Editor: Sarah Peiper

Contributors: Stephen Alberts

Nancy Busch

Joe Duszka

Paul “Max” Le Pera Frank Sciarrino

Proofreader: Marsha Jo Scott

Design: V2 Marketing & Management Printing and Distribution: LSC Communications

Countertops & Architectural Surfaces (ISSN 2372-983X) is published quarterly by the International Surface Fabricators Association (ISFA), with a fifth edition, a Buyers Guide, publishing in October.

Individual copies of Countertops & Architectural Surfaces magazine are available at the nonmember newsstand price of $14.95. Countertops & Architectural Surfaces magazine is also available by annual subscription (five issues) for $30.00. ISFA members receive a complimentary annual subscription with every membership renewal. Special rates and charges apply for orders outside of the United States. To subscribe, call (888) 599-ISFA.

For change of address, please include old label with new information, including both old and new ZIP codes. Allow 3-6 weeks for address change to take effect.

Countertops & Architectural Surfaces magazine is proudly printed in the United States of America. Copyright © International Surface Fabricators Association 2022. All rights reserved. No part of this publication may be reprinted or otherwise reproduced without the publisher’s written consent.

Countertops & Architectural Surfaces magazine and the International Surface Fabricators Association assume no responsibility for unsolicited manuscripts or photographs. Materials will be returned only if accompanied by a stamped, self-addressed envelope.

Opinions expressed by contributors in this magazine are not necessarily the opinions of Countertops & Architectural Surfaces magazine or the International Surface Fabricators Association, but rather those of the individual writers.

Photos in this publication may not depict proper safety procedures for creative purposes. ISFA and Countertops & Architectural Surfaces magazine support the use of proper safety procedures in all cases and urge readers to take steps to institute such procedures. Photography/graphics provided by:

BACA Systems Caesarstone CaraGreen Corian Design Cosentino Daltile Durat elemenAl Float Frame GEOS Gilasi

Granite Gallery

INEOS Composites

Karran USA

Kayla Dorsey Photography Kirei Board Kreoo Lapitec Laser Products Industries PaperStone Park Industries

POSTMASTER: Send address changes to: LSC Communications c/o Countertops & Architectural Surfaces magazine 3401 Heartland Drive Liberty, MO 64068

Caesarstone is a global leader of premium surfaces, specializing in countertops that create dynamic spaces of inspiration in the heart of the home. Established in 1987, its multimaterial portfolio of over 100 colors combines the company’s innovative technology with its powerful design passion, spearheading high-quality sustainable surfaces that deliver functional resilience with timeless beauty. Featured on the cover is a Master of Stone certified fabricator examining 4044 Airy Concrete in a rough finish.

To learn more, visit: www.mos.caesarstoneus.com.

The other day, my husband and I were FaceTiming with some family — catchup we play periodically to bridge the distance between us since we all live on opposite ends of the country. We shared our recent adventures: paddleboard sessions, weekend hikes and what’s thriving on the farm. They told us about their road trip through Canada from where they live in Maine, the onset of colder weather and the day-to-day that keeps everyone busy. Then the conversation turned to work. “How’s the countertop business,” my brother-in-law wondered. “Depends on who you ask,” I replied.

Admittedly, he doesn’t know much about the decorative surface industry, but the answer to his question is honest. For some of us, it’s an exciting time with new research and design developments paving the way toward advancement. For others, the hustle is real: trying to keep up with demand while hearing forecasts of a downturn; compensating for shortages with material or staff; delving into new market segments with uncertainty yet hope. It’s a fine line we walk to find success in each of our own corners of this industry.

The conversation continued, and the subject of home projects came up. We updated each other on the progress with new windows for them, a new fence for us, and the kitchen renovation that is still on the to-do list. My brother-in-law asked, “So when you get around to it, what kind of countertop will you put in your kitchen?”

I paused. It’s a tough call to make, I told him. There are so many terrific options on the market; they all have their merits. Choosing one would be easier without so much context, I think. Maybe it would be simpler to choose based on color and texture rather than be inspired by sustainable processes or scientific developments.

He pressed on, “Well, what’s the most popular kind of countertop?”

“There are a few frontrunners,” I told him. “Natural stone

and quartz — these are favorites, to be sure. But these days, everyone is talking about porcelain.”

In the last issue, we featured a fabricator who deals exclusively with this material. In this issue, we take a deep dive into the benefits of porcelain surfaces (page 38). The International Surface Fabricators Association (ISFA) groups porcelain under the Mineral Surfaces category, which also includes sintered stone and ultra-compact surfaces. ISFA held its first Mineral Surfaces fabrication training in Kent, Washington, earlier this year with plans for additional sessions in 2023 as demand for these materials continues to climb.

It’s one trend to keep an eye on for sure. Another rising pillar of the industry is sustainability. This year, Countertops & Architectural Surfaces carved out a recurring section on the subject, with regular features on what it means to be sustainable in your business. We continue to share strategies and define goals that everyone can take steps to achieve in some way, including leading by example (page 18 and page 24). Read on, and you’ll find that sustainability is more than just recycling.

We’ve rounded up more than a dozen materials, tools and other products that derive from sustainable processes or help fabricators become more sustainable in the shop (page 28). It’s a central theme of this issue, and it should be a priority for all of us to take steps to be better stewards of our planet and its communities.

As we close out another year and look forward to the next, it’s clear that there is determination and progress among all of us, which brings me to Gary Gutteridge of Granite Gallery, this issue’s fabricator profile — someone who took a big leap and hit the ground running (page 32).

I still don’t know what kind of countertop I’ll choose for my new kitchen. For now, I’ll keep my options open because, in some respects, there is no wrong answer.

Middle East Stone Show December 5-8 Dubai, UAE www.middleeaststone.com

20222023

ISFA Holiday Mixer December 8 5:00 p.m. ET Virtual www.ISFAnow.org

ISFA Installing Profitability Workshop Part 15 Delegating with Confidence December 14 2-3 p.m. ET Virtual www.ISFAnow.org

C.Next Fabricators 2023 January 10-14 Riviera Maya, Mexico www.cosentinonext.com

KBIS 2023 January 31-February 2 Las Vegas www.kbis.com

The International Surface Event (TISE) January 31-February 2 Las Vegas www.intlsurfaceevent.com

NAHB International Builder Show January 31-February 2 Las Vegas www.buildersshow.com

ISFA General Member Meeting February 16 Virtual www.ISFAnow.org

ISFA Roundtable February 21-23 Raleigh, N.C. www.ISFAnow.org

ISFA New Member Workshop March 8 Virtual www.ISFAnow.org

Mineral Surfaces Training March 21-23 Location TBD www.ISFAnow.org

Xiamen Stone Fair March 26-29 Xaimen, China www.stonefair.org.cn

Coverings April 18-21 Orlando, Fla. www.coverings.com

HD Expo & Conference May 2-4 Las Vegas www.hdexpo.hospitalitydesign.com

ISFA General Member Meeting May 25 Virtual www.ISFAnow.org

AIA Conference on Architecture June 7-10 San Francisco www.conferenceonarchitecture.com

ISFA Fabricator Crawl June 13-15 Farmer City, Ill. www.ISFAnow.org

ISFA New Member Workshop July 12 Virtual www.ISFAnow.org

ISFA General Member Meeting August 31 Virtual www.ISFAnow.org

Woodworking Machinery & Supply Conference + Expo November 2-4, 2023 Mississauga, Canada www.woodworkingnetwork.com

ISFA New Member Workshop November 8 Virtual www.ISFAnow.org

Holiday General Member Meeting December 14 Virtual www.ISFAnow.org

Submit your event for consideration in Calendar of Events by emailing Editor Sarah Peiper, Sarah@ISFAnow.org.

Cosentino Group released its 2021 Sustainability Report, which represents significant advancement concerning its previous Corporate Social Responsibility (CSR) reports, adopting a comprehensive approach to sustainability based on Environmental, Social and Governance (ESG) criteria.

In its commitment to the planet, its people and great design, Cosentino reports its achievements in the social, environmental and good governance fields. These pillars are underpinned by a well-established business model with financial strength based on innovation, efficient production, circular economy, training, social action, and above all, the strength and high professionalism of the company’s team.

In 2021, Cosentino invested almost $30 million in environmental assets and improvement costs. The company demonstrates its commitment to the circular economy and the reduction of its carbon footprint through a series of milestones such as the use of 99% reused water, zero water discharge (daily treatment and recirculation of 800,000 m3 of water), the use of 100% renewable electric energy or the development of sustainable products such as Dekton, a carbon neutral product for its entire life cycle, and the HybriQ+ technology for Silestone products.

Other milestones include last year’s production of more than 3 million m2 of slabs from recycled or recovered materials, almost one-third of the company’s total production. This was made possible thanks to Cosentino’s waste treatment plant, which enabled the company to manage 400,000 tons of solid waste in 2021, of which 13% was recovered, thus increasing the use of recycled raw materials by 26%.

In addition, Cosentino implemented a new industrial energy model based on renewable energy sources and self-consumption, which also covers the management of water resources. Cosentino plans to set up the largest ground-mounted self-consumption photovoltaic plant in Spain. The plant will have a peak power of 20 MW and an energy production capacity of approximately 34 GWh per year, which will be complemented by installing solar panels on the roofs of the factories. Looking ahead to 2023, Cosentino aims to activate and operate its own wastewater reclamation plant, which will put the wastewater discharged by its neighboring communities to new use.

Cosentino’s commitment to people is a core value for the company; its human capital is its most important asset. In 2021, Cosentino created nearly 700 new jobs, ending the year with a workforce of 5,425 employees — representing 76 different nationalities.

Cosentino’s commitment to prosperity and growth also extends to the communities where the brand has a presence, emphasizing the regions of Almanzora and Almería. In addition, Cosentino makes a pioneering contribution to education and training by promoting dual vocational training programs conducted at its facilities and through activities carried out by its Eduarda Justo Foundation. The company also supports the fields of architecture, design, sport and gastronomy through a series of partnerships and sponsorships and promotes art and culture through the Ibáñez Cosentino Art Foundation. The company directly donated to various organizations and associations, totaling nearly $1 million, 20% more than in 2020.

Cosentino’s roadmap embraces ESG criteria. It moves forward on the basis of integration and transparent communication with its employees and its entire value chain of suppliers, customers and collaborators. Its responsible governance body encourages talent development through recruitment and management programs such as Acelera, Ingenia or Impulsa, which increasingly invests in health and safety and promotes equality and diversity. Women represented 22% of management positions and 50% of the board of directors in 2021.

Once again this year, this performance has proactively contributed to the achievement of some major Sustainable Development Goals (SDGs), both primary and secondary, such as SDG 3 (Good health and well-being), SDG 8 (Decent Work and Economic Growth), SDG 9 (Industry, Innovation and Infrastructure), SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action) or SDG 17 (Partnerships for the Goals), among others.

Celebrating its 20th anniversary, Granite Gold Inc. is partnering with Folds of Honor, a nonprofit organization that provides scholarships to spouses and children of military members serving in the U.S. Armed Forces and first responders who have fallen or been disabled. Scholarships support tuition for private school or tutoring in grades K-12, college, technical or trade school and post-graduate work.

“Of course, we’re excited to look back at what we’ve

accomplished over the past 20 years,” said Lenny Sciarrino, president, CEO and co-founder of Granite Gold Inc. “We’re extremely proud to be kicking off the next chapter with Folds of Honor. Our home base, San Diego, is a military town, and it’s an honor to support these families and those of first responders.”

Since 2007, Folds of Honor has awarded nearly 44,000 scholarships totaling almost $200 million in all 50 states to military dependents. Among the students served, 41% are minorities. Academic scholarships for first responders’ families were added in 2022. It is rated a four-star charity by Charity Navigator and Platinum on GuideStar. It was founded by Lt. Col. Dan Rooney, a decorated F-16 pilot who served in three combat tours in Iraq.

Founded in 2002, Granite Gold is a family company with an entrepreneurial spirit to find innovative solutions to help customers protect the delicate surfaces in their homes. The Granite Gold brand was born out of three generations of expertise in fabrication, installation and restoration.

Similar to the rapid advances seen for engineered stone during the past decade, porcelain slab has grown considerably since 2016 and is expected to be the fastest-growing countertop material in the U.S. through 2026, according to a new Freedonia Group analysis. Porcelain slab is rapidly gaining popularity as consumers seek alternatives to engineered stone and granite. These consumers want to differentiate their homes but still install countertops with a natural appearance and favorable performance properties, such as:

• Stain resistance in both indoor and outdoor settings, as well as heat and frost resistance, which makes porcelain a top choice for outdoor kitchens.

• Greater strength and durability when compared to granite.

• Absence of discoloration or color change issues.

• Wide variety of finishes, patterns, and colors available from manufacturers.

• Easy-to-clean, hygienic surface.

Demand for porcelain slab countertops is driven primarily by strong single-family kitchen and bathroom remodeling activity. Going forward, the countertop material mix in the residential market is expected to shift significantly. In addition to porcelain slab’s fast growth, laminates are expected to continue their long-term decline following years of market dominance due to the rising popularity of more durable surfaces such as engineered and natural stone. Rapid market share gains are expected for engineered stone as the material becomes more widely available and favored for its durability and aesthetics, while granite will continue to be a significant product in kitchen and bathroom countertops.

You can make a professional presentation in the home and gain a lot of business if you have the right tools.

By Frank SciarrinoAs fabricators, we were taught that the best way to sell countertops to retail consumers is to draw them into the showroom, where you can impress them with your facility, show them samples and slabs of different materials, and give an excellent sales presentation. It’s a successful model; selling in the showroom is a high conversion opportunity. But there is another way to close more sales and make it easier for the consumer: in-home consultations. This is when your salesperson goes out to the client’s home, reviews the project onsite, and sells them your products and services.

It’s a popular strategy with remodeling and refacing companies. They call it a “one-call close” when they go out to the home and make the sale on their first attempt. For fabricators, this isn’t typically an ideal approach because they do not want to “waste” the time and gas to make house calls on a client that isn’t even a client yet. Time is money, and fabricators are busy, but in today’s market, you have to compete, and many fabricators may lose business by not offering this service.

With modern software, it is extraordinarily easy to close a home sale, making the trip

worth the time and investment. Quoting and visualization software can render the project using digital images of your inventory and figures the pricing right there on the spot, even if the project changes throughout the conversation. It makes it easy to keep the conversation going toward the close of the sale. You can make a professional presentation in the home and gain a lot of business if you have the right tools.

Some affiliate programs will require you to sell in-home. The Costco Countertop Program, for example, is a lead program that requires service providers to meet customers in the home. Fabricators using this program are seeing an increase in business by being available to approach the customer in a different way.

You might be thinking, “Don’t I give the client some advantage, or upper hand, by having this conversation on their turf?” The short answer is no, and there’s some psychology to it. When you are a guest in someone’s home, they are less likely to put their guard up, and may be less reserved about the sale. You see the job site firsthand, and the conversation becomes more natural when you’re in or near the space you’ll be working on. They’ll be emotionally invested

in your suggestions on materials, finishes and accessories because you’re in the space. Being a guest in their home also opens the door to a stronger relationship with your customer and leads to higher ticket sales.

If you decide to offer an in-home consultation to your customers, here are five tips to get you started:

1. Make sure your salesperson has a tablet or laptop with quoting software so they can do a full quote, sign contracts and take payments in the home.

2. Identify the stakeholders. Always make sure the decision makers are present during the meeting. It’ll be nearly impossible to close the sale if one or more of your decision makers is not present.

3. Do the research. Get as much information about the project from the customer before the consultation. Find out if the customer has a product or design or color scheme in mind so you

can bring relatable samples. Ask about the budget, so you keep your suggestions within the scope.

4. Determine a signing promotion. Incentivize your client to sign on the spot with a discount or additional complimentary service.

5. Build in extra time for the appointment. Schedule more time than you need so you don’t rush the conversation. Allot two to three hours to make the presentation, build a relationship with the customer, answer any questions and close the sale.

No doubt about it, your showroom is still an integral part of your business. But consider the possibilities if you broaden your strategy and start offering other ways to sell. It is only a matter of time before your competitors start offering inhome consultations, which some customers prefer instead of going to your showroom. Beat them to the service and give your customers another easy way to buy from you. C

Frank is a third-generation stone fabricator with more than 20 years of experience in the stone industry. Currently, Frank is a managing partner of Quote Countertops, a leading consumer-facing visualization and quoting platform, and president of Granite Gold Services, Inc., a provider of countertop care products and services. He regularly advises fabricators and marketing companies across the nation to help drive more sales through digital marketing strategy and technology.

When it comes to marketing your countertop shop, it’s not always about advertising, social media ads, SEO and website optimization. I’m not saying that you shouldn’t focus on these digital marketing strategies, but there’s another way to get your brand out there that you may not be considering. Community marketing is a strategy that primarily involves helping a local cause or charity and secondarily markets your business as a supporter or sponsor. Examples include fundraiser events, charity sponsorships, or volunteering your and your team’s time to a community project or service.

Many of these opportunities offer brand representation for your company, including your logo on websites, flyers, newsletters and more. Looking at the bigger picture, it factors into the value of your business. You may have heard about Environmental, Social and Governance (ESG), a set of standards for a company’s behavior used by socially conscious investors. The social aspect of ESG looks at how a company manages relationships with employees, suppliers, customers, and the communities where it operates.

According to Lauren Taylor Wolfe, co-founder of Impactive Capital, an activist investment firm focused on ESG investing, ESG initiatives are good business. “It makes companies more competitive, more profitable and more valuable over the long run,” she said. “If you look at millennials and Gen Z, they care about how they spend their two most important assets: their dollars and their time. They’re doing so in a way that aligns with their

value system. These are the same people who are your employees, your customers, your shareholders. And as a company, think about this to the extent you can attract and retain stickier customers, stickier employees, stickier shareholders; you lower your customer acquisition costs, you lower your human capital costs, and you lower your overall cost of capital. That makes your business more competitive, which makes it more profitable, which makes it more valuable in the long run.”

So take a look at what you can do to support your community, engage your employees, clients and partners, set an example, and elevate your brand by giving back and setting a new standard for excellence within your business. It can bring a return on investment in more ways than one.

Using your business to help your community is, of course, the top reason you should be doing this. If you have a successful business, you should be incredibly proud. Take that success to the next level by helping others. We should all be doing this as business owners. You’re investing in your community and your people by being part of the solution to your community’s challenges. What’s the adage? A rising tide lifts all boats. I think it applies here. The perception that you’re a part of that solution can come back to you through new business, partnerships, employee retention and engagement, and more. It’s time to think bigger and beyond what’s happening on the shop floor.

It’s time to look at the bigger picture when marketing your fabrication business.

Back to basic marketing strategy. When you sponsor an event, you donate your and your employees’ time; how does this reflect your brand? Often sponsorship opportunities include your logo, company description and more in event promotions. This builds your brand in your community. You’re not just a countertop shop anymore; you are a business connected to the community. You drive awareness around your brand and the work you do, but you also leave a lasting impression that kindness and social responsibility are priorities in your business.

Since people are more likely to work with kind companies, it’ll align your shop with those expectations. When it comes down to picking a fabricator for their next project, it could just be the thing that puts you at the top of the list. Consumers trust companies that give back, no matter in what direction. By investing in community marketing, there’s potential to get your brand or product in front of more eyes, and you’ll immediately build trust with those new eyes because you’re part of something charitable or progressive.

And it’s not just consumers. Consider your competition, vendors, suppliers and partners. They’ll want your shine to rub off! These days, they’ll be looking to do business with a company with a strong moral compass because association also lifts their brand. It’s all connected!

By sponsoring an event or doing something for the community, you will get some press around it. Since my mind is usually 90% marketing, I’m going to tell you

how to take advantage of this opportunity and get more impressions on your website.

As I mentioned, you’ll get your logo displayed on the charity or event website. Great brand awareness! Even better is to get a backlink to your website from their website. A backlink is simply a link on their site that goes back to your site. In the SEO world, this link is as good as gold. Google looks at links and validates your company to some extent because it sees the affiliation. Getting a link back from a .org site or a local business will help your Google rankings — elevate your website in search results — and bring you more traffic.

You’ll most likely get some local press (and more backlinks!) from local news outlets that cover the event. And if they don’t pick it up, give them a call! Local media is always looking for a do-good story. Tell them you’ll give them a quick interview to discuss the cause. It could mean an hour of your time, but these days, press lives perpetually on the internet. Long after the event, the story of your involvement is still discoverable.

This extra website traffic could lead to more countertop sales. It might not happen immediately, but that one solid backlink from a .org site alone will grow your Google rankings and bring in sales months down the road.

Being able to display logos of charities or local organizations on your website gives your countertop shop social proof. Social proof is something that makes your business special when viewed by others. This might be a lot of likes on your shop’s social media posts or a lot of Google reviews. But being a part of the community and showing that you sponsor events and charities by displaying

You drive awareness around your brand and the work you do, but you also leave a lasting impression that kindness and social responsibility are priorities in your business.

Stephen Alberts is the owner of the Countertop Marketing Co. and STONE ENGAGE. They specialize in helping countertop companies grow the retail side of their business outside of word-of-mouth and referrals. They also offer software to help you engage more with customers and close more countertop projects. To learn more, visit https://countertop marketingco.com/ or https://stonengage.com/. You can also email Stephen at steve@countertop marketingco.com.

this on your shop’s website gives someone visiting your website a reason to pay a little more attention to your business. And sometimes, that’s all that a business needs!

When you sponsor a good cause or give time to community charities, you are making a positive impact. Engage your employees, and give them a chance to participate in the event. It’s great for morale and team building and creates trust between you and your associates. It’s all about mutual respect. People are inherently good, and by providing these opportunities, you show them you care and you give them a chance to give back. Improved engagement is likely to help with employee attraction and retention, and studies show that it can positively impact productivity.

And who knows who’s watching; maybe there’s a contractor or a builder who’s also involved with the event, and now your mutual participation gives you something in common — a connection. This is how relationships start, and in the business world, it’s an experience

It’s time to think bigger and beyond what’s happening on the shop floor. Take your success to the next level by helping others.

they’ll remember when they’re looking to specify a fabricator for their next project.

Community marketing has a compounding effect. When you make it a priority to give back, it opens the door to opportunity.

Success builds success. Start with what’s possible, and you might find you can do more. Next year you’ll write a bigger check, devote more resources, get more involved or even spearhead a new effort. The more you get involved with the community, the more you witness how this can benefit your business. Ultimately, it’s a win-win for everyone involved, and it doesn’t have to break the bank. C

Working with quartz — be it fabricating or installing — takes effort, skill and extreme safety consideration.

From fabrication to installation and everything in between, the Masters of Stone training program offers essential information on each element of the quartz stone processes. The online program is updated regularly according to best practices and keeps your team informed of the latest important safety information.

Share the comprehensive guide and program with your employees and use it in all health and safety training. There are four main tabs on the page, each with easy-to-follow instruction guides and an extensive video library. There are nine modules in the training program that can be completed in less than an hour. The program’s userfriendly format makes implementing this tool in the daily work environment a breeze.

Quartz is a human-made stone material, and the end result is a highly durable surface with all the aesthetic appeal that natural stone offers. It can be used as trendy backsplashes or modern flooring, in addition to its most common use as a fashionably functional countertop. Due to its seemingly endless list of benefits and abundance of uses, quartz can be found in millions of homes across the nation.

Caesarstone is committed to offering one of the best fabricator training programs. To continue its mission of excellence, it’s important to stay up to date on the latest practices of the trade. Creating a product that customers can use for a lifetime is what Caesarstone strives for. True quality extends far beyond consumer satisfaction. The company believes high-quality quartz requires skilled manufacturing and expert installation to achieve a maximum lifespan and showstopping appearance. Fundamentally, it’s easy to succeed with stonework when the right tools and training are always at your fingertips.

Working with quartz — be it fabricating or installing — takes effort, skill and extreme safety consideration. To avoid error and reduce the frequency of workplace accidents, having the right tools is nonnegotiable.

However, not all the latest and greatest tools are physical. In fact, most of the regularly used tools are mental and fall under the health and safety or best practices category. By recognizing the ongoing learning aspects of quartz masonry, Caesarstone looked to develop an easily accessible learning hub for its international team of employees and

fabricators. The learning hub needed to offer 24/7 access to vital information about every aspect of stoneworking. In response, the team came up with a creative and effective online solution: The Masters of Stone.

Finally, in addition to offering complete information around the clock, Caesarstone encourages employers and fabricator feedback to ask any lingering questions that might have been missed.

Here are just a few of the most elemental best practices when working with high-quality Caesarstone quartz materials.

Material measurements need to be precise and exact to to maintain quality. Never skip out on measurements or cut corners to save time. Paying special attention to set times is vital to achieving aesthetic patterns, finishes, and durable composition.

For employers, it is your responsibility to provide workers with appropriate personal protective equipment (PPE) in workplaces where health and safety hazards exist and to ensure that they use it as required. The Masters of Stone training program has a detailed list of which kind of masks need to be used in which cases.

Clean wet or dry sludge immediately; never wait for the end-of-day cleanup. Prevent water pooling and drying on surfaces, which leave dry dust deposits. Recommended methods for cleaning floors, walls, and other surfaces with RCS are low pressure wet hosing, wet sweeping, and HEPA vacuum systems. Under no circumstances should dust be swept up with a dry broom or removed using compressed air.

Create a regular, recurring schedule for cleaning all equipment and systems at least once a day. Check that the work area is clean at the end of each shift.

Access to hazardous work areas should be restricted to authorized workers who are equipped with the necessary PPE. These areas should be clearly marked with appropriate signage to ensure that workers are aware of the hazards.

For more detailed information on maintaining a facility that abides by the best practices, start your Master of Stone certification online. Learn more at mos.caesarstone.com. C

Our journey to elucidate the myriad tendrils of holistic sustainability thus far has centered around shaping the mission and establishing an overall framework around how and why companies would want to champion this mindset. We have also defined acronyms that various industries, companies and socially conscious groups have created to establish their tenets as they align with the notions of sustainability. Now that the landscape is set, let’s focus on two compulsory precursors to executing and maintaining the optimal efficacy of holistic sustainability: leadership and teamwork.

On the surface, leadership and teamwork may seem like mutually exclusive disciplines. While they certainly can command their unique structural paths, there are elements of both that are inextricable. Understanding the cooperative bond between them is essential so that every company can establish the strongest pillars onto which they will build a holistic sustainability framework.

Teamwork is the personification of synergy; the whole is greater than the sum of its parts. Separate and distinct individual efforts lose the ability of a “greater mind and effort of many” to formulate and execute strategies. For example, cross-functional members with diverse backgrounds, ethnicities, viewpoints and experiences can offer a supremely positive X-factor to the yield of the team’s efforts by including a wider breadth of knowledge.

The stronger the team, the better the outcome, and that is what we want to focus on as part of creating sustainable practices in a company.

The corollary to this would be a like-minded team with singular backgrounds, which can present an invisible barrier to any viewpoints outside the box. Likewise, a group of too few constituents with diametrically opposed views could apply a substantial negative weight to the degree of synergy achieved.

The idea here is to peel back the teamwork component to maximize the team’s overall effectiveness. A weakly formulated team provides far less than optimal results — despite doing their best. The point is that the return on a team is directly related to the individual members of that team. The ideal team is not defined by its quantity of constituents but by the quality of its constituents. The quality of the team’s output is strengthened by those who can think critically — offering success using a different approach — and who remain focused on the goal, not their personal agenda.

At the end of the day, teams are formulated to achieve a goal: corporate culture, a specific task or a project. The stronger the team, the better the outcome, and that is what we want to focus on as part of creating sustainable practices in a company.

Consider a symphony orchestra. At the beginning of a concert, you might see a group of musicians individually

warming up simultaneously — a cacophony. But behind those chaotic sounds are skilled contributors, waiting for their cue to come together as one holistic harmony. And who do they need to guide them but the conductor? The role of the conductor is to ensure the individual musicians play to the right beat, tempo and timing. The conductor can enliven the orchestra — organize and elicit the vision of the composition and make that vision come alive. This is the role of a leader — a leader of a team, a department, a company, and yes, even oneself.

What makes a highly effective and sustainable leader? Leadership is dynamic; it’s a journey, not a destination. I have an immutable conviction that leaders are made, not born. Much like the statue of David, the finished piece started as a block of marble. It became iconic and enduring through countless chisels and an unquantifiable resolve to persevere. No doubt, some marks and cuts were neither planned nor wanted, yet the master made mistakes, learned from them, and blended them to create a masterpiece.

Such is the life of a leader. A leader learns and adapts; they fall and get up. They collect all their experiences into a playbook of wisdom. They don’t know it all, but they have the confidence to figure it out. They understand and leverage synergy as free energy to achieve superior results; they participate more than they direct. They give (serve) to receive authentic and relatable. They lead by example. They listen more than they speak. They are empathetic.

These characteristics work in concert to create cooperative atmospheres and empower individuals to elicit results. They are the conductors of their team, department, company, and equally important, themselves. But there’s a distinction to be made here. While leaders may be bosses or managers, bosses and managers are not necessarily leaders, and therein lies the greatest risk to sustainable teamwork and corporate culture.

When leaders are not evolved, confident, humble, emotionally intelligent, balanced and self-secure, there seems to be a modus operandi to achieve at the expense of everything else. They gain by taking from or taking advantage of those around them, pushing down responsibility to avoid accountability. This is one of the

It’s that squeeze that can define and create a good leader. It’s how they react to adversity that builds a foundation for leadership. Failure is a means, not an end. The strongest leaders will take failures and learn and grow from them.

most toxic elements within a company that can jeopardize any desire for synergy.

Highly effective and sustainable leaders are wise and balanced, people who have practical experience and intelligence and can listen, motivate and be empathetic to the contributors around them.

Stresses of all kinds act like microscopes on one’s core vulnerabilities. A leader’s ability to withstand business and personal challenges that are omnipresent in the day-today depends on a balanced foundation. Dr. Wayne Dyer, an author and motivational speaker, says people are like mystery fruit; you don’t know what’s inside until they are squeezed. It’s that squeeze that can define and create a good leader. It’s how they react to adversity that builds a foundation for leadership. Failure is a means, not an end. The strongest leaders will take failures and learn and grow from them.

Imagine if each team member was well vetted for their ability to contribute toward the goal and had the qualities of a leader. How one governs themselves, values relationships, their emotional and physical well-being, education, spirituality, maturity, and so forth are harbingers of how long and effectively one can thrive.

One of the keys to building a holistic framework in your company and making it thrive is to be the change you want to be. Leaders are made, not born. They are not perfect, but they are being perfected. Holistic sustainability requires sustainable leadership. Leadership requires teamwork and teamwork requires leadership, and as you can see, it is all connected. Bosses are negative weights on sustainability, as seen by turnover and toxic corporate culture. Leaders inspire. Their energy and their influence are contagious. At every level in your company, inspire leadership that constantly evolves with accountability and trust. It starts at the top and trickles down.

To fulfill mission statements that clarify

company values, sustainable leaders are needed to execute and remain stable through the myriad challenges a business faces: hypergrowth, economic downturns, unforeseen catastrophes and even prosperity.

Holistic sustainability is like dynamic energy; energy needs a medium to propagate. Leadership and teamwork are the fabric through which your sustainability goals will be reached — or not. The stronger and more malleable the material, the more it will endure. Defining executables for your goals is compulsory and will shape your foundation.

Your leadership and teamwork, however, will be the structural elements that deliver results and to what extent. C

Paul “Max” Le Pera is the president and founder of Proprietary Ventures, LLC, a boutique-style global firm devoted to researching, discovering, and deploying disruptive and sustainably oriented proprietary products and technologies. He serves on the ISFA board of directors as vice president of standards. He can be reached at paul.l@ proprietaryventures.com.

These days, sustainability should be in the framework of any successful company. The betterment of our communities and the health of our environment depend on every business, no matter how big or how small, taking responsibility for how they work and contributing to a better planet. There are all kinds of companies, materials, tools and solutions for the decorative surfacing industry that can help you achieve sustainability goals. Here are 12 products to consider for your shop.

PURE is a water filtration system that removes stone particulate, so gray water can be recycled and reused in cutting. PURE Systems are available in varying sizes to meet the shop’s needs, filtering from 80 gpm to 320 gpm.

The PURE System pumps dirty water from a collection pit by a heavy-duty, seal-less pump to a centrifugal separator, where solids are filtered to 40 micron. The water is further filtered to approximately 10 micron through a series of hydrocyclones. Solids are collected in a sludge hopper and settling weir, both of which are lined with removable bags for easy disposal. The filtered water enters a holding tank before a horizontal pump delivers the water back to the shop at 75 psi. Additional features can be added to the PURE System. Learn more at www.bacasystems.com/ baca-pure.

Durat is a unique solid surface material that creates colorful, durable counters, furniture, sinks and tubs. Durat recently launched a brandnew collection of five colors, all in shades of blue! Durat surfaces are nonporous and show no seams, making them easy to keep clean, and they last a long time. Durat consists of up to 28% recycled hard plastics diverted from the waste stream and is 100% recyclable at the end of its life through Durat’s take-back program. Durat is made in multiple international locations but can be made in the U.S. for projects seeking to localize their procurement. Durat sheets are typically 114 inches by 32 inches but can also be customized for maximizing yield and minimizing waste. For more information about Durat or to request a fan deck of all pigment options, please contact info@caragreen.com.

Float

Brackets are made in the U.S. using steel, a highly recycled and recyclable material. They use post and stud brace technology to provide one of the highest carrying capacities available in counter support applications, eliminating the need for excessive mullions and decorative millwork to disguise the brackets. The fastening configuration allows easy installation using a clamping format that securely and seamlessly supports large overhangs. These cantilevered brackets are ideal for ADA-compliant designs, freeing up valuable floor space and increasing clearance under the counter. Brackets

are available in two styles: Straight Arm (16.5 inches or 22.5 inches in length) and Low Profile (10 inches, 16 inches or 22 inches in length). With a weight capacity of 750 pounds, Float Frame Brackets can be combined with any surfacing material to create the free-floating look you desire for countertops, shelving, storage, work benches and more. For more information or to order brackets, please contact info@caragreen.com.

Gilasi’s surfaces are made of recycled glass and a VOC-free epoxy resin, carefully engineered for superior performance. Gilasi offers two standard lines of nonporous solid surface: one with large glass aggregate that creates a terrazzo aesthetic and one with very tiny glass aggregate that creates a monochromatic look. In addition to the 20 standard colors, Gilasi can create custom recycled glass surfaces, allowing customers to specify the colors and sizes of glass used. Gilasi goes above and beyond when it comes to sustainable commitments. The material uses locally sourced glass, has a Declare label, is 100% recyclable through Gilasi’s take-back program, and the company is a Green America Certified Business and purchases carbon offsets for all its production energy consumption and employee commuting. For samples or more information, visit www.caragreen.com/brands/gilasi/.

elementAl acrylic surfaces are made in Buffalo, New York. Made with up to 93% recycled content, these highly thermoformable sheets are a solution to the massive amounts of industrial waste, with over 100 pounds of plastic diverted from landfill in every sheet. The manufacturing process repurposes hard plastics and metal scraps from the post-industrial waste stream into a versatile designer surface. The material comes in two collections of semi-translucent colors and is now offered in thicknesses up to one inch. elementAl LIGHT is 93% recycled acrylic by weight, one of the highest percentages in the industry, and does not include any metal. elementAl Heavy is 87% recycled content by weight. This collection introduces pins and shaving of aluminum, copper and brass into the colorful acrylic. The material is excellent for backlighting, thermoforming and furniture, in addition to traditional vertical and horizontal surfacing applications. For more information, visit www.caragreen.com/brands/elemental/.

Pre- and post-consumer recycled glass are combined to create GEOS Surfaces, a unique surface with superior strength and remarkable beauty. GEOS is a nonporous, durable recycled glass surface that performs, fabricates and installs like engineered stone. Combined with proprietary resin binders, GEOS Recycled Glass Surfaces do not require sealing. GEOS surfaces are available in several unique color combinations and are suitable for both commercial and residential applications searching for a terrazzo countertop look and a recycled backstory. GEOS is low maintenance, nonporous, easy to clean, and does not require sealing. GEOS Surfaces are a fun way to make your countertops the central design element. Get a quote or samples today by contacting info@caragreen.com.

Kirei Board is a lightweight and durable sheet product made from reclaimed sorghum stalks. Sorghum stalks are a byproduct of the food industry that is often burned or thrown into landfills. Kirei Board turns what would be waste into a dynamic sheet good with a linear pattern that emphasizes the natural beauty of the product. The panels are a great substitute for wood in furniture, cabinetry, casework, signage and wall panels. Kirei Board mills and finishes much like wood. The panels come unfinished but can be finished with nearly all standard wood finishes for a glossy or nonporous surface. Use VOC-free products to retain the product’s natural, healthy and sustainable characteristics. For more information, contact info@caragreen.com.

Lapitec is the only true sintered stone, using innovative technology to create largeformat slabs from only minerals. Based in Italy, the company has always been dedicated to finding the best solutions for performance with the lowest impact. Lapitec does not use any resins or glues to bind its proprietary mineral mix into a durable scratch-, stain- and weather-resistant surface. All colors and textures of Lapitec are now 100% crystalline silica-free, prioritizing the health and safety of workers in the industry. Since Lapitec is all minerals, the colors and patterns are not printed but are created using the minerals and are consistent throughout the body of the material. Lapitec is an incredibly versatile material that creates sleek indoor and outdoor kitchen elements, flooring, cladding and furniture. The variety of surface textures ranges from high-gloss Lux to nonslip Vesuvio. For more information, visit www.caragreen.com/brands/lapitec/.

Manufactured in Washington state, PaperStone products are certified to sustainable forestry standards and certified food safe by NSF International. All of the paper used in this product is post-consumer recycled paper layered and pressed into “stone” using resin made from industrial byproducts that would otherwise go into the waste stream, and have been specially designed to produce a hardwood-like, nonbrittle composite panel. PaperStone is both durable and easy to install. You can cut and finish PaperStone panels with standard woodworking tools and refinish them for a long-lasting surface. PaperStone offers a warm alternative to stone and quartz and is a great choice for homes, restaurants, office buildings and other commercial spaces. Panels come in a variety of colors, styles and sizes, so you create exactly what you need for your next earth-conscious project. For more information, visit www.paperstoneproducts.com.

HybriQ+ Technology for the manufacturing of Silestone is a true testament to Cosentino’s commitment to sustainability and taking care of the present to protect the future.

HybriQ+ Technology is a high-performance blend of premium minerals, quartz, and recycled materials

produced with 100% renewable electric energy and 99% recycled water. HybriQ+ is the result of four years of research and development, and it represents a $12+ million investment and 1,200 hours of laboratory and facility testing.

“We want our customers to feel confident that they are getting the best of the best not only from a quality and design perspective but also from an environmental standpoint, and we’re not afraid to take risks to push the industry forward,” said Eduardo Cosentino, executive vice president of global sales and CEO of Cosentino North America.

Silestone sets a new standard for the industry, propelling us toward a more sustainable future. Learn more at www.cosentino.com/usa/silestone/hybriq-technology.

Corian Design offers a wide portfolio of beautiful, on-trend designs that are harmonious with human health and the environment. The company is innovating to reduce waste and incorporate postconsumer and post-industrial recycled content. The Corian Solid Surface portfolio includes a variety of high-recycled content aesthetics, including the new Artista colors. Corian Endura High Performance Porcelain is made from 100% natural minerals and clays. The North American manufacturing facilities are zero waste, and electricity comes from renewable energy sources.

Corian surfaces are GREENGUARD

Gold certified and contribute toward LEED points. In alignment with the AIA Materials Pledge, they’re NSF certified, UL certified as mold resistant and do not contain BPA. A low-VOC material, Corian is free from dangerous chemicals, which supports better indoor air quality. The Corian Design portfolio allows for beautiful and safe interiors with sustainability as a top priority.

To learn more, visit www.corian.com.

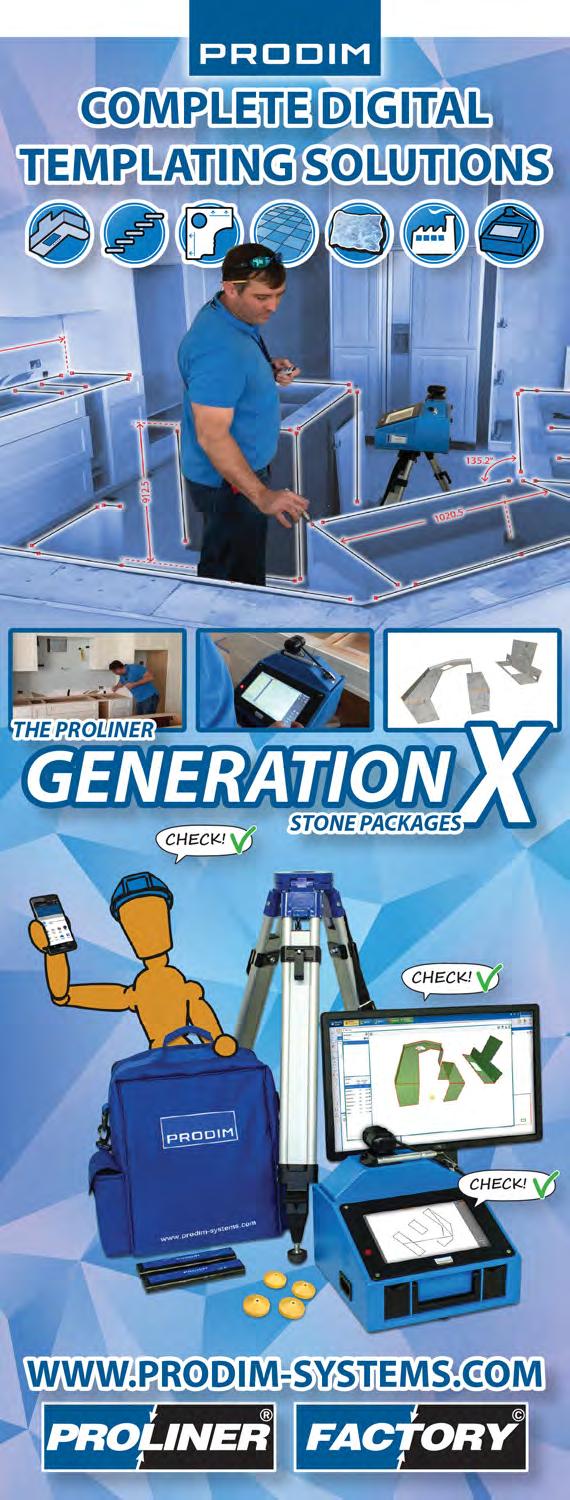

Practice sustainability by going digital with the LT-2D3D from LPI. Eliminate waste from used wood, paper or plastic templates and go paperless by creating digital template files. Did you know that many wood templates cannot be recycled due to glue and adhesives? Get more usage out of slabs with the accuracy of digital templating and nesting capabilities to reduce landfill waste and prevent costly reworks and in-field modifications.

With a digital templator, you can reduce gas consumption, emissions and your company’s overall carbon footprint by minimizing the need to travel back and forth between job sites and the shop, by emailing files back to the shop or uploading files to cloud storage. You can downsize to smaller, more fuel-efficient cars with the compact nature of the LT-2D3D and eliminate large physical templates, supplies and tools.

To learn more about the LT-2D3D Laser Templator and its environmental benefits, please visit www.laserproductsus.com.

Today, Granite Gallery is one of the best fabrication shops in the area, primarily serving western Washington with plans to expand to the entire state and beyond.

After working in the utility sector for almost 20 years, Gary Gutteridge decided it was time for a change. In 2018, he stumbled upon an opportunity to buy the Granite Gallery in Tumwater, Washington, and he jumped on it. Never having worked in surface fabrication previously, Gary welcomed the challenge to take an existing business and turn it into a household name. Gary and his staff have worked hard to rebrand and modernize a fabrication business that, while having been around since 2006, needed some fine-tuning. Today, Granite Gallery is one of the best fabrication shops in the area, primarily serving western Washington with plans to expand to the entire state and beyond.

With no previous experience in surface

fabrication, Gary admitted he was making a pretty big leap. “I didn’t know anything about making countertops, honestly. I just went for it. I bought Granite Gallery, and most of the employees stayed on staff with me after the acquisition. The business was really struggling when I took it over. I ran parallel with the existing team — they knew more than I did at the time — and we worked together to make this thing what it is today. We’ve seen tremendous growth year over year, and I’m really proud of how far we’ve come.”

Gary has about 30 employees on staff, which includes 12 fabricators working two shifts, nine installers, and 10 working in sales and office management. “We’ve got a really good crew,” added Gary. “Everyone is really loyal and committed to doing great work. We have the big picture in mind at all times.”

In 2018, Gary Gutteridge stumbled upon an opportunity to buy the Granite Gallery in Tumwater, Washington, and he jumped on it. Never having worked in surface fabrication previously, Gary welcomed the challenge to take an existing business and turn it into a household name.

According to Gary, what sets Granite Gallery apart from the competition is attitude, energy, quality control, fair pricing, on-time service and putting employees first. When it comes to inspiring his team, he implements incentive programs and sets frequent goals that everyone understands and can achieve. “We have a lot of fun as a team; we charter boats for daytrips and organize other outings as rewards for our achievements. Our employees know we appreciate everything they do — the extra mile — and we have an open dialogue with each other.”

Like most shops, growth means more staff. Gary admitted it can be challenging to find new, experienced employees in this labor market. He’s fostering the next generation of fabricators and ushering them into a career with Granite Gallery. “We have 5-6 fabricators who are under 25 years old. They didn’t have much experience when I brought them on board, but they’re so smart — very tech savvy and they learn quickly. We’re

“We’ve got a really good crew,” said Gary. “Everyone is really loyal and committed to doing great work. We have the big picture in mind at all times.”

leaning on these younger folks to learn the ropes, and offer new perspectives, too. They challenge us to rethink and revise so we can be the best we can be. It’s enlightening and inspiring to watch them grow in the work.”

Granite Gallery was doing mostly residential work when Gary acquired it. Today, they’re split about 50-50 between residential and commercial business, some of which is multifamily. “It’s been a

growth opportunity for us to expand more into commercial work,” added Gary. “We’ve recently added some new machinery in the shop that will enable us to increase our output and support the commercial side while still being able to take care of residential.”

Gary and his team have been doing more luxury commercial, as well. From high-end facades with bookmatched details to backlighting and more, the team is having fun getting more creative. Currently remodeling the showroom, Gary will feature some stunning statement walls and unique applications, and the showroom will be divided to better serve residential and commercial clients. “We want our customers to see the breadth of our craftsmanship and all the possibilities there are using these beautiful slabs,” he added.

Granite Gallery works primarily with granite, marble, quartzite and quartz,

going through more than 300 slabs per month. “The benefit of offering a wide selection is that we can bring everyone’s dreams to reality,” clarified Gary. “From basic countertops to luxury slab fireplaces, shower surrounds and more — there’s really no drawback other than storage space. Everybody’s got their own taste, and we try to stay current with the latest trends so that our offerings meet the needs of our clients.”

Gary has been pouring every dollar he makes back into the business. “It’s really a long game I’m playing, trying to grow the framework of the company to support expansion.” He’s recently purchased two BACA Robo SawJets, a Montresor Vela 7.2 edge polisher, a Turrini Claudio dual silo water recycling system and two Turrini Claudio dust collectors to help keep the shop running at maximum capacity,

and support the health and safety of his fabricators.

Also in the shop you’ll find a crane system, a Brio 5-axis saw and an Intermac Master 33 CNC. The team uses the Flexijet 3D laser measuring system for projects that include walls, fireplaces and full-height backsplashes, and Laser Products Industries’ Laser Templator for countertops. “It’s tech like this that has really helped us maintain accuracy and maximize efficiency,” added Gary. “It’s all about working smarter.”

Another new piece of tech Gary’s excited about is a green screen photo booth that enables his team to take pictures of every slab that goes into inventory. “When we get a container, we capture images of our slabs, label them and upload them to a database,” clarified Gary. “Using software, we can provide digital renderings so the client can see the project and understand how their slab will be used.”

In Washington state, it’s so important to be environmentally friendly and

energy efficient. It’s part of the social and political fabric. Granite Gallery prioritizes vendors who quarry stone using sustainable practices. “Our customers are focused on sustainability and so we’re trying to change the way we do things to support a better environment,” added Gary. “We try to educate customers and help them make the best decisions for their projects. The new technology we’re using for digital slab inventory and mockups enables us to minimize waste for customers. For example, the offal from the kitchen slab may be enough to make a table or a bathroom vanity, and because our customers purchase by the slab, we encourage them to avoid letting that extra material go to waste. It often leads to more projects — a win for everyone.”

In the shop, they recycle wastewater and the slurry created during the stone cutting and fabrication process is recycled into concrete. “Even if stone is discarded, we do whatever we can to recycle it,” said Gary.

For Granite Gallery, the most popular

material right now is Quartzite. “We stock this material by the container. Our slabs are handpicked from multiple providers and delivered to our showroom so our customers can see their beauty firsthand.”

And to serve their customers with the best experience possible, Granite Gallery offers other services that help complete their remodeling projects with ease. The team offers cabinetry, tilework, sinks and other accessories, and more. They work with subcontractors for plumbing and electrical work to create a seamless experience for their customers.

And since word of mouth is Granite Gallery’s main marketing strategy, it’s important they build trust and rapport with each and every client. They’re also connected with a builder exchange, which helps them get specified by key local businesses and contractors in their area. They stay involved with the local community, exhibiting at the local home and builder show each year.

“We sponsor charity events like golf

Granite Gallery was doing mostly residential work when Gary acquired it. Today, they’re split about 50-50 between residential and commercial business, some of which is multifamily.

tournaments, little league baseball teams and more,” added Gary. “We donate materials to Habitat for Humanity. We put flyers out in every house on the local tour of homes each year. Part of it is about being involved in the community, but the flip side: I want the community to recognize that “G” in our logo and immediately know it’s Granite Gallery. I want that “G” to be the Nike swoosh of countertops!”

Since Gary’s only been in this business for a short while, he’s found a lot of value in being connected to others in the industry, including the International Surface Fabricators Association. “Learning from each other is so important, and since I’m rather new to this business, it’s been a big help for me to learn from others who have faced the

same adversities,” added Gary. “Our door is always open to other fabricators who want to learn how we do things.”

Gary’s philosophy for success: Dream big to know what you’re shooting for. Surround yourself with good people and continue to educate yourself. “My advice to others,” he continued, “is to just jump in and do whatever it takes. Always put your staff and your customers first. Every decision you make should trickle down to a good customer experience.”

What’s next for Granite Gallery? Gary has hopes to open additional showroom spaces in Washington and beyond to expand his market presence. C

Gary Gutteridge can be reached at Gary@ granitegallery.net. For more information about Granite Gallery, visit www.granitegallery.net.

Porcelain is chasing quartz in terms of popularity, and there’s no shortage of reasons. From slabs to tile, there are endless options on the market today that solve for aesthetics and functionality. Extra-large porcelain slabs provide the style of natural stone with the performance of porcelain tile at a reasonable price. Porcelain slabs can be used on a multitude of surfaces, including countertops, floors, walls, fireplaces, vanities, backsplashes, shower walls, tub surrounds and even as exterior flooring and cladding. They bring the stunning on-trend colors and patterns of marble, slate and natural stone, as well as modern concrete looks to a space while still standing up to real-life activity.

Because these slabs are made of authentic porcelain, they are heat-, stain-, scratch- and chemical-resistant, as well as durable and easy to maintain. The lifespan of a porcelain countertop is at least 10 years and as much as a lifetime, depending on usage, care and maintenance. The bottom line: Porcelain countertops stand up to everyday life, and they look good doing it!

Porcelain slabs are a solid solution for today’s germ-aware world. The material is resistant to the growth of bacteria, mold and mildew, and it’s easy to clean. Regular, basic cleaning with warm water and mild detergent is sufficient, but more aggressive

cleaning methods will not damage porcelain.

Porcelain slabs are an excellent solution for designs that require a highend look but have budget constraints. These panels bring the scale and style of natural stone slabs to projects when other materials might be cost-prohibitive. Thanks to modern technology, the industry’s best manufacturers can create realistic designs that make it hard to tell the difference between porcelain slabs and the natural materials they emulate.

The thin nature of porcelain slabs makes them easy to install. A porcelain

countertop is light to carry, lift, and put into place during installation. In addition, porcelain countertops can be installed over an existing countertop — no demolition is required.

Creating style and luxury with seamless, continuous design is one of the hottest trends in interior design. Extra-large porcelain slabs make it easy to achieve continuity throughout the surface area. Porcelain slabs add powerful design impact, whether via a single installation, through the wraparound luxury of a floor-to-wall-tocountertop continuum, or even bookmatched for a stunning feature wall. They create beautiful kitchen islands with minimal or no seams.

The latest trends in bathrooms call for luxury, spa-like retreats — an adult oasis in a chaotic, kid-friendly home or simply an escape from today’s stressful, fast-paced world. Porcelain slabs provide seamless design and the ability to easily

create the kind of wraparound luxury consumers want, including zeroentry showers and floor-to-ceiling cladding.

Extra-large porcelain slabs are well-suited for commercial spaces

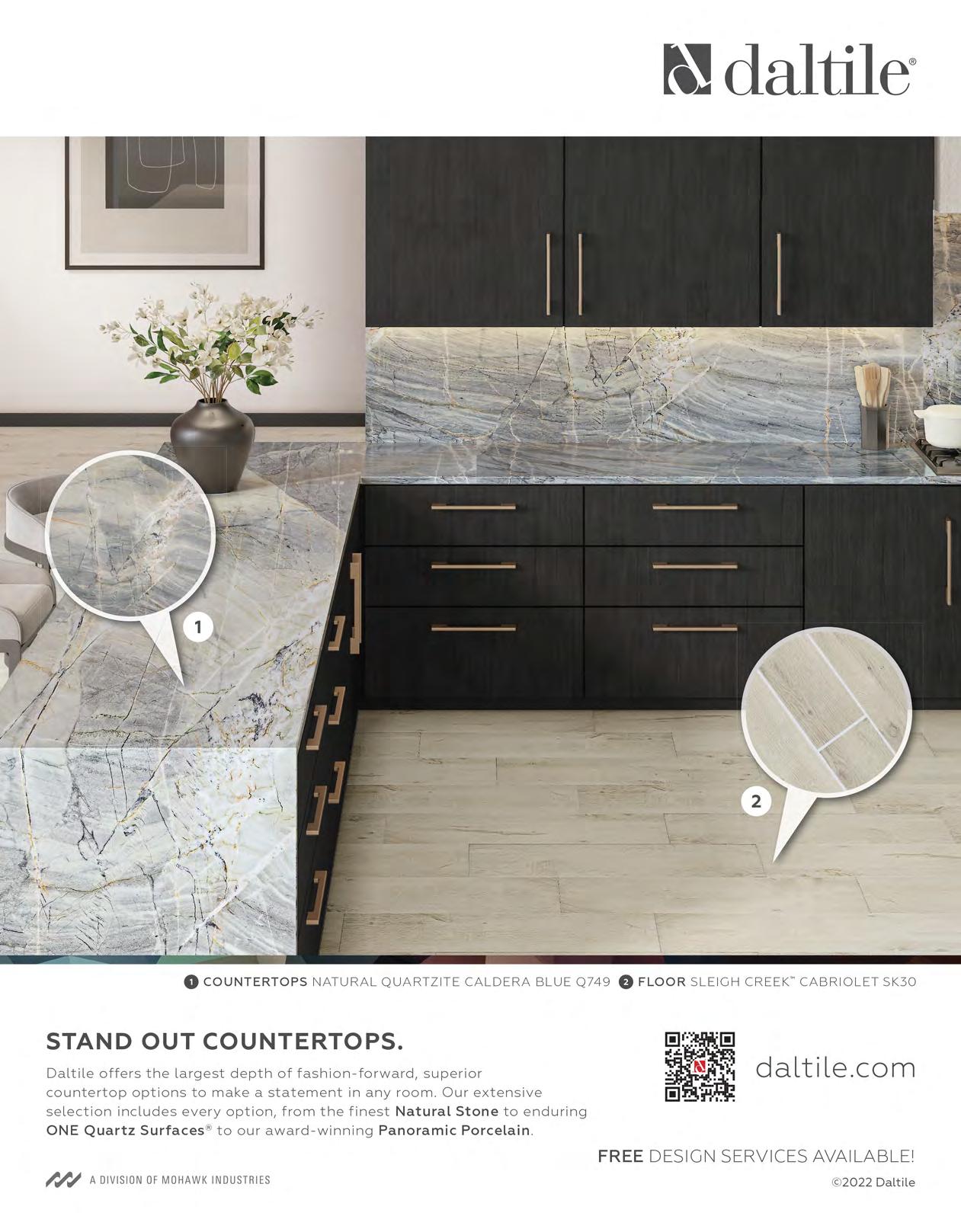

DalTile has the nation’s largest slab and countertop brick-and-mortar footprint, with 40 locations across the country. The brand’s nationwide network includes high-end showroom and warehouse locations that stock and display an incredibly broad range of natural granite, marble and quartzite slabs, as well as DalTile’s One Quartz and Panoramic Porcelain Surface offerings. DalTile’s awardwinning Panoramic features extra-large wide porcelain slabs that offer extraordinary design, affordability and durability. Learn more at www.daltile.com.

and ideal for many types of interior and exterior design. This durable material stands up to the elements as well as normal wear and tear. It’s cost-effective, sanitary, and comes in styles and colors for every design. C

When the International Surface Fabricators Association was founded, it was the International Solid Surface Fabricators Association. Twenty-five years ago, solid surface was near the top of many homeowners’ wish lists. Other manufactured surfacing materials have been developed since then, and ISFA dropped an extra S to support the decorative surface industry on a broader level.

That said, solid surface has also evolved over the last 25 years. What many thought of as a speckled particulate surface often associated with ’90s era design has now become available in veined marble looks, metallics and translucent patterns. In addition, the material’s excellent performance attributes have continued to make it relevant. Yet, I’m always amazed how many budding fabricators and artists are surprised to discover the wonders of this material.

ISFA recently held the fall session of solid surface training at Gecko Solid Surface Solutions in San Antonio, Texas. The attendees had a wide range of experience; most had some background working with the material. Many had questions about special applications, and the class became energized when Augie Chavez, who led the training, demonstrated thermoforming with his oven and vacuum table.

We could have spent all day learning about thermoforming and more advanced techniques, but we had coursework to finish. When

the training was over, many headed straight to the airport to return to their busy shops.

I gave a lift to a few fabricators, either back to their hotel or the airport. After I dropped off the rental car, I had time to kill at the airport. I enjoyed a great visit with one attendee who was waiting for his departure flight. That extra time passed quickly, getting to know my new friend, and before I knew it, it was time to say our goodbyes. We headed to our respective gates.

I was surprised to see two more (new) friendly faces at the gate! Unbeknownst to me, they were on my flight! We boarded the plane, and after an hour, we deboarded it due to engine issues. (The joys of travel!) After about an hour, it became clear that we weren’t going anywhere. So off we went to find a hotel for the night, which was no easy task since they were all booked.

When we finally got to a hotel, I suggested we head to the airport early the following day to get in what I knew would be a long line. The next day, we discovered the plane was still grounded. The airline shuttled us to nearby Austin to catch a different flight, and finally, it looked like we were heading home.

At the gate, waiting to board, we see another (new) friendly face, another training attendee! Happily, we made our way back to Seattle from there. Phew!

In total, it was a 24-hour delay spanning two airports and a hotel, which were all clad with plenty of — you guessed it — solid surface. Despite the travel hiccups and changes to plans, it was an excellent opportunity to connect with my new fabricator friends. I enjoyed learning about their families, their lives and their shops. We were gifted with the luxury of time to discuss solid surface fabrication further, and we brainstormed about the potential solid surface can have on the future of their businesses. For them, and for ISFA, the future is solid.

Reach me any time at Nancy@ISFAnow.org.

Several ISFA Annual Conference attendees set aside time ahead of this year’s Annual Conference in Tampa, Florida, to assist with cleanup efforts in Venice, Florida, an area hit hard by Hurricane Ian. The storm made landfall in the Fort Myers area as a Category 4 hurricane on Sept. 28, just a few weeks prior to the event. The ferocious 150mph winds pushed ashore massive amounts of water from the Gulf of Mexico that tore through homes and businesses all along the coast.

ISFA partnered with the Sarasota Baptist Church to coordinate this volunteer effort, including removing tree limbs, cleaning up storm debris, tarping roofs and boarding broken windows.

“We all witnessed the aftermath of Ian’s devastating path across Florida, and it was heartbreaking to see the extensive damage to so many homes and businesses,” said Jim Callaghan, ISFA board member and sales director for GranQuartz. “We organized this volunteer effort so that we could give back to the communities that desperately needed help cleaning up after the storm.”

About a dozen conference attendees spent the day prior to the conference helping homeowners and businesses clean up and assisting in any way they could. GranQuartz donated work gloves, safety glasses and N95 masks.

“True to form, the ISFA community stepped up to help the struggling communities in Florida,” added Nancy Busch, ISFA executive director. “It is a testament to ISFA’s core values and ethics, which include serving others by acting with a sense of responsibility and integrity.”

Read full coverage of the 2022 ISFA Annual Conference in the next issue of Countertops & Architectural Surfaces.

77 Stone El Paso, Texas Alfonsini San Antonio, Texas

Allbuilders Millworks, LLC Ruston, La.

Atlantic Countertops Raleigh, N.C.

Classic Rock Harrisburg, Pa.

Creative Granite Group West Columbia, S.C.

Custom Craft Works, Inc. Paoli, Penn.

Dominis Stone Kent, Wash.

DuBois Granite & Quartz DuBois, Pa.

Floor Covering Express University Place, Wash.

GSW Construction Craig, Colo.

H&S Stone, Inc. Toms River, N.J.

House of Cabinetry, Inc. Dothan, Ala.

Legacy Countertops Alpharetta, Ga.

Natural Stone & Design, LLC Shreveport, La.

Outlaw Construction, LLC Kodiak, Alaska

Padron Marble and Granite Hialeah, Fla.

Parthenon Marble and Granite New Port Richey, Fla.

Petra Stone Gallery Fairfax, Va.

QVG, LLC Houston, Texas

Rock Solid Creations by John Crawley, Inc. Inverness, Fla.

Southeastern Marble and Granite Wilmington, N.C.

Southern Inventions, LLC Granbury, Texas

Stone Top Granite & Tile Sanford, N.C.

Tomco, Inc. San Antonio, Texas

323 Design Team Chenoa, Ill.

Accent Countertops Murray, Utah

American Countertops Albuquerque, N.M.

American Epoxy Scientific Mountain Home, Ark. ASST McSherrystown, Pa.

Counter Fitters, LLC Savannah, Ga.

Countertop World, LLC Bryant, Ark.

Countertops of Memphis, LLC Memphis, Tenn.

Craftmark Solid Surfaces, Inc. Norcross, Ga.

Custom Components Corporation Ionia, Mich.

DFC-Dakota Fixture & Cabinet Co. Madison, S.D.

Eastern Surfaces Allentown, Pa.

European Granite and Remodeling, LLC Phoenix, Ariz.

Expression Stone Construction Gig Harbor, Wash.

Floor Diva Georgetown, Ontario

Gecko Solid Surface Solutions San Antonio, Texas Granite Gallery, LLC Tumwater, Wash.

Great In Counters Providence, R.I. Gunckel Architectural Stoneworks, LLC Seguin, Texas

Hartson-Kennedy Cabinet Top Co., Inc. Marion, Ind.

Italstone Marble & Granite Yakima, Wash.

Kauffman Kitchens New Holland, Pa.

KLC Supreme Homes, LLC Baltimore, Md.

L.E. Smith Company Bryan, Ohio

Legacy Granite and Marble Houston, Texas

Marvic Corp. Union, N.J.

Maxwell Counters, Inc. Farmer City, Ill.

Mill-Rite Woodworking Company Pinellas Park, Fla.

Modern Home Distributing Nunda, N.Y.

Nelson Tile and Stone Bend, Ore.

Onslow Stoneworks Swansboro, N.C.

Rock Tops Springville, Utah

Routt Construction Company, LLC Van Buren, Ark.

Rumford Stone, Inc. Bow, N.H.

Sterling-Miller Designs, Inc. Brockton, Mass.

Stone Works International, Inc. Eugene, Ore.

StoneMark Granite, LLC Louisville, Ky.

Surface Creations of Maine Portland, Maine

The Countertop Factory Midwest Addison, Ill.

Tops Solid Surface Lacey, Wash.

Joe Duszka, president

Carolina Custom Surfaces (336) 215-5518

Joe@carolinacustomsurfaces.com www.carolinacustomsurfaces.com

Austin Maxwell, vice president

Maxwell Countertops (309) 928-2848

Austin@maxwellcounters.com www.maxwellcounters.com

Laura Grandlienard, secretary

ROCKin’teriors (919) 577-0207

Laura@rockinteriors.com www.rockinteriors.com

Ted Sherritt, treasurer

FLOFORM Countertops (204) 474-2334

Tsherritt@floform.com www.floform.com

Steve Mast, immediate past president

Precision Countertops (503) 660-3023

Steve.m@precisioncountertops.com www.precisioncountertops.com

Augie Chavez, director

GECKO SSS (210) 227-3100

Augie@geckosss.com

Mike Langenderfer, director

The Countertop Shop (419) 868-9101

Mike@countertopshop.net www.countertopshop.net

Paul “Max” Le Pera, director

Global Surfacing Alliance (908) 358-5252 pmlp33@gmail.com

Rodrigo Velazquez, director INDEKO 52 331-028-7863 Rodrigo@weareindeko.com www.indeko.mx

Eric Tryon, director

The Rockheads Group (678) 614-7111 Tryonea@gmail.com www.rockheadsusa.com

Kimberly Homs, director Great in Counters (401) 233-0666 Kimberly@greatincounters.com www.greatincounters.com

Travis McDermott, director McDermott Top Shop (262) 593-2456

Travis@mcdermotttopshop.com www.mcdermotttopshop.com

Jim Callaghan, associate member representative GranQuartz (248) 660-3291 Jcallaghan@granquartz.com www.granquartz.com

Jessica McNaughton, associate member representative CaraGreen (919) 929-3009 Jessica@caragreen.com www.caragreen.com

ISFA P.O. Box 627 Ingomar, PA 15127 (888) 599-ISFA www.ISFAnow.org

Executive Director Nancy Busch (253) 691-0169 Nancy@ISFAnow.org

Operations Manager Carol Wilhite (412) 487-3207 Carol@ISFAnow.org

Content Manager | Editor Sarah Peiper (888) 599-ISFA Sarah@ISFAnow.org

Member Experience Coordinator Samantha Winslow (888) 599-ISFA Samantha@ISFAnow.org

Web/Database Administrator Amy Kyriazis (412) 487-3207 Amy@ISFAnow.org

Administrative Assistant Kanani Camacho (888) 599-ISFA Kanani@ISFAnow.org

Sponsorship opportunities are available for qualifying manufacturers, distributors and other industry-related companies. These businesses are dedicated to the success of the International Surface Fabricators Association and fabricators everywhere. Through their contributions, sponsors enable ISFA to create meaningful opportunities for its membership including training, education, business development, networking and more.

Through additional support, these fabricator members are committed to serving and fostering ISFA’s mission, programming, membership benefits and more.

AAA Adhesive

2020 Wild Acres Rd. Bldg. D Largo, FL 33771 877-422-4583 www.aaaglue.com

ACS International 4775 South 3rd Ave. Tucson, AZ 85714 520-889-1933 www.acstone.com

Aetna Plywood Inc. 1401 St. Charles Rd. Maywood, IL 60153 708-343-1515 www.aetnaplywood.com

Akrilika Svobody Str., 29 Moscow 125362 Russian Federation 79119451961 www.akrilika.com

Al-Badaha Company for Modern Industries P.O. Box 126444 Jeddah 23643 Saudi Arabia 966920002964 www.albadaha.com

Alf Noon for Modern Kitchen Co. P.O. Box 54210 Al Raboua, Sari St. Beside the Municipal Airport Jeddah 21514 Saudi Arabia 966122752309

Andres O’Neil & Lowe

212 N. Defiance St. Archbold, OH 43502 419-636-5050 www.andresoneilandlowe.com

Aristech Surfaces

7350 Empire Dr. Florence, KY 41042 859-283-1501 www.aristechsurfaces.com

BACA Systems

101 Premier Dr. Orion Township, MI 48359 248-791-3060 www.bacasystems.com

BB Industries, LLC 4100 Appalachian Way Knoxville, TN 37918 800-575-4401 www.bbindustriesllc.com

Better Vacuum Cups, Inc. 13841 Roswell Ave., Ste. K Chino, CA 91710 877-379-9909 www.greenbvc.com