The digital printing market continues to expand. A recent study published by Coherent Market Insights estimates the global digital print market is worth $27.35 billion in 2022 and is poised to reach $102.55 billion by 2031, growing at a compound annual growth rate of 18 percent throughout the forecast period.

DPS magazine has focused on digital printing since our onset, following its growth and expansion into new markets.

Digital Publishing Solutions (DPS) magazine has focused on digital printing since our onset, following its growth and expansion into new markets. We regularly cover the equipment, software, and media that make maturation possible. Many of these technologies are highlighted in DPS’ annual Top 30 Readers’ Choice Awards—Congratulations Are In Order.

One area rapidly expanding is inkjet, penetrating a range of markets from transitional and direct mail to wide format, labels, and packaging. We focus on advancements in cutsheet inkjet in Competing in Cutsheet. Find more information on inkjet, including webinars and a Target Chart online at dpsmagazine.com.

Speaking of digital label production, vision and inspection systems are essential for print inspection, intuitive operation, and compliance with industry standards for label and package production. Read more in Quality Control. Also, find an expanded web series online.

2024 is poised to be a big year for trade events. Find the first of many articles on Drupa 2024 in this issue, as well as highlights of the Dscoop Edge Indy 2024 conference.

Don’t miss out on real-time news announcements, exclusive editorial, webinars, and more online at dpsmagazine.com.

Best regards,

Cassandra Balentine, editor cbalentine@rockportpubs.com

Cassandra Balentine, editor cbalentine@rockportpubs.com

dpsmagazine.com

Volume 26, Number 2 • ISSN: 1529-2320

EDITOR IN CHIEF

Thomas Tetreault 978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

100 Cummings Center, STE 321E Beverly, Massachusetts 01915

Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon

Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE

100 Cummings Center, STE 321E Beverly, Massachusetts 01915

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy

We’ve compiled news releases from the industry to keep you up to speed with the most recent stirrings in the digital print, packaging, and publishing arena. Check out eleventh-hour updates in each print issue and daily online at dpsmagazine.com. For FREE information about products and services visit dpsmagdirect.com.

Kyocera Corporation developed a new inkjet printhead with ink recirculation technology at the nozzle. It is set to be available in April 2024.

In recent years, ink formulations have diversified to increase productivity and accommodate a wider range of applications. Consequently, demand is rising for printheads that can handle a wider variety of inks at higher speeds while offering better print resolutions and enhanced durability. New printheads must deliver optimized drop volumes to print not only on traditional high-quality papers but also coated papers and films. In addition, as print speeds continue to increase, faster-drying inks are becoming a key priority, placing new compatibility demands on printheads. INFO #206

SCREEN Graphic Solutions Co., Ltd. announces the finalization of the development of its new Truepress JET 560HDX roll-fed digital inkjet press. The system will join SCREEN GA’s lineup for the commercial printing, direct mail, and publishing printing markets.

The Truepress JET 560HDX is expected to drive further innovation in printing. The Truepress JET 560HDX can operate in a variety of print modes, enabling it to handle paper widths up to 560 millimeters at speeds up to 150 meters per minute with a maximum resolution of 1,200x1,200 dpi. It is also compatible with SCREEN GA’s Truepress ink SC2. This high optical density ink set allows printing directly onto offset coated papers without any pretreatment. INFO #207

Baldwin Technology Co. Inc. invests in resources and manufacturing capabilities to meet growing demand across multiple print, packaging, and industrial markets in the Americas. This includes additions to the Americas sales team, and expansion of its LED-UV and IR manufacturing capabilities.

Fueling funding for the investments is Baldwin’s recent integration into BW Converting, a strategic alliance of resources and services that bring together six Barry-Wehmiller companies. Along with Baldwin, they include Paper Machine Converting Co. (PCMC), Winkler+Dünnebier

STAX Technologies, Hudson-Sharp, and Northern Engraving and Machine. INFO #205

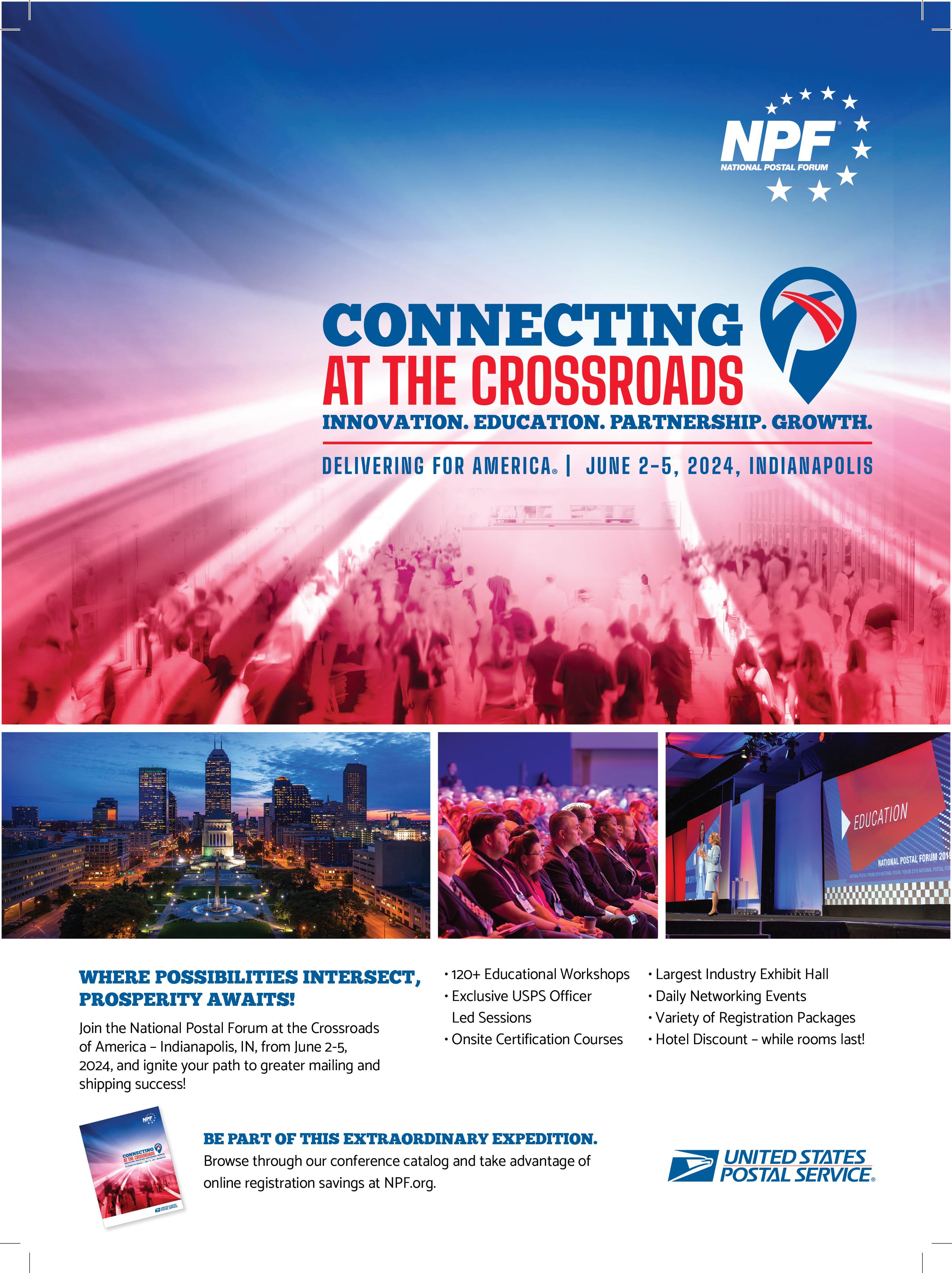

Held from March 24 to 27, 2024 in Indianapolis, IN, Dscoop Edge Indy hosts users of HP industrial print and large format technologies. The event is designed to connect attendees to the people and ideas that help expand business, sell more, find talent, improve sustainability, add automation, and transform.

Attendees have access to a range of educational sessions, keynote presentations, and networking opportunities throughout the conference.

Print business owners and key staff attend Dscoop to network and learn. The conference breaks out its education sessions under a series of tracks, including Owner & Executive, Sales & Marketing, IT Manager, Production Manager, and Operator.

Topics under the Owner & Executive track include sustainable print practices, growing with business diversification, driving scalable growth through partnerships, young talent recruitment and retention, opportunities in flexible packaging, seizing ecommerce business, and photo market trends and opportunities.

Sales & Marketing sessions cover omni-channel marketing, differentiating with sustainability, selling and marketing photo products, optimizing vendor networks, growing and connecting with social media, selling across generations, and accelerating sales and marketing efficiency with artificial intelligence (AI).

IT Managers find insight on print security, load balancing in multi-site print environments, software solutions for business diversification, the realities of AI in the photo applications, robots and the growing labor challenge, and revolutionizing print with AI.

The Production Management track includes standard operating procedure strategies for production managers, achieving production excellence with print metrics, regulatory considerations

from labels to flexible packaging, precision analytics, production floor visibility, and automating print quality control.

Operators learn key ares of HP technologies and solutions, including HP Spark, xRServies, PrintOS, VDP E2E, and OEE.

A large portion of Dscoop Edge Indy focuses on partners. Attendees learn about the latest workflow innovations,

1. HP showcases the power of cutting-edge digital printing technology that is pushing the boundaries of what’s possible. HP Indigo discloses, for the first time, its Drupa portfolio of presses and innovations for labels, commercial print, and flexible packaging.

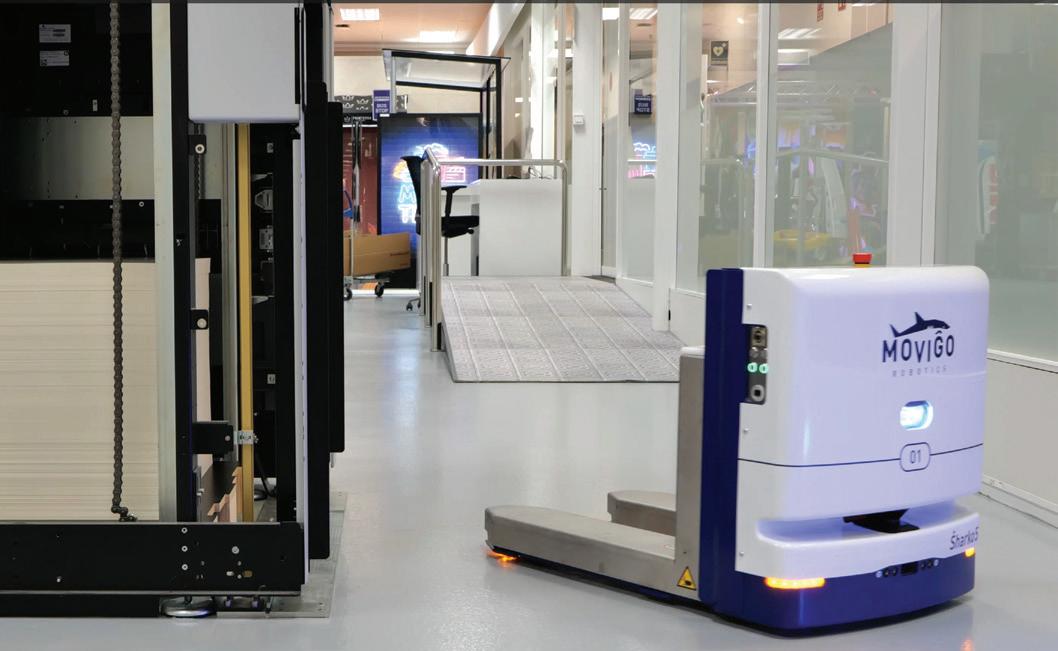

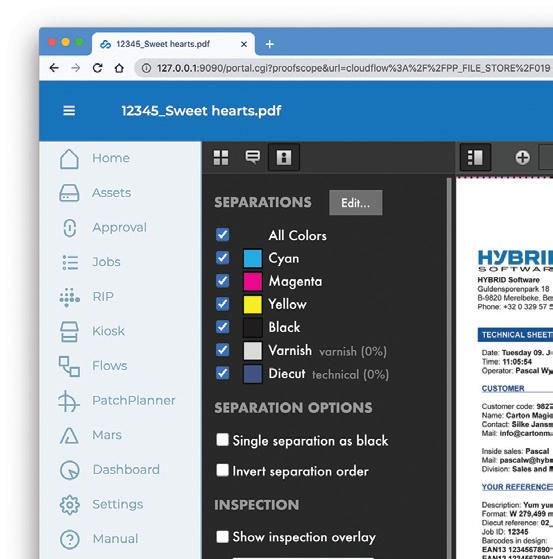

2. MoviĜo’s AMR, the Ŝharko5m, is specially designed and manufactured to load and unload feeders and stackers. 3. HYBRID Software works with partners from MIS to color management to inspection systems to show how to integrate labels and packaging solutions.

for the first time, its Drupa portfolio of presses and innovations for labels, commercial print, and flexible packaging. As it continues to push the industry forward, HP shares its vision of an Intelligent Factory, reinforced by advanced innovations in productivity, automation, versatility, and sustainability. INFO# 260

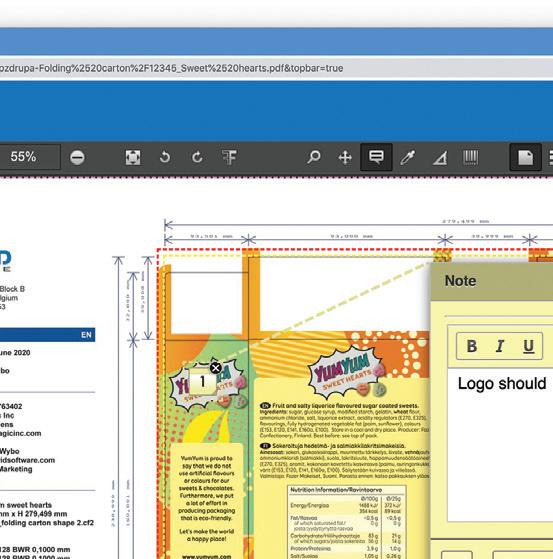

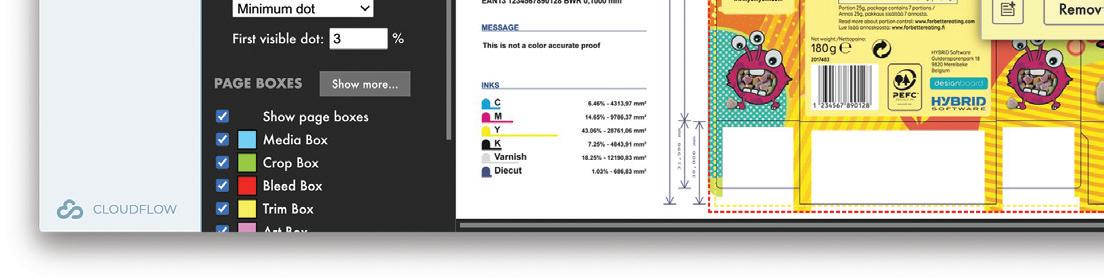

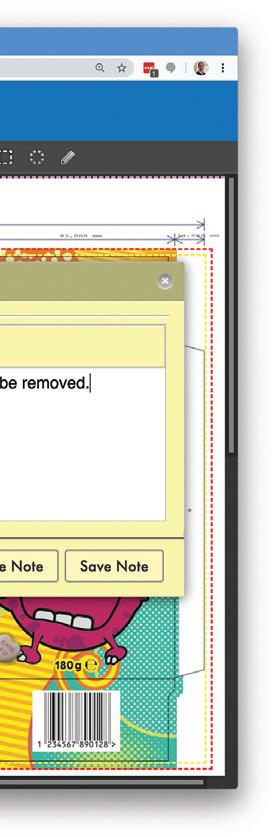

HYBRID PACKZ and CLOUDFLOW are exceptional prepress systems focused on openness and interconnectivity. At Dscoop Edge Indy 2024, HYBRID Software works with partners from MIS to color management to inspection systems to show how to integrate labels and packaging solutions. HYBRID Software is also the provider of front-end systems for the HP T Series digital presses for corrugated printing. INFO# 261

locr GEOservices and MAPS is a leading provider of geomarketing solutions. It helps its partners use location data for marketing success and more costefficient campaigns. Personalized maps show customers the way to your business, which is proven to boost response rates. Its newest solution, the locrFINDER, allows users to create engaging cross-media campaigns with a customized, online location finder and insights on open rates connected to geodata. INFO# 262

Since 2008, Mediaclip has been a global pioneer, providing reliable software platforms for online product personalization and merchandise customization. At Dscoop, it showcases Mediaclip Designer, an empowering editor for retailers and creative end users, along with Platform Plug-ins for Shopify, Magento, and WooCommerce. The Mediaclip W2P platform is compatible with HP web to print (W2P) software and presses. INFO# 263

Michelman showcases DigiPrime Vision, a new series of water-based digital print primers that provide broad substrate compatibility and were engineered to enable the efficiencies of HP Indigo Digital Presses. It showcases its full line of inline primers for all HP Indigo digital dresses, including the HP

Indigo V12 Digital Press. Michelman’s Molly Hladik, global R&D manager, digital printing, presents an educational session on Regulatory Considerations When Moving From Labels To Flexible Packaging In Digital Printing and Lori Gobris, global marketing director, packaging, provides insights on the circular economy on the Initiating Sustainable Print Practices panel. Its deep bench of application experts, who are on-site at the show, look forward to sharing Michelman’s solutions for every application and press platform in the HP Indigo ecosystem. INFO# 264

MoviĜo Robotics and HP launch the first step to the semi-autonomous print shop. MoviĜo Robotics Autonomous Mobile Robot (AMR)—the Ŝharko5—is specially designed and manufactured to load and unload feeders and stackers. It can operate stand alone or completely integrated with HP Print OS, offering a fully automated material flow that supports your production process. INFO# 265

Muller Martini is looking forward to seeing all Dscoopers in Indy! Its staff will be on hand to discuss its new digital solutions. INFO# 266

Nobelus showcases a variety of finishing solutions for the prime label, flexible packaging, digital photo, and general commercial print markets. Both thermal laminates and print web films for solventless/solvent-based lamination are on display to highlight the extensive range of finishes and effects Nobelus offers. FineGrit Film, the newest unsupported film in the Nobelus portfolio, makes its debut as a rugged rough-tough option for the label and flexible packaging space. INFO# 267

As a provider of W2P innovation, OnPrintShop consistently addresses the evolving demands of the print industry with its regular upgrades. Dscoop attendees witness its amplified W2P capabilities across multi-print segments. It is also set to showcase the best-fit usage of advanced business to business (B2B) retail

storefronts for better client engagement. Print enthusiasts witness its capabilities in server SME and ways to leverage B2B storefronts with SSO and punch-out capabilities. INFO# 268

Rollem displays the Revolution and Slipstream, the industry standard machines for playing and trading card converting. Sheets of cards are slit, collated, corner punched, and delivered into decks at record speeds. The company also shows the Insignia7H sheet-fed die-cutting system producing playing card boxes and other folding cartons. The Champion 990 2D system is our economical bi-directional slitting, scoring, and perforating system. Visitors are treated to live demonstrations and sample decks of playing cards at Rollem’s booth. INFO# 269

Standard Finishing highlights its portfolio of print finishing and paper handling solutions. INFO# 270

Other partners exhibiting at Dscoop include B&R Moll, CERM, Contiweb, D&K Group, Inc., EMT, eProductivity Software, E.F. Cooling, Esko, Felix Schoeller, Grafisk Maskinfabrik A/S, GPA, Horizon, Infigo, Karlville, KAMA, Kurz, LabelTraxx, Lemorau, Mamata, Martin Automatic, Matik, Maxcess, Midland Paper, MindFire, Monadnock Paper Mills, Neenah, Newlife Magnetics, Rollem, S-One Labels & Packaging, SEI Laser, Significans Automation, Spencer Metrics, Standard, Taopix, Technotrans, Tracer, Ultimate TechnoGraphics, VerifyMe, VITS International, WestRock, XMpie, and Zaikio.

Dscoop provides a worldwide network designed to offer effective and efficient options to engage with prospective customers. The organization is committed to connecting people and ideas to help businesses grow sales, find talent, expand offerings, automate, transform, and implement sustainability initiatives throughout the year and at in-person events like Dscoop Edge Indy 2024. dps

A leading worldwide trade fair for print technologies, Drupa 2024 is expected to bring in approximately 1,400 exhibitors from 50 countries to Düsseldorf, Germany. The event takes place over 11 days, from May 28th to June 4th, 2024 and promises to be the global stage for a range of new products and innovative technologies designed to serve and grow the print industry.

Last held in 2016, the print industry is once again looking forward to this tradition. We’re already hearing a lot of buzz surrounding this year’s Drupa event.

According to event host, Messe Düsseldorf, the production of packaging and printed packaging are two areas which have also significantly gained in importance. From global players to aspiring newcomers and start-ups—the list of registered exhibitors includes but is not limited to Bobst, Canon, Comexi, Duplo, EFI, Epson, ESKO, Fujifilm, Heidelberg, Horizon, HP, Kodak, Koenig & Bauer, Kolbus, Komori, Konica Minolta, KURZ, Landa, Müller Martini, Ricoh, Screen, Windmöller & Hölscher, and Xeikon.

One highlight of the event is The Cube, which serves as a central discussion forum for print and packaging leaders. Here, internationally recognized top speakers share presentations and panel discussions in line with the Drupa motto—Engage, Entertain, and Educate.

Messe Düsseldorf GmbH, has started building the topics covered in The Cube. Here, visitors find answers to key questions like why print is more important than ever in the digital age; why consumers don’t always see print products as sustainable; and how organizations can calculate their carbon footprint.

Located in Hall 6 of the Düsseldorf fairgrounds, The Cube serves as a place for unique knowledge transfer and networking. Speakers include thought

leaders from the printing sector as well as personalities from advertising agencies, market research, academia, consulting, and associations who each provide in-depth insights on a range of topics.

For those that can’t make the trip to Germany, you’ll find all the news relevant to the digital print space in DPS magazine’s pre-show highlights in May/ June and post-show coverage in July/ August. And of course, find product announcements as they are unveiled online at dpsmagazine.com. dps

1. & 2. Photo Source: Messe Düsseldorf/drupa 2024. Over a period of eleven days, 1,427 exhibitors from 50 countries will present innovative technologies, solutions, and topics that affect the industry now and in future at Drupa 2024.

The evolution of digital printing techniques bring a range of innovations that drive even more demanding requirements from inspection/verification systems providers. John Cusack, product line manager, Inspection Products, Baldwin Technology Co., says the main areas include variable content, more data-driven workflows, more complex brand owner requirements, and the ability to support shorter run lengths.

Guy Yogev, senior director product marketing, AVT Inspection Product Line, Esko, points out that the global packaging and labels markets faced many challenges in recent years after the COVID-19 pandemic and the situation of economy, instability, high interest rates, and inflation; sustainability and recyclability; rising costs of materials and energy costs; and limited, experienced professional labor; as well as changes in brand owners’ needs with increasing number of SKUs and shorter job lengths.

Further, special features are increasingly added to print and packages, as well as special coatings, variable codes, and security factors that need to be verified. “Quality standards remain high and require high-resolution, high-speed inspection solutions,” shares Yogev.

Inspection and verification systems for labels and packaging segments are expected to ensure quality and reliability. “Users are looking for a quality inspection ‘insurance policy’ for consistent flawless output and minimal errors,” shares Meredith.

It is also important to consider prepress. “Of course, an inspection/verification system needs to know what it is looking for, and this is best prepared in the prepress system,” shares Mike Agness,

EVP, Americas, HYBRID Software. Solutions like HYBRID PACKZ and CLOUDFLOW prepress systems set up each job for inspection/verification and advise inspection systems to look for items such as color, variable data, and barcodes—among many others.

Particularly with digital presses, time is of the essence. “As jobs race through the facility, a prepress system must be able to set up these parameters quickly. Remember that two PDF files are usually created—one for the RIP and press, and one for the inspection system. A good prepress system prepares them automatically and from the same incoming file. What makes them different is the removal of die layers in the PDF for inspection, but these might be on the print file for lead-in/lead-out creation. Just as important, they have to be accurate in defining what to look for. You don’t want to stop a 1,000-foot roll from a digital press either because the verification parameters have not been defined or, worse, defined incorrectly,” explains Agness.

Meredith says security and traceability also play a role, and these areas have become more critical as companies are expected to protect data integrity and comply with regulations.

Rising demands in different industries, such as food, pharmaceutical, or fast-moving consumer

goods, increase the complexity of information on labels and packaging.

We cannot forget about sustainability. By preventing printing errors and minimizing reworks, Schwarz admits that vision/inspection systems eliminate a large amount of waste and ensure environmentally responsible production processes.

As digital print technologies continue to advance, shifting market needs and demands, vision and inspection systems are on par to keep up. One technology in particular is poised to have a big effect on the future of verification/inspection systems. You guessed it—artificial intelligence (AI).

“AI is going to be one of the innovations we see getting into print inspection to improve manual processes, streamline quality standards, and improve the focus on sellable product versus rejected/non-sellable,” agrees Yogev.

Transactional and direct mail environments rely on vision inspection systems. In both the transactional and direct mail markets, Yashashree Potdar, workflow solutions analyst, Standard Finishing Systems, explains that inspection systems have evolved to keep up with higher speed digital presses as print providers identified inspection systems as a major bottleneck in production.

Today, inspection systems perform better and are working in real time. For inkjet production, vision and inspection systems quickly find defects like nozzle streaks and color issues as well as reduce waste and overprints.

In the transactional market, vision and inspection systems are essential. “Print providers in this space aren’t just concerned with the cost of reprinting; they open themselves up to liability if they do not meet data integrity standards or compliance regulations. The room for error in the finished product is functionally zero. Vision and inspection systems in this market must have a high level of accuracy or print providers could be putting their clients at risk,” states Potdar.

Feizi sees AI impacting inspection systems over the next couple of years through the development of AI algorithms trained to automatically detect and classify various defects, such as misprints, color variations, streaks, and registration errors and thus reduce the rate of false positives flagged. This will reduce time spent on verifying alerts that slow down production.

“As AI continues to expand, our inspection systems will have the ability to learn from extensive data sets, leading to more intelligent defect detection and automatic classification. This will enhance the accuracy and efficiency of the

Vision and inspection systems in this market must be able to work inline to identify issues before a printed web is rewound, track and verify at the individual page level, generate audit reports, verify material imprinted with 1D and 2D code, optical character recognition characters, MICR, addresses, or optimal marking recognition, and easily integrate with existing software and compliance frameworks.

As variability and complexity increase in the direct mail market, manual inspections are no longer cost effective. “The cost of a reprint—both financial and time cost—also increase as mail pieces become more complex and personalized. Providers need inspection solutions that improve application quality without slowing down production.”

When used effectively, today’s quality assurance systems also prevent waste by identifying defects earlier in the production process. “These systems identify printing errors in real-time to prevent costly re-work, even on high-speed presses, and automatically generate a variety of exportable production reports for compliance,” concludes Potdar.

systems, reducing instances of false positives and negatives,” predicts Schwarz.

By integrating machine learning algorithms and cloud-based systems, Schwarz says inspection systems will become more adaptable and proficient in handling intricate printing and finishing environments, optimize packaging, as well as labeling efficiencies.

Yashashree Potdar, workflow solutions analyst, Standard Finishing Systems, finds it difficult to speculate on what role AI will have in print inspection in the future. “Going forward, any technology that removes manual touchpoints and improves end-to-end

automation will be important in the development of vision/inspection systems. At this exact moment, print inspection requires a level of precision that most market-ready AI still hasn’t mastered. But that doesn’t mean that day will never come. Companies are already making in roads with high-precision AI image classification.”

Further, Ben Avraham points out that predictive maintenance will be a game changer. “It will enable the systems to anticipate and address potential failures before they occur, thus minimizing downtime,” he offers.

Vision and inspection systems are important to label and packaging environments. As digital adoption grows, the pressure is on to ensure not only quality, but accuracy complies with shorter runs and variability in a way that doesn’t impede production and profit.

Visit dpsmagazine.com for a web series that digs deeper into the evolution, challenges, and solutions for vision and inspection systems. dps

Stojanovski points to the ability to print on synthetic or specialty stocks, thick stock, and specialty inks beyond CMYK as a continued limitation of inkjet.

Little sees speed and media as current limiting factors when compared to offset and toner production printers. “However, the market is maturing and these challenges are being solved with top-tier technologies,” he stresses.

“Substrate latitude is often the first thing customers see as a limitation,” shares Graupman. He says this is addressed with new solutions like enhanced drying capabilities and technologies that allow direct-to-gloss coated offset paper without any additional steps or special papers.

Shalev points out that direct inkjet places wet ink directly on paper, which may create unwanted interactions between paper fiber and ink. Nanography avoids these issues by placing NanoInk on a blanket, and then transferring a dry image from the blanket to the paper.

Limitations are reduced every year as cutsheet inkjet capabilities grow. “The main difference remaining between web and cutsheet presses is the production throughput,” shares Toole.

In addition, Toole admits that variable print costs may be lower with a web inkjet. However, this may not necessarily be true for the total print costs including capital costs or depreciation. “Because of this, the lower capital cost associated with cutsheet presses makes most applications attractive to print on a cutsheet device.”

Experts feel that despite progress, there are still misconceptions about today’s inkjet capabilities.

“The first misconception would be that inkjet image quality is unable to match Xerographic image quality. Now that we are there, most people think there is a single device that can do everything. There are limitations to both Xerographic and inkjet-based solutions so there is room for both,” shares Stojanovski.

If you asked the question about the limitations of inkjet a decade ago, quality would be among the top concerns. However, Graupman suggests that while quality used to be perceived as a limitation, it is rarely the case today. He

stresses that as with many other print processes, cutsheet inkjet only continues to improve. “Today, there are many cutsheet and roll-fed inkjet solutions that can address just about any ink on paper quality requirement.”