06 - AUTOMATION MAg - NOveMber 2022 automation mag HMS NETWORKS EXPANDS RANGE OF HIGH-PERFORMANCE ANYBUS GATEWAYS 4 EMERSON’S NEW ELECTRIC ACTUATORS OFFER SUPERIOR APPLICATION FLEXIBILITY, PRECISION AND REPEATABILITY 15 ROHDE & SCHWARZ ANNOUNCES UNIQUE 56 GHZ AND 67 GHZ FREQUENCY OPTIONS FOR R&S SMW200A VECTOR SIGNAL GENERATOR 20 LEUZE LAUNCHES THE WORLD’S FIRST SAFETY BAR CODE POSITIONING SYSTEM 6

OPTIMIZE YOUR INTERNATIONAL PR AND ADVERTISING FOR THE INDUSTRIAL MARKET!

International capability

More than 80 employees in 35 different countries, ensuring a strong relationship with main local media. Mepax distinguishes itself through its extensive media knowledge and ability to select the best international online/print advertising options. PR can be translated into 35 languages.

Outstanding results

45,000 published articles in 2021: EMEA: 48% - Asia: 31% - Americas: 21%. Most of the articles are published in the top 1000 media worldwide.

Optimized process

With a proven process set for more than 200 active customers, we can adapt to all specific client needs with the highest reliability. We have developed in house the most advanced PR dedicated ERP, enabling transparency and real-time full online reporting. International media management is then made easy, fast, and efficient for optimal results.

www.mepax.com info@mepax.com

THE MOST INNOVATIVE PR AGENCY

4 HMS Networks expands range of High-Performance Anybus gateways

6 Leuze launches the world’s first safety bar code positioning system

7 Wachendorff presents World’s most compact ethernet/IP encoder

8 DFI’s revenue in the First Half of the Year Sets a New record for the Same Period

10 Fuzzy Logic and CAIre, on the way to automating the painting process

12 robustel release Next generation IoT gateways Featuring eDge Computing and robustOS Pro a new Debian based Operating System

14 smartLink product family from Softing offers extended functionalities for Plant Asset Management

15 emerson’s New electric Actuators Offer Superior Application Flexibility, Precision and repeatability

16 Monitoring of energy networks – How to make it easy and secure

19 DFI Is Listed in CommonWealth Magazine’s 2021 “Fast 100”

THIS ISSU e… automation

20 rohde & Schwarz announces unique 56 gHz and 67 gHz frequency options for r&S SMW200A vector signal generator

22 100 years of Mitsubishi electric – a story of success

Send your press releases to: editor@ipmediaonline.com

AUTOMATION Mag is the ultimate source for automation engineers: industry 4.0, IA, motors, sensors, controls, software… Our international team covers product developments, application stories, and technical articles, as well as offering comprehensive analysis of the latest engineering trends.

AUTOMATION Mag edits its articles with the greatest of care, however we cannot guarantee the accuracy of the information presented in them. Our teams disclaim all responsibility concerning the content of this media or how it might be used.

To receive the AUTOMATION Mag newsletter, subscribe online: https://www.automation-mag.com

INDUPORTALS MEDIA PUBLISHING

IN

mag

HMS NETWORKS EXPANDS RANGE OF HIGH-PERFORMANCE ANYBUS GATEWAYS

New Anybus® Communicator™ gateways enable fast and simple communication between industrial networks for improved operational performance.

HMS Networks now expands its second-generation Anybus Communicator range of highperformance gateways, enabling more and faster data to be transferred across networks in industrial applications. Thirteen new versions for data connectivity between e therCAT, etherNet/IP, Modbus TCP, P r OFI b US, and PrOFINeT make it simple for users to connect between different control systems, remove automation islands and maximize operational performance.

Proven and fast communication using Anybus NP40 technology

The award-winning Anybus NP40 industrial network processor ensures that the Communicators meet demanding requirements in terms of industrial performance, reliability, and security. Featuring new hardware and software, the gateways enable instant data transfer – up to 10 times faster than their predecessors. Users can also exchange significantly more data between the networks as the gateways transfer up to 1 500 bytes to and from connected PLCs.

Robust and secure communication built using carefully selected industrial components and verified against the Ce and UL industry standards, the gateways are designed to handle harsh industrial environments.

To protect users from cyberattacks, the gateways have an onboard physical security switch that prevents unauthorized configuration changes and secure boot functionality to resist attacks and infections from malware.

06 - AUTOMATION Mag - November 2022 4 HMS INDUSTrIAL NeTWOrKS

Fast installation and intuitive configuration

Fast installation and configuration procedures are guaranteed thanks to an optimised housing design, an intuitive gUI, and easy-to-understand documentation.

Installation is simplified thanks to the compact gateway design with forwardfacing ports and DIN-rail mounting, which enables gateway installation close to connected devices, reducing the amount of needed wiring.

Users can configure the gateways using drag-and-drop functionality in the webbased g UI, which is accessible via a dedicated ethernet port on the gateways. In the gUI, users can also monitor network traffic and diagnose issues before they become problems.

Hands-on assistance is also available, as a Qr code in the gUI provides a step-bystep installation and configuration guide.

“We are very excited to release these Communicators, our most advanced range of gateways,” explains Fredrik b rynolf, Product Manager for Anybus gateways at HMS Networks. “The Communicators are reliable, powerful, and secure. On top of this, they offer a new level of user-friendliness thanks to the optimised design and the intuitive gUI. All this makes the Communicators excellent choices for anyone looking to connect data between industrial networks. The Communicators make it simple to connect PLCs, remove automation islands, and maximize operational performance.”

Anybus Communicators are available off the shelf as stand-alone ready-toinstall units. Users can personalize the Communicators to meet OeM and brand labeling requirements. The gateways can also be pre-configured and locked to be used as tightly integrated communication components of an automation device or a machine.

https://www.anybus.com/products/ gateway-index/anybus-communicator

06 - AUTOMATION Mag - November 2022 5 HMS INDUSTrIAL NeTWOrKS

LEUZE LAUNCHES THE WORLD’S FIRST SAFETY BAR CODE POSITIONING SYSTEM

With the FBPS 600i, only one device is needed for safe position detection. In the past, system manufacturers had to use two sensors and two different technologies for position detection. But not anymore: The new FBPS 600i safety bar code positioning system from Leuze enables position detection with a single sensor.

Simple implementation of safety functions

In intralogistics, it is important that the stacker cranes and transverse transfer cars pose no danger to the staff. The position and speed must be monitored during maintenance work or when operating with a manned car. Until now, system manufacturers had to use a redundant setup with two sensors in order to meet performance level d. This problem is now solved with the new single-sensor safety bar code positioning system FbPS 600i, which already meets the requirements of performance level e. This means that safety functions can now be easily implemented. The unit is connected to a safe connection unit, for example, a frequency inverter, via two SSI interfaces. The FbPS 600i also requires less space in the system, and the installation effort is reduced significantly.

Ideal for quick movements

The FbPS 600i has an impressive error reaction time of only ten milliseconds. This makes it especially suitable for position detection when quick movements are involved. Important parameters, such as the speed curves and the throughput can be optimised as a result. The sensor’s large working range of 50–170 millimeters also enables flexible integration in different types of systems.

Reliable in operation

The new safety bar code positioning system is installed on the stacker crane or transverse transfer car. A bar code tape is affixed on the opposite rack. In the development of the FbPS 600i, the Sensor People emphasized maximum reliability: With every scanning pass, the FbPS 600i reads multiple codes of the

The FBPS 600i is connected to a safe evaluation unit via two SSI interfaces and is suitable for applications up to performance level e.

tape, from which the software determines highly precise position values.

The sensor scans the code at various locations through the diagonal path of the scanning beam and the movement of the transfer car. This prevents reading errors caused by local soiling or damage. The self-adhesive bar code tape, which was optimised for industrial application, also facilitates flawless operation: It is U v resistant, extremely resilient, and mechanically durable. In addition, the

printed position values are easy to read and simplify handling.

Fast installation

The well-thought-out fastening concept with a quick-change system ensures simple mounting of the F b PS 600i devices. The device can be safely secured with an easy-to-access screw on the mounting clamp. This saves time during assembly.

https://www.leuze.com/

06 - AUTOMATION Mag - November 2022 6 LeUZe

WACHENDORFF PRESENTS WORLD’S MOST COMPACT ETHERNET/IP ENCODER

Universal Industrial Ethernet encoder with PROFINET, EtherCAT and EtherNet/IP. Wachendorff is expanding its range of Ethernetbased encoders: Encoders with the EtherNet/IP protocol are now available, including the most compact in the world: the WDGA58F. Wachendorff’s R&D team has succeeded in minimising the sensor to an installation depth of just 46.5 mm.

The encoders are certified by the OD vA. The resolution in single and multi-turn can be individually configured via an integrated web server (single-turn 16 bit, multi-turn 43 bit).

The very high environmental data, e.g. temperature range from -40 °C up to +85 °C, shock 1,000 m/s² or vibration 50 m/s² at 10-2000 Hz, allow the use in harsh industrial environments as well as in mobile working machines.

The devices with hollow end shafts eliminate the need for additional couplings and the devices with shafts guarantee a long-lasting and stable connection with their very high bearing loads of up to 400 N.

In the Universal Industrial e thernet version, it is possible to switch between e thernet/IP, e therCat and P r OFIN e T. This noticeably reduces storage costs and increases flexibility.

https://www.wachendorff-automation. com/

06 - AUTOMATION Mag - November 2022 7 WACHeNDOrFF

DFI, the world’s leading brand in embedded motherboards and industrial computers, held an online investor conference on August 15 to announce our consolidated financial statements for the second quarter and first half of 2022. The consolidated revenue in the first half of the year reached €255.21million.

The annual increase of 46.29% set a new high for the same period. DFI stated that in the future, the company will continue to optimise various internal operating indicators and prepare for overall economic risks in the second half of the year in advance.

The President of DFI, Alexander Su, expressed that as material shortages begin to improve, we are adjusting the price of raw materials with our customers. Together with the continued increase in production capacity of the new plant, DFI’s consolidated revenue in the first half of the year reached €255.21million (NT$7.723 billion), representing an increase of 46.29% compared to the same period in the previous year. DFI’s operating gross profit was €48.95million (NT$1.482 billion) and gross profit margin was 19.19%, which showed improvement for 3 consecutive quarters. The net income attributable to the parent company was €6.57million (NT$199 million). earnings per share ( e PS) reached an annual increase of 55.36%. In the second half of the year, material shortages are expected to ease and raw material prices will stabilize. It is expected to improve quarter by quarter.

In terms of single-quarter operations, the second quarter book-to-bill ratio ( b / b ratio) of DFI’s embedded system business was 1.43. The overall order delivery is gradually being optimised to fully satisfy customer needs. In the face of the pressure for general inventory adjustments in the industry, DFI has also implemented inventory controls. The company will carefully respond to graphic and machine tool needs. The inventory levels are expected to be adjusted quarter by quarter and return to the levels in 2019.

The vice Chairman of DFI, Michael Lee, stated that although the company will face inventory adjustments, inflation, economic slowdown, overall economic uncertainty and other market changes in the second half of the year, the needs for new infrastructure in various markets are clear. These needs will product growth in automation, 5g, AIoT, and other smart applications through the strong demands. Therefore, aside from carefully responding to external risks in advance, DFI will optimise internal inventory controls. Overall performance is being optimised quarter by quarter according to the various operating indicators, and we are cautiously optimistic about the second half of the year.

Considering the demand for and diversity of smart applications on the market and deployment developments, apart from the focusing on factory automation, invehicle applications, and smart healthcare in the future, DFI will extend its market presence to applications such as green energy, information security, and Fintech, helping the company to accelerate the deployment of its transformations and improve its production capacity, thereby satisfying customer needs for different applications.

https://www.dfi.com

06 - AUTOMATION Mag - November 2022 8 DFI

DFI’S REVENUE IN THE FIRST HALF OF THE YEAR SETS A NEW RECORD FOR THE SAME PERIOD

06 - AUTOMATION Mag - November 2022 9 DFI

FUZZY LOGIC AND CAIRE, ON THE WAY TO AUTOMATING THE PAINTING PROCESS

Fuzzy Logic, with its Repplix software module, allows a robotic system to learn trajectories in a single gesture and without any specific training. With the help of a portable learning device, an operator can transfer their professional know-how to the robot by simply executing their task. The task can then be repeated as many times as needed in total security.

Since 1987, Caire’s teams have been assisting factories in the creation of special machines. They are experts in mechanics and automation master servo-controls, computer science, industrial vision and robotics. With their partner STI, they integrate numerous processes, including the application of products such as paint or varnish.

David Mangin, business Manager at Caire, explains: “Currently, the vast majority of product application lines that we create or modify are manual lines that our customers want to robotize. However, programming a robot for small series production activities with great diversity involves many trajectories, which is timeconsuming and requires the intervention of a highly qualified roboticist. This difficulty, coupled with the scarcity of skilled painters, hinders their robotization. Caire’s rare customers who do use robots on their product application lines also face programming difficulties. Faced with the number and diversity of parts to be processed, they create “approximate” or rough trajectories that cover all the parts to be processed. Some of these trajectories are then reprogrammed for greater precision, which requires several weeks of work by the roboticists. Despite these adjustments, the trajectories do

06 - AUTOMATION Mag - November 2022 10 FUZZY LOgIC rObOTICS

not always match the parts completely. This then requires complex air flow and product flow adjustments. e ach adjustment requires the production equipment to be stopped.”

Controlling a robot without programming, a unique software solution repplix solves this problem by eliminating robot programming and allowing the operator to create his own trajectories with millimeter precision.

ryan Lober, CeO of Fuzzy Logic, explains: “With the r epplix software module, developed by Fuzzy Logic, it is easy to robotize where it was previously impossible. The robot becomes a precision tool in the hands of the operator and allows him to automate his task autonomously, without any intervention from a specialist.

repplix works in a simple way: a portable teaching device, handled by an operator, teaches the software a trajectory. The software Fuzzy Studio provides a monitoring system via a real-time digital twin of the robotic installation, and takes into account collision monitoring and the feasibility of the trajectories in the robot’s environment. Furthermore, alerts are set up to warn the operator on the fly. The trajectory capture associates several process parameters such as the trigger pull of the gun and its flow rate. The

operator, who isn’t a robotics expert, can then modify the trajectory and process parameters via the graphical interface, even after the trajectory has been taught.

Then, using Fuzzy Studio, the cycle is launched and the robot executes the application exactly as it was demonstrated by the operator. The speed at which the robot moves is set directly in the software and can be modified from the learning speed. The cycle is performed autonomously by the robot, without the need for operator supervision. The operation is repeated in a few minutes for each new series of parts to be processed. Another advantage is that the module can be used immediately, without any real training being required.”

David Mangin adds: “While repplix takes control of the robot and pilots it on the fly, we are working with Fuzzy Logic on securing the process and interfacing repplix with the safety PLCa integrated into the system. Our roboticists have started to define exchange tables to control external actions via repplix, such as the triggering of cylinders, motors, application guns and flow regulators, etc. This safety aspect is designed within a normative framework.”

ryan Lober concludes: “Allowing expert painters to show a robot how to execute an application changes the whole game. The expert passes on their know-how

intuitively to a robot that takes care of repeating it. The robot allows the expert to multiply his or her productivity and allows the factory to imagine new manufacturing processes. This is what we call Automation Independence.”

Three projects in collaboration with Caire are set to be deployed in the near future with a major aerospace player. repplix will be used for product application on parts with high production variability. The line is scheduled to be installed in September 2023.

www.flr.io

06 - AUTOMATION Mag - November 2022 11 FUZZY LOgIC rObOTICS

ROBUSTEL RELEASE NEXT GENERATION IOT GATEWAYS FEATURING EDGE COMPUTING AND ROBUSTOS PRO A NEW DEBIAN BASED OPERATING SYSTEM

Robustel strengthen their industry leading portfolio of Industrial IoT routers and gateways with a brand-new series of cost competitive, fully integrated EDGE Computing gateways.

With a deep, well-established product range specialising in industrial IoT/M2M solutions, robustel are always looking for new and innovative ways to service customers in key industrial verticals. Since the company’s founding in 2010 the key directive has been to listen and engage with the market to provide solutions that meet real world requirements and a competitive price point allowing for the scale and potential of massive IoT.

06 - AUTOMATION Mag - November 2022 12 rObUSTeL

With the release of r obustel’s first generation 5 g Industrial g ateway the r5020 in 2020, the company has seen a massive global trend in customers relying on Cloud IoT infrastructure to deliver a variety of IoT solutions across all verticals; However, there is a growing subsector of customers with demand for more processing being performed at the network edge, to avoid unnecessary network noise and congestion from high volumes of data being streamed over the cellular network.

The requirement for e D ge /FO g processing sees a need for new generation devices, boasting the cutting-edge network connectivity and management features customers have come to know from r obustel devices but with the inclusion of much higher levels of onboard smarts and processing combined with a more versatile and scalable operating system.

This is where the edge gateway series from robustel hopes to revolutionise the industrial computer + router market by providing products that are not only available at a mass market price point but that also offer specifications and features that customers desperately need.

“Traditionally the industrial edge IoT market has been the domain of two very distinct solutions…” says robustel global Sv P of Sales and Product Marketing, Desmond Kuang, “We have seen customers unable to scale successfully because they are either buying a solution that is completely over specified for their requirements or they are trying to build their own solution with an industrial PC + router combination that adds an additional point of failure. Our e dge gateway products are designed to solve both market issues in a single elegant solution.”

The edge gateway series from robustel will initially launch with 3 product lines, of which the eg5100 and Lg5100 with ArMv7 Architecture and eg5120 with ArMv8:

The eg 5100 – Industrial e D ge router with global 4g/LTe connectivity

The eg 5120 – Industrial router with global 5 g connectivity (3 g PP release 16) and 2.3 TOPS NPU to support AI Applications

The Lg5100 – An industrial LoraWAN e D ge g ateway with global 4 g /LT e backhaul.

To support the new hardware, robustel are releasing a brand-new version of their popular Linux based operating system r obustOS, called r obustOS Pro. This new operating system offers customers a Linux Debian11 (bullseye) environment with support for Docker based applications. This move to a broadly adopted platform allows robustel customers to rapidly develop, test and deploy new applications in whatever language they are comfortable developing in; in addition to giving customers access to over 50,000 existing applications in the Debian repository.

With these products r obustel hopes to enable adoption in cutting-edge IoT applications like: robotics

• Smart Cities

• Automated/Autonomous vehicles

• Camera based image recognition

• real-Time energy & grid Management

And so much more… Samples of r obustel’s e dge g ateway series are available now for proof of concept and design work from any of robustel’s global distribution partners with mass market availability planned for Q4 2022.

The eg5100, eg5120 and Lg5100 shared features:

• Utilises highly stable cellular connectivity for global band coverage.

• High performance engine for running complex applications.

• 2 X rS232/rS485 ports for connection to industrial devices.

• 2 X DI and 2x DO simple monitoring and control.

• Dual SIM card slots for multiple back-up communication options.

• Wide operating temperature ranges, ideal for industrial applications.

• Supports C, C++, Java, Python, giving users the ability to develop their own applications.

• Access to more than 50,000 applications from the Debian repository.

• Access to vPN options like Wireguard, IPsec and Openvpn.

• Full Modbus TCP and rTU to support transfer to cloud platforms.

• r obustel’s management platform r CMS for effective management of large devices.

The eg5120 feature:

• Cutting-edge (release 16) 5g interface

The Lg5100 feature:

• Supports global Lo raWAN frequency bands

• Compatible with LoraWAN and private protocols

• Supports embedded LoraWAN network server

• Up to 8 channels supports receive data simultaneously

• Supports Packet Forwarder version 2.2.1 and Packet Forwarder Protocol version 1

https://www.robustel.com/en/ robustos/

06 - AUTOMATION Mag - November 2022 13 rObUSTeL

SMARTLINK PRODUCT FAMILY FROM SOFTING OFFERS EXTENDED FUNCTIONALITIES FOR PLANT ASSET MANAGEMENT

Two product releases from Softing’s smartLink family offer enhanced functionalities for Plant Asset Management and the implementation of Industry 4.0 connectivity in industrial networks.

The smartLink product family from Softing enables end customers to make efficient use of connectivity at the interface between OT and IT. The products allow simple and scalable integration of device data into plant asset management applications. The new versions of smartLink HW-DP v1.20 and smartLink SW-HT v1.20, which are now available, offer enhanced functionalities for data transfer and connectivity.

smartLink HW-DP - Integration of Industry 4.0 applications in PROFIBUS and HART systems

smartLink HW-DP enables access to process, asset, and diagnostic data from P r OFI b US devices and HA rT devices connected to PrOFIbUS remote I/Os, as well as secure export to any system inside and outside the user’s own network. The new version v1.20 now adds support for providing asset and diagnostic data from field devices via MQTT. This allows easy integration into typical IoT system architectures, such as the Namur Open Architecture (NOA) or the IoT reference architectures of large cloud platforms. smartLink SW-HT - Data access via Emerson AMS Device Manager and other HART IP-enabled Plant Asset Management applications smartLink SW-HT allows access to configuration and diagnostic data via e merson’s AMS Device Manager or other HA r T IP-enabled Plant Asset Management applications. As the only solution available on the market, smartLink SW-HT has so far supported Schneider e lectric M580 controllers and drop I/Os as well as Allen-bradley controllers and remote I/Os. version v1.20 now also connects emerson AMS Device Manager to HArT devices connected to r.Stahl IS1+ remote I/O. More and more modern remote IOs are using ethernet as a connection to the controller. smartLink SW-HT takes this trend into account by

providing an e thernet connection for tunneling HA rT commands to remote IOs. As a Docker container, smartLink SW-HT can be managed via Kubernetesbased management platforms or services of the major cloud platforms.

b oth new product versions expand the possibilities for end customers to implement open, standards-based, and scalable system architectures with the smartLink product family and to integrate connectivity into IT-managed edge solutions.

https://industrial.softing.com

06 - AUTOMATION Mag - November 2022 14 SOFTINg INDUSTrIAL AUTOMATION

The BXT motors deliver considerably higher torques than those usual in this drive class.

smartLink products enable Plant Asset Management and Industry 4.0 connectivity in industrial networks

EMERSON’S NEW ELECTRIC ACTUATORS OFFER SUPERIOR APPLICATION FLEXIBILITY, PRECISION AND REPEATABILITY

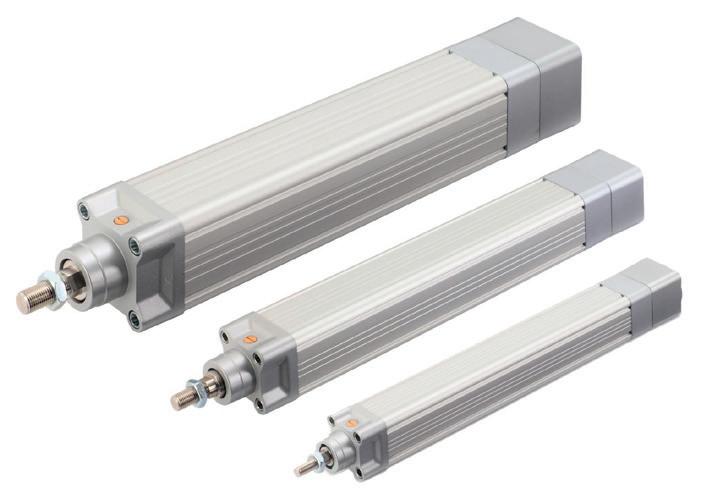

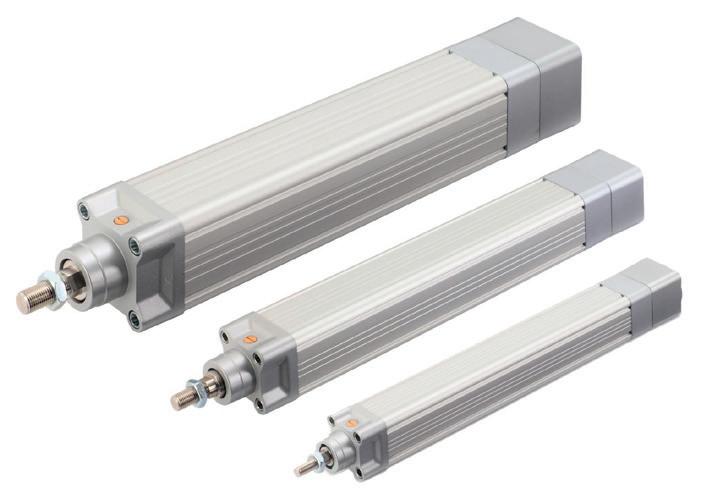

Featuring three different screw technologies, AVENTICS Series SPRA rod-style electric actuators offer unmatched versatility that can better meet exacting application requirements.

Emerson today launched its new Ave NTICS™ Series Servo Profile Advanced (SPrA) electric Actuators, a line of precise and highly repeatable rodstyle cylinders. While only one electric actuator screw type is typically available in the market, the SPrA actuators offer three screw technologies. These include a precision ball screw, which provides exceptional durability and accuracy for applications that need optimal quality or throughput, a cost-effective lead screw option and roller screws for precision, speed and heavy loads.

This versatile range of rod-style cylinders lets users in the automotive, food and beverage, packaging and life sciences industries configure electric actuators to meet exacting application requirements, such as improved sustainability or efficiency, rather than settle for standard approximation.

“With four sizes and multiple mounting options, the Ave NTICS Series SP r A e lectric Actuators are cost-effective, high-performance solutions that cover most machine automation applications,” said Linda Schwartzen, product marketing manager with e merson’s Ave NTICS actuator business. “Compliance with the ISO-15552 standard offers a wide range of accessories and our online calculation tool and configurator ensures the appropriate implementation and can meet exacting application requirements.”

Interconnected online tools allow users to instantly size and customize electric actuators, with no software installation or registration necessary. The configuration includes a direct download of CAD files, which comprises all elements of the configured solution, such as electric cylinder, accessories, mounting options and motor adapter.

https://www.emerson.com/en-us/ catalog/aventics-spra

06 - AUTOMATION Mag - November 2022 15 eMerSON AUTOMATION SOLUTIONS

MONITORING OF ENERGY NETWORKS – HOW TO MAKE IT EASY AND SECURE

Cloud and cyber security in critical energy applicationsDigitalisation and IoT (Internet of Things) is a clear trend within power plants and substations, just as it is in industrial automation. The Smart Grid is certainly a driving factor, but there are also other reasons for this change. Operators often find that only having data available in the control room is insufficient. Instead, they want to monitor transformers remotely, implement new maintenance concepts from anywhere, optimise utilization and commissioning, or retrieve environmental data online. This requires a solution with a high level of cybersecurity that guarantee critical control data to be strictly separated from monitoring data. The solution should also be easy to use and have a compact form factor to ensure that it is suitable for retrofitting and that it fits into existing cabinets.

06 - AUTOMATION Mag - November 2022 16 HMS INDUSTrIAL NeTWOrKS

By using Smart Grid gateways for monitoring energy networks, existing systems, new devices and control systems can be connected – regardless of the communication technology or the manufacturer brand.

Cybersecurity of utmost importance

Substations which convert high transmission voltage into consumer voltage are an important part of the electrical grid, not only for municipalities but also for the railways and industrial companies to name but a few. They usually consist of power transformers, switchgear and a lot of equipment for measurement and control. Substations are usually managed from a control room, or remotely from control centres. This control path is subject to strict security regulations as a successful hacker attack could have catastrophic consequences. There is also a need for cloud-based monitoring. b ut how can this be achieved without neglecting the required cybersecurity?

Two separate data streams

In principle, there are two different data streams in substations: the first is the control data with which the control room communicates with the substation or individual devices. Control data means sending commands such as “Turn switch on”, “Measure now” or “Send measured value”. This critical communication runs in real time according to the protocols used in the energy sector such as IeC61850 or I e C60870-5-104. The security requirements are high and unauthorized data must be excluded.

The second data stream delivers monitoring data from sensors and devices to the control room. real-time communication is not required here but the data packages are usually more extensive for this IoT data. Of course, the data must not be compromised here either, which is why communication is usually handled via TLS or v PN, for example.

There are also event-based alarm notifications that can be transmitted via independent data channels such as MQTT or SMS. Since the data only flows one way towards the control room or the cloud, this data stream and the transmitting device are well protected against attacks.

Typical data that is monitored

The data typically transmitted along the monitoring path includes, for instance, temperatures of transformers, highvoltage lines and motors, or oil pressure in transformers. If we take SF6-insulated circuit breakers as an example, it is possible to monitor gas pressure, temperature and gas humidity, and transformers, cables or battery back-up systems can provide voltage data. Data from building management can also be made available via the monitoring path. For example, door sensors of the access control system, air conditioning values or even a robot lawn mower can be monitored.

The data involved can come from various sources. Some data comes directly from the “heart” of the substation –values of the IeDs (Intelligent electronic Devices), i.e. the control computer for the switchgear or measuring devices in the station. Other data is provided by additional sensors that are commonplace in the industrial environment or in building management.

How to gather and forward the data? So how is it possible to gather the various data and how is it transmitted to ensure the required level of cybersecurity?

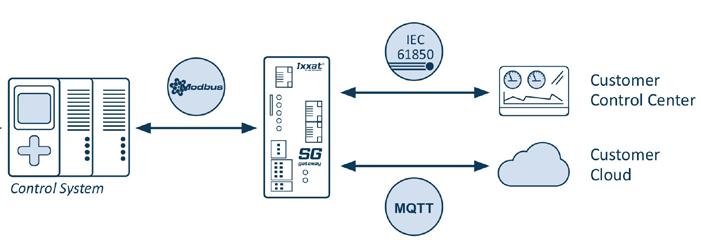

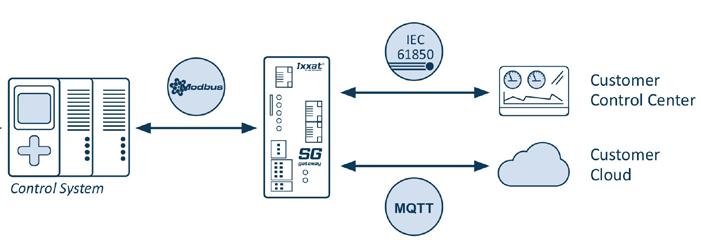

There are readily available gateways for this task (Fig. 1), such as the Ixxat Sg gateway from HMS Networks. These gateways combine the functionality of rTUs (remote Terminal Units), controllers and gateways; opening up possibilities to digitize substations and distribution networks. existing systems, new devices and control systems can be connected quickly – regardless of the communication technology or manufacturer.

Here is an example to demonstrate how the monitoring works in practice:

A gateway collects the data from various sources via the relevant ports (Fig. 2). It supports the communication protocols used in the energy sector, including I e C61850 and I e C60870-5-104, and can simultaneously feed in the data from IoT sensors connected via Modbus and analogue interfaces (for example).

06 - AUTOMATION Mag - November 2022 17 HMS INDUSTrIAL NeTWOrKS

The control unit of the UPS communicates with the gateway via Modbus and is connected to the control room via an IEC61850-based gateway. The status data of the individual battery cells is sent in parallel via MQTT to the manufacturer’s private cloud.

Monitoring and added value

Protocol conversion and, where applicable, media disruption, mean that such a cloud connection is very secure. In addition, the data is only transmitted in one direction; access options are initially not provided but can be defined as exceptions if necessary. Configuration of these types of gateways is usually graphical and does not require any programming knowledge or additional software.

There are many use case scenarios. For example, a sensor manufacturer can use a Smart grid gateway as a platform for communication with its private cloud, for remote monitoring, surveillance and maintenance planning. Substations can digitize the energy supply in an easy way: The gateway feeds the measured data – either from IeDs or sensors into the control system and can forward it directly to the cloud (MQTT) via an integrated LTe

modem where it remains available for continual status monitoring.

Another example of an application can be found in battery back-up systems for local control networks, for example in converter stations in the railway power supply system (Fig. 3). The control unit of the Uninterruptable Power Supply (UPS) communicates with the gateway via Modbus and is connected to the control room via I e C61850. The status data of the individual battery cells is sent in parallel via MQTT to the manufacturer’s private cloud. This guarantees functional reliability through continuous monitoring and prompt, plannable maintenance. It can even lead to new business models, e.g. renting a UPS system according to usage. And the best part: thanks to the ability to retrofit, older existing facilities can also benefit from the new possibilities of digitalisation.

https://www.ixxat.com/products/

06 - AUTOMATION Mag - November 2022 18 HMS INDUSTrIAL NeTWOrKS

energy/sg-gateway-overview

Author: Freddy Dahlberg, Business Development Manager Ixxat at HMS Networks

The US-China trade war, coupled with the spread of the COVID-19 epidemic around the world, has triggered a series of technological and financial wrestling, and to restart the growth momentum of enterprises at this moment has become an arduous challenge. CommonWealth Magazine uses 2020 revenue in the range of 100 million to 10 billion and three consecutive years of profit growth as the screening criteria. Industrial computer leader, DFI, has a revenue of NT$8.35 billion (equivalent to 300 million U.S. dollars), an annual increase of 18.8%. Due to these good results, DFI has been ranked amongst the Fast 100 in CommonWealth Magazine for two consecutive years.

CommonWealth Magazine, founded on June 1, 1981, is Taiwan’s first financial-oriented professional news magazine. In 2007, CommonWealth Magazine became the first financial news media in Taiwan to launch an englishlanguage website. In the years since, it has presented stories of Taiwanese companies, and industries as well as Taiwan’s political, economic, and social environment to the world through comprehensive and in-depth reports while providing news with a perspective.

DFI joined the Qisda group in 2017. In 2019, DFI acquired A e WIN to expand into the cybersecurity business, and Ace Pillar to expand diversified & comprehensive solutions, specialise in smart manufacturing, smart healthcare, and intelligent transportation systems/ infrastructures. According to a research report released by TrendForce in July, in the first half of 2021, DFI ranked third with a revenue of NT$5.28 billion (equivalent to 186.7 million U.S. dollars) and a 25.2% YoY increase.

“In recent years, in response to the trend of edge computing, industrial computer products have been widely used in the field of Internet of Things and becoming an important key to accelerating the introduction of artificial intelligence

technology. The industrial Internet of Things and digital healthcare are growing rapidly. With 40 years of experience and with the strength of the Qisda group, the rapid growth has deepened the supply chain’s recognition of DFI. This allowed DFI to continue to be listed in the Fast 100 of CommonWealth Magazine” said Steven Tsai, President of DFI.

Founded in 1981, DFI is a global leading provider of high-performance computing technology across multiple embedded industries. With its innovative design and

premium quality management system, DFI’s industrial-grade solutions enable customers to optimise their equipment and ensure high reliability, long-term life cycle, and 24/7 durability in a breadth of markets including factory automation, medical, gaming, transportation, smart energy, mission-critical, and intelligent retail.

https://www.dfi.com

06 - AUTOMATION Mag - November 2022 19 DFI

DFI IS

LISTED IN COMMONWEALTH MAGAZINE’S

2021 “FAST 100”

Rohde & Schwarz has introduced not just one but two new maximum frequencies for the R&S SMW200A vector signal generator, bringing previously impossible high performance to digitally modulated signals up to 67 GHz and beyond. The R&S SMW200A is first to enable flat frequency response and 2 GHz modulation bandwidth above 44 GHz. In addition to all applications already supported up to 44 GHz, the 100 kHz to 56 GHz option covers all currently used 5G frequencies, plus earth-to-satellite applications. The 100 kHz to 67 GHz option also supports planned higher frequency 5G bands, the 60 GHz WiGig band, and intersatellite links.

For the past decade the ceiling for a stand-alone vector signal generator capable of creating complex digitally modulated signals with high accuracy has been 44 g Hz. Higher frequencies have only been possible with additional external frequency upconverters or lower accuracy, both of which have limitations.

Now, with new options for maximum frequencies of 56 g Hz and 67 g Hz, the r &S SMW200A from r ohde & Schwarz dramatically raises the limits for generating wide bandwidth digitally modulated signals of high quality. A maximum modulation bandwidth of 2 g Hz is supported, meeting the requirements of even the wider subcarrier spacings defined for 5g Fr2 release 17, and wideband satellite transmissions. The established r&S SMW200A signal qualities including excellent modulation, flat frequency response, and four hardware-based levels of phase noise performance equally apply to the new frequency options.

06 - AUTOMATION Mag - November 2022 20 rOHDe & SCHWArZ

ROHDE & SCHWARZ ANNOUNCES UNIQUE 56 GHZ AND 67 GHZ FREQUENCY OPTIONS FOR R&S SMW200A VECTOR SIGNAL GENERATOR

Applications in the U and v bands now supported include mobile radio, Wireless LAN, and satellite communications. For mobile radio engineers developing r F components and products to support the 5g mobile radio spectrum available in the 47 gHz frequency band already allocated by the FCC to US network operators, the r&S SMW200A with 56 gHz or 67 gHz option is the ideal signal generator. 3 g PP r elease 17 specifying further enhancements to 5g has reached a welldefined stage, so the developers will be looking for a signal generator to cover the now extended Fr2 frequency range from 52.6 gHz up to 71 gHz. The only suitable signal generator currently available is an r&S SMW200A with a 67 gHz frequency option – supporting up to 72 g Hz in overrange mode.

The new frequency options are equally interesting for high frequency WiFi and Wireless LAN, including Ieee 802.11ad, which operates in the 60 gHz unlicensed band (57-71 g Hz). For satellite communication applications, forward and reverse links operate between 37.5 gHz and 52.4 gHz; inter-satellite links use frequencies up to 66 gHz with bandwidths up to 2 gHz.

In addition, for demanding applications above 44 gHz throughout the Aerospace and Defense industry, or for generating digitally modulated signals including early research on 6g components and systems, an r &S SMW200A with frequency options for 56 gHz or 67 gHz, is the highperformance single instrument signal source of choice.

The new r&S SMW200A vector signal generator frequency options are now available from rohde & Schwarz.

The R&S SMW200A vector signal generator now covers up to 67 GHz as a single-path instrument.

www.rohde-schwarz.com/ products/_63493-38656.html

06 - AUTOMATION Mag - November 2022 21 rOHDe & SCHWArZ

100 YEARS OF MITSUBISHI ELECTRIC – A STORY OF SUCCESS

A century of Mitsubishi Electric – a company with a rich history which parallels that of modern-day Japan. Since 1921 Mitsubishi Electric’s success has grown as a global player in the field of automation.

06 - AUTOMATION Mag - November 2022 22 MITSUbISHI eLeCTrIC

The very first Mitsubishi company was established back in 1870 by Yataro Iwasaki. This company provided the foundations for what would later become the group of independent companies which are active in almost every industrial sector. In 1921 the company known today as Mitsubishi e lectric Corporation was formed and became renowned the world over for its expertise and innovation in the development of high-quality electrical and electronic products.

Products developed and manufactured by Mitsubishi electric can be found in all fields of industry, including information processing and communications, space development and satellite communications, home electronics, industrial automation, energy, mobility and building technology, as well as in HvAC systems.

e urope has long been a key market for Mitsubishi e lectric, and in 1969 the company as it opened its first representative office in the region which would form the basis for its e M e A operations today.

Factory Automation

Throughout its history, the Factory Automation division of Mitsubishi electric has been one of the global leaders in automation product development. Combining innovative technologies with advanced functionalities and feature sets, with the highest levels of reliability. As early as 1973, the company developed its first PLC which was designed to replace relay control panels.

Innovations in frequency inverters, servo/ motion products and industrial robots followed, and in 2007 the company launched the iQ Platform, the first automation platform to combine four types of controllers on a single platform – robot, motion, CNC and PLC.

Digitalisation pioneer

In 2001, Mitsubishi e lectric launched its e-F@ctory concept – a pioneering approach to digitalisation that was years in advance of the definition of Industry 4.0 or the rise of the Internet of Things. It has seen the company develop a reputation with customers as a trusted partner through all stages of their digital transformation.

Strong partnerships have also driven the company to continuously evolve its e-F@ctory Alliance, an integral part of e-F@ctory concept. This has enabled Mitsubishi e lectric and its partners to offer their joint customers a wider range of optimised solutions that help them to enhance their competitive advantage and further drive their digital business transformation.

With the development of Maisart (“Mitsubishi e lectric’s AI creates the State-of-the-A rT in technology”), the stage has been set for the company to continue to be a driver of innovation for the next 100 years.

Mitsubishi electric – Factory Automation https://www.mitsubishielectric.com/fa/ business/history/index.html

Mitsubishi electric overall: https://www.mitsubishielectric.com/ en/100th/index.html

06 - AUTOMATION Mag - November 2022 23 MITSUbISHI eLeCTrIC