UDDERMINT ® www.uddermint.com

Christmas from Pages 44-55

30-43 MILKING MUCK AND SLURRY

the

parlour technology

options, grants

automated scrapers

10-12 ON FARM FEATURE MILK PRICES

60-62

forage figures TIP OF THE MONTH: Reed beds an option to manage dirty water – p54 December 2023 Volume 70 Issue 12 Pages 16-17 Vet’s View Sole depth critical for lameness prevention

Happy

Pages

Exploring

benefits of

Storage

and

Pages

Pages

Grassland focus drives milk from

LEGAL CATEGORY: UK: POM-V. Veterinary medicinal product subject to veterinary prescription. Use medicines responsibly. Under veterinary prescription, advice should be sought from veterinary prescriber.

HIPRABov1s·�: Inactivated vaccine with Histophi/us somni and Mannheimia haemolytica leukotoxoid in injectable emulsion for cattle. INDICATIONS: For the reduction of clinical signs and lung lesions caused by Mannheimia haemolytica serotype Al and Histophilus somni in calves from 2 months of age. For more

Nottingham,

IS BRD BOTHERING YOU? HIPRABOVIS ® SOMNI/Lkt NASYM ® BREATHE EASY NASYM" : lyophilisate and solvent for suspension for injection or nasal spray for cattle. Each 2ml dose contains: Live attenuated bovine respiratory syncytial virus (BRSV), strain Lym-56 10 4.7 - 6.5 CCIDS0. INDICATIONS: Active immunisation of cattle to reduce virus shedding and respiratory clinical signs caused by bovine respiratory syncytial virus. For more information about side-effects, precautions, warnings and contra-indications please refer to the packaging or product leaflet. Further information available from SPC or on www.hipra.com. MARKETING AUTHORISATION NUMBERS: UK(GB) Vm17533/5008, UK(NI): EU/2/19/241/001-2. MARKETING AUTHORISATION HOLDER: Laboratories Hipra, S.A. Amer (Girona), SPAIN. LOCAL REPRESENTATIVE: HIPRA UK&IRELAND, Foxhall Lodge, Foxhall Road, NG7 6LH, Nottingham, United Kingdom, Tel.: (+44) 0115 845 6486, ukandireland@hipra.com, www.hipra.com.

information about side-effects, precautions, warnings and contra-indications please refer to the packaging or product leaflet. Further information available from SPC or on www.hipra.com. MARKETING AUTHORIZATION NUMBER: UK: Vm 17533/4005 MARKETING AUTHORIZATION

HIPRA, S.A. Avda. La Selva, 135. 17170Amer (Girona) Spain.

(972) 430660 -

(972) 430661. LOCAL REPRESENTATIVE: HIPRA UK&IRELAND, Ltd. Foxhall Business Centre, Foxhall Lodge, Foxhall Road, Nottingham - NG7 6LH - UNITED KINGDOM. LEGAL CATEGORY: UK: POM-V. Use medicines responsibly. Under veterinary prescription, consult your veterinary prescriber for further advice. Safety and efficacy of these products together have not been evaluated. A decision to use either of these vaccines before or after any other veterinary medicinal product therefore needs to be made on a case-by-case basis. HIPRA UK AND IRELAND Foxhall Lodge, Foxhall

NG7 6LH,

United Kingdom Tel (+44) 0115 845 6486 · ukandireland@hipra.com · www.hipra.com

HOLDER: LABORATORIOS

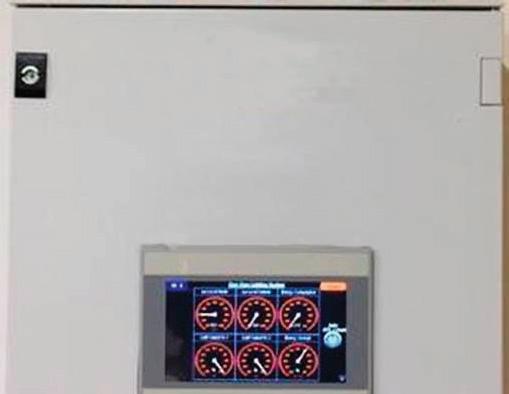

Tel.

Fax

Road,

As we hurtle towards the end of the year, it is a good time to take stock on what has been another whirlwind of a 12 months in the dairy sector.

is time last year, there were warnings suggesting milk prices were going to drop, and those warnings played out to be true. Unfortunately, this was not matched by a rapid drop in costs of production and it looks like these increased costs are here to stay.

ere are now some signs that there might be greater stability to the milk price, which is indeed welcome news, but there is still some way to go it seems.

ere has also been plenty going on in the political world with us having to learn more about yet another Defra Secretary.

Steve Barclay will be the eighth Secretary of State in just seven years. is perhaps tells us all we need to know about the state the Government is in at the moment.

But on the ip side, as I have a ended shows, events and conferences around the country over the last 12 months, there is also a great deal to be positive about, despite everything else which is going on.

Investment

ere is still plenty of investment to be seen on dairy farms around the country, a avour of this is given in this month’s milking technology special (p30-43) and there are still plenty who remain passionate and positive about this industry.

As we approach Christmas, I would like to wish you all a Merry Christmas and a prosperous 2024.

3

NOW AVAILABLE FOR ON FARM DEMO Call Wilson Agri on 028 7086 8430 to book your demo now! As seen on Save time & bedding - bed 250 cubicles in less than 20mins Minimal noise, pollution and running costs Low maintenance - no filters Fully hot-dip galvanised - ensures no damage to the hopper when collecting bedding Easy loading - loading is simplified to the pull of a lever Fast energy efficient charging - standard 13amp socket Petrol & diesel options also available FULLY ELECTRIC

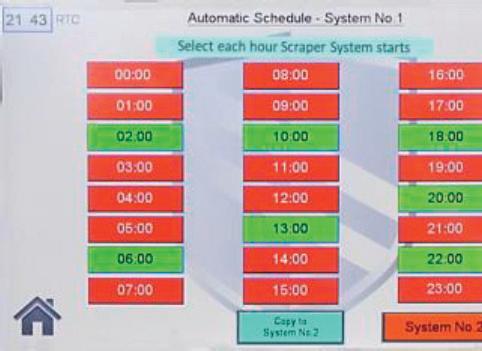

Dairy Farmer, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ Origination by Farmers Guardian, Unit 4, Fulwood Business Park, Caxton Road, Preston, Lancashire PR2 9NZ. Printed by Precision Colour Printing, Halesfield 1, Stirchley, Telford TF7 4QQ. No responsibility can be accepted by Dairy Farmer for the opinions expressed by contributors. Editor Katie Jones 07786 856 439 katie.jones@agriconnect.com Content Editor/Designer Mike Begley 01772 799 405 mike.begley@agriconnect.com Picture Editor Marcello Garbagnoli 01772 799 445 marcello.garbagnoli@agriconnect.com Sales Director Stephanie Ryder 07917 271 987 stephanie.ryder@agriconnect.com Account Manager Mark Jackson 01322 449 624, mark.jackson@agriconnect.com Classified Advertisements 01772 799 400 fgclassified@agriconnect.com Advertising Production Justine Sumner 01772 799 437 Fax: 01772 796 747 justine.sumner@agriconnect.com Circulation and subscriptions 0330 333 0056 help@subscribe.farmers-guardian.com Subscription rates: UK £65 a year Europe: £85 World: £95 ISSN 1475-6994 © Farmers Guardian 2023 All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system without the express prior written consent of the publisher. The contents of Dairy Farmer are subject to reproduction in information storage and retrieval systems. Contacts DECEMBER 2023

a word from the editor

26-27 British Farming Awards

Farmer fury over Senedd member’s ‘deplorable’ TB comments

Dairy farmers in Wales were angry after Labour Senedd member for Mid and West Wales, Joyce Watson MS, said dairy farms with ‘perpetual TB should find another business’.

Minister for Rural Affairs Lesley Griffiths had delivered her statement on the picture of bTB in Wales when Ms Watson questioned the Minister on whether she had ‘looked at any farms which had perpetual TB’ and if she had considered whether those farms ‘should be dairy farms at all and should find another business’.

Ms Griffiths has since come under fire for not ‘addressing the hurtful comments’ with Plaid Cymru’s Llyr Gruffydd MS, adding the Minister had ‘missed her opportunity to challenge and stand up for agricultural community’.

Ms Watson said she was talking about ‘several farms which have been continuously impacted by TB’.

Cycle

She said: “I know that the cycle of having to test, to cull, then to start all over again causes a huge stress to dairy farmers.

“In those cases, I think there

Revolving door at Defra

JThe new Secretary of State at Defra Steve Barclay has pledged to ‘back British farming’ as he takes up his new role following Prime Minister Rishi Sunak’s reshuffle and resignation of Therese Coffey.

But while industry bodies exchanged pleasantries in ‘welcoming’ the latest Secretary of State, many dairy farmers are feeling less optimistic about the appointment.

On hearing the news, many spoke out about Mr Barclay’s lack of agricultural or environmental experience, asking how further changes at the top would ease farmer concerns over ‘changeable farming policy’ and ‘continued uncertainty’.

Dairy farmer Charles Goadby,

from Warwickshire, said: “Like that of his predecessors, his appointment demonstrates the Government’s view of food and farming which is very much in tune with the majority of electorate.

“It is not a priority and something many of them take for granted.”

Support

Mr Barclay said: “I am excited to be championing rural communities, supporting our excellent food producers and continuing to drive our Plan for Water which is delivering more investment, stronger regulation and tougher enforcement.”

4

DECEMBER 2023 VOLUME 70 ISSUE 12 DECEMBER 2023 8 DAIRY TALK Updates from Dan Burdett and Matthew Winter 10 ON FARM Grassland focus drives milk from forage figures 14 DAIRY MATTERS ‘Britain is ripe for the next agricultural revolution’ 16 VET’S VIEW Sole depth critical for lameness prevention 18 YOUNGSTOCK Care for calves and keep consumers on side 20 WORLD DAIRYING Challenging time for Israeli family farm 22 BREEDING Grassland nutrition for a sustainable future 26 BRITISH FARMING AWARDS Highlights from the event 28 CONFERENCE 30 MILKING Exploring the benefits of parlour technology 44 MUCK AND SLURRY Storage options, grants and automated scrapers 56 MACHINERY Using solar panels to generate electricity 60 MILK PRICES 64 MILK ANALYSIS UK commodity prices trending up 66 NEW PRODUCTS Round-up of products and updates hitting the market 70 GOOD EVANS ‘It’s a merry-go-round where one sector supports the other’ 72 BUSINESS CLINIC Milk output falls behind UK population growth 74 RESEARCH

What’s inside?

56-59 Machinery

NEWS

should be a conversation about how that situation can be resolved or at least improved.”

Dairy farmers who listened to Ms Watson’s comments were furious about the lack of empathy and understanding she showed.

Susie and Mark Mo ershead run a pedigree Holstein herd on the Welsh border and have been ba ling bTB for over a decade.

Mrs Mo ershead said: “ Comments like this make me want to cry; we are that farm. We trust in Welsh Government to eradicate

TB and support their farmers.”

NFU Cymru has called the comments ‘deplorable’ and has wrote a le er to Ms Watson to underline the hurt her comments have caused to livestock farmers and their families in Wales.

NFU Cymru bTB focus group chair Roger Lewis and dairy farmer said: “I am struggling to put into words my frustration that a Member of the Senedd elected to represent Mid and West Wales could make such deplorable comments, so lacking in empathy and respect.

“Your suggestion that these families, many of whom are su ering persistent bTB breakdowns despite adhering to strict veterinary and scienti c advice, should just walk away and nd another business is – frankly – shocking.”

Mr Lewis invited Ms Watson to spend a day on-farm in her constituency to meet farming families who are determined to get rid of the disease from the countryside.

He said: “ ey have no intention of walking away and nding something else to do.”

Project awarded £700k for early disease detection

JA project to develop automated and real-time monitoring of disease in cattle has been awarded nearly £700,000. The DETECT project, involving scientists from Scotland’s Rural College, focuses on developing an automated, datadriven system for non-invasive and real-time monitoring of respiratory disease in dairy-bred calves. The project will utilise stateof-the-art technology, alongside commercially relevant lower cost sensors, to characterise the volatile metabolites found on the breath of healthy cattle and of those diagnosed with respiratory infection.

Grant competition

JThe Digital Dairy Chain has announced the winners of the 2023 collaborative research and development grant competition, run by the UK’s national innovation agency, Innovate UK.

The winning projects will receive funding totalling £2 million, with individual projects receiving grants of between £200,000-£350,000, which will be invested in work taking place predominantly across Cumbria and South and West Scotland, the Digital Dairy Chain’s geographical reach. The projects cover topics including calf environment ventilation, genomics and the breeding of methane-efficient cattle.

AGRICULTURAL & INDUSTRIAL STEEL FRAMED BUILDINGS Livestock Housing, Crop Storage, Industrial & Commercial, Tip Troughs Schurr Cow Brushes BEDDING MACHINES Telephone: 01524 792247 e-mail: sales@rebuildings.co.uk www.rebuildings.co.uk Scrape, Sweep and Spread in one pass. Bedding Material and Labour saving. Reduce cell count and increase production. Prevent disease and maintain good animal Health. Self-loading models available. Simple to drive and manoeuvre. 1 or 3 wheel drive. ELECTRIC ASK FOR DETAILS NOW AVAILABLE NEW

NEWS 5

DECEMBER 2023

Minister for Rural Affairs Lesley Griffiths had delivered her statement on the picture of bTB in Wales.

Feed savings by starling-proofing sheds

Investing £30,000 in starling-proo ng ca le housing is a major outlay for a Welsh dairy farming business, but it calculates a payback period of just two months in feed savings alone.

Between October and March, Nantgoch Farm, near Oswestry, is plagued by starlings foraging for maize and other grain in the total mixed ration fed to the 770-cow dairy herd.

Before the Jones family embarked on a programme of work last year to protect buildings with welded wire mesh panels, it was estimated that about 50,000100,000 starlings were helping themselves to four tonnes of feed daily at a cost of £15,000 a month. ere were also nancial losses from reduced milk production – up to two litres per cow per day due to the lower energy density of the fed ration from predation, with negative e ects on fertility as a consequence.

Bryn Jones, who farms with his wife Bev and son Mathew, told farmers a ending a recent Farming Connect open event at Nantgoch that the money spent so far on measures to deter starlings had been a very worthwhile investment.

He said: “It is a lot of money to

Protecting feed passages on the outside of buildings had been one of the biggest challenges.

nd and we still have another 20% of the buildings to do, but it is the only way we can protect the feed and the cows from the infestation.”

Protecting feed passages on the outside of buildings had been one of the biggest challenges, but it was achieved with cage-like canopies which can be raised o the passage when the feed wagon is depositing the ration and winched back into

position when ca le are feeding. One of the next hurdles is to protect the maize clamp during times when access is not needed.

Milk production

Graphs produced by the farm vet, Rob Edwards, of Cain Vets, show dips in milk production during the months of peak infestation, with a potential 4.4% loss in

energy corrected milk during those months compared to the period when starlings have migrated, although other factors such as day length and a dip in maize silage quality later in the year can in uence that too.

Mr Edwards also warned of the health risks from starlings as potential vectors of infectious diseases, such as salmonella typhimurium.

Minister rethinks in calf bTB slaughter

J e policy of on-farm slaughter of heavily pregnant cows and heifers with TB is being considered as a ma er of ‘priority’, Welsh Rural A airs Minister Lesley Gri ths told the Senedd in November.

Ms Gri ths said while there was an obvious need to remove positive reactors from farm as quickly pos-

sible, she acknowledged the emotional toll the action had on both the animals and the farmers.

Delay

However, Conservative MS and Shadow Minister for Rural A airs Samuel Kurtz questioned the delay and said it should not

take a ‘seismic change in policy’ to enable Wales to adopt another model such as that in England which, under strict circumstances, allows slaughter to be delayed until the animal has given birth if it is in the last 60 days of pregnancy.

Ms Gri ths also announced

changes to pre-movement testing to ‘strengthen’ the Welsh Government’s approach to TB eradication.

From February 1 next year, pre-movement testing for cattle will be reintroduced within and from the low TB area and post-movement testing extended in intermediate TB areas.

6 DECEMBER 2023

NEWS

PERFECT PARTNERS FOR EARLY-LIFE PNEUMONIA PROTECTION

Vaccinate from the day of birth onwards against the key pneumonia viruses BRSV, Pi3 and now Bovine Coronavirus (BCoV) with Bovilis® INtranasal RSP™ Live and Bovilis Nasalgen®-C.

Part of the MSD Animal Health Respiratory Programme. Contact your vet for further information.

Bovilis Nasalgen®-C contains live bovine coronavirus, strain CA25. POM-V. Bovilis® INtranasal RSP™ Live contains live BRSV and Pi3. POM-V. Bovilis® Bovipast® RSP contains inactivated BRSV (strain EV908), Pi3 virus (strain SF-4-Reisinger) and inactivated Mannheimia (Pasteurella) haemolytica (serotype A1). POM-V. Bovilis® IBR Marker Live contains live bovine herpesvirus type 1 (BHV-1), strain GK/D (gE¯)*: 105.7 - 107.3 TCID50**. *gE¯: glycoprotein E negative. **TCID50: tissue culture infective doses 50%. POM-V. Bovilis® Huskvac contains viable Dictyocaulus viviparus 3rd stage irradiated larvae. POM-V Further information is available from the respective SPC, datasheet or package leaflets. MSD Animal Health UK Limited. Registered office Walton Manor, Walton, Milton Keynes MK7 7AJ, UK. Registered in England & Wales no. 946942. Advice should be sought from the medicine prescriber. Use Medicines Responsibly. Copyright © 2023 Merck & Co., Inc., Rahway, NJ, USA and its affiliates. All rights reserved. UK-BOV-230700002

Dan Burdett

DAIRYTalk

Dan and his family own and run the 300-hectare (741-acre) Cockhaise Farm, near Haywards Heath, West Sussex. The farm is home to an organic autumn-calving herd of 240 Holstein and Friesian crosses. He also contract farms another organic autumn-calving herd of 220 cows at Bore Place, near Edenbridge, Kent.

“ I feel the strain of farming pulling a little tighter, with challenges coming from many angles

As the last of the autumn-born beef calves leave the farm, I can look back on a very good 2023 calving season down here in Sussex.

The difference that using Cow Manager made last winter shone through as we calved 85% in the first three weeks of calving, and 98% within six weeks. To say calving was a blur would be an understatement.

Cows are in excellent condition and the weather gods looked down favourably on us to keep cows out day and night until October 20, saving some muchneeded cash before we head into an expensive winter.

The recent price rise for our organic milk was much needed and will certainly help to move closer to financial parity this year, but we are by no means out of the woods yet.

Our belief in organic is strong – similar to so many in our position – but we must keep an open mind as to where the future of dairy farming is moving.

On our Kent farm, we are still shut down with bovine TB, having failed a third test this year, and went into calving knowing that our calves now had minimum value in the market.

I would estimate that we would be £10,000 to £15,000 down on the calf enterprise this year, and the strain of holding more calves than our buildings can cope with has tested both man and beast.

As with all farmers in this situation, we now find ourselves just hoping that things turn around.

Alongside the vets and other local farmers, we are vaccinating the local badger population in the hope that this brings some long-term relief, but the hundreds of deer that roam the local area may have a say in the situation too unfortunately.

Due to bTB, we will be using sexed semen on that farm for the first time, having resisted using it for years. Unbelievably, only about 10% of dairy semen sold in the South East is now non-sexed, making me occasionally feel like a laggard.

The flip side to this is the continuing pressure this seems to be putting on the calf buyers in this part of the world. With a huge drop in the number of black and white bulls available, they are finding it hard to justify the huge increase in the costs of buying calves and many have had enough and packed up.

As dairy farmers, I believe it is our responsibility to ensure that we have a thriving beef chain working alongside us in the coming years.

As we move into winter and the storm clouds gather, both physically and metaphorically, I feel the strain of farming pulling a little tighter, with challenges coming from many angles and the opportunities seemingly just out of reach.

Small things

In times like this, it is incredibly important to cherish the small things about our jobs that we love, the beautiful places that we work and the love and support of those around us.

I feel lucky to have many friends within the industry who I feel able to talk to in times of strife, and that organisations such as Farming Community Network are there 24 hours a day to support those when they are most in need.

8

DECEMBER 2023

Matthew Winter

Matthew Winter returned to the family farm in 2011 and is one of four partners in the mixed dairy/arable family farm in Lincolnshire, where 210 Holsteins are milked under the Corringham prefix. He sits on the Holstein UK board of trustees and started his career at Holstein UK as an animal breeding analyst before training to be a chartered accountant.

“ Events are a welcome social break from a job that can be isolating at times

Our embryo transfer technician joked that when he drove away from a farm in late March he cheerily wished his client a ‘Happy Christmas’ having just implanted 30 embryos. Well, a bit of bad planning in the Winter household means we have put ourselves in a similar position for 2023.

We still do some embryo transfer work, although less than we used to, mainly because sexed semen has made it easier to breed replacements from our best cows.

But we find buying embryos is a handy way to get into new cow families, and we genuinely feel investing in high-quality genetics makes a real difference to improving our herd and our profitability.

For me, it is also an interest and it means there is always something to look forward to even in the middle of winter and when times are tough.

Like many, our milk price has fallen about 40% during 2023, and with some costs still rising we are starting to feel the pinch.

High interest rates are particularly significant for us, having purchased our home farm in 2015 and another block of land in 2021.

We have a flat farm with heavy clay soil, and with an incredibly wet autumn we only completed about half of our winter cereal drilling – some seed we managed to drill looks as though it would have been happier left in the bag.

All our youngstock have been inside for some time, and it looks like it’s going to be a long winter. But, fortunately, we have good stocks of forage this year, so hopefully that should not be too much of an issue.

UK Dairy Day

As I have not written since UK Dairy Day, it would be remiss of me not to mention it. There were over 8,000 visitors, and the event as always was a really enjoyable day out. Much of the success was due to the hard work of Hannah Williams and the events team at Holstein UK.

There really is a tremendous amount to see at the event and it has deservedly cemented its place as an unmissable event for the dairy industry.

The quality of cattle in the Holstein ring was the best I can remember, and we were treated to a masterclass in judging courtesy of Iwan Morgan of the Erie Herd.

To top off a great day for me, we were delighted to be the overall runner-up in the Premier Pedigree Herd competition behind worthy winners, the Wills family from Willsbro.

All Breeds All Britain

The All Breeds All Britain Calf Show was back at Stoneleigh this year and was considered to be a great success.

It generates tremendous enthusiasm among the young members and is the highlight of the year for many.

There were over 300 participants from all over the UK, and it is a fantastic opportunity for them to make lifelong friends as well as being a great way to nurture budding enthusiasm for our industry.

In addition to being educational opportunities, both events are a welcome social break from a job that can be isolating at times.

9 DECEMBER 2023

TALK

DAIRY

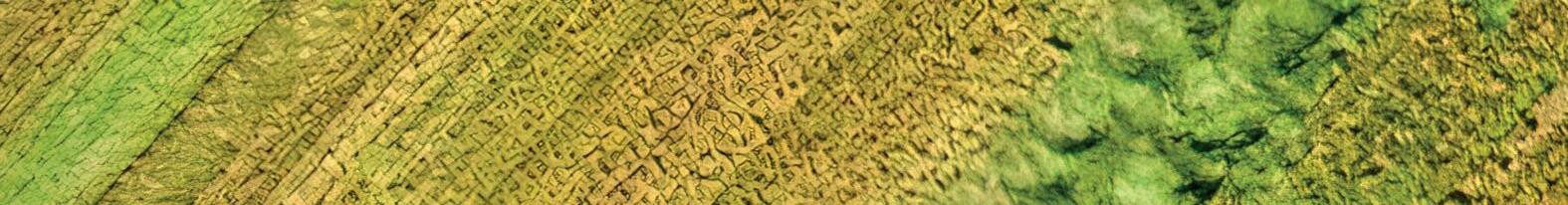

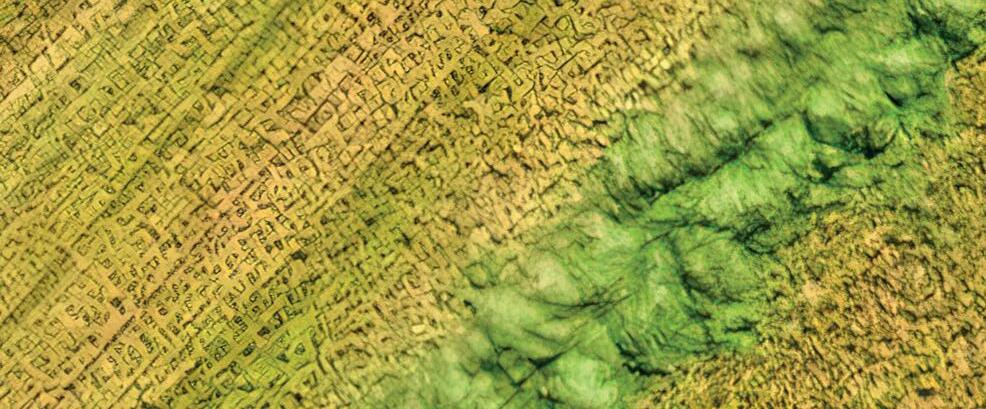

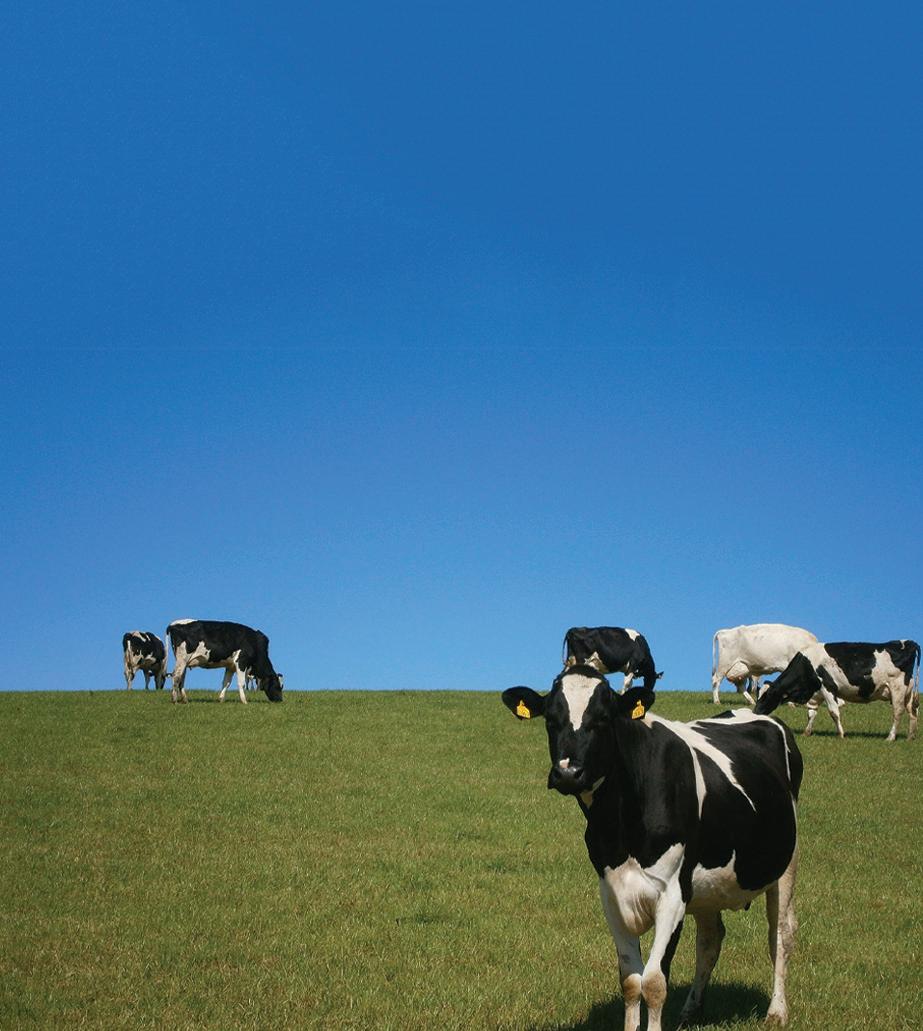

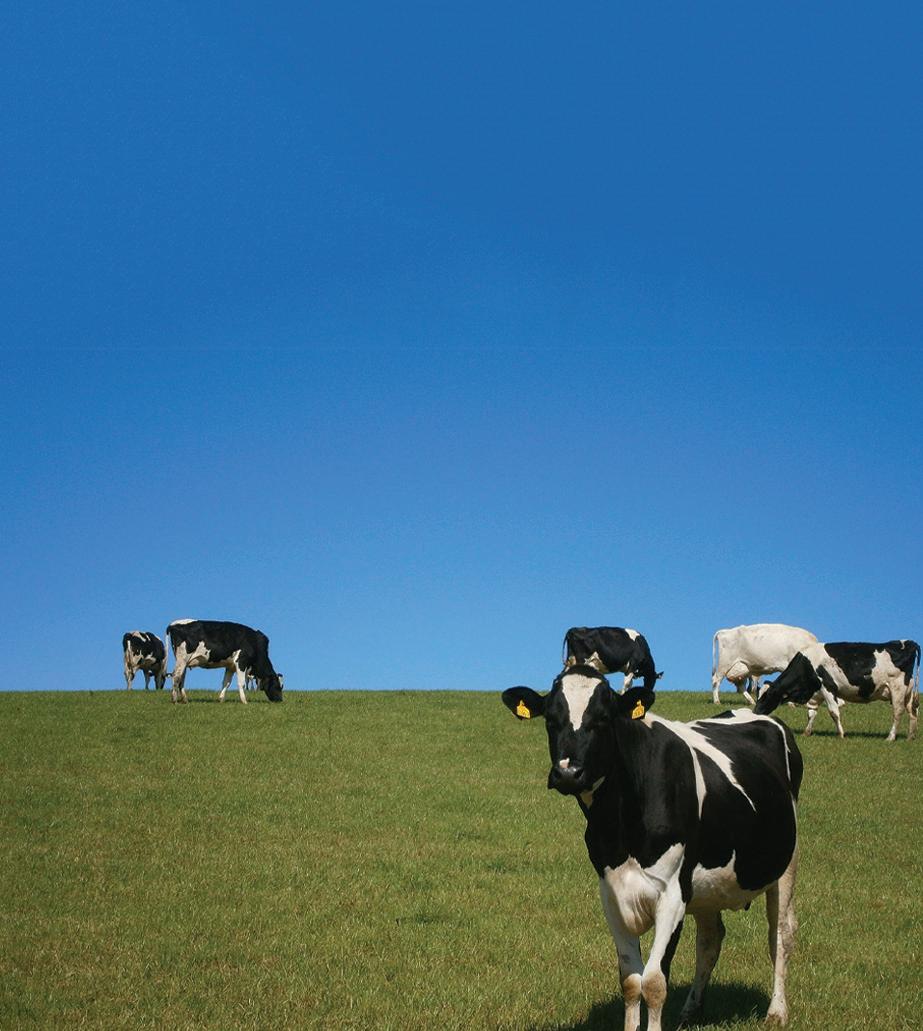

Forage quality and grassland management is driving performance in a Pembrokeshire autumn block-calving herd. Debbie James reports.

Grassland focus drives milk from forage figures

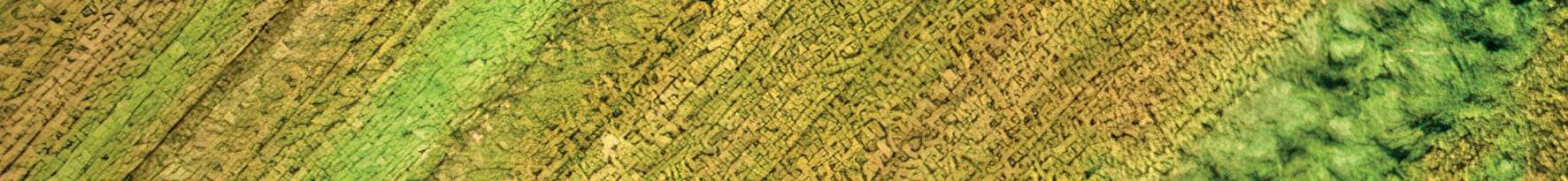

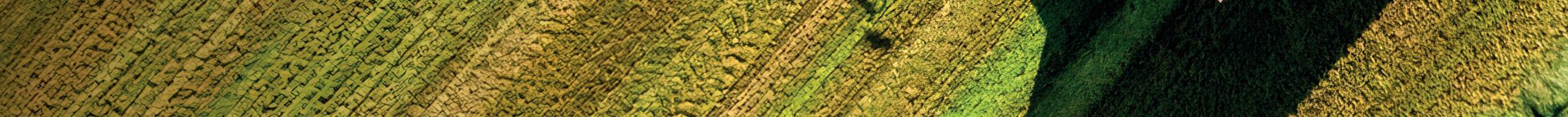

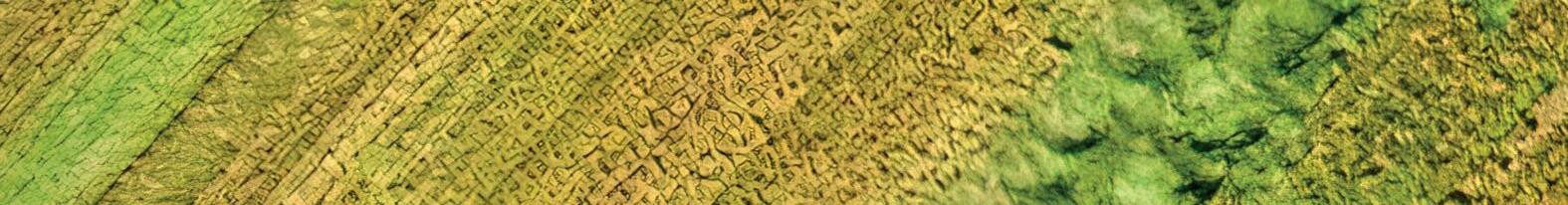

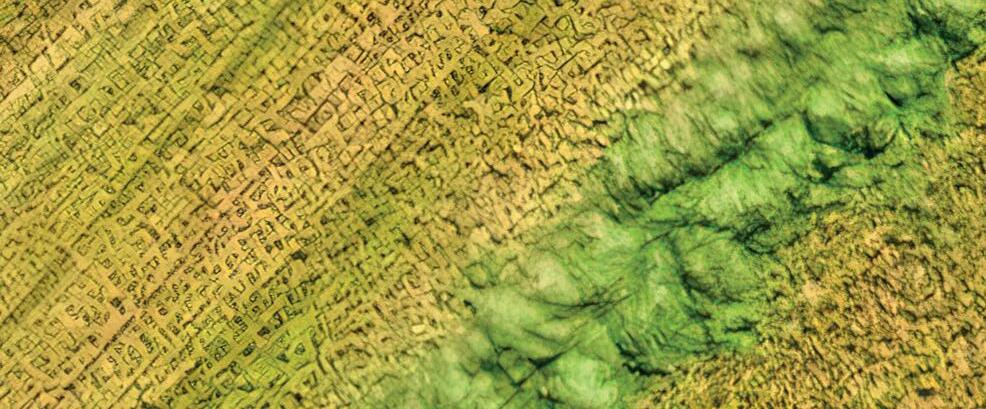

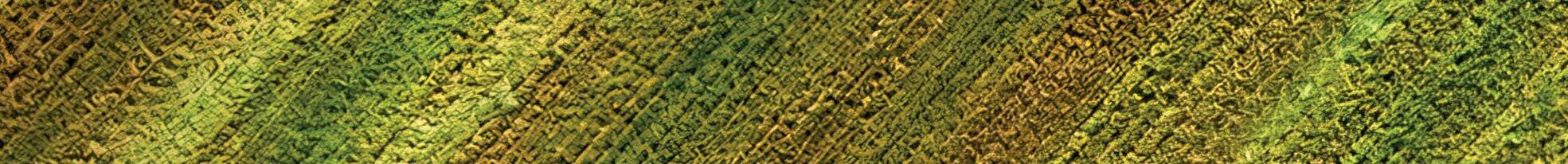

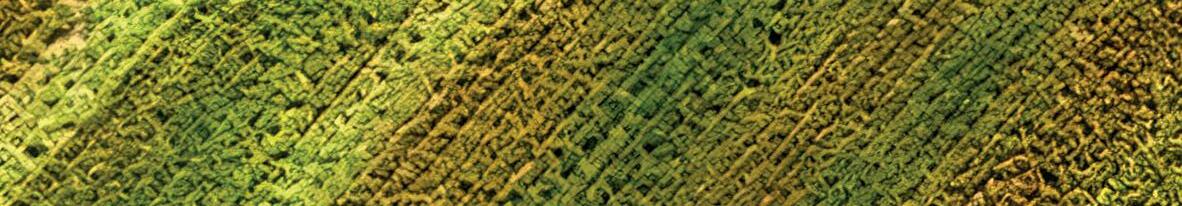

Grazing quality grass and making good silage has helped push milk from forage to 4,650 litres in Richard Morris’ 550-cow British Friesian cross Holstein herd.

e focus at Bowe Farm, near Pembroke, has been on improving the protein and energy in grass to reduce the requirement to buy feed.

Concentrate and fertiliser use is diminishing by focusing on growing high quality silage and grass through targeted use of nutrients, soil sampling, reseeding every ve or six years and incorporating red clover into the silage leys.

With home-grown maize silage from 36 hectares (90 acres) in the winter ration,

more than half of the 8,000-litre annual milk yield average comes from forage.

“We try to utilise everything we can grow, adding value to everything we have on the farm and, to do that as environmentally sustainably as we can,” says Richard, a runner-up in the British Grassland Society Grassland Farmer of the Year 2023 and a member of the Cleddau Grassland Society.

e Morris family have been producing milk at Bowe Farm for 100 years, a farm purchased by Richard’s grandfather, Joseph, in 1923.

Richard joined his parents, Bill and Ann, in the business in 1998. ey, together with his wife, Claire, have steadily grown the herd from the 90 cows milked at that time.

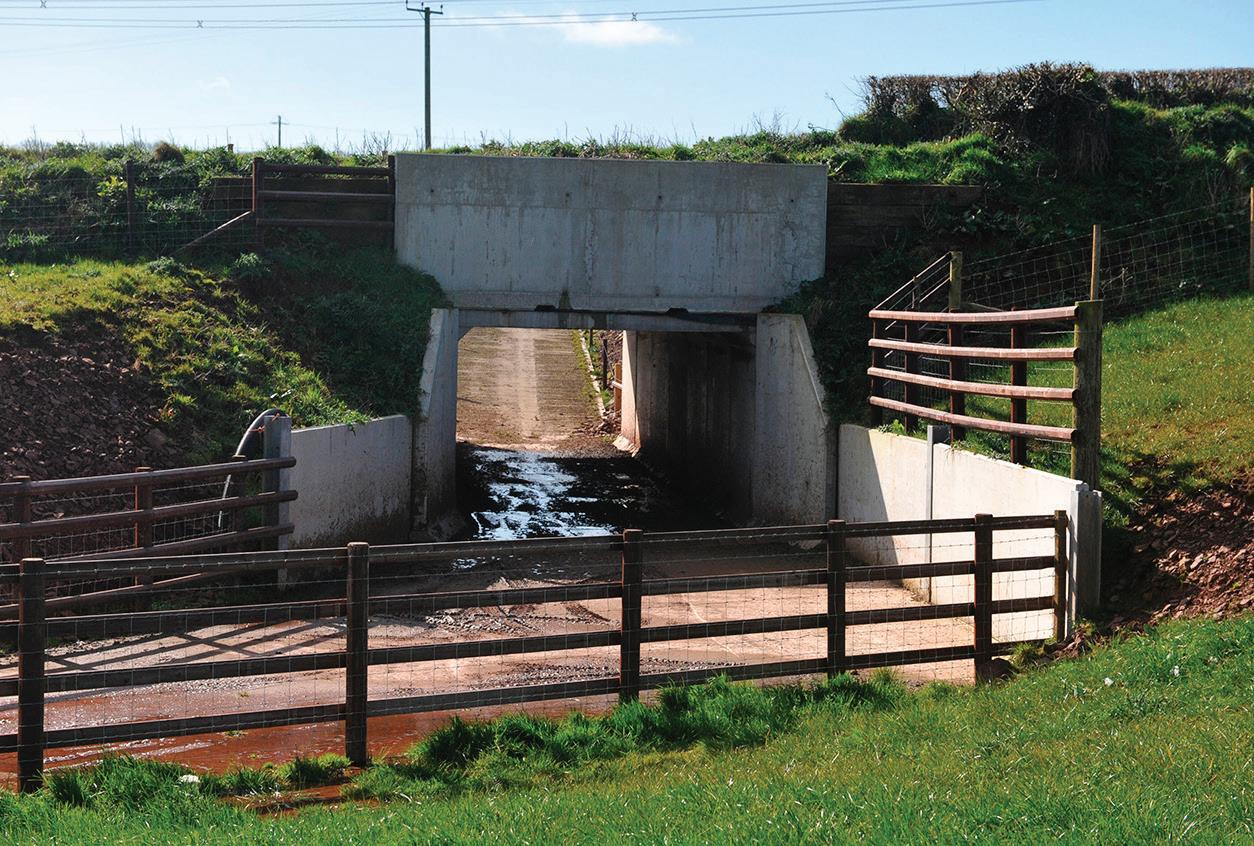

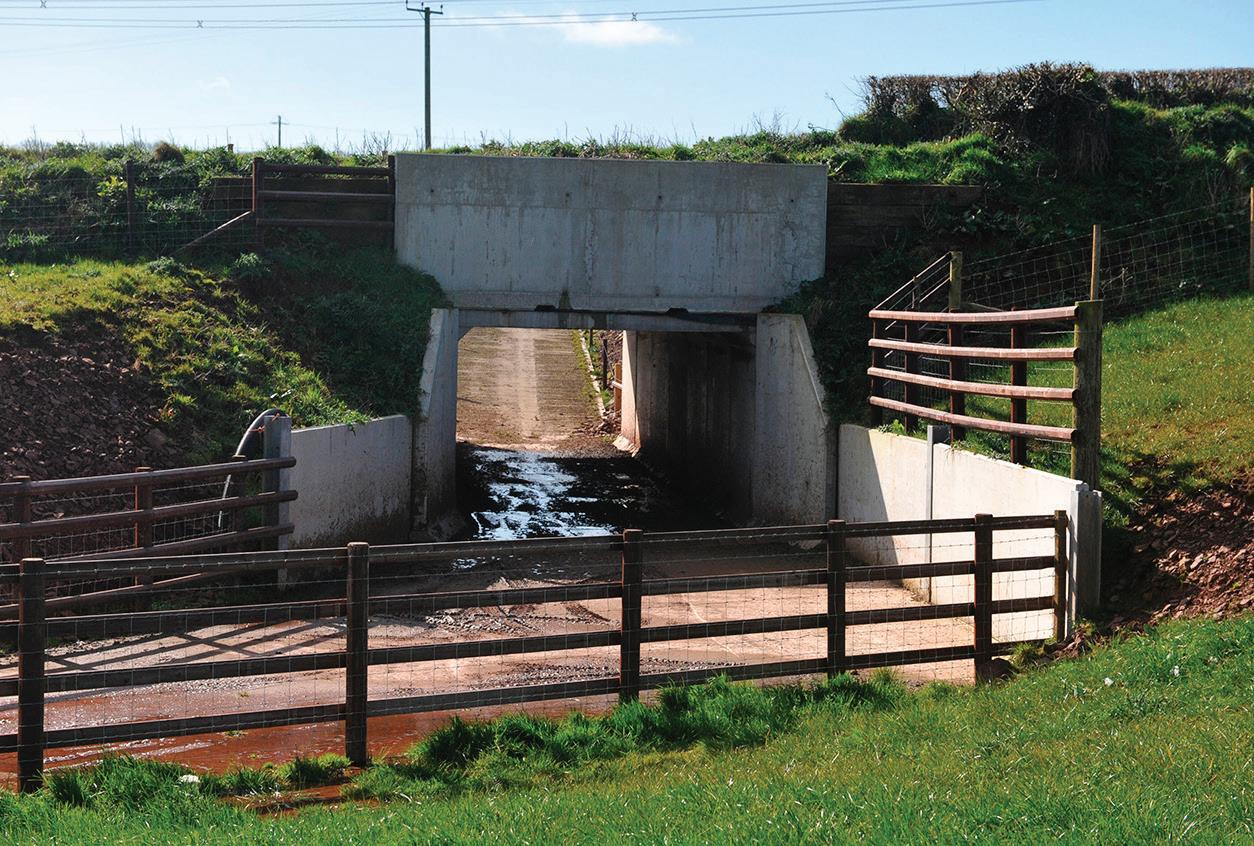

Installing a 54-point rotary in 2019 was a turning point, halving milking times to two-and-a-half hours and operated by one milker, but Richard credits the creation of an underpass in that same year, to connect two grazing blocks, as the investment that really transformed the business.

As the herd expanded there had been pressure on grazing, so 32ha (80 acres) of farmland that was separated from the farm’s main land block by a busy road was brought into the rotation.

Hostility

is meant the farm’s entire 121ha (300 acres) could be grazed, but walking the cows across the road took up to 15 minutes, resulting in hostility from motorists and stress for the family and their sta .

“Even though we stopped cow ow at intervals to let motorists through they were becoming less tolerant as cow numbers grew,’’ says Richard. ree people were needed to cross the cows which was a problem at weekends when there were fewer sta .

“We decided that if we were to continue running this system we needed to be more helpful to the public and also ease pressure on labour,’’ says Richard.

An underpass linking the two blocks solved the problem.

e family hired an architect and planning consultant with

good experience of designing farm underpasses. Securing the necessary permissions and road closures was straightforward. e job of constructing it was given to a local contractor who had built underpasses on other farms.

e whole project cost around £76,000 at 2019 prices. e underpass — 3m wide and 2.4m high — was built over 10 days in May 2019.

“Building the underpass is one of the best things we have ever done, the cows are very relaxed going out to grass and we now only need one person to move them to and from grazing,’’ says Richard.

DECEMBER 2023 10 ON FARM

The new underpass has transformed the business. Richard Morris

The 54-point rotary has halved milking times at Bowett Farm, Pembroke.

“We can manage the farm a lot better because we can graze the blocks when they need grazing, not when people are

available to cross the road.’’ Cow flow has improved and waiting times on concrete halved.

“We are seeing less lameness and higher utilisation of grass as a result,’’ says Richard. Cows, which are turned out to grass from February until November, enter grass covers of 2,800kg/ha (1,134kg/acre) dry matter.

During the grazing period, covers are measured weekly and the results are recorded on AgriNet software, giving Richard a wealth of information from which he can earmark the poorest yielding fields for reseeding each year.

Disturbance

Soil disturbance is kept to a minimum and fields are sprayed off and direct drilled, allowing the land to come back into production much more promptly compared to cultivation with a plough. Cost is a factor too. Richard calculates that net of seed and glyphosate costs, direct drilling

Farm facts

r162 hectares (400 acres) owned and 243ha (600 acres) rented

rTwice-a-day milking

r4.5% butterfat and 3.6% protein

r8-10% empty rate

rCows graze for 180-200 days

r12-hour grazing break

rMilk sold to Leprino Foods on a solids contract

rThree full-time workers

works out £75/ha (£30/acre).

Early establishment is key – he aims to drill the seed at the end of July, or early August at the latest, applying dirty water immediately afterwards using a trailing shoe.

He favours Aber HSG3 long term grazing mixture with clover.

Liquid ammonium nitrogen

Eliminate farm paperwork & make better decions with the UKs No.1 Farm Management app!

Simple medicine records.

Easy calf registration & animal movements.

Full breeding cycle management.

Milk records & insights to help drive cow performance.

Easily run repor ts for farm assurance.

New Grass & Crops service for land & fer tiliser management.

Map your farm & much much more...

S can me to download the FREE app!

DECEMBER 2023 11

ON FARM herdwatch.com

ON FARM

fertiliser is injected into the soil.

“In a dry spell it keeps the grass growing for longer because the fertiliser is much more accessible to the plant and it does not need moisture in the same way as prilled,’’ says Richard.

In total, 200kg/ha (80kg/ acre) of nitrogen is applied annually and the remainder is slurry, applied using low-emissions spreading equipment.

Three cuts of silage are taken annually, the first in the last week of April. This year it

analysed at 11.8ME and 15% protein. As well as maize, 121ha (300 acres) of winter corn is grown for crimping, with 5-6kg/ head/day fed in the winter.

“The more protein we have got available in the diet from homegrown sources, the less we rely on buying it in,’’ says Richard.

Rape meal protein has replaced soya in the total mixed ration (TMR).

Concentrates are fed at a rate of 1tonne/cow/year.

A succession of dry summers

resulted in some buffer feeding, but only during periods when grass availability was under pressure.

All the harvesting and slurry work is outsourced to contractors.

Dirty water is applied after each grazing and before and after silage cuts, while solids are applied to the cropping land.

Fields are soil-tested every four years. Soil pH across the farm ranges from 6.2–6.6 and P and K 2.5–3.

Calving is in an 11-week block from September 1, with 70% in the first four weeks.

All sexed semen is used on 300 animals for the first three weeks of insemination, with a 53% in-calf rate achieved in the last breeding season.

Genetics

Charolais genetics are used on the rest of the herd and Aberdeen-Angus on the heifers.

Calves are reared for six to eight weeks on calf milk replacer fed twice a day with ad-lib straw and cake also offered.

Weaning is at 42-48 days, or at 70kg when calves have doubled their birthweight.

Calves are introduced to a TMR of homegrown feed from four months old and turned out to grass in early April.

“As soon as they hit the grass, heifers do not see concentrates again until they hit the parlour at two years old,” says Richard.

Richard and Claire have a five-year-old daughter, Ava, so one day there could be a fourth generation of the Morris family farming at Bowett Farm.

With that next generation in mind, Richard says farming as sustainably as possible is important, not just for business performance, but also for the environment.

“Farmers are great ambassadors for looking after the environment and wildlife,” he says.

Bowett has 16ha (40 acres) of woodland which has been fenced off to provide wildlife habitat, and the farm’s carbon footprint for milk is ahead of the benchmark set by its milk buyer, Leprino.

The business has also invested in a 50kW wind turbine, a biomass boiler and 70kW solar array to reduce electricity costs, making it almost entirely self-sufficient in energy use.

DECEMBER 2023 12

It takes one milker two-and-a-half hours to milk the herd.

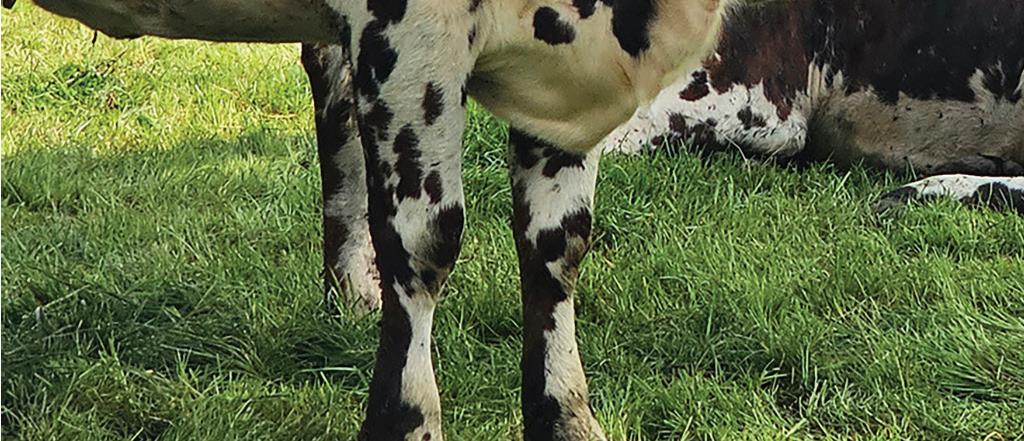

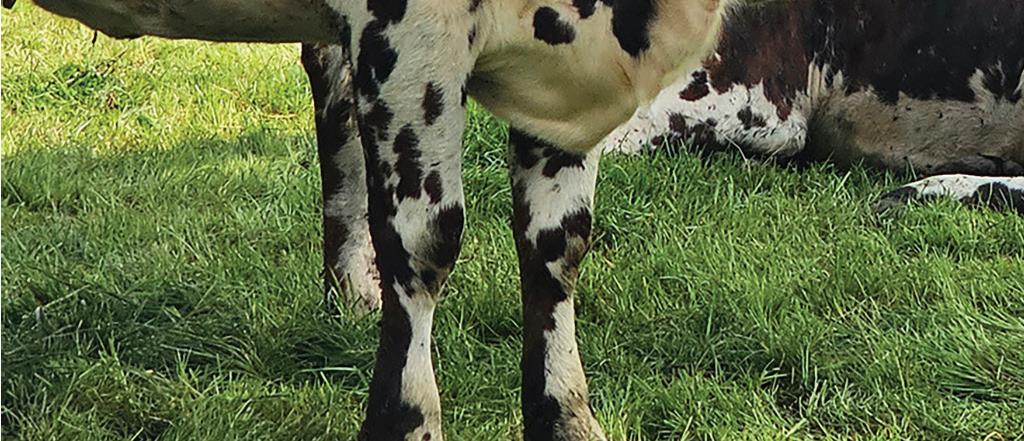

Sexed semen is used on most of the herd, alongside Charolais and Aberdeen-Angus genetics.

Contact us to nd out how we can help protect the long-term productivity of your herd or visit www.msd-animal-health-hub.co.uk Solving scour... one piece at a time* *Use as part of an integrated approach to calf disease prevention including colostrum management, hygiene and biosecurity. Reference: 1. APHA 2012-2019 Neonatal, Prewean, Postwean calf groups. https://www.gov.uk/government/statistics/veterinary-investigation-diagnosis-analysis-vida-report-2012 Bovilis® Rotavec® Corona contains inactivated rotavirus, coronavirus and E. coli strain CN7985, serotype O101:K99:F41. POM-VPS. Bovilis® Bovivac® S contains inactivated cells of Salmonella dublin, strain S342/70 and Salmonella typhimurium, strain S341/70. POM-V. Halocur® contains 0.5mg/ml halofuginone lactate in an aqueous excipient. POM-V Vecoxan® contains 2.5mg/ml diclazuril. POM-VPS. Further information is available from the respective SPC, datasheet or package leaflets. MSD Animal Health UK Limited. Registered office Walton Manor, Walton, Milton Keynes MK7 7AJ, UK. Registered in England & Wales no. 946942. Advice should be sought from the medicine prescriber. Use Medicines Responsibly. Copyright © 2022 Merck & Co., Inc., Rahway, NJ, USA and its affiliates. All rights reserved. UK-VCN-210800003 ONLY MSD Animal Health covers all the key calf scour pathogens in GB.1

DAIRYMatters ‘Britain is ripe for the next agricultural revolution’

Robert Kelly is senior vice-president for the Europe region of MSD Animal Health.

Ten billion. That is what we can expect the world population to reach by 2050, according to the United Nations. That is about 2bn more people than the number of people alive today.

It is also about 2bn more mouths to feed, which means the global agriculture sector must become much more productive in order to meet the expected 35% to 56% increase in global food demand over 2010 levels.

Yet the imperative to produce more food comes with the urgent need to protect our environment.

These are lofty goals. But they are attainable, especially with help from the many emerging agricultural technologies that are helping farmers produce more with less.

And British farmers are uniquely positioned to help lead the charge.

For a myriad of reasons, including food security,

Robert Kelly

Robert Kelly

the challenge of reducing the environmental impact of farming and the need to ensure the welfare of animals, the blistering rate of innovation in the agricultural sector is fantastic news for British farmers.

Britain’s agricultural sector is of vital importance to the economy, worth £120bn and employing nearly four million people.

Exports of agricultural products are worth tens of billions of pounds each year. The future of British agriculture is at a critical point. As the globe’s population grows and people increasingly desire more meat in their diets, the industry must evolve.

Consider the state of livestock farming in Britain. As of late 2020, farmers were raising more than 9m cattle and calves, 4.8m pigs, and 21.8m sheep and lambs.

Chicken production that year reached an estimated 1.7m tonnes. Those are impressive numbers for a relatively small country.

Consumption

The Organisation for Economic Cooperation and Development estimates that global meat consumption will increase 14% by 2030.

British farmers will need to produce more meat to keep pace with that demand — and they’ll have to do so in the face of several headwinds.

For starters, small and large farms alike are struggling to keep up with labour shortages that have kept livestock from reaching consumers.

Disease also poses a threat. To avoid sickness in their animals, livestock producers will need to focus more on preventive health practices.

Vaccinations are critical to preventing the spread of disease in livestock. Already, the UK’s National Office for Animal Health is leading the way with its expert-led vaccination guidelines encouraging robust vaccine uptake in livestock. Such preventive health approaches bring sustainability advantages too.

14 DECEMBER 2023

“ The tools we need to make it happen are here. Now, it’s just a matter of getting them into farmers’ hands

Data suggest that UK vaccination programmes for infectious bovine rhinotracheitis (IBR) reduce carbon emissions by 277 kilotonnes of carbon dioxide, the equivalent to removing about 60,000 cars from the road each year.

And several new technological approaches aid these proven tools and help British farmers boost production of meat and dairy in the face of these challenges and contributing to a greener future.

Livestock monitoring technologies can help farmers keep tabs on the health of their herds and identify potential diseases before they have a chance to spread to other animals. Take technologies that improve conception rates in dairy ca le.

One such tool uses a predictive algorithm to collect health and behaviour data, providing farmers with timely information on an animal’s reproductive status.

Not only does this technology allow farmers to improve milk production, it reduces reliance on reproductive medicines.

at way, farmers can deliver more calves while adhering to the highest animal welfare standards. ese technologies cannot replace proven tools such as vaccines, which are the cornerstone

of preventive health in livestock farming, or routine veterinary care.

But they can give farmers a leg up as they race to meet consumers’ increasing demand for protein while building a more sustainable future for the farmers and the communities in which they live.

An added bonus is that many of the creators of these innovative agricultural products are based right here in Britain.

Leader

Additional Government investment in technologies such as these could further help establish British agriculture as a global leader in the sector and support the local economy.

With the latest advancements in agriculture technology, there’s reason to believe that the farms of the future will be more e cient, sustainable, and productive than ever imagined.

ose advances also make for healthier animals living in more humane conditions.

Britain is ripe for the next agricultural revolution. e tools we need to make it happen are here. Now, it’s just a ma er of ge ing them into farmers’ hands.

15 DECEMBER 2023

Robert Kelly says technology can help improve efficiency, boost environmental efforts and help establish British agriculture as a global leader in the sector.

Research carried out at the University of Liverpool has highlighted the importance of sole thickness in the prevention of sole lesions, says Prof George Oikonomou. Wendy Short reports.

Sole depth critical for lameness prevention

Foot angle is generally considered one of the most relevant aspects of foot trimming, along with heel depth, says Prof George Oikonomou, a cattle health and welfare expert. However, an indepth study of 2,400 cows has indicated that sole depth may be more critical for lameness prevention, as cows with thick soles showed a marked reduction in hoof lesions.

“The cows were studied in detail at calving and in early and late lactation, with all cases of lameness and foot lesions noted and ultrasound scanning used to determine sole thickness,” says Prof Oikonomou.

“Angle was not statistically significant in relation to the

incidence of sole lesions, and the same was the case for heel depth, but sole thickness was influential.”

The guidelines for sole thickness are based on three categories: thin (-5mm), moderate (5 to 7mm) and thick (7mm+). The results of the research team’s project found sole lesions during early lactation in 52% of the cattle which fell into the thin sole category at calving, with a figure of 36% for cows with moderate sole depth. Only 26% of cows classified as having thick soles were diagnosed with lesions.

“It was clear that cows with the thickest soles gained the greatest protection from sole lesions. This raises questions about the general guidelines on foot trimming, which focus largely

on target measurements for foot angle and heel depth for lameness prevention,” says Prof Oikonomou.

“The current recommendation is to trim soles to the moderate category of sole thickness, but it seems that thicker soles should be the aim when feet are being trimmed.”

Cattle foot trimmers may feel under pressure to deliver an aesthetically pleasing result when they trim a cow’s feet, he adds.

He says: “If a claw is excessively

overgrown and the foot angle is too low, my advice is that cattle will benefit from foot trimming and sole thickness reduction, although it should be carried out with caution.

“However, in many cases, routine trimming could only involve modelling of the typical sole ulcer site and nothing else. More work is needed on the subject, but there is every indication that the original sole thickness could be left untouched in the toe triangle area.”

It was clear that cows with the thickest soles gained the greatest protection from sole lesions

PROF GEORGE OIKONOMOU

DECEMBER 2023 16 VET’S VIEW

Research suggests thicker soles should be the aim when feet are being trimmed.

The use of artificial intelligence to monitor herd lameness

JFurther research by Prof Oikonomou and his team was carried out in conjunction with technological development company CattleEye on a video surveillance system for automatic lameness detection, using a combination of cameras placed in cattle housing and linked to artificial intelligence software.

The results from the automated system were compared with visual evaluations by highly trained vets.

Prof Oikonomou says: “CattleEye has been installed on a number of UK farms and more than 35,000 mobility scores have been analysed. At present, in the identification of lame cows, it has equalled the performance of veterinarians

MONITORING TO FINE-TUNE THE MANAGEMENT OF HOUSED HERDS SPONSORED

The SenseHub herd monitoring system from MSD Animal Health can be tailored to meet the needs of every size and type of dairy farm, with the system’s Premium application plan enabling herd managers to closely monitor their cattle on a group-by-group basis.

Closely monitoring cattle on a group-by-group basis is useful when looking after housed animals as it enables the herd manager to assess how well each group is being managed in terms of fertility and reproduction, nutrition and day-to-day welfare.

with accreditation by the Register of Mobility Scorers. The system is most suited to herds which are milked in the parlour, as the best position for the camera is upon exit.

“The software will generate a list of cows whose mobility score has risen above a set level. They can be diverted into a separate area for further examination, which may lead to the necessity for foot trimming.

“On some farms, it may be more appropriate to leave cow mobility scoring to the human labour force, but CattleEye could be a more efficient option on large herds, for example.

“It may also help to detect early lameness cases; prompt treatment can help to minimise long-term damage and potentially reduce culling rates.”

By analysing the activity, rumination and behavioural patterns of cows assigned to the same management group and comparing this data to anticipated trends, SenseHub enables herd managers to assess if, how and when changes in housing conditions, feeding regime or day-to-day management have impacted the group’s productivity, feed intake and/or fertility.

Armed with a better understanding of how each group of animals (high and low yielders, dry cows and freshly calved cows) is faring, herd managers can then

make informed management decisions to fine-tune the group’s consistency of performance.

The data generated by SenseHub can also be shared quickly and easily with third parties so the farm’s vet and nutritionist can have a better understanding of how the group’s daily management regime is impacting on feed intake, rumination and the oestrus cycle.

This all adds up to make the management of multiple groups of housed animals easier, quicker and less stressful. It also takes the guesswork out of assessing what does and does not work for a specific group so every aspect of the herd’s management can be amended, adjusted and improved to reduce the impact of planned changes and unforeseen events on the herd’s productivity and fertility.

To find out how more about how SenseHub could help you to manage your herd please call the SenseHub team on 01207 529 000.

Alternatively, to send us an email, please contact us at allflexuk@msd.com

SenseHub is not intended to diagnose, treat, cure or prevent any disease in animals. For the diagnosis, treatment, cure or prevention of disease in animals, you should consult your veterinarian. The accuracy of the data collected and presented through this product is not intended to match that of medical devices or scientific measurement devices.

For more information, visit www.msd-animalhealth-hub.co.uk/farmers/livestock-monitoring

DECEMBER 2023 17

CONTENT

The growing gap between dairy farmers and society was one of the topics discussed at the recent LifeStart Calf Symposium organised by Trouw Nutrition and held at Nottingham University. Jonathan Wheeler reports.

Care for calves and keep consumers on side D

airy farmers must engage with their customers and be prepared to change their practices if they are to retain their ‘social license’ to farm, said Prof Nina Von Keyserlingk, director of the animal welfare

Prof Nina Von Keyserlingk

Prof Nina Von Keyserlingk

programme at the University of British Colombia.

Prof Von Keyserlingk said there could be huge benefits from bridging the gap between farmers and their customers, but farmers had to be honest and be prepared to explain awkward issues.

She said that could include issues like cow/calf separation – a topic the industry has generally been reluctant to address in the past.

“The public believe the animal has a reasonably good life, but society is asking questions far more frequently, and those questions are getting harder and harder to answer,” she said.

This, she said, was putting the industry’s ‘social license’ to operate under pressure.

And she added that failing to listen to which practices were contentious and not amending them when required, could result in the industry being subjected to legislation formulated

by people who lacked a proper understanding of the issues involved.

She said: “Animal rights campaigners are very good at taking the things we do not want to talk about and putting them on the front of newspapers. We need to think how we react.”

Trusted

She said she believed most of the public still trusted farmers to ensure their animals were healthy and productive, but they would also start to feel uncomfortable when they see or hear about things that do not resonate with their values.

To retain a social licence to farm, individual farmers should constantly re-examine their practices, even if they have used them for years, and be prepared to talk about them to the public and be prepared to change.

“Telling them they do not understand the industry will not work. The first thing farmers should do is listen to the

The average person does not expect us to change overnight, but they do expect us to get better every day

PROF NINA VON KEYSERLINGK

customer and try to understand their values.

“The public want to know you care about your animals, but also they want assurance that you are constantly trying to improve your standard of care.

“The average person does not expect us to change completely over-night, but they do expect us to get better every day.”

DECEMBER 2023 18 YOUNGSTOCK

Farmers need to re-examine practices such as cow and calf separation and be prepared to talk about them to the public said Prof Nina Von Keyserlingk.

Importance of cutting calf mortality

JDairy farmers have a great opportunity to improve the sector’s image if they can cut calf mortality said Dr David Renaud, of the University of Guelph, pointing out that data suggests some 7% of calves die in the first 48 hours of life and a further 7% before weaning.

“That’s 14% before 60 days of age, and reducing that toll represents a major opportunity to ensure we continue to have social buy-in to the industry,” he said.

Performance

He identified four key areas of management that can improve performance; colostrum, calving, environment and nutrition. He said colostrum was essential to successfully transfer positive immunity to the calf and calving should be as easy as possible.

“Difficult calvings are just setting you up for failure. The calf is much more likely to die and have to be treated for disease and face a multiplicity of risks before weaning.”

He said the calving cow should

be monitored at least every 30 minutes and intervention made if she failed to progress.

Correct feeding during pregnancy was also essential to ensure the cow was not over condition.

That feeding needed to be especially accurate with heifers, because it had to achieve a delicate balance between ensuring they were well enough grown to calve successfully while not getting them over condition.

The cow and calf environment was the next crucial factor, and should be clean, dry and well ventilated.

And he said correct nutrition was the final element. “High quality feed is essential, not only for all growth aspects but to support health a high line of nutrition is really important.”

YOUNGSTOCK

Dr David Renaud

DECEMBER 2023 19 Prefer to speak to a human? Give us a call on 01963 824448 "Thank you to Steve and his team for an excellent and very quick service and very competitive prices every time, thanks!” JOHNNY MILLER, LANCASHIRE LAMENESS WORKSHOPS October 22 £125 per person Steve Paul Limited The UK's leading cattle foot care company TRIMMING • TRAINING • SUPPLIES

next working day UK mainland & Ireland delivery ORDER BY 3PM when you spend £100 online excluding VAT Make your life easier with our Electric Farmer Crush Do ring us if you’d like more information! From farmer cattle crushes to wooden blocks, we have everything you need to keep your cows' feet healthy! Cowsfeet advert Farmers Guardian 200x130mm March 2020.indd 1 14/02/2020 09:40

Free

Challenging time for f

Plans are in place to take cow numbers up to 400, which will allow Israeli dairy farmer Yoel Strauss to work full-time on his family’s dairy farm in the future. Chris McCullough reports.

When Yoel

Strauss completed his military service in Israel back in 2007, he could not wait to return home and become more involved in dairy farming.

Yoel is the third generation to work on the family farm at the moshav Sde Ilan, following in the footsteps of his dad, Ariye, and late grandfather, Yitzhak Strauss, known as Itzu. A er surviving the Holocaust, Itzu relocated from his native Hungary to Israel, and started the farm in 1952. He was allocated three milking cows, chickens and some land by the Jewish agency.

Today, the farm runs a herd of 200 Holstein cows plus 150 replacement heifers. Yoel works part-time on the farm alongside his dad and brother Yackob, but hopes to become full-time someday and keep the family tradition alive.

For the time being, Yoel

Farm facts

rThe farm is five hectares (12.4 acres), including 1ha (2.5 acres) of farm shades and buildings

rBull calves are sold at 60 days old to a nearby farmer for rearing

rCows are milked in a 12:12 herringbone parlour with Afimilk equipment, which was updated in 2002 and stands in a shed built in the early 1980s

Editor’s note

JThe team at Dairy

Farmer recognise the unimaginable challenges that the people of Israel are currently facing, and the Israeli people and farmers are in our thoughts.

works as a ruminant nutritionist at Ambar feed mill, and also works occasionally with O er Langer, the owner of the Israeli dairy school.

Yoel says: “My dad worked with grandad from childhood, combining the farm’s work with managing a regional feed centre, producing total mixed ration [TMR] for cows and sheep.

“I have worked at the farm all of my life, and got more involved a er nishing army service in 2007.

“Currently, my dad manages the farm full-time, with my younger brother and I assisting him. We also hire two employees from ailand.”

Israel operates a quota system for its dairy industry, and Yoel’s farm has an allocation of 2.16 million litres per year.

Yoel says: “We try to produce most of our milk during the summer months from May to October, because if we overproduce in the winter season, we are ned.

“Our cows are milked three times per day yielding 12,000kg per cow, corrected to 305 days, at 3.8% bu erfat and 3.35% protein.”

In terms of breeding, Yoel uses Holstein semen on the

majority of the herd, with about 10% of semen used imported from the USA.

“For the low genetic cows, about 5% of the herd, we use beef semen, usually Belgian Blue,” says Yoel.

“For some of the heifers, we are using sexed semen, but on a relatively small scale.”

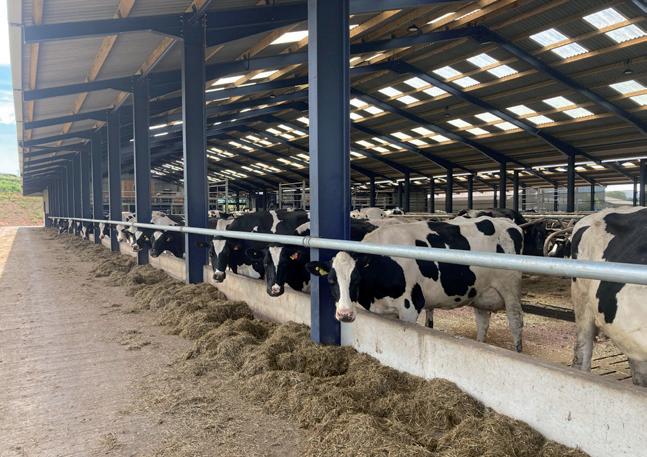

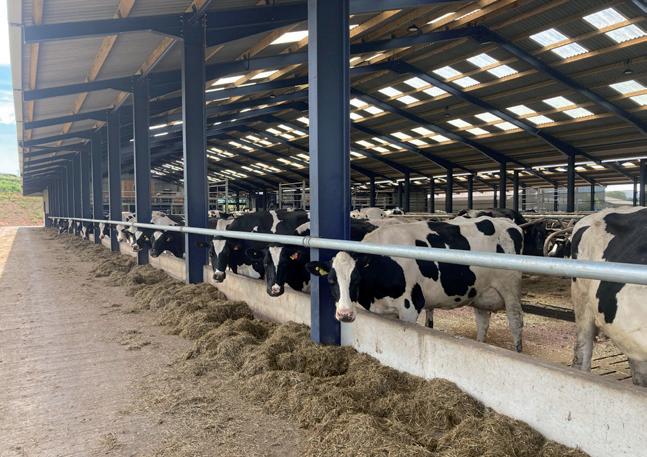

e milking herd is split into two groups, with the rst lactation heifers kept in one group and the rest of the herd in the other. All cows are kept indoors all year round and fed a TMR.

e milk is sold to Tara, the second biggest milk factory in Israel. e most recent milk price was 2.4 Israeli New Shekel (52ppl).

Feed

Yoel says: “All our feed comes from a local feed mill owned by one of the village dairy farmers. It comes pre-mixed and we use four di erent TMRs; for the milking cows, growing heifers, young heifers aged four to nine months, and dry cows.

“Calves receive an 18% protein pellet from Ambar feed mill. For the cows and heifers close to calving, we add 3kg of 18% pellet on top of their TMR.”

Yoel likes to keep in touch with the latest technology, and last year he purchased an Urban pasteuriser wagon to feed

DECEMBER 2023 20 WORLD DAIRYING ISRAEL

Yoel Strauss (centre) with dad Ariye (left) and brother Yackob (right).

Cows are kept indoors all year round and are fed a TMR.

amily farm

We try to produce most of our milk during the summer months from May to October

YOEL STRAUSS

milk to the young calves.

As Israel has periods of relatively hot weather, most of the farm’s reinvestment goes into cooling systems and fans to prevent heat stress and other associated problems.

Yoel is hopeful that dairy farming in Israel has a good future, but there are some challenges to overcome if his family farm is to succeed.

Future plans

He says: “Our future plans include expanding the farm as we have room for 400 milking cows

and 250 replacement heifers.

“Hopefully, the milk industry will stay pro table in the future, as we would like to increase production by 100,000 litres each year. By expanding the herd, we hope to build the business to a stage where my brother and I can work full-time at home.

Challenges

“Dairy farmers in Israel do have some challenges ahead. Our two biggest problems over the last decade have been the import of dairy products, including raw milk, from east European countries, and also the issue of manure handling.

“Regulations are becoming harder and harder every year to comply with, and we need to gure out what to do with all the slurry.

“For now, we store all our cow manure in big bunks, and spread it on the elds at springtime.

“As we only have a few hectares of our own land, we also deliver manure to a few other farmers close by who grow crops and vegetables.”

Calf Health

Dairy farmers are being advised against ignoring the important role trace minerals have in achieving the best possible outcome from their cattle vaccination programmes.

Trace minerals are integral to immune function, whether that be enabling an effective response to natural disease challenges or to vaccination.

Deficiency in trace minerals can limit the immune system’s ability to respond to vaccination.

Stressors, such as vaccination itself or transport and, for calves, weaning, can exacerbate imbalances, which can also lead to a reduced response.

A 2012 study¹ demonstrated how vaccination altered the trace mineral status of beef steers, when 14 days after vaccination they experienced decreased serum trace mineral concentrations.

Even when trace mineral status is adequate, mounting an immune response to a vaccine can deplete stores.

Therefore, when farmers are investing in vaccination programmes to protect their cattle from disease, it makes sound economic sense to ensure those animals are not deficient in the trace minerals they need to maximise the response.

Trace mineral supplementation has

been identified as having a positive effect on immune function, with several studies highlighting the benefits of strategic injectable trace mineral supplementation in conjunction with vaccination.

The findings of one such study in 2014² showed that injectable trace minerals may be beneficial to humoral immune response in cattle.

For farmers considering using an injectable, Multimin™ contains zinc, copper, manganese and selenium and is designed to correct clinical or subclinical deficiencies of these four trace minerals, deficiencies which can arise during critical phases of the production life cycle.

It provides a fast, effective and reliable way to boost essential trace minerals ahead of times of high demand, such as breeding and calving.

Multimin™ acts rapidly, reaching peak levels in the blood after only eight to 10 hours and the liver after 24 hours.

As Multimin™ is a prescription-only medicine, it is recommended farmers talk to their vet about how and when to introduce it.

For more information, scan the QR code or go to farmersguardian.com/virbac-dairy-bitesize

DECEMBER 2023 21 ISRAEL WORLD DAIRYING

A FOCUSED LOOK AT VACCINATION PROTOCOLS SPONSORED CONTENT MultiminTM solution for injection for cattle contains Zinc (60mg), Copper (15mg), Manganese (10mg) and Selenium (5mg). Further information is available from the SPC or by contacting Virbac Ltd. Unit 16 Woolpit Business Park, Windmill Avenue, Woolpit, Bury St. Edmunds, Suffolk IP30 9UP. Tel: +44 (0) 1359 243243 Email enquiries@virbac.co.uk. POM-V - Advice on the use of this medicine or alternatives must be sought from your veterinary surgeon. Use medicines responsibly www.noah.co.uk/responsibly. References: 1. Arthington, J.D. and Havenga, L.J. (2012). Effect of injectable trace minerals on the humoral immune response to multivalent vaccine administration in beef calves. Journal of Animal Science. 90(6):1966-1971. 2. Arthington, J.D., Moriel, P., Martins, P.G.M.A., Lamb, G.C. and Havenga, L.J. (2014). Effects of trace mineral injections on measures of performance and trace mineral status of pre- and post-weaned beef calves. Journal of Animal Science. 92:6:2630-2640.

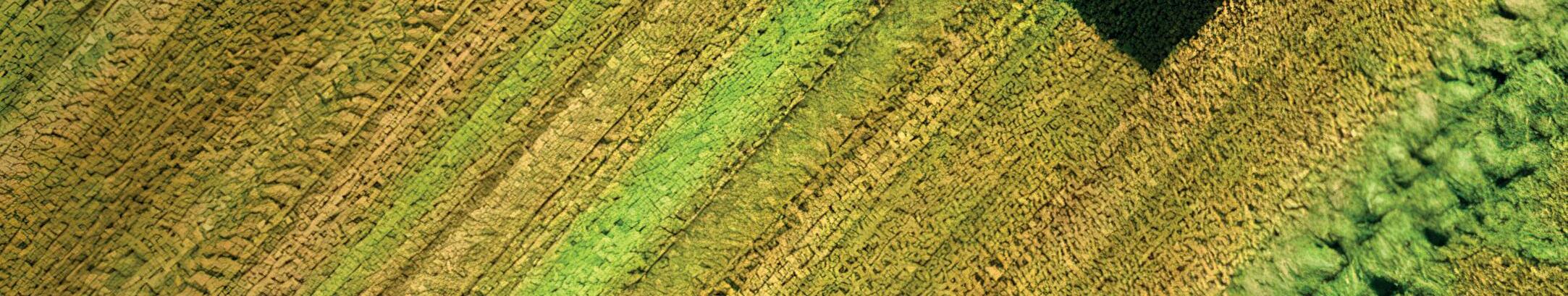

Focusing on naturally occurring sulphur sources could have a major role to play in optimising nitrogen utilisation in grassland and deliver significant productivity, carbon and environmental benefits in line with the new Sustainable Farming Incentive. Dairy Farmer reports.

Grassland nutrition for a sustainable future

However you look at it, the latest Sustainable Farming Incentive (SFI) challenges dairy farmers to be er manage their use of nitrogen, look more at nitrogen- xing leguminous species in leys and use organic sources more e ectively, says Allison Arden of nutrient planning specialists Navigate Eco Solutions.

Ms Arden says: “It is all about optimising N applications from all sources, encouraging growers to be er target nutrient inputs to match grass demand and ensuring farmers get as much production out of every kg supplied as possible.

“It is also promoting a wider awareness of best practice for nutrient use in grassland while incentivising use of N- xing legumes in leys, testing of FYM and slurry before application and working from a comprehensive nutrient plan.

“What it also covers is making sure as much of the available N in the soil as possible nds its way into

plants thereby reducing the risk of excesses in the soil becoming vulnerable to leaching or ammonia loss to the air.”

Improving nitrogen use eciency (NUE) is one of the biggest challenges facing dairy producers currently. It has signi cant e ects on the bo om line of production as well as the marketability of milk as buyers look to reduce the carbon footprint of their products, she says.

“We have to look at the most

Numerous trials have shown 20% lifts in forage yields when appropriate levels of sulphur are used ALLISON ARDEN

appropriate ways of increasing NUE, and while this is not always easy in livestock systems, one of the key factors o en overlooked by dairy farmers is the role of sulphur in the NUE equation.

Sulphur

“Levels of atmospheric sulphur have been falling rapidly since the industrial clean-up some years ago, yet it plays an essential role in the ability of many crops, grass included, to

recover and utilise N e ciently,” says Ms Arden.

“Numerous trials have consistently shown 20% li s in forage yields when appropriate levels of sulphur are used to drive NUE, with a corresponding increase in grass quality too.

“Sulphur is also essential in the production of speci c amino acids and, if absent, plants cannot use N as e ectively and manufacture all the necessary protein e ciently.

“At a time when crude proteins in forage have been falling and the cost of bought-in protein supplements have been rising, this is something few milk producers can a ord to ignore.

“It is also true that N- xing plants, such as clover and other legumes, are disadvantaged if sulphur supply is reduced.

“It is a necessary element for N xation and, if in short supply, de ciency symptoms can quickly

Continues over the page...

DECEMBER 2023 22 BREEDING

Improving nitrogen use efficiency (NUE) is one of the biggest challenges facing dairy producers.

Dry Silage

KW liquids and moist feed can encourage intakes and reduce sorting.

Low Protein

KW have a wide variety of dry, moist and liquid protein feeds to increase ration protein content.

Wet Silage

These can be acidic so neutralise fermentation acids with KW rumen buffers and KW Soda Wheat.

All of our feed solutions and our tailor-made blends can support you in getting the most out of your forage.

Call today on 01977 686262 or contact your sales rep for information.

High Protein

Complement the abundance of rumen degradable protein with KW NovaPro and SoyPass.

more

kwfeeds.co.uk

Learn

at

® Variable forage quality? We o er all the products required to maximise herd performance from forage

BREEDING

develop as the grasses starve the legumes of any availability.”

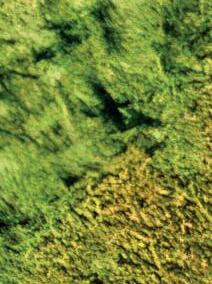

Sco Garne , head of agronomy for crop nutrition specialist ICL, says environmentally friendly sources of sulphur will have an increasingly important role to play under the new SFI.

“NUM2 pays £102 per hectare for improving grassland by growing legumes from spring until early autumn, while growers will receive £151/ha under LIG1 and LIG2 to include owering grasses and wild owers in grass leys during the summer months,” he says.

Nitrogen focus

“All such schemes require that nutrients are managed e ectively, with a particular focus on optimising the use of N, so one of the most e ective ways to achieve this is to use sulphur to improve the NUE of all the N resources you have available.

“ ese could be from applied N, or N xed by legumes or that contained within FYM and slurries.”

One of the issues with ge ing sulphur into grassland is that it usually comes with N a ached, as is the case with the popular ammonium sulphate (AS) fertilisers, Mr Garne points out.

He says: “Having your sulphur locked in with large quantities of N might not be what you want when you are trying to manage your use of N in line with SFI.

“Decoupling N from sulphur could be a good start in being able to make more use of this vital element.

“ ere are, therefore, some compelling reasons why the naturally occurring mineral polysulphate, mined from under the North Sea, could be a be er source of sulphur for grassland than the traditional AS-based fertilisers in the future.

“For a start, it contains no N at all, with a composition of 48% SO3, 14% K2O, 17% CaO and 6% MgO.

“ is high concentration of sulphur makes it ideal for

The naturally occurring mineral polysulphate is mined from under the North Sea.

maximising the N produced from the growing use of legumes in grass mixes encouraged by SFI and reducing the overall dependency on inorganic fertilisers.

“Furthermore, Rothamsted Research has estimated the separation of N and sulphur could decrease ammonia emissions from sulphur fertiliser applications by 90%.

“ is is the result of growers being able to choose low-emission N fertilisers to apply alongside the polyhalite mineral, rather than relying solely on traditional combined N sulphur products.

Polysulphate [...] could be a better source of sulphur for grassland than [...] AS-based fertilisers

SCOTT GARNETT

“Another key advantage is its prolonged release characteristics that deliver the sulphur and other nutrients over a period of eight to 10 weeks, so these are constantly available to drive NUE throughout the growing season.”

It also means N and other key nutrients are utilised more fully so they are not le in the soil for long periods where they are vulnerable to leaching, he explains.

“ is is also in contrast to stan-

dard fertiliser practice, where large amounts of available sulphur are usually applied to crops when they are not really in a position to utilise them fully.

“Extensive trials have, in fact, shown this sustained nutrient supply and ability to improve NUE can deliver an increase in grass yields of 29%, together with an increase in dry ma er of over 10%.

Protein

“ e additional sulphur provided also signi cantly improved the protein content of the grass. All in all these improvements lead to denser, heavier, more nutrient-rich forage which, combined with the increased palatability and digestibility from a li in sugars of over 9%, produces healthier, more productive cows for the same, or potentially less, cost.”

“As a natural mineral requiring only minimal processing, polysulphate also has the lowest carbon footprint of any fertiliser on the market and is approved for use in organic grassland systems too,” says Mr Garne .

Environmentally friendly sources of sulphur will have an increasingly important role to play under the new SFI, says Scott Garnett, head of agronomy for ICL.

DECEMBER 2023 24

YOUR 2023 WINNERS ANNOUNCED

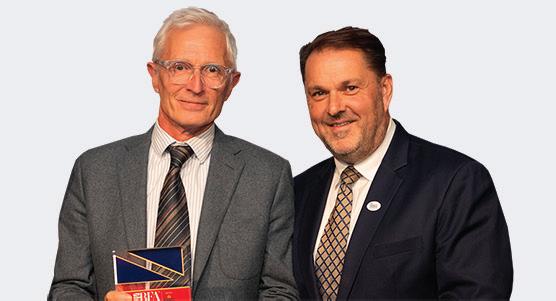

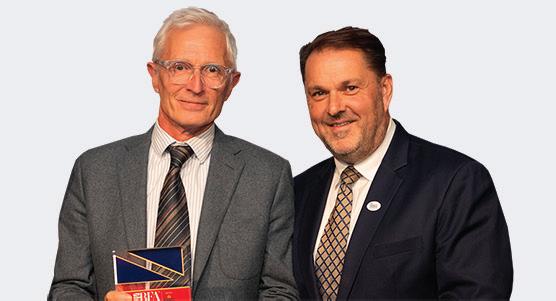

The British Farming Awards has revealed this year’s winners at the annual event, held in October at the Vox, Birmingham.

The farming industry came together in full force last Thursday (October 19) for the British Farming Awards, celebrating the in-

spiring achievements of individuals and partnerships. Sponsored by Morrisons, the event was attended by more than 750 farmers and industry professionals from across the UK.

AGRI-TECH INNOVATOR OF THE YEAR

SPONSORED BY LOW CARBON AGRICULTURE

James Duke, ADF Milking, Sussex

XA new technology based on ‘intelligent venting’, developed by ADF Milking, is improving dairy cow teat health and speeding up milking times on UK farms.

High mouthpiece chamber vacuum levels, caused by inconsistency in the size of cow teats, causes external and internal teat swelling, restricting the capacity of the teat canal, slowing down milk flow and preventing full milk-out.

The solution is called InVent, which detects when the vacuum level rises above a threshold in kilopascals.

When that point is crossed, a valve in the liner mouthpiece chamber opens, injecting clean, food-grade air into the mouthpiece and reducing vacuum,

resulting in each liner being the perfect fit on every teat during milking. Controlling vacuum levels on each teat individually results in calmer cows, less teat damage, higher yields and faster milk letdown, says founder James Duke.

XOn winning: “It is wonderful to win the award, but we could not have done it without a dedicated team at ADF.”

GRASSLAND FARMER OF THE YEAR

SPONSORED BY GERMINAL

Chris and Bella Mossman, Mossman Farming, Ceredigion

XTough times pushed Chris Mossman to transform his farming system, starting by improving soil health and diversifying his grassland.

The first 11 hectares (27 acres) of multi-species swards were sown in 2018 and, since then, all reseeds have been diverse swards with both cutting and grazing mixtures used. There is also a nitrogen reduction plan in place.

Having traditionally used 300kg/ha (121kg/acre) by 2022, this had reduced to 126kg/ha (51kg/ acre) with the eventual target being 50kg/ha (20kg/acre), with none used on the multispecies swards and the aim of producing 12 tonnes of dry matter (DM) per ha (4.8t DM/acre)

in the 2023 season. Chris has been joined in the business by his youngest daughter Bella and, with the changes already implemented, her ideas for diversification and beginning to invest in renewables, the family are confident they will be farming their improved land for generations to come.

XOn winning: “Entering the awards has made us think about the wider picture.”

The event celebrated pioneering farmers across all sectors who were leading in areas of technology, science, food production and sustainability.

Alongside farming’s core sectors – in-

cluding dairy, beef, sheep and arable –there was also recognition for students, family farms and new entrants, and the huge number of diversifications which are now so crucial to many businesses.

DAIRY FARMER OF THE YEAR

SPONSORED BY KW FEEDS

Patrick Morris-Eyton, Morris-Eyton and Son, Cumbria

XAnimal health and welfare, efficiency and sustainability are a key focus for Patrick Morris-Eyton.

Keen to create an optimum environment for cows to fulfil their potential, he invested into a new, 54-point rotary parlour, while increasing numbers from 240 to 420 followers.

A move to three times-a-day milking has increased milk yields with average annual production per cow of 11,800 litres at 4.4% butterfat and 3.4% protein.

Alongside this, there have been significant improvements in pregnancy rates, which have increased from 20% to 31%, and mastitis cases have reduced from 30 per 100 to eight.

As an Arla supplier, Patrick has been involved with its Climate Check project, improving efficiency and productivity on-farm, utilising resources and reducing waste across the business.

XOn winning: “We try to do the best we can on our farm and it is absolutely amazing for our team to be recognised. The agricultural industry needs to keep moving forwards.”

NEW ENTRANT: AGAINST THE ODDS

SPONSORED BY MASSEY FERGUSON

Alex Crawley, Grazing Management, Gloucestershire

XAlex is a war veteran who proudly served with the Armed Forces in Afghanistan. Following his diagnosis with post-traumatic stress disorder (PTSD) in 2017, he took a voluntary placement working with dairy cattle, which he said helped ‘soothe’ his PTSD.

When Alex won a Clyde-Higgs scholarship via the University of Warwickshire, it was a dream come true. His studies culminated in working numerous jobs, before settling on a large-scale beef and sheep farm upon graduation. Alex managed to secure 2.4 hectares (six acres) of rough pasture and launched Grazing Management in 2020, with one of his main focuses being contract conservation grazing

To watch all of the interviews and for more information on the evening and finalists, go to

to restore wildflower meadows, peatlands and heathlands.

XOn winning: “Whether you work as a team or on your own, we get on with it to achieve the end goal.”

britishfarmingawards.co.uk Vox Conference Centre, Birmingham Thursday, October 19, 2023 DECEMBER 2023 26

britishfarmingawards.co.uk

James Duke (left) with Nick Ornstein, managing director of Agriconnect.

Patrick Morris-Eyton (right) with Glenn Warrilow, sales specialist of KW Alternative Feeds.

Bella Mossman with Harley BrownKeech, area sales manager of Germinal.

Left to right: Emily and Alex Crawley, with Lindsay Haddon, advertising and sales promotion manager of Massey Ferguson.

2023 WINNERS AND RUNNERS-UP

FAMILY FARMING BUSINESS OF THE YEAR

SPONSORED BY GOODYEAR FARM TIRES

The Brown family, Bluebell Dairy, Derbyshire

XBluebell Dairy has grown from milking a small herd of cows into a thriving family farm business and micro-dairy producing award-winning artisan ice cream.

Geoff Brown, his wife Rosemary, their son Oliver and his partner Ella have worked together to grow the business, which has not been without its challenges.

To adapt during the Covid-19 pandemic, the family had to think of innovative ways to support the farm while it was closed to the public.

For example, a ‘click and collect’ milk delivery service was set up overnight,

delivering home-produced milk, ice creams and local produce to more than 650 households. They said their key to success has been the high level of hard work, determination and input from each family member involved in the farm business.

The family are incredibly passionate about nurturing the environment, participating in Countryside Stewardship.

XOn winning: “This year marks our 15th anniversary and so winning this award is particularly important and emotional and what a wonderful memory to be able to say we had.”

All of this year’s winners take to

XAgricultural Student of the Year (Sponsored by AGCO)

Gold: Naomi Ramsay, Scotland’s Rural College; Silver: Isla Soutter, Harper Adams University

XAgri-Tech Innovator of the Year (Sponsored by Low Carbon Agriculture)

Gold: James Duke, A.D.F. Milking, Sussex; Silver: Dr Vincent Martinez, Dyneval, Midlothian

XArable Innovator of the Year (Sponsored by Kramp)

Gold: Ed Horton, S.S Horton and Sons, Gloucestershire; Silver: Colin Chappell, Chappell Farms, Northamptonshire

XBeef Innovator of the Year

(Sponsored by ABP Food Group)

Gold: Greg and Rowan Pickstock, G. and D. Pickstock, Powys; Silver: Helen Parr and Daniel Fabb, D.R.A. Contractors, Cambridgeshire

XContractor of the Year (Sponsored by Kuhn)

Gold: Kevin Heywood, A.J. Heywood and Sons, Cornwall; Silver: James Dodson, VineWorks, Sussex

XDairy Innovator of the Year

(Sponsored by KW Feeds)

Gold: Patrick Morris-Eyton, Morris-Eyton and Son, Cumbria; Silver: Richard Beck, J.S. and S.M. Beck and Son, Cheshire

XDigital Innovator of the Year

(Sponsored by Volac)

Gold: Matt Slack, E.V. Slack and Sons

Master Butchers, Yorkshire; Silver: Ally Hunter-Blair, Wye Farm, Herefordshire

XDiversification Innovator of the Year (Small to Medium) Sponsored by NFU

Mutual

Gold: Amy Bateman, Amy Bateman

Photography, Cumbria; Silver: Holly Brooks, Popell Barns Mobile Farm, Hampshire

XDiversification Innovator of the Year (Large) Sponsored by Daisy Vending

Gold: David Rawlings, D.A. and S. Rawlings, Yorkshire; Silver: Chris, Sue

and Thomas Heseltine, J.G.E. Heseltine and Son, Yorkshire

XFamily Farming Business of the Year (Sponsored by Goodyear Farm Tires)

Gold: The Brown Family, Bluebell Dairy, Derbyshire; Silver: The Pemberton family, Pemberton’s Farm Shop and Dairies, Lancashire

XFarming Hero: Flying the Flag for British Agriculture (Sponsored by Eternit)

The Nicholson family, Cannon Hall Farm, Yorkshire

XFarm Worker of the Year (Sponsored by Isuzu UK)

Gold: Holly Atkinson, Carswell Farms, Devon; Silver: Jack Marlow, Moulton College, Northamptonshire

XGrassland Farmer of the Year (Sponsored by Germinal)

Gold: Chris and Bella Mossman, Mossman Farming, Ceredigion; Silver: John Fare, Fare Farms, Lancashire

XNew Entrant Award: Against the Odds (Sponsored by Massey Ferguson)

Gold: Alex and Emily Crawley, Grazing Management, Gloucestershire;

Silver: Adam and Lucy Johnstone, J.B. Countryside Services, Hampshire

XOutstanding Contribution to British Agriculture (Sponsored by NSF)

George Dunn, Chief Executive, Tenant Farmers Association

XSheep Farmer of the Year (Sponsored by SAI Global)

Gold: Robert and Becca Rennie, Rennie Livestock, Roxburghshire; Silver: Matthew and David Roberts, D.W. and A.Roberts and Son, Flintshire

XSpecial Recognition Award: Lifetime Achievement (Sponsored by Farmers Guardian) Olive Clarke, OBE

XSustainability Farmer of the Year (Sponsored by Lloyds)

Gold: David Shelton, Shoby Priory Agricultural, Leicestershire; Silver: Martin, Juliette and Matt Lines, M.T. Lines and Partners, Cambridgeshire

27 DECEMBER 2023