Interview Jamie Gentoso on her career, Holcim, and what’s coming next

Communication

Technology

Fleet management software and its impact across operations

Is digital technology the future of the construction industry?

Interview Jamie Gentoso on her career, Holcim, and what’s coming next

Fleet management software and its impact across operations

Is digital technology the future of the construction industry?

From bins and shelving to optimized mobile storage. From manual order picking to fully automated systems. All our products are modularly expandable, even to multiple floors. Our range includes the most diverse racking systems, which are fully tailored to your needs. Our experts have extensive experience in various industries. Make an appointment and discuss the possibilities for your warehouse equipment.

ssi-schaefer.com

ssi-schaefer.com

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Director Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Daniel Baksi, Alex Caesari, Danielle Champ

Editorial Administrator Amy Gilks

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork Administrator Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors

Philip Monument, Joy Francesconi

Head of Content Management

Adam Blanch

Client Sales Executives

Chloe Allman, Mark Cawston

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell

Content Managers Johanna Bailey, Mark Cowles, Jeff Goldenberg, Wendy Russell, Richard Saunders, Kieran Shukri

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Hello and welcome to the November issue of Construction Today. I was thrilled to be able to pose some questions to Jamie Gentoso, President, Holcim Building Envelope and Global Head, Holcim Solutions & Products for this issue of Construction Today. Not only very passionate about reducing the impact of the built environment, and keen to share Holcim’s journey to net zero, Jamie also holds a unique perspective as a woman in a traditionally male-dominated industry. “I want to inspire young women to understand their potential in this industry,” she says – in a sector struggling to attract workers in general, Jamie is keen to sing the praises of construction and its opportunities. The full Q&A is on page 8.

LH@finelightmediagroup.com

© 2022 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

US Office

2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

Cement Company of Alabama. He discusses the NCCA’s growing emphasis on decarbonization, and the strategies it is implementing to ensure a greener future. Find out why on page 46.

Kaufman Lynn 64 72 Hillpointe, LLC

JD Beam 78

Sunworks 88

Kaufman Lynn 64 72 Hillpointe, LLC

JD Beam 78

Sunworks 88

Nexii Building Solutions

Nexii Building Solutions

Let’s start with some more information about you:

First off, I’m a wife and a mother with kids aged 13, 11 and 10, and I know we have an opportunity to leave them with a better world. By training, I’m a civil engineer and have worked in construction materials my entire career. I love the industry and see that it has so many opportunities for those who are ambitious, hardworking and who want to make change.

Early on in my career, I learned about the tremendous impact the built environment has on the earth, both in the manufacturing of the building materials but also throughout the use of the building’s life.

I’m passionate about working to build better with less, and to reduce the overall impact of the built environment. Two of my strongest traits are my ambition and competitive spirit. They both drive me because I love a challenge, and I love to conquer it even more!

Do you have any experiences as a woman working in construction that you could share?

Initially, I tried hard to fit in and be ‘one of the boys.’ I was often the ‘only’ in the room, and it took me some time to find my voice. Finding the courage to stand out can be difficult for anyone, but I found I had to push myself to speak up or take my own seat at the table. It paid off because I was able

to voice a different opinion while also adding value. Now, I want to inspire young women to understand their potential in this industry. This industry is open to everyone, regardless of sex, ethnicity, background, etc. I believe our differences can make us stronger, and the sooner our industry is more representative, I’m convinced we will be more powerful and build even better!

The industry needs to find ways to attract workers in general - we face real issues in attracting talent in all areas of the business, from skilled trades to the back office. I take any opportunity possible to get in front of young people and sing the praises of the construction industry and its opportunities.

Appreciating staff and acknowledging the efforts of your team is important to you – how does that translate into your day to day work at Holcim?

Like any business, our people are our most fundamental and important asset. Our success is dependent on having the right people in the right places. Our teammates should feel motivated and excited by the work we’re doing, and feel like they are part of building a positive culture. As a leader, my role is to share our vision, align on our shared purpose and make sure everyone is working toward the same short- and long-term targets.

We underwent a rebrand this year - transitioning Firestone Building Products to Holcim’s Building Envelope Division and transitioning the Firestone roofing, wall and lining systems brand to a new brand name, Elevate.

Holcim Building Envelope is our new center of excellence for roofing, wall, lining and waterproofing solutions for commercial and residential customers around the

world. And Elevate symbolizes Holcim’s continued commitment to deliver superior quality and innovation with advanced building solutions. I am laser focused on bringing more solutions into our portfolio through both organic innovation and through mergers and acquisitions. The goal is for the Holcim Solutions & Products business unit is to generate more than 30 percent of Holcim’s revenue by 2025, and we are well on our way.

What are you working on at the moment?

If we start using lower-impact cement, the environmental footprint of the whole concrete (and construction) industry changes dramatically

“

“ “

Holcim is supporting The White House’s Buy Clean efforts – can you tell me more about that strategy?

We are working hard to make our products eco-friendlier, but we need help from our policymakers. The U.S. federal government is a huge procurer of goods and has the power to change markets. The Buy Clean commitment to sourcing low-carbon products will enable Holcim to invest in American manufacturing, help launch new low-carbon products and

help us build the future for people and the planet. We also work closely with our local governments to try to help them understand that ‘buy clean’ is completely necessary. While government buy-in is one of the pieces, manufacturers must also make upfront changes to their businesses.

One of the main complaints about ‘green’ products is that they cost more. Part of this issue is that they are currently only niche products and until they are in higher demand and utilized en masse or in the mainstream, it will be difficult to lower their costs. It will take manufacturers making bold moves, having the courage to defy demand and only producing low(er) impact, green products. I mention this because Holcim did just this in the cement market, moving production over the last year over to lower impact Type IL cement despite a lack of demand. We need to be leaders and do our work to move markets at the same time we work with our policymakers.

In terms of investments, they are completely in line with our purpose to build progress for people and planet.

How can the industry encourage more construction companies to look for greener concrete alternatives? What is holding them back (if anything)?

To be most efficient, cement plants run 24 hours a day, seven days a week, and typically have only one or two shutdowns per year. Buildings are responsible for 38 percent of the world’s CO2 emissions - it’s clear we need to build better. Concrete has to hold up to an 80-story building, span miles over canyons or hold back millions of gallons of water, and

specifiers have a hard time changing a product that has been standing the test of time for hundreds of years so efficiently - but it can be done. People fear change, but the outcome of not changing is worse. If we start using lower-impact cement, the environmental footprint of the whole concrete (and construction) industry changes dramatically. We need to accept that the concrete of yesterday will not, and cannot, be the concrete tomorrow.

What do you envision we will see from Holcim in the coming 12 months?

It’s an exciting time as we’re finally starting to see changes in how the construction industry prioritizes our

sustainable future. We’re growing quickly, but we only invest in businesses that are committed to this cause – like those businesses we acquired this year.

We’re amidst innovative R&D projects to replace materials that can be scarce and/or have high environmental impact.

At the end of the day, we’re focused on our customers. So we have many projects in progress that make our customers’ jobs easier, faster, and ultimately, reduce labor. This will include unique advancements in insulation and even transportation, focused on lower costs and higher efficiency.

Finally, we’re heading to net zero! While 38 percent of global CO2

emissions come from buildings, 70 percent of that is from the life of the building and 30 percent comes from the building material. Urbanization and population growth will continue driving these numbers if we don’t make changes. We have the possibility to improve that 30 percent with low-impact products, and we can also affect the other 70 percent by considering the full building envelope and using more efficient materials. My division is precisely focused on bringing these types of solutions into Holcim’s portfolio, while continuing inorganic growth through mergers and acquisitions.

It’s worth noting we were one of seven companies globally that had our 2050 roadmap verified by SBTi (Science Based Target Initiative). As the name implies, our sustainability goals are based on science - it’s not just advertising. We have also put our money where our mouth is and have sustainability-linked financing - targeted at 40 percent by 2024 - and have also linked senior leadership incentives to our sustainability targets. From the products we procure to the way we run our factories, to the products we produce, we have put sustainability at our core.

Returning to your own career again finally, what is the most important lesson you have learned in business, and also the best bit of advice you have had from someone else?

Throughout my career there have been many lessons and many times I had to remind myself that if it were easy, they wouldn’t need me. In

the end, it really does come down to people and working as a unified team with a shared purpose. This is the absolute most important part of my job as a leader. You can have the newest factory with the best equipment that money can buy, but if you don’t have a great leader with a motivated, united team, that factory will never perform as it could and will be run down before its time. Best advice - get the people right!

This industry is being hit by a tsunami of change. Twenty years ago, I was speaking to specifiers about using lower impact products and LEED was the buzz. These were just tiny waves, no surfing. Now the wall of water is upon us, and there is a huge opportunity to (surf and) join an industry that will define our future as a society and the way we live. If we can’t get the younger generations and a more diverse population excited about being part of this, I don’t know what will. I believe the next ten years will be the most dynamic this industry has ever seen. It’s an exciting time, and I am proud to be a part of a company that wants to lead. ■

For more details on Holcim’s range of building envelope solutions visit: www.holcimbe.com/content/holcimenvelope/en.html

I believe the next ten years will be the most dynamic this industry has ever seen

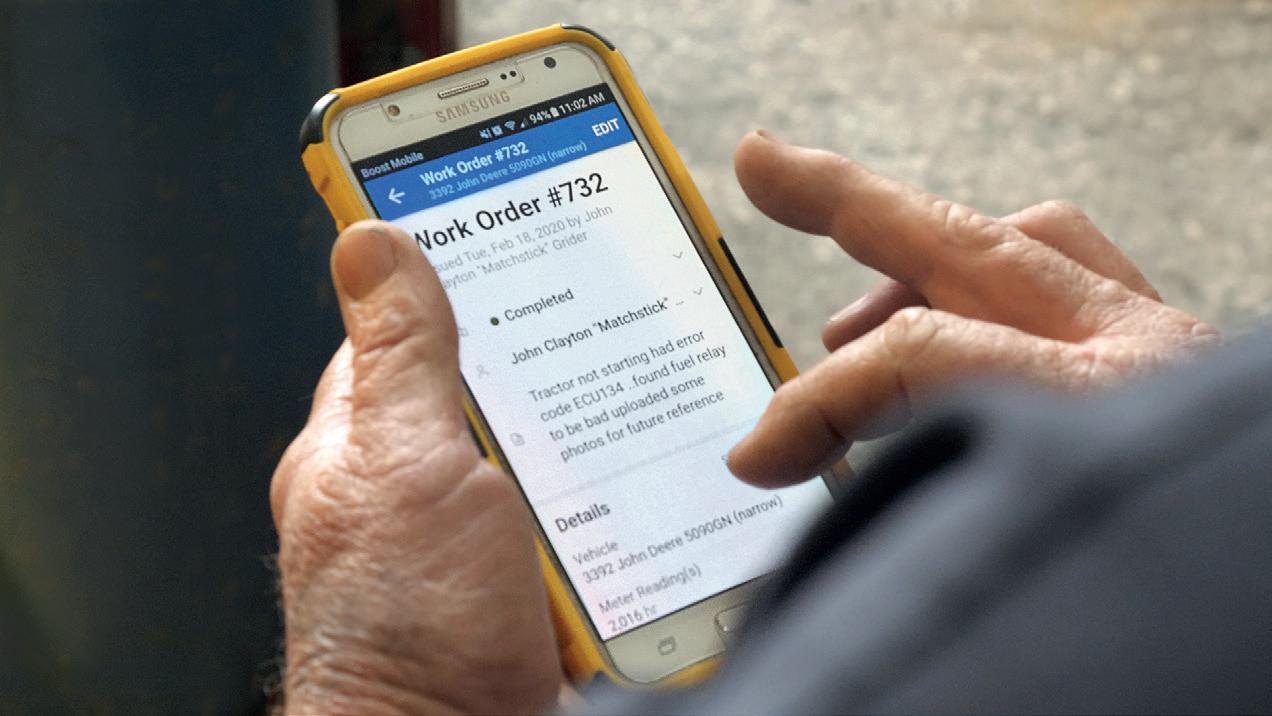

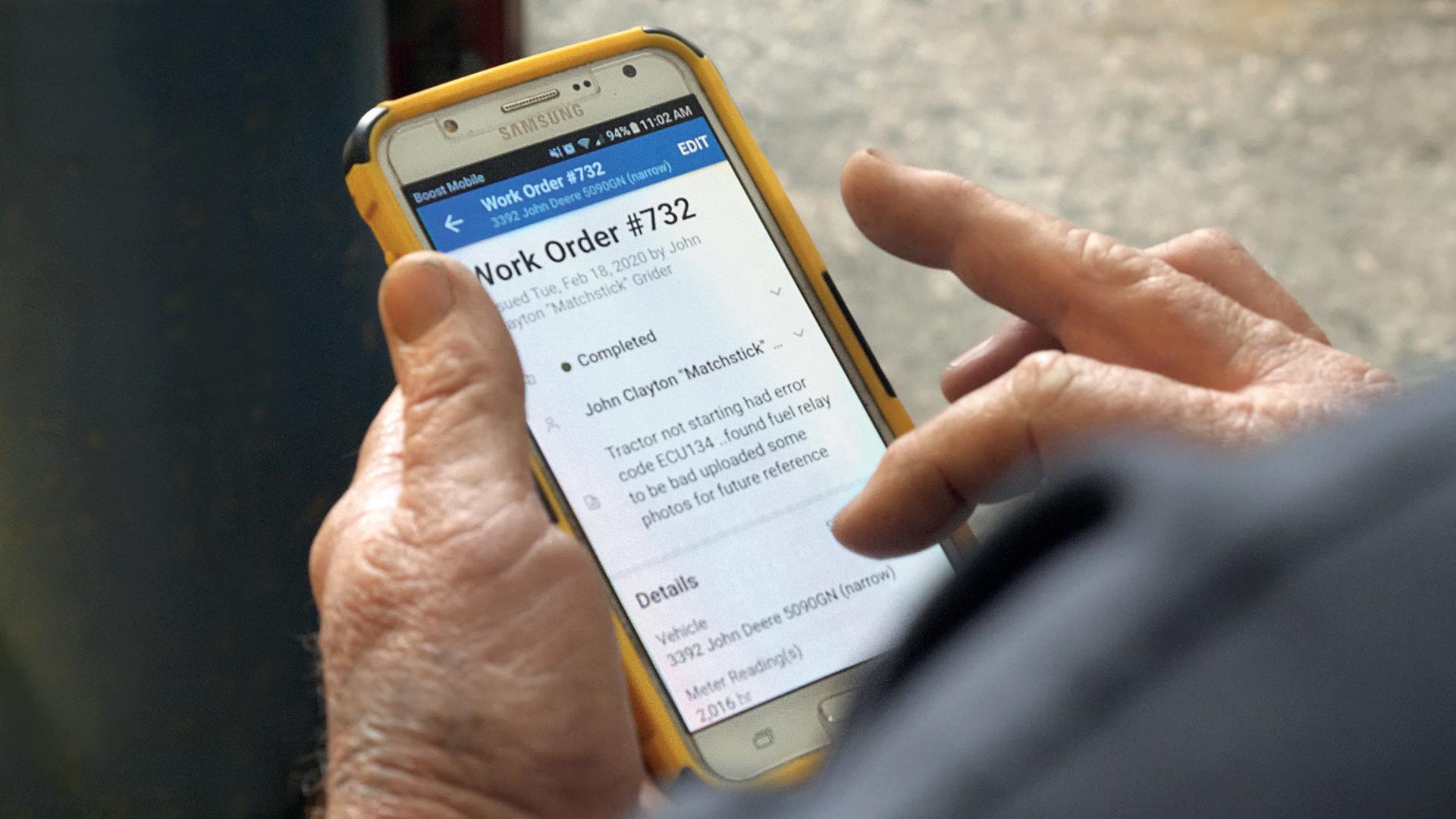

Contract mobilization takes a lot of effort and crossdepartmental coordination, from administrative tasks and setting project expectations to ensuring fleet assets are lined up and ready to work. Calculating mobilization fees is difficult enough before considering fleet; however, if a piece of fleet breaks down while

delivering equipment — or the equipment itself breaks down on site — businesses may have to tack on remobilization fees. Additionally, fleet asset breakdowns can throw an entire project off schedule and negatively impact the company’s reputation.

Mobilization time and costs relating to transportation, petrol, off-road equipment, and tools can

Rachael Plant highlights the benefits of clear communication and data transparency

Rachael Plant highlights the benefits of clear communication and data transparency

be optimized through proactive Preventive Maintenance (PM), clear communication, and fleet data visibility.

In recent years, fleets have been switching from reactively addressing asset problems, to proactively preventing them. This is largely due

to the rise in available fleet solutions, such as Fleet Management Software (FMS). These technologies allow fleets to comprehensively monitor any aspect of the operation, including service histories, asset use, fleet utilization, and Total Cost of Ownership (TCO). Fleet solutions take all collected data and automatically render it actionable through customizable

reporting to meet your specific goals — meaning clearer insights and less work to get them. Having comprehensive service histories for your fleet assets allows you to determine high-fail items and recurring issues so you can tailor PM schedules to the needs of the asset or asset type. Such service-related data as parts used can help you identify if lack of parts durability is the cause of recurring issues, or if you should look at driver behavior or the OEM as the source.

FMS uses service and other fleet data to inform fleets of service spend and downtime. Fleets can further categorize service in FMS to determine causes of failure with reason for repair, repair priority class, and system/ assembly/component codes. This data provides deeper insights into why the service was needed, whether the service was scheduled, unscheduled, or emergency-based, and what part of the asset was serviced. Automated reports around these key metrics allow fleets to optimize PM programs and increase uptime for efficient mobilization.

Clear communication around project goals and blockers is a huge component in successfully completing a contract on time and within budget. Streamlining communication around asset service tasks is equally important to avoid fleet-related delays. Vehicles and equipment deployed

to worksites should be safe, reliable, and in optimal operating condition. In addition to implementing proper PM schedules, fleets can improve uptime by automating service workflows and improving communication regarding service needs.

Using digital inspections in FMS, employees can quickly surface asset issues, and failed inspection items automatically notify the manager in real time to kick off the service workflow. Inspections in FMS are customizable, so managers can tailor forms to specific asset types or even individual assets for enhanced monitoring. Employees can attach documents and pictures, as well as leave comments, in inspections so managers and technicians know exactly the part needed for service.

With FMS, in-house technicians can clock on and off jobs within specific work orders so fleets can compare active time on the job against service duration (i.e. the amount of time the asset spent in the shop from drop-off to pick-up) to determine workflow inefficiencies such as understaffing or unnaturally high workload volume. This data allows fleets to pinpoint shortcomings in process and analyze a solution based on detailed information for improved uptime and mobilization.

Improving data visibility around fleet assets helps companies easily determine which assets are available, in the shop, sitting in the lot waiting to work, or in use on other contracts — including to whom the asset in use is assigned. In addition to providing asset status and assignment information, FMS can integrate with other fleet and business technologies to improve data

consolidation, aggregation, and visibility. This allows managers to quickly view what assets are available for contract mobilization and what will need to be procured. Business integrations within FMS also provide the added benefit of finance and HR-related fleet data transparency for improved mobilization cost estimates.

While contract mobilization hinges on multiple departments across the business, the reliability of fleet assets can impact the entire job. Improving uptime through proactive maintenance, clear communication, and data visibility allows fleets to schedule maintenance downtime appropriately, minimize unscheduled downtime, and hit mobilization goals. ■

For a list of the sources used in this article, please contact the editor.

Rachael Plant is a content marketing specialist for Fleetio, a fleet management software company that helps organizations track, analyze and improve their fleet operations. With a mobile-first mindset and focus on automating the fleet operations process through seamless integrations with business solutions like telematics devices, maintenance shops and fuel cards, Fleetio’s software powers public and private fleets in more than 80 countries.

Rachael Plant www.fleetio.com By Jim Stephen

By Jim Stephen

As construction jobs grow increasingly complex, companies strive to find new ways to increase productivity without creating unsafe working conditions or going woefully over budget. Digital technology presents an opportunity to change the way construction companies work and grants the power to adapt to the industry’s changing landscape.

In today’s tech-savvy world, there are hundreds, if not thousands, of digital technology tools available to support businesses with productivity, communication, and more. General software can help teams refine various stages of their workflow and client interactions, but can only take things so far.

To leverage the power of digital technology, firms should use tools designed for the construction industry, like BIM Collaborate Pro. Choosing products that integrate with existing tools and focused on construction-oriented tasks makes the transition easier and leads to better long-term gains.

For example, consider a Customer Relationship Management (CRM) system with the ability to use cloud-based storage and track various metrics, like employee time. It could improve project management and offer some boosts in productivity. However, a general CRM leaves out a large part of construction needs, like accessing and editing plans and models or calculating supply needs and costs.

Conversely, software created specifically for construction teams often features these key elements. It’s not easy to optimize productivity if you can’t perform all the necessary tasks through one platform.

Knowing that tools exist is one thing, but understanding how they can help a construction business grow is something else. These tools represent an investment in the business, and that means understanding the short and long-term benefits.

According to a 2021 study, around 60 percent of contractors report delays on projects. Those delays often translate to going over

only half of all projects finish on time and on budget.

Digital technology could be the solution to these costly delays. The right software can help teams create a smoother workflow and house all relevant information in one place. A cloud-based platform can make it accessible from anywhere, meaning on-site workers can see the same thing as those at the head office.

Additionally, platforms can track updates, changes, and daily progress to make appropriate adjustments. It’s possible

resources to adapt to changes faster and more efficiently.

Imagine a world where teams can craft a design, perfectly scaled to match a specific site. The team can then share the model with their clients and make real-time corrections. What could that possibility mean for the company and the client?

Digital technology can help teams limit the back and forth by providing accurate displays with real-time editing capabilities. It

reduces the chance of miscommunications and misinterpretations as all parties can simultaneously view the same model from almost anywhere.

These tools can bridge gaps between time zones and worksites to create more efficient, open communication and reduce one of the most common issues with any construction project. It’s possible to create transparency between teams, crews, and clients.

As noted, finishing a project over budget remains a significant problem. Embracing digital technology could be the best way to reduce costly errors and wasted resources.

Choosing software and hardware built for the construction industry means accessing powerful analytics to solve problems before the work even begins. For example, creating the project in

...creating the project in the virtual system allows teams to work through potential issues, get more accurate measurements, and deliver more accurate numbers to clients

“

the virtual system allows teams to work through potential issues, get more accurate measurements, and deliver more accurate numbers to clients.

When teams can construct a virtual image of the project in various modes, it’s easier to pinpoint potential problems. Additionally, using Artificial Intelligence (AI), it’s possible to get more accurate measurements and calculations for the project. Leveraging AI for calculations and predictions can reduce the impact of human error and reduce waste on the project.

Another area with room for improvement is crew member management. Digital technology improves workflow and streamlines scheduling to reduce employee downtime and overages. Instead of having crew members standing around on the clock with nothing to do, it might be possible to shift them to other sites to maximize efficiency.

Incorporating time-tracking apps within the software package also makes it easier to record progress, handle any discrepancies, and manage multiple crews. It can even include GPS location abilities to ensure teams are on track and at the proper locations.

When management, payroll, human resources, supervisors, and crew members can all access the same information, it’s easier to monitor individual employee performance. Again, it creates more transparency and open communication with fewer discrepancies and less room for error.

Embracing digital technology involves more than software with AI, analytics, and tracking abilities. It represents a way to improve worksite safety and reduce strain on employees.

Improve training and compliance Technology allows employees to use alternative training methods, like VR and 3D models to simulate real-life scenarios. It’s more effective than reading information and warnings out of a manual.

Speaking of manuals, instead of maintaining massive paper binders and manuals on sites, digitize records. It’s simpler for tracking and allows teams to complete reports through mobile devices, including safety measures.

It’s not easy for team leads to monitor an entire site, but a drone can help. Flying drones over sites allows supervisors to see what’s happening, keep tabs on site conditions, and spot any safety issues.

Wearable devices represent another way to leverage technology to improve safety on worksites. Smartwatches and smart clothing can track various metrics and alert management to dangerous situations, like dehydration or toxins in the air. Additionally, with GPS features, it’s possible to locate injured crew members faster.

Digital technology represents the present and future of the construction industry. It’s the best way to increase productivity, reduce costs, limit errors, and keep projects on track. Investing in a construction-focused, cloudbased platform could be the key to future success and continued growth. ■

Jim Stephen is an Account Executive for Construction Solutions at Microsol Resources based in New York. Microsol Resources is a recognized leader with the best software tools for architectural design, engineering, and the construction industry.

Data technology and sustainability are driving the future of construction. By

Wyatt Jenkins

Wyatt Jenkins

For construction, the pressure to meet net zero goals is immense given the extent of the industry’s climate footprint. The most recent UN IPCC report reinforced the dire state of global environmental goals needed to alleviate the worst impacts of

climate change. Taking action, the Securities and Exchange Commission (SEC) proposed a sweeping climate disclosure rule that, if adopted, would mandate detailed reporting of public companies’ climate-related risks, emissions, and net-zero transition plans.

Sustainability offers twofold benefits: Planetary health and human health. Public green spaces, for instance, sequester carbon, enhance air quality, reduce heat, gather stormwater, and remove pollutants. Simultaneously, green spaces lessen stress and enhance human cognitive performance for the people who live, work, and play within them. Optimizing the built environment will bolster the mental, emotional and physical health of the users, as described by ULI’s report ‘Greening Buildings for Healthier People,’ which, in turn, is proven to result in higher returns for stakeholders.

The construction industry’s legacy grows muddled by its colossal environmental impact: The built world, one of the largest global industries, accounts for nearly

40 percent of annual global carbon emissions. The manufacturing of building materials, particularly concrete and steel, and the construction installation process account for approximately 11 percent of emissions, and experts suggest this is a conservative estimate.

In addition to its carbon output, construction sees an annual spend of $500 billion in rework – 14 percent of total construction expenses. Rework is predominantly caused by poor communication – which causes low labor productivity and mistakes on job sites. Construction rework ultimately results in wasted materials while also requiring owners to purchase more materials – which, in turn, necessitates more spending and more carbon emissions.

General industry estimates claim that between ten and 30 percent of all building project costs can be attributed to wasted activities, such as schedule overruns from poor coordination and low labor productivity. The volume of solid construction waste generated worldwide every year is around 1.3 billion tons, according to Transparency Market Research. By 2025, this number is expected to nearly double to 2.2 billion tons.

With less than one percent of building projects currently evaluated to quantify the scale and source of carbon emissions generated, there’s a hefty learning curve in store for the industry. What’s the path forward?

Data derived from modern technology will empower the construction industry to continue rapidly incorporating environmental standards into its ethos. Strong digital tools update communication channels from fax, phone, and paper that result in poor communication with huge margin for error that provide better insights and significantly reduce construction rework and waste. The efficiencies that construction technology platforms drive into projects ultimately connote efficiencies that drive measurable sustainable action. For instance, notable time savings across project lifespans, rework reduction by addressing miscommunication and errors, connecting workforces for optimal project communication, and fuel usage reduction.

In addition, tracking and reporting on a company’s environmental impact will soon be an industry requirement. This information, when tracked and analyzed, provides insights that ultimately create data-driven, informed decisions. While a complex feat, integrating embodied-carbon tracking –and, taking it a step further by reporting

that data on a connected platform – will radically help owners and contractors understand the environmental impact of their supply chain. The digitization of the industry is an imperative ESG tactic that will soon be as fundamental for owners as tracking and reporting their safety, financials, and work productivity.

Beyond technology, green skills – those that benefit the sustainability efforts of an organization – provide an additional opportunity for transforming construction. With climate change concerns filtering into the job market – green skills listed on LinkedIn profiles increased by 38.5 percent between 2015 and 2021 – construction must emphasize the importance of green skills amongst its workforce. In turn, the industry will attract and retain talent – particularly amongst younger generations who are especially concerned about climate change.

Construction technology and embodied carbon tracking will revolutionize how the industry understands its environmental impact through data

“ “

Construction, however, has a green skill drain. Although the industry inherently utilizes green skills, construction workers are transitioning out of the industry at a faster rate than they are coming in. For every hundred construction workers transitioning into nongreen jobs, as few as 47 workers transition into green and greening jobs. Simply put, the dilemma is that construction workers with green skills are leaving for non-green roles.

This talent gap comes at a moment that holds tremendous potential for widespread adoption: From retrofitting existing properties towards carbon neutrality, to carbon accounting and calculating, and identifying opportunities to source local construction materials and save on importing from overseas.

Construction technology and embodied carbon tracking will revolutionize how the industry understands its environmental impact through data. Climate technology is becoming a central pillar to improving and decarbonizing the construction supply chain.

Technology and big data have proven to be powerful tools. Embodied carbon data in the hands of sustainability professionals will be nothing short of transformative.

Let’s rebuild construction with sustainability in its foundation for the health of everyone involved. ■

Wyatt Jenkins is SVP Product at Procore, the global leader in the digitization of CRE. It provides heightened visibility throughout the project life cycle to key project stakeholders - owners, contractors, investors - and tracking and reporting on safety, financials, and productivity. It is the leading construction technology platform, with over one million projects and $1 trillion in construction volume, providing hyper communication across the CRE build cycle.

Wyatt Jenkins www.procore.com

Wyatt Jenkins www.procore.com

Jeff

The construction and demolition industries continue to see steady change. Contractors, laborers and project managers are pushing for safer and more productive solutions to transform modern jobsites while facing an evergrowing backlog of projects fueled by the $1.2 trillion Infrastructure Investment and Jobs Act. At the same time, ‘The Great Resignation’ and Baby Boomer mass retirements contribute to labor shortages across the board.

With all these factors at play, relying on manual labor is simply unsustainable - in terms of worker recruitment and retention, safety, productivity and overall costeffectiveness. As a result, successful contractors think outside-the-box and supplement experienced crew members with technologically advanced equipment like robotic demolition machines to increase efficiency and reduce the physical strain on laborers. Additional mechanization options

◀ Contractors who invest in mechanization reduce the amount of dangerous and hard manual labor workers must perform, which is a powerful benefit to young and experienced workers alike. A young employee may consequently see construction as a long-term profession while an experienced worker may see it as more realistic to remain in the industry for the duration of their career

help contractors take advantage of current opportunities while accommodating industry trends.

Handheld pneumatic breakers and other highly physical methods have been commonplace on jobsites for decades. However, increased jobsite mechanization has allowed contractors to revolutionize productivity.

A demolition robot paired with a hydraulic breaker, for example, improves upon previous productivity goals with an impressive hitting power, on par with excavators three times their size, and offer industryleading power to weight ratios. These compact machines access some of the most confined and restrictive jobsites - including those with dust,

centimeters) wide and weighing 1,235 pounds (560 kilograms), the most compact units are small enough to fit through standard doorways and light enough to be transported on passenger elevators, making them ideal for confined spaces and interior demolition projects. Larger models are available with higher power ratios for more challenging applications.

By employing these heavy-hitting machines, contractors can greatly increase efficiency in applications previously limited to large crews with handheld equipment. For example, one contractor was able to cut their demolition crew by a third during nearly one-million-square-foot (92,903-square-meter), multi-level tear out. The two 2,183-pound (990-kilogram) demolition robots were

▶ Successful contractors work to think outside the box and supplement experienced crew members with technologically advanced equipment like robotic demolition machines to increase efficiency and reduce the physical strain on laborers

▶ Remotecontrolled demolition equipment addresses some of the most pressing safety concerns these industries face with an operating distance of up to 984 feet (300 meters)

each robot only requiring a single operator, the contractor was able to better utilize remaining employees across simultaneous jobsites while increasing productivity and lowering overall labor costs.

For many in construction and demolition, increased safety is one of the biggest benefits of mechanization. Remote-controlled demolition equipment addresses some of the most pressing safety concerns these industries face.

With an operating distance of up to 984 feet (300 meters), remotecontrolled units physically distance employees from harmful silica dust, as well as the strong vibrations of handheld equipment such as breakers, rivet busters and chipping guns. Longterm use of these common demolition tools is linked to a number of chronic injuries, including carpel tunnel syndrome, nerve damage and handarm vibration syndrome.

Additionally, remote-controlled demolition machines help prevent one of the most common causes of serious work-related injury and death in construction - falls. A remote-controlled unit allows operators to remain a safe distance from ledges and other fall hazards. This provides peace of mind for workers and project managers, but also increases productivity by minimizing the need for erecting fall protections.

For contractors using remotecontrolled machines, these safety benefits can quickly add up to significant savings on workman’s comp and insurance premiums. Remote operation paired with smaller crew size can significantly lower worker liability costs by limiting personnel in confined spaces or hazardous operations. One concrete cutting contractor who made the switch to demolition robots has seen a decrease in annual workers compensation claims by about 50 percent. The company has also seen a

▶ Technological advances, such as robotic demolition, can help change the way contractors work and make it possible to thrive in today’s environment while preparing for the future

Cutting edge technology also attracts younger workers. For one concrete cutting company, including advanced robotic technology in their fleet helped reduce the median age of their 300strong workforce to just 25 years old and cut turnover ten per cent. The machines also allowed the contractor to do more work with fewer people, increasing productivity 17 percent over three years.

- $50,000 savings, in injury costs per year. Another concrete cutting operation reduced its experience modification rate (EMR) by adding demolition robots to their equipment fleet. Insurance companies calculate EMR based on a company’s safety record. Higher EMRs result in higher insurance premiums.

Implementing cutting-edge technology also offers some powerful recruitment and retention tools. When it comes to safety, for example, the workforce is well-aware that quality of life and length of career can be significantly affected by injuries and silica dust exposure. At this time, the median age of a construction worker is 42.3 years. Contractors who invest in mechanization reduce the amount of dangerous and hard manual labor workers must perform, which is a powerful benefit to young and experienced workers alike. A young employee may consequently see construction as a long-term profession while an experienced worker may see it as more realistic to remain in the industry for the duration of their career.

It’s both an exciting and challenging time for construction and demolition. Opportunities abound for contractors, especially those who find creative ways to recruit, retain and best use the skills of their workers. Technological advances, such as robotic demolition, can help change the way contractors work and make it possible to thrive in today’s environment while preparing for the future. Mechanization allows companies to quickly adapt to changes in labor, process or regulation, keeping them ahead of the curve - and the competition. ■

Jeff Keeling www.brokk.comJeff Keeling is the vice president of sales & marketing for Brokk Inc. Brokk has been the world’s leading manufacturer of remotecontrolled demolition machines and attachments for over 45 years. Through continuous innovation in engineering and design, Brokk is able to offer unique solutions to multiple industries worldwide, including construction, demolition, mining and tunneling, cement and metal processing, nuclear and other specialty applications. .

The quality will remain long after the price is forgotten –this is a well-known quote from Henry Royce, co-founder of luxury car brand RollsRoyce. It’s usually taken to mean that quality is worth paying for. But there’s another meaning: that buying on price alone often ends with the disappointment of poor performance or potential hazards. It is this second meaning that drives the Power Tool Institute (PTI) to strongly caution tool buyers to only buy batteries manufactured by their tool’s original equipment manufacturer (OEM).

When it comes to buying power tool batteries, going cheap can have potentially disastrous consequences for power tool users. The costs related to a single fire caused by a counterfeit or knockoff battery will quickly reveal the lower initial purchase price to be no bargain at all. Spending a little more up front for a product that is designed specifically for the tool and will perform well for a longer period of time is a smart investment.

What’s inside is what counts

What makes OEM batteries the right investment over counterfeits and knock-offs? Each OEM has its own proprietary control circuity for the total system, which encompasses the tool, battery, and charger, so the three components communicate properly.

There are numerous design considerations that manufacturers address in the construction of their batteries, including type and quality of cells, durability of electrical connections, electronic controls (in the battery, charger, and tool), protective housing, compliance with standards, and independent certification.

This circuitry design is not available to third-party component suppliers, and the differences between the inner workings of these power tool systems make it virtually impossible for any other battery to match the OEM, no matter what the package claims.

Because of all these safety and compliance considerations, batteries from different non-OEMs are not cross-compatible (unless specified by the power tool manufacturer).

Why using anything other than OEM batteries can be a dangerous proposition for construction professionals who use power tools. By Susan Orenga

The quality will remain long after the price is forgotten “ “ “ “

When buying aftermarket batteries for power tools, it is important to consult with the power tool owner’s manual and purchase only the batteries recommended by the manufacturer.

Willingness to do the right thing and shop for OEM batteries might not be enough. Manufacturers of counterfeit and knock-off batteries know exactly what they are doing when they design their products to mirror the color and packaging of the specific OEM manufacturers from whom they intend to take business. Online sales in particular can confuse well-meaning buyers. One can get caught up comparing prices, which is understandable, but what seems like apples to apples can result in a deal that quickly turns rotten.

In the end, before purchasing a non-OEM battery, consumers are advised to consider all factors, not just price. What seems to work well out of the box may deliver dire consequences later. Purchasing a battery from an unknown seller without having any verification of the seller’s

qualifications or experience — or of the battery’s construction, testing or certification — can leave you with an unsatisfying, and potentially dangerous, experience.

Once you have made the safer choice and outfitted work benches and service trucks with OEM batteries, battery safety is still an important and ongoing consideration.

Most battery-operated power tools use lithium-ion batteries due to their many advantages over other battery types. They can derive greater energy from a smaller battery, are made of lower-toxicity materials, and hold their charge longer. The benefits of this newer technology have allowed higher-demand tools and applications to be battery-powered and provide significantly more work-per-charge. This extended capability, combined with the portability of battery tools, has resulted in a dramatic increase in their use.

Any lithium-ion battery, while infrequent, can become unstable, particularly if the battery is damaged, dropped, or cracked. If you encounter a lithium ion battery that is too hot to touch, melting, smoking, or on fire, it may be in ‘thermal runaway’.

Thermal runaway acts like a chain reaction, where the heat continues to build until battery stability is lost, and

a fire can start. The reaction occurs due to an internal short, causing excess heat to be generated. It requires immediate action.

The quickest way to cool down and stop an overheating lithium-ion battery is to immerse the battery in a sturdy container filled with water and keep it there for 24 hours.

Before immersing a battery, there are some things to keep in mind. Don’t physically touch the battery to move it; instead, use something like a long-handled shovel. Wear PPE to protect eyes and skin. If the overheating battery is mounted to a charger, make sure the charger is unplugged. If the battery is connected to a tool or charger, don’t try to disconnect it. It’s better to sacrifice those items than risk being injured. Put them in the water as well.

If you are not able to immediately submerge an overheating battery, pouring large amounts of water on it

to extinguish flames may slow the fire down until a sturdy container of water can be found. When the flames have subsided, transfer the battery to the container as soon as possible.

If water isn’t immediately available, a fire extinguisher may slow the fire down, but it won’t put it out completely. It must be cooled down to stop the chain reaction. Though the fire may appear to be extinguished, still immerse the battery in water as soon as possible, so additional cells within the battery don’t re-ignite.

If water isn’t available, you can isolate the battery by moving it outdoors at least 15 feet from any combustible material.

It’s important to leave the battery immersed for at least 24 hours. Even if you don’t see flames, the thermal runaway may not be over. While one cell is cooling down, a different cell might be heating up.

The bottom line is that a properly designed tool, battery, and charging system from an OEM, is the safest option, but you must respect any battery’s power and handle it properly.

Reminders like this article can help promote good decision-making around power tools and their safe operation, but the best way to improve safety on job sites is through a robust, continuous training program.

Power tool safety begins with several basic, universal tenets. Workers who learn to apply these can approach any power tool with confidence. Well-trained workers make fewer mistakes, are less apt

to become distracted on the job, and appreciate that safety is a teamfirst concept.

Many firms have their own training courses and schedules, but for any who are looking to start their first training program – or want to enhance what they already have – the Power Tool Institute offers a library of more than a dozen lesson plans, including several videos. These materials are complimentary on the PTI website (https://www. powertoolinstitute. com/pti-pages/edlesson-plans.asp).

Power tools make construction work and other job types go so much faster and easier. Arming workers with consistent, quality information and their professional dedication to staying knowledgeable and well trained can result in successful projects for years to come. ■

Susan Orenga works at the Power Tool Institute. With the vision to unify and educate others about power tools, since its founding in 1968, the Power Tool Institute (PTI) has established itself as the leading organization for building global understanding of power tools and for maintaining high standards of safety in the industry.

Well-trained workers make fewer mistakes, are less apt to become distracted on the job, and appreciate that safety is a teamfirst concept “ “

“ “

The construction industry is highly competitive, with tight margins reliant on streamlined operations. Saving time and money is key to being able to pass cost savings on to the customer while maintaining profitability. And as construction technology and equipment become more complex and expensive, the pressure is on to get the most from these valuable assets and extend their lifecycles to maximize return on investment.

These days, digitalization and automation are increasingly adopted by construction companies to help them successfully revolutionize their backend administration, asset management, workflow and innovation capabilities. Smart construction asset and equipment tracking technology helps construction companies prevent costly damage and theft, control their inventory, and predict maintenance requirements, all of which allows them to manage projects in a more profitable way. So, how does it work in practice?

Today’s construction asset management and asset tracking technology leverages the Internet of Things (IoT) to track materials, workers and equipment. Smart tags are attached to any assets and individuals on your

construction site, and data from these tags is transmitted via a secure network to a bespoke management dashboard in real time. A cloud-based construction asset management platform can be accessed through any smart device, putting a full overview of your operations into the palm of your hand. The system provides unsurpassed visibility into the construction supply chain and site operations, allowing managers to determine when maintenance should be carried out, when they need to repurchase equipment, and which assets can be shared between sites.

Building a new future for the construction industry with smart technology.

Smart, secure, connected technology is the foundation upon which construction companies of the future will be built

“ “

The system also allows teams to set predefined geofence locations to alert them instantly if any expensive assets are removed from a particular location by accident or by criminal activity. Taking control of construction assets in this way helps companies and contractors to recover lost time and expenses - which can then be redeployed in revenuebuilding activities.

Truth be told, the applications are endless, but some of the most common use cases of smart technology in the construction industry include the following:

l 24/7 asset tracking provides total visibility across various sites so that you can track and monitor all your construction assets and personnel in real time.

l Many construction businesses experience repeated theft, but smart networks can integrate with other security systems to secure remote areas and perimeters at all times.

l A good construction asset management solution allows companies to gain valuable insight into their construction site asset utilization across different sites and projects, providing invaluable insights and allowing them to optimize their operations.

l Enables more informed and effective assessment and management for similar projects in the future.

l Custom reporting enables better planning for material and equipment availability and maintenance.

l Monitoring and demonstrating high levels of worker safety and productivity helps construction companies provide a good working environment to attract and retain the best talent.

l Lone worker monitoring with instant SOS alerts, panic buttons and direct links back to the main operations team.

Working in a more environmentally-friendly and sustainable way is becoming increasingly important in the construction industry, with more regulations being introduced to ensure this, along with client, consumer and financer pressure. By using smart sensors for asset and operational monitoring, construction companies can identify efficiencies to streamline their processes, maximize resources, and prevent unnecessary wastage and repetition, which helps to reduce their carbon footprint.

Every construction project comes with inherent risk. By programming a smart system to send different data depending on the desired project outcomes, companies can plan each project

better and alleviate a large proportion of the risk. This increases the likelihood of projects being delivered to clients on time and on budget, improving the company’s corporate reputation.

In summary, the benefits of smart construction technology include:

l Streamlining your workflows

l Assessing and predicting risks

l Responding to problems immediately

l Improving labor productivity

l Improving health and safety

l Reducing theft and damage

l Saving time and money and increasing return on investment

Transformation is the foundation To gain a competitive advantage, meet customer expectations, and become more sustainable, construction companies of today need to harness new, disruptive technologies

to digitalize their businesses. Smart, secure, connected technology is the foundation upon which construction companies of the future will be built. ■

For a list of the sources used in this article, please contact the editor.

Matthew Margetts is a Director at Smarter Technologies. Smarter Technologies tracks, monitors and recovers assets across the globe in real time, providing asset tracking systems to the open market and fulfilling the world’s most complex asset tracking requirements. Its services cover a vast array of business sectors, products and equipment from container or pallet tracking to militarygrade devices; and can be used across a broad spectrum of industries.

By Ricky L. Morgan

By Ricky L. Morgan

In Hollywood disaster films, it is necessary to compel the audience into believing the earthquake, storm, or flood is truly devastating. To do this, filmmakers show bridges falling, buildings twisting, roads buckling, and more. If the audience has any questions whether the event is indeed severe, such images bring them instantly to a state of complete belief.

In the real world, such things can, and do, happen, though fortunately they are far more rare than in movies such as the blockbuster San Andreas. At least part of the reason is that a sophisticated, but little-discussed technology, is applied during and after construction. This one approach makes a world of difference. So, it is troubling that as the US considers

testing: An essential element of maintaining a healthy infrastructure

how to apply the more than $1.2 trillion in authorized spending on infrastructure, and other countries around the world consider how to further build out their environments, wider adoption of this technology is not prioritized so our cities and communities don’t mirror a Hollywood disaster film during storms and other natural events.

Nondestructive testing (NDT) is the inspection of an object for cracks, corrosion, discontinuities, or structural fatigue without cutting or breaking the object open. In the best-case scenario, there are careful considerations made throughout the design and construction process of every building and structure to ensure structural integrity during a variety of natural conditions as well as the structure’s integrity over the long term. To ensure longevity, regular inspection and evaluation of materials using NDT is vitally important. It can prevent the usage of flawed materials. It can ensure that the welds that join building elements together are sound. And it can be applied throughout the life of the structure to examine if the materials and structure retain their ability to withstand earthquakes, severe storms and similar events.

From the day materials arrive at a fabrication facility to the day an asset is demolished or mothballed, NDT should be performed to confirm integrity. Especially with respect to infrastructure, NDT can be utilized from the cradle to the grave of an asset. This includes the entire built environment ranging from bridges, dams, power lines, cellular towers, airports, runways, water facilities, and power plants to refineries, roads, and more. NDT provides an array of analysis techniques that can be used in the construction and maintenance of such facilities to evaluate the materials, components, and assemblies of these buildings and structures without causing damage.

When the 1994 Northridge Earthquake struck the California San Fernando Valley, it was NDT inspectors - including me - who examined the infrastructure. The evaluation of the status of steel structures in potentially damaged buildings was essential to determine repair protocols and procedures

for future construction of replacement facilities when a structure was too damaged to save. NDT inspectors worked day and night to provide this critical information to both asset owners and the engineers racing to determine the status of the affected buildings and structures.

Today, the NDT industry is digital and dynamic, utilizing some of the most advanced assessment technologies available. There are currently more than 11 different recognized methods of NDT and countless subsets and techniques available for almost every industry. While it depends on the project specifications and the inspection and testing plan that spells

out the areas where inspection is required, the most common NDT methods are Magnetic Particle Testing (MT), Penetrant Testing (PT), Ultrasonic Testing (UT), Radiographic Testing (RT), and Visual Testing (VT). Think of it as advanced science applied to a single compelling prioritypublic safety.

Many enhancements have been made to evolve NDT technologies to where they are today. This does not mean NDT has advanced as far as it can. Further advancements in NDT could provide useful figures for data-driven, risk-based assessments throughout the life cycle of building elements and structures.

Newer innovations are in development or coming into use. These include advancements such as advanced UT methods, like Phased Array Ultrasonic Testing (PAUT), Time of Flight Diffraction (TOFD), and Total Focusing Method (TFM)/ Full Matrix Capture (FMC). Such tools can have a great impact on the inspection of infrastructure. Already, innovations in conventional UT have been shown to provide better imagery, better probability of detection, better characterization of flaw or failure type, and more robust post processing and analysis. Similarly, the use of drones has been shown to significantly improve visual inspection of infrastructure assets with limited access by supplementing technologies with safer access, greater picture quality, and a permanent record using geotagging. In the past, those structures may have only been able to be assessed using binoculars. Similarly, Structural Health Monitoring (SHM) and Condition Monitoring (CM) are not novel technologies but have been significantly enhanced by improvements in sensor technology, as well as better and more useful data acquisition. Today, monitoring can be ongoing 24/7, scheduled, incident activated, or even mounted or embedded into steel and concrete infrastructure during new construction to monitor a structure throughout its lifetime.

As we in the US prepare to spend over a trillion dollars on new infrastructure investments and other nations continue their development, we should make certain NDT technologies are more widely adopted and required so the public can be sure they are safe.

We may not be living in a Hollywood movie, but as our natural environment changes there is no question disasters risk

becoming more frequent and more severe. The regular application of NDT inspections on aging infrastructure is essential to maintain its stability. And NDT must be applied to new builds, from the material production stage all the way through construction.

Throughout the decades, NDT technology has consistently evolved to meet the evergrowing need for infrastructure assets to withstand unpredictable and severe weather conditions. We must continue to invest in the innovation of NDT methods and the creative utilization of this valuable and rapidly evolving technology. ■

Morgan flawtech.com

Morgan flawtech.com

Ricky Morgan is the President of FlawTech America, a manufacturing company providing the very best in intentionally Flawed Specimens to the NDT/NDE Industry for more than 40 years. FlawTech also supports the American Society for Nondestructive Testing (ASNT), the world’s largest technical society for NDT professionals, by bringing together ASNT members and NDT technicians.

American Society of Nondestructive Testing (ASNT): www.asnt.org

The National Cement Company of Alabama (NCCA) first began producing cement at its current site in Ragland, Alabama in 1908, then operating under the name of the Atlantic & Gulf Portland Cement Company. The company changed its name to National Cement Company in 1920, enjoying various owners up until 1974, when it was purchased by the Vicat Group, a French company with origins stretching back as far as the early 1800s, when Louis Vicat first invested in artificial porous

cement production. Following the acquisition, Vicat Group set upon a program of modernization and plant improvements that have brought NCCA to its present-day status.

Today, the company produces Portland Cement Type I, II and III and masonry cements, which it ships via truck and rail from four terminal distribution locations around Atlanta, Georgia, and one in Greenville, South Carolina. NCCA also operates readymix concrete subsidiaries, in the shape of Kirkpatrick Concrete and Hodgson Concrete in Alabama, and Walker Concrete in Georgia.

How the National Cement Company of Alabama is steering towards a green future

Among the biggest challenges currently facing cement producers like NCCA is a growing emphasis on decarbonization, with pressure mounting both within the industry and beyond, from the consumer to the governmental level. NCCA’s own decarbonization plan sets out the company’s ambition to achieve carbon neutrality by 2050 through the value chain, and the company took a significant step towards this earlier this year, as it commenced a two-year, $300-million project to install new cement production equipment throughout its Ragland plant. As Spencer Weitman, President of the NCCA, explains, the equipment will take advantage of the “very latest carbon reduction practices and modern energy technologies,” chiefly substituting fossil fuels with alternative fuels.

Long term, we will embrace carbon capture and sequestration, capitalizing on technology that is maturing every day

“ “ “ “

“The primary goal of the improvement project is to meet the global climate challenge head-on, and to be ready for the southeast’s impending demand for building materials with a lower carbon footprint,” Spencer comments. The company has already added a new vertical raw mill, a preheater tower with an advanced kiln line and cooler, an automated clay storage system, an alternative fuel storage facility, and a fully automatic integrated laboratory and control center. Meanwhile, the ongoing installation of electrical motors is expected to reduce energy consumption by as much as ten percent.

“We’ve also eliminated coal as a fuel source, replacing it with biomass,” Spencer continues. “This alone has delivered a 30 percent carbon footprint reduction. The next step for us will be the production of Portland Limestone Cement (PLC) or Type IL, an innovative blended cement that contains up to 15 percent limestone.

We are a local full-service marketing company that has been working with Tractor and Equipment Co for over ten years. We offer visual content development with multiple RED Digital Cinema cameras, graphic development, web, photo, and print, as well as a host of other marketing and branding services. Through the years, we have worked with international brands such as BMW, Shell Oil, Komatsu, and Amerex, and are happy to help you with anything you may need for Tractor and Equipment Co in the future.

This will drop our carbon footprint by another ten percent. We’re currently in the process of conducting testing and making various initial production runs.”

By 2023, it’s expected that all Type I general-purpose Portland cement (OPC) produced in Ragland will be switched to Type IL PLC. But these aren’t the only efficiency measures underway at NCCA. The company is also revolutionizing its shipping operations, prioritizing energy-efficient modes of transportation.

“On a ton-mile basis, shipping by rail is more fuel efficient than shipping by trucks, lowering greenhouse gas emissions by up to 75 percent on average,” Spencer tells us. “Therefore, our carbon neutrality goal impels us to look at moving a larger volume of freight by rail.”

National Cement also owns approximately 4000 acres of land, of which around 800 acres are used for the plant site, storage, and

J & M Tank Lines has been a familyowned company since 1948. While headquartered in Birmingham, Alabama, we have operations strategically located across the southeast to offer the best coverage and service to our customers. As an industry leader in dry-bulk transport, J & M is backed by an elite force of professional drivers and industry experts dedicated to service and safety.

Built on a foundation of integrity and respect, we strive to provide quality service to all. Our purpose is to create an empowering environment for our stakeholders, encourage a team mindset and to exceed industry service and safety standards.

quarrying, with the remaining 3200 acres consisting of timber or grasslands.

“We’re currently studying the best management of our land to gain the best carbon offsets for the future,” Spencer reveals. “Long term, we will embrace carbon capture and sequestration, capitalizing on technology that is maturing every day.

“The Vicat Group is also researching and building new ways to reduce the carbon footprint of all their plants worldwide,” he adds. “We’ll

adopt their designs and technology in order to further reduce our carbon footprint, in addition to what we’ve already accomplished.”

Also speaking to Construction Today, Hervé Lapillonne, Project Manager at NCCA, echoes Spencer’s comments. “In several countries, Vicat Group is very active on the topics of carbon neutrality, with hydrogen, ethanol, solar energy, calcined clay and algae tests underway in some of its plants,” he says. “At NCCA, we have the advantage of being smaller and more agile than Vicat Group as a whole. Although we’re a creator of CO currently, we’re therefore wellpositioned to develop innovative solutions in the future.”

We’re ready to face the future with great confidence

“ “ “ “

“All in all, we expect our investments to make our cementitious product one of the lowest carbon cements in this market,” Spencer reiterates. “It’s a big step in the entire industry’s efforts to achieve carbon neutrality throughout the concrete value chain.”

NCCA’s aim for 2050, like the majority of carbon goals, requires change on the grandest of scales. To reach it, however, is the product of a series of small changes, driven largely by the work of hundreds of dedicated individuals. To this end, Spencer is effusive about what he describes as the company’s “unique family culture,” which he believes creates the foundation for much of NCCA’s success.

“Here, everyone knows everyone,” he confirms. “We’re a lean, largely flat organization. Our management is approachable, and they take it upon themselves to interact with our employees as

In response to the technical and environmental challenges faced by cement manufacturers, Euclid Chemical offers EUCEMTM ICARE, a patentpending strength enhancement technology that offers unequaled performance and reduced CO2 emissions potential.

EUCEM ICARE products improve cement strengths while overcoming process constraints. With the EUCEM ICARE CP range, manufacturers can achieve full cement activation potential via improved cement fineness and particle size distribution. With EUCEM ICARE VRM, customers can expect improved cement quality and reactivity through optimization of the vertical mill process.

EUCEM ICARE maximizes cement activation potential and improves transport properties, while decreasing energy and production costs, clinker factor, and CO2 emissions.

best they can. We’re also hands on in our role, which gives us the ability to react to events and make crucial decisions at speed.”

It’s a quality that came into particular use during the Covid-19 pandemic. “We were able to organize ourselves rapidly, implementing strong health and safety measures to test, isolate, and protect our people,” Spencer recalls. “Fortunately, our industry was deemed essential, as was the construction industry that we serve. Therefore, we continued to operate effectively, with projects running as best they could, and the ongoing production and shipment of cement.

“Resilience is the word,” he then insists, reflecting on some of the logistical challenges of the period. “Although we source the maximum volume of product possible from within the US, we still rely on supplies from Turkey, Egypt, Germany, and elsewhere. Regardless, we kept going, working closely with many of our supplier and vendor partners to navigate the tough times. They

stepped up to ensure they had inventory in stock, or would help us by expediting parts or materials that we needed for our plant operations. It’s a testament to the long-term relationships we’ve built up and maintained over the years.”

Alongside the expansion of NCCA’s Ragland plant, the company has also increased the capacity of its terminals in Greenville, South Carolina and Jefferson, Georgia. Now, the company is building three new terminals: one in Stockbridge, Georgia, servicing the company’s Atlanta customers, along with two in its Nashville market: one in Dickson, and another in Lebanon.

“These terminals will help us reduce truck deliveries from our Ragland plant,” Spencer confirms. “We’ll be adding to our fleet of rail cars to handle these new terminals, and increasing the loading capacity at the Ragland plant to load more rail cars. We’re continually upgrading our fleets and plants.”

For now, the NCCA remains in transition. “We have one of the most beautiful plants in the country now with the technology available,” Hervé states. “The balance, the emission control, and the tools and devices we now have at our disposal is amazing. We’re ready to face the future with great confidence.”

“With the launch of our new production facility, new raw materials, new fuels, an increasing rail fleet, and the addition of more distribution terminals, we have a lot of moving pieces in play,” Spencer concludes. “In the near future, our focus is to increase efficiency across our operations, so that five years from now we’ll have a highly efficient and productive plant. We’ll continue to execute our carbon reduction plan, servicing our customers with quality, consistent products, that allow us both to grow in tandem.” ■

www.nationalcement.com/nccal

Construction of a Macro Cell Tower

TrueNet is one of the leading specialty contractors for telecommunications infrastructure across North America. It has served the broadband, telecom, wireless and enterprise markets since 1985, with its expertise in all forms of communications networks, including: CATV, broadband, fiber connectivity, macro cellular, small cell, M2M and Wi-Fi. In its operation as the North American outside plant delivery arm of Fujitsu Network Communications, who acquired the company in 2016, TrueNet prides itself on possessing the manpower, resources and capabilities to manage, plan, engineer, and build virtually any infrastructure project regardless of its scope, geographic span or underlying technological plan.

The internet is now just as important as any other home utility to your average American, which reinforces why TrueNet has ‘continued growth’ locked in its sights for the near future. Another factor is its advantageous position as a provider of critical services to communication companies, for the provision of high-speed internet. Now, the company hopes to widen that range of services to the broader planning, engineering, and building phases of the telecommunication life cycle.

“We have been a service provider within telecommunications for 37 years now,” opens Bao Mann, Vice President of Sales at TrueNet. “Until recently, we had primarily focused on providing engineering and design services for broadband cable companies, aiding their growth or the maintenance of their outside-plant networks. The way that we are striving to develop the business is to leverage innovation and technology that increases quality and timeliness for any telecommunications company. The broadband cable industry in the US has really only been around for 50 years, and for the most part, the processes and practices have remained relatively the same. We’ve developed a culture of questioning these traditional practices.”

TrueNet’s preparations for the future of high-speed telecommunications in middle America

TrueNet holds ten offices across the US, having closed a number of what it refers to as ‘satellite operation centers’ during the pandemic. As Bao expands: “We have active programs everywhere from Seattle to South Beach, Florida, and have offices that acted as posts for our engineers and technicians based in those regions –

including operation centers in close proximity to our customer offices. During the pandemic, we closed a number of these and enhanced our remote-working model.

“The productivity of our designengineering group, which makes up roughly half of our company, increased significantly,” he continues. “And when

AFL is proud to work with TrueNet Communications, a leading provider of communications infrastructure planning, engineering and design, implementation and technical support services. As one of AFL’s prime contractors for its customers in the broadband, telco and service provider space, TrueNet’s exceptional services and experiences, specifically in fiber optic installation, splicing capabilities and test equipment, enable customers to reach their content delivery expectations. AFL is an international manufacturer that provides industryleading solutions to support the energy, service provider, enterprise, hyperscale and industrial markets. Its products, used in over 130 countries, include fiber optic cable, hardware, transmission and substation accessories, connectivity, fusion splicers, and test equipment. AFL also offers a wide variety of services supporting data center, enterprise, wireless and outside plant applications.

we ran further tests, we found that our employees’ work-life scores had improved too. So, all round it was a good thing.”

Increased productivity among the office staff wasn’t the only change that TrueNet observed. “Something noteworthy about our place within the industry, is that we provide our services to assist our customers on what we call Business As Usual (BAU) projects,” Bao says. Nearly all of our major customers provide services to both residential and commercial consumers. During lockdown, the traditional pattern of usage was turned on its head. Usually, during the day, providers have to supply high-speed internet to businesses, for which robust connections have specifically been built (in a lot of cases, fiber-to-the-business). This completely changed with everybody working from home. Suddenly, our customers needed us to augment their residential networks. We found ourselves providing higher bandwidth connections to people’s homes in order to preserve the same level of capacity. This meant a great deal more opportunities for us.”

Light Detection and Ranging (LiDAR) for the collection of data regarding our engineering efforts,” Bao states. “In the past, we would have sent out a crew of field engineers to our customers’ prospective network locations, who would gather all of the telemetry geodata, addressing and routing information and any other points of interest, such as where we would need to submit build permits. In utilizing LiDAR, we’re able to collect all of this data through a car-mounted laser-scanner in a matter of days, instead of months. As well as the overall efficiency of the collection, the accuracy has also improved dramatically; if there is an artifact of importance to us, which is visible from the street, LiDAR will find it. We’ve seen our overall speed in production increase, and a huge drop in repeat site visits.”

As technology evolves, so the demand for faster connection speeds increases, upon which the market increasingly comes to rely. For TrueNet, therefore, continual investment is a necessity. Recently, the company’s strategy has included large investments in construction machinery, such as boring rigs and trenchers, as well as developing field data collection tools and tablet applications that assist their engineering efforts. In some cases, this has seen project completion time reduce from weeks, down to mere days.

“One of the larger and more exciting technologies that we have employed is

Through multiple acts of exterior government intervention, in the form of Connect America Fund (CAF), the Rural Digital Opportunity Fund (RDOF), and most recently the US Infrastructure Bill (which includes large grants such as the Broadband Equity, Access and Deployment (BEAD) program), TrueNet’s industry has experienced a huge injection of recent finance and activity. Each of the above strive to bring greater opportunities to socalled rural America, by introducing faster, fiber-broadband connections to traditional under-served homes and local communities. This addresses a vital need: a remarkable 20 percent of US homes do not have access to high-speed internet.

“TrueNet takes pride in the fact that we are assisting our customers’ efforts to further develop US telecommunications infrastructure,” Bao explains. “ Thanks to these government initiatives, we are on the precipice of an enormous paradigm shift within our industry. The 2021 Infrastructure Bill alone is

Nearly 27 million households are without access to high-speed internet in the US

set to award $60 billion in the form of loans and grants in order to provide every American access to high-speed internet. Such a massive injection of capital will create an exciting new dynamic, unlike anything we’ve seen before.

US states have already started their application and bid processes for available funds, through which telephone companies, cable companies, non-traditional providers and utility providers will in turn be able to bid for funds to build the fiber connections. “We are about to see a huge swell of activity in US geographies that quite frankly none of us has really ever focused on before,” Bao notes.

“One of the knock-on effects of this radical modernization is that telephone and cable companies who are yet to upgrade to fiber optic cables, will now need to do so in order to stay competitive.”