We’re Creating the Future of Water for people and communities, for generations to come

The new chair of South East Water, Lynn Warneke, is charting an innovative course for the

We’re Creating the Future of Water for people and communities, for generations to come

The new chair of South East Water, Lynn Warneke, is charting an innovative course for the

Coagulation process

with an awardwinning Iranian Australian.

Testing for tomorrow –how proper water testing procedures are adapting to change.

The

could influence the future of the Australian and global wastewater industries.

Keeping

moving with the right equipment.

Do

have the proper process for

wastewater management? This company can help.

Enhancing the efficiency of

applications with the right equipment

Streamlining the rehabilitation of water mains

WE ARE NOW approaching two years of Inside Water. As the inaugural editor of this publication, I’ve had the opportunity to meet a range of people and learn an incredible amount about the industry.

We all know that water demands our constant attention, as it is the foundation, if not the bedrock, of every aspect of life. In this issue, we look at some of the issues affecting the water and wastewater industries.

All water utilities across the country and around the world are led by extraordinary people. One of the newest appointments is Lynn Warneke, who is now chair of South East Water. We spoke to Warneke about her vision for the future, emphasising the importance of collaboration and embracing cutting-edge technologies like the Internet of Things (IoT). Her insights are a must-read for anyone navigating the ever-evolving water landscape.

The role of IoT in the water and wastewater industries is continuing to expand. It is revolutionising water management, from real-time leak detection to optimising infrastructure performance. Forward-thinking companies like Dataright and Iota are leveraging the power of big data to streamline operations and ensure a reliable water supply.

It goes beyond that, though. Australia has been hit by multiple extreme weather events, and those events impact communities across the country. Having the systems in place for robust emergency management is critical. Inside Water spoke to water utilities and technology providers to see what they are doing to prepare, plan, and recover. It’s paramount reading for utilities and water managers across the country, as these weather events are only going to become more common and have bigger impacts

on communities and infrastructure. If preparing for an emergency is not enough, providing safe and clean water for everyone is a cornerstone of society. There is a range of companies providing cutting-edge technological solutions for ensuring that water quality is monitored in near real-time. It empowers water utilities and local councils to deliver safe and clean drinking water to their communities.

We also welcome the Water Industry Operations Association and WaterAid Australia in offering editorials that talk about what they are doing. These organisations play an enormous role in the water and wastewater industries, not just in Australia but at a global scale.

Of equal importance is the role of education in the development of workplace culture. There are numerous opportunities for water utilities to become leaders in the field when it comes to providing opportunities for their teams to move up and make a difference for their local community, as well as society as a whole.

We also have some unique products for our readers to review. Cuttingedge technology can be key to improving sustainability outcomes or increasing productivity. One never knows how a new product can improve operational outcomes.

Let the flow of knowledge begin!

Chief Executive Officer John Murphy john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy christine.clancy@primecreative.com.au

Publisher Sarah Baker sarah.baker@primecreative.com.au

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Editor Chris Edwards chris.edwards@primecreative.com.au

Design Daz Woolley/Tom Anderson

Head of Design Blake Storey blake.storey@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Brand Manager Marina Milisavljevic marina.milisavljevic@primecreative.com.au p: +61 411 833 795

Client Success Manager Glenn Delaney glenn.delaney@primecreative.com.au

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 enquiries@primecreative.com.au www.insidewater.com.au

Subscriptions

+61 3 9690 8766

subscriptions@primecreative.com.au

Inside Water is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Cover image

South East Water

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

Inside Water is owned by Prime Creative Media and published by John Murphy. All material in Inside Water is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Water are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The challenge of managing water resources and advancing clean energy production has become paramount in the business world today. At Hydroflux, our commitment to rethinking is ingrained in our DNA because we recognise that each challenge is unique. Whether you’re a local municipality, a global manufacturer, or anything in between, we’re driving sustainable change – now. Specialising in water, wastewater, renewable energy, climate resilience and environmental protection, Hydroflux provides a vast range of certified carbon-neutral products and services to help solve some of your most complex challenges.

With tailored solutions, ongoing support and a commitment to measurable results, Hydroflux is rethinking what’s possible to build a better future.

With the change of guard at South East Water, Lynn Warneke has stepped up her new portfolio career path. Her background in digital transformation and emerging technologies will continue to see South East Water as a pinnacle of innovation.

“I’VE JUST FINISHED a Master’s of Law, focusing on technologies, corporate, and climate law,” said South East Water Chair Lynn Warneke. “I’ve been getting very involved and passionate about digital innovation as part of a low-carbon future, and the Victorian water sector is doing a lot of work in leading action on climate change, adaptation and mitigation.”

That’s just one reason why Warneke found herself in the water industry.

South East Water has long been a paragon of innovation and digital technological leadership. She wanted to be part of the next sustainable and technological delivery phase.

“One of the things I appreciate about the Victorian water sector is that it continues to be an ESG leader,” she said. “This is not just in the digital space, but also when it comes to Traditional Owner engagement.”

At its simplest, the most fundamental benefit the water industry can provide people is life. It’s been proved that humans can only live for about three days without water.

“It’s essential for human life and our flora and fauna,” Warneke said. “Beyond that, it’s essential to the economy, for example, in agriculture and food production. Then, we need to look at the Australian way of life, which has a significant focus on recreational and sporting pursuits. It’s all about water in various ways, and that’s why South East Water’s purpose to deliver healthy water for life for customers, community and environment is critical.”

She understands that ensuring South East Water’s customers’ safe, healthy, and sustainable way of life comes from developing forward-thinking water solutions for everyone. At the same time, having

Lynn Warneke is the Chair of South East Water.Images: South East Water

that water at a reasonable price for its customers is fundamental.

During a cost-of-living crisis, every utility has to lead in supporting thousands of customers dealing with a myriad of issues. Like every Australian water utility, South East Water works to make its customers’ experience better every time.

“A huge part of what South East Water is doing when it comes to affordable water pricing is coming through our digital transformation journey,” Warneke said. “Our evolution into a digital utility is key to ensuring greater efficiency and effectiveness in the network.

Our work in that space, through investments in digital metering and the Internet of Things (IoT), will give us unprecedented visibility into our network.”

By shifting to a new digitallyenabled operating model, Warneke believes that data-driven insights will allow South East Water to optimise pre-emptive and reactive maintenance programs. That comes with additional benefits for its customers.

“This shift will provide our customers with unprecedented visibility into their household water use, as well as our business customers,” she said. “At this stage, we have notified about 14,200 customers of leaks. That represents about 15.6 per cent of all our customers with digital meters. That has saved 1.25 billion litres of water that otherwise would have been lost. To give people an idea of the benefit in dollar terms, our customers have saved $5.2 million on their water bills.”

Those numbers represent tangible outcomes from the digital metering program. It’s also just a taste of what South East Water can do to help its customers save drinking water and money. This is before the work is done on predictive, preventative, and reactive maintenance programs.

Iota and benefits to all

Part of South East Water’s drive comes from its wholly-owned subsidiary, Iota. Its job is to take

the research and development generated within South East Water and find ways to scale it up to commercial levels.

“Iota has developed a comprehensive set of products, services, platforms, and offerings that leverage IoT, technology, and telemetry across the water network,” said Warneke. “If we look at it from a platform perspective, Iota and South East Water offer a range of product offerings, with the digital water meter being central to them. The Lentic platform can provide a single pane of glass to assess water use.”

Footprint is similar in that it can offer commercial customers, such as shopping centres, granular data about how water is used across their properties.

Part of that granular data then involves communicating issues with residential and commercial customers. Customer, community and stakeholder engagement is vital for water utilities, and South East Water is doing its best with proactive, ongoing engagement.

“The digital metering program of South East Water and Iota’s services and products means that domestic and business customers can gain greater visibility into their water use,” she said. “It’s not just about engaging with customers to tell them how they can reduce their water use; it’s about optimising our digital channels to engage effectively with our diverse customer cohort and provide them with timely and actionable information.”

Any water utility worldwide faces the challenge of actively engaging with various communities. This includes not only those from multicultural communities but also those who consider different socioeconomic factors.

“It remains essential for South East Water to feed customer needs into how we think about our service design,” Warneke said. “One of the formal ways we do this is through the Customer and Community Advisory Council. The Council meets four times a year and has industry and community members representing our diverse customer base and community. Industries and fields include agriculture, behaviour change, customer advocacy, environment, local government, multicultural affairs, plumbing, building technology and youth.

The water sector has traditionally been male-dominated. However, the Australian water industry is a leader in increasing diversity across management teams. According to Warneke, the change is already underway.

“The Victorian Government and Department of Energy, Environment and Climate Action (DEECA) are to be congratulated for their gender diversity efforts,” she said. “With female chairs now slightly outnumbering male chairs among Victorian water utilities and more broadly 50:50 gender representation amongst directors, there is now more work to be done when it comes to cultural and other forms of diversity. I know this is a key focus for DEECA and the water corporations.”

There’s also a focus on data plans and actions at the management level and throughout the organisational structure for all water corporations in Victoria. Warneke pointed to the discussion at a recent Chairs Forum organised by VicWater.

“As we know, what you don’t measure, you can’t manage,” said Warneke. “VicWater is doing a lot of reporting and data gathering on diversity in the sector. As I said, the

change is already underway. South East Water remains committed to inclusion and diversity in working and doing business with the many communities within our service area.”

Labour shortages are challenging Every industry worldwide is dealing with staff shortages. The water sector is not immune to this, so having the right partnership in place is vital for water utilities.

“We are fortunate to have solid relationships with our commercial suppliers and partners,” Warneke said. “They form a critical part of our strategic direction.”

Warneke brought an extensive technology executive background to South East Water. She is already well-versed in understanding an organisation’s existing challenges while also considering the digital skills that will be required in the future.

“For our future transformation, we will need expertise in data science, artificial intelligence (AI), robotics, sensors, IoT and cybersecurity, as just a few examples,” she said. “Australia is already facing a significant skill shortage in many of these areas. I’m an active member of the Australian Computer Society (ACS), who are

projecting an annual work gap of 200,000 people by 2030 within the digital skills space, especially in relation to AI and generative AI.”

For Warneke and the rest of the water industry, understanding these potential staff shortages means a shift in recruitment and workforce upskilling strategies.

“How can we reflect the great sector that is water and attract talent across the board?” Warneke asked. “It’s a focus for all the water corporations across Australia.”

Looking into the future of a water utility can be challenging. Warneke has grasped it with both hands.

“Our price submission to the Essential Services Commission (ESC) indicates where we want to go,” she said. “It was two years of work and involved about a quarter of our workforce. We consulted over 8600 customers. That dives back into the importance of codesign and customer consultation. Altogether, the price submission represents what we call our ‘Fiveyear Customer Commitment.”

While it includes changes in charges to its customers, the price submission laid out the services

South East Water will provide, along with the support and projects it commits to delivering to its customers and communities.

“It is an essential document designed to set us up for success,” Warneke said. “We will have to spend a lot of time meeting those commitments. However, we are also looking at the challenges of climate change while meeting our obligations under the Water Act and the Ministerial Statement of Obligations.”

Warneke believes that South East Water will remain a pinnacle of

“Iota is working with Toowoomba Regional Council to roll out a significant digital utility project. South East Water’s research and development capability will remain a core driver of our innovation.

Lynn Warneke has extensive knowledge of technologies, corporate law, and climate law.

as possible save water and deliver beneficial environmental impacts beyond our borders.”

For more information, visit southeastwater.com.au and iotaservices.com.au

• A complete drive solution, available in 20 sizes

• Modular design for flexible layout & mounting

• Withstands harsh operating conditions & handles big loads

• High torque density, up to 1, 300, 000 Nm

• Effective in a wide range of working temperatures

www.bonfiglioli.com/australia/en

www.bonfiglioli.com/new-zealand/en

When the Queensland branch of the Australian Water Association (AWA) awarded its Young Water Professional of the Year, Amber Craig from the Murray–Darling Basin Authority (MDBA) was the recipient.

AMBER CRAIG IS a hydroclimate analyst and senior project officer with the Murray–Darling Basin Authority, working at the scienceto-policy interface. She further contributes to the water sector through First Nations reconciliation efforts and promotes diversity and inclusion through her leadership.

“My career in the water industry started with an earth sciences background,” Craig said. “I’m a geologist by training. As part of my Master’s, I did coursework in a range of subjects focusing on sedimentary geology, which was my specialty, and that led me to hydrogeology, meaning groundwater.”

Craig started at a consulting firm in Brisbane in 2019 before moving to the Murray–Darling Basin Authority in 2020.

“I’m really grateful that I found the water industry,” she said. “It aligns with many of my values and goals, and I am grateful I found the industry so early on in my career.”

One of the things that attracted Craig to the MDBA is the opportunity to make a difference. She reflected on the droughts between 2017 and 2019. During this period, almost all of New South Wales was declared to be in drought by the middle of 2018, and other parts of the country were also experiencing drought conditions.

“It was a big catalyst for me to join the Authority,” said Craig. “Because of my interest in groundwater, I was particularly devastated seeing Chennai and Cape Town going to

Day Zero of groundwater, meaning when they would not have any groundwater left. Closer to home, I saw the media showcasing the drought impacting the MurrayDarling Basin. I wanted to continue in the water industry, where I could utilise my training through my work and make a difference.”

She believed her movement to work in the MDBA had allowed her to make a difference in climate change. As Craig put it, it’s where the rubber hits the road when it comes to climate change and its impacts on people and the planet.

“I was excited to join the MDBA because it was a great opportunity to work at that highest level of influence,” Craig said. By working to set national-level policy, I can

Amber Craig has been working at the Murray–Darling Basin Authority.

Image: Amber Craig

Amber Craig (centre) receiving her 2023 Queensland Young Water Professional of the Year prize.

Image: Australian Water Association

see that it’s really a foundation of bringing people together and bringing the States together for the good of the Basin. We can consider different perspectives and priorities and bring in the best available science to make informed decisions. It’s this collective mission that resonated with me.”

Craig is employed in the Applied Science branch, which aims to bring the best available science into the sustainable water limits theme of the upcoming Basin Plan Review. However, it’s not just the science that encouraged her to continue working within the Authority.

“It’s the people, and the Authority’s community element,” she said. “I work with many intelligent and passionate people who bring together different ideas and skills. We need to have that to find innovative solutions to such complex problems.”

Craig relishes the opportunity to delve into the science and apply those solutions to a problem that makes a big difference.

“In some regards, I’m a knowledge broker between researchers and scientists, and policy and decisionmakers,” she said. “It’s important to ensure they are talking to each other and have the best available information.”

The challenges

Governments of every stripe and scientists across the country have long recognised that managing the Murray–Darling River Basin is a challenge.

However, it’s not just one challenge. There is a multitude of issues, with different stakeholders pushing and pulling in different directions to achieve their unique goals.

“It’s challenging to consider all the issues facing the Murray–Darling Basin,” Craig said. “However, I think it’s a worthwhile challenge. One challenge is the broad network of communities and landscapes across the Basin. It’s an incredible patchwork of communities with different perspectives, priorities, and experiences. Even environmentally, there are different characteristics and climate drivers, from the northern

Australia.”

Factoring all these things together and being able to come together for an informed decision to get the best outcome is a tricky space to work in.

Craig understands this challenge.

“I believe that much of the lowhanging fruit has already been picked,” she said. “It’s the high-value, hard work that we have to do now.

Getting out on the ground to have conversations with community members and being embedded in the environment reminds me why I do what I do.”

Working with First Nations groups

Craig has taken on additional responsibility outside her scientific research by expanding her cultural knowledge. She has spent time supporting the Authority’s Reconciliation Action Plan.

“Furthering my own cultural knowledge and reconciliation journey is something I have enjoyed from working for the MDBA,” she said. “It’s been among some of the most rewarding parts of my career and life. I’m so grateful for my experiences in this field.”

Craig has worked with First Nations staff members, as well as with nations on Country.

“The First Nations people I have worked with have been so generous with what they share and the insights

they provide,” she said. “I have been with the agency for four years, I have furthered my cultural knowledge and understanding in that time. My understanding and respect for Country and the connection First Nations people have to Country and culture has grown. It really drives me to do what I do.”

Climate adaptation

By working with a range of communities, including First Nations and irrigators, Craig has developed a unique perspective on taking both a macro and micro approach to climate adaptation across the Basin.

“When we go out and talk to communities, they talk about the changes they are already seeing in their local area,” she said. “They tell us about the changes in the environment and the climate. We can see them adapt their ways of working or land utilisation.”

Craig pointed out that changes may impact First Nations people, as some ceremonies are tied to changes in the environment, seasons, and weather.

“At the macro level, the Murray–Darling Basin Authority has many teams concentrating on climate adaptation from a policy perspective,” said Craig. “I consider myself very fortunate to be at that policy-science interface.”

Part of her work on climate adaptation involves supporting

the Murray–Darling Water and Environment Research Program (MD-WERP). This four-year, $20 million Australian Government initiative aims to strengthen scientific knowledge of the Murray–Darling Basin by generating new knowledge, innovation, and tools.

“I’m a coordinator for the climate adaptation theme,” Craig said. “In our stream, we are addressing the science within climate adaptation to bring to the Basin Plan Review. Some information from MD-WERP is already publicly available. More will be coming out in the next 18 months or so as we conclude the program. While I am not completing the research myself, I get to be an integral part of that whole process.”

The Murray–Darling Basin is a system facing profound future challenges in adapting to a hotter, drier climate. The theme aims to better understand how climate change will impact the Murray–Darling Basin, identify options to adapt to change, and evaluate potential outcomes for Basin values. The research will identify adaptation options and assess their efficacy across economic, environmental, social, and First Nations values. The

research outcomes aim to support policy decisions and reduce the risk of more harmful than helpful outcomes.

It’s been several months since Craig won the Queensland branch of the Australian Water Association’s Young Water Professional of the Year prize. She was Queensland’s representative at the national finals.

“To be a state winner and national finalist has left me both stunned and humbled,” Craig said. “I feel so grateful to be in that position. I am inspired to be nominated with many incredible young water professionals from across the country. I’m excited to meet them all at OzWater in Melbourne at the end of April.”

This is one of many awards Craig has won. Previously, she won the Chief Executive Award – Professional Staff Excellence – Team. It’s an internal award for ‘outstanding, collaborative work delivered by the River Modernisation Team’ for delivering the BarmahMillewa Feasibility Study on time and within budget ($3 million), with notable community engagement

Conducting sand samples on the Murray River.

Image: Amber Craig

success considering the sensitive nature of the work.

“I also won a few awards while studying at the University of Melbourne,” she said. “These included the P.W. Crohn Scholarship, and the P.J. Adams Research Award associated with my post graduate research. I am grateful to have received those awards, as they recognised the hard work I have put into my research and career.”

In Craig’s eyes, she wants to continue working in this space and leave the world better than she found it.

“I want to minimise the negative impact that climate change will potentially have on many people and the environment,” she said. “I want to be able to walk away and be proud of the legacy that I leave. That extends to the workspaces I am in; I want to leave them in a better space and place than when I found them. If I can achieve even a small part of this, it would be a massive achievement in my career.”

For more information, visit www.mdba.gov.au

MOVING OVERSEAS TO continue

There are many researchers across Australia working in the water and wastewater industry. One is Hiua Daraei, an Iranian-Australian who is a National Finalist in the Student Water Prize. is that research outcomes include having beneficial impacts to relevant industries and communities.”

cutting-edge research remains a priority for thousands of young people worldwide. That’s particularly the case in the water and wastewater industry, where people from around the globe have come to Australian universities to study. This includes Hiua Daraei. Originally from Iran, he moved to Adelaide to complete his Ph.D. and is now a research fellow at the Cities Research Institute, Griffith University on the Gold Coast.

“After completing my Master’s degree in Iran, I had an opportunity to serve as a university lecturer instead of completing about two years of military service,” Daraei said. “It was an excellent opportunity for me, and I worked in the Department of Environmental Health Engineering at the Kurdistan University of Medical Sciences.”

Daraei’s background is primarily in analytical chemistry and chemometrics, which made him a good fit within the Department. It also helped fulfil his potential as a researcher in the water and wastewater industries.

“In Iran, our research team worked predominantly on wastewater treatment processes,” he said. “The primary focus of our research was on development of novel modified nanomaterials, membranes and electrodic processes to efficiently remove pollutants. Our research mostly focused on proof-ofconcept studies as opposed to industry-based applications that would have measurable impacts on communities. However, for me personally, a key part that I value

to Australia

Coming to Australia was based on achieving new knowledge and skills that he considered essential in his career development. Daraei had long sought to have a beneficial impact on the water and wastewater industries and society in general. In his earlier research work in Iran, achieving that was not so clear, as his university-based research was conducted independently from direct industry involvement and input. Greater efforts have been made in recent years to address this and overcome the separation in university research work and industry involvement in Iran.

“In Australia, there are great opportunities to work with industries, including the water industry,” said Daraei. “I obtained a scholarship to undertake a Ph.D. program at the University of South Australia as part of an Australian Research Council’s Linkage Project. This Ph.D. program was undertaken under the principal supervision of Professor John Van Leeuwen.”

In Iran, many drinking water distribution systems are old, suffer from significant water leakage, and consequently the distributed waters can be of lower quality than expected at the customer tap. For Daraei, the opportunity to come to Australia to continue his research, both academically and importantly, with industrial partners being directly involved, have provided personal

What is he studying?

Professor Christopher Chow

As part of his research, he worked to advance conventional water treatment processing. The original method was developed in Egypt more than 3500 years ago and established as conventional process in modern water treatment plants during the early 19th century. However, there is still ample room for research and advancement, particularly in its process control and automation.

“The established and routinely applied process control part of this technology is a little old-fashioned,” Daraei said. “It often involves timeconsuming and labour-intensive testing to determine optimum processing. That is particularly the case when running jar tests.

often do not like doing these tests because they are time consuming and require frequent water sampling and data analyses. The output can also be subjective based on the operator’s understandings and decision-making.”

Daraei’s Ph.D. and postdoctoral

things more straightforward for water and potentially wastewater treatment operators in determining the optimum coagulant doses for targeted treated water quality. He focussed on the development of mathematical models for real time application of a novel fluorescence

called the EXO fDOM Smart Sensor. research showed

called the EXO fDOM Smart Sensor. research showed

have much turbidity and organic matter related interferences for the signal. That’s not the case for water treatment plants fed by surface waters, particularly rivers and reservoirs.”

Dealing with coagulation, flocculation and settling processes

Anyone in the water and wastewater industry would be familiar with the importance of these processes.

Daraei is no stranger to them either.

“They are known as the heart of the conventional water treatment plants,” said Daraei. “Coagulants, in the right amount, allow water treatment plants to remove most particulate matter measured as turbidity, and dissolved natural organic matter. That can make the remaining stages of water treatment easier, more efficient and affordable, also removing part of the concerns around micro-organisms.”

If the dosage of coagulants or flocculants is either insufficient or even excessive, this can cause water treatment problems. Any problems or drop in efficiency can result in higher costs in water treatment plant operations, whether using a higher volume of chemicals than necessary or having to account for more treatment through not having enough.

“It is imperative to tune in the level of coagulants carefully,” he said. “They play such an important role in removing turbidity and contaminants that other stages are nowhere near as effective.”

This is why removing organic matter properly is vital. If the

some organic matter responsible for DBPFP is removed. Chlorinebased disinfectants reacting with the residual organic matter can generate disinfection by-products, some of which have been reported to be carcinogenic.

“Australia has very tight standards around levels of residual turbidity and colour as well as DBPs and chlorine levels in produced waters,” Daraei said. “It’s because Australia wants to maintain good-quality water, and at the most fundamental level, the process of using coagulants has a key role in the resulting water quality.”

Daraei has focused on influencing society and industry to translate his research outcomes into technology. However, it can be challenging to get new technology into active use.

“The first part of my research is taking my findings and developing them into viable technology,” he said. “We also need to show that the technology is suitable for industry use and is reliable. For this we needed our partner organisations to support evaluation trials and helping us scale the developments to a commercial level.”

Daraei pointed out that this can be an issue in many countries. Rules and policies determine how things can and should be commercialised. From his side, Daraei believes that his research has made significant progress and the industry partners

opportunity to test his research in a real world environment.

help in developing the technology to translate it into practical outcomes.

“Working with companies like Seqwater, Melbourne Water and Xylem has been fantastic,” Daraei said. “I have found their support and encouragement to be brilliant. I didn’t have that experience in Iran because of the separation of academia and industry. Everyone has been open to supporting me with all that was needed for the Ph.D. project. I’m looking forward to the implementation stage of the research outcomes.”

Daraei said it is a great honour to be a finalist in the Student Water Prize for the Australian Water Association (AWA). In his own words, his Ph.D. examination process was very challenging as an overseas student, and took longer than he originally planned.

“I collected a large number of water samples and did a significant volume of water quality analyses,” he said. “Many would think the rest of the project would be just modelling. However, it was extremely complicated to analyse the large data base generated. I just fought and persevered to attain for what I was working on.”

This nomination is a gift for him as it acknowledges his work over the last few years.

“It was a relief to receive this nomination,” he said. “At the end of it all, it’s great to be recognised by experts in the field.”

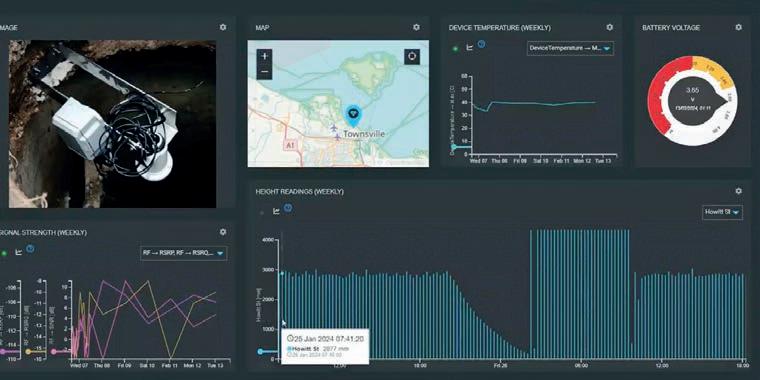

With the explosion in water utilities taking up smart water meters, those meters need to be installed and maintained. This is where companies like Data Right enter the fray.

WITH THE EXPLOSION in water utilities taking up smart water meters, those meters need to be installed and maintained. This is where companies like Data Right enter the fray.

Data Right has installed more than 120,000 automated meter readers (AMRs) around Australia. It prides itself on exceeding client expectations and always strives for 100 per cent data accuracy.

How did Data Right come about?

It’s the work of Ian Joblin, Data Right Director and Chief Executive Officer. He’s had something of a less traditional entrance into the water industry as an accountant.

“I was working with a local government that needed assistance to effectively complete their smart meter rollout, so they approached me to project manage the balance of the rollout,” said Joblin. “When completing the project, we met Taggle Systems. From there, our relationship started.”

Data Right has worked predominantly with Taggle Systems while slowly adding

local government clients who are coming directly to Data Right. Its first rollout of smart meters was for the Narrabri Shire Council in northern New South Wales. Since then, it has integrated smart water meters for 25 local governments and water utilities throughout New South Wales, Queensland, and the Northern Territory. The last twelve months have seen them complete Tamworth’s 22,000 meter rollout, stage 1 of Gladstone’s rollout in Seventeen Seventy and Agnes Waters and 9,000 meters for Townsville. They have just begun the Southern Downs 9,500 meter project and the annual meter and trade waste meter replacements for Mackay.

“We have now evolved to also offer meter network audits in preparation for meter and AMR ordering,” he said. “We also offer smart water meter maintenance programs, meter reading, project management and plumbing works associated with water meter service lines.”

In an environment where it can be challenging to attract and retain skilled tradespeople, Data Right offers local governments and

water utilities the opportunity to outsource their meter replacement and AMR maintenance programs. This ensures that existing staff within the organisation can focus on other, more crucial tasks.

For Joblin, automated meter reading is all about connectivity between a water utility and its customers as it works towards a smart city environment. He pointed out the importance of having high-quality communication between them.

“We are no longer in an environment of one-way communication between the water utility and customers in the form of a quarterly water bill,” Joblin said. “Such an approach can lead to bill shock, water wastage, and inappropriate resource allocation in attempting to manage these problems. A smart water meter system can provide customers with near real-time information about their water consumption, leaks, and overall consumption patterns. The water utility is then seen as a solution provider for its customers.”

It’s an environment centred around information sharing for the benefit of both parties. Automated meter readers eliminate the need for on-site manual meter reads, which pose a range of work health and safety risks.

Our project management skills are disciplined, personalised and adaptive. “ ”

The process difference between Data Right and other companies revolves around well-developed, auditable, disciplined processes.

“Our processes have been developed to ensure that meter installation, data capture, and data continuity are as accurate as possible,” said Joblin.

Joblin and Data Right pride themselves on consistently achieving above 99.5 per cent accuracy with in-field information gathering. This provides Data Right’s customers with confidence that their meter network data is accurate.

“We only utilise quality contractors who take the utmost pride in the quality of their workmanship,” Joblin said. “We have retained these contractors for many years, and they are a crucial part of the business. Our project management skills are disciplined, personalised and adaptive, providing customers with a guided journey through their smart metering process.”

Data Right prides itself on its operational fluidity, having no problems moving between projects and locations. It also ensures that its clients’ expectations are met and exceeded. It provides annual maintenance programs to its customers to ensure that all smart water meters are accurate and solve a range of problems that may occur.

Data Right is looking to expand further. It is looking to develop a larger customer base that utilises its smart meter rollout services and ongoing meter network maintenance programs.

“The maintenance division is an obvious area for expansion,” Joblin said. We hope to enter ongoing maintenance agreements that provide water utilities with peace

of mind around their smart meter network. By providing additional plumbing works associated with meter replacements, Data Right can continue to grow into a full endto-end solution provider for water meter networks.”

Joblin believes that there are plenty of opportunities to expand, and one of those is the agricultural sector.

“That sector has appealed to us, and we are actively working on starting this division,” he said. “There is a

Team members Travis and Glen install a smart water meter.

trend toward metering non-urban meters, so it makes sense to utilise technology and make those meters smart. We are well-placed to provide a holistic solution in that area.

There are still so many residential water meters to be upgraded to smart meters, so there are plenty of ways that Data Right can assist water utilities in achieving those goals.

For more information, visit www.dataright.com.au

Water utilities ensure that all customers, residential and commercial, have access to clean drinking water. Many utilities in Australia are looking to the future through digital transformation and the Internet of Things (IoT).

ONE OF THE challenges for water utilities is preparing for the future.

After the Millennium Drought, South East Water took its first steps towards becoming a digital utility, working towards transforming its people, processes, and technology. It now has an advanced digital network, delivering increased visibility to its customers regarding their water use so they can quickly identify potential leaks on their property. The organisation also uses network sensors, enabling a proactive approach to network leak detection that increases visibility across its network and reduces water loss.

Justin Peters is the Business and Key Account Manager at South East Water. His insight into South East Water’s digital transformation program shows how the utility is changing for the better.

“Our digital transformation is helping customers become more aware of their water usage,” Peters said. “Having digitally enabled devices means that our customers can see their detailed water usage data and receive fast alerts when there is a potential leak. This significantly helps customers better understand their water usage and facilitates quick identification of leaks. It’s also allowed us, as a utility, to better understand the demands on our network.”

Business customer complexity

Peters pointed out that residential customers tend to have a consistent diurnal water consumption pattern, with a big peak in the morning and a second peak in the afternoon

and evening. This makes it easier for water utilities to determine if something is unusual with a residential customer’s water usage. Business customers, however, cannot be compared in the same way.

“Even when we look at the businesses within the same industry, we can’t be sure of the consistency of their water usage patterns,” Peters said. “One manufacturer might operate 24 hours a day, 7 days a week. Another manufacturer may only use water during weekdays. A third may have cleaning cycles that run through the night. To add to this complexity, the nature of water usage across their site can also vary significantly. It can include inproduct, cleaning, heating/cooling, and amenities. They might all work in the same industry, but their different operations mean that water usage is unique from business to business.”

Although business customers represent only 8 per cent of South East Water’s customer base, they account for about 25 per cent of all water use.

For many small businesses, simple automated alarms are very beneficial at alerting customers to potential leaks. However, for more complex businesses, more customised leak alerts can be set based on unique water usage patterns at each specific business site. South East Water is working hard to ensure that the digital experience they provide to their customers factors in the broad range of use cases.

Empowering businesses to make decisions that help them use water

Justin Peters is South East Water’s Business and Key Account Manager, working closely with Iota.

Images: South East Water

wisely is an important step towards reducing unnecessary water loss. South East Water believes it is important to engage with and support business customers in their sustainable water usage.

Technology key to sustainability

“Population projections from the Victorian Government suggest that the state’s population is expected to reach 10.3 million people by 2051,” said Peters. “That’s nearly doubling the population in less than 30 years. On that basis, we expect water usage to almost double. So, we must consider water security for our future and start sustainable practices with water now.”

With extreme weather events impacting communities, increasing the efficient use of water and reducing unnecessary water loss will be essential. Data loggers and digital water meters will remain vital tools that will support this in the future.

One of South East Water’s goals for the near future is to have more businesses digitally enabled, either with a digital meter or a data logger.

“Most of our business customers with a digital meter receive leak alerts within 24 hours of a leak,” Peters said. “This allows them to take immediate action, rather than waiting for their next bill to address the issue.”

Another benefit of this digital transformation for businesses is identifying larger leaks, which could indicate that private plumbing infrastructure needs urgent repair/ replacement. Digital data can be very helpful in monitoring assets and being part of a business customer’s site water management plan or maintenance plan.

“This is how a digital transformation program can help explain certain things that commercial customers were previously unaware of or could not visualise,” said Peters. “It can influence their maintenance programs. In some cases, they may have had a leak for years they didn’t know about.”

To help customers better interpret this data, South East Water is piloting a customisable dashboard where business customers can view their water use, monitor consumption trends and identify usage anomalies such as leaks.

“The dashboard is the first step in giving businesses visibility of where water is being used and is especially valuable for large or complex businesses with many assets and

multiple sites”, Peters said.

Partnering for success

South East Water’s partnerships with water utilities and commercial customers are set to add to the 1.2 gigalitres already saved through digital metering of the residential network.

Even more water savings will soon follow with future developments of water monitoring platforms and IoT devices.

The rollout of a water monitoring platform and digital meters to customers is set to provide South East Water with learnings about how real-time insights can help commercial customers prevent water loss.

“Almost every business has its own targets to keep operating costs down, and many also have sustainability goals and initiatives embedded within their corporate strategies and long-term plans,” said Peters.

“From our perspective, working with businesses to help them better understand their water use helps them meet these goals

and contributes to long-term water security. By focusing on sustainability, business customers can be proud that they are optimising their water usage through active monitoring and insight-driven site water management. They are not only saving water on-site but also helping us, as a community, secure water for our future.”

No one likes an unexpectedly large water bill. Water monitoring platforms with leak alert functionality can help promptly notify customers of high usage and allow them to fix the leak on their property before it results in a hefty bill.

“The old saying that prevention is better than the cure certainly applies to water utilities. Rolling out these digital technologies is one way we can work with our business customers to help them become more aware of how to use water more efficiently and sustainably. By providing visualisation of water use over time, in addition to timely alerts and notifications, we can also prevent water loss and help them optimise their business operations through actionable insights.”

/ Ventia bring decades of experience working alongside municipal and industrial water and wastewater clients and their customers.

From the operation and management of bulk and retail water networks, treatment plants, pump stations, desalination and catchment assets we provide asset inspection, monitoring and operations and maintenance.

find out more.

There are many different radar sensors available for the water and wastewater industry. We look at one company’s cutting-edge solutions.

KALLIPR DESIGNS AND manufactures a range of Internet of Things (IoT) solutions that allow its clients to better measure and monitor their data in an easy-to-use end-to-end package. This reduces business downtime and operating costs while improving sustainability. Its asset-to-asset communication and remote monitoring solutions cross a range of industries. This includes water management, wastewater management, water quality monitoring, and commercial metering. Kallipr can create custom packages and solutions to help customers reduce water leakage, measure water quality and monitor capacity levels.

The Townsville take on IoT Kallipr worked with the Townsville City Council to roll out Kallipr radar sensors in the council’s sewer networks. When paired with the Captis devices, these sensors help manage and monitor water flow and levels throughout the wastewater network.

Alex Sims is Kallipr’s Technical Support Lead and was instrumental in rolling out the solution for the Townsville City Council.

“The solution combined our data loggers with our radar sensors,” Sims said. “We also attached a third-party radar sensor for an AB comparison. It was a great opportunity to compare a well-known, market-leading radar sensor against our sensors. We have tied that sensor with custom

brackets, pre-wiring termination and configuration.”

Kallipr then packaged the sensors and sent them to the end-user. This allowed them to be installed as a plug-and-play solution, solving the issue of collecting components from different suppliers and trying to figure out how to get them to work together.

“We do all of that ahead of the shipment, so it makes life much easier for our end-users,” he said. “That means all they have to do is install it.”

The combination rolled out by Kallipr is suited for the Townsville City Council partly because it leverages the MODBUS RS485 communications protocol. This protocol allows Kallipr and the end-user to sample a range of parameters collected by the radar sensor.

“Kallipr can capture really granular data,” said Sims. “We can also pull data from the radar sensor itself. We also provide over-the-air configurability, which allows us to remotely change and revise the configuration parameters.”

One of the challenges for water utilities is finding the right combination of devices to achieve its goals. However, Kallipr has taken a different approach.

“What we do is solve customer challenges,” Sims said. “Kallipr has found that it has the autonomy and

is no need for sophisticated equipment to install the

flexibility to create and manufacture its own devices in Australia. In the past, we were hamstrung by dealing with suppliers overseas. That reliance on third-party sensors meant that we were dependent on supply chains, product availability, lead times, and other logistical issues.”

When considering these problems, Kallipr opted to create its own radar sensor. This meant it would have control of the components going into the sensor and autonomy over the supply chain. It also allowed Kallipr to create a unique firmware/ software layer that allows for the remediation of devices or the introduction of new features.

“All of this means that we have full control of the costs of each individual component,” he said. “We can then significantly reduce the list price of our radar sensors.”

Another aspect of the Kallipr devices is their long battery life. Sims and his colleagues at Kallipr worked diligently to find a better way to do things.

“Typically, the third-party sensors… leverage device power to wake themselves up, take a measurement and then go back to sleep,” he said. “That device charge dissipates until the next time the sensor needs to do a reading. However, that means there is a large reliance on each sensor on the master device to supply that power as and when needed.”

Kallipr has integrated the power supply into the radar sensor itself. In terms of power delivery, every radar sensor is independent of the

because the sensors are not chewing into the power demands of the master device,” said Sims. “It means our solution provides a longer battery life, often by several years. This is important for water utilities and local councils. Many of our clients would otherwise need to be more conservative with the power they are using throughout their systems.”

Radar is becoming common among solutions sought by water utilities and local councils. By designing and manufacturing its own radar sensors, Kallipr can provide a more economical solution.

The night Cyclone Kirrily rolled through Townsville, the Kallipr devices picked up a blockage or partial blockage. The data suggested that this blockage occurred at around 8 pm. It caused water levels to rise steadily over the next 4 hours until the entire three-metre riser was completely inundated.

“In typical circumstances, thresholds can be configured on the device to alarm when the water level rises after the 8 pm blockage,” said Sims. “This early warning system allows maintenance crews to be deployed to the site before an overflow event occurs. Remote monitoring was paramount during the cyclone, ensuring the system cleared itself without needing onsite maintenance calls. This reduced the risks associated with callouts in unsafe conditions.”

This knowledge’s advantage was that the Townsville City Council would have had an exact location to start their troubleshooting if the blockage remained. They could identify where the flood started and work backwards from there.

Kallipr has been growing from strength to strength through its range of Captis radar sensors. Sims said there has been a lot of interest across Australia.

“We’ve worked a lot with councils and water utilities who are starting to see the benefits of early adopters digitising their networks,” he said.

“There’s now a big push from the broader water industry to make these solutions as easy as possible to deploy.”

Many industries face labour and resource shortages, making it challenging for local councils to have a single manager dedicated to operational and maintenance teams. These groups would usually

brackets, ensuring easy installation.

Above: the dashboard is easy for users to understand, as shown here during Cyclone Kirrily.

be appointed to install the devices and become the product champions within their organisations.

“More and more, we are seeing that labour dry up in councils, particularly in the regions,” said Sims. “There may be just one person who’s been in the role for a short period but manages multiple divisions.”

This is why Kallipr is working to develop solutions that can be installed, implemented and managed easily while forming part of their existing network and ecosystem. The thinking is that leveraging out-ofthe-box solutions that are preterminated and configured for the receiving organisations is better for those organisations.

This is why Kallipr is working together to show that a specialised system is not always the best option. An easy-to-manage solution makes things easier for every current, potential, and future customer.

For more information, visit kallipr.com

PFAS and other forever chemicals are causing challenges for the water and wastewater industry. Ventia continues to develop innovative technology that could improve PFAS remediation.

PFAS, KNOWN AS per- and polyfluoroalkyl substances, are a diverse group of synthetically produced chemicals resistant to heat, water, and oils. Since the 1970s, PFAS has been used in firefighting foam, industrial applications, and everyday household products.

PFAS do not break down or degrade in the environment. They are soluble, mobile, and can be found in soil, surface water and groundwater.

PFAS contamination in soils and water is well documented, and laboratories have developed an accurate analysis methodology to test for low PFAS concentrations. Due to historical PFAS applications, several high-risk sites may have high PFAS concentrations in soils. Rainfall events can increase the risk of PFAS running into surrounding waterways. Waterways must be sampled during rainfall events to determine correlations between flows and PFAS contamination load.

Ventia has a specialised team studying and developing innovative technologies to remediate PFAScontaminated soil, sediment, concrete, and water.

People like Charles Grimison (Technical Director) and Mark Pickles (Manager Environmental Monitoring) at Ventia are working to improve water quality testing in this field. Both started their careers in the water and environment space and found themselves in the contaminated water field.

Challenges of sampling for PFAS

One of the biggest challenges in sampling PFAS is that there can be large volumes of contaminated soil and water with a low concentration of PFAS and small volumes with a high concentration of PFAS. Separating these soils requires different tools, partly due to the varying properties of soil but also due to the varying properties of the PFAS

Ventia’s highly experienced specialists monitor water, soil and air for all environmental parameters, delivering accurate, real-time and in-depth data on environmental conditions that its clients can depend on to make informed decisions.

Images: Ventia

compounds themselves.

“Typically, we would use two or three technologies to clean up a contaminated site… more if water is included,” said Grimison. “There is also an evolving landscape around the guidelines and criteria because it is a relatively new contaminant. We are still dealing with these changes.”

It’s important to note that there is currently only one way to properly detect PFAS in water – to get a sample and send it to a laboratory. It is much easier to detect other contaminants. Developing tools to capture a representative sample during periods of infrequent, then heavy, rain is challenging.

Detecting PFAS in the first flush

This is where Ventia’s new technology is coming into play. It provides automated PFAS sampling systems for capturing samples during rainfall events. Users can configure and control sampling programs using standard wastewater samplers and control instrumentation through a simple SMS control system. It’s part of the first flush, a phenomenon where a larger concentration or mass of contaminants is associated with the initial stages of a storm event compared to the rest of the event.

“Ventia provides networks of monitoring instrumentation,” Pickles said. “What would usually happen in the field is identifying where PFAS is, looking at the first flush event, and capturing data on the water coming through the system. That’s why we put automated instruments in the field – to accurately sample and monitor that event. We can then accurately measure the mass and concentration of the contaminants.”

It’s not just about determining how much PFAS is being detected. It is also about where it is being detected and in what concentrations. This comes from measuring a site’s

mass flux, which is the mass of a contaminant moving through a specific cross-sectional area.

“We look at the mass and the concentration,” said Grimison. “If you have five micrograms per litre of PFAS in one drain compared to 30 micrograms in another, the instinct would be to deal with the 30 milligrams first. However, understanding the concentration of PFAS and the water flow might create a different outcome. There may be a greater PFAS mass being discharged via the 5 microgram per litre drain. That’s why you must look at both measures to get a better picture.”

There’s an app for that

One of the challenges for any water utility is being able to collect and interpret data by large teams across multiple offices for several clients. That’s particularly true for any utility working in regional Australia. The focus then turns to the most efficient way to capture that data and feed it back to the customers.

About 10 years ago, Ventia started developing field apps that supported multiple field functions to capture and host data. However, the desire to improve and innovate led to creating a route optimisation web-based program to map out its sampling programs.

“This enabled us to greatly optimise our field schedules and provided a direct link between the planning and implementation phases,” Pickles said. All Ventia apps are designed to capture data quickly and efficiently.

Charles Grimison (left) currently leads Ventia’s PFAS team, which is focused on the development and delivery of PFAS remediation solutions driven through internal and external research, laboratory trials and university partnerships.

This includes Safety, Health, Environment, and Quality (SHEQ) information, field measurements, data issues, photos, and verification systems.

The Ventia teams also have access to historical datasets against which to validate new readings. The apps can notify clients immediately of any reportable observations.

“For example, if there were a potential petrol leak in a retail service station, an email would go straight to the client advising of this,” Pickles said. “The same goes for other contaminants in other locations.”

All that data is instantly captured and stored within a secure database. This allows Ventia to add additional functionality as requested by the client, who can access and download that data when needed.

Since 2012, Ventia has captured more than 170,000 measurements and 135,000 photos. This has eliminated the need for paper-based field sheets, increasing accuracy and transparency. That improved accuracy is derived from the automated validations that can occur with the field scientists still on site, so there is less need to revisit sites in a short period. This increases the sustainability outcomes, as there are fewer rollouts of staff and vehicles, along with the elimination of printing paper field sheets.

When talking about accuracy, the accuracy rate of data captured has now exceeded 98 per cent. This has come from the built-in quality checks to ensure that the right information is where it needs to be and to pick up variances where there should be none.

All of this is leading to better outcomes for clients.

“I’m focusing on a cleaner and greener footprint for the industries we work in,” Pickles said.

For more information, visit www.ventia.com

Ventia’s sampling data is instantly captured and stored within a secure database. This allows Ventia to add additional functionality as requested by the client, who can access and download that data when needed.

Data Right is Australia’s leading smart water meter installers. Specialising in:

• Installation roll out

• Project management

• Preproject evaluation, decision making and requirement audit

• Network maintenance and replacements

• Water meter reading

• Associated plumbing works

Contact us on 1300163837 for a solution to your water meter requirements. headoffice@dataright.com.au www.dataright.com.au

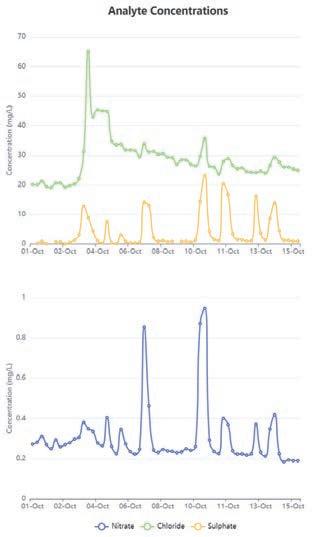

Collecting and sharing environmental data, particularly water quality, is complex. Achieving this in real time can help organisations make better decisions. Here’s how.

methodology, particularly in the face of the rapidly evolving water

“It’s usual for manual sampling to typically miss the peak events that do the damage, and the data, when you get it, is a week old,” he said. “Manual sampling processes are labour-intensive, time-consuming, and prone to human error, hindering

effective resource allocation. As we embrace technological innovation

Ion-Q+ helps WWTP operators manage potential risks of exceeding discharge

actionable data. Eco Detection’s Ion-Q+ does this by providing nutrient levels, pH, conductivity, dissolved oxygen (DO), and other water quality parameters. Having this data empowers stakeholders to take a proactive approach to managing water resources. It also safeguards public health and supports environmental sustainability goals.

“Eco Detection has put the lab in the field; no one else has done this,” said Harcourt. “Whilst probes and other types of field measurement technology exist, they don’t always work and cannot replace grab sampling and laboratory analysis to the regulator’s satisfaction. We are now being accepted by regulatory authorities in several applications as a replacement to laboratory data, thereby reducing operating costs and improving customer outcomes.”

Ion-Q+ and how it works

Harcourt points to the direct ionic

absorption or inferred measurement.

The Ion-Q+ integrates the original CZE technology, which separates target analytes injected into a capillary.

“Different ionic species travel at different speeds inside the capillary,” he said. “That is because of each ionic species’ individual physical and chemical properties. They form distinct groups as they move through the capillary. These groups pass the detector, which determines the number of ions and provides quantitative concentration measurements for ionic species.”

Accurately tuning the capillary and electrolyte chemistry has enabled Eco Detection to have highly sensitive technology. Eco Detection also provides end-toend data service for water quality measurements. It provides end users, operators, and decisionmakers with the critical information to manage their waterways and assets effectively.

“The Ion-Q+ is a fully autonomous, self-calibrated and multiparameter system,” Harcourt said. “It can operate anywhere with solar and satellite options. We offer up to 12 months of continuous operation without servicing.”

But what is it picking up? The Ion-Q+ can analyse levels of nitrite, fluoride phosphate, chloride, sulphate, carbonate, ammonium, magnesium, potassium, calcium, sodium, lithium, and ferrous iron. It can also be deployed with additional sensors for other water quality parameters, giving the system a comprehensive view of the water source.

Where is it being used?

Eco Detection’s Ion-Q+ devices are deployed with water utilities, local councils, industrial facilities, and environmental monitoring stations across Australia. For example, several devices are installed in rivers that flow into the Greater Barrier Reef. “Water utilities face the constant challenge of servicing an increasing population with ageing wastewater treatment plant (WWTP) infrastructure,” said Harcourt. “In doing so, they must continue reducing the environmental impact. The discharge of total inorganic nitrogen (TIN) and dissolved reactive phosphorous (DRP) from WWTPs into inland waterways is allowed under license from the local regulatory Environment Protection Authority (EPA).”

Ion-Q+ is a autonomous multiparameter

operators to take immediate action. Therefore, facility managers can actively control the inherent risks of exceeding the discharge license limits, associated penalties and, ultimately, pollution of waterways and ecosystems. Eco Detection now provides a practical field solution to monitor upstream and downstream of the WWTP discharge point, providing TIN and DRP in near real-time, with data fed directly into plant supervisory, control and data acquisition (SCADA) systems for immediate action when required.

The future for Ion-Q+ Harcourt believes that the future is positive. As a technology entrepreneur, he could not ignore the pressing challenges facing global water resources. Having witnessed the devastating impact of water-related crises has spurred him into action.

“I am fortunate to have been able to leverage technology and innovation and find a way to channel my passion for water into meaningful and tangible solutions,” he said. “In the coming years, I hope to advance Eco Detection’s technology further. We want to expand its deployment into new markets, like the United Kingdom. Ideally, we will strengthen partnerships with water utilities, regulatory agencies, and industry stakeholders.”

Harcourt and Eco Detection aim to enhance public awareness and engagement on water quality issues by driving innovation and promoting sustainable water management practices.

“We want to foster a collective commitment to preserving our most vital resource for future generations.

For more information, visit

There are many situations where seemingly inert water can be incredibly corrosive to devices. An established company provides cutting-edge devices to one of Australia’s most popular home add-ons.

JPCI IS A French company manufacturing switches in China for 25 years. It has been striving for innovation ever since its creation, and its range of patents dates back to the 1950s.

While water might seem inert, pool water can be corrosive. It’s where JPCI stepped in, developing devices to resist this corrosion.

“The swimming pool market was booming in the 1980s,” Jacques Jumeau, Group CEO said. “The popularity of heat pumps for heated swimming pools only increased consumer demand for our products. We then increased production significantly by opening a 10,000-square-metre factory in Gaoming, a district in Foshan. That’s on the western side of the Pearl River Delta and puts us in a position to work with the best young talent across China and worldwide.”

Since then, JPCI has expanded its facilities to more than 30,000 square metres and employs more than 400 people. To achieve the highest quality, it has adhered to the values of innovation, customer engagement, and continuous improvement.

JPCI has found the water industry to be an attractive sector. With vertical integration, it can develop things quickly while maintaining high quality throughout.

“In general, the water industry requires more operational controls, whether it comes to drinking water or managing the impact of corrosion on circuits in water,”

Jumeau said. “That’s why our paddle flow switches are mechanically simple, economical, and robust.

JPCI has also designed its switches to be easy to install with a fool-

In-house UL and TUV-certified laboratory ensure test reliability and quicker time-to-market developments.

Images: JPCI

proof design.”

JPCI’s testing laboratory takes up a large part of its efforts. TÜV Rheinland and UL Solutions have recognised the laboratory for creating safe, high-quality products.

“TÜV Rheinland stands for safety and quality in virtually every aspect of business and life,” Jumeau said. “The company is one of the world’s leading testing service providers, and its highly qualified experts test technical systems and products. Similarly, UL Solutions is a global leader in applied safety science. It transforms safety, security, and sustainability challenges into customer opportunities.”

Another key brand for JPCI is Ultimheat. Ultimheat is the European subsidiary of JPCI. Its mission is to support the business development of JPCI in Europe. Ultimheat provides its customers with technical support, from the first contact through to product delivery.

When floodwaters rise, the resilience of water infrastructure is tested. Data from digital water meters can prove valuable for making informed decisions to secure the water supply.

REGIONAL WATER UTILITIES face many challenges during flood events, and data pointing to leaks and breaks can make a real difference.

Sammy Jung has worked with Taggle Systems as Engineering Manager at Goldenfields Water and has been at the forefront of understanding data from smart water meters across the network.

In late 2022, flooding in Regional NSW put the water supply at risk when the bores that supply water to the townships of Weethalle, Tallimba and Naradhan flooded, causing an outage in that water scheme. Goldenfields Water, which manages the water supply for 46,000 customers across an area of 22,562 square kilometres, faced the extremely challenging task of maintaining the water supply.

Goldenfields Water’s first action in these areas with the flooded bores was to truck water in and implement high-level water restrictions, which limited customers to 100 litres of water per person daily. However, even with these measures in place, the reservoir levels were still dropping.

The next challenge was limiting the amount of water lost through the system due to leaks and bursts.

Taggle to the rescue

Luckily, Goldenfields Water has Taggle Systems digital water meters installed at every property, allowing the leaks to be quickly and easily identified. Goldenfields Water engineering manager Sammy Jung spoke about how the water meter data helped secure the water supply during the emergency.

“With Taggle’s equipment, we could identify specific customers who had huge leaks on their side of the meter and communicate directly with them, which was a great success in reducing losses,” Jung said. “In emergencies such as these, every drop counts.”

Taggle delivers hourly water usage data for its digital water meters and sensors. For Jung and Goldenfields Water, they could track where the water was going.

Network Leaks

“We knew we had significant leaks in both our water network and on

customer properties,” said Jung. “To address the network leaks, we split the scheme into smaller pieces by turning some valves off,” she said.

“We could then compare the quantity of water entering the supply network with what gets delivered to our customers and quantify how much water was being lost along the way.”

“We focused our energy first on areas with the highest losses and had staff patrol the water lines. This was extremely challenging, with over 300 kilometres of pipeline network in rural areas, but our teams quickly discovered significant bursts as part of this program,” said Jung.

Working with our customers

To address customer leaks, Jung and the team at Goldenfields Water worked through the leak report in Aqualus Water, Taggle’s meter data management software.

“We contacted individual customers starting from the largest leaks,” said Jung.

“We also contacted the highest water users to make sure they were aware of the restrictions and the consequences of using water during these times. When we spoke to them, many would say they only use water for the bare minimum requirements, as per the water restriction communications. That led to a conversation about leaks existing on their property.”

“Everyone was very appreciative of our efforts to save water and helped us find and fix the leaks. We had customers walking up to two kilometres, trying to find a leak in the pipe between the meter and their home.”

“Many of those customers could find the leaks and get them fixed, but not all could be located. Some of these customers had to have restrictors installed at their meter in the meantime, which allowed enough water to pass through to fulfil their daily requirements without wasting too much. This had a huge impact on securing our water supply,” said Jung.

“The flood emergency was extremely challenging, but we achieved incredible success in managing our water resources with the help of the meter data and the community,” she said.

What was learned?

“This was the first time Goldenfields Water had experienced such an extreme weather event in which the digital water meters managed supplies. It provided us with the

opportunity to learn a lot from the experience,” said Jung.

“One thing we learned was about the accessibility of the data to different team members,” Jung said.

“We now have more staff with system access who can benefit from the data and make informed decisions relative to their projects and tasks.”

“We also took a closer look at the Aqualus Water platform. We’ve had the system for over ten years, and there are many functions we haven’t adopted into our workflow,” said Jung.

“Goldenfields Water also uses the data for modelling. It helps them understand water consumption patterns, which are incorporated into its predictions of future water demand, population growth, and other utility information.”

“We also looked at how to analyse that data more effectively and use it to troubleshoot various problems. Sometimes, the customer tells us

inhibiting water availability for the local area.

Image: Goldenfields Water

The Taggle Systems smart water meters are easy to install and communicate to static receivers across the water network.

Image: Taggle Systems

data to drill down potential causes or help facilitate further investigation.”

Ongoing partnership

“Goldenfields Water was an early adopter of Taggle’s technology. Our deployment was over ten years ago now,” Jung said. “Taggle has grown a lot in the time that we have worked with them,” Jung said. “We are doing our best to keep up with their technology and all the functionality we can capitalise on.”

The Goldenfields Water digital meter fleet is approaching endof-life after ten years in the field, so plans are being made for a replacement program.

Taggle has been on-site to work through the replacement program.