5 minute read

TOY STORY

Next Article

Oliver Johnson speaks to Hasbro about its new range of customizable 3D printed action figures, the Selfie Series.

This summer, Hasbro announced the Selfie Series, a new product range which allows customers to have their face 3D printed onto the body of a six-inch action figure; a Stormtrooper, Spider-Man, a Ghostbuster, a Power Ranger, amongst several others.

The production process starts by taking a scan of the customer’s face through the Hasbro Pulse mobile app, where they can also select their preferred action figure and hair color. The information is then sent to the Hasbro print factory and queued up for 3D printing. Multiple customized heads are printed at the same time on a single build plate, using Formlabs stereolithography (SLA) technology. The heads are then assembled with a standard off-the-shelf action figure body, before finally being shipped to the customer.

The IPs that Hasbro works with are some of the most beloved in the world of pop culture. To create a product that would be well-received by fans, selecting the right 3D printing process for this range of action figures was crucial. The toy company has been using 3D printing since 1995, primarily for rapid prototyping, and began using Formlabs printers in 2014. According to Hasbro, as it saw 3D printing cross over from being a prototype-centric technology, it had the dream of developing something with the technology that was truly innovative, hence the idea of mass customization.

Gary Rowe, Global Head of Business Development at Formlabs, told TCT: “Many companies turn to SLA 3D printing for the strength and resolution of the prints, and Hasbro had used Formlabs SLA 3D printers for prototyping in the past. When seeking the right solution for the Selfie Series, Hasbro selected the Form 3 SLA 3D printer that would provide the high resolution and accuracy needed to create life-like faces of Hasbro’s fans, with a smooth finish that would also be durable. In addition to the quality of the prints, the Form 3 worked well with the resin created for the manufacturing of these action figures.”

Mass customization enabled by 3D printing allows for the commercialization of products that are unique to the customer. The audiences the Selfie Series are targeted towards - Star Wars fans, Marvel fans, Power Rangers fans and more - often embrace the opportunity to dress up as their favorite characters at fan conventions and premieres, so Hasbro believes the market is there for products that invite fans to put their face onto their favorite characters too. Patrick Marr, Sr Director of Model Development at Hasbro, spoke to TCT about the implementation of mass customization in Hasbro products: “Our fans continue to look for new ways to engage with our brands and see becoming their favorite action figure as the ultimate expression. 3D printing has allowed us to offer that experience at scale in a quality that was never possible before. We see utilizing 3D printing as

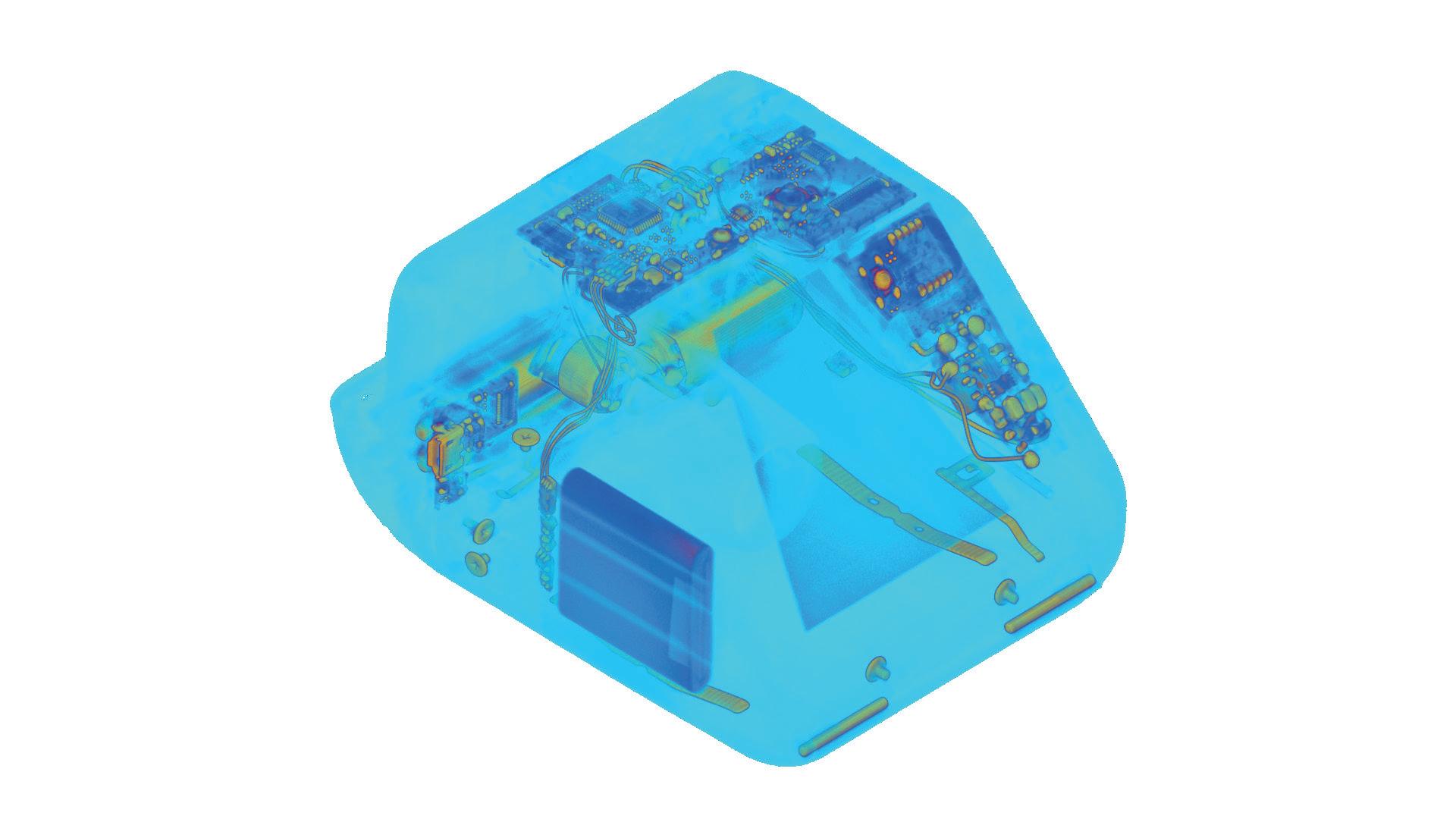

SHOWN:

A BATCH OF FACES PRINTED USING SLA

“Selfie Series is an example of how Formlabs 3D printing solutions can deliver mass customization to consumers.”

SHOWN:

SELFIE SERIES GHOSTBUSTERS ACTION FIGURES

opening many future opportunities for our fans. Leveraging the technology allows us to deliver products faster, create custom products, and then continue to evolve that platform by offering new features.”

The material that Hasbro chose had to be able to create figures that were highly detailed, to accurately replicate the consumer’s face, but also durable enough for everyday wear and tear. Formlabs assisted in the process of deciding on a material that could be available in a variety of skin tones and hair colors, which ultimately led to the creation of a new resin, based on its Tough 1500 material, specifically for this application. Rowe shared how Formlabs worked closely with Hasbro to meet quality assurance and safety testing standards required for commercial products in the toy industry. While the hair pieces for the figures are currently not personalized, these are also manufactured using the same SLA technology.

Marr added: “Hasbro Selfie Series is really our first consumer-directed product that utilizes 3D printing in the mass customization space. The product was driven by leveraging our 25-year knowledge in 3D printing to bring an experience and product to market that sets the bar on personalization and quality. We spent about two years developing the scanning, printing, and production process to ensure we could offer an amazing customer experience.”

An important aspect of the production for Hasbro was the ability to match the quality of its collector figure lines. Hasbro action figures have been a staple for collectors for decades, and the company wanted the Selfie Series to match the quality that fans have been used to. Rowe spoke about the future for Formlabs and Hasbro, and for mass customization, saying: “Selfie Series is an example of how Formlabs 3D printing solutions can deliver mass customization to consumers. Hasbro has understood this potential innovation and created this first application of mass customization to foster engagement with its customers. 3D printing will continue to advance in end-use-parts and mass customized products as complimentary technologies such as scanning technology and material development increase the quality, speed, and applications. Consumer demand for personalized products will also rise in tandem with this technological development to make 3D printing a more sought-after approach for delivering new products that strengthen brand awareness and loyalty.”

Emphasizing Hasbro's ambitions for future personalized products, Marr added: “We look at Hasbro Selfie Series as just the first expression in this space, and we want to continue developing and expanding our engagement with our fans. Again, it is really the perfect flexible platform that allows us to leverage ideas from some of the company’s amazing talent.”

SHOWN:

SELFIE SERIES FACES ON A FORM 3 BUILD PLATE

Celebrating ten years of accelerating the adoption of additive manufacturing