3 minute read

FORMNEXT LAUNCHES

Next Article

A selection of key hardware, materials and software announcements from Frankfurt.

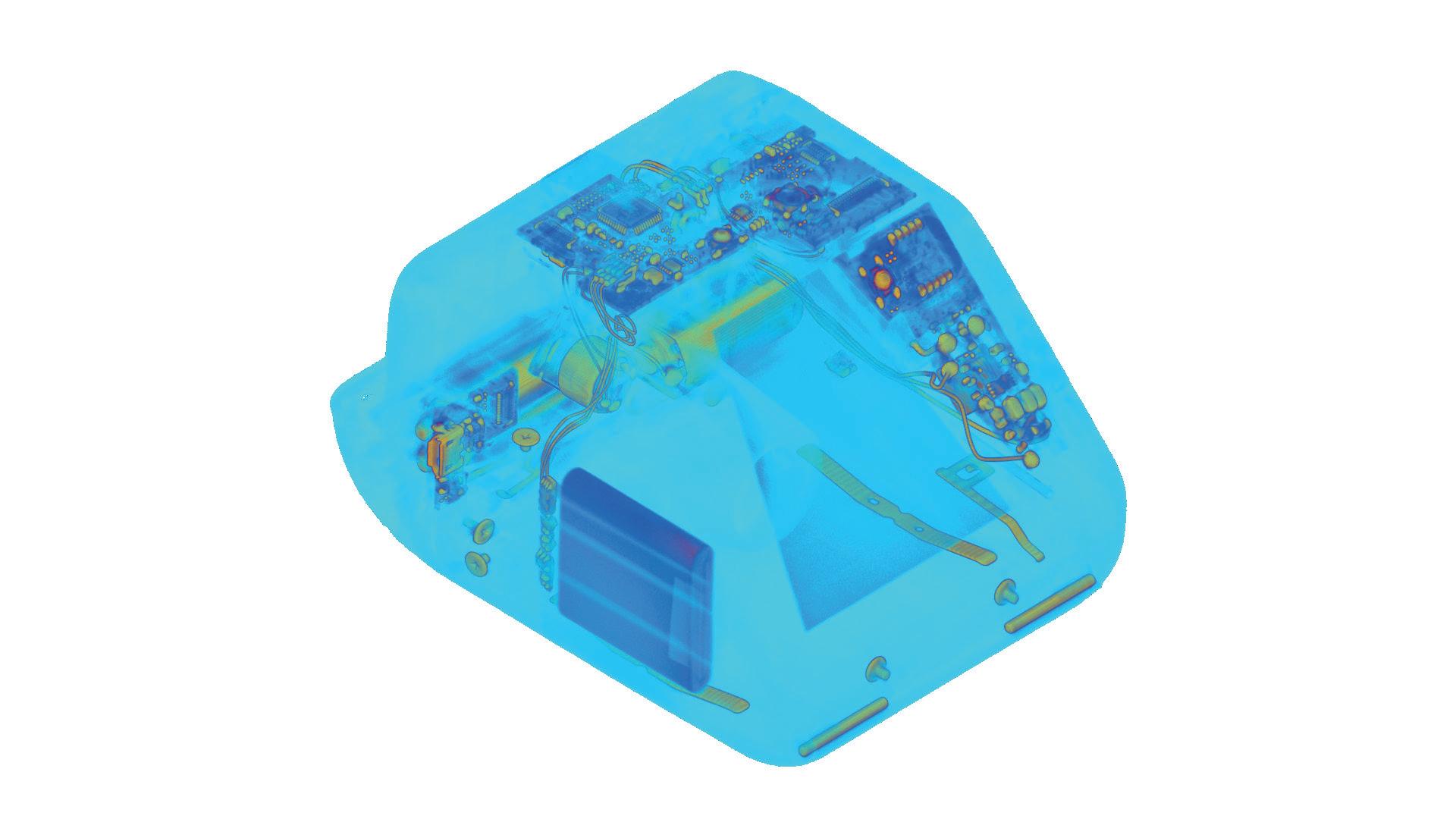

NEW HP JET FUSION MACHINE ANNOUNCED FOR 3D PRINTING WHITE PARTS HP announced the launch of its HP Jet Fusion 5420W 3D printing system to facilitate the additive manufacture of white parts. A partnership with DyeMansion allows these parts to be dyed.

“There are some applications which required lighter tones, bright colors, this was the demand from the market, especially in healthcare, for example, in surgical guides,” Francois Minec, HP’s Global Head of Strategy, Personalization & 3D Printing told TCT. “So, we're covering this gap. We're going beyond that because our solution has a much better UV resistance and the white that you can see is really a very nice color, whatever the angle.

This machine is said to provide all the benefits of HP's Multi Jet Fusion technology, initially commercialized via the 4200 and 5200 Series, and is geared towards automotive, consumer goods, healthcare, and industrial markets. Early customers using the new system to produce innovative white applications include DI Labs, Prototal Industries, and Weerg.

“The response is huge. We're really happy,” Minec added.

Full story: mytct.co/HP5420W MATERIALISE ADDS NEW COAM TECHNOLOGY PARTNERS Materialise announced seven additional technology partners on board its CO-AM platform including Trinckle, Twikit, Additive Marking, SLM Solutions, AMT, DyeMansion, and PostProcess.

CO-AM allows users to access a range of software tools from Materialise and third parties, enabling AM operations to be planned, managed and optimized. When CO-AM was first announced, Materialise said the platform will help manufacturers address the ‘untapped potential’ of AM for serial manufacturing and mass personalization.

CTO and EVP of Materialise Bart van der Schueren spoke to TCT about what the new partners will bring and how AM companies have a responsibility to learn from each other.

“Materialise is really opening up our ecosystem for third parties,” van der Schueren told TCT. “We recognize that we are able to not develop every single step. If we would be able to do that we would not have the time because this industry is needing solutions today. Not tomorrow, not next year. That’s why we opened up CO-AM by design, so the whole architecture of the system is an open system with API’s and allows us to have partners that log on to the CO-AM platform.”

Full story: mytct.co/co-am

6K ADDITIVE LAUNCHES ULTRA-LOW OXYGEN TI64

During Formnext, 6K Additive announced the immediate availability of ultra-low oxygen titanium 64 with a parts per million (PPM) rate of 500-700.

The company says this announcement 'greatly surpasses' what is available with today's AM capabilities, and provides customers with a high-quality material that enables low oxygen levels at production scale, and the ability to process additional jobs through their 3D printers without sacrificing quality.

“The global supply chain crisis has caused volatility in the market for metals like titanium which leads to uncertainty in costs and availability. Our ability to provide low-oxygen titanium at production volumes enables our customer to stretch their powder use well beyond what’s available today, essentially increasing value and lowering costs for their Ti64 parts,” said Frank Roberts, President of 6K Additive.

Mark Barfoot, Director of AM programs at EWI, added: “When we talk to Ti64 users in the market, quality always is top priority with costs following a close second. Increasing the value of their Ti64 purchase by extending the life of the powder with more uses is a definite win.”

Full story: mytct.co/6KTi64

North America’s largest and most influential Additive Manufacturing event.