April 2024 - Vol 50 - No 4 ISSN : 2031-9193 www.ien.eu INDUSTRIAL ENGINEERING NEWS 10 16 26 32 Intelligent Automation: Efficient Handling of Flexible Parts with Robots Digital Plant Asset Management: Connectivity Boosts Efficiency and Availability Hannover Messe Special: Helping Achieve Net Zero CO2 Emissions with Single-Pair Ethernet Fixed Flange Bearings Become Intelligent APRIL Building Illusions with Light page 12 HANNOVER MESSE 2024 Page 24 Radar Safety for Intralogistics page 24 PCN Europe Supplement page 15 to 23 Special

TIM Global Media BV

140 Rue de Stalle - 3ème étage, 1180 Uccle-Brussels, Belgium o.erenberk@tim-europe.com - www.ien.eu

Editorial Director: Orhan Erenberk o.erenberk@tim-europe.com

Editor: Kay Petermann k.petermann@tim-europe.com

Editorial Support Flavio Steinbach Energy Efficiency: f.steinbach@tim-europe.com

Associate Publisher: Marco Marangoni m.marangoni@tim-europe.com

Production & Francesca Lorini

Order Administration: f.lorini@tim-europe.com

Website & Carlo Cucchi

Newsletter: c.cucchi@tim-europe.com

Marketing Manager: Marco Prinari m.prinari@tim-europe.com

President: Orhan Erenberk o.erenberk@tim-europe.com

ADVERTISING SALES OFFICES

EUROPE

AUSTRIA/SWITZERLAND

Monika Ailinger

Tel.: +41 41 850 44 24 m.ailinger@marcomedia.ch

BENELUX, NORWAY, SWEDEN

Nadia Liefsoens

Tel.: +32-(0)11-224397

Fax: +32-(0)11-224397 n.liefsoens@tim-europe.com

FRANCE

Roxanne Akbulut

Tel: + 33 06 52 31 41 56 r.akbulut@tim-europe.com

M’fumu Tiya Mindombe

Tel: +32 465 443 530 m.mindombe@tim-europe.com

GERMANY

Simone Ciolek

Tel: +49-(0)9771-1779007 s.ciolek@tim-europe.com

ITALY, SLOVENIA

Andrea Rancati

Tel: +39-02-7030 0088 arancati@rancatinet.it

TURKEY

Onur Dil

Tel: +90 212 366 02 76

Fax: +90 212 366 58 02 E-mail: o.dil@tim-europe.com

UNITED KINGDOM/DENMARK/ FINLAND

Dave Harvett

Tel: +44 (0)121 705 21 20 daveharvett@btconnect.com

NORTH AMERICA

Hamilton-Murphy Global, LLC

John Murphy

Tel: +1 616 682 4790

Fax: +1 616 682 4791 john@hamiltonmurphymedia.com

JAPAN

Ichiro Suzuki Incom Co. Ltd.

Tel: +81-(0)3-3260-7871

Fax: +81-(0)3-3260-7833 isuzuki@INCOM.co.jp

OTHER COUNTRIES

Cristian Son

Tel: +39 027030631 c.son@tim-europe.com

Dear Readers,

KayPetermann k.petermann@tim-europe.com

In this issue we have integrated a PCN Europe Supplement, which will be published four times a year in future. This special section will deal with the requirements of the process industry and the many challenges that affect both factory and process automation. After the two areas have grown apart over a long period of time, there are now many topics and areas that are converging again. These include software and overcoming the division between IT and OT, Ethernet and communication networks, but also energy efficiency and the shortage of skilled workers, which affects all industrial sectors.

We address these topics at various points in this issue, e.g. in the article on energy-efficient motors for metering pumps on page 20, but also on page 10, in an article that shows how robots can process difficult components. In addition, the article on page 28 takes up the topic of digital twins and aims to show what opportunities this can offer small and medium-sized companies in particular.

I look forward to receiving your feedback and comments and to making personal contact with you at trade fairs in the coming weeks, e.g. at the Hannover Messe.

KayPetermann Editor IEN Europe

Digital File Requirements available at: www.ien.eu/technical-guidelines/

2024

POSTMASTER

Send address changes to: Industrial Engineering News Europe

Marco Prinari - m.prinari@tim-europe.com

N° 4 - APRIL 2024 FREE DIGITAL SUBSCRIPTION

©

TIM Global Media BV Production by design3, Milano, Italy Printing by Logo Srl - Padova, Italy

FREE Digital Subscription 3

editorial

In the next issue:

New Products

Intelligent Automation: Efficient Handling of Flexible Parts with Robots

Intelligent Automation: Smart Components Digitize the Industry.

Motion & Drives:

Building Illusions with Light. Accurate motors enable elaborate laser shows for events and art installations.

Energy Efficiency: Metering Precisely – And Saving Energy. Advanced IE5+ motors for high-precision

pumps

Exclusive Interview:

Focus on: Material Inspection and Sorting. PCN Europe spoke to Mark Pontin, Managing Director of Resolve Optics.

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 4 Industry News

Processing & Control News Europe Supplement Digital Transformation: Connectivity Boosts Efficiency and Availability New Products

metering

Hannover Messe Special Radar Safety for Intralogistics Helping Achieve Net Zero CO2 Emissions with Single-Pair Ethernet Digitalisation Delivers a Competitive Advantage to Small and Medium Businesses Field Level Upgrade. Single Pair Ethernet for Process Industry New Products Index & Events 5 6 10 10 12 15 16 18 20 22 24 26 28 30 32 34 6 30 32 12 10 contents

Renewable Energies and Green Hydrogen Sensors, Test & Measurement N° 4APRIL 2024 20

WebMag May:

Revamping the Plastics Recycling ChainFlagship Project for the Circular Economy

Today, the majority of consumer goods and everyday items are made from petroleum-based plastics. In Germany alone, around six million tonnes of plastic waste is generated every year. About half of this is mechanically recycled into new materials; the rest is used for energy recovery. The incineration of this waste results in the release of CO2, a greenhouse gas. It is therefore important to keep more plastics in the material cycle for climate and environmental reasons. Eight Fraunhofer Institutes are developing new ideas and processes to significantly improve the mechanical recycling rate of plastics as part of the Waste4Future flagship project. Those involved in the project are investigating potential mechanical (melt extrusion, solvent-based purification and fractionation) and chemical (solvolysis, pyrolysis, gasification) recycling processes and testing them for their suitability for different compositions of plastic waste. By the time the project ends in December 2024, it will be possible to compare components made from old plastics against new materials. Detailed information on the project can be found here: https://www.waste4future.fraunhofer.de/en.html

Llifecycle Services for Industrial Data Networks

Dr Michael Berger Appointed to the IDS Management Board

Westermo has launched a range of pre-packaged service agreements to help manufacturers, utilities, transport and other industries maintain, secure and improve data communication networks throughout their lifecycle. The increasing reliance on data communications to run critical applications places greater emphasis on reliability and security. Through the use of Westermo's extensive experience and expertise, organisations will be able to improve network performance and maximise availability of operations. “The need for more robust and reliable data communications continues to grow, but achieving this requires more than just state-of-the-art products. It is also essential to have a reliable and accessible partner with the right expertise to support companies throughout the lifecycle of their networks," states Peter Ahlström, services product manager at Westermo. “Many organisations lack the necessary in-house expertise to implement and maintain critical data networks. Westermo has a wealth of experience, which enables us to provide essential advice on implementation, operation and maintenance,” explains Alice Frykberg, services and support manager at Westermo. “The new service agreements allow our customers to leverage our expertise, enabling them to reduce the complexity of network design and ensure continued high levels of availability and performance over the lifecycle of the network.”

Seita Hagihara Takes Over as President of Yokogawa Europe

Dr Michael Berger (r.) has started as Managing Director of IDS Imaging Development Systems GmbH beginning of 2024. After 27 years at the helm, Jürgen Hartmann (l.), founder and shareholder of the industrial camera manufacturer, is stepping down. The generational change at the Obersulm-based machine vision specialist has been successfully completed with the appointment of 42-year-old Berger to the IDS management team. In future, Berger will be responsible for sales, marketing, product management and system consulting. Jan Hartmann, son of the founder, will now be responsible for Finance, Human Resources, IT and Business Innovation & Ecosystem, while Alexander Lewinsky will take over Development in addition to his previous responsibilities in Operations. Jürgen Hartmann is handing over the management of the operational business and will advise the family business in the areas of technology and innovation as Chief Innovation Manager. He will remain managing partner of Hartmann Holding GmbH. Dr Michael Berger studied business administration at the University of Bayreuth and obtained his doctorate in sales and market management at the University of Constance. He was most recently General Manager of Li-Ion Cells at VARTA AG. A clear market orientation always characterises his actions.

Yokogawa Europe B.V. announces that Seita Hagihara has been appointed as the new president of the Yokogawa regional headquarters for Europe. He succeeds Takayuki Matsubara, who will be moving into the role of CEO in Yokogawa Group company KBC. After studying Economics & Geography at the University College of London, Hagihara began his career as a sales engineer at Yokogawa Electric Corporation in Tokyo, Japan. He can look back on 26 years of experience in various roles at Yokogawa, ranging from sales to finance and global major account management. In 2021, Hagihara was appointed vice president of System Sales & Sales Operation at Yokogawa Corporation of America. Based in Texas, his responsibilities included leading system sales, business development, proposals, and sales operations from Canada to Central America, as well as supervisory management of Yokogawa Mexico. In addition, he led the regional Energy & Sustainability business. Seita Hagihara will be in overall charge of managing Yokogawa’s operations in Europe from the Yokogawa Europe headquarters in The Netherlands.

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024

industry news 5

© Holger Jacoby

12VPOWERSUPPLYWITH2040WOUTPUT

Operateswithwiderangeofthree-phaseinputs

TDK-Lambda announces theadditionoftheTPS 4000-12powersupply, furtherextendingtheexisting3kWto4kWrated TPSseries.Deliveringupto 2040Woutputpower(12V at170A)ina2Uhighpackage,theTPS4000seriesoperatesfroma widerangeDeltaorWye350-528Vacthreephaseinput.Thehigh voltage,three-phaseinputavoidstherequirementforcostlystepdowntransformersandassistsphaseloadcurrentbalancing. The TPS4000seriesisfullyfeaturedwithisolatedACFail,DCGoodand droppedphasesignals,remoteon/off,remotesense,anda12V 0.3Astandbysupply.APMBus™communicationsinterfaceallows remotemonitoringoftheoutputvoltage,outputcurrent,internal temperature,statussignalsandfanspeed.Inaddition,theoutput voltage,overcurrentlimitandtheremoteon/offcanbeprogrammedbythePMBus™.Theoutputvoltagecanalsobeadjustedfrom 9.6to14.1Vandthecurrentlimitpointby70-105%usingfront panelpotentiometersorananalog0-5Vdcvoltage.TheTPS400012canoperateatfullloadinambienttemperaturesofupto50°C anddeliverupto55%loadat70°C.Coolingisprovidedbyan internaltemperature-controlledfantoreduceacousticnoise.The casemeasures107x84.4x335mm,makingitsuitablefor2Uhigh rackingsystems.Theweightoftheproductisjust4kg.

64662atwww.ien.eu

SENSORLESSSPEED&FREQUENCYMONITOR

Withsafety-relateddirectionofrotationmonitoring Inadditiontosensorlessspeed monitoring,theUH6937from D Dold nowalsoofferssafemonitoringofthephasesequenceresp. directionofrotationofmotors with3-phaseACvoltages.Ifthe motordoesnotmoveinthe desireddirection,thedevice switchesoffsafely.Thespeedand frequencymonitorUH6937ofthe SAFEMASTERSseriesistherefore perfectforapplicationswherethe correctdirectionofrotationisessential,suchasinautomation processes,compressors,machinetoolsandwindturbines. The directionofrotationmonitoringfulfilsPLd/Cat.2accordingtoEN ISO13849-1andSIL2accordingtoEN61508whileretainingthe previoussafety-relatedcharacteristicdataPLe/Cat.4andSIL3 forspeedandfrequencymonitoring.Thedevicecanbeoperatedin auser-friendlywayviathefourbuttonsonthefrontandtheLC display,thusenablingsimpleandtime-savingparameterisationcompletelywithoutaPC.Uptofouroperatingmodesarepossible fordifferentconfigurationsofoverfrequency,underfrequency, windowrangeanddirectionofrotation.Ifthesetparameterisation isviolated,thefrequencymonitorswitchesoffdangerous situationsinasafety-orientedmanner.

OVERMOLDEDM12CABLECONNECTORS

DevelopedaccordingtotheUL2238standard

64276atwww.ien.eu

IPCSFORAVARIETYOFHMIAPPLICATIONS

ForHuman-Machine-Interactioninmodernproduction ADS-TECIndustrialIToffersits newMES9000seriesasshop floorterminal,machinepanel PCorasruggedshopfloor terminalforharshenvironments.Dependingondevice variationtheMES9000series canbemountedonasupport arm,onthetablebaseviaVESA 100socketsoronthemachine wall.Availableindisplaysizes15,6",18,5"and23,8",theindustrialPCscanbecustomisedexworks,e.g.withacustomimage withpre-installedsoftware,aBIOSthatincludesacustomer-specificbootlogooraspecialdisplaytouchbehaviour.Thankstoits largeandintuitivemulti-touchdisplay,machinesandsystemscan becontrolledefficientlyandoperatingdatacanbemanuallyand digitallyrecordedincombinationwithanMESsystem.TheHMIs areentirelyfan-lessbutstillallowtheuseofthepowerfulIntel® Celeron®andIntel®Core™CPUsofthe8thgeneration.Thisensurestherequiredperformanceevenwithhighsoftwarerequirementsforhigh-performancerecording,visualisationandcontrolof manufacturingprocesses. Thefrontismadeoftemperedglassand isshock-proofaccordingtoIK08.Thehousingisfullyprotected againstdustandjetwatermeetingIP65requirements,whenused withthecorrespondingaccessorykit.

binder isexpandingitsM12portfoliobyaddingK-andL-coded overmoldedcableconnectorsofthe 823and824series,whichwere developedaccordingtoUL2238. Theseareprimarilyintendedforuse inthepowersupplyoffielddevices inautomationtechnology.Theconnectorsprovideacompactalternativetopowerconnectionsusing7/8-inchtechnology. The K-codingindicates5-pinconnectorsforACsupplyofe.g.,drivesor frequencyconverters.Targetapplicationsofthelikewise5-pin connectorswithL-codingincludeDCminiaturedrives,decentralizedI/Omodules,andotherautomationcomponentsthataresuppliedwithDCvoltageinfieldbussystems.TheK-codedproducts ofthebinder824serieswithscrewlockingarecharacterizedby theirampacityofupto12Aperpinundercontinuousloadatrated voltagesof630V(AC)respectively.TheL-codedproductsinthe 823serieshavearatedcurrentof16Aandaratedvoltageof63V (DC).Gold-platedcontactsguaranteereliablecurrenttransmission. Thefullyovermoldedconnectorsensureprotectionoftheinterface accordingtoIP68andhaveanoperatingtemperaturerangefrom: -40°Cto+90°C.ForexporttoNorthAmerica,UL2238certificationiscurrentlyinpreparation.TheK-andL-codedovermolded M12cableconnectorsweredevelopedinconformancewithIEC 61076-2-11foruseinindustrial-automationenvironments. 64515atwww.ien.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 6

64660atwww.ien.eu

SAFERADARSYSTEMWITHFSOECONNECTION

Protectionzonemonitoringwithadptablefieldofvision

Withthesaferadarsystem PSENradarfrom P Pilz,itisnow possibletoimplementprotection zonemonitoringinharsh environmentsforadditional applications.Extendedfieldof viewfunctionsmakeiteasierto integratetheradarsensorsinto differentproductionenvironments.Theflexibilityprovidedby adaptablefieldsofviewisparticularlybeneficialinconfined spaces.ItisalsonowpossibletoconnecttotheopenSafetyover EtherCATFSoEsafetyprotocol,resultinginlesswiringandlower costs. Inadditiontotheexistingradarsensorswithadetection rangeof0to5metres,thesaferadarsensorPSENrd1.2sensor F-FOVLRisnowalsoavailablewitharangeof0to9metres.Anew featureofbothsensordevicesistheoptionofflexiblyconfiguring thefieldsofview:inadditiontothesymmetricalviewingangle, asymmetricalandcorridor-likeviewinganglescannowalsobe configured.ThismeansthatPSENradarcanbeusedreliablyin differentproductionenvironments.Italsosavesspaceinthe productionarea,particularlywherespaceislimited,forexample wheremachinesarelocateddirectlynexttoeachotherorwhere walkwaysleaddirectlypastthemachines.Nowthatthefieldof viewsettingscanbeconfiguredmoreindividually,theradarsensor canbepositionedmoreflexiblywithoutrestrictingproduction.

64658atwww.ien.eu

CC-LINKCERTIFIEDENCODERS

Opticalandmagneticversionswithoutbatteries

Lika Electronic'sEthernetencodersfamilygrowsandaddsthe CC-LinkIEFieldBasiccompatibilitytoitsEXM58magneticand EXO58opticalseries.CC-LinkIE FieldBasicisthepopular,100 MbitversionoftheCC-LinkIE openindustrialEthernet.Itisanultra-highspeedandultralarge capacitynetwork,whichprovidesbothsynchronousdeterministic (cyclic)communicationandasynchronouson-demandmessaging (transient)communication.OriginatedwiththeCC-Link(Control& Communication)fieldbusin1996developedbyMitsubishiElectric Corporation,itismanagedbytheCC-LinkPartnerAssociation (CLPA)currently. TheEXM58andEXO58absoluterotaryencoders areCC-LinkcertifiedandbelongtoLika'swideEthernetfamily whichalsoincludesProfinet,EtherNet/IP,EtherCAT,POWERLINK, andMODBUS/TCPdevices.TheEXM58encodersmounttherobust magneticsensingtechnologywhiletheEXO58encodersare equippedwiththehighaccuracyopticalsensingtechnology.They areverylightandcompactthankstotheintegrationoftheEnergy HarvestingTechnologycircuit.Itenablesthemultiturncounterto bebattery-freeandgearlessandtheriskofmechanicalfailuresto besignificantlyreducedatthesametime.Therangeofthe workingtemperatureisextendedfrom-40°Cto+100°C(-40°Fto +212°F)tocovermanyindustrialapplications.

EDGEPLATFORMSTRAINGAUGEMODULES

SSRoutputandrelayoutputoptionsforupto4bridges

Red Lion hasannouncedthelaunch ofnewstraingaugemodulesand J1939andCANprotocolsleds. Thesearedesignedtoextendand scaleitsFlexEdge®intelligent edgeautomationplatform. The newstraingaugemodulesareeasy toinstallandconfigureandare availableinbothSSRoutputand relayoutputoptions,bothoffer single-loopPIDcapabilitiesfor monitoring,measuringandcontrollingequipment.Themodules acceptsignalsfromloadcell,pressureandtorquebridgetransducersandaredesignedtooperateinharshenvironments.Witha softwareselectable5VDCor10VDCstablebridgeexcitationvoltage,eachDMSmodulecandriveuptofour350Wbridges.Theinputsarealsosoftwareselectableforlowlevelinputsat±20mV, ±33mVand±200mVfullscale. Inadditiontothenewstrain gaugecapabilities,RedLionhasintroducedtwofield-installable sledsthatsupporteithertheJ1939orCANprotocol.Providinga seamlessinterfacebetweenindustrialequipmentandthecontrollerenvironment,theprotocolsledscanbepoweredandconfigured directlyfromtheFlexEdge®DA50orDA70controllerusingRL's Crimsonsoftware.Thenewmodulesmakecriticalperformance dataeasiertocollect,moreaccurateandactionableinrealtime.

64644atwww.ien.eu

COMPACTETHERNETMODULEFORPLCSERIES

Upgradeforcloudconnectivityandnewsecurityfeatures Mitsubishi Electric hasupdatedits FX5-ENETEthernetunittooffer advancedIndustrialInternetof Things(IIoT)capabilitieswithin machinesusingMELSECiQ-F seriesPLCs.Endusersand machinebuilderscannowdrive operationalefficiencyevenfurther byleveragingexpandedaccessto cloudcomputing,cybersecurity andemailfunctionsthatsupportenhancedconnectivityanddata management. Asaresult,machinesusingthisunitcanbenefit fromdata-drivenanalyticstosupportpredictivemaintenance strategies,simplifytroubleshootingandimprovingproductivity. TheCloudconnectivityfunctionissupportedbyMQTT,acommunicationsprotocolthatisoptimisedforIIoTdevicesandcan maximiseaccessibilityandenabletherealisationofawiderange ofapplications.Inadditiontothis,theuseofMQTTwithinthe FX5-ENETEthernetunitassistsusersinsettingupseamlessly interconnectedmachinesforsmartoperationswhileprotecting theirfactoriesfromcybersecuritythreats.Theprotocolalso includeskeysecurityfeatures,suchasencryptionanddigital certifications,thathelptoprevent,detect,respondtoandaddress potentialrisksthroughretransmissionifamessageisnotreceived, TLSencryptionandclientauthentication.

64336atwww.ien.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 7

64272atwww.ien.eu

RUGGEDIZEDEDGEAISYSTEM

IP67ratededgedeviceforharshenvironments

THERMALIMAGERWITHGIGE-INTERFACE

OptionsforstandaloneoperationandPC-basedanalysis

64646atwww.ien.eu

HIGH-SPEEDLASERMARKINGSYSTEM

Foron-the-flymarkingwithupto240m/min

Availablein10W,20Wand30W, thenewPPanasonic LP-RHCO2 lasermarkingsystemsare designedforindustriesthatrequirespeedandfunctionality. Theyofferimprovedmarkingand processingqualityandmark movingobjectsontheflyatconveyorspeedsofupto240m/ min,thankstotheultra-fast galvanometerscanner. Somemodelsoftheseriesareidealfor markingsmallcomponentswithextremelyfinemarkingsdueto theirsmalllaserbeamdiameter.Othermodels,withashorter wavelengthof9.3µm,areidealformarkingtransparentplastics suchasPETorPC.TheCO2laserisalsosuitableforthemarkingof organicmaterialssuchaspaperandwood. Thestart-uptimehas beensignificantlyreducedfrom90to15seconds.Thisincreases efficiencyandavoidsunwantedproductioninterruptions.The engravingachievesimpressiveuniformity,speedandprecision comparedtothepreviousseries,thankstothenewlyintegrated motor.Themarkingfieldoftheseriesisupto160x160mm.Anew scanningmethodforDataMatrixcodesreducescycletimesbyup to40%withoutanylossofquality. Fineadjustmentofthefocus settingiseasytouse.Withoutmovingthelaserhead,theworking distancecanbeeasilyadjustedfrom-/+3mm.

Advantech announcesthe releaseoftheMIC-715-OX-an innovative,ruggedisededgeAI systemforapplicationsinharsh environments.Basedonthe NVIDIA®JetsonOrin™NXsystem-on-module,thissolution featuresanIP67ratingforwateranddust,lockableconnectorsfor vibrationtolerance,amachineignitionprotectionsystem,built-in PoEandGMSL2videointerfacesupport. Heavyindustryoften involvescostly24/7operationsinharshenvironmentsthatcanbe dangerousforworkers.AI-enabledautonomousequipmentoffers anopportunitytoimprovethissituationbyincreasingtheefficiency,accuracyandsafetyoftheseindustries.TheMIC-715-OXis designedwiththeseneedsandin-vehicleAIapplicationsinmind. ItispoweredbytheNVIDIA®JetsonOrin™NXmodulewithAIperformanceofupto100TOPS.ItleveragesM12connectors,supports operationinbroadtemperatureranges(-25~60°C),andoffersan IP67rating.Similarly,allofMIC-715-OX'sI/Oarelockable,providingadvancedvibrationresistance.Thesystemsupportscameras viaanintegratedPoEportandwillsoonsupportupto6xGigabit MultimediaSerialLink2(GMSL2)cameras.Asamemberofthe MIC-AIseries,itoffersflexibleI/O,diverseperipherals,excellent durabilityandBoardSupportPackage(BSP)capabilitiesandsupportsWi-Fi,4G/LTEand5Gsimultaneously. 64631atwww.ien.eu

Fluke Process Instruments extendsitsThermoViewTV30 series,launchingaGigEthermographiccamerainadditiontothe spearheadstandaloneversion. Theinfraredcamerasforfixed installationenable24/7thermal monitoringofprocessesandassets.Theyidentifytemperature anomaliesandsendalerts,allowingplantstafftorectifyany problemsearlyonandavoidpoorqualityoutputanddamageto productsandequipment. Thestandaloneversionwithonboard analyticsandremotesetupviawebbrowserneedsnoPCinthe fieldtoautomaticallymonitorupto32valuesforuser-specified AreasofInterestandcriteria. TheGigEversionwasdesignedto meetthemostsophisticatedrequirements.Itenablesdirect communicationbetweenprogrammersandthecamerausing standardapplicationslikeLabvieworMatlabortheproprietary ThermoViewsoftware.Itconnectstoashop-floororcontrol-room PCandcanstreamthermalimagesatupto60framespersecond. Thethermalimagerscandetecttemperaturesfrom-10°Cto1300 °C(14°Fto2372°F).Forimprovedaccuracy,userscanspecify tightertemperatureranges. Theimagersfeaturearugged, IP67-ratedhousing.Theseriesalsoprovidesachoiceoftwo resolutionoptions,threelensesfordifferentfieldsofviewand protectiveaccessoriesfordemandingenvironments.

64365atwww.ien.eu

SMARTHMISMALLCONTROLSYSTEM

TouchdisplayswithintegratedgraphicsandI/Ocontrol TheHMIdisplaysintheuniTFT seriesfrom D DISPLAY VISIONS offer brilliantgraphicsdisplaysand intelligentsmallcontrolsystems inone.Thankstotheintegrated I/Oandhigh-performancegraphicscontroller,userscanimplementcompletecontrolapplicationswithouttheneedforadditional µCorPLCforuseinbuildingautomation,controlpanelsinmobile homesorcontrollingindustrialproductionprocesses.TheuniTFT displaysmasterlogicalandarithmeticoperationsanddatacommunicationandstorage.Theyalsohavefouranalogueinputsand eightfreelyprogrammableinputsoroutputs(3.3V).Theyhave externalsensorsandmicrocontrollerstocommunicateviaI²C,SPI, RS232andUSBports.Themodelsupto4.3-inchstoreyourdatain internalflashmemories.Thedisplaysfrom5-inchto10.1-inchhave anaddedmicro-SDslot.Thereisalsoanaudiooutputforacoustic alerts.Theoperatingvoltageis3.3Vonly.Thankstostate-of-theartIPStechnology,theoptimalviewingangleis170°horizontally aswellasvertically.Thismeansthatthedisplaysshowanimage withthecolourandcontrastjustastheyshouldbe,evenfromvery peripheralperspectives.Withtypicalbrightnessof1,000cd/m², theyarealsostilleasytoreadinsituationswithunfavourable ambientlight.Forprogramming,DISPLAYVISIONSprovidesthe uniTFTDesignerfreeofcharge.

64592atwww.ien.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 8

SAFETY-RELATEDPLC

ForProfisafeuptotheSIL3

ThenewAXCFXT

SPLC3000safetycontrollerfrom P Phoenix Contact canbeoperatedasaleft-side extensionmoduleon thePLCnextControlAXCF2152andAXC F3152devices.ItextendsthePLCnext portfoliowithapowerfulsafetyPLCfor ProfisafedevicesinProfinetnetworks.The safetycontrollercanbeusedinapplicationsuptosafetycategorySIL3inaccordancewithIEC61508/61511andPLein accordancewithENISO13849-1. Inoperation,theSPLC3000cancommunicate withupto300F-DevicesasanF-Hostand simultaneouslyactasanF-Device.The controllerisfullyintegratedintotheopen PLCnextTechnologyecosystemandprovidesahighdegreeofmodularity withthe ProfisafeI/OextensionsoftheAxiobus, thatcanbealignedontheright-handside. TheredundantlydesignedARM-basedsafety-relatedCPUshaveaclockrateof800 MHzforchannel1, 600MHzforchannel2.

64513atwww.ien.eu

LASERPROFILESCANNERS

Forfastandaccuratemeasurement

Theperformanceofthe M Micro Epsilon scanCONTROL3000scannershas beenincreasedwithimprovedalgorithmsand components.Twonew modelscompletethescannerportfoliowith measuringrangesof430mmand600mm. Thelaserprofilescannersnowhavean accelerateddataacquisitionrateofupto 10millionmeasuringpoints/second,while theprofilecalculationandevaluationspeed oftheSMARTsensorshasbeenincreased by60%.TheSMARTscannersnowhaveone ofthefastestprofileevaluationsonthe market.Thespeedincreasewilltakeeffect forallcurrentscanCONTROLSMARTmodels withanupdatetoscanCONTROLConfigurationTools6.8.Inconjunctionwiththe updatetothenewv54firmware,thesmart scanCONTROL30xxsensorsachievean increaseinevaluationspeedofupto60% andthepointrateupto10millionmeasuringpointspersecondcomparedtothe previous7.5million.

64649atwww.ien.eu

POSITION-MULTI-SENSOR SensorModulewithCANFD

PEAK-System

releases PCAN-GPSFD, amodernsensormodule withCANFDconnection. Thesensortechnologyof thenewmoduleisdesignedforthedetectionofposition,orientation,andacceleration.Theu-bloxMAX-M10SsatellitereceiverforthenavigationsystemsGPS,Galileo, BeiDou,andGLONASScandeterminethe positionwithanaccuracyofupto1.5meters.Amagneticfieldsensor,anaccelerationsensor,andagyroscopefromSTMicroelectronicsprovidethedatafororientation andacceleration.Theprocessingandtransmissionofsensordatabytheintegrated ArmCortexM4microcontrollercanbe programmedasdesired.Forthis,PEAKSystemprovidesauser-friendlydevelopmentpackageforCandC++withvarious examples. TheresultingfirmwareistransferreddirectlytothemoduleviatheCAN bus.ThePCAN-GPSFDisdeliveredwitha ready-to-usestandardfirmwarethatsends allsensordataperiodicallytotheCANbus.

64359atwww.ien.eu

9 We keep your industry alive Our cables are the lifelines of industry and distribute energy to where it is needed. We provide reliable connections for your project, for your company, for your industry. www.lapp.com/en/de Get your free ticket now! Visit us at the Hannover Messe in Hall 11 Stand C15

64600 at www.ien.eu

Efficient Handling of Flexible Parts with Robots

Grasping and plugging cables is child's play! For us humans, yes. However, automated processing of such flexible parts presents robots with considerable challenges. Nevertheless, the potential is huge; in terms of efficiency and quality as well as in terms of relieving employees, for instance when it comes to handling large, heavy cables.

The pressure to automate and digitize manufacturing processes is increasing significantly in the automotive sector. High quality requirements, a shortage of skilled workers or the desire to reshore production are three of the reasons. At the same time, cable-processing tasks such as the handling of cables during assembly or the production of small cable harnesses are still a classic case of manual work in many places. Robot-assisted solutions could often reduce this significantly.

Increasing flexibility by using robots

The quantities produced in the automotive industry usually change over time. In most cases, the quantities required by the market are smaller at the beginning, then gradually increase and, when demand is saturated, decrease again. Conventional production facilities are optimized for a specific task, are designed for peak times, and are therefore not ideally utilized during parts of their life span. If the product is no longer manufactured, the machine is no longer needed.

Production with flexible robot cells, which contain a high proportion of standard components, is more sustainable. These can be individually adapted to the respective technical requirements and product characteristics. The number of robot cells used can scale production quantities. This applies to the processing of limb parts. To compensate for the tolerances that prevail with flexible parts, the robots are equipped with flexibly configurable sensors such as laser scanners, force-torque sensors or smart cameras. Once the robot has specifically grasped the end of the cable, wire, or tube, it can flexibly perform various production steps, such as fitting connectors, loading machines for crimping or welding, attaching components to the wire and much

more. For a robot to be able to grip flexible parts reliably, a number of requirements have to be met. ArtiMinds has developed a laser scanner approach for parts location in combination with their ArtiMinds RPS programming software. Rainer Jäkel, ArtiMinds-CTO, explains that there are three main approaches for feeding, for instance in cable assembly or wire harness production, depending on production environment and quantities, length and weight of the parts:

Cut to size directly on site

The more defined a cable or tube is fed to a robot, the easier it is for the robot to grip it. If the material is available on a reel or drum, for example, the gripping point is already sufficiently known. Tolerances arise due to the gripping process itself and properties of the material, such as twist. Once the robot has grasped the cable securely, it is easy to carry out further processing

steps. "Of course, this requires vision tools that precisely measure the end of the gripped wire depending on the next processing step, so that the software can determine in which direction the wire sticks out from the gripper or at what angle it should be inserted into another part, for example," adds Jäkel. Once the cable has been grasped in a defined way, there are many things the robot can do with it. Although the robot does not reach the speed of a classic cutting machine, the ability to integrate additional process steps and thus save time throughout the entire handling process compensates for this in no time.

Using hanging racks

For longer cables, the use of suspension racks can be useful. These cables are often not only long, but also thick and therefore heavy, for example in the high-voltage range. The robot

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 10 intelligent automation

Suspended racks are suitable for long, heavy cables. ©: ArtiMinds Robotics GmbH

therefore often only grasps the end of the heavy cables, while the rest of the cable remains on the suspension frame. The difficult task for the robot is to find the correct gripping point on a freely suspended cable. To do this, the robot uses a laser scanner to scan the end of the cable and determine the ideal gripping point and angle. To ensure that the work is carried out efficiently, such racks are often equipped with many cables and inserted into the robot cell. The robot can now work for a longer period of time without the intervention of an employee until it needs to be restocked. "With this flexible solution, customers can often open up existing machines for automating the processing of cables and thus reduce the necessary investment," says Jäkel.

Cables in boxes

Cables with a length of up to approx. 1,000 mm are usually best fed in boxes. For automation purposes, the cables are placed in vertical compartments to ensure minimal structuring, which enables the robot with sensors to safely pick up the cables. "The robot solution that we implemented with a customer using this method significantly reduced the time required to prepare the material and thus improved machine utilization," reports Jäkel. The robot also knows roughly where to expect the cable, then measures it in detail with the laser scanner and accesses it with pinpoint accuracy. After one or more processing steps, it then places the cable back in another box. The advantage of this procedure is that working with boxes is an established standard process that fits in well with the overall production process. It is therefore a particularly suitable approach for brownfield systems.

Defying Elements

Programming made easy

Regardless which of the three feeding methods is chosen, the user benefits from a robot solution with flexible standard components because the same system or production process can be used to process different cables and integrate additional production processes without major retrofitting work and costly additional developments. Besides the question of a suitable feeding concept, there is also the question of programming the robots and integrating sensors and tools.

With its Robot Programming Suite (RPS), ArtiMinds is taking a path that makes it noticeably easier to get started with robots using flexible sensors and tools and enables

Special templates from the ArtiMinds Robot Programming Suite enable reliable, forcecontrolled insertion. ©: ArtiMinds Robotics GmbH

the robot-based automation of advanced applications. With its graphical user interface and predefined templates, robots can be programmed more easily, more efficiently and therefore more profitably without additional hardware. Thanks to suitable interfaces, ArtiMinds RPS ensures the smooth integration of sensors and tools without the need for specialist knowledge for this components or knowledge of the respective robot language. Corresponding templates simplify the scanning, measuring and precise gripping of flexible parts and enable reliable, force-controlled insertion.

64657 at www.ien.eu

64648 at

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 11

Hal l9B ooth D76 04/22–04/26/24 Industrial RadarS ensors with CANinter face pepp erl-fu ch s.co m/ pr-i ndus tria l- rada r Interference -freedistanceand velocity measurement. Even in rain,fog,wind, or dust.

.

www.ien.eu

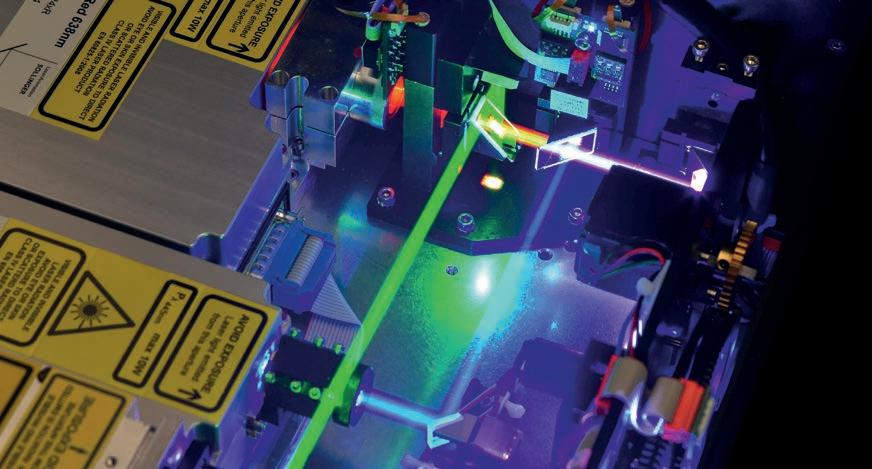

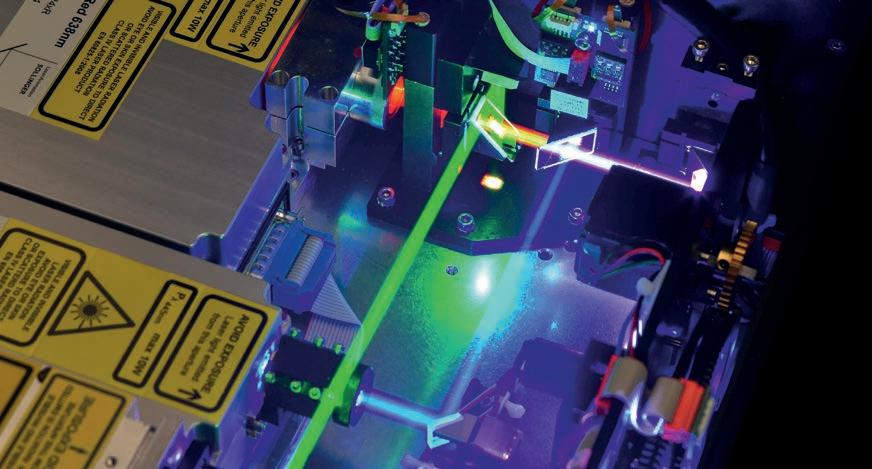

Building Illusions with Light

Today, every large event includes an elaborate laser show. Laser projections are used at trade fairs, in advertising, art, and at architectural events. The magically glowing light patterns are made possible by highly complex technology, and at many of the most spectacular installations this technology is provided by Berlinbased LaserAnimation Sollinger. When it comes to the alignment of beams and the creation of effects, motors from FAULHABER play an important role for their laser projectors.

The often surprising and sometimes breathtaking light effects are based on the unique qualities of the laser beam. In terms of intensity, beam focus, and range, it outperforms light beams from other artificial sources many times over. On the other hand, the laser is subject to optical and technical limitations, as sales manager Richard Schäfer explains: “The beam is usually very small. With our devices, its diameter is usually around 4.0 millimeters. So only a small dot appears on a projection surface.” In order create a pattern – such as a logo, lettering, or cartoon-like moving images – laser projection relies on the inertia of the human eye. To be precise, it is the image processing in the brain, which also creates a continuous progression in a film made up of 24 individual frames per second. If the laser beam moves fast enough, the person “sees” the projected

animation instead of a point of light darting around. To achieve this, the beam in the projector is deflected by means of two mirrors –one each for the x and y axes. Its movement is induced electro-magnetically and reaches a very high speed.

Another limitation is the color. The color of a laser depends on the laser-active material in which the beam is generated. In the case of laser projection, it is the semiconductor, since diode lasers or Coherent OPSL sources are used here. But laser diodes can only produce a few basic colors, mainly red, green, and blue. The high-end devices from LaserAnimation Sollinger also have Coherent OPSL sources for yellow, orange, and cyan. To produce a white beam, beams of multiple colors must be “collinearly superimposed.”

The same is the case for other colors: in order to create the different tones of the entire

If you are “building” with light, you need maximum precision.

palette, the intensity of the individual rays is modulated.

Not even a hundredth of a degree of deviation is allowed

But that only works if the beams stay together very precisely and, above all, for a long time and at a great distance, because laser installations often have to be visible from hundreds of meters or even several kilometres away. The dichroic filters have to be adjusted with the appropriate precision, as Richard Schäfer explains: “A deviation of one hundredth of a degree results in an offset of 1.7 centimetres per one hundred meters. This means that the individual colors are no longer on top of each other and can be distinguished by the human eye – the color mixing effect is lost.”

Despite high-quality materials and sophisticated fastening technology, a certain level of distortion in the optics is inevitable. This means that the position of the dichroic filters may need to be slightly readjusted. This is the reason why the dichroic mirror holders are equipped with a drive: brushless DC motors from FAULHABER with integrated gears are used for software-controlled fine adjustment to at least a thousandth of a degree.

Optical gratings for breathtaking effects

Another motor is used for protection. To prevent the intense laser light from penetrating the human eye in an uncontrolled manner, the projectors are equipped with a two-stage switch-off mechanism. In addition to an electronic protective circuit, there is also a mechanical shutter for emergencies. Its flap is held open during regular operation by a

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 12 motion & drives

motorized rotary magnet. In the event of a fault, the safety circuit stops the motor and allows the flap to fall into the beam exit. Other drives from FAULHABER are used in the grating module. Diffraction grating is an optical element that uses the deflection of light rays when passing through very narrow gaps. In addition to beams and graphics, a laser projector can also generate a variety of patterns and effects, such as a kind of artificial polar light or the wafting, abstract forms

of Robert Henke's “Destructive Observation Field”: A light object that changes continuously and looks like a mix between cosmic fog and biological cell structure, reflecting the micro- and macrocosm, as it were. The effects can not only be produced on a projection wall, but also freely suspended in space.

Highest demands on drives

“For these types of effects, we often use several projectors," explains Richard Schäfer.

“They can only unfold their effect if the gratings move completely synchronously, at the highest and lowest speed as well as in start/stop operation with constant changes of direction.” The projectors and the grating modules are full of technology, which means that the installation space is extremely tight. Only very small motors can be accommodated here.

Maximum precision and repeatability are additional minimum requirements. The integrated backlash-free gears play an important role here. When asked about the beginning of the collaboration with FAULHABER, Richard Schäfer replies that it must have been before his time. Looking for the very first order, he finds the year 2003. This means that FAULHABER motors have stood the test of time for this demanding application over the course of twenty years.

64665 at www.ien.eu

13

Cooling systemsRegulation systemsHeating systemsClimate Cooling systemsRegulation systemsHeating systemsClimate control system Cooling systemsRegulation systemsHeating systemsClimate Cooling systemsRegulation systemsHeating systemsClimate control system Follow us: Fandis meets various needs for climate control , cooling , heating , and temperature & humidity regulation to optimize the performance of the electrical panel. Effective Thermal Management Reliable solutions for the control and protection of electrical panels

Faulhaber motor 64563 at www.ien.eu

Brushless

14 motion & drives

GREASEDEGRADATIONDIAGNOSISBYAPP

On-siteanalysisoflubricantconditioninbearings

Abroadspreadofmachineryand equipment,frommachinetools torailcars,utilisegrease-lubricatedproductslikeballscrews, bearings andlinearguides. However,greasedegradesover timeasmachineryoperates,so on-sitelubricantinspectionisvitaltohelpmaximiseuptimeand OEE(overallequipmenteffectiveness).Aneedthereforeexistsfora greasedegradationdiagnosismethodcapableofrapidandhighly accuratedeploymentonsite. Existinghigh-accuracydiagnosis methodsrelyonlaboratoryanalysis,butthiscomeswithhighcost, alackofsuitabilityforon-siteuse,andalongwaitforresults. Visualobservationordensitometermethodsaremorecommonbut sufferfromlowaccuracy.Somanycompaniesreplenishlubricant earlytoensurestableoperation,resultinginwastefulgreaseusage. Thenew NSK appcananalysetheleveloflubricantdegradationusingjustasmallsampleofgrease.Chemicalchangestothe baseoilandadditivesofthegreaseoccurduetoheatfromoperationandoxidationwiththepassageoftime.Thesechangescause themolecularstructureofthelubricanttochangeandabsorbmore short-wavelengthlight,affectingitscolour.Greaseitselfstartsoff whitewhennew,turningyellowororangewithuseandeventually becomingblack,whichindicateszeroremaininglife.TheNSKapp quantifiesgreasebyitscolourtocalculateremaininglife.

64664atwww.ien.eu

480WBRUSHLESSMOTOR

One-cableconnectionforawiderangeofmarkets

The newDDunkermotoren BG75 dMovecombinesprovenfeatures with innovations.Forexample,the overalllengthhasnotchanged comparedtoitspredecessors,and thehybridconnectors(M23hybrid connector,14+4-pin(powerand logicsupply,inputsandoutputs) thatarefamiliarfromthehigh-enddProversionarenowalso availableinthisdMoveversion.Commissioningandconfiguration iscarriedoutinthefamiliarDriveAssistant5environment.TheBG 75dMovehasanumberofnewfeatures.Itoffersparticularly extensivefunctionalityintheareasofpositioning,currentand speedcontrol.ItiseasilycontrolledviaCANopenor,alternatively, viaconfigurableinputsandoutputsinstand-aloneoperation.It alsosetsnewstandardsintermsofperformance.Witharated powerof480W,theBG75dMoveachievesaratedspeedof3,190 rpmandaratedtorqueof1.44Nm.Peakvaluesaremanytimes higherthanthenominalvalues,makingthemotorarealpowerhouseforawiderangeofapplicationsinallmarkets-fromintralogisticstomechanicalengineeringandagriculturaltechnology.As acost-effectivealternativetothedPro,theBG75dMovecanbe combinedwithgearboxes,brakesandencodersfromthecompany'smodularsystemtomeetanyindividualrequirementfora robust,intelligentanddurabledrivesolution.

HIGH-PRECISIONPLANETARYGEARBOXES

Highperformanceandtorqueindifferentstageversions

ThenewMDandMF

64518atwww.ien.eu

RETROFITTABLEMOTORMONITORING

Fordetectionofdifficult-to-measurefailuremodes

OMRON haslaunchedtheK7DD-PQ seriesforadvancedmotorcondition monitoring.Byanalysingover400 typesofcharacteristicvaluesderivedfromcurrentandvoltagemeasurements,thedevicecandetect specificfailuremodessuchasworn blades,chipentanglementordeterioratingbearingsinmachinetool spindlemotors.Thisautomation reducesinspectioneffortandpreventsunexpectedequipment failuresbyeliminatingtheneedtorelyontheexperienceand intuitionofskilledoperators.Itisequippedwithhigh-speed2.5µs samplingtechnologythatdetectseventhemostfleetinganomalies,and6-channelsimultaneous/continuousoperationcapability thatprocessesdatawithoutomissionordeviation.Itcaneffectivelymonitorservoandinductionmotors,detectinganomalies causedbygapsbetweentherotorandstatororchangesintorque. Itprovidesself-containedconditionmonitoringwithinthemanufacturingsite,eliminatingtheneedforcomplexinstallationsor cloud-basedsystems.Easyretrofittingtothecontrolpanelmakes localmonitoringandimmediatedetectionofanomaliesstraightforward.Itsimplifiesdataanalysisbyautomaticallyselecting effectivefeaturevaluesandsettingthresholds,enablingthe identificationofdifferentfailuremodesandtheirrootcauses.

planetarygearboxranges arenowlaunchedbyAApex Dynamics.Designedto provideacombinationof unparalleledcostandhigh performancethrough enhancedtorqueoutput, precisionandefficiency, botharehighprecision planetarygearboxeswith longlifetimes,highrigidity,andbacklashintherangeof3to4arc min, dependingonthenumberofstages.MDandMFprecision planetarygearboxesareidealforanarrayofprecisionapplications, includingrobotics,industrialautomation,machinecontrolor machinetooling.Deliveringhighprecision,highefficiencyand hightorqueatagoodpriceboththeMDandMFrangesinclude right-angledversions-MDKandMFK-andareprovidedinratios from4(singlestage)to10,000(4stage).Availableinframesizes 064to450,theMDandMDKgearboxeshaverotaryfaceoutput, withanalternativeMDSversionoftheproductavailablethat incorporatesthesamesetoffeatures,aswellasthechoiceof smoothinputshaftorinputshaftwithkeyway.TheMFandMFK gearboxeshaveshaftoutputandareavailableinframesizesfrom 060to240. 64659atwww.ien.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024

64516atwww.ien.eu

22

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024

DIGITAL TRANSFORMATION Connectivity Boosts Efficiency and Availability AUTOMATION & MEASUREMENT New Products Metering Precisely - And Saving Energy Page 20 ISSN : 2031-9177 April 2024 - Volume 21 APRIL

16 18

Interview: Focus on: Material Inspection and Sorting

Connectivity Boosts Efficiency and Availability

Digital Plant Asset Management is a topic that often comes up in discussions about process engineering facilities. Today, while intelligent field devices might be the standard, system owners have yet to exploit their full potential. To provide the connectivity needed, Softing offers the right solutions with the smartLink product family.

Author: Dr. Christopher Anhalt, Vice President Product Marketing, Softing Industrial Automation GmbH

Raw material scarcity and high energy bills are increasing the pressure on users to optimize their plants and processes. This is where digitalization in process engineering facilities can offer a wide range of options. For system owners, the main advantage here is achieving high productivity at low cost, with efficiency and availability also being decisive factors. Disruptions to production and unplanned system shutdowns are key pain points here, so the idea is not merely to respond quickly to faults if and when they happen but also to identify potential malfunctions at an early stage and take preventive action that will avoid expensive downtime.

The primary tool used for these tasks is Plant

Asset Management (PAM), which aims to give facility owners a comprehensive set of data about the state of their systems. Alongside the process data the control works with, this dataset includes diagnostic data for the individual components as well as asset data that provide information about the installed components and units. To extract useful information from all of this data, it needs to be available to higher-level systems such as the Plant Asset Management system. So how can transparent access be provided to all of these data? Answering this question is a key issue for many plant owners.

Heterogeneity is the rule on the ground

One specific challenge in this context is the

sheer volume of field devices that are in use in the process industry. A further difficulty is a lack of homogeneous interfaces. Traditional connectivity using 4…20 mA is still often found here, with digital integration typically using remote I/O modules via the Hart protocol. A mix of other protocols like PROFIBUS PA or FOUNDATION Fieldbus may also be deployed in the same plant.

This means that, in many cases, users have only been able to integrate some of their field devices with PAM to date. In addition, these structures make field device parameter setting more complex. During operations, making use of these data in Plant Asset Management also requires other steps to be taken, which means that maintenance activities cannot be planned according to demand. The result is a higher risk of an unplanned plant shutdown.

Simple, fast access to Hart field devices

But help is at hand with products from Softing Industrial Automation’s smartLink family. First up is smartLink SW-HT, which provides a software-based Hart multiplexer and an integrated Hart IP Server that facilitates transparent communication over the open Hart IP protocol. The Hart IP Server provides higherlevel Hart IP-compatible applications with simple and secure access to Hart field devices. Typical examples here include Emerson AMS Device Manager, ABB Field Information Manager, or Endress+Hauser Netilion.

As a Docker container, smartLink SW-HT can be used on standard hardware and managed using industry-standard solutions for con-

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 16 digital trasformation

As a Docker container, smartLink SW-HT can be used on standard hardware and managed using industry-standard solutions for container management. ©: Softing Industrial

tainer management. In the corresponding system environment, the product therefore provides various opportunities for highly efficient and scalable operation. Alternatively, smartLink SW-HT can also be configured as a virtual machine.

In this case, the software multiplexer uses the existing hardware to access Hart field device data and makes these available within the plant network. A lean solution like this offers obvious advantages: apart from avoiding extra spending on hardware, this option also avoids the need for hardware installation or maintenance. Thanks to its browser-based configuration interface, commissioning is also very straightforward with smartLink SW-HT.

To set parameters on the connected field devices, the corresponding Hart commands are sent to the Hart IP Server, which forwards these transparently to the corresponding field devices. Any Hart command can be used without restrictions and smartLink supports many remote I/O modules from leading manufacturers, including Allen-Bradley, Siemens, Schneider Electric, or R. Stahl. Licensing costs are based on the number of Hart field devices to be integrated.

Gateway solution for Hart and PROFIBUS

Alongside the software-based smartLink SWHT product, Softing’s smartLink HW-DP provides a hardware solution for accessing field devices. The gateway can act as a PROFIBUS DP master, which provides an access point to a PROFIBUS DP segment and lets existing PROFIBUS segments run inside a digitalized environment and integrate with Industry 4.0 solutions.

Centralized field device parameter setting from the control room is also possible here, which lets users work independently of respective project planning tools. PAM applications are granted access to field device configuration based on the FDT/DTM and EDDL standards, with smartLink HW-DP being configurable for use as a Hart IP Server, OPC-UA Server, or MQTT Publisher. This therefore enables the use of a second, parallel communication channel as specified by the Namur Open Architecture (NOA), which feeds the data to the higher-level Industry 4.0 applications without any need for interventions into the control architecture.

A strong track record

Softing has already used smartLink to suc-

cessfully complete numerous projects. In petrochemical applications, for example, several hundred Hart field devices have been integrated with a PAM system. VMware was used here for the installation of smartLink SW-HT on an IPC used by the Plant Asset Management system.

In a process industry project, more than 60 smartLink HW-DP gateways were deployed to provide an Emerson AMS Device Manager with access to Hart field devices connected via remote I/O modules from R. Stahl. There are also many other examples from different areas of manufacturing where solutions from the smartLink product family are providing users with access to Hart and PROFIBUS devices for their PAM systems. Softing’s smartLink solutions grant access to all of the many kinds of information available from the installed base of smart field devices. This, in turn, gives users access to a data-driven approach to their work that allows them to make informed decisions about optimizing plant operations, ultimately resulting in improvements both to efficiency and availability.

64512 atwww.pcne.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 17

Softing’s smartLink HW-DP provides a hardware solution for accessing field devices. ©: Softing Industrial

SINGLEPAIRETHERNETSENSORPORTFOLIO

Bringingsensorsdirectlytothecloud

TheJJUMO SPE-capableproductportfolioisnowgoingintoseriesproduction.TheinnovativeSPEtechnology hasbeenintegratedinto3newproducts: hydroTRANSS20 (temperature, humidity, CO2transmitter), flowTRANS MAGH20(flowtransmitter)and DELOS S02(pressuretransmitter). Inthisway, individualsolutionstailoredtothe operationalprocesscanbeimplemented.SPEisinterestingforallautomationapplications-andtherebyforallindustries.Manyoperational processesthatneedtoensureahighlevelofavailabilitycanbenefitfromend-to-endEthernetnetworkingthankstoSPEtechnology. Asaresult,theuseofSPEcanavoidstandstillsandenableeven greaterefficiency,whichinturnenableslong-termcostsavings,in manyapplicationscenarios. Importantmeasurandssuchastemperature,airhumidity,CO2,flow,andpressureareforwardedwith highaccuracyandspeedtosuchdestinationsastheJUMOCloud. Forthefirsttime,thisenablescontinuousEthernetnetworkingof thesensorsbasedonthefamiliarautomationpyramidrightdown tothefieldlevel,withoutanymediadisruptioninEthernetcommunication. Eachofthe3sensorsissuppliedviaPoweroverData Lines(PoDL). Cabledistancesofupto1000meterscanbeachieved whenmountingandcablingthesensors.

64280atwww.pcne.eu

INTELLIGENTACTUATORSERIES

Adjustablespeedformodulatingandpart-turnactuators

Rotork announcesthatnew featureshavebeenaddedtothe industry-leadingIQ3Prorange ofintelligentactuators.The newfeaturesincludeincreased speedsfortheIQT3FPro electricmodulatingactuators, independentopen/closespeedsforpart-turnactuatorsand closed-loopcontrolforthemulti-turnandpart-turnactuators. The optionalincreasedspeedfortheIQT3FProelectricmodulating actuatorsisavailableforsizes50,100and125.Adjustablespeed, includingaslowmodeforaccuratepositioningandahigh-speed optionwherefasterspeedsarerequired,makingthemsuitablefor chokevalveapplications.Withtheindependentopen/close speeds,customerscanconfigureIQ3Propart-turnactuators'speed settingsforclockwiseandanti-clockwiserotation.Closed-loop controltakestheon-off/bang-bangcontrolorPIDcontrolmethodologiesthataretypicallyusedinaPLCordiscretePIDcontroller andincorporatesthemintotherange.Multi-turnnon-modulating IQ3Proactuatorsuseasetpointpositioningmethodknownas "bang-bang",whilepart-turnIQT3ProandIQ3MProactuatorsuse thePIDclosed-loopcontrolmethod. TheIQ3Prorangevalve actuatorsarerobust,flexible,andreliableandhaveadoublesealedenclosure,'non-intrusive'commissioning,andpredictive maintenancecapabilitiesusingthein-builtdataloggers.

64366atwww.pcne.eu

IP69KSTAINLESS-STEELIPCS

Withscratch-resistantandshatter-proofdisplay

ThestainlesssteelIPCsfromthe pro-V-padSTEELIP69kseriesfor systemandprocesscontrolin harshandhygiene-sensitive areasoffoodproductionwillbe presentedatAnugaFoodTec 2024bypproLogistik.Thespecial featuresincludehighimpermeabilityagainsttheingressof particlesandmoisture-especiallyduringsteamjetcleaning.ThestationaryandmobileIPCsare specifiedforanoperatingtemperaturerangeof-30°Cto+50°Caheatingmoduleisoptionallyavailable.Thefood-safematerials arecharacterisedbyhighmediaresistance.Thehousingwithits scratch-resistantandshatter-proofdisplaymadeofthreemillimetrethicksafetyglass(15.6"or21.5")fulfilsallrelevantdesign hygienerequirements.TheIPCsinthepro-V-padSTEELIP69K seriesaredesignedforWindows,Android10andLinuxoperating systemsandcanbecustomisedandfunctionallyexpandedin termsofdesign,processortechnology,screensize,userinterface, connectivityandmuchmore. ThestainlesssteelIPCsareusedfor recordingoperatingandmachinedata,fordataandprocessvisualisationorforqualityassuranceintheproduction,processingand packagingoffoodstuffs.Theycanbeoperatedwithoutrestriction inworkglovesforinputsafetyanduserergonomics.

64347atwww.pcne.eu

FREEROTATINGRETRACTOR

Highlyefficientcleaningorhygienicprocessinglines

ThenewAAlfa Laval FreeRotatingRetractor, isahigh-efficiencyretractablecleaning device,providescompletecleaningassurance,enhancingproductsafetywhile boostinguptimeandproductivity. Preparing hygienicvesselsquicklyandeconomically sothatallinteriorsurfacesarespotlessly cleanandreadyforproductioniseasywith theFreeRotatingRetractor.Dynamicand resource-efficient,thisretractableCleaning-in-Placedeviceremainssealedofffrom theproductareaduringproduction,flush withthevesselwall.Thesprayheadslides out,expellingcleaningmediaina310°-upspraypatternacrossthe vesselsurface.Uponcompletionofthecleaningcycle,thespray headretracts,andthevesselisproduction-ready. Theretractor quicklyandeffectivelyremovesresiduesfromtheinteriorsurfaces ofhard-to-cleanvessels,limitingcross-contamination,minimizing downtime,andincreasingproductivity.ItcomplieswithFDA,EU andChinaregulationswhilesecuringgoodmanufacturingand hygienepracticesatdairy,food,beverage,homeandpersonalcare, andotherprocessingfacilities.Forhigh-puritypharmaceuticaland biotechnologyprocessinglines,theFreeRotatingRetractor UltraPureisavailablewitha3.1documentationpackageformetal partsisavailableuponrequest.

64390atwww.pcne.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 18

20 energy efficiency

Metering PreciselyAnd Saving Energy

LEWA, a manufacturer of metering pumps and systems, relies on IE5+ motors from NORD DRIVESYSTEMS for high precision applications. They combine a wide control range with outstanding energy efficiency.

For 70 years, the provider LEWA from Leonberg in Baden-Württemberg has specialised in pumps and plants for fluid metering. The world’s leading manufacturer of metering and process diaphragm pumps produces individual, efficient system solutions for its customers. Areas of application are metering requirements, conveyance, mixing and odorising tasks – i.e. mixing of odour-intensive substances, especially with gases – in very different industries: from chemicals to mining. The diaphragm metering pumps of LEWA’s ecodos series are used in sensitive areas such as food or pharmaceuticals, for example for adding additives in the pharmaceutical sector or metering aroma in food. One specific application is the addition of omega-3 oil to baby

food. The ecodos series operates in the socalled low-pressure range, i.e. at a maximum discharge pressure of 20 bar, and with a flow rate of 16 to 1460 litres/hours. This requires pumps that not only allow precise control of the amount and time of addition, but also deliver the ingredients particularly gently.

Drives for wide ranges

“For this application, we now also offer our ecodos pumps with IE5+ motors from NORD for wide range control”, Maurice Wirkner, application manager at LEWA, explains. The permanent magnet synchronous motors are either operated as stand-alone motors – i.e. directly flanged to the motor – or with a decentralised frequency inverter.

For the high precision diaphragm pumps of its ecodos series, LEWA GmbH uses the efficient IE5+ motors from NORD DRIVESYSTEMS

NORD DRIVESYSTEMS offers the IE5+ with powers from 0.35 to 3.7 kW. With its fanless design, it is ideal for hygiene-sensitive applications and easy to clean. The optional IP69K protection class even allows the motors to be cleaned with a high-pressure cleaner.

An end to overdimensioning

Until now, LEWA had operated its diaphragm metering pumps with classic asynchronous motors or with servo drives including corresponding servo inverters, often combined with stroke adjustment. In the meantime, the pump expert has expanded its selection to include NORD motor technology. For good reason: Permanent magnet synchronous motors are significantly cheaper to purchase than servo drives and they make servo inverters and stroke adjustment superfluous. Classic asynchronous motors, on the other hand, are relatively inefficient outside the nominal speed range and therefore often had to be used in an overdimensioned form. Here, too, the NORD motors are much more efficient alternatives.

“The drive system with the IE5+ is much easier to handle and realises high-precision metering over a very wide adjustment range”, Wirkner emphasises. The NORD IE5+ has a constant torque that can be called up from motor speed 0 rpm (standstill) to the nominal motor speed. This ensures a particularly smooth start-up of the system, which protects the sensitive products LEWA customers work with in the food and pharmaceutical sectors.

Efficiency of 95 percent

The extreme control range and the short-term high overload capability of the IE5+ motors

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024

Image: LEWA GmbH

With its smooth, fanless design, the efficient IE5+ motor is ideal for applications in the food and pharmaceutical industry

from NORD often make the use of several pumps for different flow rates superfluous for LEWA’s customers, which results in a reduction of the drive variants in the overall system. This minimises administrative costs and streamlines production, logistics, storage and service processes. The outstanding 95 percent energy efficiency of the IE5+ motors adds to this.

“With its high energy efficiency, this drive system provides many advantages for our customers and thus also for us as a future-oriented pump and system provider”, Maurice Wirkner explains.

Development accompanied as a project partner

LEWA accompanied the development of the highly efficient IE5+ motor as a kind of project partner. “We were already able to test the motor together with our pumps as a system during the prototype state and thus gain initial experience”, application manager Wirkner says. Technical sales, product management and the NORD service were able to provide very good and competent support here. “We are also very satisfied with the cooperation with NORD for the previous orders, especially with the flexibility.”

The cooperation between LEWA and NORD is definitely to be continued. The next project is already planned: The partners are developing a trade fair demonstrator of a pharmaceutical metering pump with IE5+ motor and decentralised NORDAC ON+ frequency inverter from NORD, which illustrates the advantages of the wide-range control in metering with the LEWA ecodos diaphragm metering pump.

64653 at www.pcne.eu

FREE DIGITAL SUBSCRIPTION

Image: NORD DRIVESYSTEMS ASME VIII Approved US Patent Technology 100% Italian Design WWW.DONADONSDD.COM 64259 at www.pcne.eu

exclusive interview

Focus on: Material Inspection and Sorting

PCN Europe spoke to Mark Pontin, Managing Director of Resolve Optics about the challenges for lenses in optical material inspection and sorting applications.

PCN Europe: What experience and expertise does Resolve Optics bring to materials inspection and sorting – a common task in many industries?

Pontin: Drawing upon a highly experienced team of optical designers and engineers – Resolve Optics has a proven track record in designing and producing high performance custom lenses for materials inspection and sorting applications. In the last few years, we have received several major orders for instrument optimised versions of our Model 363-000 – a 16mm Short Wavelength Infrared (SWIR) lens for inspection and material sorting applications. Our aim is to provide a fast and flexible optical and mechanical design assessment on all projects. A project engineer is assigned to closely liaise with customers at all points of a development to ensure complete satisfaction with the final product. The experience of our design staff combined with cutting-edge Computer Aided 3D modelling ensures that top performance is designed into all our lenses and optical systems. Advanced optical manufacturing and CNC machining technology is used to produce high quality components. In assembly, our experienced workers build complete assemblies with care and attention to detail. All products are tested before leaving our factory to ensure complete satisfaction. It is this blend of skills,

Mark Pontin, Managing Director of Resolve Optics

Mark Pontin, Managing Director of Resolve Optics

experience and flexibility that have established Resolve Optics as a leading manufacturer of special lenses and optical products for materials inspection and sorting.

PCN Europe: What are the advantages of using Short Wavelength Infrared (SWIR) rather than Visible lenses in a materials inspection or sorting system?

Pontin: The SWIR region covers wavelengths between 0.7 and 1.9 µm. Compared to imaging sensors operating in the MWIR or LWIR regions, those that capture SWIR’s shorter wavelengths deliver images with higher resolution and stronger contrast, which are key criteria for inspection and sorting applications. SWIR imaging can also highlight features and defects that visible imaging systems cannot. Because water absorbs strongly at SWIR wavelengths it means that objects or features with a high moisture content appear black in images captured using a SWIR camera. Consequently, SWIR imaging systems are widely used to determine moisture content and bruising damage in fruit, produce and grain.

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 22

Model 363-000 SWIR lens used to determine bruising in fruit.

PCN Europe: Why when the cost of an off-the-shelf lens is typically lower – should material sorting and inspection instrument developers consider a custom SWIR lens?

Pontin: An off-the-shelf lens will almost always provide a cheaper option, therefore one of the first steps we take with any new project, is to determine if a suitable off-the-shelf solution is available. However, using an off-the-shelf SWIR lens typically forces you to accept compromises such as a reduction in optical performance, achievable resolution, a larger less attractive product, shorter product life and no control over security of supply. By contrast, demand for custom versions of our Model 363-000 SWIR lens that exactly meet the needs of individual customer applications are rising dramatically. This is not just because of performance advantages but also these custom SWIR lenses provide security of supply and exclusivity to a solution that can give you a market advantage.

PCN Europe: How are inspection and sorting system instruments evolving and what challenges does this pose to developing optimised optics for them?

Pontin: The evolution of materials inspection and sorting systems tends to be driven by new sensors. Sensors are improving all the time, often driven by customer desire for different formats and higher resolution. This trend is the major driving force behind the growth in demand for SWIR lenses that meet the demands of high-resolution Indium Gallium Arsenide (InGaAs) sensors. Our Model 363-000 SWIR lens design uses carefully selected glass types and AR coatings to ensure maximum transmission, colour correction and best image quality throughout the SWIR waveband. Operating at f/1.6, with less than 2 per cent geometric distortion, the Model 363 lens produces a clear crisp 12.8mm diameter image.

While we look to future proof an optical design as much as possible it is very difficult to account for format changes without making the initial design more expensive than is required for the application. Therefore, if a material inspection or sorting system sensor format

Lens quality assurance at Resolve Optics

changes significantly you will typically require a new lens design.

PCN Europe: Can you describe a typical project process and duration when a customer wanting to improve their material inspection or sorting capabilities contacts you?

Pontin: As I have previously mentioned - the first step is for our design team to discuss the customers application to see if an offthe-shelf optical solution is available. If a lens or optical system with the required attributes is not yet available, we would work with the customer to write an optical specification, ensuring that the final agreed version meets and or exceeds the customer application requirements. We then undertake some initial design work to identify what is possible and to enable us to confirm budgetary costing. Then from the point of the customer placing an order it typically takes between 5 to 6 months for the first application specific custom lenses to be supplied.

PCN Europe: What testing systems and procedures do you employ to ensure the quality of the lenses and optical systems?

Pontin: Resolve Optics carries out 100% inspection and optical testing prior to any lenses being shipped to a customer. All our optical testing is carried out on a state of the art fully automated MTF testing system This equipment allows us to qualify that each lens exceeds the designated customer specification requirements for resolution, distortion, FOV and register. Due to the automated nature, and the accuracy of the test set-up, we can ensure that each lens is tested under the exact same conditions. Any lenses that do not pass this testing are then reworked and retested. This guarantees that every lens that leaves Resolve Optics UK facility meets or exceeds the specification as agreed with the customer.

PCN Europe: Thank you for your insights.

64509 at www.pcne.eu

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024 23

special Hannover Messe

Radar Safety for Intralogistics

Air traffic and shipping are no longer conceivable without radar technology. Their electromagnetic waves provide extremely reliable signals for object detection and collision protection. What has proven itself over long distances at sea and in the air is just as useful at near range: radar also ensures precision and safety when controlling autonomous vehicles and machine booms. The new radar sensors from Pepperl+Fuchs are optimized for use in the intralogistics and material handling sections, among others.

Radar (RAdio Detection And Ranging) is based on the transmission of electromagnetic waves and the detection of their reflection. This method makes it possible to determine the distance to objects in the path of the waves - or moving in their propagation range - at practically the speed of light. Pepperl+Fuchs has developed a series of compact sensors that make this robust principle of measurement usable for safeguarding machine movements in the materials handling and warehousing section.

Stable signaling, high EMC

The devices use the frequency-modulated continuous wave (FMCW) method, which ensures particularly stable signaling. The frequency band of 122-123 GHz ensures strong resistance to interference such as dust, steam, temperature fluctuations and weather conditions. In terms of electromagnetic compatibility (EMC), the devices achieve values comparable to classification E1 in almost every category. Reliable measurement is therefore guaranteed even in the case of conducted and high-frequency radiation with high interference levels. From the reflected waves and the derived measurement data,

the devices can determine the distance, direction of movement and speed of objects in the detection area with high accuracy.

The sensors are housed in a casing measuring just 40x40x83 mm, so they can easily fit into tight spaces. The sensor head can also be rotated and swivelled so that it can be optimally aligned to the target area in practically any installation situation. Equipped with IP68/69 degrees of protection, the device is also well suited for harsh environments or constant switching between indoor and outdoor use. The new product series also allows great flexibility when it comes to electrical connections. In addition to the standardized M12 connector plug, connector types such as DEUTSCH or AMP Superseal are available specifically for use in vehicles.

Integration and diagnostics with CANopen

The integrated CANopen interface is responsible for transmitting measured values and parameterization commands. Integration into an existing CAN bus infrastructure is therefore very simple and possible without complex individual wiring. Device parameters and extended functions can be accessed either via the CAN network or with

24

The radar sensor measures the height of the fork.

Measurement modes with application-related priorities: First object (1), Strongest reflection (2) and Fastest object (3)

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024

the help of the FDT framework program PACTware and a Device Type Manager (DTM). The sensor can thus be adapted to the respective application with minimal effort.

The connection via CANopen also opens up the possibilities for detailed status monitoring. This is an important prerequisite for use in safety-relevant applications, which is possible in conjunction with a fail-safe PLC. Thanks to the features of the sensors and their diagnostic capability, a single device is sufficient for safety level PL c (Cat. 2) and SIL 1. When integrated into a safety concept and with a redundant sensor design, the requirements for PL d (Cat. 3) and SIL 2 are met. Several devices can be used in close proximity to each other as they do not interfere with each other's function. A sampling rate of up to 200 Hz can be parameterized for applications with fast response times.

Adapted measuring mode

Electromagnetic waves are not reflected to the same extent by all materials; this is most pronounced with metal. With wood or plastic, on the other hand, the proportion of penetration clearly outweighs that of reflection. Depending on the type of application, it may make sense to fit corner reflectors made of sheet metal in the detection area. These are available as standard accessories.

However, the radar sensors are also able to largely compensate for the different reflective properties of the objects in the detection area or make use of them. For example, non-metallic objects can be specifically masked out by setting the appropriate parameters and selecting the measurement mode. In such an operating mode, the sensor then reliably detects the actual target object behind a partially transparent object that is located between them.

The radar sensors offer three different measurement modes for fine adjustment:

- "First object" - material-independent detection of the object closest to the sensor. Objects within the extension range or radius of action of the vehicle and boom are detected in all cases.

- "Strongest reflection" - detection of the object with the best reflection properties

- In "Fastest object" mode - detection of the object that moves towards or away from the sensor the fastest. This measurement mode is intended, among other things, for path monitoring and collision protection in driverless transport systems.

Application examples

Automatic reduction of maximum speed - Forklift trucks and other transport vehicles may and should drive faster on outdoor storage areas than in production halls and warehouses. However, a reduced maximum speed must be maintained there. An upward-facing radar sensor on the vehicle detects the hall roof on entry. The device gives

the signal for the automatic speed restriction and for its lifting after the exit.

Height control for forklift forks - The higher the forks are, the lower the permissible speed of the forklift truck. The approval ratio between lifting height and load weight is also precisely defined. The radar sensor directed from the fork to the ground detects the lift height in "strongest reflection" mode and suppresses interfering objects. The height control can also be used to control the pallet insertion into the high rack: The sensor signal indicates whether the pallet base has reached the necessary height.

Collision protection for overhead crane - In the case of an overhead crane with several crane bridges mounted on its rails, the sensor monitors the distance between these elements. Slow travel is triggered when approaching and a safety stop is triggered if there is a risk of collision.

Hall 9, Stand D76

64509 at www.ien.eu

•

with axial or radial connector output

• Through hollow shaft, direct integration into the motor

• For high performance applications

• Robots, cobots, drones / UAVs, surveillance systems, electro-medical equipment, servomotors

Lika Electronic • info@lika.biz

64477 at www.ien.eu

lika.biz

25

CMYK 90, 0, 60, 64, 60, 65, 55 Smart encoders & actuators Kit-encoders for robotics R 22 - 26 April HALL 9 • F59

kit-encoder

Ultra flat

FREE DIGITAL SUBSCRIPTION N° 4 - APRIL 2024

Helping Achieve Net Zero CO 2 Emissions with Single-Pair Ethernet