for drupa 2024.

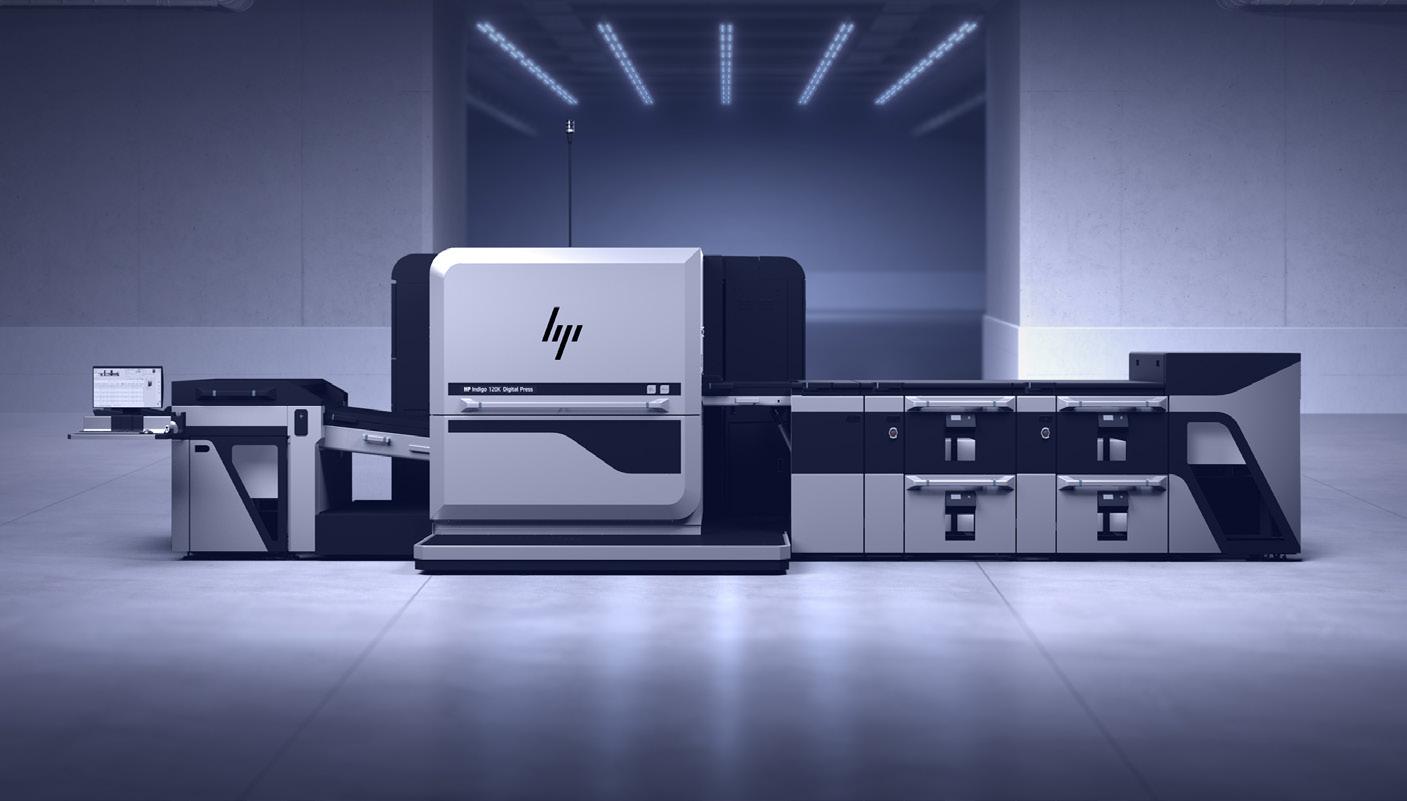

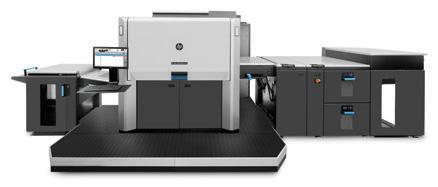

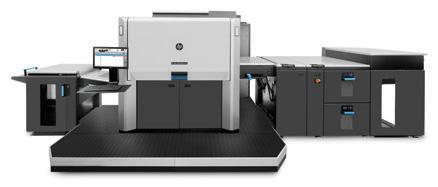

At the recent Dscoop Edge Indy event, HP introduced two new generation B2 presses, the HP Indigo 120K Digital Press and the HP Indigo 18K Digital Press, as well as the HP Indigo 7K Secure Digital Press, and innovations across the intelligent production floor.

Currie Group supplies HP Indigo solutions across New Zealand and Australia. Craig Paul, country manager for Currie Group New Zealand, says, “HP Indigo is relentless in its pursuit of innovation and continuous improvement. This pre-drupa announcement shows a commitment to providing HP Indigo customers with new ways to grow their business with advancements in technology and outside of the box thinking.”

“The HP Indigo 120K Digital Press offers best-in-class productivity, while the HP Indigo 18K Digital Press handles the widest range of print applications ever produced with a single B2 digital press. The HP Indigo 7K Secure Digital Press shows an innovative approach to digital security printing.

“We look forward to showing you these exciting solutions when you visit the stand at drupa 2024.”

HP is also rolling out the commercial availability of the HP Indigo V12 Digital Press after successful beta site installations.

In addition, HP has expanded its platform for monitoring and managing presses and workflow with enhancements to PrintOS; HP Indigo PQ Maestro; Autonomous Mobile Robots (AMRs) and advanced print modes. Haim Levit, senior vice president and division president of HP Industrial Print, says, “We are committed to unlocking profitable and sustainable growth for our customers. Our LEP, LEPx, and inkjet technologies have improved in terms of quality, versatility, productivity, sustainability, and economics and our commitment and significant investment into continuous innovation has enabled over 8,000 printers and converters to expand their businesses and grow sustainably.

“HP has been a digital transformation leader for more than 30 years, and our digital printing technology has established the gold standard in commercial print and labels and packaging production.”

HP is defining the industry approach to automation through AI and robotics, launching a comprehensive print production automation ecosystem.

Based on internal studies, customers who leverage automated processes achieve 51 per cent higher volume and 80 per cent more jobs per press compared to less automated customers. These customers also grow at an average of 27 per cent

year-over-year which is higher than the industry average. HP’s holistic approach combines effective presses with intelligent features from job submission to delivery.

Specific efficiency innovations include:

PrintOS Production Beat Support –for analogue printing and finishing equipment, to enable customers to monitor their entire production floor, not only HP presses, capturing data in real time from analogue equipment and digitalizing the entire production.

HP Indigo PQ Maestro – offering an intelligent start-of-day wizard that optimizes press performance.

Preflight – an AI-based decision-making tool that automatically predicts the suitability of the best-fit print mode by learning customers preferences.

AAA 2.0 (Auto Alert Agent) advanced – a machine-learning algorithm that increases print productivity with zero human intervention.

As the industry moves towards a more productive production floor, HP has introduced Autonomous Mobile Robots (AMRs) in collaboration with MoviĜo Robotics to automate media transfer, saving up to two hours per day, per press.

Developed in collaboration with printers and converters, HP has launched the HP Sustainability Amplifier programme enabling printers and converters to accelerate their sustainability agenda and offer more sustainable prints. The programme, in collaboration with HP’s Sustainable Impact Strategy, aligns with HP’s commitment to renewable energy and reducing CO2 emissions.

a new

HP says the HP Indigo 120K Digital Press sets a new standard for high-volume production and automation, while enabling printers to move jobs from analogue to digital more intuitively and economically to meet demanding customer needs.

Optimising production floors by combining analogue and digital technologies, the HP Indigo 120K reduces human touchpoints and enables multi-press operation by a single operator. It delivers print speeds of 6,000 sheets per hour with up to 90 per cent press availability. Designed to deliver tens of thousands of B2 sheets every day, it produces over two million B2 sheets per month.

The ECO print mode reduces the press’s carbon footprint by 11 per cent, supporting sustainability goals. It also reduces click price by intelligently creating a vivid image while using less ink.

HP Indigo 120K Digital Press features:

• Prints at 6,000 sheets per hour 3/02 and 4,500 sheets per hour 4/0.

• Generates over two million B2 sheets per month.

• True digital continuous operation that enables non-stop paper feeding; non-stop colour measurement; and continuous stacking.

for

• Multiple input and output paper sources allow a seamless and automated switchover process for jobs and paper on-the-fly.

• Reliable and predictable paper transport uses a robust gripper-togripper paper feed technology.

• Designed with durable parts for easy service handling

• Highly automated production with reduced press attendance allows multipress operation by a single operator.

• AI-based technology for image quality troubleshooting and diagnostics.

• High uptime and low service costs with AI-based predictive press care and maintenance capabilities.

• Increase press availability and end-toend line efficiencies and reduce paper waste with advanced and automated AI-based inspection system.

• Reduce labour and turnaround time with Auto-Pallet Replacement (APR) at the delivery.

• Automated colour control system eliminates the need for manual colour tracking.

• Enable quick operator onboarding with intuitive and straightforward user interface innovations.

• The widest range of both coated and uncoated substrates.

• HD Imaging option delivers a smooth and sharp image with high LPI screens.

• Lower cost and environmental impact using the digital printing process to

eliminate aluminium consumption, reduce paper waste, and shorten and makeready time.

• HP Indigo Enhanced Productivity Mode (EPM) boosts productivity by 33 per cent; reduces operating cost per sheet; and saves 25 per cent of energy consumption per sheet while printing.

• The new ECO four-colour print mode option helps reduce carbon footprint by 11 per cent.

• HP Indigo’s Recycling Imaging Oil (RIO) technology reuses imaging oil and reduces up to 35 per cent of waste.

The HP Indigo 18K Digital Press takes versatility, efficiency, and user-friendliness to new heights. It handles the widest range of print applications ever produced with a single B2 digital press, accommodating diverse substrates and job types seamlessly.

Advanced AI features like auto recovery and proactive alerts enhance productivity and simplify the entire production process, achieving up to 80 per cent press availability within a single shift. Aligning with HP’s sustainability commitment, the Indigo 18K supports Enhanced Productivity Mode (EPM), delivering 24 per cent energy savings per sheet6.

HP lists the 18K features:

• The widest application range produced with a single press produces everything from general commercial print applications and high-end photo printing to folding carton applications, secure printing, heat transfer, gaming, and more.

• The new press supports more than 2,000 certified substrates, 75 per cent of which are sustainable media, ranging from 75 to 600 microns.

• Flexibly accommodate different media thicknesses with new exclusive duplex printing on thick substrates (450-600 microns) and smooth handling of light substrates.

• Produce unlimited colour combinations with seven ink stations, featuring 12 specialty ElectroInks and

a countless array of spot colours.

• Advanced AI tools that help produce more jobs in a single shift.

• Enhanced operator experience through clear visualisation and navigation as well as proactive communication and real-time notifications.

• Auto recovery and proactive prediction of potential downtime alerts increase press utilisation by up to five per cent.

• Machine learning algorithms and the PrintOS Productivity Power Pack enable multi-press operation by a single operator.

• Enhanced Productivity Mode (EPM) enables printing of 4,600 colour pages per hour, reducing the cost per sheet by 25 per cent as well as gaining a 33 per cent productivity boost and 24 per cent energy saving per sheet.

• AI-powered Auto Alert Agent (AAA 2.0) requires zero human intervention to detect print defects, discard faulty output, and reprints on the fly.

• Print continuously with non-stop feeding technology featuring the digital flexibility of up to five input sources.

• Boost output quality with the HD Imaging option to deliver exceptional smoothness and sharpness.

• Print solid micro-text quality with the fine line RIP option.

• Achieve top-tier photo quality at the touch of a button. The Photo-Pro Mode eliminates the need for a photo specialist by automatically using CMYK+LLK inks on demand.

• AI-based automation for image quality PQ Maestro troubleshooting, and diagnostics.

• Experience consistent, perfect colour reproduction across presses and sites. Monitor colour with the HP PrintOS Quality Power Pack.

• Achieve G7 master5 or FograCert certification using HP Print OS Color Beat.

The HP Indigo 18K Digital Press produces everything from general commercial print applications and high-end photo printing to folding carton applications, secure printing, heat transfer, gaming, and more

Executing security-focused print jobs in a single pass, the HP Indigo 7K Secure Digital Press does what no other security printing press does.

Collaborating with Jura JSP, the HP Indigo 7K Secure Digital Press enables workflows tailor-made for security production lines. It allows print companies to diversify their offerings, cater to a comprehensive range of security needs, and acquire new customers to grow their business.

HP lists the HP Indigo 7K Secure Digital Press features:

• One pass compared to traditional security solutions that typically require multiple passes through multiple devices. For example, HP Indigo Secure solutions can print secure inks, secure graphical design, and secure serialisation on one press, in one pass.

• HP Indigo security printing solution, including solutions based on HP Indigo LEP technology, HP Indigo inks, and new solutions, based on

alliances, designed specifically for HP Indigo technology.

• On the fly composer creates more efficient workflow for variable page composition with on-the-fly RIP for variable documents. It enables quicker printing and less time spent in prepress.

• Mix Mode gives you the ability to switch easily between secure and non-secure jobs.

• Print within a secure printing environment (Secure DFE) with job auto-delete, encrypted workflow, controlled production, and no reprinting.

• Secure your print process with JURA software and features developed exclusively for HP Indigo secure presses.

• Provides an Original Producer mark that can be embedded into security documents, suitable for lab inspection.

• Print with exclusive security inks restricted to the HP Indigo secure press (invisible red, colour shifting taggants).

• Offer your customers secure variable

data printing for mass customisation of documents.

• Six dedicated ink stations deliver for high quality colour, including spot colours, invisible inks, taggant inks, premium white, and easy release.

• Increase production efficiency with high-performance Secure Composer, which builds secure jobs while printing

HP Indigo V12 Digital Press roll out

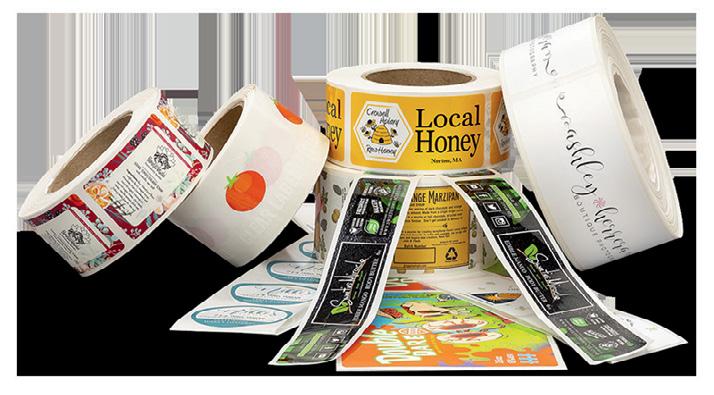

Noam Zilbershtain, vice president and general manager for HP Indigo and Scitex, “We are excited to announce that HP will roll out general commercial availability of the HP Indigo V12 Digital Press, the fastest narrow web digital press on the market and first press to utilise the new LEPx technology. Commercial availability comes after successful beta site installations including Brook + Whittle, a leader in sustainable packaging and digital printing in the US.”

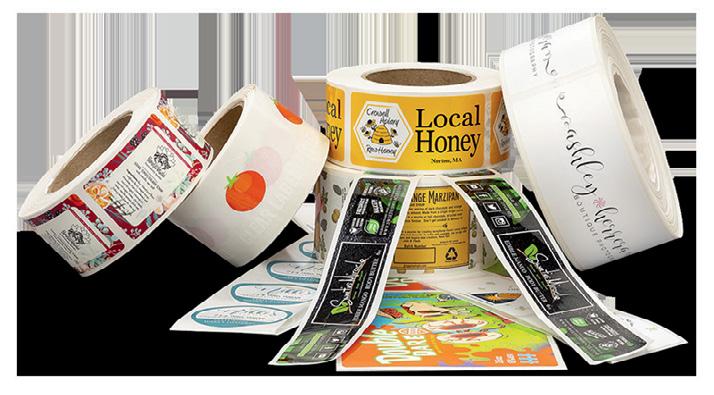

HP Indigo V12 Digital Press features:

• Print up to six colours at 120 linear metres per minute, using six inline imaging engines running simultaneously. Produce up to 130,000 linear metres per day with one operator.

• High definition (HD) imaging: HD Imaging System on press offers native to 1600 dpi resolution.

• Up to 12-colours on press. Change inks on the fly and create any combination of colours.

• Print on one of the industry’s largest range of digital label printing range of substrates, from 12 micron film to 450 micron (18pt) board. Support pressuresensitive, sleeves, flexible packaging, tubes, IMLs and more.

2-5 Currie Group: HP has revealed the latest HP Indigo presses, which will feature on the company’s stand at drupa 2024: the HP Indigo 120K Digital Press; the HP Indigo 18K Digital Press, and the HP Indigo 7K Secure Digital Press. The company will also show a raft of other innovations to drupa, and Currie Group will be there.

12-13 Helping Hand: Iain MacIntyre profiles Hammerking Rollers as it approaches its 50th anniversary.

14-16 Comment: Ruth Cobb introduces the Top 10 apprentices in the running for the Apprentice of the Year.

18 Fujifilm Business Innovation: Pure Print has upgraded its digital production to a new Revoria PC1120 Press.

20 Currie Group: Easy2C, our biggest calendar maker, has installed an HP Indigo 15K HD Digital Press.

22 Think Laterally: Mick Rowan says the time has come to tap into the power of collaboration

36 Epson: The new Auto Table for the SD-10 spectrophotometer will make colour management easier and more reliable.

23-25 Showtime: Excitement is building as drupa prepares to open on May 28 in Düsseldorf, Germany.

26 RMGT: Automation will feature heavily on the RMGT stand with two offset presses in operation.

28 Durst: The new P5 Super Multi Pass (SMP) printer from Durst will launch at the show.

30 Fujifilm: A robotic automation system for the Acuity Hybrid wide format printers will feature on the Fujifilm stand.

21 Heidelberg: The press giant promises an automated packaging workflow as part of its drupa offering.

32 Konica Minolta: A new top-of-theline AccurioJet 60000 will take centre-stage on Konica Minolta’s stand.

34 Kodak: A focus on helping printers increase productivity and profitability has Kodak ready for the show.

35 Xeikon: From flexible labels to automated workflows, Xeikon has something new for everyone this year.

38 News: All the latest news and trends in wide format.

40-41 Aarque Group: Industry experts shared their knowledge at Aarque’s recent Open House.

42 Durst: Leading manufacturer Durst continues to deliver the solutions the industry needs.

44 Hi-Tec Ink: Coldenhove dye sublimation solutions deliver high quality and productivity improvements.

46 NZSDA: Mikaya Hopkins has all the latest about the NZSDA’s regional meetings and upcoming conference.

47 Currie Group: Elitron cutting systems offers precision Italian finishing, now supplied through Currie Group

48 HP: Wellington-based Sign Foundry’s is making the most of the HP Latex 800W printer’s capabilities.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Dave Fellman, Mikayla Hopkins, Iain MacIntyre, Mick Rowan

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - svella@intermedia.com.au

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer

Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2024: Contents of

KODAK is celebrating its 20th anniversary as the first manufacturer and supplier of process free printing plates. Jim Continenza, executive chair at Kodak, says, “I am proud that we have been able to advance this efficient and sustainable plate technology thanks to the innovation of our research and development teams and our tireless pursuit of excellence. Kodak Sonora XTRA process free plates set the standard in the print marketplace, and we will continue to invest in our process free technology.”

XSYS has announced the introduction of EcoFillX, a software feature developed for ThermoFlexX imagers to reduce washout solvent usage. EcoFillX incorporates imageable structures into the non-printing areas of the flexographic plate. Using image analysis, it populates areas in the LAMS layer with the designated pattern, leveraging the ThermoFlexX optics to expedite imaging. As a result, more polymer material stays on the final imaged plate, reducing the accumulation of solid content in the washout solvent.

ESKO and GlobalVision have launched a new integration solution, bringing next-gen proofreading and inspection capabilities to Esko’s WebCenter packaging workflow solution.

Key Features of the integration include single click file inspection tools for compliance; security and data protection; and artwork management workflow. Esko says operators will save time and maintain compliance by automating proofreading in the artwork management process, adding that the user-friendly workflow streamlines quality inspections.

Jet Technologies has announced the availability of AFP-R reduced solvent flexographic plates from Asahi Photoproducts to enhance press efficiency.

The company says the AFP-R plate represents a breakthrough in platemaking technology, boasting a 50 per cent reduction in platemaking time and a 30 per cent reduction in solvent use. It adds that these plates last twice as long on press compared to other solvent wash plates, marking a substantial improvement in operational efficiency and environmental impact.

Jack Malki, director at Jet Technologies, says, “The introduction of Asahi’s AFP-R plates is significant for New Zealand printer s. These plates ensure a dramatic reduction in platemaking time and

solvent use. They support our clients’ goals for sustainability without compromising on quality or productivity.”

Designed for high-quality flexible packaging, label, and paper applications the AFP-R plate forms part of Asahi’s Roadmap to Solvent Zero initiative, featuring reduced environmental impact while enhancing prepress and

Kale Print’s acquisition of Te Awamutu-based Rosetown Print will broaden clients’ access to a wider range of print offerings according to Peter Lloyd, general manager of Kale Print, the Bay of Plenty’s leading print company.

He says, “We are delighted with the acquisition of Rosetown Print. It marks another significant milestone for Kale Print, enabling us to offer more products and services to Rosetown clients.

“Kale Print has had a long standing relationship with Rosetown Print providing trade services for larger print work. Rosetown Print will continue as a stand-alone business unit as part of Kale Print.”

Rosetown Print’s former owners, David and Trudi Morris will step away from the day-to-day business, allowing more time for travel and connecting with family at home and abroad. David says, “For us, Kale Print is a really nice fit in terms of its family

press productivity. Asahi says the incorporation of Asahi’s CleanPrint technology enables clients to achieve better press efficiency, with plates lasting on average twice as long due to reduced need for press stops for plate cleaning. This technology ensures that all remaining ink transfers to the printed substrate, further reducing makeready time, ink consumption, and delivering consistent quality.

Malki adds, “We expect to see some great outcomes for our customers in their platemaking and printing processes. This technology is expected to double the lifespan of plates by significantly reducing the need for press stops for cleaning. We anticipate that CleanPrint will ensure a more efficient transfer of all remaining ink to the printed substrate, which will not only reduce makeready time and ink consumption but also deliver exceptionally consistent quality.”

ownership, environmental drive, and the overall culture of the business. It has a young team with a real passion for print.

“Many businesses like ours face the challenge of having to look at purchasing new print technology. It is becoming harder to keep reinvesting in plant. Kale Print has been an industry leader in terms of investing in new technology, which can only be good for Te Awamutu and the wider community. Really for our customers, not much will change apart from offering more print capabilities.”

Trimatt Systems has repeated its award win for its ColourStar AQ solutions at the APPMA Awards for Excellence held in Melbourne recently.

The ColourStar AQ won the Australian Manufacturer Machinery Award – SME for the second time after winning in the same category in 2022 for the Cardline 7000.

This time the award went to the Trimatt ColourStar AQ for customising a wide range of sustainable packaging products.

The first ColourStar model, the V, offers a 297mm print width; 100mm height and angle adjustment; and organic, pigment watermarked CMYK inks. Trimatt says it helps packaging

Fujifilm will show the world’s first B2 full colour dry toner digital press at drupa 2024.

The company says its new Revoria Press GC12500 offers high production efficiency, user-friendly operation, and media versatility. It adds that the new press supports the largest size available

Embattled industry supplier Starleaton has provided further background on its business. In a statement, the company says: “After navigating a challenging 2023, Starleaton, a leading wide-format provider, has successfully avoided liquidation, marking a pivotal moment with the implementation of a DOCA (deed of company arrangement). This achievement signals a profound turnaround for the company,” the company said in a statement published on the Starleaton website.

“Established in 1978, Starleaton faced voluntary administration on 18 January of this year. The approval of the DOCA,

businesses open new markets in short run, on demand markets.

The company recently launched a new version of the machine, the ColourStar AQ BoxPro, the third in the model range. The new ultra-wide single pass box printing machine provides the ability for on-demand CMYK printing up to 891mm wide. Trimatt has designed this box printer for fast turnaround short runs with low maintenance and easy operation.

Mel McFarlane, marketing manager at Trimatt Systems, said, “This award

in the current digital B2 printer market. Printing a 750mm x 662mm sheet means it delivers up to six A4-sizes in a sheet. This equates to 250 pages per minute with A4.

The new press enables small sized applications and large-format applications, such as posters. The company says that consolidating the paper feeder/stacker and machine control panel in one place significantly improves the daily work efficiency and productivity for printing operators.

Fujifilm developed the new press to enable B2 printing on demand without the need for specialised operators. It has improved maintenance capabilities and optimised routine operations to minimise downtime.

achieved by a narrow margin with the administrator’s decisive vote, stands as a significant triumph for the Eaton family and the committed staff. This agreement ensures the fulfilment of all employee entitlements, including unpaid superannuation, albeit over a potential two-year period for full disbursement.

“While unsecured creditors may recover only a portion of their dues, the DOCA presents a more favourable outcome compared to liquidation. Despite initial scepticism, the acceptance of the DOCA was bolstered by an $800,000 contribution from company founders Peter and Leanne Eaton, as well as Starleaton Pty Ltd. Ben Eaton’s commitment to allocate $33,000 per month for 24 months underscores a dedication to revitalising operations.

“The proposed business restructuring, focusing on core consumable sales with a streamlined footprint and workforce

is testament to the hard work and dedication of the Trimatt team in listening to customers’ needs and creating machinery that exceeds expectations.

“We are absolutely elated to have won this award 2 years in a row but know it is a deserving of recognition. We look forward to an exciting year ahead installing the Trimatt ColourStar V into many more packaging companies, printers, ecommerce businesses and coffee roasters throughout Australia and New Zealand, helping them to open new markets and profit more.”

Printing on B2 paper with dry toner has presented challenges, but Fujifilm has incorporated proprietary new technology to overcome these. By developing new mechanisms for the fuser unit and developing unit, the stress on the paper during the printing process is reduced, improving image quality. Fujifilm says that, with this new technology, you can expand the maximum paper size to B2XL while also enabling automatic duplex printing on paper weights ranging from 64gsm to 450 gsm.

The company adds that the Revoria Press GC12500 can produce a broad range of applications when combined with the wide media versatility inherent to dry toner.

reduction, positions us optimally to fulfil our obligations going forward.

“While liquidation might have seemed easier with the FEG scheme covering staff entitlements, it was not an acceptable outcome, as it would have yielded no returns for other creditors. The intent behind entering into the DOCA is to honour the company’s past commitments, particularly in regard to staff entitlements, in their entirety.

“We are actively engaging with individual unsecured parties to achieve a mutually beneficial resolution. The DOCA grants us the opportunity to collaborate with suppliers and make good where we can.

“The restructuring under the DOCA will streamline Starleaton’s operations, focusing solely on consumables and closing all warehouses except the one in Sydney. This positions the company for renewed stability and growth.”

Epson has become the first ever international corporate partner with Earth Hour, the world’s largest grassroots movement for the environment.

Known best for its “lights off” moment, Earth Hour is held every year on the last Saturday of March and engages supporters in more than 190 countries and territories.

As part of the newly announced corporate partnership, both organisations will increase awareness around Earth Hour 2024 and Hour Bank, an online counter of planet-positive activities, and introduce daily energy saving action.

Epson has also implemented various initiatives to Earth Hour’s goal in achieving decarbonisation, such as increasing the efficiency of electricity use and switching to 100 per cent renewable electricity at all Epson group sites.

Epson Australia and New Zealand will also be undertaking key initiatives around and beyond Earth Hour. Craig Heckenberg, managing director for Epson ANZ, says, “Epson is deeply committed to making a meaningful difference in promoting sustainability both in the environment and the communities we serve.

“Earth Hour and the continued local sustainability initiatives we are undertaking are key to and underscore that commitment,” said Heckenberg.

Epson publicly committed to becoming carbon negative and underground resource free in its Environmental Vision 2050.

Earlier this year, Epson announced that, as of December 2023, all electricity used at Epson Group sites around the globe is from renewable sources. This makes Epson the first in the domestic manufacturing industry to complete the

Kissel + Wolf Australia has signed a Memorandum of Understanding (MoU) with Highcon. The agreement aims to explore opportunities for market expansion in the Australia/New Zealand region with the view of Kissel + Wolf Australia becoming a distributor following drupa 2024.

Founded in 2009 and headquartered in Yavne, Israel, Highcon has developed a proprietary technology for digital die-cutting solutions. Highcon provides of digital die-cutting solutions for the folding carton and corrugated packaging industry.

transition to renewable electricity at all its sites worldwide.

Yasunori Ogawa, global president of Epson, says, “Since our founding, we have upheld the mission of coexistence with local communities as a manufacturing company that coexists with nature and people’s lives.

“While fulfilling our mission as a company, we also believe that the importance for each of us to take action as a member of society eventually makes big differences. Through this partnership, we hope to expand understanding and empathy for environmental activities and provide the opportunity as many people as possible to take action.”

Yves Calmette, senior director, brand, and network communications for International Earth Hour, said the partnership with Epson represents a united front when it comes to this year’s event.

“Together we can unleash the power of collective action, but we need everyone’s involvement to make it the biggest hour for Earth yet,” said Calmette.

Shlomo Nimrodi, chief executive at Highcon, says, “In this drupa year, the time is right for Highcon to explore the market opportunity in the digitally advanced ANZ market.

“Kissel + Wolf Australia looks to be the right partner to help Highcon access the market and bring the opportunity of digital die cutting to ANZ’s folding carton and corrugated converters.”

Bruce Caldwell, sales manager ANZ for fibre-based packaging – sign and display at Kissel + Wolf Australia, says, “I am excited to embark on this journey with Highcon to explore the immense potential of the ANZ market. Highcon’s commitment to innovation and their digital die-cutting solutions perfectly complement our new digital offerings for the fibre-based packaging industry.

“Partnering with the leading, proven, and most technically advanced digital

“We want Earth Hour to be a moment of celebration for our one shared home, our planet. Earth Hour isn’t just about acknowledging the problem; it’s about celebrating the solutions. We want Earth Hour to be a beacon of hope, so that we can build a brighter, more sustainable future for all.”

die-cutting company in the world is genuinely inspiring. We can now offer accurate digital end to end solutions and demonstrate greater efficiencies and long-term environmental benefits in the analogue space. With a forecast of more jobs and shorter runs, the digital solution is a real consideration for many converters.

“The agreement also highlights and enhances Kissel + Wolf’s commitment and reputation within the packaging industry in Australia and New Zealand.”

Jamie Weller, managing director at Kissel + Wolf Australia, adds, “We see tremendous opportunity in partnering with Highcon to bring their innovative digital die-cutting solutions to our customers across Australia and New Zealand. Together, we aim to drive the analogue to digital transformation and deliver enhanced value to our clients.”

with our new Canon varioPRINT iX3200

Delivering short run printing on a wide range of media at incredibly high speeds with stunning image quality and the ability to personalise without breaking the bank.

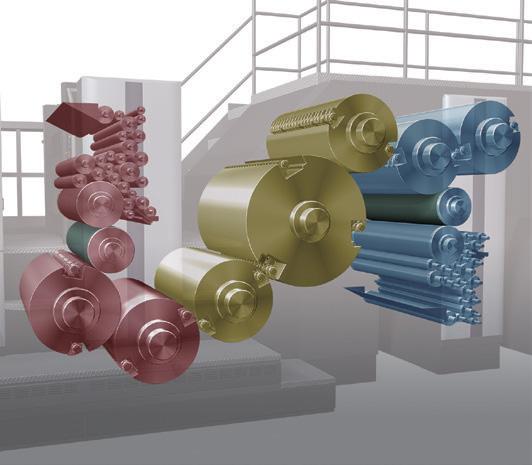

Approaching its 50th anniversary, Hammerking Rollers has moved into a modern, fit-forpurpose premises heralding increased productivity and fresh drive.

Lindsay Farr started Hammerking Rollers in 2018. The Marston familyowned business Rubber Developments (RDL) acquired Hammerking in 2018. It upgraded to another East Tamaki location in July 2023.

Lester Alimurong, Hammerking division manager, says, “While noting Hammerking’s potential, the Marston Family also observed we were burdened by the previous factory’s unforgiving layout, which caused a vigorous and exhausting process.

“Moving into new premises allows us to cut down lead times and eliminate double handling. I take my hat off to RDL’s managing director Leigh Marston and general manager Josh Marston for giving us the opportunity to relocate and improve our processes to evolve the company.”

He adds that, prior to the RDL acquisition, directors Selwyn Pratt and Mark Slane drove Hammerking’s growth trajectory. He says, “Special mention to Selwyn who was the main driver for the development and growth of Hammerking over 35-plus years, and whom I was very privileged to work next to and now continue the firm’s legacy under the new management of RDL.

“Hammerking has come a long way over the last decade in particular, obtaining key knowledge and processes, and maintaining quality around the precise tolerances required in our products.”

The business has serviced a wide range of industries and products over its history, including print and packaging, forklift

tyres, conveyors, forestry, pulp and timber mills and steel mills. Lester says, “We offer rubber and polyurethane roller refurbishments which involves removing the worn compound and applying a new coating, whether it be polyurethane or rubber. Sometimes rollers don’t always need to be recoated, whereby we offer regrinding services making the roller parallel and concentric again.

“We also manufacture moulded components for various applications, and we export specialised metal coating applicator rolls to various countries such as Indonesia and India. The list goes on – if it has a rubber or polyurethane covering, we can do it.”

“Hammerking’s moulded components go around the world, especially with the components we manufacture for the forestry industry. We were, however, a finalist in the export awards about eight years ago.”

Hammerking offers in-depth know how; flexibility on short lead times; and handles bespoke jobs of all sizes. He says, “We have multiple and ongoing

points of quality, which starts with our trusted suppliers who supply our raw manufacturing materials. For example, RDL supplies our calendeared rubber and has a state-of-the-art laboratory to ensure the physical properties of the compounds are manufactured within specification.

“RDL can further develop rubber compounds based on the customer’s requirements and notified improvements via field testing through feedback on the component’s application. Once the rubber compounds are mixed and milled, they are all tested in their laboratory to ensure our raw materials are within specification.

“Quality does not stop there. It continues through our factory at every stage of our process through quality regimes.

“We also offer leading compound technology for our metal coating rollers. Customers from India and Indonesia send us their rollers to be refurbished.”

Hammerking prioritises the ongoing development of its compounds to ensure optimal performance. He says, “We also deal with a business partner, Techno Roll in Japan, which supplies a specialised compound for the UV print rolls. The compound, Trust B, can handle the aggressive UV inks and solvents, minimising the rubber to swell over time; it provides amazing print quality.

“Trust B is a better alternative to EPDM (ethylene propylene diene monomer) rubber, which is known for its chemical resistance, but also has its limitations, just like any other elastomer, always compromising one physical attribute for another.

“From my experience with elastomer compounds, there is never a compound that can do it all. It is through wise selection and experience from the wide range of elastomer compounds we choose specifically for the roll based on the roller’s application to optimise the best performance where needed. We have the equipment to handle most shapes and sizes.”

Team unity

The company has a strong team ethos. Lester says, “We have long-term staff members who have gained considerable experience and know-how, which influences our training and development of systems to keep our quality control practices in order.

“The attitude and persona in my factory are like that of a strong family at times, with the way we have trained and developed each member, no matter their educational background, experience and constraints. We love a good underdog

story – witnessing where they were at as an individual when they first started and where they are now.

“I believe that is why we have such a great workforce and dynamic team. Each member of Hammerking believes in the work they carry out on a day-to-day basis – heavily reliant on teamwork and getting things across the line, together achieving quality control and improving where we can.

“Don’t get me wrong – we still have our issues and constraints from time to time, but who does not experience these problems? It is how we have learnt to work together, adapt, tolerate and overcome whatever the constraint or challenge we may encounter, which I believe is what keeps my team motivated and to do our best, which revolves around our level of quality and continuous improvement: Kaizen.”

Hammerking is currently developing a new product with Techno Roll. Lester explains, “We are working on a compound called J Squared for the print industry which we are hoping to launch in upcoming months. This is a specialised rubber compound specifically made for water dampening and pan rollers for the print industry. It is meant to provide excellent hydrophilic properties, abrasion resistance and UV resistance, which also delivers consistent water transfer through lower surface tension.

“The idea behind the compound is to prolong the life expectancy on the damping and pan rollers as they are among the fastest to wear-and-tear on a printing press. Those rolls are traditionally made from a Nitrile rubber compound.

“When RDL purchased the company our knowledge with rubber increased and we have started to handle jobs that we would not have previously, such as expandable air bags where the processing requires out-of-the-box thinking. More-difficult rubber compounds have become easier to process.”

With growth in domestic and international marketplaces, Hammerking continues to evolve and has an exciting future. He says, “We certainly are not the same company I joined 14 years ago. We are always trying to grow our industry, including from the size of rollers we handle. The next goal is to explore new growth opportunities within the Australasian printing rollers market. I believe our reputation as a trusted, quality supplier can be further established around the globe.

“It is all about the service we offer to our customers, trying to exceed their expectations where we can. We find ways to keep on trucking along, no matter what situation may arise.”

Excelling in their work, our top apprentices demonstrate the qualities we need in the industry.

PRUTH COBB

PRUTH COBB

rintNZ has confirmed the Top 10 print apprentices who concluded their qualifications last year.

We will present the 2023 BJ Ball Print Apprentice of the Year as part of the Pride In Print Awards at Wellington’s Tākina Events Centre on Friday July 12.

The Top 10 apprentices are:

• Martina Carroll

– Freedom Plus, Palmerston North

• George Cunningham

– Allied Press, Dunedin

• Anna Hodge

– Be My Guest Design, Dunedin

• Levi Lindsey

– MCC Auckland, Auckland

• Ruth Pollock

– Be My Guest Design, Dunedin

• Amit Shankar

– Labelmakers, Hamilton

• Satend Sharma

– Polyprint Packaging, Auckland

• David Smith

– MCC Auckland, Auckland

• Kathryn Wheeler

– Freedom Plus, Palmerston North

• Keanu Wipani

– Opal Packaging Hawke’s Bay, Napier

Martina Carroll

A graphic design graduate, Martina Carroll joined the-then four-year-old Freedom Plus as a digital print operator in 2006. Dan Wheeler, managing director of Freedom Plus, says, “Her eye for detail and quality control that is second to none.

“As the moderator from our office that verified and signed off on her assignments, I was always impressed with the level of research and technical understanding of all her assignment work.

“Her assignment presentation blew me away. She designed these as if they were new work booklets with all her answers written and illustrated, then printed as

a new booklet for presentation to the assessor. I was so impressed.”

George Cunningham

Allied Press day print supervisor Justin Aitken says George Cunningham’s journey from publisher’s assistant to printer is testament to his dedication and steadfast work ethic. Justin says, “George’s focus is sharp and his attention to detail is unmatched, making him an invaluable asset to the team.

“In the press room, laughter mingles with the hum of machinery as work continues

under George’s leadership. Whether tackling a challenging project or simply sharing a light-hearted moment, George’s presence brings consistent results to the work environment, turning colleagues into friends and tasks into triumphs.

“For nine years, George has been more than just a co-worker; he has been a steadfast and trusted teammate, a beacon of positivity in the fast-paced world of Allied Press.”

Anna Hodge

Having joined Be My Guest Design as graphic designer during the initial

pandemic lockdown, Anna Hodge soon demonstrated a methodical and creative approach with a calm and collected demeanour even in stressful situations, according to Amanda Cookson, owner at Be My Guest Design.

Amanda says, “Anna came from the design team at Allied Press, taking great pride in working on the pullout publications. She came to my attention via the volunteer design work that she did for the Mornington Toy Library, a client. All the printing files we received were well designed, tidy, and print-ready, so I shoulder-tapped her to take over the design aspects of my workload.

“I am so proud of Anna’s Top 10 achievement. When I found out, and even when I think about it now, I get tears in my eyes. She didn’t just have her paperwork to complete. Of course she had work, but she also had personal challenges including being mum to two young kids.”

Haydn Mitchell, Auckland technical manager at Multi-Colour Corporation (MCC), formerly Adhesif Labels, says Levi Lindsey’s first role in the print industry was in the post-press cleaning area.

Haydn says, “Having shown a keen interest in printing, Levi progressed to the role of flexo printer’s assistant, and he excelled at this, so we offered him a flexo printing apprenticeship.

“After completing his apprenticeship, he is now employed as a qualified flexo printer. Levi is really proving his worth at MCC Auckland. His proactive approach, combined with consistently delivering top-notch-quality work and keeping that positive attitude, speaks volumes about his dedication and work ethic.

“I was not surprised at all to see Levi do so well in his apprenticeship. With his

commitment and upbeat demeanour, it was pretty much a given.”

Ruth Pollock

Also, from Be My Guest Design, via its Positive Signs + Print division, Ruth Pollock commenced as part-time graphic designer in 2009.

Amanda Cookson says, “Now that Ruth’s daughters have left high school, she is our full-time senior graphic designer for the Positive Signs branch of the business and supports the design team at Be My Guest as required.

“She has experience working with a number of printing processes and equipment and possesses an almost photographic memory of where a file might be stored in backups. Ruth is fast, reliable and efficient. You would struggle to find someone who works harder.

“I could not do what I do without Ruth and Anna, they are an integral part of the businesses. I am so proud of them. And at 40-something, Ruth has finally received recognition for everything she has learned over her career and was even able to learn a bit more.”

Satend Sharma

After walking in the door to enquire about work opportunities in 2018, Satend Sharma began in Polyprint Packaging’s extrusion department on night shift before moving to bag machines, fork hoists and then printing.

David Cornish, managing director at Polyprint, says, “Satend is a quick learner who excels at problem solving and getting the best out of whatever equipment he is operating.

“A team player with a can-do attitude, he has a well-honed set of skills which he uses day-to-day in the print room and across all departments throughout our plant.

“He is a talented, dedicated sort of guy and strives to do his best in whatever task he faces. If someone is struggling in a factory with a machine, he will go over and help them, he is that sort of guy: a great asset to our business and valued member of our team.”

Amit Shankar

Switching from tertiary education to enter the print industry with Labelmakers as a finishing operator in 2018, Amit

Shankar quickly proved to be a reliable, hardworking, and consistent producer of good quality work, says the firm’s business improvement manager, Rachel Wymer.

She adds, “Amit is keen to learn new things and willingly takes on feedback and advice to improve his knowledge and skills. He is a great team player and puts his hand up for extra duties such as health and safety rep for his team.

“A self-motivated individual, Amit worked incredibly hard on his apprenticeship. He always completed his assignments to a high standard, reflecting the learning and understanding he obtained from each unit. He has moved through the apprenticeship as expected, completing assignments on time, and being prepared for assessments where required.

“It is no surprise that Amit has achieved a Top 10 place for his apprenticeship, and we are incredibly proud of him.”

David Smith

A second Top 10 apprentice this year for MCC Auckland, David Smith also joined the business when it was known as Adhesif Labels as an ETI coating machine operator in 2016.

Haydn Mitchell, says, “In no time, David progressed to the flexo printer assistant role where he accepted the offer of a flexo printing apprenticeship. This was David’s first role in the printing industry, having completed his apprenticeship in 2023 he is now employed as a qualified flexo printer.

“David has become an asset to MCC Auckland. His proactive approach to managing and taking ownership of his apprenticeship, coupled with achieving a high level of quality and maintaining an enthusiastic attitude, speaks volumes about his dedication and work ethic.

“David has done so well in his apprenticeship, testament to his commitment and positive attitude.”

Kathryn Wheeler

Freedom Plus’s other Top 10 apprentice Kathryn Wheeler came to the business to work as a print finisher in 2009.

Dan Wheeler says, “Kath has continued to evolve in the role. While she was not involved in the print industry prior to her work at Freedom Pus, she came from a very process driven role with strict standard operating procedures. She also had a keen interest in arts and crafts, making cards and the like, which boded well for dealing with printed work, for example, trimming, creasing, embellishing and so on.

“Kath is another staff member with a keen eye for detail. She can multitask with running various print finishing machines at one time. She is very good at ensuring all deadlines are met – after all our company policy is to ‘Deliver on time, every time or it is free!’”

“Kath puts one hundred per cent effort into everything she does.”

Opal Packaging Hawke’s Bay technical supervisor Bruce Coombe recalls Keanu Wipani joining the business in late 2016 as a trainee operator on the rotary diecutter in the converting department.

Bruce says, “Keanu did not come from the printing industry before joining Opal but has fitted in well to our production environment and has shown an aptitude for operating our equipment.

“Currently, he is a senior machine operator, and his knowledge of the production processes allows him to stand in as a team co-ordinator when required.

“Keanu has a can-do attitude; he is a quick learner and can operate three rotary die-cutters. Having an operator who can operate several machines gives us a lot of flexibility, especially if people are away for any reason.

“He works well with the rest of the team and crew members on the other machines, and this helps to get the most out of any machine he is working on.”

New Fujifilm solution expands options for Bay of Plenty print company.

Last year, Tauranga-based Pure Print installed a Revoria Press PC1120, supplied through Fujifilm Business Innovation New Zealand (FBNZ).

Steve Wagstaff, managing director at Pure Print, says, “The Revoria Press PC1120 is an upgrade on our Colour 1000i Digital Production Press. We see innovation as key in the business and the Revoria installation forms part of our strategy to continue innovating.

“It gives us a range of features that we did not have before. For example, the long sheet/banner printing; the improved registration; and duplexing up to 300gsm. The Revoria Press PC1120 prints on heavier media up to 400gsm.

“We can now offer more personalised colour options to those clients who require a more vibrant result that we cannot always achieve with other printers. We use the pink toner to make more vibrant reds and oranges as well as achieving closer matches to PMS colours.

“Colour management is made very easy with calibrations done every couple of weeks with the spectrometer. We are getting a more consistent print in terms of even coverage across the sheet with next to no banding issues.

“The Revoria Press PC1120 produces much cleaner, sharper results in images and smoother gradients than our previous machine.

“Our productivity is definitely higher with the speed of the Revoria Press PC1120, which in no way compromises with quality of print. Having the extra paper bins with the air suction feeder is great for lighter weight stocks and those synthetic stocks that are prone to sticking together.

“Another benefit for us is that we are now able to offer our clients a wider range of personalised corporate marketing material such as gift boxes, greeting cards, transparent labels using unique colour combinations and embellishments opening up a world of possibilities.”

Since its inception in 2002, Pure Print has expanded, now offering a comprehensive range of print services to its clients. It covers everything from design to post production, with its own finishing gear.

Steve says, “We started as a small digital shop with a full colour A3 digital printer and a black and white press. Now, 22 years on, we have a staff of 14 employees. We have been a loyal supporter of Fujifilm for over 20 years and we appreciate the relationship, especially when we look at the amazing jobs that we can output with the help of the larger sheet and the choice of metallic, pink and white toner on the Revoria Press PC1120.

“One of the great things about this machine is the similarity with the operating system and layout to our

previous machine. This meant as soon as it was implemented into our premises, there was a seamless cross over regarding how to use the machine. And now almost a year later, we can almost push a button and walk away!

“We find the Revoria Press PC1120 to be very user friendly for our job management, colour control and automation, maximising efficiency and minimising our need for manual intervention with the options of hot folders and auto imposing on the fly. We use Fujifilm’s Revoria Flow RIP and GX Print Server.”

Steve sees the slowing down in the market as a big challenge facing companies in New Zealand. He says, “This puts pressure on buying print but to make a brighter future we have to continue doing the best for our clients, delivering great service and great products.

“Every member of the Pure Print team gets a buzz seeing our great products go out the door. We have a great week when we have smooth operations, positive feedback and customer satisfaction with our finished product and delivery of a quality service.

“Pure Print’s investment in new innovation allows us to stand apart from our competitors. Innovation is important to the Pure Print team; it is leading us into the future through delivery of high-quality work we are proud to put the Pure Print name on. We see a very bright future for Pure Print in the years to come.”

What makes Fujifilm unique is the way we combine both analogue and digital expertise with one goal in mind – to help you grow your business.

Get to know us and you’ll discover our passion for building successful, long-lasting partnerships driven by core values of trust, innovation and sustainability.

Discover the difference at drupa 2024 Hall 8B, Stand A02

Discover More

Currie Group helps improve productivity at the country’s biggest calendar printer.

Anyone who loves printed calendars but fears they might become an endangered species owing to the dominance of all things electronic in this digital age, can breathe a sigh of relief: Easy2C is on the case.

The Kiwi-owned and operated company specialises in calendar production, fulfilling a demand for all kinds of calendars from across New Zealand and Australia.

Steve Walmsley, chief executive officer at Easy2C, says, “We produce a range of printed material, but calendars remain our main business. Our customers are quite demanding; they want customised calendars, and they want the best.”

Recently, Easy2C installed an HP Indigo 15K HD Digital Press, supplied through Currie Group. Steve says, “The HP Indigo 15K replaces two toner machines but it does much more than that. We realised a long time ago that we needed a press that could take bigger sheets and a B2 machine could meet our requirements.

“We also needed more speed and from that perspective, we thought it was either inkjet or HP Indigo but, in the end, the HP Indigo 15K is the right machine for us, especially considering the quality it delivers.

“Nothing else in digital can match the HP Indigo print quality. We have it calibrated to the ISO standard and we have offset presses also calibrated to the same standard. The HP Indigo 15K gives us consistent colour across offset and digital.

It is as close a match to offset print quality as you can get. On some substrates, the HP Indigo surpasses offset. It gives us exceptional results. While it is a big investment for us, we will get the return on our investment.”

Craig Paul, country manager for Currie Group New Zealand, says, “We are excited that Easy2C installed the HP Indigo 15K HD Digital Press, which can handle everything from general commercial print applications and high-end photographic printing to folding cartons and more. It offers the widest substrate range in the industry of 70-600 microns of media for an almost endless range of substrate types including uncoated, black and coloured, synthetics, and metallised.

“The HP Indigo 15K Digital Press gives Easy2C the flexibility to switch between and integrate substrates seamlessly, even within a single job. Its seven ink stations offer virtually unlimited colour combinations, featuring 14 applicationspecific inks and unlimited spot colours.”

Steve adds, “There is also the HD option, which gives us a smaller dot, making it excellent for photographic printing. We are getting higher quality print.

“We also need high productivity. The HP Indigo 15K can print much faster than the technology we had. It also gives us the ability to run it in EPM (enhanced productivity mode), which is 33 per cent faster. Before we got it, we were printing only 50 per cent of our calendars digitally, or we were printing in offset, then

overprinting on digital. But now, we can print everything digitally.

“The installation went very well with everything pretty much on track and withing the time frame. A technician came from Singapore, and we took the opportunity to have four operators trained on the HP Indigo 15K. We still have a toner press, so this gives us the flexibility to move operators from offset to digital to toner.”

With 95 employees across New Zealand and Australia, Easy2C is the region’s premier calendar producer.

In 1932, Roy Allen established the company, printing calendars in a six-bysix shed in his back garden. Later, Roy’s son Ken Allen took over the business and now, while the family still owns the company, Steve Walmsley oversees the business. He began as operations manager 15 years ago, then general manager in New Zealand before taking the role of Australasian chief executive officer seven years ago.

Starting as a wallpaper printer, Steve completed his apprenticeship and worked in several sectors including textiles, flexible packaging, and self-adhesive labels.

He sees postal costs as a huge challenge for the business. He says, “Many customers need to mail the calendars so increased postage impacts our business. Customers order calendars months in advance so it is important to stay one step ahead.

“We have a great team, and we believe in continuously improving quality. In this regard, the HP Indigo 15K is a welcome addition to our business. It is already contributing to our ongoing success.

“Currie Group has supported us for many years with our proofing and now the relationship is stronger. Craig and the team provide great support.

“HP Indigo is absolutely the gold standard in digital print. To be honest, nothing compares with it.”

The time has come to tap into the power of collaboration.

IMICK ROWAN

IMICK ROWAN

n the dynamic landscape of modern business, small and mediumsized business owners often find themselves in a delicate balancing act, where the demand for innovation is high, but resources and expertise are limited. Here’s where cross-functional collaboration emerges as a potent force, serving as the great accelerator of a company’s innovation engine.

Traditionally, businesses have organised themselves into functional departments, each with tasks, goals, and priorities. However, this siloed approach can act as a barrier to innovation, hindering the free flow of ideas and information across the organisation. By fostering a culture of cross-functional collaboration, business owners can effectively break down these barriers, tapping into the collective intelligence and expertise of diverse teams.

Small and medium-sized enterprises (SMEs) are well positioned to embrace cross-functional collaboration. With smaller teams, greater opportunities exist to create connections between different functions, leading to quicker decisionmaking and a more agile response to market changes.

Cross-functional collaboration has driven transformative change in businesses across various sectors. For instance, software start-ups have found success by integrating their customer service and development teams. By doing so, they can swiftly identify customer pain points and develop solutions at an unprecedented speed. This virtual closeness allows developers to gain a deeper understanding of the real-world applications of their work, leading to products that better meet consumer needs and expectations.

Another compelling example is a manufacturing plant that brought together its production and sustainability teams. This collaboration led to the development

In virtual workplaces, businesses can use collaboration tools and platforms to emulate an interactive environment

of a recycling program for the plant’s waste materials, thereby reducing environmental impact and saving costs on waste management. The innovative solution stemmed from integrating expertise from various functions, showcasing how collaboration can yield impressive results that benefit both the business and the wider community.

Integrating teams from different backgrounds and disciplines broadens the scope of problem-solving. Each function brings a distinctive perspective, skill set, and approach to the table, which can lead to out-of-the-box thinking and breakthrough innovations. By encouraging employees to work across silos, businesses foster an environment where creativity and innovation thrive.

One effective way to promote crossfunctional collaboration is by breaking down physical barriers within the workplace. For companies operating from physical offices, this could involve creating shared spaces where teams can meet for collaborative discussions and brainstorming sessions. In virtual workplaces, collaboration tools and platforms can be utilised to emulate the same interactive environment, fostering spontaneous interactions and ideasharing among team members.

While the benefits of cross-functional collaboration are clear, integrating teams from different departments can come with challenges. Differences in work processes, communication styles, and priorities can create friction and hinder collaboration efforts. Business owners must proactively address these hurdles by setting clear goals, establishing protocols for communication and decision-making, and fostering a culture of openness and mutual respect.

Leadership also plays a crucial role in cultivating a collaborative culture within an organisation. Managers must lead by example, connecting with colleagues across functions. Leaders must champion collaborative projects and provide the necessary resources and support.

Cross-functional collaboration is an investment in a business’s future success and sustainability. As companies scale their collaborative efforts, they can consider implementing cross-training programmes and team-building activities to familiarise employees with different functions and foster greater understanding and empathy among team members.

Additionally, establishing crossfunctional project teams to work on innovation initiatives provides a structured framework for collaboration and ensures that diverse perspectives are represented throughout the process.

Measuring the impact of cross-functional collaboration on key performance indicators and business outcomes is crucial. By tracking metrics such as project success rates, time-to-market for new products or services, and employee satisfaction levels, businesses can gauge the effectiveness of their collaboration initiatives and identify improvement areas.

For small and medium-sized businesses, a strategic emphasis on cross-functional collaboration has the potential to ignite innovation and enhance competitive advantage. By dismantling departmental silos, embracing diverse perspectives, and surmounting challenges through adept leadership and open communication, businesses can cultivate an environment where creativity thrives, and the collective wisdom of their teams is fully realised.

Now is the time to seize the moment and tap into the power of collaboration, propelling your business towards a trajectory of perpetual innovation and lasting triumph.

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

The giant print show holds great promise for everyone in the industry.

Organisers report excitement building across the industry for drupa 2024, which starts at the end of next month.

The global printing industry’s premier event runs May 28 to June 7, 2024 in Düsseldorf, Germany.

Over a period of 11 days, visitors will see technologies, solutions and learn about industry topics at the show. Special events will focus on digitalisation and sustainability.

On a net area of approximately 140,000 square metres with 18 show halls, 1,427 exhibitors from 50 countries will present the entire spectrum of current trends and ideas within print technology. Production of packaging and printed packaging are two areas which have also significantly gained in importance.

drupa 2024 focus topics

Sustainability has become an essential part of long-term company strategies. Depending on the use of resources, the print and packaging industries are already using manufacturing procedures that save energy and resources today. drupa will cover important facts for sustainable production of print and packaging solutions and trends evolving within the sector in order to achieve the goal of a circular economy.

For digitalisation and artificial intelligence, drupa will show top technologies across the industry’s entire added value chain with a special focus on future and cross-sectional technologies. With this scenario in mind, topics like circular economy, automation, printing/finishing 4.0, artificial intelligence, platform economy and connectivity will be taking centre stage in the conference programme and expert forums.

The drupa special forums provide impetus and show best practices in the industry. Together with its partners, drupa relies on its impressive range of competence across the industry and the topics which concern the future of its target groups.

Questions that drupa cube will address include: Why is printing more important than ever in the digital age? Why do customers not always perceive printed products as sustainable? And how do you calculate your carbon footprint?

In more than 50 sessions, the conference offers inspiration and expertise. The programme features five keynotes from international industry specialists and presentations about topics like increasing your business success, circular economy and sustainability, the future of print and packaging as well as sessions and best practice examples regarding new business models and trends.

drupa touchpoint sustainability

Dealing with the role of the printing and paper industries in sustainable transformation, touchpoint sustainability offers an overview of current, mid and long-term developments. Technologies from mechanical and systems engineering are especially important in this context with regard to quality, process safety

during production and sustainability.

Digitalisation and AI play key parts in order to accelerate the transformation process in the print and paper industries and to realise scaling effects. Manufacturers, industry players, brands and users together show how change can become reality in their many exhibits at touchpoint sustainability. Visitors to touchpoint sustainability can also enjoy a broad accompanying programme.

Hall 14/Booth D60

drupa touchpoint packaging

Touchpoint packaging concentrates on visionary, intelligent packaging solutions and brings brand owners together with designers, print service providers and converters. The involvement of students and young talents in partner projects with exhibitors promises unique packaging solutions for folding boxes, labels, flexible packaging and corrugated cardboard. Beyond this, there will be discussion of important questions regarding global megatrends and their impact on packaging production, for example sustainability or e-commerce. The five key topics of touchpoint packaging are neo-ecology, connectivity, glocalisation, consumer mind and future regulations.

drupa dna

drupa has created a special platform: drupa next age (dna). Newcomers, young talents, start-ups and established companies can network on a level playing field, find matching partners for cooperation and exchange innovative business ideas. For some participants, this is the first chance ever to present their businesses to an international audience of experts.

drupa touchpoint textile

The drupa touchpoint textile presents the world’s first digital textile micro factory. This fully connected, integrated process chain covers digital simulation, design, animation, virtual rendering, and production. The industry constantly gains new fields of application. Inkjet technology opens doors to sectors like clothing and fashion, interior design, architecture, automotive, and other vertical markets.

How important is artificial intelligence for the printing and imaging

At this year’s drupa, Messe Düsseldorf will present the drupa Imaging Summit for the first time as part of the ‘drupa next age’ event series.

Top-class speakers from well-known companies will give 20-minute keynote speeches and panels on the most important topics at the interface between imaging technologies and printing. This includes, in particular, the potential offered by the use of AI.

The imaging industry has come a long way in the last few decades. The shift to digital photography and workflows, and now the new big challenge of AI, are transforming the value creation of creators, companies, and the industry. Along with many challenges, the new tools also create new opportunities and business areas.

At the drupa Imaging Summit, one of the main themes will be the big trend topic of Imaging Artificial Intelligence, to learn about the current status and tools, discuss new product ideas and ways to enhance images for better prints.

All these presentations and many others will take place on the drupa dna stage on Thursday, May 30 and Friday, May 31 in Hall 7. The programme is part of the drupa ticket.

Denis Oberfeld

In a presentation called ‘Picture This: How Artificial Intelligence (AI) is Revolutionizing Image Creation’,

Dennis Oberfeld, Google Cloud/Customer engineer, will show how AI is supercharging the image creation process.

Participants can delve into Google’s powerful AI solutions, demonstrating how they streamline workflows and produce stunning results. You can learn about upscaling, watermarking, and more – practical tools (not only) for print businesses and creatives alike. Dennis Oberfeld is passionate about enabling digital transformation, he works closely with clients to understand their unique needs and implement tailored cloud strategies for optimal business outcomes. Prior to Google Cloud, he spent nearly a decade at SAP driving cloud adoption for enterprise customers.

Andreas Jürgensen

‘Image generation via Artificial Intelligence: Tools & Workflows’ is the title of Andreas Jürgensen’s presentation. Andreas, the founder of AI Imagelab, will give an overview of the current status of AI-generated images. Hi insight includes

which programmes are currently relevant, and which ones you should keep an eye on; in which processes AI-generated images are currently being used; and in which fields of application, they are becoming relevant.

the presentation will be illustrated with application and image examples. Andreas Jürgensen is a photo engineer and has been working in the photo industry since 1993. His company operates Germany’s largest network of photo communities. At the end of 2022, he started to work with artificial intelligence and its use for image generation. Together with Adrian Rohnfelder he started the AI Imagelab, a news blog about everything related to AI generated images and videos.

Sarah Lefebvre

Director of marketing at EyeQ Imaging, Sarah Lefebvre, will deliver a presentation called AI Unveiled: Navigating Past, Present, and Future in Photo Print Innovation.

The Creators of the leading Imaging Software, Perfectly Clear, show the remarkable advances AI has made in recent years as Sarah connects today’s applications of AI to real-world use cases and their impact on the printing industry. Be prepared to delve into the exciting possibilities of the future as she

unravels the transformative impact of AI on photo printing. Don’t miss this opportunity to explore the intersection of innovation and practicality at the forefront of AI technology.

Sarah Lefebvre is on a mission to help businesses achieve optimal photo quality. As Director of Marketing at EyeQ, she focuses the company’s core message on the ROI businesses can achieve with Perfectly Clear, its automated photo and video editing technology.

Adrian Rohnfelder

The founder of AI ImageLab, Adrian Rohnfelder, will deliver a presentation called ‘The influence of Artificial Intelligence on future print products’.

In this highly illustrated and entertaining short presentation, Adrian Rohnfelder will outline possible print products of the future as a result of the new generative AI capabilities:

• Changes through AI support of existing products.

• Key social media drivers such as pets and selfies for a flood of AI-generated images.

• Possible consumer desires for 2D, 3D and 4D printing.

Adrian Rohnfelder studied business administration, worked for a long time as a freelance management consultant, and made photography his profession in 2017. He has already won several awards, published in renowned publishing houses, and appeared as a speaker at well-known events.

At the end of 2022, Adrian Rohnfelder discovered artificial intelligence as a fantastic creative tool. He has published on the subject in magazines and has been working as a trainer since the beginning of 2023. Together with Andreas Jürgensen, he founded the AI Imagelab in mid-2023 as a platform for AI-generated images and videos.

Servi Pieters

In his presentation called ‘Viesus: Prints enhanced in the blink of an AI’, Servi Pieters, chief executive officer of Viesus will try to answer these questions:

How do you deal with thousands or even millions of images daily for printing?

Do you often find these images lacking in quality or pixels?

Are you facing lost time, complaints, and missed opportunities?

Discover the behind the scenes algorithms used by leading names in the photo printing industry to minimise suboptimal prints. This talk reveals how AI algorithms improve image print production, delivering quality without the need for manual intervention.

As chief executive officer, Servi Pieters leads Viesus in further developing AI and making it available on various platforms. In October 2022, he founded MyPrint. ai AG, driven by innovation with the application of generative AI technology in a webapp to print personalised and specific AI generated artworks.

Packaging printing and commercial printing set to benefit from RMGT innovations.

Recently, Ryobi MHI Graphic Technology (RMGT) Limited hosted a 10th Anniversary Open house at the company’s Head Office and Showroom Factory. Mr. Hirokawa, president of RMGT gave a welcome speech to 154 guests from 24 countries before RMGT senior managers and leaders delivered presentations on the company’s solutions.

Mr. Taguchi, general manager of International Sales at RMGT, delivered a presentation on RMGT’s recent business situation, successful products, a start of operation of new No.3 factory and RMGT presentation at drupa 2024.

The company also gave a demonstration of the new RMGT features and technologies under the theme of “Assist Your Potential”. Showcasing three kinds of presses at its showroom, RMGT highlighted solutions for labour saving, autonomous printing, and quality assurance.

Mr. Matsuoka, group leader of International Sales, made a brief presentation of the recent success of RMGT 10 series in the packaging segment. He pointed out that 52 per cent of B1 sales went to packaging customers in 2023. Sales volume of packaging presses keeps growing year by year.

The company demonstrated micro flute (G flute) printing with a chemical embossing effect by LED-UV. Automated features included the automatic non-stop feeder,

retractable coating unit, anilox changer, delivery shutter and double delivery in combination with PQS-D inspection.

Mr. Yamada, assistant manager of International Sales, introduced the 970 model’s flexibility from commercial printing to light packaging printing and recently, the 970’s successful installation at packaging customers all over the world. Its demonstration used 350gsm paper for packaging images with chemical embossing by LED-UV. The company also demonstrated a density tracking function by PQS-D, showing how the press automatically adjusted colour against the density of the OK sheet registered by PDS-E Spectrodrive.

The RMGT 9 series convertible perfector, RMGT’s best-selling model, counted for more than 40 per cent of RMGT total sales in 2023. The perfector press models include the 790PF, 920PF, 970PF and 1060TP.

Mr. Ishibashi, Group leader of the International Sales spoke about the history of the 9 series since 2005. RMGT global 9 series installations exceed 1,800 presses. He also explained the ability of 970 models to meet worldwide paper sizes. During the 970 demonstrations, RMGT also showed two printing jobs (from A4 8up to full size poster) by continuous operation on RMGT 970PF-8 with PQS-D Smart Assist printing function.

The company also introduced a connection between 1060LX-6+CC+2LD

RMGT says its 1060LX significantly boosts productivity for packaging printing.

and AGV (Auto Guided Vehicle) through RMGT Press Information Edge during the demonstration. At the end of printing, AGV received a signal from the press and came to a delivery section automatically. After a paper pile was lowered, following the operator’s instruction, AGV moved inside the delivery area and picked up the paper pile before returning to its designated position.

In the evening, RMGT hosted a dinner party get-together at New Castle Hotel in Fukuyama. At the event, Mr. Urakami, president and chief executive of Ryobi; Mr. Hirokawa, president of RMGT; and Mr. Murashige, vice president of RMGT Sales and Service, gave speeches to show the companies’ deep appreciation to all guests.

drupa showcase

With a focus on automation, RMGT looks forward to showing its solutions at drupa 2024 under its theme ‘Assist Your Potential with Technological Expertise and Constant Innovation’. Its exhibits and demonstrations will focus on two major concepts:

• Further automation for package printing.

• Increased productivity for commercial printing through autonomous operation.