MAIN TERMINAL EXPANSION

Everybody loves the Portland airport. We had a tall order to evolve a terminal that’s essentially multiple buildings pieced together since the 1950s - and double the capacity while designing an experience people will love as much as the original.”

GENE SANDOVAL | DESIGN PARTNER | ZGFZGF + PDX

AN ENDURING 6-DECADE RELATIONSHIP

ZGF Architects began its decades long association with PDX in 1966 when the Port of Portland commissioned the firm to develop a master plan for doubling the size of its original 1958 terminal.

Today, nearly six decades later, ZGF remains the Port’s primary architectural partner, having completed numerous remodels and major expansions at PDX. ZGF’s current endeavor is the airport’s most aggressive expansion yet, doubling its size again, and reimagining the terminal core. In addition to master planning, concourse extensions, concessions upgrades, and various other airport improvements, a number of major expansions have been completed in the intervening years.

ORIGINAL PORTLAND AIRPORT / 1958

1960s

Major Projects

1965

Airport Master Plan

1980s

1983 Terminal Master Plan

1987

Concourse B

1990s

Alaska Airlines

4-gate Concourse Addition

1988

Terminal Expansion

1989

1995

Terminal Expansion North

2000s

$208 Million 433,000 SF New & Renovated Concourses

Concourse D | Delta Airlines

$295.2 Million

102,000 SF Concourse Expansion; New FIS; Airline Lounge

2000

Terminal Access Project

$470.4 Million

120,000 SF Canopy; 7-story Garage / Expanded Roadway

2001

Mass Transit Integration

$215.8 Million

Addition of MAX Light Rail Line Airport Station; 5.5 mile LRT Extension

2003

2001

Terminal Expansion South

$474.7 Million

140,000 SF Concourse Addition; 536,000 SF Terminal & Concessions Expansions

2010s

2010

Port Headquarters & Parking Structure

$218.7 Million

205,603 SF Office atop 7 floors of Long-Term Parking

2014

PDX Terminal Master Plan

2020s

2021

Concourse B - Alaska Airlines

$120 Million Concourse Replacement

2014

On-Call Services Contracts

2025

Terminal CORE Redevelopment

$1.7 Billion Terminal Transformation

The Ask

To accommodate growth, PDX was faced with doubling the footprint of its landlocked airport to 1 million square feet. Goals and challenges:

BY 65%

To 35 million annual passengers by 2045

GROW IN PLACE

Unify 12 existing, operating structures over existing complex baggage systems

FLEXIBLE & ADAPTABLE

Long span structure to avoid obstructions

PRESERVE HEART & SOUL OF PDX

“No. 1 Airport In America” (Travel & Leisure)

SUPPORT LOCAL INDUSTRY

Promote Diversity, Equity + Inclusion

SUSTAINABLE

& RESILIENT

Double the terminal footprint and cut energy use in half

MINIMIZE OPERATIONAL DISRUPTIONS

During 5 years of construction

The Program

The $1.7 billion Terminal Core Replacement project is to be accomplished in two major phases and comprised of the following:

• 400,000 SF Terminal Expansion

• 400’ by 1,000’ Long Span Roof

• New Ticket Lobby: 110 Counters

• New Security Processing: 20 Lanes

• 58,500 SF of Concessions

18,500 SF Pre-Security

40,000 SF Post-Security

• Expanded & Updated Baggage Screen Facility

New and upgraded make-up units

Reconfigured baggage claim devices

All new CBRA system

• 20,000 SF of New Airline Lounges

• 17,000 SF New Restrooms

• 10,000 SF All-User Restrooms

• 25,000 SF Port Conference Center/Offices

• 15 New Art Commissions

SECURITY CONCESSIONS

A Decade in the Making

The project remains on schedule for completion in December 2025. At the beginning of Schematic Design, it was determined to break off the development of Concourse B as a parallel project.

Apr 2016

Concept Selected

Dec 2017

Concept Complete

Feb 2018

Concourse B

Design Start

Sep 2015

Project Start

Apr 2019

Design Development Start

Mar 2019

Schematic

Design Complete

Jan 2018

Schematic Design Start

May 2019

Enabling Package: Civil / Site / Utilities

May 2020

Package: MEP / Terminal Demo

Nov 2019

Enabling Package:

Columns / Baggage

Apr 2019

Concourse B Construction Start

Oct 2021

Concourse B Complete

Feb 2021

Package: Building

Enclosure / Interior Construction

Aug 2021

Roof Modules Install Start

Jun 2020

Package: Structure / Roof Prefab

Mar 2024

Central Terminal Construction Complete

May 2023

Dec 2025

North & South

Nodes Complete

Ground Source Mobilization

Dec 2022

Roof Modules Install Complete

Dec 2025

Project Complete

The Passenger Experience

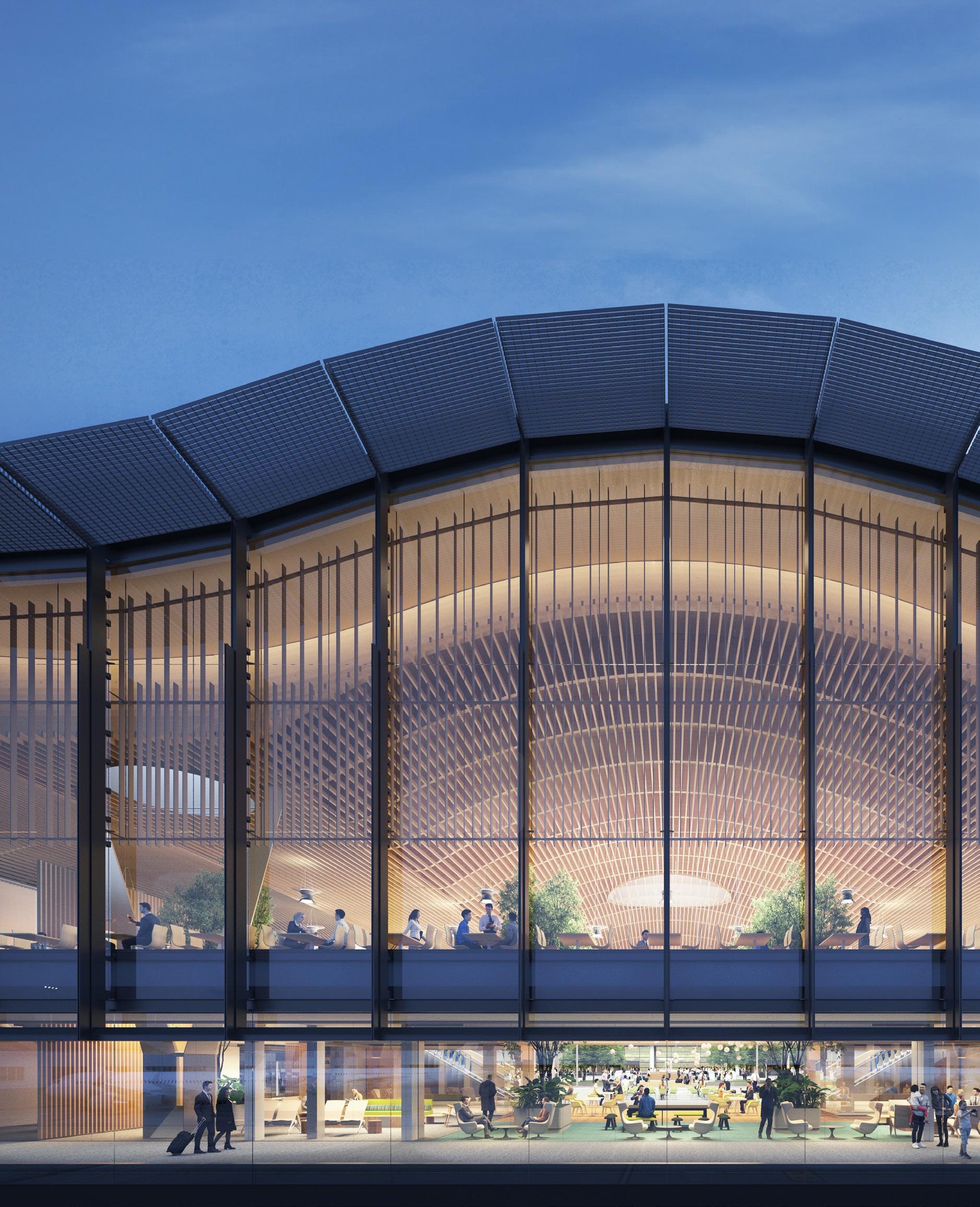

The main terminal expansion at PDX invites all users to enjoy the beauty of the Pacific Northwest region–where forests cover nearly half the state of Oregon. In addition to reflecting the natural environment, a primary driver in doubling the airport’s terminal’s footprint is to maintain its uniquely curated Portland vibe – progressive, creative, and intimate.

BIOPHILIC DESIGN

Humans have an innate affinity for nature – a phenomenon known as “biophilia.” A growing body of research has led to recognizing elements of nature in the built environment can reduce stress, improve cognitive performance, and enhance moods. ZGF collaborated with Terrapin Bright Green to apply the concept of biophilia exponentially to the new PDX terminal, while reinforcing a primary design driver to celebrate the beauty of the Pacific Northwest region.

A WALK IN THE FOREST

Daylight filters through a stunning, nine-acre wood roof with lattice work and large skylight openings, while pathways are filled with trees and lush interior landscaping, all contributing to a sense of walking through one of the region’s renown forests. Clear sightlines signal the way through a marketplace and security, while beyond security, people gather in common areas that look more like city parks. In almost every corner of the new 400-by-1,000-foot volume are live trees and hanging plants, touches of Oregon’s signature greenery in an environment designed to reduce stress.

The choice of wood for the massive roof structure is supported by research as “warm, inviting, comfortable, and relaxing.” The abundance of living landscape – 72 large trees, up to 25’ tall, cascading gardens, and over 5,000 plants –is strategically placed throughout the terminal to provide stress relief from beginning to end of a passenger’s journey.

ARRIVALS + MEETER GREETER

A SERIES OF ROOMS

Taking cues from the human-friendly scale of Portland’s short city blocks and the rhythm of its urban neighborhoods, the new terminal is imagined as “a series of rooms.” Beyond security checkpoints, small plazas and pavilions with active corridors recall Portland’s tradition of urban planning and achieve a more intimate scale. Meanwhile, a large span roof structure not only opens up space between columns for operational flexibility, it allows for a sequence of smaller independent structures below for concessions, offices, restrooms, and other airport services.

EACH NEW STEP IN THE JOURNEY

ARRIVALS + MEETER GREETER

CHECK-IN

A reconfigured and expanded ticket hall considers future changes in traveler needs and evolving technology. Islands can expand and contract as airlines’ needs change.

GARDEN SEAM

Passengers move from ticketing into a “seam” of lush interior landscaping, evoking a walk through a Pacific Northwest forest, while signaling the way to security checkpoints.

MARKET HALL (PRE-SECURITY)

The “seam” leads to a pre-security marketplace, beloved for its uniquely regional goods and dining. Clear sightlines allow passengers to monitor security queues.

RECOMPOSURE + CONCESSIONS

Post-security, the new terminal evokes the more intimate scale of the city itself with a series of concession experiences and lounging spaces within the large volume.

ARRIVALS + MEETER-GREETER

Passengers step into the vibrant spirit of Portland when they land. An inviting Arrival Garden path leads straight to baggage claim. Loved ones are reunited under dense green hanging gardens marking the exits beyond.

CHECK-IN + GARDEN SEAM

CONCESSIONS EXPERIENCE

Portland’s urban vibe also inspired the organization and design of the concession nodes, with shops and restaurants clustered along pedestrian-friendly landscaped “streetscapes.” “Urban furniture” denotes the edges for passengers strolling and shopping; a wider thoroughfare in the middle allows passengers a more expedited path to their gate. Wood screens overhead punctuate concessions, while hanging gardens, trees and plantings contribute to the experience. All passengers travel through these areas on the way to their gate.

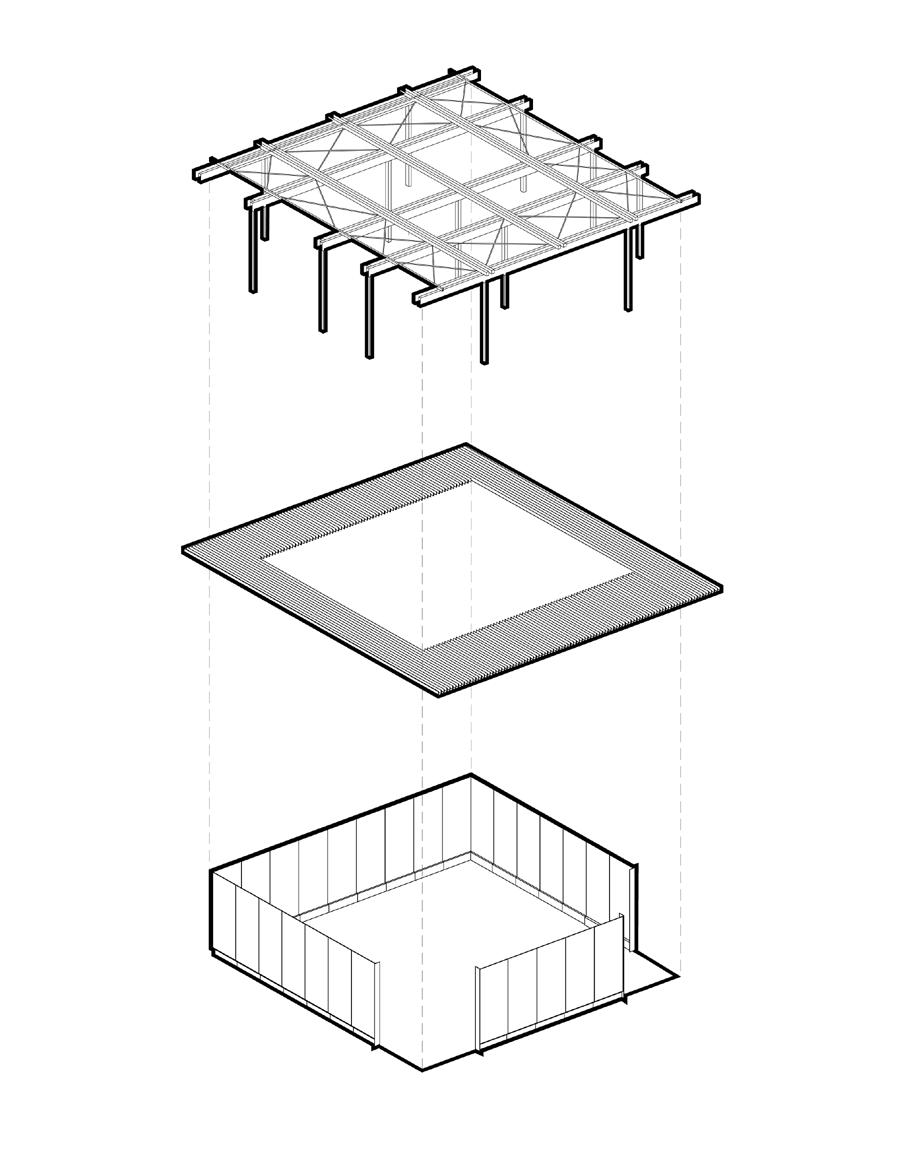

The concessions were imagined as a “Kit of Parts” with plug and play utilities for ease of installation and to give operators flexibility and choice in configuration and brand expression.

CONCESSIONS KIT OF PARTS

WOOD STRUCTURE

LATTICE CANOPY

MODULAR GLASS ENCLOSURE

The Roof

A UNIFYING SOLUTION

The most prominent feature of the reimagined terminal is its regionally sourced mass timber roof. Serving as a gateway to the Northwest’s Forest Products industry – reflecting its spirit of craftsmanship and ingenuity –this nine-acre wood and steel structure spans the expanded lobby, check-in, security, and concession areas.

AN OVERSTORY OF WOOD

Undulating in a basket weave of arches and scalloped shapes, a 400,000 SF glulam beam and lattice “overstory” is supported by a grid of 34 Y-shaped columns that branch upwards 36 feet above the terminal floor. The lattice is comprised of nearly 35,000 3-by-6-inch pieces of Douglas fir. The roof is penetrated by 49 thoughtfully placed skylights of different shapes and sizes that, along with the lattice work, filter the daylight into the tree- and plant-filled new terminal. Along with custom light fixtures that hang from the roof, the play of shadow and light, even glittery at times, offers passengers an experience of both calm and delight.

LONG SPAN FLEXIBILITY

A 100’ x 150’ span between columns provides adaptability for a wide variety of security layouts, ticketing and baggage configurations, and concessions strategies now and into the future.

The team was able to fine tune the grid and locate just 10 of the massive 53-foot columns within the existing terminal footprint, with the remaining 24 all outside its perimeter.

This innovative solution left more infrastructure in place and minimized operational disruptions during construction, saving both time and money.

Utilizing Local Resources

“FOREST-TO-FRAME”

Key project goals for the mass timber roof were to source the wood locally and sustainably, and to track the final wood products back to their origin forest.

This goal set the project team on a trajectory that cultivated transparency in the wood supply chain and literally transformed how the wood products industry operates. Dialogue with landowners and mills, and a number of innovative new procurement approaches resulted in nearly 100% of 2.6 million board feet coming from sustainably managed forests. Roughly 1 million board feet are tracked back to 13 different forests of origin in Oregon and Washington.

HIGHLIGHTS

• 100% of wood comes from a 300-mile radius of the site

• 1 Million board feet of roof lumber sourced from and tracked back to 13 landowners – all small family forests, tribal nations, public lands, or non-profits practicing best-in-class forest restoration

• 2 million board feet of curved glulam beams are either FSC certified, or tracked back to tribal nations meeting sustainable forestry criteria

• Largest landowner, Yakama Nation, provided 370,000 board feet

• The wood roof accounts for 15% of the project’s embodied carbon reductions, increasing to 38% when including forestry practices

Maintaining Operations

One of the most significant project challenges for PDX was to keep the airport fully operational during five years of phased construction, most importantly the check-in lobby and security checkpoints. A key strategy was to prefabricate the roof nearby, then set it into place over the existing terminal.

CONDUIT WITH PRE-INSTALLED WIRING

SKYLIGHT WITH WOOD FRAMING

ROOF PREFABRICATION

ZGF and KPFF, its structural engineer, designed the massive 400-by-1,000-foot roof to be fully assembled—including skylights, insulation, mechanical components and finishes—on a site within the PDX airfield. The structure was built 15 feet off the ground for ease of access and safety over the course of 18 months. The roof was then “unzipped” into 18 separate “cassettes” of varying-sized modules, the largest being 240-by-140 feet and weighing 1.4 million pounds.

ROOF DRAINS

SKYLIGHT

FIRE SUPPRESSION

LONG-SPAN GLULAM, FLAT & ARCHED

STEEL GIRDER

ACOUSTIC PANELS

LATTICE

ROOF DRAINS

SKYLIGHT

FIRE SUPPRESSION

LONG-SPAN GLULAM, FLAT & ARCHED

STEEL GIRDER

ACOUSTIC PANELS

LATTICE

ROOF INSTALLATION

The cassettes were then installed over a 3 ½ - month period – from late August to mid-December 2022 – during an FAA-regulated window at night when there were no passengers or occupants below the construction area. Crews first lifted the cassettes to the height of their final elevation of 53 feet. They were then driven from the prefab yard to the terminal by giant transformers. The final step was sliding them into place over the existing terminal and setting atop the Y columns. With the new roof in place, construction of the reimagined terminal continues below where workers are shielded from outside elements.

Sustainability

PDX set an ambitious goal of doubling the size of its main terminal while cutting energy in half, reusing as much existing infrastructure as possible and electrifying its heating plant for a low carbon future.

Primary energy-saving and sustainable design strategies include:

ENERGY

A HIGHLY EFFICIENT, OPEN-LOOP GROUND SOURCE HEAT PUMP SYSTEM PROVIDES NEAR 100% OF THE AIRPORT’S HEATING WITHOUT THE USE OF FOSSIL-FUELS. THIS TYPE OF ELECTRIFICATION ALLOWS PDX TO CAPITALIZE ON THE GREENING OF THE ENERGY GRID OVER TIME.

EMBODIED CARBON

INSTEAD OF BUILDING A NEW AIRPORT, THE DECISION TO REUSE MUCH OF THE EXISTING TERMINAL ACHIEVED A 70% REDUCTION IN OVERALL STRUCTURAL EMBODIED CARBON FOOTPRINT. CONSIDERING MATERIALS ONLY, A 30% REDUCTION WAS ACHIEVED THROUGH THE USE OF SUSTAINABLY-HARVESTED MASS TIMBER, LOW CARBON CONCRETE, AND LOCALLY PRODUCED STEEL.

LIGHTING

THE MAIN TERMINAL’S USE OF LEDS, DIRECT/INDIRECT LIGHTING APPROACHES, AND ABUNDANT DAYLIGHTING REDUCES LIGHTING LOADS BY 50% COMPARED TO OREGON ENERGY CODE REQUIREMENTS.

MATERIALS

THE TEAM DEVELOPED AN AIRPORTSPECIFIC FRAMEWORK TO OPTIMIZE HEALTHY MATERIALS SELECTION WHICH IDENTIFIES 16 DIFFERENT PRODUCT CATEGORIES AND REQUIRES LIMITS ON VOC CONTENT, VOC EMISSIONS, AND CHEMICAL DISCLOSURE AND SCREENING.

WATER

A 58% REDUCTION IN POTABLE WATER GALLONS PER PASSENGER WAS ACHIEVED THROUGH LOW FLOW FIXTURES AND USE OF WELL WATER FOR NONPOTABLE USES.

DAYLIGHT

A VARIETY OF SKYLIGHTS EMBODY THE DIVERSE LIGHTING CONDITIONS OF PACIFIC NORTHWEST FORESTS. THEY WORK TOGETHER TO DAYLIGHT 60% OF THE TERMINAL, EVEN UNDER PORTLAND’S CLOUDY SKIES.

HIGH PERFORMANCE EXTERIOR

TO REDUCE PEAK COOLING LOADS BY UP TO 18%, BUILDING FACADES COMBINE STRATEGIES OF SPECTRALLY-SELECTIVE GLASS; EXTERIOR STRUCTURAL MULLIONS; INTERIOR VERTICAL SCREENS; AND TRELLIS OVERHANGS.

Resiliency WITHSTANDING NATURAL DISASTERS

Resiliency to the threat of a natural disaster was another core project driver. Given the airport’s location within the Cascadia subduction zone, PDX is designed to withstand a 9.2 magnitude seismic event. The airport is intended to remain the LIFELINE to the region, ensuring aid, services, and goods continue to flow after any event.

SEISMIC ISOLATION BEARINGS LOCATED AT THE TOP OF THE NEW COLUMNS SUPPORT THE ROOF STRUCTURE, AND ISOLATE IT, ALLOWING LATERAL MOVEMENT UP TO 24 INCHES IN ANY DIRECTION DURING A SEISMIC EVENT.

THE CURTAINWALL IS ATTACHED TO THE ROOF WITH HINGED CONNECTIONS THAT PERMIT IT TO SLIDE AND PIVOT RELATIVE TO STRUCTURE BELOW.

A TIGHT BUILDING ENVELOPE, PASSIVE HEATING AND COOLING SYSTEMS, AND INCORPORATION OF NATURAL DAYLIGHT ALL ALLOW FOR PASSIVE SURVIVABILITY AFTER BEING DISCONNECTED FROM THE POWER GRID.

Even More Innovations

TECH POLES

Inspired by an urban streetlight, the design team created “technology poles” to house the myriad of technologies required in a terminal setting – cameras, speakers, lighting, emergency strobes, convenience outlets, WiFI, and wireless access points, as well as space for unknown future technology.

The poles are modular and able to accommodate any combination of elements. Over 50 poles are located along all circulation paths, every 25-50 feet, depending on required services. The poles fit within other “urban furniture,” such as benches and planters, situated along the streetscape-inspired circulation pathways. This innovative concept allows for the integration of technology without dependence on walls or ceilings, offering better coverage and a more permanent infrastructure solution.

ALL-USER RESTROOMS

The Port recognized washrooms as the airport’s most important amenity - most times the first and last impression.

There are 4 main banks of restrooms in the highly trafficked project spine that have been identified as All-User, meaning universally all-inclusive. Traditional restrooms remain throughout the airport to accommodate all comfort levels. A variety of spaces are incorporated—including universal stalls, family rooms, lactation rooms, baby changing stations, adult changing—all providing different levels of privacy and access points.

LIVING LANDSCAPE

ZGF worked with landscape architect PLACE to integrate a robust interior landscape program as a primary element of the biophilic terminal design, intended

to de-stress a passenger’s journey.

72 large trees and over 5,000 plants are strategically located in the new terminal to announce thresholds; mark important locations; and reinforce connections to the roof structure above. The location of the living landscape is tied to the architecture and concept of a “series of rooms.” Large tree wells with 25-foot high trees and plantings initiate the passenger journey from ticketing to security. A series of 40-foot hanging gardens punctuate large openings, while offering glare control and nature-infused surroundings near floor-to-ceiling window walls.

Continuous planters along the top of restroom walls are filled with cascading vines. The volume of greenery offers biophilic stress relief, while reflecting Oregon’s native flora. Abundant natural light, a consistent interior environment, simple irrigation systems and maintenance protocols, ensure plant life will remain healthy.

ART PROGRAM

PDX will continue its commitment to public art, with 1% of construction dedicated to 15 new art installations to be integrated into the new terminal core.

An Art Committee, with diverse representation, is making selections based on the following Port goals:

• Represent artists of diverse genders, races, geographic origins, and ethnicities with the purpose of advancing fair and equitable inclusion;

• Reflect the region’s creative and cultural heterogeneity; and

• Incorporate a variety of artistic mediums/materials, and aesthetics.

A sampling of what’s to come in the new terminal can be seen in the new Concourse B extension:

RYAN! Feddersen, a member of the Confederated Tribes of the Colville Reservation, created three interactive elements for “Inhabitance,” the grand artwork that Concourse B visitors move through: the landscape portraits, which she calls “The Sentinel;” the “Cloud Walk,” a rainbow-dappled sky with shimmering glass clouds; and, a woodslat wall with “Habitat Tiles,” patterns symbolizing different biomes.

ARCHITECT: ZGF ARCHITECTS LLP

CONTRACTOR: HOFFMAN/SKANSKA, JV

PRIMARY CONSULTANTS

AVIATION PLANNING: ARUP

STRUCTURAL ENGINEERING: KPFF

M/E/P ENGINEERING: PAE

LANDSCAPE: PLACE

BIOPHILIA: TERRAPIN BRIGHT GREEN

LIGHTING: FISHER MARANTZ STONE

EXPECTED COMPLETION: PHASE 1: 2024; PHASE 2: 2025

GROSS SQUARE FOOTAGE: 1,000,000

TOTAL CONSTRUCTION COST: $1.7B

CONTACTS

SHARRON VAN DER MEULEN MANAGING PARTNER sharron.vanermeulen@zgf.com

GENE SANDOVAL DESIGN PARTNER gene.sandoval@zgf.com

TONY MARTINEZ LEAD AVIATION ARCHITECT tony.martinez@zgf.com

TAMI FULLER MARKETING DIRECTOR tami.fuller@zgf.com