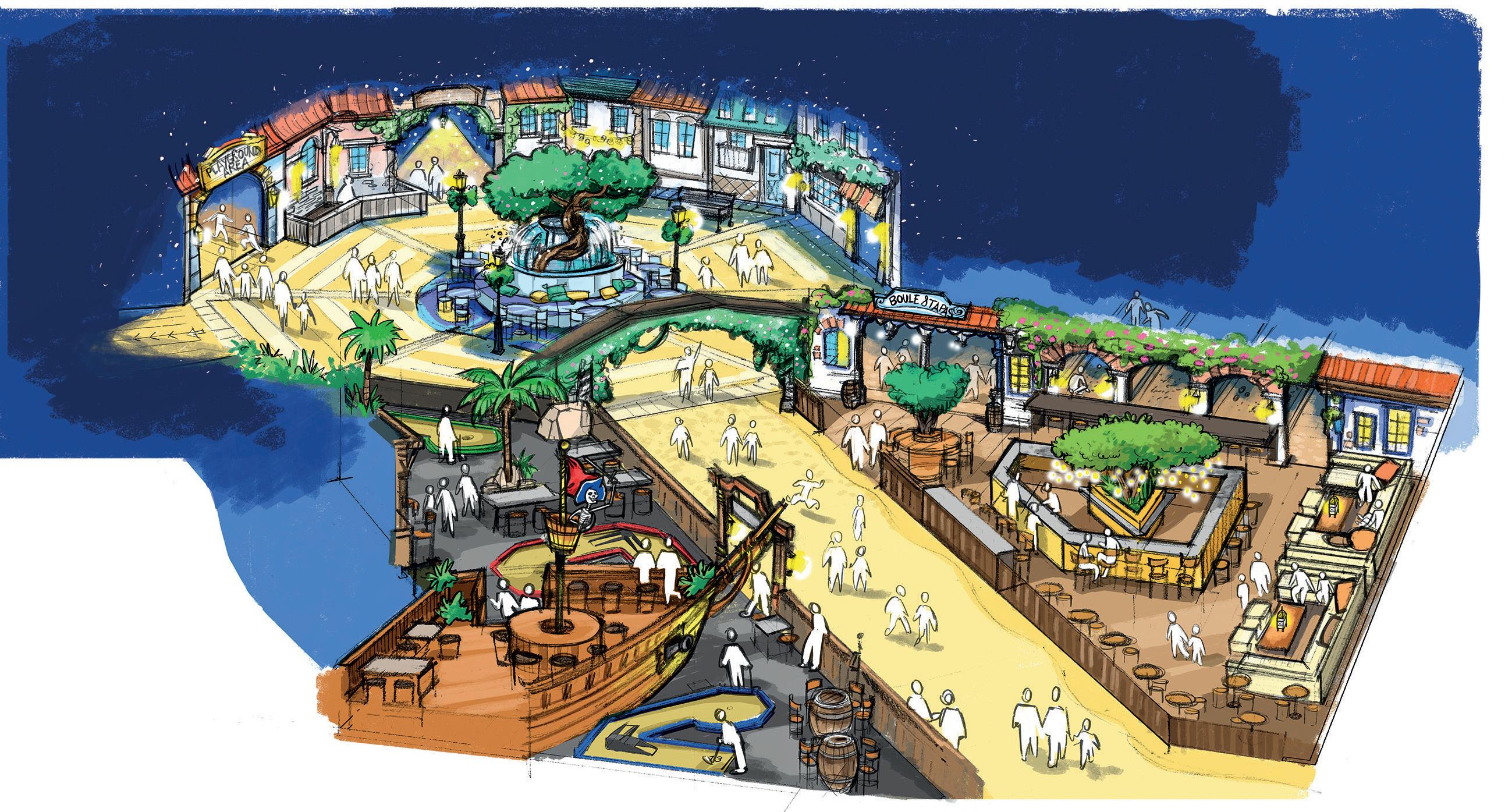

WORK HARD. PLAY HARDER.

Macron discusses its strategies for staying ahead of the game

34 Cover Story

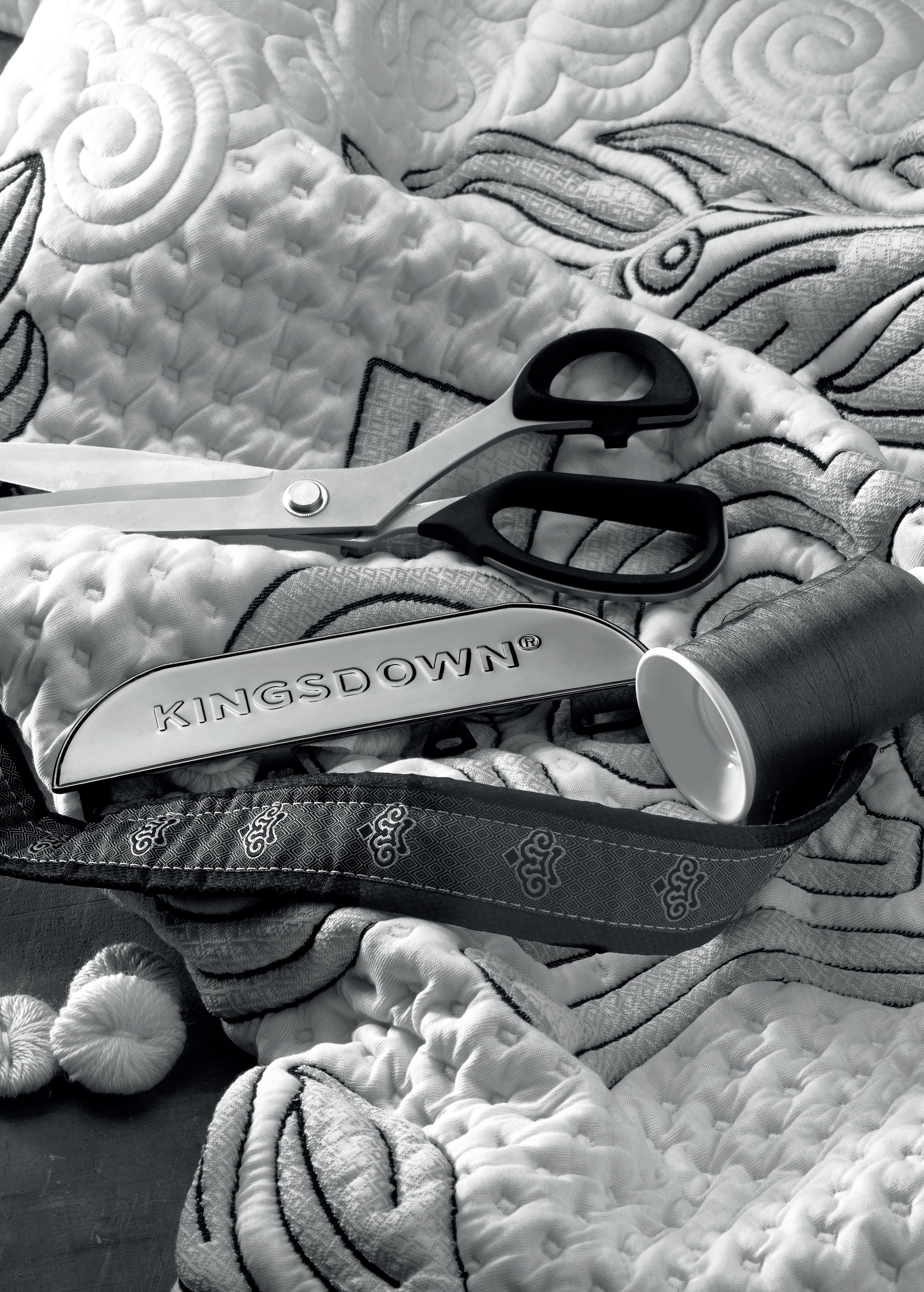

Founded in 1971, in Bologna, Italy, today Macron is a leading European company in the production and sale of technical sportswear. Working hard to create cutting-edge, highperformance products, the business is proud to support athletes, from grassroots to professionals, in their efforts to become their own hero on and off the field.

Placing intrinsic importance on high standards of good management, social responsibility and respect for the environment, the business strives to build a community that shares its passion for true sport.

Top quality

Currently operating in five main business areas, Macron supplies sportswear and accessories for team sports, technical apparel for individual runners and for training sessions at the gym, and sports inspired apparel for leisure time. In 2021, the business launched a new padel collection, including apparel and technical accessories from rackets to bags and balls. Thanks to its superior inventory, the business can also supply a wide range of catalog items, with a 24-hour turnaround, boasting millions of off-the-shelf products, available for immediate shipping. Additionally, the business is the technical sponsor of over 90 worldwide professional clubs, to whom it offers top quality merchandise and a high standard of service, also producing official kits and accessories for the supporters of those clubs.

Macron manufacturing-today.com 35

Tailor-made service

According to COO, Paolo Guizzardi, one of the main reasons why Macron’s products stand out from the sporting crowd is because of their collaborative approach: “Our high-performance sportswear is created together with professional athletes, and we have strong relationships with the clubs we sponsor. This allows us to get first-hand feedback from the professionals using our products: feedback on design, materials and prototype testing prior to final mass production. Additionally, we believe in providing a tailor-made service for each club. We can offer a complete bespoke service, and both professional and amateur clubs can design their own kit, for both on and off the field.

“We moved into our new headquarters and distribution center in 2020,” Paolo continues. “This 22,000-square-meter facility will allow us to fulfil our next ten years’ growth. In the first quarter of 2023, we will migrate to an SAP ERP solution to support our position as an international company with subsidiaries around the globe. The distribution center is set up as a bonded warehouse, which allows us to optimize product distribution outside the EU, avoiding double duty, but enabling the same service level in terms of deliveries.”

Relationship building

As an integral element of its operations, the company is undertaking a series of initiatives, under the moniker, ‘Macron 4 The Planet,’ to drive greater environmental sustainability. From the production of goods to their distribution,

“ “

all areas of the organization

champion this ‘green’ attitude that ultimately translates into the optimization of work and costs, coupled with waste reduction.

As Paolo explains: “The company’s new headquarters was built with particular attention to environmental impact, and obtained BREEAM Excellent Certification, which is a highly respected methodology for assessing the environmental sustainability of buildings. The build included the installation of a photovoltaic system to produce electricity for the plant’s activities, tanks for storing rain to be repurposed for irrigation, the planting of 150 trees, 3200 square metres of shrubs and 15,000 square metres of lawn, alongside dedicated car parks for parking and powering electric vehicles.”

As Paolo elaborates: “The business is committed to caring for its people, and the environment, to create a shared value chain. Workspaces are designed for people’s wellbeing, with functional open-plan offices, lit by

This 22,000-square-meter facility will allow us to fulfil our next ten years’ growth

“ “

36 Macron

manufacturing-today.com 37

natural light. We also boast a modern in-house restaurant with a fully equipped kitchen, offering daily service of freshly prepared, healthy meals.

“Our employees have free access to our state-of-the-art indoor gym, and Macron also offers supplementary health care to cover family members. This commitment takes the form of a system of benefits and corporate welfare that includes services, initiatives and tools aimed at improving the wellbeing of employees, and the implementation and promotion of environmentally sustainable activities and behaviour.

“To top it all off,” adds Paolo, “the company provides one-off bonuses on the occasion of weddings and births,

alongside a range of team building events, such as Christmas and cocktail parties, and free match-day tickets.”

In terms of company culture, Macron strongly believes in the values of hard work and constant improvement. Much like the effort, and strong will required by the sportsmen and women the business supports, Macron works hard to succeed, fostering a ‘work hard, play harder’ culture within the team.

Indeed, the business places similar importance on nurturing its wider relationships, including those with suppliers. “When producing on a make-to-stock basis,” explains Paolo, “it is crucial to have an ongoing partnership with our suppliers. Our relationships are longstanding, and for many of our suppliers, we are likely to

“ “

We’ll strongly expand business mainly in North America and Oceania as well as in some parts of Europe

“ “

38 Cover Story

be one of their top three customers. With our focus on reducing the time to market, we require our partners to be reactive and flexible to our needs. As a result, mediumsized companies tend to be the best fit for us.”

Key advantages

Looking back over the past few years, the fall-out from Brexit has been a big challenge for the business. The UK is the first market for Macron, and as such, the organization needed to pivot to find new ways to distribute products without burdening its customers. Paolo explains: “This was made possible thanks to the combination of several different actions. From a new bonded warehouse, and subsidiary in the UK to ad-hoc partnerships with our logistics providers, we have been able to pack, ship and customsclear single customer orders, distributing them as domestic deliveries without any actionable customs requirements expected of our local customers.”

In fact, Macron’s strong supply chain came to the fore at the height of the pandemic. It enabled the business to react within a matter of weeks, facilitating the import and distribution of more than 50 million items of PPE in support of the NHS and the fight against Covid.

Despite rising to this global challenge, the business has experienced additional barriers in recent years. As Paolo expounds: “Uncertainty around sea and air transport, not only in terms of high cost, but also long transit times, has been a major challenge in 2021 and 2022. That said, we rallied our pioneering spirit, and in partnership with our logistics provider, secured a direct charter service between the Far East and Italy. As a result, we have been able to keep a regular flow of products available to our customers, and after Covid restrictions were lifted and sales started again, this has proved to be a key advantage over our competitors.”

Expansion plans

Looking to the future, Paolo states that surely this year will be the best yet for Macron: “Our proven track record in supply reliability and stock availability has been bolstered by our new distribution center, and has provided the reassurances our customers were looking for. We have strengthened customer relationships, retaining established ones, and building the foundations for new ones.

“Macron is a global player in football and rugby. As such, we aim to be among the top three brands in other sports too. We’ll strongly expand business mainly in North America and Oceania as well as in some parts of Europe. Moving forward, our main focus will be to find and develop new ways of servicing the needs of amateur clubs and athletes with our ecommerce-based platform,” he concludes. ■

www.macron.com

manufacturing-today.com 39 Macron

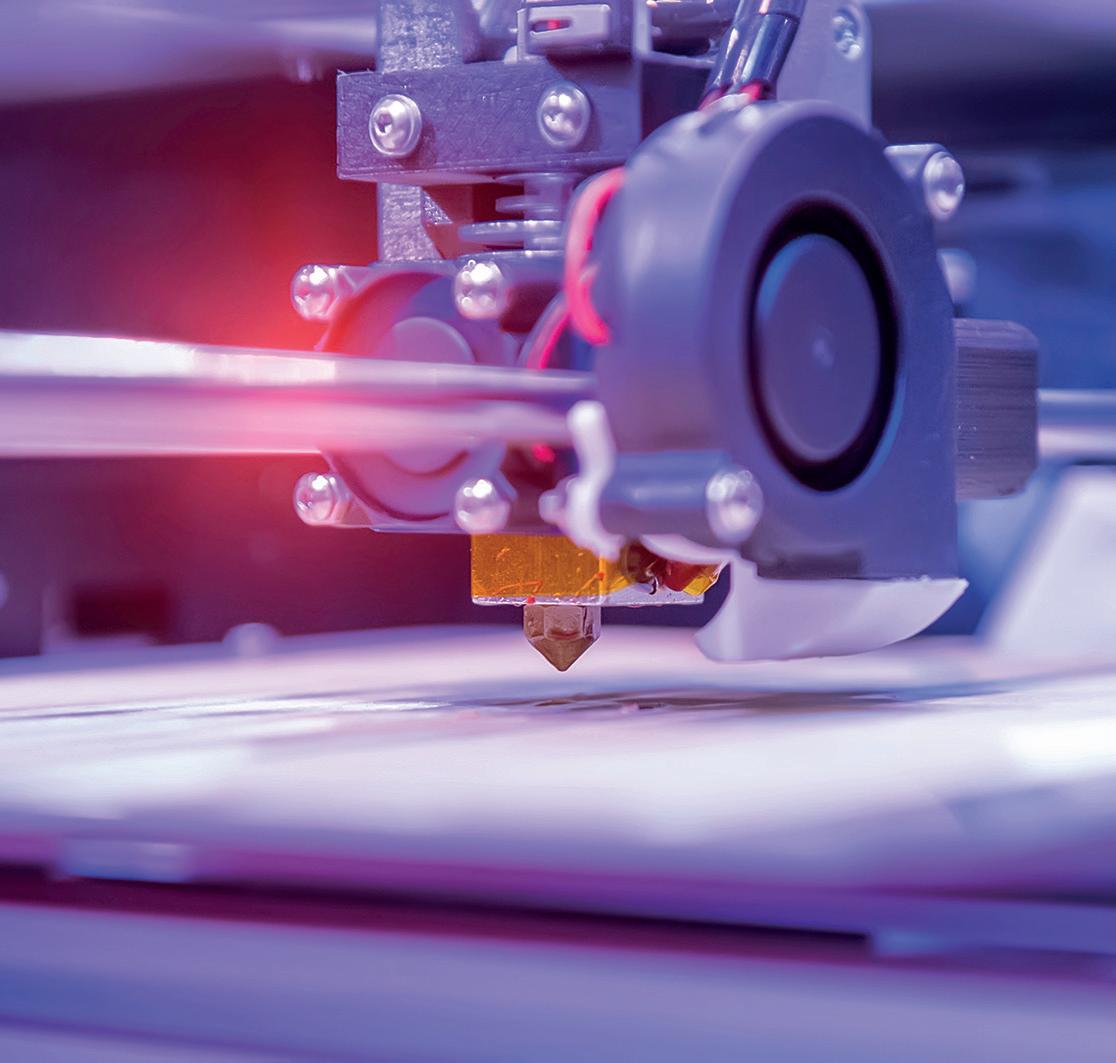

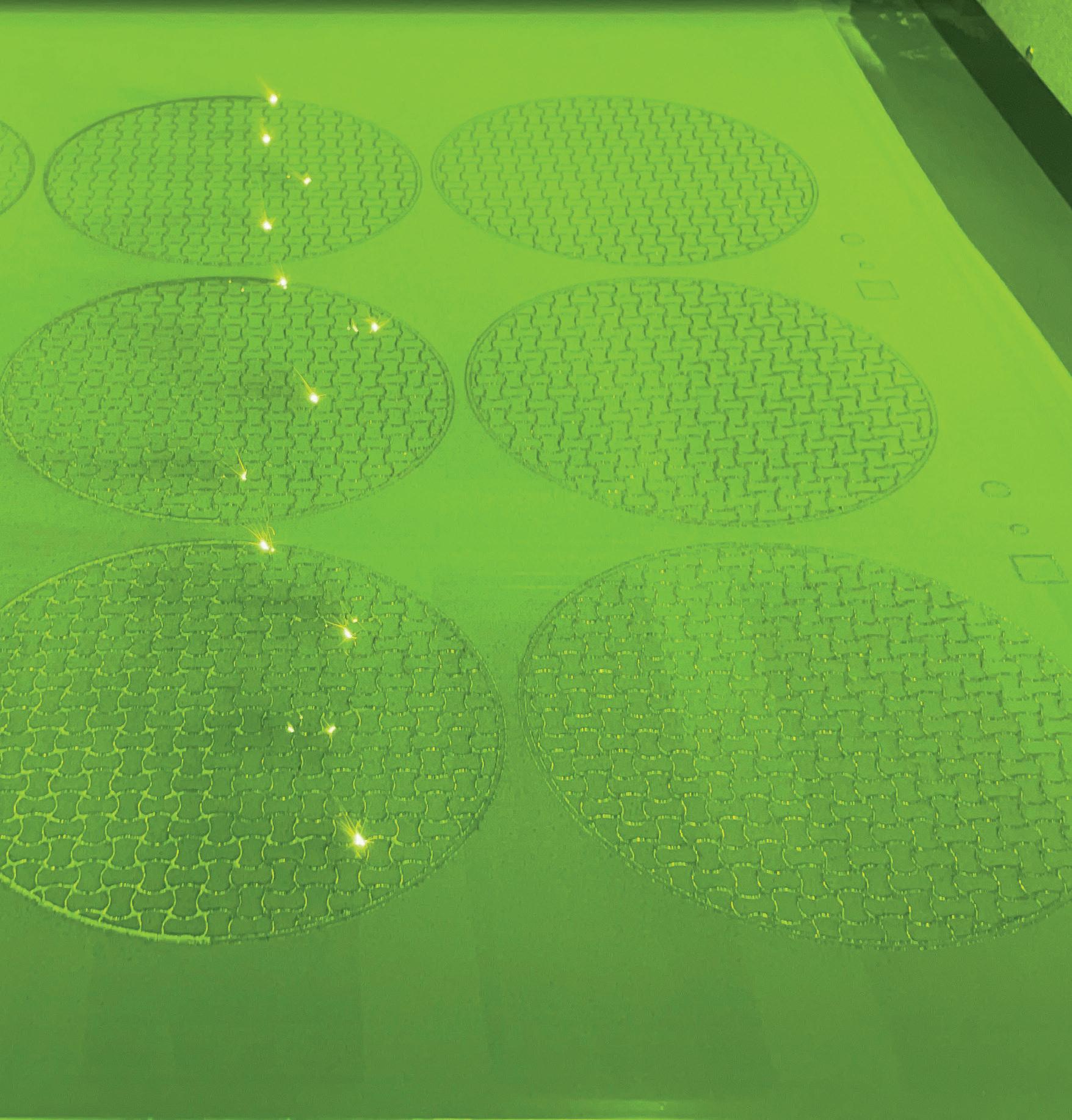

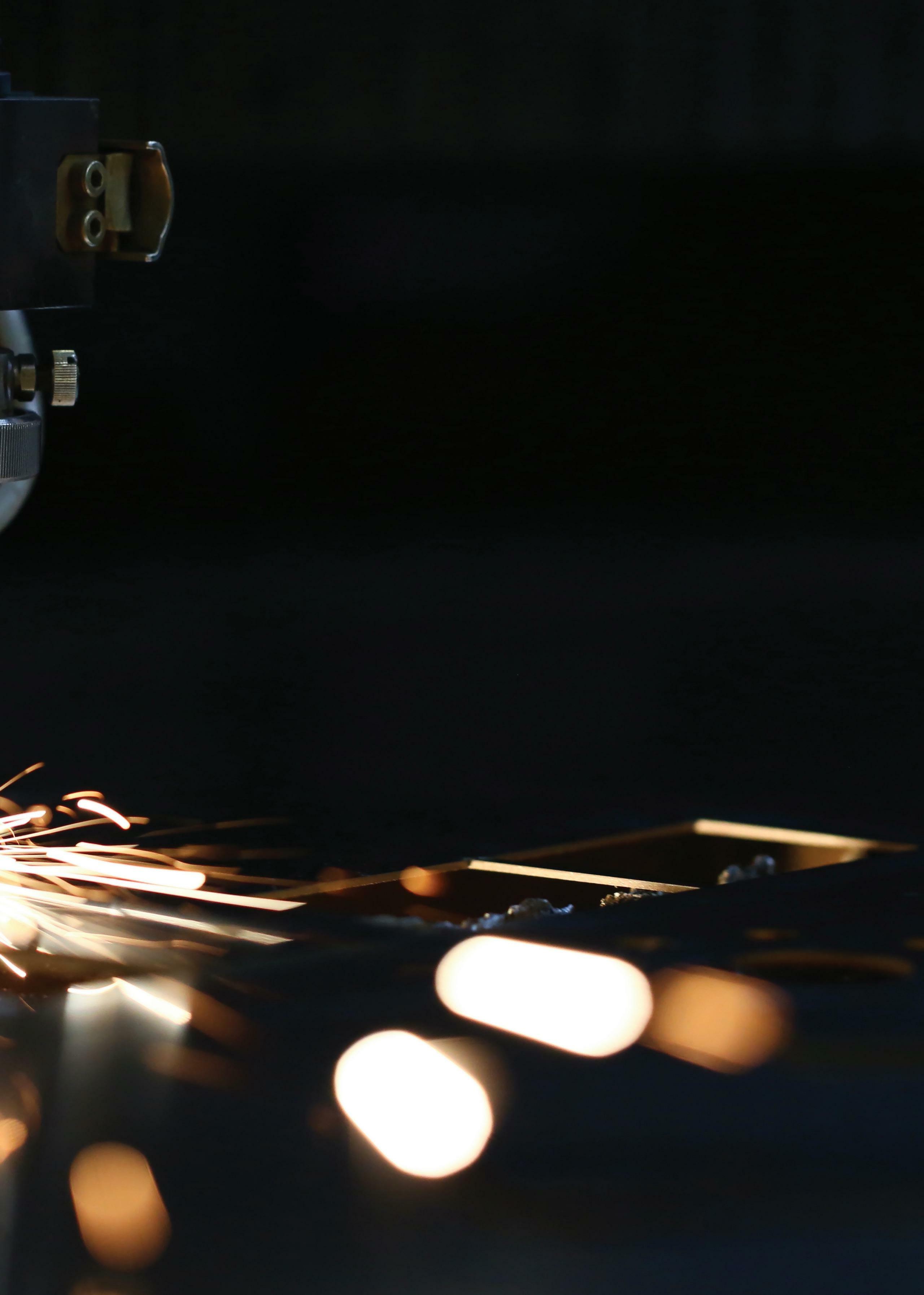

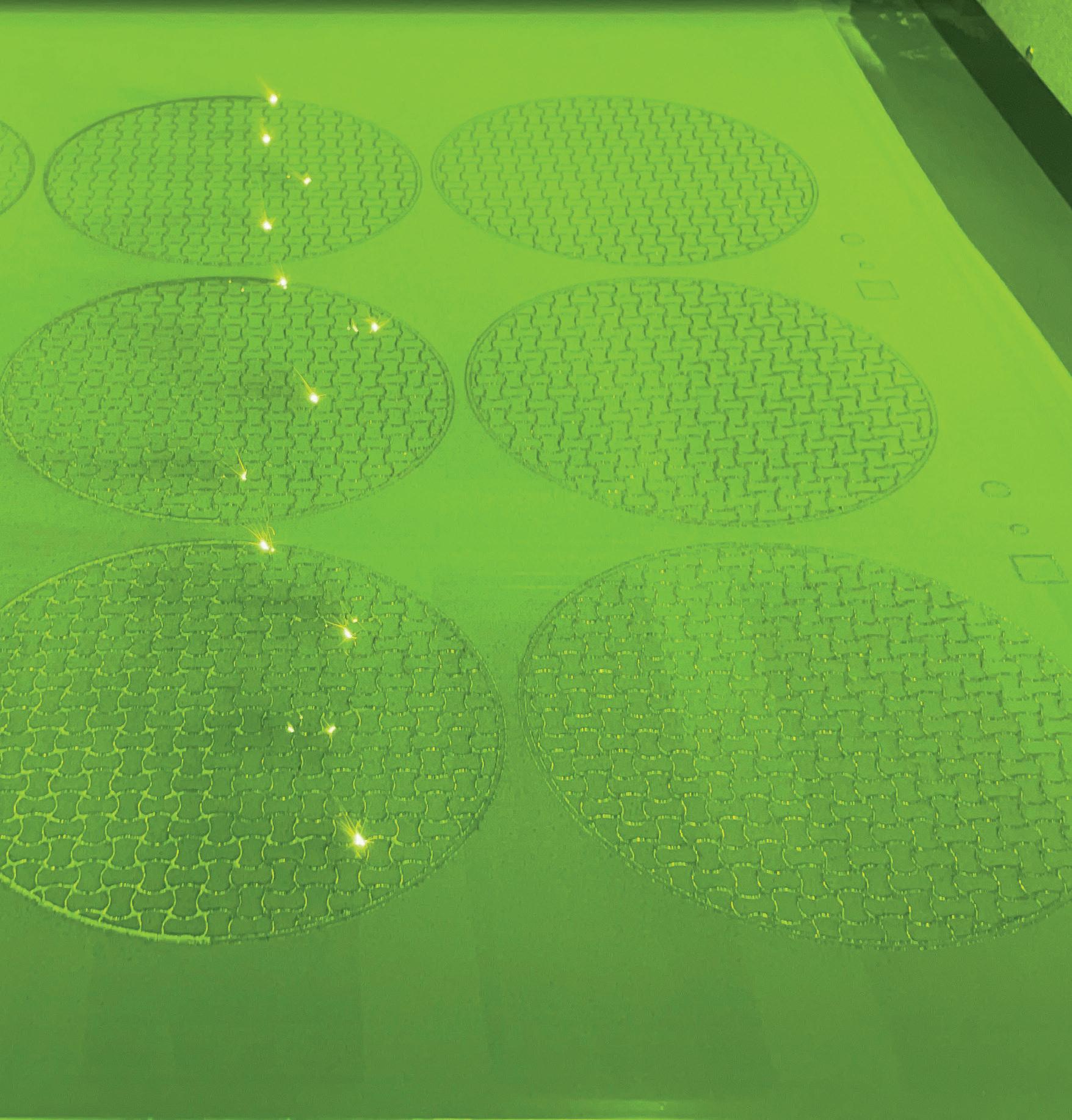

Streamlined solutions

SLM Solutions Group AG (SLM) is a publicly traded company headquartered in Lübeck, Germany. As an inventor of the selective laser melting process, the company focuses on the development and distribution of the most innovative, production-oriented metal Additive Manufacturing (AM) systems.

A leader in product performance and innovation, the SLM team utilizes its engineering facilities around the world to foster collaboration on metal AM projects and help scale its use in production. SLM provides consultation, installation, maintenance, and training opportunities for customers to harness the capabilities of selective laser melting.

It has been just over 20 years since the organization released its first product. As Sam O’Leary, CEO, explains: “We are relentless innovators at heart. We continuously focus on industrializing our technology and making it more productive. That is essentially what will drive the future of additive manufacturing. While 3D printing has a million and one benefits, in reality, unless you can do it cheaper and better than the existing method, it’s not going to be adopted. That is what we have been pushing year after year.

“We are getting to a point where more and more industries are moving away from traditional casting, forging, and machining towards our technology. In fact, some of the

How SLM Solutions is enabling and changing the future of manufacturing

SLM Solutions 40

manufacturing-today.com 41

tragic or disastrous events in the world can be catalysts for growth. From geopolitical events to Covid-19 and the energy cost crisis, events have the capacity to be huge growth drivers. As our process is a great deal more energy efficient than traditional processes, these short-term headwinds can manifest as longterm growth strategies.”

The business offers one of the widest ranges of 3D printers in the market place. From build

plate size to complexity, SLM’s offering sets it apart from the competition. “We take the benefits of additive manufacturing and strive to make it more productive and more reliable. It’s very difficult to have multiple lasers working on one build plate, and that is one of our key differentiators. We launched and now deliver a 12-laser system. Most of our competitors are still trying to get into the market with a four-laser system.”

With a global workforce of 570 people, nearly half of whom are engineers, SLM prioritizes harnessing this expertise to improve its solutions. Over the last two years, the business has grown its R&D and technology staff, and invested approximately 20 percent of its revenue in R&D, and will continue to do so as the business grows.

“We examine trends in technology, and the needs of our customers, to target innovation and streamline solutions. Our 12-laser system is more of an example of a technology push rather than pull, as many of our customers were not aware that it was even a possibility,” says Sam. “We are going through our 2023 budgeting process now. We currently have

42

125 people working directly on new product development. With our myriad ideas, we could easily have twice that number in the next year. We have a young team, full of fantastic ideas, and our business is at a great size where we can balance innovation within the structure of our technological capabilities. This a real sweet spot for us, and the future of what we do. It’s really the DNA of the business, and the one thing in my position, as CEO, that’s closest to my heart.”

Despite 80 percent of the workforce being based in Northern Germany, SLM employs 32 different nationalities. Working times are flexible and with many employees starting to have families, hybrid and remote working are increasingly popular and appreciated. Sam endeavors to foster a flexible culture that enhances creativity. “If an employee has a mental block during the day, they can go and take a break, play table football or pool.

No-one questions it. We are proud to have a culture of openness, as well as a questioning mindset. Flexibility is key, innovation is a driver and everyone contributes to and questions rationale.

“We also host events and get-togethers for our employees and their families. Many people don’t get to show their families or children where they work. We produce parts across the

“ “

We are proud to have a culture of openness, as well as a questioning mindset

“ “

manufacturing-today.com 43 SLM Solutions

broadest spectrum of industries; from space travel to locomotives, from f1 cars to busses, from hip implants to aircraft landing legs: these are just some examples of the exciting end products of our day-to-day operations and its really incredible for our teams’ families to see just how cool that is!”

SLM’s focus on technology also drives the corporate attitude to sustainability. To SLM, sustainability is about much more than automatic light switches or solar panels. Sam explains: “We make what is needed, when it’s needed, using only the necessary material. There is a

knock-on effect further down the supply chain too. This is the exciting part about sustainability to me, changing the whole manufacturing methodology, using less energy, and then, the end-use application again using less energy. Every single aspect of it is driving a better future for the planet, and that is what I prefer to focus on.”

To reinforce this vision for the future of manufacturing, Sam is excited to discuss the company’s recent acquisition by Nikon: “First and foremost, this is a marriage made in heaven. Like us, the senior leadership of Nikon also comprises engineers. We have made great progress as an independent business, pushing our technology to the limits, but what this gives us is another level of possibilities to really drive the future of our technology.

“I have been through a few acquisitions in my career. Normally, there’s a level of nervousness in the team, but we don’t have that. People are just excited by the opportunity. While most people have an awareness of Nikon’s heritage, many don’t appreciate the sheer scope of its work. We are combining our experience, research and development capability to push opto-electronics to the next level. This is essentially what our technology is built around: the capability to harness, direct, and utilize energy. Quite what that will mean for our products, and customers, is something that we will work on together.”

The business was also excited to showcase a new product at the recent AM industry’s main

44

trade show, Formnext, as Sam explains: “This is a game-changing piece of technology and heralded as the world’s biggest metal 3D printer. We were able to show potential customers how this innovation could support them in certain applications, and how our technology profile is continually evolving.

“Moving forward, we will continue to aggressively deliver more of our 12-laser machines, and set ourselves up for a significant increase in output in 2023. On top of that, we will continue to recruit and make the team stronger. I think we have recruited more than 100 people in the last 12 months already. Cherry-picking new recruits to build a young, dynamic, fantastically diverse team is one of the nicest things about this job,” enthuses Sam.

While Sam is proud that the business has delivered on its key milestones to date, as part of its five-year plan, he highlights that this is not really the basis for what makes the organization successful. “We are changing the way the world manufactures. From aerospace to energy to automotive and way beyond, we are instrumental in the shift away from traditional to additive manufacturing. Right now, perhaps twoto-three percent of the world’s metal components are produced by AM. This is perfect for us in terms of having a niche market. However, we see a world where we are constantly moving towards five, eight, ten percent which heralds an incredible change in the scale of this business. Not only is it an advance in technology utilization, it also means the world is able to do more. Designs can be more creative, fuel can be saved in every application and we can help align manufacturing with the needs of today’s world. Our strategy is based around exactly that, enabling and changing the future of manufacturing,” he concludes. ■

www.slm-solutions.com

manufacturing-today.com 45 SLM Solutions

46

A CUT ABOVE

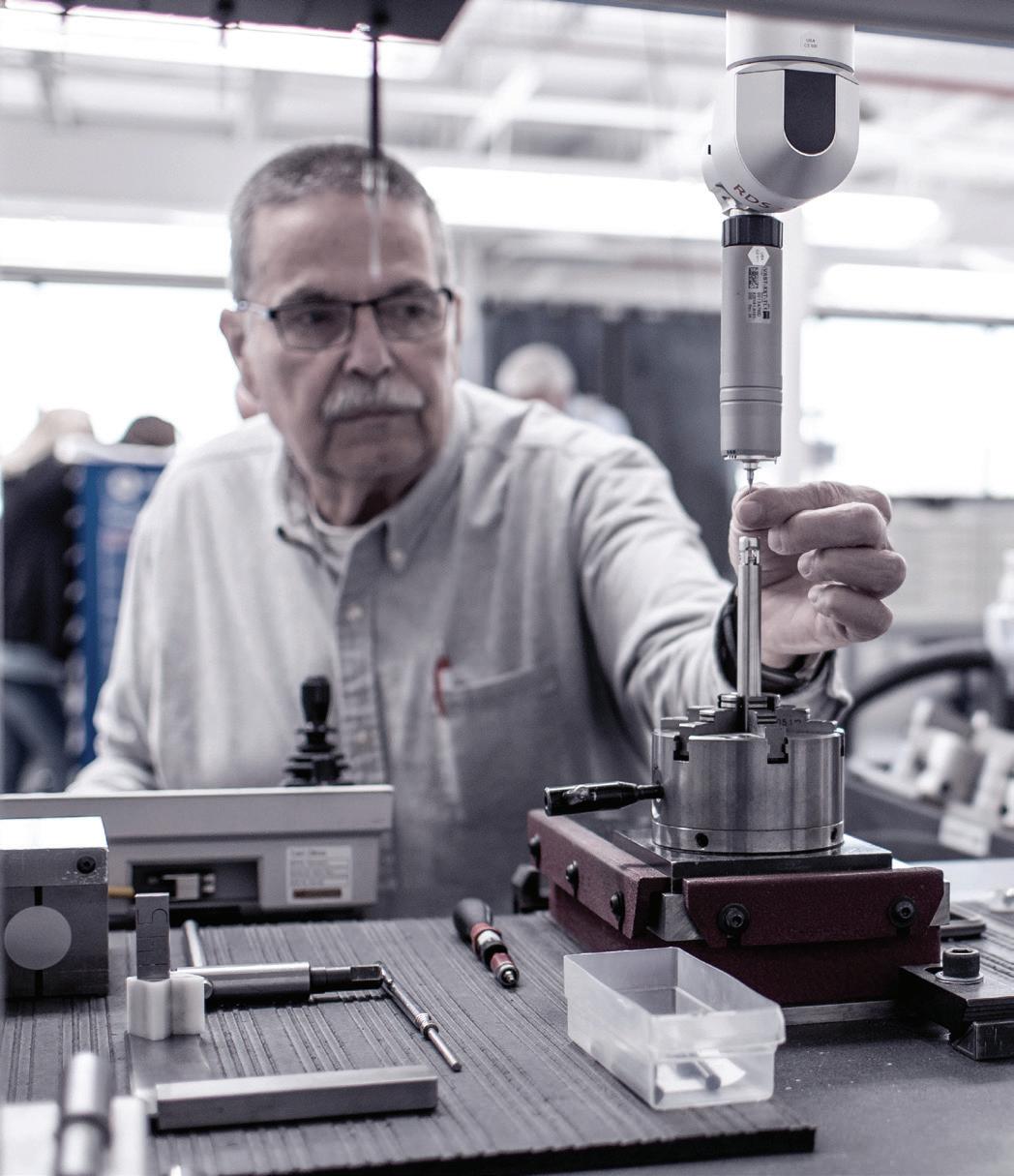

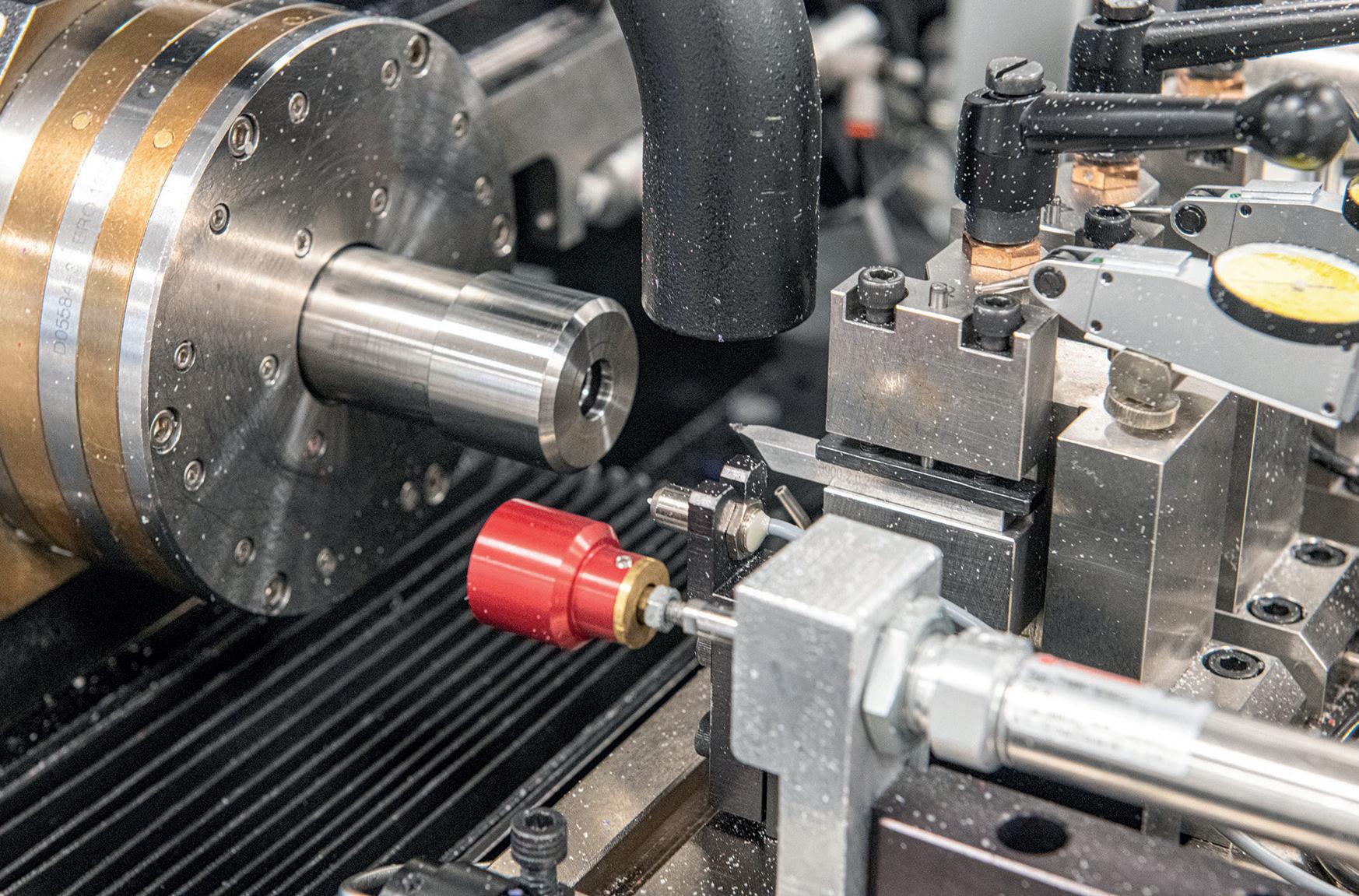

Get to know NCMT – the UK-based distributor of Japanese-made machinery

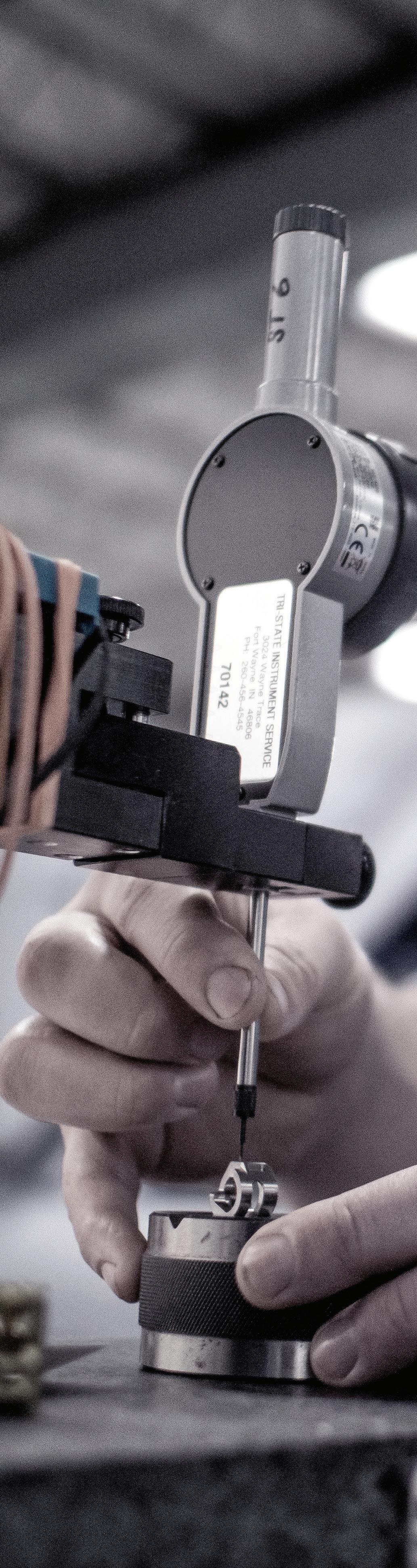

Established in 1964, NCMT offers high technology machine tools and bestin-class engineering solutions for metal cutting and grinding applications. Though its history is old, the latest iteration of the company is relatively young: a management buyout took place in March 2020, which was, from this privileged place of hindsight, remarkable timing for those walking into their new positions.

Recently, Manufacturing Today sat down with two of NCMT’s latest owners – Jonathan Smart, Managing Director and Ian Horton, Sales Director – to reflect on the last two years as well as the bright future that is evidently ahead of them.

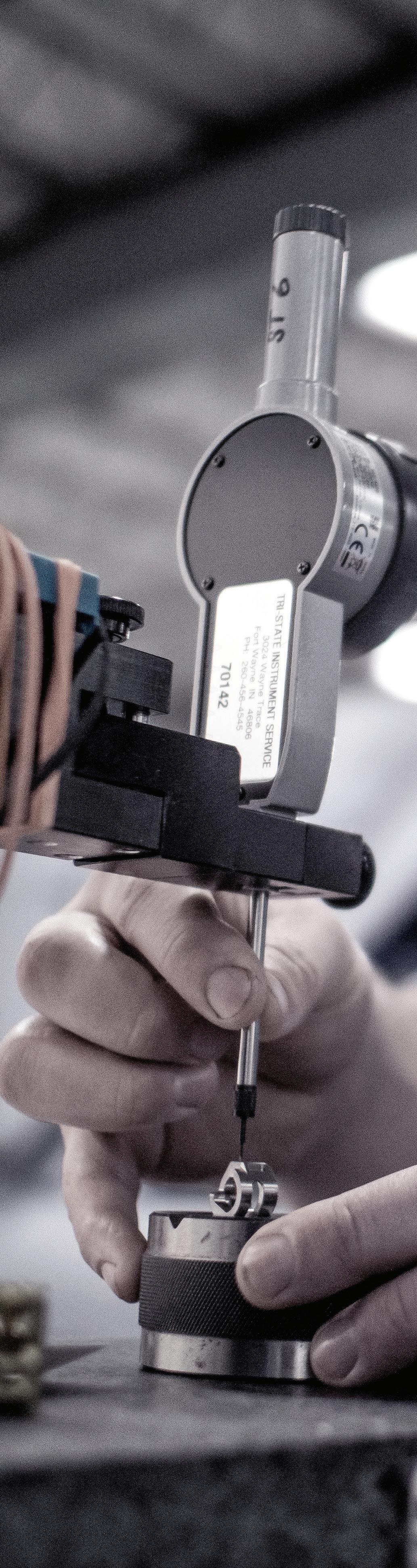

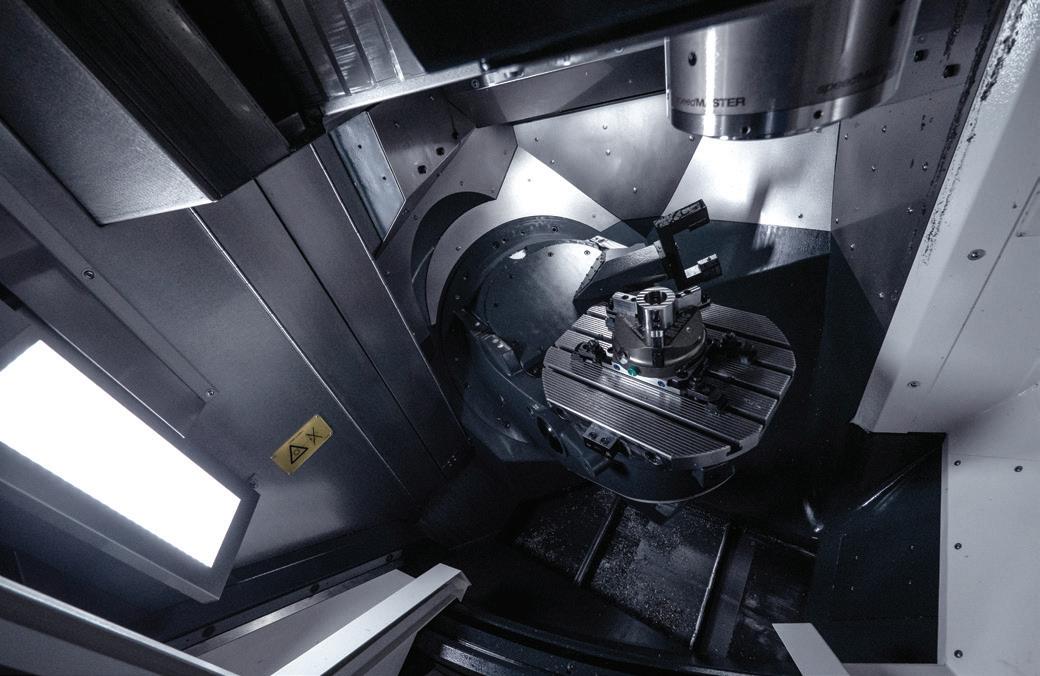

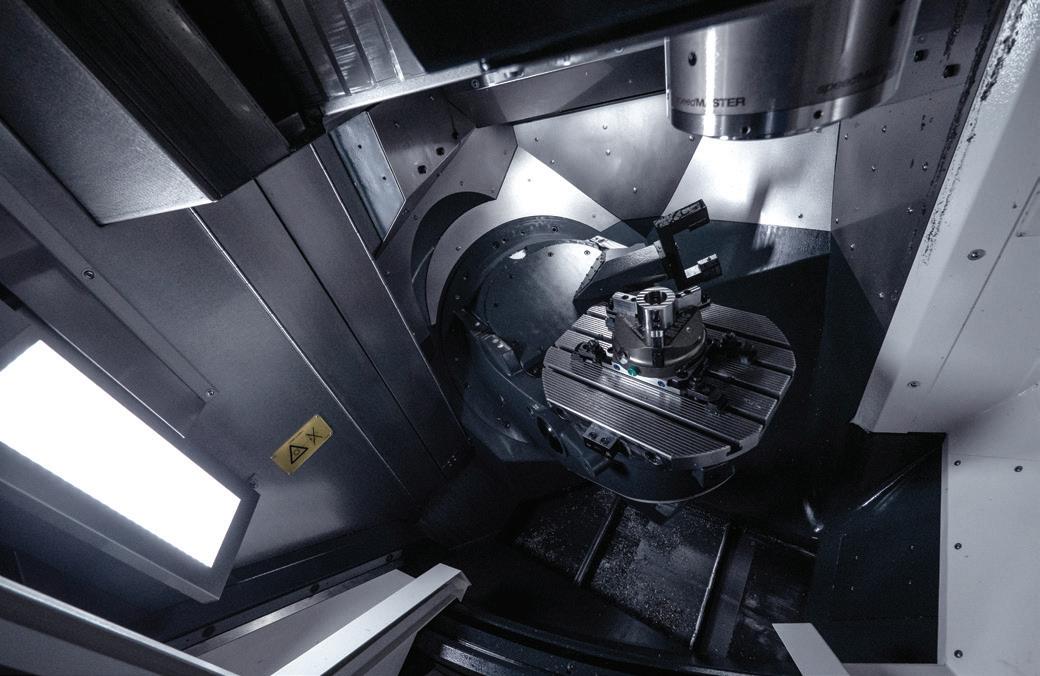

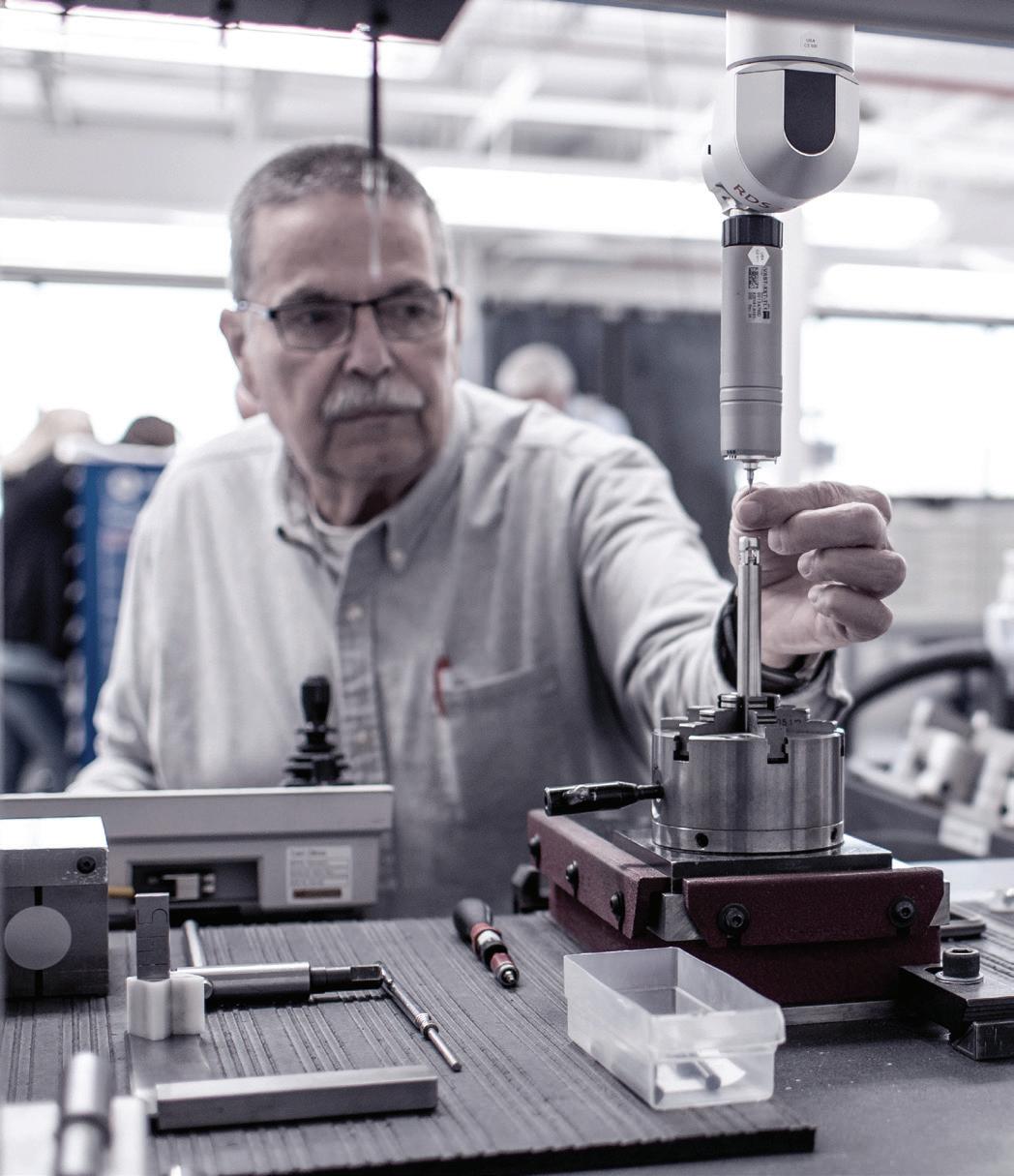

As an innovative leader within a recognized niche, NCMT is specialized in demanding fields of engineering – fields from which, according to Jonathan, many other machine and tooling suppliers shy away. “Japanese-built machines are the best in the world, and we have the two premier brands in our stable: Okuma and Makino,” he begins. “That is where we are, and that quality and diversity of product firmly separates us from our competitors.

“Moreover, with nearly six decades of company experience, we have an incredible range of technical ability and a fantastic engineering team who are able to support us at all times,” he continues. “The new directors, myself and Ian included,

NCMT manufacturing-today.com 47

are not new to any of this, either. We have demonstrated an enthusiasm for the product – and the company as a whole – and between us have clocked up many decades at NCMT.”

“Indeed, it has not been a typical buyout, where someone just walks into the business and decides to make a load of changes,” adds Ian. “There is still the history of the company here; our idea is to maintain what NCMT has done for its customers in the past, while also taking the business forward. We have our own fresh ideas and approaches to various tasks, so it will be the same NCMT for customer service, but hopefully with some improvements as well.”

Along with aftersales support, including but not limited to training, back-up, technical expertise, and responsive engineering aid, NCMT’s 100-plus-strong team has carved out a robust reputation by delivering a world class, tried-and-tested product. As mentioned previously by Jonathan, NCMT distributes two primary brands: Okuma and Makino.

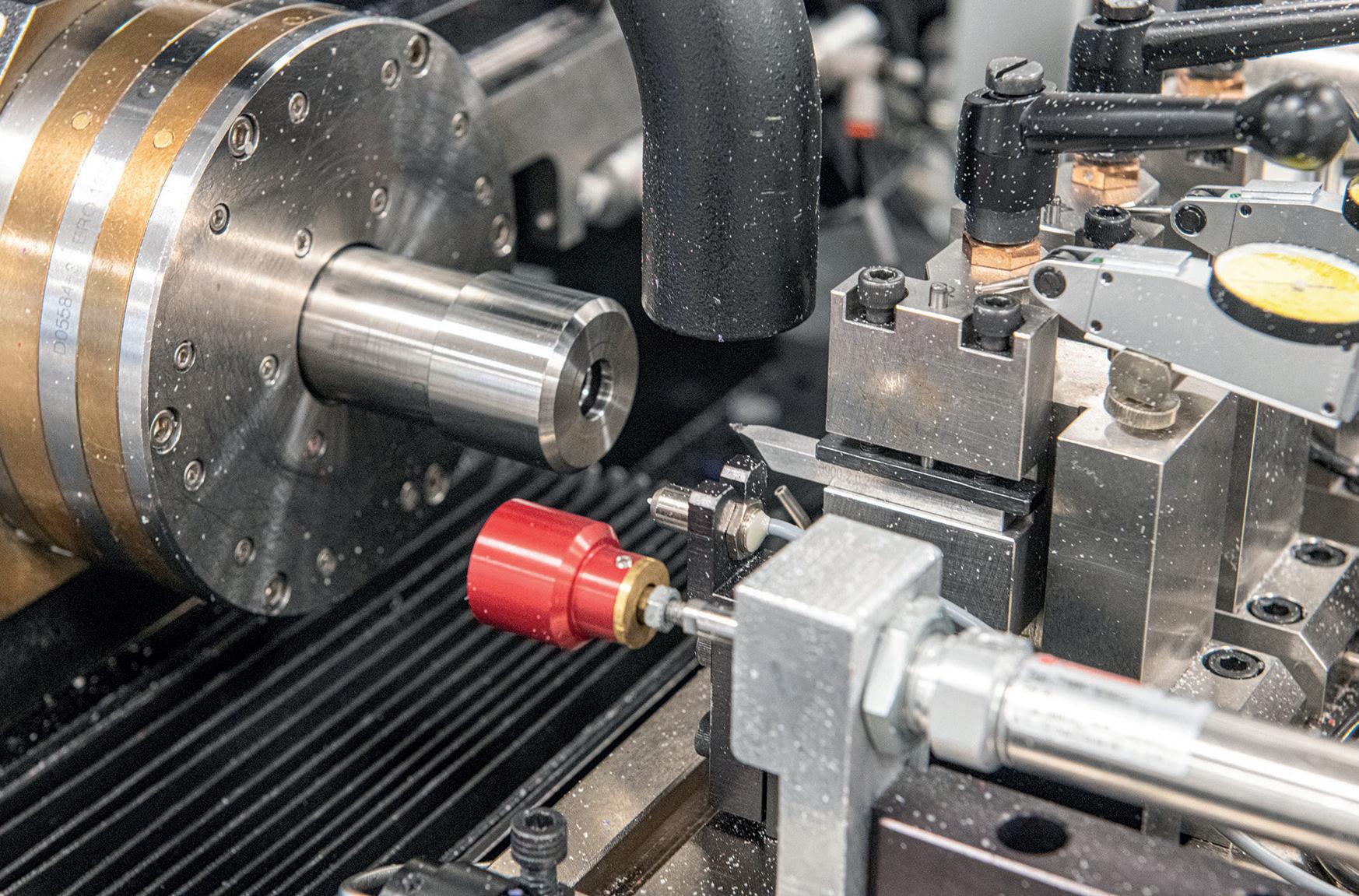

The former range includes turning (single, twin, and triple turret), multitasking (horizontal and vertical lathe), milling (five axis and double column), grinding (internal and external), additive, and automation (automatic pallet changers and ROID Series) machines. The latter includes milling (horizontal 4 and 5, vertical 3 and 5, and graphite milling), grinding (G5 and G7), and EDM (sinker, wire, and hole drilling) machines. Between the two technically superior brands, NCMT has every customer covered when it comes to metal cutting and grinding processes.

“From an automation point of view, the build and quality of these machines is integral,” explains Ian. “If a machine is going to be running 24-hours-a-day in a production environment, then it needs to be reliable. Fortunately, the machines manufactured by Okuma and Makino that we stock are the best in the industry.

“ “

If a machine is going to be running 24-hoursa-day in a production environment, then it needs to be reliable 48

“ “

“Recent investments, moreover, take these machines even further,” he adds. “Okuma and Makino are always looking towards the future in what they do; however, more specifically, from the Okuma brand, we are talking about the world’s only singlesource machine tool. Put simply, that means almost everything on an Okuma piece of kit is built by Okuma; the company is at the fore of technology because it does not rely on the ability of external suppliers or third parties. If something new in the industry comes out, then you can bet it has been Okuma leading the way from the front –other companies tend to merely follow.”

However, that is not to say that NCMT simply passes on these high-end pieces of technology to its customers. In fact, as Jonathan informs us, the company has been directly involved on a technical level with Makino in the development of new products.

Kyocera SGS

Kyocera SGS Precision Tools Europe (Kyocera SGS) is proud to have been working with NCMT for over a decade on a multitude of challenging projects in both the aerospace and medical sectors. By working in close partnership with the NCMT engineering team and their customers, Kyocera SGS has been a key component in the success of its most demanding milling projects.

Our solid carbide special tools, created using unique geometries, coatings and tooling solutions, combine to deliver the high quality and reliability of component production for which NCMT machine tools are renowned.

As we move into 2023, we are developing new process strategies and specific tooling with NCMT to cement our relationship and continue the tremendous success achieved in delivering our customers’ goals.

manufacturing-today.com 49 NCMT

“The Makino Viper G Series was developed in a collaboration between NCMT, Makino, Rolls Royce, and Tyrolit, a grinding wheel manufacturer,” he reveals. “There was a gap in a the market since Rolls Royce needed a new machine, and the brand came to NCMT so that we could have Makino develop an appropriate piece of kit for a new range of products. We acted as a driving force on that project.”

Relationships are key in any trade. A strong bond between company and external supplier, vendor, customer, and commercial partner ensures success on every level. With NCMT, it is no different.

The company has, for instance, worked with Makino since it opened its doors in 1964 – long before the Japanese firm’s European or North American divisions even existed. “Internally, when we go to Makino meetings, we are referred to as Makino NCMT, even though we are actually two completely separate businesses,” reveals Ian. “That just goes to show how strong the relationship is.

“Likewise, from an Okuma point of view, we have been working with the brand since 1976, and also have a very long-standing, highly productive relationship with the team over there,” he goes on. “It was only recently that we were sat down with the President of Okuma Japan and the President and Vice President

of Okuma Europe. Indeed, these are not flyby-night relationships; rather, they are living, breathing, collaborative partnerships that are built on trust and best-in-class engineering. Decades of work attest to as much.”

The wheels are firmly in motion at NCMT. Following the buyout in early 2020, the company has got through the pandemic (in all its various waves) and come out the other side arguably stronger. Most recently, for instance, the company has moved into a new facility in Leatherhead, Surrey.

“Having been located at its previous facility for 41 years, it is safe to say that it has been all hands on deck since the move,” details Jonathan. “We had to clear out four decades worth of stock: some was very old! Unusually, we have taken on a smaller facility. Our previous location was our sole site back when we first arrived; however, today, we have more than one, so we are adjusting accordingly. From a showroom standpoint, we have now started to upgrade our primary location in Middlemarch, Coventry, which was built 22 years ago. So, again, there has been lots to tidy up and modernize!”

As our conversation draws to a close, we begin to talk about the future. For Ian, there is nothing like the endless opportunities that are afforded by strong sales and continued growth. “We have had an incredibly good start to the financial year, and I want that to carry on as we look ahead,” he says. “If we continue to grow both the Okuma and Makino brands, then we will be able to achieve that. However, we will then need to match that growth by expanding internally, meaning more salespeople to keep the momentum going. We want to bounce back to pre-pandemic figures, and we can firmly say that we are on the right track to getting there.” ■

www.ncmt.co.uk

“ “

...we are on the right track to getting there

NCMT manufacturing-today.com 51

“ “

52

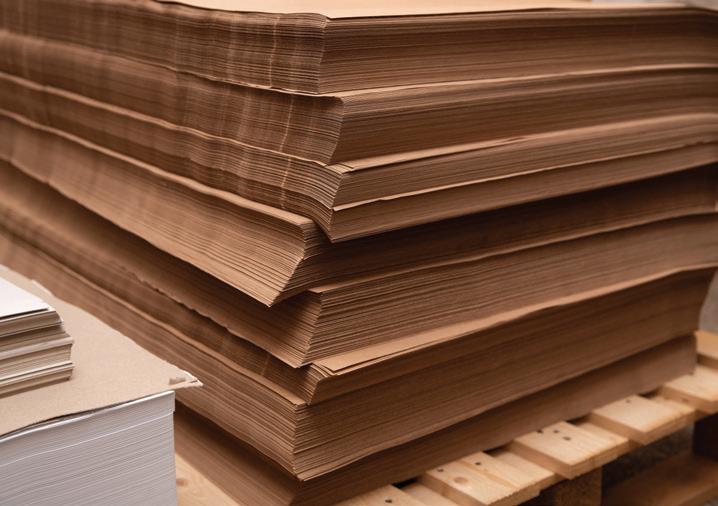

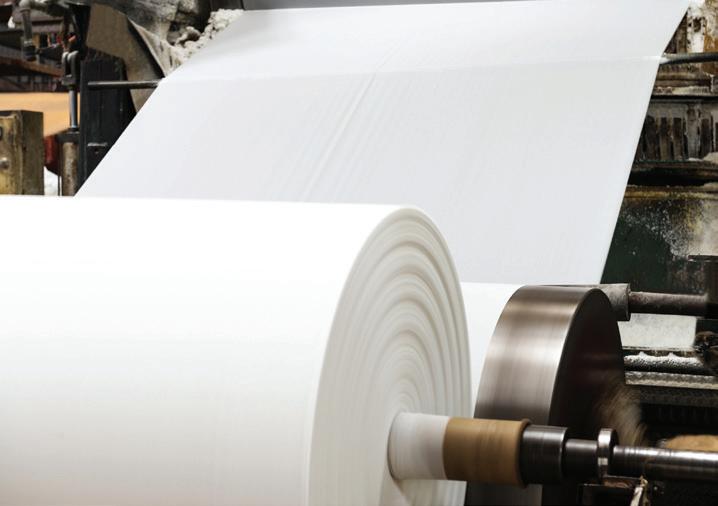

MANUFACTURER PROCESSOR MERCHANT All images copyright holder: © Gerald Lampe, foto:hölzen GmbH

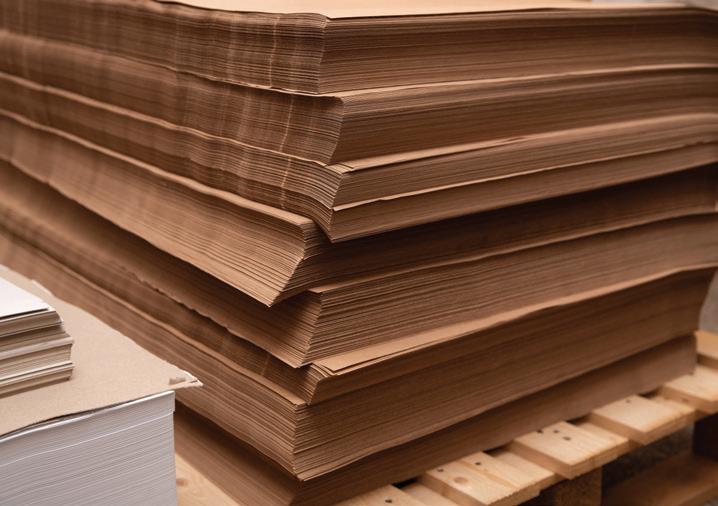

The ladder of growth that Zerhusen Kartonagen (Zerhusen) has climbed, since the breaking of ground at its first site in 1986, is as natural as its mainstay product’s original form. Over the last 35 years, the family-owned company has progressed from a merchant to processor, and now, manufacturer, making its way, step-bystep in the corrugated cardboard industry. It was founded by Günter Zerhusen on 1st January 1987 in Damme, Germany – with nothing more than a tight-knit team of three people and an 1800-square-meter operations hall. From these humble beginnings, the current enterprise now employs 675 people, and this year, has generated €175 million.

Zerhusen Kartonagen’s 35-year history of organic and monumental growth, in every direction

▶ From left to right:

Günter Zerhusen

Robert Zerhusen

Zerhusen Kartonagen manufacturing-today.com 53

Linda Stärk Roland Zerhusen

From its earliest days, themes of innovation and constant expansion have threaded through its story.

Within its first five years, whilst operating as a merchant, the company built a further three halls, a workshop, a dispatch center with an ever-growing fleet of vehicles and vastly expanded its workforce. During this period, Zerhusen also started to implement its own form of processing. The company was able to obtain largeformat, corrugated cardboard from other businesses for free, in the form of return boxes or goods from insolvency estates that would otherwise go to waste. It would then cut these down

using a bandsaw and sell them on for a profit – proving to be a very lucrative addition to the model.

Major evolutions

In 1993, Zerhusen purchased its first large-scale processing machine, which marked its progression into a processor. From this point onwards, the company started buying in raw corrugated cardboard that it could process into finished packaging and, due to the existing customer base, it was able to go straight into production. The following decade saw further growth and reinvestment in the forms of two more production lines, an entire product-development department, three more operations halls, a vast range of new equipment and even an early recycling initiative. The purchase of a new Paal paper press allowed the company to reuse what would otherwise have

“ “ . . . the team was achieving around 250,000 square meters of corrugated cardboard per day “ “ 54

Zerhusen Kartonagen manufacturing-today.com 55

been disposed of as paper waste – around 300 tons per month. This waste, which is a byproduct of the production of finished packaging from corrugated carboard, could now be repressed into corrugated raw material and used again.

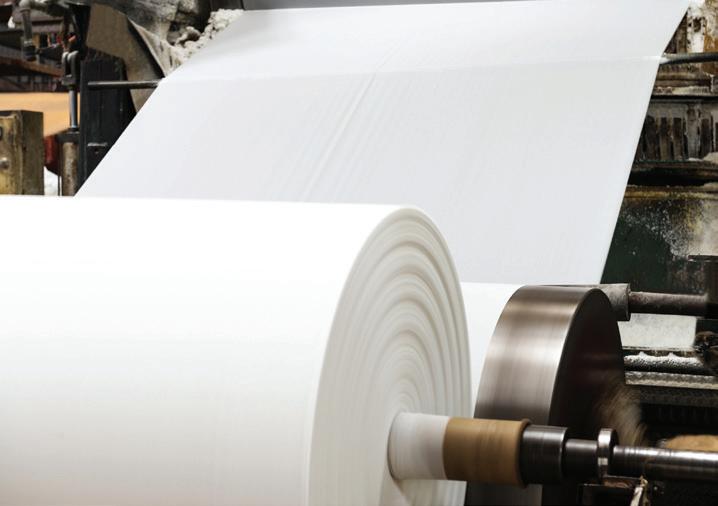

The final milestone came 13 years later, when Zerhusen climbed the next step and became a manufacturer. 2016 was a significant year, despite the numerous other extensions, technological advancements, and construction of the fully automated high-bay warehouse that preceded it. It marks the implementation of the company’s initial corrugated board format plant, a 17,000-square-meter structure that cost around €33 million. Within its first month of

operation, the team was achieving around 250,000 square meters of corrugated cardboard per day. Although impressive, this pales in comparison to the company’s output capabilities today. Zerhusen’s contemporary product range features a succinct collection of services: the production and processing of corrugated board, the development of packaging designs, quality management, warehousing and transport and logistics.

Welcome ‘Vicky’

In speaking to Robert Zerhusen, Production Director of Corrugators, he explains: “Our processing plant has continued to grow in recent times. This has been a necessity, on account of the extreme pressure

56

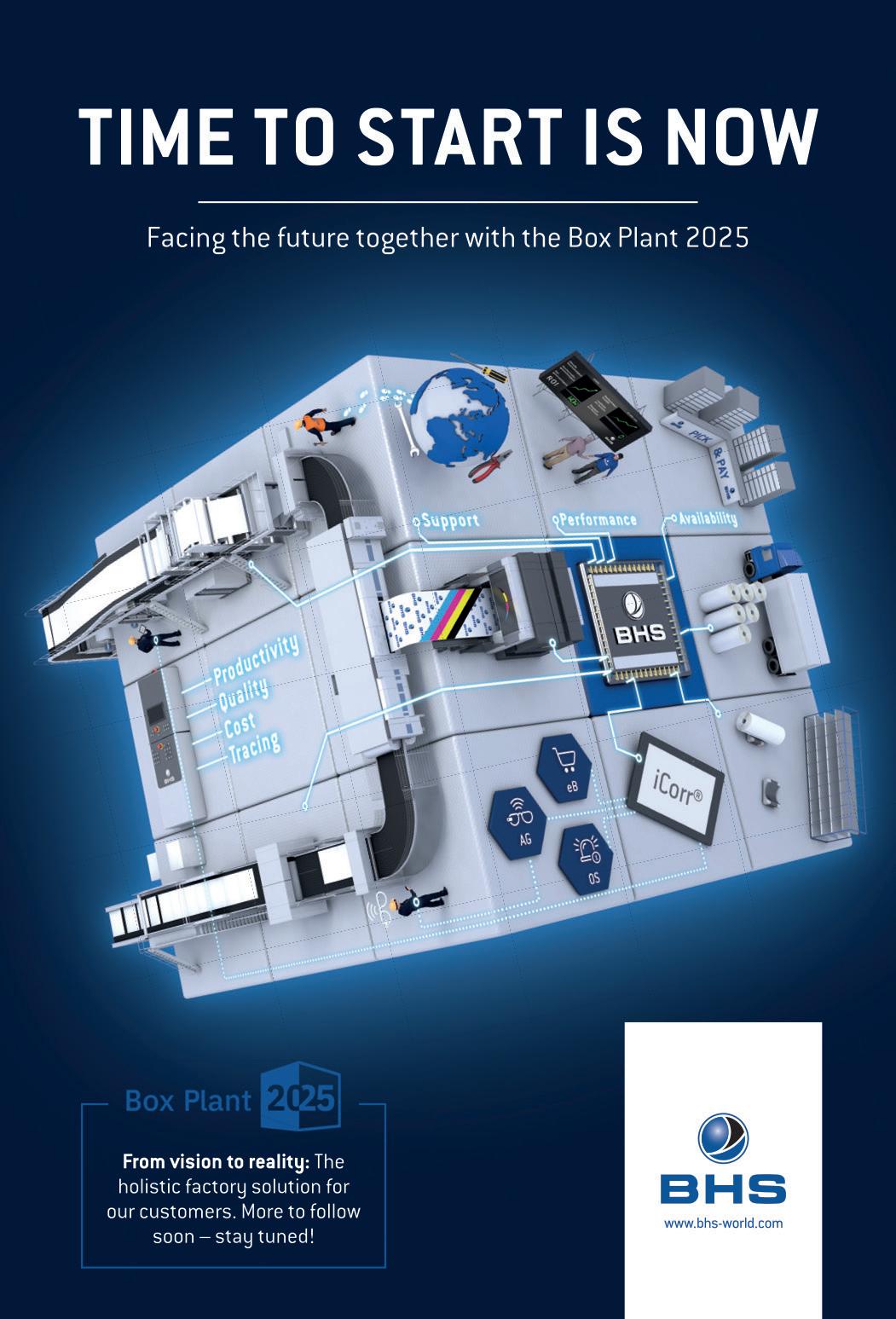

that our initial corrugator has been under during the last couple of years. We’ve been required to implement weekend shifts and overtime in order to keep up with the demand for corrugated cardboard. This has placed a great deal of stress on both our machines and our employees and doesn’t fit in with our working culture. So, we made the decision to order our second corrugator, ‘Vicky,’ in March 2021. It’s a Speedline from BHS Corrugated with a maximum speed of 450 meters-per-minute, which has enabled us to guarantee greater production capacity. Besides the additional features the newer model carries, its implementation means that overall, theoretically, we can now produce 500 million square meters of corrugated cardboard.”

Family focus

The second corrugator only represents a fraction of the €100 million, five-year investment plan that started in 2018. It has also seen the construction of a second highbay warehouse in 2019, a new development center in 2020 and another projected plant for 2023. Due to its physical size, technical equipment and processing volume, Zerhusen is now in the top three largest corrugated board plants in Germany, but that doesn’t mean it’s lost any emphasis on the importance of its people. Linda Stärk, Commercial Manager, says: “Our main goal as a company, is to provide a stable working environment for our employees. We want them to be happy when they come to work, as we want our suppliers and customers to be happy to work alongside us. It takes something a little more special to survive in today’s competitive market.

“For us, the employees are the heart of our company. We are a family-owned business and vow to keep it that way,” Linda continues. “Even if we have over 650 employees, we still try to maintain the family spirit in our daily working

“ “

lives. Communication is key and it works both ways, we must listen to our team members in order to understand their ways of working or hear the improvements or new ideas they bring to the table. We try to ensure that everyone has an opportunity to lead across our different programs, to

We place the utmost importance on our supplier relationships.

We believe in long-term relationships as they bring the continuity that we require from our vendors Zerhusen Kartonagen manufacturing-today.com 57

“

“

give people a chance to develop themselves further. Beyond this, we offer a number of financial benefits and support systems for our teams, complemented by the company events that we host to strengthen our team morale and family spirit.”

In terms of supply chain working relationships, Roland Zerhusen, Chief Executive Officer, says: “We place the utmost importance on our supplier relationships. We believe in long-term relationships as they bring the continuity that we require from our vendors – but we understand it’s a two-way street. We are always keen to continue working with the same people, especially when it comes to sales consultants, and we vie to grow alongside our partnered companies as we do our customers. It’s all centered around being a

family company, which empowers us to concentrate on our practices in manufacturing, production and logistics.”

New site

Back in October, the team-family was bonded closer together by working towards and achieving a world record –which has subsequently been broken. Within an eight-hour shift, the team managed to produce 196,299 meters of corrugated cardboard. This thenrecord-breaking run on ‘Vicky,’ the 2.8-meter-wide corrugator, had no downtime and managed to maintain an average speed of 408 meters per minute, as well as a top speed of 452 meters per minute. A total of 545,933 square meters were produced, a surface area equivalent to that of 70 football fields, using 195 tons of containerboard.

58