The unique feed to improve production, health and fertility. The benefits of omega 3 all year round. high energy high oil content (Omega-3) high digestibility high protein Lintec is a specific variety of linseed, high in Omega-3 fatty acids, that has been specially processed to produce a unique feed for dairy cows. It is a sustainable high quality feed, suitable for all dairy production systems. For more information contact your local account manager or call: 0330 678 0982 info.uk@forfarmers.eu www.forfarmers.co.uk Pages 48-55 Pages 30-47 GRASSLAND & FORAGE DAIRY-TECH REPORT Harvesting, silage machinery and technology Highlights from this year’s Stoneleigh Park event Pages 56-59 MACHINERY MILK PRICES Pages 60-62 A look at options for rejuvenating grassland TIP OF THE MONTH: Getting to grips with digital dermatitis problems – p16 Pages 14-15 Dairy Matters Animal Health and Welfare Pathway March 2024 Volume 71 Issue 3

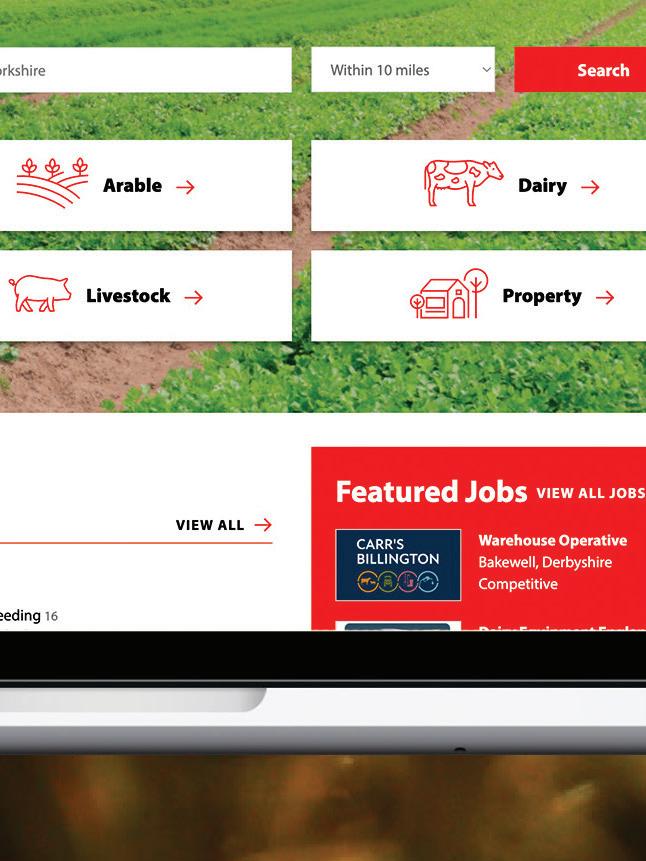

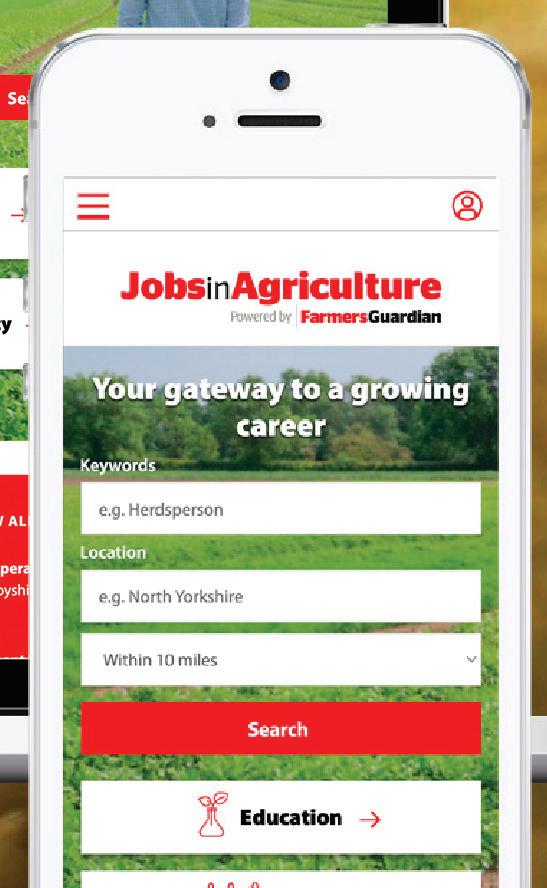

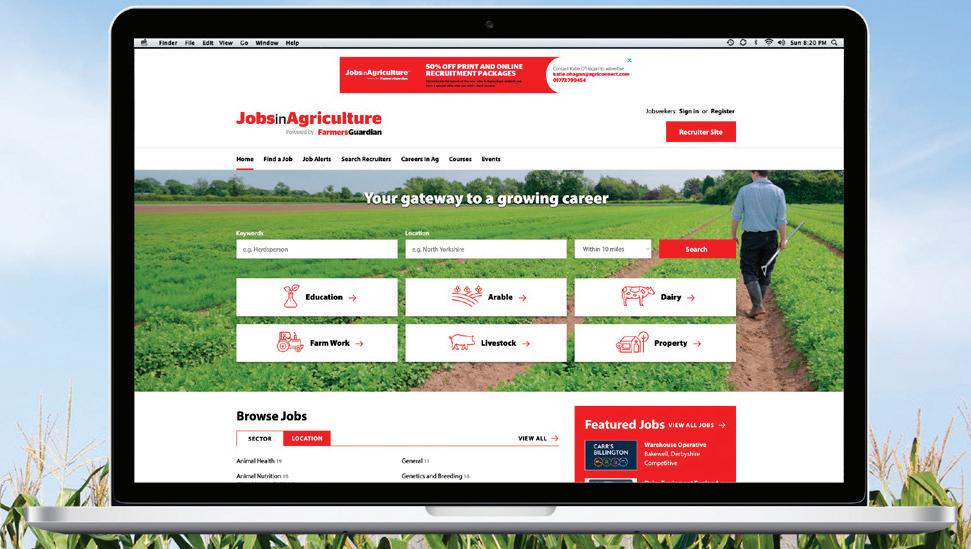

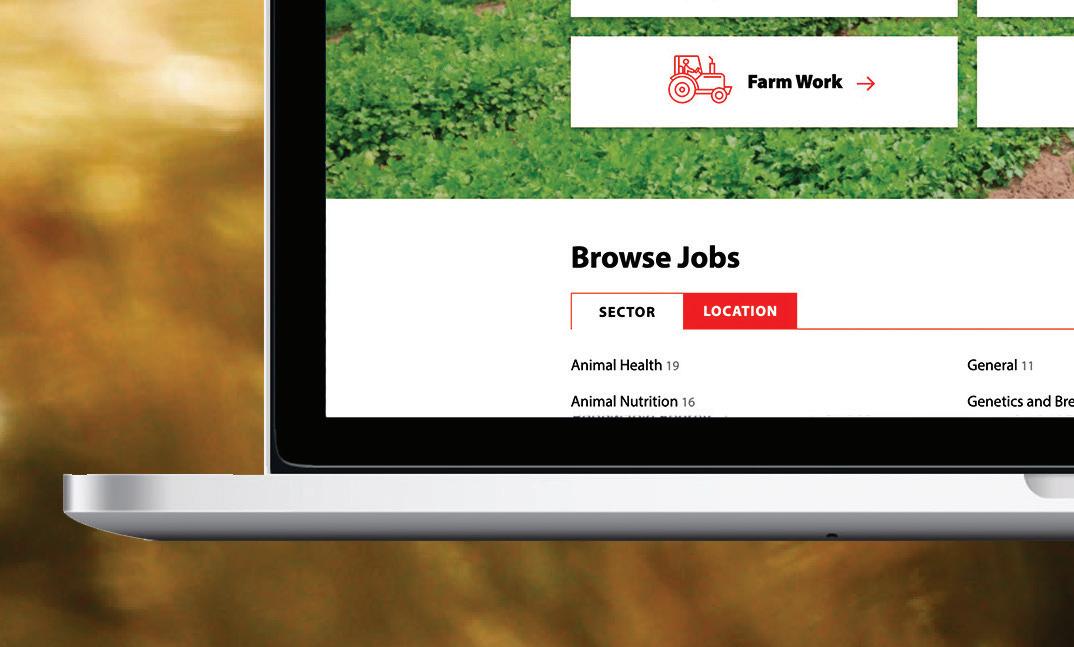

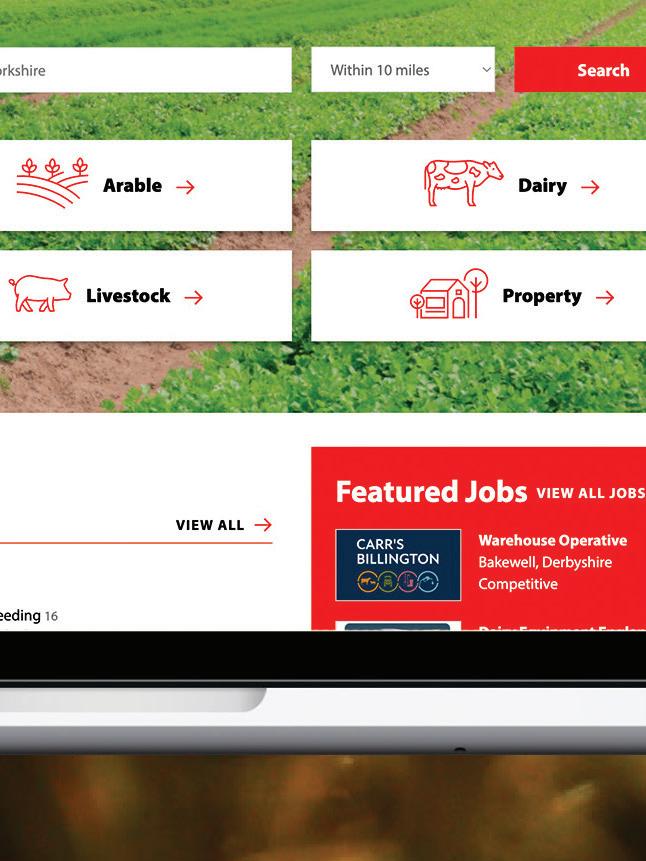

Explore the wide range of career opportunities beyond farming

Whether you are seeking a new career path or aiming to further develop in your current role Jobs in Agriculture can help.

We are dedicated to connecting the right individuals with the right opportunities. With a diverse range of opportunities available, including on-farm positions, exciting roles in science and technology, engaging marketing and sales positions and more.

Ready to explore beyond farming? It is time to open the gate to your growing career

Check it out!

Jobs in Agriculture connects talented individuals with industry leading agricultural roles.

Powered by Farmers Guardian, we highlight agricultural jobs to our extensive network of engaged, jobseeking readers who regularly look to us for quality, trusted, relevant and beneficial content.

For more information scan the QR code or visit, jobs.farmersguardian.com

jobsinagriculturefg @JobsInAgriculture @JobsInAgriculture @Jobs_In_Ag

Contacts

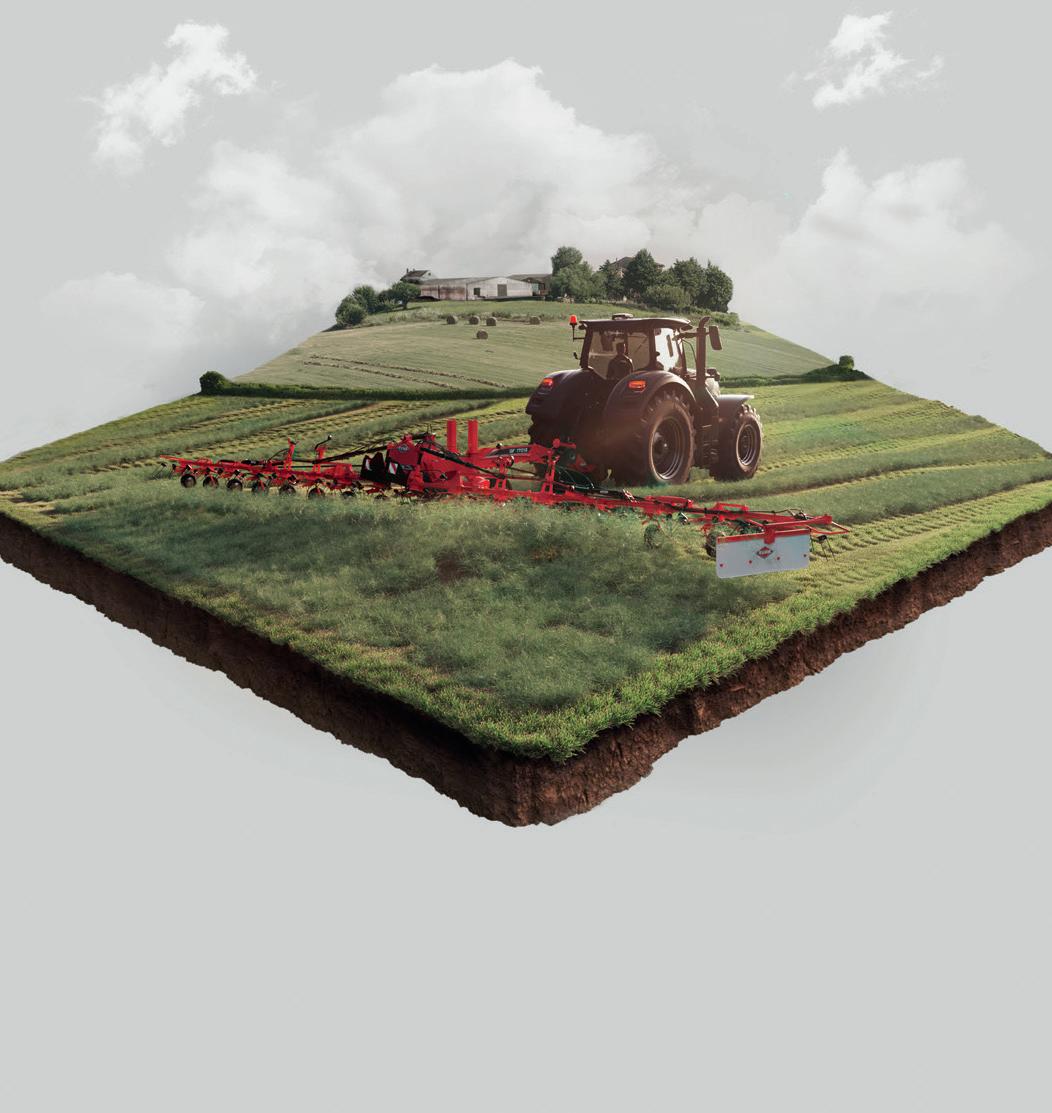

As we head into March, a ention will start to turn towards ge ing some stock out to grass followed by silage-making.

Who knows what the weather will throw at us this year, but as everyone knows grass is the cheapest feed on-farm, it is essential we make the most of this asset during the growing season and utilise it to its full potential to ensure clamps are full going into the la er part of the year.

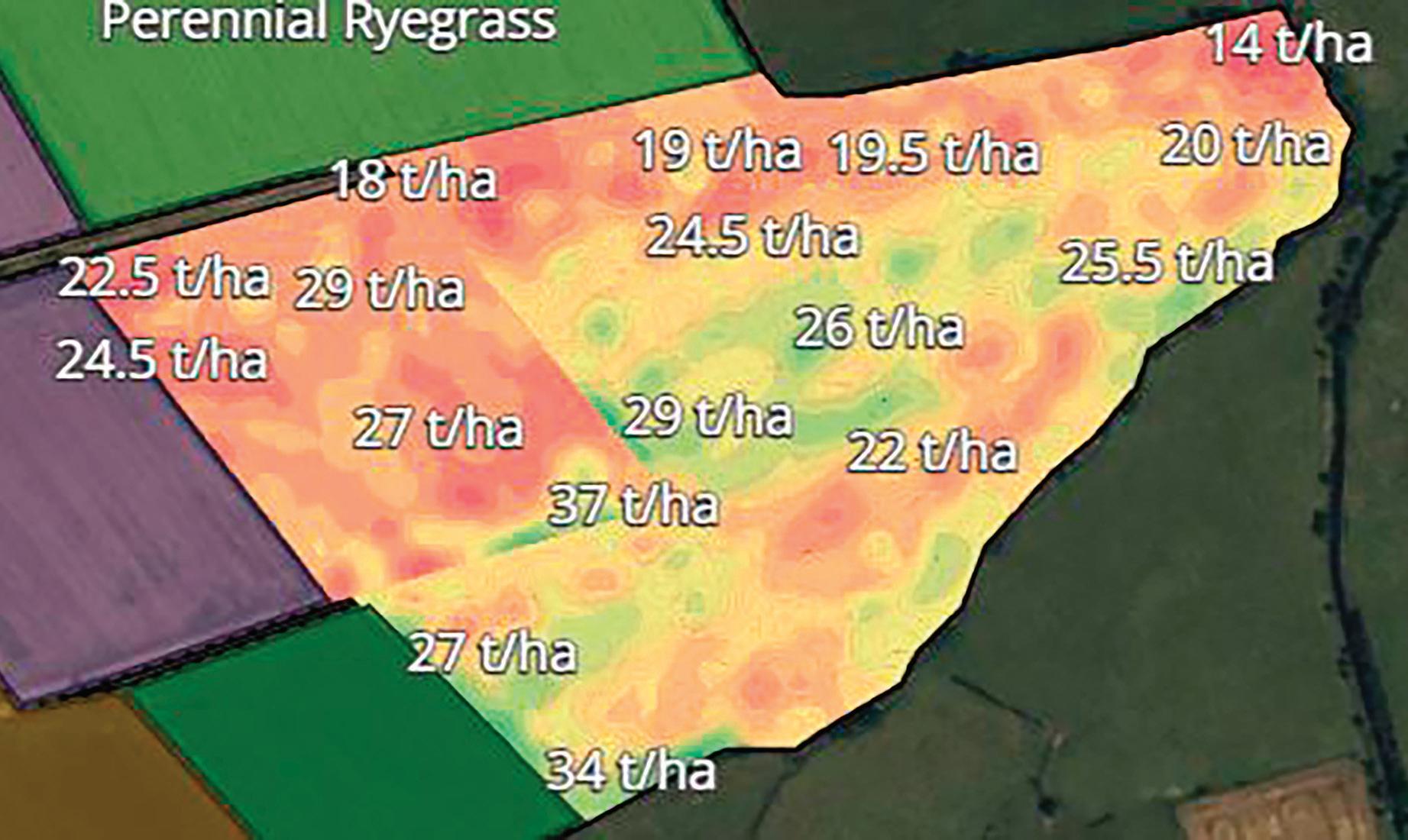

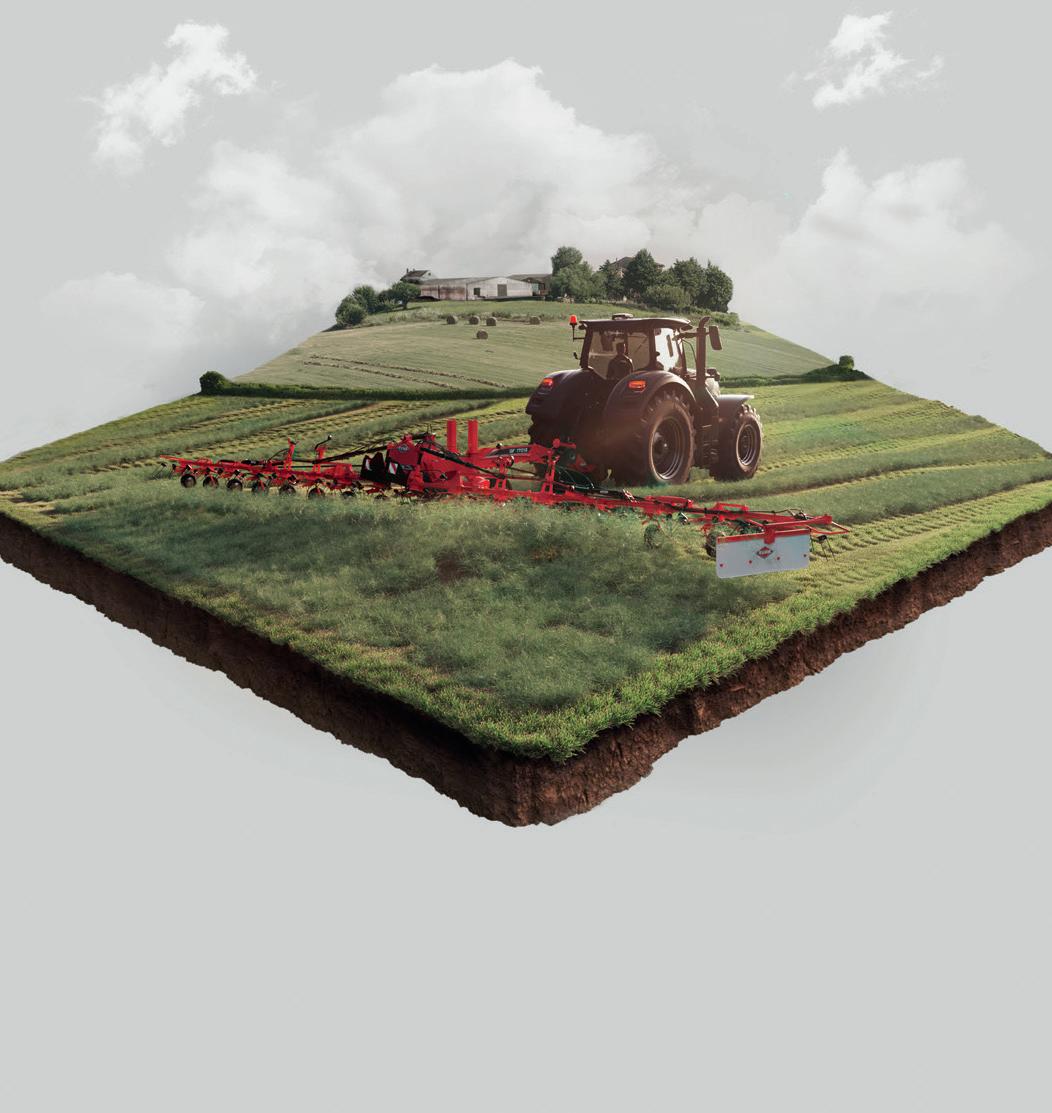

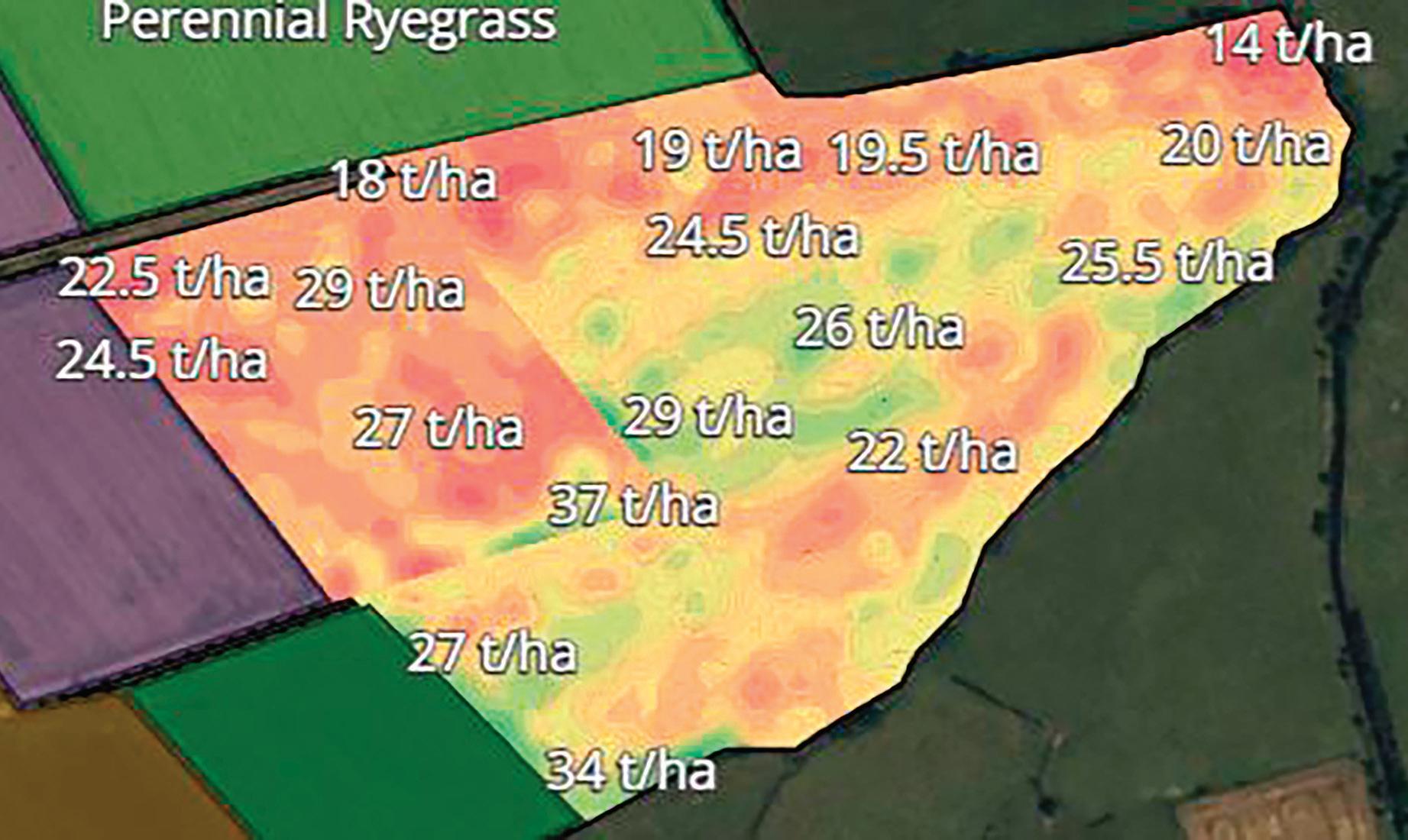

e grassland and forage special in this month’s edition addresses issues around grassland management, including reseeding, yield mapping and grass nutrition.

e Dairy-Tech event was once again a great opportunity to get o -farm and nd out about some of the new technology on o er.

I a ended a seminar session looking at disease prevention and, in particular, the take-up of the Animal Health and Welfare Pathway funding. I was, however, disappointed to hear that only about 7.5% of eligible dairy farmers have applied for the funding so far.

Money available

As the speakers at the session pointed out, while some might think the money available is a paltry amount, it should be regarded as gateway funding, which could potentially have an impact on future access to grants. is is a theme taken on by this month’s Dairy Ma ers writer, vet Ian Cure (see pages 14-15), who warns that if this funding is ignored, then it might lead to the Government withdrawing budgets allocated to supporting farmers in the future.

3

UDDERMINT ® Also available from your favourite merchant... TEISEN TEAT WIPES Improve teat condition Fast milking preparation Milker’s hands cleaned between cows.

cleaning and drying More information at www.uddermint.com

Dairy Farmer, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ Origination by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ. Printed by Precision Colour Printing, Halesfield 1, Stirchley, Telford TF7 4QQ. No responsibility can be accepted by Dairy Farmer for the opinions expressed by contributors. Editor Katie Jones 07786 856 439 katie.jones@agriconnect.com Content Editor/Designer Mike Begley 01772 799 405 mike.begley@agriconnect.com Picture Editor Marcello Garbagnoli 01772 799 445 marcello.garbagnoli@agriconnect.com Sales Director Stephanie Ryder 07917 271 987 stephanie.ryder@agriconnect.com Account Manager Mark Jackson 01322 449 624, mark.jackson@agriconnect.com Classified Advertisements 01772 799 400 fgclassified@agriconnect.com Advertising Production Justine Sumner 01772 799 437 Fax: 01772 796 747 justine.sumner@agriconnect.com Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com Subscription rates: UK £65 a year Europe: £85 World: £95 ISSN 1475-6994 © Farmers Guardian 2024 All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems.

Rapid

a word from the editor

MARCH 2024

What’s inside?

MONTH 2024

Ministers approve AHDB levy rise

Levy rates will rise for dairy farmers after Ministers in Defra and the devolved administrations approved the rise.

The new rates will be implemented from April 2024 which AHDB said would allow it to maintain its focus on delivering the objectives set out in the sector plans, published in November 2022.

10-12 On Farm

The levy for dairy farmers will increase from 0.06ppl to 0.08ppl.

There have been no increases to the levy in the beef and lamb and cereals and oilseeds sectors for more than 10 years and no change in more than 20 years for dairy and pork.

Reduction

The levy body said this meant the spending power of levy funds over the past decade has been reduced by up to 40%.

AHDB chair Nicholas Saphir welcomed the approval from

Milk price gap is ‘unjustified’

JThe gap in the base milk price in Northern Ireland compared to the rest of the UK and the EU is ‘unjustified’ and widening.

That was the message from Ulster Farmers’ Union (UFU) dairy committee vice-chair Cyril Orr after a Copa-Cogeca farm lobby meeting in Brussels.

Mr Orr said the meeting was a chance to share the challenges facing the dairy industry in NI, including bovine TB, local climate action plan and the impact of the ammonia strategy.

He said: “It was the dramatic

drop in the milk prices and the widening gap hitting farmers in NI that was the stark takeaway message. We now seriously lag behind the industry in Great Britain, let alone the EU.”

In November 2022, the average milk price in NI was 51.93ppl, close to the EU average of 51.69ppl. By October 2023, the price was 32.39ppl – a drop of almost 20p.

The EU average has fallen by 12ppl. In October 2023, the GB published average milk price was 36.99ppl – 4.6ppl higher than NI.

NEWS 4

8 DAIRY TALK Updates from Becky Fenton and Dan Burdett 10 ON FARM Farm achieving the herd expansion goal 14 DAIRY MATTERS Animal Health and Welfare Pathway funding in England discussed 16 VET’S VIEW Prevention of digital dermatitis should start with youngstock 18 NUTRITION Science says protein content of diets can be reduced safely 20 WORLD DAIRYING Investing to future-proof business in Hungary 22 WINTER FEED 24 ANIMAL HEALTH 28 CONFERENCE 30 GRASSLAND & FORAGE Harvesting, silage machinery and technology 48 DAIRY-TECH REPORT All of the highlights from this year’s Stoneleigh event 56 MACHINERY A look at options for rejuvenating grassland 60 MILK PRICES 64 MILK ANALYSIS Global milk volumes rise again after major exporters dip 66 NEW PRODUCTS Round-up of products and updates hitting the market 70 GOOD EVANS ‘Hoops to negotiate’ 72 BUSINESS CLINIC Global outlook mixed

VOLUME 71 ISSUE 3

66-67 New Products MARCH 2024

The AHDB levy for dairy farmers will increase from 0.06ppl to 0.08ppl.

Ministers, adding it would allow it to ‘enhance’ its key activity.

He said: “Levy payers can be assured our commitment to helping them navigate through an unprecedented period of change for the industry is secure and we will continue to listen to their feedback to ensure we are delivering real value for money.”

e Government has also agreed that Nicholas Saphir will serve a further 12 months as AHDB chair.

e extension to Mr Saphir’s appointment means he will remain in the role until March 31, 2025.

Challenging

NFU president Mine e Ba ers said: “In a challenging environment, a properly resourced AHDB will be vital to promote the value of our products, to seek new markets at home and abroad, enhance the productivity of the industry in the face of

increased competition from other countries and to defend the farming sector’s reputation.

“As with any business or organisation, AHDB needs to be able to adapt and respond to whatever challenges come our way.

“Crucially, evidence and data must drive the work of AHDB and value for money must be evident in everything it does – this value must then be demonstrated to levy payers.”

NI Farming Minister

JAndrew Muir has been named as Northern Ireland Farming Minister after Northern Ireland’s power sharing executive returned to Stormont this week and has already admitted there are ‘challenges’ ahead. Mr Muir, who has no links to the farming community, will head up the newly restored Department of Agriculture, Environment and Rural Affairs.He is the Alliance Party representative for North Down and was previously Chief Whip for his party.

Nuffield Farming Scholarship

JThe application window for a Nuffield Farming Scholarship is now open for 2025.

Run by the Nuffield Scholarships Trust, the scholarships are open to applicants between the ages of 22 and 25, providing funding for research, study and overseas travel.

Opportunity

Rupert Alers-Hankey, director of Nuffield Farming, said: “A Nuffield Farming Scholarship is the opportunity of a lifetime. Not only is it a transformative experience for the Scholar, it also creates unique insights and learnings for an ever-changing industry.”

rDetails on nuffieldscholar.org

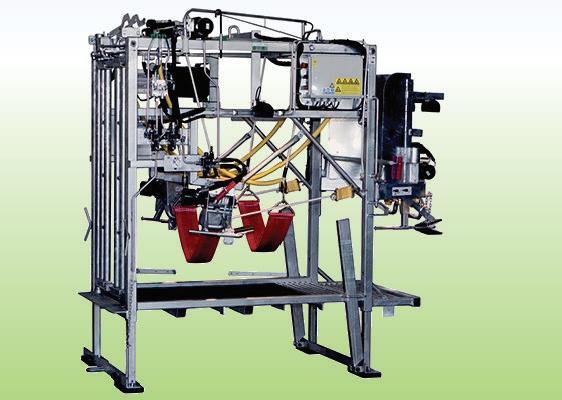

AGRICULTURAL & INDUSTRIAL STEEL FRAMED BUILDINGS Livestock Housing, Crop Storage, Industrial & Commercial, Tip Troughs Schurr Cow Brushes BEDDING MACHINES Telephone: 01524 792247 e-mail: sales@rebuildings.co.uk www.rebuildings.co.uk Scrape, Sweep and Spread in one pass. Bedding Material and Labour saving. Reduce cell count and increase production. Prevent disease and maintain good animal Health. Self-loading models available. Simple to drive and manoeuvre. 1 or 3 wheel drive. ELECTRIC ASK FOR DETAILS NOW AVAILABLE NEW

NEWS 5

MARCH 2024

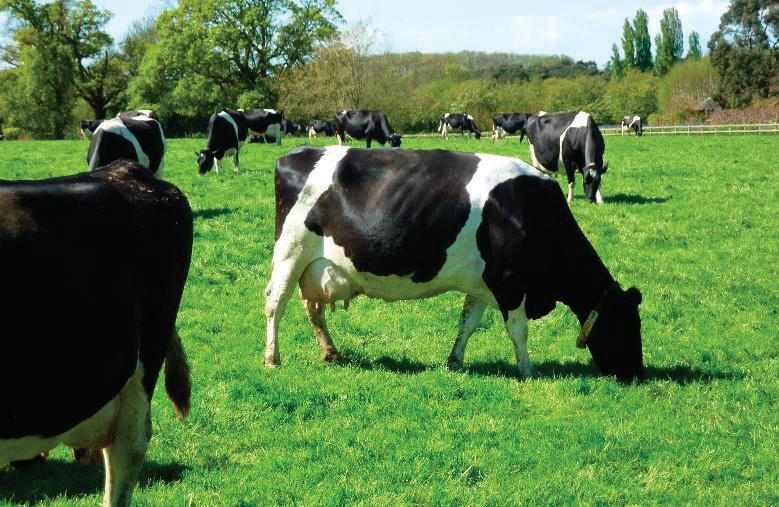

Cross-bred herd breaks the mould to win Gold Cup

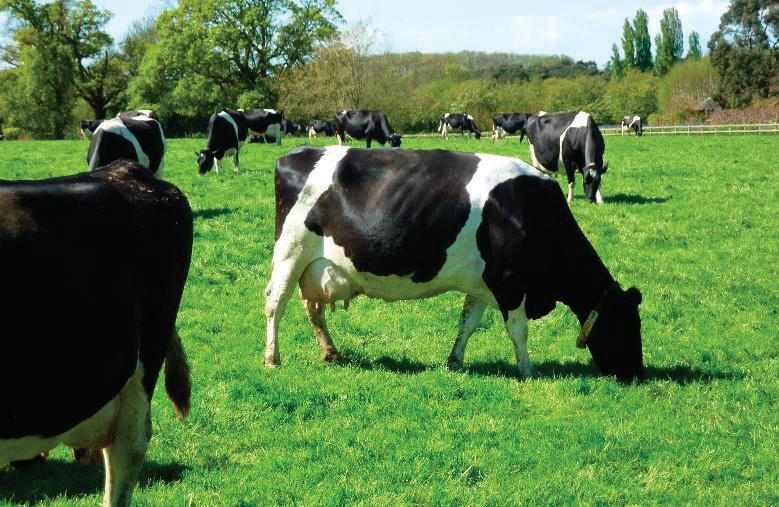

The winner of the 2023 National Milk Records (NMR) and Royal Association of British Dairy Farmers’ ( BDF’s) Gold Cup Award, which was announced at Dairy-Tech, is Bisterne Farm in Ringwood, Hampshire.

is is one of the rst farms in the competition’s recent history to receive the award with a crossbred, low-input, grass-based herd.

Estate owner Hallam Mills and contract farming partner George Brown are milking 600 cows within the 1,500-hectare (3,706-acre) estate near Ringwood, focusing on producing milk from grazed grass.

ey produce 3,730 litres of milk from forage and have a target to reach 4,000 litres with cows yielding 550kg of milk solids per cow per lactation.

Current average yield is 6,282kg of milk at 5.06% bu erfat and

3.84% protein from this spring and autumn block calving herd.

Team work at Bisterne Farm was one of the a ributes which stood out for this year’s judges, which included BDF chair Robert Craig and trustee Di Wastenage, NMR’s veterinary adviser Dr Karen Bond and 2020 Gold Cup winner Essex dairy farmer John Torrance.

Mr Craig said: “George

and his team are a great example of what modern pasture-based dairying should look like.

“All the judges unanimously decided on Bisterne Farm as the 2023 winner, not only because of their excellent a ention to detail and focus on key performance indicators across their system, but also because they go above and beyond to showcase dairy to the consumer.

“

ey have a really positive a itude towards dairy farming and have an excellent social engagement, hosting more than 4,000 visitors during last year’s Open Farm Sunday and opening the farm up to other groups such as Scouts, National Federation of Young Farmers’ Clubs and ex-o enders.” rFor more from Dairy-Tech, see pages 48-55.

Tenant farmers say they are feeling bullied

JMore than one-third of tenant farmers feel bullied by either their landlords or their landlord’s representatives, with 70% of those questioned revealing they only saw their landlord’s agents when they wanted something.

Evidence

ese gures come from a survey the Tenant Farmers Association (TFA) sent to members and nonTFA members in England and Wales. e study is in response to Defra’s call for evidence regarding the appointment of a Tenant Farming Commissioner.

A total of 90% of respondents said they were in favour of appointing a commissioner.

Out of the 425 tenant farmers surveyed, 40% of respondents said they felt ignored by their landlords, while more than 30% went as far as to say they felt bullied by their landlords. e survey allowed farmers to share anonymous comments.

One farmer said: “I feel if you do not do as you are told or have an opinion, you are dancing on thin ice. ey are bullies.”

TFA chief executive George Dunn said the ‘scores of comments’ like this ‘hit hard’ and demonstrated the struggle tenants have with their landlords and landlord’s representatives, adding it was ‘unacceptable’ for anybody to feel bullied.

e survey found the relation-

ship between tenant farmers and landowners’ representatives to be ‘worse’ than with the landlord – 40% said they were not easy to speak to, while 37% claimed they felt ignored or bullied by them.

Disputes

Prolonged disputes were also brought into focus in the survey, with criticism around the current mechanisms available to resolve tenant-landlord disputes.

Only 6% of respondents felt that resolving disputes through court action was ‘accessible, reasonable and cost-e ective’.

CLA president Victoria Vyvyan said positive working relationships would always be in

the best interests of the landowner. She said: “No-one in the tenanted sector bene ts from combative approaches and we will always support all parties working e ectively together.”

She added the CLA was also surveying its own members and hoped the ndings could form the basis of ‘future discussions’.

A Defra spokesperson said: “Tenant farmers are at the heart of our rural economy and we are working hard to ensure our policies and schemes support a thriving tenanted sector.”

It welcomed the insights from TFA, adding it would feed into the analysis of responses to its call for evidence.

NEWS 6

MARCH 2024

Left to right: Judge Robert Craig, with George Brown and James Dunning of Bisterne Farm.

DAIRYTalk

Becky Fenton

Becky Fenton and husband Paul milk 200 pedigree Holsteins under the Springlebee prefix at Centenary Farm, a Cheshire county council farm. In 2021, they bought a farm in Staffordshire and they plan to farm there once the new dairy setup has been built.

“ At Centenary Farm we don’t take ourselves too seriously

Istart this column on a high; we have just returned from a skiing holiday in France. It was our first family ski holiday and the boys took to it like duck to water (annoyingly they’re better than me already).

I expect this will be a yearly vacation now. We are very fortunate to have reliable and responsible staff. They all did a superb job while we were away and we’re very grateful.

While in France we did incur one blocked road due to the farmer protests. Having seen the French farmers actions on social media, they’re certainly taking protesting to another level.

I can remember the peaceful protests outside the Muller factory in Market Drayton, where farmers would have a catch up and a beer or two, and then the respectful London march. All very timid compared to the French. I do admire their passion and bravery.

Due to the vast rainfall we had in autumn (well, the whole of last year really), we were unable to get our cover crop in on the maize ground.

Therefore, we have a reduced number of acres for first cut and a loft full of seeds to feed the rat population.

Also, the 24 hectares (60 acres) of grass seed we sowed are stunted in growth and in some parts quite patchy. We intend to address this when it dries up.

When we bought New House Farm in Staffordshire, it provided more youngstock housing. This led our business to take a different direction and, over the last three years, alongside milking 200 cows, we have been buying heifers (calves to bulling age), rearing them and then selling them calved down.

Finances

With the poor milk price, this has helped financially. We have purchased about 300 heifers over the last 36 months.

Initially for ease, the heifers were put with a continental bull. However, all heifers are now only served to sexed semen, and 90% of our milking cows are now served to sexed semen also.

So over the next three months we have 68 due to calve to sexed semen and nine to beef.

The Future Farmers Programme delivered by the School of Sustainability I am involved in is well underway now.

I was slightly dubious at first. When I hear the

word sustainable, I can’t help but roll my eyes and wonder what am I going to be preached about this time?

Yet, this course is enlightening and doesn’t focus on your carbon footprint/net zero. It suggests a pivot in your attention.

My take home message so far would be to improve your efficiency. An efficient system will have a greater output, resulting in generating an increased income and therefore becoming more sustainable.

You don’t need to make big changes, and some of the efficiencies suggested include reducing the amount of time cows stand before/after milking, pushing the silage up once more, soil testing and improving calf housing.

At Centenary Farm we don’t take ourselves too seriously and I have always had the motto that I’d rather be laughed at, than laugh at someone else.

A couple of years ago on Christmas Eve, my youngest son asked for a pig. Father Christmas couldn’t deliver on such short notice sadly.

But unbelievably, our friend gifted his wife a micro pig as a house pet. She didn’t think fondly of her Christmas gift and gave it to our son.

Said pig, now known as ‘Bitsy’, turned up the size of a Jack Russell but now she is the size of a walrus.

Bitsy is our free-range farm pig and brings a smile to every person who visits the farm.

8

MARCH 2024

Bitsy the pig.

Dan Burdett

Dan and his family own and run the 300-hectare (741-acre) Cockhaise Farm, near Haywards Heath, West Sussex. The farm is home to an organic autumn-calving herd of 240 Holstein and Friesian crosses. He also contract farms another organic autumn-calving herd of 220 cows at Bore Place, near Edenbridge, Kent.

“ I have learned in recent years to take any opportunity to graze that I can at this time of year

Despite telling myself I should enjoy each day of the year, I find it hard not to wish away the long winter, with the perpetual dark mornings and dank skies overhead.

Up until the new year I am too busy concentrating on getting cows and heifers in-calf in the first six weeks of mating to worry too much about the fading light. As exciting as those six weeks are, the following six can certainly drag on and the energy levels certainly start to drop.

This is the first season where I have served all the cows and there is no doubt that it has been more of a challenge for me than usual, with nobody to back me up on the odd cow I struggle to serve.

Having said that, the non-return rates are looking promising for the first six weeks and I haven’t served anything yet in week 10.

There seems to be a consensus here in the South East that it has been a poorer than average year for bulling heifers, with submission and conception rates down on where we would expect them.

Perhaps this has something to do with grass and silage quality, but we go through the same process with them every year, so perhaps we should just put it down to being ‘one of those years’.

I am also hearing and seeing higher than usual 50- to 70-day returns on cows. With bluetongue active to the east of us, there are also fears that maybe this has something to do with Schmallenberg, something we haven’t seen for a few years, and hopefully is just wild speculation.

Weather

The weather this winter has been the usual mixed bag, but it has dried out enough in the recent weeks for us to be able to turn the cows out starting on January 29 for a few hours each day.

I have learned in recent years to take any opportunity to graze that I can at this time of year as you can never tell what is waiting in the weather wings.

The cows haven’t milked very well this winter, peaking two litres below last year, and feed costs remain high, so this is an opportunity to cut a little cost out of the system.

In our organic system we often see milk drop

when cows are housed for winter and then pick up again at turnout, so I am hopeful we can make the most of the rising milk price to help pay some of the outstanding bills.

Over the past few years I have tried to go with best practices in silage-making so we can stop losing milk over winter.

Our first cut is early May. We make four cuts, roughly every six weeks, and have plenty of new leys to keep quality up.

The one area where I have my doubts is silage additive. It is a no-brainer on dry crops and wholecrop, but it doesn’t seem to be having a marked affect on milk output.

On a recent grassland group visit, only about 25% of the farmers were using additive, so perhaps this is something we can look to make savings on in the budget for 2024-25?

9 DAIRY TALK

MARCH 2024

A plan to increase the milking herd size from 270 to 330 head through replacement breeding is well underway at the Morgan family’s Graig Olway Farm. Wendy Short reports.

Farm achieving the herd expansion goal

Increased con dence in the future due to securing an aligned milk supply contract with Muller, as well as the desire to spread costs, are two main reasons behind the herd expansion plan at Graig Olway Farm, near Usk, South Wales, explains Russell Morgan.

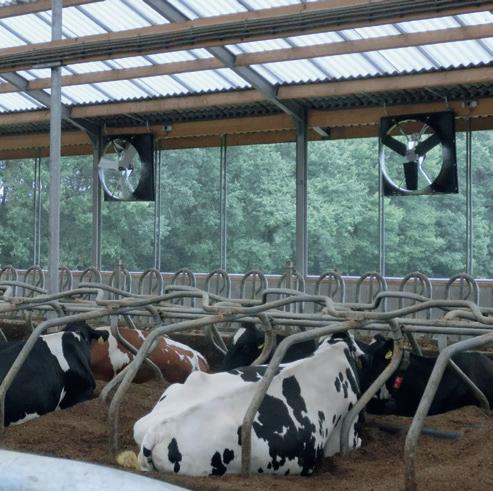

e family’s Holstein herd is milked through a series of six robots in the cubicle housing.

e business operates a 120150-day grazing policy for up to six hours daily in accordance with milk buyer requirements, while the cows also receive a total mixed ration containing grass and

maize silage, wholecrop and caustic wheat, and rapemeal.

e diet is topped up with concentrates fed to yield.

e family’s ‘Llangeview’ herd pedigree dates back to the 1950s, although some cow families have been added.

“My late father liked to buy-in new female bloodlines and the progeny of some of his purchases have worked out very well,” says Mr Morgan, who farms with his partner, Sarah, his mother, Glenys, and his aunt, Jane Morgan.

“However, we are constantly striving to improve health status

and for that reason the herd is now closed, apart from buying in an occasional stock bull.

“Many of the original families are still thriving, especially the Be ys, which have proved to be outstanding.”

Due to the decision to increase cow numbers, which was taken a couple of years ago, as much as 90% of the herd was served with sexed Holstein semen at one point. e present strategy is to produce 120 replacement heifers a year.

Mr Morgan admits that the family was ‘late to the party’ with genomic testing, but they were

pleasantly surprised with the herd performance a er its introduction three years ago for heifers and rst lactation females.

He says: “Breeding for high Pro table Lifetime Index has not historically been a goal, but the results were favourable and it has become a useful selection tool. Many other factors are considered when choosing breeding animals and the genomic data tends to act as a nal decision-maker.”

Genosource Captain, Lars-Acres Raiton, Aurora Mitchell and Penn-England Barclay are among more than a dozen Holstein bulls currently being used for replacement breeding.

Stand-out sires that have been used in the past include Mapelwood Brewmaster, Seagull-Bay Supersire and Picston Sho le.

Robotic

e switch from parlour to robotic milking in 2013 has slightly changed the farm’s bull selection criteria, which makes use of a sire-matching program.

Mr Morgan says: “Like most other milk producers, our priorities are ease of calving and good feet, legs and udders.

“Mobility score is another important trait, especially with robotic systems, as the cows are required to travel for greater distances compared with parlour milking. Robotic milking values must also be considered; they cover teat position, teat length and milking speed.

“We used to buy semen from a

MARCH 2024 10 ON FARM

Russell Morgan (left) – pictured with daughter Eleanor and herdsman Christian Dewfield – is increasing the herd from 270 to 330 dairy cows at Graig Olway.

single company, but we now use a range of sources, as we were nding that adding positive robotic milking traits to the list of requirements was limiting our range of options.

“In general, proven bulls are

the rst choice, but a young bull will be used if his gures indicate herd suitability.

“Our cows are edging towards becoming slightly too large at 720-750kg for maximum suitability for the building layout

and design, probably because of our general focus on breeding for type. erefore, we are trying to pull back slightly, in terms of stature.”

e Morgans have made great strides in tackling herd lameness,

with help from vet, Sara Pederson.

“At its height, lameness was a ecting 40% of the herd and the gure is now down to about 1012%,” says Mr Morgan.

“Part of the problem can be traced back to one particular bull, which transferred his weakness on the trait to some of the heifers.

“To tackle the issue, we have adopted a range of measures, in addition to breeding selection.

“ ey include fortnightly mobility scoring and prompt treatment, with a blitz approach to digital dermatitis, frequent footbathing and improvements to cow comfort.

“ e AHDB’s Lameness Advantage predicted transmiing abilities system uses a range of information to rank animals, expressed as a percentage, and that is also given weight when making selection decisions.

“My daughter, Eleanor, who is studying agriculture, will always

ON FARM Calf Health Is Critical To Your Business! Our E ective Biosecurity Programme Can Help Reduce Disease On Your Farm www.kersia.uk Please Note: Disinfectants are regulatory biocides. Use biocides safely. Before use read the label and product information. *For full DEFRA approval visit: disinfectants.defra.gov.uk For more information, contact your local Kersia Ruminant Sales Manager, or call our Lockerbie o ce on +44 (0) 1576 205480 Or email enquiries.uk@kersia-group.com

PICTURES : Ruth Rees

The farm switched from parlour to robotic milking in 2013.

ON FARM

ask us to justify our choices when she comes home from university.

“She will look at all the data in great detail, so the gures have to stack up.”

Bovine TB is one of the region’s greatest challenges on dairy farms and it was con rmed at Graig Olway in 2002, following the foot-and-mouth crisis, with some resulting losses.

Meanwhile, the other main diseases have been addressed systematically and the herd is bovine viral diarrhoea and IBR-clear, with great progress having been made on stamping out Johne’s. e only routine vaccination is for protection against leptospirosis.

While both British Blue and Limousin semen is used on the lower end of the dairy herd, the la er is the dominant breed and Ashledge Leofric and Tweedale Lennox have performed well. e current stock bull is Whiskey O’Brien.

Farm facts

rThe farm is 270 hectares (667 acres)

rCows are averaging 11,500kg at 4% butterfat and 3.3% protein

rCalving is all year round, with a calving interval of 385 days

rAverage number of cow lactations is four

rHeifers are calved at 24 months

Mr Morgan says: “We have always run a pedigree Limousin stock bull for use as a sweeper and on our small continental suckler herd, which is being phased out as dairy cow numbers rise.

“ e breed is easy-calving and Limousin cross calves tend to be quick to get up on their feet a er they are born. ey also have the potential for very high growth rates.

“O’Brien has a good temperament and his calves have ful lled all our expectations. In fact, we are so impressed with him that semen collection is being considered. Our previous bull was sourced from the same herd, which is fairly local to the farm.” Due to building limitations, about 50% of calves from the dairy herd are fully housed,

with the remainder in igloos and veranda-style accommodation.

Replacement heifers and beef breed crosses are run as one group, with the la er sold as six to eight-month stores.

“New-born calves receive colostrum and milk from their dam for the rst four days, before going on to milk replacer,” he says.

Weaned

“At about one-week-old, they are moved into group pens of about a dozen head and weaned at nine weeks, a er which they move on to a starter pellet.

“ e batches are introduced to a mix containing home-grown rolled barley over a two-week period and it will be their staple diet by the time they reach three

months old. At the 16- to 20-week stage, they will be switched to a total mixed ration which includes grass silage, rolled barley and a protein blend.”

With the breeding strategy on course for expansion, the family is now reviewing the calf housing.

Mr Morgan says: “ e automatic milk machine in the building works well and reduces labour input. Nevertheless, we feel that the calves on the outdoor system bene t from a healthier environment.

“In addition, the outdoor calves are fed manually via teated buckets and that o ers the opportunity for closer observation.

“No rm decision has been made at this point, but new calf accommodation is likely to represent our next major investment.”

MARCH 2024 12

Calves get colostrum and milk from their dam for four days. Half of the calves are housed outdoors in igloos.

A pedigree Limousin bull is used as a sweeper on the lower end of the dairy herd.

There is life after Soya

Try our award winning high quality rumen bypass protein in your blend or as a straight today.

01733 422214

tridentfeeds.co.uk/novapro

www.

DAIRYMatters

‘Use it or lose it: Animal Health and Welfare Pathway funding in England’

Ian Cure is a veterinary surgeon and director of LLM Farm Vets, and is farm director for VetPartners, the parent company of the practice.

Iknow many are sick of hearing about the Animal Health and Welfare Pathway (AHWP), while others do not know what it is or feel frustrated that it is using the subsidy money they are now losing due to the loss of the Basic Payment Scheme.

My strong suspicion is that if this funding is widely ignored, it could be a green light for the Government to withdraw budget allocated to supporting farmers, leaving the industry in a worse place than it is now.

It is important to share here that Defra has already stated it intends to apply payment by results, so low levels of funding take-up could well mean the model will not be there in future.

For all farmers, I think this is a major concern at a time where profit margins are increasingly hard to make.

Ian Cure

Ian Cure

I strongly feel these grants need to be approached with the bigger picture in mind; that if they are used correctly, they can open doors to more funding.

For example, if your vet recommends changes to your farm and there is another grant available in future, you stand a much greater chance of being successful if you have already accessed and used the Pathway, for example for the recent calf housing grants.

Priority

For larger dairy units, the relatively small amount of money (£372/year for three years) may make the funding seem less of a priority than other grants, but I would urge those farms not to write it off and instead consider it as a gateway fund.

Engaging with the Pathway and considering how vets can support you will open the door as future larger grants are announced.

Yes, due to a fairly tricky start with IT and personnel challenges, Pathway applications were initially nigh on impossible, and I know farmers were put off by this, or if they did apply many did not hear back.

However, I understand it is now streamlined and should take just minutes to apply and claim, so long as you have all the details to hand.

For those concerned about the process, it is straightforward and can be extremely valuable. Once the application is successful, the first step includes a veterinary visit – the ‘review’ – where you can discuss any topic which you feel is beneficial to your herd and business.

A compulsory element of the visit is testing for bovine viral diarrhoea, which can generally be done by taking a bulk milk sample.

The aim of the vet visit and any outcomes is to

14 MARCH 2024

For larger dairy units, the relatively small amount of money (£372/year for three years) may make the funding seem less of a priority than other grants, says Ian Cure.

“ I would strongly advise using this funding while it is available

reduce endemic disease, improve welfare, increase productivity and to ensure veterinary medicines are being used to get maximum e cacy and reduce antimicrobial resistance.

It is important to note the review is not an audit and should not be used replace a farm assurance visit. is is an opportunity for you and your vet to think outside the box to deliver continual improvement.

With areas such as improved biosecurity, increased trade opportunities and reduction of emissions all on the table as stated aims of the Pathway project, it is not a big leap to think that in the future the Government may plan to reward farmers focusing on working with these improvements in mind, as well as the highest animal welfare standards.

e Pathway will also help farmers set up their businesses to meet future governmental funding criteria.

erefore, I would strongly advise using this funding while it is available or we could nd our industry in seriously deep water.

About Ian Cure

15 MARCH 2024 NOW AVAILABLE FOR ON FARM DEMO Call Wilson Agri on 028 7086 8430 to book your demo now! As seen on

time & bedding - bed 250 cubicles in less than 20mins Minimal noise, pollution and running costs

maintenance - no filters

hot-dip galvanised - ensures

the

collecting bedding

of a lever

standard 13amp socket

also available FULLY ELECTRIC

Save

Low

Fully

no damage to

hopper when

Easy loading - loading is simplified to the pull

Fast energy efficient charging -

Petrol & diesel options

JIan Cure qualified from Glasgow Vet School with a passion for farm animal work. He and Rob Howe founded the LLM Lancashire branch in 2008 where he is now based.

Ian gained a diploma in bovine reproduction in 2012. His veterinary interests among others include fertility, lameness and nutrition.

Each digital dermatitis case has been estimated to cost £80, but Dr Nick Bell describes the figure as ‘conservative’ and prevention and treatment should be the priority. Wendy Short reports.

Prevention of digital dermatitis should start with youngstock

The prevalence of digital dermatitis in the UK dairy herd is relatively unknown, although one fairly recent survey showed that 3040% of cows per herd had associated lesions and the numbers could be higher, says Dr Nick Bell, a vet who runs the Herd Health Consultancy.

“Some units will have the disease almost under complete control with cases down to single gures, while in others, half of the herd may be a ected,” he says.

“Lameness caused by digital dermatitis will have a negative e ect on production and fertility. Financial losses can be signi cant, particularly in a high-yielding herd.”

He advises that preventative measures should start with the youngstock.

“Some herds are still struggling with infection levels, despite the regular footbathing of the milking cows.

“On these farms, the problem will generally lie within the youngstock, which will be naive to the bacteria.

“Dry cows are another major source of infection and digital dermatitis should be regarded as a whole herd problem.

“Producers will o en comment that the disease will are up about a week a er they stop footbathing, but US studies have indicated that it can take 150 days from the rst skin lesions, to full-blown development.

“Infected heifers can join the

Infected heifers can join the herd without showing clinical signs of the disease

milking herd without showing clinical signs of the disease.”

Heifers at grass are at low risk, because the bacteria will not thrive when exposed to air and oxygen and it is believed that it will not persist beyond a few days without its animal host.

A footbath should be set up in the youngstock housing and used at least once a week, he suggests. A long, narrow footbath is the best design for optimum cleaning and disinfection.

Design

“It will give multiple foot plunges, compared with a short, wide design which is sometimes viewed as superior due to its increased cow ow potential.

“If cow ow is a priority, a pair of adjacent narrow footbaths is preferable for the milking herd.

“For youngstock and dry cow housing, the ideal set up is to sink the footbath into the concrete, but a mobile plastic bath can also work well.

“Any footbath system should be as simple and easy to use as possible, because that will encourage maximum frequency of use.”

e cleaning of the foot is probably more important than the disinfection process, he stresses.

“In many instances, infection

Long narrow footbaths are the best to use as they encourage multiple foot plunges, Dr Bell says.

will start in the recess between the heel bulbs due to slurry build-up.

“ e material must be removed on a regular basis, as even a thin layer will prevent the disinfectant from reaching the contaminated skin.

“ e launch of spray systems about a decade ago was not a success, as it did not thoroughly clean between the claws and the heel bulbs.”

He considers formalin, which has been under threat of withdrawal for the past 15 years, the most cost-e ective chemical on the market.

“It works well when used at the right concentration, which is 3-4% of the total volume.

“Farms with robotic milking systems could reduce the inclusion rate to 2.5%, as the cows may be using the footbath up to four times a day upon exit.

“As a rule of thumb, one litre of solution is su cient for each cow pass before the mix will need to be refreshed.

“Accurate dosing is vital to avoid formalin burn on the skin.

MARCH 2024 16 VET’S VIEW

DR NICK BELL

e industry has relied on the chemical for many years and is important to follow data sheet precautions, to maintain product access and ensure sta safety.

Other products are available, but they must be backed up by research data.”

One common issue with mixing footbath solutions is the miscalculation of the water element.

Dr Bell says this can be avoided, by installing a water tank with a ballcock and measuring gauge, with the precise volume of water released before the concentrated liquid is added.

Hosing

For drain installations, one 15cm or two 10cms (four-inch) products are recommended per bath, preferably with the addition of an o set, vertical pipe. And Dr Bell says the treatment of digital dermatitis should include hosing o cows’ feet in the parlour.

“Some producers are reluctant to adopt this routine because it can initially lead to increased dunging. However, in my ex-

perience, the cows soon become accustomed to the procedure and it is very helpful.”

Good foot trimming protocol is another preventative measure. e recommended approach is to record individual cases and treat infected feet with a licensed antibiotic spray, following cleaning and drying. Research has also highlighted the bene ts of administering pain relief.

“Digital dermatitis has a stress component, so isolation is not advisable. Chronically infected cows are sometimes culled, but nevertheless even severe cases can recover well a er e ective treatment.

“ e disease has a strong genetic component, with some bloodlines having greater resistance than others. Genetic selection indices will include a ‘digital dermatitis advantage’ rating.

“It seems that some ca le bloodlines show greater resistance than others.

“Personally, I suspect that selecting for high yield may have increased susceptibility.”

Monitoring behavioural patterns of adult cows, first time calvers and maiden heifers for the purposes of heat detection and health monitoring can help herd managers to maximise the dairy herd’s productivity.

Without knowing how youngstock are performing, the herd’s future productivity could be compromised.

How well replacement heifer calves are reared can have a long-lasting influence on the herd’s performance, with any diseases, respiratory problems or welfare issues during the animal’s first year having a potential detrimental effect for the rest of its life.

Ensuring the farm is producing healthy, well cared for and disease-free replacements is therefore critical to the herd’s future viability.

Thanks to its new SenseHubTM Dairy Youngstock application plan, SenseHub® from MSD Animal Health now allows herd managers to monitor calves during their first 12 months. It can can be used to identify any signs of ill health or opportunities for welfare improvements in nipple-fed calves in single hutches and post-weaning calves in group pens.

Using a monitoring system to watch over youngstock also reduces the farm’s reliance on skilled staff and ensures each and every calf gets off to the best possible start and that it can make a positive contribution to the herd’s income sooner.

UNIQUE SYSTEM

The SenseHub Dairy Youngstock application plan uses the SenseHub monitoring

eartag to assess the behavioural patterns of calves from birth and is suitable for nipple-fed calves in single hutches or post-weaning calves in group pens.

As soon as the SenseHub system detects any irregular patterns which could be indicative of a developing health or welfare issue, the relevant animal is entered on the Youngstock Health Report to highlight which calves need attention. A programmable flashing LED on the eartag also helps to locate the relevant animals so the necessary care or treatment can be administered as quickly as possible.

The SenseHub Dairy Youngstock application can be used as a standalone plan or in combination with other SenseHub Dairy application plans. It is also included as part of the SenseHub Lifetime application, which also offers reproduction and health monitoring for individual cows and heifers and for groups of animals within the herd. SenseHub can also be used to control an MSD Animal health sorting gate and with the SenseHubTM Dairy In-Line Somatic Cell Count and SenseHubTM Dairy In-Line MilkPlus sensors.

All the above are available via the SenseHub GO subscription, which gives customers access to the full suite of SenseHub hardware and software for one affordable monthly payment and no upfront costs.

MARCH 2024 17 VET’S VIEW

MONITORING YOUNGSTOCK TO GIVE THEM THE BEST

CONTENT To find out more, please call the SenseHub team on 01207 529 000, or email us at allflexuk@msd.com For more information, visit www.msd-animalhealth-hub.co.uk/farmers/livestock-monitoring SenseHub is not intended to diagnose, treat, cure or prevent any disease in animals. For the diagnosis, treatment, cure or prevention of disease in animals, you should consult your veterinarian. The accuracy of the data collected and presented through this product is not intended to match that of medical devices or scientific measurement devices.

START SPONSORED

With downward pressure on margins, the opportunity to reduce feed costs is something pre-occupying many dairy farmers. So what needs to be done? Dairy Farmer reports.

Science says protein content of diets can be reduced safely

Speaking at the British Society of Animal Science national dairy nutrition conference, attended by more than 100 nutritionists and nutritional advisers, Prof Liam Sinclair, of Harper Adams University, suggested there were real opportunities to reduce protein content in many diets.

He said dairy and beef cattle were responsible for 50% of the UK’s ammonia emissions and about 75% of all nitrogen in dairy diets was just excreted.

Benefits

Anything which can reduce the amount of protein fed and increase the efficiency of nitrogen use will bring both environmental and economic benefits, he said.

However, he added that many cow diets were still formulated to crude protein.

And he said compounds, blends and straights were still talked about in terms of crude protein content, but he added crude protein did not address the quality of the protein, nor did it reflect how protein was used by the cow.

Prof Sinclair said: “There is a considerable weight of research to show we should be able to reduce the quantity of protein fed. As an industry, we remain pre-occupied with crude protein, yet it is an outdated term and method of rationing cows.

“We formulate diets on metabolisable energy and we should always formulate for metabolisable protein, which more accurately describes how cows use the protein in the ration.

“The better we reflect how cows use protein, the more accurately we can meet those requirements and reduce the

We formulate diets on metabolisable energy; we should always formulate for metabolisable protein PROF

total protein fed, which will reduce costs and also reduce the nitrogen lost in the urine.”

Prof Sinclair explained metabolisable protein is made up of two principal fractions.

Microbial protein is synthesised from protein broken down in the rumen, while bypass protein in the diet moves through the rumen undigested to be absorbed in the intestines.

The relative proportions are not represented in a crude protein figure.

Grass silages

Prof Sinclair said: “For example, the protein in most grass silages is 15-20% bypass protein, while for rapeseed the figure is 30-40% of protein as bypass protein.

“Where rapeseed has been protected, this increases to more than 55%, but the crude protein content of protected and unprotected rape is the same.”

Prof Sinclair said that rationing for crude protein was simply leading to excess protein being fed, as metabolisable protein requirements were often exceeded by such an approach.

He told delegates the key to feeding protein efficiently was maximising the supply of microbial protein from the rumen as this was the fraction of metabolisable protein which was most efficiently utilised by cows.

Prof Sinclair said: “We know

that as milk yield increases demand for metabolisable protein rises. However, the supply of microbial protein does not keep pace.

“This is why higher yielding cows need to be supplied with more bypass protein, but equally why lower yielders can perform quite adequately with less bypass protein.”

He said that if cows were rationed on metabolisable rather than crude protein, it was possible to feed fresh calved cows on diets equivalent to 16% crude protein or less, which is lower than most freshly calved diets in the UK.

He said: “You can reduce protein to 160g/kg of dry matter [DM] with no major impact on yields. However, going below this level in fresh cows could reduce yields unless the diet is formulated very carefully.

“In mid and late lactation, it would be possible to reduce protein content further to about 140g/kg DM without affecting performance.

“Reducing protein content by more precisely meeting cows’ requirements will reduce feed costs and also cut nitrogen waste and the production of ammonia, a win-win for

MARCH 2024 18 NUTRITION

LIAM SINCLAIR

environmental and economic sustainability.”

However, he did caution that when reducing total protein content to high yielders it would be important to be conscious of amino acid supply, particularly of methionine and lysine. He said supplementation with rumen-protected amino acids may be bene cial in some circumstances. Prof Sinclair said: “By challenging protein contents in rations, it should be possible to feed cows more e ectively and reduce crude protein inclusion rates while maintaining metabolisable protein levels. “We know how to do this, so nutritionists need to be challenged to move away from crude protein for the good of cows, pro ts and the environment.”

No major upfront costs

Open phone camera & scan

Tailored re-payment options

Potential tax benefits

Same day finance decisions

Scan the QR code to watch the video.

Discuss agricultural finance solutions for livestock, machinery, vehicles and more.

MARCH 2024 19

is

for

is

is

certain types of consumer credit lending

credit related activities that are regulated under the Consumer Credit Act 1974 and by the Financial Services and Markets Act 2000.

Finance for business use customers only. All finance

subject to credit status, approval, terms and conditions. Finance

Farms

a trading name of Shire Leasing PLC who

authorised and regulated by the Financial Conduct Authority for

and

01827 300 333 farmers@shireleasing.co.uk www.financeforfarms.co.uk

Prof Liam Sinclair told delegates the key to feeding protein efficiently was maximising the supply of microbial protein from the rumen.

Hungary’s dairy industry has taken a beating in recent years, forcing some dairy farmers out of business, but one farm is bucking this trend. Chris McCullough reports.

Investing to future-proof business

The Covid-19 pandemic, the war in Ukraine and, in 2023, one of Hungary’s worst droughts have all created endless challenges for the country’s dairy farmers, forcing pro t margins to su er.

However, one larger farm has made a number of changes, investing in new technology and improving key performance indicators to future-proof the business.

Extra Tej operates its farm in the north western region of Hungary, near Beled, extending to 1,060 hectares (2,619 acres).

e company, owned by the Harsanyi family and Zsolt Pinter,

took over the farm from previous owners, Elore Agricultural Co-operative Society, in May 2003.

Kovacs Balint, manager of the dairy, says: “Extra Tej has made a number of investments to improve the infrastructure of the farm and in new technology to increase overall e ciency.

Modernisations

“ ese modernisations included a new feeding system in 2010, followed two years later by a new Boumatic Xcalibur 360EX rotary parlour which holds 50 cows.

“Two new barns, to house 578 and 418 cows, were built in 2014 with a liquid manure handling

system nanced by a modernisation grant. Also, a new barn for transition cows was added in 2023.”

In addition to these improvements, the company is constantly upgrading its machinery and technical equipment, including the renovation of the silos for storing bulk feed, the road networks and other infrastructure.

e farm is home to 1,000 cows which are milked three times a day, with an average daily production of 40.41kg at 3.81% bu erfat and 3.32% protein.

Focus

Mr Balint says: “In the early 2010s, the focus of breeding was mainly on milk production and calving ease. However, in recent years, in addition to these value traits, an important criteria for the selection of bulls is the somatic cell count and the sire has to be A2A2 homozygous for beta-casein and should improve the milk bu erfat and protein as well.”

Cows are separated into groups depending on number of lactations and stage of lactation. e milking herd is housed in cubicles and the

Farm facts

rArtificial insemination is used across the whole herd

rTo try and safeguard some forage production against droughts, the farm has

dry and transition groups are in deep straw-bedded loose housing.

Currently, there are 39 workers carrying out the duties on-farm, as well as seven management sta and an external veterinary service.

Demonstration farm

Mr Balint says the high number of employees is justi ed by several factors, including the need to ensure a continuous supply of quality sta and the fact that the farm acts as a demonstration farm.

He says: “We produce the bulk feed for the herd ourselves, with most of the forage required being grown on-farm. e ration for the milking cows consists of maize silage, rye silage, sorghum silage, rapeseed groat, soya groat, maize groat and barley.

“The average dry matter intake of the milking cows is about 26-28kg per day per animal. Dry cows receive a mix including alfalfa silage, grass silage, hay and straw. All the ingredients are collected, mixed and distributed by a self-propelled RMH feed wagon to the milking cows and by a trailed RMH feed mixer to the heifers.”

installed an irrigation system on 237 hectares (585 acres)

rMilk is sold to Alfoldi Tej at about 146 HUF per kg (28p/kg)

MARCH 2024 20 WORLD DAIRYING HUNGARY

Extra Tej runs close to 1,000 Holstein cows.

Kovacs Balint is dairy farm manager at Extra Tej.

New technology is playing a major role in helping Mr Balint get the most from cows and make the management process more e cient.

Rubber mats

Cow comfort in the barns has been vastly improved by switching the old rubber mats in the cubicles to waterbeds to help increase lying times.

Mr Balint says: “We have also

replaced the heat detection system with a SmartTag system from Boumatic. is will enable us to have continuous data on activity, eating and rumination, besides the individual identi cation of the cows.

“In the new transition barn, which has been in use since August 2023, we have an automatic curtain, ventilation and a manure handling system which are nowadays

standard equipment. In addition, there is a DeLaval OptiDuo feed pusher robot installed.”

Mr Balint says there are no further plans for expansion at the moment.

Infrastructure

He says: “ e infrastructure is su cient to serve the current number of animals, so an increase in the number of dairy cows

would require an expansion of the silos and the storage capacity of signi cantly increased liquid and solid manure.

“ e aim is to optimise processes with the current number of animals, improve key performance indicators and achieve the highest pro tability in line with the economic environment by increasing e ciency.”

MARCH 2024 21

your new team members Find out more

DeLaval feed pushing robot OptiDuoTM

DeLaval milking robot VMSTM V300/V310

DeLaval manure robot series

YOUR TEAM COMPLETE www.delaval.com

Meet

•

•

•

MAKE

Calves are kept individually in hutches for the first few weeks.

Most of the forage needed by the herd is grown on-farm.

Grazing fodder beet as a winter crop for beef and dairy cattle is reducing wintering costs at a Pembrokeshire farm. Dairy Farmer reports.

Grazing fodder beet for quality winter feed

The James family currently grows 10 hectares (25 acres) of fodder beet for wintering dairy beef stores produced by their dairy herd at Stackpole Home Farm, Pembrokeshire, but are scaling that up to 45ha (111 acres) to also provide feed for lactating and dry cows.

Cows are currently wintered on deferred grazing or kale with baled silage, but switching to fodder beet will provide a cheaper, higher quality source of feed.

During a recent Farming Connect open day, George James, who farms with his parents, Chris and Debbie, said growing kale was getting trickier because of periods of prolonged drought following drilling in late May or early June.

Advantage

“The earlier drilling dates for fodder beet give it an advantage and we can comfortably get 20 tonnes of dry matter from it, so it is by far the highest yielding winter grazing crop,’’ said George.

At around 9p/kg of DM, it works out at around half the cost of silage, therefore the new system would

reduce winter feed costs, plug feed gaps in late and early lactation and capitalise on the farm’s free-draining sandy soils.

But transitioning the herd on to the crop and correctly allocating it will be crucial to animal health and performance.

During the open day, fodder beet expert Dr Jim Gibbs, a vet and research scientist in ruminant nutrition at Lincoln University, shared important advice on how to get that transition right — and how to avoid some of the common pitfalls.

Fodder beet has a high sugar and water content so sufficient time must be given for feed intakes to adjust. Dr Gibbs warned that dairy cows are the livestock class most susceptible to transition acidosis due to gorging, a situation which occurs if too much fodder beet is allocated too early in the transition process.

To prevent this, he advised feeding low amounts of fodder beet initially, building up intakes slowly and providing supplementary feed

to keep the cow’s rumen fully fed.

Feeding grass or silage as the supplement initially was advisable, because if less palatable feed such as straw was offered, cattle would not eat the amount needed to maintain condition and performance.

A marker for whether cattle had properly transitioned is if they were leaving beet behind — Dr Gibbs suggested this should be around 5-10% a day.

“There is no risk of acidosis after full transition, providing intakes are adequate,’’ he said.

A lactating cow needs 15-18kg DM in total, therefore 5-6kg DM of fodder beet plus grass or silage should be the target for lactation feeding, as the crop should not make up more than a third of their feed.

“Start by offering them 1kg DM/ day and, once all the animals are eating the bulb, move up 1kg DM/day every two days,’’ said Dr Gibbs.

He recommended transitioning until target intakes were met. For dry stock weighing 500kg

and for in-calf heifers, the daily feed requirement is 14kg DM.

As fodder beet could make up 80% of their diet, they could be allocated 11-12kg DM of fodder beet and 2kg DM roughage once they have transitioned.

He advised building them up to this in stages, 1-2kg DM at day one, increasing 1kg DM every other day, with 7-8kg of supplement until day seven, gradually dropping supplement to 2kg at 14 days when they have fully transitioned.

If feeding 2kg of supplement, careful consideration needed to be given as to how the supplement would be fed to enable all animals to access it. If feeding bales in ring feeders, increasing to 3-4kg was needed due to the restricted feed space.

Youngstock

For youngstock aged from six months, Dr Gibbs recommended starting with a daily intake of 0.5kg DM per head of fodder beet, increasing this by 0.5kg every other day, fed with 3-5kg of grass or silage. At day 14 that mix should be 5-6kg of fodder beet and 1-2kg of grass or silage.

Also speaking at the event, independent grass and forage consultant, Marc Jones, said matching fodder beet varieties to class of stock was important.

He said Lactimo and Geronimo were excellent grazing varieties because they have a high proportion of leaf and more of the bulb sits out of the ground, which allows for a high level of utilisation. A lower DM variety such as Brigadier was more palatable and would achieve better utilisation in smaller calves weighing around 200kg, he added.

MARCH 2024 22

WINTER FEED

Left to right: Dr Jim Gibbs, George James and Marc Jones, at Stackpole Home Farm, Pembrokeshire.

Transition to sugar beet must be gradual, Dr Jim Gibbs said.

2.0

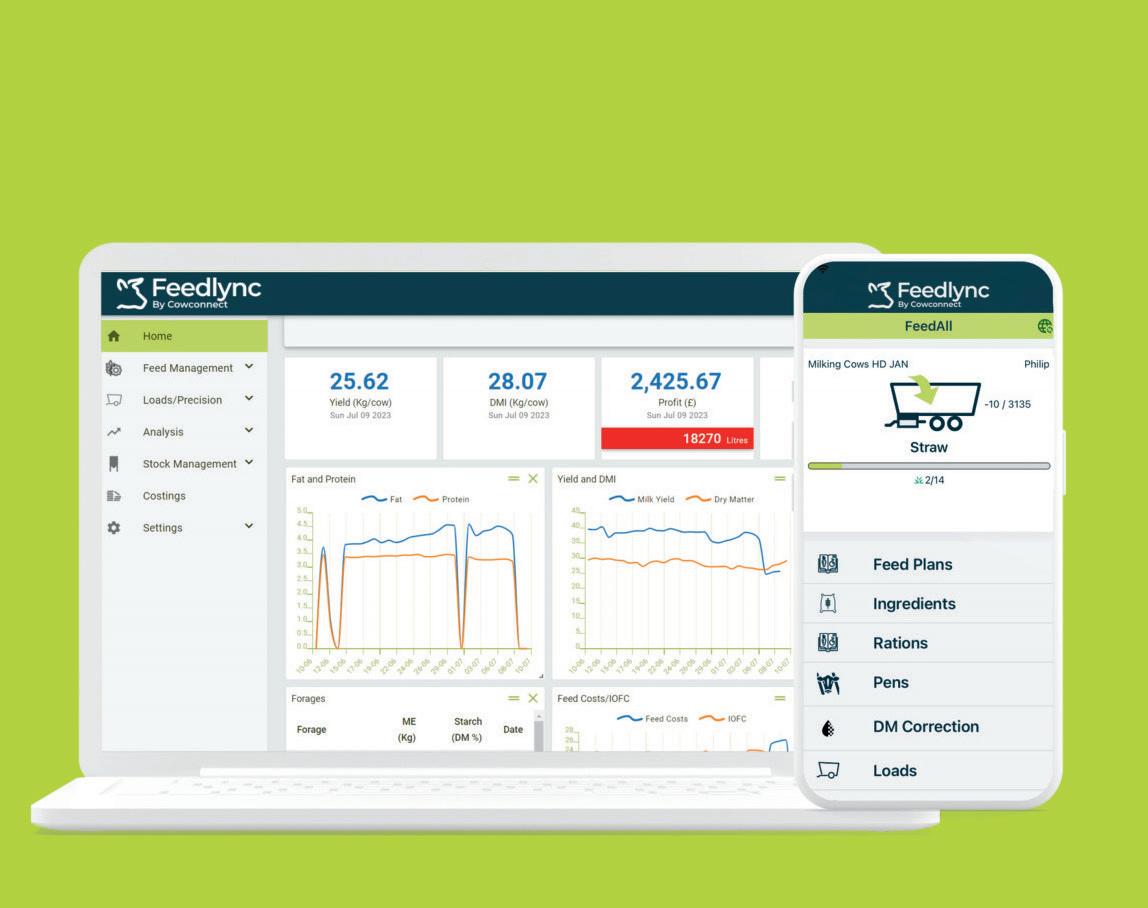

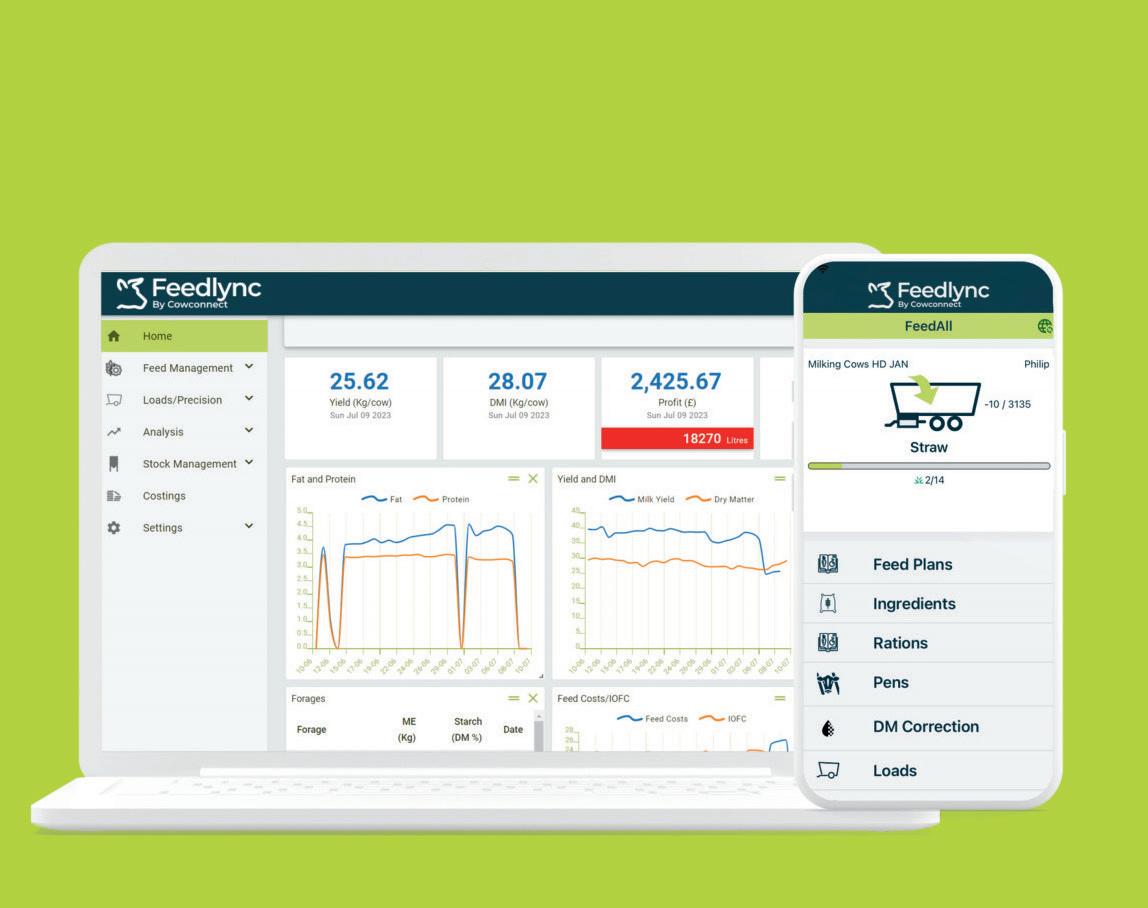

HOW YOU FEED YOUR HERD WITH OUR NEXT GENERATION APP

Feedlync is smart feed management software that reduces feed costs and increases milk yield by improving loading accuracy and monitoring of feed intake and usage.

Contact us to talk saving money on your feed bill and to check out our new app and user interface.

CONTACT US www.feedlync.com 020 3966 9063

An infection caused by bacteria entering a sore or area of abrasion, udder cle dermatitis is a common skin condition present on most dairy farms. However, the extent of the infection is not always understood due to the nature of the condition.

Primarily a ecting the udder cle , where the front of the udder meets the body wall, the condition causes ulcerative lesions, which in severe cases can be fatal. Vet Will Gratwick, of LLM Farm Vets, says fatalities can occur in chronic cases when the infection spreads from the lesion into the milk vein and through to the lungs.

While udder cle dermatitis can be a common issue in most herds, the lack of research into the condition means its cause is not entirely agreed upon, with several factors in uencing whether a cow will get it or not, says Mr Gratwick.

He says: “ e prevalence of udder cle dermatitis varies from farm to farm, as it is not an infectious disease which will spread from cow to cow; it is more a case of whether you have the right conditions for lots of cases.”

When looking at the conditions in which udder cle dermatitis can develop, Mr Gratwick says cow conformation has been identi ed

Udder cleft dermatitis is a common issue in many UK dairy herds, so what do we know about cause, prevention and treatment? Katie Fallon reports.

How to deal with udder cleft dermatitis

If a cow has got a deep cleft at the front of the udder [...] they are more likely to develop udder cleft dermatitis WILL GRATWICK

as one of the main in uencing factors.

He says: “If a cow has got a deep cle at the front of the udder, with a narrow angle between the body and the udder, then they are more likely to develop the condition than a cow with a wide angle.”

He also says older cows with larger udders are at greater risk of developing udder cle dermatitis.

Abrasive bedding material can in uence the development of the condition, says Natalie Parker, vet tech development coordinator at LLM Farm Vets. She explains any form of abrasive bedding, particularly sand, combined with dirty conditions and a wet environment could cause

abrasion and lead to udder cle dermatitis developing.

A lack of research means that, when it comes to treatment, there is ‘no magic solution’, says Mr Gratwick. erefore, he advises early treatment is best.

However, as udder cle dermatitis is quite di cult to spot in the early stages, largely due to where the condition presents itself on the udder, Ms Parker says it is a di cult condition to identify and treat.

She says: “Most farmers will know they have got some cases of udder cle dermatitis, but probably do not realise how many they have got until it gets so bad that you can smell it and it becomes obvious.”

Easily missed

She says that, in the early stages of infection, the condition can be easily missed due to it not being something farmers are necessarily looking for when milking.

Mr Gratwick says: “From a farmer’s perspective, it is di cult to spot because the udder cle is not easily visible when stood behind the cow, but it is possible to look for it.”

He advises using an inspection mirror to look at each cow’s udder cle when in the parlour, in order to identify the early cases.

“Treatment should be discussed with the farm vet, and involves cleaning the lesion,

drying it out and applying a topical treatment which can be used to treat skin infections,” says Mr Gratwick.

Treatment

He advises treating cows in a foot crush in order to li the cows’ legs to gain be er access to the lesions, followed up by routine spraying in the parlour.

“In terms of a protocol, it is something which could be done when foot trimming as most farmers will trim cows’ feet at drying o , so it would be easy to check cows then and treat where necessary, with severe cases requiring treatment repeatedly,” he says.

Ms Parker says bedding management is key when looking to prevent the condition, with emphasis on clean beds using less abrasive bedding materials, as well as making sure passageways are scraped out regularly.

“Ventilation is also important, so make sure there is a dry atmosphere in the shed, as sweaty cows could be more prone to infection,” she says.

For long-term prevention of udder cle dermatitis, Mr Gratwick advises farmers who are actively struggling with the condition to breed selectively for udder conformation, including strong fore udder a achment.

MARCH 2024 24 ANIMAL HEALTH

Udder cleft dermatitis can be difficult to spot because the udder cleft is not easily visible when stood behind the cow.

Having the best genetics is great but knowing they’re BVDFree makes them GREATER © Neogen Corporation, 2024. Neogen and Igenity are registered trademarks of Neogen Corporation. All rights reserved. Igenity ® Genomic Technology, powered by Neogen® Follow us on: @ Neogen EMEA - Animal Safety & Genomics @ Neogen iEMEA For more information email us at neogengenomics@neogen.com or call us on + 44 (0) 1292 525 600 Igenity® Extra: Test for Genomics & BVD Together ENGLAND *Our lab is accredited for BVD eradication schemes in England and Scotland Extra Scan here for more

After a two-year break, the National BVD Survey will take place in 2024, as announced recently by organiser Boehringer Ingelheim Animal Health at this year’s Dairy-Tech.

Dr Ailsa Milnes, ruminant brand manager for Boehringer Ingelheim, says: “This will be the seventh time the National BVD Survey has taken place.

“It gathers data from farmers and reflects the national and regional pictures across the UK, which is useful to farmers, vets and policy-makers alike.

“There is no other BVD information gathering exercise on this scale. With BVD remaining a health and financial issue for many beef and dairy herds, understanding what actions farmers are taking, and plan to take, is helpful as the findings will be shared nationally and with respondents directly.”

As with previous years, the National BVD Survey 2024 is being carried out in collaboration with the regional eradication programmes in England, Wales, Scotland and Northern Ireland, along with the producer stakeholders in those countries, including the National Beef Association and the Royal Association of British Dairy Farmers.

It is free to enter – at surveys.farmmetrics.net/s3/Boehringer-IngelheimBVD-Survey – and after indicating which nation your farm is in, respondents will be directed to the relevant questions which relate to their national scheme.

National BVD Survey: A chance to have your say

There is also a prize of 10 Beats Studio Buds True Wireless Bluetooth In-Ear Headphones with Active Noise Cancelling, worth £120, up for grabs, so why not take a few minutes to enter?

Dr Milnes says: “The 2021 survey gathered responses from 1,236 farmers with a split of 43% dairy and 57% beef; many also have youngstock on-farm.

Changes

“Since it was run last time, there have been some significant changes for producers in both England and Wales and it will be interesting to see how this is reflected in the responses.”

For Wales, funded testing under the Gwaredu BVD scheme ceased at the end of 2023. A voluntary scheme, which differed from those elsewhere in the UK, it led with blood screening for antibodies at the same time as the herd’s TB test.

National BVD Survey: Have your say

● 2024 is the seventh time the survey has run

● More than 1,200 farmers responded to the 2021 survey

● Vital information on what is happening on-farm with BVD prevention and eradication

● Helpful for farmers, vets and policy-makers

● Whether you are in a nation with a compulsory voluntary control scheme, having a BVD control plan specific to your challenges is important

Over the lifespan of the project, the scheme carried out tests on 85% of farms with cattle in Wales and identified 1,582 suspected PI animals through testing 93,191 animals1

These animals were found on 1,296 farms with some farms having multiple PI animals and some having none. This work suggests the percentage of positive farms dropped from 27% to 23%1

Meanwhile, for producers in England in receipt of Basic Payments, the Annual Health and Welfare Review, part of the Defra Pathway, offers a funded vet, with a focus on BVD for enterprises with cattle.

These were launched during summer 2023 and, while slow to get up-and-running, are now being utilised by farmers.

Dr Milnes says: “I guess a fair question to ask is ‘why?’ Why are we running it again and what do we hope to learn?

“BVD remains one of the most important cattle diseases globally due to its high prevalence and wide range of symptoms which negatively affect health and productivity.

“Some of the more obvious effects of BVD are relatively easy to quantify, such as the direct losses associated with abortion, cost of treatment and veterinary care, and loss of livestock.

“However, it can be difficult to determine the economic outcome of

the more insidious effects of BVD, such as immunosuppression and poor milk quality in beef suckler herds.

“It is also important to keep in mind the different costs associated with endemic [long-term presence of BVD in the herd] versus epidemic [acute outbreak in a naive herd] infections.”

A recent study estimates that the economic impact ranges from up to £552 per cow per year. Nationally, it is estimated that BVD costs UK farmers about £61 million per year2

Naturally, these figures are estimates and vary between dairy and beef production, and between individual farms.

Breakdowns

Dr Milnes says: “No-one can stand aside and tolerate these losses or run a herd which is at risk of being infected with this virus. And, in spite of the best intentions, through screening and biosecurity, time and time again we see naive and vaccinated herds suffer devastating BVD breakdowns. For naive herds, this is usually as the result of an unpredicted biosecurity breach.

“For vaccinated herds, it tends to

SPONSORED CONTENT

For more information, visit boehringer-ingelheim.com/animal-health MARCH 2024 26

Complete the survey at surveys.farmmetrics.net/s3/Boehringer-Ingelheim-BVD-Survey

Scan the following QR code to complete the survey

be where the timing of vaccine administration has gone awry, something easily done with the more complex killed vaccine protocols, especially for year-round calving herds.”

The 2021 National BVD Survey showed that farmers in every home nation – Scotland, England, Wales and Northern Ireland – had been caught out by vaccine timing protocols and had been forced to restart vaccination programmes3

Dr Milnes says: “Most commonly this was due to going beyond the 12-month window, followed by missing

About Boehringer

the six-month booster and getting the timing of the second vaccination wrong in killed vaccine protocols.

Vaccine programme

“And while the BVD virus could have crept in when a herd’s protection was compromised leading to losses, it is also expensive to restart a vaccine programme. Either way, opting for a live vaccine, such as Bovela®, which has a simple, single injection, more flexible protocol can make a busy life managing a herd slightly easier. Talk to your vet to find out more.”

References

1 Gwaredu BVD (2023) Voluntary Phase Summary 2017-2022; bvd. ahww.cymru/workspace/uploads/ files/bvd_impact-flyer_v16-compresse-64104277dce06.pdf [accessed January 3, 2024].

2 Yarnall MJ, Thrusfield MV. (2017) Veterinary Record (13):347. doi: 10.1136/vr.104370.

3 Boehringer Ingelheim Animal Health (2021) National BVD Survey 2021.

A recent study estimates that the economic impact of BVD is up to £552/cow/year.

Dr Ailsa Milnes

than 150 countries, we offer a large and innovative portfolio of products and services to improve the health and well-being of companion animals and livestock. As a global leader in the animal health industry and as part of family-owned Boehringer Ingelheim, we take a long-term perspective. The lives of animals and humans are interconnected in deep and complex ways. We know that when animals are healthy, humans are healthier too. By using the synergies between our Animal Health and Human Pharma businesses and by delivering

through innovation, we

of

lyophilisate and solvent for suspension for injection for cattle contains modified live BVDV-1, non-cytopathic parent strain KE-9: 104.0–106.0 TCID50, Modified live BVDV-2, non-cytopathic parent strain NY-93: 104.0– 106.0 TCID50. UK: POM-V. Advice should be sought from the prescriber. Further information available in the SPC or from Boehringer Ingelheim Animal Health UK Ltd, RG12 8YS, UK. Tel: 01344 746957. Email:vetenquiries@boehringer-ingelheim.com. Bovela® is a registered trademark of Boehringer Ingelheim Vetmedica GmbH, used under licence. ©2024 Boehringer Ingelheim Animal Health UK Ltd. All rights reserved. Date of preparation: January 2024. BOV-0001-2024. Use Medicines Responsibly.

SPONSORED CONTENT

Ingelheim Animal Health UK: Boehringer Ingelheim Animal Health Boehringer Ingelheim Animal Health is working on first-in-class innovation for the prediction, prevention, and treatment of diseases in animals. For veterinarians, pet owners, farmers, and governments in more

value

enhance the health and well-being

both. Bovela®

MARCH 2024 27

Cross-breeding genomic indexes, the latest tech and the validity of human dietary recommendations were all topics discussed at the British Cattle Breeders conference. Katie Jones reports.

Are recommended diets ‘nutritionally adequate?

Scientists, policy-makers and all those involved in the food system should be ‘extremely wary’ of food consumption guidelines that are not rigorous and transparent in their evidence,

and which ignore the protections against de ciencies and chronic diseases a orded by animal-source foods, said Prof Alice Stanton, of RCSi University of Medicine and Health Sciences.

Prof Stanton highlighted

Developing a cross-breeding index

JDairy farmer Rory Christie, from Dourie Farming Co in south west Scotland, spoke about a project he and three other farmers, led by geneticist Mike Coffey from SRUC, are involved in which is aiming to create the first cross breeding genomic index as part of the Fast Breeders Project.

Mr Christie said he decided to get involved in the project after realising the problem within his own herd was the ‘long-tail’ of cows that were not producing enough milk.

“We wanted to solve that problem and we wanted to increase income by £1 million per 1,000 cows per year,

without more cows or more feed.

“In 10 years we want to go from 475kg milk solids per cow and less than 1kg milk solids per kg liveweight, to 750kg milk solids per cow, and 1.5kg milk solids per kg liveweight.

“This is an audacious aim, but we want to help ourselves become financially sustainable.”

DNA testing

In order to create the Fast Breeders Index, the farms involved DNA-tested their entire herds to create an SNP key. And now, nearly 9,000 animals have been genotyped.

Mr Christie also explained they had created a ‘cows own

the EAT-Lancet report as being something that had wielded in uence over food consumption guidelines, but she questioned whether it was ‘nutritionally adequate’.

She said: “EAT-Lancet recommends doubling of fruit

worth’ tool, which identifies the least profitable cows to cull.

While, Mr Christie said the process was taking longer than he had originally expected, he is seeing an improvement in milk volumes, fat and protein.

However, he also said that he questioned whether this was

and vegetables in the diet and halving animal-sourced foods from 25 per cent to 13 per cent.

“It advises a reduction in red meat consumption to 7g a day, which is the equivalent to one 7oz steak a month.

also because management had also improved.

He said: “When doing a project like this, it really does bring everything into focus.”

And he added he was also concerned that cow size was also increasing, which he said was a worrying trend because it takes a long time to make genetic change.

“We are worried that we set in motion a change of cow size that neither works for the environment nor the profit and takes us a long time to unpick.

“A liveweight of 500-535kg remains the ideal, but I think we will exceed this and have to cross to Jerseys again.”

MARCH 2024 28 CONFERENCE

MADE IN GERMANY

Rory Christie

“But we need to ask whether this is going to be nutritionally adequate, and in particular whether the micro-nutrients of these recommended diets are going to be adequate.”

Research

Prof Stanton said research had found that these diets were de cient in key micro-nutrients, particularly for women of child-bearing age.

“We need to move animal-

sourced foods back up to more than 25 per cent.”

Prof Stanton said she expected the second EAT-Lancet report would include more meat-based foods within its recommended guidelines, but said there were multiple dietary guidelines and recommendations that continue to be in uenced by the report. She added that it was vital the scienti c review system for these reports was tightened up on.