MANUFACTURING Engineering

Innovation

Issue 64 2023

£4.95

www.pecm.co.uk

ROCKWELL AUTOMATION - 16

ROTZINGER GROUP - 42

PPMA SHOW - 1 1 1

Packaging and processing innovations on display at the 2023 PPMA Show

Rotzinger Group Unveils a Hygienic Conveyor at In-House Show and iba 2023

Rotzinger Group Unveils a Hygienic Conveyor at In-House Show and iba 2023

Process Control & PECM Global Success Through

Bring robots into the heart of the control system

www.jasic.co.uk wilkinsonstar247.com

MANUFACTURING Engineering

Inside Issue 64

CP AUTOMATION

CP Automation helps GA Pet Food Partners ensure uptime

GLOBAL HEAT TRANSFER

New coils increase solenoid valve energy efficiency by 80%

RE-FLOW

How to Strike the Right Balance in Business

PRIME VISION

Barcode reading between the lines

SPELSBERG

Ticking all the boxes for control systems

ABB

ABB expands large robot family with four energy saving models, 22 variants

FAMATEL UK LTD

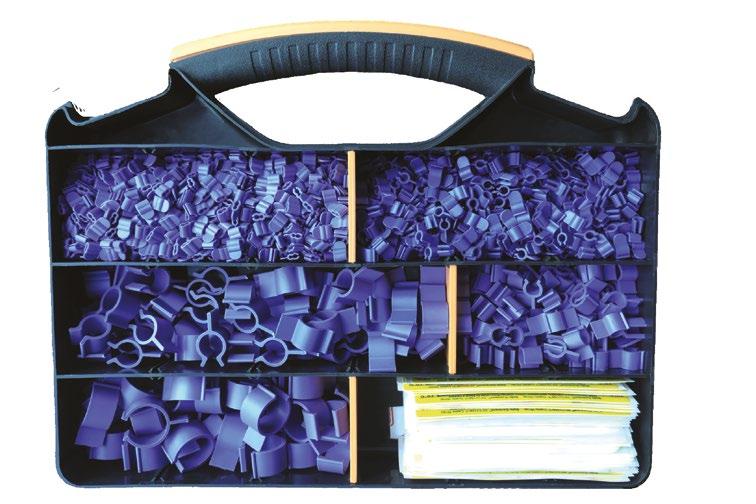

Quality, service and a competitive product

KASTO

Retrofitting acrobatics under the roof

BURCKHARDT COMPRESSION

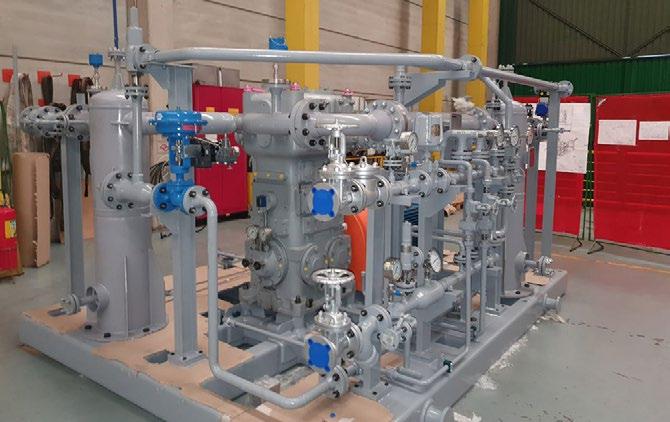

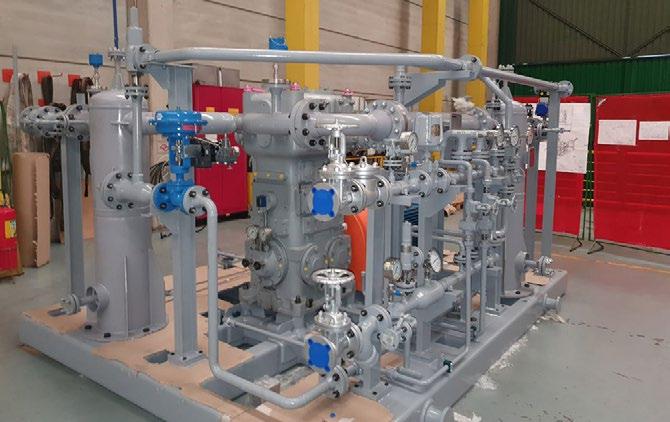

Burckhardt Compression’s Response to Hydrogen Production

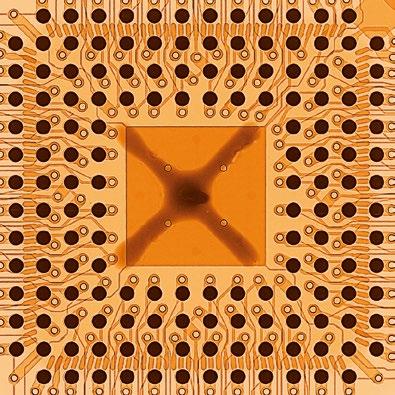

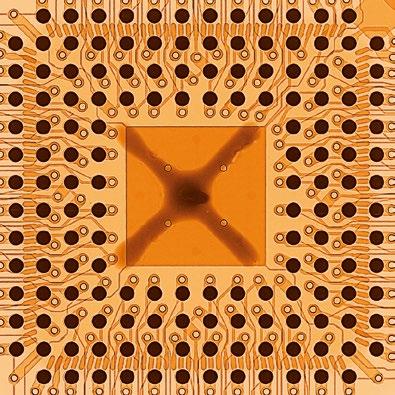

SWINDON SILICON SYSTEMS

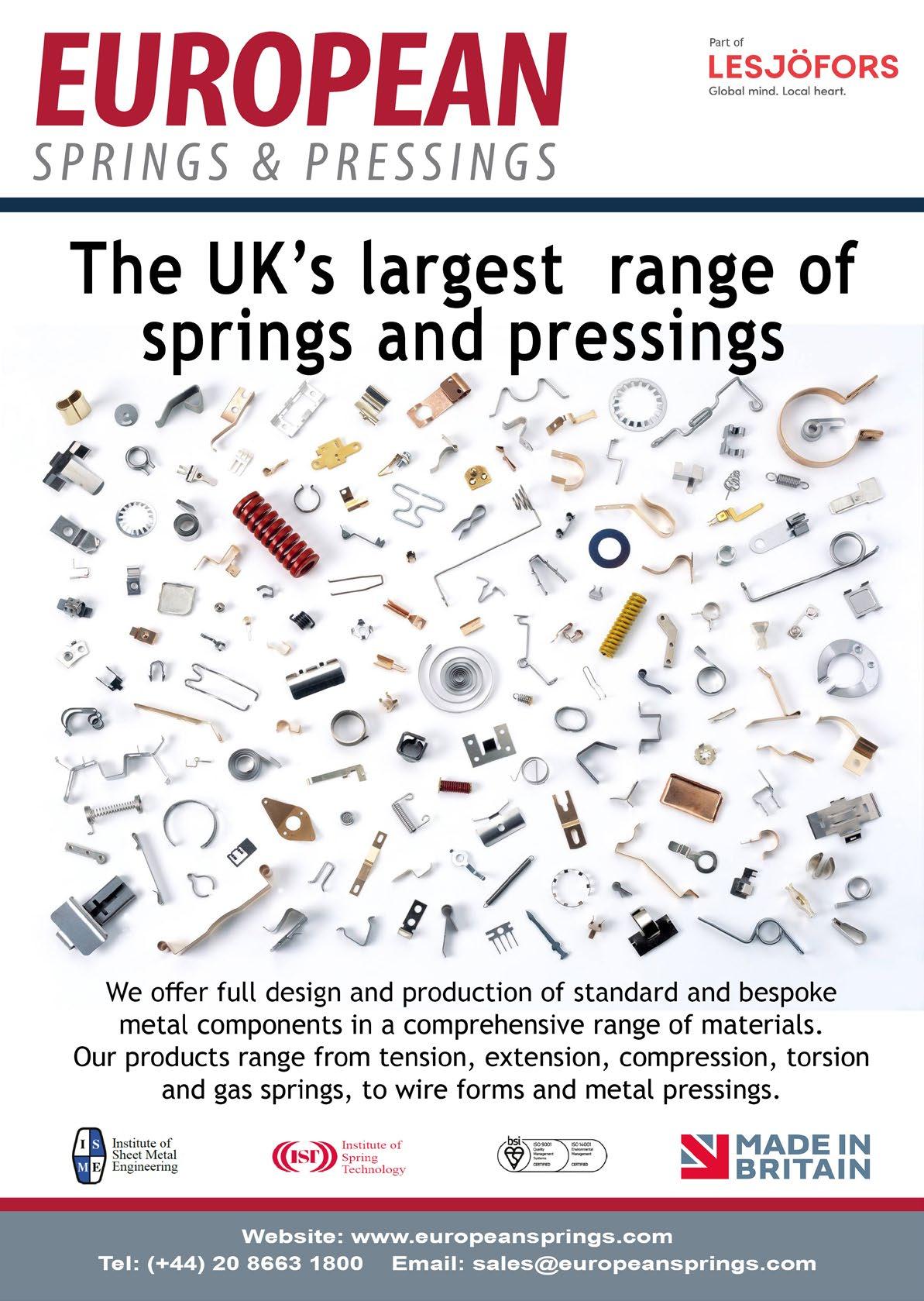

How ASICs can help businesses maintain and prove compliance

EMS LIMITED

Micromotors driving 3D measurement systems

SICK

SICK Announces Major Upgrade to Colour Sensor Portfolio

Issue 64 PECM 3 Inside... Sections Editor’s Choice Boilers & Maintenance Control & Automation Drives, Gears & Motors Electrical & Electronics Gears, Drives & Motors Health & Safety Machining & Machinery Measurement & Monitoring Packaging Process Technologies Pumps Switches & Sensors Software & Systems Tools Valves & Flow Control 6 63 64 44 76 82 84 87 96 108 114 118 123 124 126 128

Process Control &

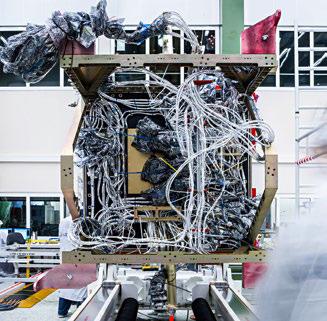

Cover photo: Sumitomo

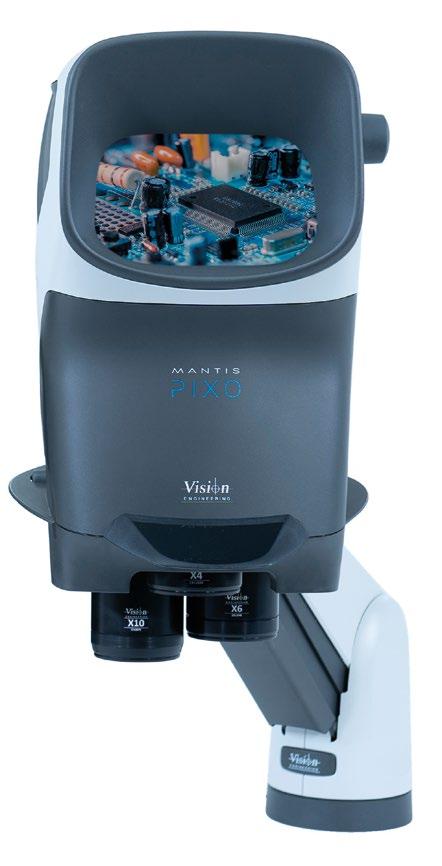

THE stereo microscope

Meet Mantis, THE stereo microscope brand trusted by thousands of customers globally to deliver excellent high quality images for a wide range of magnification applications, in an easy to use ergonomic system.

To see what you’ve been missing search vision engineering mantis, scan the QR code or call us on 01483 248300.

Subscribe

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 140,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

Hardcopy Edition

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

Digital Edition

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices. All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

MANUFACTURING Engineering Process

The Team

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Harrison James harrison@pecm.co.uk

Tel: 0203 907 9166

SALES MANAGER

Martin Richardson martin@pecm.co.uk

Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk

Tel: 01227 936971

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk

Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk

Tel: 01304 806039

DIGITAL ASSISTANT Stacey Goodwood

Tel: 01227 936971

Please mention Process Engineering Control & Manufacturing when responding to items in this issue.

Issue 64 PECM 5

MH Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk Every effort is made to ensure the accuracy and reliability of material published in Process Engineering, Control & Manufacturing however, the publishers accept no responsibility for the claims or opinions made by the contributors, manufacturers or advertisers. No part of the publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including printing), recording or stored in any information retrieval system without the prior written consent of the publisher.

Control &

ENHANCED PRODUCTIVITY

Levelling up productivity promises

If you were to put a figure on enhanced productivity, what would your ultimate manufacturing output goal be? Five percent, maybe ten? Given the current challenges, some processors may even push for 20 percent! Research by Sumitomo (SHI) Demag reveals that when all the productivity production stars align –including optimising all-electric technology, engaging people, utilising automation and other digital tools, and reducing production downtime – 50 percent or higher is entirely reachable.

Productivity is the hot topic at Interplas 2023, with a number of seminars and panel discussions already scheduled. Inevitably, these programs will showcase and share best practice on how to ‘achieve more output with the same or less effort’. After-all, this is the ultimate quest.

Ahead of the productivity curve is Sumitomo (SHI) Demag. Gathering information and data when visiting customers following new all-electric and machinery installations, the team reveals everything they’ve learned. Including how both small and large polymer processors can lean on their technology and team to unlock more untapped productivity opportunities.

All of this information is being captured in an insightful new Whitepaper. However, given the significance of this trailblazing evidence and yield-boosting benefits, the team shares a taster of how mass moulders can, with just a bit of expert support and guidance, double their manufacturing capacity and productivity.

TURNING EMPTY PROMISES INTO REALITY

Imagine the profit possibilities if each all-electric injection moulding machine within your fleet delivered an extra six months of processing capacity. How many extra projects could you take on? How much machine footprint could this save? What would this mean for your delivery schedules and customer satisfaction?

Phased Total Factor Productivity improvements to manufacturing processes holds huge promise. For many UK moulders, this could finally be the

golden egg to change the operational landscape and future prosperity of polymer manufacturing firms of all sizes?

Integrating an all-electric machine into production lines, alongside intelligent utilisation of digital tools and automation, combined with investing in training and development, can decrease cycle times by up to 55% percent. This can equate to an extra 168 days of production, illustrates the Processing Productivity whitepaper.

It doesn’t require doing everything all at once. Instead, the Sumitomo (SHI) Demag team assures customers that in a short space of time, marginal gains can unlock accumulative enhancements to boost profit margins.

ALL-ELECTRIC CLOSES THE PRODUCTIVITY CHASM

It’s widely considered a ‘given’ that energy efficiency and reduced pollution are the benefits of all-electric injection moulding machines. Especially in today’s ecoconscious manufacturing world. However, beneath the hood of these machines are a number of velocity and injection power features that, when used correctly and repeatably by moulding operatives, result in faster cycle times and more stable start-ups. Even before any process optimisation steps have been introduced and expert setting knowledge has been imparted.

The advanced direct drive technology deployed by the IntElect series illustrates this point. Reducing a 10 second dry cycle time by just 0.55 seconds, for instance, can equate to an additional 2,274 cycles every day. Multiplied, this productivity improvement alone can add up to 14.3 extra production days!

MGS Technical Plastics is just one customer that observed an instant dry cycle time improvement of six seconds after switching from a Demag Ergotech 50ton to an IntElect2 50ton. “From these figures we can deduce that it equates to a 20 percent increase in cycles per year, giving MGS over 53 days of extra production capacity,” notes area sales manager Ashlee Gough.

6 PECM Issue 64

EDITOR’S CHOICE

When teams feel like you are invested in their development and future, they champion further process improvements.

SUMITOMO

In-person field support and professional development courses play a huge role in delivering the right diffusion of skills to maintain productive team members.

PEOPLE POWER

As efficient as these state-of-the-art machines are, they are only as good as the people operating them. For teams and individuals to put their best efforts into their work, they need to feel engaged, confident and valued. When they do, quality rises and

productivity soars. These are the people you want to keep. They work harder, complete tasks to the best of their ability, deliver better customer service, question processes and are innovative problem solvers.

In-person field support and professional development courses plays a huge role in delivering the right diffusion of skills to maintain this proactive level of productivity engagement. “When teams feel like you are invested in their development and future, they champion further process improvements. This, in turn, has a lasting and invigorating effect,” reports MGS Technical Director Judson Smythe.

Nothing illustrates this point better than the eyewatering results gained when MGS participated in post-installation training. By optimising the machine set up, the Lancashire firm improved their ‘before training’ dry cycle times on the IntElect by a further 10.1 seconds. Compared to the original 29 second cycle time process, the optimised IntElect after training ran at 12.9 seconds. Resulting in over 761,000 more cycles per year, equating to 168 days of extra production “This on-site training helps even the most astute and skilled operatives to explore the full potential of features like parallel functions and how this supports the mould opening and closing speeds,” affirms Ashlee.

Adding robotics into the mix generates at least another five percent in higher productivity. More, if manufacturers can

introduce ghost shifts. To demonstrate the potential untapped after-hours production opportunities, this year’s Interplas showcase premiers a compact, fully-automated, compact IntElect75 ton turnkey cell. “Rather than operate split shifts or keep people in the factory until late at night, this cell illustrates to trade moulders and SMEs how they can confidently harness the benefits of automation when manufacturing standard components. To save costs, moulding firms may introduce ‘ghost’ night shifts to ramp up their manufacturing capacity even more. Equally, day-shift teams benefit from augmented workflow processes,” points out Managing Director Nigel Flowers.

For productivity to be sustained, marginal gains is the best approach. Every incremental improvement boosts productivity that little bit more. Providing polymer manufacturers with greater capacity to take on new customers and more projects. “Even in the most profitable organisations, there’s great potential for improving efficiency and workforce competence. The key is to start with the basics; correct operation and setup times; review manual and automated routines; optimise machine cycle times, etc.,” states Nigel.

Find out more and pick up your copy of the Sumitomo (SHI) Demag Processing Productivity Whitepaper at Interplas, Hall 4, Stand C40 or download it today here: https://uk.sumitomo-shi-demag.eu/makemore-for-less

For further information, please visit www.sumitomo-shi-demag.uk

Issue 64 PECM 7

Field site tests prove that integrating an all-electric machine into production lines, alongside digital tools and automation, combined with training and development, can reduce cycle times by 49.3% .

At Interplas 2023, Sumitomo (SHI) Demag will unveil its new Productivity Whitepaper along with a compact, full turnkey cell featuring an IntElect75 and SAM-C5 handle & box robot

MAINTAINING UPTIME

CP Automation helps GA Pet Food Partners ensure uptime

In any industrial facility, electric motors and drives are a strong source of harmonic currents and utility-level voltage distortion. Together, these can wreak havoc with plant equipment and the mains power supply. When GA Pet Food Partners, a dry pet food manufacturer, began designing a new treatment plant at its Preston site, it knew that it needed to design harmonic mitigation into the plans to prevent unplanned outages from occurring. During the design process, it approached power quality specialist CP Automation to find a solution.

Beginning its journey in 1972 as a mixed arable and livestock farm, GA Pet Food Partners is a private label family-owned and family-run business specialising in the production and delivery of pet foods. The company is headquartered in Preston, alongside an additional Preston facility and two sites in Chorley, Lancashire.

As part of the company’s expansion, GA was developing a new water treatment plant and an odour abatement plant with biobeds, to address any environmental impact the expansion may incur. Following treatment, GA would then sell these products onto its consumers. During the site design process, GA knew that the site would contain many drives, and that this could introduce risks associated with harmonics and adverse noise unless properly addressed.

THE TROUBLE WITH HARMONICS

Harmonic frequencies are multiples of the fundamental frequencies and usually cause distortion in the voltage and current waveforms. Any drive, power supply or other load causes a nonlinear current draw, which generates harmonics at various frequencies. For example, single phase switches, such as those found in computers, predominantly generate third order harmonics, while AC drives generate fifth and seventh order harmonics.

Third order harmonics are undesirable for GA’s operations, because they cause a sharp spike in the zero-sequence current, and therefore increase the current in the neutral conductor. Meanwhile, fifth and seventh order harmonics will go straight to

the transformer and can cause derating, as well as premature insulation when present in excessive amounts.

The need was also legislative. The latest Engineering Recommendation G5/5 raised the limit on the measurement of voltage harmonics, total harmonic distortion (THD) and sub-groups from the 50th harmonic (2.5 kHz) to the 100th (5 kHz). Given that the new water treatment site would include at least 40 motors — one of GA’s sites also had over 300 drives — it was clear that harmonic mitigation would need to be designed into any future facility. At this point, the pet food manufacturer turned to power quality specialist CP Automation for support.

DESIGNING FOR MITIGATION

To support GA’s engineering team with the design, CP Automation supplied five P300 active harmonic filters from Swedish cleantech company Comsys. Some were used for the design of the new site, while other filters were retrofitted to replace legacy units.

“The active harmonic filters are a specialist type of inverter that measure the harmonic load on the mains and generate the exact inverse to cancel out any noise,” explained Jayne Whittaker, engineering director at GA Pet Food Partners. “In doing so, the Comsys filters can correct power factor, which is

vital as power factor capacitors are highly vulnerable to harmonics and the insulation failure they cause.

“As we’ve continued to expand and add more to kit to our sites, this growth has compounded power quality issues,” continued Whittaker. “I first realised these challenges 24 years ago, but only in recent years has mitigation technology caught up so that we can now resolve them constructively and cost effectively. Previously, we would have to overrate equipment to account for harmonics, but this had cost and efficiency implications.”

By supplying the active dynamic filtering (ADF) units, CP Automation could help GA achieve Engineering Recommendation G5/5 compliance while reducing the premature failure rate of equipment, nuisance tripping and other issues.

CLEAN, RELIABLE ELECTRICITY

The new ADF P300 units are designed for all size loads and are functioning as intended — eliminating harmonics and reactive displacement at GA’s site. Unlike other mitigation technologies, the Comsys units can correct both harmonics and power factor, which not only improves resilience against noise but also reduces the current drawn from the mains, meaning less power is consumed.

“One of the unique selling points of the P300 is its compact build and that it can deliver significant value with a minimal footprint,” added John Mitchell, global sales and marketing director at CP Automation.

“This was especially important for GA, who was looking for ways to expand sustainably and in a way that would futureproof its sites from adverse load behaviour.

“On one site, we managed to save the space of four large panels by retrofitting two in their place, achieving a 50 per cent reduction in footprint,” continued Mitchell. “The P300 units are an investment in GA’s future growth, freeing-up floorspace for additional equipment while protecting its sites from harmful power quality issues. We really enjoyed being a part of this project.”

For further information, please visit www.cpaltd.net

8 PECM Issue 64

CP AUTOMATION

EDITOR’S CHOICE

THE REX-SYSTEM

Your all-in-one solution

circuit protection solution for mechanical and plant engineering. The REX system combines power supply, communication, circuit protection and power distribution in one system.

Benefit from the comprehensive DC 24 V circuit protection solution for mechanical and plant engineering. The REX system combines power supply, communication, circuit protection and power distribution in one system.

E-T-A Circuit Breakers Ltd. +44 (0) 1296 420336 info@e-t-a.co.uk

www.e-t-a.co.uk

E-T-A Circuit Breakers Ltd. +44 (0) 1296 420336 info@e-t-a.co.uk

www.e-t-a.co.uk

YOUR BENEFITS:

Clear error detection, high transparency and remote diagnosis

DESIGN DEVELOPMENT MOULDING TOOLING

BEYOND THE MOULD

Pentagon delivers a full turnkey solution for plastic injection moulding from one site of UK Manufacture.

With over 50 years’ experience you can be confident that your Bespoke Moulding project is in the hands of the experts for both mould tooling and repeat production.

Meet us at this years’ Interplas UK –26- 28 September at the NEC, Birmingham.

• Flexibility: Easy assembly, modularity and convenient adjustment

• Increased machines availability: Clear error detection, high transparency and remote diagnosis

• Time saving: Innovative and flexible connection technology

• Flexibility: Easy assembly, modularity and convenient adjustment

• Cost efficiency: No further accessories necessary

• Time saving: Innovative and flexible connection technology

• Cost efficiency: No further accessories necessary

www.pentagonplastics.co.uk | websales@pentagonplastics.co.uk Tel: +44 (0) 1403 264 397 |

Issue 64 PECM 9 EDITOR’S CHOICE E NG I NE E R I N G T E CHNOLOG Y

Pentagon - Quarter Page.indd 1 20/04/2023 14:43 E NG I NE E R I N G T E CHNOLOG Y

UPS HIRE RENTAL SYSTEMS

Any Where - Any Event - Any Time

Containerised UPS systems provide emergency backup power on a temporary basis. Power Continuity UPS containers available for various scenarios. From 100kVA to 3000 kVA temporary Uninterruptible Power systems for ‘must have’ critical contingency to prevent power loss during planned site works. ensuring reliable power supply to sensitive electronics, servers, and site operations.

UPS HIRE CONTAINERS FOR TEMPORARY POWER

UPS hire containers offer installation, maintenance, and support services, ensuring you can rely on an uninterrupted power supply throughout the temporary deployment.

All our containers are ‘walk inside’. Weather protected. Resilient Air Conditioning and remote monitoring.

UPS HIRE SYSTEMS - FLEXIBILITY

UPS hire temporary systems offer multiple advantages, including:

EMEGENCY POWER: UPS failure can happen anytime. Deployment can be arranged to position our UPS container on your site, complete with 25 metres of cabling to allow us to temporarily install our UPS system to support your site load.

BESPOKE CONTAINER: UPS hire systems can be customised to meet the specific power requirements of power requirement. Plan in advance to ensure we provide the right level of resilient UPS power for your critical site.

INSTALLATION: Whether temporary or long term hire, Power Continuity offer professional installation services, working day or out or hours.

REMOTE MONITORING: Power Continuity remote monitoring support with maintenance services, ensuring that businesses have uninterrupted power supply throughout the temporary hire installation.

UPS HIRE SYSTEMS- COMBINED WITH OUR EMERGENCY GENERATOR

Power Continuity UPS hire systems combined with our emergency generators:-

Healthcare: Hospitals and other healthcare facilities just don’t have enough power to ensure uninterrupted power supplies to their energy consuming medical equipment. UPS rental containers bridge that power gap. Especially with generator back up.

Emergency Generator: UPS rental containers have battery autonomy for up to 20 minutes but for extra resilience we recommend installing our temporary diesel generators to allow running for up to 72 hours. Back up power to the Back up UPS container.

Manufacturing: We can install short term UPS rental systems to increase your output capacity, without worrying about power spikes or brown outs.

www.powercontinuity.co.uk

Football Stadiums: UEFA televised matches must have UPS power protection. UPS hire systems to protect from power disruptions during high value ticket international events.

Data centres: UPS Failure happens. UPS hire systems can be deployed to site, ensuring uninterrupted power supply to data centres, with emergency generators, before power loss damages the reputation of your brand. Call Power Continuity when you need resilience immediately today.

Rotary Fly Wheel UPS systems

Rotary Flywheel UPS hire systems for motor drives and heavy loads.

Only Power Continuity has long term hire Rotary Flywheel UPS systems available

Power Continuity has containerised UPS resilient system from 30KVA N+1 up to 2 Megawatts all available, to be delivered to site, installed on a temporary basis.

Your Reputation requires reliable UPS temporary when you need it most-which can only mean – Power Continuity Ltd. – There when you need us 24-7.

For more information call us on 0845 055 8455.

10 PECM Issue 64

EDITOR’S CHOICE

POWER CONTINUITY LTD

Reliable temporary UPS hire when you need it most, can only mean –Power Continuity.

SAVE SPACE, ENERGY & MONEY

MICRONEL

Micronel dc blowers save space, energy and money compared to other air sources such as bulky side channel blowers and compressed air systems.

Saving energy not only conserves resources but is also good for the balance sheet. That is why machine and plant manufacturers as well as production companies rely on Micronel high-performance blowers in process control and automation applications. The reliable high-tech solutions enable new and more efficient application possibilities and promote independence in comparison with previous compressed air systems.

Thanks to their very small compact sizes, Micronel blowers are suitable for decentralised installations and can be placed adjacent to the relevant process reducing pressure losses incurred in long air supply lines and allows flexible installation without the need to install or relocate air lines. Dynamic blower control allows air supply to be called up as on demand as required, increasing the efficiency of the application.

Here is a simple example: compared to

and ease of use, M16 connector and has G¾ inch pipe threads for 32mm tight hose connections. The housing complies with protection class IP67 with connected suction and discharge ports.

The 2 stage U100H4 can generate over 165 mBar (16,500 pascals) of pressure and achieve free blowing air flow over 900 litres per minute (54 metres cubed per hour) all from a very compact small size package of 107mm x 107mm x 118mm. With typical power consumption of 100 – 180 watts depending on working point they can pay for themselves in energy savings after only a few months.

Micronel blowers are also extremely advantageous in suction and extraction processes, such as pick & place processes or vacuum holding or conveying technology. A full range of accessories are also available including air knives, filters, and anti-vibration mountings.

a conventional Air-Knife compressed air application, with an annual consumption of 60000 m³ air volume, a Micronel Radial Blower U100H4 (pressure 165 hPa, flow volume 820 l/min) with a power consumption of 100 watts pays for itself in energy savings after only half a year.

The compact U100 dc blower family features a tough full aluminium IP67 housing, efficient brushless dc motor with integrated electronic driver for plug n run capability

The performance and cost savings of the blowers is particularly evident in applications such as drying and cleaning processes, where high pressure and a considerable volume of air are constantly required.

Micronel specialise in High Performance Blowers and Fans, their fan and blower products meet the needs of industries with special performance characteristics – Medical, Electronics Cooling, Personal Protection, Packaging, Gas Analysis, Laboratory, Transportation, Process Control and many more applications. Micronel offer customers the widest choice of standard ultra-slim fans, axial fans and high performance high pressure radial blowers from UK stock and provide technical design support for modified products and client specific designs.

For further information, please visit www.micronel.co.uk

12 PECM Issue 64 EDITOR’S CHOICE

Micronel reduce operating costs with decentralised compact dc blower solutions

LEADING THE WAY

EXPROMET

Expromet delivers global casting and machining sourcing solutions

In a rapidly changing world, customers need the flexibility to source their cast and machined products from a range of locations to satisfy different requirements. Expromet Technologies Group makes it easy for customers to find the right casting and machining solution by providing a range of options and expert advice.

MADE IN BRITAIN

Expromet businesses are market leaders in their respective fields and offer extensive UK casting, machining and fabrication capabilities:

• Investacast is one of the leading suppliers of investment castings in the UK, with a manufacturing base in Devon

• Haworth Castings specialises in fullyfinished aluminium sand and gravity die castings from two production facilities in Hampshire

• Metaltech Precision offers high quality precision CNC machined components and fabrications from its state-of-the-art facilities in Somerset.

GLOBAL SUPPLY CHAIN

Expromet also has an extensive global supply chain, enabling each of the Group companies to help customers source high quality castings products from a range of international manufacturing partners.

Customers may opt to outsource their requirements for a range of reasons, such as leveraging lower labour costs and greater economies of scale. Haworth Castings, Investacast and Metaltech Precision each provide clear advice and guidance on the relative benefits of overseas manufacture for specific types of products.

TURNKEY SOLUTIONS TO ENGINEERING CHALLENGES

Where outsourcing supply is the best solution, Expromet Technologies Group companies will provide a turnkey solution, taking ownership of technical development, logistics and relationship

management to deliver a fully integrated service to the customer.

Expromet is proud of its skilled workforce across all three businesses, and continues

to expand its capacity to deliver worldclass casting and machining solutions both within the UK and overseas.

“As a leading group of advanced precision casting and machining businesses we understand the need to manufacture quickly, efficiently and to the highest quality, safety and environmental standards,” says Expromet CEO Alistair Schofield. “Our customers know we will help them find the best solution for manufacturing their casting products, be it local manufacturing or international sourcing, and know they can trust us to deliver.”

To take advantage of Expromet’s UK manufacturing capabilities and global supply chain contact us on + 44 (0) 1271 866200 or email enquiry@expromet.com.

For further information, please visit www.expromet.com

14 PECM Issue 64

EDITOR’S CHOICE

Expromet Technologies Group makes it easy for customers to find the right casting and machining solution by providing a range of options and expert advice.

• Casting • Machining • Forging • Welding & Fabrication www.expromet.com Precision casting, machining and fabrication solutions for performance-critical applications • Casting • Machining • Forging • Welding & Fabrication www.expromet.com Precision casting, machining and fabrication solutions for performance-critical applications

UNIFIED ROBOT CONTROL

ROCKWELL AUTOMATION

Bring robots into the heart of the control system

By Roberta Tanzariello, Platform Lead Robotics and Digital Tools, Rockwell Automation

Industry is facing a multitude of diverse challenges to remain competitive amid skills shortages and greater product variety. In such a fast-changing market, flexibility, and the ability to make changes rapidly is crucial to success. Manufacturing is becoming increasingly automated, and robots need to be integrated into machines to improve resource utilization and enhance data availability across different components. Traditionally, robot control systems were fragmented and tailored for specific robot applications. However, that is now changing with an integrated robot approach that can help accelerate robot deployments, simplify work, and improve productivity.

INTEGRATING ROBOTS INTO THE CORE CONTROL SYSTEM

Maximizing the full benefit of robots is becoming even more crucial as competition increases. There is a greater expectation on the production teams, whether that means achieving higher output, shorter lead times, or more product customization. But improving operational performance can be complex and challenging when robots, although a crucial part of the solution, are often on the boundary.

To ensure that production is flexible and optimized, robots must be fully integrated as a core piece of the control system. At first glance, that increases the complexity and adds further challenges to manufacturing. This integration must be as simple as possible to be a viable solution. In today’s

more-intelligent production operations, integrated robots can help speed up deployment with a simplified control system that allows organizations to build and validate programs more efficiently using digital engineering tools and a single, integrated design environment.

HOW TO ACHIEVE INTEGRATED ROBOTICS

When embarking on a robotic integration plan, two approaches can be followed. The robot and control system can be connected via EtherNet/IP, or you can combine them into a single, unified system. The best methodology depends on each precise use case and will depend on the operation’s specific needs.

Better coordination between robots and other equipment in manufacturing can make operations more responsive to demands. In addition, connecting robots with information solutions, such as analytics, can help optimize processes and reduce downtime. Connectivity can transform more than how robots operate. Centralizing control in a single design environment and using the latest digital tools can improve how robots are programmed, deployed, and supported.

A RACE AGAINST TIME TO DEPLOY ROBOTS

Speed is always crucial when designing a new cell or production line. When that involves coordinating separate robot and machine control systems, that can eat up the time and increase the pressure on delivery schedules. In the traditional scenario, both the core and robot control systems must be programmed individually. Trying to align their performance can be cumbersome and involve a lot of trial and error.

There are two paths you can take to achieve integrated robots. The first is to connect a dedicated robot controller to a Logix PLC via the standard, unmodified EtherNet/ IP protocol. Robot programs are written in either the robot vendor’s programming environment or via Rockwell Automation’s Studio 5000® robot integration features. The other option is to use a Logix controller and Kinetix® drives to control a robot arm directly. The Logix controller hosts the robot kinematics, and the entire program is made in Studio 5000 to direct all robot movement without a dedicated robot controller.

EtherNet/IP connection allows the robots to be effortlessly added to the control network

16 PECM Issue 64

EDITOR’S CHOICE

with a simple, single-cable connection. This makes it easy to meet different application requirements while providing access to the Logix platform. It facilitates more centralized control by sending commands that initiate robot movement, obtain status, change recipes, and modify configurations. The platform can operate with more clarity and control by performing essential functions from an HMI without needing a robot pendant.

EtherNet/IP allows organizations to deploy faster and streamline advanced safety functionalities. It speeds up identity configuration, communications, and I/O data transfer using EtherNet/IP Add-on Profiles. In addition, it creates a simplified, more easily managed safety network using CIP Safety. The robot appears and is handled like any other EtherNet/IP network safety device. Integrated robots help people across job functions do more with robots by significantly reducing the effort for programmers by writing, testing, and refining in the Studio 5000 environment. It allows organizations to leverage skilled engineers who are already proficient with Studio 5000 software to bring systems up to speed faster, with no need to train or wait for the availability of a specialized robot programmer.

THE ADVANTAGES OF UNIFIED ROBOT CONTROL

To meet the needs of the smart factory, it is vital that robots can be rapidly deployed and that they are flexible and easily integrated into the entire plant network. The challenge here is that this entails workers being comfortable with multiple systems. This is where unified robot control comes to the fore, to provide a more straightforward catalogue-number-driven approach. It eliminates the need for dedicated robot controllers and programming environments. Instead, unified control is an out-of-the-box, catalogue-number-driven solution based

on configuration instead of programming. It is possible to select a robot vendor, drag and drop it into an Ethernet/IP network, and generate an automatic bill of materials. Dedicated robotics libraries can generate project files and faceplates for overall robot device status, diagnostics, path configuration, homing and brake control.

Digital engineering allows the control code to be tested and validated so that the mechanics and logic work harmoniously before the robot cell is built. It offers the ability to stress test the real-world performance of the robot system digitally, to confirm cycle rates and recognize any potential bottlenecks before implementing any changes. Working in a digital environment using digital twins, engineers can design, iterate, test, and prove solutions faster.

The benefits of a digital platform do not end at the design stage; it offers advantages across the entire cell lifecycle. By designing with Rockwell Automation’s Emulate3D™ software, it is possible to create more efficient, practical robot applications and advanced tools using data to better control, operate, and support the system.

Utilizing the digital twin allows programmers to reduce design time and costs by shifting essential controls programming tasks earlier in the project. This strategy lowers the risk by using virtual commissioning to diagnose and remedy late-stage issues early.

By better connecting the controllers or unifying them into one system, you can create robot applications with less time and effort. This has multiple benefits, including reducing engineering time and costs by programming the robot and machine together in one place and reducing complexity and footprint with a centralized control architecture. It allows organizations to deliver high-speed, highprecision operations more efficiently with better synchronization of the devices on the machine network.

For more info, please visit www.rockwellautomation.com/en-gb/capabilities/industrial-automation-control/robot-automation.html

Issue 64 PECM 17

Maximizing the full benefit of robots is becoming even more crucial as competition increases.

ViSWIR … Bringing Visible & SWIR into Focus

ViSWIR Hyper APO Features:

• Capable of fully corrected focus shift in visible and SWIR range (400nm - 1700nm)

• Achieves spectral imaging with a single sensor camera by simply syncing the lighting

Floating design adjusts focus for different wavelengths

8mm, 12mm, 16mm, 25mm, 35mm* and 50mm* (*2023)

ViSWIR Lite Features:

High transmittance at whole wavelength of 400nm - 1700nm by adopting hyper wideband AR coat

Outstanding cost-performance for single-wavelength lighting & narrow-band imaging

Compact design

5mm, 8mm, 12mm, 16mm, 25mm, 35mm, 50mm

EDITOR’S CHOICE

ViSWIR-Series A computar-global.com info@cbcuk.com

8457 2618 catalyst of optics

Introducing the award-winning Computar

020

Work smarter, not harder

A workspace that adapts to your needs, not the other way around.

The widest range of accessories on the market. Future-proof

Multiple sizes and combinations available. Productivity and well-being

DESIGN

YOUR PERFECT WORKSTATION

Suitable to any environment, application and industry. Concept workbench

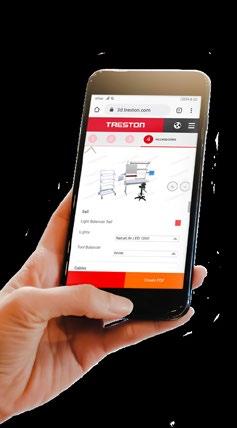

The Treston 3D Configurator can be used to design an industrial or technical workstation that best meets your needs. To get started, all you need is a mobile phone or a computer with an internet connection; no downloading is required and using the software is free.

3D.Treston.com ERGONOMICS | ESD | LEAN treston.com

Safety in Profits in Safe-Connect Thermochromic www.iriss.com Safety in Profits in Safe-Connect Thermochromic www.iriss.com

in Color, in Sight! Thermochromic Service Kit www.iriss.com IRISS.com in Color, in Sight! Thermochromic Service Kit www.iriss.com IRISS.com

PROACTIVE FLUID MONITORING

GLOBAL HEAT TRANSFER

The ins and outs of thermal fluid analysis

How do you know when a kitchen sink is about to clog and overflow? Most residential pipes are hidden, so food waste and product build-up can go unnoticed until it leads to damage. In manufacturing, leaving pipework unmonitored can lead to unexpected downtime and safety issues, particularly when working with thermal fluids, so proactive monitoring is the best way to prevent these problems. Here Clive Jones, managing director of thermal fluid supplier and condition management expert, Global Heat Transfer, outlines the steps of thermal fluid analysis for proactive fluid monitoring and how businesses can use the results to increase fluid lifespan.

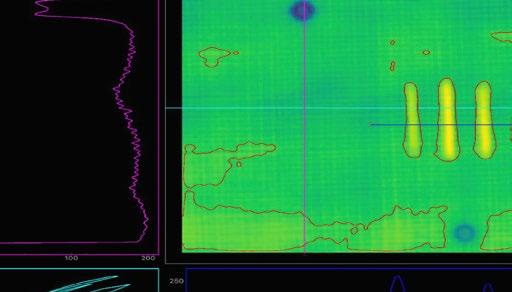

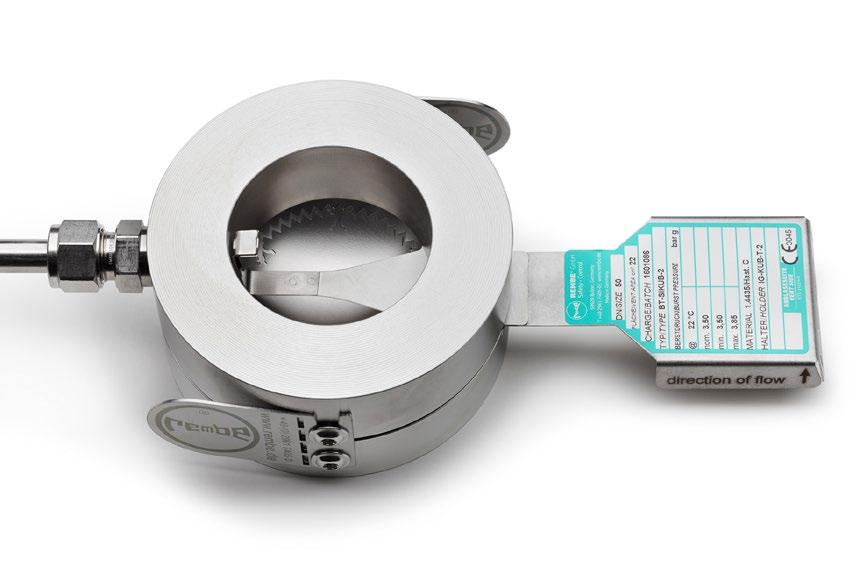

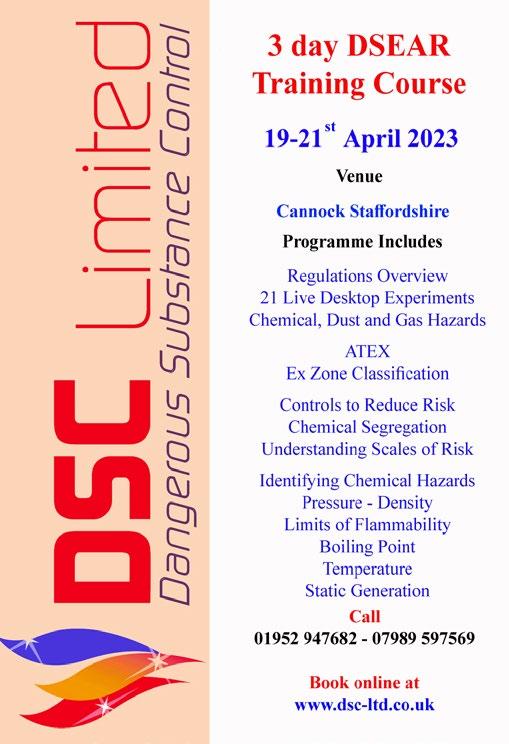

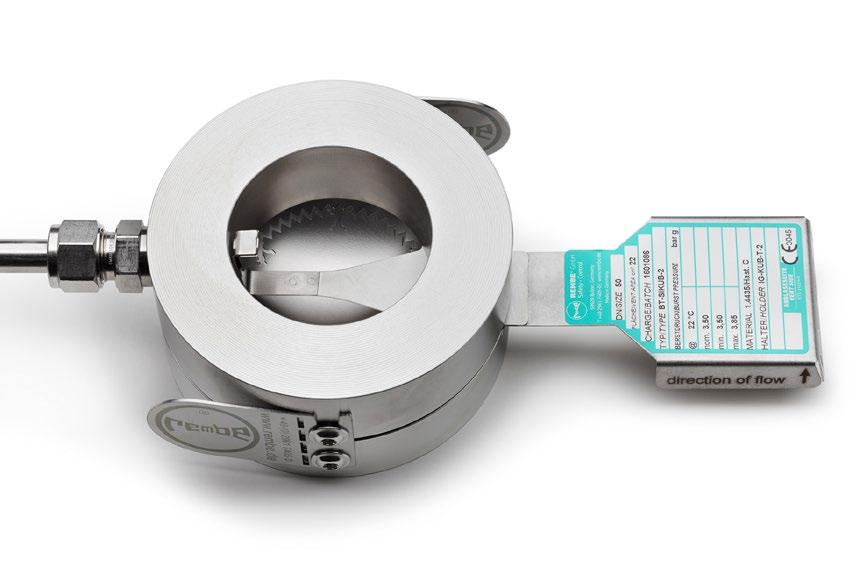

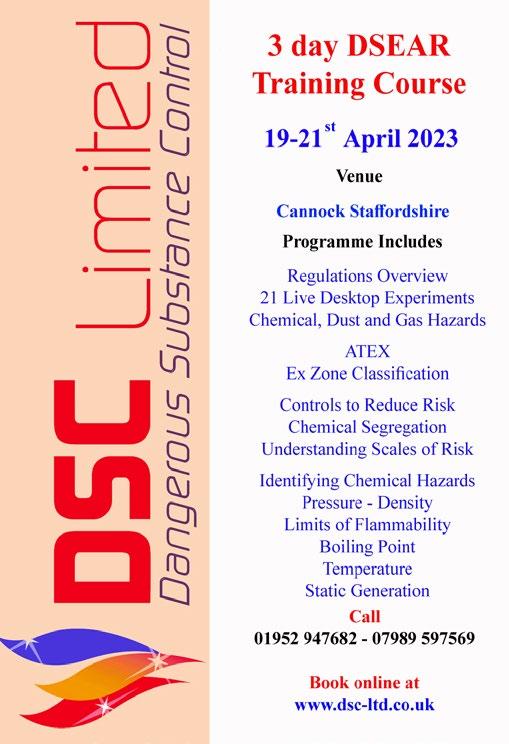

Thermal fluids are designed to operate effectively for many years, but over time, operating at and maintaining high temperatures means that the oil will naturally degrade. Thermal fluid analysis provides a deep dive into the condition of the oil and allows businesses to gain expert advice about how to effectively maintain the fluid and the system. Analysis also ensures health and safety compliance with The Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) of 2002 and UKEX (formally the Explosive Atmosphere Directive ATEX 137 in the UK).

To comply with relevant safety regulations, such as DSEAR in the UK, manufacturers must take proactive steps to reduce the risk of fire or explosion caused by working with dangerous substances. If this fluid is left unattended, for example, fluid degradation — where thermal oils can be broken down into carbon molecules that stick to the pipes — can occur, reducing heat transfer efficiency. If not monitored effectively, degradation may go unnoticed until it causes significant production issues and system failure, leading to costly downtime and risk to health and safety.

Instead of reacting to issues, regular thermal fluid sampling and analysis enables businesses to proactively monitor fluid condition and intervene before issues impact production, extending thermal oil lifespan and reducing maintenance costs.

ANALYSING A SAMPLE

Effectively monitoring heat transfer oil condition requires engineers to regularly

take samples of the oil and send it to a specialist for analysis. Historically, thermal fluid experts conducted seven tests, however, in our experience conducting eleven tests provides results that best reflect the reality of what’s happening inside the system.

Once the sample arrives to an impartial lab for testing, an analytical chemist will look at its appearance, looking at the colour and for any particulates in the fluid. Fluid colour can range from clear and bright, which is common to newer fluids, to hazy, which can be a sign of high-water levels, to dark, which shows there is a high level of carbon build up in the system. These initial observations are confirmed in later steps to ensure the thermal fluid specialist provides the best recommendations.

Testing the water content of the oil is vital to regulatory compliance. Any water in the system and oil will convert to steam and expand, increasing the pressure in the system. By analysing water content, analysts and heat transfer fluid specialists can advise on how best to reduce the risks associated with high pressure.

The next step is to test viscosity and assess the impact the fluid has on the system pumps. If a fluid is too thick, flow rate will reduce, increasing the pressure on the pumps. This reduced flow rate can

create hot spots in the system, leading to inconsistent heating or cooling of products that results in waste products, increased damage to the system and rising maintenance costs.

Measuring the level of carbon in the system is key to understanding the degree of system fouling. If the thermal fluid expert detects high levels of carbon deposits, it suggests that there is more carbon in the system, which can harden in the pipes, acting as an insulator. As a result, the entire system heat transfer efficiency will reduce and more energy is required to heat up the system. Manufacturers should consider how they can prevent carbon build-up as it can create hot spots that accelerate wear on the pipes and increase the risk of leaks.

Analytical chemists will then test the total acid number (TAN). If there is a high level of acid in the fluid, it can lead to increased corrosion of the system and accelerated carbon creation. By measuring this parameter, manufacturers can understand how the fluid impacts the pipes of the system, ensuring that they can slow down degradation and reduce the frequency of scheduled maintenance needed to replace corroded parts.

Particulate quantity and iron tests highlight the degradation of components of the heat transfer system. Both tests can show signs that there is wear in the system that needs addressing so that manufacturers can intervene before the wear turns into a dangerous leak.

Manufacturers should also look at the results of the Pensky-Martens Closed Cup flash point, Cleveland Open Cup flash point and fire point tests to reduce health and safety risks. The industry standard suggests that closed flash point of the fluid cannot be below 100 degrees Celsius, because it means the fluid could ignite at lower temperatures, so these tests are vital to understanding if the fluid is safe for use.

REPORTING

Once analysis is complete, the thermal fluid expert delivers a report to the plant manager, organising points into cautions, actions, or serious findings. At this point engineers

22 PECM Issue 64

EDITOR’S CHOICE

To comply with relevant safety regulations, such as DSEAR in the UK, manufacturers must take proactive steps to reduce the risk of fire or explosion caused by working with dangerous substances.

can take the recommendations and plan interventions based on the priorities in the report. Making a record of each result will also help plant managers in the long term. By monitoring thermal fluid condition over time and looking for trends, helping them to anticipate when the system will require maintenance before downtime occurs.

Maintaining an efficient heat transfer system is integral to productivity, so unlike domestic

pipes where a blockage may cause a minor overflow, manufacturers should consider how they can effectively monitor fluid inside the system. Thermal fluid testing can be complex, so manufacturers can work with thermal fluid experts, like Global Heat Transfer, to ensure they complete the process effectively and get an accurate representation of what’s happening inside the system. For example, by including Global Heat Transfer’s Thermocare® as part of a

preventative maintenance programme that aligns with the ATEX triangle, experts can offer both on-site and remote technical support to help manufacturers rapidly sample and analyse fluid. From this, manufacturers can track fluid condition, anticipate and resolve issues quickly and implement preventative measures to extend fluid lifespan, reduce downtime and the facility’s environmental impact, and ensure system compliance.

For further information, please visit www.globalhtf.com/heat-transfer-management/heat-transfer-fluid-analysis/.

Issue 64 PECM 23

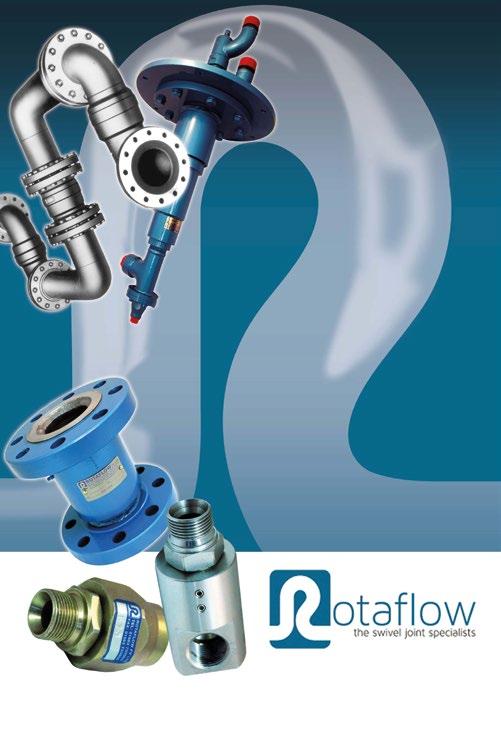

Rotaflow: Specialists in the Design and Manufacture of Swivel Joints

Rotaflow swivels are regularly utilised in the following engineering sectors with tailored or stock designs for specific needs: Brewery, Chemical, Dairy & Farming, Food & Drink, Nuclear, Process & Plant, Drilling & Mining, Oil & Gas, Subsea, Water & Waste.

A Swivel Joint reduces costs by reducing the risk of leakage with its associated downtime. By fitting a quality designed swivel, you are improving your production capacity. Rotaflow are specialists in taking your bespoke requirements and being able to design a solution that can fit your budget, dimensions, materials, FAT/witness testing; hygienic and pressurised environments. We regularly test to Hyperbaric, Seal Life and conduct Temperature/Pressure/ Load Cycle Testing. We are ISO 9001:2015 certified.

We have off-the-shelf solutions, or we can redesign and in-house manufacture to enable a quick turn-around with minimal fuss and maximum design experience. Photo attached shows a batch of 3” Hardened Carbon Steel Swivels mid machining. These will be stocked and ready for the drilling industry when requested. Rotaflow have built up a reputation for providing reliable and quality designed products that resolve your engineering needs and we are proud to say many customers request our services over and over again.

To find out more please visit our website and/or give us a call. Tel: +44(0)1663 735003 | sales@rotaflow.com www.rotaflow.com

Fluid Carr ying Flexibility Swivel Joints

Swivel joints allow pipework to pressure 1/4” to 40” and beyond. Vacuum to over 20,000psi. Stock and bespoke production. Unique bearing/seal design for longer life.

ISO 9001 CE marked where applicable.

Tel: +44(0)1663

RMIG is the world’s largest manufacturer and supplier of perforated metal and its related products.

We know our customers’ requirements for price and quality and meet their demands with uncompromising service.

Not only do we offer standard and bespoke perforated metal sheets, we are able to offer you a range of secondary operations as detailed below.

Complete solutions

With a continued investment in the latest equipment and a network of professional partners we are able to produce prime quality products and solutions – from a simple perforated sheet to the fully formed and coated custom made part.

Cutting

We can cut and shape perforated sheet to meet the needs of your nal application.

Levelling

For some applications a high degree of atness is required, we have processes in place to ensure our perforated coils and sheets meet with your most demanding requirements.

Rolling and forming

We can roll, bend and form perforated sheets to match your design.

Aesthetic nishes and protective coating

We can offer powder coating and hot dip galvanizing solutions to meet your speci cations.

For more information please contact us tel: 01925 839610 | email: info.uk@rmig.com | www.rmig.com

24 PECM Issue 64

Bingswood Trading Estate Whaley Bridge | High Peak | SK23 7LY | UK Articulated Pipework Torsion In Hoses

Rotating Cylinders

735003 E-mail: EDITOR’S CHOICE we make ideas come to life

Disc Filters

You design, we create

Helapet

Our

Issue 64 PECM 25

that no single filter can be suitable for the varied filtration applications

are used

industries.

knows

that

across

new

a simple-to-use

Inline

Try out our filter design tool for yourself today! Visit filterdevices.com EDITOR’S CHOICE More choices, information and registration at www.eemua.org and events@eemua.org Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Publication 159 Edition 5 Specialist Training for the Storage Tank Industry Live online, classroom, blended, e-learning or in-house

or renew your 5-year Certificates of Competence* •Courses based on EEMUA 159 • English, Dutch, German and French language options •Select from courses throughout 2023, including: –TankBasics courses TankInspector courses* 18-20 September 2023 – in Dutch – live online 16-18 October 2023 – in English –live online TankBasics courses 25 September - 3 November 2023 – in English – blend of live online classes, 1-1 tutorials, e-learning, and more In-house courses By arrangement for your choice of: time, language, location, or live online TankAssessor courses* 4-7 September 2023 – in English – live online 2-5 October 2023 – in French –classroom – Près de Lyon, FR 9-12 October 2023 – in Dutch –classroom – Rotterdam, NL 6-9 November 2023 – in German – live online Storage Tanks e-learning On-demand – in English or in Dutch Also... Storage Tanks Seminar – 30 November 2023 – R Rotterdam, NL

online design tool provides customers with

design wizard, combined with enhanced information to guide customers through the 100’s of available filter combinations. Custom

•Gain

SeaShield 70/80™ System: Effective protection for submerged and shoreline pipelines

For over 50 years, SeaShield™ corrosion control systems have provided enduring protection on jetty piles and marine structures from the devastating effects of corrosion. The recent addition of the SeaShield 70/80™ System is a response to the industry’s need for a robust, UVstable, easy-to-apply system designed specifically for submerged and shoreline pipelines situated in aggressive marine environments.

The SeaShield 70/80 System, from Winn & Coales (Denso) Ltd, was created by combining a waterdisplacing petrolatum tape and primer with a tough PVC-backed bitumen tape (the SeaShield 80™ System) and a moisture-cured glass-fibre reinforced outerwrap (from the SeaShield 70™ System). The resulting system provides exceptional mechanical and impact strength and is available in three variations to suit the level of protection required.

The flexibility offered by the SeaShield 70/80 System marked it as the ideal choice for a recently completed project on the West Sussex coast. Leith Hill Plant Ltd., on behalf of Arun District Council, applied the heavy-duty version of the system in stages, both off-site and in-situ, to protect newly laid pipe sections on two outfall pipes that had previously suffered significant damage from shingle movement.

26 PECM Issue 64

www.denso.net

EDITOR’S CHOICE

Sections of the pipe were wrapped in the contractor’s yard (inset) then transported to site, whilst others were wrapped in-situ.

DRIVEN BY GLOBAL DEMAND

PRECISION MICRO

£1.8m investment at Precision Micro supports journey to net zero

Global chemical etching supplier Precision Micro has unveiled a further expansion of its manufacturing capacity and capability with the addition of a second new etch room at its Fort Dunlop-based site in Birmingham, UK.

In an investment totalling £1.8 million, the etch room is home to three new highly efficient etch machines alongside a bespoke semi-automated print frame.

Believed to be an industry first, the business’s new print frame boasts a design that minimises human input in printing photoresists onto larger sheet metals up to 1500mm x 600mm in size, increasing throughput and delivering cost savings to its customers. Furthermore, the shift towards a more automated approach enhances component quality by eradicating the issue of foreign object debris which can impact the photochemical etching process, as well as reducing the manual handling of heavier materials.

Driven by global demand for nextgeneration energy technologies such as hydrogen production and storage, carbon capture, green energy buffering, electric and hydrogen electric vehicles, the expansion enables Precision Micro to supply larger, thicker etched sheets in higher volumes. Supplying enabling components such as printed circuit heat exchanger flow plates for waste energy recovery and hydrogen pre-coolers, busbar battery interconnects for EVs and bipolar plates for fuel cells and

electrolysers used for hydrogen production, the investment will support companies looking to productionise these products and overcome capacity constraints in the existing supply chain.

Karl Hollis, Precision Micro’s Director of Engineering, said: “We’ve worked closely with our suppliers to ensure all the new equipment is developed in line with our ESG strategy, automating many parts of our manufacturing process using less power to achieve the same consistent results. Chemical etching is often the only appropriate method for manufacturing the precision components needed for many emerging renewable technologies. This latest £1.8 million investment marks the next stage of our expansion, and we are excited to be able to support our customers’ rapid growth.”

In 2019, Precision Micro invested £5.1 million in plant and new equipment, a move which increased the business’s etching capacity by 30% which in turn opened new opportunities within sustainable energy markets. The latest addition has increased this by a further 40%.

Precision Micro also plans to add a fourth etch machine to its new etch room in early 2024.

For further information, please visit www.precisionmicro.com

28 PECM Issue 64

EDITOR’S CHOICE

This latest £1.8 million investment marks the next stage of our expansion, and we are excited to be able to support our customers’ rapid growth.

GROWING ON DEMAND

Professional plastic part manufacture

As a company that specialises in industrial 3D printing for low volume manufacture and batch production, 3DPRINTUK continues to grow at an impressive rate. The Londonbased company is unwavering in its use of high-end 3D printing systems to bridge the significant gap that exists between prototype and injection moulding. 3DPRINTUK provides an invaluable service for a wide range and growing number of customers where tooling costs are prohibitively expensive for their product or the volume demanded by injection moulding is excessive.

According to Nick Allen, 3DPRINTUK’s CEO: “Our primary focus is absolutely low volume and batch production. As a result, we are seeing new and repeat customers using our service to manufacture their parts. We are consistently manufacturing more than 1 million parts annually and the numbers keep going up. However, because of the nature of the 3D printing processes and our focus on quality, we can produce parts in volumes of 1, 10, 100, 1000 or 10,000 parts, so we can still offer a high-quality prototyping service for our customers that are in a new product development phase. They can test and quickly iterate their parts using our service, before using the same machines for manufacture.”

THE YEAR IN VIEW

Over the last 12 months, 3DPRINTUK has taken the company to an even higher level, not least by becoming part of the Trimech Group through acquisition by Solid Solutions. With an approach based on the premise “if it’s not broken, don’t fix it” this move has solidified 3DPRINTUK’s position as a leading 3D printing service provider while extending its resources and supporting further growth.

ISO 9001

Some key goals have been the foundation of 3DPRINTUK’s success over the last year, notably the company achieved ISO 9001 certification at the end of 2022. Quality has always been at the heart of the 3DPRINTUK service, but this certification provides reassurance to customers that the company operates at the highest levels for quality assurance and validation of 3D printed parts on a daily basis, in full compliance with the ISO 9001 standard.

Alessandro Catania, Quality and Compliance Manager at 3DPRINTUK stated at the time: “It is really gratifying after going through the extensive ISO 9001:2015 process to be notified that there are zero findings. Quality and quality assurance are a central feature

of all of the manufacturing and production services that we offer. And now we can prove it. By achieving ISO 9001 certification, we can demonstrate that all of our systems, processes and procedures meet the high demands that this certification requires for all of our 3D printed parts.” Following this successful outcome, 3DPRINTUK is in the process of qualifying for ISO 14001.

ROAD TO NET ZERO

3DPRINTUK has also strived to ensure the company is run in full alignment with its stated values. Undertaking its Road to Net Zero initiative was essential to this and earlier this year, 3DPRINTUK set itself an ambitious target to become the first fully certified, net zero 3D printing bureau by the end of 2023 and to be the first 3D printing service to offset 100% of its plastic output. Achieving certified net zero is no easy task, but the company takes climate change and its impact seriously and this is the driving force behind its roadmap.

Allen went on the record, saying: “As a manufacturer of plastic parts, we cannot hide from the environmental impact of plastic on the environment. However, we also believe that plastic materials continue

30 PECM Issue 64

EDITOR’S CHOICE

3DPRINTUK

to offer benefits and do have a part to play in a sustainable economy. This can be seen in the way that plastics can replace some metals making parts and components that are lighter in weight.”

Just a few months later, in June, 3DPRINTUK was able to announce that it had indeed achieved certified carbon neutral status and is the first 3D printing service bureau to do so.

SOME FACTS AND FIGURES

It is not all that surprising then that 3DPRINTUK has continued to experience significant growth. One independent testament to this, was 3DPRINTUK being named as one of Europe’s fastest growing companies in 2023 on the FT 1000. This appearance was based on an absolute growth rate of 171.6% over the last four years. The list also highlighted how 3DPRINTUK is the third fastest growing manufacturer in the UK.

Inside the facility, the company’s fleet of 3D printers has grown significantly and now includes 14 in-house EOS SLS machines, four HP 5210 systems and a recently installed Stratasys SAF H350 industrial 3D printer. These machines are all complemented by a full DyeMansion suite of post processing equipment, which has also expanded significantly over the last 12 months. So much so, that the company is currently in the process of expanding the facility’s footprint to 15,000 square feet, adding an additional 5,000 square feet in the form of a new building in the same location, that will become a dedicated post processing hub.

The heart of 3DPRINTUK, however, is the team of talented and experienced people that offer a wealth of expertise. This expertise is not just dedicated to running the machines for optimum, high-quality output, but also

for software development and customer partnerships and liaison. The core team at 3DPRINTUK has now grown to 25 people, with sound leadership in each department.

A BROAD CUSTOMER BASE

The low entry cost of the 3DPRINTUK service sets it apart from other manufacturing options. With a minimum order of just £40, the service is open to a vast potential client base spanning across diverse sectors, and enabling the company to cater to a wide range of industries, as mentioned above, from volumes of 1 through to 10,000. 3DPRINTUK partners with clients working in sectors ranging from Cycling & Sport Technology to Marine & Subsea equipment; across Academia and the Creative industries; as well as Green Energy, Autonomous & Electric Vehicles, VR, Prosthetics & Robotics. The company also supplies a significant number of Design Consultancies with high end, functional prototypes and low volume production parts.

CUSTOMER TESTIMONIALS

Third party testimonials are perhaps the surest way to garner understanding of how a company operates and delivers for its clients.

Below are just a couple, that speak to the capabilities and capacity of the 3DPRINTUK service:

Andrew Magnier, Founder of MagCAD, has utilized the company’s service for a number of years to develop and manufacture parts for his cycling business: “3DPRINTUK’s instant online pricing model showed us that its costs were very competitive and would scale well with our business. Initial test runs also demonstrated that the quality of parts is outstanding and the 3DPRINTUK team is very communicative and knowledgeable.” MagCAD now regularly places repeat orders for production parts.

Jeremy Sitbon, Chief Robotics Engineer – Marine Robotics Systems at ecoSUB Robotics also regularly use the 3DPRINTUK service for the production of some key parts for their underwater, autonomous vehicles. He said, “We are constantly on the look-out for the most cost-effective 3D printing solution for our underwater vehicles, but we cannot compromise on quality at all…. We will continue to use 3DPRINTUK as we have not found an on-line ordering system that comes close to theirs in terms of ease-of-use, and the team has an enormous depth of knowledge in material selection, DfAM, and print optimisation that benefits us on every level.”

The future is looking bright for 3DPRINTUK with continued growth and strengthened client partnerships for production applications featured high on the agenda.

For further information, please visit www.3dprint-uk.co.uk

Issue 64 PECM 31

3DPRINTUK’s instant online pricing model showed us that its costs were very competitive and would scale well with our business.

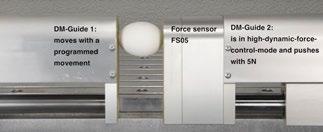

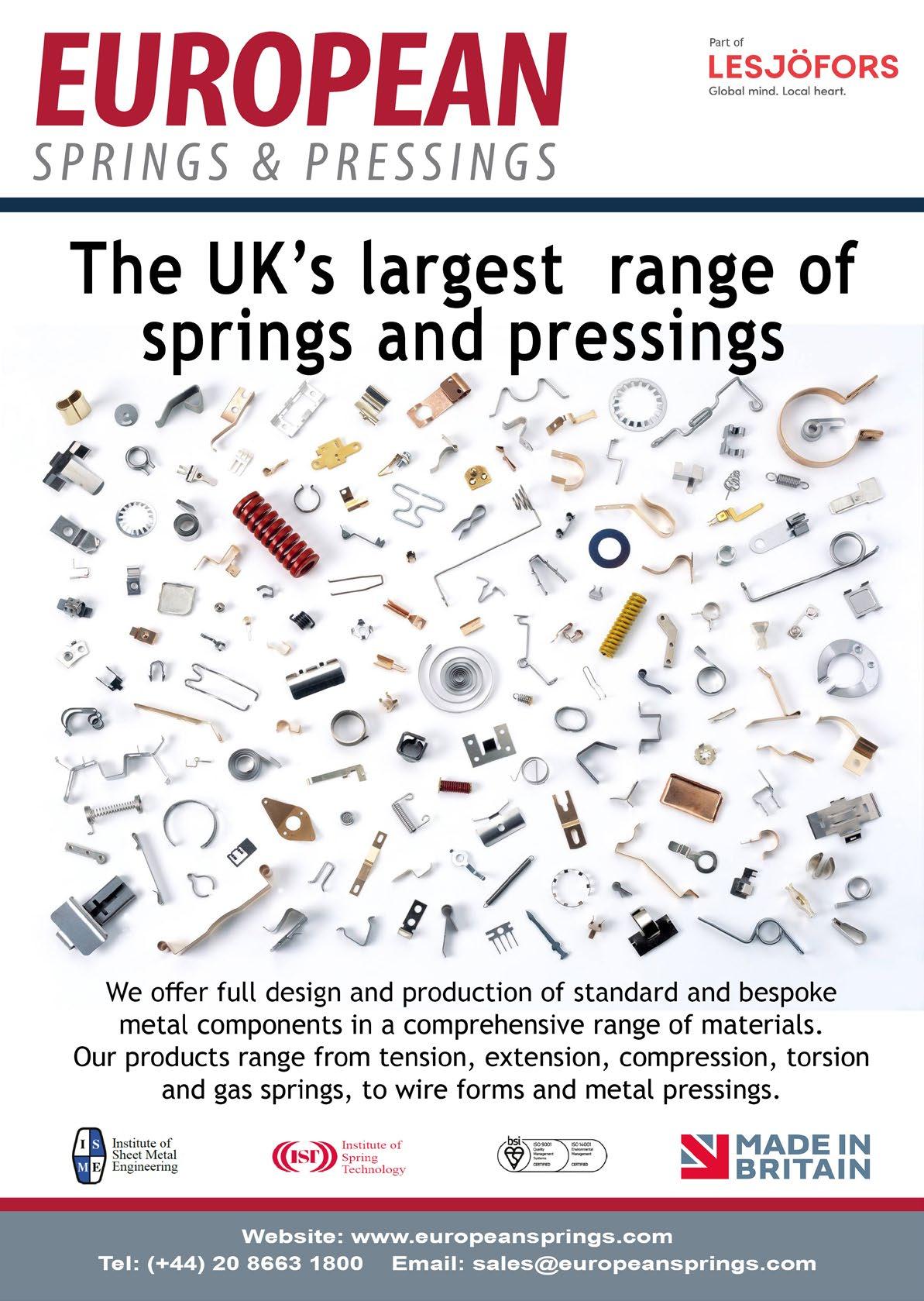

High precision Linear motors now with force feedback

Linear motors are ideal for fast and accurate motion in a machine.

Linmot, the leading manufacturer of cylindrical linear motors, has made them even more suitable for demanding products that require exceptional cleanliness in the production environment. This has always been demanding for machine designers, but has been made much easier by using the Linmot DM01 Linear motor modules.

The DM01 Linear modules provide high precision positioning while supporting high loading with the following features:

• Stroke up to 575mm and peak force up to 572N

• Direct load mounting up to 30kg

• Clean Design

• No Slider lubrication is required.

• Higher stiffness / lower bending

• Load balance (MagSpring) & pneumatic holding brake option

• Can be combined to form two-axis systems

• Are available certified for Clean Room Applications.

INCREDIBLY SENSITIVE FORCE CONTROL

The latest option that has just become available is the addition of a force sensor combined with force control software.

This is an option that can be added to any of the DM01 modules.

Just to demonstrate how sensitive, you can place an egg between two DM01 modules, one equipped with the new Force sensor.

One DM01 module moves with a programmed movement while the other follows while maintaining a precise 5 N force at all times to hold the egg without breaking it as shown in the picture.

A video of this application is available on our website (see below).

Using a regular force sensor requires precision alignment or measurement error will occur.

Linmot’s special design provides excellent

measurement accuracy even with axially offset loads or with side loading from an attached load (such as a gripper for example).

Here is a section through the sensor to show how the load is guided combined with the special design of the sensor itself.

While handling such delicate tasks, it can also handle up to +/- 500N of force combined with an accuracy of 1%.

This exciting new option opens up many new applications and makes the Linmot DM01 a unique and powerful new tool for the machine designer who needs sensitivity as well as force and dynamic speed.

For more information, please contact Quin Systems on 0118 977 1077 or sales@quin.co.uk. Website: www.quin.co.uk/linmot

32 PECM Issue 64

• Clean hygienic design • Stainless Steel • Easy to clean • Minimum maintenance • High performance • Low energy

EDITOR’S CHOICE

Training to prevent loss of hazardous substances

…

EEMUA's MIPC® course helps practitioner-level engineers to be where needed on-site, and to stay on top of the latest industry developments and good practice in primary containment of hazardous substances – including in pressure systems. Blending live online classes, e-learning, and one-to-one sessions with expert tutors, enhanced by a mentor’s support and guidance throughout, EEMUA’s Mechanical Integrity Practitioner Certificate course delivers in-depth training to engineers where they work – giving professionals the flexibility to learn, on-site or on-call, for industry-recognised 5-year certification.

Registration open now for the next MIPC course. Learning starts 23 October 2023.

Induction of 2 hours to fit diaries from September 2023 adapts coursework to the engineering needs of each Learner and their site/s.

For more information please contact online-learning@eemua.org

+44 (0)20 7488 0801 www.eemua.org

On Demand Failure Analysis and In-Depth Non-Destructive Inspection

Cupio Services provides x-ray, acoustic, optical and electronic test, inspection and analysis services.

If you only require inspection, test or analysis services occasionally throughout the year, the requirement to purchase our equipment may not be necessary, this is where Cupio Services is the answer.

• Cutting-edge inspection and test equipment

• Functional testers and counterfeit part detection

• High resolution x-ray with multiple CT imaging options

• Acoustic microscopes for delamination detection within boards or complex devices

• Full failure analysis reports.

Speak to one of our experts today:

Cupio Services Ltd

+44 (0) 1256 262800

info@cupioservices.co.uk

www.cupioservices.co.uk

Beechwood, Chineham Business Park, Basingstoke, Hampshire, RG24 8WA

Issue 64 PECM 33

MIPC® shortlisted for the Best E-learning/ Online Education Initiative memcom membership excellence awards 2020 and 2022

Cupio 2023_SM&E Ad_PECM Magazine 180x132 NO FLASH.indd 1 11/04/2023 16:18 EDITOR’S CHOICE

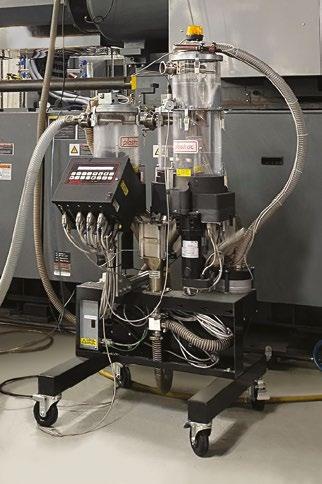

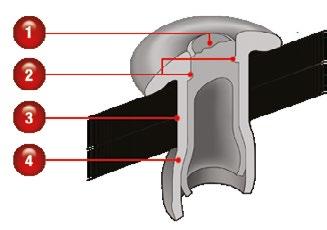

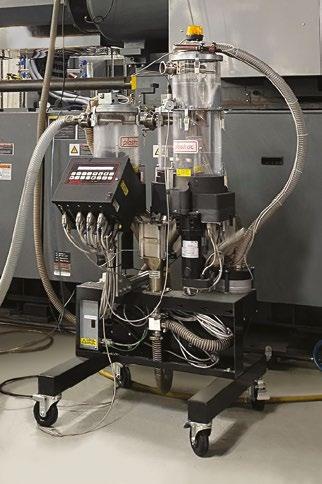

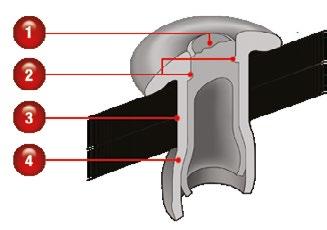

Why blend with Plastrac?

We design and manufacture disc-based gravimetric blending equipment as well as material loaders for all plastics processing. Our equipment is engineered to make plastics processing easier and more cost efficient.

We put our combined 75 plus years of experience in plastics processing to use in the development of Plastrac’s Auto-Disc™ systems to provide you with versatile and effective machinery that will exceed all of your blending requirements.

Plastrac was established in 1995 in order to provide the best, most affordable, most effective, easy-to-operate blending systems available to market. We continually strive to keep our customers online and producing only the best product which fully meets the requirements of their respective customers and consumers.

We surround ourselves with outstanding employees who take the utmost care in the assembly of all Plastrac machinery and take pride in their work. Our knowledgeable staff is available to provide assistance should the need arise. Plastrac is here to supply your company with the latest blending technology available and is committed to support it for years to come.

Quick, accurate blending and color changeovers.

Plastrac offers a variety of gravimetric material blenders and loader systems that are ideal for a multitude of plastic processing methods. Our plastic processing machines and auxiliary equipment is engineered

and loading systems synchronize in real-time with plastics molding machines to provide an accurate and consistent material mixture with no mechanical mixing. The Auto-Disc™ material feeder is engineered for quick material changeovers to reduce downtime. Our gravimetric blending systems will handle just about any injection, extrusion, or injection blow molding application. Disc based metering allows our equipment to cost-effectively feed at a wide range of throughputs without compromising consistency. The Auto-Disc™ can be configured into self-contained systems with material feeders and loaders that are all operated from a single controller.

Our newest innovation – ColorStream™ –is a Blending Revolution.

ColorStream is not just another cart system. It feeds colors and additives from the plant floor in real-time and transports them to the machine throat to blend with the main resin still being flood-fed out of the central loading system. ColorStream eliminates the need for climbing to the top of process machinery to change canisters or perform maintenance. It increases safety, slashes capital equipment costs, saves time, labor, and energy, and allows even faster color changes. So no more climbing on top of presses to perform maintenance or move blenders! ColorStream can easily be moved from machine to machine, and is nearly 100% maintenance-free. It also works for almost all injection molding, injection blow molding, extrusion, and PET applications.

610-356-3000 • Plastrac.com sales@Plastrac.com

The Blending Revolution is Here! Increases Safety Reduces Costs on Time/Labor/Energy Quick Color Changes Our patented, modular, virtually maintenance-free system moves dosing and master batch changing to ground level. No more catwalks, scissor lifts, ladders, or climbing to swap out canisters or perform maintenance. And because it is cart-based, ColorStream can move easily between multiple machines. Join the Blending Revolution. On the Plant Floor!! 610-356-3000 • Plastrac.com sales@Plastrac.com Slashes Costs of Capital Equipment TM

LED DRIVERS

Impact of driver quality on lighting projects

LED performance, efficiency and durability are tied not only to the lights themselves, but also to the drivers that operate them. Russell Parr, CEO at PowerLed, highlights what to look for when sourcing LED drivers.

Innovations in LED technology are providing lighting designers and contractors with increasingly sophisticated options. However, a crucial component of bringing these options to life is driver technology.

Drivers are responsible for converting, regulating, and supplying the appropriate electrical power to ensure the optimal performance and longevity of LEDs. As with LED systems, driver technology is not static or universal – every application requires a specific driver, the quality of which has a significant impact on the project’s result. This makes it vital to assess LED driver suppliers and their products when scoping a project.

WHY QUALITY COMPONENTS ARE KEY

Because LEDs must operate failure-free in a variety of conditions, the drivers that power them should be durable, reliable, stable, and efficient. As such, there are several factors to consider when selecting drivers to ensure optimal performance. These include voltage and current ratings, power capacity, dimming capability, compatibility, efficiency, and reliability.

Higher-grade components should not be a nice to have but ‘non-negotiable’, particularly when selecting LED drivers. This is because it will ensure they:

• Offer good thermal behaviour, meaning all facets function safely

• Can withstand voltage spikes, which pose a particular challenge for control gear

• Boast a reduced ripple value, which serves as a solid performance indicator

• Have no-load, overload, thermal and short-circuit protection, to resolve potential installation issues

• Are EMC compliant, with the appropriate testing and certification

What’s more, the quality of the components used to manufacture drivers has an immense impact on power factor – the ratio of real power used compared to apparent power into the circuit or more simply put, how efficiently the electrical power is consumed. While there may be several contributing factors, inefficiency can often be attributed to poor driver design or low-quality components.

As a key element of any LED lighting system, the quality of the driver is crucial. Ultimately, LED drivers built with premium components will help to achieve the optimal performance, safety, longevity, and sustainability of a LED lighting system.

SELECTING THE RIGHT SUPPLIER

The range of available LED drivers can make it challenging to choose the right solution – and the right supplier. This is further complicated by the fact that not all manufacturers provide the same quality or depth of technical information on their products, leaving electrical contractors unable to make accurate comparisons.

With this mind, a good place to start is by looking for best-in-class solutions from accredited suppliers with a reputation for honesty, and excellence. Also add Energy-related Products (ErP) compliance to the list of criteria.

The ErP directive is an eco-design directive intended to encourage manufacturers and importers to provide products that are more energy and resource efficient, and adherence to this directive shows that a supplier’s products meet the energy guidelines set out by the EU.

In addition to product peace of mind, working with reputable and compliant suppliers will result in other benefits, from energy savings and reduced maintenance costs to longer LED lifetime, overall reduction in the cost of ownership, and reduced environmental impact.

Working with a trusted and established supplier like PowerLed, part of Sunpower Group Holdings LTD, will result in a dependable, high quality ‘fit and forget’ solution.

The company’s range of drivers is suited to both indoor and outdoor installations and, in addition to standard features such as power factor correction, high efficiency, compact size and isolated or non-isolated design, boasts unique advantages – they are CE approved, meet stringent safety certification, and offer a warranty of up to 5 years.

Besides its status as an official Tier 1 MEAN WELL partner, meaning it provides access to more than 4,000 products from one of the largest switching power supply manufacturers in the world, the ErP compliant company’s UK-wide network offers expert advice, bespoke technical design support, as well as premium LED drivers and lighting solutions for a range of residential, commercial, and industrial projects. Moreover, all its products meet both environmental and performance criteria while offering value for money.

For more information, visit https://www.powerled.uk.com/

36 PECM Issue 64

EDITOR’S CHOICE

POWERLED

As with LED systems, driver technology is not static or universal – every application requires a specific driver, the quality of which has a significant impact on the project’s result.

THE BEATING HEART OF LED LIGHTING 0118 982 3745 sales@powerled.uk.com www.powerled.uk.com MEAN WELL YOU PEACE OF MIND FOR MORE INFORMATION ABOUT OUR PRODUCTS & SOLUTIONS

SUPERIOR CORROSION RESISTANCE

STAR FASTENERS

The Huck® 316 (A4) Stainless Steel Magna-Lok®