THE HARDEST WORKING MACHINES HYDRAFORCE. RELY ON

What are your machine challenges? You’ll find the answers with HydraForce – the world leader in precision hydraulic motion con for mobile and industrial applications. Partnering with HydraFo you’ll have access to unmatched engineering expertise; the indu broadest range of cartridge valves; custom integrated-circuit m and best-in-class remote-management solutions. Now you have the power to build a better machine. Visit HydraForce.com.

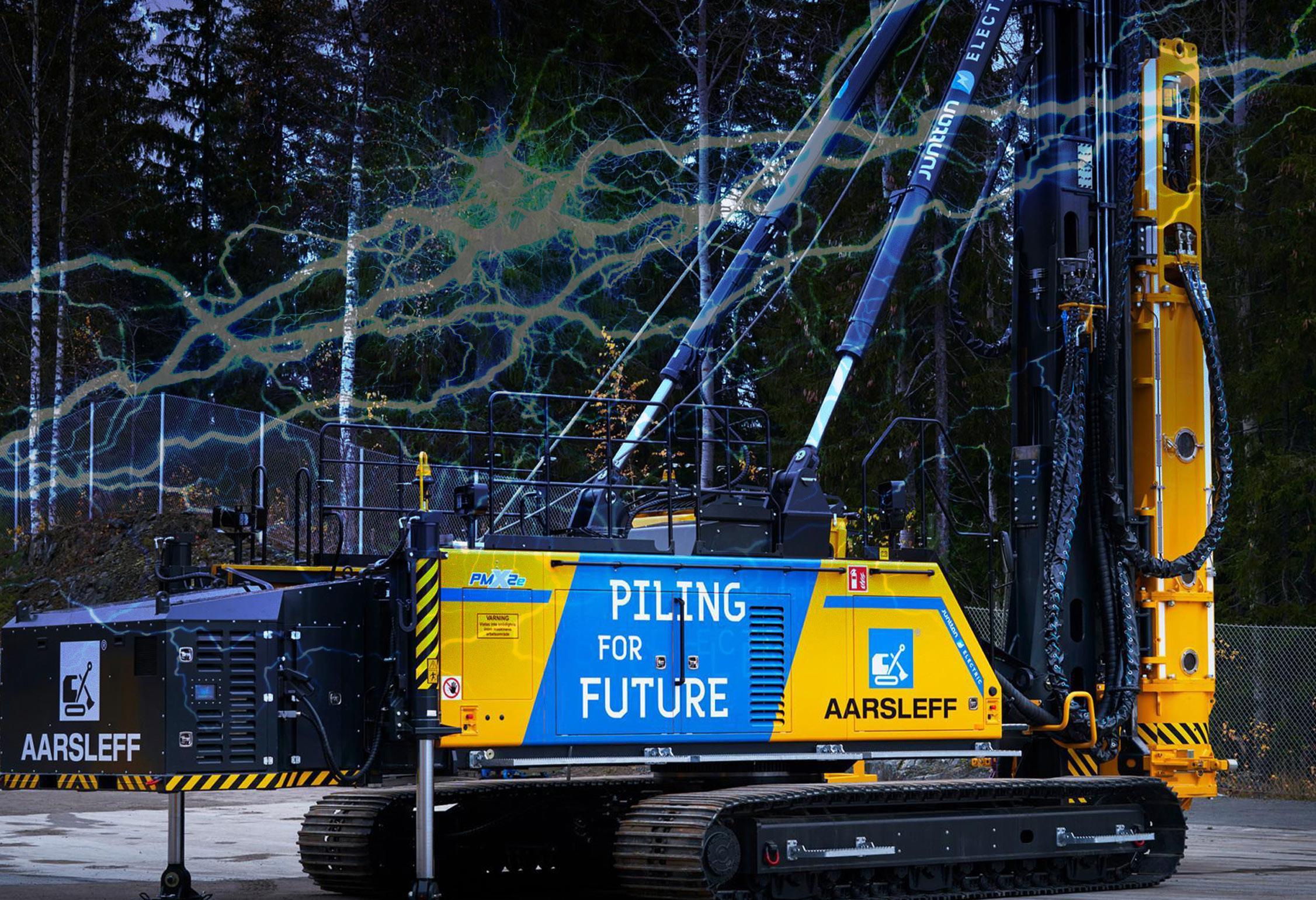

COVER SERIES: THE POWER ISSUE

18 Rumsey Encourages OEMs’ Patience Through the ‘Messy Middle’

The zero-emission transition includes optimized diesel technology, alternative fuels and battery electricity.

22 Hydrogen Offers Power Options

Whether an HICE or FCEV, this power source is part of a zero-emission future.

24 Why Electrified Machines Are Simply Better

Much more than environmental benefits, EVs perform better and reduce operating costs.

27 Thermal Management in the Electric Age

How to keep commercial EVs working year-round

30 What Has Europe Done to Spur Adoption of Electric Machinery?

By 2030, the EMEA region will have a penetration rate of electric excavators that is double that of North America.

SPECIAL REPORT

12 From the Show Floor: CONEXPO Post-Show Roundup

Some aspects exceeded expectations, including more than 139,000 attendees.

LUBRICATION

32 Environmentally Friendly, Sustainable & Bio-Based: Untangling Common Terms

As environmental protection becomes an increasingly hot topic, it is important to understand the subtle but critical differences between environmental protection and sustainability and between bio-lubricants and environmentally acceptable lubricants.

This is our POWER issue! Our cover series this month features stories about power sources, from optimized and new diesel engines to the Number One power topic during CONEXPOCON/AGG (CONEXPO): hydrogen. All engine original equipment manufacturers (OEMs) were talking about this abundant element and how it may be the future of large, off-highway equipment operation. Most manufacturers had a hydrogen-combustion engine product prototype in their booths.

The Hydrogen Focus

Hydrogen is discussed in nearly every article in the cover series, particularly in “Hydrogen Offers Power Options” on page 22 and “What Has Europe Done to Spur Adoption of Electric Machinery?” on page 30.

Cummins CEO and President Jennifer Rumsey discusses the messy middle of the move to zero emissions on page 18, where hydrogen also plays a role.

Ready for more about CONEXPO-CON/AGG because we aren’t done yet! Check out our Special Report from the show floor on page 12 to learn everything we saw and experienced during the event.

Summer Trade Shows

We also look forward at upcoming trade shows we will be attending including iVT Expo in Chicago and The Battery Show and Electric & Hybrid Vehicle Technology Expo in Novi, Michigan. Our team enjoyed attending them last year and look forward to seeing everyone again this year. Check out our Trade Show Preview on page 6 to learn more.

EDITORIAL ADVISORY BOARD

Craig Callewaert, PE, Chief Project Manager, Volvo Construction Equipment

Roy Chidgey, Business Segment Head, Minerals Projects and Global Mobile Mining, Siemens Large Drives US

Andrew Halonen , President, Mayflower Consulting, LLC

Terry Hershberger, Director, Sales Product Management, Mobile Hydraulics, Bosch Rexroth Corp.

Steven Nendick, Marketing Communications Director, Cummins Inc.

John Madsen, Director Engineering & Product Management, GKN Wheels & Structures

Doug Meyer, Global Director of Construction Engineering, John Deere

Andy Noble, Head of Heavy Duty Engines, Ricardo

Daniel Reibscheid, Business Development Manager, MNP Corporation

Matt Rushing, Vice President, Product Line, Global Crop Care, AGCO Corp.

Allen Schaeffer, Executive Director, Diesel Technology Forum

Keith T. Simons, President – Controls Products, OEM Controls, Inc.

Alexandra Nolde , Senior Communication & Media Specialist, Liebherr-Components AG

Bob Straka, General Manager, Transportation SBU, Southco, Inc.

Luka Korzeniowski, Global Market Segment Leader, Mobile Hydraulics, MTS Sensors

Chris Williamson, PhD, Senior Systems Engineer Global Research & Development, Danfoss Power Solutions Company

EDITORIAL

Editor Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Kimberly Fleming

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

Sales Representative Mark Gates mgates@acbusinessmedia.com

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: 877-201-3915 Fax: 847-291-4816 circ.OEMOff-Highway@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Sales Representative Greg Schulz 920-542-1239 | gschulz@acbusinessmedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication shall be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

SUBSCRIPTION POLICY: Individual print subscriptions are available without charge in the United States to original equipment manufacturers. Digital subscriptions are available without charge to all geographic locations.

Publisher reserves the right to reject nonqualified subscribers. Subscription

Prices: U.S. $35 One Year, $70 Two Years; Canada and Mexico $60 One Year, $105 Two Years; all other countries, payable in U.S. funds, drawn on U.S. bank, $85 One Year, $160 Two Years.

OEM Off-Highway (USPS 752-770, ISSN 1048-3039 (print); ISSN 2158-7094 (online) is published 6 times a year: January/February, March/April, May/June, July/August, September/October and November/December by AC Business Media, 201 N. Main Street, Ste 350., Fort Atkinson, WI 53538. Periodicals

Postage paid at Fort Atkinson, WI and additional entry offices. POSTMASTER: Send address changes to: OEM Off-Highway, PO Box 3605 Northbrook, IL 60065-3605. Printed in the U.S.A.

@OEMOffHighway

Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 800-538-5544 www.ACBusinessMedia.com

www.OEMOffHighway.com www.IronPros.com

Challenge Everything

We created solutions that deliver more power, reliability, and fuel savings. Leveraging the R&D resources and proven experiences of the Volvo Group to bring our customers to the forefront of sustainable driveline technologies.

Together, let’s rethink the possibilities and take your operations – and bottom line – to the next level with Volvo Penta´s industry-leading Tier 4 Final solutions.

Lower Total Cost of Ownership

Better Value In The Long Run

Fuel Efficiency

Reduce Your Operational Cost

Service and Support

Global Dealer Network With Local Expertise

iVT Expo USA 2023

August 23 & 24, 2023

Donald E. Stephens Convention Center, Chicago

The show last year was the first iVT Expo in the U.S., and it was a huge success. Our team was thrilled to attend and talk with attendees and exhibitors about trends in the off-highway vehicle industry. The show will be held again this year in Chicago, at the Donald E. Stephens Convention Center in Chicago.

A Show for Designers & Engineers

While many of us spent a week in Las Vegas for CONEXPO-CON/ AGG, this show is different. It is for the design and engineering community only. It’s about coming to an event created specif-

ically for finding technology solutions, supply chain partners and new concepts. There will only Tier 1, 2 and 3 suppliers exhibiting. This includes technology and component providers of electric and hybrid solutions.

Conversations from 2022

During the expo last year, our team visited numerous exhibitors and had informative and fun conversations. Some of these exhibitors are included in this preview so that you get an idea of some of the folks you’ll get to see.

If you want to be part of the fun and conversation this year, you can learn more and register at ivtexpo.com/usa.

This will be the second year for this show to be held in the U.S.We met friends and colleagues, like Ben Chiswick from Drive System Design, at the OEM Off-Highway booth and other booths. We learned about the joystick technology exhibited by APEM. The Turntide Technologies team shared their technology for oil production during iVT Expo 2023. In 2022, we enjoyed talking with the Grayhill team during iVT Expo.

The Battery Show & Electric & Hybrid Vehicle Technology Expo

Access four educational tracks and more than 775 exhibitors during these events.

September 12 to 14

2023 Suburban Collection Showplace, Novi, Michigan

The Battery Show and Electric & Hybrid Vehicle Technology (EHVT) Expo are collocated in Novi, Michigan, in September 2023 at the Suburban Collection Showplace. The battery and electric industries attend and exhibit in full force.

From manufacturers to companies that help manufacturers create batteries, the battery industry is at The Battery Show. These events give attendees access to four tracks of education. Attendees can also talk with more than 775 suppliers.

To learn more or to register, visit thebatteryshow.com or evtechexpo.com.

It was great to talk with the Webasto team last year and learn about their EV solutions.

We talked with Littelfuse right before their Off-Highway webinar.

We enjoyed talking with the GROB team last year. They will be back this year highlighting their turnkey EV manufacturing and assembly solutions.

Cool to see the Dow team and their awesome car.

We enjoyed talking with the GROB team last year. They will be back this year highlighting their turnkey EV manufacturing and assembly solutions.

Cool to see the Dow team and their awesome car.

US MACHINERY NEW ORDERS UP MORE THAN 17% & TRUCK PRODUCTION INCREASED.

Elevated interest rates may affect many of the indicators further into 2023. Many of these indicators and data for this article are on upward trends. However, fears of a recession and several bank failures with increasing interest rates may stall growth. Learn more from this report.

• The U.S. OECD leading indicator declined in February. The monthly rate of change has moved higher in recent months, but more data would be needed to confirm a shift in momentum.

• The indicator suggests that downward pressure on the U.S. economy will persist into at least the latter half of this year.

QUESTIONS?

US Industrial Production

• In the three months through February, U.S. industrial production came in 0.4% higher than during the same period one year ago.

• Recent bank failures, in part because of a failure to hedge interest rate movement, have made headlines. The situation appears to have stabilized but likely means that tighter borrowing conditions are ahead for businesses.

US Private Nonresidential New Construction US Total Public New Construction

• U.S. private nonresidential new construction in the three months through January was 19.7% higher than it was for the same period one year ago.

• As the nonresidential sector lags the macroeconomy by roughly one year, the early-2022 growth rate peak in the U.S. economy suggests a growth rate peak for construction is likely approaching.

• U.S. total public construction totaled $366.4 billion in the 12 months through January, up 6% from one year prior.

• Trends in the quarterly growth rate suggest accelerating growth for construction in at least the near term.

Sponsored by Eberspächer

US Farm Machinery Production Europe Ag & Forestry Machinery Production

• In the 12 months through January, U.S. Farm Machinery and Equipment Shipments totaled $30.1 billion, down 3.5% from the same period one year ago.

• U.S. Farm Proprietors Income (with inventory valuation adjustments) tentatively ticked down from a late-2022 record high. While high Income bodes well for the ability to invest in machinery, elevated interest rates and lower commodity prices are downside pressures.

• In January, annual European agricultural and forestry machinery production was 6.3% more than the year-ago level.

• Ukraine officials have stated that they expect grain production to be lower this year because of the war in their country. The war may negatively impact demand for agricultural machinery.

Europe Leading Indicator

• Monthly data for the four big European nations (France, Germany, Italy, and U.K.) leading indicator has been relatively flat since October. The monthly rate of change has risen for the last four months.

• The indicator trend could be a sign of an upcoming cyclical trough for the European economy. However, tightening monetary conditions and volatility in the banking sector could mean a more prolonged period of cyclical decline.

US HeavyDuty Truck Production Germany Industrial Production

• U.S. heavy-duty truck production in the 12 months through February was 12.7% higher than one year prior.

• Flat freight activity, declining freight rates and elevated interest rates will likely hinder demand in the coming quarters.

US Mining Production

• Annual U.S. mining production in February was 7.6% above the year-ago level.

• Performance varies by component. Mining excluding oil and gas is declining, and oil and gas production growth is slowing.

• For the three months through January, German industrial production came in essentially even when compared with the same three months one year ago.

• Recent increases in equity prices in Germany signal some upside potential for the German economy. However, the high interest rate environment and cooling global demand ultimately suggest further cyclical decline for production.

US Construction Machinery, New Orders US Defense Industry, New Orders

• U.S. construction machinery new orders in the 12 months through January totaled $44.5 billion, up 17.9% from the same period one year ago.

• Elevated interest rates will likely impact this market via reduced demand from the residential sector and higher financing costs.

NUS Mining & Oil Field Machinery Production Index

• Annual U.S. mining and oil field machinery production in February was up 6.7% from the year-ago level. Production has tentatively transitioned to a slowing growth trend.

• With economic demand slowing, and oil and gas production in a slowing growth trend, it is likely that demand for mining and oil field machinery will slow; expect more rate-of-change decline this year.

• Annual U.S. defense capital goods new orders was 10.9% above the year-ago level in January.

• Rising geopolitical tensions and trends in the new orders quarterly growth rate signal that accelerating growth will continue in at least the near term.

NOKIAN TYRES TRI 2

VERSATILE PROFESSIONAL CONTRACTING TIRE FOR YEAR-ROUND USE

Nokian Tyres TRI 2 excels in a wide variety of tasks from job sites to highways, from snowy winters to hot tarmac. Its durability, economy and comfortable driving response make it a reliable choice for versatile contracting work.

nokiantyres.com/heavy

From the Show Floor: CONEXPO Post-Show Roundup

by Lori Ditoro

by Lori Ditoro

The madness of March was not limited to the basketball court. My first CONEXPO-CON/ AGG (CONEXPO) experience was as advertised by my colleagues and coworkers: large square footage, miles of walking, sore feet all day, and great people and conversations at every booth.

However, some aspects of the event exceeded expectations, according to the Association of Equipment Manufacturers. More than 139,000 people attended the event, with 2,400 exhibitors sharing innovative technologies and introducing new brands. Many of the new equipment and brand updates follow.

Caterpillar’s New Engine

During several events at CONEXPO, Caterpillar unveiled its new C13D engine. These events included a preshow press meeting, a dealer presentation at Allegiant Stadium and a booth unveiling where I interviewed experts to get more details about the engine.

Engineered for reliability and productivity, the inline, six-cylinder Cat C13D engine platform will offer eight

power ratings from 456 horsepower (hp) to 690 hp—340 kilowatts (kW) to 515 kW with up to 3,200 Newton meter of peak torque.

In addition to the new engine, the team discussed its focus on sustainability that includes:

• Right sizing the engines in machines

• Exploring all power sources

• Helping charge/fuel equipment

• Supporting infrastructure for electric and alternative fuel accessibility

• Using technology to manage idling

• New apps were also discussed Media also received a preview of the Global Operator Challenge and met the nine operators competing in the Operator Stadium during CONEXPO. Most of the operators began their love of equipment riding with their fathers at a young age. The competitors were:

• Fernando Nasciemento – Brazil

• John Schiedeck – U.S.

• Lukasz Mokrynski – Poland

• Masato Imai – Japan

• Matt Ferris – U.S.

• Nick Thompson – Australia

• Patrick Doheny – Australia

• Pontus Eriksson – Sweden

• Sebastian Behr – German

During the conversation, I asked what technology has most helped them do their jobs better. Most mentioned connective or IoT technology, saying it moved them from the stone age to the modern age. Some of the technologies highlighted were:

• Graders

• Trenchers and grade assist

• 3D and 2D systems (slope precision and geofencing)

On Tuesday, March 14, 2023, Patrick Doheny of Australia took the crown out of nine finalists from around the world who competed in the final round of the Global Operator Challenge in the Cat Operator Stadium in Las Vegas.

During the main show, we talked with the Cat team about the new technology at the show, including the smallfootprint C13D.

Accelera, the New Brand by Cummins

At a press conference during CONEXPO, the Cummins team discussed its plans for moving to zero emissions for its customers. Eric Neal, Cummins executive director, off highway, discussed recent acquisitions and partnerships, including

Meritor, and how they help Cummins’ future. They provide:

• Strategic partnerships to help decrease carbon emissions

• Secured supply chain partners

• Paths to electrification, alternative fuels and advanced internal combustion engine performance

“Cummins powers more types of machines and vehicles than anyone else. The breadth of our business across market segments and regions means that we are the ideal partner to help our customers through this transition,” Neal said.

Then Amy Davis, president of

Next generation displays

Accelera, Cummins’ new brand with a zero-emission mission, talked about the goals and products of the brand, which represents a new era for Cummins.

Davis echoed the sentiments that Cummins President and CEO Jennifer Rumsey shared during her keynote

Giotto and Leonardo have been first choice customizable displays for manufacturers of agricultural and earth-moving vehicles for many years now. Today the two successful displays have been upgraded and based on the Linux operating system and the Qt framework.

NO NEED TO RECODE

With the new version of Giotto and Leonardo featuring Linux and Qt tools, OEMs have the possibility to reuse some existing applications on MTA hardware without the need to recode them from scratch.

SOFTWARE ADVANTAGES

Thanks to Qt, the new displays will enable future-proof and best-performing applications’ development.

HARDWARE FOR TOUGH ENVIRONMENTS

Giotto and Leonardo are built to resist the rugged conditions and harsh environments typical of construction applications.

at the Green Truck Summit and in her podcast with OEM Off-Highway. There is no one answer for powering future off-highway equipment. Power providers must consider battery electric, hydrogen fuel cells, alternative fuels, and hydrogen combustion. Davis talked more about this in our exclusive interview following the press conference. Learn more with this article.

The OEM Off-Highway team also joined Cummins Marketing Communications Director Steve Nendik for a full tour of the equipment featured at the booth. One of the most popular was the fuel agnostic engine that showed the common parts of the engine and the different parts (the top) for each fuel.

Isuzu Motors America Presents Engines That Generate Power

During Monday’s media day, we were happy to join the Isuzu Motors America team for lunch and a great conversation around what the company was exhibiting at their booth.

The equipment included Open genset power units that help OEMs provide power to machines and standby power solutions.

Yanmar Goes Green at CONEXPO

At its press conference, the Yanmar team presented its Green Challenge 2050 vision for the future. This included:

• 4TN107FTT Powerpack

• HIPOWER SYSTEMS’ EHR Battery Power Generator

• ELEO modular, high-density battery

• The vision includes new Yanmar products and acquisitions and partnerships.

JCB: All in on Hydrogen

The JCB team debuted its hydrogen combustion engine in North America during CONEXPO. The press conference covered the details that OEM OffHighway featured in its March/April 2023 cover series. The hydrogen combustion engine was designed from the ground up, and features:

• Hydrogen and air mixing—Using a gas as fuel required a uniform mixing

of fuel and air.

• Air compression—Forcing the air into the mixing/combustion chamber or cylinder required a turbocharger.

• Spark ignition—Better sparkplugs were necessary.

• Steam management—Steam is the only emission and corrosion could occur.

Parker Hannifin Mobile Smart Systems

Our team was pleased to talk with Anne Marie Johlie, head of Internet of Things (IoT) and connected products, who gave us a tour of several technologies on exhibit. Among them was the technology through Parker’s partnership with Camgian for machine learning, mobile IoT, converters, a controller module and mobile pumps.

Impact sensors, part of the mobile IoT, are important for equipment owners and operators. They monitor the magnitude of an impact, which is beneficial for operator safety and for warranties.

DEUTZ Shares Plans to Grow Classic Business & Move Toward Alternative Power

During a conversation with CEO Sebastian Schulte and senior vice president, communications and investor relations, our team learned more about DEUTZ and its future. Schulte discussed the need and desire to support and grow their classic diesel business, where the company produced 185,000 engines. The diesel engine range is 2.2 liter to 18 liter.

However, he knows that DEUTZ must look to the future. A carbon-zero future

includes a mix of power alternatives: electric, alternative fuels, hydrogen fuel cells and hydrogen combustion. Schulte said he feels that hydrogen combustion is best for off-highway applications that require more power than battery electric energy can provide.

Also, a strength for DEUTZ is its partnerships. Specifically, the partnership with Daimler Truck to provide its medium-duty and heavy-duty engines has been positive and helped consolidate the market.

Bosch Rexroth Features Partnerships & Acquisitions

Providing breakfast and information, the Bosch Rexroth team hosted a press conference to discuss the recent Hydraforce acquisition, the partnership with Hägglunds and its electrified technology. President and CEO Greg Gumbs discussed the company’s growth in Mexico and the goal of transforming mobile machines.

JDPS Displays Battery Electric Technology

Our team took a booth tour with the John Deere Power Systems (JDPS) team. Expanding its sustainable technology, JDPS exhibited its growing battery portfolio that includes more modular power options and new electronics hardware solutions. As more of the industry moves to electric, JDPS is investing significant resources in battery and charging technologies for off-highway equipment applications. Together, JDPS and Kreisel Electric (Kreisel) are working to expand the production capacity of Kreisel and accelerate the development of the company’s battery technology.

In addition to the 63 kWh Kreisel KBP63 battery that was displayed at bauma 2022, three new concept Kreisel batteries were displayed during CONEXPO, including 20 kWh and 40 kWh power options. JDPS has also designed a family of electronics hardware that enables seamless connection to help deliver a complete system for original equipment manufacturers (OEMs). The

newest technology, on display at the booth, was the Gb Ethernet Switch. This module manages the transfer of controls information and other data to multiple devices in a system, all in real time.

Volvo Penta & Gradall Share Fully Electric Excavator

During a joint press conference, Volvo Penta and Gradall shared a fully electric, highway-speed excavator powered by a Volva Penta electric driveline. The

excavator will have another year of testing before it is available. The Volvo Penta team took a systems approach and provided

a complete system including batteries, motors and cabling. According to Darren Tasker, vice president, industrial sales, for Volvo Penta, the product will evolve over time. His team is committed to sciencebased sustainability.

Moog Construction Features Automation & Electric Technology

Moog Construction launched TerraTech during CONEXPO, an ecosystem for

DEPENDABLE

compact construction OEMs to design and build all-electric, zero-emissions vehicles, in some cases within six months. It is included on the newly launched Bobcat S7X.

While at the booth, I had the opportunity to program a loader to perform a series of tasks. It doesn’t matter what equipment is used. The system performs the same way.

Littelfuse Shared Equipment with Our Team

The OEM Off-Highway team enjoyed talking with Littelfuse. They told us about their portfolio of direct current contactors. In addition, we discussed the difference between fuses for the automotive industry and for the offhighway industry.

The team also exhibited a fuse holder for up to 70 volts.

If dependability is something you value in life, look no further than Ace brand pumps. Every Ace pump features state-of-the-art design, advanced components and uncompromising quality control. The end result: pumps you can count on for years of reliable service. To learn why an Ace pump is a farmer’s best friend, please visit us at www.acepumps.com, or contact your nearest Ace Pumps distributor.

Danfoss Fluid Power Featured Dextreme for Excavators

When our team met with Danfoss Fluid Power, they shared the new Dextreme system. According to the press release, Dextreme systems improve excavator

energy efficiency by 15% to 50%, regardless of the power source, while maximizing productivity.

The Dextreme pathway consists of three incremental system solutions: Swap, Flex, and Max. The simplest configuration of the system, Dextreme Swap, is now available. Dextreme Swap replaces the excavator’s main hydraulic pump with a Digital Displacement pump, custom software and digital controller, delivering a 15% reduction in fuel use and carbon dioxide emissions.

The team also shared the PC36 Controller and PC-Go Software. PC-GO is a propel solution for single pump/ motor hydrostatic transmissions. Comprising the new PC036 safety controller and PC-GO propel software, the ready-to-use platform cuts propel subsystem development time by up to 35% while simplifying compliance with environmental and safety regulations.

The last new technology the team

shared was a family of CAMLOBE motors. These motors took 4 years to produce and have improved life and efficiency, smooth operation for the operator and a compact design.

Hatz Diesel Showcased Digital Solutions, Concept Cube

New digital solutions featured at the Hatz Diesel booth during CONEXPO included:

• Vehicle performance tracking

• Productivity

• Maintenance planning

• Geoposition/geofencing

• Error codes

• IoT dashboard

The digital solutions can be retrofit into equipment.

FPT Featured Engines

Our team caught up with FPT and learned about its range of engines, including the technology that operates

THERMAL MANAGEMENT SOLUTIONS FOR

We partner with OEMs and suppliers to design and manufacture custom solenoids, valves, and valve systems for current and emerging mobility platforms.

+ Multiple in/multiple out

+ Coolant control/switching

+ Proportional control

+ Diaphragm, spool, & pilotoperated

+ Valve systems and manifolds

+ Magnetics for axial flux motors

+ Customized sensor integration & feedback

on alternative fuels. These fuels include hydrotreated vegetable oil, biodiesel and natural gas. The team is working on a move to hydrogen and produced a 13-liter engine prototype last year. They are also improving customer service with connectivity services, an extended warranty program, a lubricants with Shell and remanufactured engines.

Electrification a Major Focus for Dana Incorporated

Similar to other manufacturers, Dana Incorporated continues to optimize legacy equipment, but the team is looking to the future with electrification. With electric options, they have added two new equipment categories to their portfolio: excavators and forklifts. Other developments include:

• The Spicer Electrified eSP502 e-Transmission was debuted for North America. It is designed to support the electrification of wheel

• A new modular Spicer drivetrain solution for telehandlers with 12,000-pound lifting capacities.

Schaeffler Applies Insight from Automotive Technology to OffHighway Applications

We talked with Eric Berndt, mobility and electrification technologies engineer at Schaeffler Group USA (Schaeffler) about the new technology for off-highway electrification. Among the technology was its concentrated wound (more adaptive to different applications), hairpin-wound electric, and hub motors. An excellent tip shared by Berndt was, for a compact solution, electric rotary actuators can be used instead of a rodstyle actuator.

Read More

https://oemoh.co/CONEXPO23

SOME JUDGE ENGINES ON POWER. OTHERS ON TECHNOLOGY.

WHY NOT BOTH?

• Dependable, heavy

duty

• DPF-free after treatment systems

• Reduce maintenance & increase uptime

We enjoyed talking with the Hatz Diesel team and learn more about the new technology featured at their booth

About the Author

Lori Ditoro is editor of OEM OffHighway

Rumsey Encourages OEMs’ Patience Through the ‘Messy Middle’

The zero-emission transition includes optimized diesel technology, alternative fuels and battery electricity.

by Lori DitoroRight before Cummins CEO and President Jennifer Rumsey presented the keynote during the Green Truck Summit in March 2023, I was excited to have a few minutes to talk with her. Interestingly, when we talked, it was also Women in Construction Week and Women’s History Month.

We discussed her whirlwind seven months being president and CEO of Cummins, how Rumsey champions women in the industry, and previewed her keynote talking points.

In her keynote, she called this period of transition we are in the “messy middle” of the journey to zero emissions. Learn more from this Q&A interview with Rumsey.

What has been the most exciting part of the last seven months as president and CEO of Cummins?

I was incredibly honored to become just Cummins’ seventh CEO in our over 100-year history, and it’s been quite a whirlwind, I would say, the last seven months. For me, the most exciting part has been that my career has really been focused around three things: purpose, people and impact and shaped by [the question] “How do I use my skills and experiences towards something that really matters that has real purpose,” and

doing that through leading people and thinking about the role that people play to have impact. It’s what drew me to Cummins to start with, after starting my career working for a fuel cell technology company because I love our industry and the impact that our customers have on the world around us.

So, as I became CEO, it was just an incredible opportunity to be out with our customers, with our employees talking about destination zero, which is Cummins’ strategy to decarbonize our industry and our business, and to hear from them, what they’re excited about, what concerns they have, and really have the conversation that helps us get more clear-headed on where we need to go. And that was just, you know, really exciting for me to do.

Do you have any advice that you would give to other women who want to work in one of these technical fields?

Well, there’s tremendous opportunities.

One of my focuses as a CEO, as I think about people, is the role our employees play in tackling some of the tough challenges and the innovation needs that we have. I have a strong view that we need to attract a diverse workforce and create an environment where everybody can contribute and reach their full potential.

Women don’t always see all the opportunities that are available to them, because you don’t always see other women in some of those roles, especially in a construction industry or technical industry. There’s not always those role models. So, seeking role models, really understanding what motivates you and gets you excited, and not being afraid to try new and different things that you may not see others, doing, finding mentors. For me, the most influential people in my life were my mother and then two male mentors, John Wall, former chief technical officer for Cummins, and Tom Linebarger, the CEO before me.

That really helped me also see what I could become and encouraged me. So, setting those big goals for yourself, really understanding and opening your mind to the possibilities, and then finding that supportive network of people that will help you reach higher than you might on your own.

Can you give us a brief preview of what you plan to talk about during your keynote today?

So, we’re talking about really the technology transition that needs to happen in our industry, and Cummins’ view around what’s required to do that and how we plan to use our entire business to help our customers succeed and make that transition.

We have a strong view that we need to decarbonize our industry. We contribute meaningfully to global carbon dioxide (CO2) emissions in the world. And our industry is really important in driving the economy and keeping the world and many of the things that we all depend on running and successful. So how you do that in a way that is good for the environment, helps our customers businesses to be successful and continues to serve all our needs is really important.

And in that, we think the approach to that is to start today in really reducing CO2 and accelerating solutions that use engines. Cummins built 1.2 million engines last year. So, there’s a lot of engines going out into the field, ours and others, that will operate for many years. Decarbonize those and then also really focus on accelerating and innovating on some of the alternate technologies that will be necessary to reach zero and building the infrastructure to do that.

So, I’ll be talking more about what we think that looks like and what some of the challenges and opportunities are.

Those are a lot of the topics, major topics, that readers want to see and hear about in the magazine … the step changes, because you can’t just, tomorrow, get rid of every diesel engine, right?

And you must do it in a phase step way. And the reality is, we can say construction, but there’s a lot of different applications in the construction equipment or in the trucking business. So, there’s not one solution that will work for all those applications today.

So, Cummins is investing in a broad portfolio of technologies: engines, certainly, which we’re pretty well known for. Also, we are a leading player in zero emissions technologies through our new power business and growing that business as well.

Where is your favorite place to travel for work and or trade shows?

I love that question. You know, it’s a tricky one for me. I am the kind of person that likes change. So, I will say, I enjoy going different places.

My favorite place is where I have an opportunity to go out and actually

see our product in use by a customer and even better if I can actually drive or operate the piece of equipment and experience that. But just seeing firsthand how our customers are using products, some of the environments in which they operate.

I will say from a trade show perspective, I have a bias towards CONEXPO because it was one of the first trade shows that I went to. I spent kind of the middle part of my career working in off highway.

I remember going to my first CONEXPO. My youngest daughter was like nine months old, and she went with me along with grandma to help take care of her. Then the three years later, both my daughters were there.

So, I have these great pictures of them sitting in excavators and wheel loaders. CONEXPO is amazing, to just see in one place all the different construction equipment that is there.

MOBILE MACHINES SENSORS FOR

Position sensors for stroke measurement in hydraulic cylinders

Dynamically compensated inclination sensors for precise angle measurement

Compact safety rotary encoders for position and speed measurement SIKO

Is there anything else that our listeners should know about the work that Cummins is currently doing?

As I said, we believe that to decarbonize our industry, it includes both decarbonization of engine-based solutions, and we’re investing in next generation engine platforms that will really be best-in-class in terms of efficiency, power and weight, and then also have fuel flexibility. We call them our fuel agnostic platforms.

In addition, we have the broadest portfolio of zero-emission technologies for commercial and industrial equipment. We may be less known for the battery electric vehicles that we have

in operation in buses and trucks, fuel cell vehicles again, marine applications, and trains.

And then we’re also investing in electrolyzers for green hydrogen production. So, Cummins is transforming.

We’ve done some acquisitions. We’ve made big investments, a record investment last year in R&D of $1.2 billion. The company is transforming along with our customers and their changing needs.

“There’s a lot of engines going out into the field, ours and others, that will operate for many years. Decarbonize those and then also really focus on accelerating and innovating on some of the alternate technologies that will be necessary to reach zero.”

— Jennifer RumseyListen to the full podcast with Rumsey.

Thomas at IFPE Las Vegas

A Game-Changer for Off Highway Solutions

From March 14 to 18, 2023, IFPE Las Vegas, one of the most respected trade shows for fluid power, power transmission and motion control, took place. Thomas was also represented at the show with innovative solutions. In their luggage: products that promise maximum efficiency and precision in the off-highway segment. And plenty of ideas on how to realize future trends such as steer-by-wire. Highlights included the Integrated Pilot Head (IPH), the electromechanical actuator (EMA) and the Compact Pilot Actuator (CPA).

Valve concepts re-envisioned: the IPH and CPA

With its Integrated Pilot Head (IPH) and Compact Pilot Actuator (CPA), Thomas is once again demonstrating how the company likes to think outside the box. Both represent completely innovative, cost-efficient valve concepts.The IPH, for instance, is a proportional pressurereducing valve that is the only one of its kind on the market and that is ideally suited to compact construction machinery. Because all its hydraulic functions are contained within the solenoid, it does not need a valve sleeve on top. This makes it compact and space-saving while maintaining a flow rate of 2,5 l/min. What is more, the IPH also makes installation easier, because the connection interface does not require any time-consuming drilling. And, last but not least, an integrated filter element protects the hydraulic connections and prevents system contamination.

Integrated Pilot Head (IPH)

"We used IFPE Las Vegas to exchange ideas with the numerous visitors to our booth about our solutions for electrification, digitization and automation in the off-highway world. Thomas also deals with topics such as steer-by-wire, control valves for hydrogen applications or integrated valve solutions for thermal management in battery-powered vehicles. We are already thinking about tomorrow’s technologies today and are taking away many ideas and impressions from the trade show."

HEINZ STRICKLER, DIRECTOR OF SALES AND MARKETING AMERICAS

HEINZ STRICKLER, DIRECTOR OF SALES AND MARKETING AMERICAS

www.thomas-group.com/en/products/off-highway-solutions

Hydrogen Offers Power Options

Whether an HICE or FCEV, this power source is part of a zeroemission future.

by Guy Youngs, Power Systems ResearchDuring CONEXPO’S huge fiveday run in Las Vegas this year, one of the most interesting trends was the number of hydrogen-powered units on display. Perhaps one of the most advanced new production introductions was that managed by JCB when it displayed its hydrogen internal combustion engine (HICE).

Initially, JCB had designed an excavator that used a hydrogen fuel cell. But after extensive testing, JCB decided fuel cell technology was not the best option for their customers at this time, and they decided to move toward a hydrogen-combustion solution.

Now, JCB is investing $1.2 million (£100 million) to produce super-efficient hydrogen engines. The company has showcased working prototypes of a backhoe loader and telescopic handler powered by hydrogen.

The company also have announced another industry first—a mobile hydrogen refueller, providing a quick and easy way for customers to refuel machines onsite. About 97% of construction machines have fuel delivered to them onsite, and customers are used to using transportable fuel, which allows refueling onsite in minutes.

JCB also has a range of electricpowered vehicles, but these are not always a realistic solution for all customers.

Instead, JCB has developed a diversified approach, one that encompasses multiple forms of

alternative fuel and helps achieve carbon-neutral goals. Currently, the most important and most mature alternative is hydrogen.

Hydrogen is the most abundant element in the universe, and there is tremendous potential for a hydrogen ecosystem using both hydrogen fuel cell system technology (FCEV) and the relatively new HICE.

Fuel cell systems generate electricity using hydrogen, and their only emission is water vapor. HICE burns hydrogen as a fuel source for an internal combustion engine (ICE) and emits gasses into the atmosphere.

The Differences between HICE & FCEV

Since both technologies are similar, the choice for customers generally comes down to their unique operating environments. HICE units are more efficient under heavy loads and can be refilled quickly.

However, they sometimes are difficult to start in cold weather, and there can be packaging problems for the storage tanks. FCEVs are more attractive with light loads, such as passenger cars, and they provide regenerative braking.

HICEs

Hydrogen engines burn hydrogen in an ICE in the same way gasoline or diesel is burned in an engine. In fact, HICEs are nearly identical to traditional sparkignition engines. Hydrogen engines release near zero, trace amounts of carbon dioxide (CO2) from ambient air and lubrication oil but can produce nitrogen oxides (NOx). As a result, they are not ideal for indoor use and require exhaust aftertreatments to reduce NOx emissions. The way hydrogen is made can also have an impact: green hydrogen (hydrogen made with renewable energy) is desirable, but currently most produced hydrogen is gray hydrogen (see Table 1). As a result, purists consider HICE vehicles not to be true zero emissions vehicles.

Hydrogen engines can operate with lower grade hydrogen. This is handy for specific use cases, for example, siteproduced hydrogen. HICE can use this without the need for purification. The engine’s resistance to impurities is also convenient for a transportation industry where the transition to high-quality green hydrogen will take time.

HICE are generally considered to have a high level of maturity as ICEs have been universally used for decades and are supported by extensive service

networks. For manufacturers and fleet operators, the switch to hydrogen engine drivetrains involves familiar parts and technology.

Risk-averse end-users find comfort in the tried-and-tested, reliable nature of ICEs. Servicing and repairs are also easier for HICE because the technology is familiar to most users.

FCEVs

FCEVs generate electricity in a device known as a fuel cell that uses hydrogen to generate electricity. That electricity is used by an electric motor like it’s used in an electric passenger vehicle.

They also use a battery pack, although it is much smaller than that of an electric vehicle. Water vapor is the only emission they produce. This is a very attractive feature for vehicles operating in spaces with limited ventilation.

FCEVs are designed to enhance and build upon battery and electric drive platforms. While each system has advantages, combining the developing technologies of batteries and fuel cells helps reduce overall carbon and increases adoption of sustainable power without affecting performance.

This allows users to address distance and refueling issues that have hindered the adoption of battery electric vehicles for some applications. So, in FCEVs batteries will not be replaced by fuel cells, but they will be enhanced by them.

HICEs or FCEVs?

Picking between these two hydrogen power sources often comes down to one’s operating environment, as we’ll

see. A shortage of hydrogen fueling structure poses problems for both, as well, but both are fueled more quickly than battery EVs can be charged.

While engine efficiencies suggest that battery electric vehicles are the way forward, other factors such as range, refueling time, battery weight, end-of-use recycling, infrastructure, environmental impact, carbon costs and fuel cost must also be considered.

An FCEV is an electric car with its own on-board power station and fuel storage instead of a battery, so they have most of the advantages of electric vehicles.

Efficiency Problems

Efficiency is a problem for both HICE and FCEV vehicles. There are many ways to measure the efficiency of a vehicle. In the chart below, we look at engine efficiency combined with the efficiency of fuel production and distribution.

There are often extreme outliers to bear in mind, such as the efficiency of a Formula 1 car can be several times that of a gasoline ICE when measuring only engine thermal efficiency.

The engine efficiencies suggest that battery electric is clearly the way forward. However, the choice of energy source is not just about engine efficiency because many other factors come into consideration, including:

• Range

• Refueling time

• Battery weight

• End-of-use recycling

• Infrastructure

• Environmental impact

• Carbon costs

• Fuel cost

Summary

FCEVs and HICEs do not compete with one another. The development of one supports the other, since both drive the growth hydrogen production, transportation and distribution infrastructure. Both also involve the same vehicle storage tanks and are complementary technologies that are part of reducing vehicle and transportation emissions towards zero carbon.

Ultimately, it’s not a matter of which technology is better, but rather which is more suitable to an end user’s conditions, applications and needs.

Why Electrified Machines Are Simply Better

Much more than environmental benefits, EVs perform better and reduce operating costs.

By Ryan Rizor, Danfoss EditronWhile environmental benefits are often championed as the primary reason to look at alternative power sources, offhighway and construction equipment manufacturers have many reasons to switch to hybrid and fully electric systems and machines. While there are emerging environmental regulatory requirements resulting in machine and system electrification, many original equipment manufacturers (OEMs) are taking advantage of the performance improvements to reduce their customers’ operating costs and improve machine productivity.

The Driving Forces Behind the Electric Transition

While a positive total cost of ownership (TCO) for most large machines has yet to be realized, given the costs associated with the substantial amounts of energy storage required, TCO can be quite compelling for smaller and

medium-sized machines and even larger machines for certain applications.

While initial acquisition costs are typically higher for electrified machines than their conventional diesel-powered counterparts, electrified machines yield operating cost benefits by reducing the total energy consumed because of the higher efficiency of electric systems and their ability to capture and store energy through regeneration.

Electrified machines also increase machine productivity and reliability, and they reduce maintenance costs. In some cases, operators of hybrid or electric machines and systems see more than a 50% improvement in productivity and 20% to 30% reductions in operating cost. These improvements help owners and users recover their investment in the more expensive machine in less than one year.

During the past few years, customer decarbonization obligations and investor pressures have influenced OEMs to develop equipment that

supports their operational objectives and commitments. According to a 2019 IEA report, building construction and operations accounts for approximately 39% of CO2 emissions globally, with around 11% coming from the construction industry. In some regions, developers must report on and meet emission targets which are increasingly difficult with traditional construction equipment.

For example, Komatsu, a construction, mining and forestry equipment manufacturer, is aiming to reach carbon neutrality by 2050. The company’s comprehensive roadmap, which addresses Scope 1, Scope 2 and Scope 3 emissions, shows a significant commitment to carbon neutrality, demonstrating how the influence of the market and anticipated regulatory pressures have led to an explosion in demand for solutions to address emissions from industrial and construction operations.

To achieve significant reductions in

the construction industry, construction machines will have to change. Therefore, to meet emission reduction pledges, many construction industry players are turning to component and subsystem manufacturers to find powerful solutions to achieve their targets.

Regulatory Changes Also Play a Role

The final key driver is the dynamic and evolving regulatory environment. To reach emission reduction targets, new local, national, and international mandates require that traditionally heavy-polluting industries make serious changes to their operations. These regulations are increasingly common, particularly in the E.U. They are often the catalysts that drive equipment manufacturers to commit to environmental emission reduction targets as they anticipate increasing mandate requirements and the global reach of those mandates.

However, not all regulatory restrictions are climate related. Noise regulations are also a significant and growing category. Compliance is vital to site productivity, with permits required to perform work during authorized working hours. This can affect meeting project timelines and, in some cases, operator and employee wellbeing. More work sites are requiring reduced operating hours or permits based on evidence of minimal noise pollution disruption in neighborhoods.

Electrified machines can play an important role in helping contractors meet these demands because electric systems are much quieter than diesel engines and traditional hydraulic systems. Additionally, eliminating mechanical components, which are essential in conventional internal combustion engines, makes electric machines unmatched for reducing noise pollution levels.

A Purpose Design System Architecture for Each Application

The diversity of off-highway machines is extensive, but with this variety comes the need for attention to application and system design details to ensure that machine performance and improvements are realized. Therefore as with traditional diesel and hydraulic

systems, a collaborative effort between the OEM and the electrification system solution providers is critical.

While not all applications are currently suited for full electrification, those that can benefit from a fully electric or hybrid solution typically outperform legacy systems because they are quicker, quieter and more responsive. They use less energy and enable higher precision for their work functions. Electric systems also provide immediate power and torque, are more productive, and provide a faster dynamic response for operators.

Embrace an Electrified Construction Industry

The off-highway industry faces pressure to change, and it’s becoming clear that electrification is a fundamental part of the solution. For those who want or need to invest in a new machine, hybrid-

electric and full-electric offerings that deliver high performance, reduced emissions, reduced noise and a lower TOC are becoming a natural choice. With the external pressure for more sustainable solutions and regulations, buying an electrified machine now is investing in the future .

Resources

• 2021 Global Status Report for Buildings and Construction, GlobalABC

https://oemoh.co/o1mb1b

• Komatsu’s Vision for the Workplace of the Future, https:// oemoh.co/6ksxiz

Ryan Rizor is off-highway Americas sales leader for Danfoss’ Editron division.

Thermal Management in the Electric Age

Across the country, commercial fleets are transitioning from internal combustion engine (ICE) vehicles to electric vehicles (EVs). A shift of this magnitude comes with challenges, including higher vehicle acquisition costs and the need for charging infrastructure. However, the total cost of ownership (TCO) of commercial EVs will likely outperform ICE vehicles as soon as 2025. Given the increasing availability of EVs and their improving range, the need to reduce carbon emissions, and government incentives and regulations, the commercial EV market is primed for growth.

Questions continue about how commercial EVs will perform compared to their ICE cousins. Can a battery store enough energy to reliably power rugged medium- and heavy-duty vehicles? Will those EV systems withstand the harsh,

dirty environments? Which technologies best protect and optimize the performance of commercial EV components? Being asked with increasing frequency are questions about whether EVs require seasonal, temperature-related preparation like the winterization ICE vehicles undergo. The answer is a qualified yes because the most important aspects of EV winterization happen in manufacturing, not at the depot.

The lithium-ion (Li-ion) batteries in modern EVs are larger versions of those in smartphones. Anyone who has left a phone in the sun or in a car on a cold night knows that temperature extremes negatively affect a phone battery’s life and performance. Similarly, maintaining the right battery temperature range is essential for reliable EV operation.

In cold temperatures, the chemical reactions inside Li-ion batteries slow

How to keep commercial EVs working yearround

by Gina Bonini, Modine Manufacturingdown, increasing internal resistance, which reduces battery capacity and, in turn, reduces vehicle range. Cold temperatures also result in slower charging. On the other end of the mercury, high temperatures cause chemical reactions in the battery to speed up, draining the battery more rapidly. If it is continually exposed to extremes, it will degrade.

The good news is that vehicular thermal management is well-trodden ground. Some companies have more than 100 years of experience in the field. Some thermal management companies have developed new technologies and methods, including high-fidelity temperature control for EV components using refrigeration and heating circuits with sensors and sophisticated controls. Using these technologies help make commercial EVs viable in even the most severe environments.

What Is Battery Thermal Management?

Battery thermal management is one of the less visible but critical frontiers in EV transportation. Ambient temperature impacts the range, charging time and the lifetime of batteries. For rugged specialty and commercial EVs, however, battery thermal management systems (BTMSs) must efficiently manage battery temperatures, be able to accommodate novel space constraints, and survive unforgiving and often dirty environments.

For peak performance during charging and operation, what is effectively a double-duty cycle, battery pack temperature should ideally remain between 25°C and 35°C (77°F and 95°F). As such, a BTMS should heat and cool the battery pack. In practice, if the ambient temperature drops too low, the BTMS heating loop will increase the temperature of the coolant circulating within it until the

battery pack reaches the ideal temperature. Once the vehicle is in operation—or while charging—the BTMS removes the resulting heat to prevent overheating. The switch between cooling and heating, as well as the intensity of each, are managed automatically by the system.

A key consideration in a BTMS design is optimizing temperature control while minimizing power consumption. A BTMS, therefore, may have an active loop with a refrigerant circuit to remove heat in hotter temperatures and a passive loop with a radiator and fans—which draws less power—if the ambient temperature is moderate. For off-highway applications, BTMSs can be designed to protect fans or exposed heat transfer modules from potential clogging by dirt and debris.

As with all batteries of this type, maintaining optimal thermal conditions shortens charging time and maximizes the range and battery lifetime.

Other Considerations

The inverters, converters, traction motors and related power electronics that charge the batteries or turn battery-stored electrical energy into kinetic energy are similarly affected by ambient and operating temperatures. Given the weight, payloads and workloads of heavy-duty commercial EVs, their powertrain electronics require significantly more power than average light-duty or consumer passenger EVs. With more and higher power comes more heat and more stress on electrical components. As a result, performance, durability and safety may be affected. With inverters, for example, power output is limited by the maximum temperature threshold of the power module, impacting performance. It may even shutdown without intervention from a BTMS.

Commercial EVs are typically equipped with a cooling package for inverters,

MOSAIC LIGHTING SYSTEM

ENDLESS POSSIBILITIES

The Mosaic Modular Lighting system gives OEMs the freedom and versatility to create impactful, affordable designs by using standard lighting modules. OEM designers can incorporate a wide range of multifunctional DOT and ECE standard LED’s into custom bezels to reduce cost and expedite time-to-market.

converters and traction motors, each with a coolant loop to cool the power electronics, which is then routed through the cooling package to reject the heat to ambient. This circuit keeps the power electronics within the temperature range for the best performance and the lowest risk of damage. In most commercial applications—where unexpected downtime is unacceptable— reliable thermal management of drivetrain electronics protects the asset and the operation it serves.

Changing Fuel & Changing Habits

As a wave of resources flows toward domestic engineering, manufacturing and EV infrastructure, more vehicles will be electrified. While little re-training is required of professional drivers who switch to EVs, a few adjustments to old habits are unavoidable.

A large earth mover or a truck that pulls heavy loads requires a larger battery pack, which means more thermal mass. When heated indoor parking is unavailable, the larger the battery pack is, the longer it takes to reach equilibrium with ambient temperature. This means the battery pack will take longer to reach optimal operating temperature again. Connecting to a charger whenever stationary, especially in the cold, allows a BTMS to protect the battery pack and mitigates the risk of a cold-battery performance reduction of up to 40%.

Also, the battery power draw from cabin heating is responsible for nearly two-thirds of range reduction in cold weather. Drivers who rely more on in-cabin comfort features like heated seats and steering wheels and turning heaters off when not in the vehicle, will get more range between charging sessions.

Electricity in the Fast Lane

EV technology is now viable across dozens of vehicle segments. Engineers have made advancements in thermal management that are putting commercial EVs on the path to outperform their ICE predecessors. Backed by the spirit of innovation, rapidly growing demand, incentives and guidelines from governments, and broad support to reduce emissions, the electrification of commercial transportation is already more advanced than most prognosticators thought it would be.

Resources

• “Why the economics of electrification make this decarbonization transition different,” McKinsey.

• “Does Cold Weather Affect Lithium Batteries? The Effects of the Temperature on Battery Performance,” Lithium FAQ. “How Temperature Affects EV Range,” Recurrent.

• “The History of the Electric Car,” Energy.gov.

Gina Bonini is the vice president and general manager of advanced thermal systems for Modine Manufacturing.

What Has Europe Done to Spur Adoption of Electric Machinery?

Europe can be viewed as a frontrunner in the transition toward low- and zero-emission offhighway machinery. But why is this the case? There aren’t any technical advantages—many of the companies in the market are international—nor is there any significant difference in how the machines are used in Europe versus the rest of the world. The difference, to date, lies in the policy response of certain countries in Europe and how this in interacting with the R&D efforts of original equipment manufacturers (OEMs) and suppliers in that region.

Interact Analysis forecasts that the Europe, Middle East and Africa (EMEA) region will have a penetration rate of battery-electric excavators that is double that of North America in 2030—12% compared to 6%. Looking only at Western and Northern Europe, that figure could be three or four times that of North America.

Public & Private Partnerships

The Big Buyers for Climate and Environment is a European Commission

program run by ICLEI and Eurocities. The aim of the project is to encourage the adoption of sustainable technologies by supporting major public and government purchasing teams to buy those technologies. The Big Buyers program has supported a working group on zero emission construction sites across Europe. Examples include:

• Oslo has committed to ensuring that all public construction sites are zero-emission by 2025, and that all construction sites in the city are zeroemission by 2030. Fossil-free works has been a minimum requirement for public construction procurement in the city since 2017. Overall, Oslo has a target of reducing carbon dioxide emissions by 95% by 2030, compared to 2009 levels.

• All public construction sites in Copenhagen must be carbon neutral by 2030. The city’s own substantial fleet of off-road mobile machinery must be fossil-free by 2025. Work has begun on a series of civil works and construction projects in the city, where all machines up to 2.5 tons

must be electric, and machines above that size should preferably operate on either electric or biofuels.

• Helsinki is striving to become carbon neutral by 2035. In line with the Finnish green deal, all public construction sites should be 100% fossil-free by 2025. By the end of 2030, this will be extended to include machinery and heavy vehicles that travel to and from sites. In addition, the city made the decision that all new infrastructure sites and roadworks will be fossil-free and lowemission. The value of construction contracts affected by these initiatives was approximately €143 million in 2021.

Specific “mega-projects” are also driving a shift toward the use of lowand zero-emission equipment in Europe. High-speed rail 2 (HS2), which is a major U.K. project to create a high-speed rail network from London to Birmingham, has a roadmap toward net zero. HS2 announced that the project aims to be net-zero carbon from 2035, with the target of achieving its first diesel-free

By 2030, the EMEA region will have a penetration rate of electric excavators that is double that of North America. by Alastair Hayfield, Interact Analysis

construction site in 2022, and all being diesel-free by 2029.

Innovations on its first diesel-free site include one of the U.K.’s first 160-tonne, emission-free fully electric crawler cranes, the use of biofuels (hydrotreated vegetable oil) to power plant and machinery on site, an electric compressor, and access to main power on a 100% renewable energy tariff.

OEMs have also trialed electrified and low-emission vehicles successfully. Volvo

Construction Equipment has been one of the most advanced in this, creating an electric site research project with its customer, Skanska. The research project, dubbed Electric Site, aimed to electrify each transport stage in a quarry—from excavation to primary crushing, and transport to secondary crushing— although a negligible amount of diesel power will still be used. Tests showed a 98% reduction in carbon emissions, a 70% reduction in energy costs and a 40% reduction in operator costs.

Perhaps, though, the most extensive development of projects involving electrified machinery have been in the Netherlands. The Emisseloos Netwerk Infra (ENI) or Zero-emission

Infrastructure Network is an organization of multiple companies across the construction industry with the goal of promoting the widespread adoption of zero-emission equipment in the 2026 to 2030 timeline. ENI has demonstrated how electric equipment can be integrated into small and large projects, including successful charging approaches and technical feedback, for example, on the correct battery size required in an excavator to meet its expected duty cycle.

OEMS & Suppliers

Although many suppliers and OEMs are global, it is also fair to say that they have focused development efforts and product launches in Europe as there is more market demand for electrified solutions. This becomes a virtuous circle because fleets and operators get experience with the technology, learn about its advantages and disadvantages, and suggest feedback to further enhance the products. This speeds up market acceptance, driving more sales, feedback and better products.

While calling out a leader is difficult, OEMs like Volvo and JCB have brought multiple electrified models to the European market since 2020.

European suppliers like Danfoss, Bosch, Zapi Group, Forsee and Turntide Technologies have developed technologies—batteries, motors and power electronics—specifically for the off-highway market. These capabilities

have helped these companies become market leaders.

Can the U.S. Catch up?

What is clear is the importance of policy support in driving the adoption of electrified off-highway machinery. In the U.S., the direction of policy isn’t fully clear, and this causes a lack of certainty over which technologies will be used to reduce emissions and improve sustainability.

This lack of policy is also compounded by a lack of funding. Other than the Clean Off-Road Equipment Voucher Incentive Project funding program from, there has been little in the way of financial support for the purchase of electrified machinery in the U.S. Funding is necessary because the upfront cost of electrified machinery is not positive when compared with diesel machinery. For the U.S. market to catch up, the lack of funding needs to change. It’s hard to comment on policy, but many manufacturers are optimistic that funding from the Inflation Reduction Act will support the introduction of low- and zero-emission construction equipment. If this happens, the U.S. market should be optimistic about catching up with Europe.

Environmentally Friendly, Sustainable & Bio-Based: Untangling Common Terms

Sustainability is topic of much discussion in today’s off-highway industry. OEMs and equipment owners/operators are in continuous pursuit of new ways to decrease emissions, improve fuel economy and extend the useful lifespans of all forms of critical equipment.

Industrial fluids—be they hydraulic fluids, greases, metalworking fluids, industrial gear or other fluids—have an important role to play in this pursuit of sustainability. High-performance options can help equipment operate to its full potential, optimizing fuel consumption and overall machine efficiency, while protecting critical parts to extend lifetimes.

But for these fluids, there are other characteristics to consider. For example, biodegradability and environmental friendliness. Because considerable

amounts of industrial fluids make their way into the environment every year, a fluid’s ability to safely decompose has become a highly sought-after trait. The U.S. Environmental Protection Agency (EPA) defines such fluids as environmentally acceptable lubricants (EALs). While EALs have traditionally been seen as a niche product, demand is rising due to evolving regulatory requirements.

As all industries seek to enhance their eco-conscious reputation, it is important to understand some of the subtler differences between sustainability and environmental friendliness, and how EALs differentiate from bio-based fluids.

Sustainable or Environmentally Friendly?

The preferred framework for sustainability evaluates a product’s overall effect on the environment across its entire life

cycle. This accounts for the product’s impact while it is in use and in the steps leading up to its creation and those of its eventual end of life. Calculating these figures, taking into account the entire history of how the product is made, involves a methodology commonly known as life cycle analysis.

It is against this backdrop that we can better evaluate different lubricant and fluid formulations and classifications that have emerged in recently. EALs offer a good example. As noted earlier, EALs are explicitly defined by the U.S. EPA as formulations that have demonstrated acceptable levels of biodegradability, minimal aquatic toxicity and non-bioaccumulative potential. And it is worth digging into the specifics of these terms:

• Biodegradability: The capacity of lubricants to be decomposed by microorganisms over time into:

As environmental protection becomes an increasingly hot topic, it is important to understand the subtle but critical differences between environmental protection and sustainability and between bio-lubricants and environmentally acceptable lubricants.

by John Uhran, Lubrizol

• A combination of simpler by-products (primary biodegradation)

• Carbon dioxide and water (ultimate biodegradation)

• Minimal Aquatic Toxicity: Low toxicity to aquatic organisms according to tests defined by the Organization for Economic Cooperation and Development (OECD) and EPA test guidelines.

• Bioaccumulative potential: the buildup of chemicals within the tissues of an organism over time.

These characteristics are particularly important within the realm of off-highway equipment. Because whether via machine seepage, accidental spillages or careless disposal, the final part of any industrial fluid’s life cycle may very well occur within the natural environment. Their ability to minimize harm to delicate ecosystems is critical. Traditional industrial fluid formulations do not typically account for these consequences.

Growing environmental awareness has also seen increased adoption of bio-based lubricants and fluids in off-highway applications. Frequently, bio-lubricants are made from natural oils and avoid the use of petroleum-based oils in their formulations—making them generally viewed as a more sustainable option. However, bio-lubricants need only be made from natural oils to be labeled as such, and unlike EALs, do not need to meet stringent criteria that certifies their eco-friendliness. A bio-lubricant may be biodegradable, but isn’t necessarily so by definition. For example, a bio-lubricant may still incorporate an additive component that is not bio-degradable. These are important distinctions to make as the off-highway market continues to seek to maximize its environmental protection.

Coming back to what makes a lubricant sustainable, the source of raw materials and EAL-qualifying characteristics of a lubricant only represent portions of a lubricant’s life cycle. One needs a complete life cycle analysis to honestly say that one particular formulation is more sustainable than another. That doesn’t minimize the positive impact of using EAL qualified lubricants, of course.

Included in that life cycle analysis is the in-use performance of the lubricant.

Making an Impact in Off-Highway Equipment

As mentioned at the beginning of this article, advanced fluids have the potential to optimize today’s most efficient off-highway equipment. By delivering high levels of performance across a broad range of performance characteristics, the right fluid can help machines achieve optimal fuel consumption, maximum efficiency, and extensive service life. It follows, then, that EALs—in order to best benefit the end user, and the planet—should be able to do just the same.

There are a range of performance characteristics that any reliable industrial fluid—EALs, bio-lubricants or others— should be able to provide. They include:

• Wear protection. Preventing the premature wear of metal surfaces as they contact each other is the core function of lubricants.

• Extreme-pressure protection. Industrial fluids in demanding applications require extreme-pressure additives to withstand severe conditions.

• Emulsibility. Depending on the application, many industrial fluids must properly emulsify with water. Other fluids may need to resist emulsification. The right chemistry is required.

• Antifoam performance. When air becomes entrained within an industrial fluid, foam can result, which may compromise its ability to form a protective film. A high-performance fluid will be resistant to such foaming.

• Corrosion and rust prevention. A variety of off-highway fluids come into regular contact with water and air at elevated temperatures—conditions that can lead to damaging rust and corrosion.

• Viscosity and friction performance. Some applications require specifically calibrated thickness and friction to enable proper machine performance. Many traditional chemistries deployed in most off-highway fluid formulations are not applicable in EAL products. This

is because many of those ingredients, which help a completed fluid deliver each of these performance characteristics, do not meet EAL standards for biodegradability, non-toxicity, and bioaccumulation. For example, some of the most common and reliable anti-wear chemistries used today are zinc based. A nonmetallic option is required to meet biodegradability standards.

Applicable chemistries do exist, making high-performance EAL formulations are possible—and they will only become increasingly important as industries everywhere seek to minimize their environmental impact. For the off-highway equipment industry, it is worth investigating the application of these kinds of formulations today. They are only expected to gain market share as regulatory pressure grows, and as the world grows increasingly eco-conscious. Ensuring that EALs maintain the right performance characteristics—to enable off-highway machinery to achieve peak efficiency and reliability—is essential. Such formulations represent an important tool for the off-highway equipment industry to maximize environmental protection, and it can be worth opening the conversation about such options with your fluids supplier.

New PC-GO Software